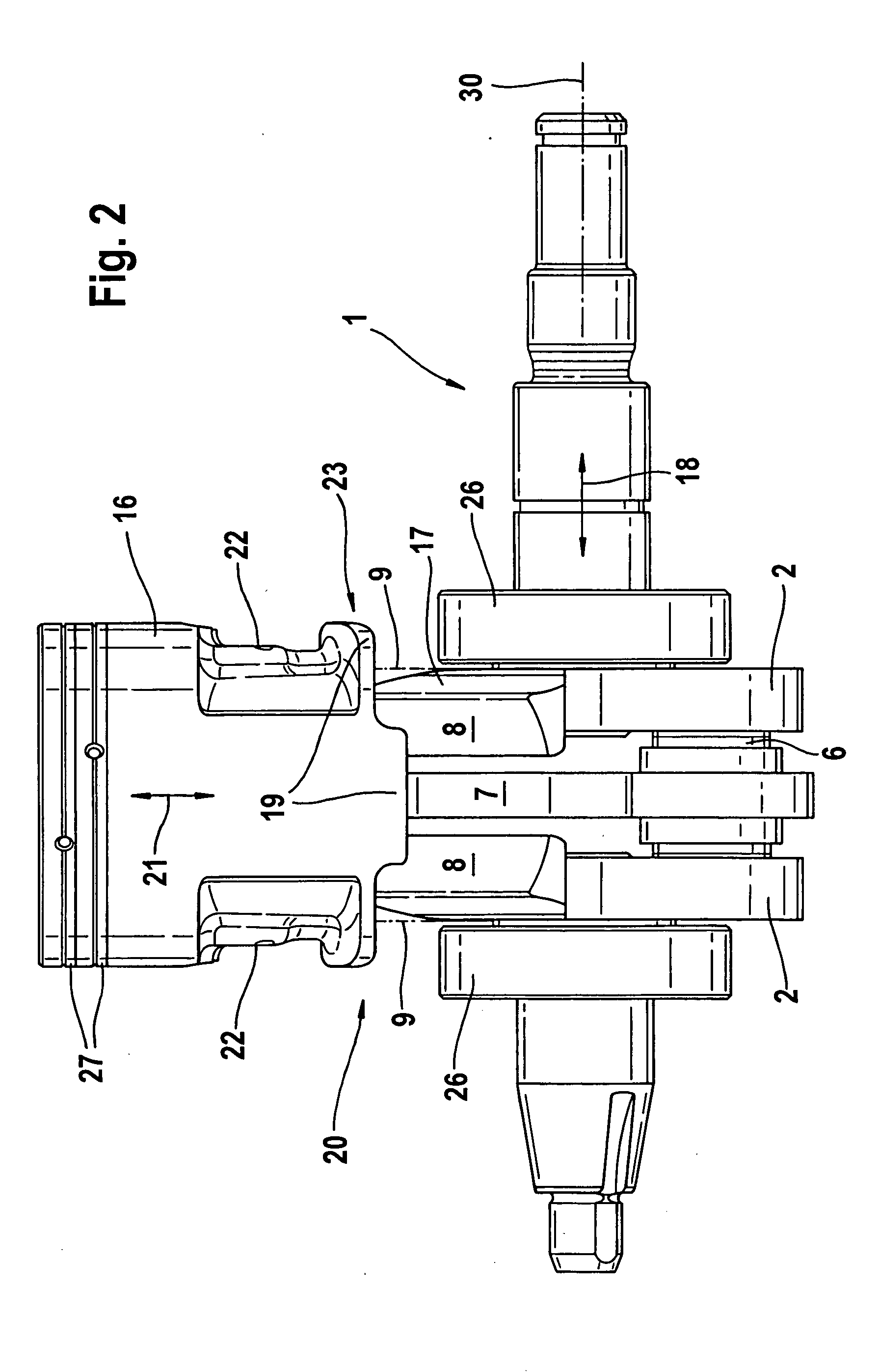

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

128results about How to "Reduced overall construction space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

