Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Eliminate edges and corners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

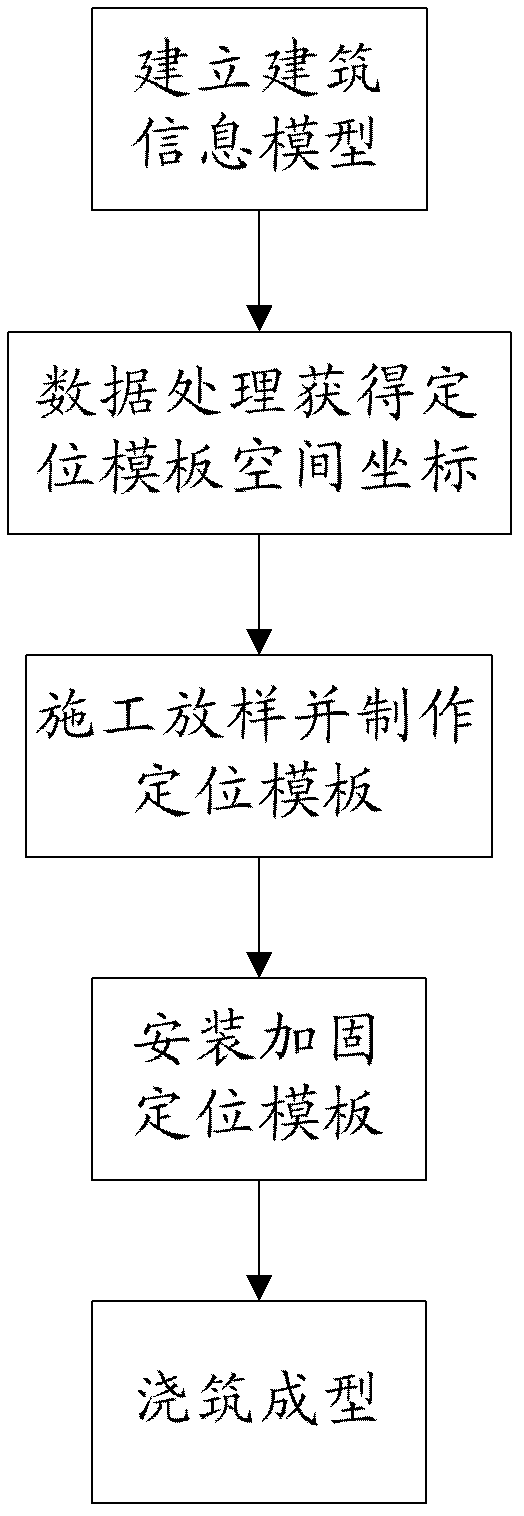

Construction method of variable curved-surface steel-concrete tubular structure

InactiveCN102587658ASolve the problem of inner and outer curved formwork formingResolve continuityBuilding material handlingArchitectural engineeringAbnormal shaped

The invention discloses a construction method of a variable curved-surface steel-concrete tubular structure, which includes the steps: establishing a building information model; subjecting the building information model to data processing to obtain space coordinate data of positioning forms of the tubular structure; performing construction layout according to the space coordinate data and fabricating the positioning forms; installing and reinforcing the positioning forms; and performing casting. By the construction method, construction of the variable curved-surface steel-concrete tubular structure is achieved, the solid sensory artistic effect of the variable curved-surface steel-concrete tubular structure is guaranteed, cost is low, and facade streamline is highly continuous in variation.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

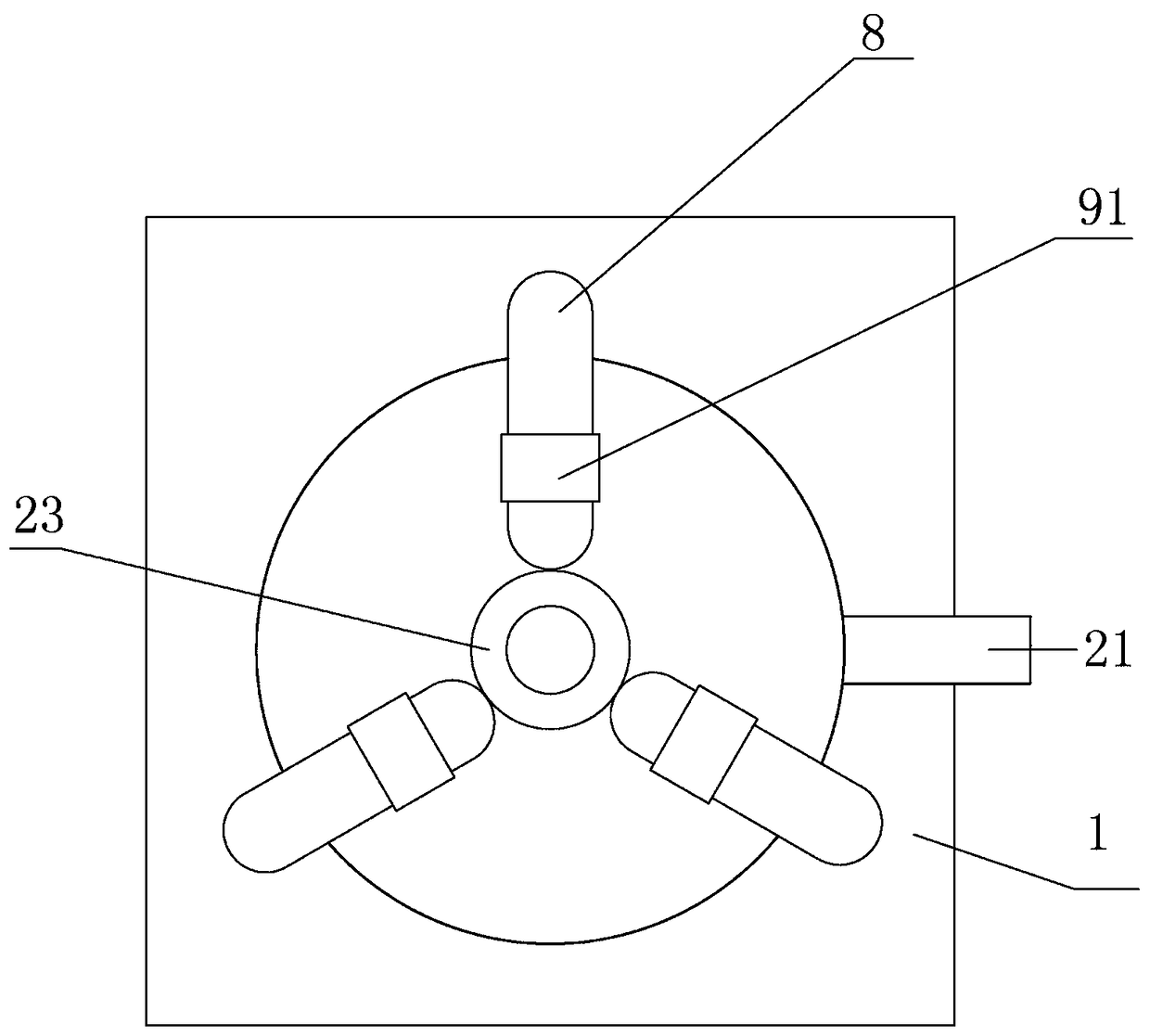

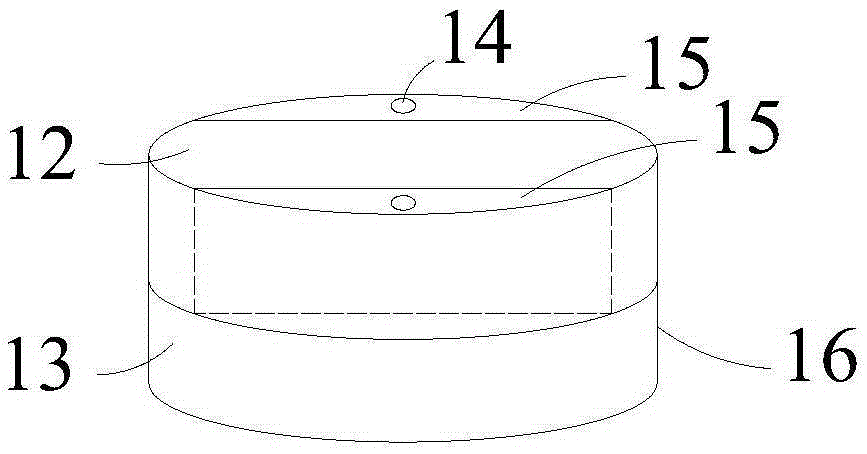

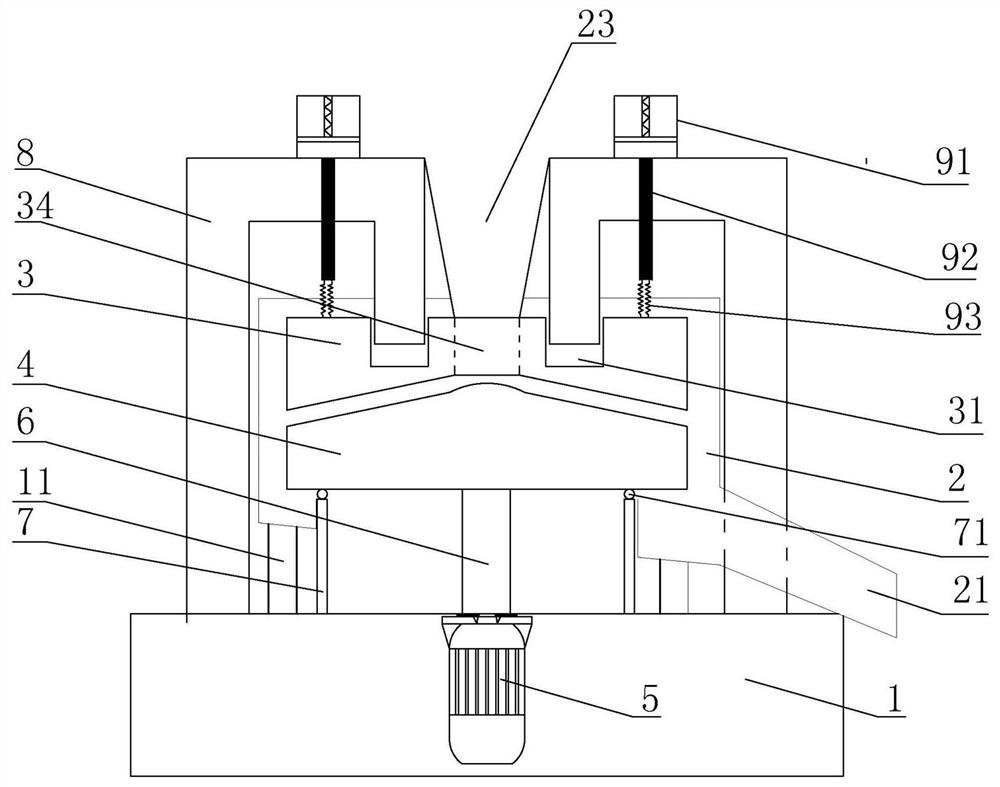

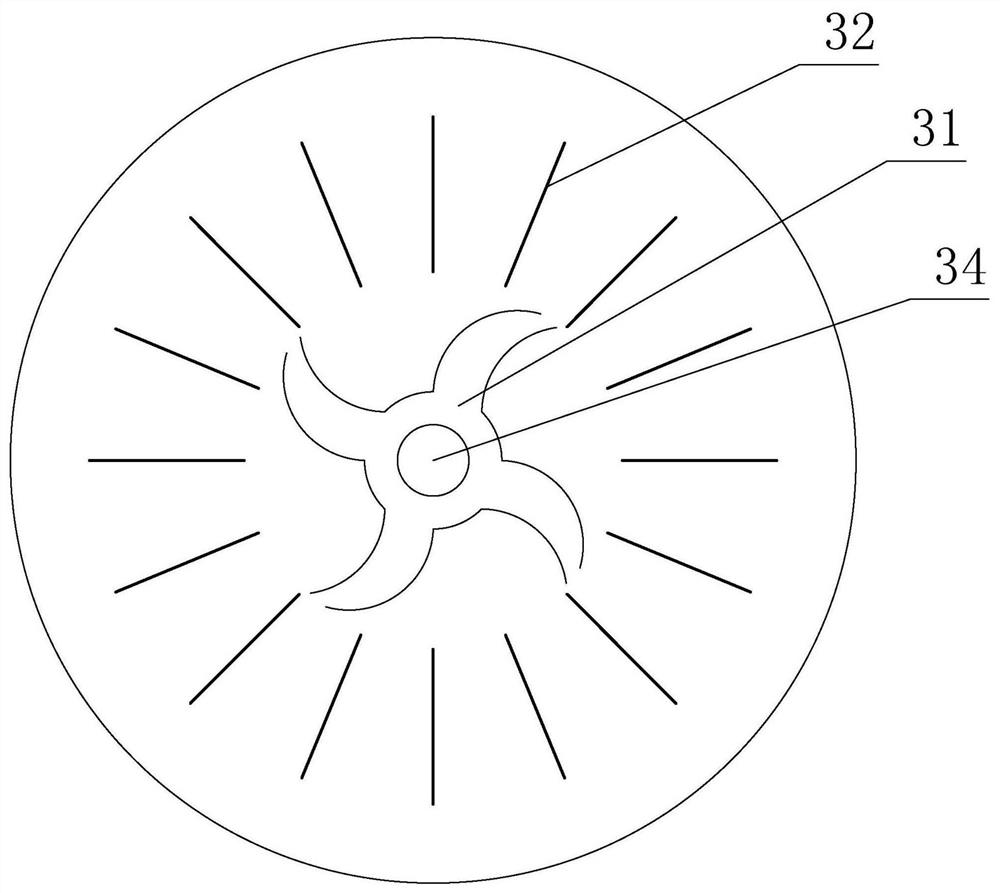

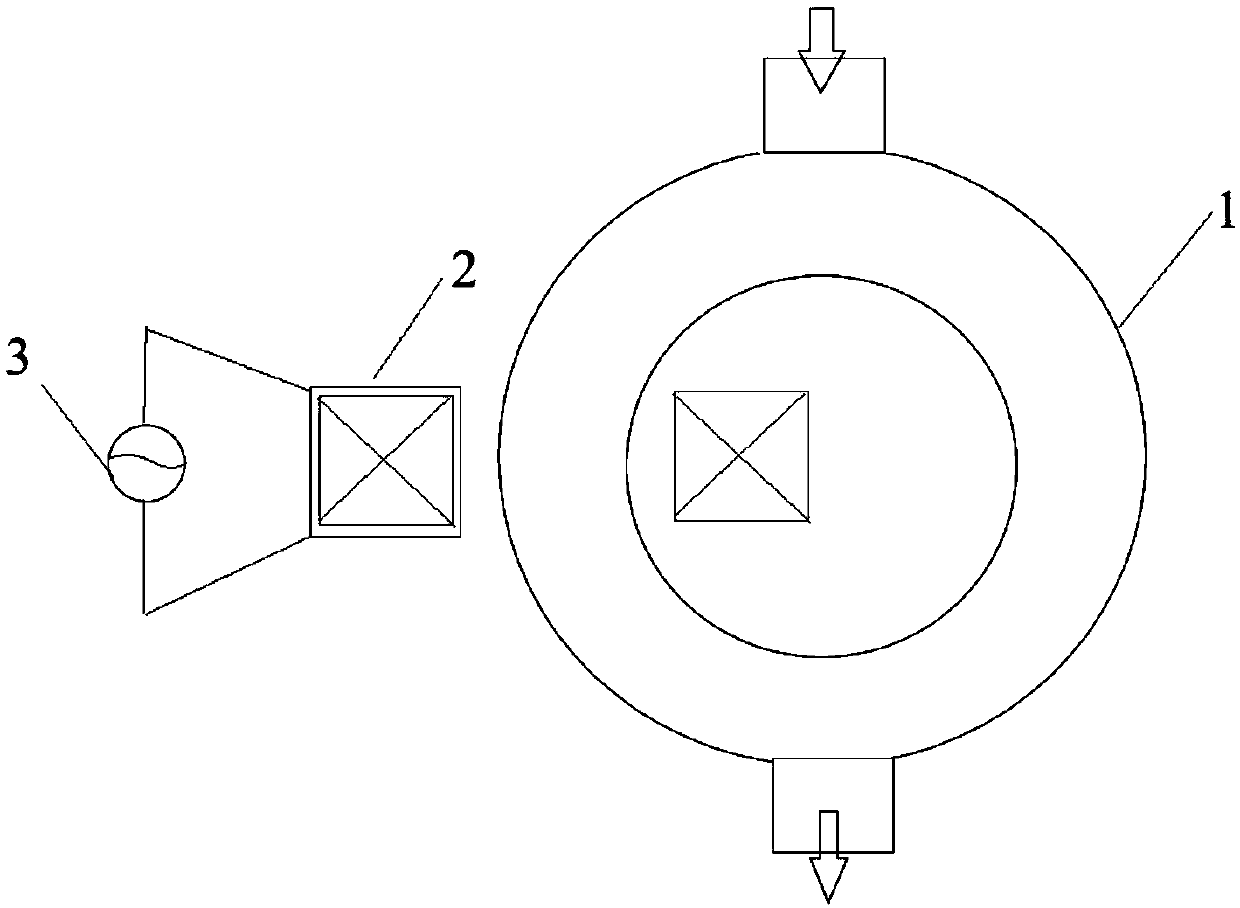

Cone-disc type waste concrete regenerated coarse aggregate mortar stripping device

