Construction method of variable curved-surface steel-concrete tubular structure

A construction method and concrete technology, which is applied in the direction of building structure, construction, and building material processing, can solve the problems that the artistic effect of polymorphic cylinders cannot be constructed, and solve the continuity problem of streamlined changes in facades. Strong continuity and smooth façade streamline changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments.

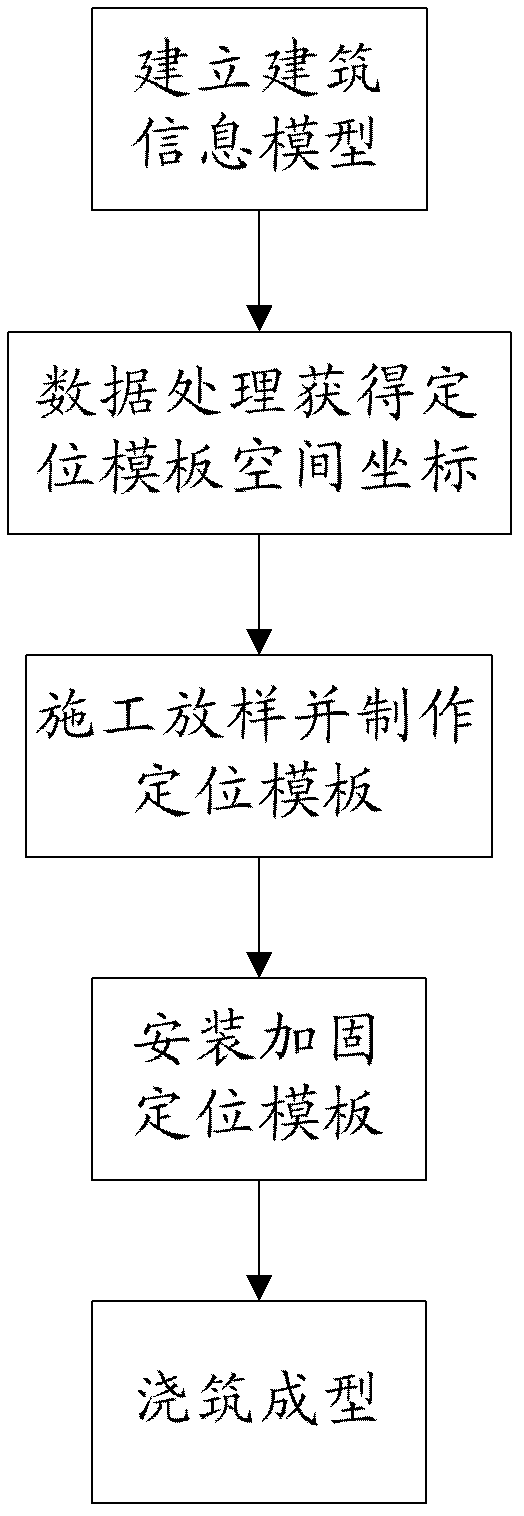

[0031] See figure 1 , The construction method of a multi-variable curved surface steel concrete tube structure of the present invention includes the following steps:

[0032] First, build a building information model through BIM application software;

[0033] Then, use AutoCAD application software to process the building information model to obtain the spatial coordinate data of each positioning template 1 of the cylindrical structure;

[0034] The data processing steps include:

[0035] Obtain the positioning curve of the horizontal section of each elevation of the building information model through AutoCAD;

[0036] Radial ray to the positioning curve of the current elevation at every 3 degrees from the central axis of the cylindrical structure at each elevation;

[0037] Pick up all the intersections of the positioning curve and the ray at each elevation, and use the space coordinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com