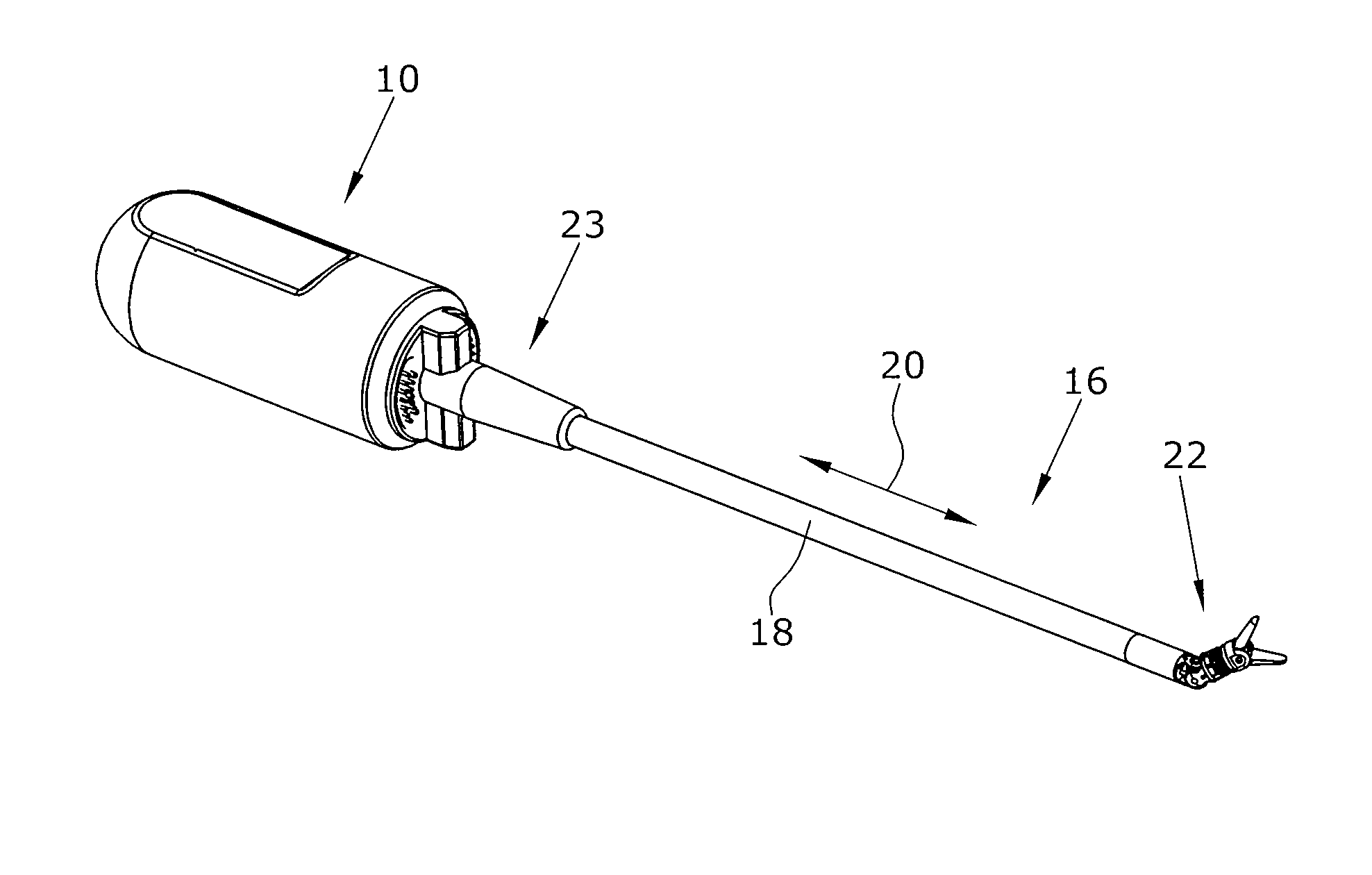

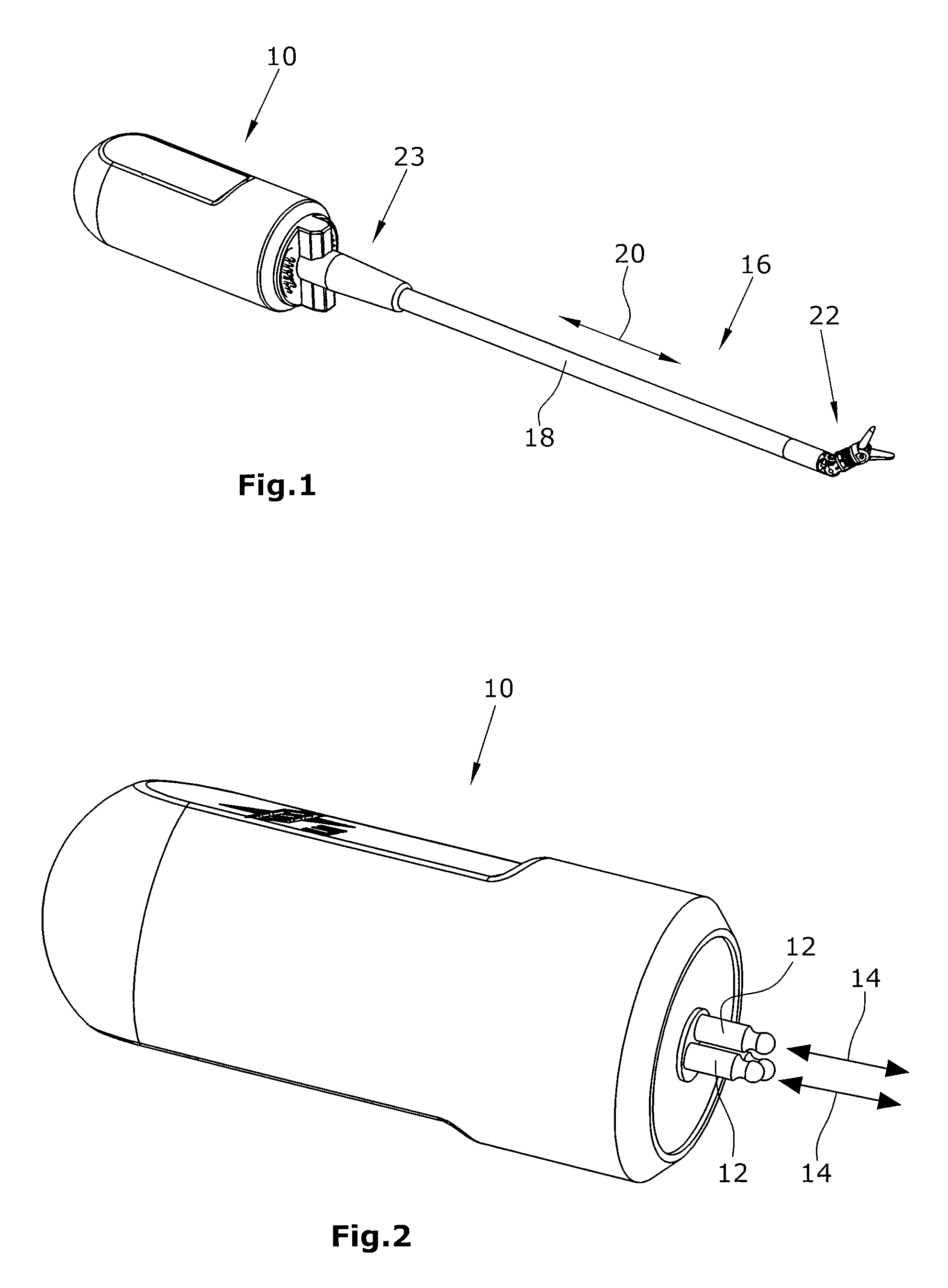

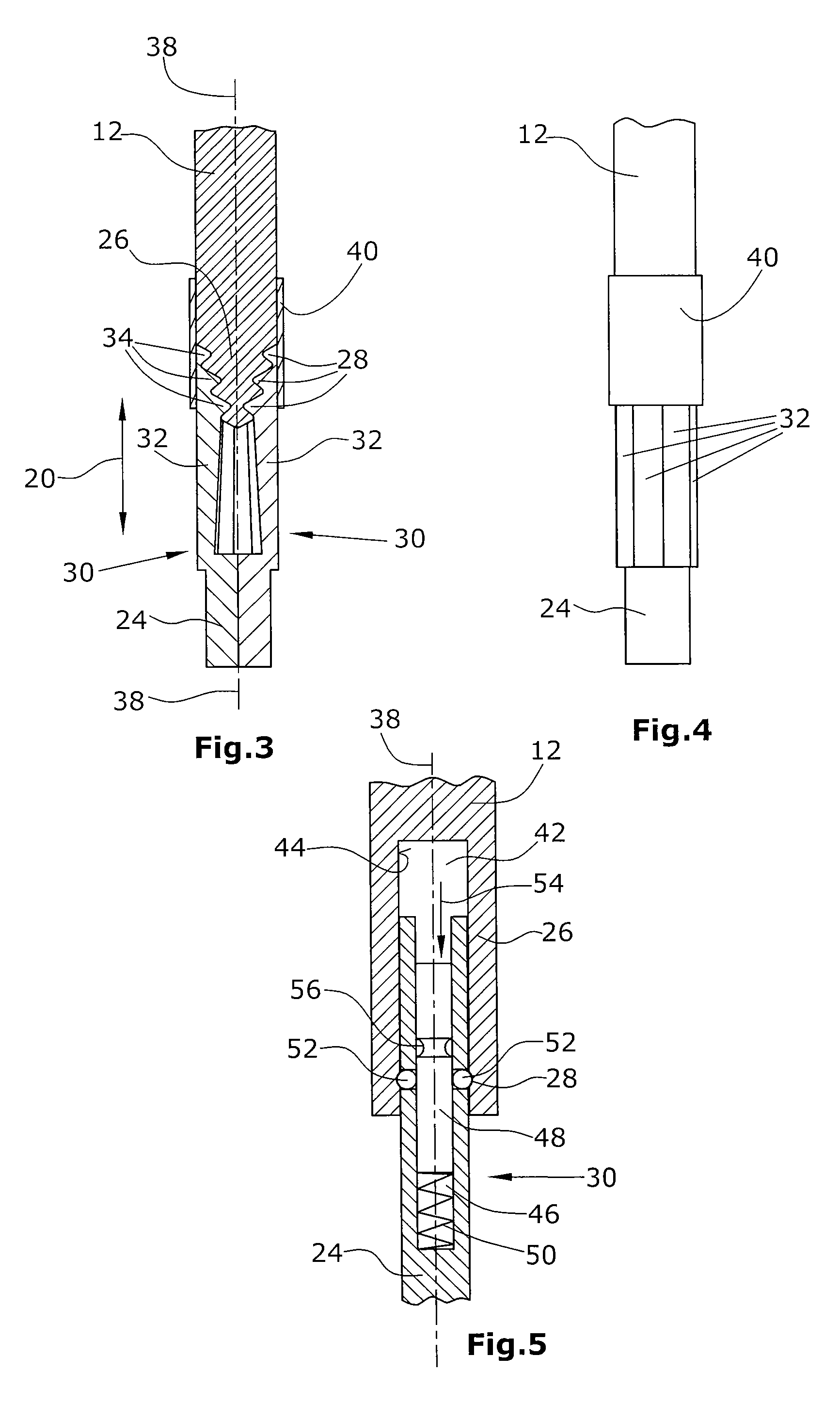

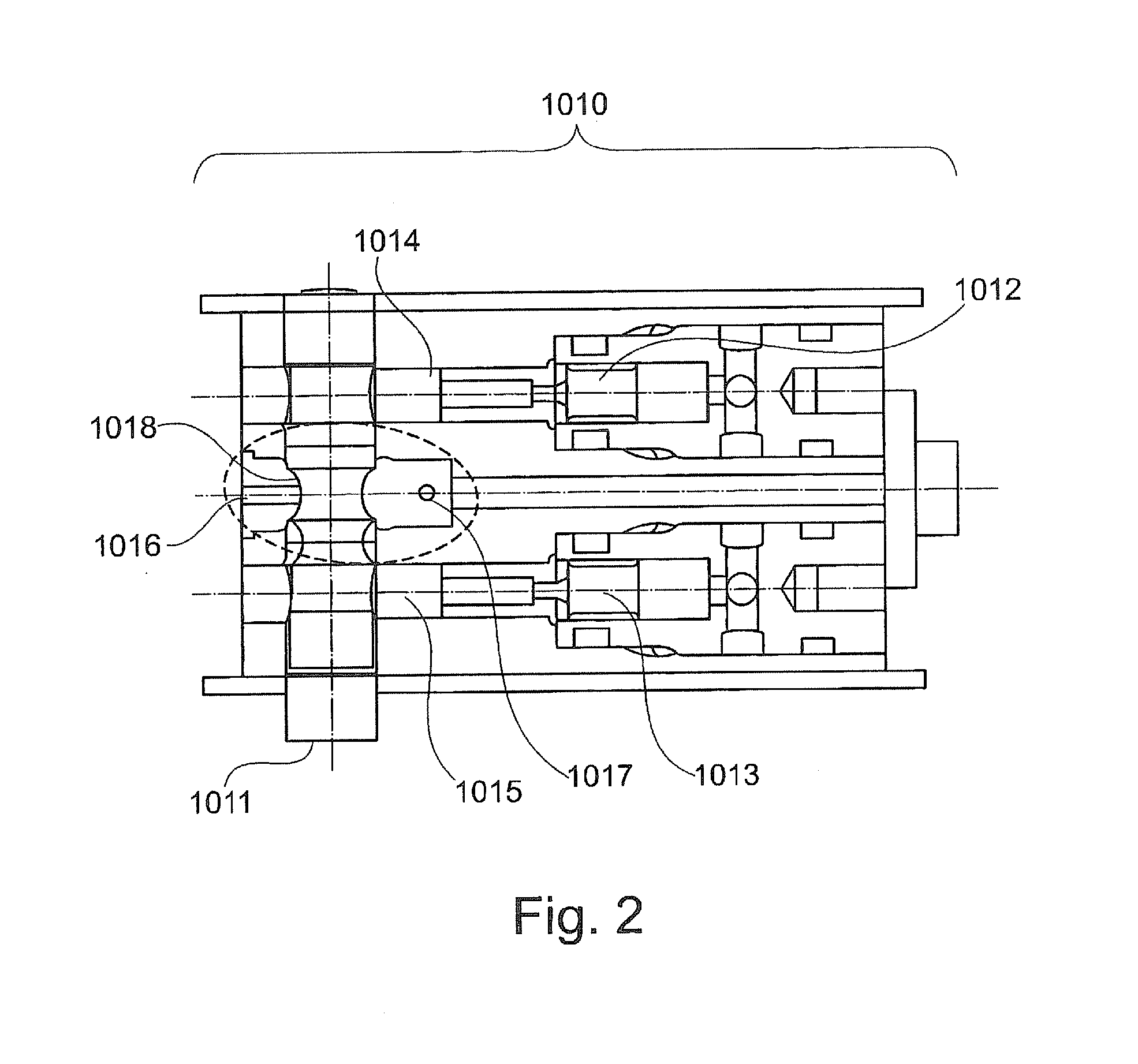

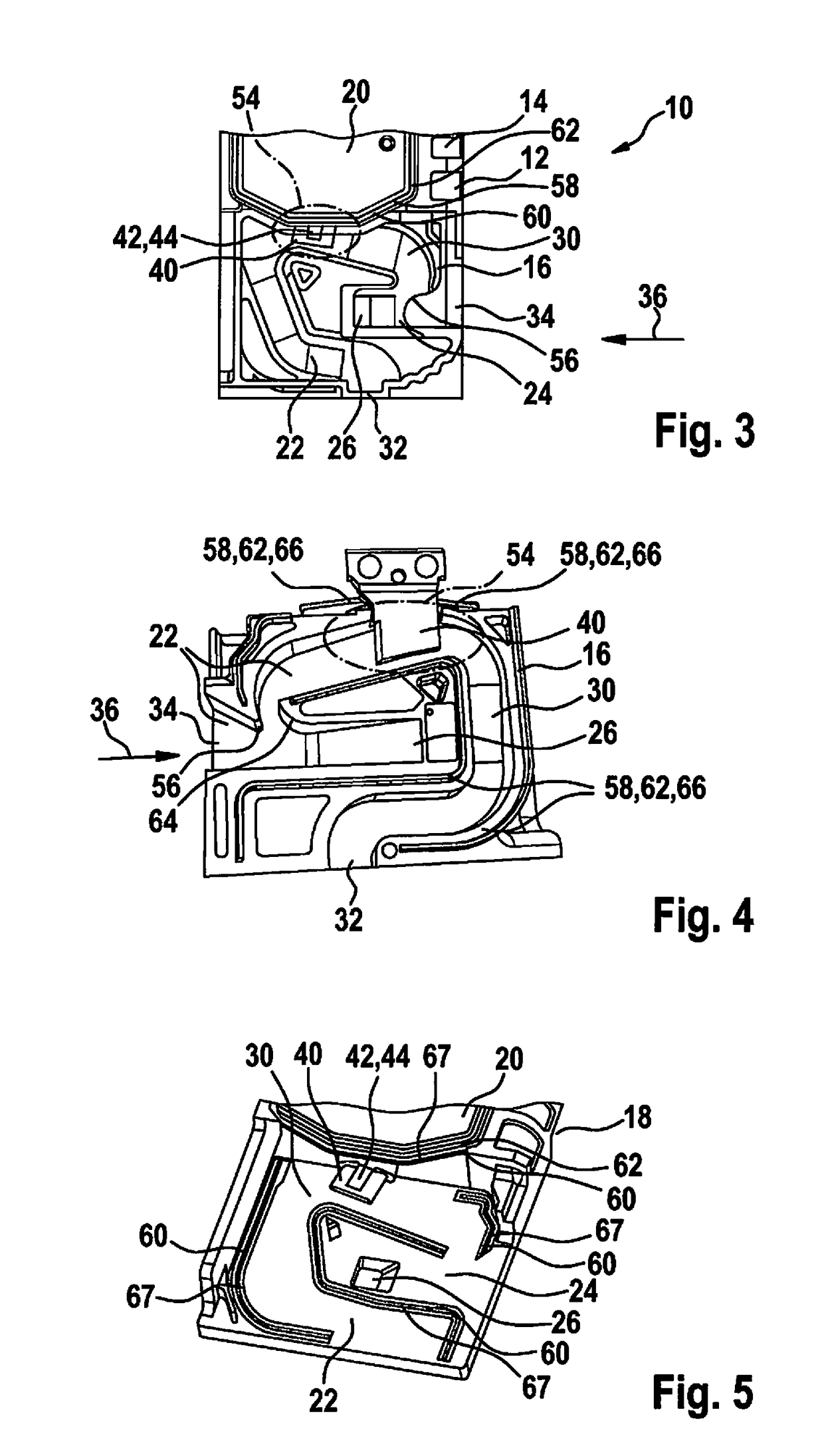

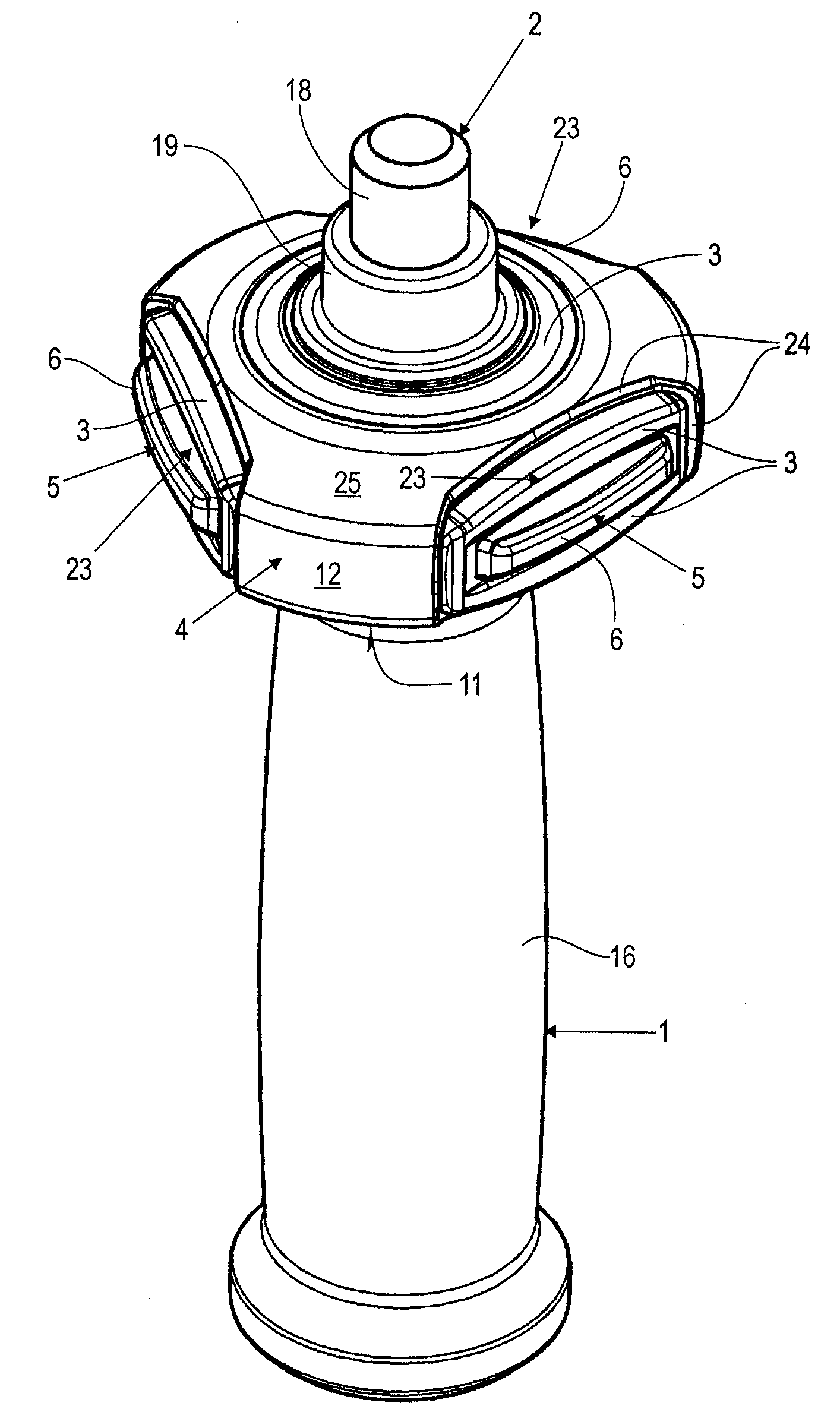

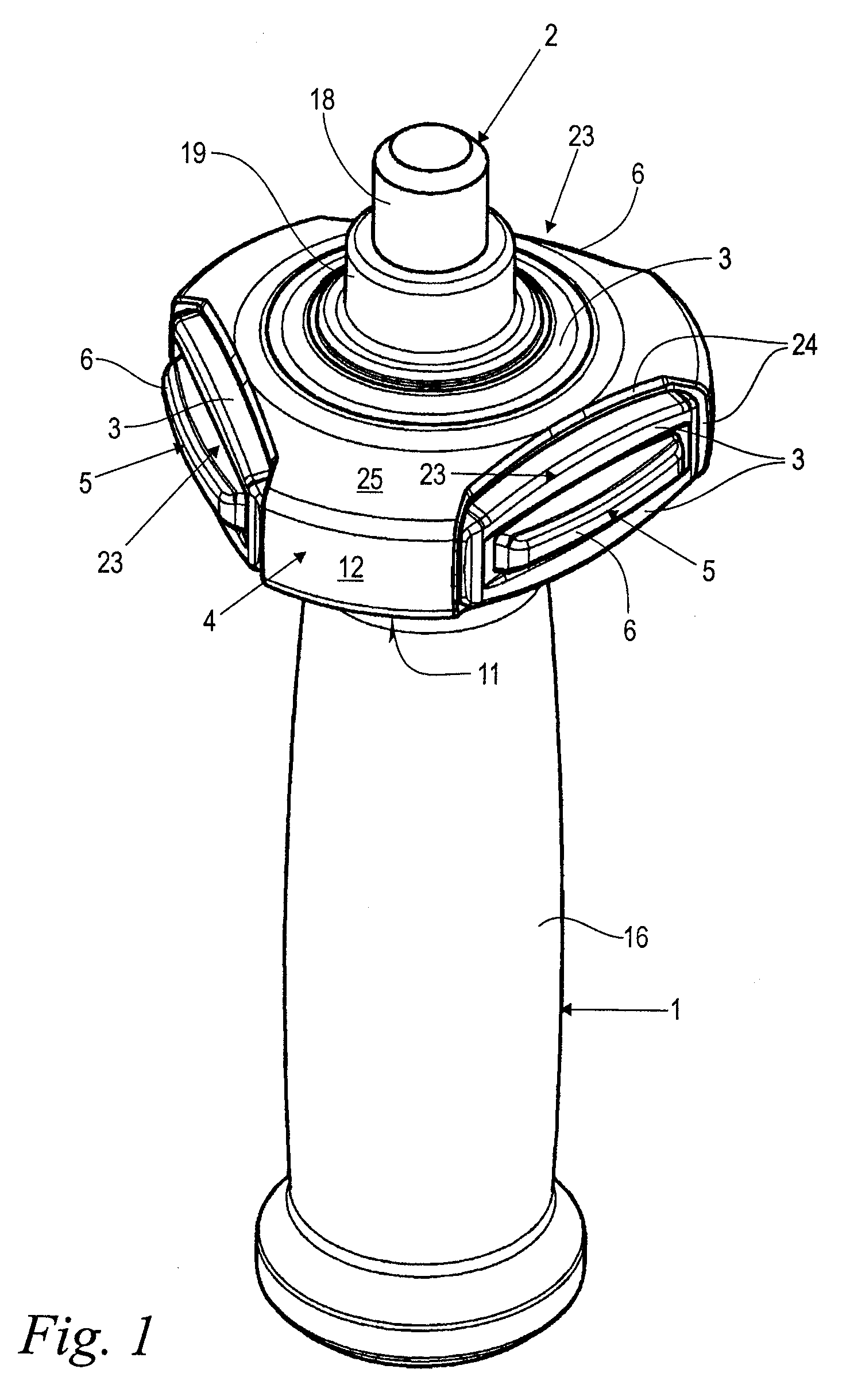

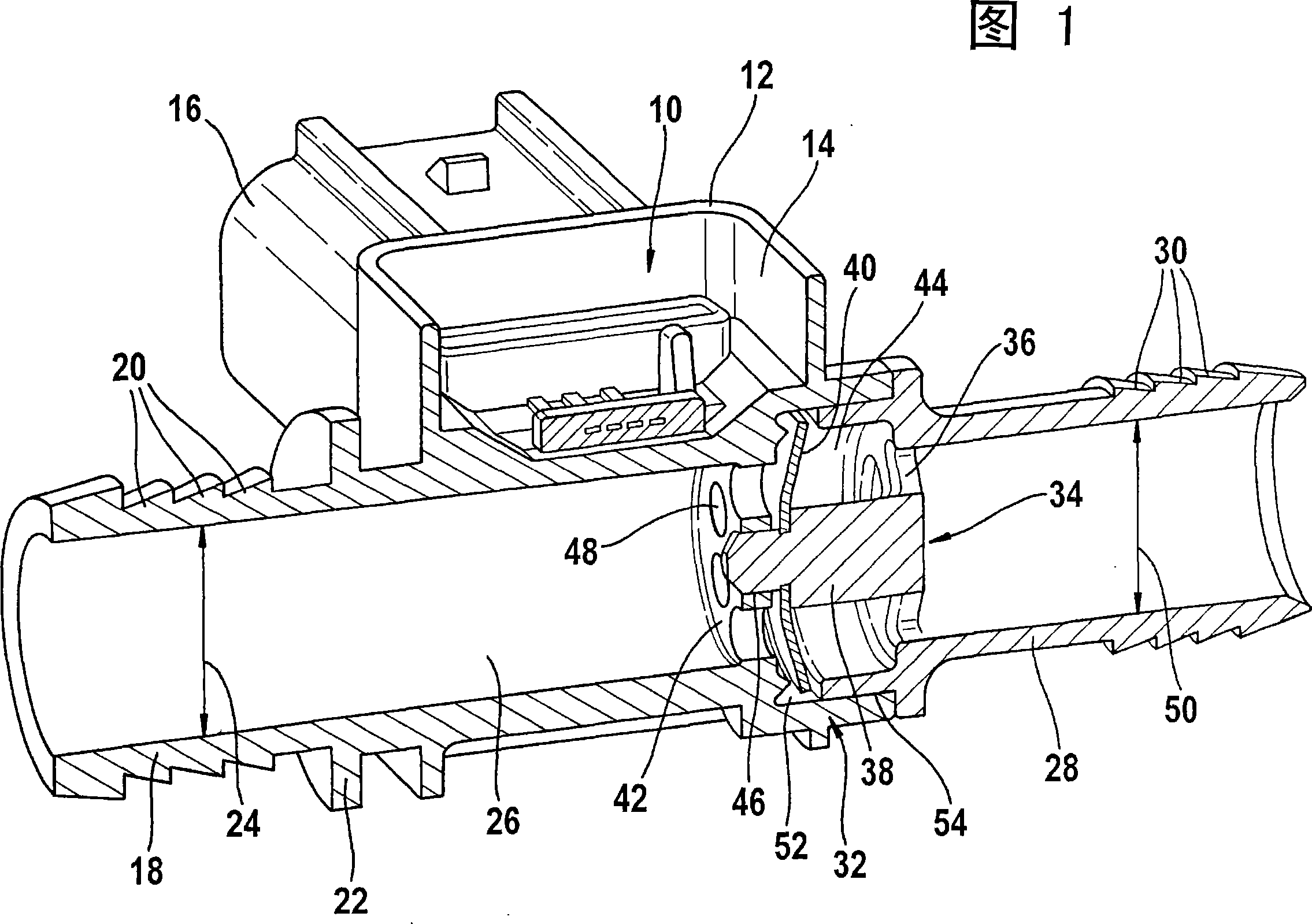

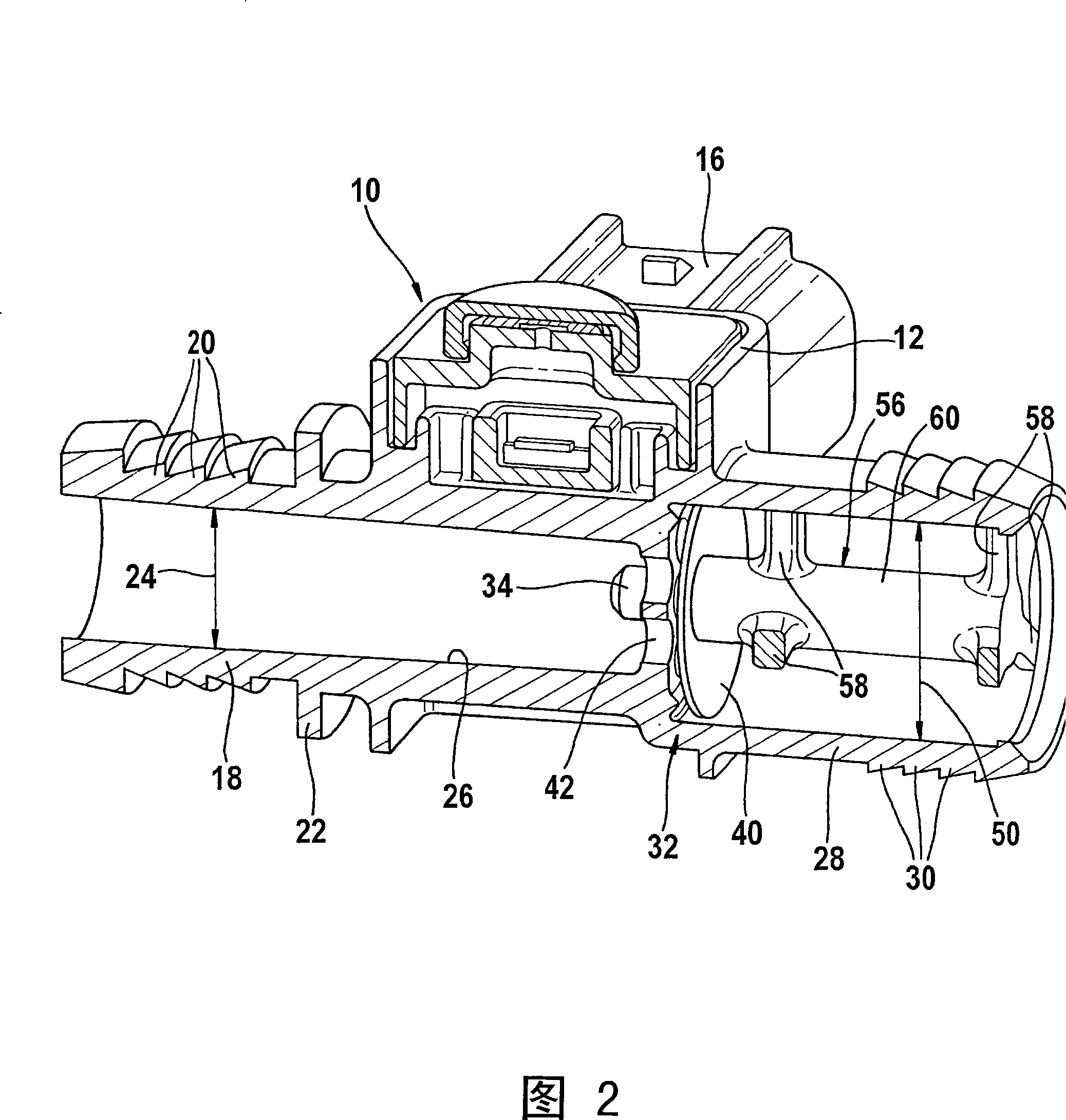

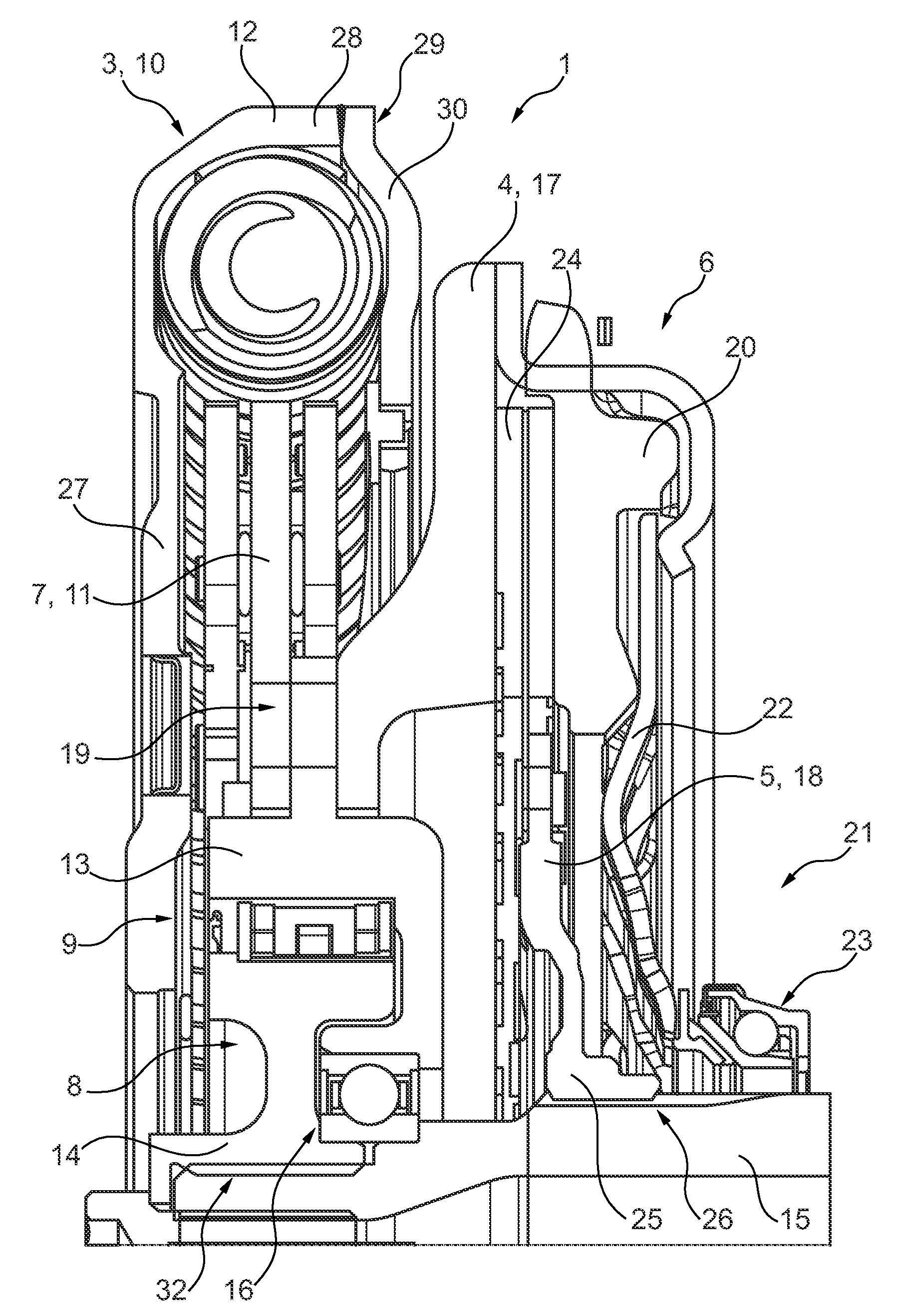

Surgical manipulation instrument

ActiveUS8945098B2High strengthSmall structure sizeDiagnosticsSurgical forcepsSurgical ManipulationMinimal invasive surgery

A surgical manipulation instrument which is particularly suitable for minimal invasive surgery, comprising an extra-corporeal drive device and a partial intra-corporeal manipulator part. The drive device comprises several axially displaceable first actuation elements. The first actuation elements are detachably connected to axially displaceable second actuation elements, by a coupling device, the second actuation elements being used to actuate an end effector. The coupling device comprises two coupling elements, one of the coupling elements having undercut recesses in which the second coupling element engages.

