Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

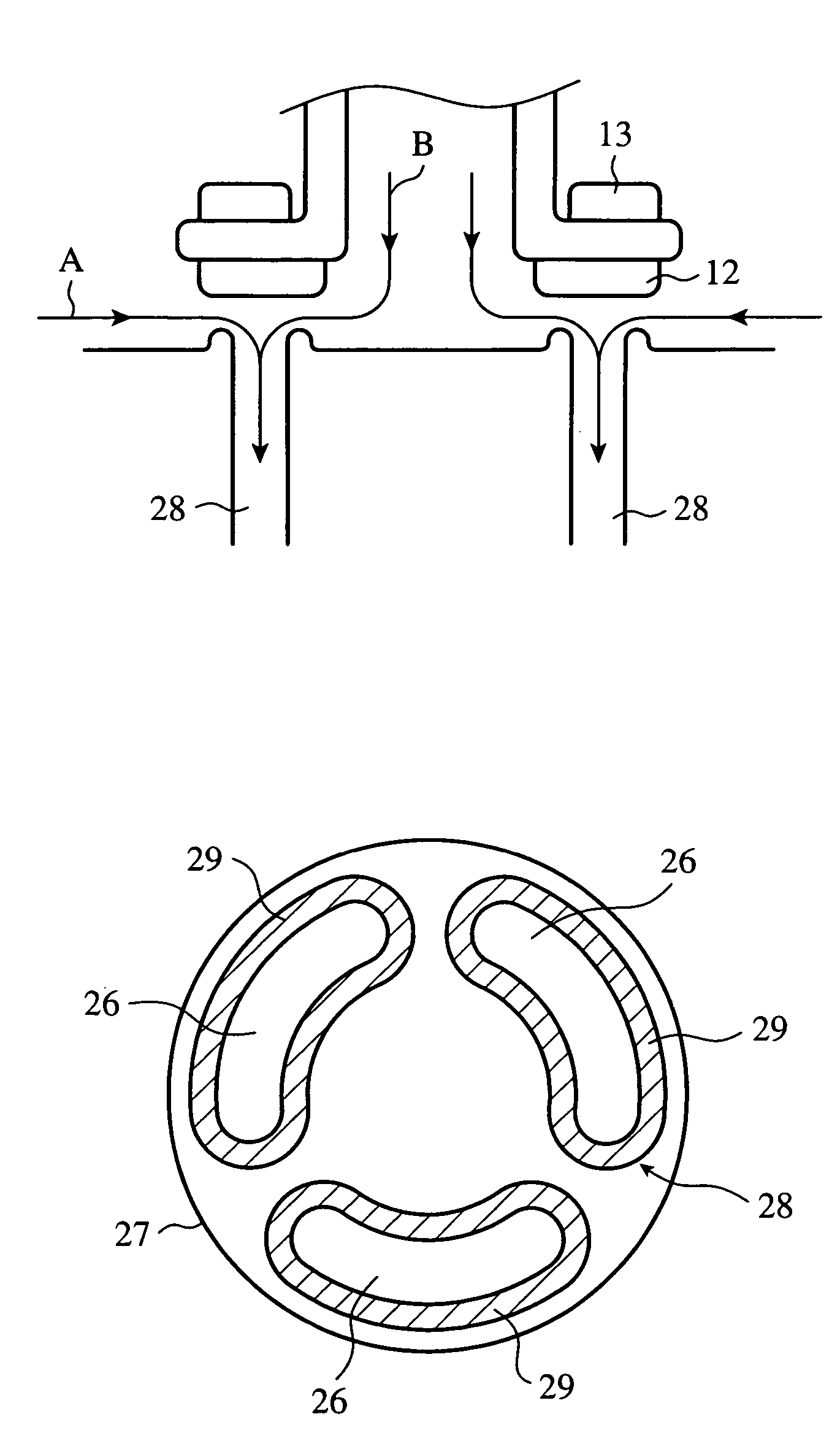

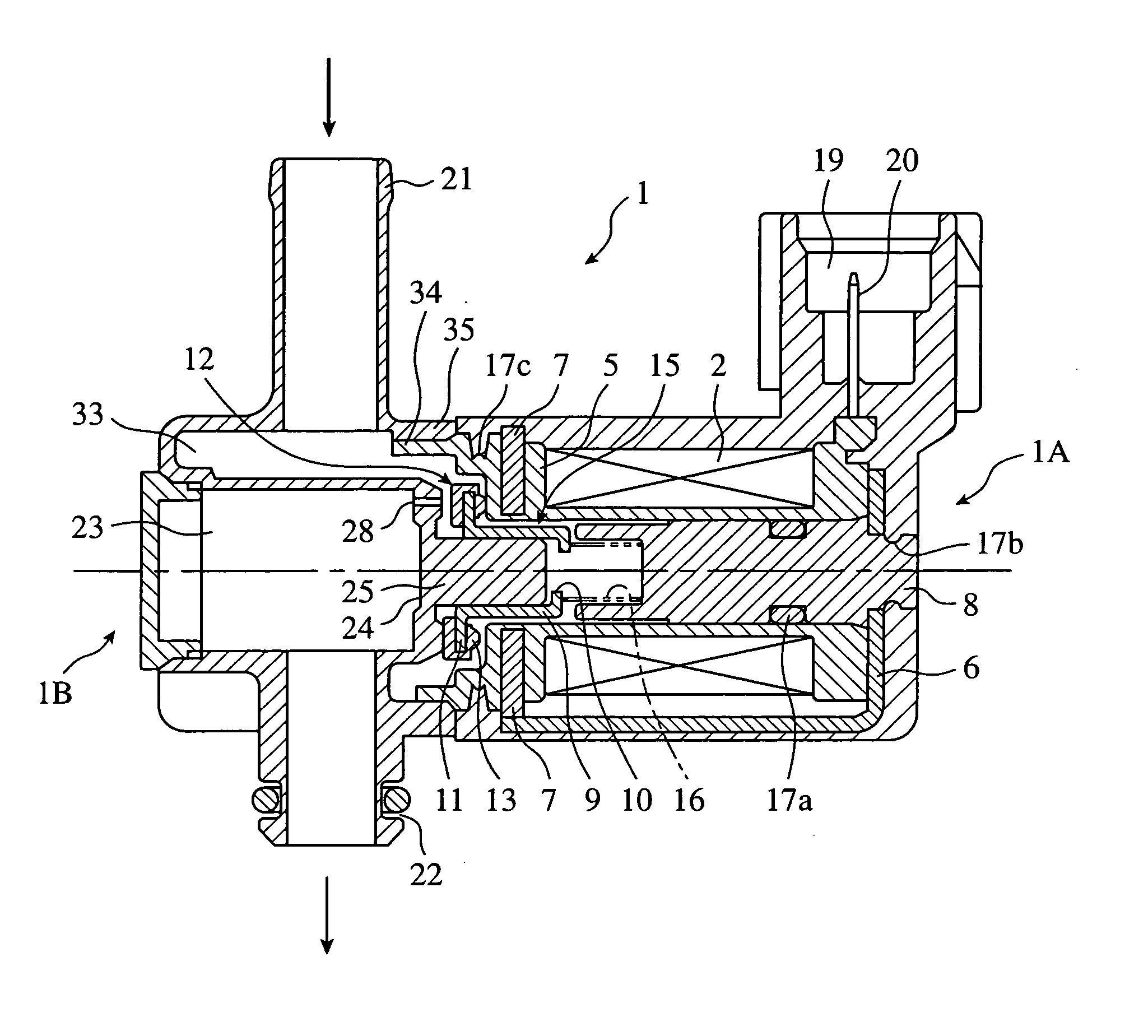

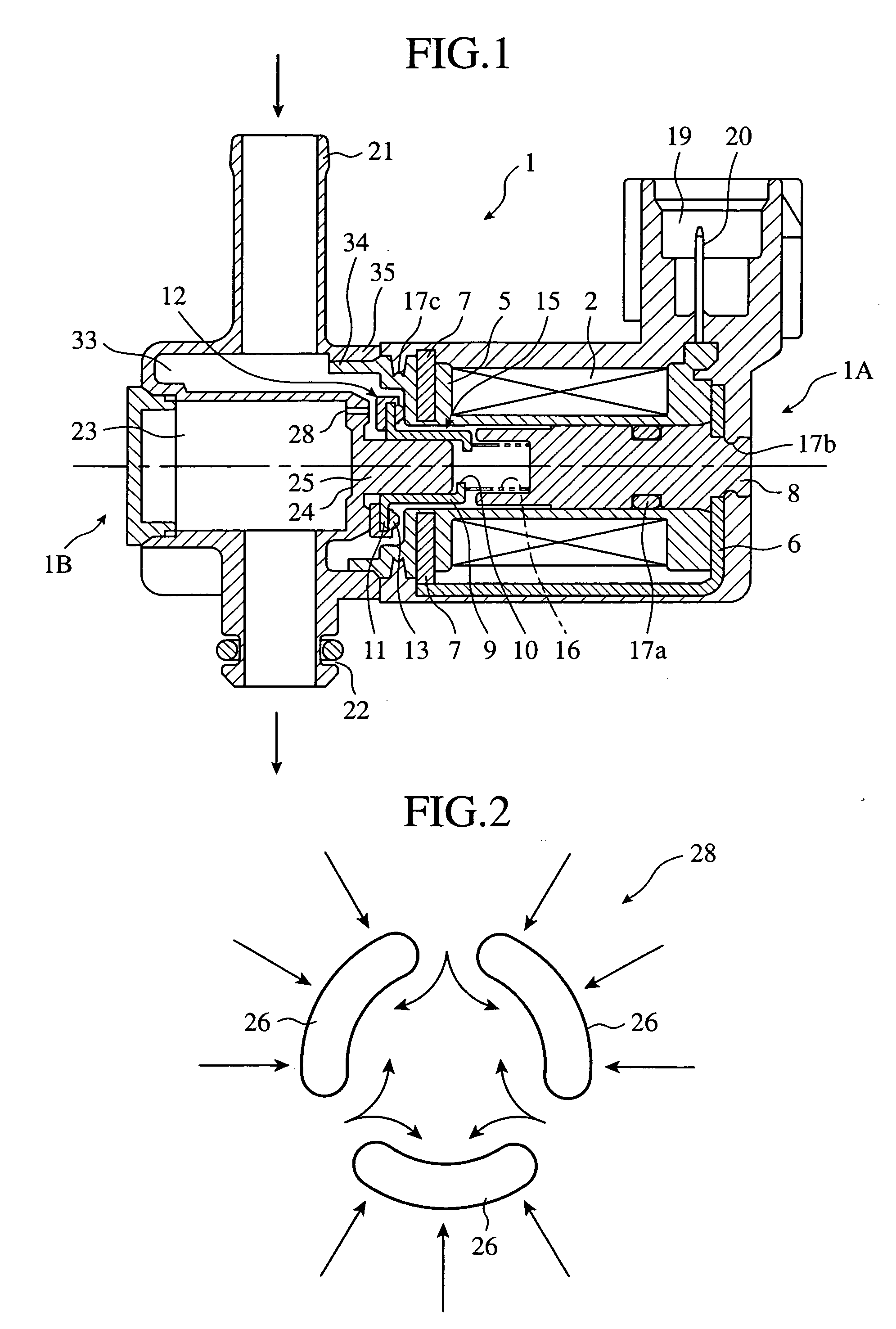

Solenoid valve

InactiveUS7290564B2Flow rateEasy to followOperating means/releasing devices for valvesNon-fuel substance addition to fuelSolenoid valveEngineering

A guide boss is provided in a diaphragm blocking the halfway portion of a channel; a valve disk is formed in the shape of a cylinder; the inner face of this cylinder-shaped valve disk is slidably engaged around the guide boss; and further, a valve port consisting of a plurality of long bores are formed in a diaphragm surrounding the guide boss. Thereby, fluid can responsively flow into the valve port when the valve disk is opened, and the follow-up of the fluid is accelerated.

Owner:MITSUBISHI ELECTRIC CORP

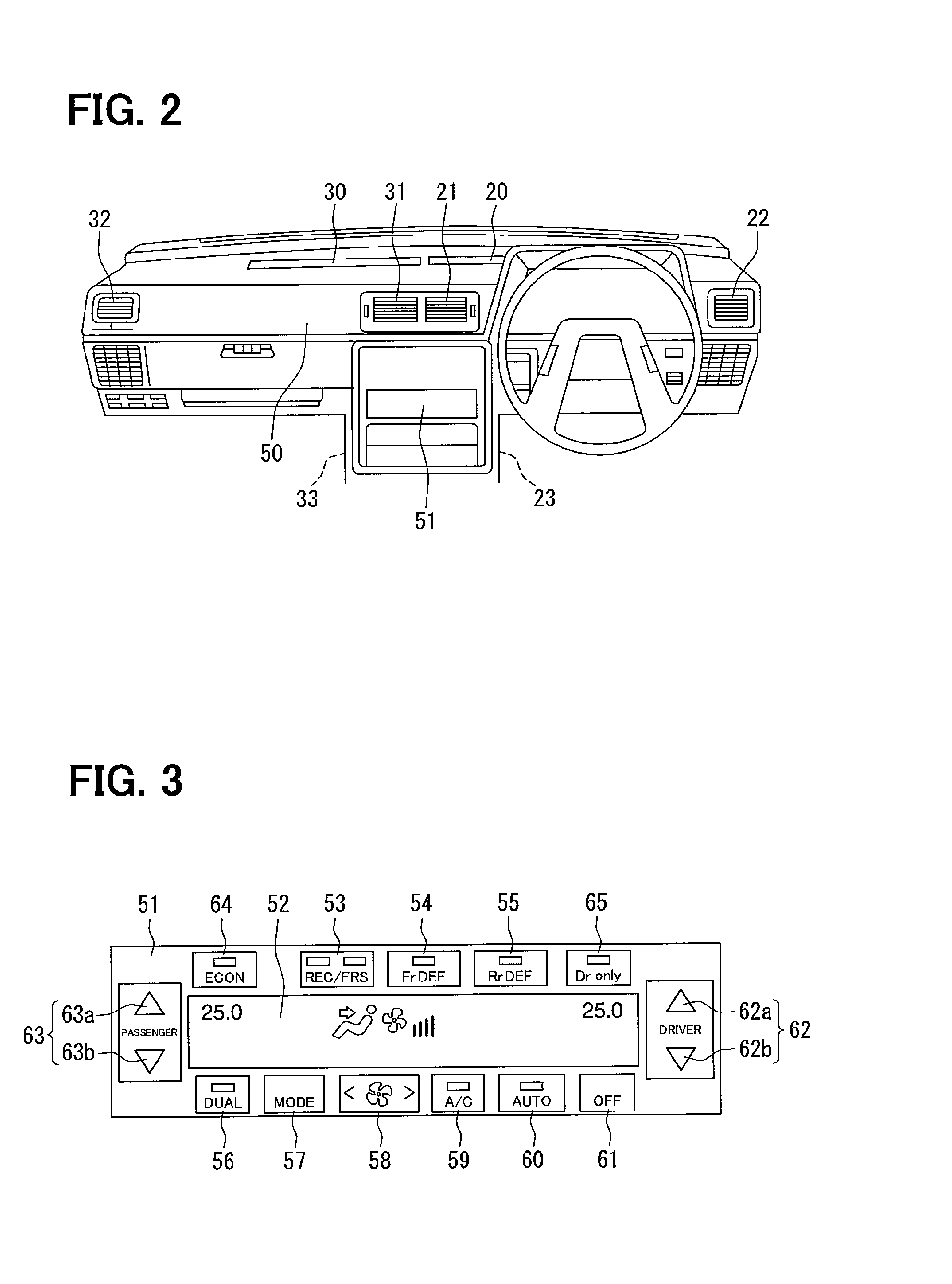

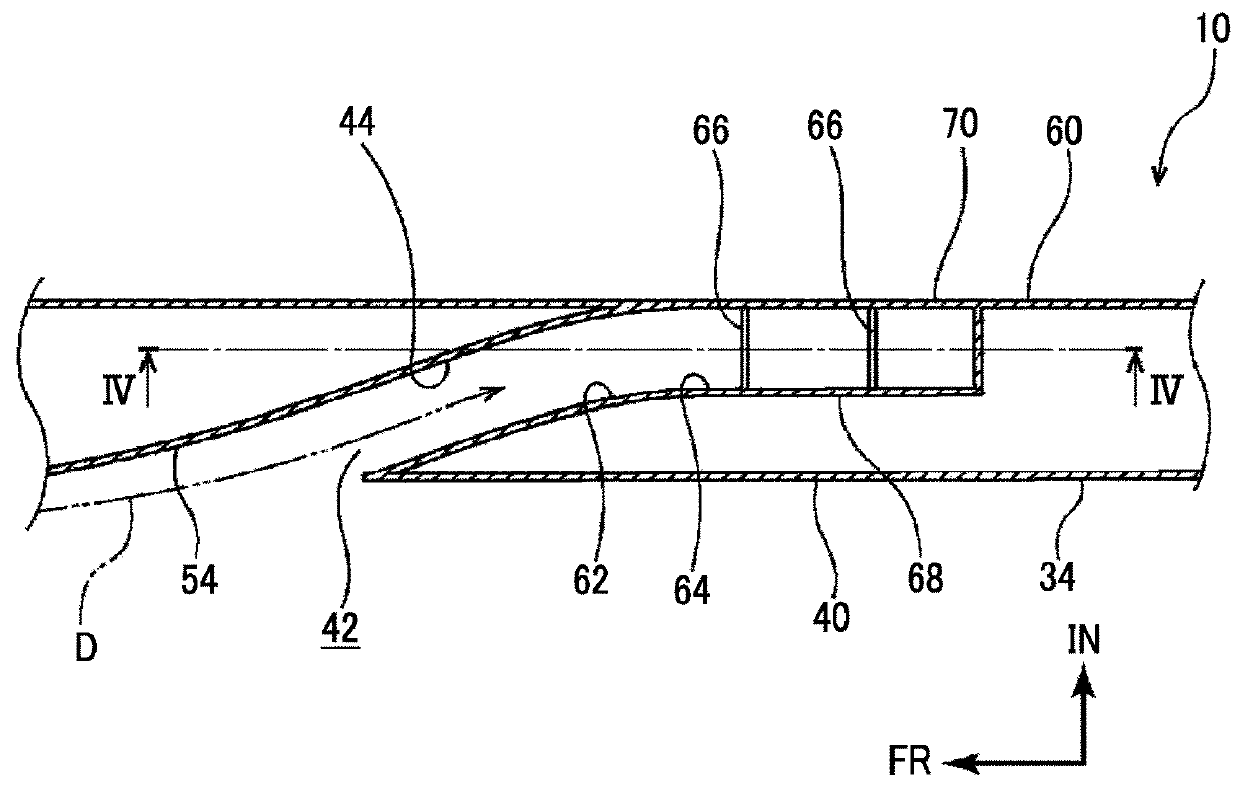

Air conditioner for vehicle

InactiveUS20140373563A1Reduce airflowReduce flow rateAir-treating devicesLighting and heating apparatusEngineeringAir conditioning

In an air conditioner for a vehicle, a flow speed of air flowing through a first ventilation part of an evaporator is faster than a flow speed of air flowing through a second ventilation part of the evaporator when an intensive air-conditioning operation for a driver seat is operated, with respect to a case where a normal air-conditioning operation is performed. In this case, a correct target evaporator temperature is calculated to be higher by a predetermined temperature than a target evaporator temperature, and a detected temperature detected by an evaporator sensor is approached to the correct target evaporator temperature. Therefore, it can restrict the second ventilation part from being frosted.

