Honeycombed ceramic slurry water cooling vacuum refiner

A ceramic mud and water cooling technology, applied in the field of ceramic mud, can solve the problems of large power consumption and large upper shaft resistance, and achieve the effect of reasonable layout, uniformity and automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

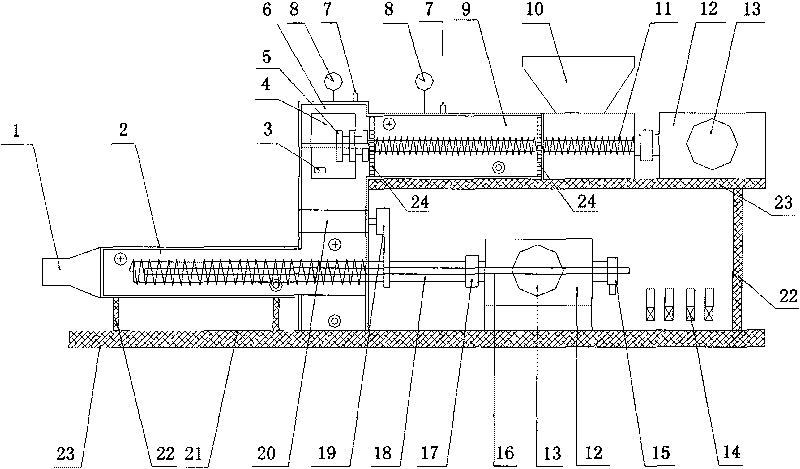

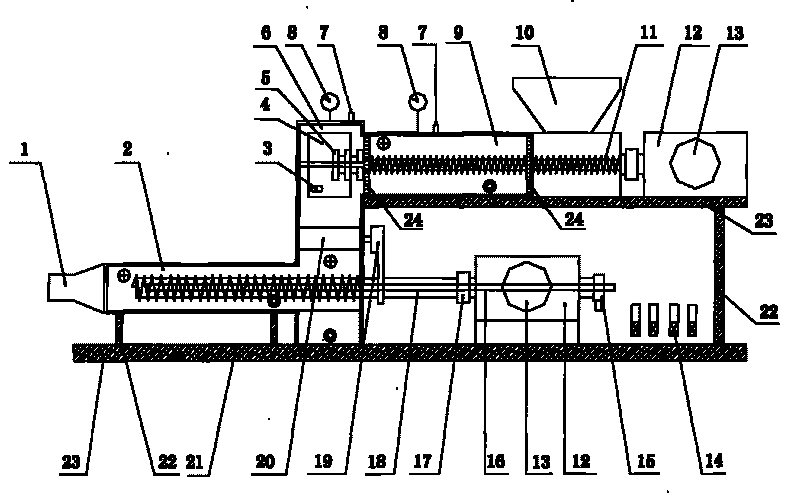

[0030] figure 1 In the schematic diagram of the honeycomb ceramic mud water cooling vacuum refining machine, the area within the double line is the cooling and vacuum area, ◎ is cooling water outlet, ◎ is cooling water inlet.

[0031] 1 mud outlet, 2 mud outlet, 3 photoelectric control device, 4 vacuum chamber window, 5 scraper, 6 vacuum chamber, 7 suction port, 8 vacuum gauge, 9 mud inlet, 10 feed port, 11 double agitator Mud shaft, 12 reducer, 13 frequency conversion motor, 14 control valve and flow meter, 15 cooling water inlet and outlet device, 16 shaft water inlet pipe, 17 coupling, 18 extrusion shaft, 19 transmission device, 20 double kneading stick, 21 slides, 22 supports, 23 bases, 24 fences

[0032] specific implementation plan

[0033] Firstly, the overall design scheme is put forward according to the performance index, mechanical and electrical components, processing capacity, and finished product quality requirements of the honeycomb ceramic slurry water-coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com