Owner:DEUTSCHES ZENTRUM FUER LUFT & RAUMFAHRT EV

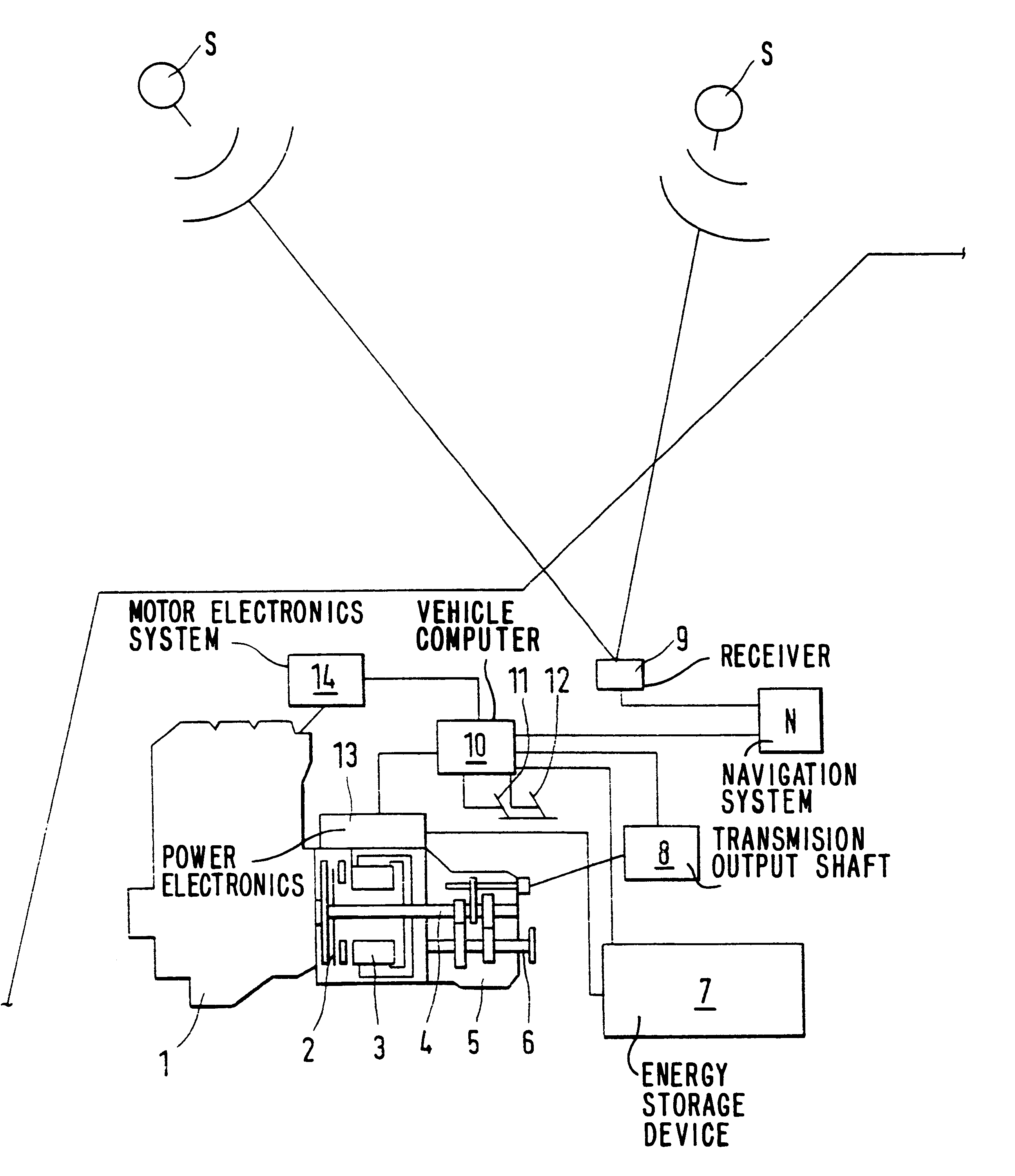

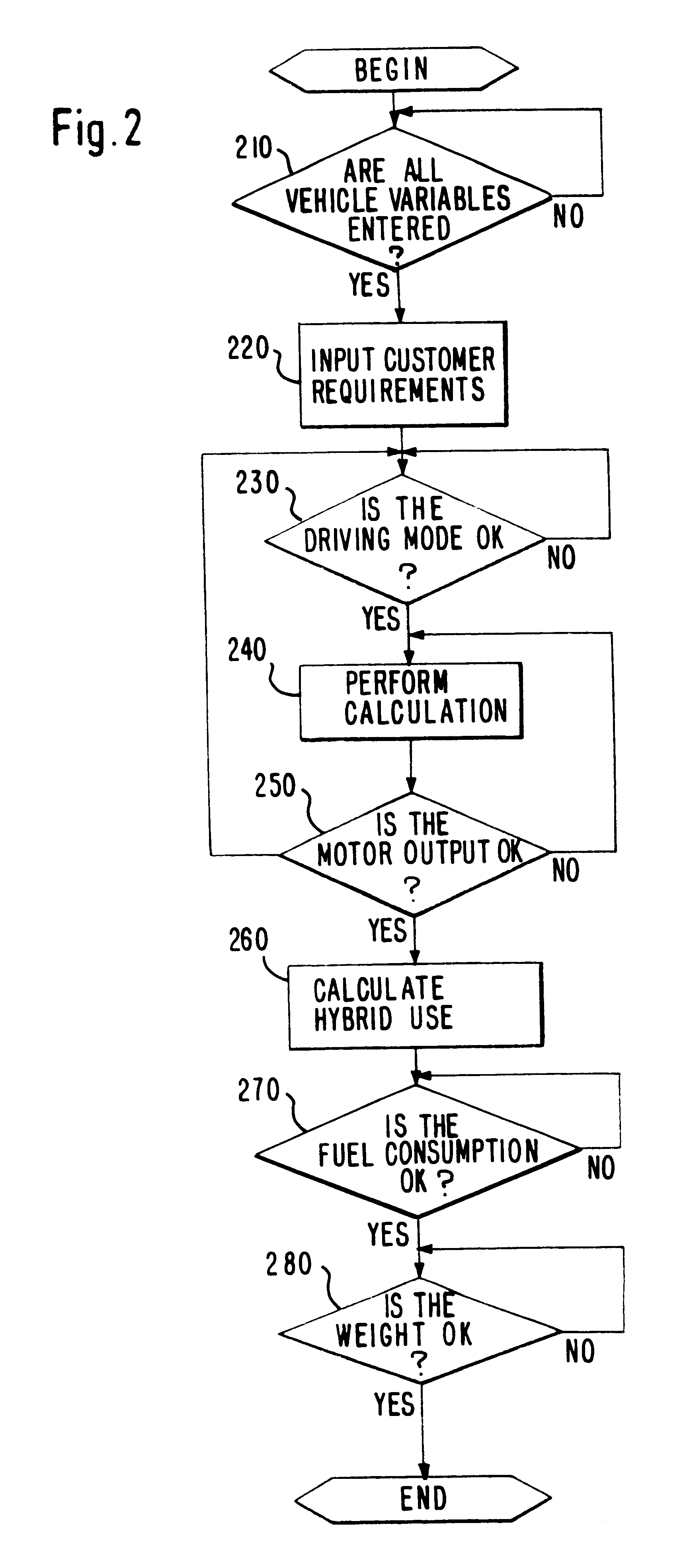

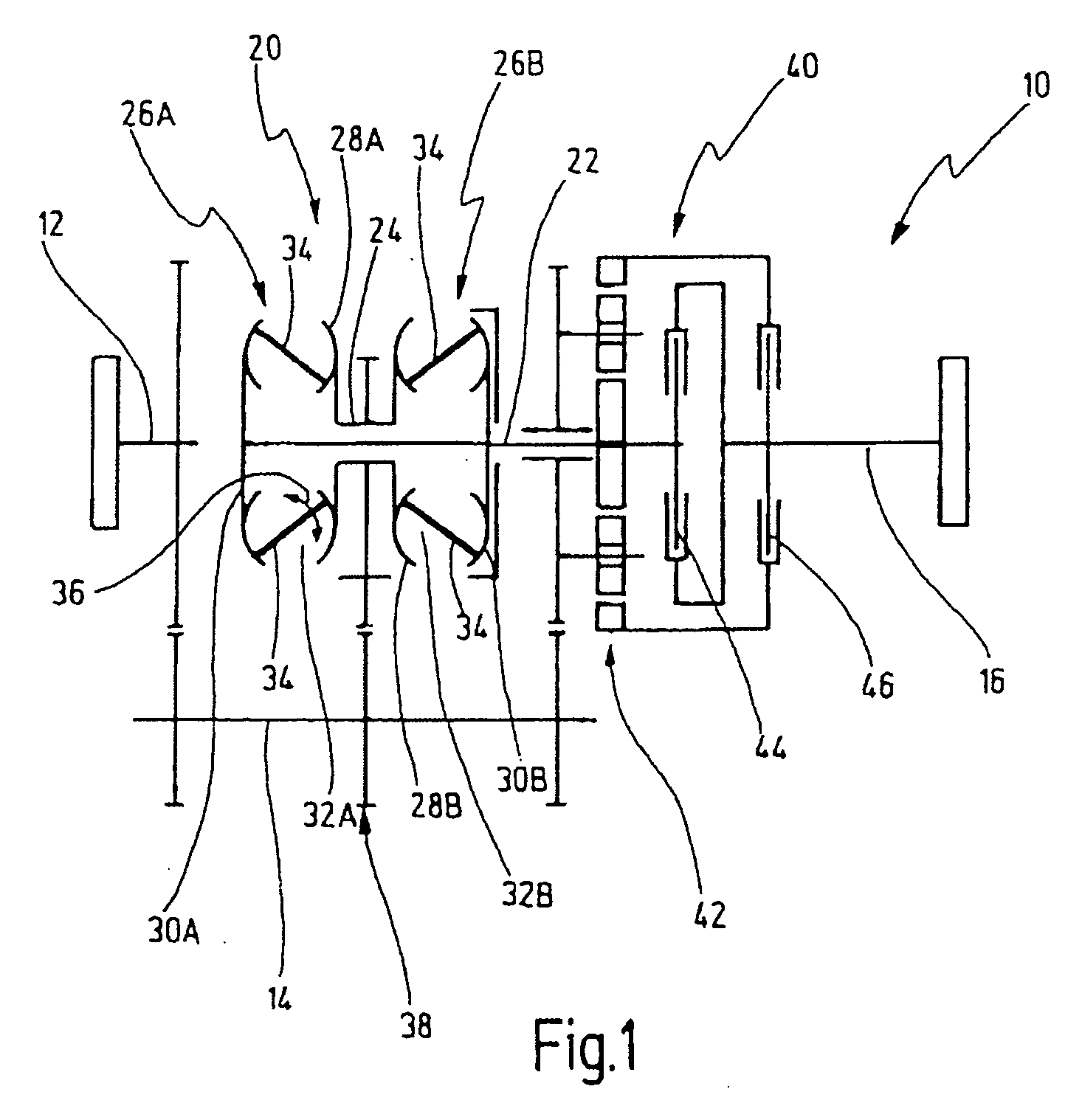

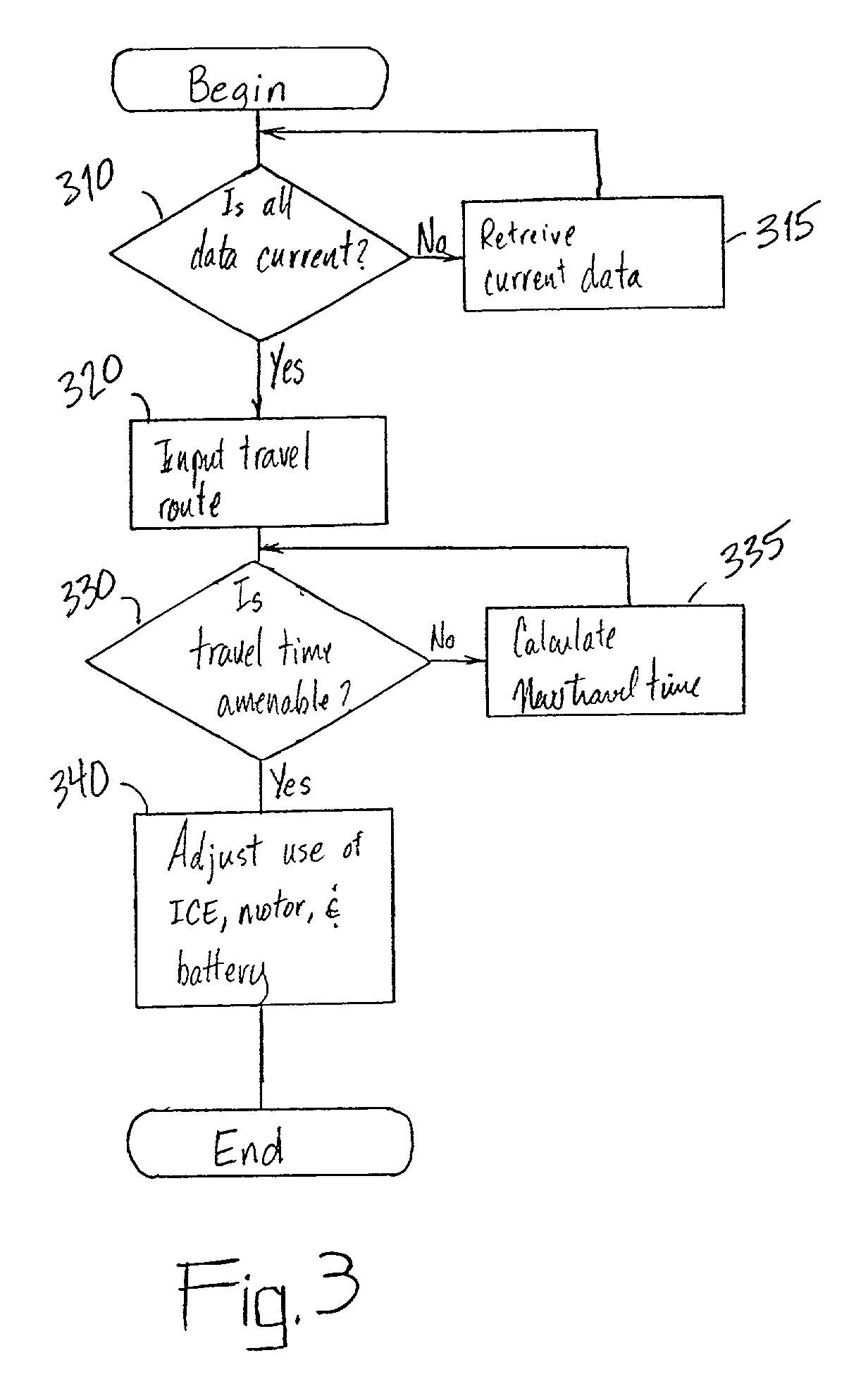

Hybrid vehicle and process for operating a hybrid vehicle

InactiveUS6249723B1Reduced overall construction spaceIncrease torqueDigital data processing detailsRailway vehiclesElectricityCoupling

A hybrid drive for a vehicle in which the driving power provided by an internal combustion engine (ICE) or an electric motor may be fed via a transmission with a transmission input shaft and a transmission output shaft to the drive train. The ICE and the electric motor are connectable to each other via a coupling and the electric motor is directly connected to the transmission. An electric energy storage device is connected to the ICE for receiving a charge and to the electric motor for providing power to the electric motor. The hybrid drive is designed so that the torque that can be provided by the electric motor is greater than that of the internal combustion engine. In addition, the transmission input shaft always turns in the same direction as the transmission output shaft so that reverse drive by the hybrid drive is only possible using the electric motor.

Owner:ZF FRIEDRICHSHAFEN AG

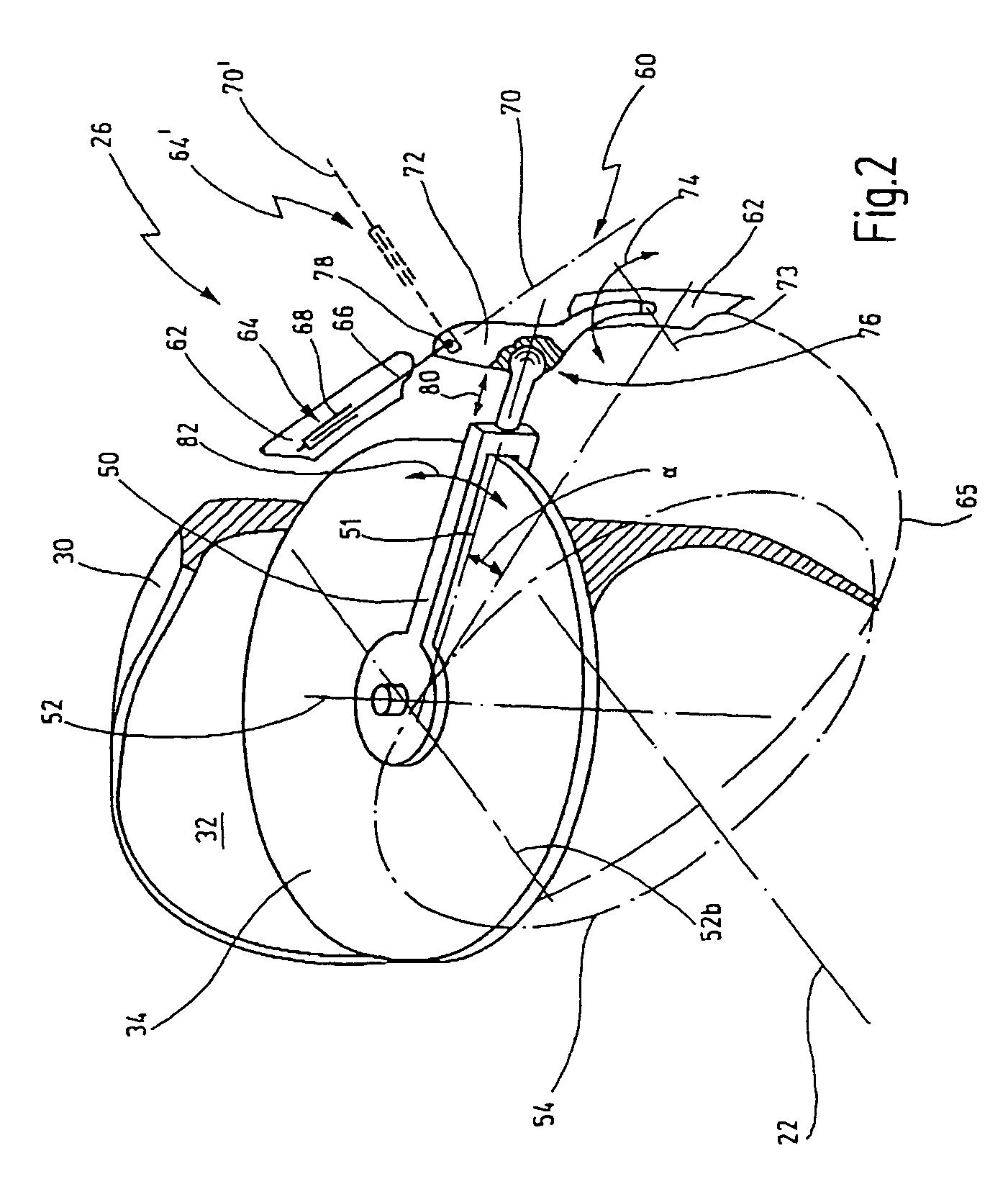

Torque converter with a turbine shell integrated with a torsional vibration damper

InactiveUS6056093AReduced overall construction spaceReduce in quantityYielding couplingRotary clutchesImpellerRotational axis

A torque converter includes a converter housing and a turbine wheel arranged in the converter housing and rotatable relative thereto around a rotational axis. The turbine wheel has a turbine wheel shell which has a plurality of turbine blades and a turbine wheel hub connected to the turbine wheel shell. An optional bridge coupling selectively connects the converter housing to the turbine wheel. A torsional vibration damper is connected between the turbine shell and the turbine wheel hub and a coupling mechanism of the bridge coupling is connected to the turbine wheel for torque transmission via the torsional vibration damper. The turbine shell forms a component of the torsional vibration damper.

Owner:MANNESMANN SACHS AG

Tensioning or deflector pulley in particular for the belt drive on an internal combustion engine

InactiveUS8235851B2Improve carrying capacityReduce wearRoller bearingsGearingExternal combustion engineEngineering

Owner:SCHAEFFLER TECH AG & CO KG

Door hinge

InactiveUS6851159B1Reliably permitCompact structureHingesWing openersEngineeringElectrical and Electronics engineering

Owner:EDSCHA AG

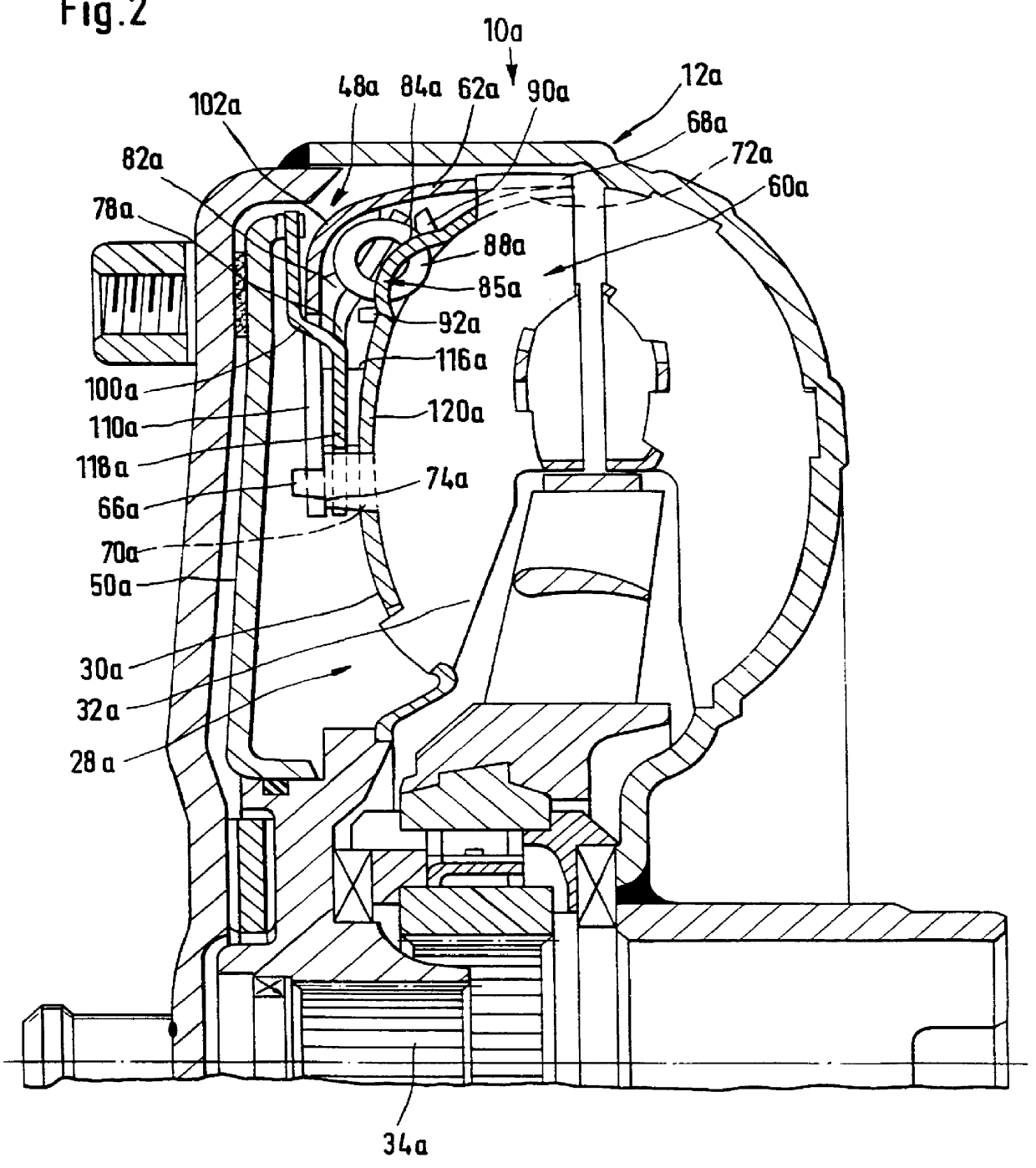

Variator and variator arrangement

ActiveUS20060189435A1Avoid bendingSuperior in pointGearing controlFriction gearingsMechanical engineeringPiston

A variator for a toroidal transmission, with a driving disk and with a driven disk, between which is set up a toroidal space which defines a toroidal reference circle. The variator, further, comprises at least two rollers which are arranged in the toroidal space for torque transfer between the driving disk and the driven disk. The rollers are in each case mounted rotatably on a roller carrier. The roller carriers are in each case spatially adjustable by means of a piston / cylinder arrangement, in order to adjust the transfer ratio of the variator. The pistons of the piston / cylinder arrangements are in each case adjustable along a stroke axis. Also, the pistons are connected to the roller carriers via respective levers.