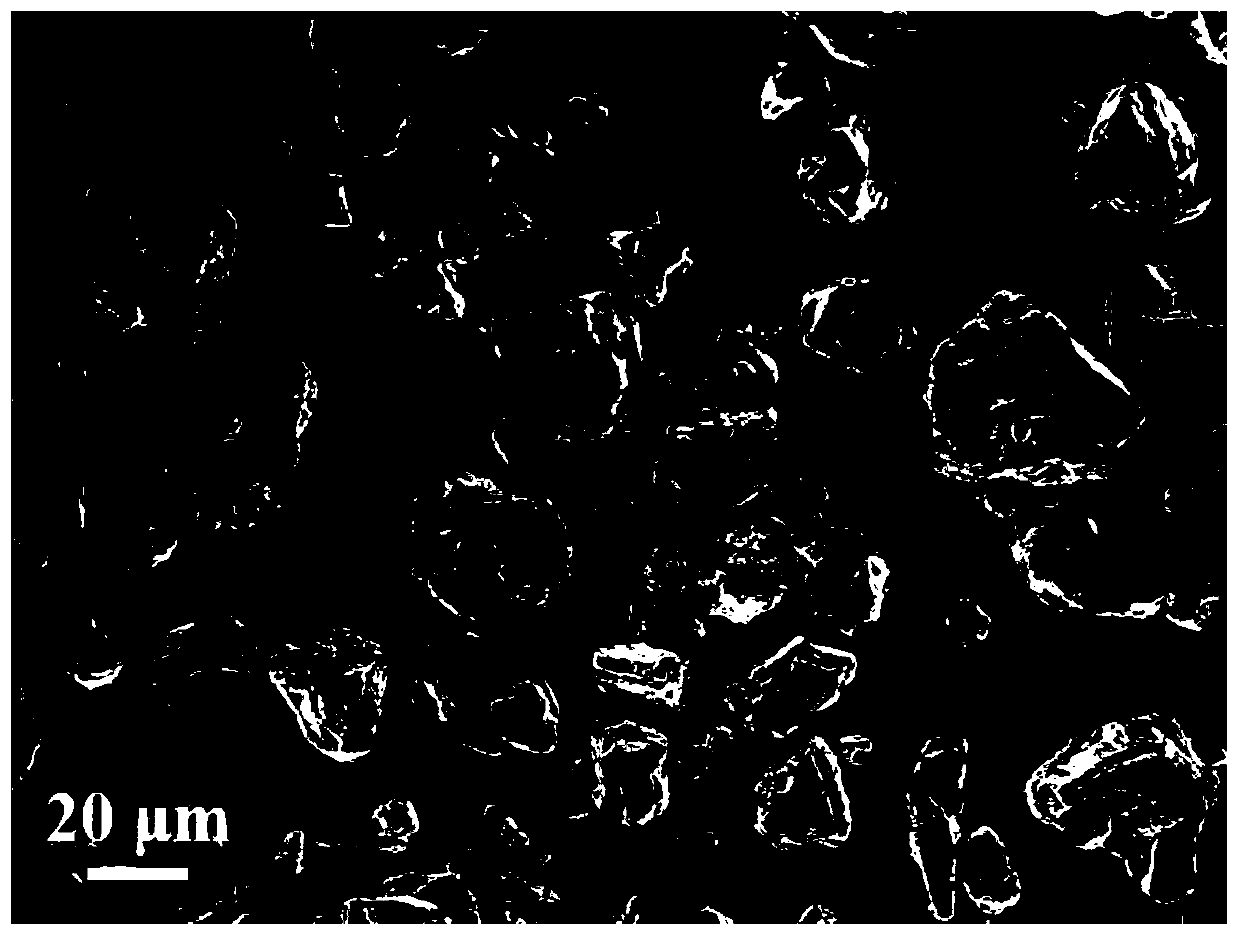

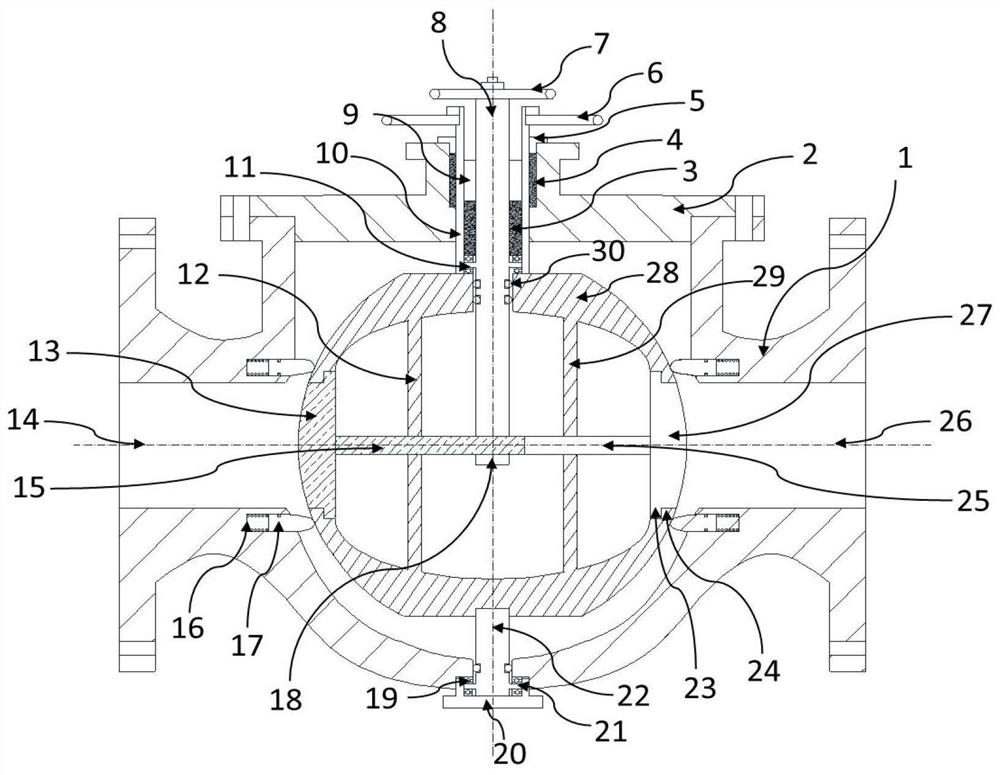

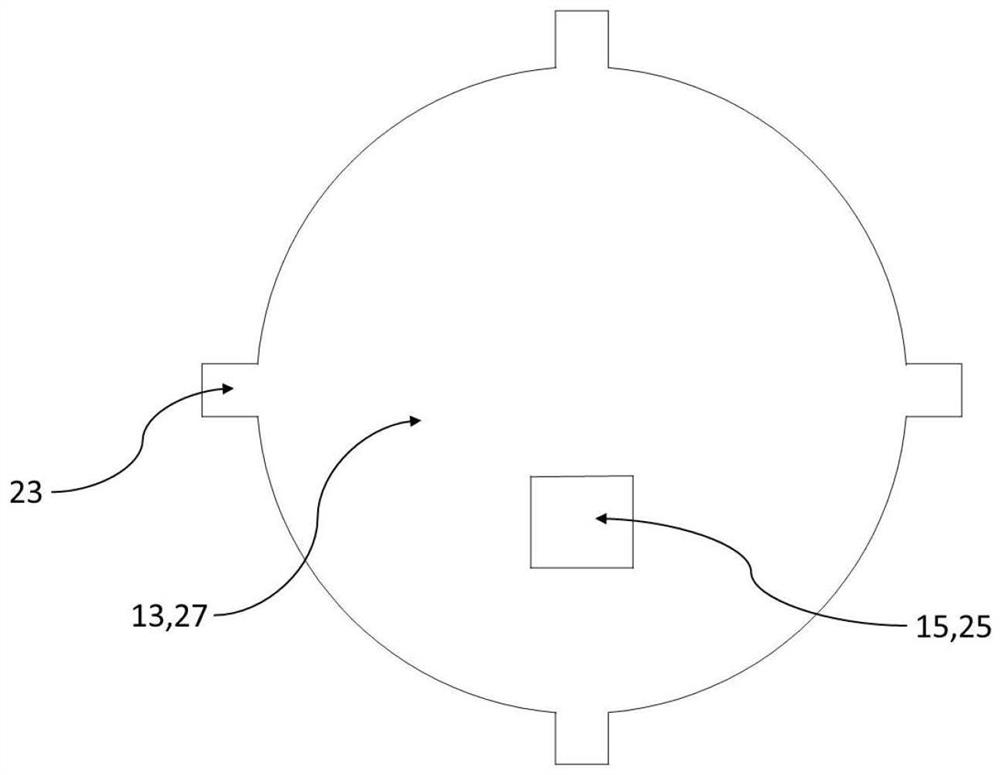

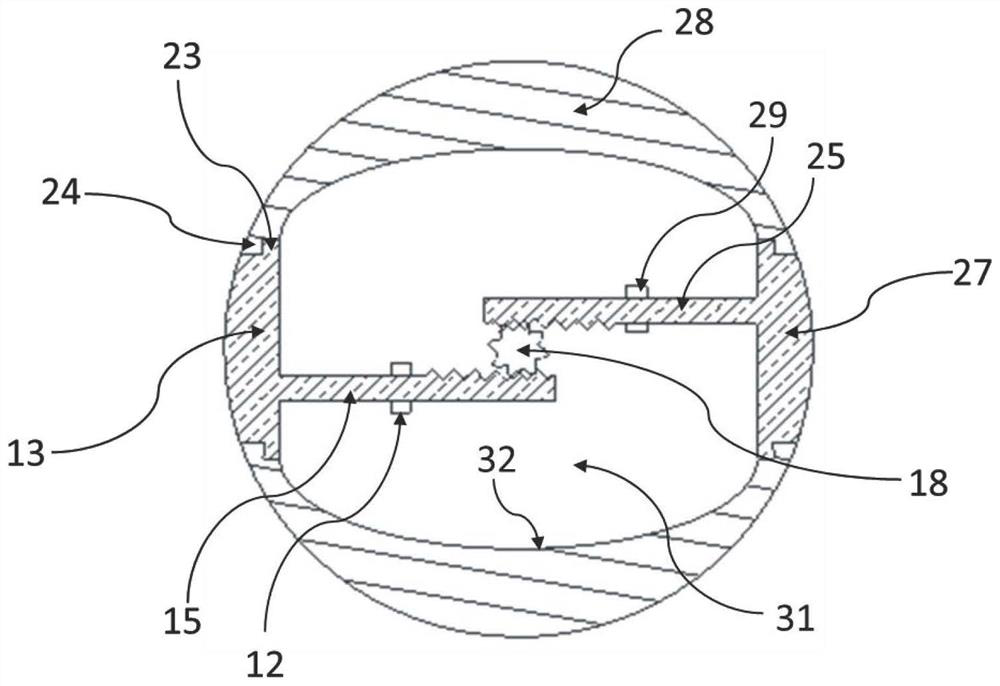

ActiveCN109012867AWeaken protruding cornersReduce mud contentCocoaGrain treatmentsMetallurgyConstruction aggregate

The invention discloses a cone-disc type waste concrete regenerated coarse aggregate mortar stripping device. The cone-disc type waste concrete regenerated coarse aggregate mortar stripping device comprises a base, a material collection bin and a cone-disc type grinding disc, wherein the cone-disc type grinding disc is composed of an upper grinding disc and a lower grinding disc, the grinding surface of the lower grinding disc is of a convex cone type, the grinding surface of the upper grinding disc is of a concave cone type, and the grinding surface of the upper grinding disc is in fit with that of the lower grinding disc; the base is provided with a plurality of reverse-hook-shaped supports, the disc surface of the upper grinding disc is correspondingly provided with position-limiting holes, and reverse hooks of all the reverse-hook-shaped supports penetrate into the corresponding position-limiting holes to restrict the upper grinding disc to be only capable of sliding up and down; ahydraulic force transmitting device is arranged between the upper grinding disc and all the reverse-hook-shaped supports, and ascending and descending of the upper grinding disc are controlled through stretching and contracting adjustment of the hydraulic force transmitting device; and the center of the upper grinding disc is provided with a material inlet, the material inlet penetrates out of the top of the material collection bin, and the lower portion of the material collection bin is provided with a material outlet. The cone-disc type waste concrete regenerated coarse aggregate mortar stripping device is simple in structure, the aggregate mortar stripping effect is good, and the original particle size of coarse aggregate can be maintained to make the performance of the coarse aggregate be close to natural aggregate, so that the workability, strength and durability of freshly-mixed waste concrete are improved.