Owner:DENSO CORP

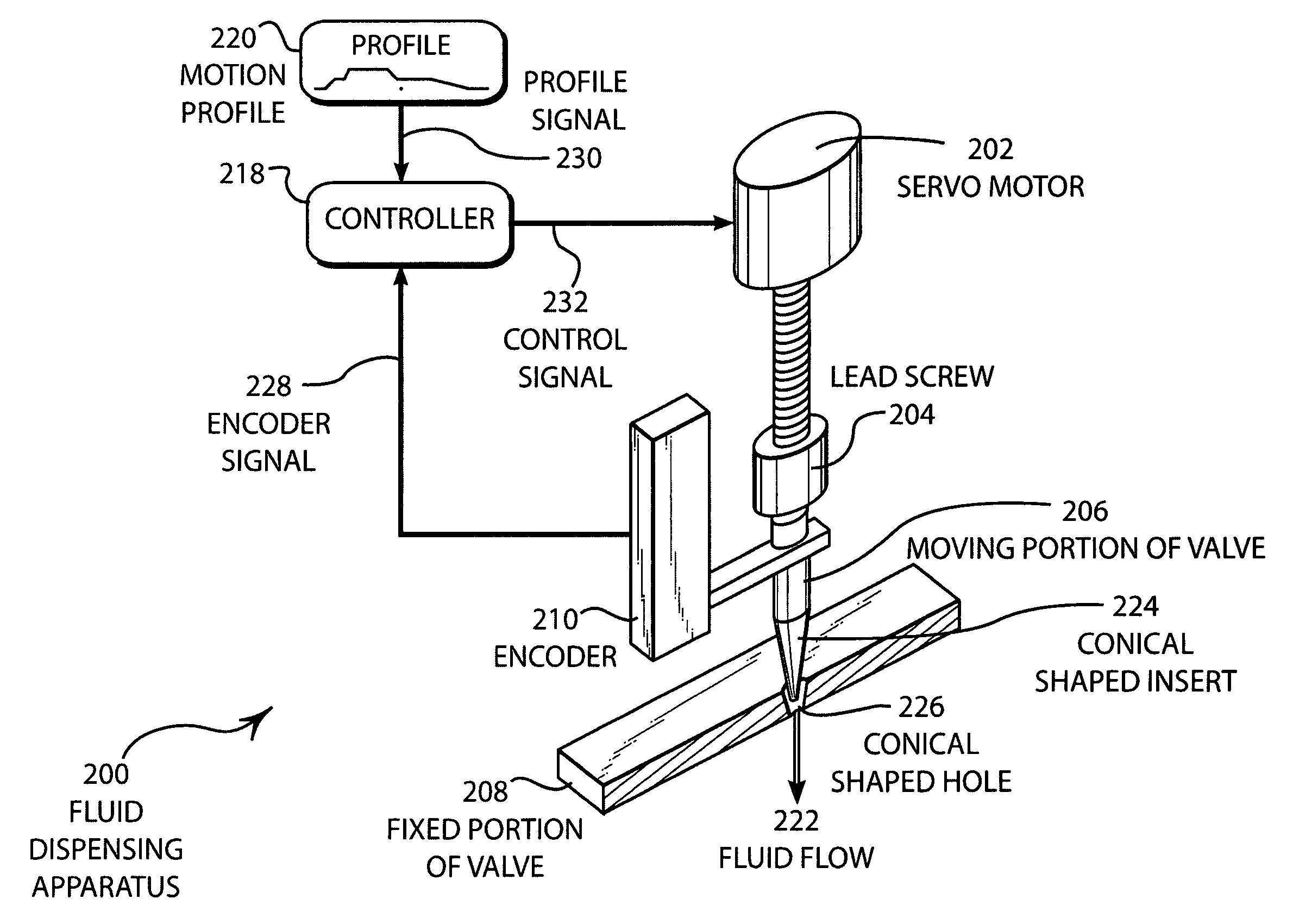

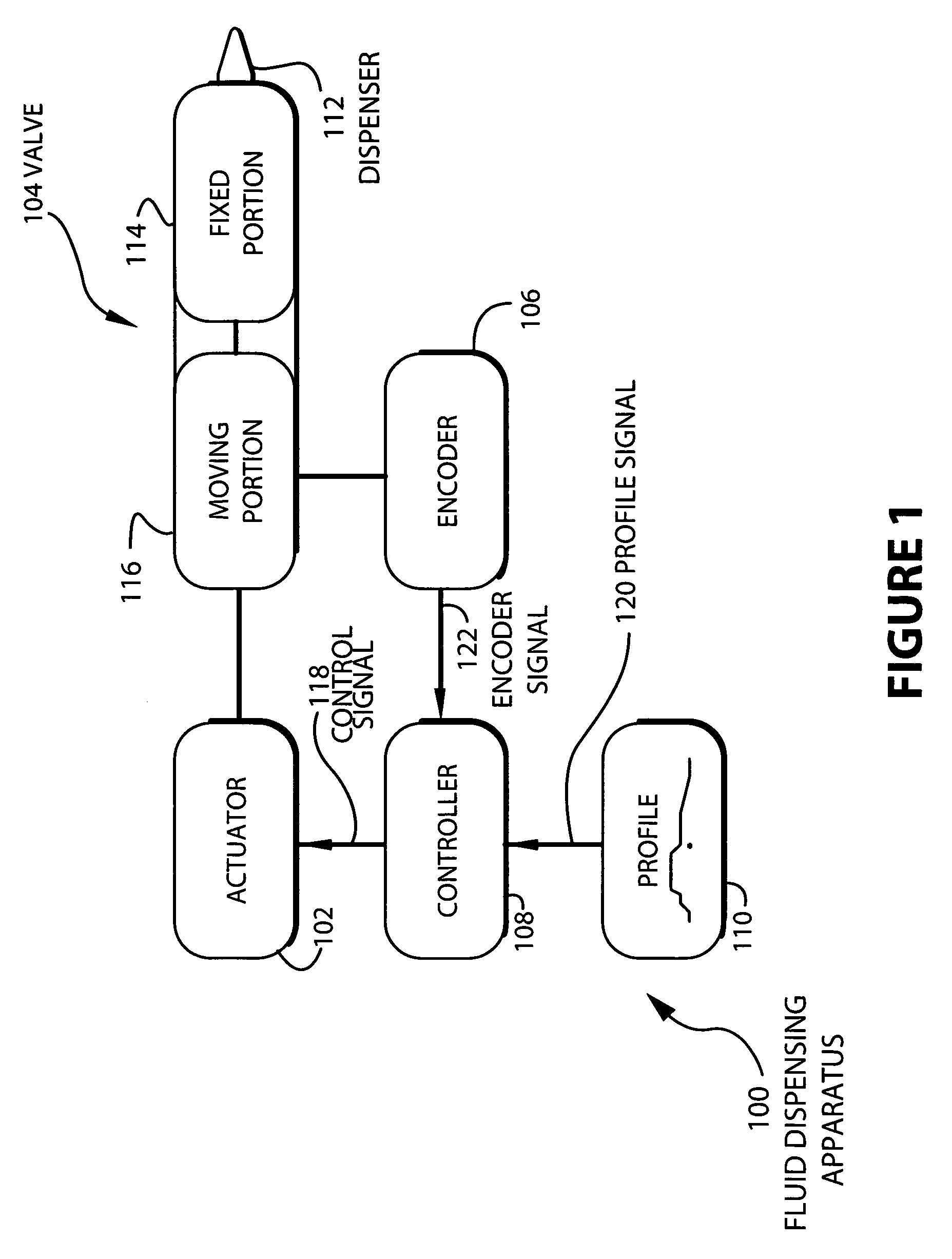

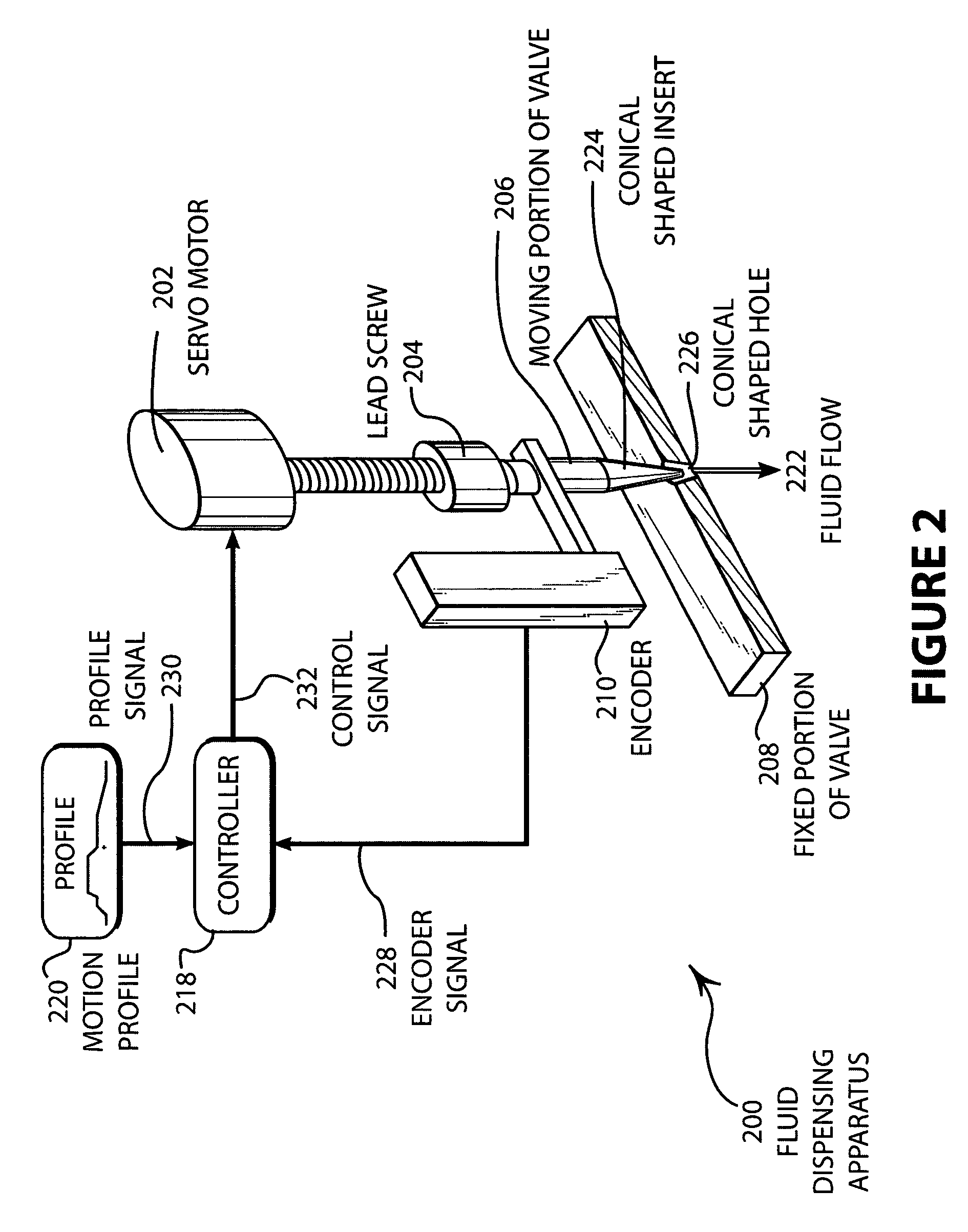

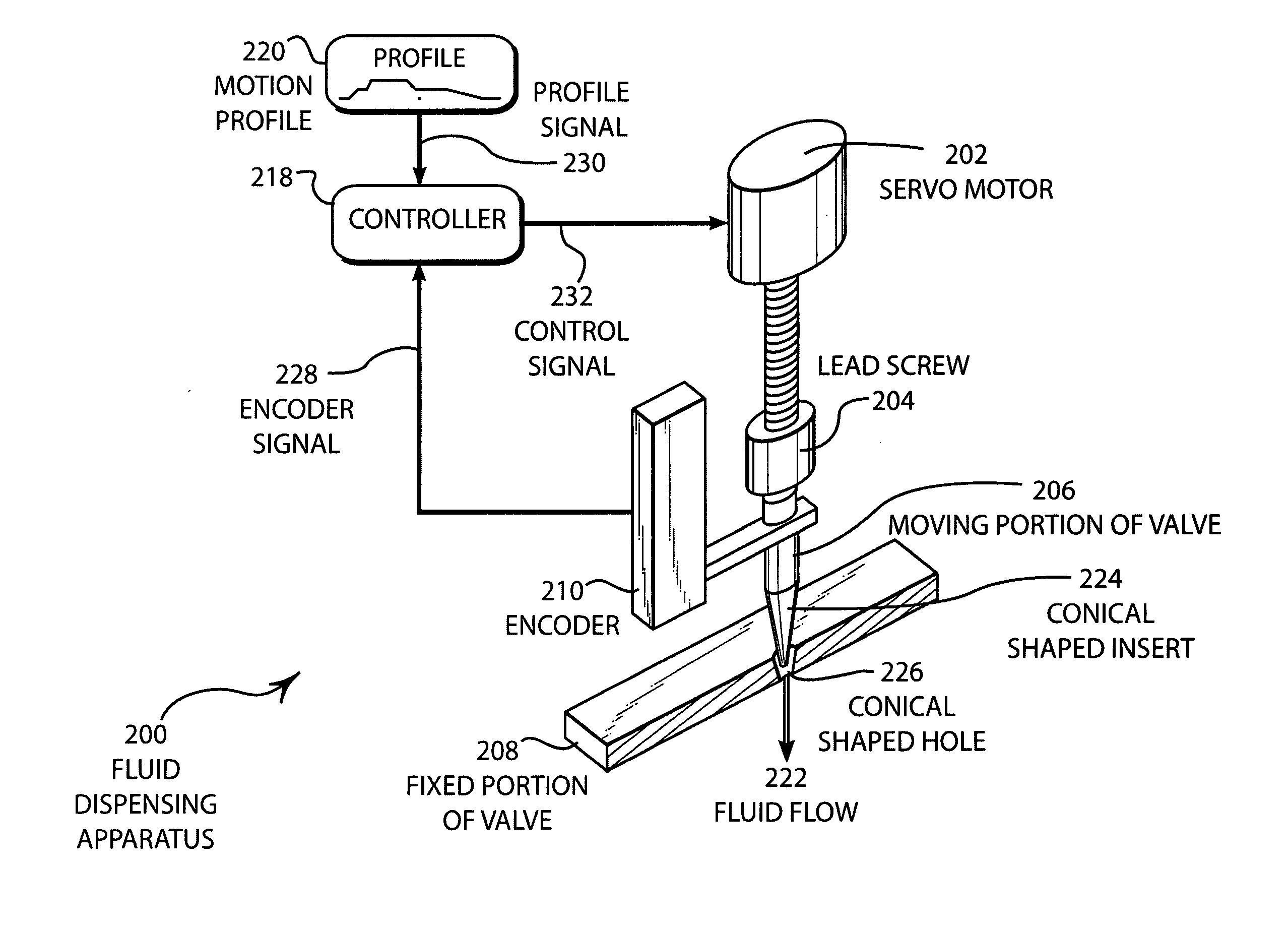

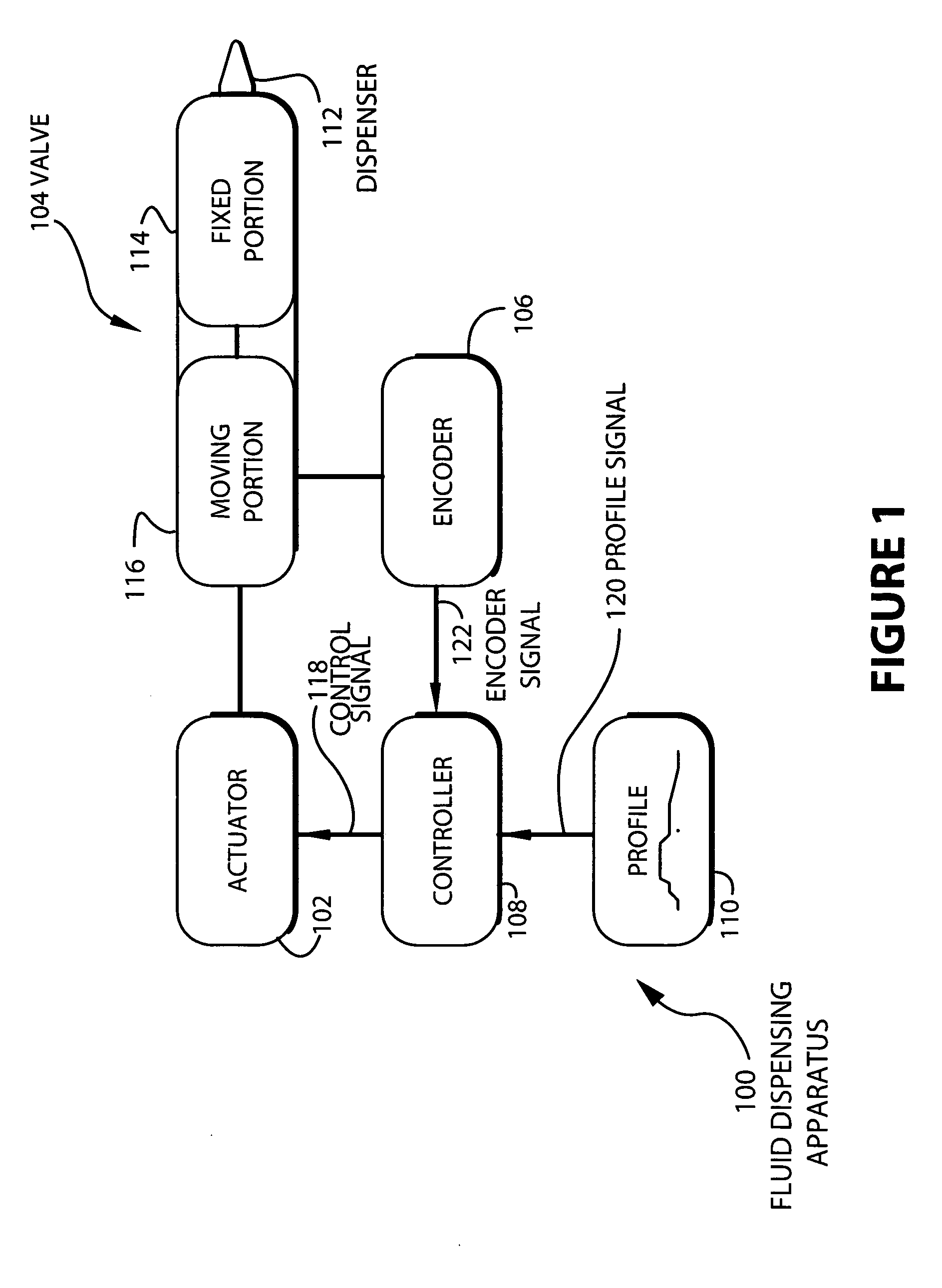

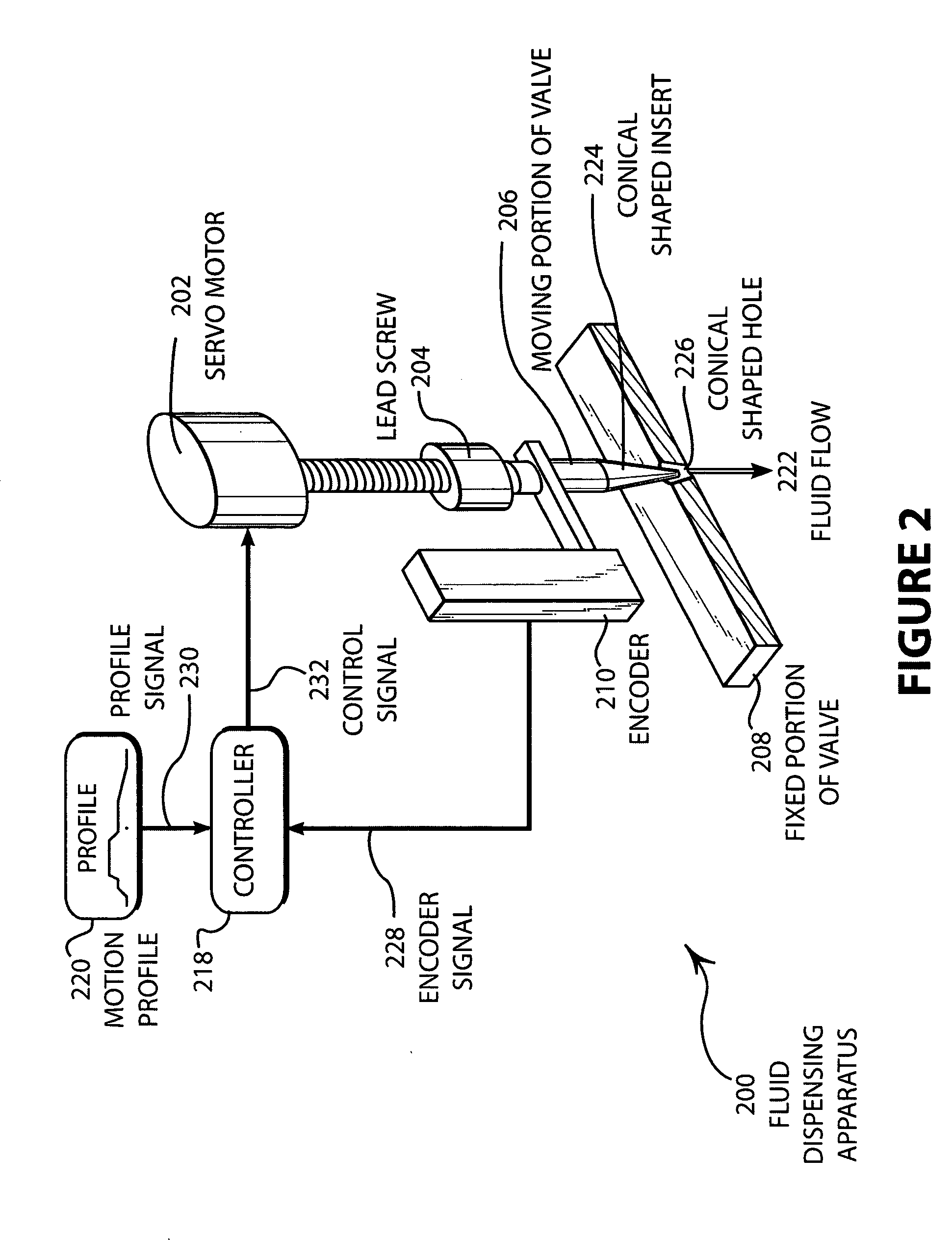

Variable fluid dispenser

InactiveUS7592033B2Flow rateLiquid transferring devicesLiquid/solution decomposition chemical coatingControl systemActuator

A dispenser that dispenses fluid is controlled using a feedback control system. The control system uses a positional encoder to determine the precise position of a valve contained in an actuator in order to control the dispensing of the fluid. Various motion profiles may be used to control the position of the valve. The motion profiles of the valve enable controlled variation of the amount of fluid dispensed over time and enable several specific improvements to the dispensing of sealant in the manufacture of metal and composite cans.

Owner:COMPUTROL

Variable fluid dispenser

InactiveUS20050158467A1Flow rateLiquid transferring devicesLiquid/solution decomposition chemical coatingControl systemActuator

A dispenser that dispenses fluid is controlled using a feedback control system. The control system uses a positional encoder to determine the precise position of a valve contained in an actuator in order to control the dispensing of the fluid. Various motion profiles may be used to control the position of the valve. The motion profiles of the valve enable controlled variation of the amount of fluid dispensed over time and enable several specific improvements to the dispensing of sealant in the manufacture of metal and composite cans.

Owner:COMPUTROL

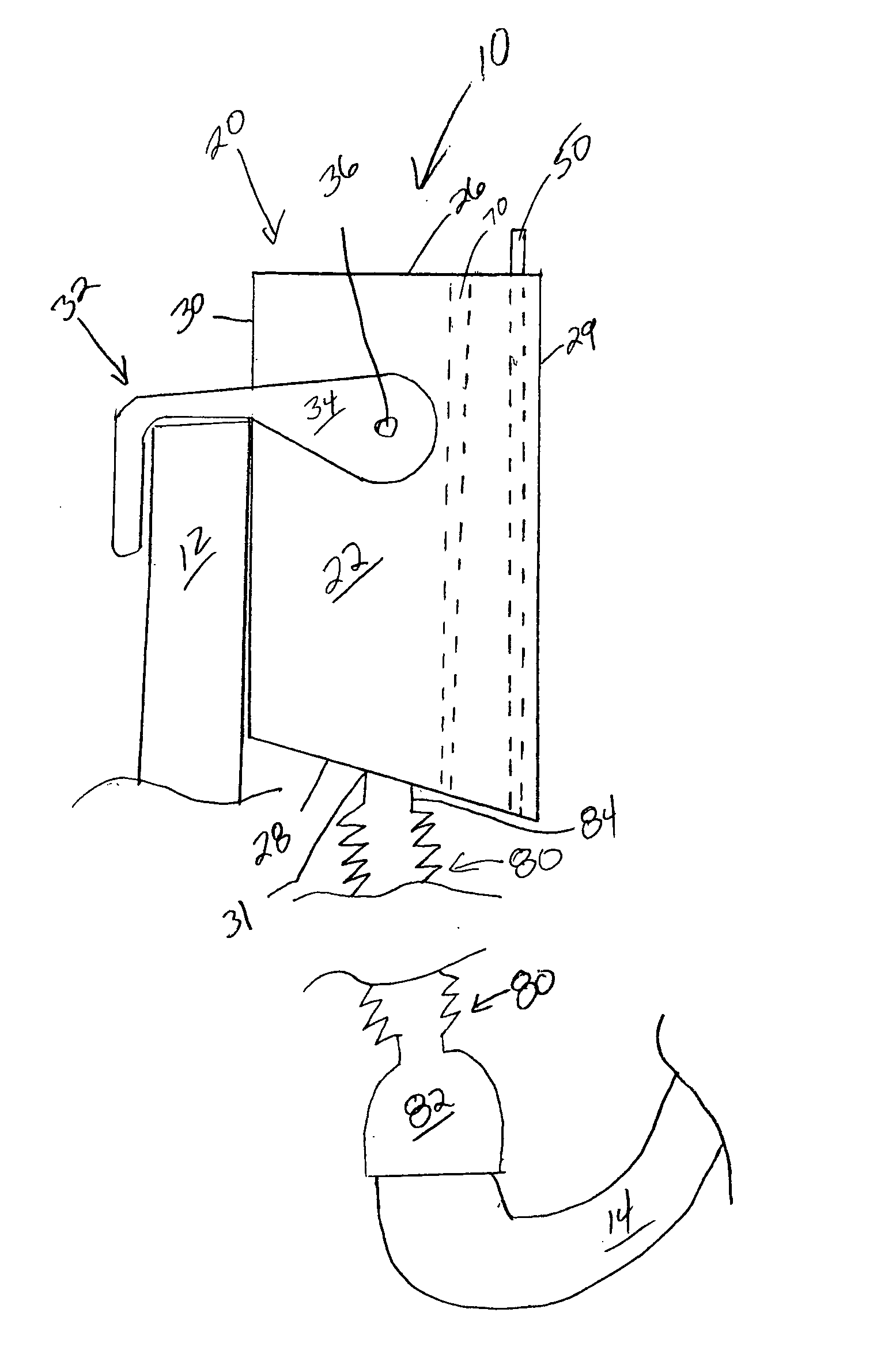

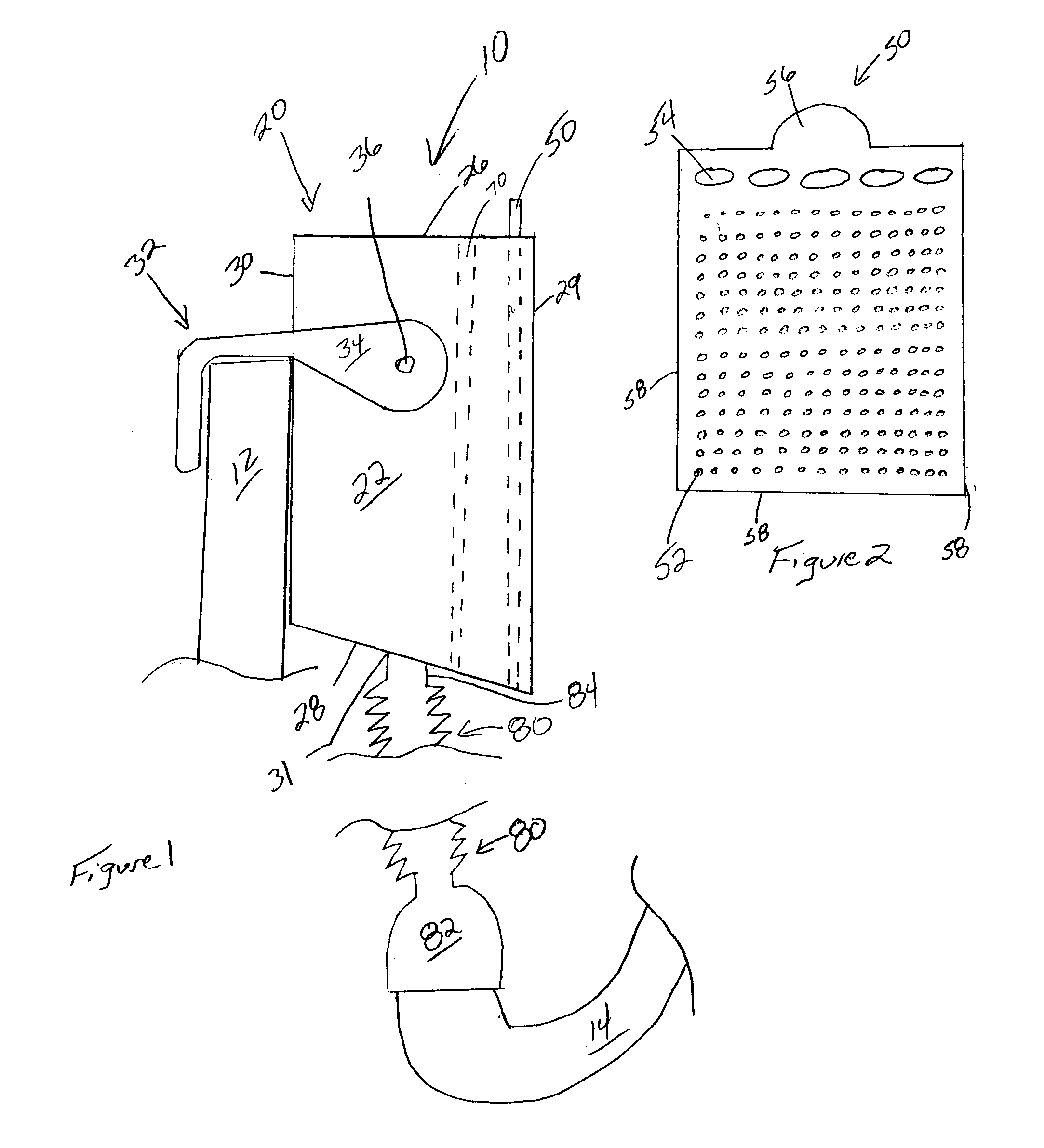

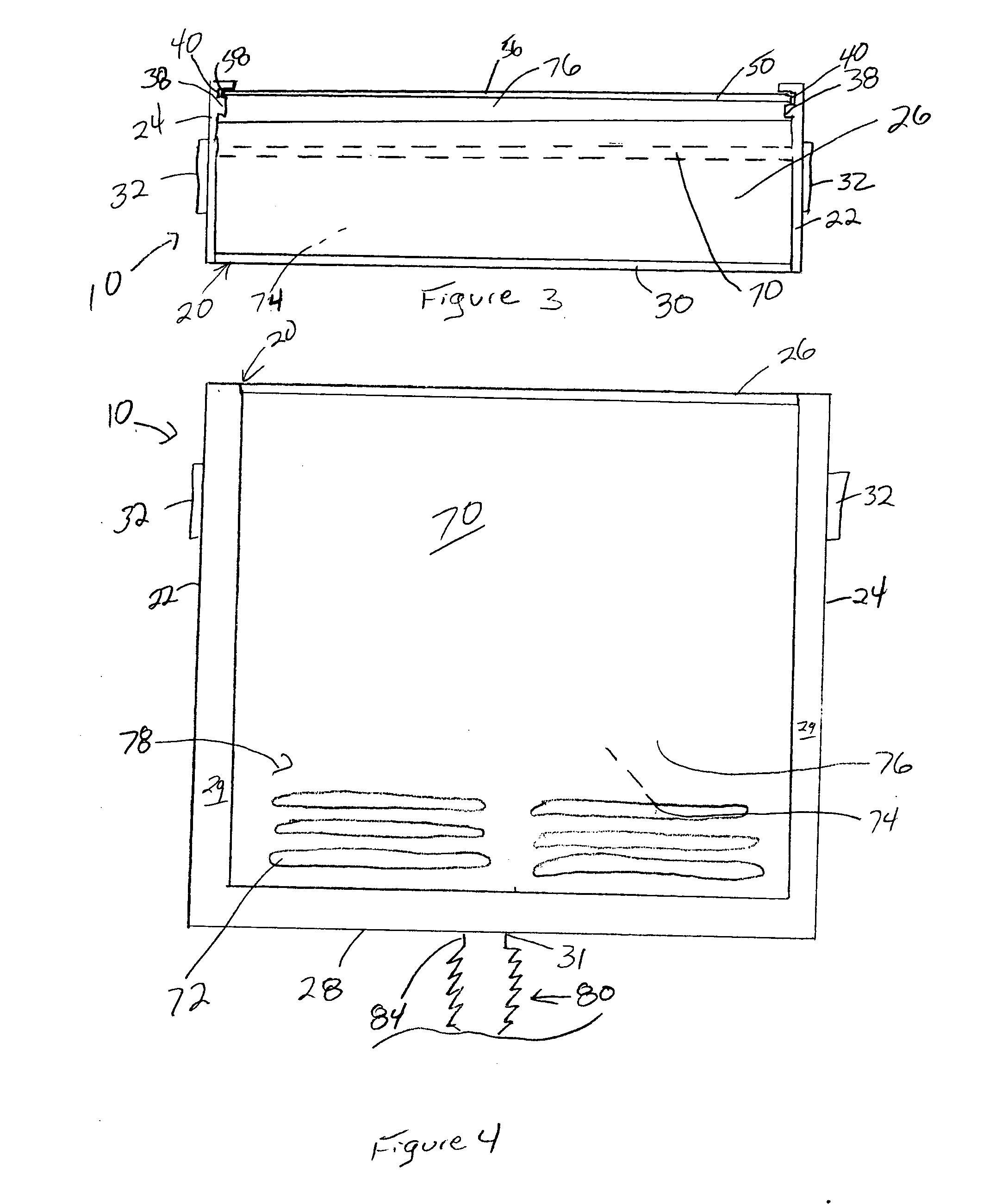

Lint trap

InactiveUS20050000920A1Flow rateEasy dischargeOther washing machinesWater/sewage treatmentWaste managementWater release

A lint trap, including a housing having a first side wall, a second side wall, a top wall, a bottom wall, a back wall and a front wall, and the bottom wall defining an aperture; at least one attachment mechanism joining the housing to a utility sink; a lint collection plate slot defined in the side walls; a lint collection plate, the lint collection plate being slidably received within the lint collection plate slot; and an adapter having a hose end and a trap end, the hose end being adapted to join to a hose of a washing machine and the trap end being joined relative to the aperture defined in the bottom wall and a method of use including the steps of flowing water into a flow rate control chamber of a lint trap; flowing water from the flow rate control chamber to a water release chamber; flowing water from the water release chamber through a lint collection plate; removing the lint collection plate from the lint trap; wiping lint off the lint collection plate; and reconnecting the lint collection plate to the lint trap.

Owner:SMOLLEY JOHN M

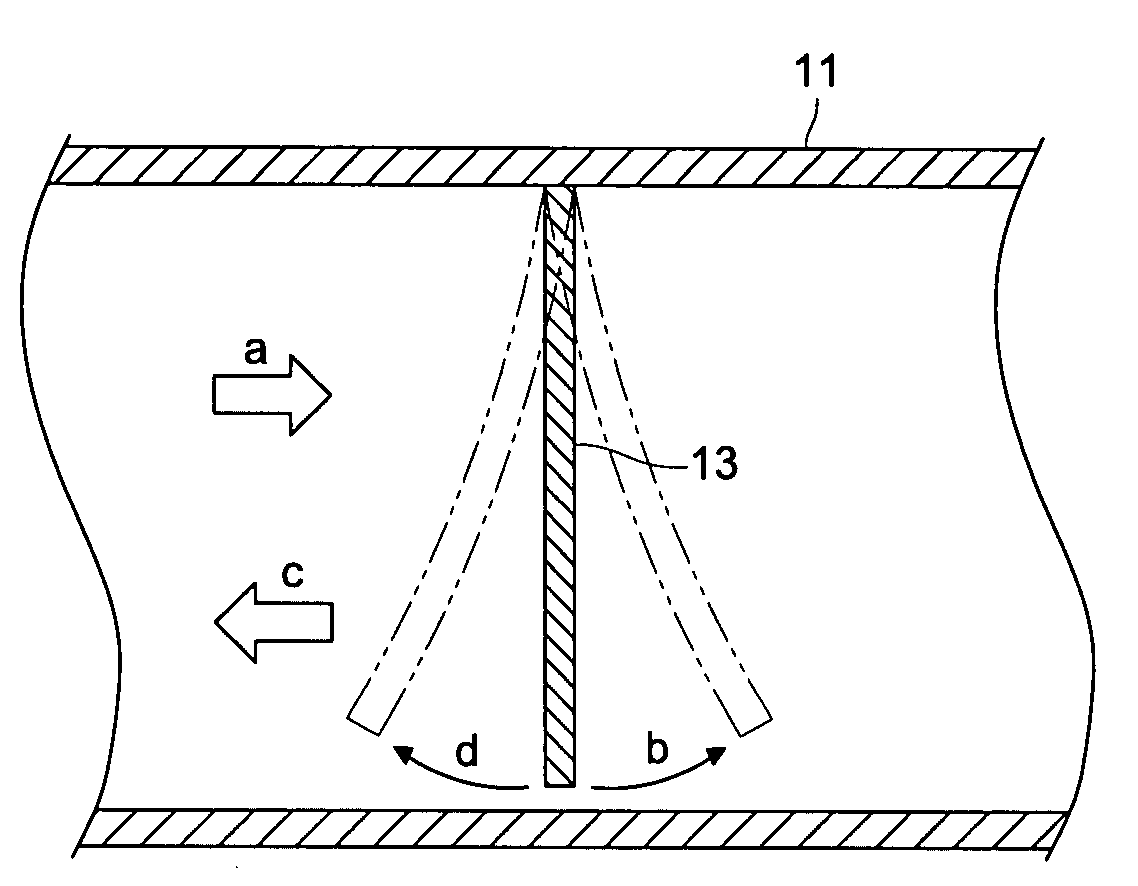

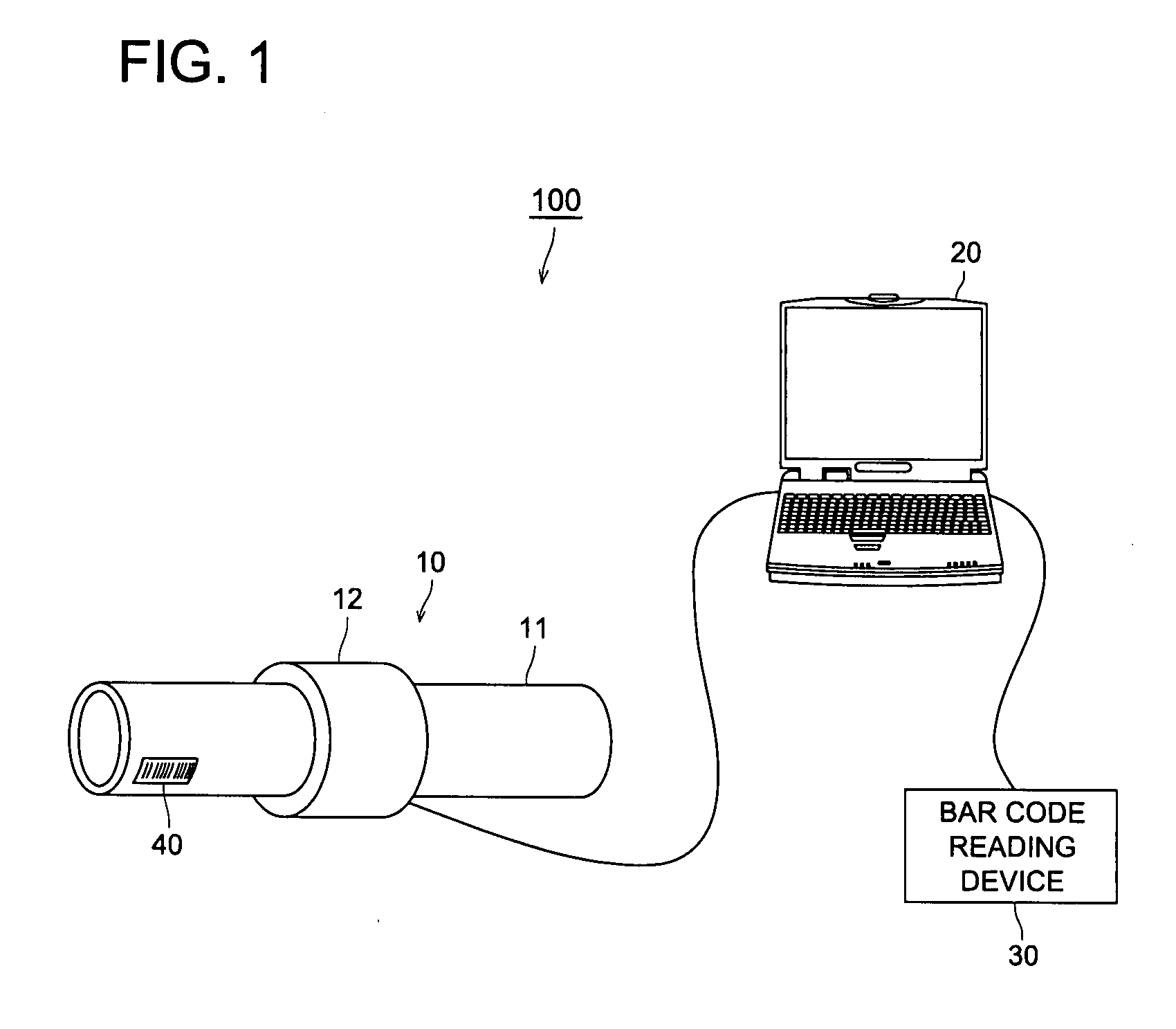

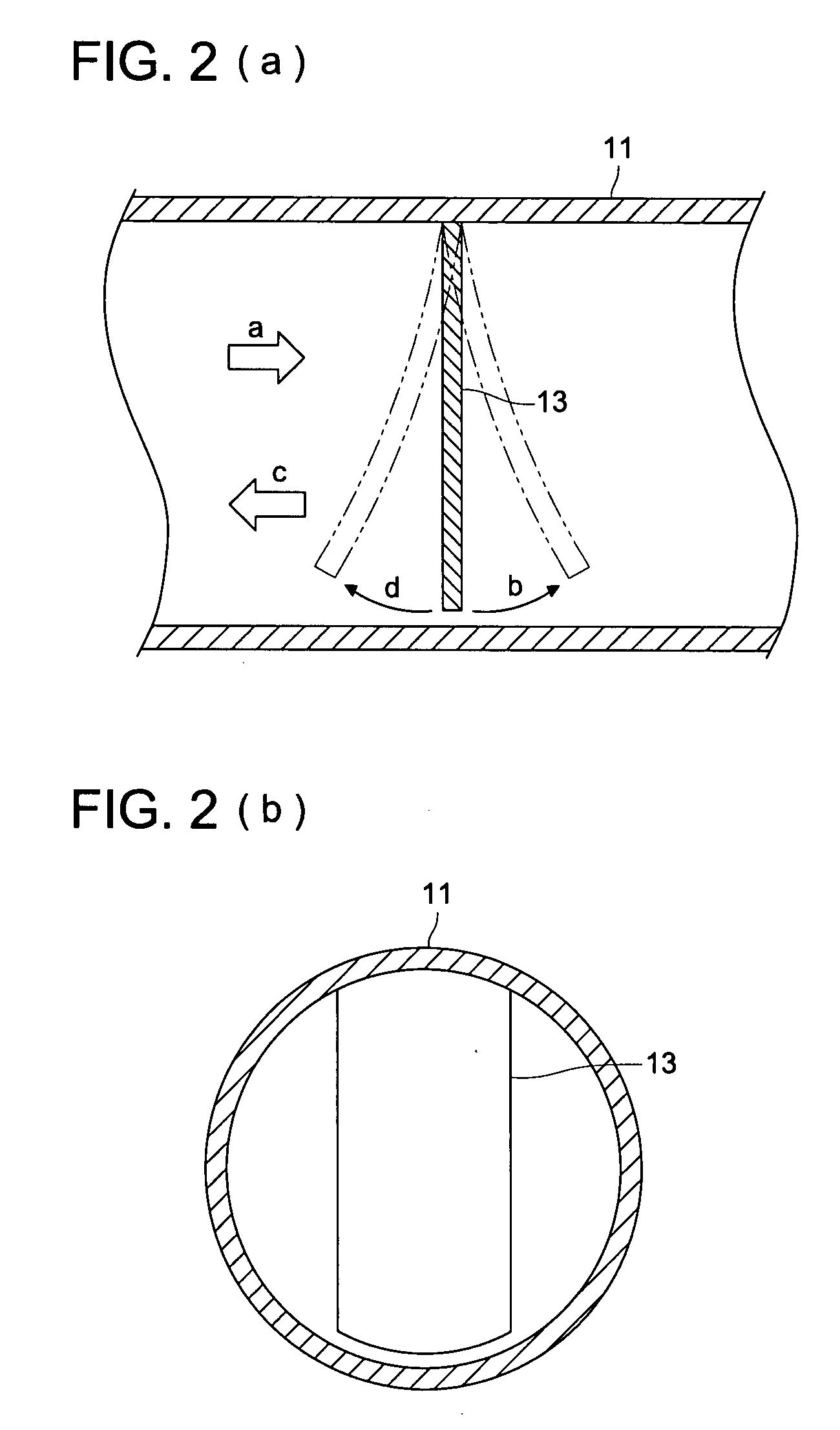

Flow Rate Measurement Apparatus

InactiveUS20080119756A1Simplify structure of apparatusLess-expensiveRespiratory organ evaluationSensorsRespiratory flow rateEngineering

A movable member 13, whose physical change occurs corresponding to a respiration flow rate, is disposed in the pipe 11. The pipe 11 and holder section are structured to be capable of being detachable. When staring respiration with the mouth touching pipe 11, the movable member 13 bends corresponding to respiration flow rate. Image data of the movable member 13 is obtained through the pipe 11 by a CCD area sensor disposed outside the pipe 11 and the bending amount is detected. The respiration rate is calculated based on the flow rate data corresponding to the bending amount of the movable member 13 in use.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