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

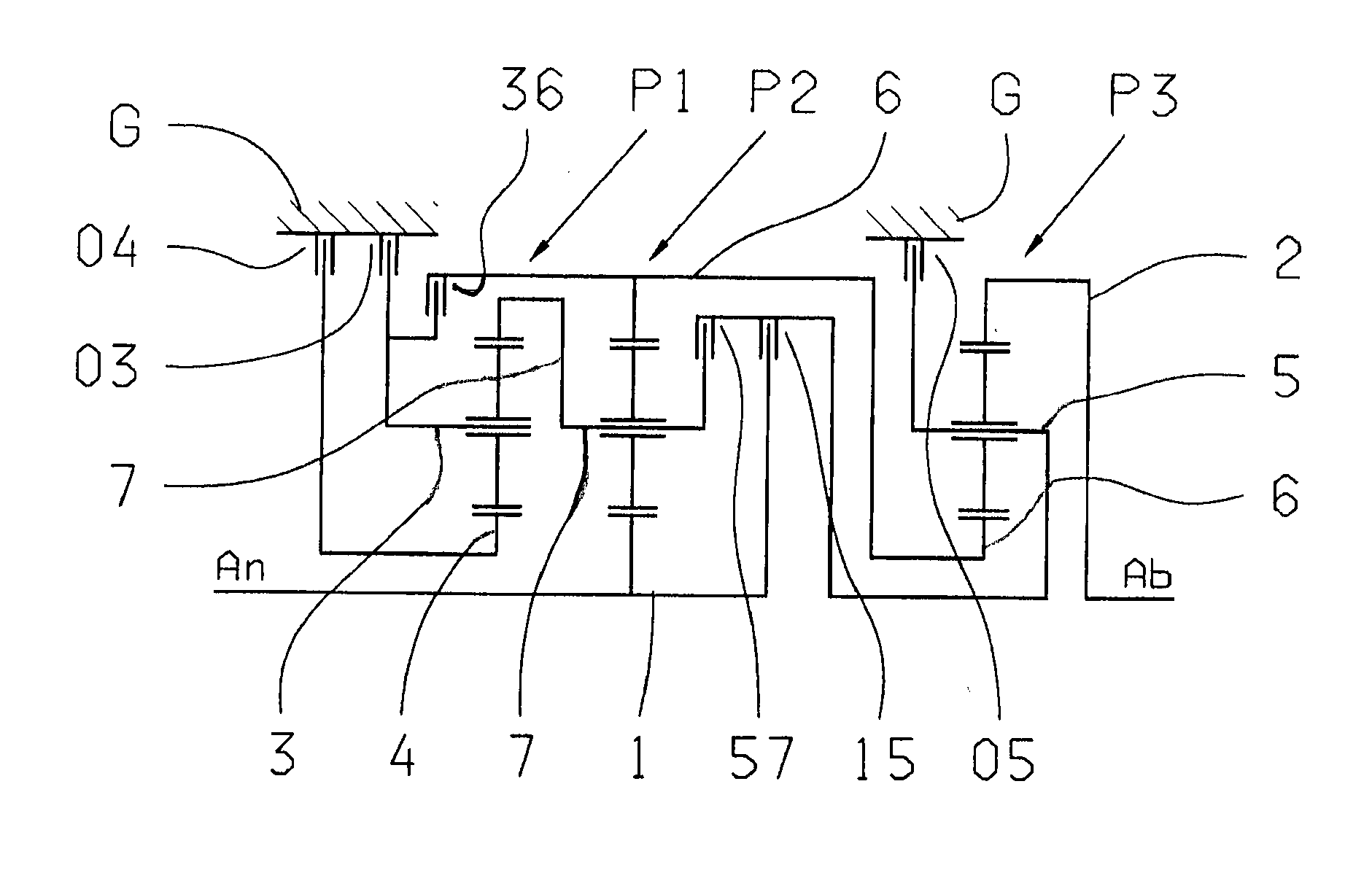

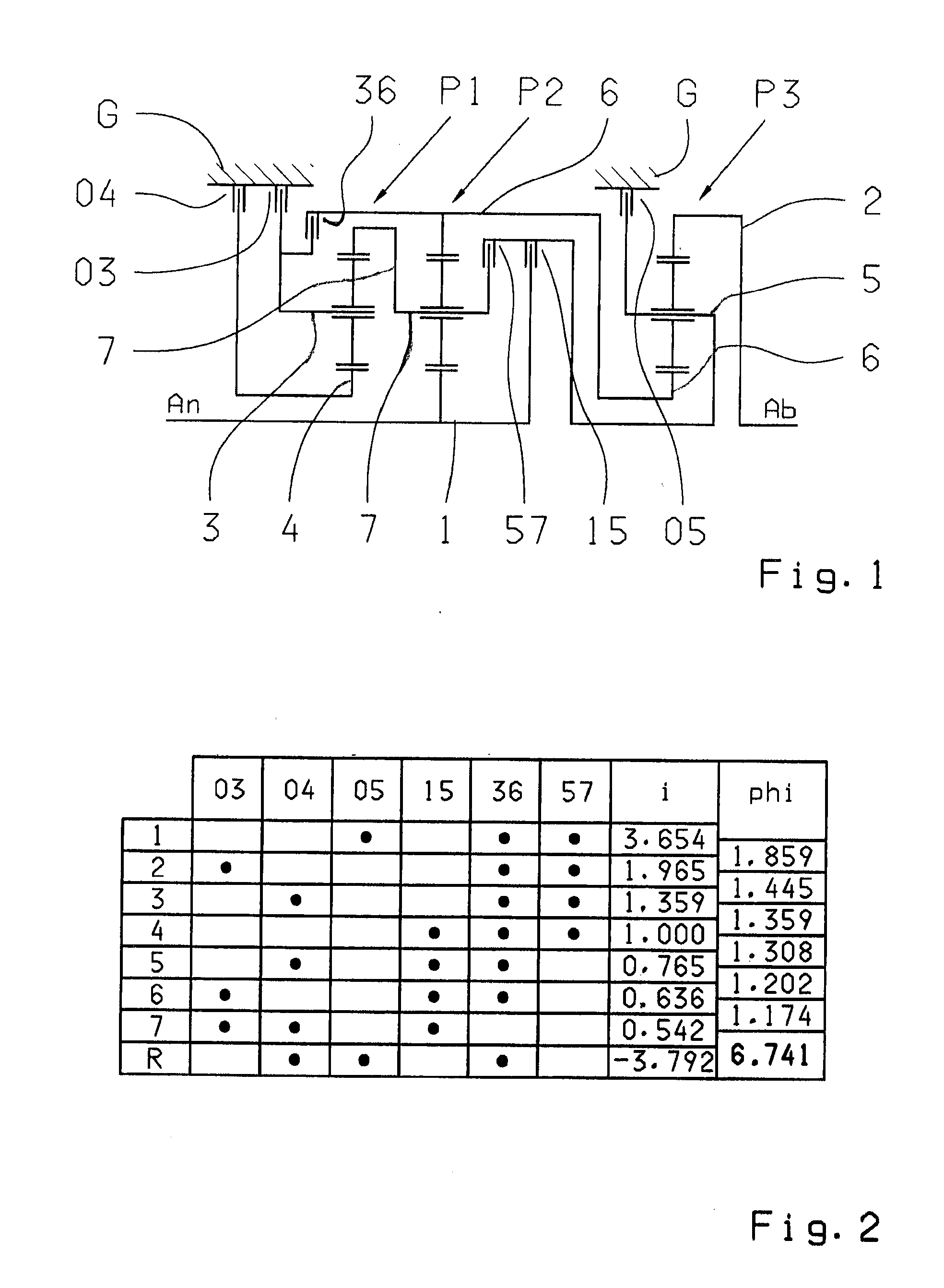

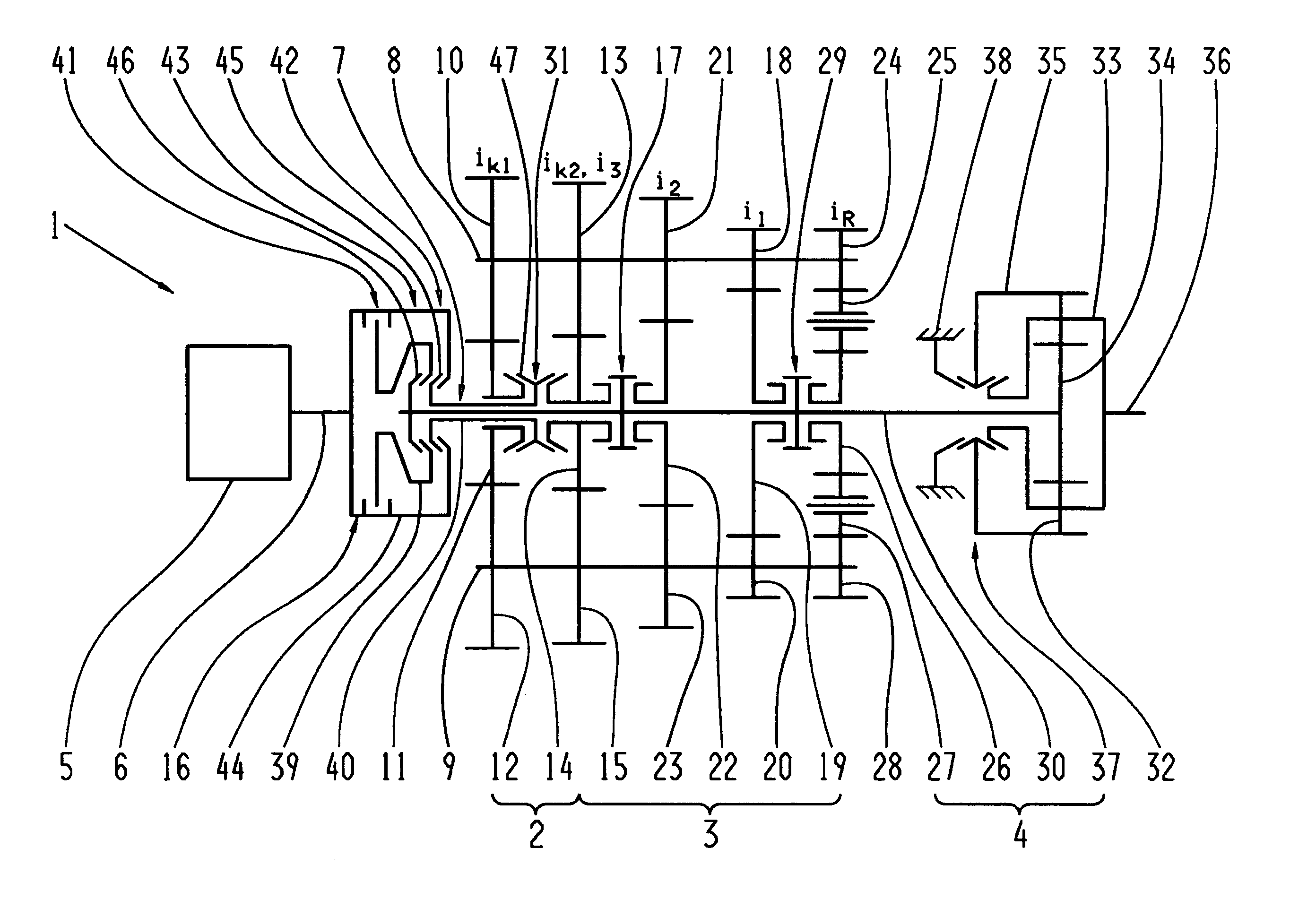

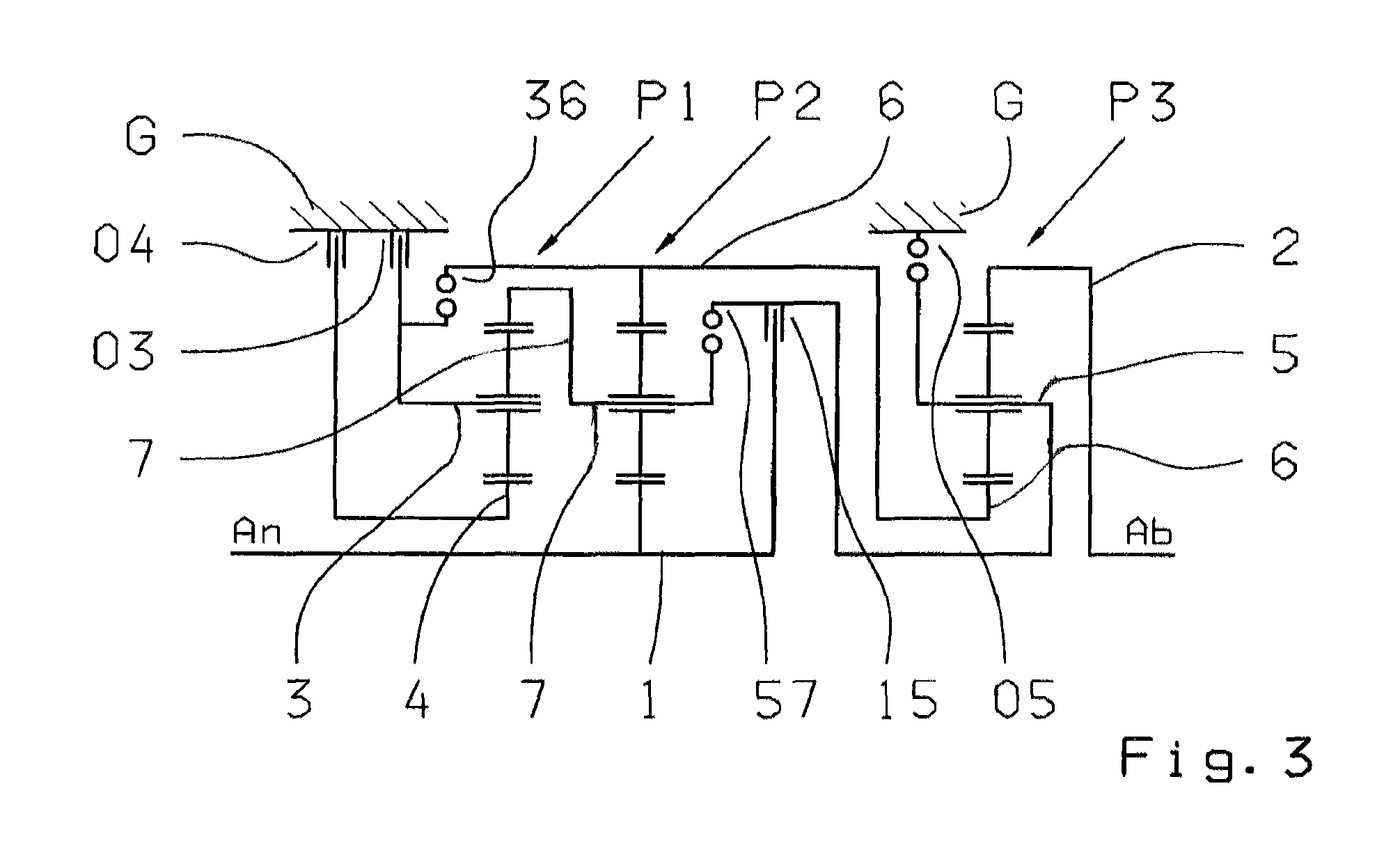

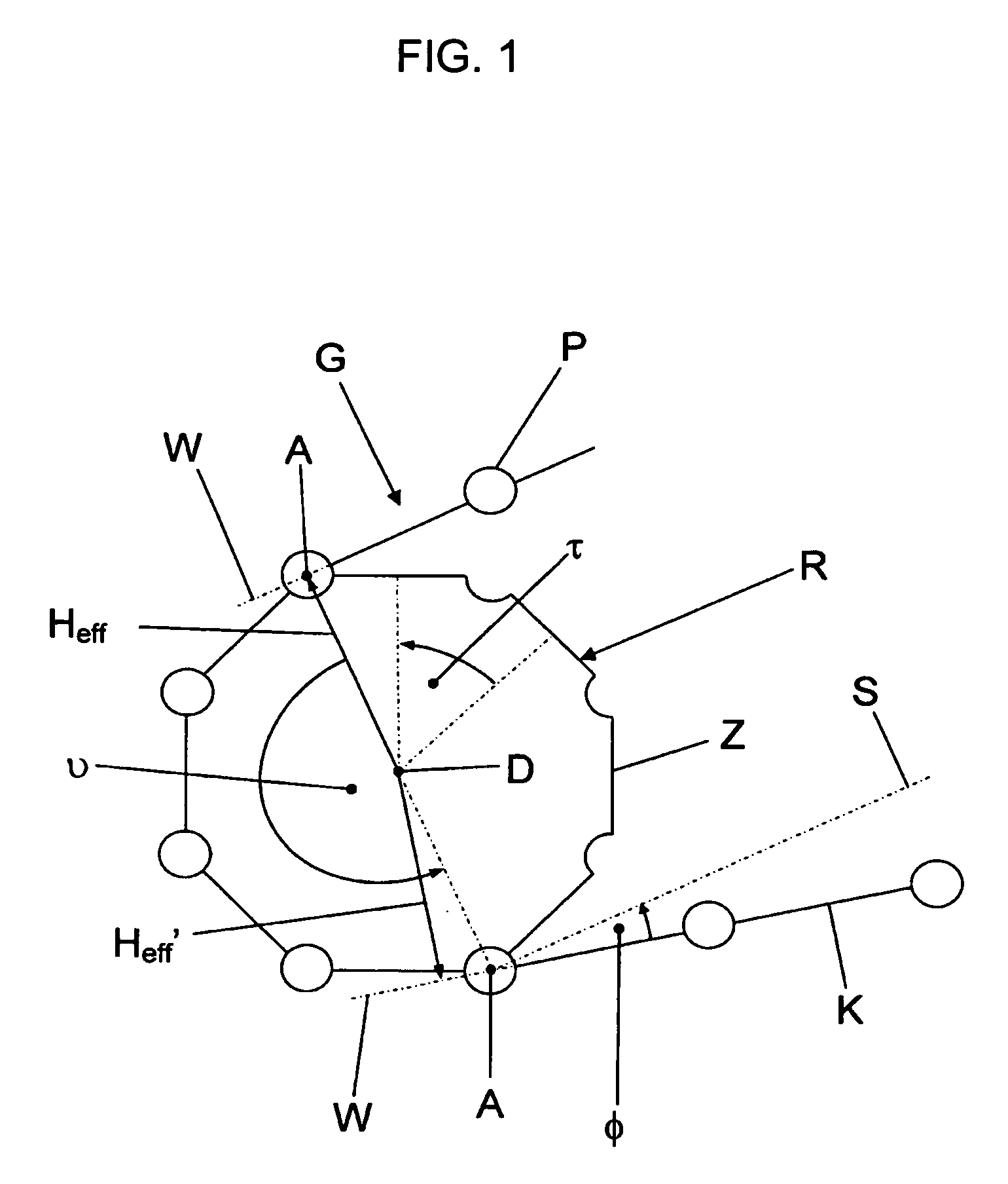

Multi-step transmission

InactiveUS20100130323A1Simple structureReduced overall construction spaceToothed gearingsTransmission elementsGear wheelControl theory

A multi-step transmission with forward and reverse gears comprises planetary gearsets, shafts and shift elements. The input shaft is coupled to the sun gear of gearset (P2) and, via a clutch (15), to a shaft (5) which is coupled to the carrier of gearset (P3) and, via brake (05), to the transmission housing and, via clutch (57), to shaft (7). Shaft (7) is coupled to the carrier of gearset (P2) and the ring gear of gearset (P1). Shaft (6) is coupled to the sun gear of gearset (P3) and the ring gear of gearset (P2) and, via clutch (36), to shaft (3) which is coupled the carrier of gearset (P1) and, via brake (03), to the housing. Shaft (4) is connected to the sun gear of gearset (P1) and can be coupled, via brake (04), to the housing. The output shaft (2) is connected to the ring gear of gearset (P3).

Owner:ZF FRIEDRICHSHAFEN AG

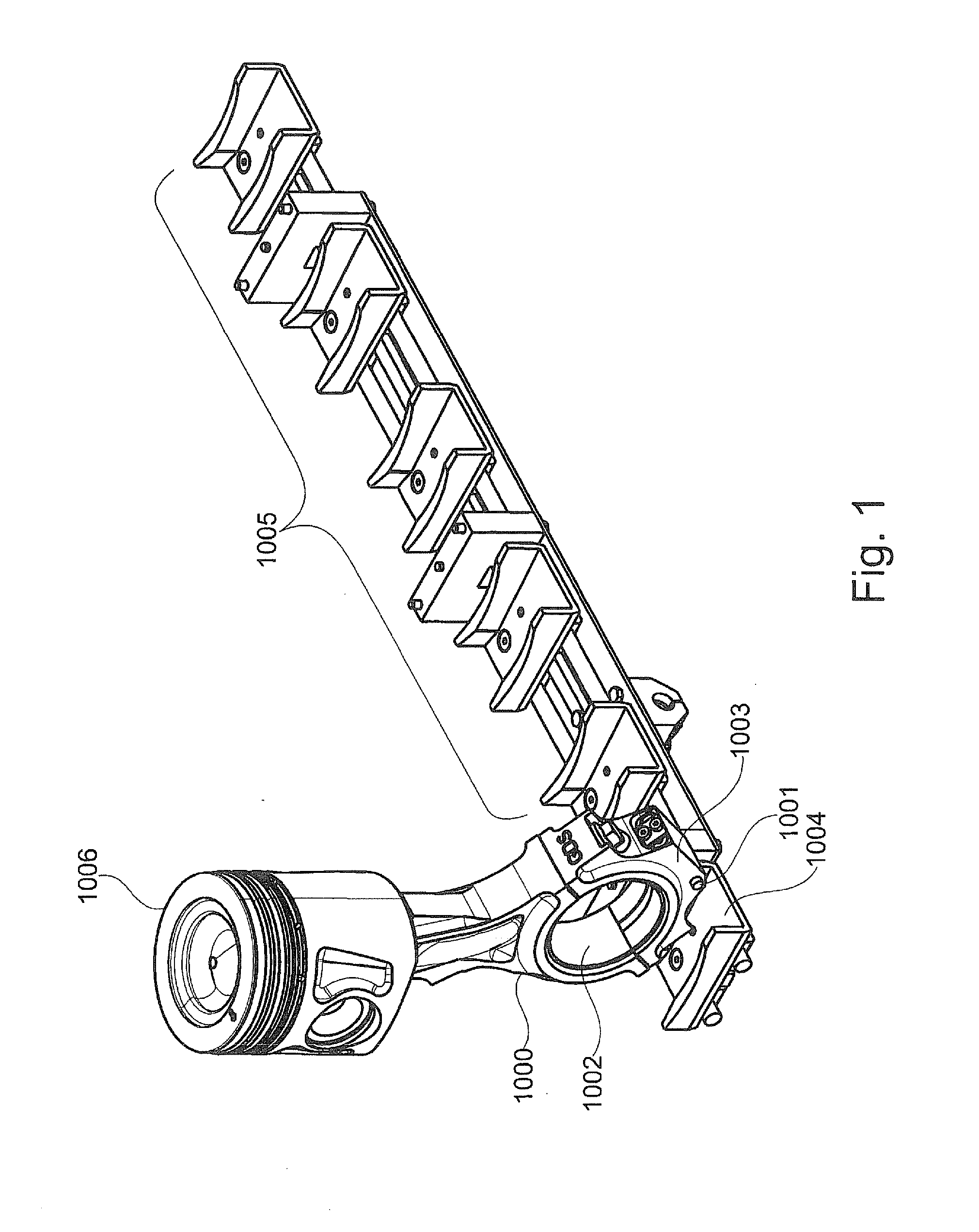

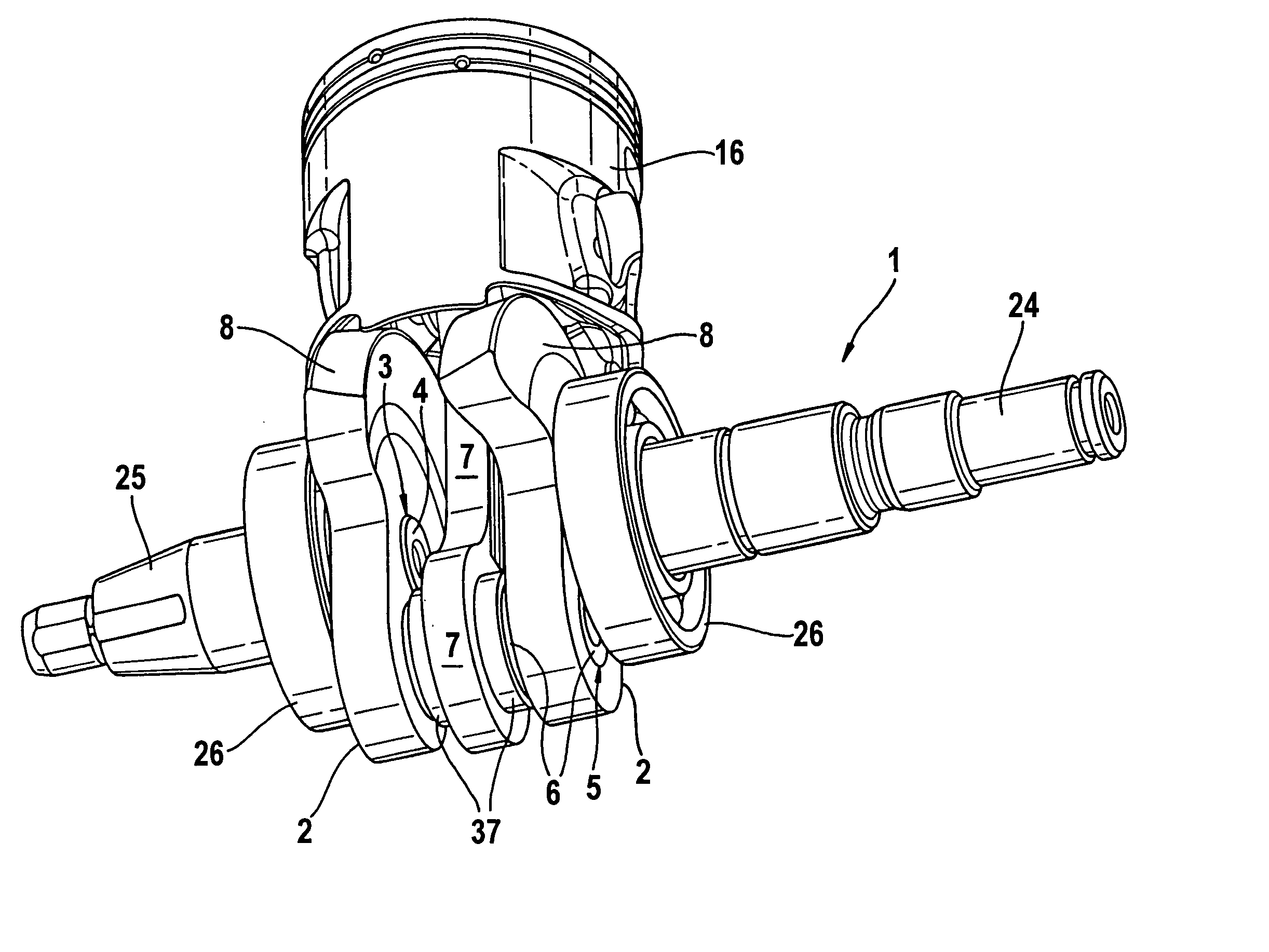

Actuating unit for variable power plant components

InactiveUS20150260109A1High strengthSimplify the assembly processMechanical controlConnecting rodsInternal combustion engineVariable length

The invention relates to a reciprocating-piston internal combustion engine with variable compression, having an actuating unit for changing a variable compression of the reciprocating-piston internal combustion engine, wherein, to change the variable compression, the actuating unit actuates a variable engine component of the reciprocating piston internal combustion engine in the form of a connecting rod with variable length, a piston with variable compression height and / or a crankshaft with variable crankshaft radius, and the actuating unit is arranged at a lower level than the reciprocating-piston internal combustion engine. Also proposed are a method and also an actuating unit for the same.

Owner:FEV

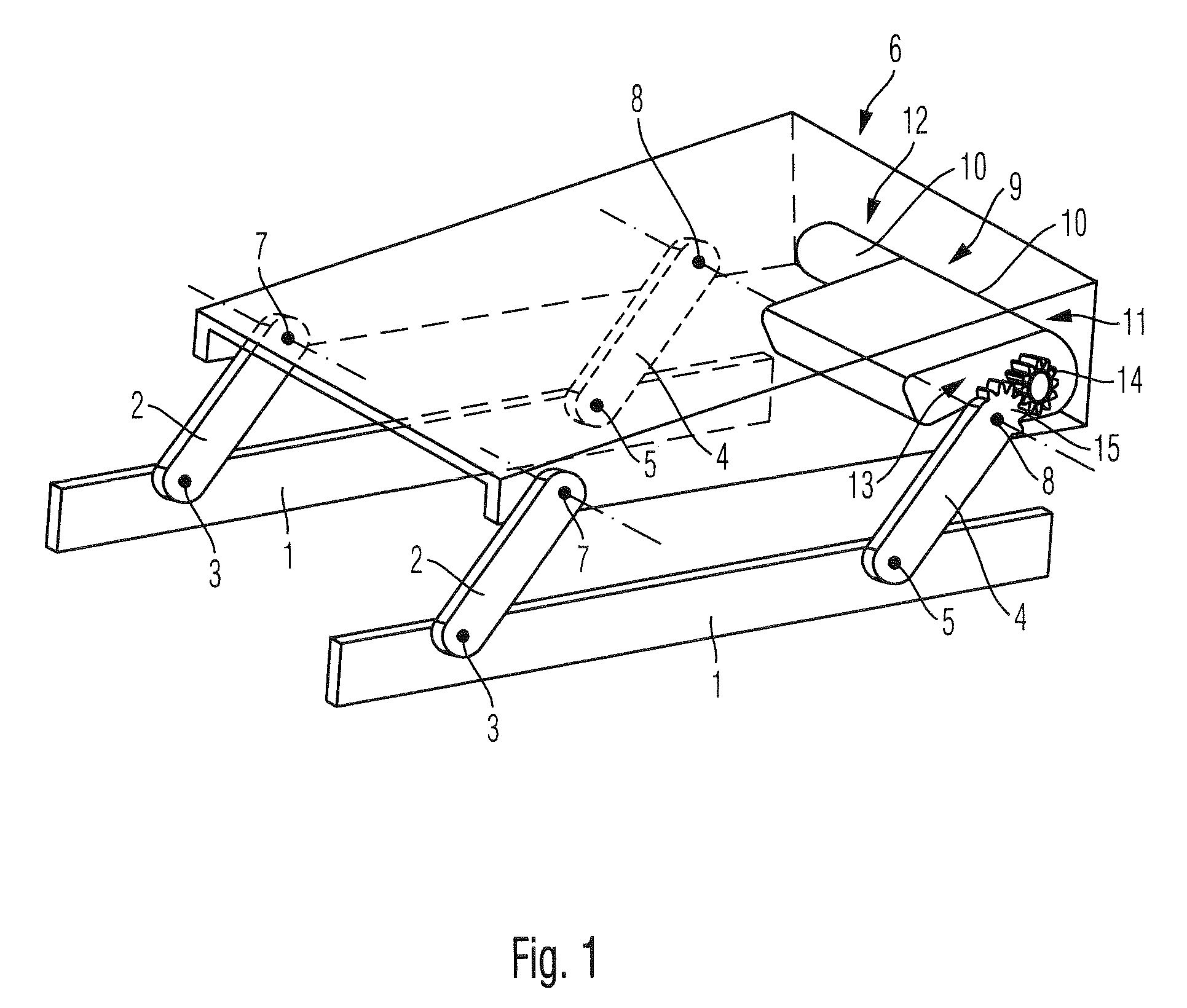

Arrangement of a component and of a drive element assigned to this component

InactiveUS20100148532A1Improve component stiffnessReduced overall construction spaceStands/trestlesKitchen equipmentDriven elementPlastic injection molding

An arrangement is provided for a component (6) and a drive element (11, 12) for the component. The drive element has a housing (9). The component is produced by a primary forming process, such as die-casting, thixomolding or plastic injection molding so that a region of the component defines the housing of the drive element. The component and the housing are distinguished by a low weight and a small structural space requirement.

Owner:DR ING H C F PORSCHE AG

Multi-group transmission of a motor vehicle

InactiveUS8066606B2Improve the level ofReduce speed lossToothed gearingsGearing controlDrivetrainGear wheel

A multi-group transmission of a vehicle is arranged in a drivetrain and includes traction force support during gearshift operations. A clutch mechanism, including a frictional clutch and two shifting clutches is arranged between a drive motor with a driveshaft and a transmission input shaft, such that the driveshaft can be connected to the transmission input shaft by one shifting clutch in a first shift position in combination with the frictional clutch or in a second shift position with bridging of the frictional clutch, such that the driveshaft can be directly connected to a main transmission shaft by the other shifting clutch in a shift position in active combination with the frictional clutch. In a method for operating the transmission, the frictional clutch is controlled and operated in combination with the first shifting clutch as a starting clutch and with the second shifting clutch as an intermediate-gear clutch.

