Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about How to "Efficient continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feed additive composition for ruminants and method of producing the same

InactiveUS20090232933A1Enhancement of milk yieldIncrease productionAnimal feeding stuffAccessory food factorsBasic amino acidsChemistry

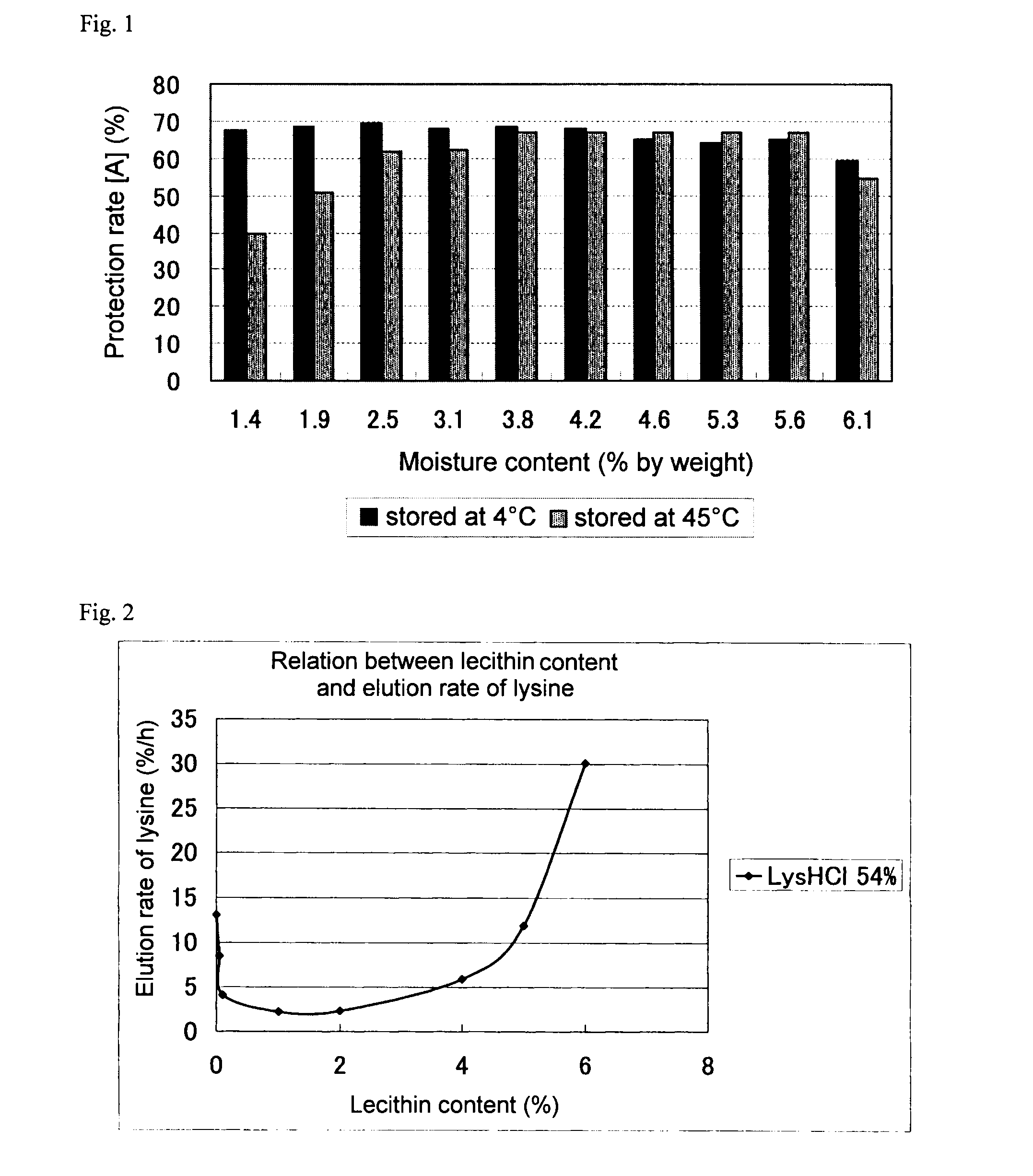

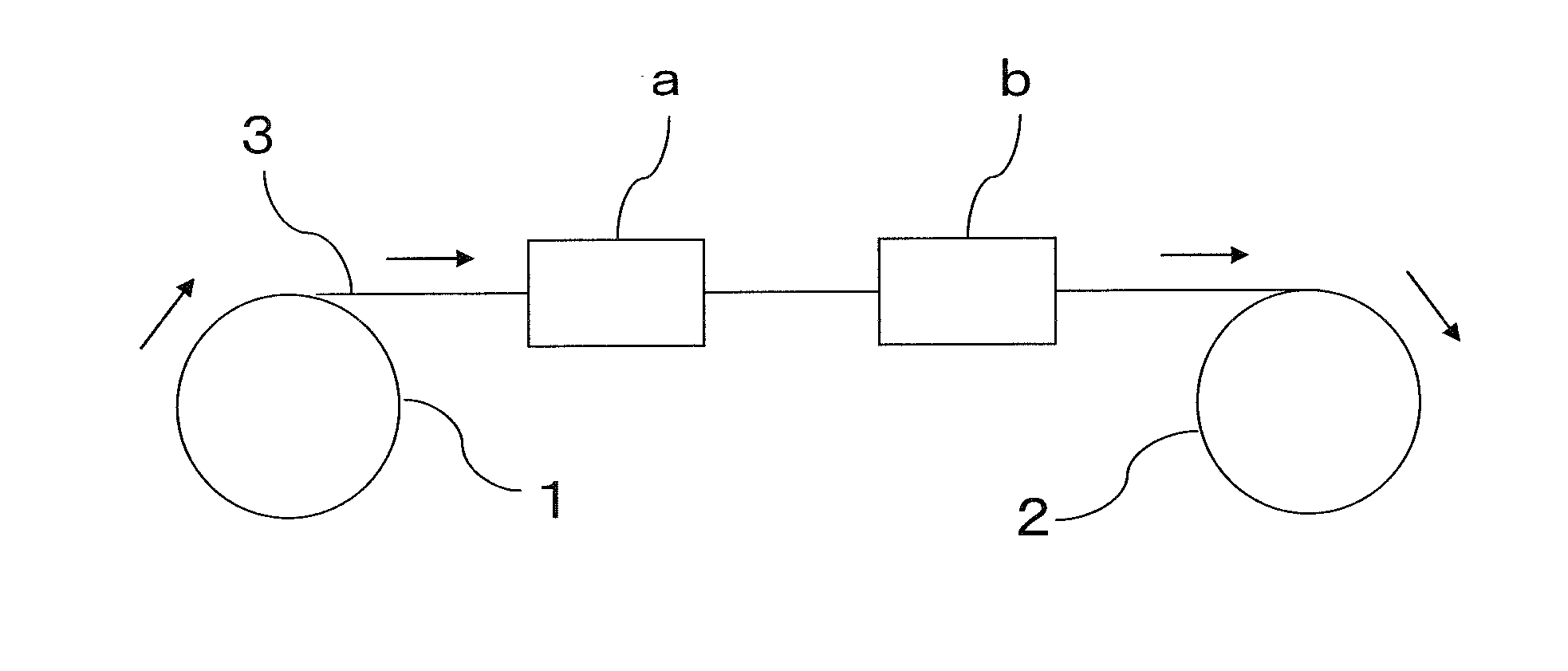

A food additive composition for ruminants of the dispersion type and a method of continuously producing the same. This food additive composition for ruminants, which contains 40% by weight or more but less than 65% by weight of a basic amino acid and has rumen bypass properties, is formulated into granules in an arbitrary shape which are scarcely classified when added to a silage or another feed. Thus, attempts have been made to develop a method of producing granules by which the milk yield of a lactation cow can be increased. Namely, it is intended to provide a food additive composition for ruminants which contains at least one protecting agent selected from among a hardened vegetable oil and a hardened animal oil having a melting point higher than 50° C. but lower than 90° C., 0.05 to 6% by weight of lecithin, water and 40% by weight or more but less than 65% by weight of a basic amino acid. It is also intended to provide a method of producing a food additive composition for ruminants characterized by comprising solidifying a molten mixture, which comprises at least one protecting agent selected from among a hardened vegetable oil and a hardened animal oil having a melting point higher than 50° C. but lower than 90° C., lecithin and a basic amino acid, by dipping in water.