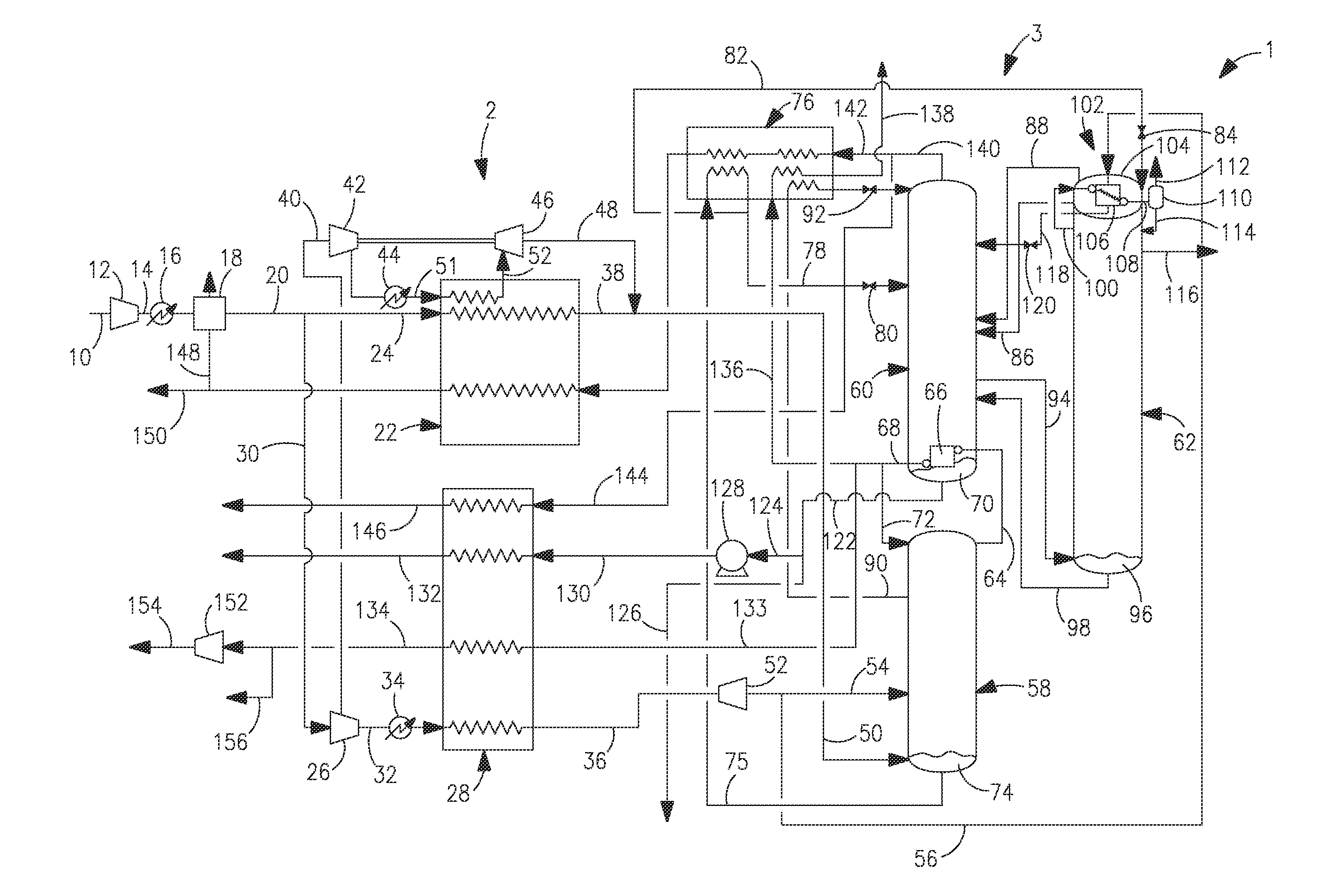

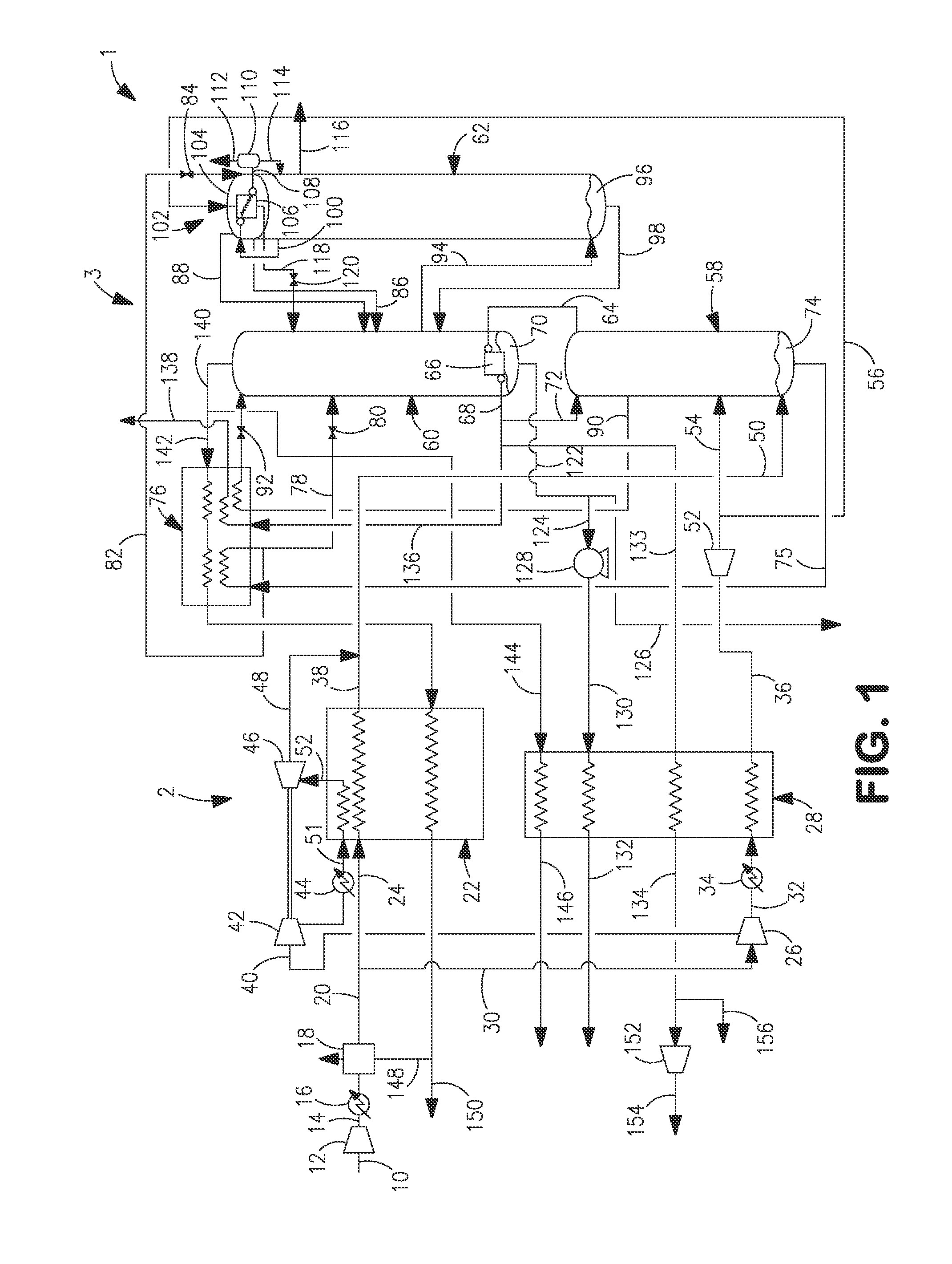

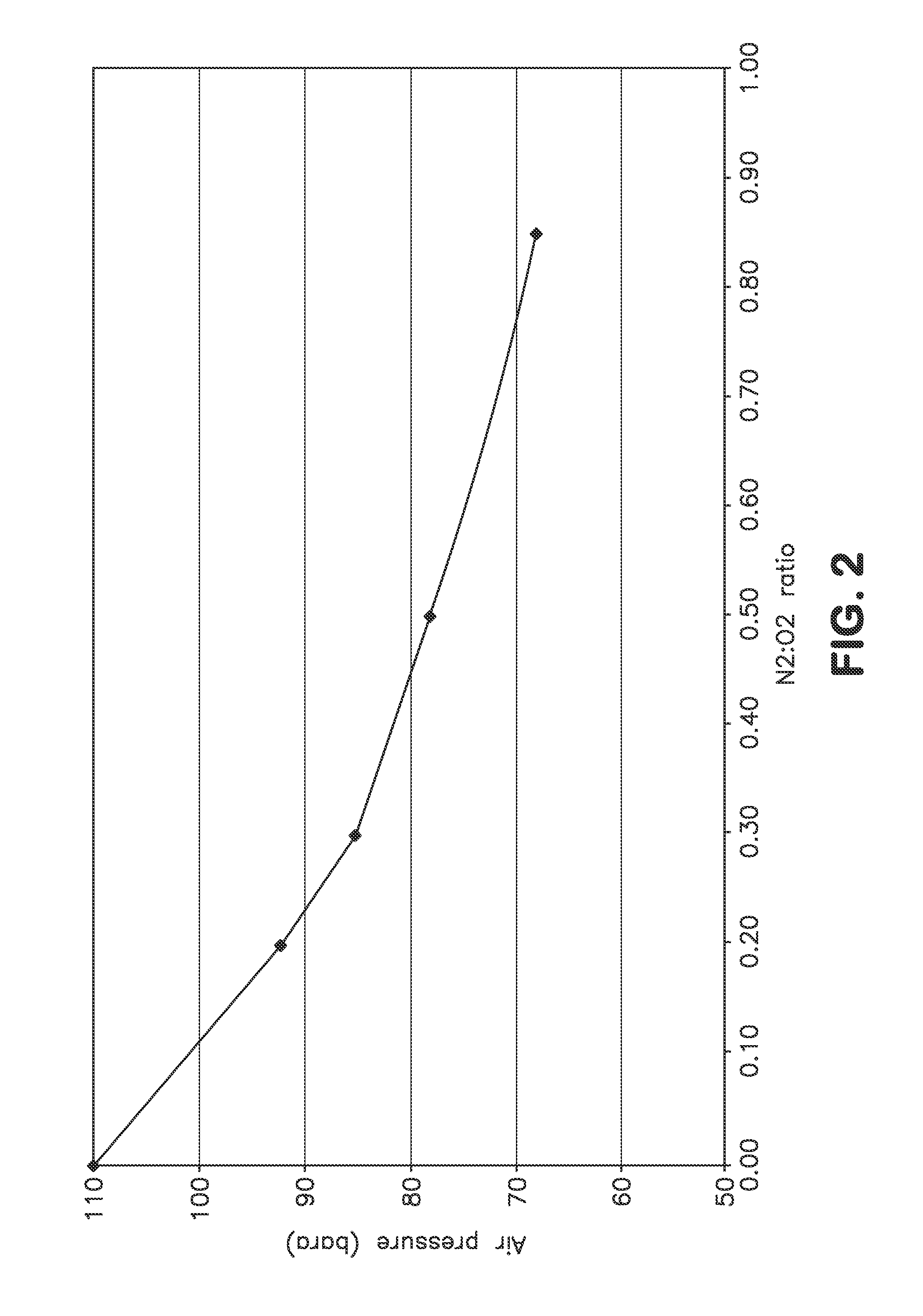

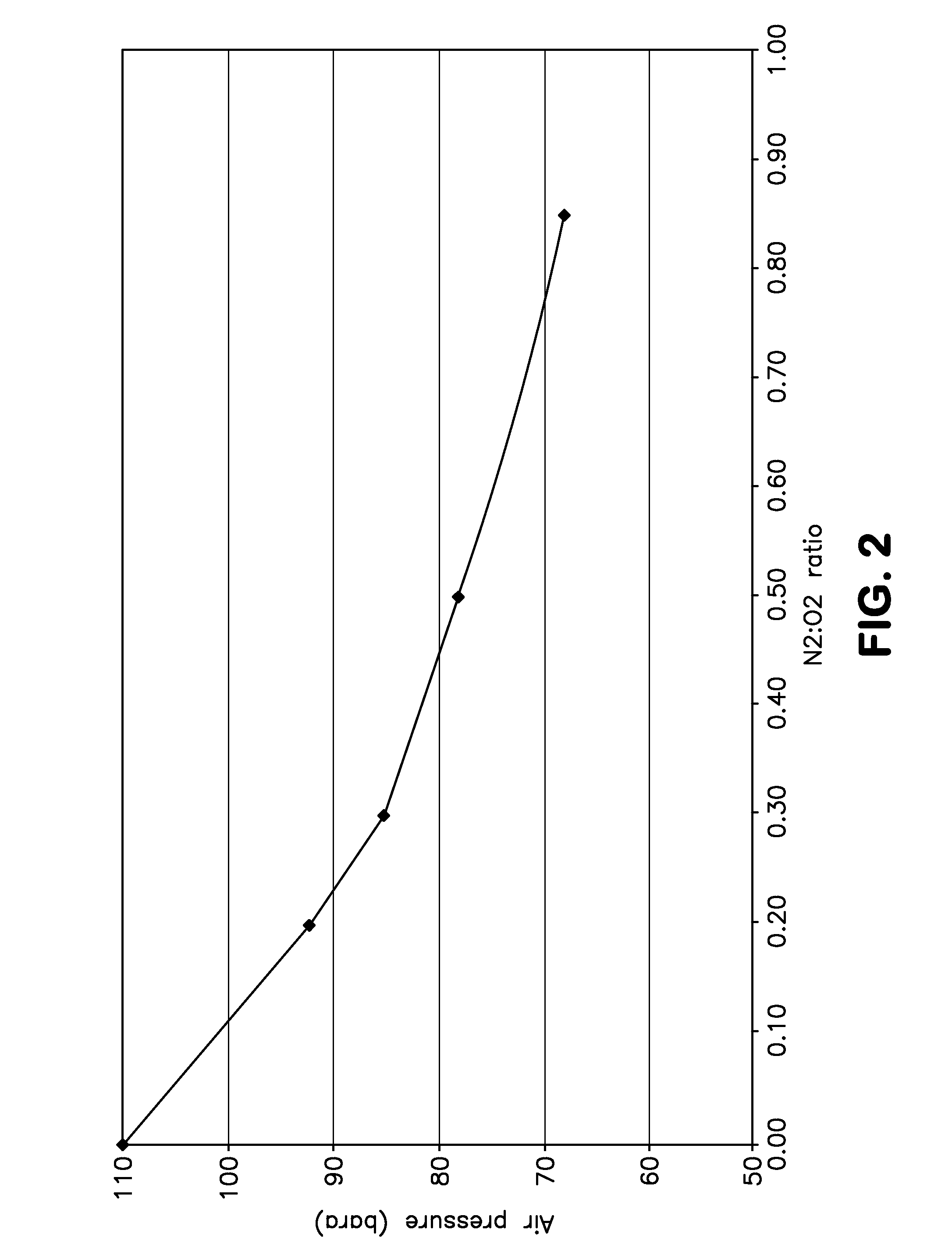

Air separation method and apparatus

An air separation method and apparatus in which a supercritical oxygen product is produced by heating a pumped liquid oxygen stream having a supercritical pressure, through indirect heat exchange with a boosted pressure air stream. The indirect heat exchange is conducted within a heat exchanger and a liquid nitrogen stream is vaporized in the heat exchanger to depress the pressure that would otherwise be required of the boosted pressure air stream to heat the pumped liquid oxygen stream. The pumped liquid oxygen stream constitutes 90 percent of the oxygen-rich liquid removed from an air separation unit in which the air is rectified, the liquid nitrogen constitutes at least 90 percent of the liquid nitrogen that is not used as reflux and a flow-rate ratio between the liquid nitrogen stream and the oxygen-rich liquid is between about 0.3 and 0.90.