Owner:CHINA UNIV OF MINING & TECH

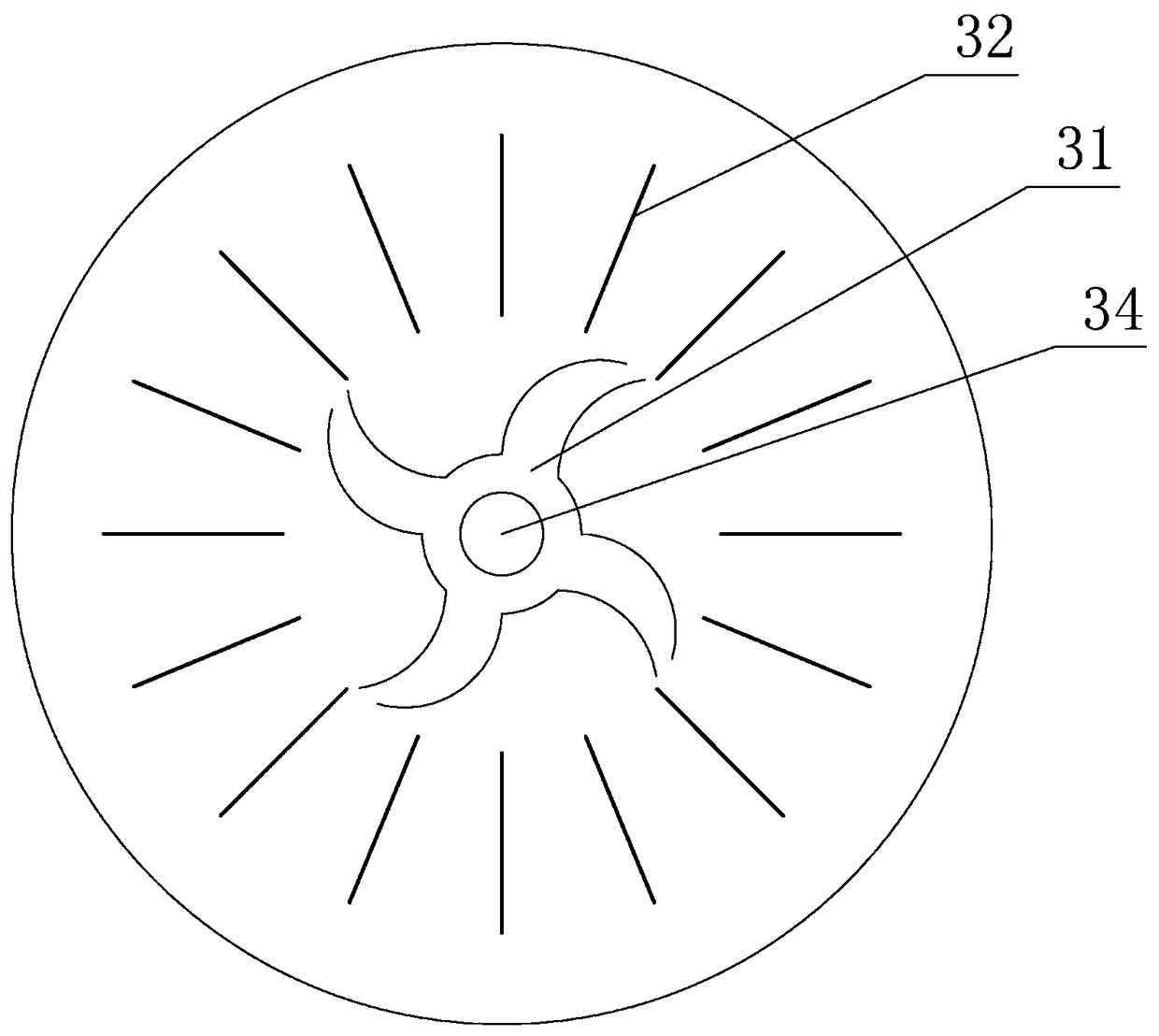

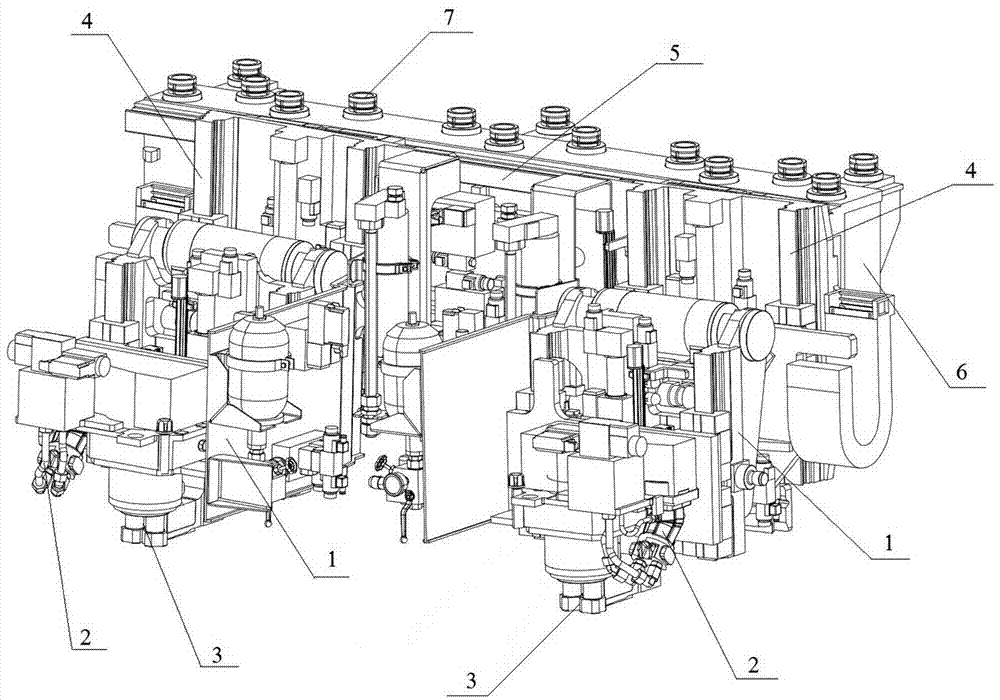

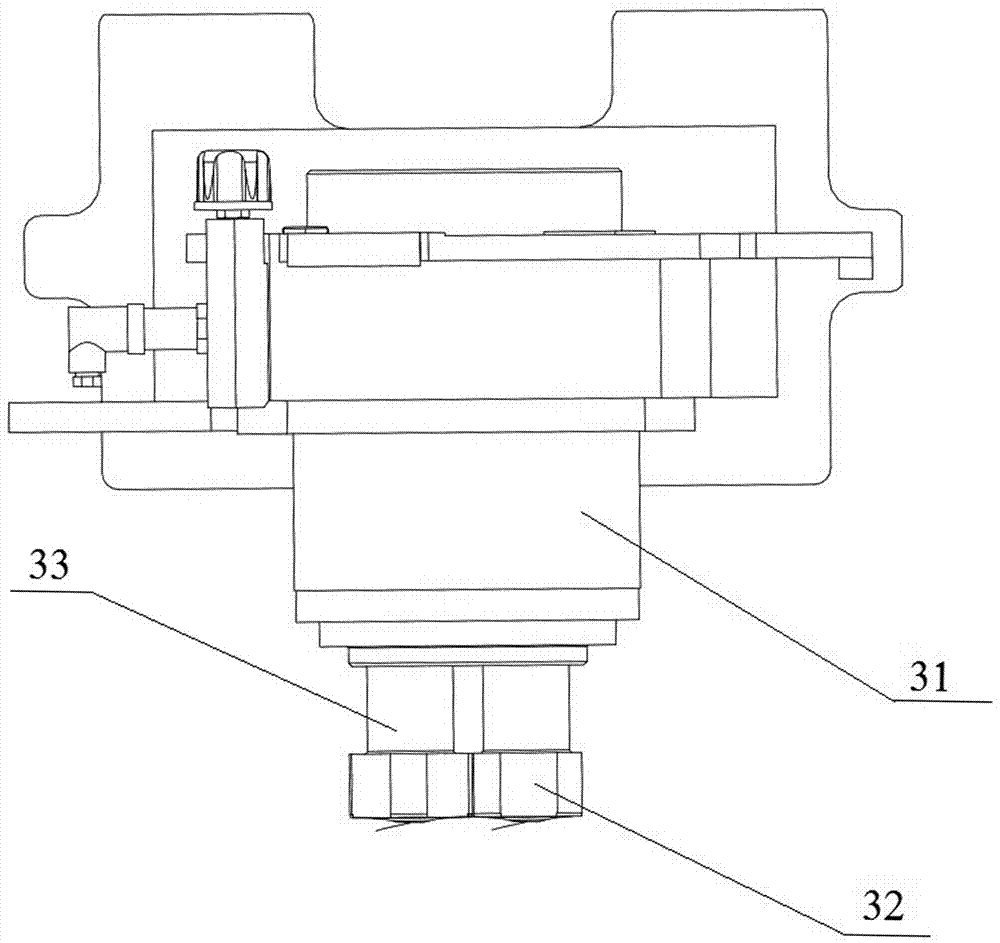

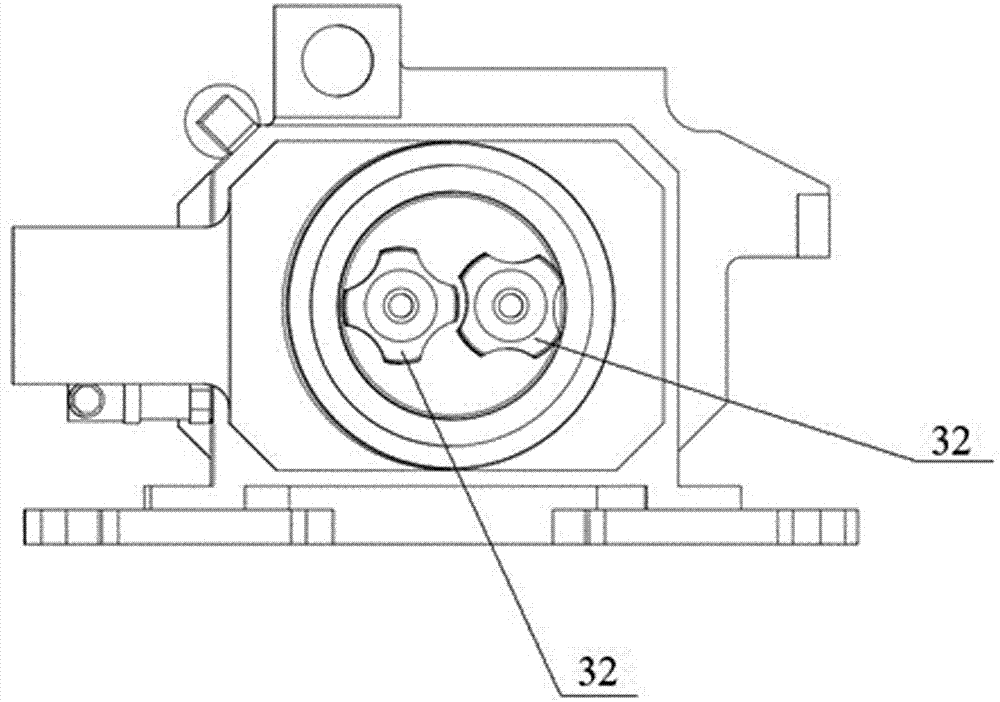

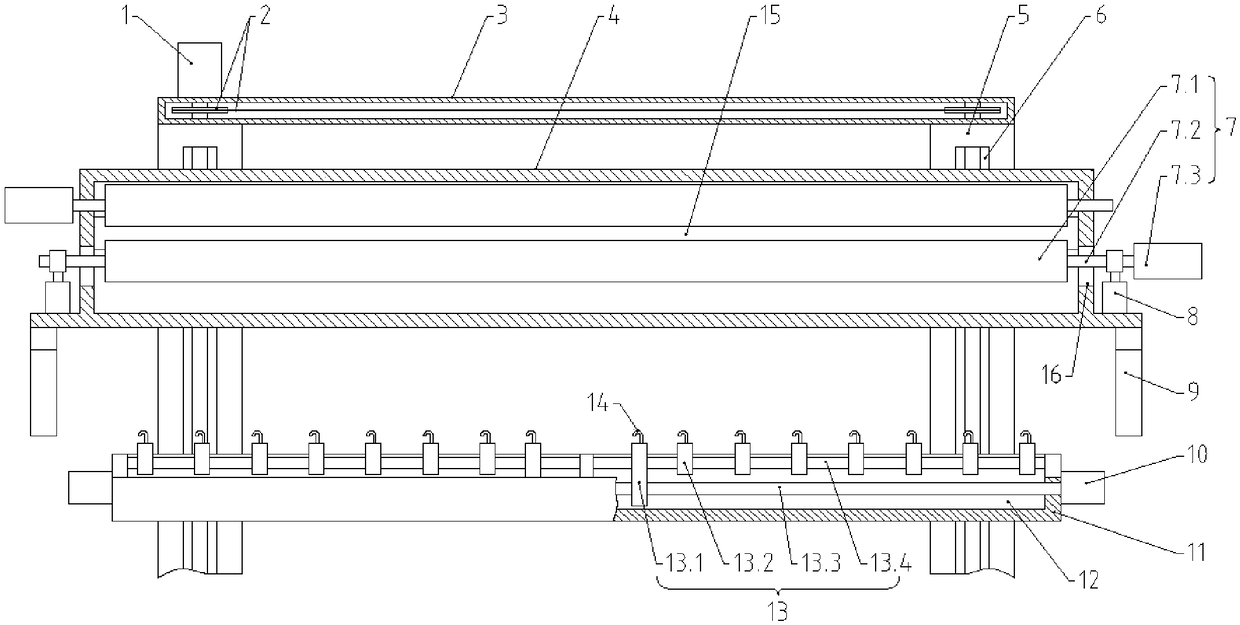

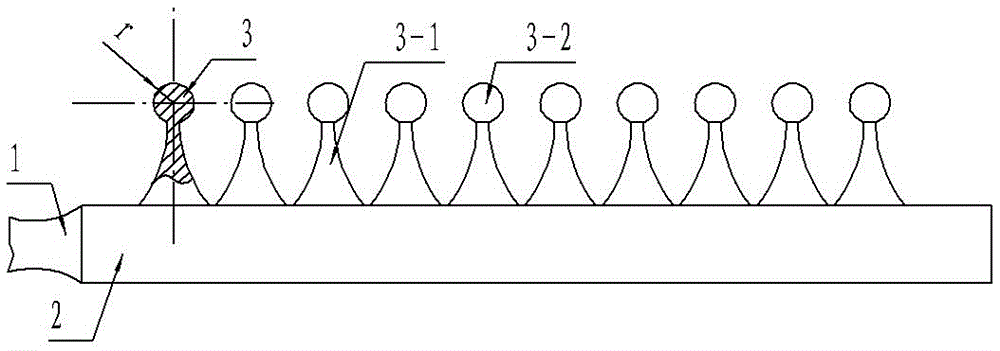

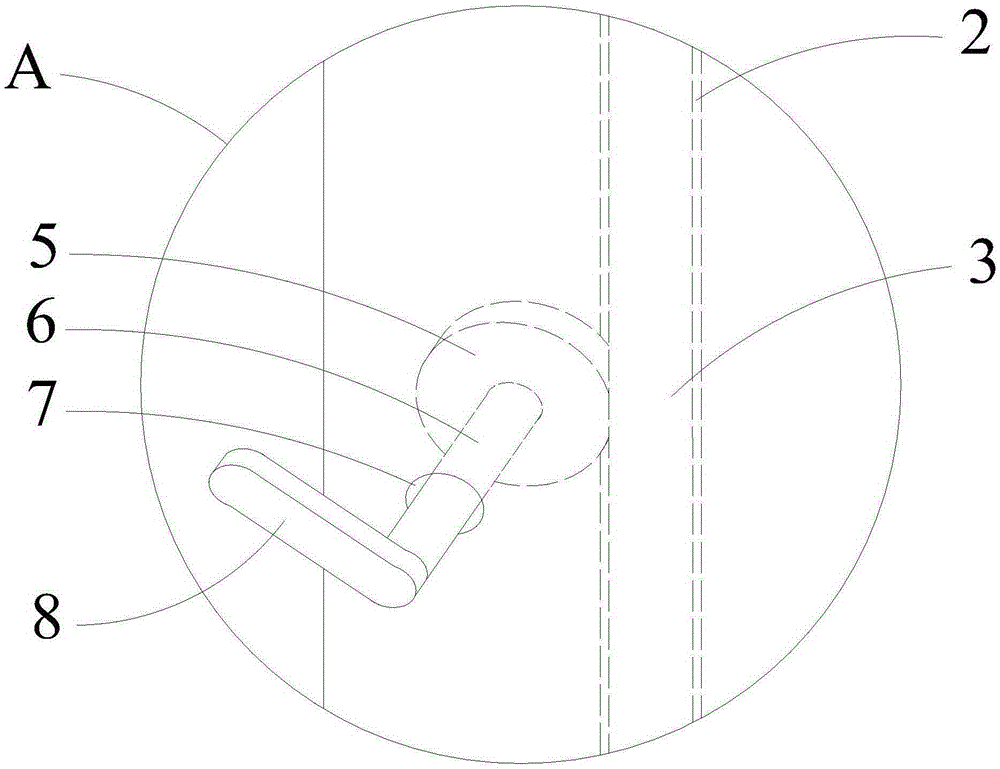

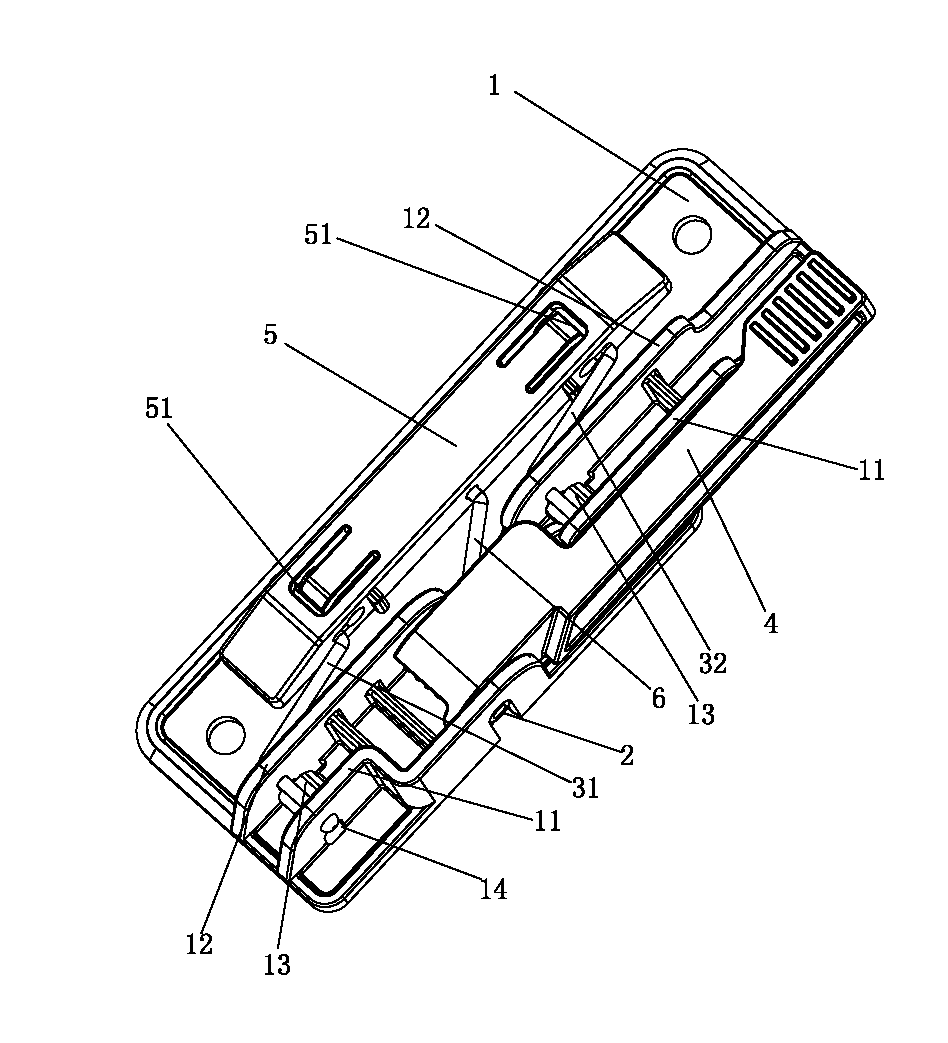

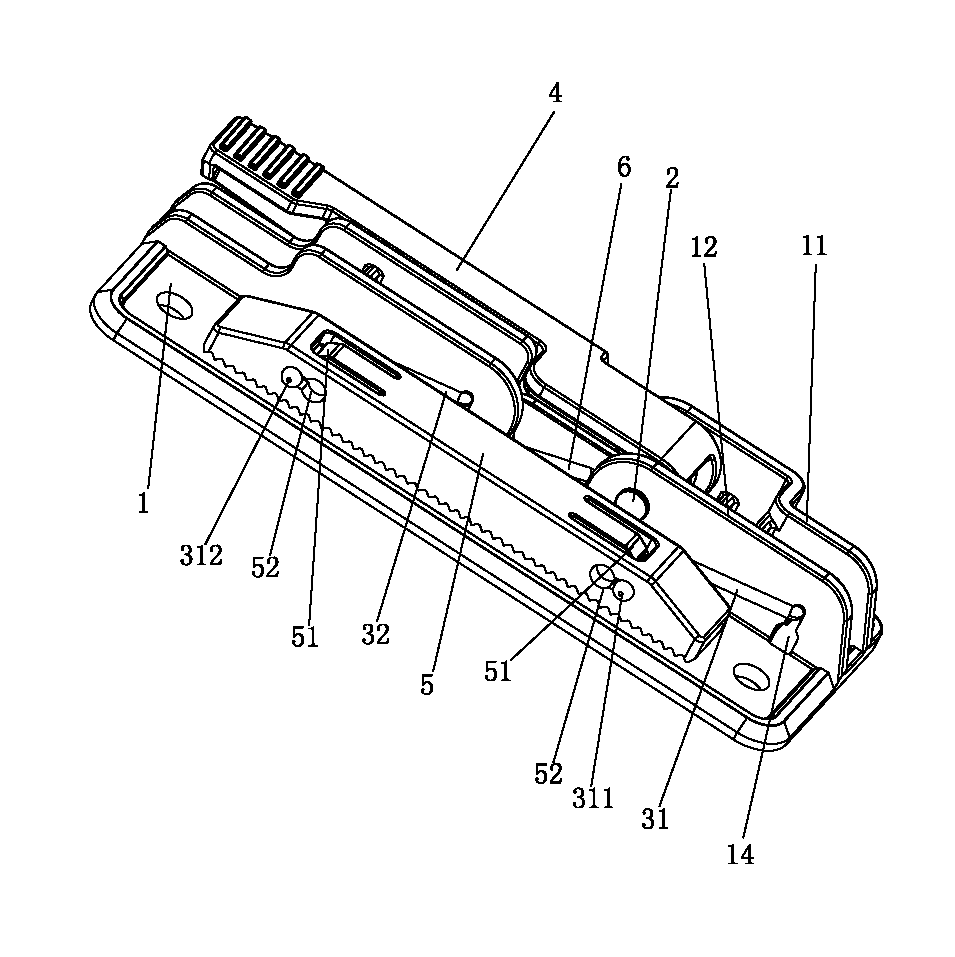

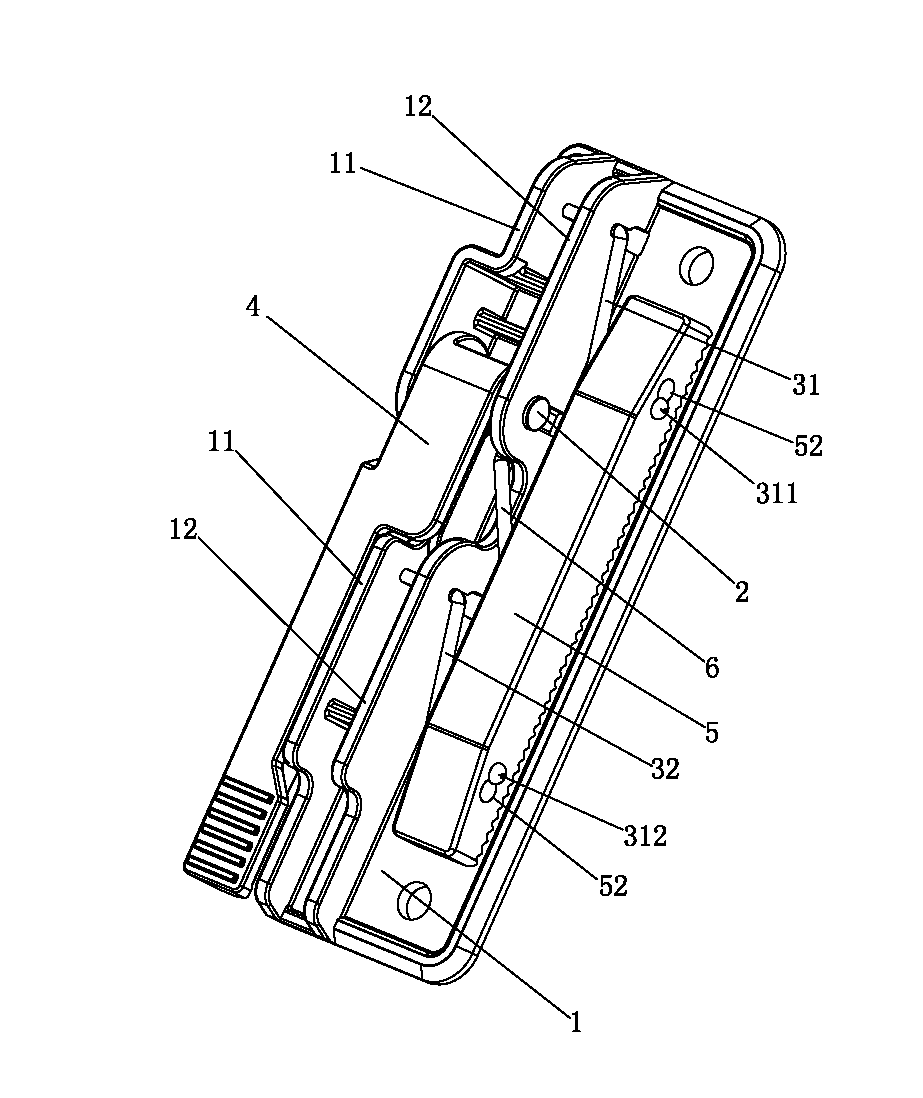

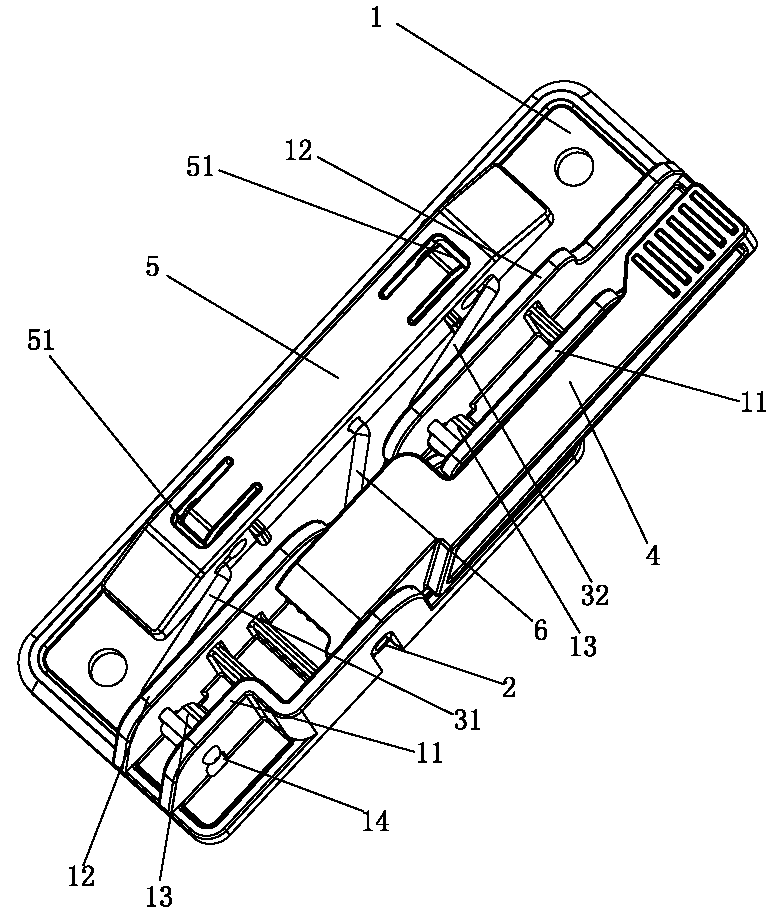

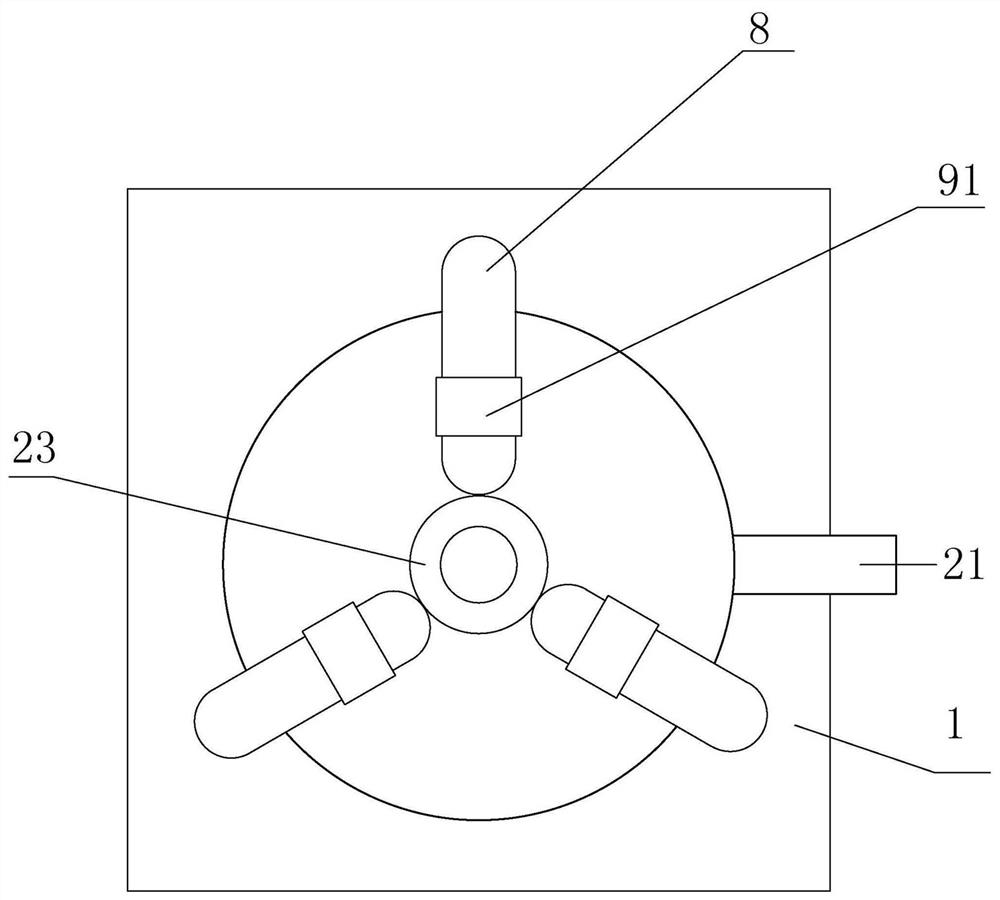

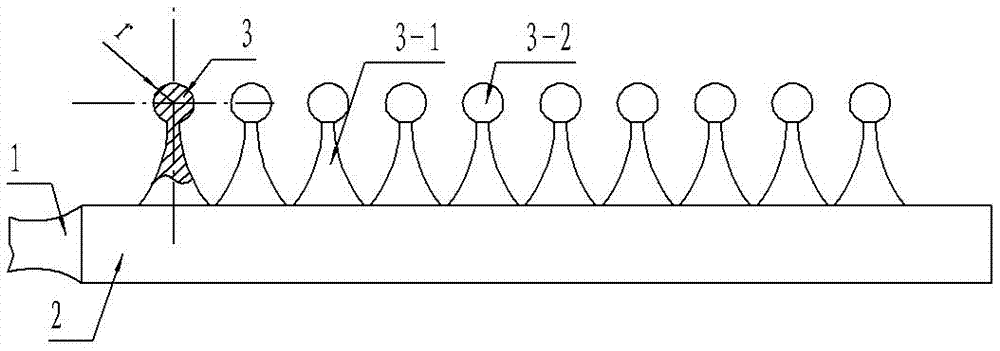

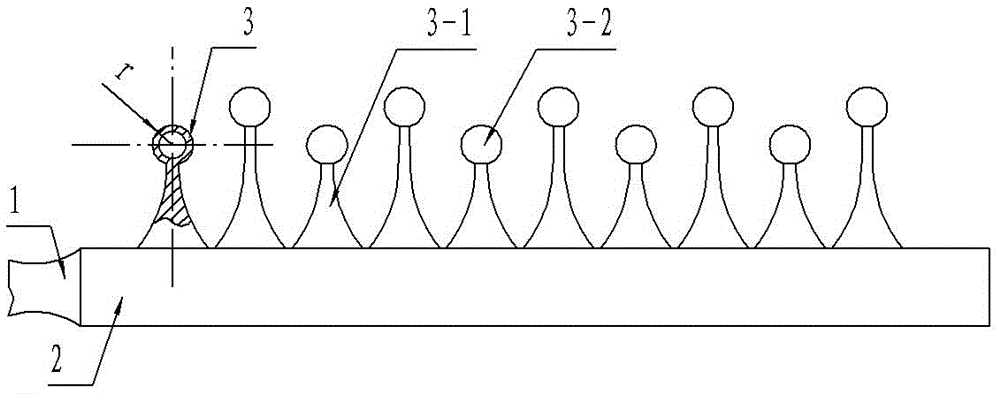

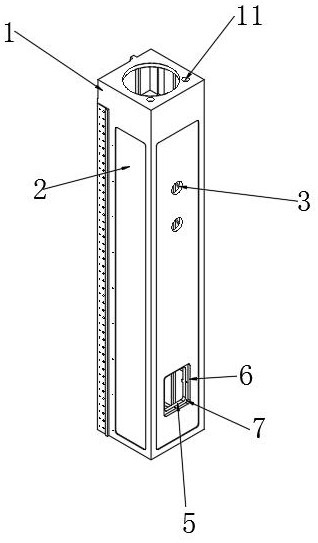

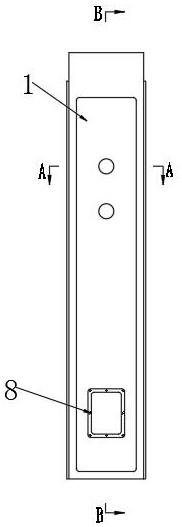

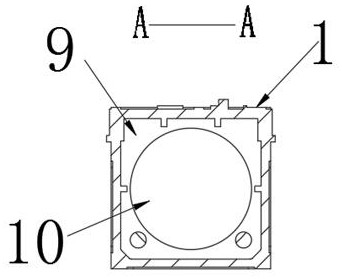

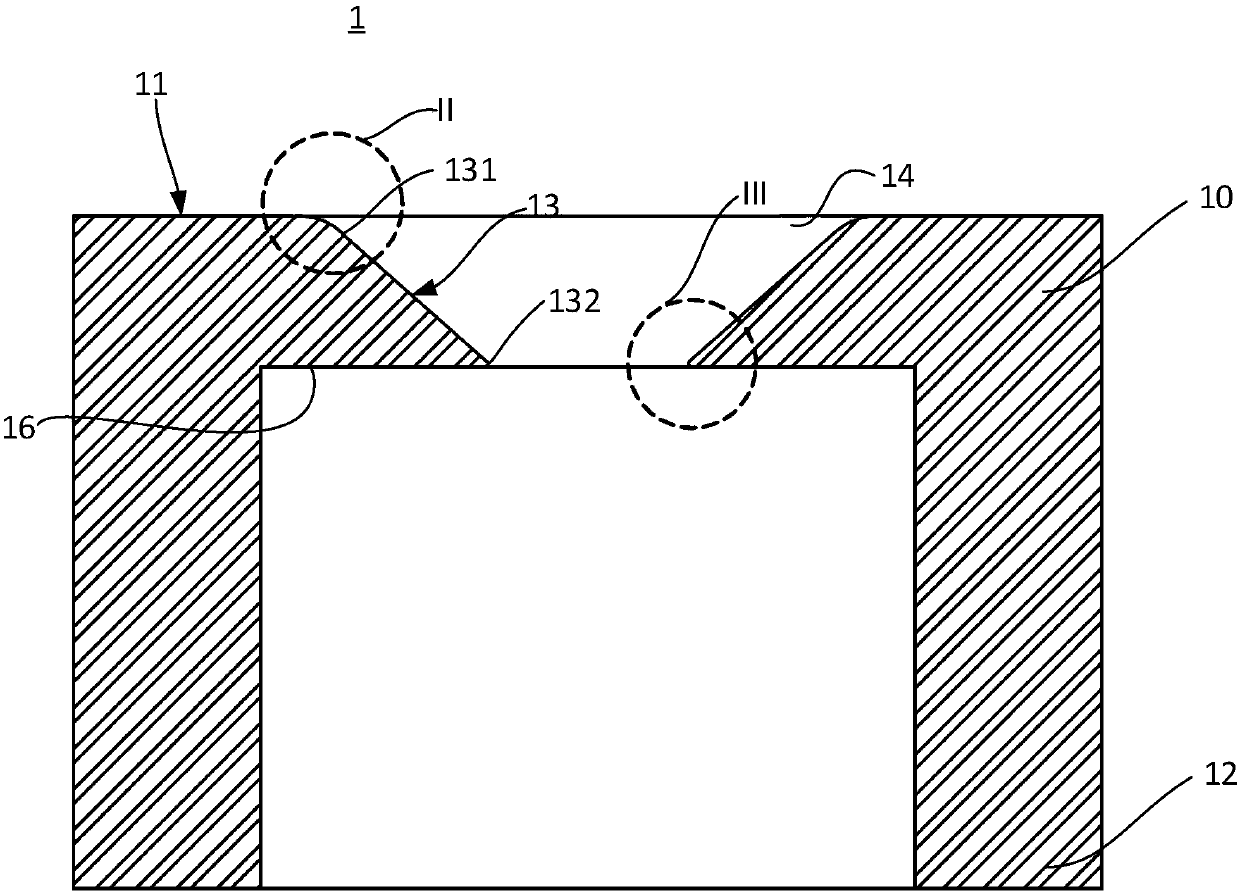

Finish-milling unit of mobile rail-milling car

ActiveCN104846707AEliminate edges and cornersAchieve remodelingRailway track constructionRotational axisMilling cutter

A finish-milling unit of a mobile rail-milling car comprises at least one tool rest (1); the tool rests (1) are connected with milling driving devices (2); the lower end of each tool rest (1) is provided with a milling head (3); the output end of each milling driving device is connected with a drive shaft of the corresponding milling head through a mechanical transmission device; one side of each tool rest (1) is further connected with a group of hydraulic vertical movement and positioning devices (4) and a group of electric horizontal movement and positioning devices (5); each group of hydraulic vertical movement and positioning devices (4) is connected with the corresponding electric horizontal movement and positioning devices (5); the electric horizontal movement and positioning devices (5) are used for positioning the horizontal positions of milling tools. The finish-milling unit has the advantages that a steel rail which is roughed can be finely dressed again, dressing effect is good, and operating efficiency is high; omission of the grinding method for secondary dressing of the steel rail leads to low environmental pollution; owing to the tool rests capable of rotating around their rotational axes, the tool rests and blades on the same are convenient to change.