Owner:AJINOMOTO CO INC

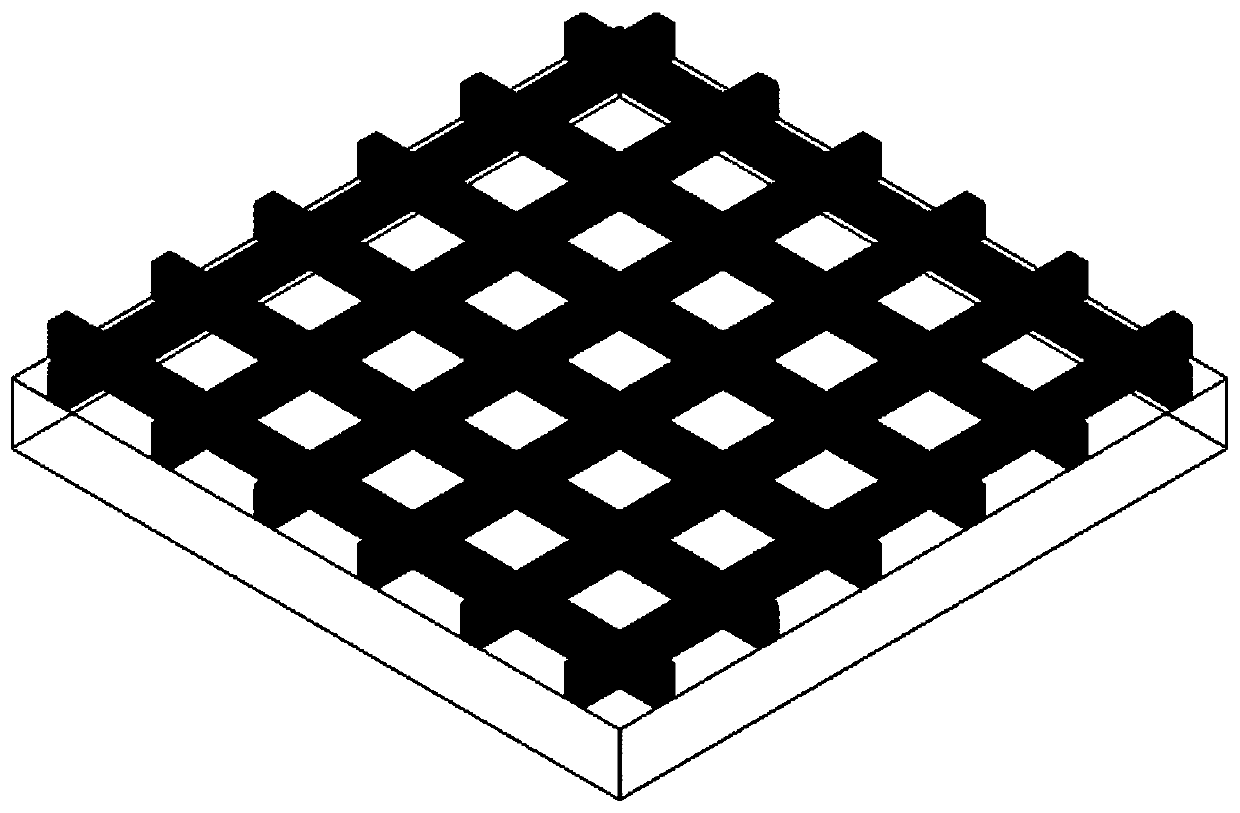

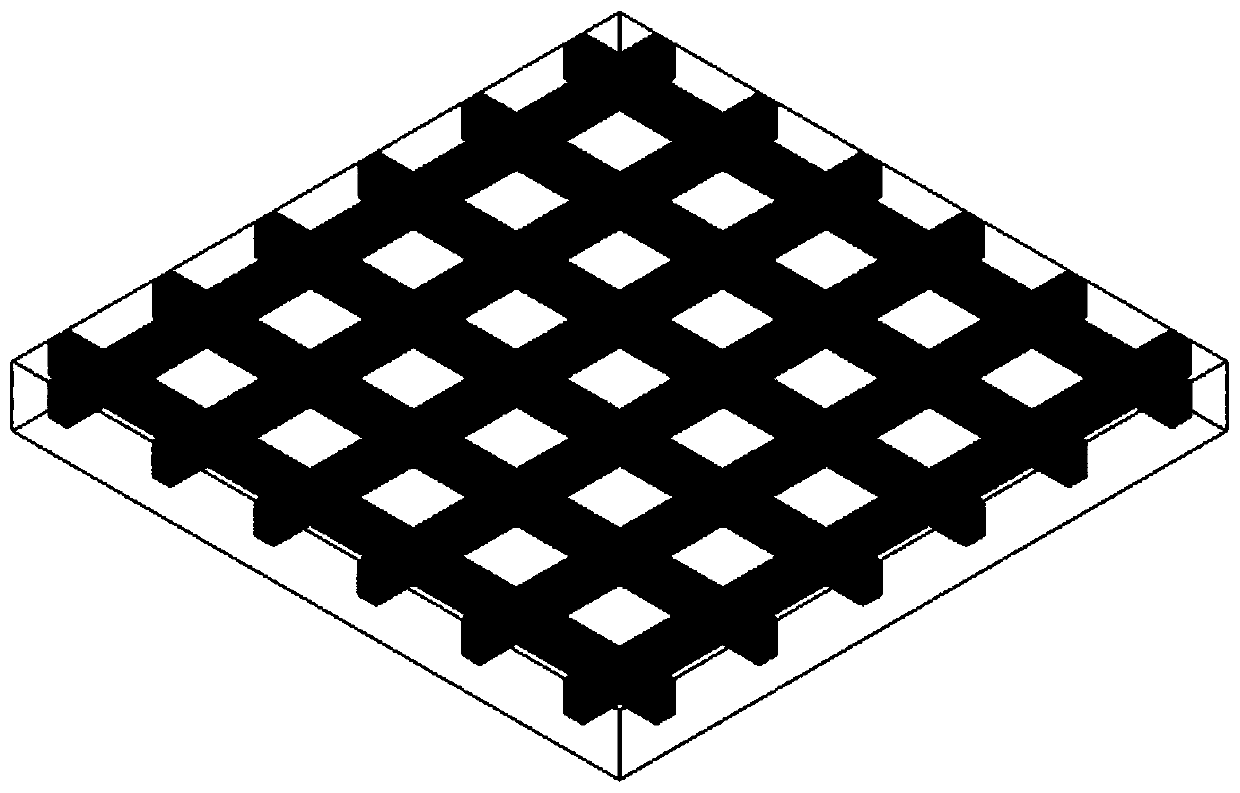

Manufacturing method and application of embedded metal grid flexible transparent electrode

ActiveCN110021462AIncrease profitNo wasteAdditive manufacturing apparatusConductive layers on insulating-supportsHot stampingMicro nano

The invention belongs to the field of flexible transparent electrodes, and particularly relates to a manufacturing method and an application of an embedded metal grid flexible transparent electrode. The method comprises the following steps: 1) by use of an electric field driven spray deposition micro-nano 3D printing technology, a metal grid transparent electrode is directly printed on a hard substrate; 2) conductive treatment is carried out on a printed metal grid structure by adopting a sintering process so as to realize conductive treatment of a metal grid; 3) a flexible transparent substrate and the hard substrate are heated to a set temperature, and a hot stamping process is adopted for completely embedding the metal grid structure on the hard substrate into the flexible transparent substrate; and 4) the metal grid which is completely embedded into the flexible transparent substrate is separated from the hard substrate to obtain the embedded metal grid flexible transparent electrode. According to the method, the electric field driven spray deposition micro-nano 3D printing technology is combined with the roller pair plane hot stamping technology to realize efficient and low-cost batch manufacturing of the large-sized embedded metal grid flexible transparent electrode; and the prepared transparent electrode also has excellent square resistance and light transmittance.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

Gas barrier laminate, method for producing same, member for electronic devices, and electronic device

ActiveUS20150099094A1Excellent gas barrier capabilityExcellent durabilityFibre treatmentSynthetic resin layered productsStatic friction coefficientStatic friction

The present invention provides: a gas barrier laminate comprising a base, a primer layer, and a gas barrier layer, the primer layer and the gas barrier layer being sequentially stacked on at least one side of the base, the primer layer having a modulus of elasticity at 90° C. of 1.6 GPa or more, and a coefficient of static friction between a surface of one side of the gas barrier laminate and a surface of the other side of the gas barrier laminate being 0.35 to 0.8; a method for producing the gas barrier laminate; an electronic device member comprising the gas barrier laminate; and an electronic device.