Owner:PRAXAIR TECH INC

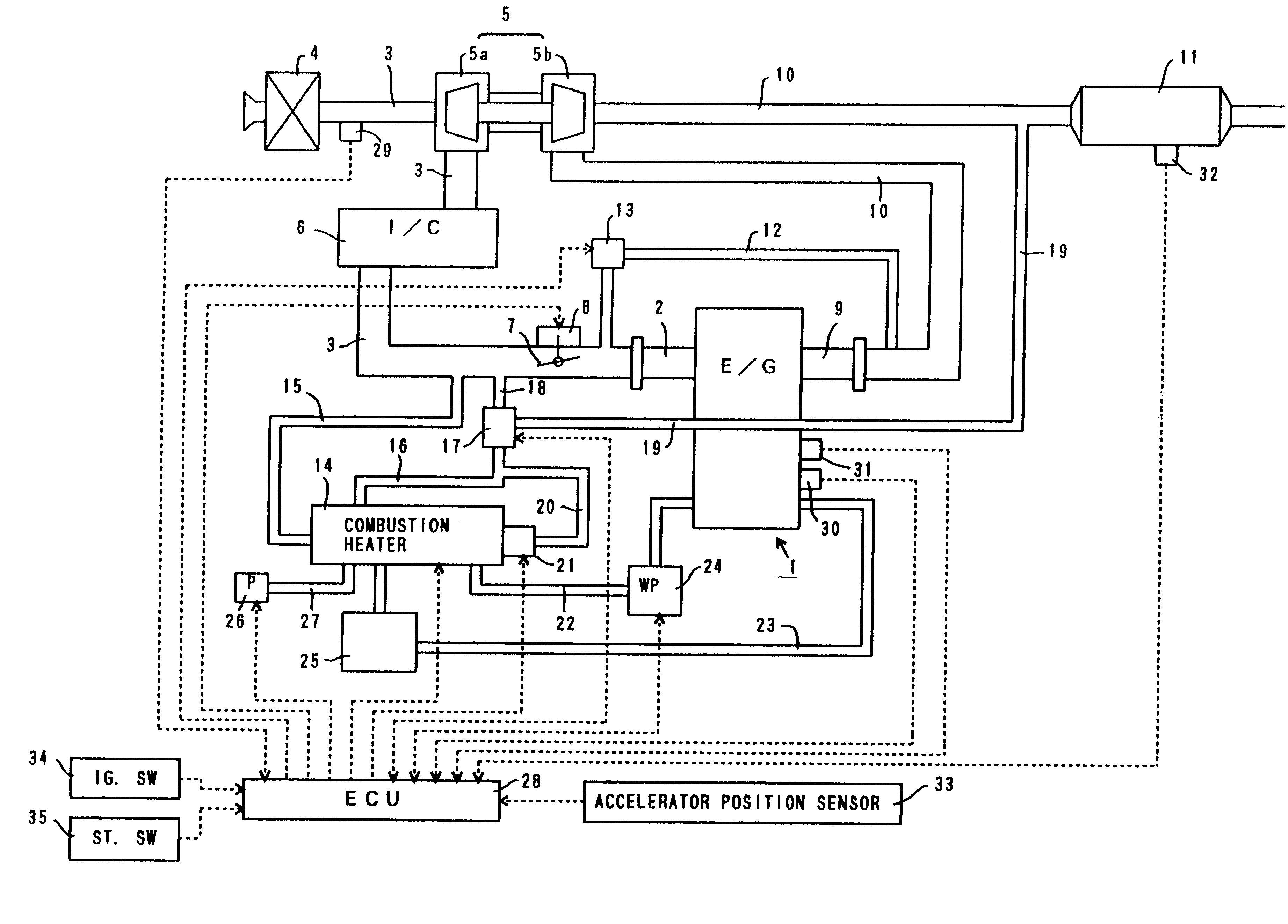

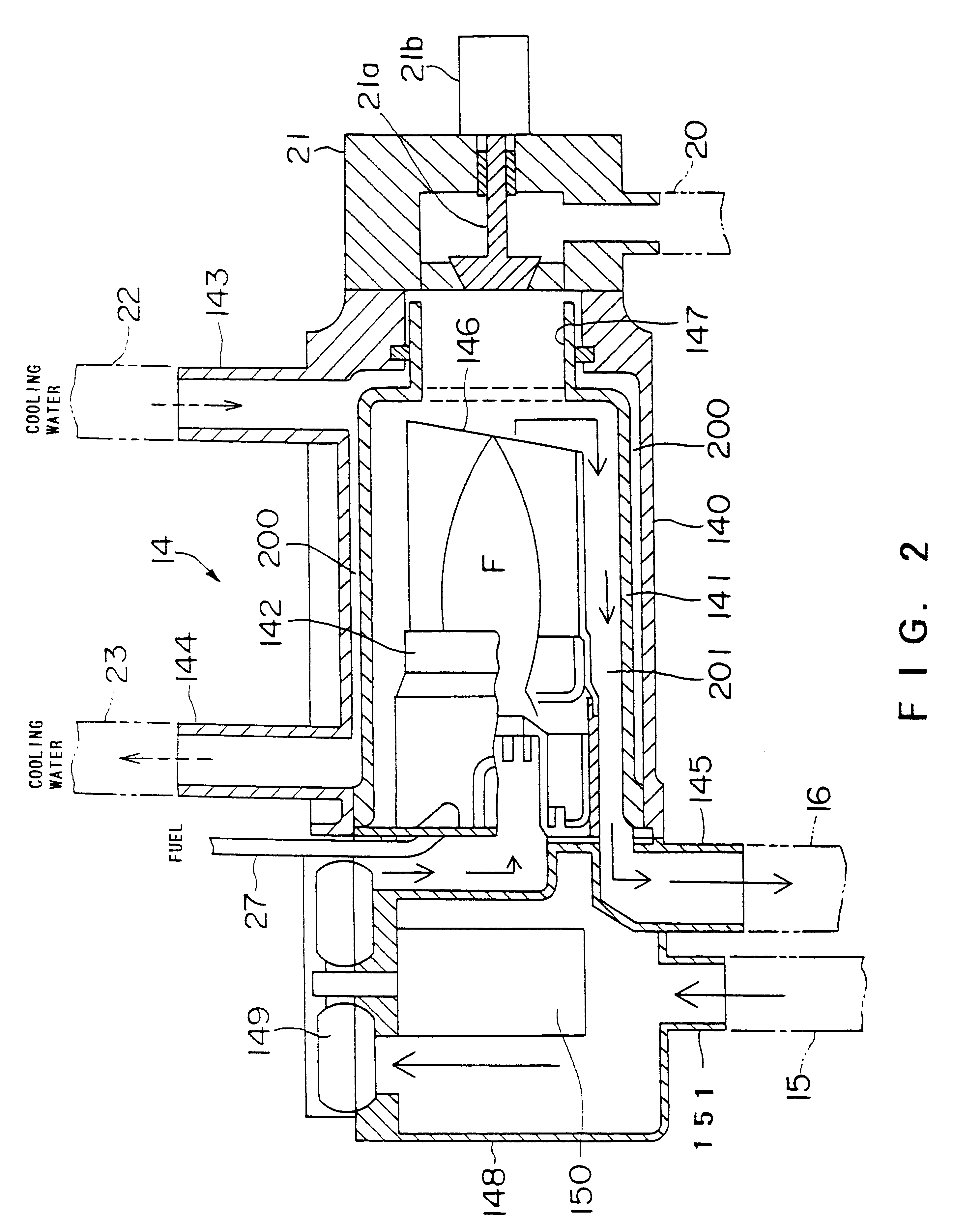

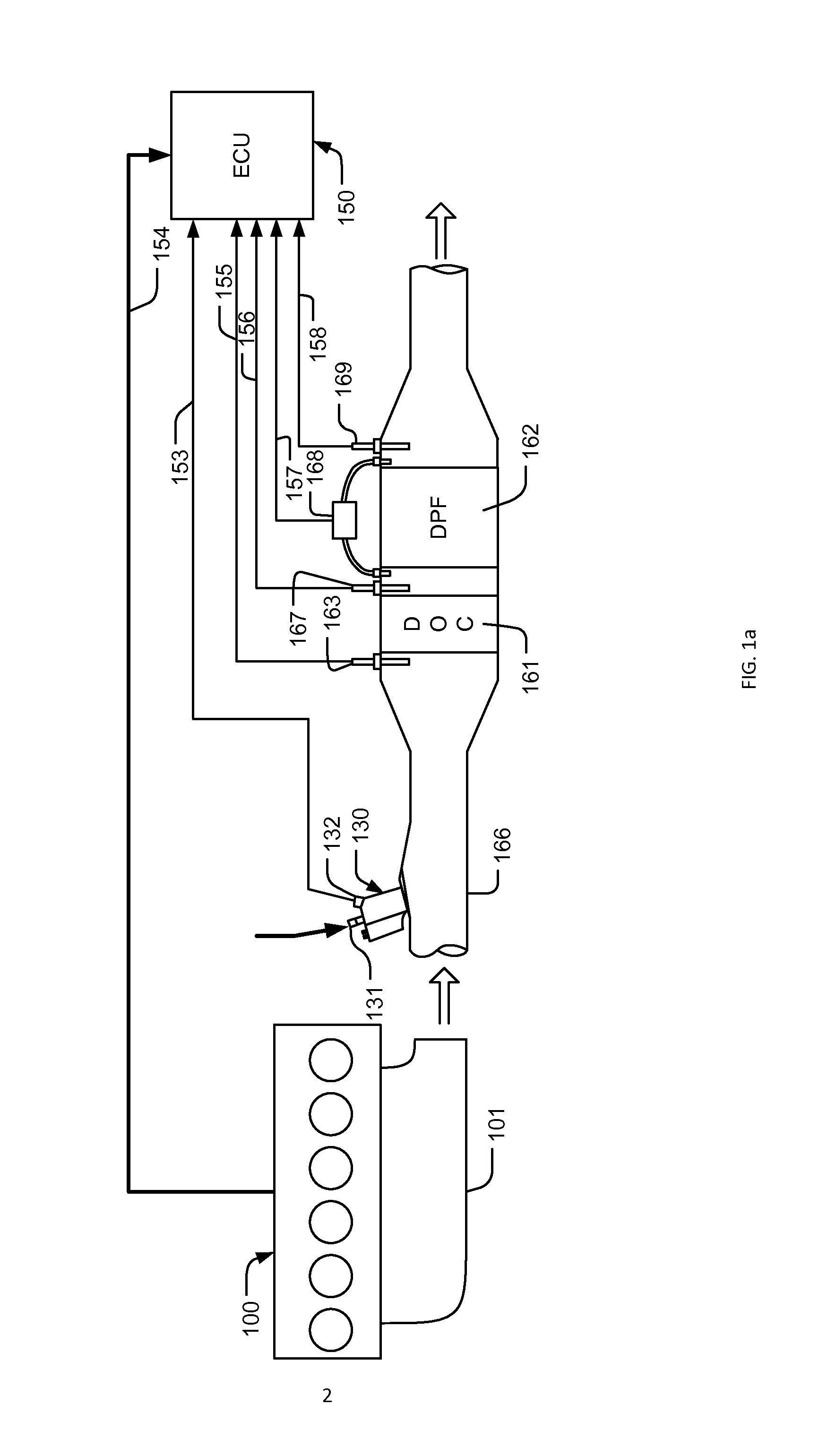

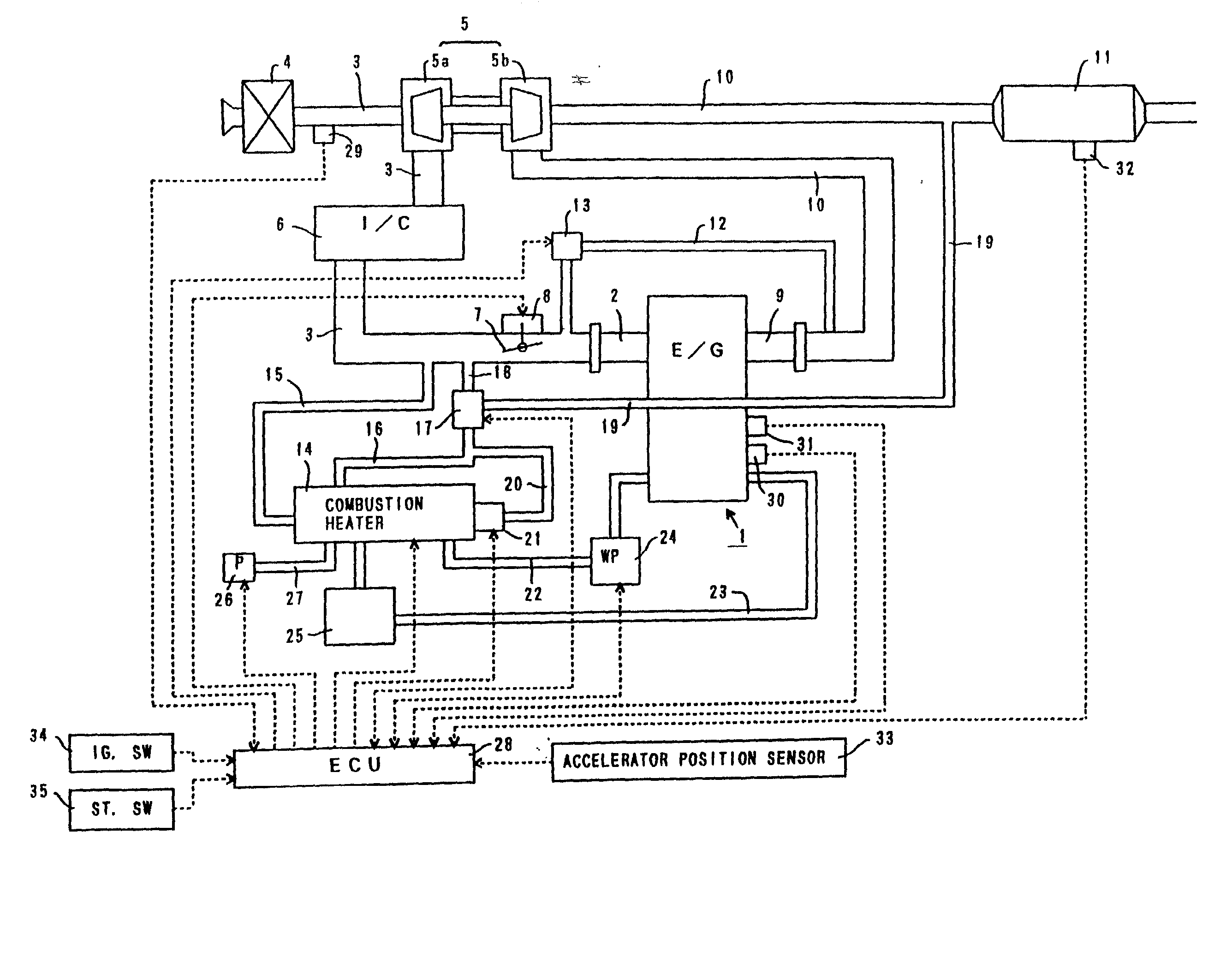

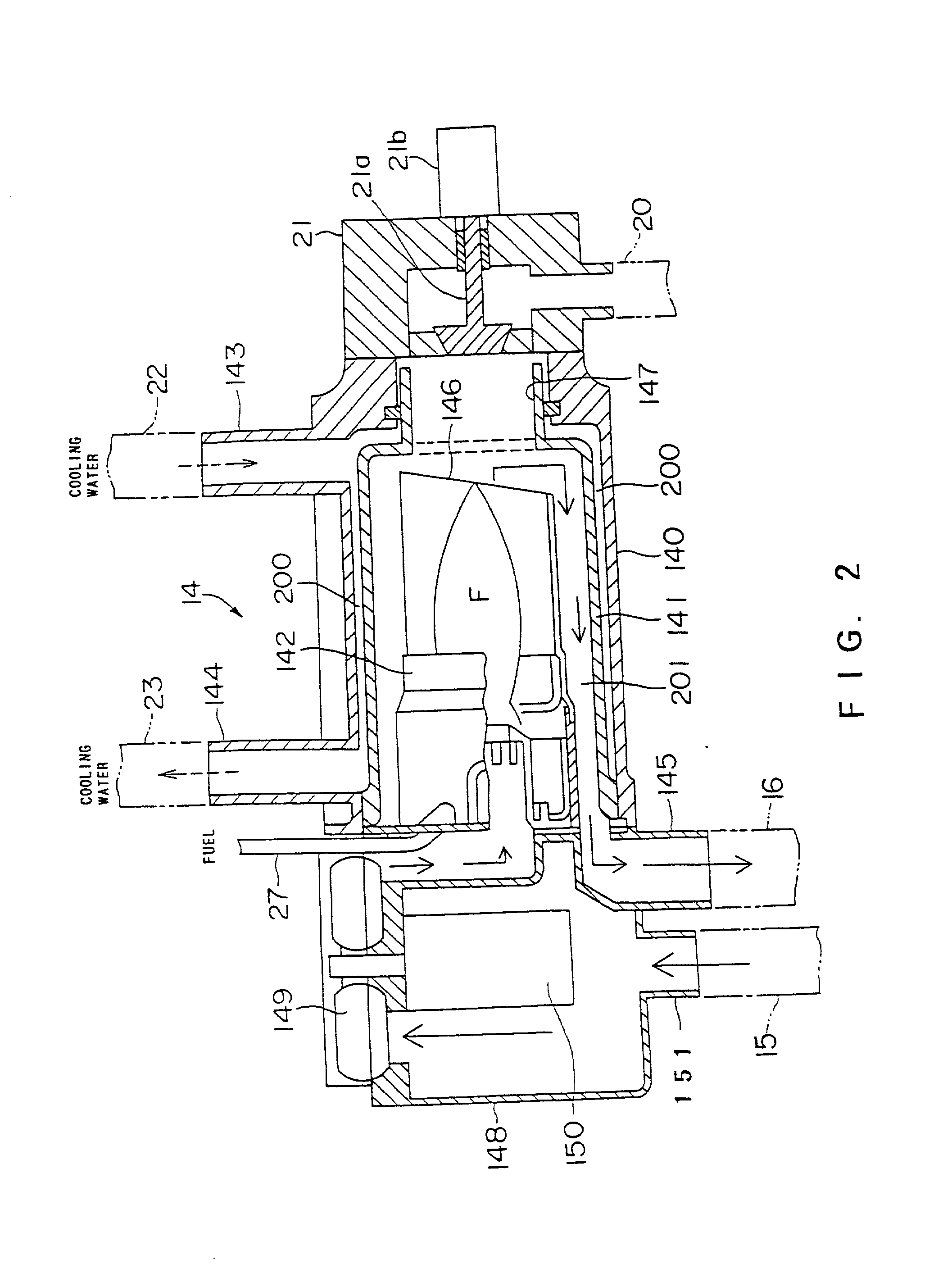

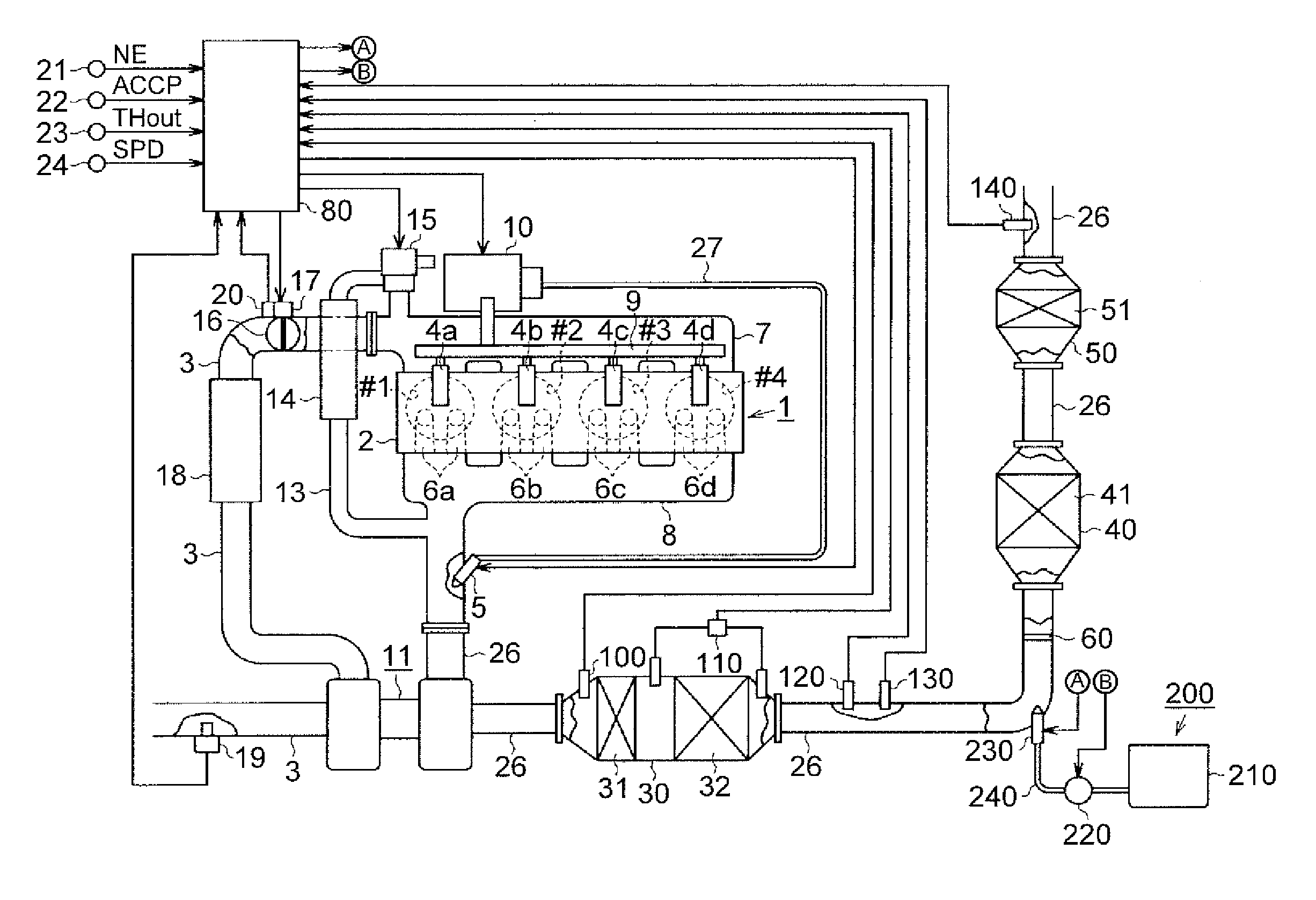

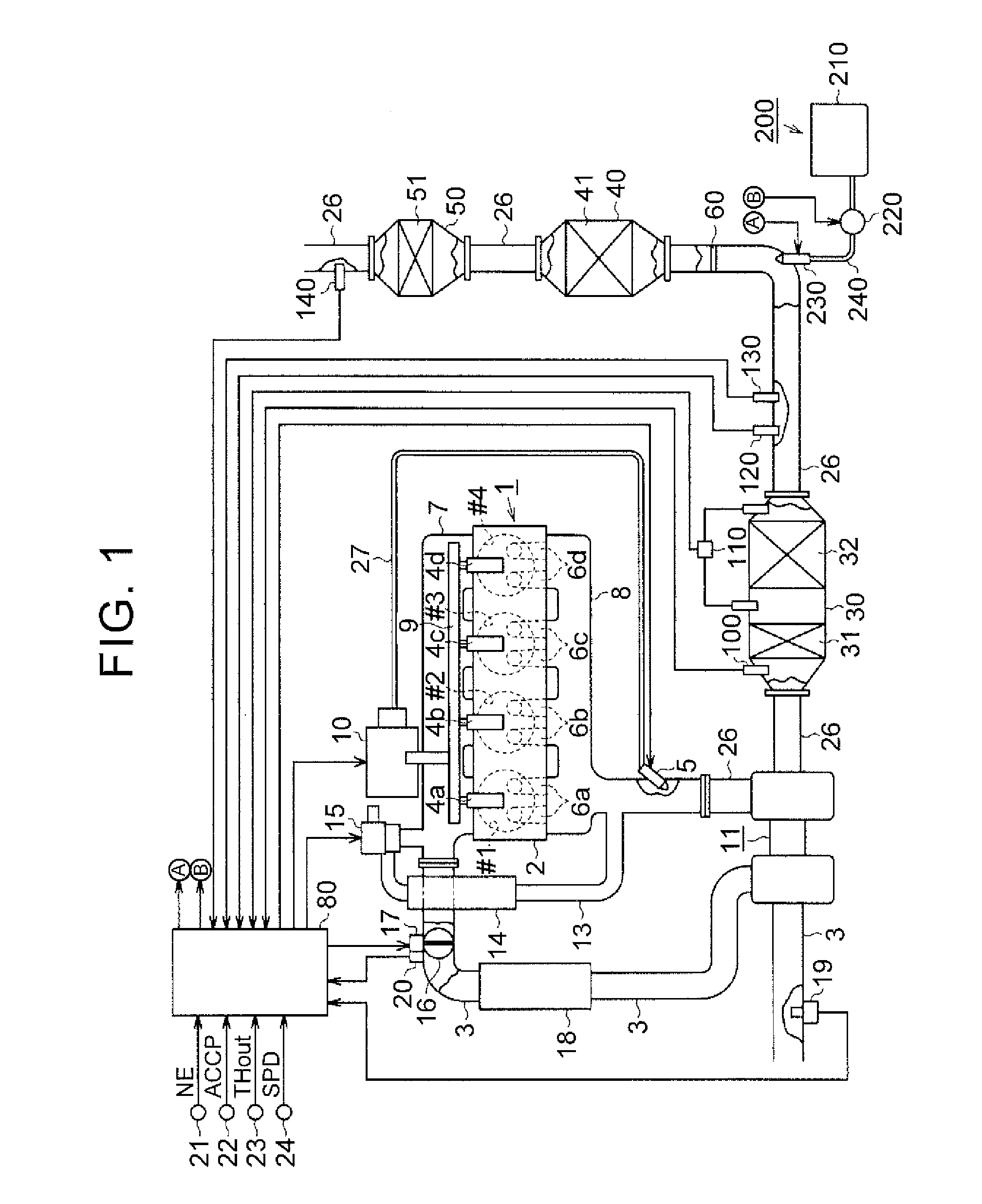

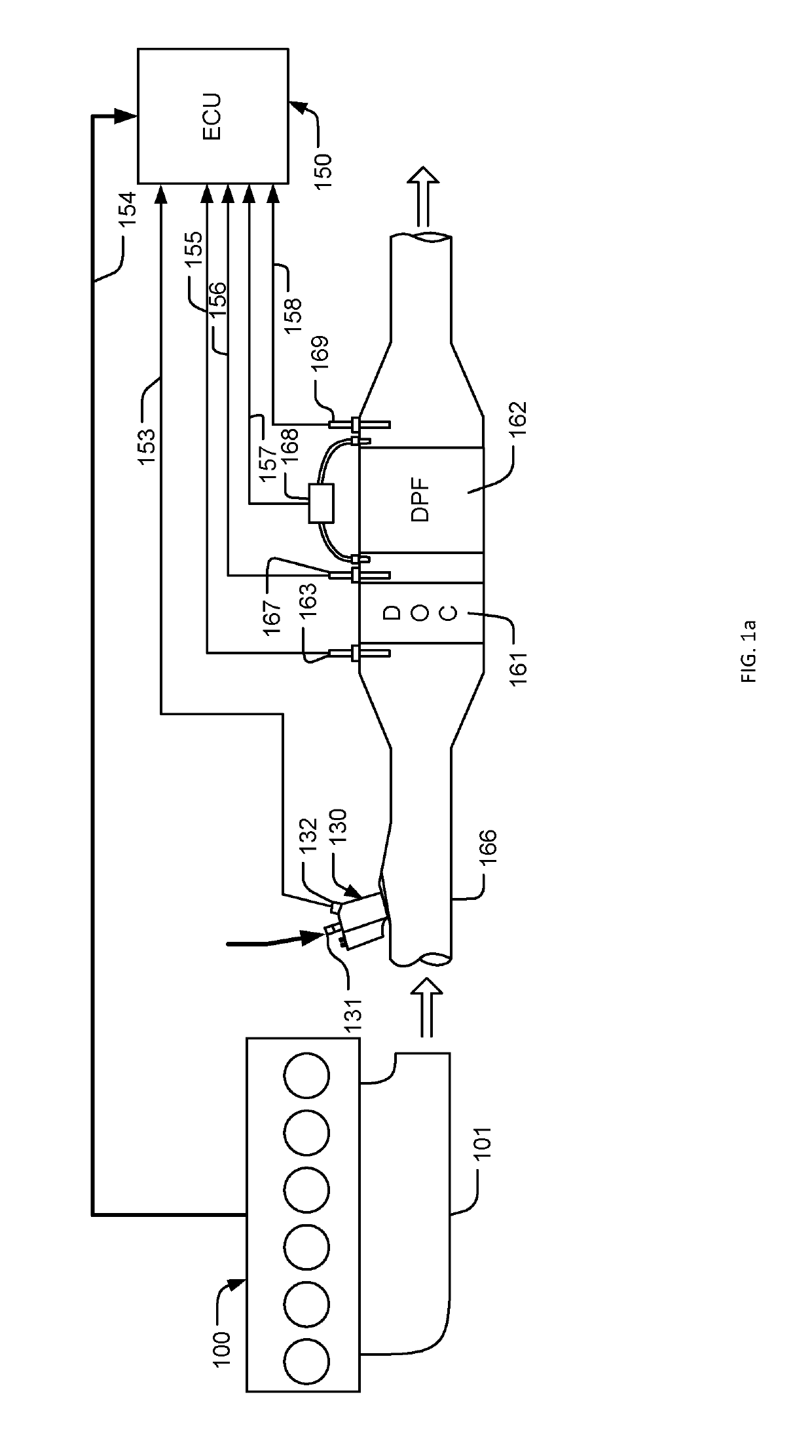

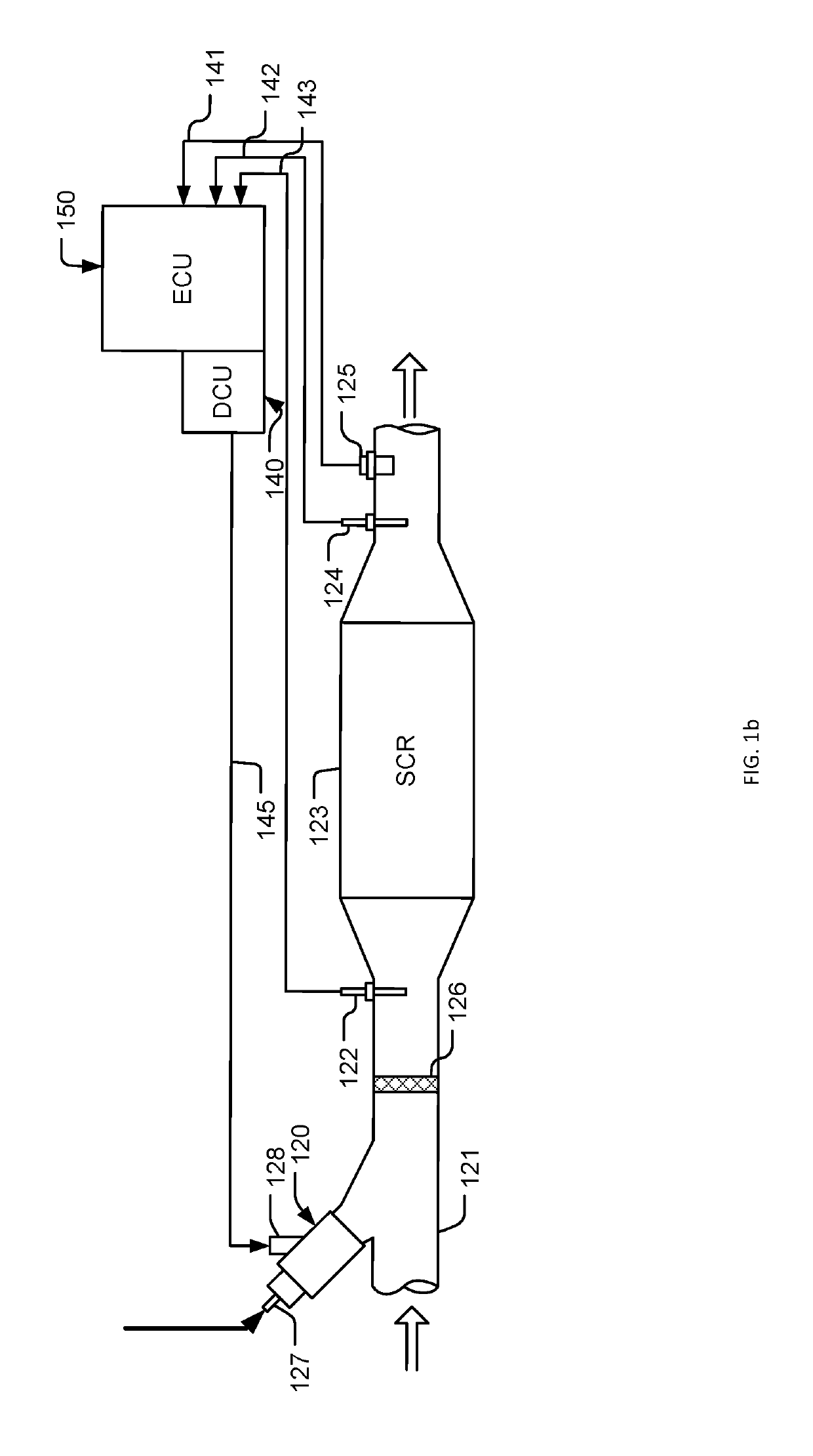

Internal combustion engine with combustion heater

InactiveUS6293241B1Flow rateReduce flowFuel supply regulationAir-treating devicesCombustion chamberProduct gas

In an internal combustion engine with a combustion heater for elevating a temperature of an engine related element, an object of the present invention is to provide a technique that may effectively performs temperature elevation of an exhaust gas purifying device. In order to attain this object, according to the present invention, the internal combustion engine having an exhaust gas purifying catalyst provided in an exhaust passage of the internal combustion engine, and a combustion heater comprising a combustion chamber and a heat exchange portion for transmitting to an engine related element heat held by burnt gas that has been burnt in said combustion chamber, characterized by including a first burnt gas discharging portion for discharging from the combustion heater the burnt gas which has passed through the heat exhcange portion, a second burnt gas discharging portion for discharging from the combustion heater the burnt gas which has not yet passed through the heat exchange portion, and a burnt gas passage controlling unit for supplying at least one of burnt gas discharged by the first burnt gas discharging portion and burnt gas discharged by the second burnt gas discharging portion to the exhaust gas purifying catalyst.

Owner:TOYOTA JIDOSHA KK

Solenoid valve

InactiveUS20060081801A1Improve sealingFlow rateOperating means/releasing devices for valvesNon-fuel substance addition to fuelEngineeringVALVE PORT

A guide boss is provided in a diaphragm blocking the halfway portion of a channel; a valve disk is formed in the shape of a cylinder; the inner face of this cylinder-shaped valve disk is slidably engaged around the guide boss; and further, a valve port consisting of a plurality of long bores are formed in a diaphragm surrounding the guide boss. Thereby, fluid can responsively flow into the valve port when the valve disk is opened, and the follow-up of the fluid is accelerated.

Owner:MITSUBISHI ELECTRIC CORP

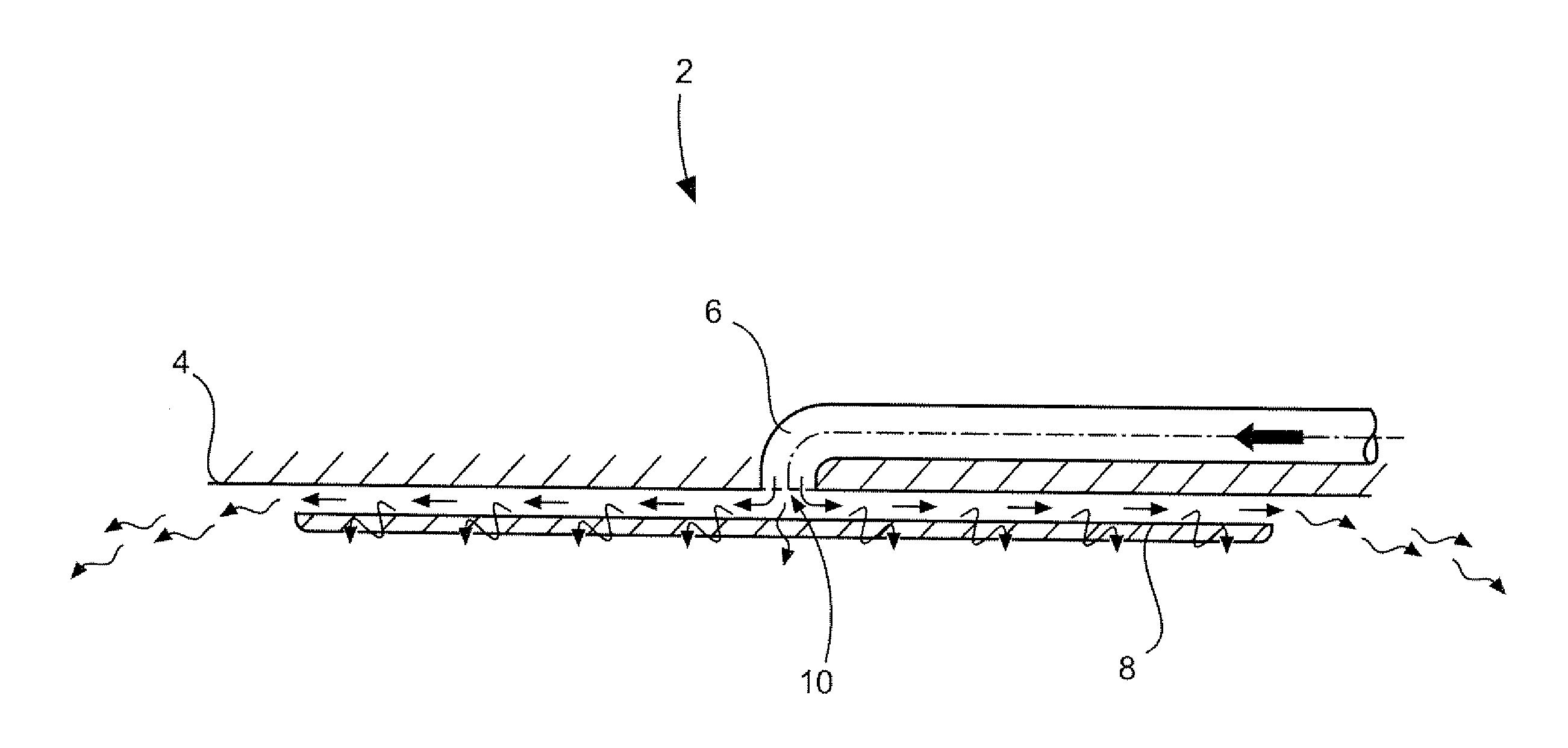

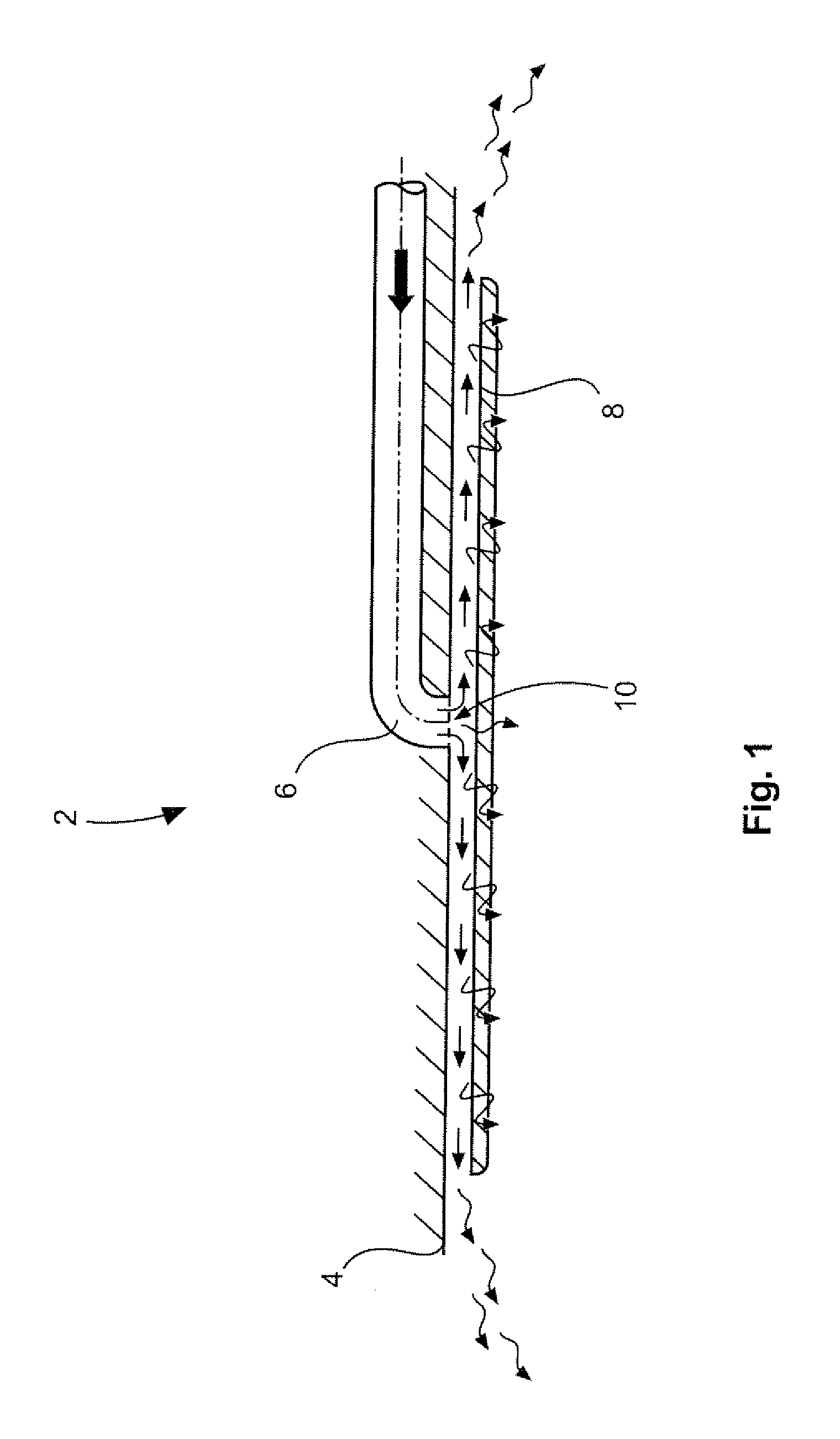

Air outlet

InactiveUS20100317277A1Increase flow rateImprove ventilation qualityDucting arrangementsAir-treating devicesLine tubingWaste management

Owner:AIRBUS OPERATIONS GMBH

Printing on Cylindrical Objects

ActiveUS20170050446A1Simplify the calibration processSimplifying pressure distributionTypewritersMechanical engineeringPhysics