Owner:ZF FRIEDRICHSHAFEN AG

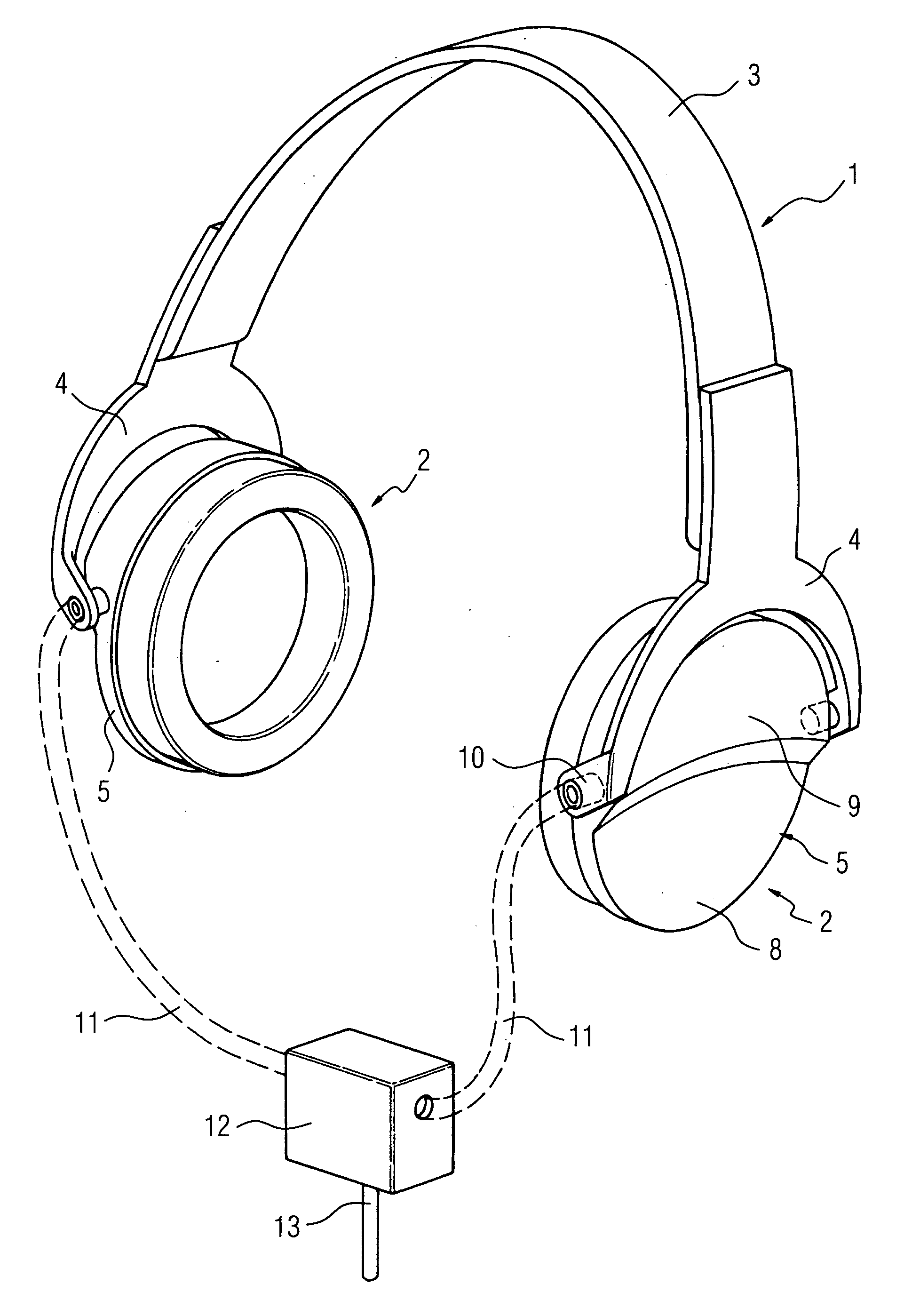

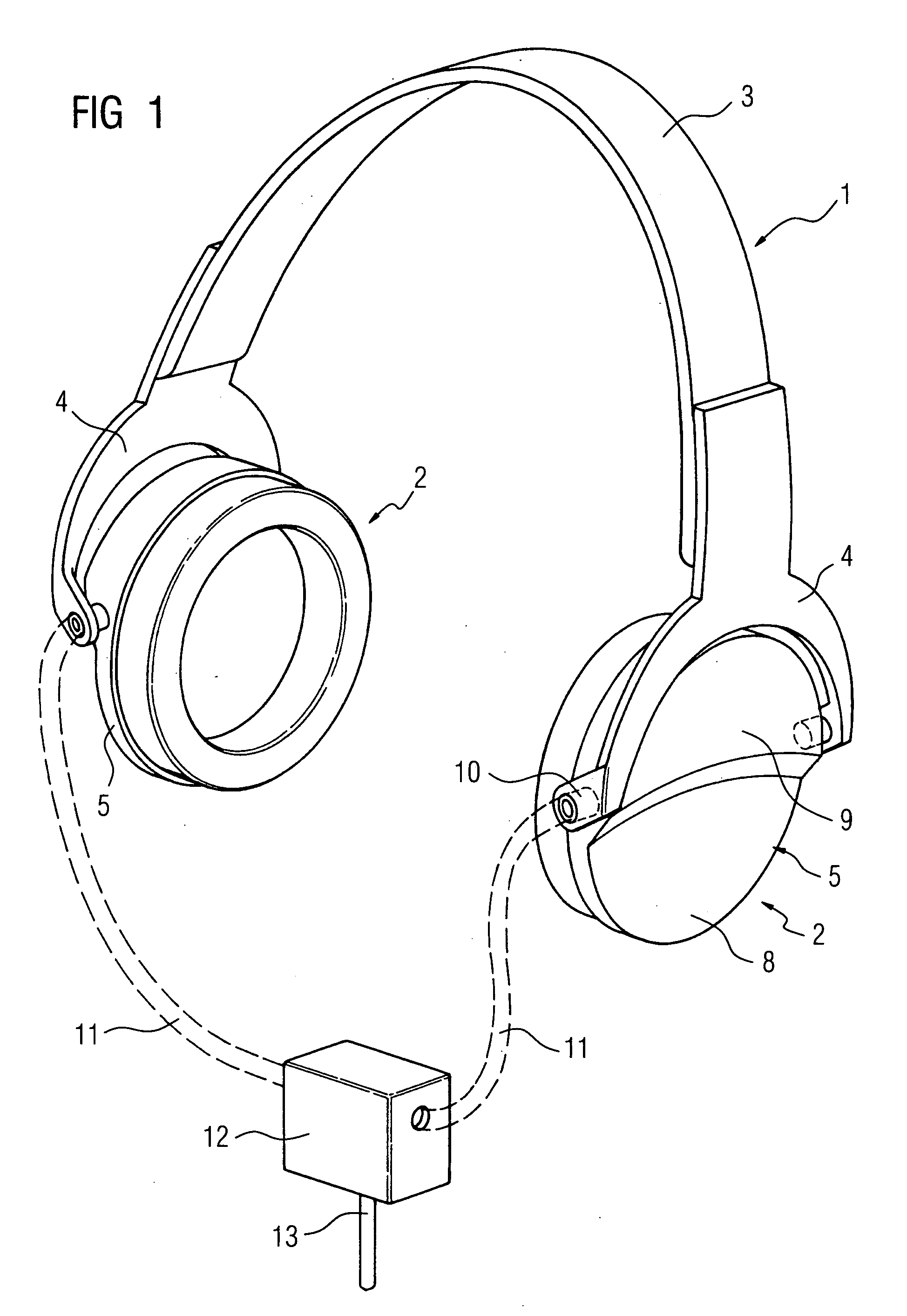

Hearing protection for use in magnetic resonance facilities

ActiveUS20060123527A1Simple tube managementPrevent claustrophobiaDiagnostic recording/measuringSensorsResonanceEngineering

A hearing protection for use in magnetic resonance facilities, comprising two protective covers for covering the ears of an examination patient, said covers being connected to each other via a clip, wherein each cover has a plastic outer shell, wherein a compact inner part is arranged in and permanently connected to the outer shell, said inner part consisting of a dimensionally stable plastic mass and essentially filling the outer shell completely.

Owner:SIEMENS HEALTHCARE GMBH

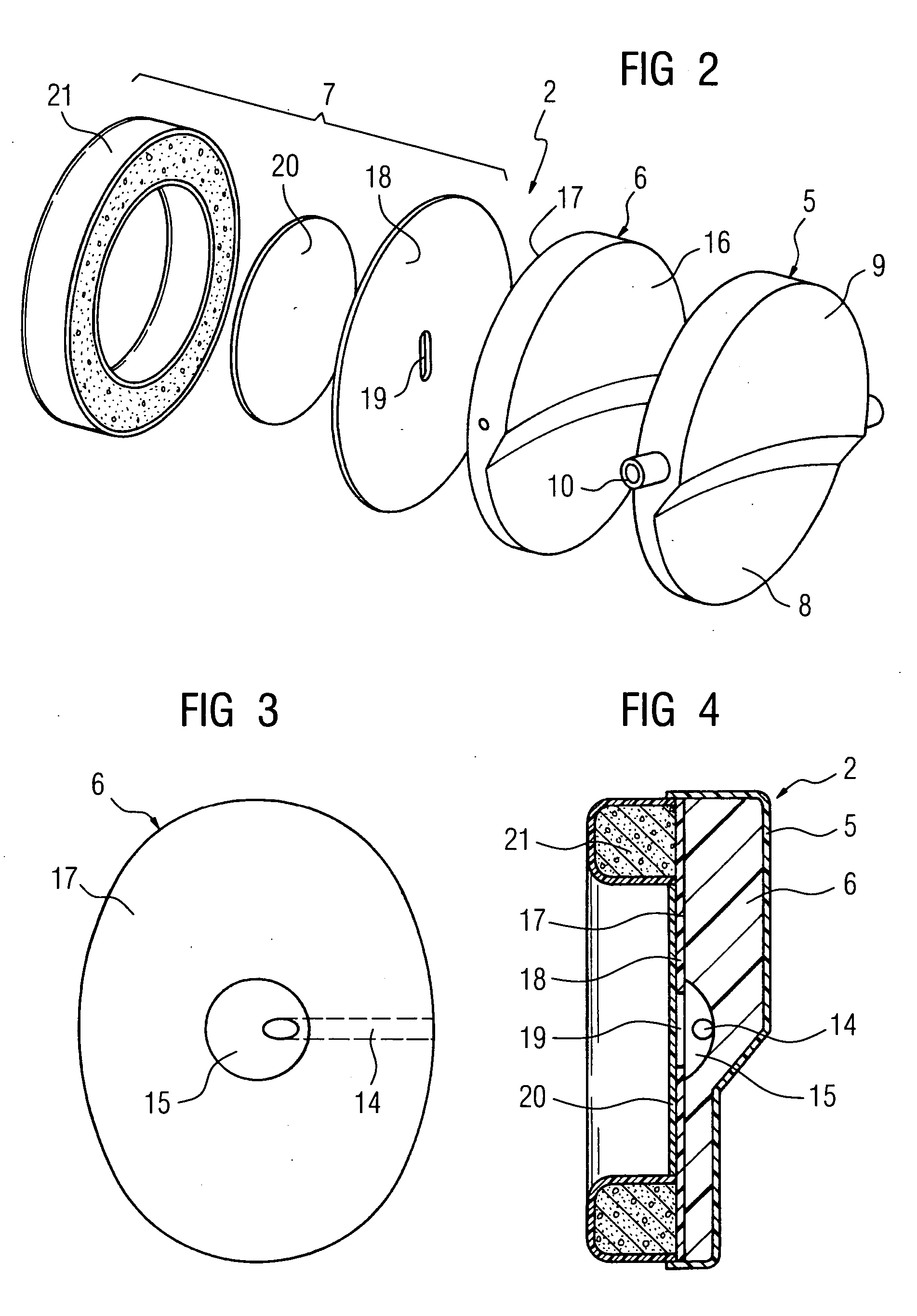

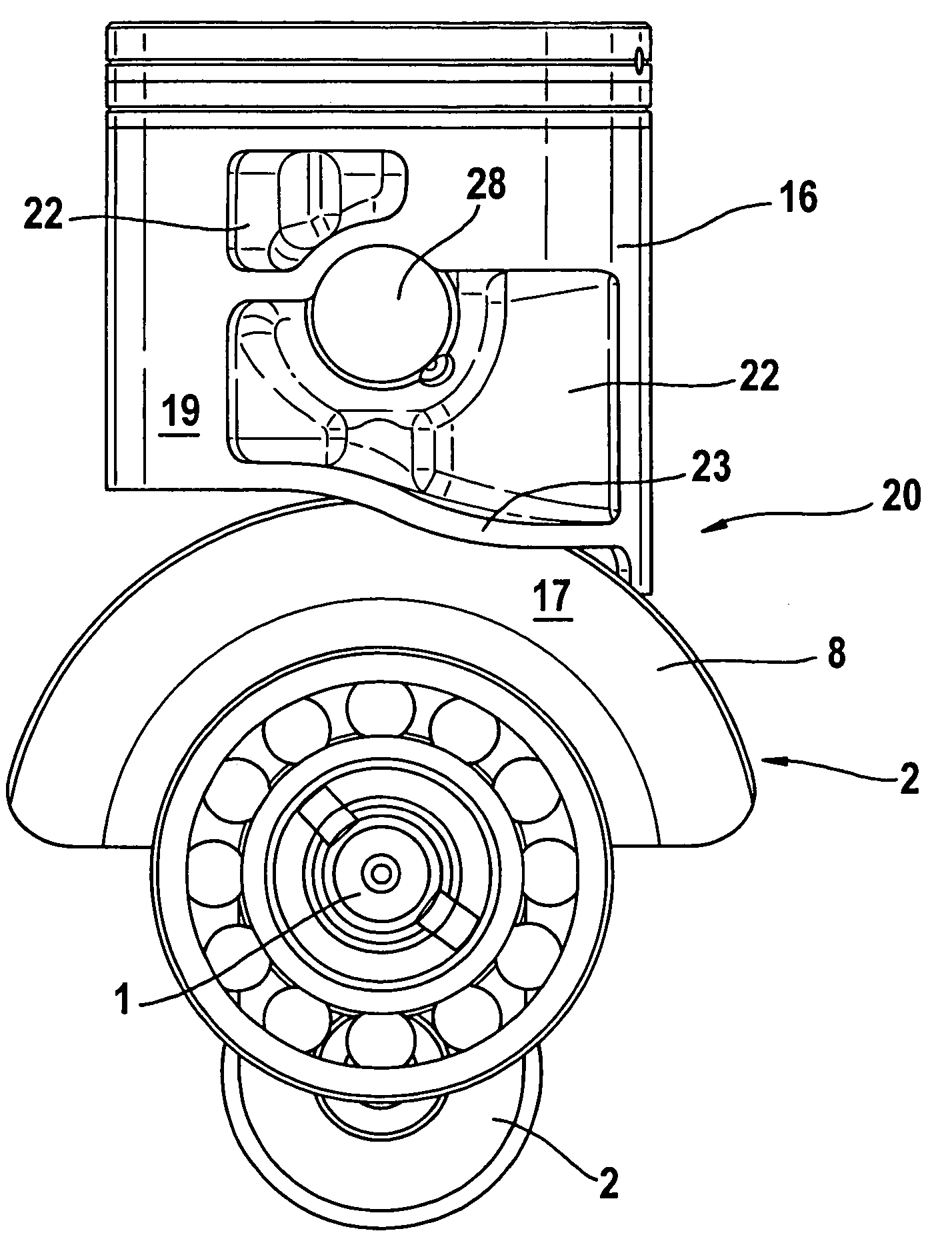

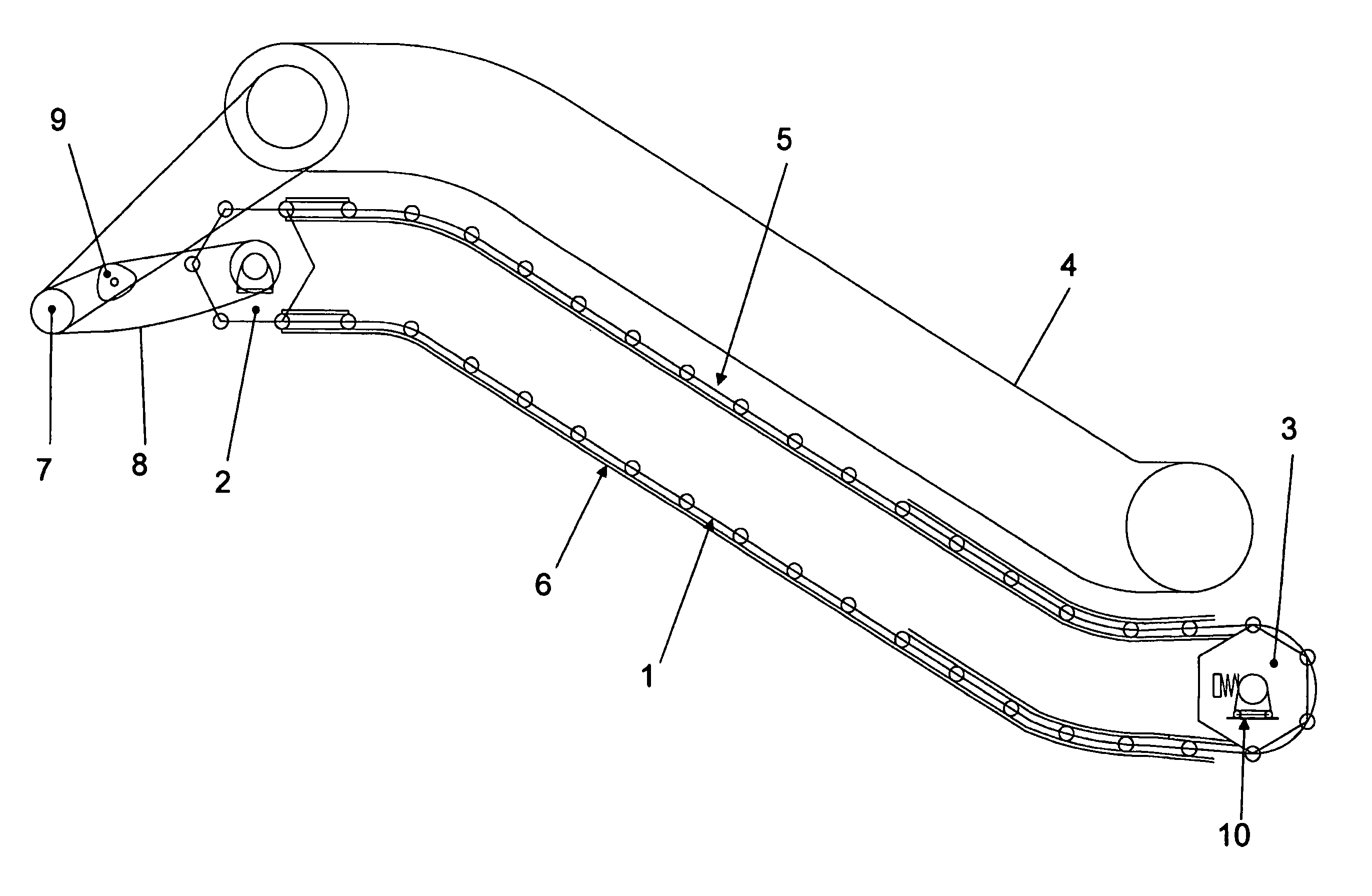

Crankshaft assembly of an internal combustion engine

InactiveUS20050205043A1Good centrifugal mass characteristicReduced overall construction spaceCrankshaftsConnecting rodsMotor driveHand held

The invention is directed to a crankshaft (1) of an internal combustion engine including an internal combustion engine for a portable handheld work apparatus such as a motor-driven chain saw or the like. The invention is also directed to a method for making the crankshaft (1) as well as an internal combustion engine with a corresponding crankshaft (1). The crankshaft (1) is made up of separately manufactured parts and includes a crank arm (2) having a central cutout (3) for accommodating a shaft lug (4) of the crankshaft (1) and an eccentric cutout (5) for accommodating a crank pin (6). The crank pin (6) journals a connecting rod (7). A centrifugal mass portion (8) is provided on the crank arm (2) at its end lying opposite the eccentric cutout (5). The centrifugal mass portion (8) is configured as one piece with the crank arm (2) and is bent out of a plane (9) of the crank arm (2) in the direction of the connecting rod (7).