Owner:LINTEC CORP

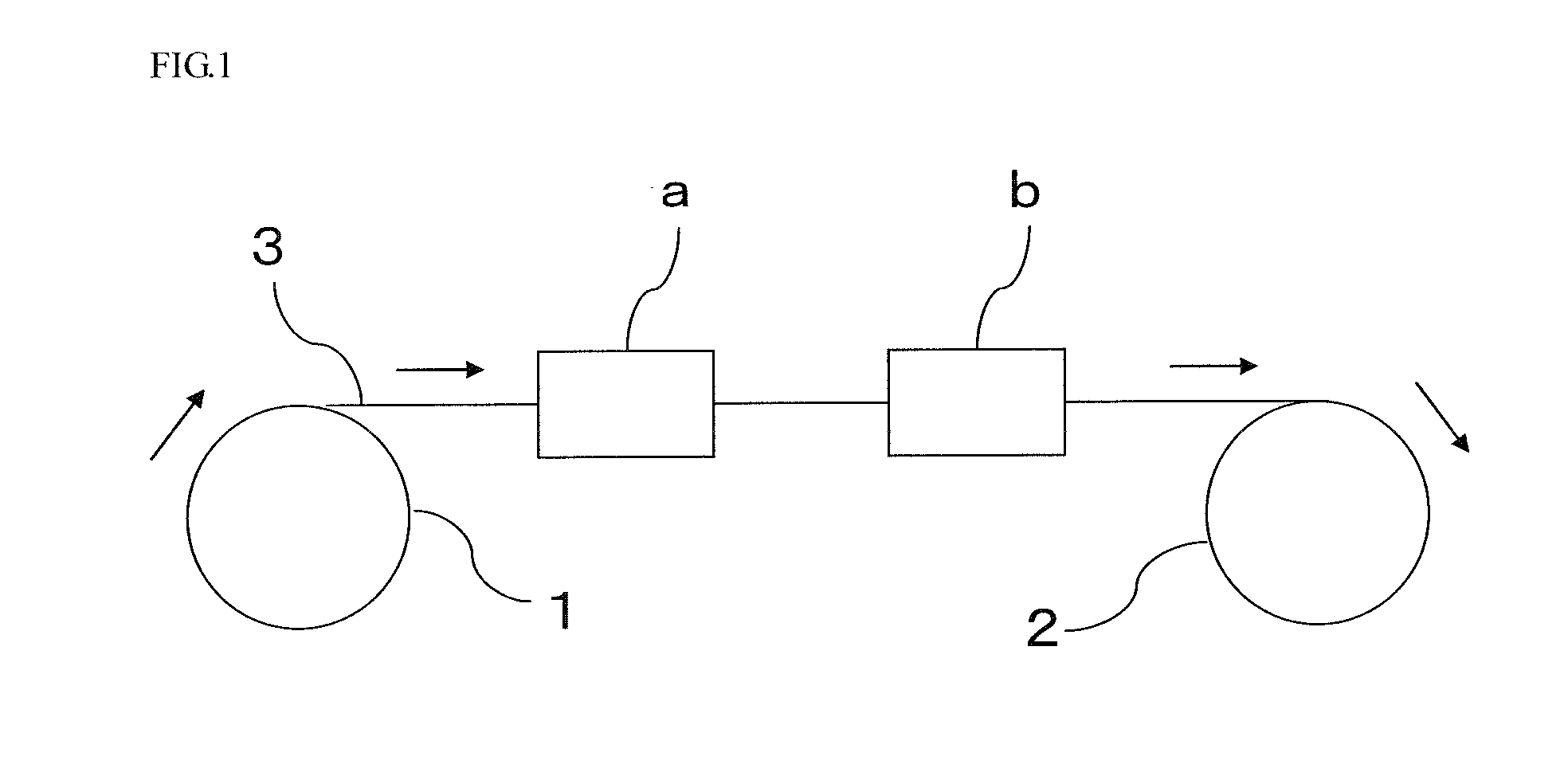

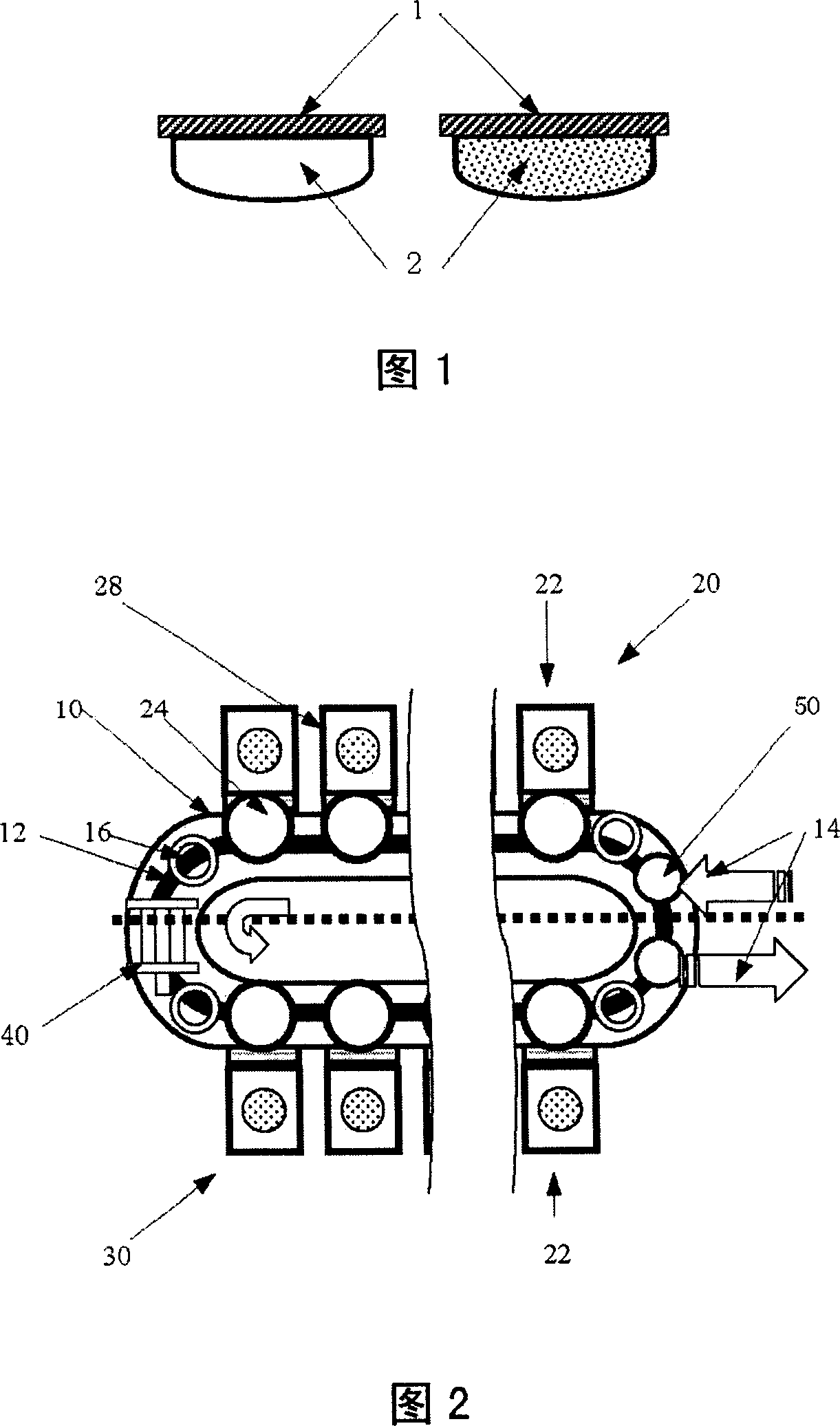

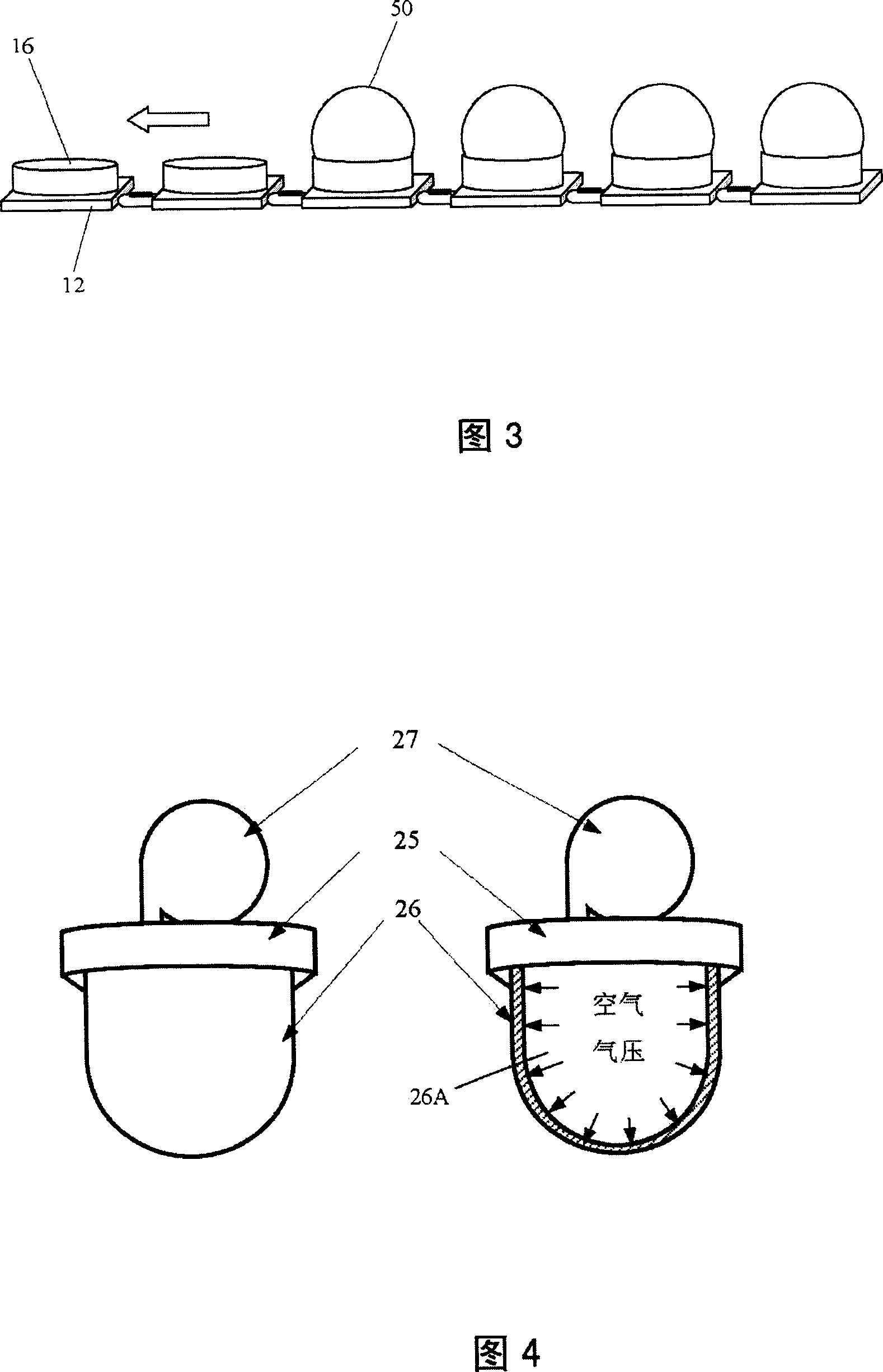

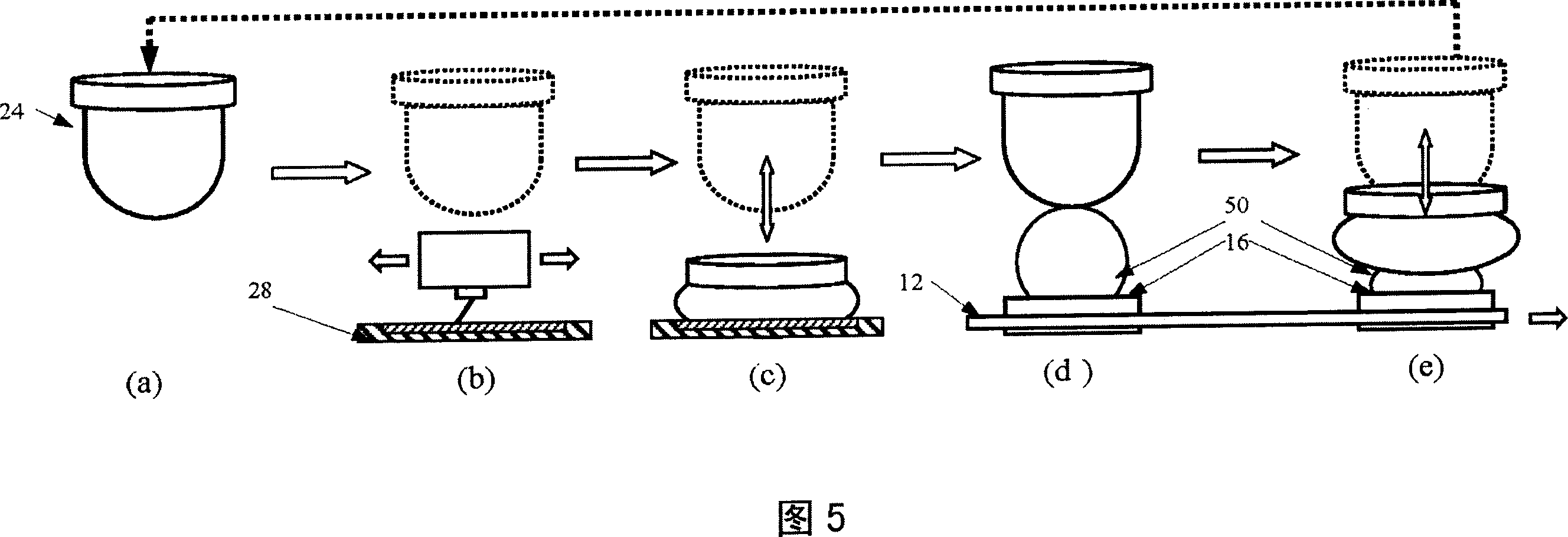

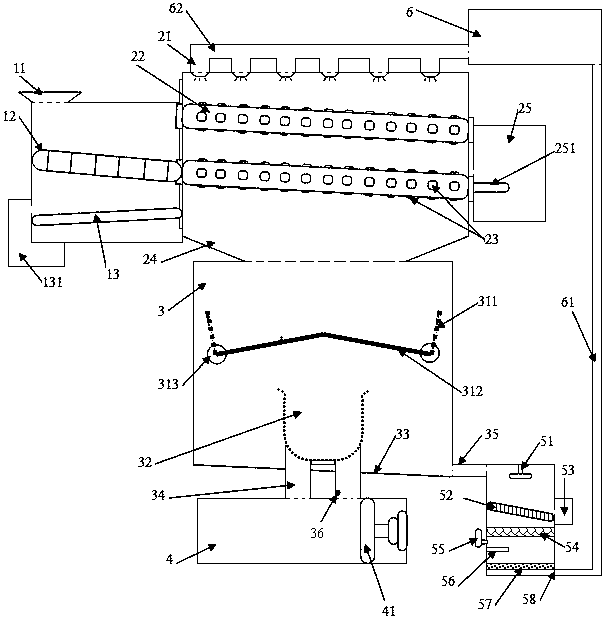

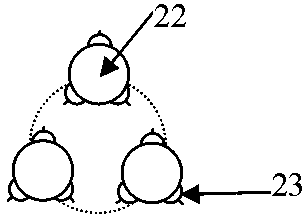

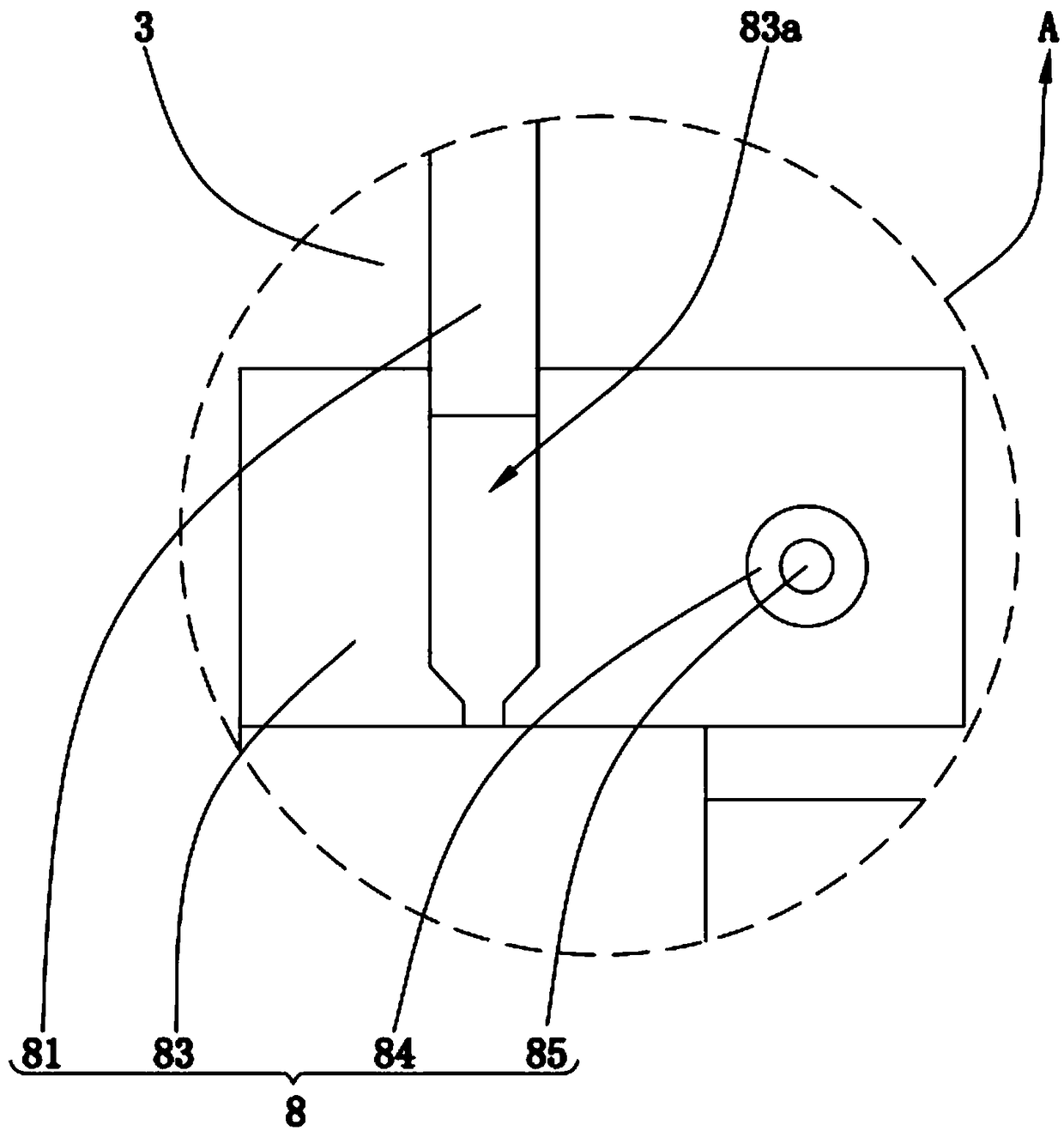

Spherical/special-shaped product all-print printing process and apparatus

InactiveCN101007475ARealize efficient continuous productionRealize printingRotary pressesOther printing apparatusColor printingAbnormal shaped

A spherical / heteromorphic products all-printed equipment is used for printing the whole spherical / heteromorphic products. It is characterized by, it includes a transmission frame, conveyer belt installed on the transmission frame, upper and lower semi-surface printing areas installed on conveyer belt and the turn-over device installed on the interface part of upper and lower semi-surface printing areas; the conveyer belt is equipped with products input and output channels and many transmission discs with gaps each other; the upper and lower semi-surface printing areas respectively includes at least one single color printing device, each single color printing device consists of a flexible air pressure jelly mould head installed below the transmission disc and a printing gravure installed below one side of transmission disc. The spherical / heteromorphic products all-printed method includes: processing at least single color printing of the upper semi-surface of spherical / heteromorphic products through using the flexible air pressure jelly mould head; turning over the spherical / heteromorphic products 180degree through a turn-over device; processing at least single color printing of the lower semi-surface of the product through using the flexible air pressure jelly mould head.

