Preparation method of novel nickel-based material for petroleum valve rod

A technology for petroleum and valve stems, which is applied in the field of preparation of new nickel-based materials for petroleum valve stems. It can solve the problems of high processing costs and poor plasticity during hot processing, and achieve low processing costs, excellent high-temperature strength, metallographic structure and chemical properties. The effect of uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

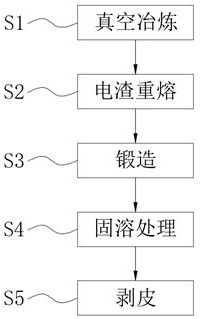

[0020] The invention provides a method for preparing a novel nickel-based material for petroleum valve stems, comprising the following steps:

[0021] S1 Vacuum smelting: The alloy raw materials are accurately proportioned according to the established weight ratio, and baked according to the process requirements. The return material is less than 30%, and the amount of other elements is strictly controlled. The vacuum smelting is carried out according to the high-temperature smelting process, and the carbon is strictly controlled. The content is brought in, the vacuum degree is less than 8 Pa during the melting period, Ni-Mg0.05% and rare earth 0.3kg / furnace are added during refining, Al and Ti small materials are added for deoxidation when the power is cut off after refining, and the composition is controlled. Temperature ≤ 8Pa, using no less than two high-temperature instant refining and one low-temperature long-term refining, the steel temperature is raised to 1580 ° C for 1-...

Embodiment 1

[0046] In a new type of nickel-based material for petroleum valve stems in Example 1 of the present invention, the weight percentages of each element are: C: 0.10%, Si: 0.30%, Mn: 0.20%, P: 0.010%, S: 0.010%, Cr: 10.0%, Co: 14.5%, W: 5.0%, Mo: 4.50%, Al: 3.90%, Ti: 1.50%, Fe: 1.0%, V: 0.30%, B: 0.015%, Ce: 0.010%, Cu: 0.050%, the balance is Ni and unavoidable impurities.

[0047] The preparation method of the nickel-based material for the novel petroleum valve rod of the present embodiment is as follows:

[0048] S1 Vacuum smelting: The alloy raw materials are accurately proportioned according to the established weight ratio, and baked according to the process requirements. The return material is less than 30%, and the amount of other elements is strictly controlled. The vacuum smelting is carried out according to the high-temperature smelting process, and the carbon is strictly controlled. The content is brought in, the vacuum degree is 7.8 Pa during the melting period, Ni-M...

Embodiment 2

[0054] In a new type of nickel-based material for petroleum valve stems in Example 2 of the present invention, the weight percentages of each element are: C: 0.08%, Si: 0.50%, Mn: 0.40%, P: 0.010%, S: 0.010%, Cr: 10.5%, Co: 15%, W: 5.5%, Mo: 5%, Al: 3.90-4.30%, Ti: 1.80%, Fe: 1.10%, V: 0.40%, B: 0.020%, Ce: 0.0150 %, Cu: 0.055%, the balance is Ni and unavoidable impurities.

[0055] The preparation method of the nickel-based material for the novel petroleum valve rod of the present embodiment is as follows:

[0056] S1 Vacuum smelting: The alloy raw materials are accurately proportioned according to the established weight ratio, and baked according to the process requirements. The return material is less than 30%, and the amount of other elements is strictly controlled. The vacuum smelting is carried out according to the high-temperature smelting process, and the carbon is strictly controlled. The content is brought in, the vacuum degree is 4.5 Pa during the melting period, N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com