Owner:ANDREAS STIHL AG & CO KG

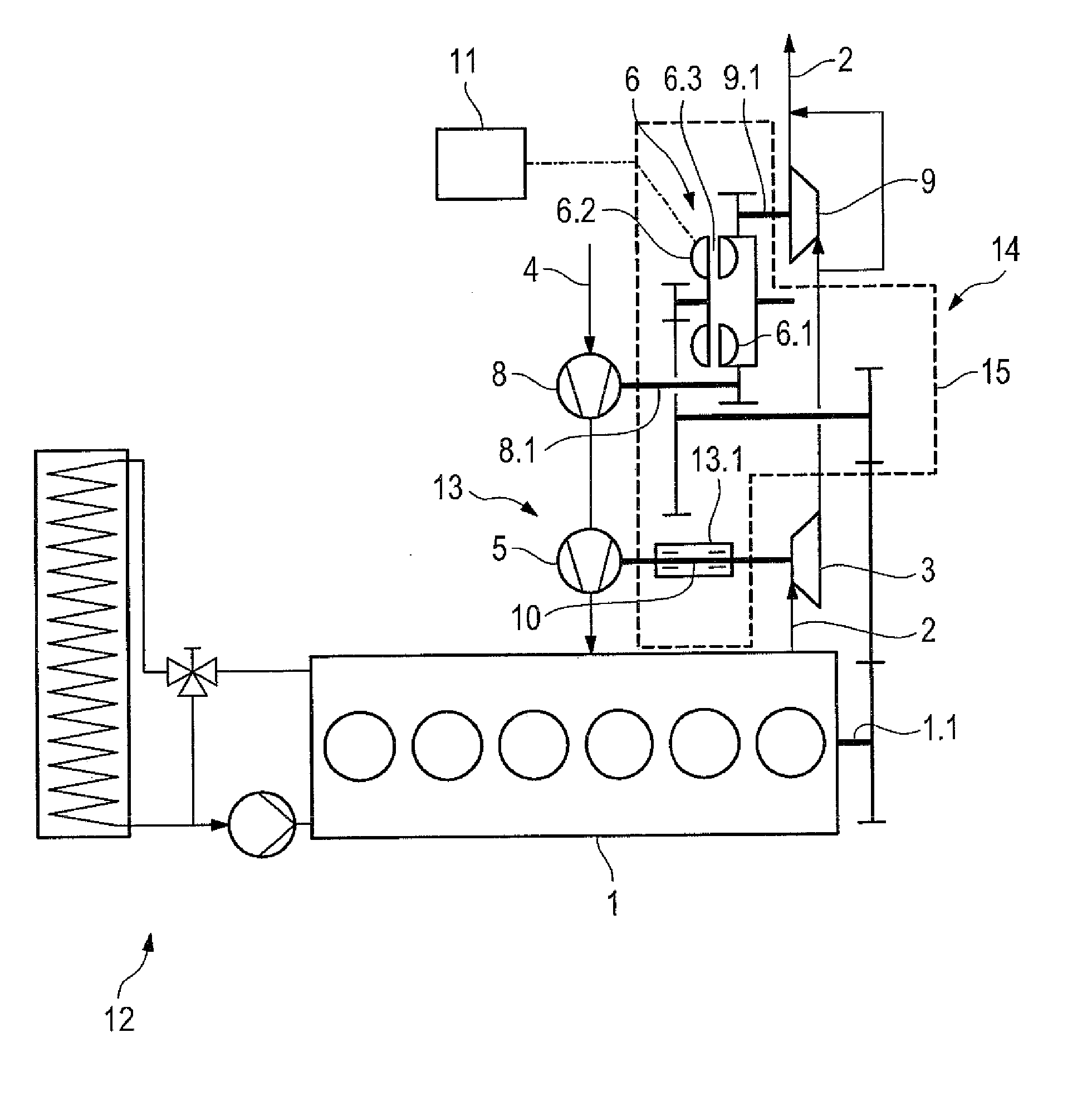

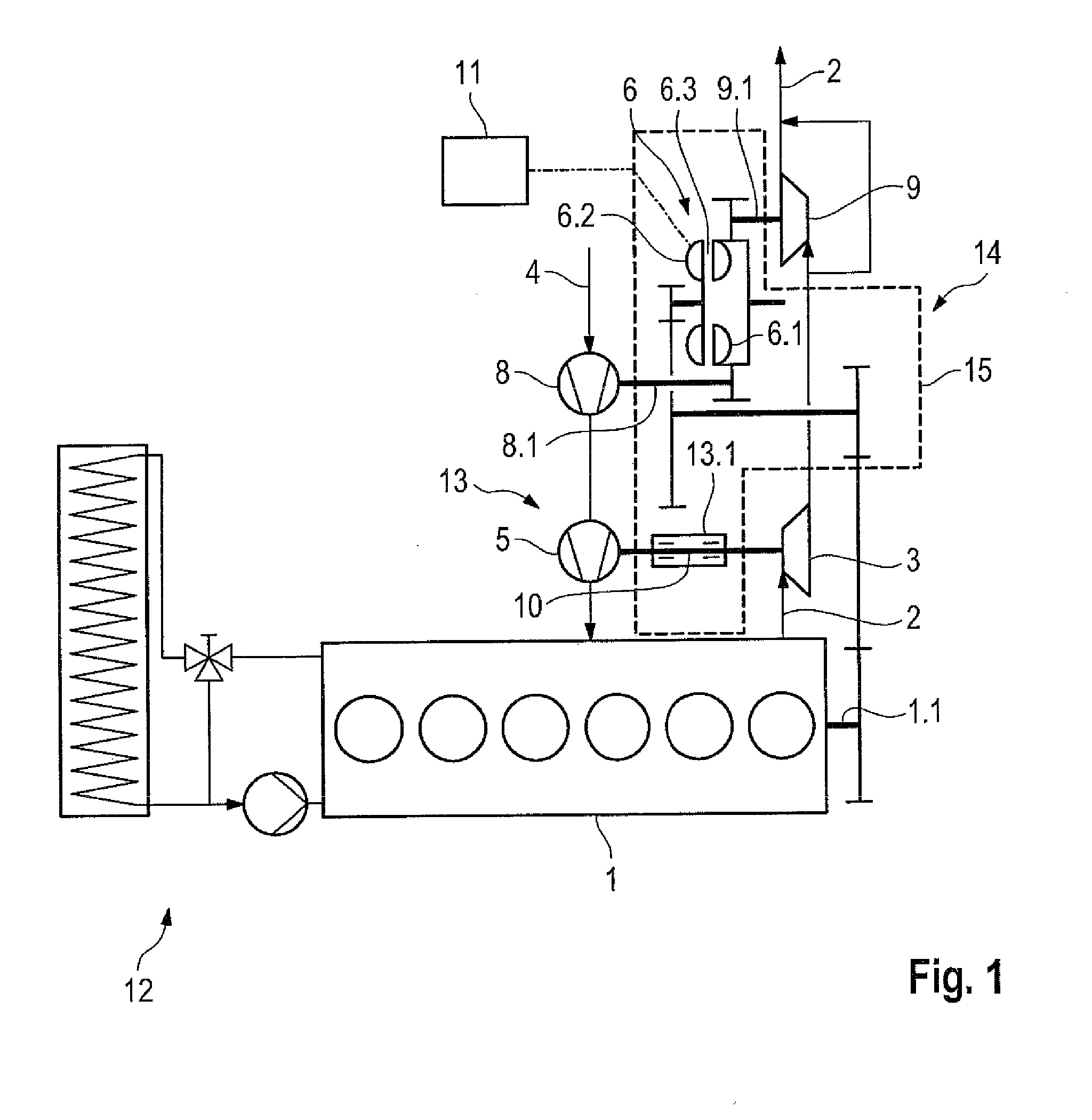

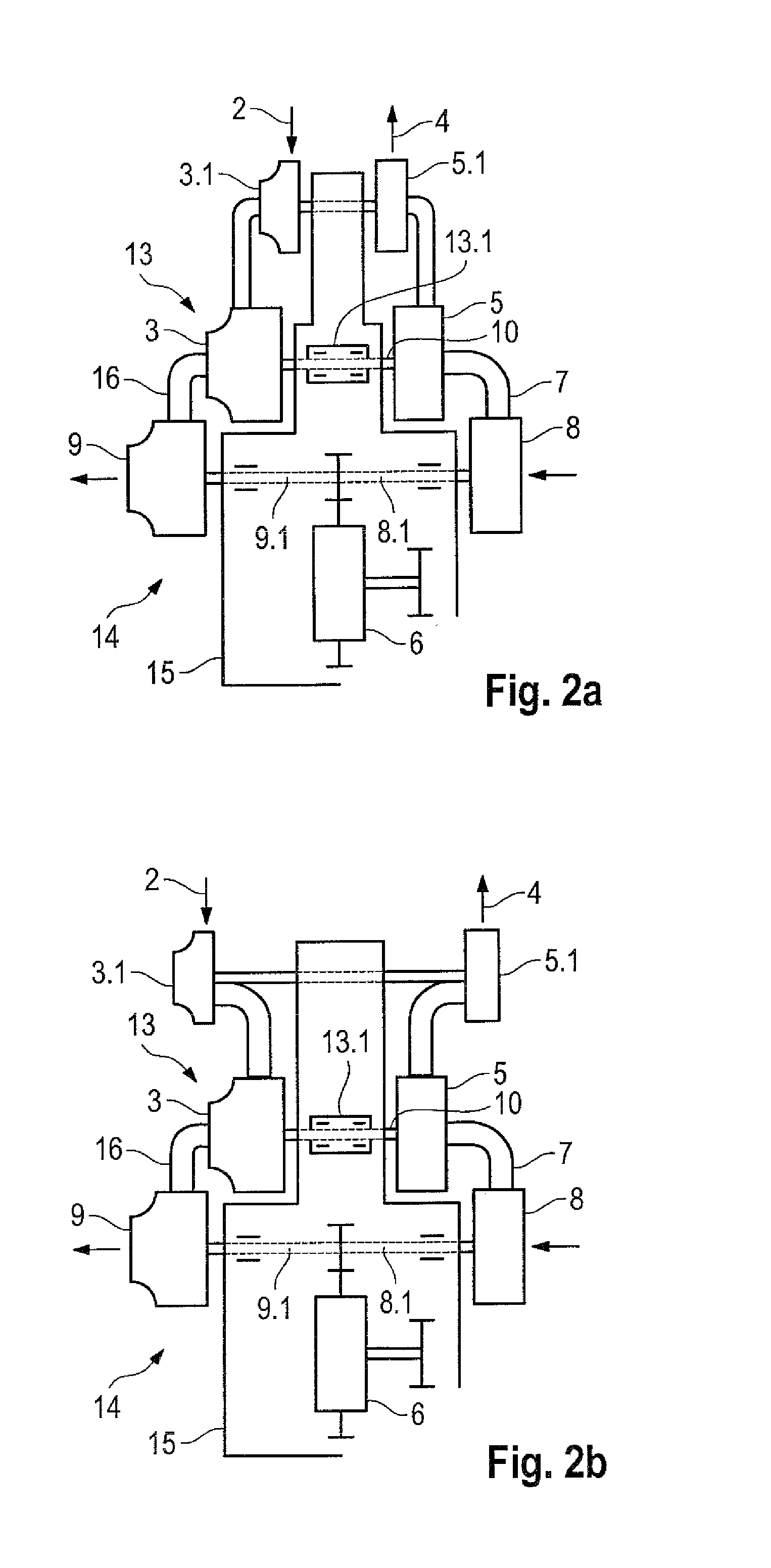

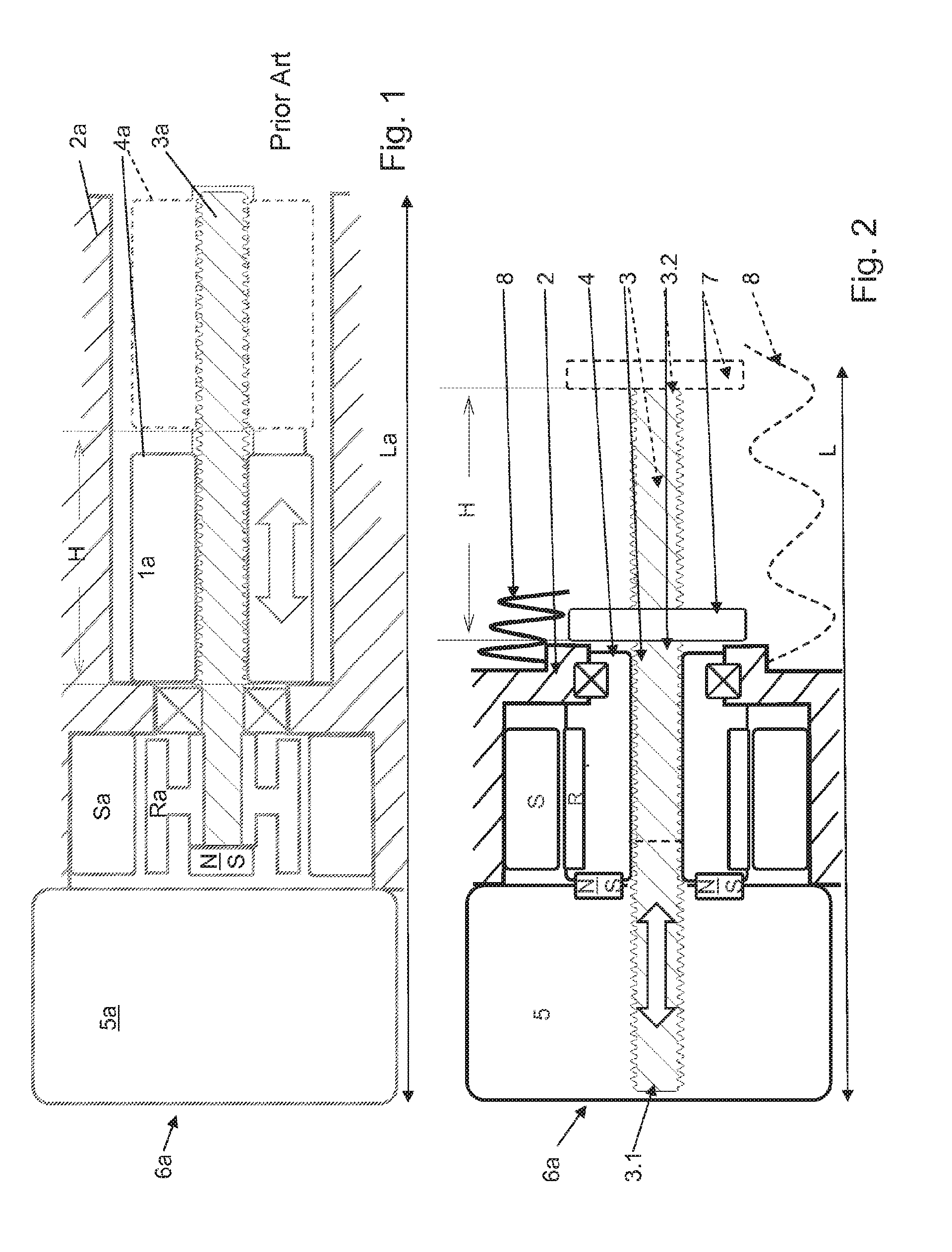

Drive train, in particular vehicle drive train

InactiveUS20140116043A1Reduce traffic lossImprove efficiencyInternal combustion piston enginesEngine componentsTurbochargerInternal combustion engine

A drive train having an internal combustion engine which includes an output shaft feeding drive power into the drive train. A first turbo charger includes a first exhaust-gas turbine arranged in an exhaust-gas flow and mounted rotatably in a turbine housing that drives a first fresh-air compressor via a first turbine shaft. A turbo-compound system includes a power turbine arranged in the exhaust-gas flow and can be drive connected via a power turbine shaft to the output shaft, with the power turbine shaft mounted rotatably in a power turbine housing and extending parallel to the turbine shaft. The turbine housing and power turbine housing can be supported in or on or integrated into a transmission housing. The first turbocharger is arranged radially outside the turbo-compound system. The first turbocharger and turbo-compound system are arranged on a common side or on different and adjoining or opposite sides of the transmission housing.

Owner:VOITH PATENT GMBH

Automatic vehicle gearshift transmission

InactiveUS20070049444A1Save componentSimplify the generatorToothed gearingsGas pressure propulsion mountingElectric machineEngineering

An automatic gearshift transmission with a drive input shaft and a drive output, a mechanical gearshift with first and second planetary gearsets, the first planetary gearset being a single planetary gearset downstream from which is connected a double planetary gearset, with several shift elements, including clutches and brakes and with an electric machine provided as a starter and / or generator and / or for the at least partial electric operation of a vehicle, such that the electric machine can be connected by way of a fourth clutch to the combustion engine and by way of a fifth clutch to a first shaft of the first planetary gearset. The combustion engine can be connected by way of the fourth and fifth clutches to the annular gear of the first planetary gearset and / or the electric machine can be connected by way of the fifth clutch to the annular gear of the first planetary gearset.

Owner:ZF FRIEDRICHSHAFEN AG

Sensor for determining at least one parameter of a fluid medium flowing through a measurement channel

ActiveUS20170328753A1Reduce dust pollutionLow costInternal-combustion engine testingVolume/mass flow measurementComputer moduleEngineering

A sensor is provided for determining at least one parameter of a fluid medium flowing through a measurement channel, in particular an intake air mass flow of an internal combustion engine. The sensor has a sensor housing, in particular a plug-in sensor that is inserted into or is insertable into a flow tube, in which sensor a measurement channel is fashioned, and has at least one sensor chip situated in the measurement channel for determining the parameter of the fluid medium. The sensor housing has an electronics compartment for accommodating an electronics module and has an electronics compartment cover for closing the electronics compartment. The electronics compartment cover has, at least in part, electrically conductive properties. For example, the electronics compartment cover is placed onto the electrical ground of the sensor and, viewed in projection, partly or completely covers the sensor chip.

Owner:ROBERT BOSCH GMBH

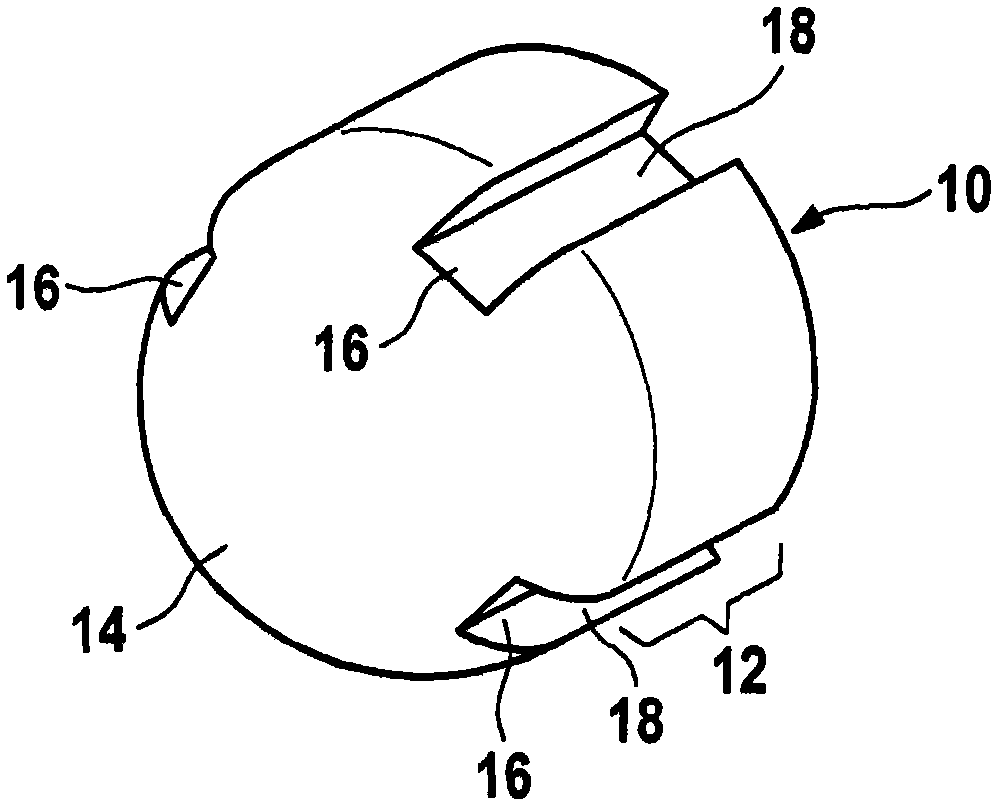

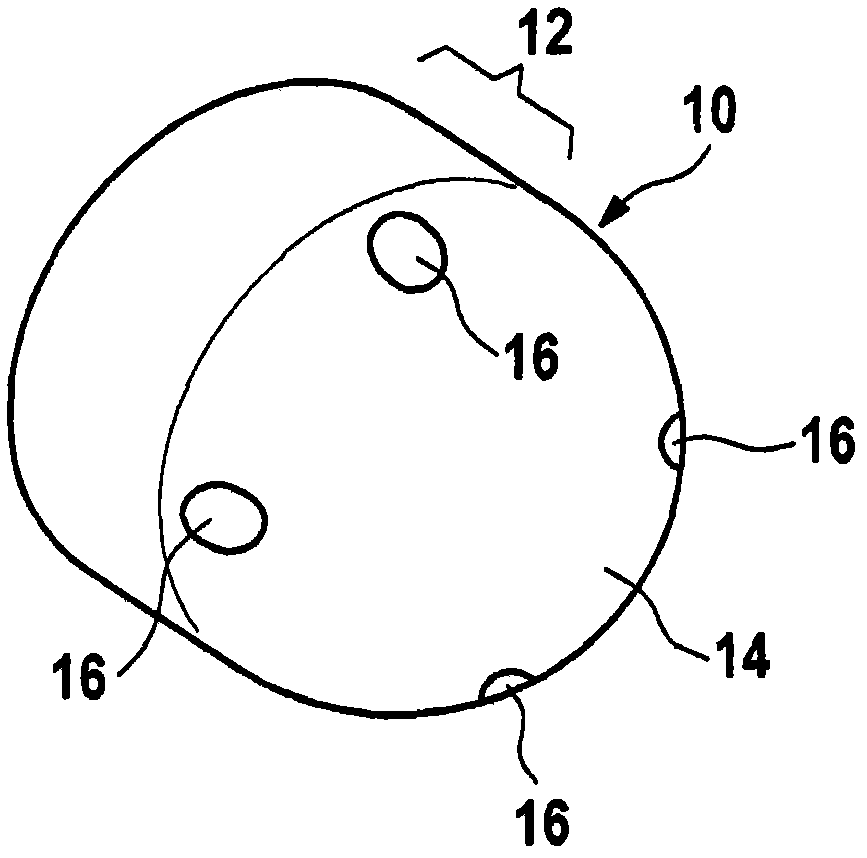

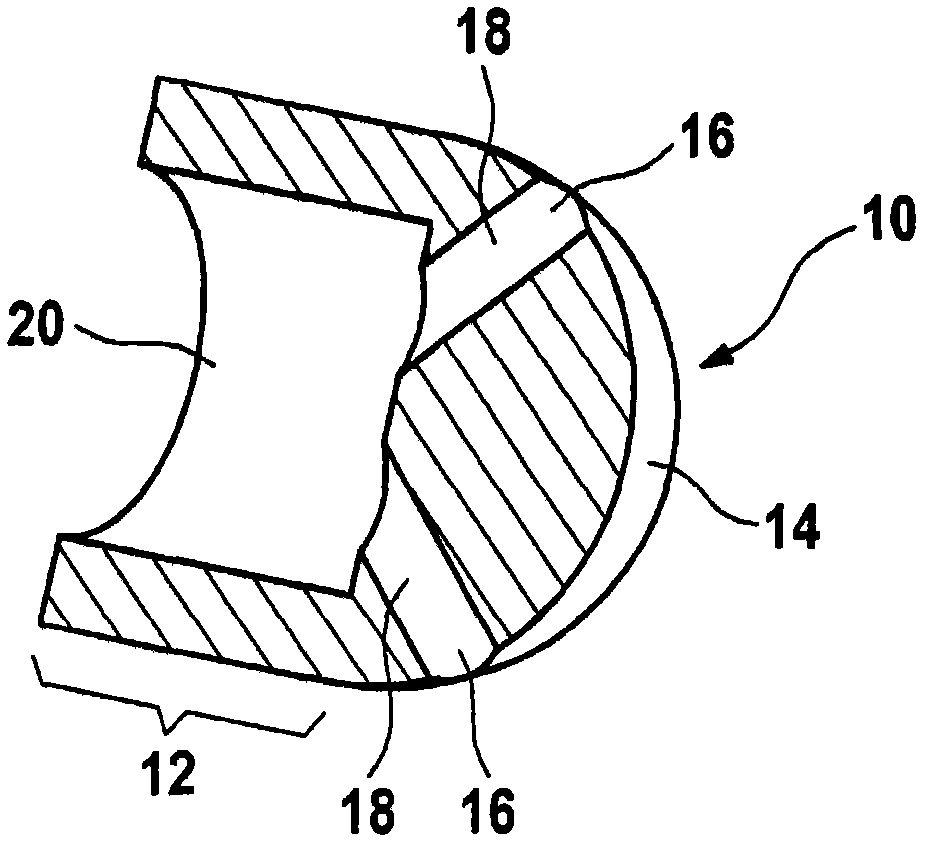

Valve with valve closure body

InactiveCN102072146AReduce manufacturing costEasy to integrateOperating means/releasing devices for valvesPositive displacement pump componentsEngineeringValve seat

The invention relates to a valve for a piston pump, wherein the valve (22) comprises a valve closure body (10) and a valve seat (26) disposed longitudinally facing to the valve closure body (10); the valve closure body (10) comprises a cylindrical guide section (12) and a hemispheric sealing section (14) longitudinally facing to the cylindrical guide section (10) and facing to the valve seat (26); the sealing section is used for selectively closing and opening a hole (30) enclosed by the valve seat (26); according to the invention, the sealing section (14) comprises at least one channel opening (16) which is located out of the hole (30) enclosed by the valve seat (26) under the state that the valve (22) is closed, and extended into a channel (18) in the valve closure body (10) substantially extending along a flow direction.

Owner:ROBERT BOSCH GMBH

Auxiliary Handle for a Hand-Held Power Tool

InactiveUS20070289761A1Lower manufacturing requirementsReduced assembly expenditurePortable percussive toolsPortable power-driven toolsHand heldEngineering

An auxiliary handle for a hand-held power tool has a handle part gripped by a hand of an operator and defining an axial direction. An attachment part with which the auxiliary handle is to be attached to a power tool is provided. An elastic damping element connects the handle part and the attachment part, wherein the handle part is secured to the attachment part by positive fit. A unitary holding section is connected to the handle part or the attachment part and a unitary securing section is connected to the attachment part or the handle part. The holding section surrounds with lateral play in all directions the securing section on all sides so that a damping space is generated between the securing section and the holding section. The damping element fills out the damping space at least partially.

Owner:ATLAS COPCO ELECTRIC TOOLS

Multi-step transmission

InactiveUS8113983B2Simple structureReduced overall construction spaceToothed gearingsTransmission elementsControl theorySpur gear

A multi-step transmission with forward and reverse gears comprises planetary gearsets, shafts and shift elements. The input shaft is coupled to the sun gear of gearset (P2) and, via a clutch (15), to a shaft (5) which is coupled to the carrier of gearset (P3) and, via brake (05), to the transmission housing and, via clutch (57), to shaft (7). Shaft (7) is coupled to the carrier of gearset (P2) and the ring gear of gearset (P1). Shaft (6) is coupled to the sun gear of gearset (P3) and the ring gear of gearset (P2) and, via clutch (36), to shaft (3) which is coupled the carrier of gearset (P1) and, via brake (03), to the housing. Shaft (4) is connected to the sun gear of gearset (P1) and can be coupled, via brake (04), to the housing. The output shaft (2) is connected to the ring gear of gearset (P3).

Owner:ZF FRIEDRICHSHAFEN AG

Crankshaft assembly of an internal combustion engine

InactiveUS7178501B2Good centrifugal mass characteristicReduced overall construction spaceCrankshaftsConnecting rodsMotor driveHand held

The invention is directed to a crankshaft (1) of an internal combustion engine including an internal combustion engine for a portable handheld work apparatus such as a motor-driven chain saw or the like. The invention is also directed to a method for making the crankshaft (1) as well as an internal combustion engine with a corresponding crankshaft (1). The crankshaft (1) is made up of separately manufactured parts and includes a crank arm (2) having a central cutout (3) for accommodating a shaft lug (4) of the crankshaft (1) and an eccentric cutout (5) for accommodating a crank pin (6). The crank pin (6) journals a connecting rod (7). A centrifugal mass portion (8) is provided on the crank arm (2) at its end lying opposite the eccentric cutout (5). The centrifugal mass portion (8) is configured as one piece with the crank arm (2) and is bent out of a plane (9) of the crank arm (2) in the direction of the connecting rod (7).

Owner:ANDREAS STIHL AG & CO KG

Hybrid vehicle and process for operating a hybrid vehicle

InactiveUS20010044682A1Reduced overall construction spaceIncrease torqueDigital data processing detailsRailway vehiclesCouplingControl theory

A hybrid drive for a vehicle in which the driving power provided by an internal combustion engine (ICE) or an electric motor may be fed via a transmission with a transmission input shaft and a transmission output shaft to the drive train. The ICE and the electric motor are connectable to each other via a coupling and the electric motor is directly connected to the transmission. An electric energy storage device is connected to the ICE for receiving a charge and to the electric motor for providing power to the electric motor. The hybrid drive is designed so that the torque that can be provided by the electric motor is greater than that of the internal combustion engine. In addition, the transmission input shaft always turns in the same direction as the transmission output shaft so that reverse drive by the hybrid drive is only possible using the electric motor.