Owner:SHANGHAI INNOVATIVE TOYS

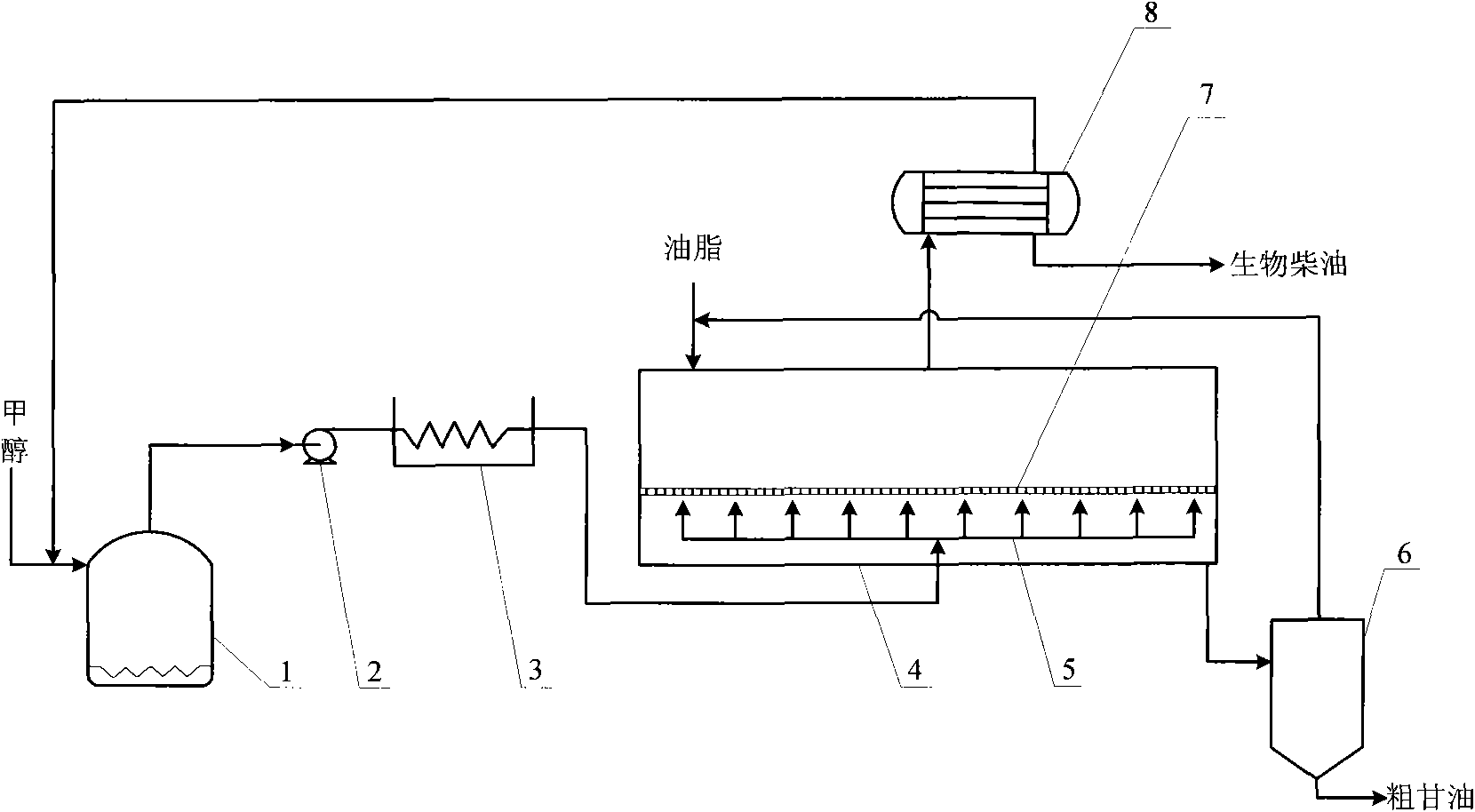

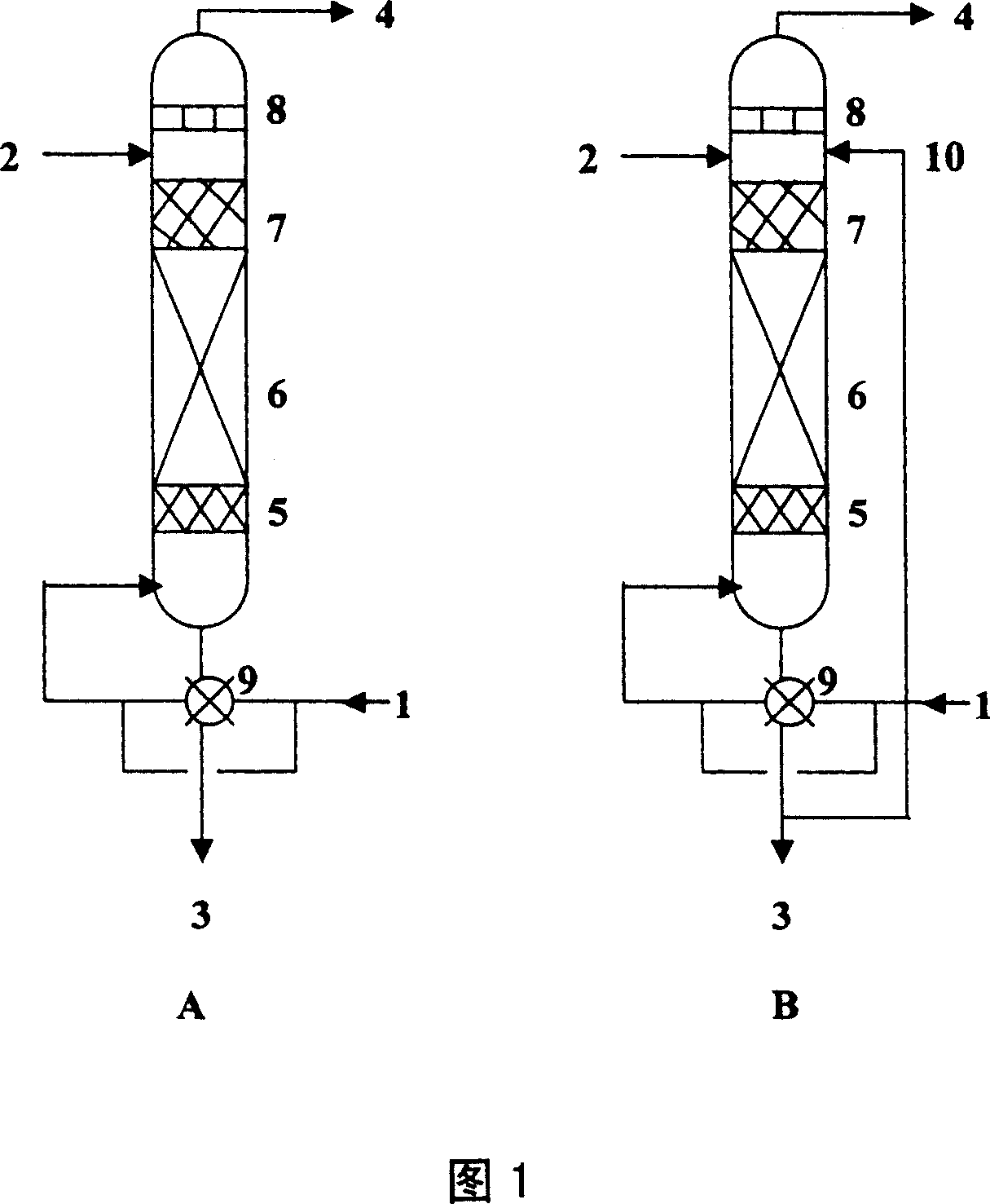

Biodiesel preparation method

InactiveCN101892127AReduce energy consumptionEasy to recycleFatty acid esterificationBiofuelsOil and greaseBiodiesel

The invention relates to a biodiesel preparation method, which comprises that: ester exchange reaction is performed on fat and methanol vapor produced by hot-bath heating in a continuous ester exchange reactor, and the reaction product biodiesel is discharged out of the reactor and enters a condenser along with the methanol vapor remaining after the reaction; and after being subjected to temperature-controlled condensation, the product biodiesel is discharged from the bottom of the condenser in a liquid form. The biodiesel can be timely separated from the reactor to promote the completely positive development of the reaction, and simultaneously the methanol is recycled to reduce energy consumption; in the reaction system, the methanol not only serves as a reagent to participate in the reaction, but also plays a role in stirring; a mesoporous solid catalyst is adopted, so the product is easy to separate, does not need washing with water and is environmentally-friendly, and glycerol is simple to recycle and purify; and the method has the advantages of simple process, wide raw material application and the highly-efficient continuous production of the biodiesel.