Owner:CRCC HIGH TECH EQUIP CORP LTD +1

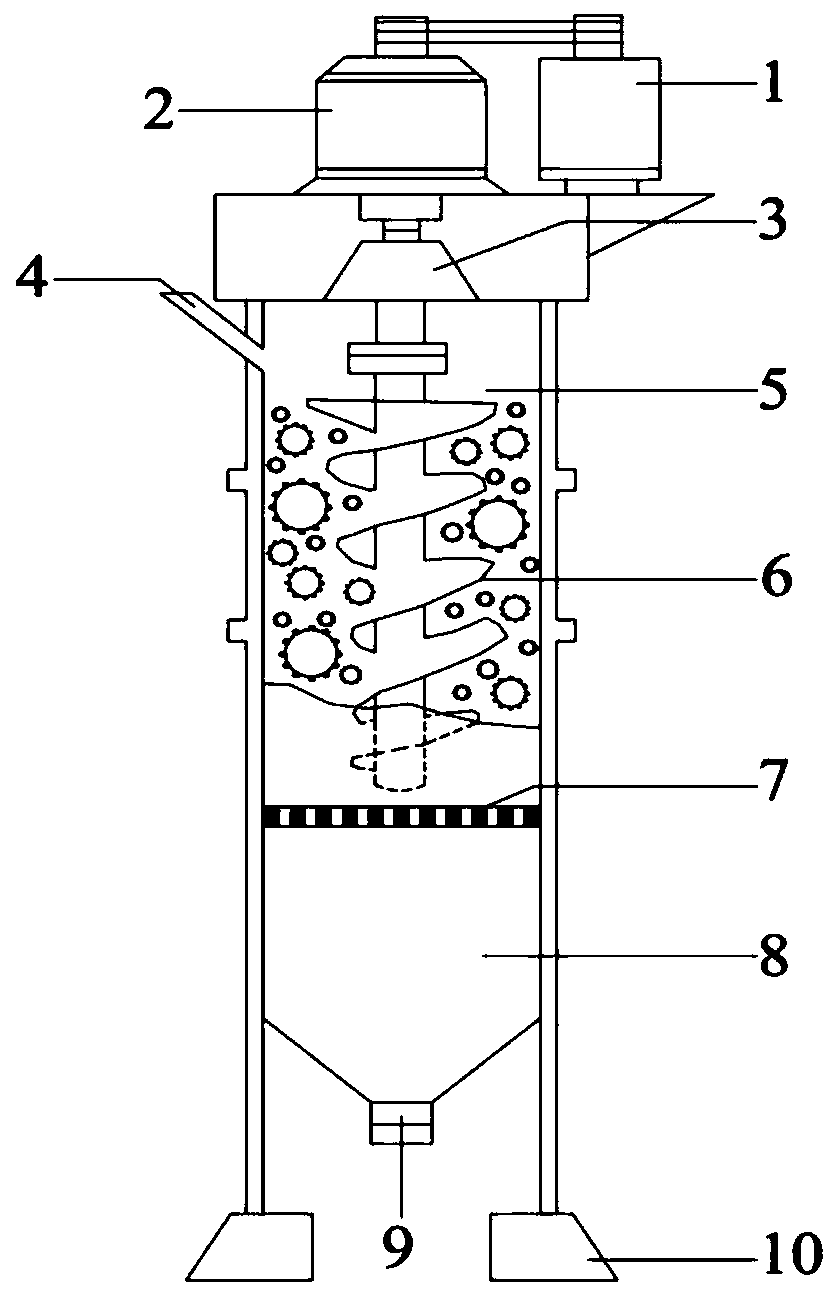

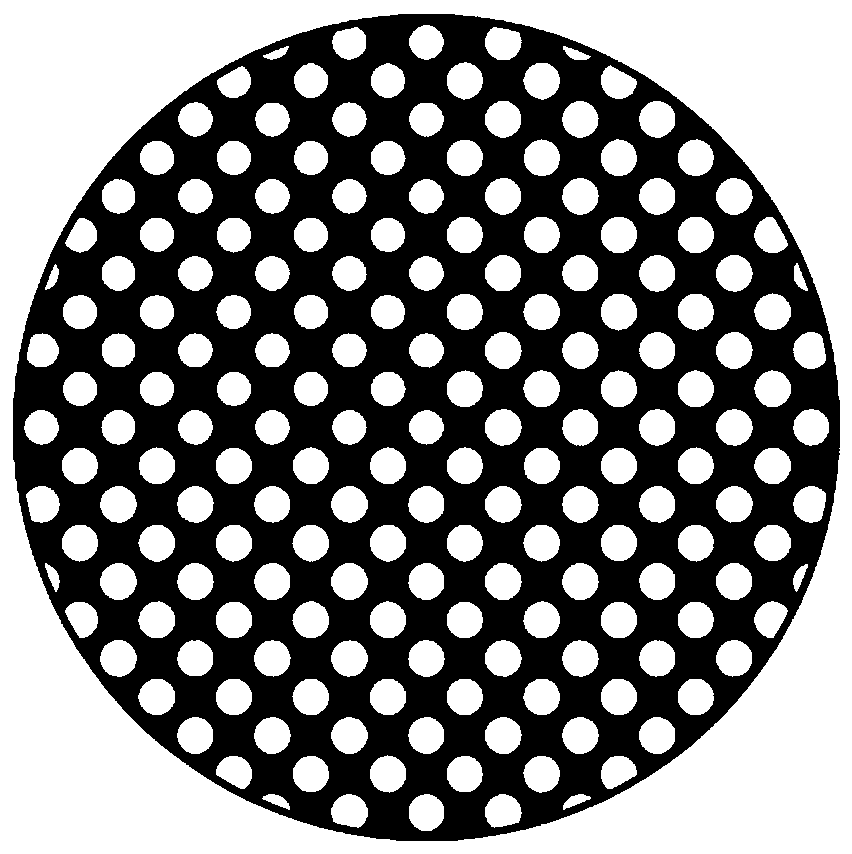

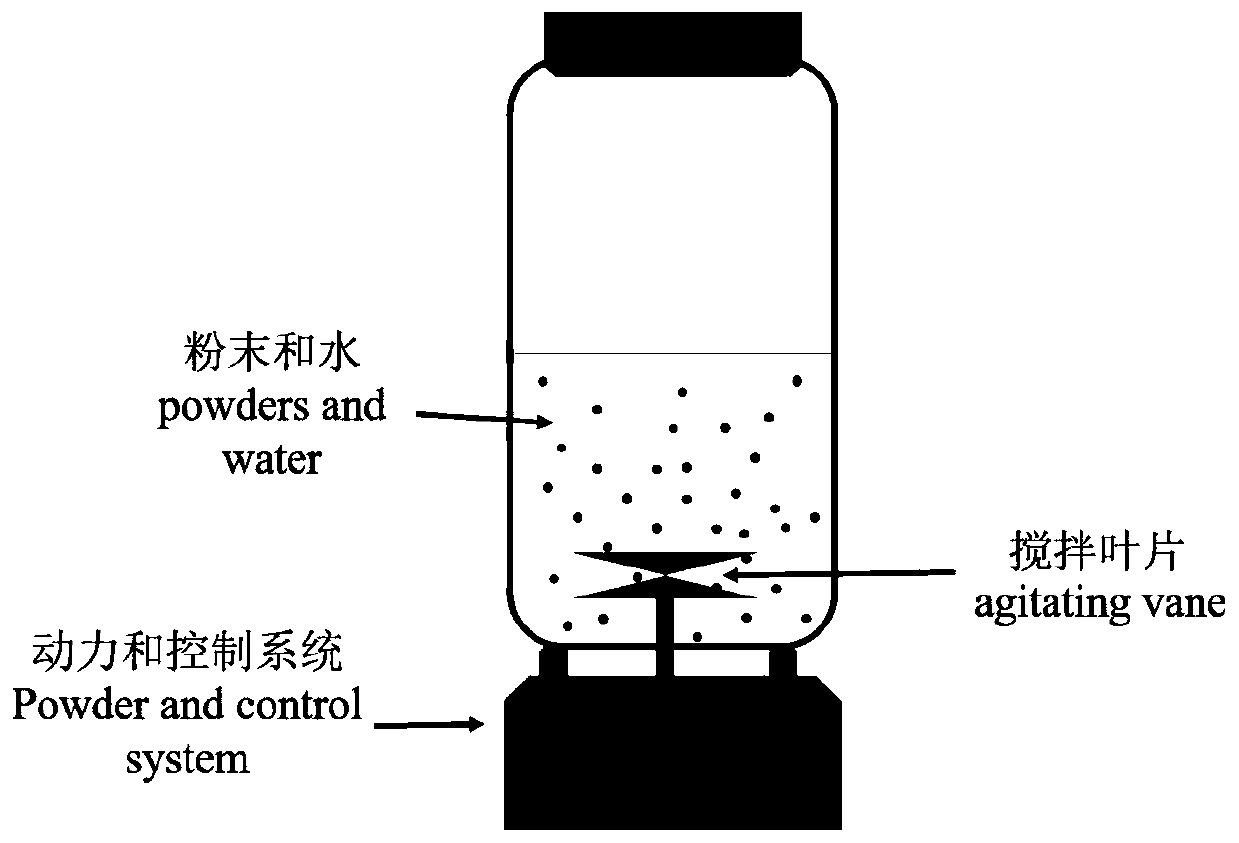

Particle shape modifying device for concrete or asphalt mixture aggregates

InactiveCN108500819AMaterial volume synchronizationRealize reciprocating continuous operationEdge grinding machinesSievingAsphaltEnergy consumption

The invention discloses a particle shape modifying device for concrete or asphalt mixture aggregates. The device comprises a material bin and a stirring device, wherein the material bin is divided into a particle shape modifying bin and a material collecting bin through a material separating plate; the stirring device is a spiral stirring device and is vertically arranged in the particle shape modifying bin; a plurality of metal grinding balls are arranged in the particle shape modifying bin; a feeding port is formed in the upper side part of the particle shape modifying bin; charging holes are uniformly distributed in the surface of the material separating plate; and a discharging port is formed in the bottom part of the material collecting bin. The device is simple in structure, convenient to mount and use, and low in energy consumption; the particle shape of the aggregates can be effectively improved, and edges can be removed; the aggregate modifying time can be controlled during use, so that the aggregates can be prevented from being damaged and broken; the device is matched with a screening machine and realizes continuous production work.

Owner:CHINA UNIV OF MINING & TECH

Intelligent household electric curtain

InactiveCN108294591AMeet different lighting needsRealize left and right movement and opening and closingCurtain accessoriesEngineering

Owner:郑州神盾智能科技有限公司

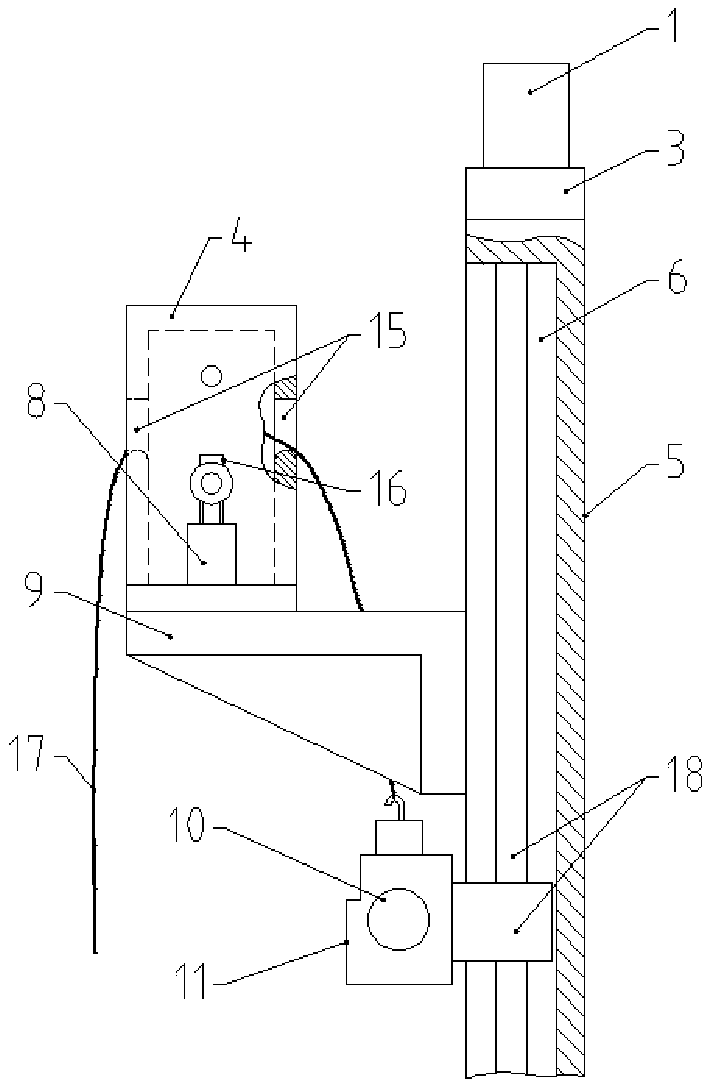

Liquid-solid fluidization shaping method for low-cost titanium powder for 3D printing

PendingCN110560682AImprove smoothnessHigh sphericityAdditive manufacturing apparatusTransportation and packagingTitanium powderImpurity

The invention provides a liquid-solid fluidization shaping method for low-cost titanium powder for 3D printing, and belongs to the technical field of powder metallurgy and preparation. The method comprises the following steps: using hydrogenated dehydrogenated titanium powder as a raw material, adding deionized water and titanium powder to mix, and stirring the deionized water to make the titaniumpowder move in a fluid state in the deionized water at a fluidization speed of 3,000 rpm, wherein the liquid-solid fluidization time is 1.5-15 min. In the process of liquid-solid fluidization, irregular titanium powder collides and rubs against each other to achieve the purposes of removing irregular powder edges and improving the smoothness of the powder, so that the fluidity of the powder is improved, and the requirements of powder metallurgy processes such as 3D printing and injection molding are achieved. The method has the advantages of low cost, simple equipment and technology, high efficiency, controllable impurity content, and obvious improvement effect of powder liquidity.

Owner:UNIV OF SCI & TECH BEIJING

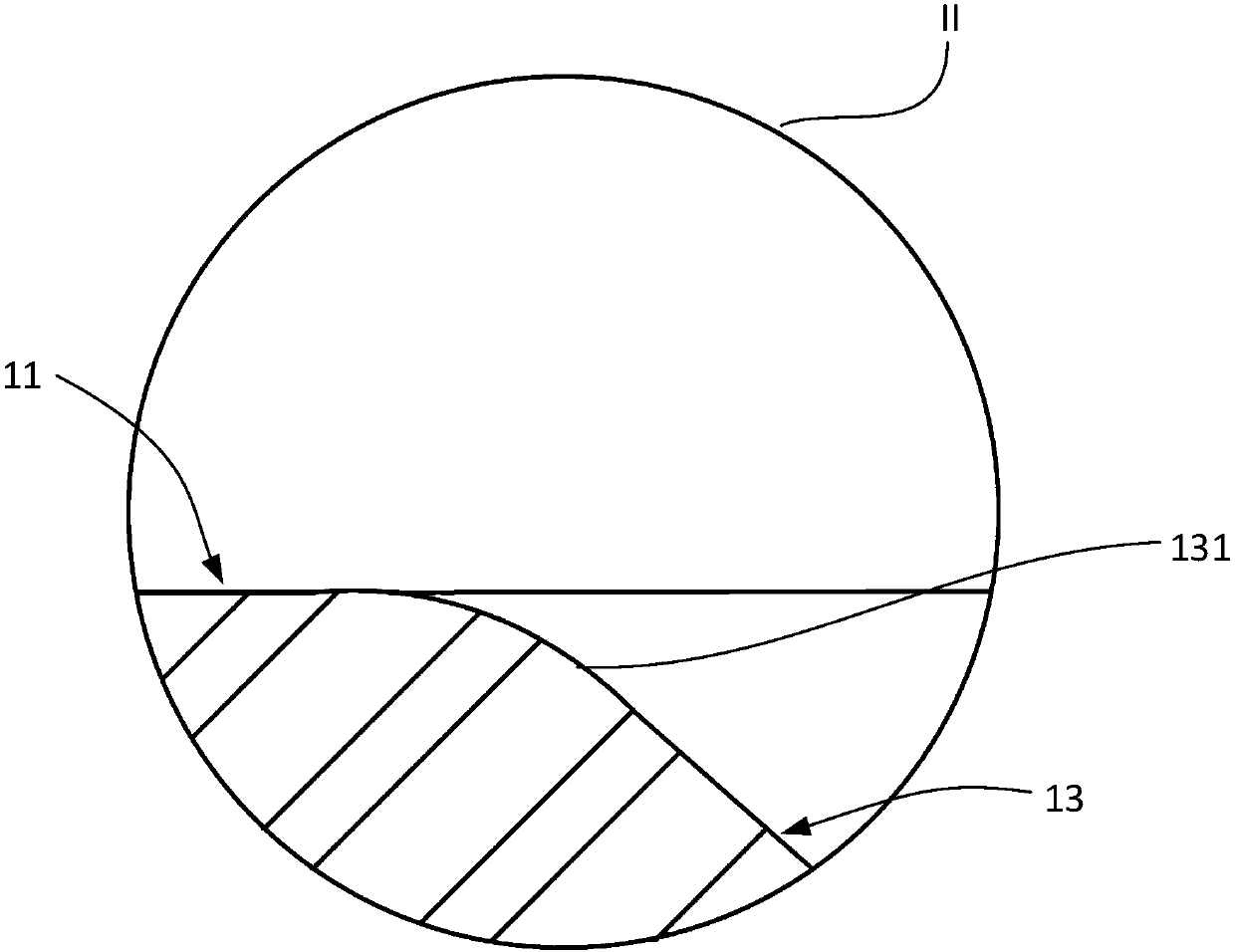

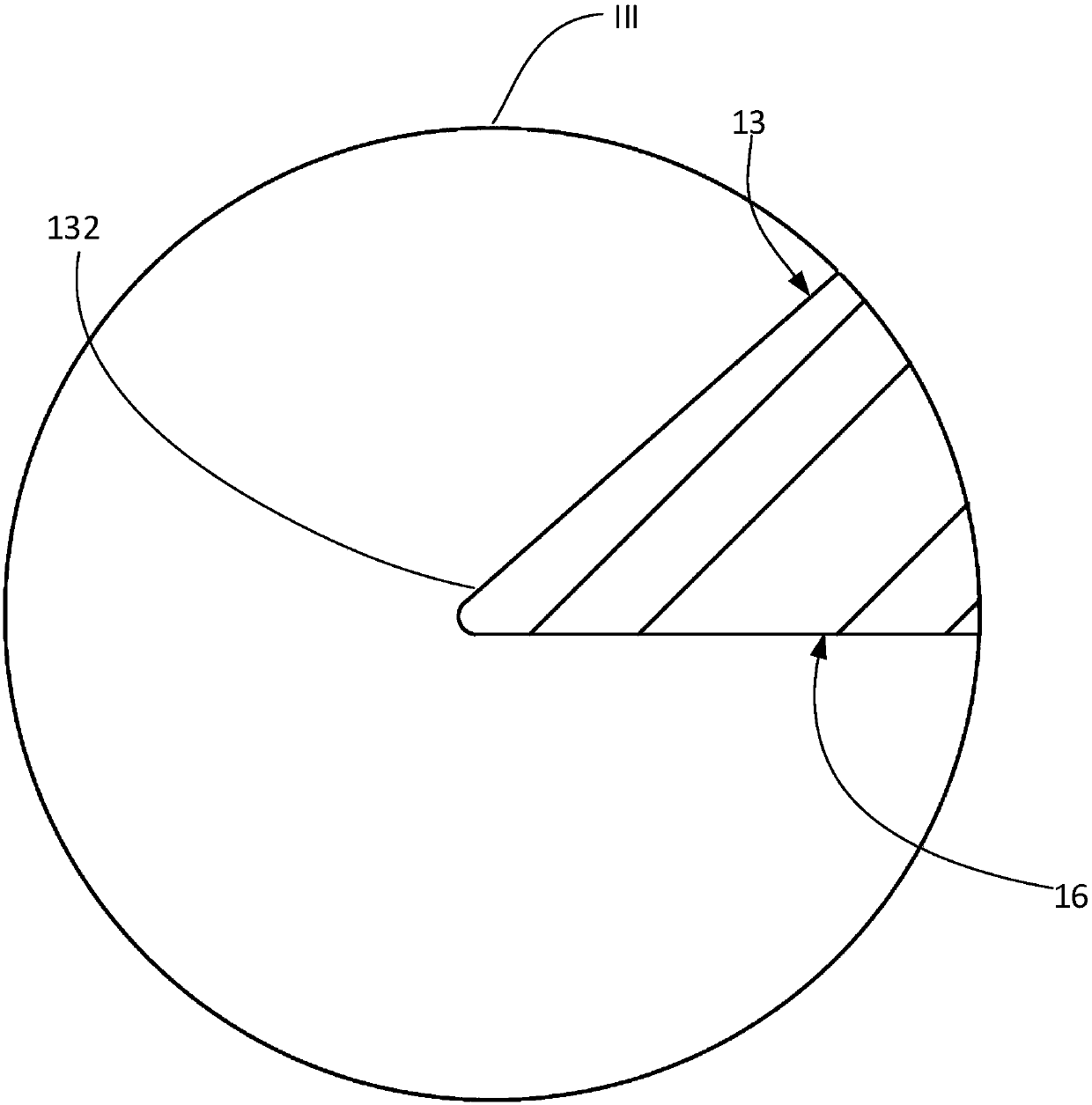

Heat supply wear-resistant ball valve

ActiveCN112066027AAvoid scratchesReduce wearPlug valvesOperating means/releasing devices for valvesEngineeringVALVE PORT

The invention discloses a heat supply wear-resistant ball valve. The heat supply wear-resistant ball valve comprises a valve body, a valve cover, a ball body, an outer valve rod, an inner valve rod, avalve clack assembly and a second valve clack assembly, wherein the outer valve rod is fixedly connected with the ball body, the inner valve rod is in transmission connection with the first valve clack assembly and the second valve clack assembly, the outer surfaces of the first valve clack and the second valve clack are spherical surfaces, the diameter of the spherical surfaces is the same as the diameter of the outer surface of the ball body, and when the first valve clack and the second valve clack are in a completely closed state, the first valve clack and the second valve clack form a smooth spherical surface with the outer surface of the ball body, and when the first valve clack and the second valve clack are retracted into an inner cavity of the ball body, the fluid flow can be adjusted. According to the heat supply wear-resistant ball valve, when the two valve clacks are in a closed state, the outer surfaces of the valve clacks coincide with the outer surface of the ball body,so that a smooth curved surface is formed, edges and corners existing at a through hole of the ball body are eliminated, the ball body is prevented from scraping a valve seat sealing ring in the rotating process, the abrasion of the valve seat sealing ring is reduced, in the moving process of the valve clacks, the gap between the inner cavity wall of the ball body and the valve clacks is gradually increased, and fine adjustment of the valve flow is realized.