Owner:ZF FRIEDRICHSHAFEN AG

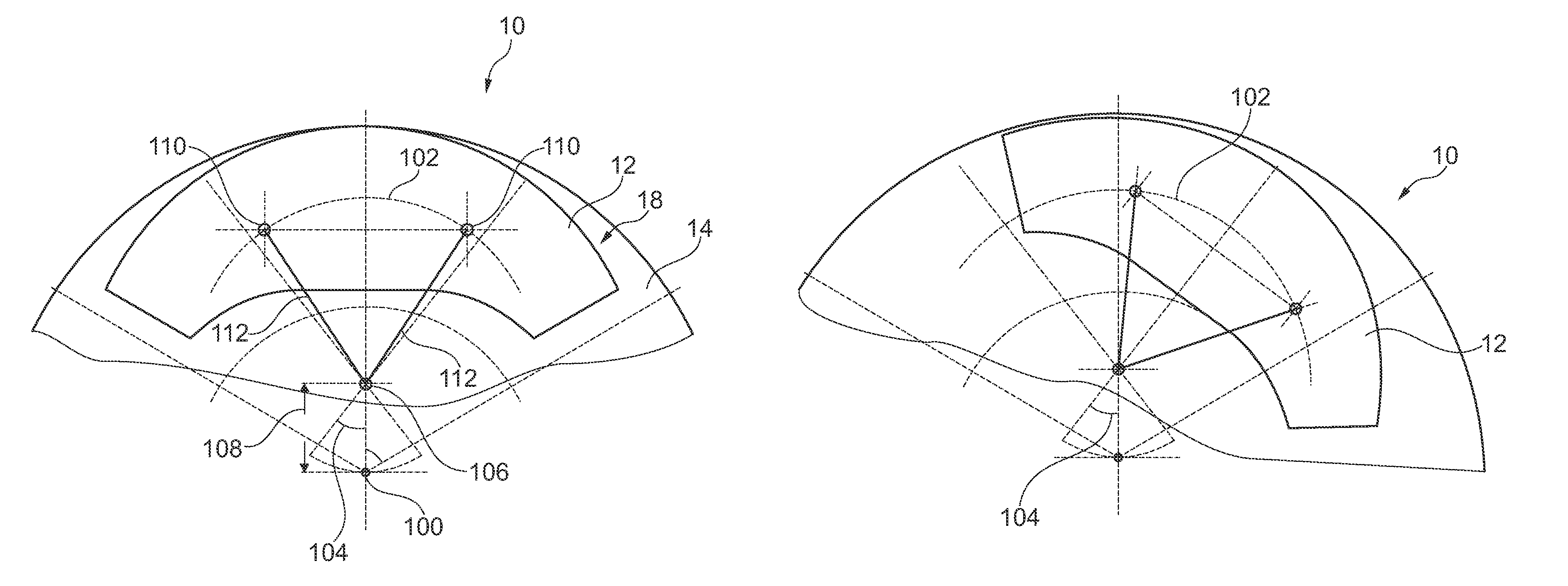

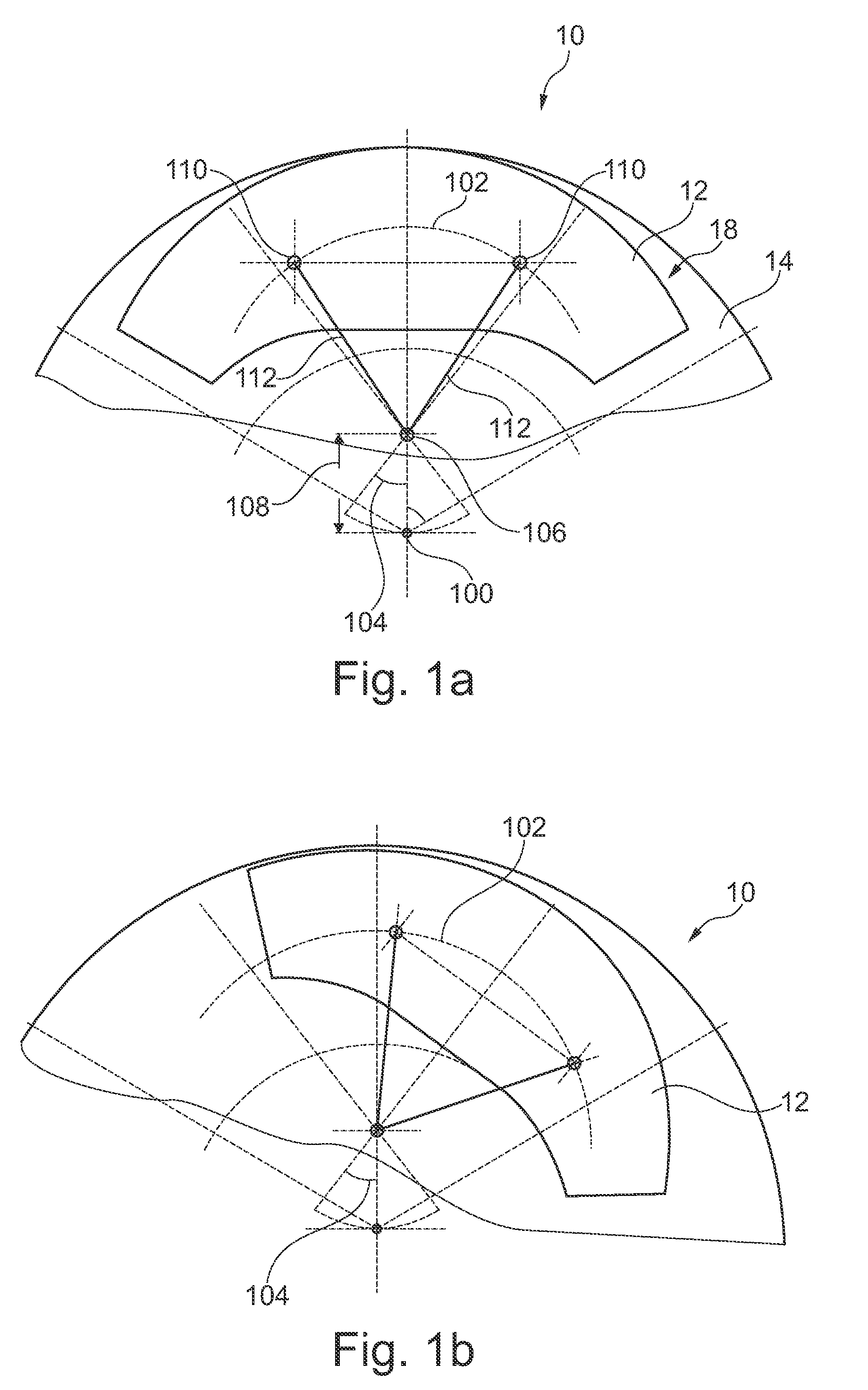

Centrifugal force pendulum device

InactiveUS20130133476A1Eliminate the effects ofIncreasing pivoting angleRotating vibration suppressionEngineeringCentrifugal force

A centrifugal force pendulum device having pendulum masses that are arranged axially on both sides of a pendulum mass carrier which is rotatable around an axis of rotation and form a pendulum mass pair, the pendulum mass pair being pivotable to a limited degree relative to the pendulum mass carrier along an arc-shaped oscillation path with the aid of at least two rolling elements that are able to roll in a single cutout or in different cutouts in the pendulum mass carrier, the oscillation path having a rotation axis that is stationary relative to the pendulum mass carrier and that is located at a radial distance from the pendulum mass.

Owner:SCHAEFFLER TECH AG & CO KG

Capteur de pression a clapet anti-retour

InactiveCN101191752AReduce in quantityLow costCheck valvesFluid pressure measurementEngineeringCheck valve

Owner:ROBERT BOSCH GMBH

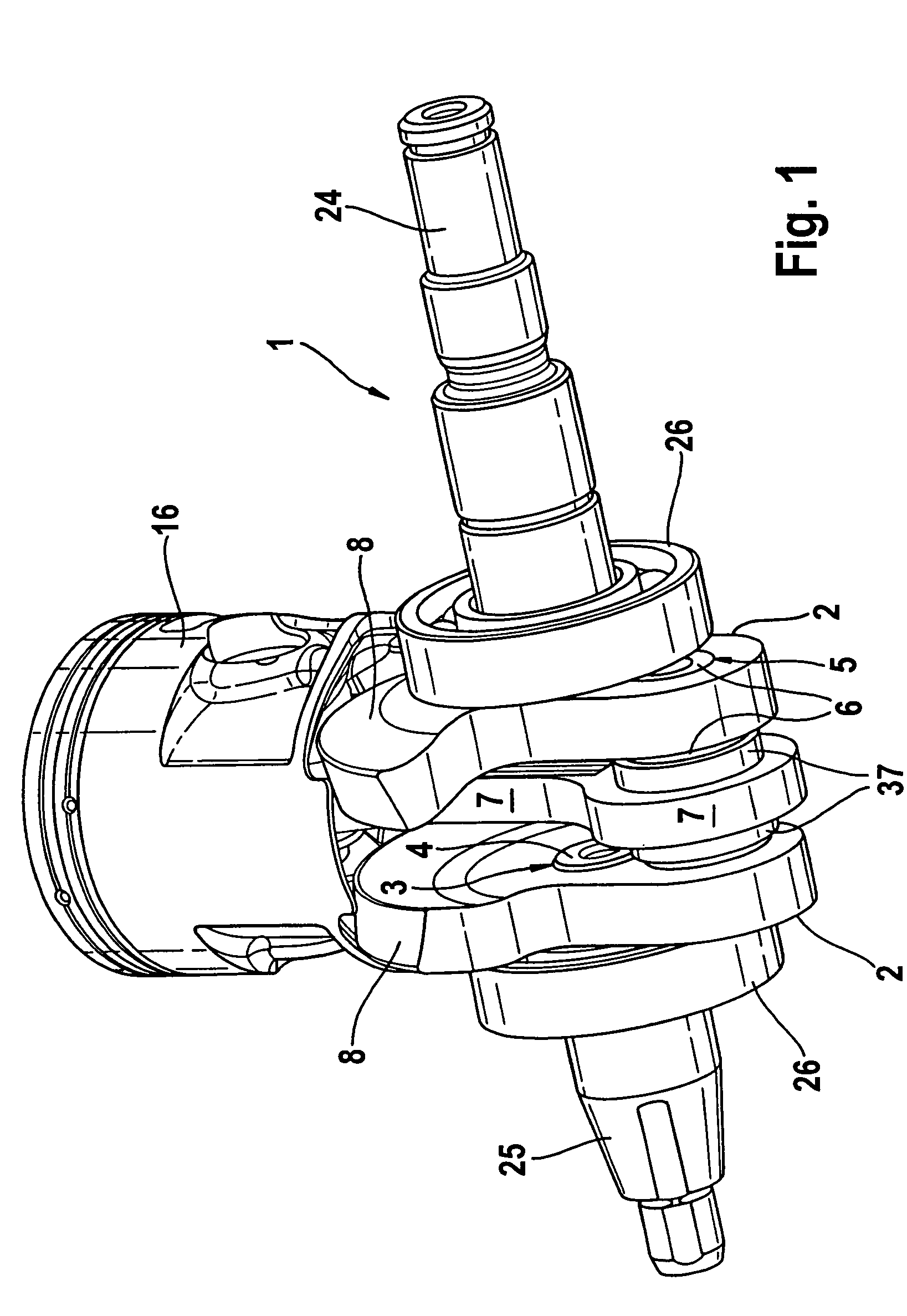

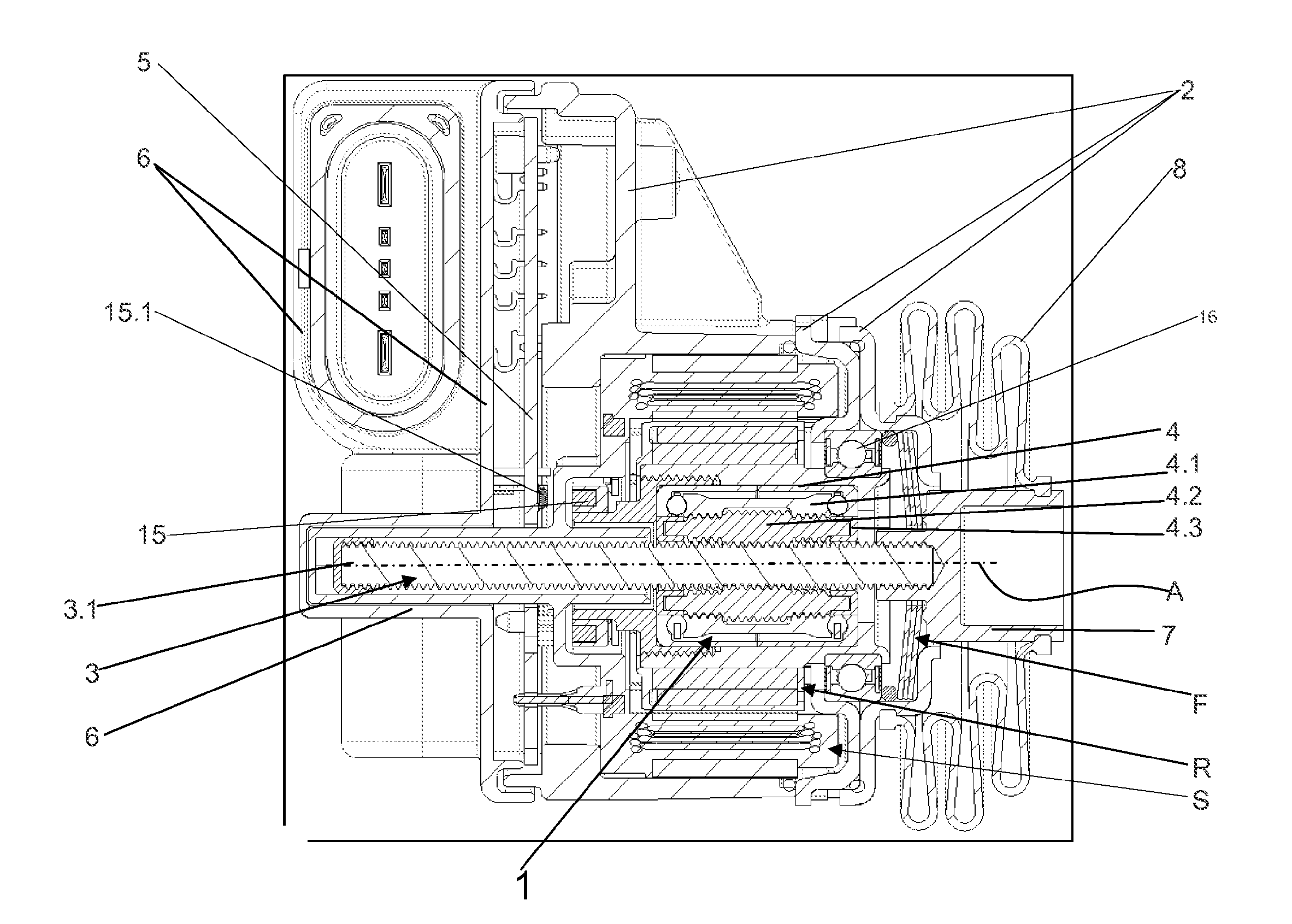

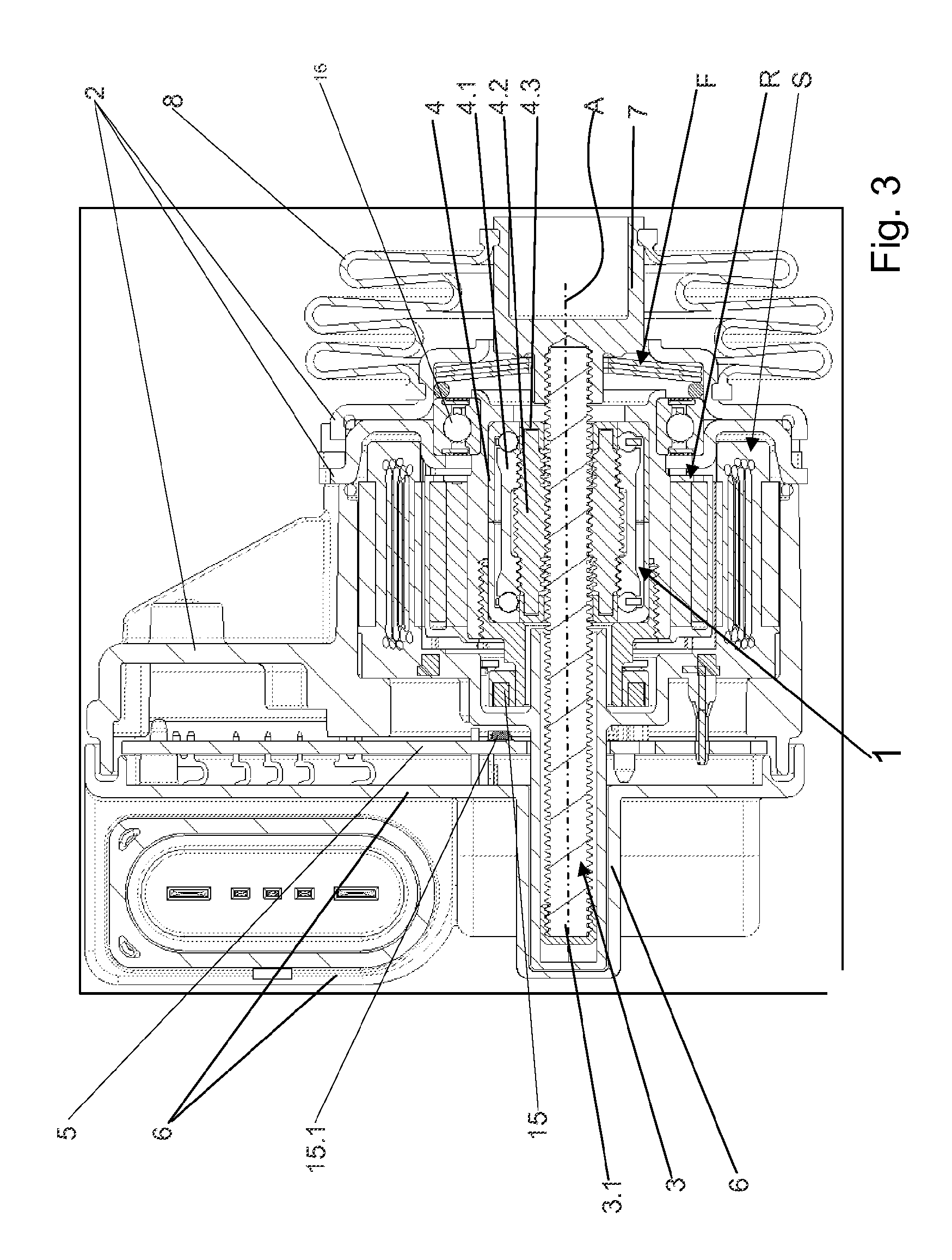

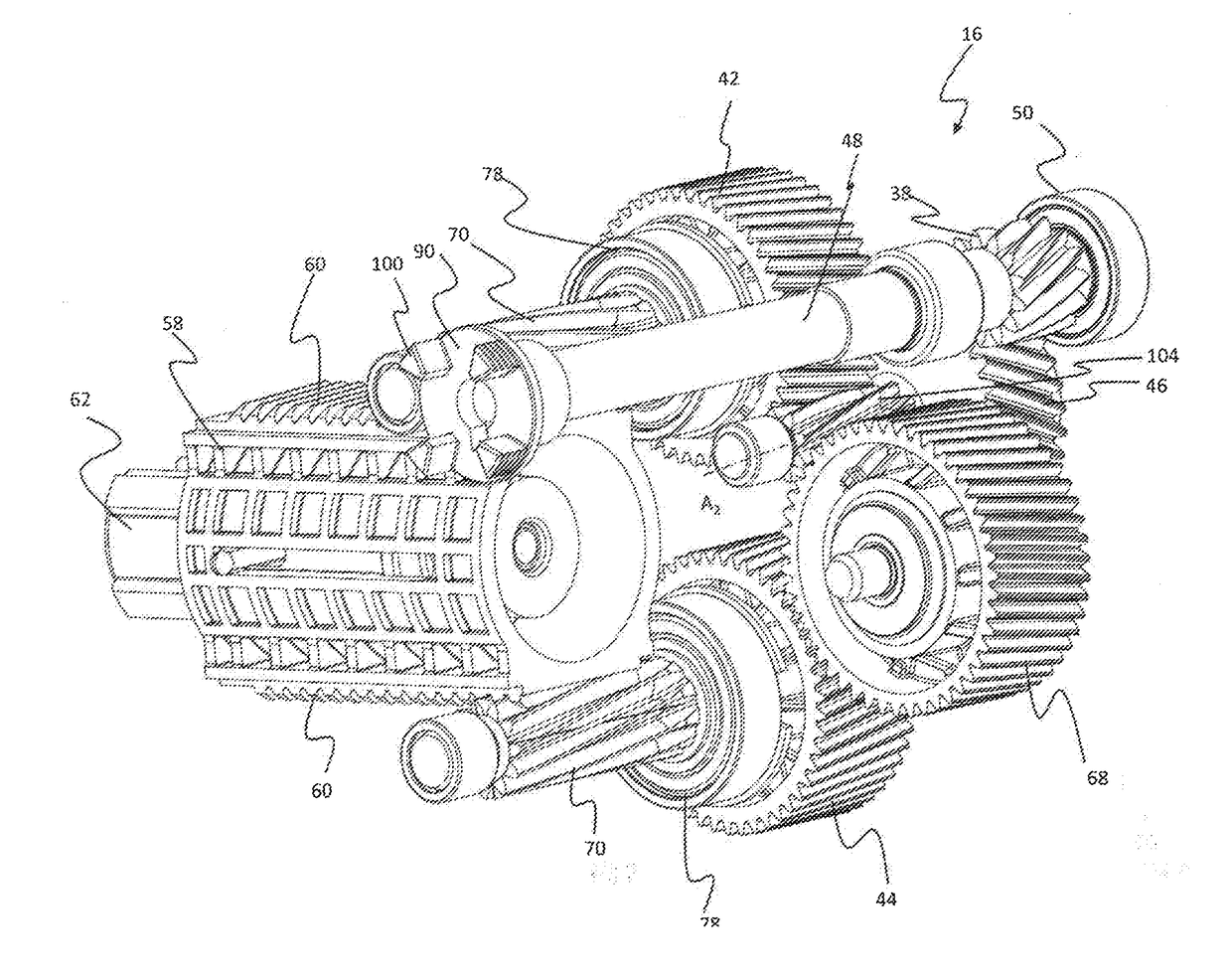

Actuator with planetary screw drive (PSD)

ActiveUS20160348775A1Simple designSmall spacingMechanical actuated clutchesGearingEngineeringActuator

An actuator having a planetary screw drive (PSD), in particular for the operation of a clutch of a motor vehicle, wherein a plurality of planetary rollers which mesh with a ring gear that encircles the planetary rollers are in contact with a spindle, where the planetary rollers are positioned at both ends in a planetary roller carrier and the planet carriers are supported non-rotatingly in a sleeve that encircles the ring gear and points radially inward at both ends, wherein the sleeve and the planetary carriers supported in it are axially fixed and connected non-rotatingly to a rotor of a drive and are drivable around an axis of rotation, the spindle is supported non-rotatingly and the spindle performs an axial stroke when the rotor and the planetary carriers supported in the sleeve rotate, is provided.

Owner:SCHAEFFLER TECH AG & CO KG

Multi-speed transmission

A multi-speed transmission for a motor vehicle, in particular for a sports car, has several forward speeds and a reverse speed, an input or primary shaft, a first output or secondary shaft for driving a first drive shaft leading to an axle differential, and a second output shaft or tertiary shaft for driving a second drive shaft leading to another axle differential. The first output or secondary shaft and the second output or tertiary shaft carry two meshing fixed gears. The fixed gear on the first output or secondary shaft meshes with an idle gear on the input or primary shaft. In one of the forward speeds the idle gear coupled in a rotationally restrained manner with the input or primary shaft directly drives the fixed gear on the first output or secondary shaft.

Owner:AUTOMOBILI LAMBORGHINI

Water adapter

InactiveCN104295820ASimple processImprove breathabilityPipe elementsFiltration separationService efficiencyFixed position

The invention relates to a water adapter which comprises a body, wherein a cooling liquid channel is formed in the body. The water adapter is characterized in that a stainless steel filtering screen is fixed in the body through an elastic snap spring; the stainless steel filtering screen completely covers the longitudinal section of the cooling liquid channel at the fixed position of the stainless steel. The water adapter disclosed by the invention has the advantages that firstly, the stainless steel filtering screen is adopted for filtering cooling liquid, so that the water adapter is simple in process, good in breathability and uniform and stable in precision; secondly, the filtering screen is fixed by means of the snap spring, so the leakage is avoided, the regeneration speed is high, the convenience for mounting is realized, the service efficiency of the adapter is improved, and the service life is prolonged; thirdly, the pollution to a water body can be suppressed from the source of a water cooling reactor, and poor heat dissipation of a finished machine caused by blocking is prevented, so that the situation that the traditional water adapter has no filtering function is broken; fourthly, the simplicity for use, the safety and the reliability are realized, no structural space is added, and the defect that the existing water cooling reactor is blocked is greatly overcome, so that the utilization rate of the whole system is improved.

Owner:SHANGHAI EAGTOP ELECTRONICS TECH

Dual-mass flywheel with integrated freewheeling mechanism

ActiveUS20160230836A1Simple torque designGreat tractionHybrid vehiclesYielding couplingDrivetrainFlywheel

A torque transfer device (1) for a drivetrain (2) of a motor vehicle, having a torsional vibration damping unit (3) and a decoupling clutch (6) having at least two clutch elements (4, 5) which can be joined to each other, wherein a first clutch element (4) is permanently connected non-rotatingly to a flange section (7) of the torsional vibration damping unit (3) and a second clutch element (5) is coupled with the flange section (7) via a freewheeling unit (8), wherein at least some sections of the freewheeling unit (8) are positioned in a radial receiving space (9) of the torsional vibration damping unit (3).