Owner:KUNMING UNIV OF SCI & TECH

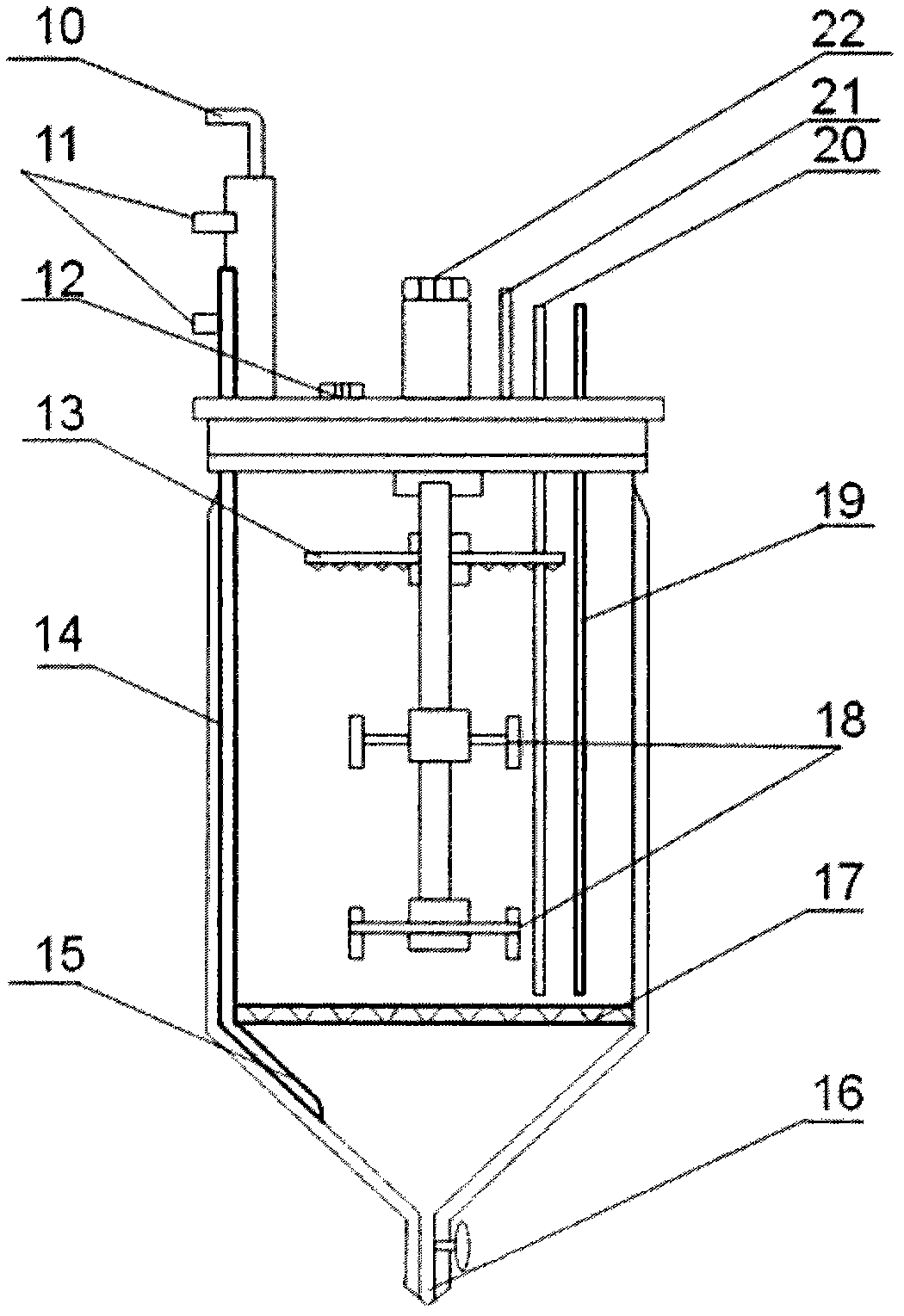

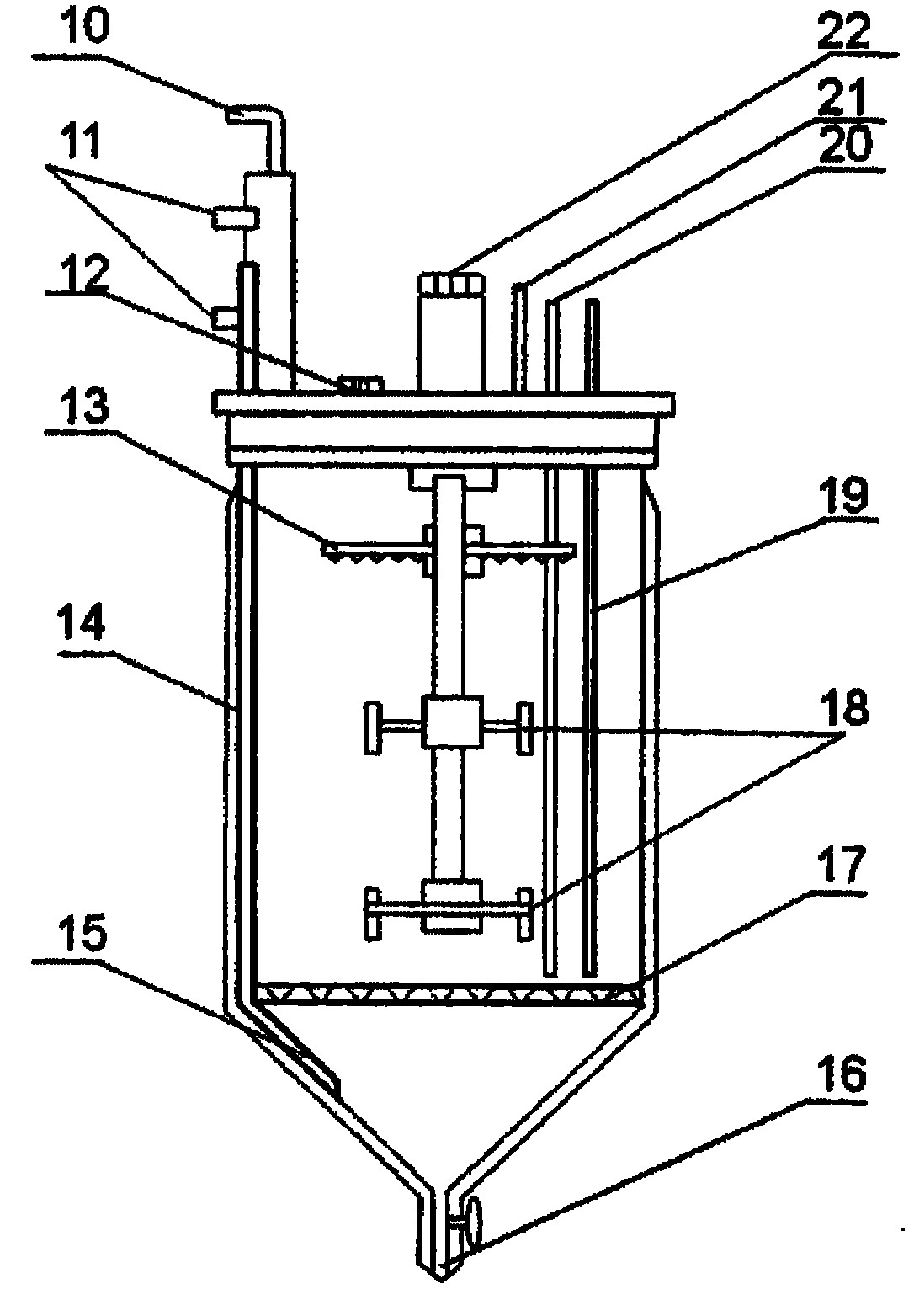

Bioreactor and sophorolipid continuous production method by using the same

InactiveCN102492605ARealize continuous productionEfficient continuous productionBioreactor/fermenter combinationsBiological substance pretreatmentsTowerFermentation broth

According to a bioreactor and a sophorolipid continuous production method by using the same provided by the invention, as fed-batch of a fermentation broth, a product is recovered at a liquid outlet through intravenous drip. A technology mainly comprises the following steps: centrifuging a fermentation waste liquid by a centrifuge and recovering precipitated yeast byproduct at a lower layer; mixing a centrifuged supernatant and a crude product from intravenous drip and recovering a lower layer product to a secondary purified product gathering tank 2-5 h after settlement layering; disinfecting the secondary purified product by an autoclave and storing directly, or drying at 55-75 DEG C in a drying tower to gain a constant weight and storing.

Owner:中海石油环保服务(天津)有限公司 +1

Novel glass compositions for fiber formation

Provided is a range of glass compositions and glass fiber products made therefrom that show a unique combination of properties for both discontinuous fiber manufacturing and end use service. The glass compositions are particularly useful in high volume, high throughput, economical processes such as rotary spinning.

Owner:JOHNS MANVILLE CORP

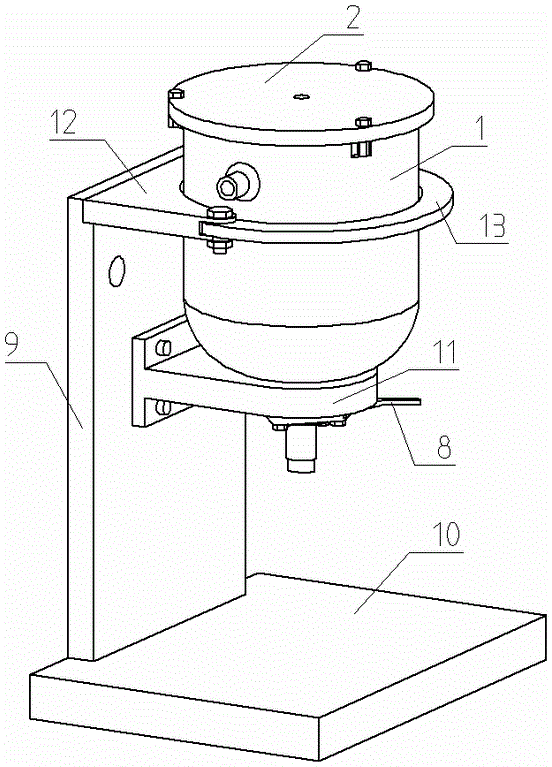

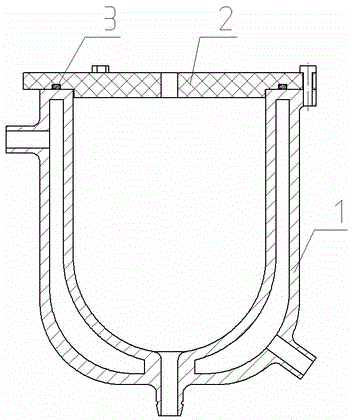

Filling device used for constant-temperature and constant-pressure continuous chemical charging of micro combined solid pushing engine

The invention discloses a filling device used for constant-temperature and constant-pressure continuous chemical charging of a micro combined solid pushing engine. A cavity wall hopper is installed on a supporting rack. A cover plate is installed at the upper end of the cavity wall hopper. A venting port communicated with an inner cavity of the hopper is formed in the cover plate. A water inlet and a water outlet which are communicated with the cavity wall are formed in the side wall of the hopper. Circulating water is introduced into the cavity wall, so that the temperature of chemical paste in the hopper is constant. A discharging port communicated with the inner cavity of the hopper is formed in the bottom of the hopper. A throttling valve is installed at the dischargingport. The circulating water is introduced into the cavity wall of the hopper so that the temperature of the chemical paste in the hopper can be constant. After the cover plate and the hopper are sealed, nitrogen is introduced, and then the chemical paste filling speed can be controlled by controlling the air pressure. The valve can be opened and closed simply and safely by operating the throttling valve. The filling device is low in cost, convenient to mount, dismount and clean, and capable of achieving efficient safety production of a large scale of micro combined solid pushing engines.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