Owner:TONEJET LTD

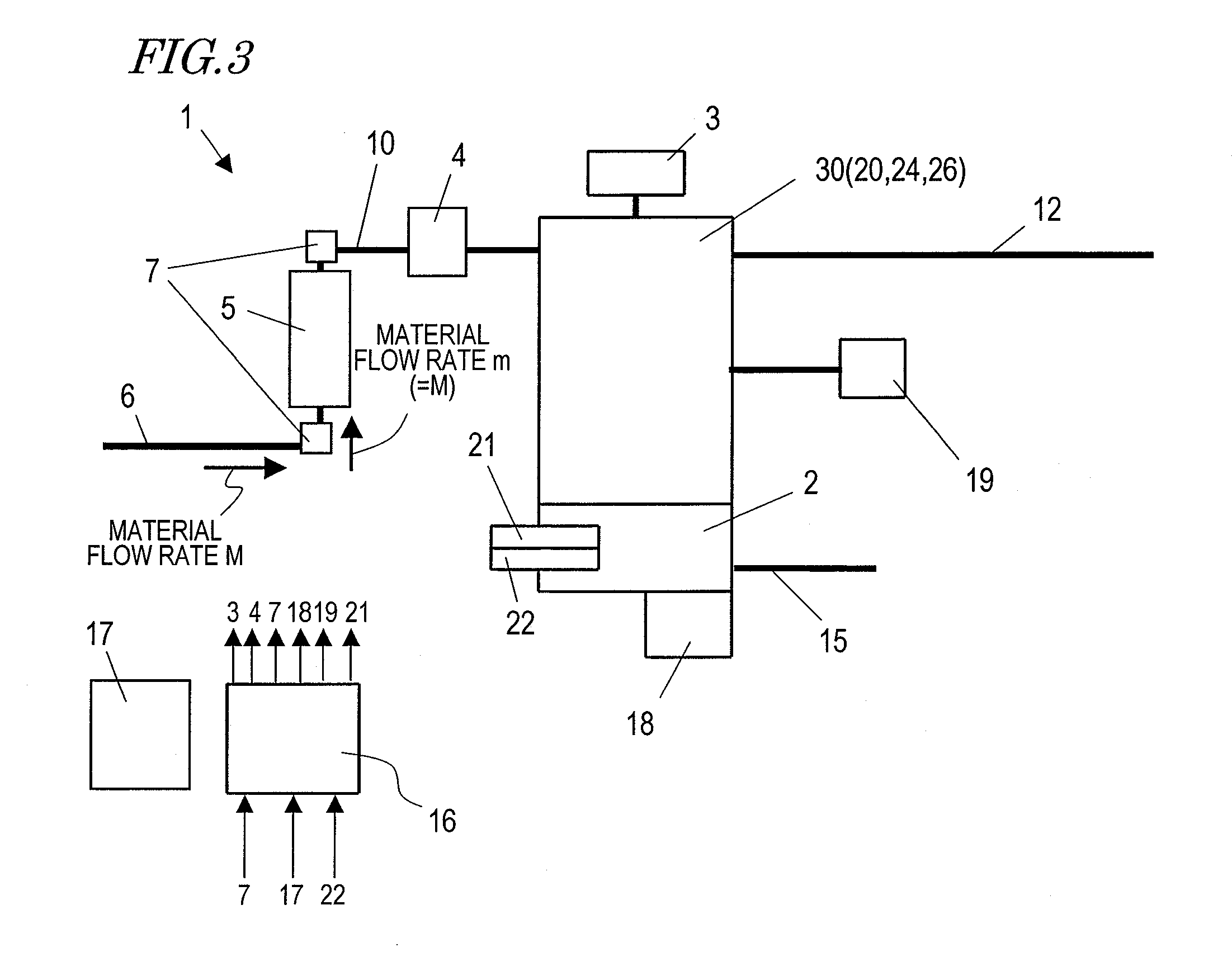

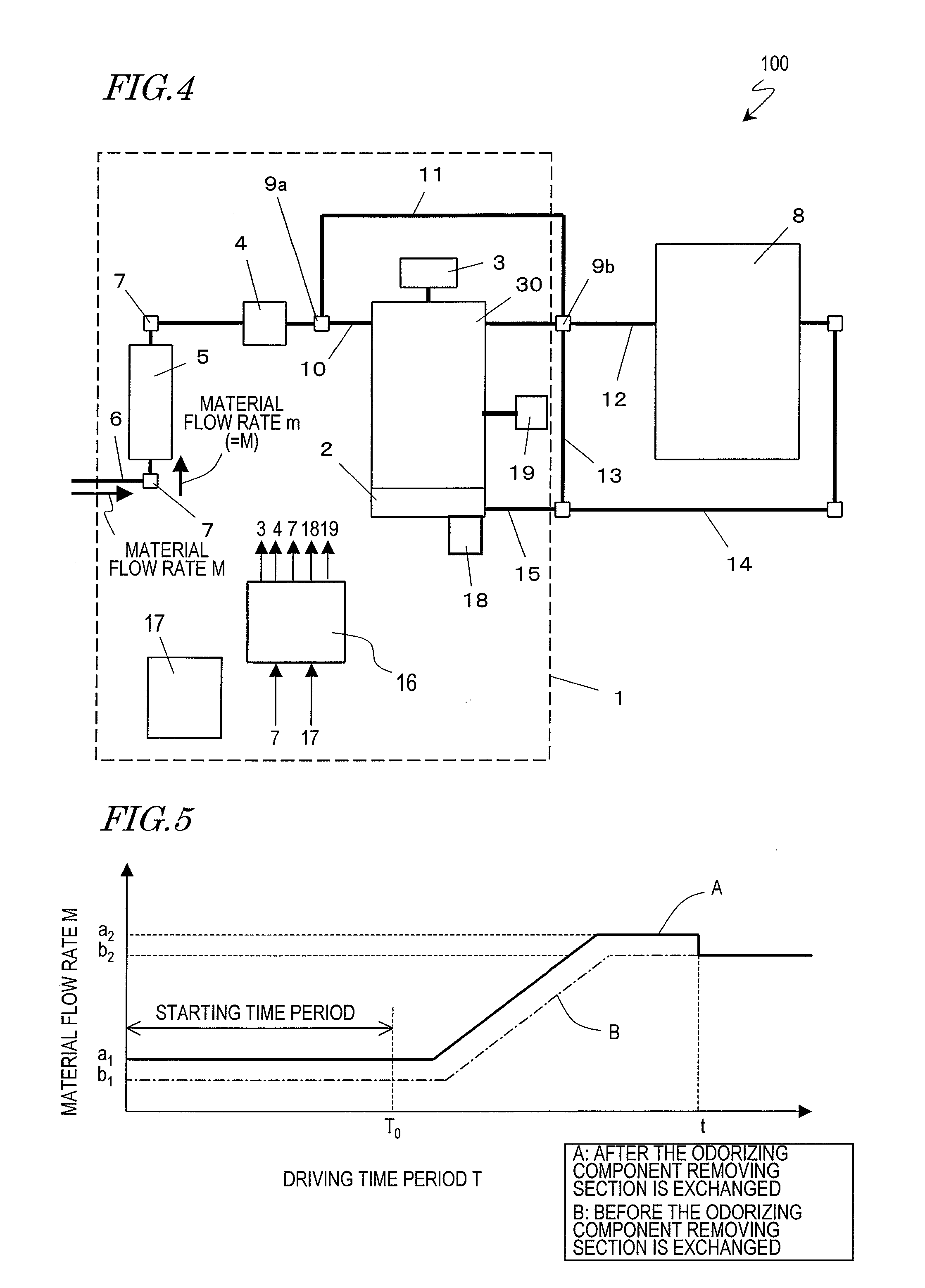

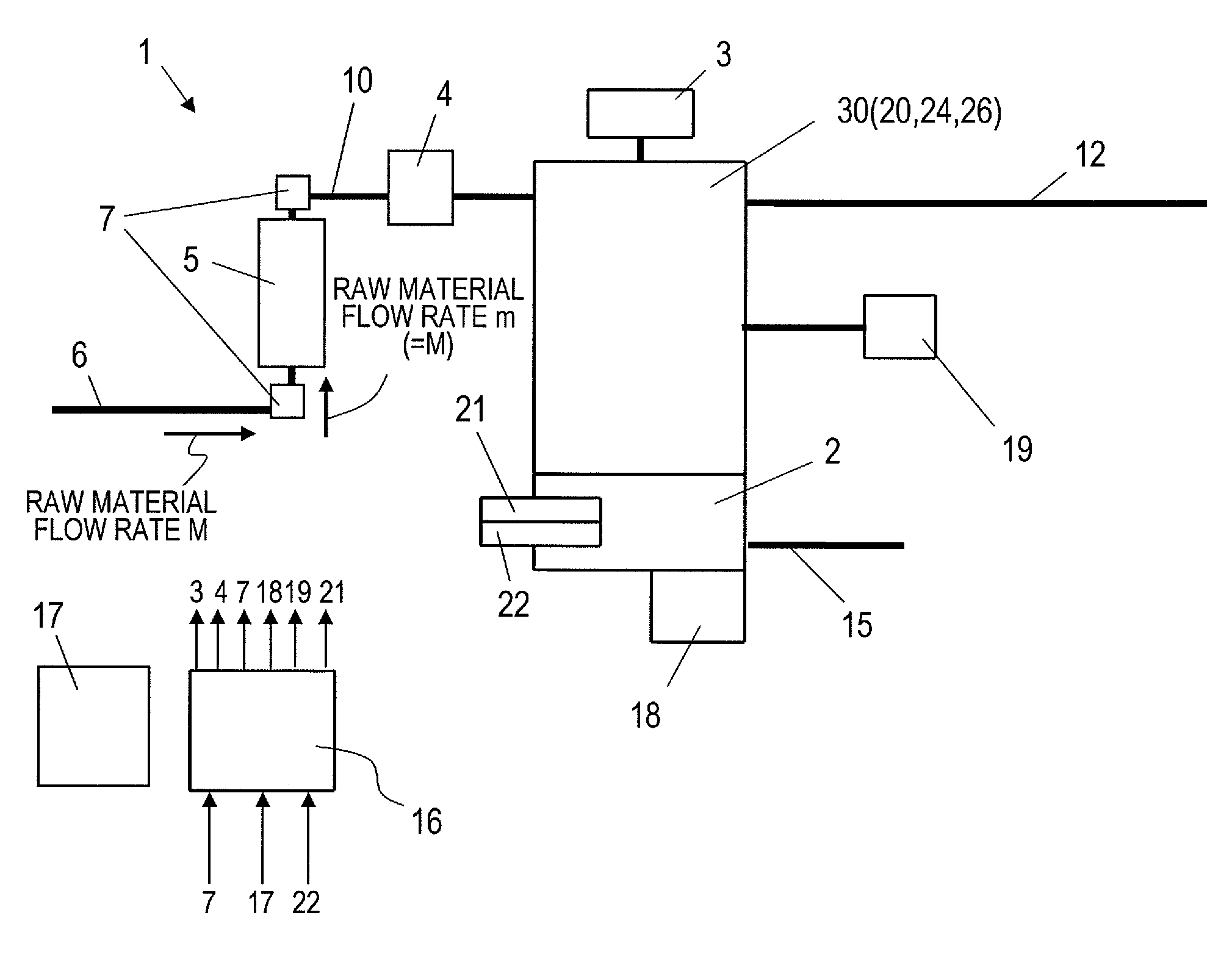

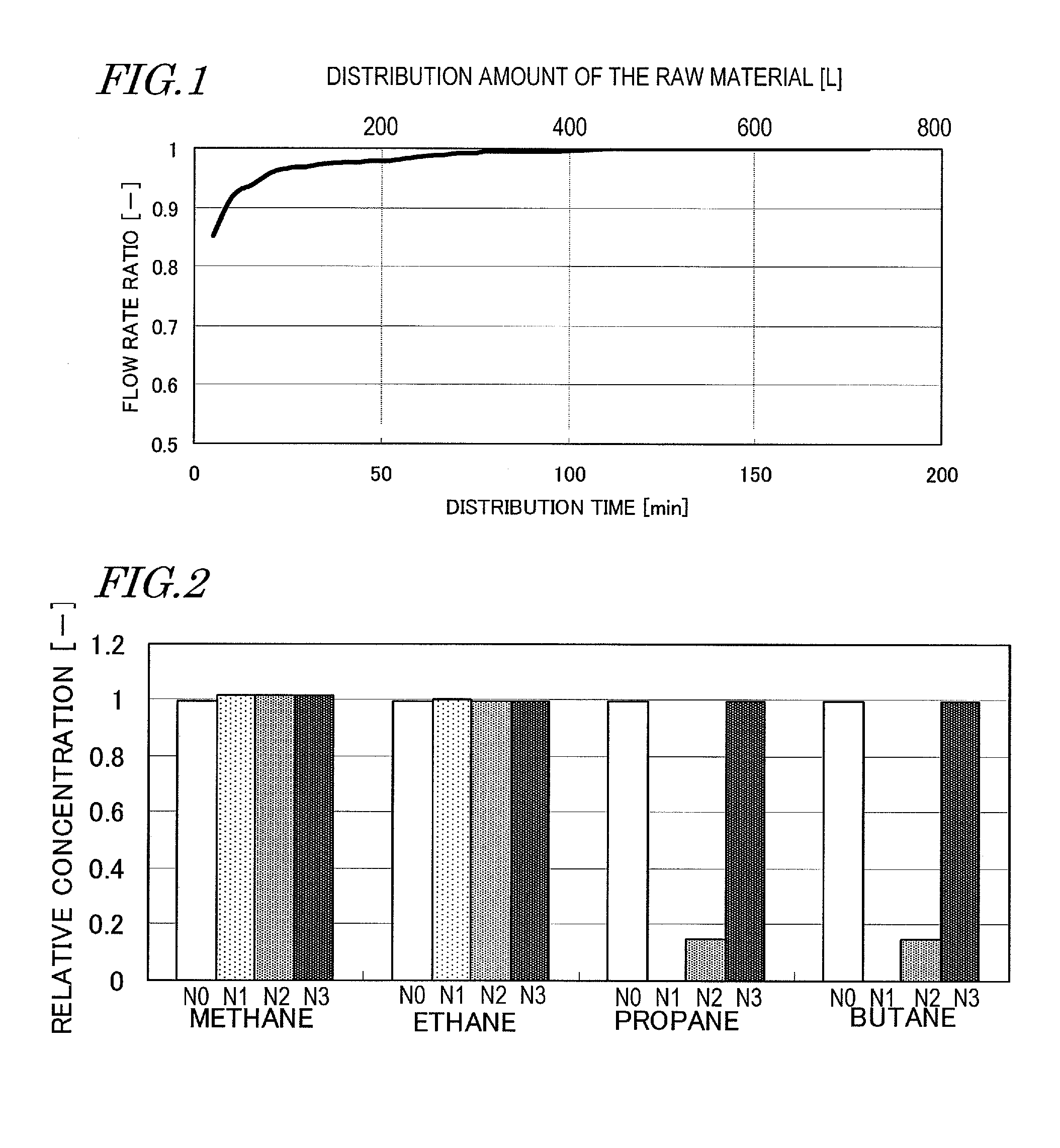

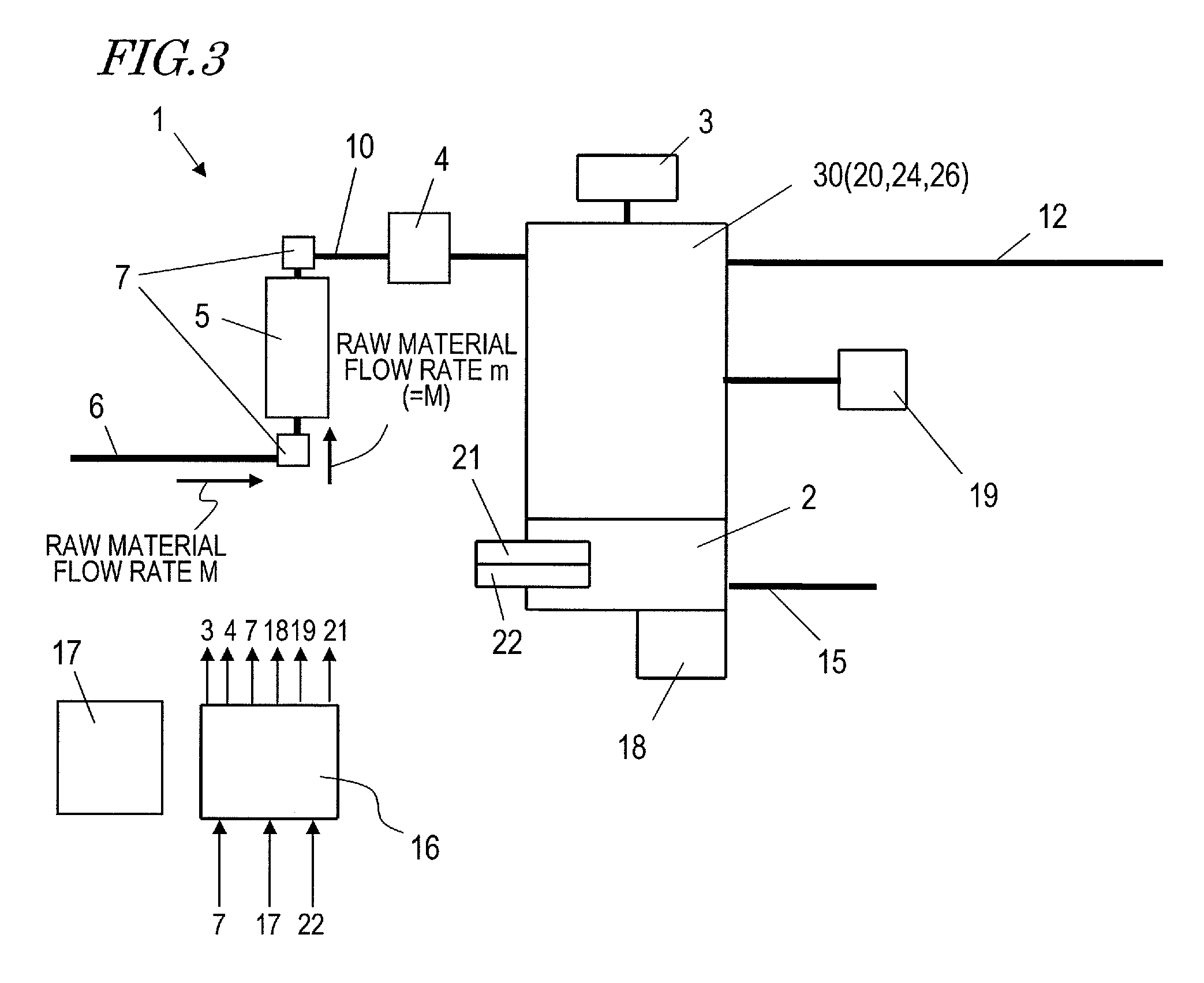

Hydrogen producing apparatus, method of operating hydrogen producing apparatus and fuel cell power generating system

ActiveUS20100203403A1Drive stabilityShorten the time periodExhaust apparatusElement comparisonCombustorFuel cells

A hydrogen generation apparatus 1 includes a raw material supply unit 4 for controlling a flow rate of a raw material to be supplied from an external element and containing hydrocarbon and an odorizing component; an odorizing component removing section 5 containing an adsorbing agent for adsorbing the odorizing component contained in the raw material; a combustor 2 for combusting the raw material; a reformer 30 for generating hydrogen-containing gas from the raw material which has passed the odorizing component removing section 5 by a reforming reaction using combustion heat supplied from the combustor 2; and a controller 16 for controlling the raw material supply unit to, during driving after the adsorbing agent or the odorizing component removing section 5 is exchanged or after the adsorbing agent is regenerated, makes the flow rate of the raw material to be supplied from the external element higher than the flow rate during the driving immediately before the exchange or regeneration.

Owner:PANASONIC CORP

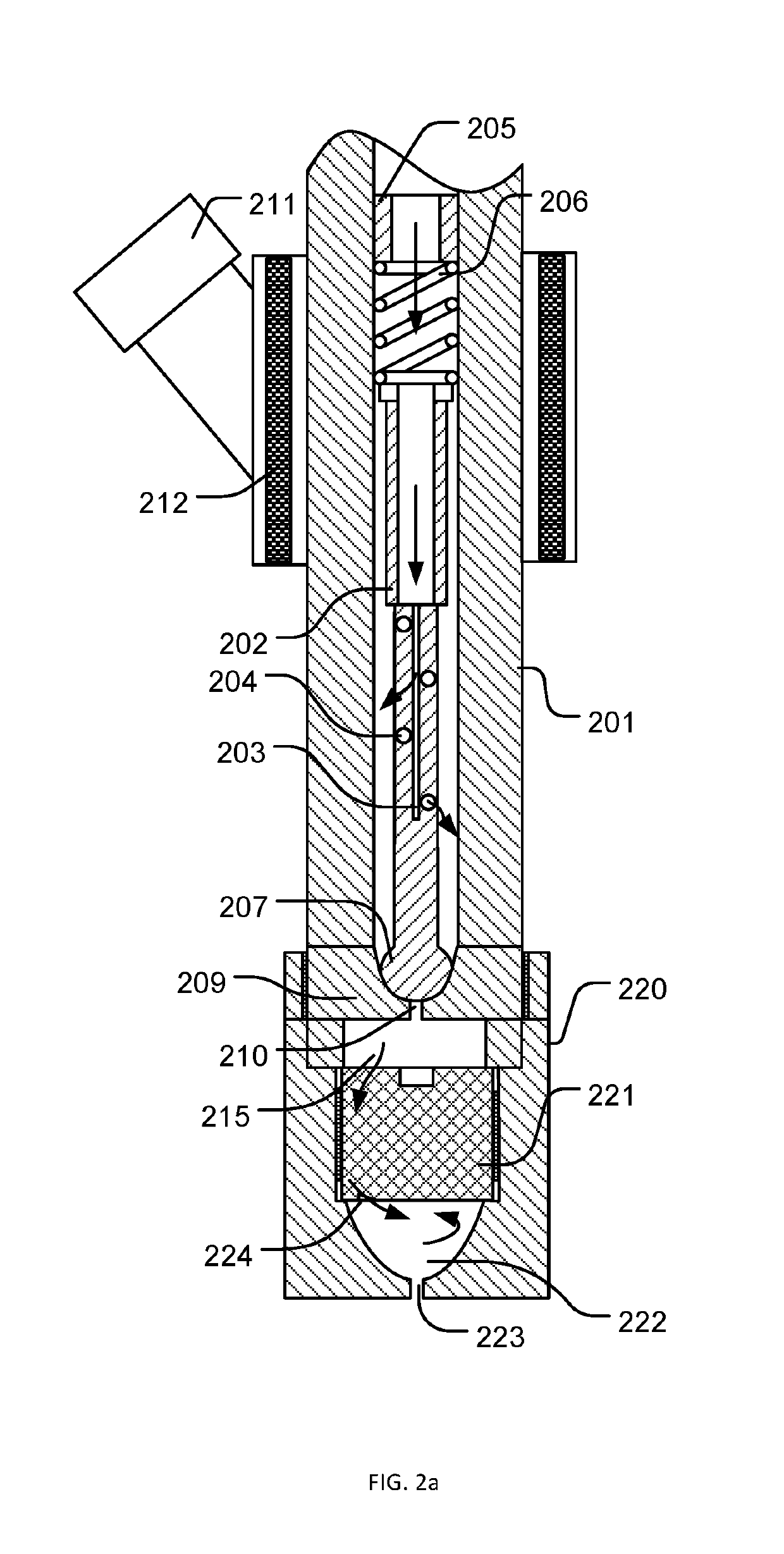

Low Pressure Atomizing Injector

ActiveUS20150176462A1Increase flow rateImprove atomization effectInternal combustion piston enginesExhaust apparatusWorking fluidWorking environment

An injector for delivering a working fluid into a working environment is disclosed. According to one embodiment of the present invention, the injector includes a pre-metering chamber and a swirl chamber. A high velocity partially atomized flow is produced in the pre-metering chamber through a first exit nozzle after impinging on an atomization element, and then a swirling flow is created in the swirl chamber with the atomization element. When the swirling flow is released through a second exit nozzle, atomization can be achieved at low injector pressure with centrifugal force and shearing of the working fluid. In another embodiment, the injector includes a swirl chamber and an atomization element with a bore, through which a control valve is positioned. The control valve forces a working fluid flow through the atomization element when the injector is energized to create a swirling flow. No flow-back is required for the injectors.

Owner:QI BAOHUA

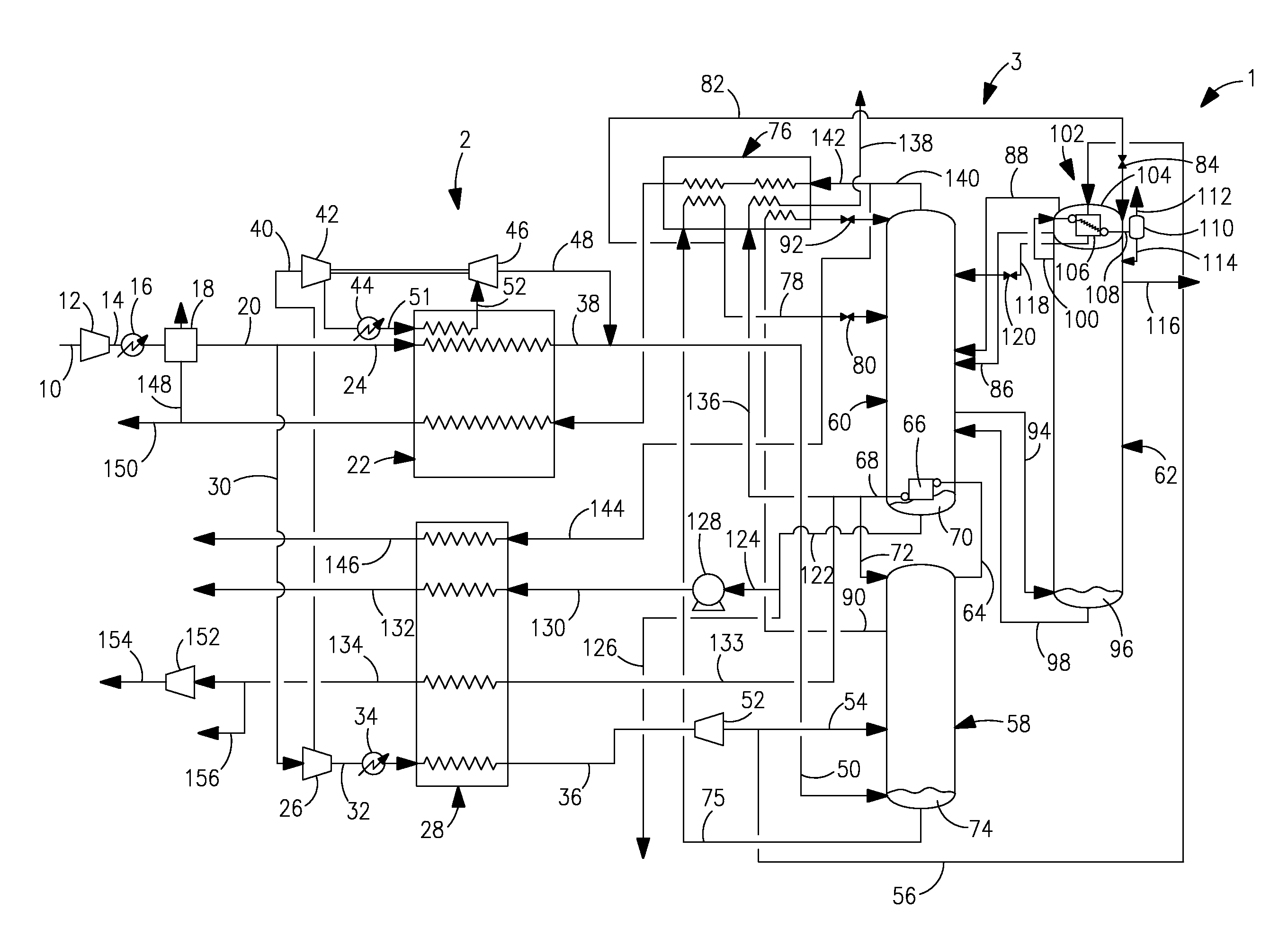

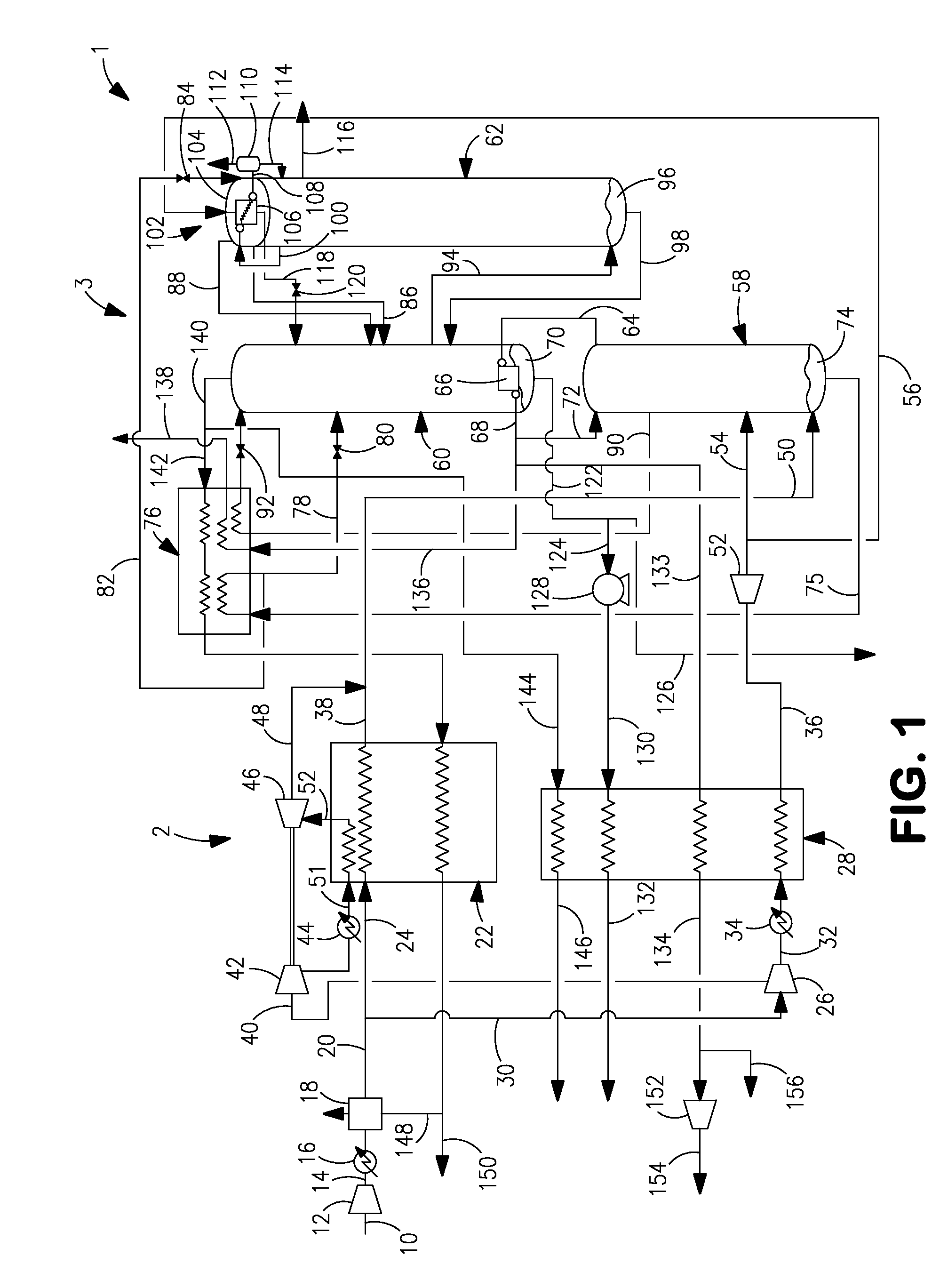

Air separation method and apparatus

An air separation method and apparatus in which a supercritical oxygen product is produced by heating a pumped liquid oxygen stream having a supercritical pressure, through indirect heat exchange with a boosted pressure air stream. The indirect heat exchange is conducted within a heat exchanger and a liquid nitrogen stream is vaporized in the heat exchanger to depress the pressure that would otherwise be required of the boosted pressure air stream to heat the pumped liquid oxygen stream. The pumped liquid oxygen stream constitutes 90 percent of the oxygen-rich liquid removed from an air separation unit in which the air is rectified, the liquid nitrogen constitutes at least 90 percent of the liquid nitrogen that is not used as reflux and a flow-rate ratio between the liquid nitrogen stream and the oxygen-rich liquid is between about 0.3 and 0.90.

Owner:PRAXAIR TECH INC

Internal combustion engine with combustion heater

InactiveUS20020029771A1Flow rateReduce flowFuel supply regulationAir-treating devicesCombustion chamberProduct gas

In an internal combustion engine with a combustion heater for elevating a temperature of an engine related element, an object of the present invention is to provide a technique that may effectively performs temperature elevation of an exhaust gas purifying device. In order to attain this object, according to the present invention, the internal combustion engine having an exhaust gas purifying catalyst provided in an exhaust passage of the internal combustion engine, and a combustion heater comprising a combustion chamber and a heat exchange portion for transmitting to an engine related element heat held by burnt gas that has been burnt in said combustion chamber, characterized by including a first burnt gas discharging portion for discharging from the combustion heater the burnt gas which has passed through the heat exhcange portion, a second burnt gas discharging portion for discharging from the combustion heater the burnt gas which has not yet passed through the heat exchange portion, and a burnt gas passage controlling unit for supplying at least one of burnt gas discharged by the first burnt gas discharging portion and burnt gas discharged by the second burnt gas discharging portion to the exhaust gas purifying catalyst.

Owner:TOYOTA JIDOSHA KK

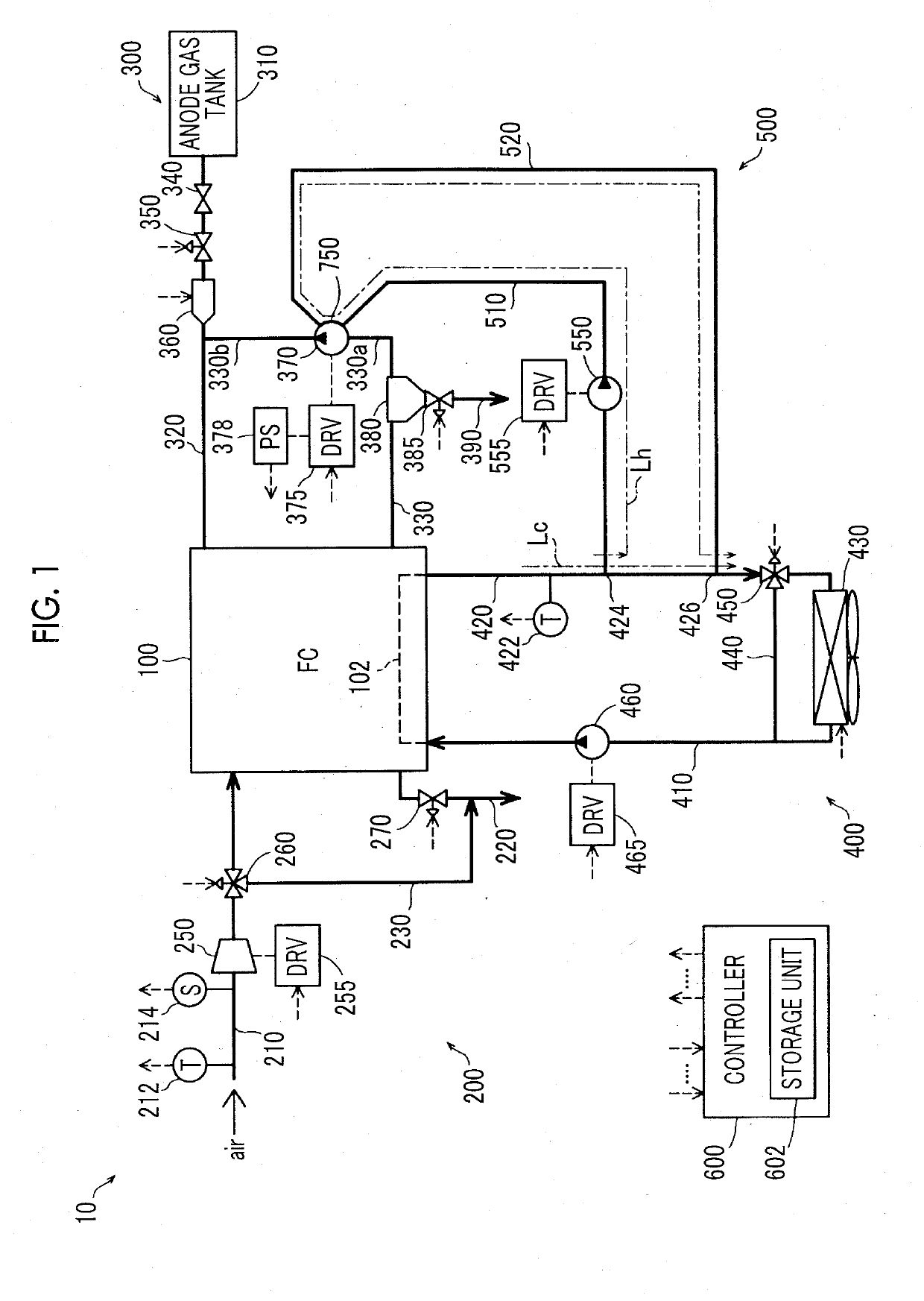

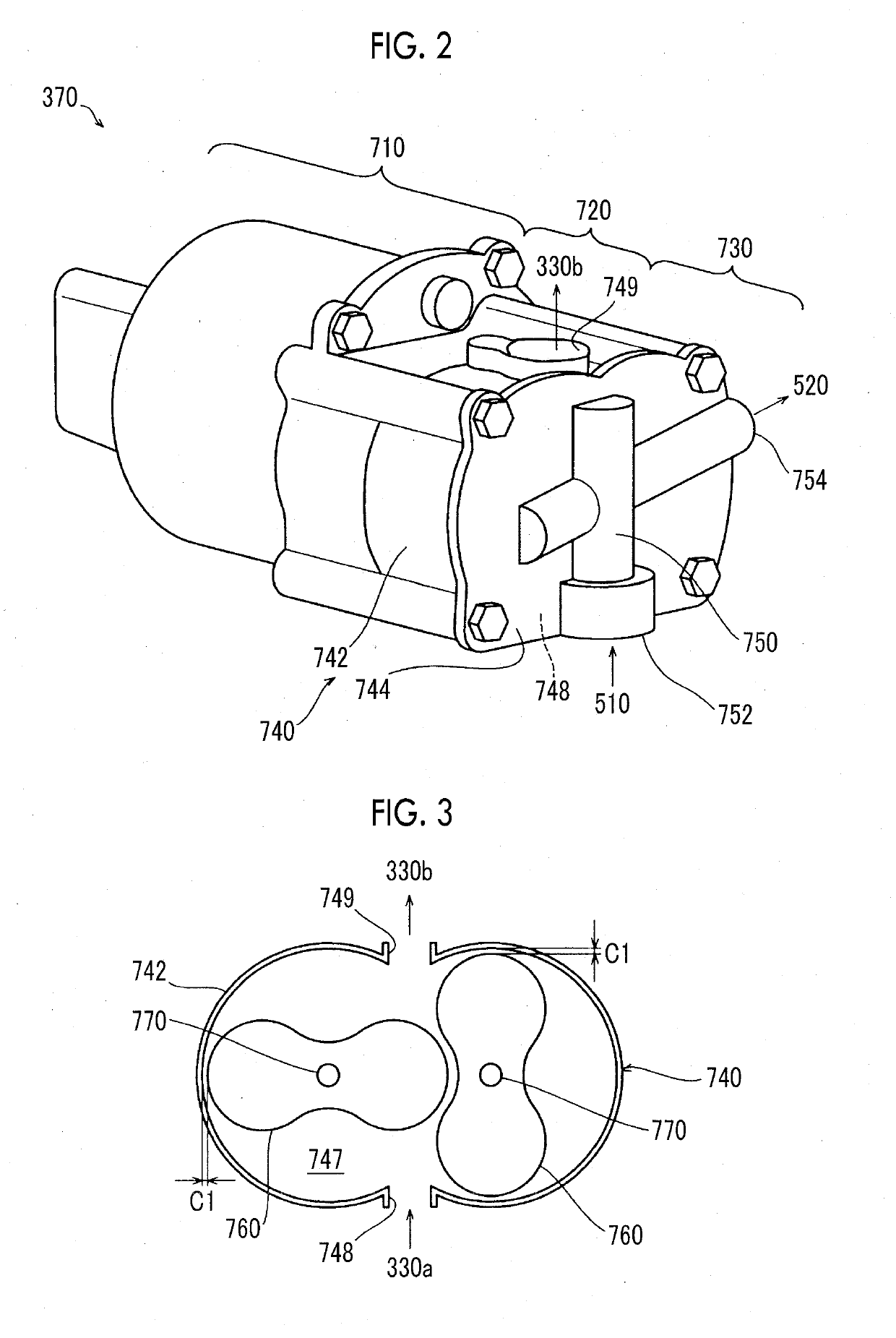

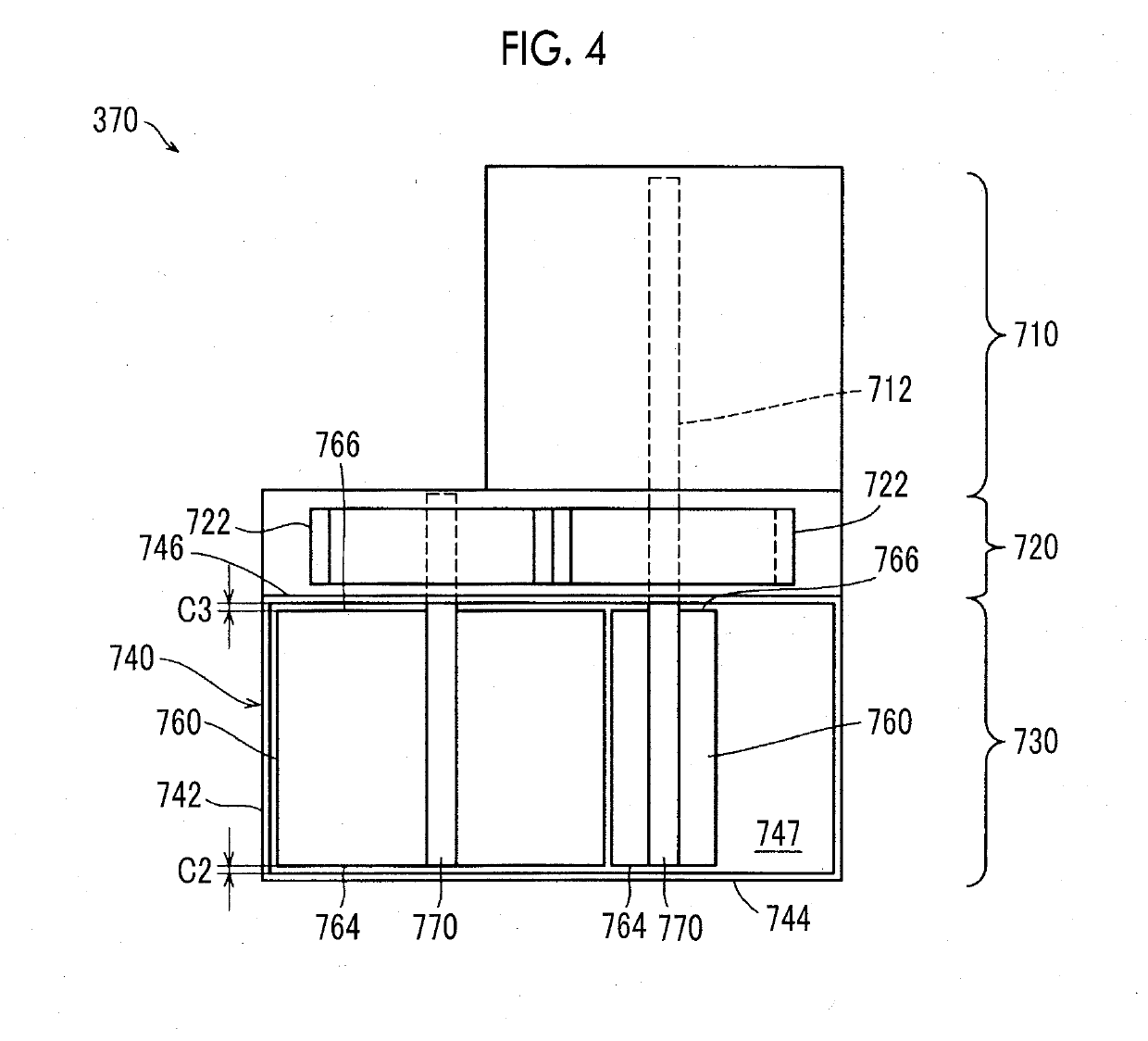

Fuel cell system

ActiveUS20190148751A1Guarantee effective circulationProne to feverFuel cell heat exchangeReactant parameters controlHydrogenFuel cells

The fuel cell system includes a fuel cell, a hydrogen circulation pump, heating portion, and a controller. The hydrogen circulation pump is configured to circulate hydrogen to the fuel cell and includes a cylinder and a rotor accommodated in the cylinder. The heating portion is configured to heat the cylinder. The controller is configured to control an operation of the heating portion. The controller is configured to cause the heating portion to heat the cylinder in a case where a driving state of the hydrogen circulation pump is higher than or equal to a standard driving state.