Owner:SCHAEFFLER TECH AG & CO KG

Bidirectional bearing, drive train, planetary gear and wind generator

InactiveCN106164509ACompact designReduced overall construction spaceShaftsMachines/enginesGear wheelEngineering

A bidirectional bearing (30), a drive train, a planetary gear and a wind generator having a bidirectional bearing are provided. The bidirectional bearing comprises a outer bearing shell (32) having a first intermediate bearing shell (34), which is coupled to the shaft (40) and which cooperates with the outer bearing shell. The bidirectional bearing further comprises a second intermediate bearing shell (36), which is arranged opposite to the outer bearing shell with respect to the first intermediate bearing shell. The second intermediate bearing shell is configured to take up a first load having a first direction (D1) from the first intermediate bearing shell. Furthermore, the first second intermediate bearing shell is configured to receive a second load having a second direction (D2), which is substantially opposite to the first direction. The first intermediate bearing shell receives said second load from the second intermediate bearing shell and is configured to transfer this second load to the outer bearing shell.

Owner:AREVA WIND

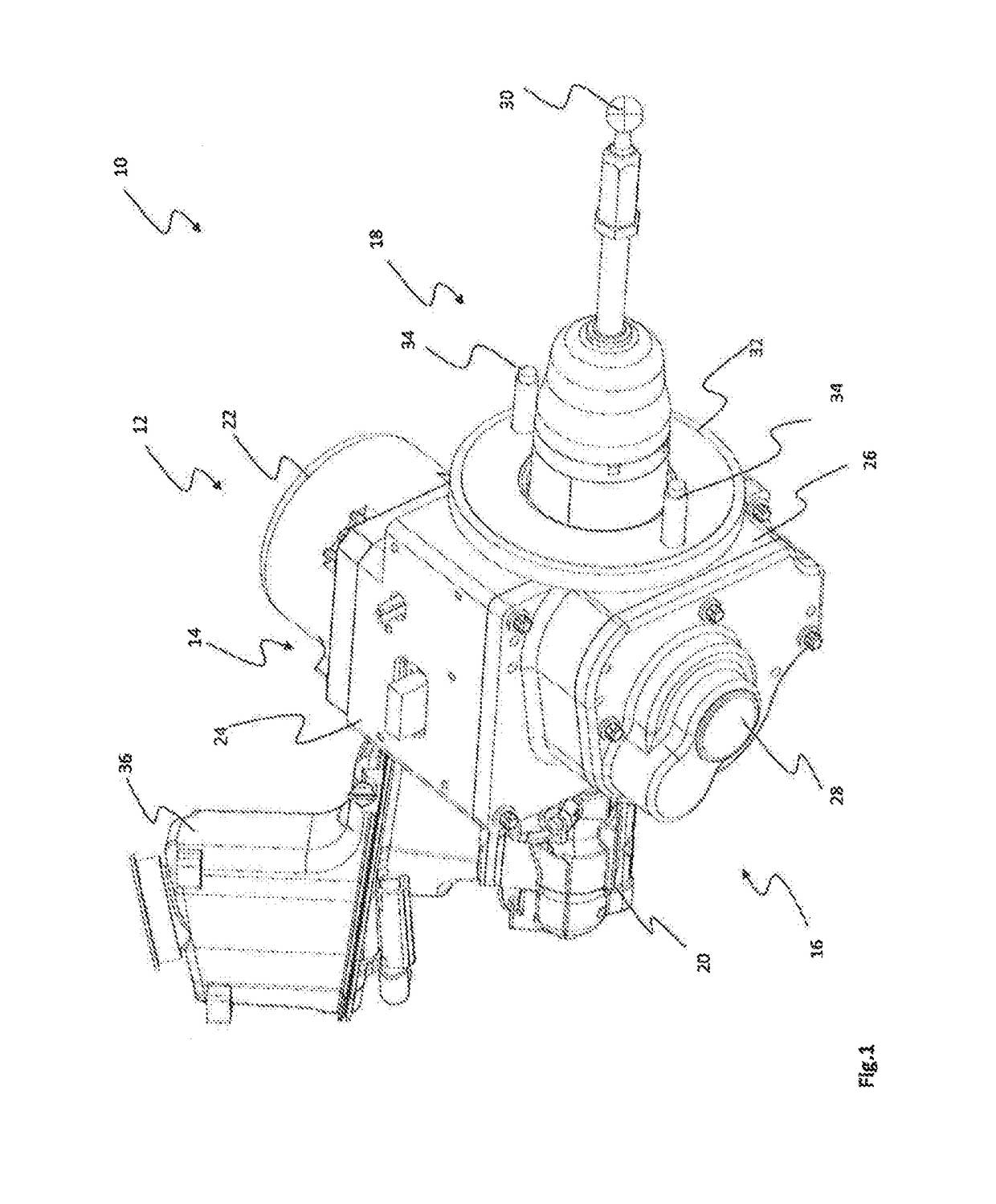

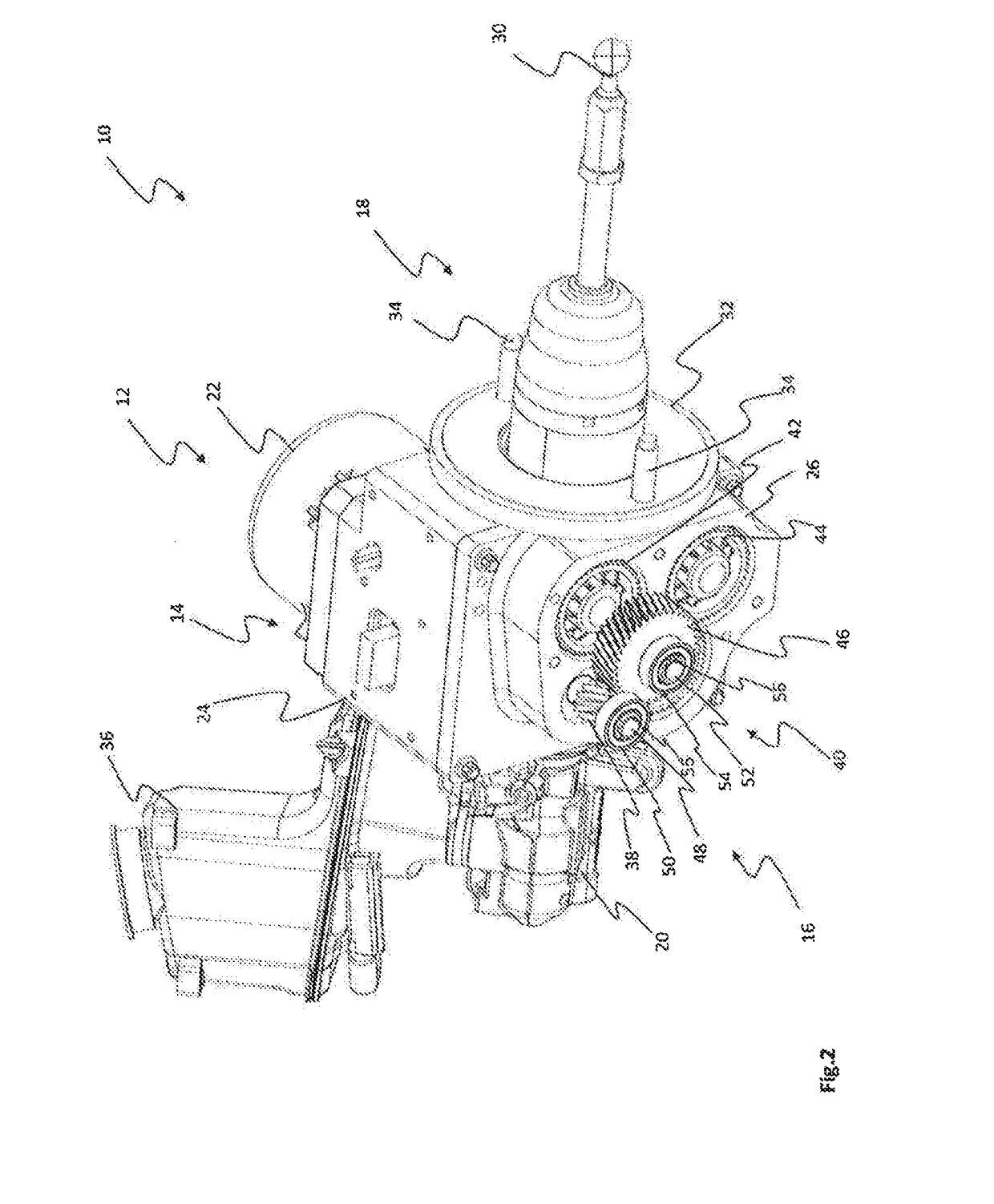

Electromechanical Brake Force Booster

ActiveUS20180257619A1Reduce requirementReduced overall construction spaceBraking action transmissionToothed gearingsEngineeringBrake force

The electromechanical brake force booster for a vehicle brake system comprises a drive arrangement for driving at least one actuating device which is designed for actuating a brake cylinder. The drive arrangement has at least one electric motor and a gearing for coupling the electric motor to the at least one actuating device. The gearing comprises at least one second spur gear and at least one first spur gear. Furthermore, the gearing has an intermediate gearing stage. The intermediate gearing stage couples the electric motor to the second spur gear and to the first spur gear in torque-transmitting fashion. The intermediate gearing stage drives the second spur gear directly and the first spur gear via at least one intermediate gear.

Owner:LUCAS AUTOMOTIVE GMBH +1

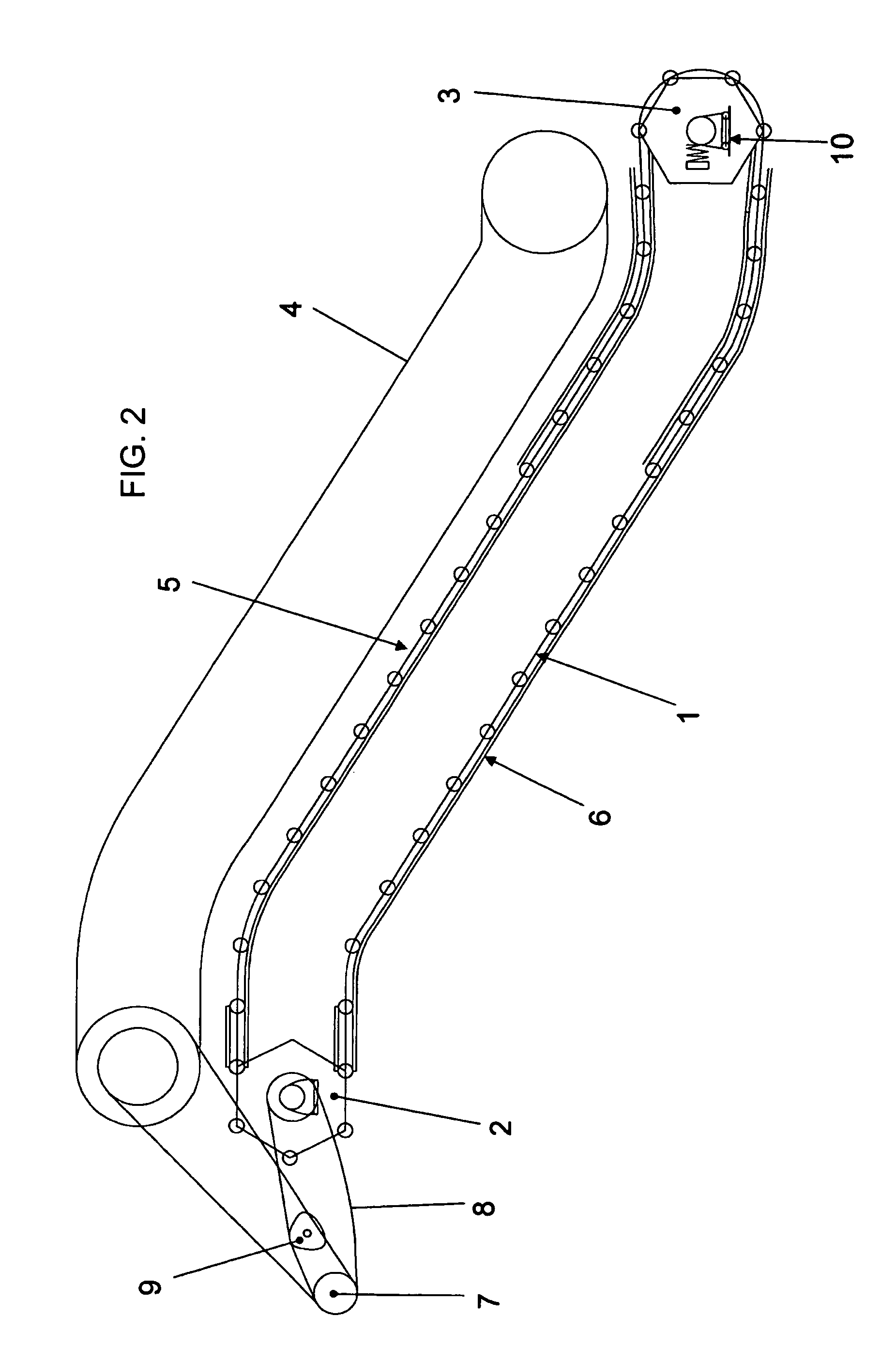

Escalator

InactiveUS8286778B2Increase pitchReduced overall construction spaceConveyorsEscalatorsSprocketEngineering

Owner:KETTEN WULF BETRIEBS GMBH & CO KG

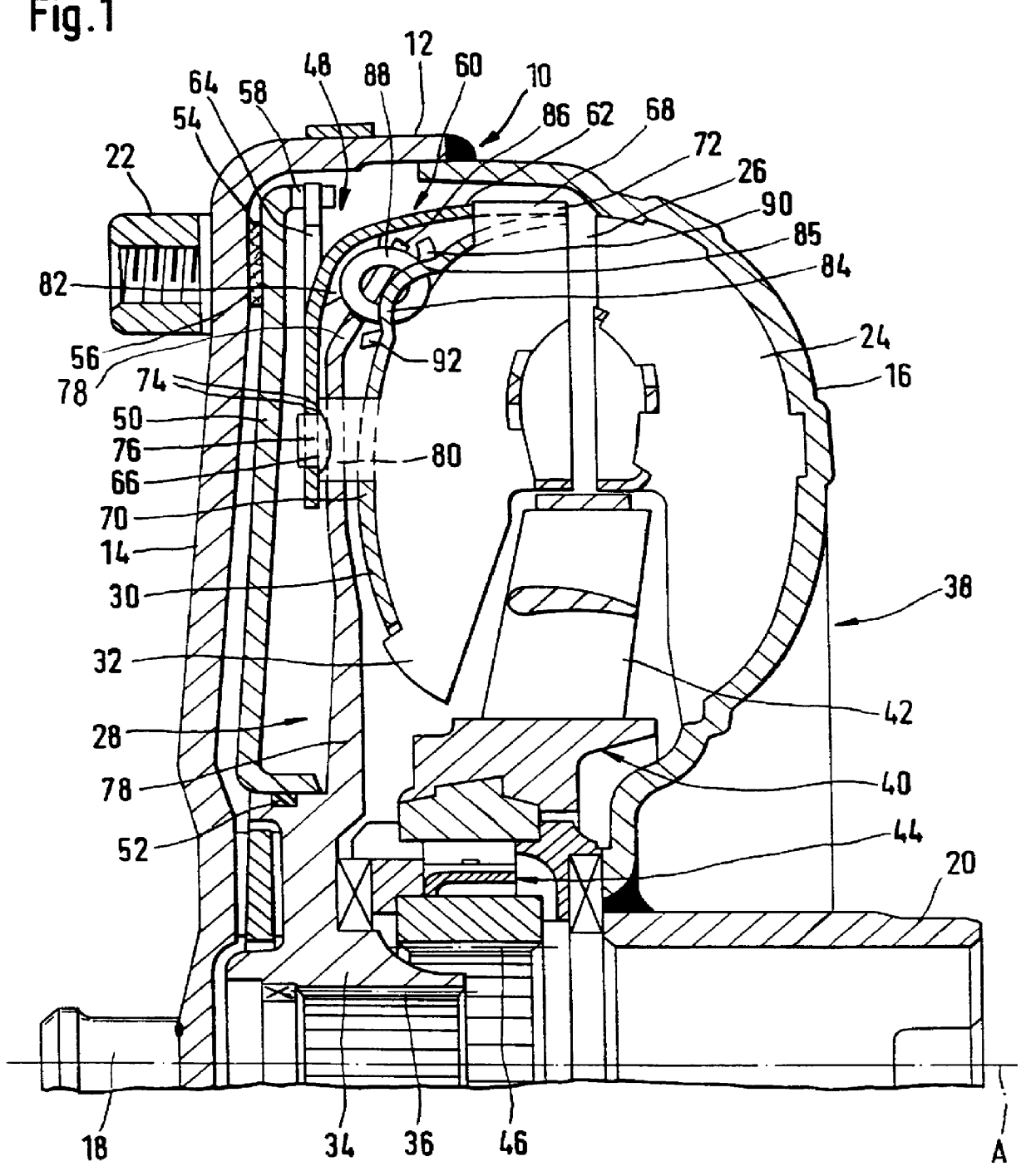

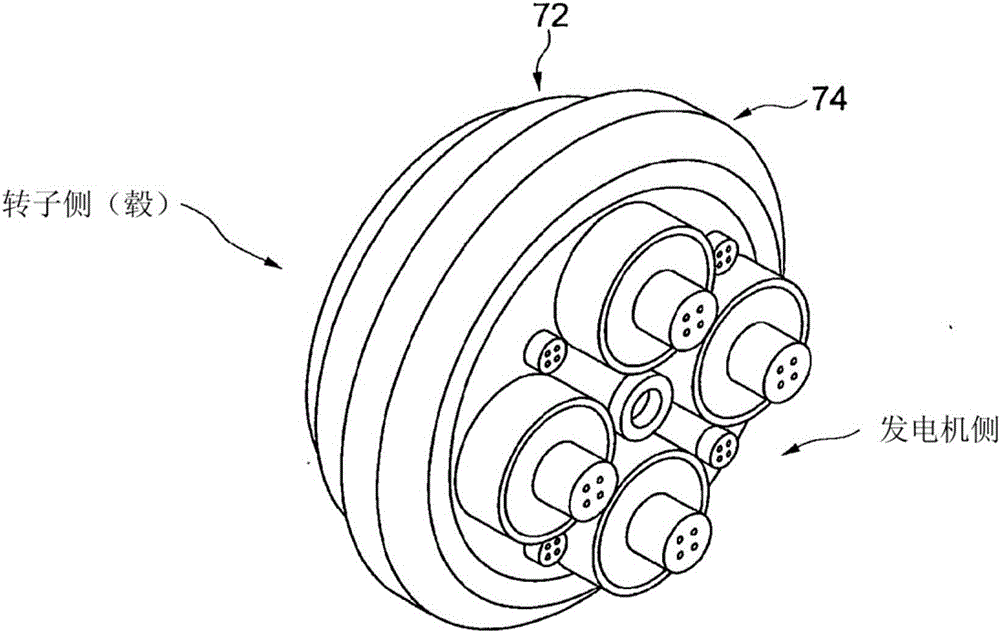

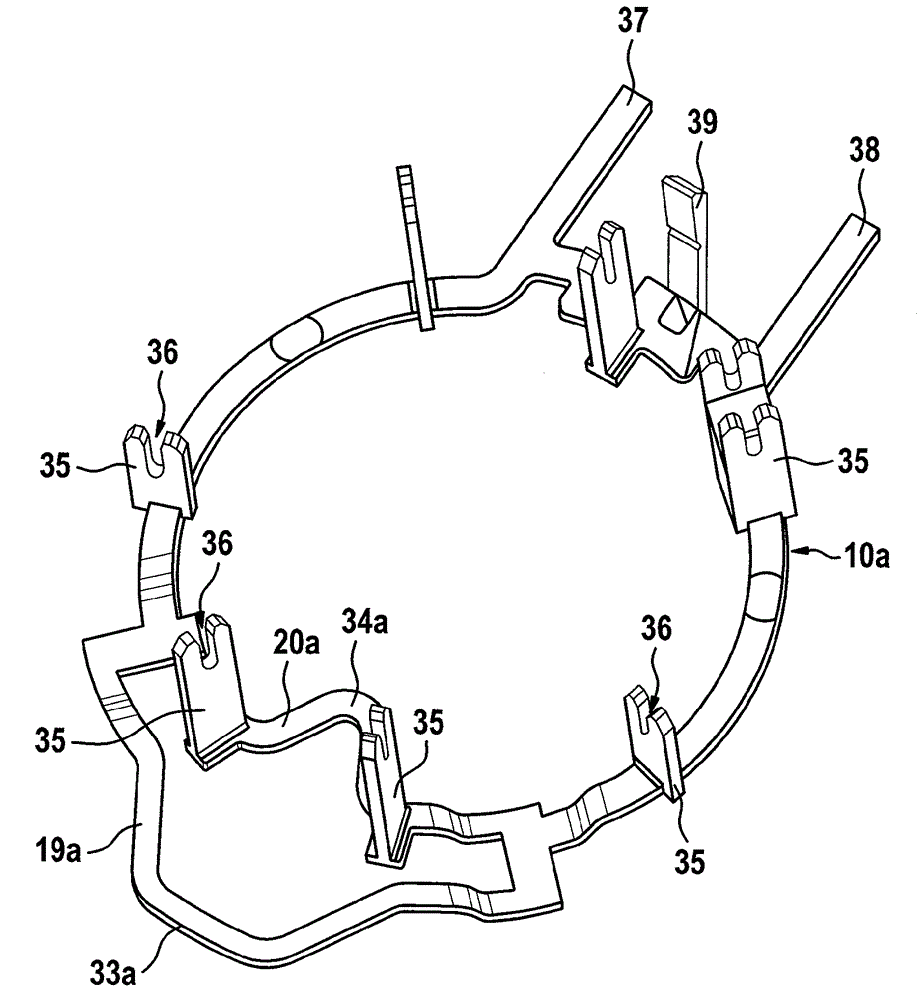

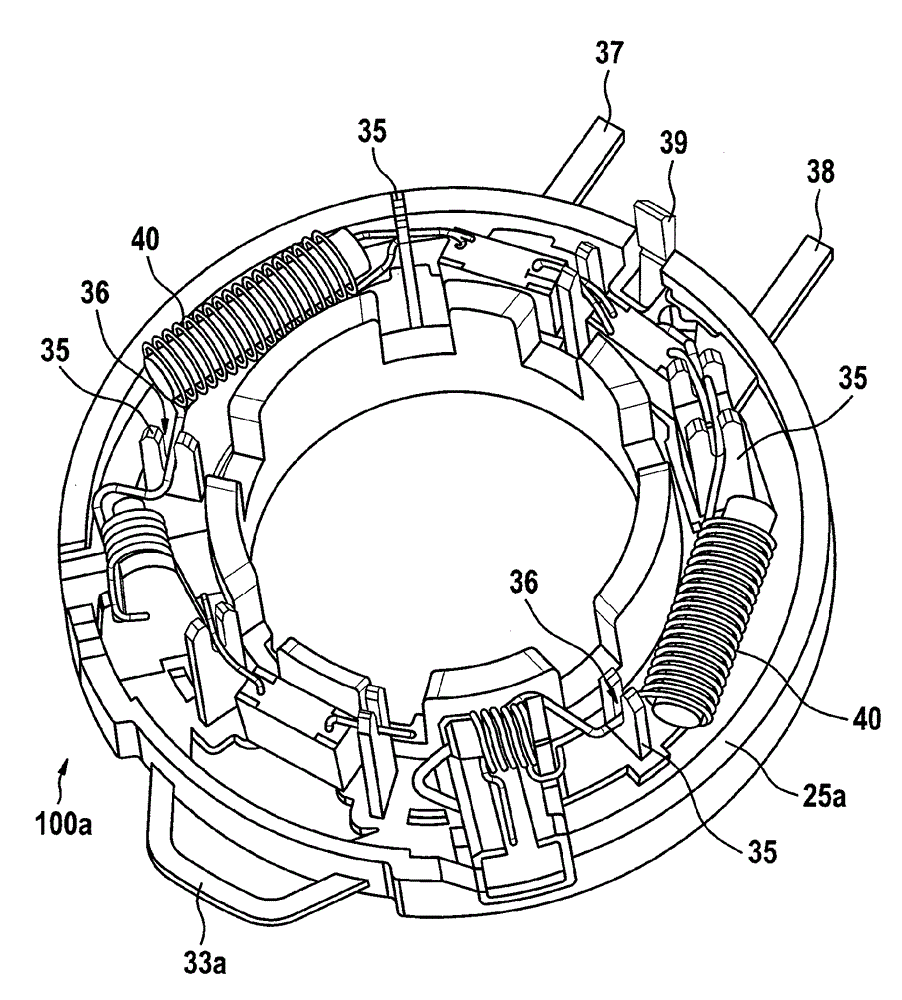

Brush carrier for electromotor, manufacturing method of brush carrier, and electromotor

InactiveCN103915742AImprove power densityFunction increaseRotary current collectorSupports/enclosures/casingsPowder injectionPowder metallurgy

The invention relates to a brush carrier (100, 100a) for an electromotor and a manufacturing method thereof. The brush carrier has two receiving elements (11, 12) for receiving brush elements. The receiving elements (11, 12) made of plastic, are connected to existing base portion (25, 25a). The receiving elements (11, 12) are formed as powder injection molded elements made from metallic powder and ceramic powder.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com