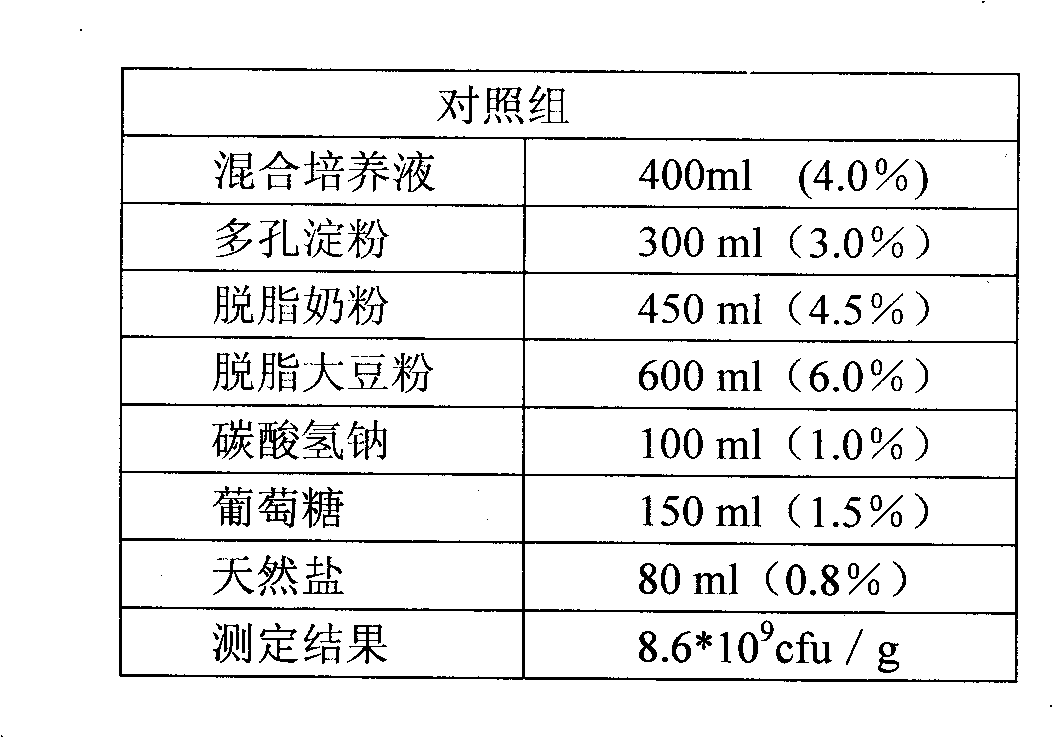

Hybrid probiotic desiccate and preparation method thereof

InactiveCN101773207AHigh bacteria rateGood bacteria rateAnimal feeding stuffBiotechnologySalt resistance

The invention discloses a hybrid probiotic desiccate and a preparation method thereof. The hybrid probiotic desiccate has high bacteria rate and viable count being up to 9.2*109-6.8*1010cfu / g. because of having double protection functions of porous starch and saccharides, and the powder of the hybrid probiotic desiccate has good acid, high-temperature and salt resistance and can be stored for a long time. Chinese medicinal herb extracts are used in a culture medium, echinacea purpurea polysaccharides and astragalus polysaccharides not only increase the content of saccharides required by the growth of flora, but also can enhance the immunity of cells, can obviously increase the quantity and the efficacy of the flora, and has more complete and effective health care function.

Owner:鲁东梁 +2

Feed additive composition for ruminants and method of producing the same

ActiveUS20130095206A1Increase productionHigh yieldAnimal feeding stuffAccessory food factorsFood additiveRumen

A food additive composition for ruminants of the dispersion type and a method of continuously producing the same. This food additive composition for ruminants, which contains 40% by weight or more but less than 65% by weight of a basic amino acid and has rumen bypass properties, is formulated into granules in an arbitrary shape which are scarcely classified when added to a silage or another feed. Thus, attempts have been made to develop a method of producing granules by which the milk yield of a lactation cow can be increased. Namely, it is intended to provide a food additive composition for ruminants which contains at least one protecting agent selected from among a hardened vegetable oil and a hardened animal oil having a melting point higher than 50° C. but lower than 90° C., 0.05 to 6% by weight of lecithin, water and 40% by weight or more but less than 65% by weight of a basic amino acid. It is also intended to provide a method of producing a food additive composition for ruminants characterized by comprising solidifying a molten mixture, which comprises at least one protecting agent selected from among a hardened vegetable oil and a hardened animal oil having a melting point higher than 50° C. but lower than 90° C., lecithin and a basic amino acid, by dipping in water.

Owner:AJINOMOTO CO INC

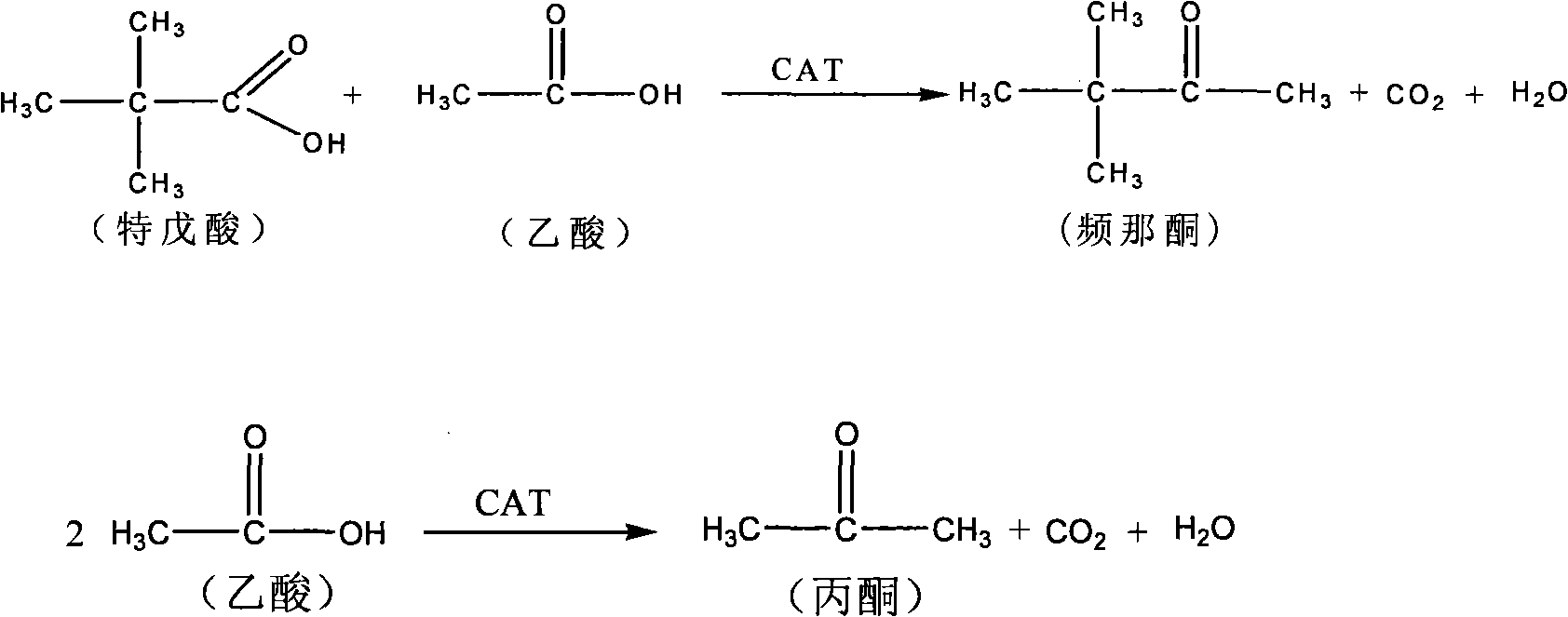

Process for synthesizing 3,3-dimethyl-2-butanone

ActiveCN101289376ASimple processEasy to operateCarbonyl compound preparation by condensationPivalic acidGas phase

The invention relates to a synthesis method of 3, 3-dimethyl-2-butanone by using pivalic acid and glacial acetic acid as raw materials which are catalyzed to react by gas phase under the conditions of normal pressure. The pivalic acid and the glacial acetic acid and water are uniformly mixed up under the normal temperature according to the molar ratio of 1:1:3 to 1:1.4:3; after vaporization, the pivalic acid and the glacial acetic acid and the water are catalyzed to have a decarboxylation reaction and then pinacolone is produced under the normal pressure with the temperature of 380 to 400 DEG C in a fixed bed reactor; the carrier of the catalyst is A12O3; active components are one or two compounds of rare earth metals Ce, Nd, La or oxides thereof; the active component content which is calculated according to the weight of metal oxides takes up 20-30 percent of the weight of the carrier A12O3; the bulk density of the catalyst is 0.47 to 0.5; after analysis, the selectivity of the pinacolone is above 95 percent and then the 3, 3-dimethyl-2-butanone product with the purity of 99 percent can be obtained after the pinacolone is purified by rectification under the normal pressure.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

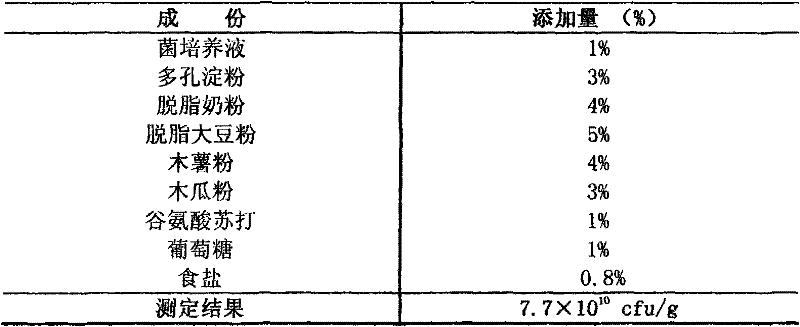

Microbial compound preparation and preparation method thereof

ActiveCN102210454AImprove securityUnique functionBacteria material medical ingredientsFood preparationBiotechnologyPorous starch

The invention relates to a microbial compound preparation containing Lactobacillus acidophilus and a processing technology thereof. The microbial compound preparation contains a Lactobacillus acidophilus fermentation culture; the Lactobacillus acidophilus is taken as an active ingredient; and the viable count of the Lactobacillus acidophilus in the microbial compound preparation is more than 7.7*10<10>cfu / g, and the average particle size is less than 10mu m. The Lactobacillus acidophilus fermentation culture is obtained by culturing in a fermentation culture medium containing 3 to 5 percent of porous starch, 4 to 5 percent of defatted milk powder, 5 to 7 percent of defatted soybean powder, 4 to 6 percent of tapioca flour, 3 to 5 percent of papaya powder, 1 percent of glutamic acid soda, 1to 2 percent of glucose, and 0.8 percent of table salt. Production processes are simple, and production cost is low. The microbial compound preparation can be prepared into medicinal preparations, health-care products, foods and nutritional supplements, can be taken as a core functional ingredient in feed additives, and has a broad application range.