Owner:TOYOTA JIDOSHA KK

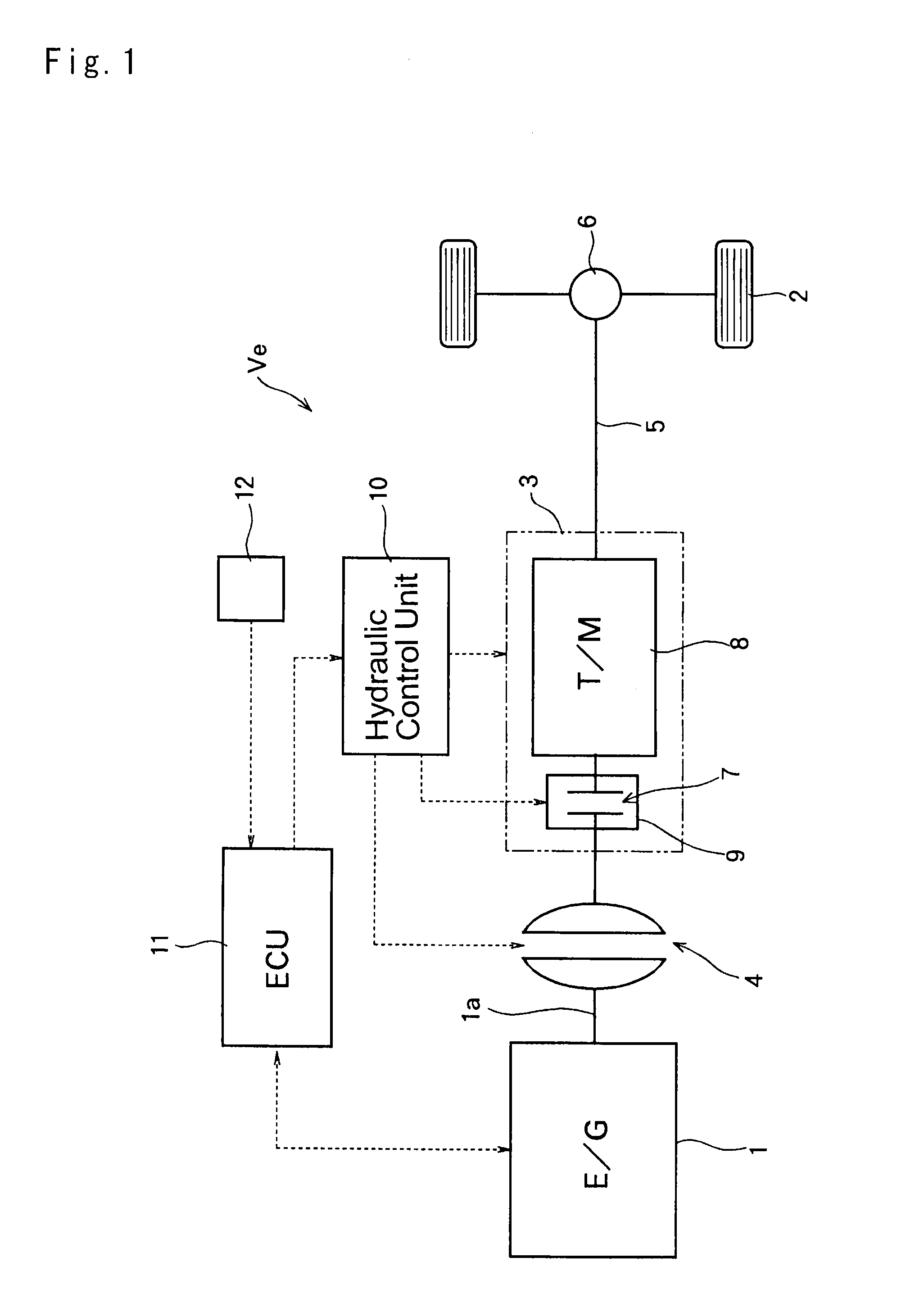

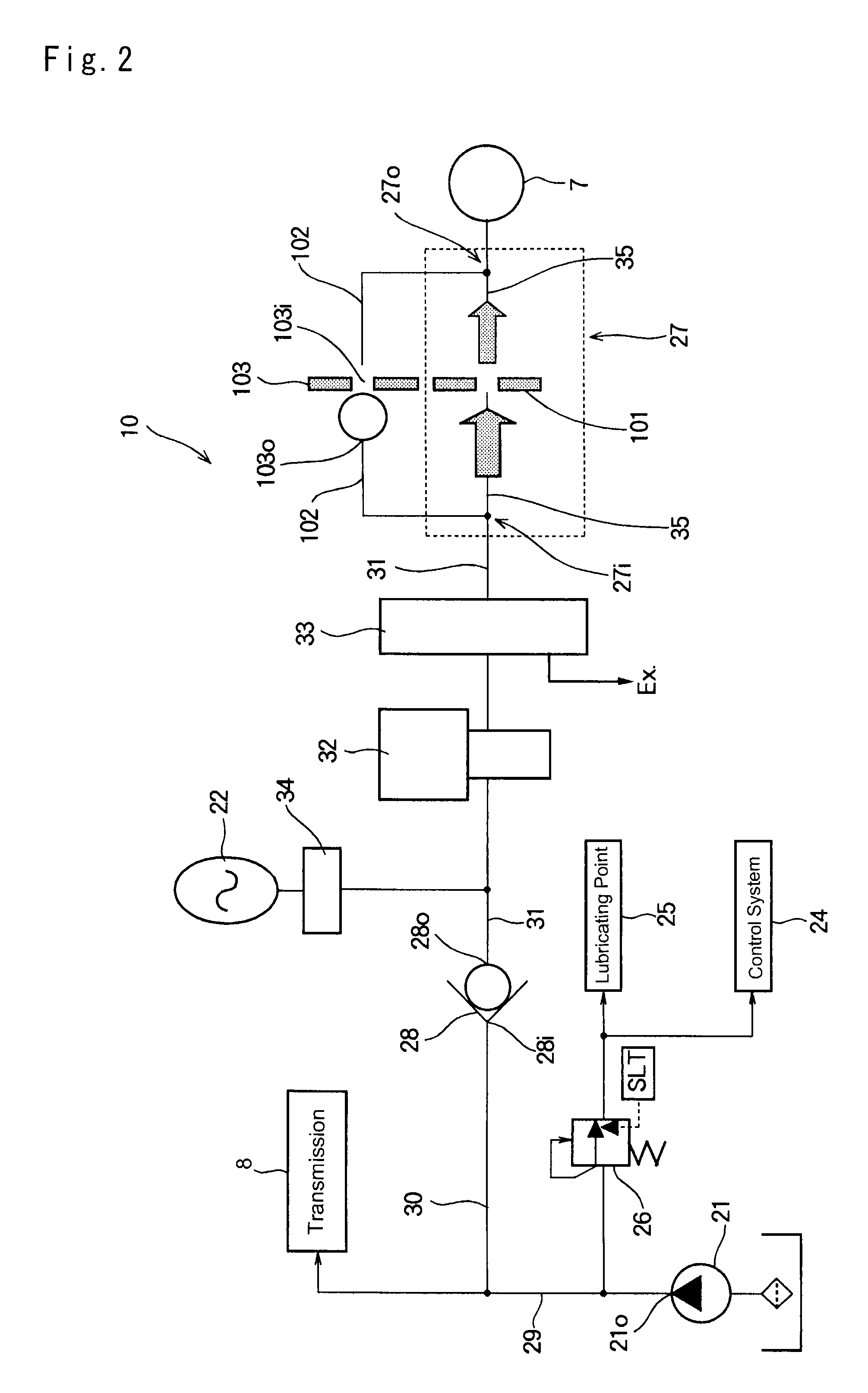

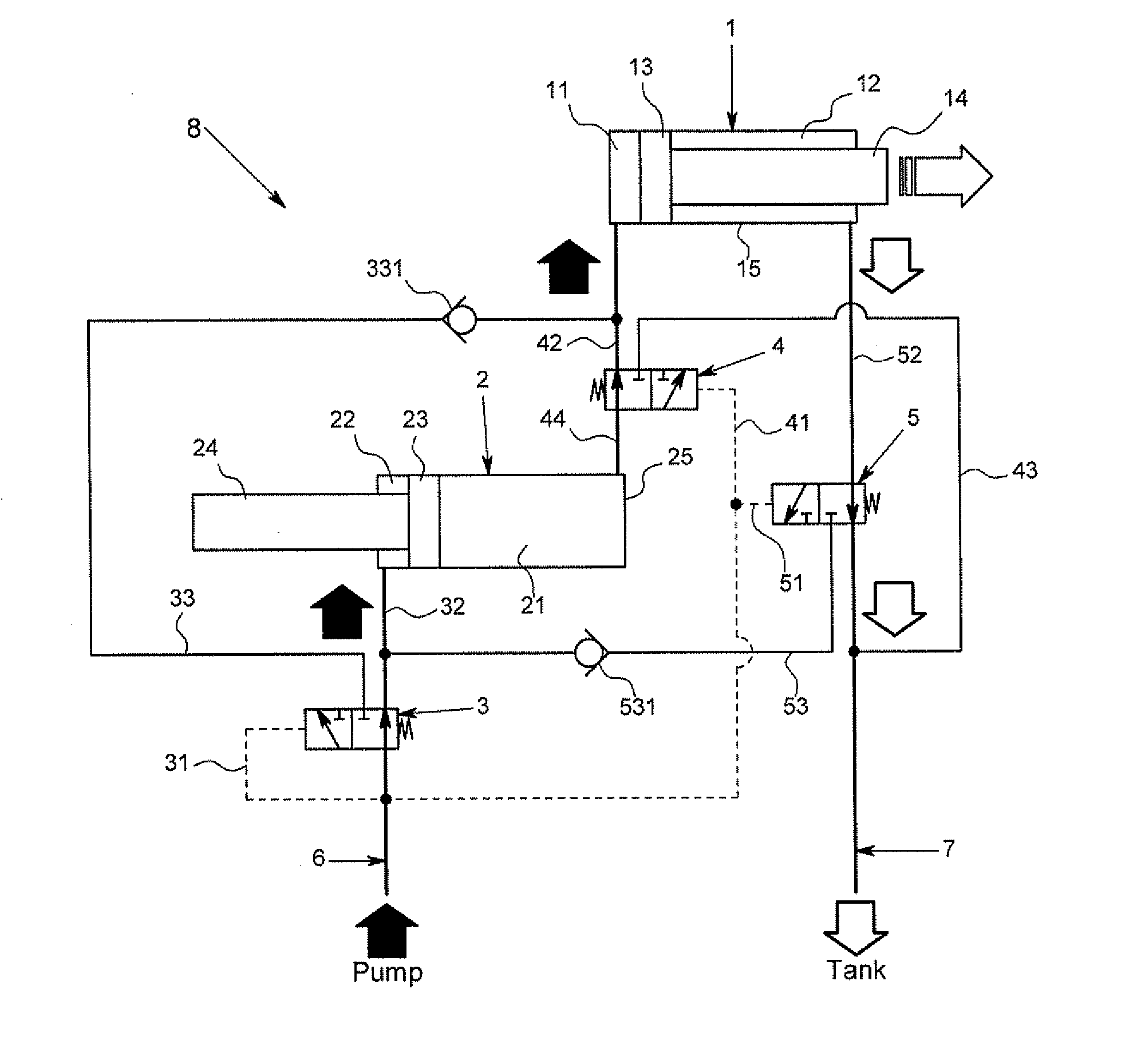

Hydraulic control system for vehicle

InactiveUS20150232102A1Hydraulic response can be improvedIncrease flow rateClutchesGearing controlDrive wheelControl system

A hydraulic control system for vehicle includes: an engine; an oil pump driven by the engine; a clutch device brought into engagement to enable power transmission between the engine and drive wheels by delivering a pressurized fluid thereto, and brought into disengagement to interrupt the power transmission between the engine and the drive wheels by discharging the fluid therefrom; and an accumulator storing the fluid delivered to the clutch device. The hydraulic control system is configured to control the hydraulic pressure applied to the clutch device, to stop the engine while bringing the clutch device into disengagement upon satisfaction of a predetermined stopping condition, and to restart the engine while bringing the clutch device into engagement upon satisfaction of a predetermined restarting condition. In the hydraulic control system, a hydraulic circuit increases flow rate of the fluid flowing between the accumulator and the clutch device when the engine is stopped.

Owner:TOYOTA JIDOSHA KK

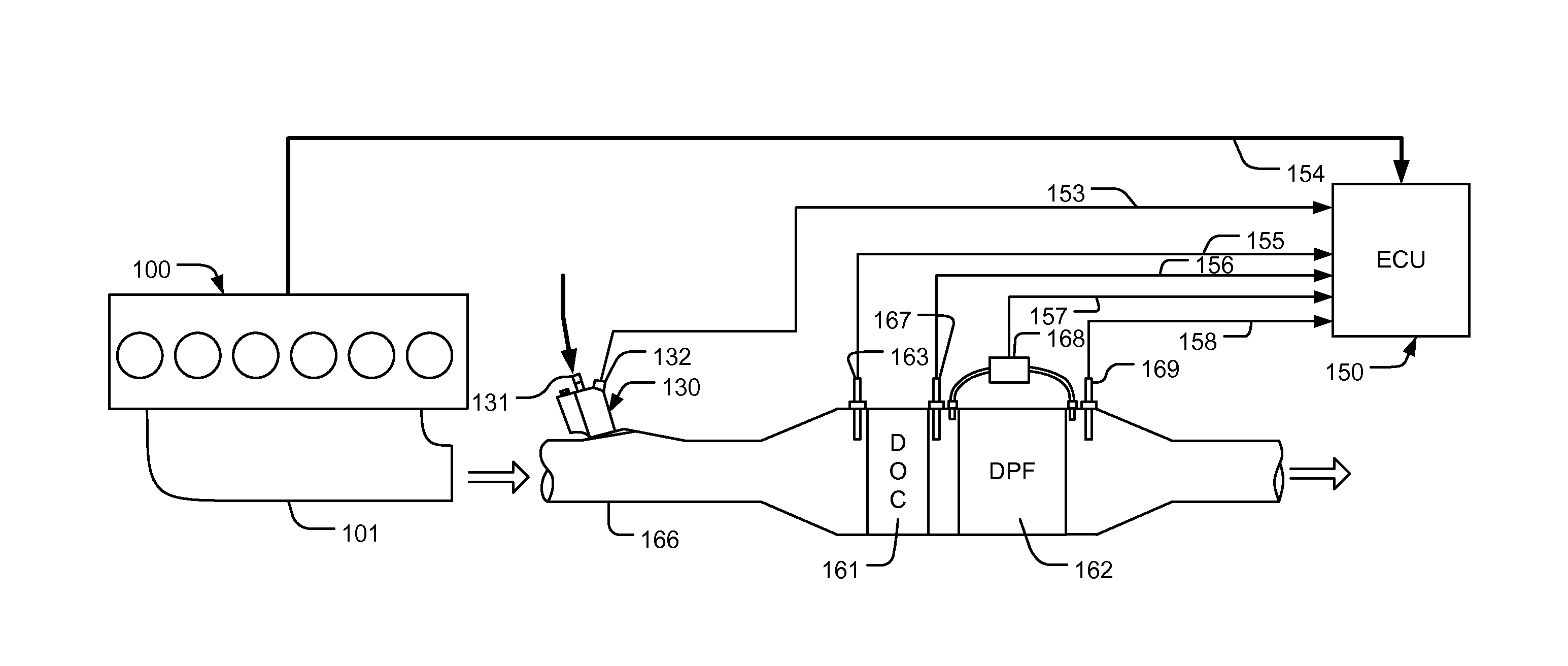

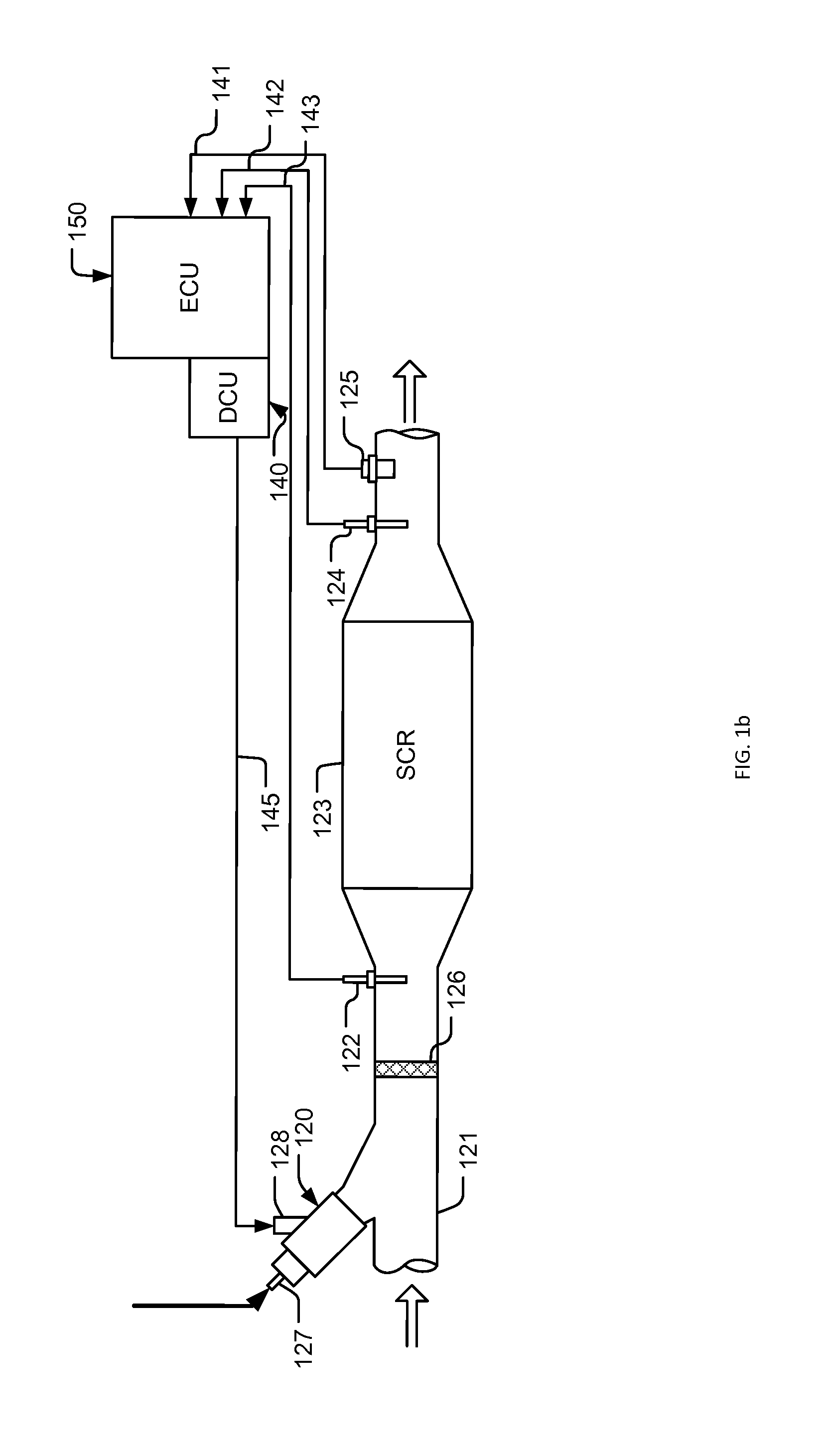

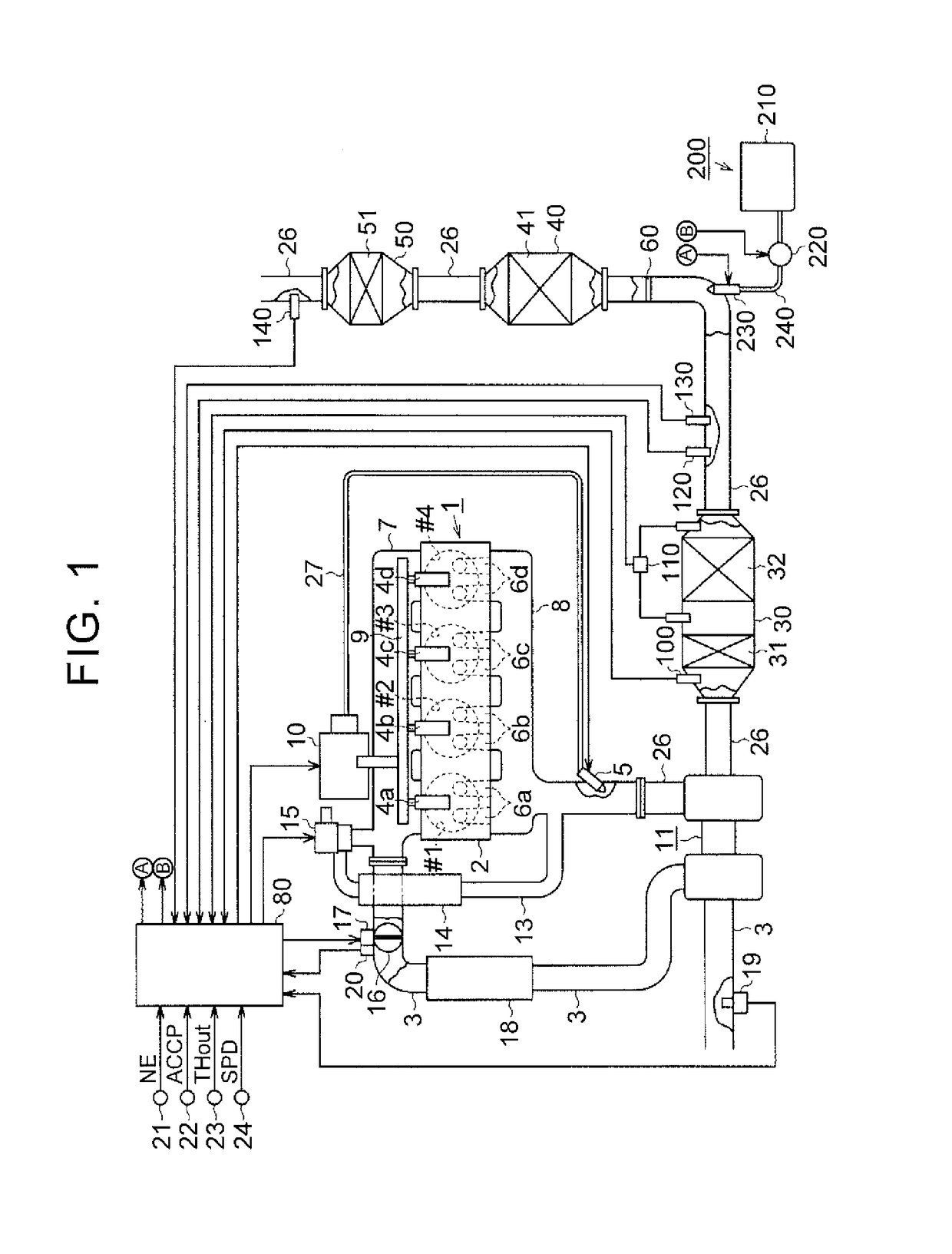

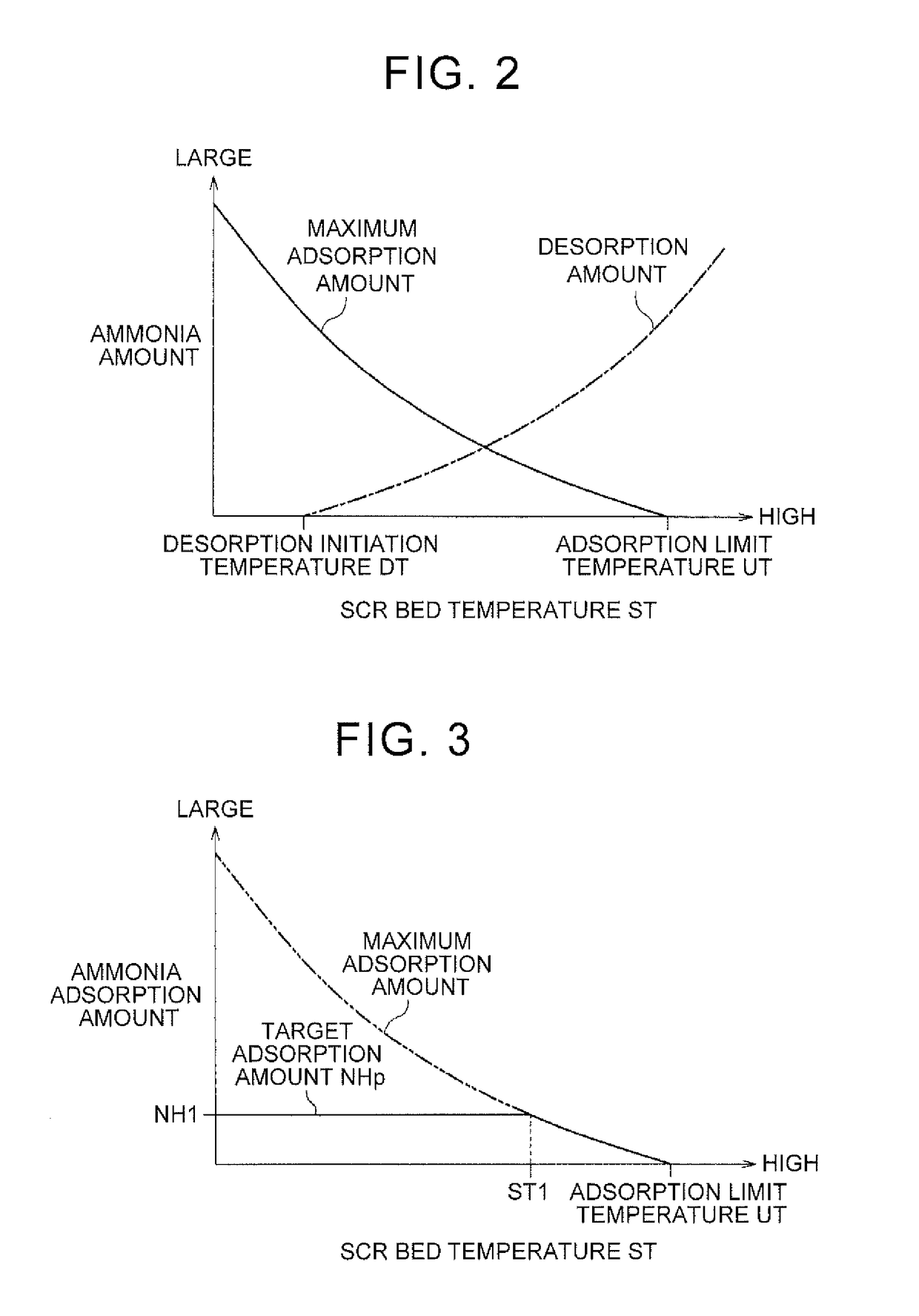

Exhaust gas control apparatus and exhaust gas control method for internal combustion engine

InactiveUS20170037801A1Accurate calculationFlow rateElectrical controlInternal combustion piston enginesExternal combustion engineExhaust fumes

An exhaust gas control apparatus and method for an engine includes a urea water supply mechanism that adds urea water to exhaust gas, a SCR catalyst that adsorbs ammonia and removes NOx in the exhaust gas by using the adsorbed ammonia, and a control device that controls a urea water addition amount based on a target adsorption amount for the ammonia adsorbed onto the SCR catalyst. The control device executes an integration processing that acquires a temperature of the SCR catalyst at a predetermined cycle and integrates the acquired temperature of the SCR catalyst when equal to or higher than a threshold, and an initialization processing that decreases the amount of the ammonia adsorbed on the SCR catalyst on a condition that an integrated value of the temperature of the SCR catalyst calculated in the integration processing has become equal to or higher than a predetermined value.

