Oil consuming system

An oil consumption and fuel tank technology, applied in clutches, friction clutches, belts/chains/gears, etc., can solve problems such as short residence time, short oil circulation time, and inability to discharge free air, achieve rapid degassing and reduce structure space, the effect of reducing the flow cross section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

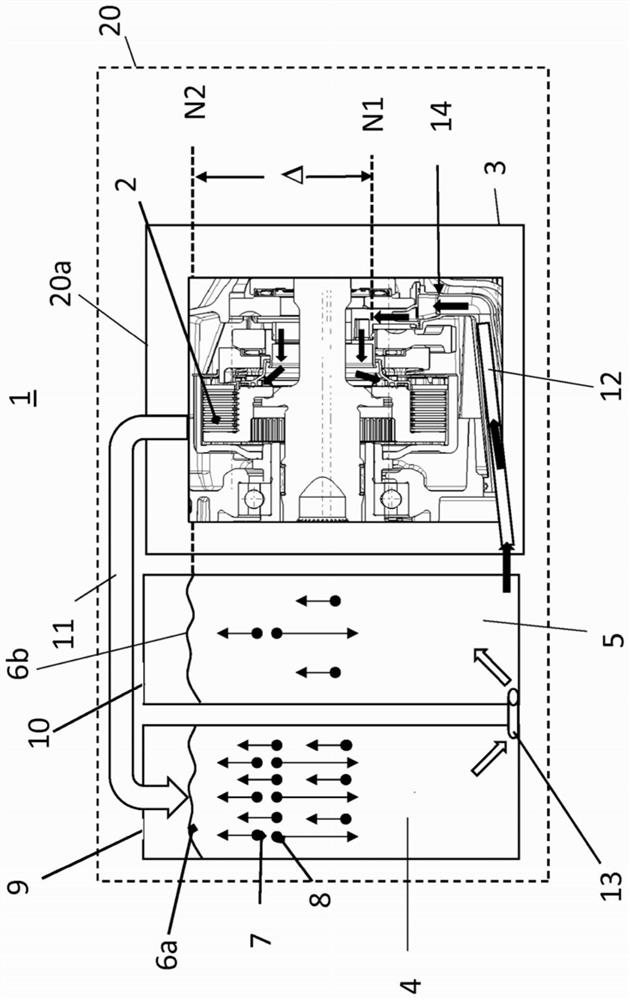

[0018] This is a wet multi-disc clutch, which is supplied with oil via the oil supply 12 . Oil is fed into the disc carrier of the clutch via suitable oil supply bores 14 , which are indicated by arrows in the figure.

[0019] By the rotation of the clutch, oil is thrown out at the highest point of the clutch and delivered to the oil return portion 11 . Oil guides can also be used here, as are already known. In this case, the oil guide is shown schematically in the drawing and can represent a return line conducted in the housing 20 a or a separate return line which is also arranged outside the housing 20 a. The oil return line 11 leads into the first oil tank 4 in which the air-oil mixture is deposited. As shown in the figure, the air 7 is separated from the oil droplets 8 . The rising air 7 escapes via the first exhaust mechanism 9 . In this case, an oil level 6 a is formed in the first oil tank. The first oil tank 4 is connected to the second oil tank 5 via a connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com