Owner:TEX TECH GRP LISHUI FLUID EQUIP CO LTD

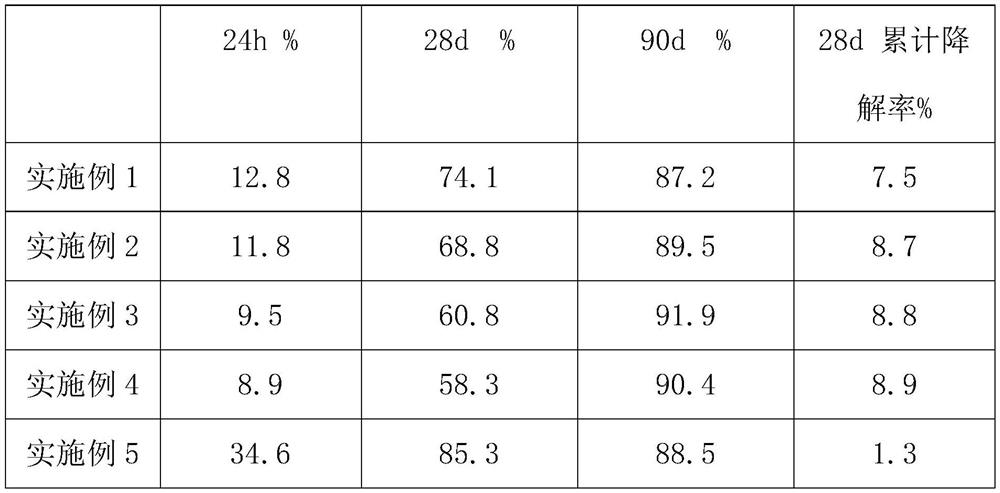

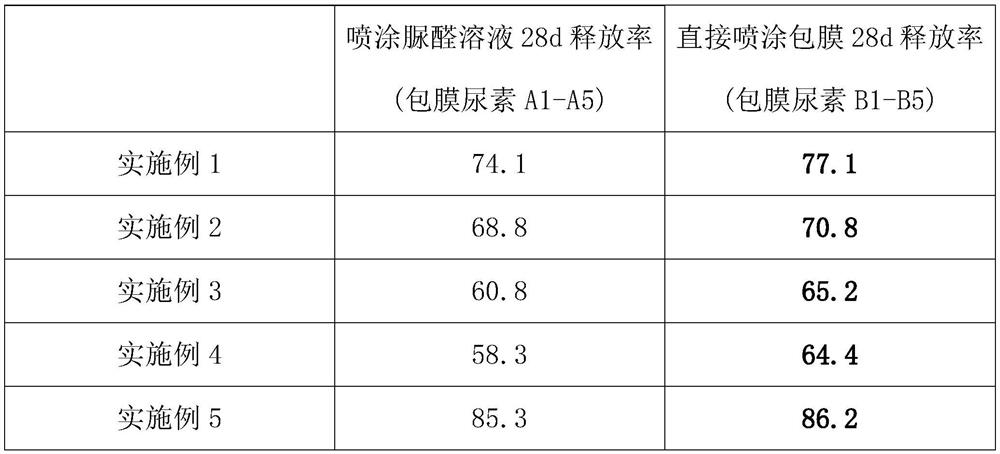

Method for preparing biodegradable coating material by ammonolysis modified vegetable oil and application of biodegradable coating material

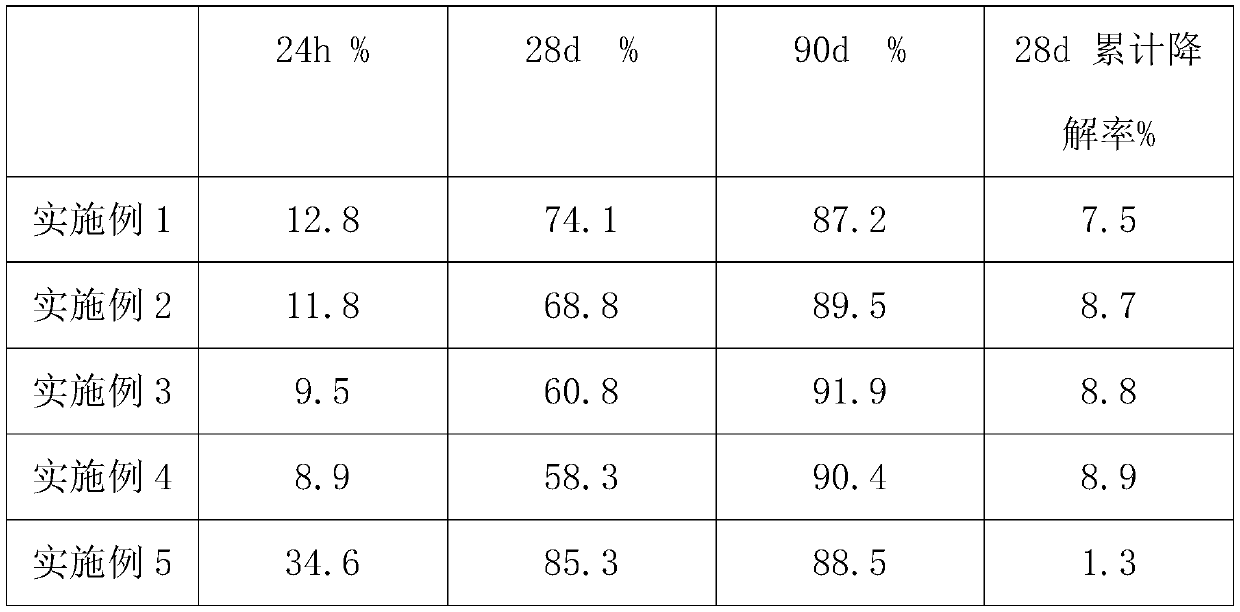

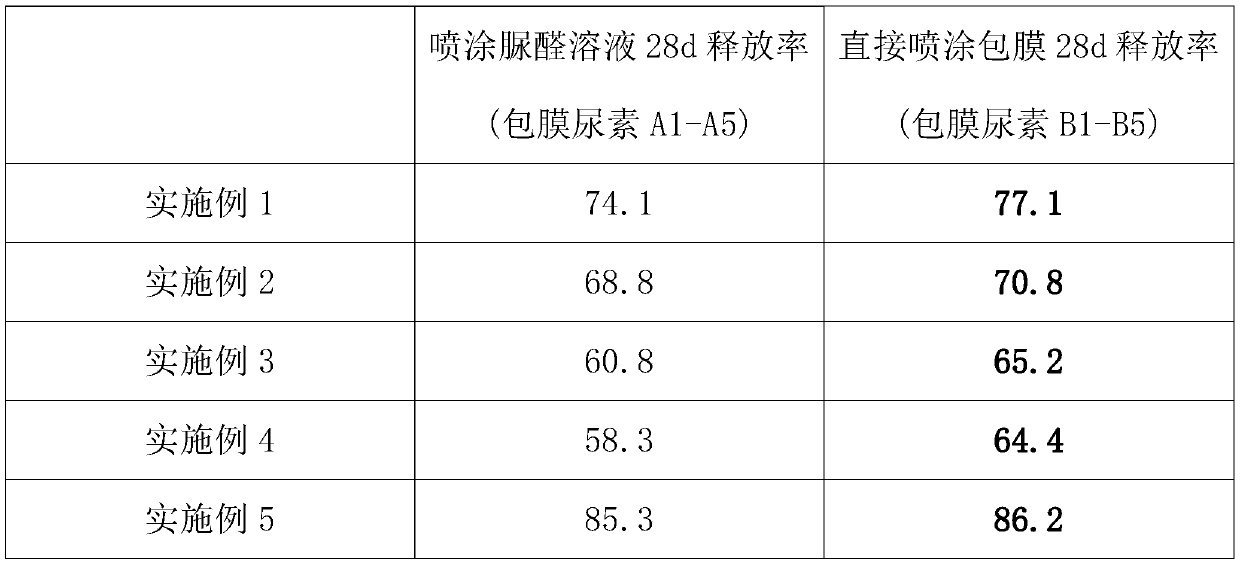

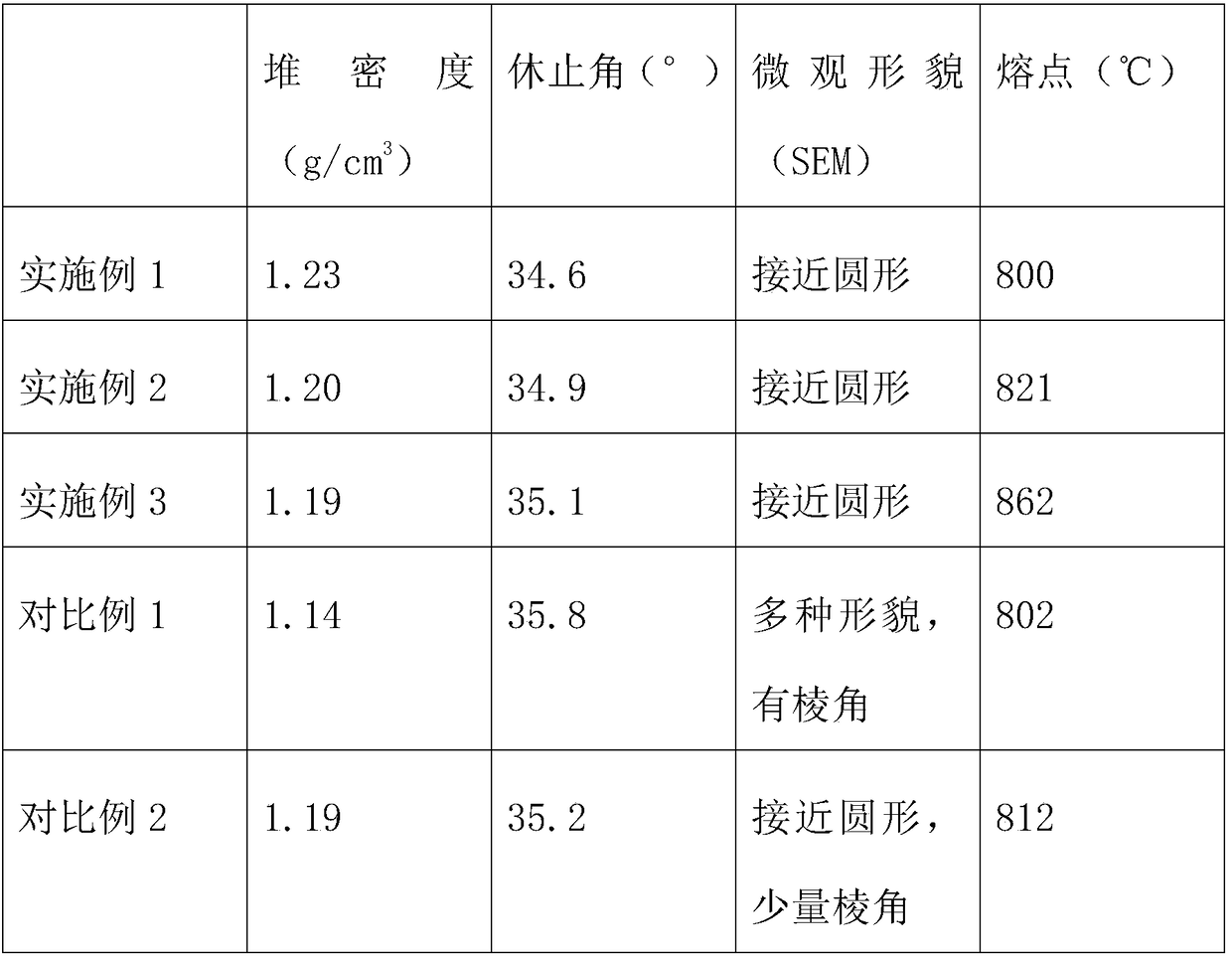

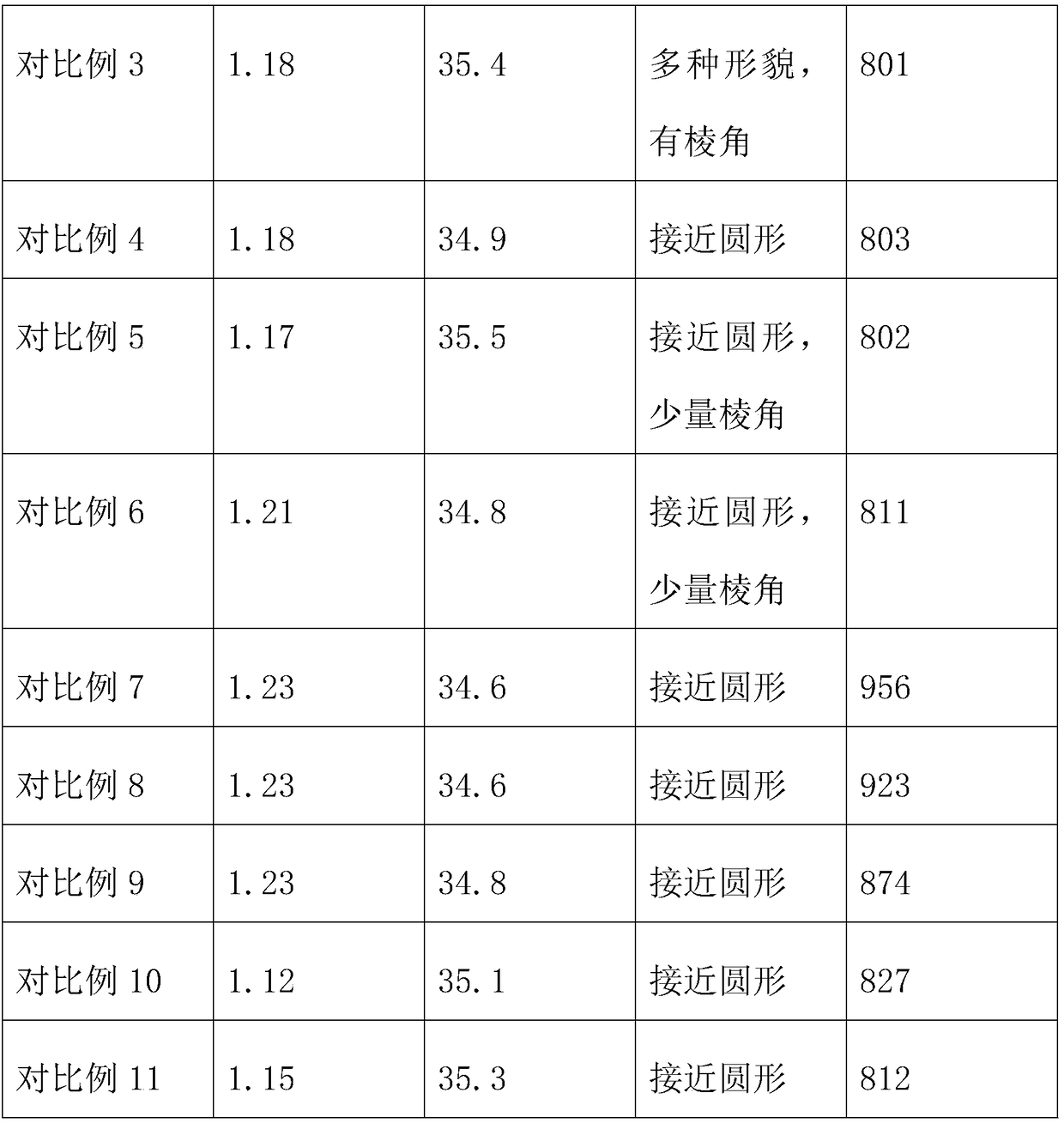

ActiveCN110437415APrevent instantEliminates corners and surface crystallizationFertilizer mixturesN-methyldiethanolamineFertilizer

The invention discloses a method for preparing a degradable coating material by an ammonolysis modified vegetable oil and an application of the biodegradable coating material. The method comprises thefollowing steps: firstly preparing the modified vegetable oil by using an ammonolysis method, respectively adding an isocyanate and a polyoxypropylene diol into the modified vegetable oil, adding a chain extender and a catalyst for carrying out a reaction, and finally adding N-methyldiethanolamine for carrying out a reaction to obtain the degradable coating material. A urea-formaldehyde solutionis sprayed on the surface of fertilizer particles during a preheating stage of the coating. The prepared coating material has relatively good micro-porous air-permeability, is relatively convenient for controlling a release rate of a fertilizer, and has relatively good degradable function. At the same time, the surface of the fertilizer particles is modified before coating to eliminate surface crystallization and angularity of the fertilizer particles to make the surface be relatively smooth and further enhance coating effects.

Owner:WUZHOUFENG AGRI SCI & TECH

Quartz glass powder and preparation method thereof

InactiveCN108929041AReduce generationImprove stabilityGlass furnace apparatusGlass shaping apparatusPolyethylene glycolSilica gel

The invention provides a quartz glass powder and a preparation method thereof. The quartz glass powder comprises silicon dioxide powder, aluminum oxide, red lead, boric acid, barium oxide, bismuth oxide, titanium dioxide, tellurium dioxide, zincate, manganese dioxide, sodium oleate, polyglycol stearate and yttrium oxide. A preparation method of the silicon dioxide powder comprises the steps: removing impurities in quartz ores by using a color sorter, and carrying out wet ball milling, ore pulp is composed of quartz powder and a water solution, and the water solution contains an anionic surfactant and sodium silicate; carrying out drying under the condition of 300-500 DEG C for 2-4 h after ball milling, removing iron under strong magnetism, then, entering an acid pickling process, drying the quartz powder with acid pickling impurity removed impurities under the condition of 100-150 DEG C, and carrying out uniform dry mixing on the quartz powder and micropowder silica gel according to aproportion of 10:(0.5-1).