Owner:TOYOTA JIDOSHA KK

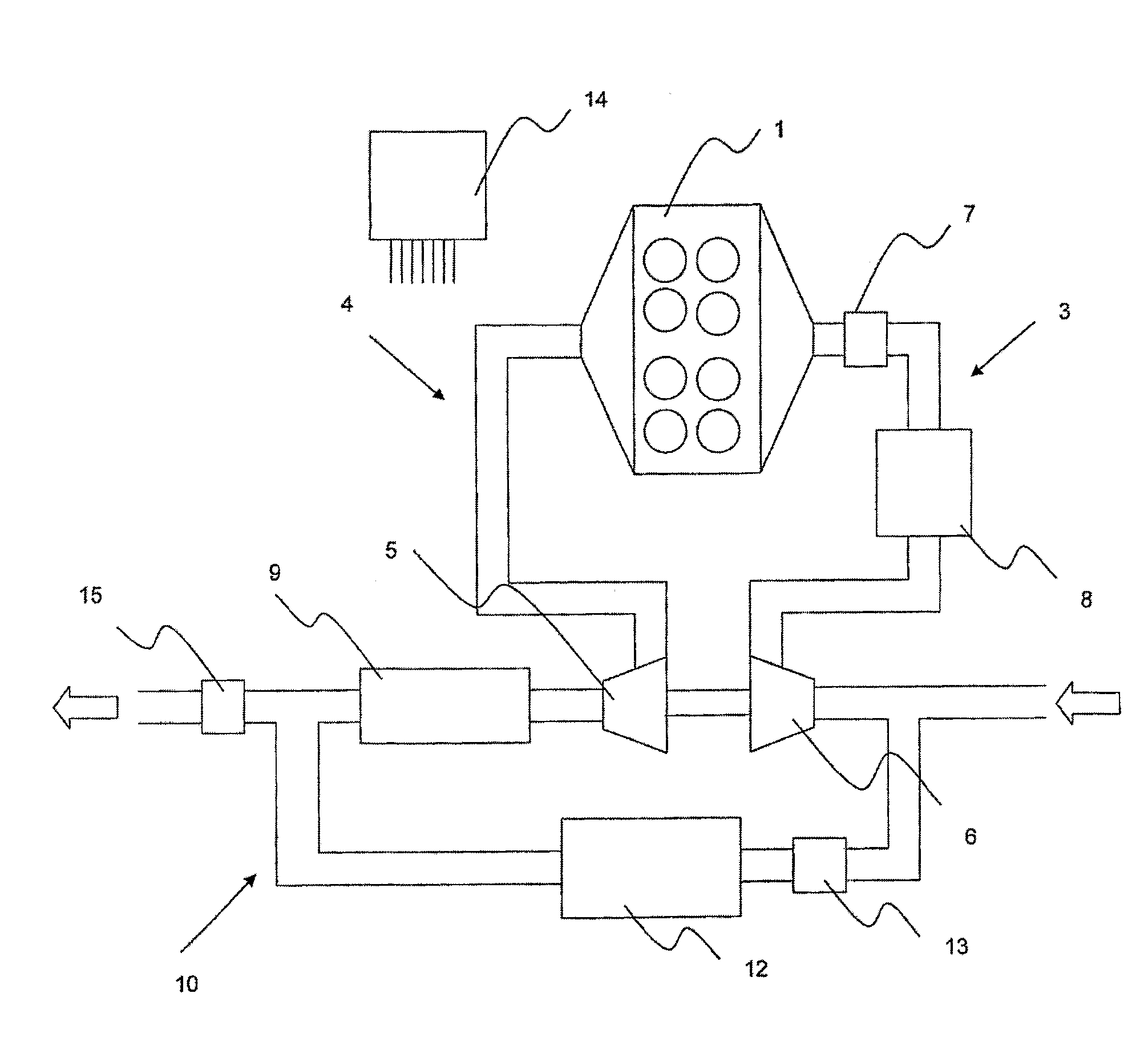

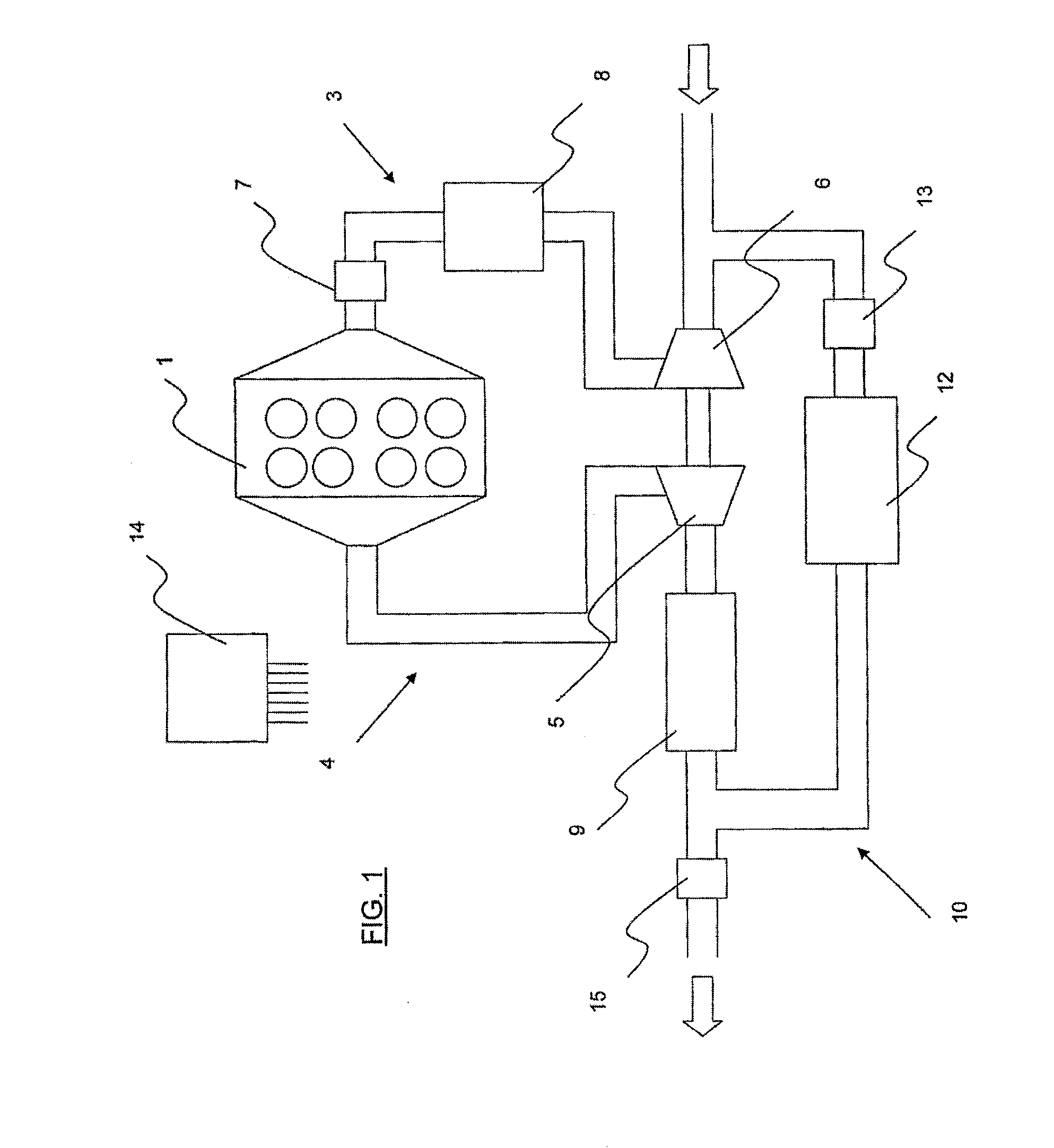

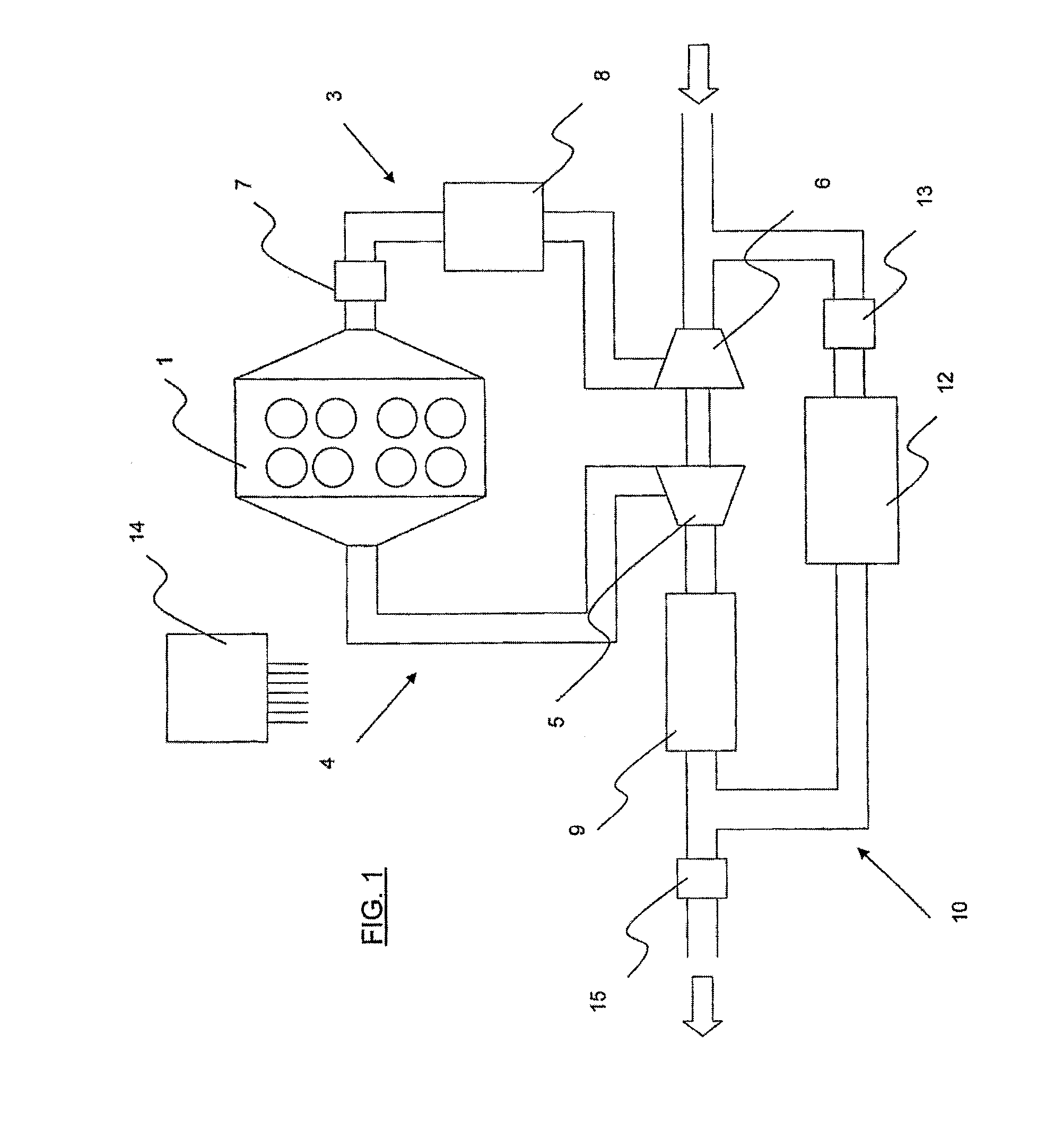

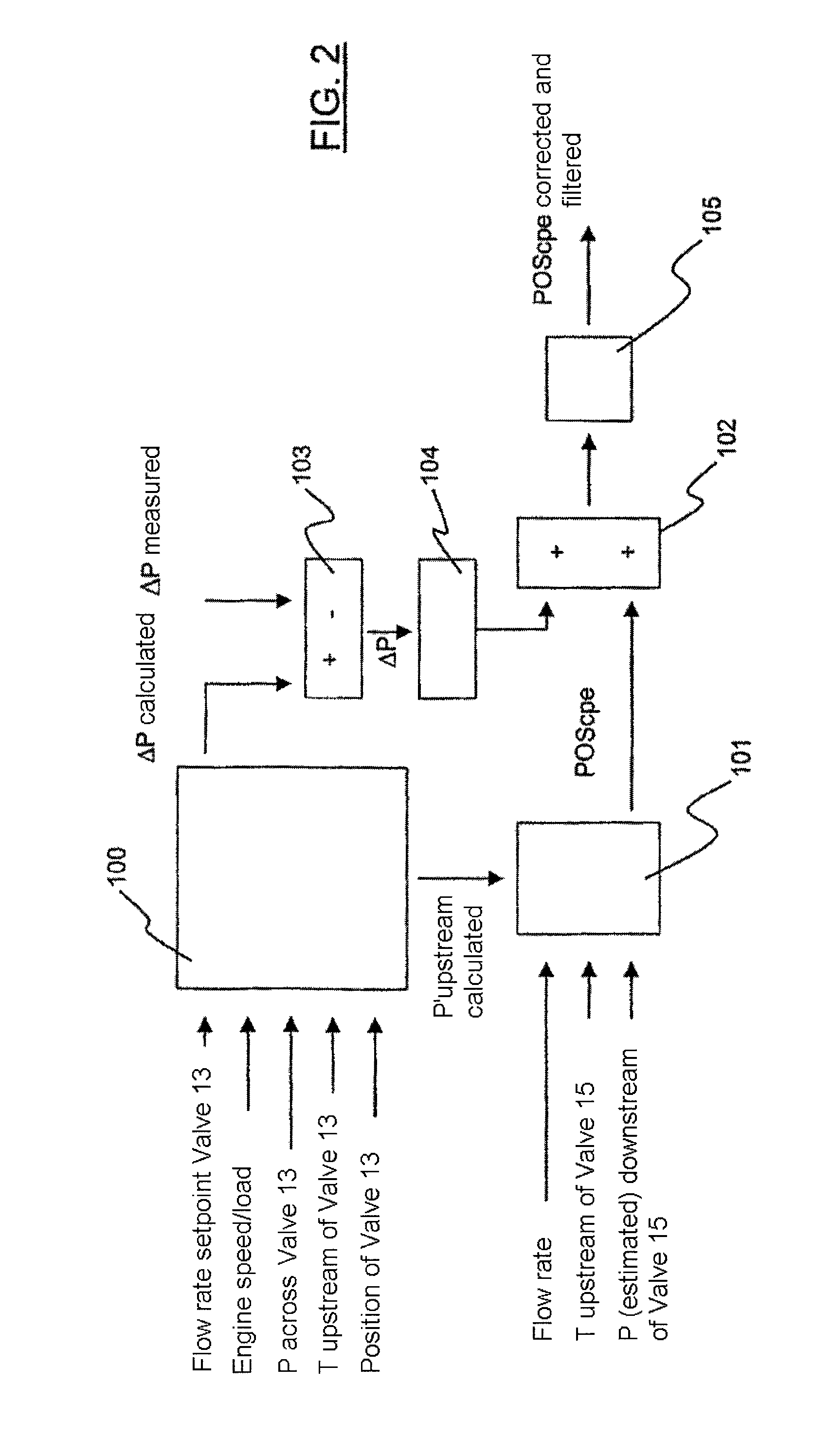

Method for managing the exhaust gas circulation circuit of a petrol thermal engine and corresponding recirculation system

ActiveUS20110180048A1Increase the differential pressureEasy to operateElectrical controlInternal combustion piston enginesCombustion chamberGasoline

The invention relates to a method for managing an exhaust gas recirculation circuit of a petrol thermal engine, the engine including at least one combustion chamber connected to an inlet line and an exhaust line between which extends said recirculation circuit, the recirculation circuit including a flow-rate adjustment valve, wherein said method comprises the step of adjusting flow-rate adjustment valve based on a flow-rate setpoint, said method further comprising the steps of: detecting an operation parameter representative of a pressure difference between an upstream pressure and a downstream pressure relative to the flow-rate adjustment valve, and, after comparing the parameter with a threshold corresponding to a minimum pressure difference, adjusting the flow-rate in at least one of the lines in order to increase the pressure difference.

Owner:VALEO SYST DE CONTROLE MOTEUR

Exhaust gas control apparatus and exhaust gas control method for internal combustion engine

InactiveUS10024259B2Accurate calculationFlow rateElectrical controlInternal combustion piston enginesExternal combustion engineProcess engineering

An exhaust gas control apparatus and method for an engine includes a urea water supply mechanism that adds urea water to exhaust gas, a SCR catalyst that adsorbs ammonia and removes NOx in the exhaust gas by using the adsorbed ammonia, and a control device that controls a urea water addition amount based on a target adsorption amount for the ammonia adsorbed onto the SCR catalyst. The control device executes an integration processing that acquires a temperature of the SCR catalyst at a predetermined cycle and integrates the acquired temperature of the SCR catalyst when equal to or higher than a threshold, and an initialization processing that decreases the amount of the ammonia adsorbed on the SCR catalyst on a condition that an integrated value of the temperature of the SCR catalyst calculated in the integration processing has become equal to or higher than a predetermined value.

Owner:TOYOTA JIDOSHA KK

Low pressure atomizing injector

ActiveUS10473014B2Increase flow rateImprove atomization effectInternal combustion piston enginesExhaust apparatusWorking fluidWorking environment

An injector for delivering a working fluid into a working environment is disclosed. According to one embodiment of the present invention, the injector includes a pre-metering chamber with a control valve controlling fluid delivery rate and a swirl chamber, in which a swirling flow is created and atomization is achieved at low injector pressure when it is released. In another embodiment, the injector includes a swirl chamber and an atomization element with a bore, through which a control valve is positioned. The control valve forces a working fluid flow through the atomization element when the injector is energized to create a metered swirling flow. To avoid issues with deteriorated working fluid, a purging apparatus is used for emptying working fluid residue in the injector, and a special control method is used when the injector works in a high-temperature working environment.

Owner:QI BAOHUA

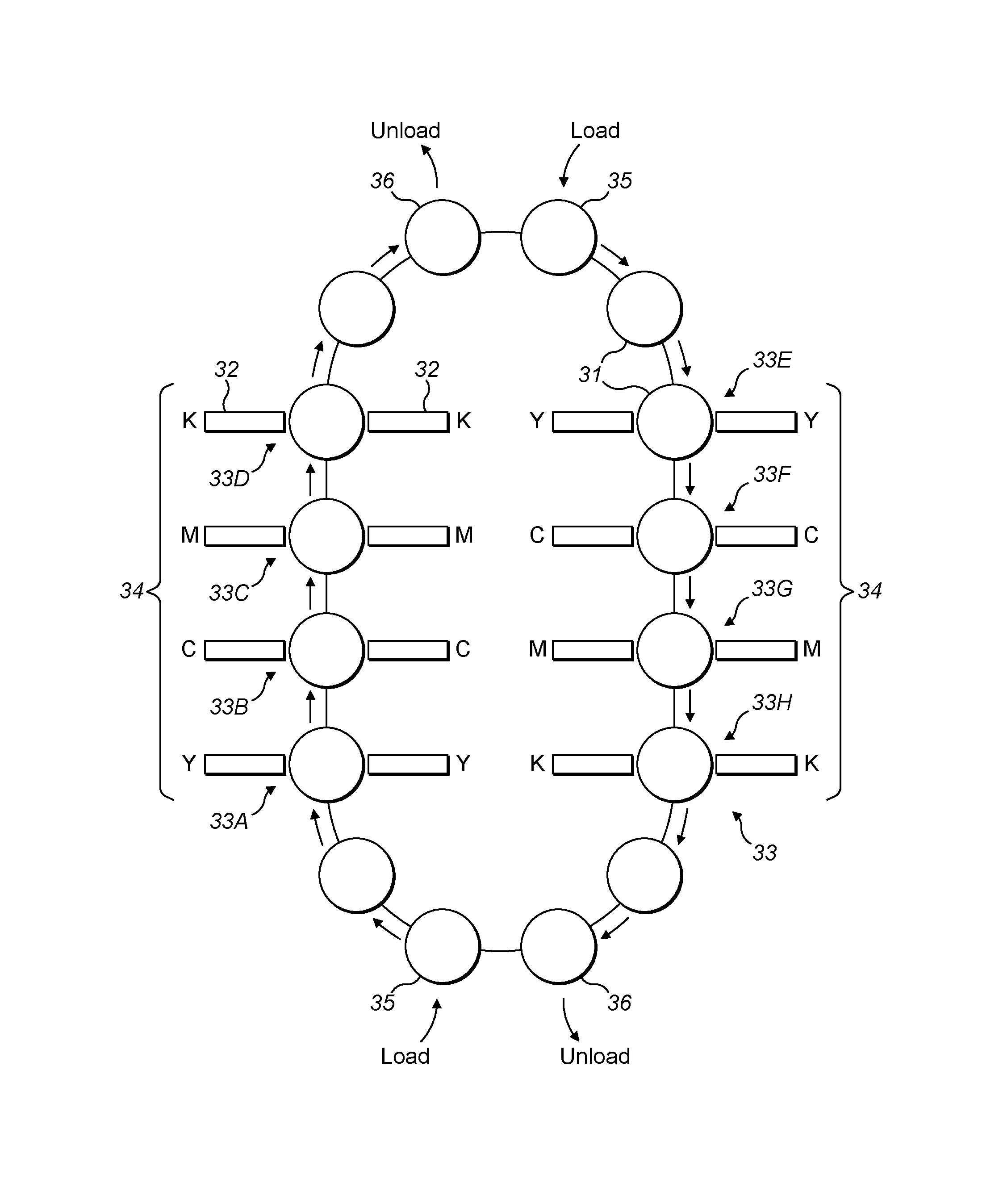

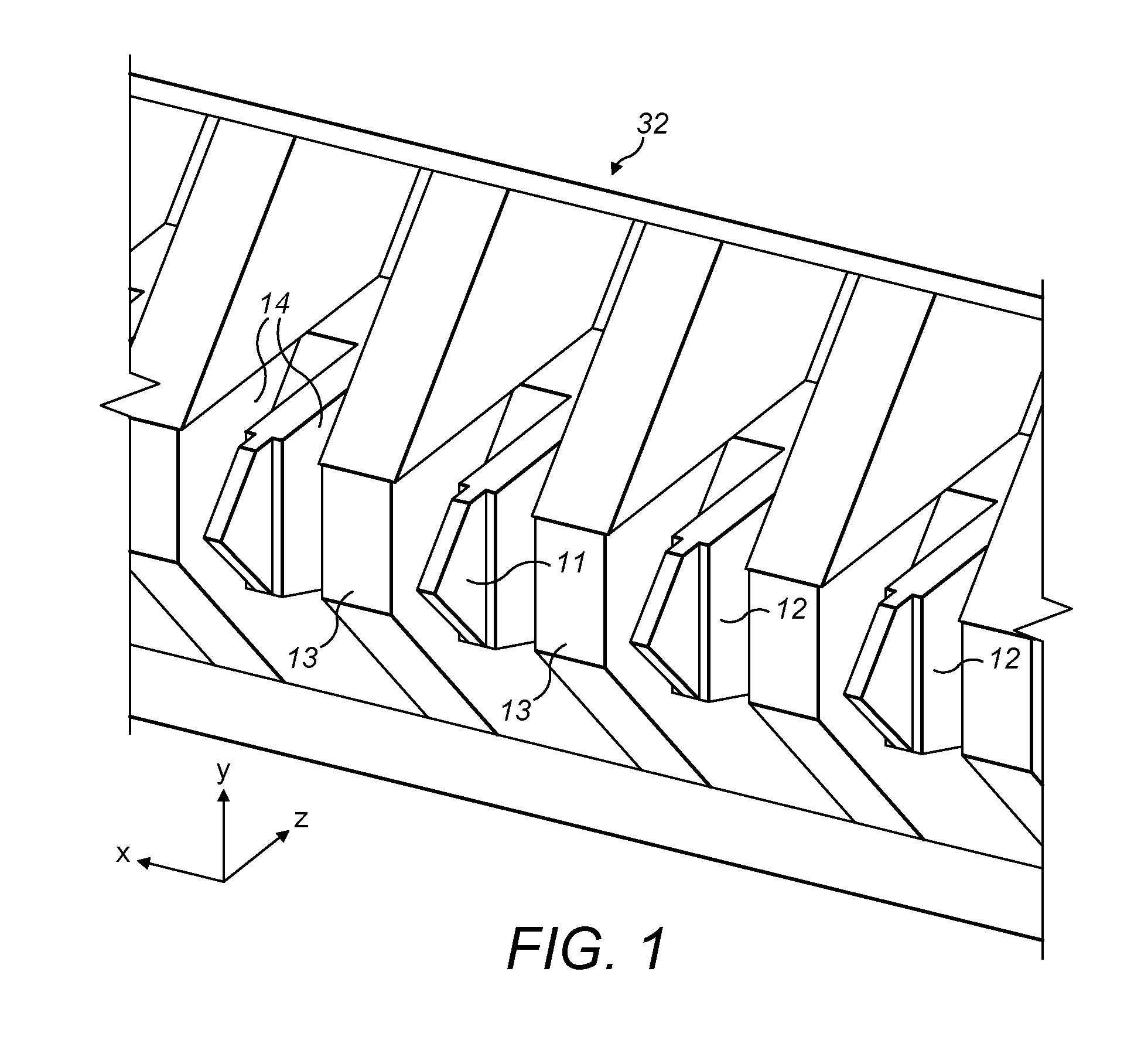

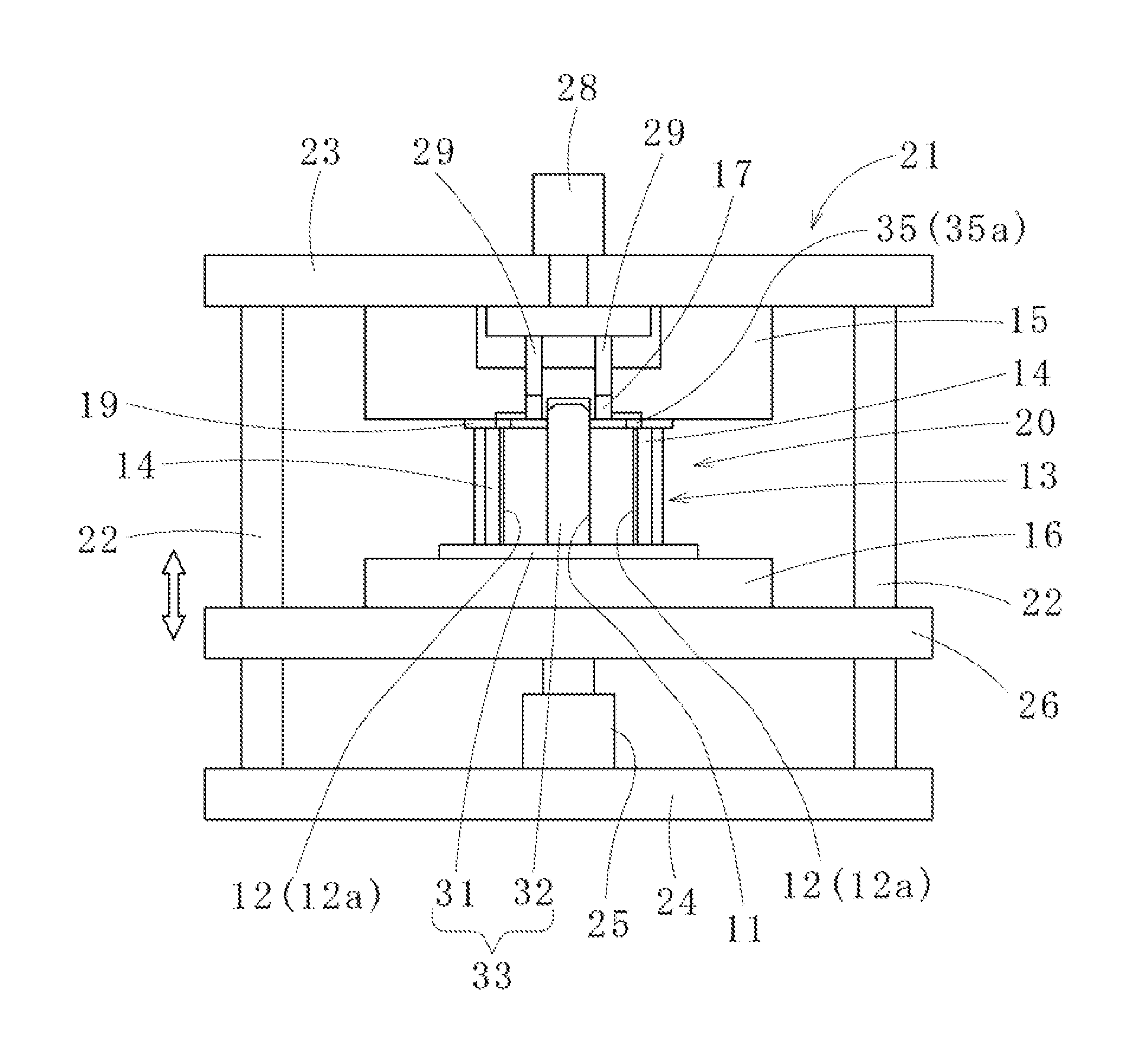

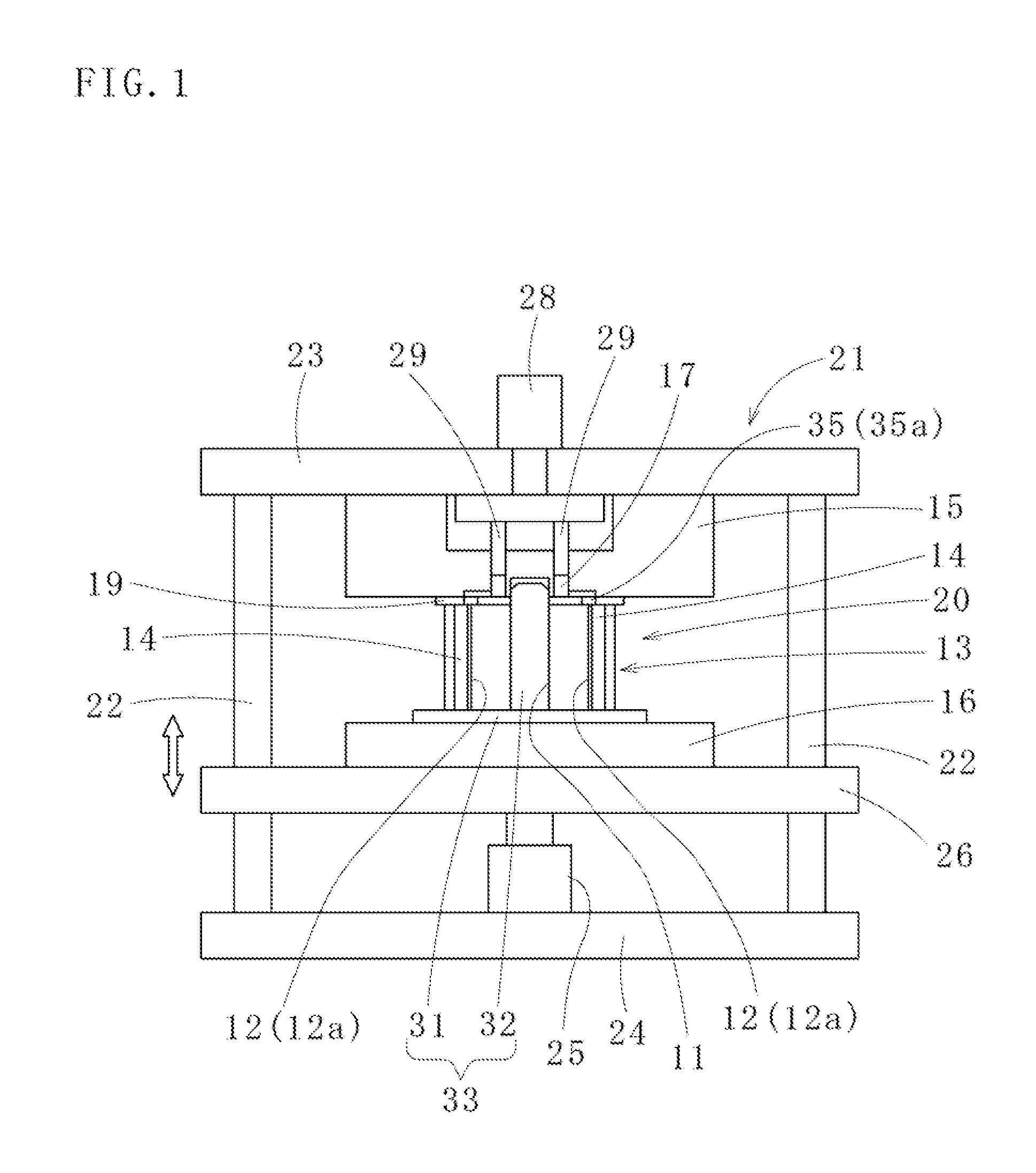

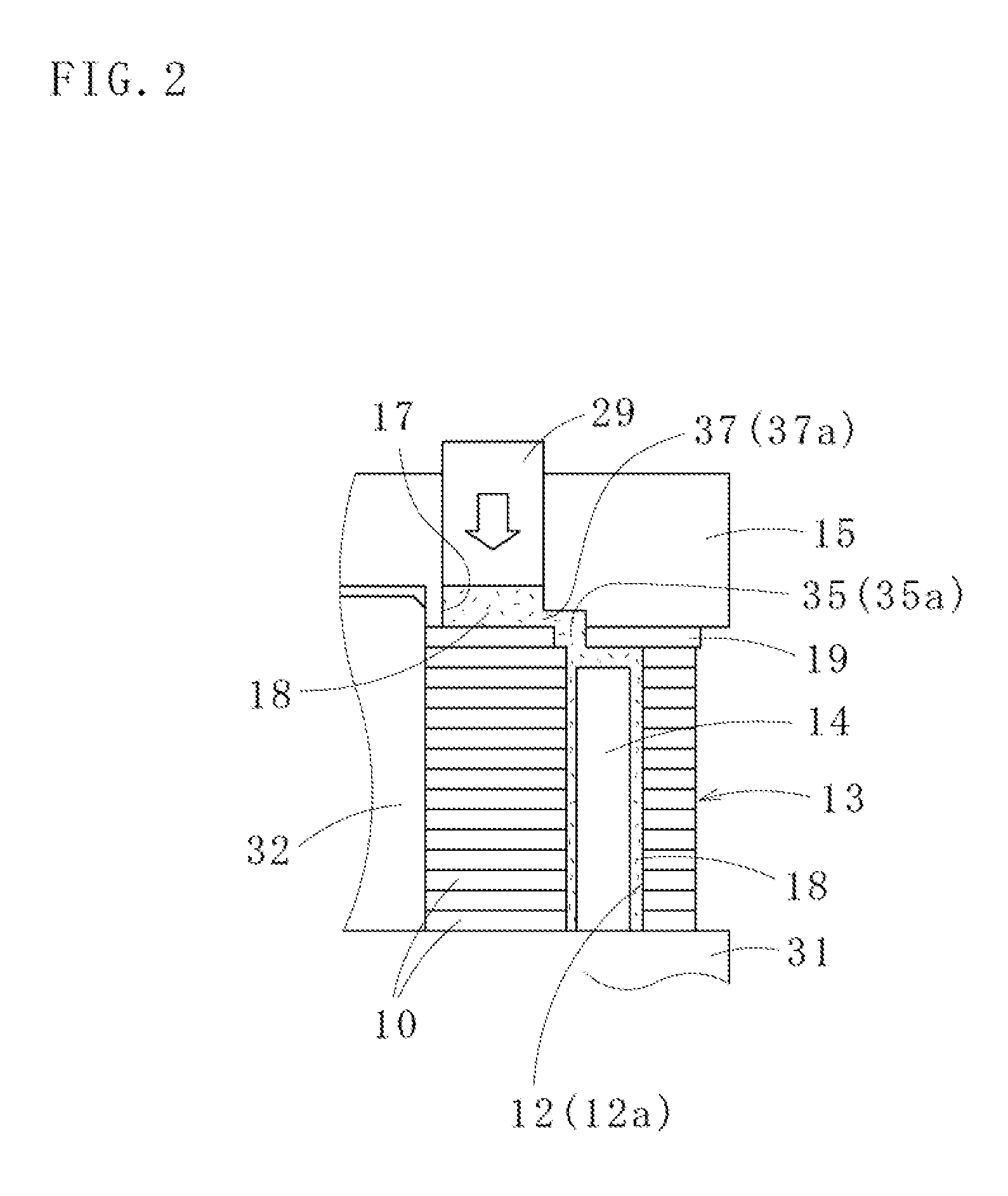

Method of manufacturing laminated core

A method of manufacturing a laminated core includes inserting permanent magnets 14 into magnet insertion holes 12, 12a of a core body 13; injecting a resin 18 into the holes 12, 12a from resin reservoir pots 17 in the die 15 (16) to fix the magnets 14; placing a dummy plate 19 between the die 15 having the pots 17 and the body 13, the plate 19 having gate holes 35, 35a guiding the resin 18 from the pots 17 into the holes 12, 12a, the hole 35 (35a) overlapping with both of a part of the hole 12 (12a) and a surface of the body 13; poring the resin 18 via the holes 35, 35a and curing the resin 18 in the holes 12, 12a; and separating the plate 19 from the body 13 to remove the resin 18 overflowed from the holes 12, 12a.