Owner:RIHONG SEMICONUCTING MATERIAL NANTONG CO LTD

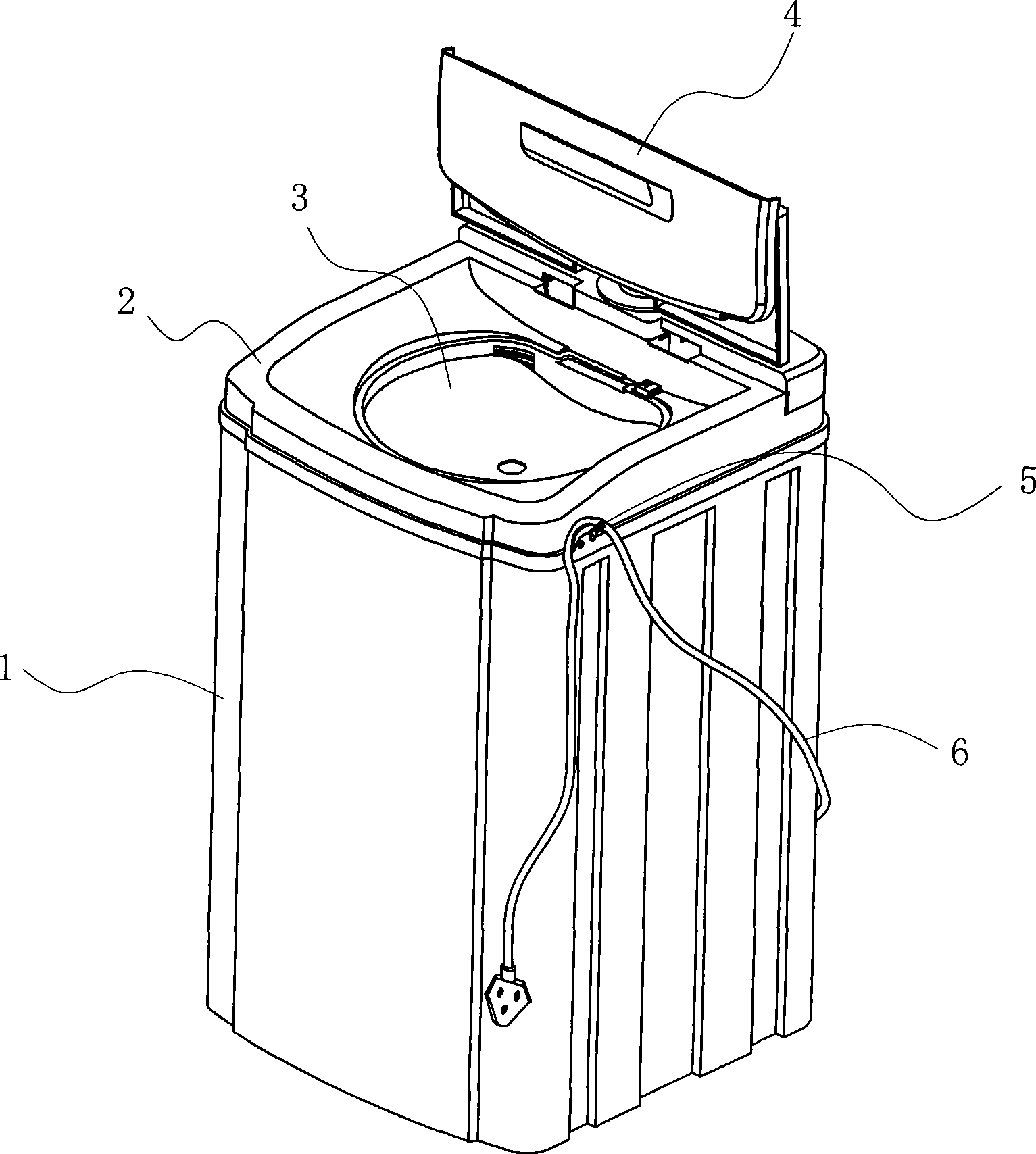

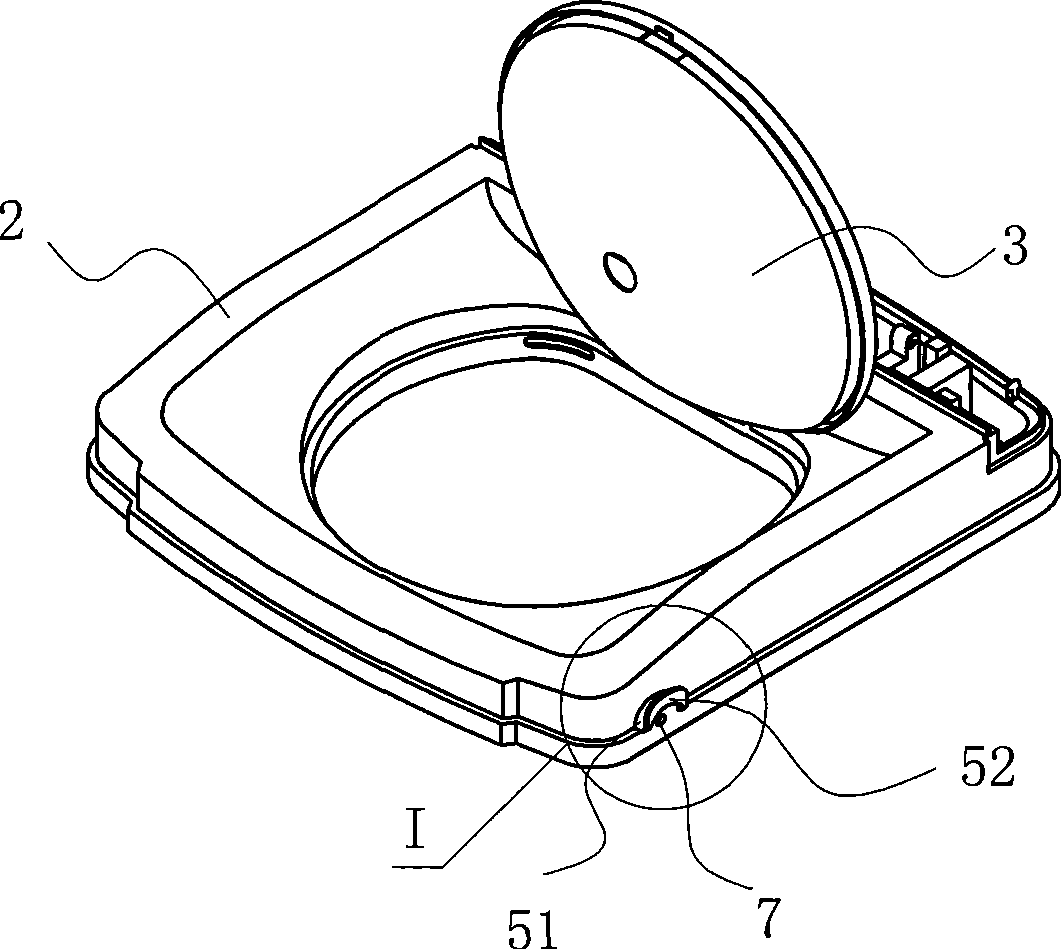

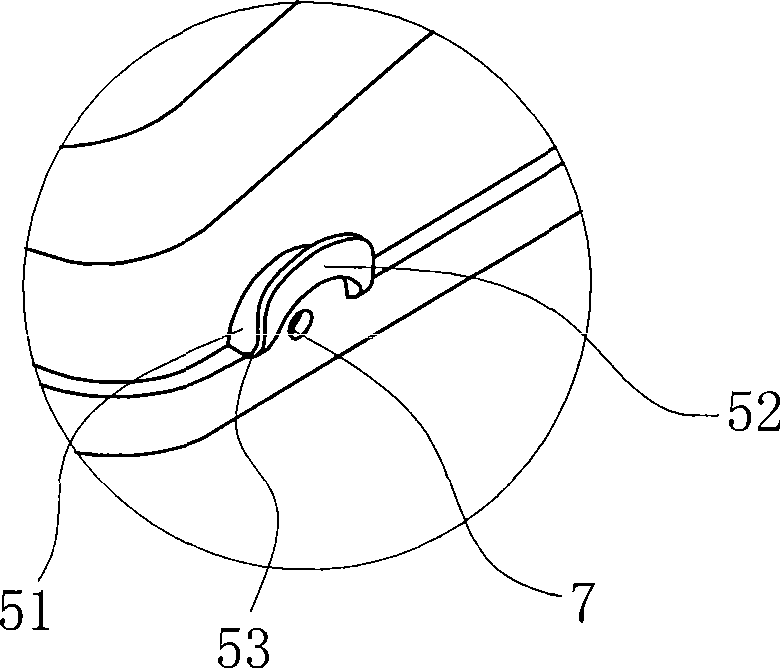

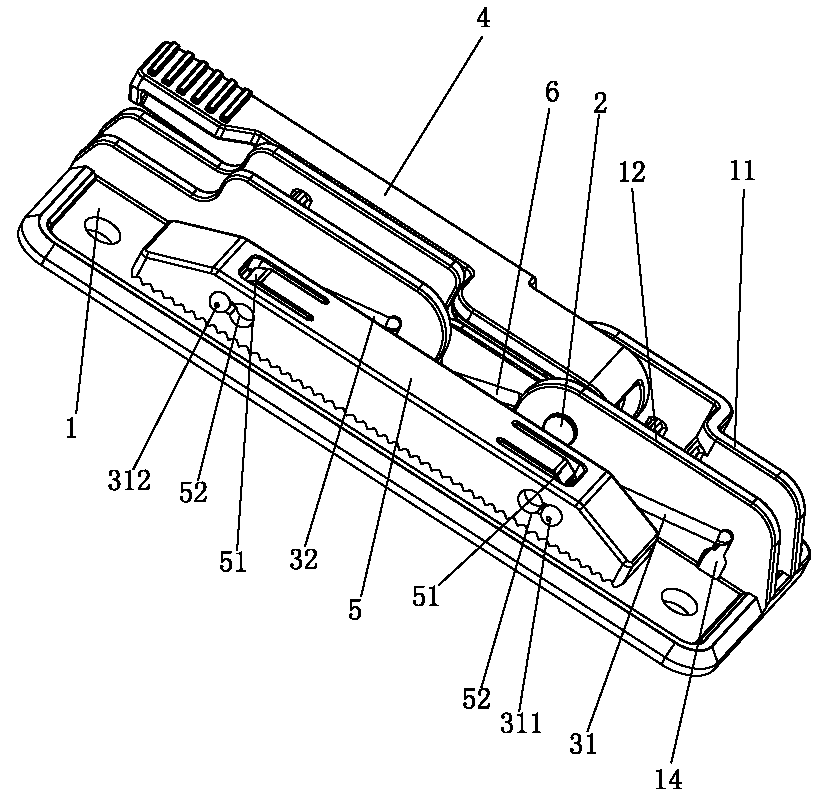

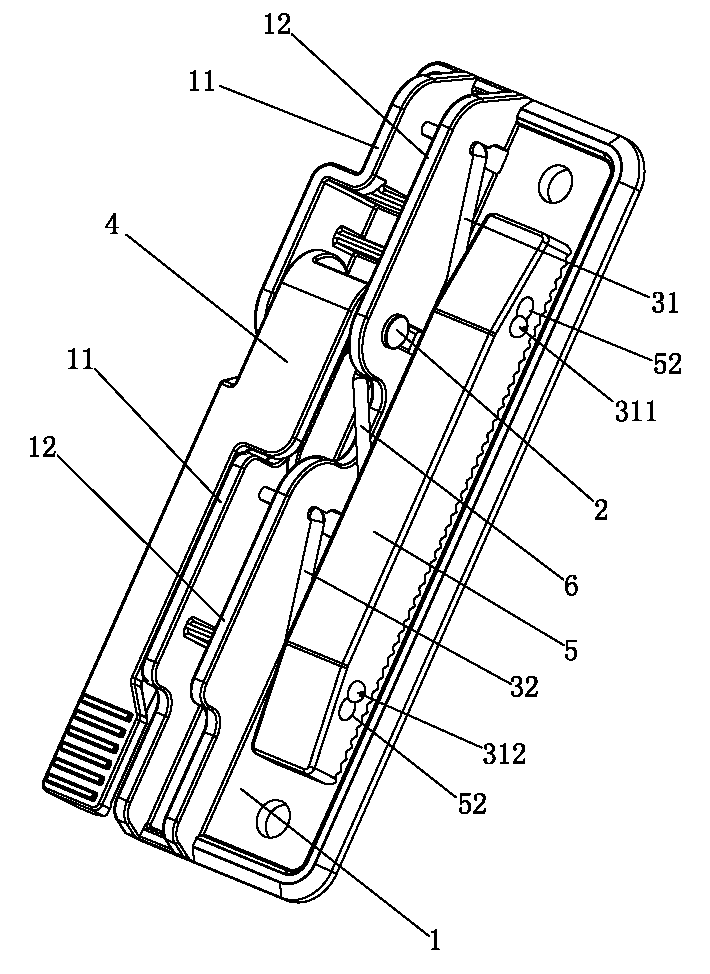

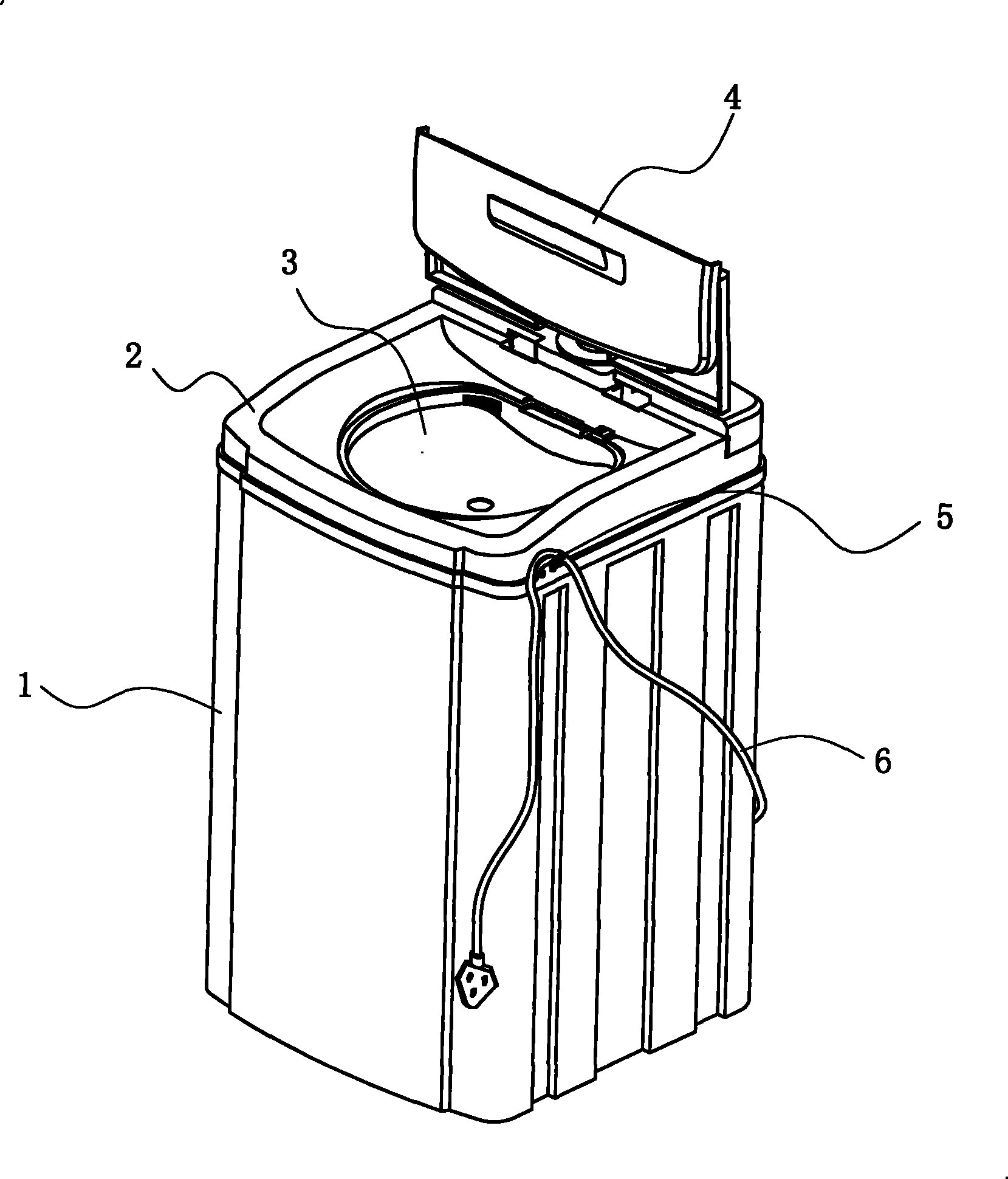

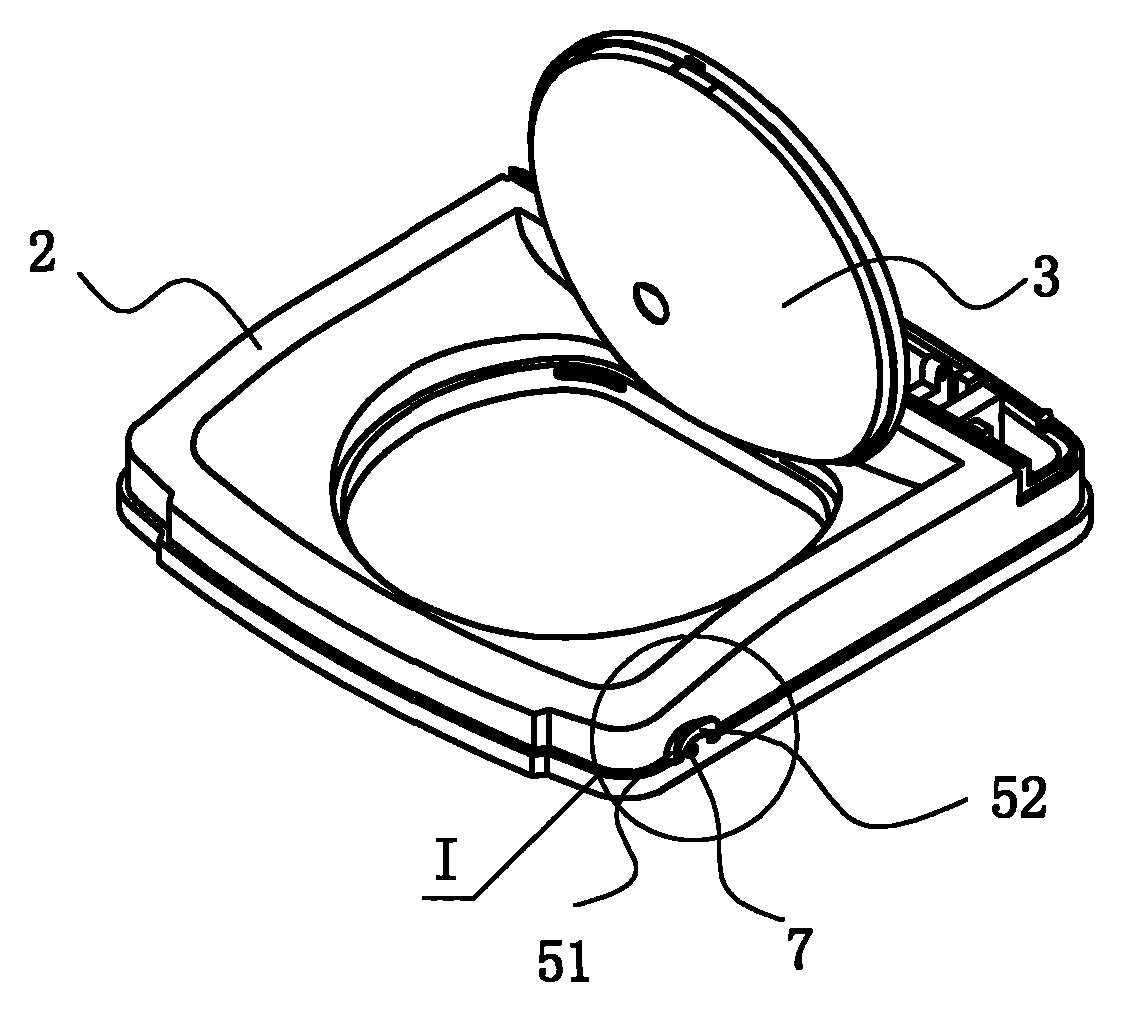

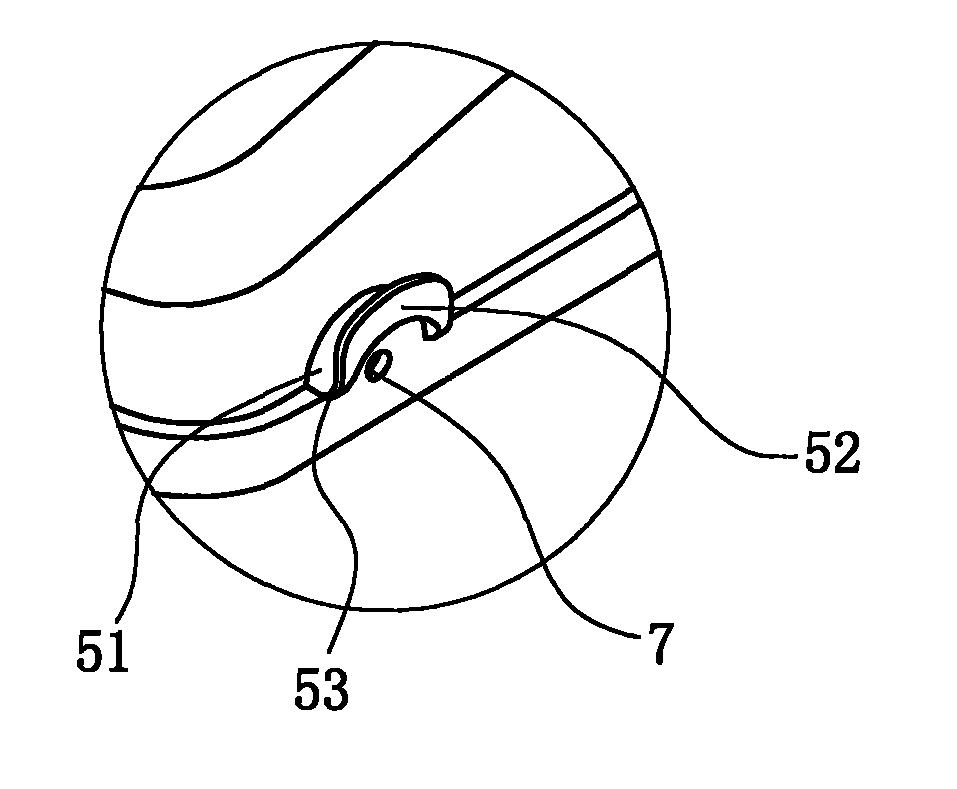

Electric power cord accommodation structure for electric appliance

InactiveCN101478137AReduce stress concentrationAchieve strengthCable arrangements between relatively-moving partsHand ironStress concentrationEngineering

The invention relates to a power line collection structure of electric apparatus, in particular to a hanging hook arranged on the side surface of the machine body of electric apparatus and provided with an L-shaped cross section. A connecting piece is arranged on the side edge where the hanging hook is connected with the machine body, and a limiting piece is arranged on the other side edge of the hanging hook. The hanging hook is characterized in that the connecting piece is designed into an arc-shaped piece with an outward convex upper surface, the arc-shaped edges at the two sides of the connecting piece are respective connected with the machine body, and circular arc transition structures are respectively arranged at the edge parts at the two sides of the connecting point between the connecting piece and the limiting piece. After the structure is adopted, the connecting part among the hanging hook, the machine body and the limiting piece form an arc-shaped structure, when the hanging hook is applied with force, the force disperses along the arc-shaped structure, so that the problem of stress concentration of the traditional hanging hook is solved, the connection between the hanging hook and the machine body is firmer, meanwhile, the edge angle of the edge is better eliminated, and when the power line is arranged on the hanging hook, the damage to the power line is avoided; and in addition, the hanging hook is skillfully arranged above the connecting screw, thereby playing the role of blocking the screw out, and the screw is avoided from being invaded by water to prevent the screw from rusting.

Owner:胡杰波

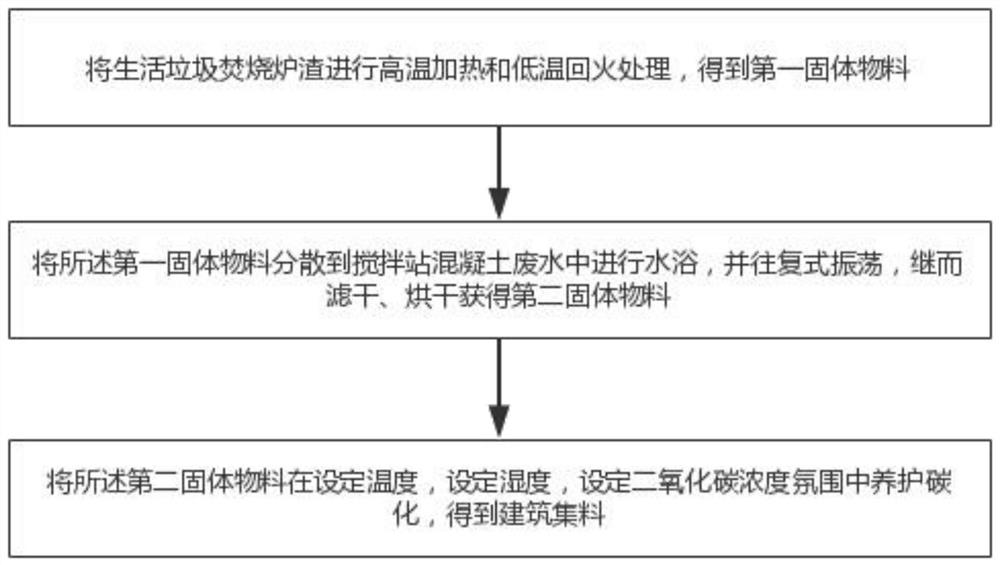

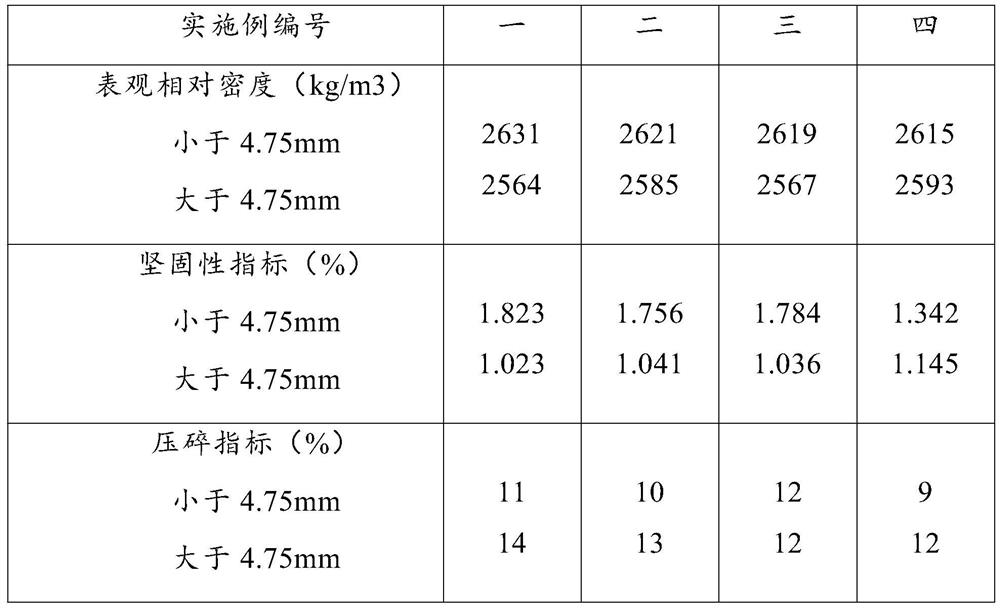

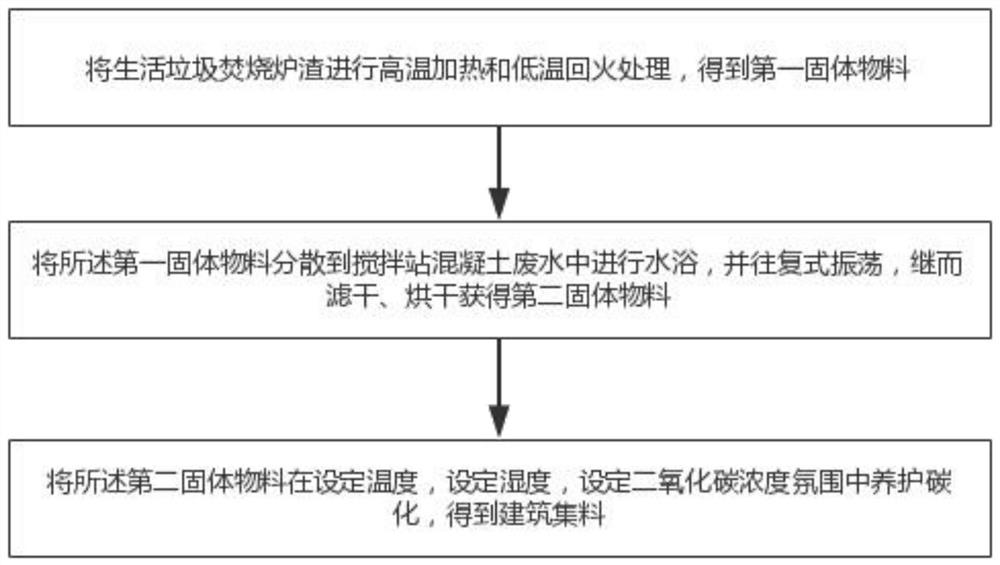

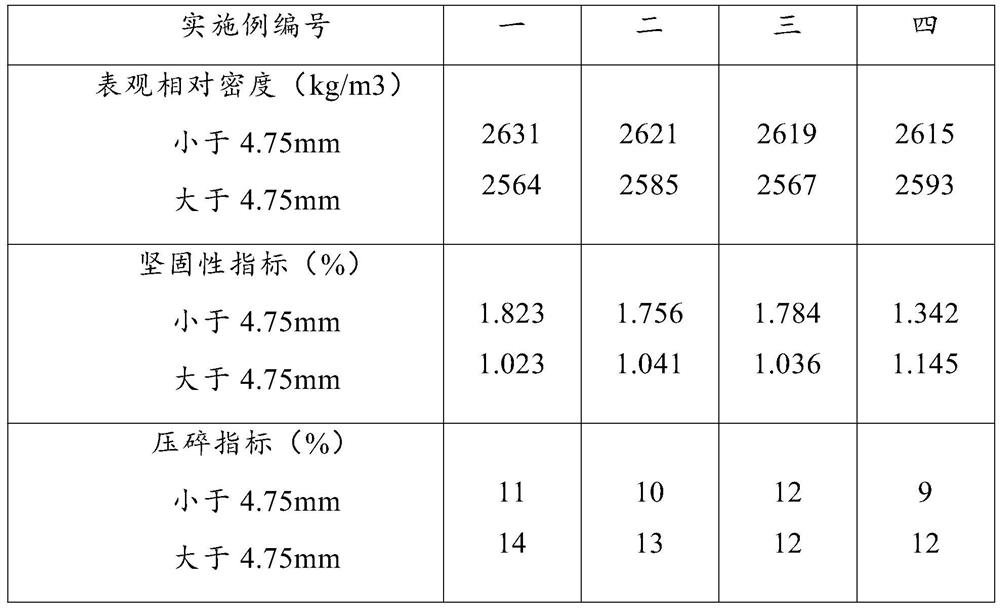

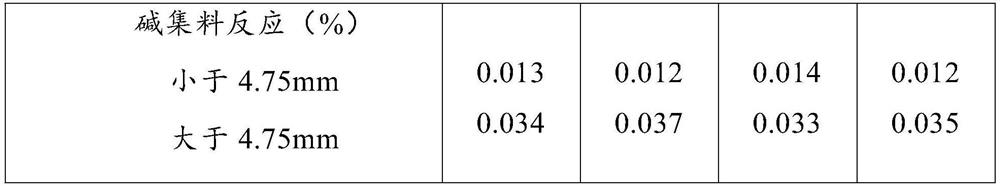

A method for preparing building aggregates with domestic waste incineration slag

The invention belongs to the technical field of solid waste resource utilization and waste water treatment, and discloses a method for preparing building aggregates from domestic waste incineration slag, which comprises: heating the domestic waste incineration slag at high temperature and low temperature tempering to obtain the first solid material; disperse the first solid material into the concrete waste water of the mixing station for a water bath, vibrate reciprocally, then filter and dry to obtain a second solid material; set the second solid material at a set temperature, set Set humidity, set CO 2 Carbonized curing in a concentrated atmosphere to obtain building aggregates. The method for preparing building aggregates from domestic waste incineration slag provided by the invention can efficiently recover and reuse domestic waste incineration slag, concrete waste water from mixing station and greenhouse gas CO 2 , It also uses the unique physical and chemical properties of waste to prepare new high-quality building aggregates through modification treatment, reducing the risk of durability defects and structural defects.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +1

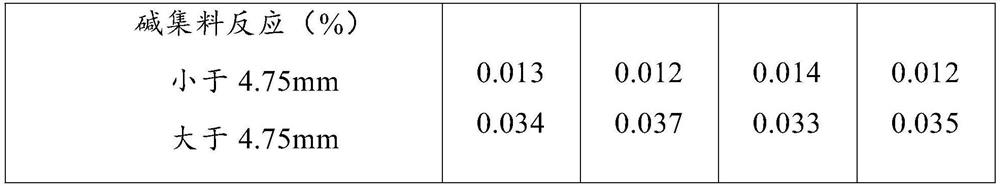

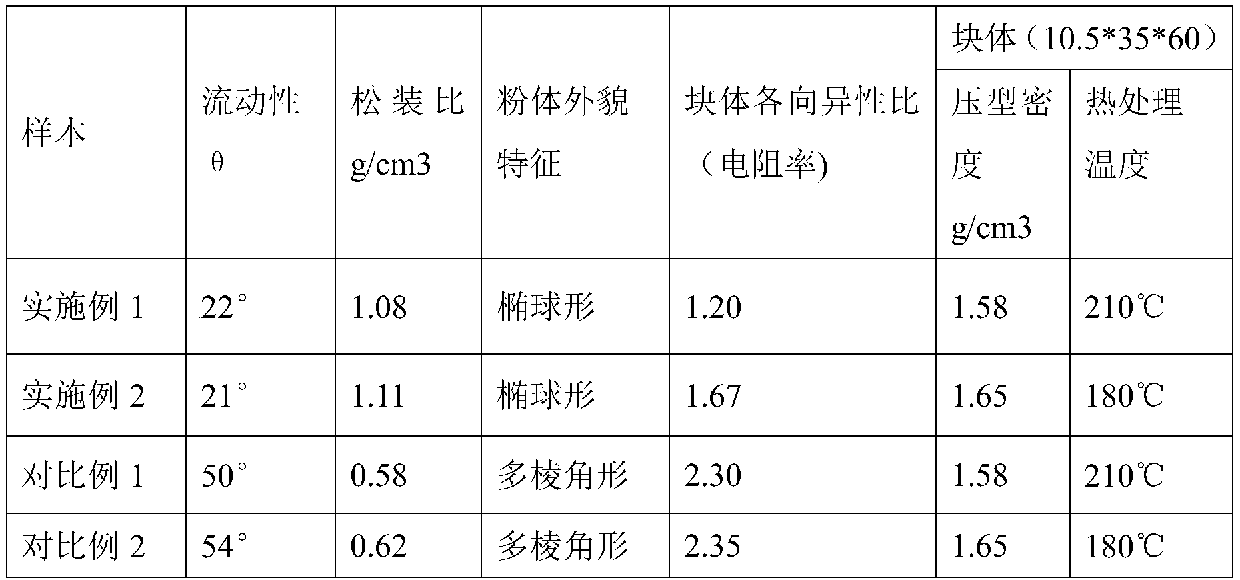

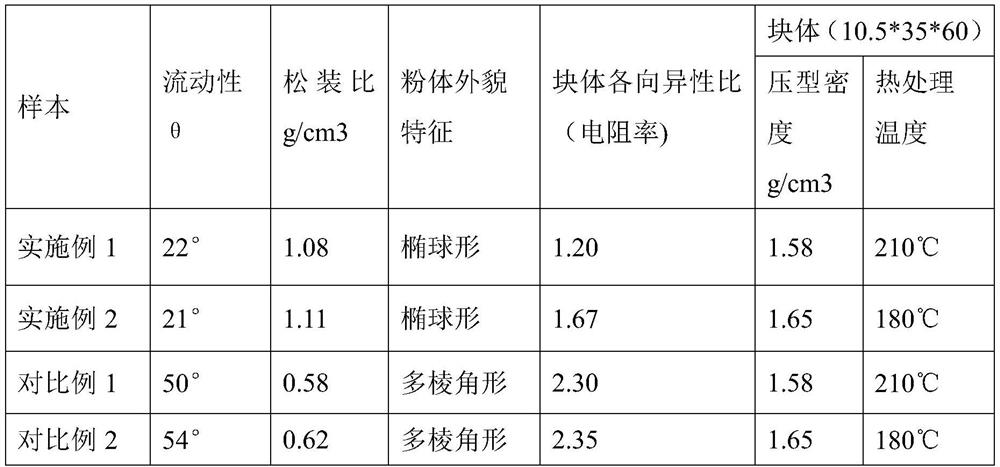

Spherical resin-based electric brush composite material and preparation method thereof

The invention relates to the technical field of material preparation, and discloses a spherical resin-based electric brush composite material and a preparation method thereof. The spherical resin-based electric brush composite material comprises the following components in percentage by mass: 15-30% of amorphous graphite powder, 43-63% of graphite powder, 0.5-3% of a chelating agent, 20-27% of anadhering agent, 1.5-4% of a composite lubricating agent, and 0.02-0.08% of a die releasing agent. According to the spherical resin-based electric brush composite material, the graphite resin powder issphered, and the edges of the powder are removed, so that the self-flowing property of the powder is improved, and the property of isotropy is achieved; the spherical resin-based electric brush composite material is particularly suitable for a high-radial-ratio one-time formed electric brush; the properties of the material are matched with the working properties of a motor to the maximum.

Owner:丽水市长新电器制造有限公司

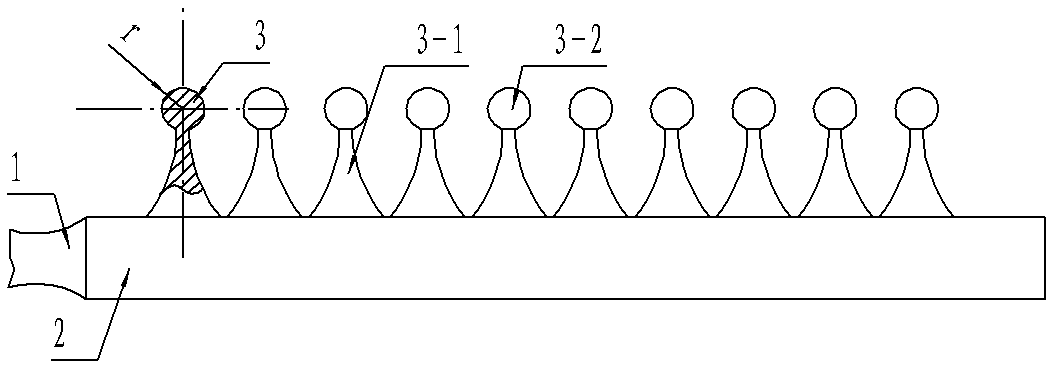

Tooth cleaning brush head

The invention discloses a tooth cleaning brush head, which comprises brush bristles which are vertically arranged on a brush base and a connecting part which is arranged at one end of the brush base and is connected to a handle; the tooth cleaning brush head is characterized in that each brush bristle comprises a brush body which is arranged at the lower part of the brush bristle and is connected to the brush base and a brush ball which is arranged at the top of the brush body; each brush body is represented as a frustum with downside bigger than upside; the conical surface of each frustum sinks inwards, so that an arc-shaped form is shaped; and the brush balls are solid balls. Compared with the prior art, the tooth cleaning brush head disclosed by the invention can solve the problems of the brush head of an existing toothbrush which is poor in effect on cleaning teeth and can cause damage to tooth faces.

Owner:TAICANG CENTURY BRIDGE IND & COMMERCIAL OFFICE

Surface anti-oxidation treatment method of NdFeB magnetic powder

ActiveCN107116211BEfficient and fast finishing treatmentEliminate burrsTransportation and packagingMetal-working apparatusComposite filmO-Phosphoric Acid

Owner:HAIAN INST OF HIGH TECH RES NANJING UNIV +2

A spherical resin-based brush composite material and its preparation method

The invention relates to the technical field of material preparation, and discloses a spherical resin-based brush composite material and a preparation method thereof. The spherical resin-based brush composite material of the present invention comprises the following components in mass percentage: microcrystalline graphite powder 15-30%, graphite powder 43-63%, chelating agent 0.5-3%, binder 20-27%, compound lubrication Agent 1.5‑4%, release agent 0.02‑0.08%. The present invention spheroidizes the graphite resin powder and eliminates the edges and corners of the powder, thereby improving the self-fluidity of the powder and achieving isotropic characteristics. Get the greatest degree of matching with the working characteristics of the motor.

Owner:丽水市长新电器制造有限公司

Carbon fiber river protection pile body, preparing method thereof and carbon fiber river protection pile

The invention belongs to the field of riverway peripheral facilities, and particularly provides a carbon fiber river protection pile body. The carbon fiber river protection pile body is mainly prepared from, by weight, 70-80 parts of polypropylene, 8-12 parts of ABS resin, 4-6 parts of carbon fibers, 4-6 parts of polyvinyl butyral, 0.5-1 part of antioxidant, 0.5-1 part of anti-aging agent and 1.2-1.7 parts of fire retardant. The invention further provides a preparing method of the carbon fiber river protection pile body and a carbon fiber river protection pile composed of the carbon fiber river protection pile body. The carbon fiber river protection pile body and the carbon fiber river protection pile obtained through the preparing method are low in manufacturing cost, high in strength, long in service life, convenient to disassemble and assemble and suitable for industrial application and popularization.

Owner:陈鹤忠

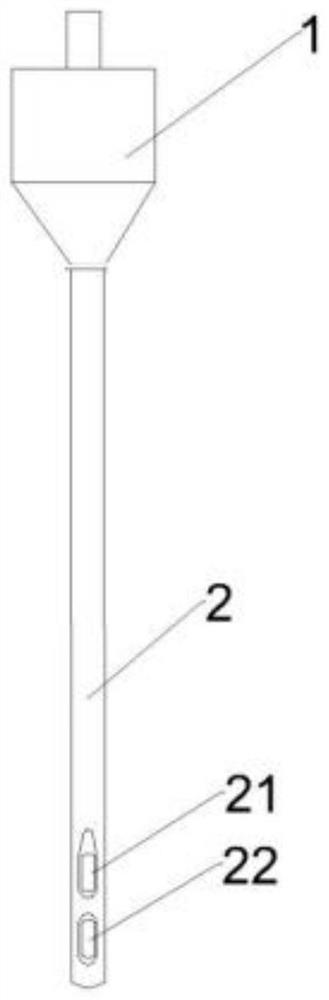

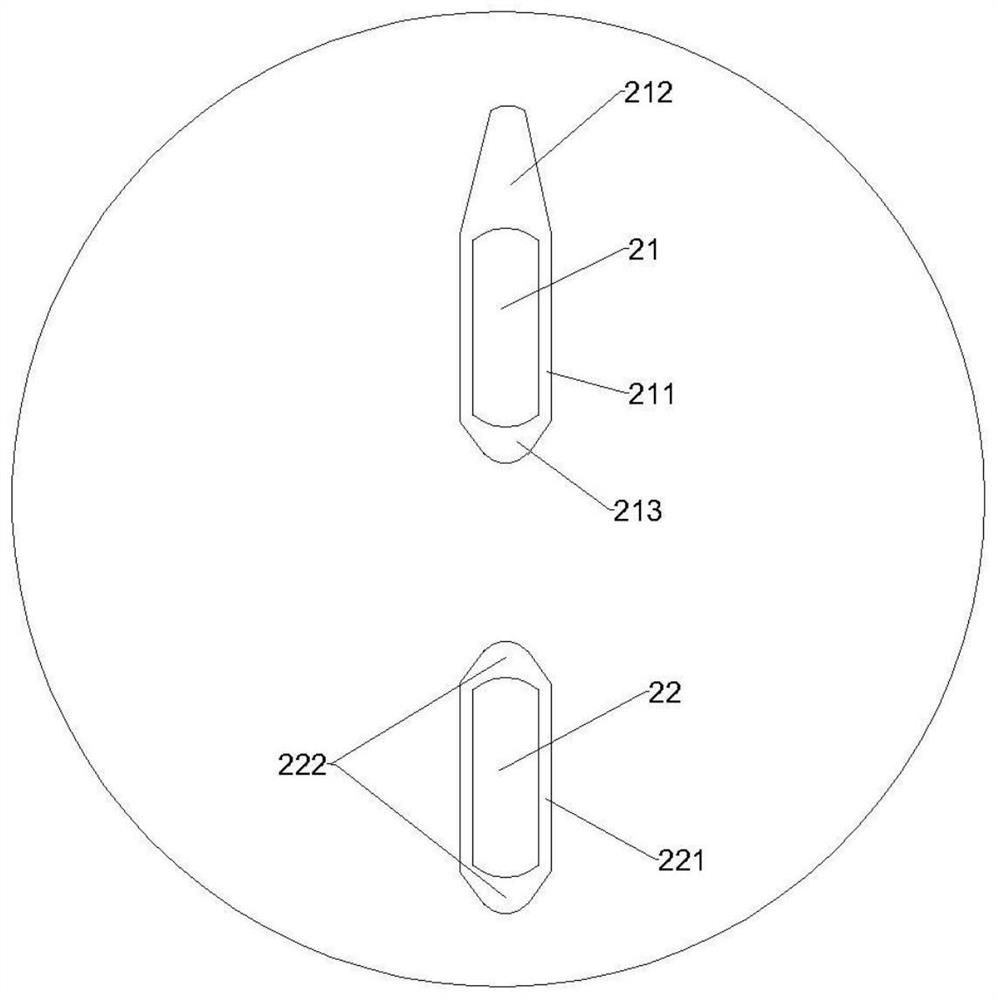

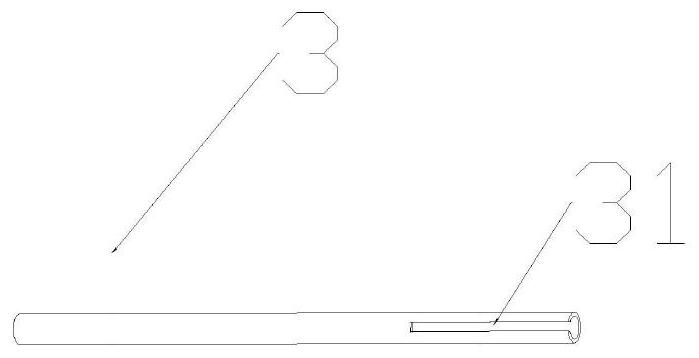

Liposuction needle capable of reducing adipose cell scratches

PendingCN111920461AReduce scratchesConducive to retransplantationDiagnosticsSurgeryLipoblastLiposuction

The invention discloses a liposuction needle capable of reducing adipose cell scratches. The liposuction needle comprises a handle and a needle tube connected with the handle. A liposuction hole is formed in the front end of the needle tube, arc-shaped transition is arranged between the upper surface and the lower surface of the end face of the liposuction hole, wedge-shaped transition is furtherarranged between the upper surface and the lower surface of the end face of the liposuction hole of the liposuction needle in the length direction of the needle tube, and the wedge-shaped face is gradually enlarged from the end away from the liposuction hole to the liposuction hole. According to the invention, arc-shaped transition between the upper surface and the lower surface of the end surfaceof the liposuction hole is arranged; therefore, edges and corners formed on the edge of the upper surface of the end face of the liposuction hole are eliminated, scratches to capillaries on the surface layers of the sucked adipose cells are greatly reduced, the survival rate of the sucked adipose cells is greatly increased, and retransplantation of the sucked adipose is facilitated.