Owner:MITSUI HIGH TEC INC

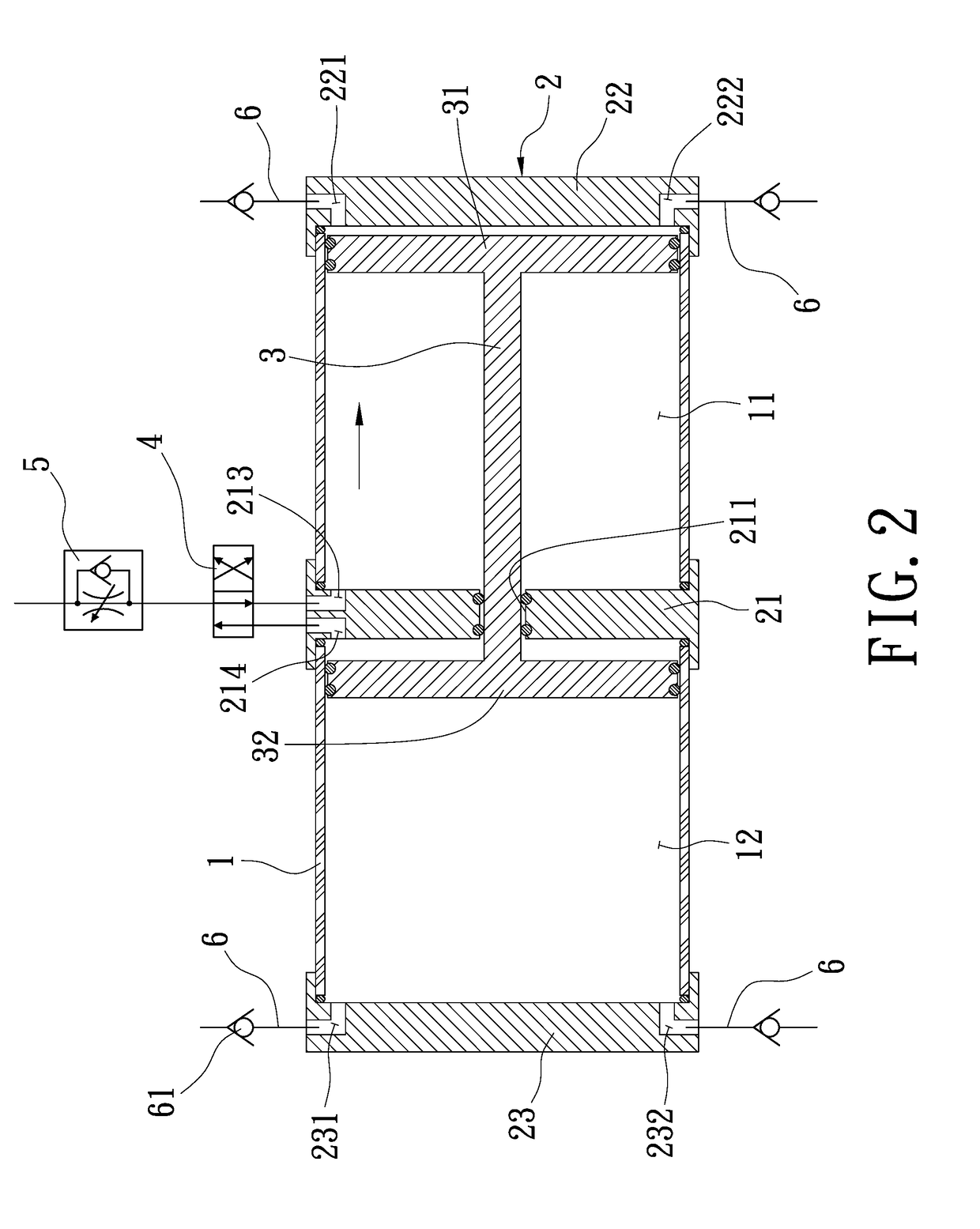

Double-acting pneumatic pump

InactiveUS20180347553A1Easy to controlFlow rateMultiple way valvesPump controlEngineeringMechanical engineering

A double-acting pneumatic pump is disclosed herein. It comprises a main body; three partitions including a first partition dividing the main body into two chambers, and a second partition and a third partition respectively disposed at the opposite ends of the two chambers divided by the first partition; a piston rod inserted into the first partition disposed between the two chambers and having a first piston and a second piston at two ends thereof arranged in the two chambers respectively; a switching valve and an air flow valve sequentially connected to inlets of the first partition by pipelines; and a plurality of working pipes respectively connected to each of inlets and outlets of the second partition and the third partition.

Owner:STPAPE CO LTD

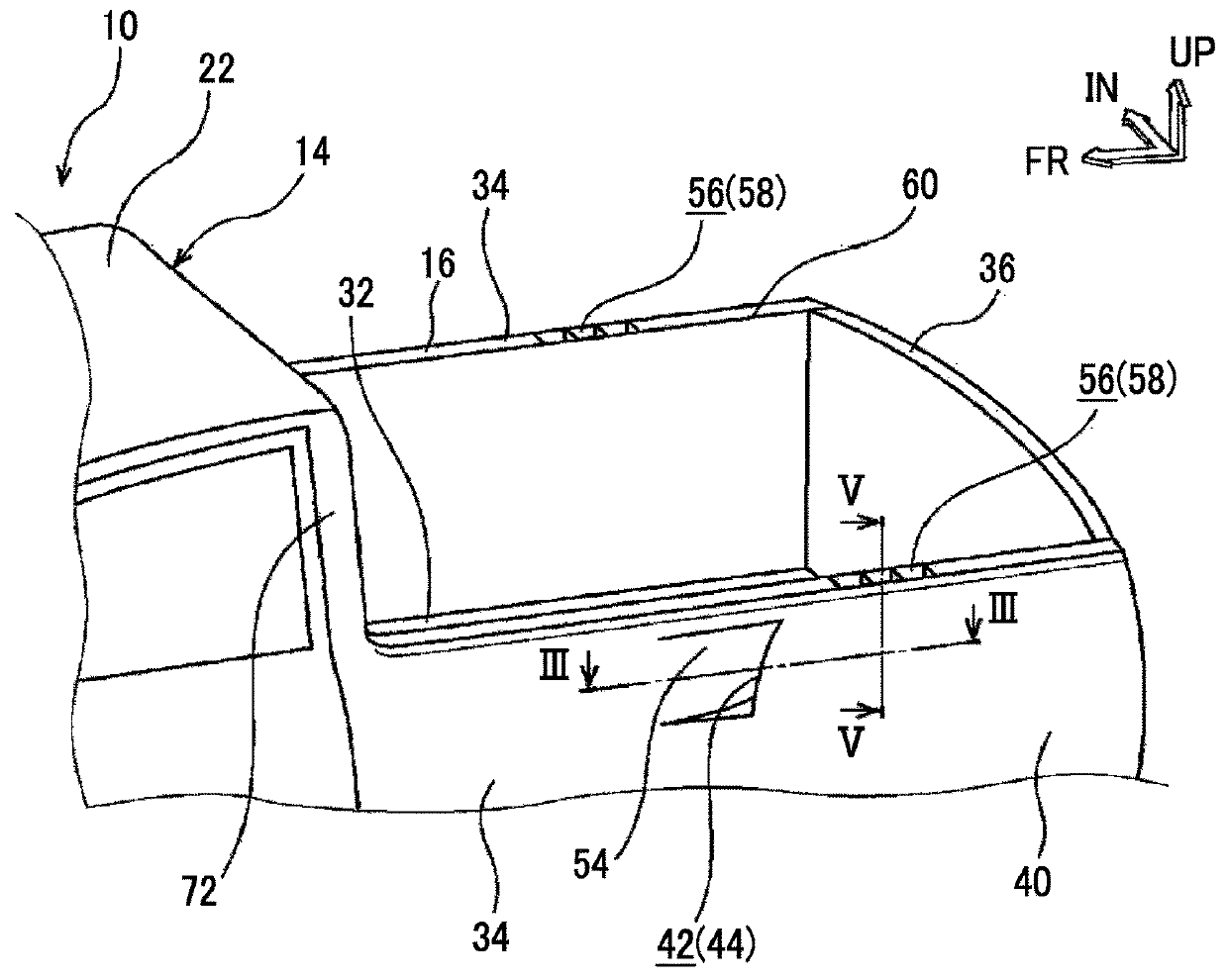

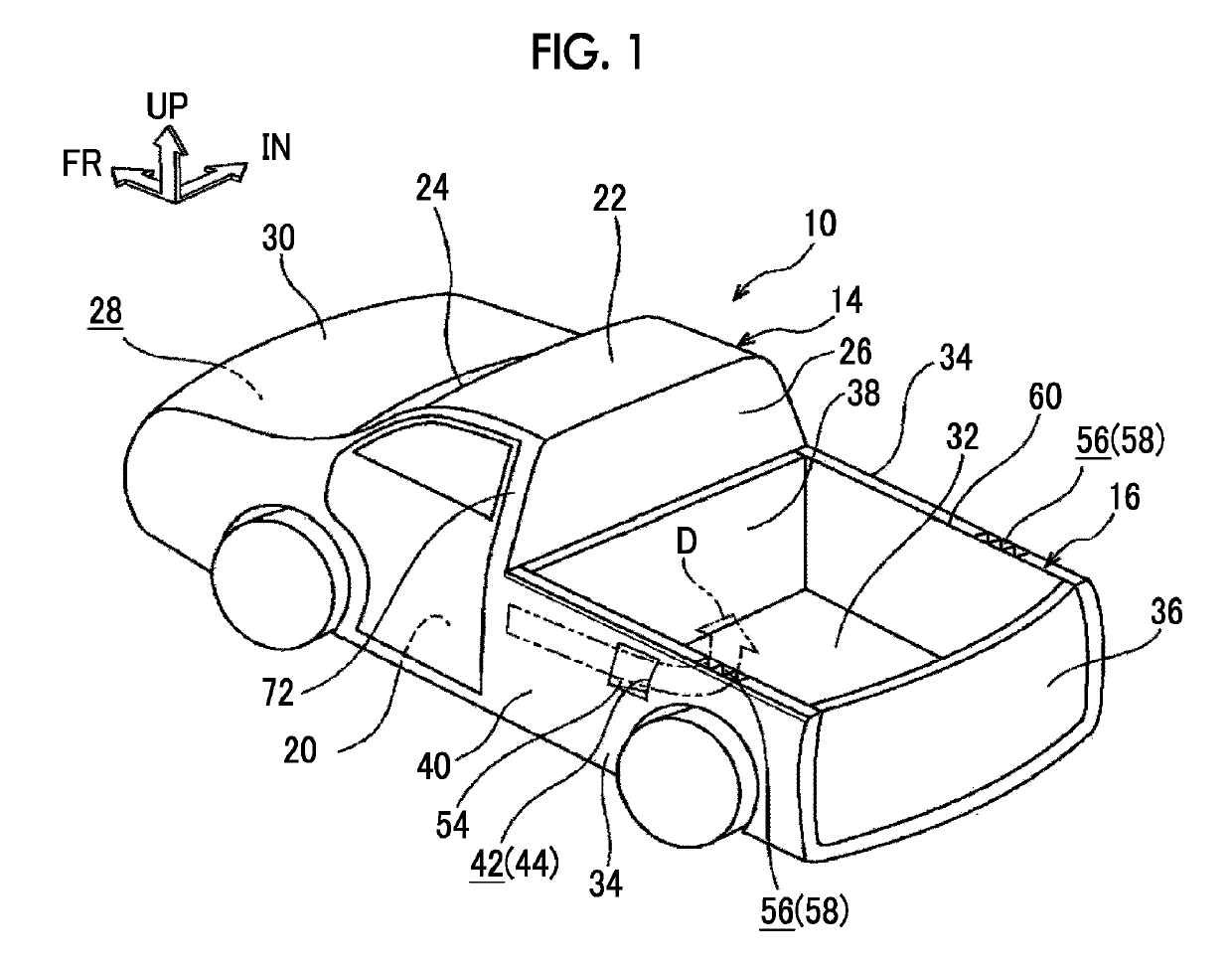

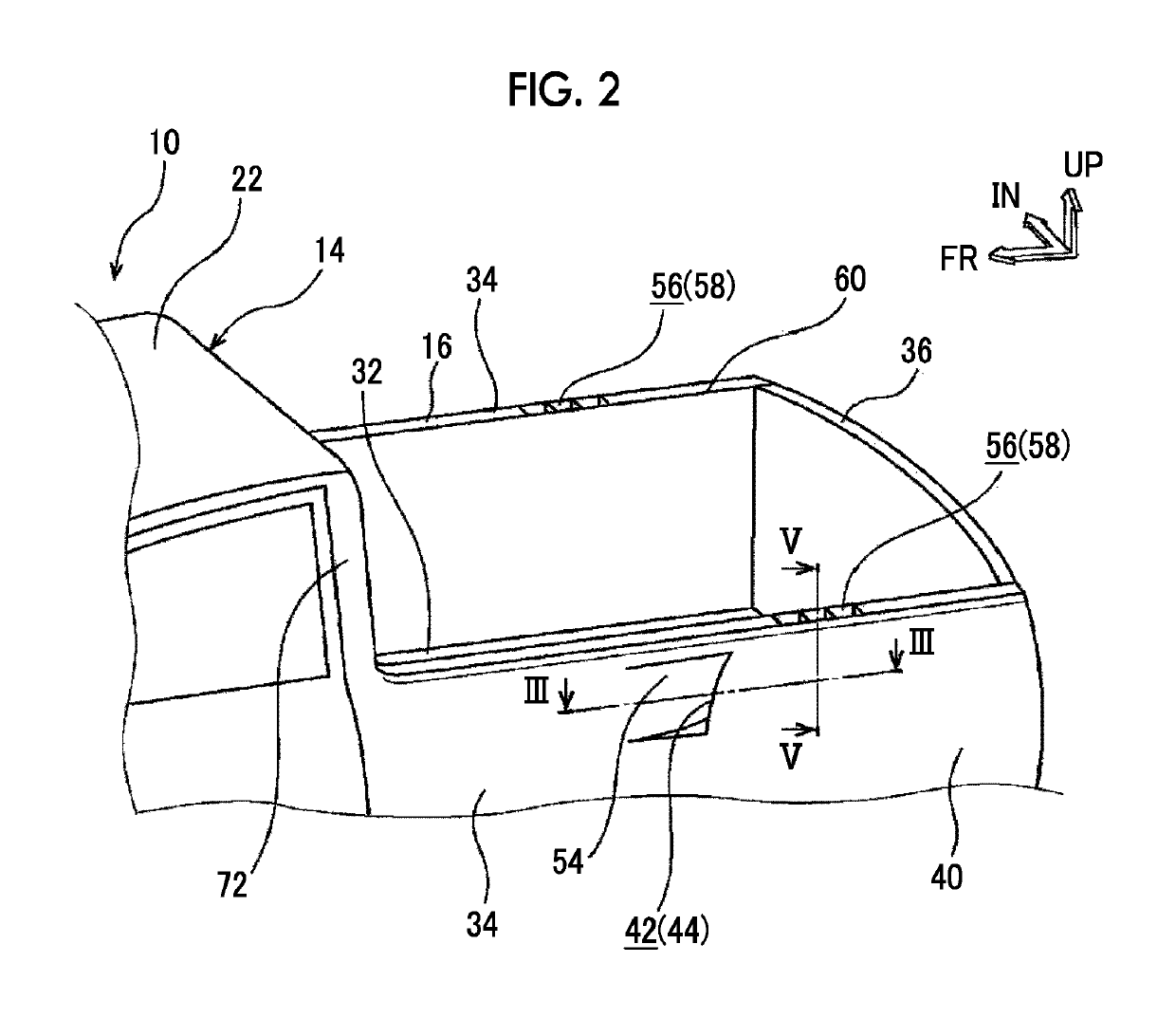

Vehicle side structure of pickup truck

ActiveUS20180178860A1Flow rateReduce air resistanceAerodynamics improvementVehicle body streamliningRear quarterPickup truck

A vehicle side structure of a pickup truck includes a cabin; and a loading platform that is disposed adjacent to a rear side of the cabin in the vehicle forward-rearward direction, is configured to include a bottom plate, a pair of right and left side panels, and a tail gate, and is formed in a box shape that opens toward a vehicle upper side. Each of the right and left side panels includes a traveling wind inlet part that is disposed at an outer part of each of the right and left side panels in a vehicle width direction, opens toward a vehicle front side, and includes a first opening, a traveling wind blowing part that is disposed at an upper end part of each of the right and left side panels, opens toward the vehicle upper side, and includes a second opening, and an intermediate part.

Owner:TOYOTA JIDOSHA KK

Hydrogen producing apparatus, method of operating hydrogen producing apparatus and fuel cell power generating system

ActiveUS8435684B2Drive stabilityShorten the time periodLevel controlExhaust apparatusHydrogenCombustor

A hydrogen generation apparatus 1 includes a raw material supply unit 4 for controlling a flow rate of a raw material to be supplied from an external element and containing hydrocarbon and an odorizing component; an odorizing component removing section 5 containing an adsorbing agent for adsorbing the odorizing component contained in the raw material; a combustor 2 for combusting the raw material; a reformer 30 for generating hydrogen-containing gas from the raw material which has passed the odorizing component removing section 5 by a reforming reaction using combustion heat supplied from the combustor 2; and a controller 16 for controlling the raw material supply unit to, during driving after the adsorbing agent or the odorizing component removing section 5 is exchanged or after the adsorbing agent is regenerated, makes the flow rate of the raw material to be supplied from the external element higher than the flow rate during the driving immediately before the exchange or regeneration.

Owner:PANASONIC CORP

Oil-Pressure Apparatus

InactiveUS20130180395A1Prevent pressure lossShorten timeServomotor componentsServomotorsOil pressureControl theory

Owner:TAGUCHI INDAL

Vehicle side structure of pickup truck

InactiveUS10377431B2Reduce air resistanceWeight increaseAerodynamics improvementDoorsRear quarterPickup truck

A vehicle side structure of a pickup truck includes a cabin; and a loading platform that is disposed adjacent to a rear side of the cabin in the vehicle forward-rearward direction, is configured to include a bottom plate, a pair of right and left side panels, and a tail gate, and is formed in a box shape that opens toward a vehicle upper side. Each of the right and left side panels includes a traveling wind inlet part that is disposed at an outer part of each of the right and left side panels in a vehicle width direction, opens toward a vehicle front side, and includes a first opening, a traveling wind blowing part that is disposed at an upper end part of each of the right and left side panels, opens toward the vehicle upper side, and includes a second opening, and an intermediate part.

Owner:TOYOTA JIDOSHA KK

Method for managing the exhaust gas circulation circuit of a petrol thermal engine and corresponding recirculation system

ActiveUS8844505B2Increase the differential pressureEasy to operateElectrical controlInternal combustion piston enginesCombustion chamberGasoline

The invention relates to a method for managing an exhaust gas recirculation circuit of a petrol thermal engine, the engine including at least one combustion chamber connected to an inlet line and an exhaust line between which extends said recirculation circuit, the recirculation circuit including a flow-rate adjustment valve, wherein said method comprises the step of adjusting flow-rate adjustment valve based on a flow-rate setpoint, said method further comprising the steps of: detecting an operation parameter representative of a pressure difference between an upstream pressure and a downstream pressure relative to the flow-rate adjustment valve, and, after comparing the parameter with a threshold corresponding to a minimum pressure difference, adjusting the flow-rate in at least one of the lines in order to increase the pressure difference.

Owner:VALEO SYST DE CONTROLE MOTEUR

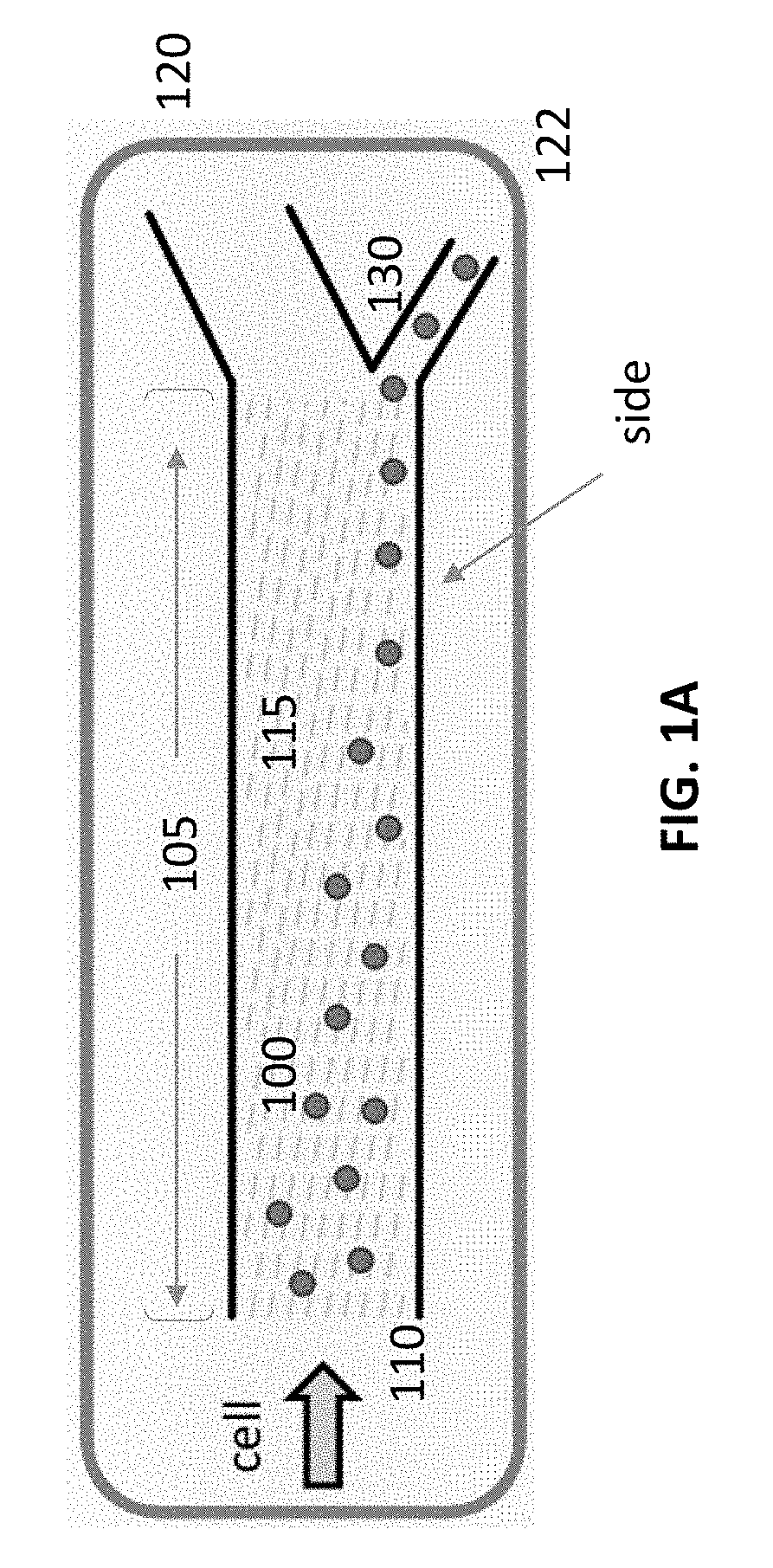

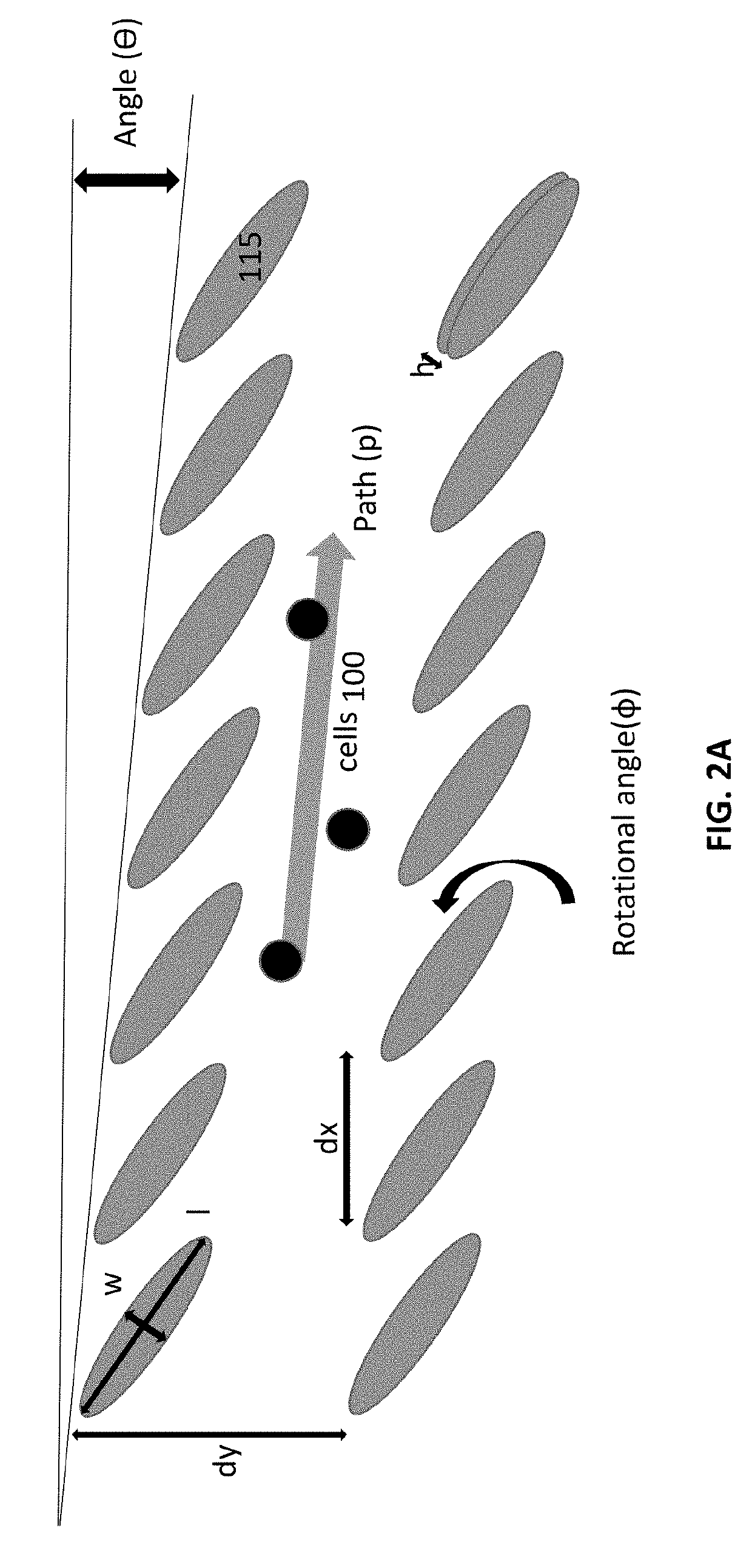

Microfluidic Cellular Device and Methods of Use Thereof

ActiveUS20190210019A1Rapid concentration of cellHigh cell recovery rateCell dissociation methodsPreparing sample for investigationDiagonalCell based

Systems and methods for using microfluidic devices to concentrate cells, to perform buffer changes, to sort cells based on size, and / or to isolate particular types of cells in a rapid manner, are presented. Cells flow into a matrix of posts, wherein the posts are distributed along diagonal lines in the chamber. The cells are deflected in a lateral manner, towards a side of a chamber and are collected upon exiting the chamber.

Owner:NANOCAV LLC

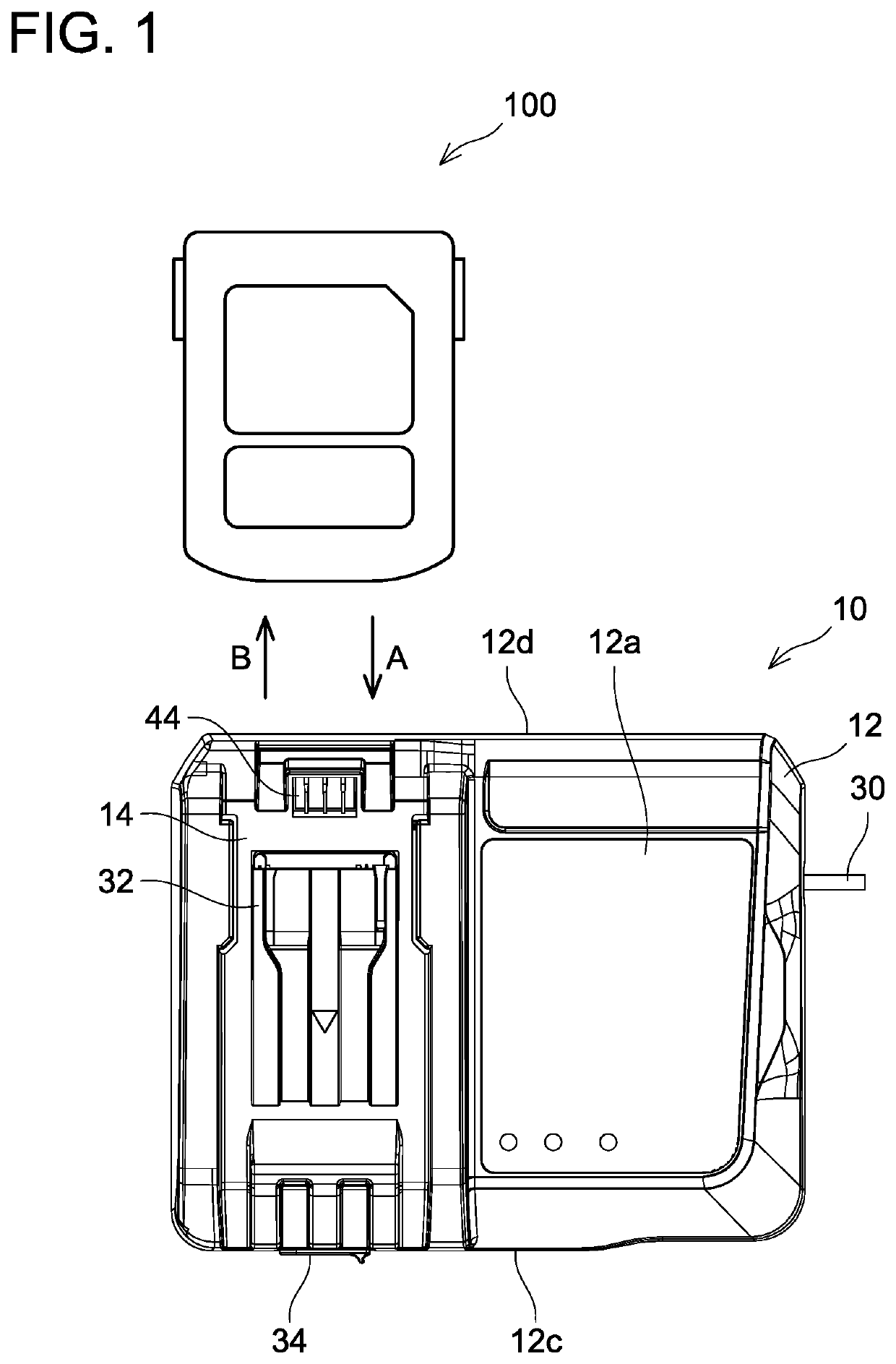

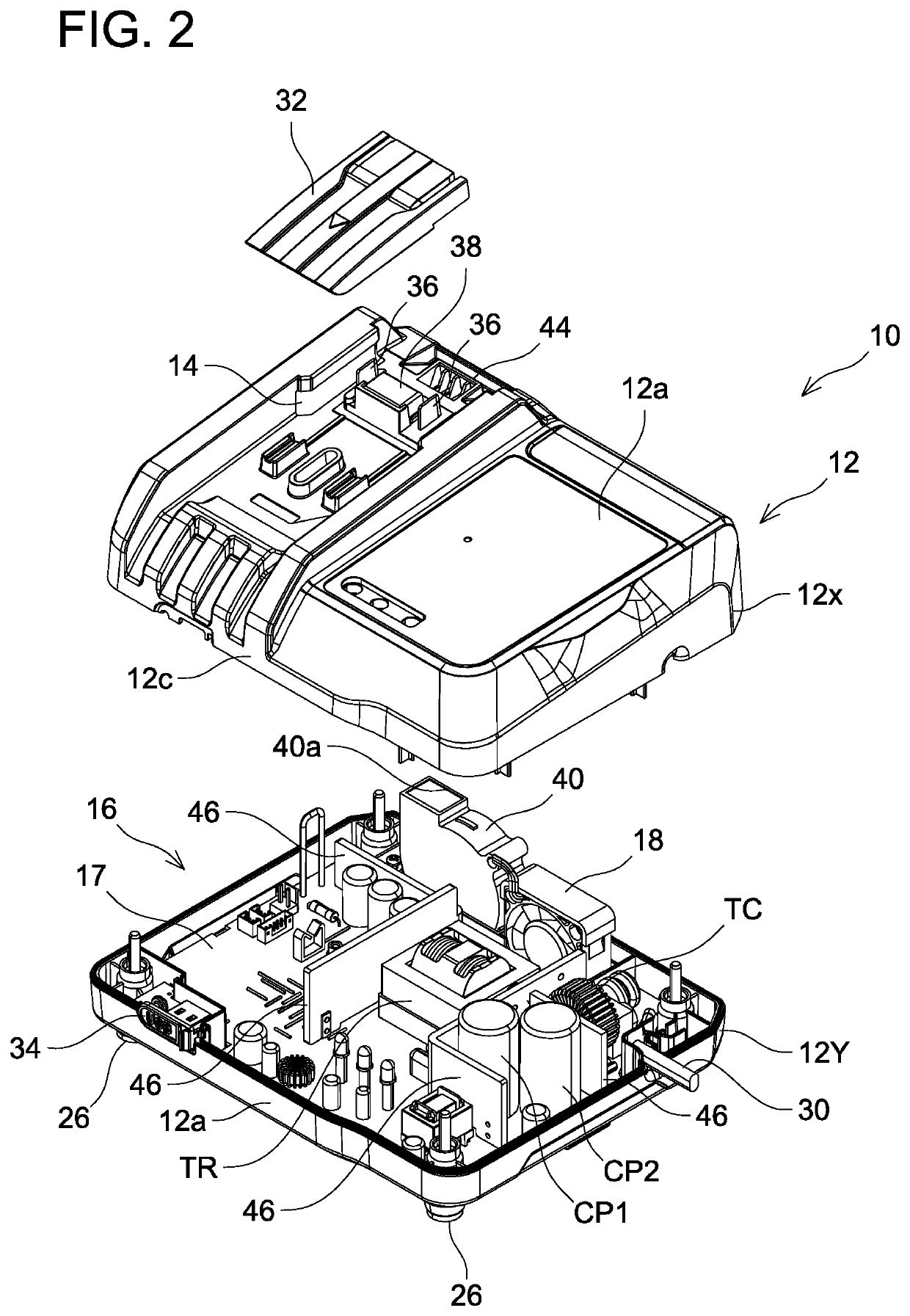

Charger configured to charge battery pack of power tool

ActiveUS20200280200A1Reduce dust accumulationFlow rateBatteries circuit arrangementsDc-dc conversionPower toolAir blower

A charger configured to charge a battery pack of a power tool, and the charger include: a housing having an intake port and an exhaust port; a battery interface included on the housing and configured to removably receive a battery pack, a charging circuit in the housing and configured to supply charging power to the battery pack attached to the battery interface; and a blower configured to introduce air from the intake port into the housing and discharge the air from the exhaust port to the outside of the housing. The intake port includes a plurality of intake holes formed in the housing, and the exhaust port includes a plurality of exhaust holes formed in the housing. Each inscribed circle of the plurality of intake holes is smaller than any of inscribed circles of the plurality of exhaust holes.

Owner:MAKITA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com