Owner:广州市华丽医疗美容门诊部有限公司

Method and application for preparing degradable coating material by ammonolysis modified vegetable oil

ActiveCN110437415BHigh hardnessImprove heat resistanceLayered/coated fertilisersFertilizer mixturesBiodegradable coatingVegetable oil

The invention discloses a method for preparing a degradable coating material by an ammonolysis modified vegetable oil and an application of the biodegradable coating material. The method comprises thefollowing steps: firstly preparing the modified vegetable oil by using an ammonolysis method, respectively adding an isocyanate and a polyoxypropylene diol into the modified vegetable oil, adding a chain extender and a catalyst for carrying out a reaction, and finally adding N-methyldiethanolamine for carrying out a reaction to obtain the degradable coating material. A urea-formaldehyde solutionis sprayed on the surface of fertilizer particles during a preheating stage of the coating. The prepared coating material has relatively good micro-porous air-permeability, is relatively convenient for controlling a release rate of a fertilizer, and has relatively good degradable function. At the same time, the surface of the fertilizer particles is modified before coating to eliminate surface crystallization and angularity of the fertilizer particles to make the surface be relatively smooth and further enhance coating effects.

Owner:WUZHOUFENG AGRI SCI & TECH

Rubber rod clamp

InactiveCN102673223AFeel smoothEasy to assemble and disassembleSheet bindingRubber materialPlastic materials

The invention belongs to the technical field of office supplies, and in particular relates to a rubber rod clamp. The rubber rod clamp comprises a front rotating arm, a rear rotating arm, a pin, and a bottom plate, a handle and a press strip which are made of plastics, wherein the handle is pivoted on the side edge of the bottom plate through the pin; a first end and a second end of the front rotating arm and a first end and a second end of the rear rotating arm are connected with the press strip and the bottom plate respectively; the tail ends of the first ends of the front rotating arm and the rear rotating arm are extended out of the outer side surface of the press strip, and the front rotating arm and the rear rotating arm are connected with the press strip in a detachable mode; and the tail ends of the second ends of the front rotating arm and the rear rotating arm are extended out of the outer side surface of the side edge, and the front rotating arm and the rear rotating arm are connected with the side edge in a detachable mode. The rubber rod clamp is mainly made of plastic materials and can be manufactured in an integrated mode, so that the cost is saved; edges and corners of metal pieces are eliminated by the plastic rubber rod clamp, and the plastic rubber rod clamp has smooth handfeel compared with a metal handle clamp; and in addition, the rubber rod clamp is convenient to assemble and disassemble, and a single part is convenient to replace, so that metal and rubber materials can be conveniently separated and recycled when products are discarded, and the rubber rod clamp extremely meets the requirement of environment friendliness.

Owner:东莞市新原文具有限公司

Rubber rod clamp

InactiveCN102673223BFeel smoothEasy to assemble and disassembleSheet bindingRubber materialPlastic materials

Owner:东莞市新原文具有限公司

Electric power cord accommodation structure for electric appliance

InactiveCN101478137BReduce stress concentrationAchieve strengthCable arrangements between relatively-moving partsHand ironStress concentrationEngineering

Owner:胡杰波

A cone-disk type waste concrete recycled coarse aggregate mortar stripping device

ActiveCN109012867BWeaken protruding cornersReduce mud contentCocoaGrain treatmentsStructural engineeringMechanical engineering

The invention discloses a cone-disc type waste concrete regenerated coarse aggregate mortar stripping device. The cone-disc type waste concrete regenerated coarse aggregate mortar stripping device comprises a base, a material collection bin and a cone-disc type grinding disc, wherein the cone-disc type grinding disc is composed of an upper grinding disc and a lower grinding disc, the grinding surface of the lower grinding disc is of a convex cone type, the grinding surface of the upper grinding disc is of a concave cone type, and the grinding surface of the upper grinding disc is in fit with that of the lower grinding disc; the base is provided with a plurality of reverse-hook-shaped supports, the disc surface of the upper grinding disc is correspondingly provided with position-limiting holes, and reverse hooks of all the reverse-hook-shaped supports penetrate into the corresponding position-limiting holes to restrict the upper grinding disc to be only capable of sliding up and down; ahydraulic force transmitting device is arranged between the upper grinding disc and all the reverse-hook-shaped supports, and ascending and descending of the upper grinding disc are controlled through stretching and contracting adjustment of the hydraulic force transmitting device; and the center of the upper grinding disc is provided with a material inlet, the material inlet penetrates out of the top of the material collection bin, and the lower portion of the material collection bin is provided with a material outlet. The cone-disc type waste concrete regenerated coarse aggregate mortar stripping device is simple in structure, the aggregate mortar stripping effect is good, and the original particle size of coarse aggregate can be maintained to make the performance of the coarse aggregate be close to natural aggregate, so that the workability, strength and durability of freshly-mixed waste concrete are improved.

Owner:CHINA UNIV OF MINING & TECH

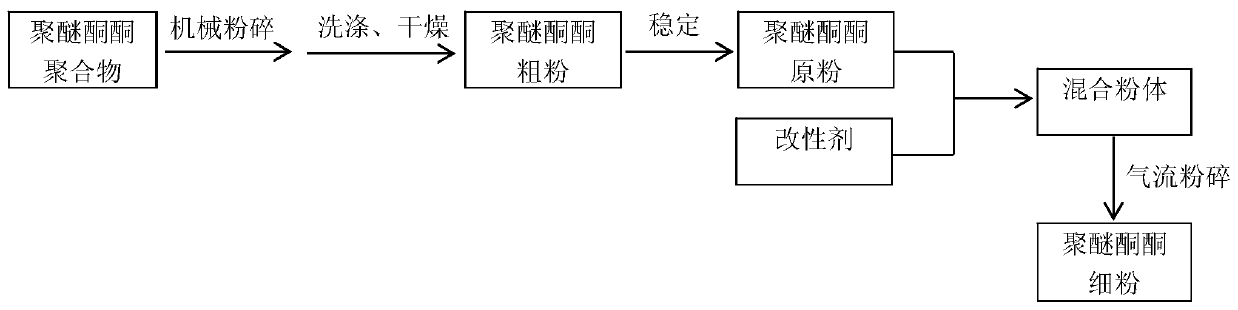

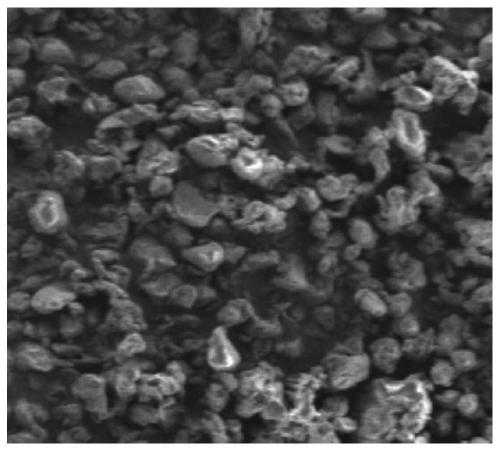

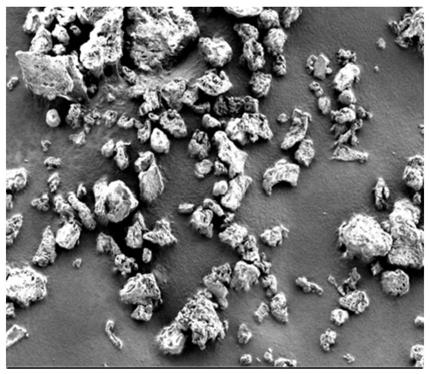

Preparation method of polyether ketone ketone fine powder for coating

ActiveCN106752805BImproved melt stabilityGood film formingPolyether coatingsPowdery paintsKetoneSpherical form

The invention belongs to the technical field of polymer powder processing, and in particular relates to a preparation method of polyether ketone ketone fine powder for coating. The preparation method comprises the following steps: mechanically pulverizing a polymerized polyether ketone ketone polymer, washing and drying to obtain polyether ketone ketone coarse powder, performing stabilizing treatment on the coarse powder, then adding a certain amount of modifier to obtain mixed powder, and pulverizing the mixed powder with air flow to obtain polyether ketone ketone fine powder. The preparation method has a simple process, high pulverization efficiency and low impurity content, the prepared polyether ketone ketone fine powder has uniformity of dispersion and concentrated particle size distribution, the granular form is near-spherical, and the polyether ketone ketone fine powder is particularly suitable for an electrostatic spraying process, and can effectively improve the uniformity and liquidity of coating, decrease coating defects, play the characteristics of the polyether ketone ketone and improve the stability of coating.

Owner:SHANDONG KAISHENG NEW MATERIALS

Method for preparing building aggregate from household garbage incineration slag

ActiveCN113620630ASatisfy safety and reliabilityHigh particle strengthSolid waste managementGreenhouse gasCarbonization

The invention belongs to the technical field of solid waste resource utilization and wastewater treatment, and discloses a method for preparing building aggregate from household garbage incineration slag, which comprises the following steps: performing high-temperature heating and low-temperature tempering treatment on the household garbage incineration slag to obtain a first solid material; dispersing the first solid material into concrete wastewater of a mixing plant for water bath, conducting oscillating in a reciprocating manner, and then conducting draining and drying to obtain a second solid material; and subjecting the second solid material to carbonization curing in the atmosphere of set temperature, set humidity and set CO2 concentration, so as to obtain the building aggregate. According to the method for preparing the building aggregate from the household garbage incineration slag, the household garbage incineration slag, mixing plant concrete wastewater and greenhouse gas CO2 can be efficiently recycled and reused, the novel high-quality building aggregate is prepared through modification treatment by utilizing the specific physical and chemical properties of waste, and the risk of generating durability defects and structural defects is reduced.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +1

Processing method of tooth cleaning brush head

The invention discloses a processing method of a tooth cleaning brush head. The tooth cleaning brush head comprises brush bristles which are vertically arranged on a brush base and a connecting part which is arranged at one end of the brush base and connected with a handle, and each brush bristle comprises a brush body and a brush ball. The processing method of the tooth cleaning brush head comprises the following steps that all installing through holes are punched in the positions where the brush bristles need to be installed at a time through a punching machine and a multi-needle model; a brush bristle female mold is provided with pits of which the shapes are matched with the brush bristle shapes of all the brush bristles; the brush bristle female mold is arranged on the brush base with the holes in an inverted mode, compressed air for silicon rubber is blown from the holes formed in the lower portion of the brush base, and then the through holes are filled with packing from the bottom of the brush base. According to the processing method, the problems that an existing toothbrush head is bad in tooth cleaning effect and causes harm to the tooth faces can be solved.

Owner:苏州迈迪赫兹医疗器械有限公司

Tooth-protecting brush head

The invention discloses a tooth-protecting brush head, which comprises bristles which are vertically arranged on a brush base and a connecting part which is arranged at one end of the brush base and is connected to a handle, wherein each bristle comprises a brush body which is arranged at the lower part of the bristle and is connected to the brush base and a brush ball which is arranged at the top of the brush body; the brush bodies are represented as frustums with downsides bigger than upsides; the conical surfaces of the frustums sink inwards, so that arc-shaped structures are formed; the brush bodies are different in height; and the brush balls are hollow balls. In comparison with the prior art, the problems of an existing toothbrush head which can cause damage to tooth faces and is poor in massaging and health care effects on teeth are solved.

Owner:ZHEJIANG YANTONG FURNITURE CO LTD

Tooth brush head

The invention discloses a tooth cleaning brush head, which comprises brush bristles which are vertically arranged on a brush base and a connecting part which is arranged at one end of the brush base and is connected to a handle; the tooth cleaning brush head is characterized in that each brush bristle comprises a brush body which is arranged at the lower part of the brush bristle and is connected to the brush base and a brush ball which is arranged at the top of the brush body; each brush body is represented as a frustum with downside bigger than upside; the conical surface of each frustum sinks inwards, so that an arc-shaped form is shaped; and the brush balls are solid balls. Compared with the prior art, the tooth cleaning brush head disclosed by the invention can solve the problems of the brush head of an existing toothbrush which is poor in effect on cleaning teeth and can cause damage to tooth faces.

Owner:TAICANG CENTURY BRIDGE IND & COMMERCIAL OFFICE

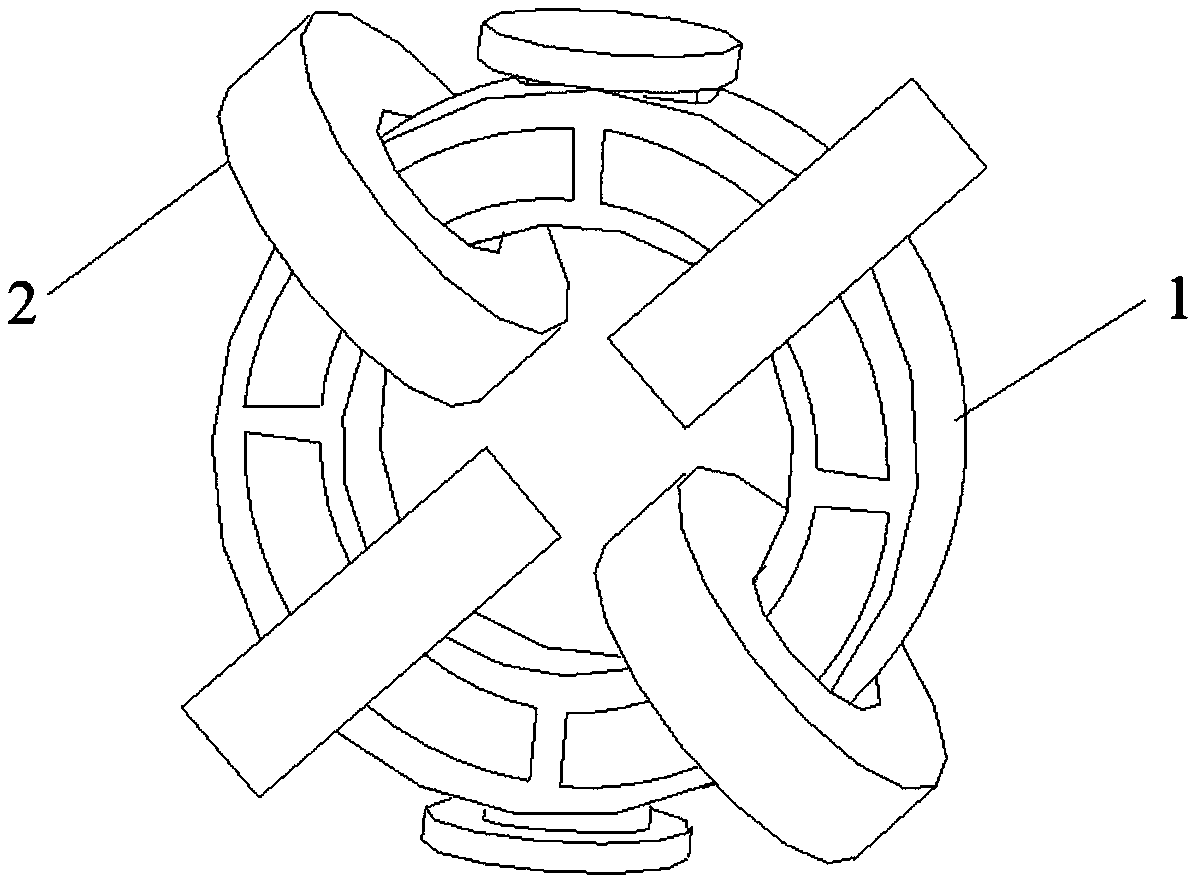

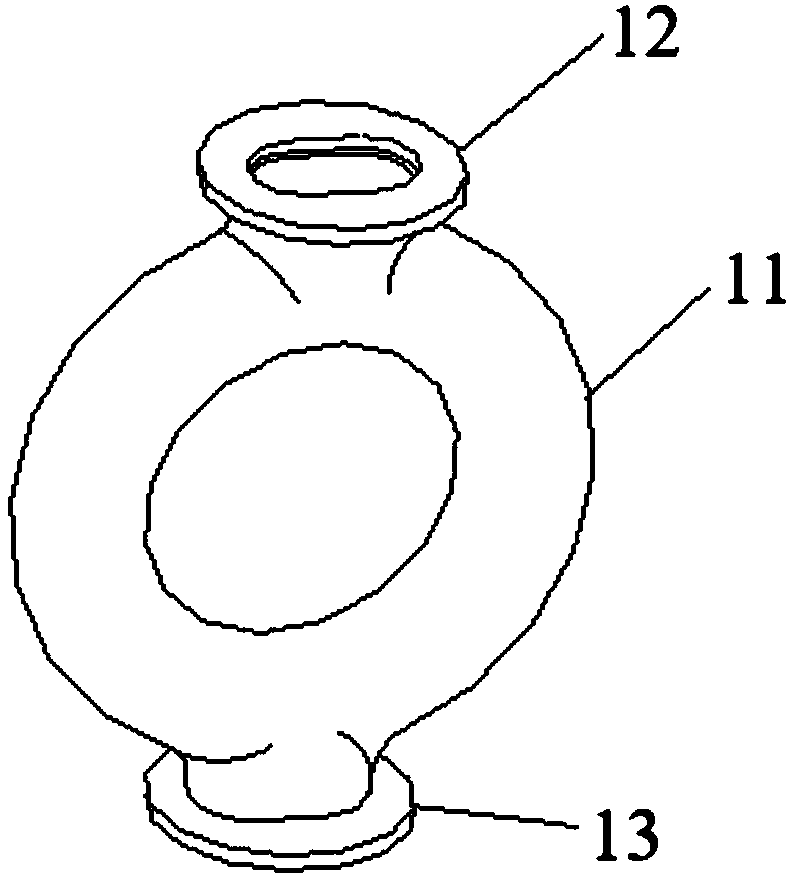

Ion source and plasma processing apparatus

The invention provides an ion source and plasma processing equipment. The ion source comprises a reaction cavity comprising an annular cavity, the annular cavity is provided with an air inlet pipe andan air outlet pipe, the radial section of the inner wall of the annular cavity is circular, the radial sections of the inner walls of the air inlet pipe and the air outlet pipe are oval, and the inner walls of the air inlet pipe, the air outlet pipe and the annular cavity are in smooth transition. An annular magnetic core surrounds the annular cavity and is connected with a radio frequency powersupply. According to the ion source, edges and corners of the inner wall of the cavity are eliminated, a smooth annular generation loop without edges and corners is provided for plasmas, smoothness ofa plasma loop can be guaranteed to the maximum extent, unnecessary collision loss and heat conduction are reduced, and the plasma benefit time is prolonged; and moreover, the heat flux of each part of the reaction cavity is reduced, and the efficiency loss is reduced.

Owner:CHANGXIN MEMORY TECH INC

Ram mechanism of machining center

PendingCN113857880AReduce wearAvoid entanglementLarge fixed membersInternal cavityStructural engineering

The invention relates to a ram mechanism of a machining center. The ram mechanism comprises a ram body, the ram body is of a center hole structure, first sinking grooves are formed in multiple side walls outside the ram body, end holes are formed in the top end and the bottom end of the ram body, multiple rib plates are arranged in the ram body at equal intervals, each rib plate is provided with an inner cavity, two line holes are symmetrically formed in the top end of the ram body and the rib plates, multiple sand washing holes and an observation hole are formed in one first sinking groove, and a cover plate is detachably mounted on the outer side of the observation hole. The inner cavities of the rib plates are made into round shapes, edges and corners are eliminated, the structure is improved so as to reduce the abrasion degree of a rotary connection pipeline, meanwhile, the two line holes penetrating through the top and the rib plates are formed in the ram and allow an unmovable fixed pipeline on a five-axis head to penetrate through, and the winding phenomenon is avoided.

Owner:江苏普拉迪数控科技有限公司

Lens cone, lens module and electronic equipment

The invention relates to a lens cone, which is provided with a first end part, wherein the first end part is provided with a light inlet hole communicated with internal part of the lens cone, the first end part comprises a first end surface and an annular inner wall connected with the first end surface, the annular inner wall is arranged around the light inlet hole, and the junction of the first end surface and the annular inner wall is a circular arc chamfer. The invention further provides a lens module comprising the lens cone and electronic equipment. The first end surface of the lens coneprovided by the embodiment of the invention is in circular arc connection with a first periphery of the annular inner wall, so that corner angles and ridges are enabled to be eliminated at the first periphery, and the consistency of structures such as the lens module applying the lens cone and the electronic equipment is greatly improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com