Owner:SHANGHAI HONGYUAN BIOTECH

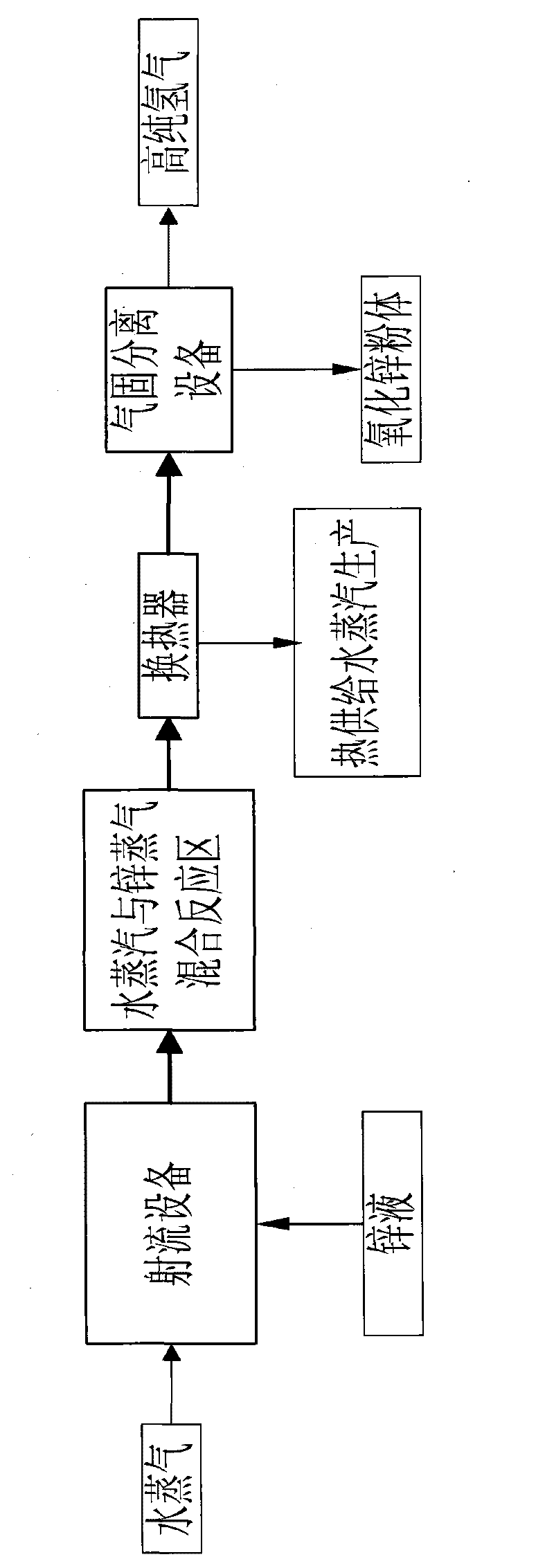

Method for simultaneously preparing hydrogen and zinc oxide powder

InactiveCN101746724AEfficient continuous productionNo pollution in the processHydrogenZinc oxides/hydroxidesHydrogenWater vapor

The invention discloses the technology for preparing hydrogen and zinc oxide powder through the reaction between water vapor and metal zinc. The jet flow vacuum technology is utilized, and high-speed water vapor jet flow forms vacuum in a zinc solution container connected with a jet flow pipeline, so the evaporation temperature of the metal zinc is reduced, the volatilization of the metal zinc is accelerated, the volatilized metal zinc vapor enters the water vapor jet flow, after being mixed, the volatilized metal zinc vapor and the water vapor immediately react for generating the hydrogen and the zinc oxide powder, the pure hydrogen and the zinc oxide powder can be respectively obtained through the heat exchange by a heat exchanger after the gas-solid separation, and heat recovered by the heat exchanger can be used for producing water vapor. The temperature range of the water vapor at an inlet is between 100 DEG C and 2000 DEG C, and the temperature of the zinc solution is higher than 419 DEG C. The invention utilizes the jet flow vacuum technology, lowers the evaporation temperature of the metal zinc, solves the problem of zinc-water reaction interfaces, improves the reaction speed of the water vapor-zinc vapor, and belongs to the high-efficient preparation technology for the pure hydrogen and the zinc oxide powder.

Owner:KUNMING UNIV OF SCI & TECH

Intelligent fruit peeling apparatus based on internet of things

ActiveCN108903007AImplement peeling operationContinuous productionSievingScreeningEngineeringMaterial Separation

The invention relates to an intelligent fruit peeling apparatus based on internet of things. The apparatus comprises a fruit screening device, a peeling chamber, a foreign material separation chamber,a foreign material compression chamber, a water regeneration chamber, a circulating water control chamber and a control display part. Through the peeling device with a specific structure, differently-sized fruits can be quickly peeled. By adjusting heights of friction heads, fruit with different thicknesses can be peeled. Fruit peels and other waste can be processed with high efficiency because aseparation board with a specific structure is arranged and a separation rotary cylinder rotates.

Owner:瑞安市浙工大创新创业研究院

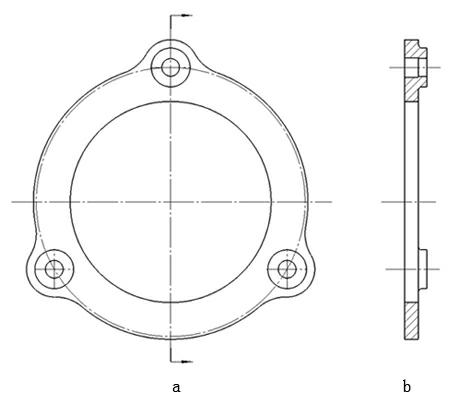

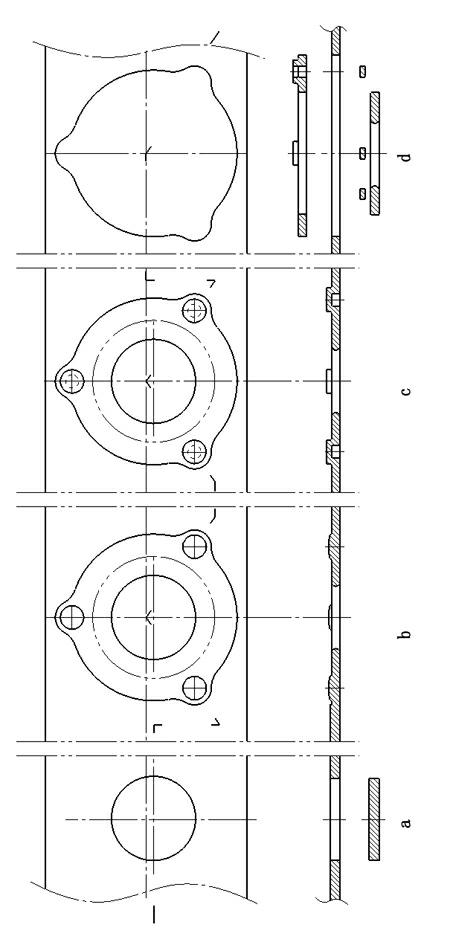

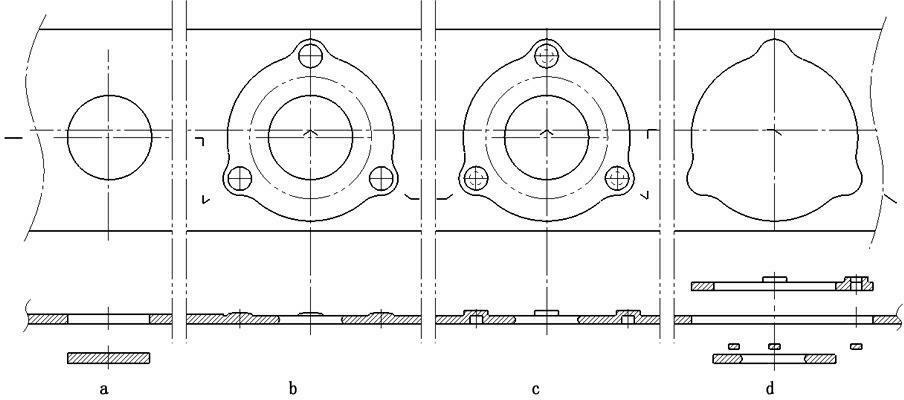

Continuous press forging precise forming process of automobile retaining frame part

InactiveCN102689149AHigh precisionEfficient continuous productionMetal-working apparatusSteel platesSheet steel

The invention provides a continuous stamp forging precise forming process of an automobile retaining frame part and belongs to the field of metal pressure processing. The process adopts the process route that a forming process method of combining precise stamping and cold forging is adopted, an annealed steel plate with the thickness a little greater than the thickness of a part flange part is selected as raw materials, after uncoiling and flattening work procedures, the steel plate is clamped by a feeding roller and is conveyed into a multi-station stamp forging forming mold, workpieces are formed in four steps, the four steps respectively comprise the first work step of inner hole blanking, the second work step of flattening / bulge extrusion, the third work step of hole extrusion and bulge forming and the fourth work step of bulge hole punching / inner hole punching / blanking, and the workpieces are obtained. The parts obtained by adopting the process do not need the subsequent machining at all. Compared with the traditional forging process, the continuous stamp forging precise forming process has the advantages that the precision of the forged piece is improved, the efficient and continuous production of retaining frame part products is realized, and the production efficiency is greatly improved.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH +1

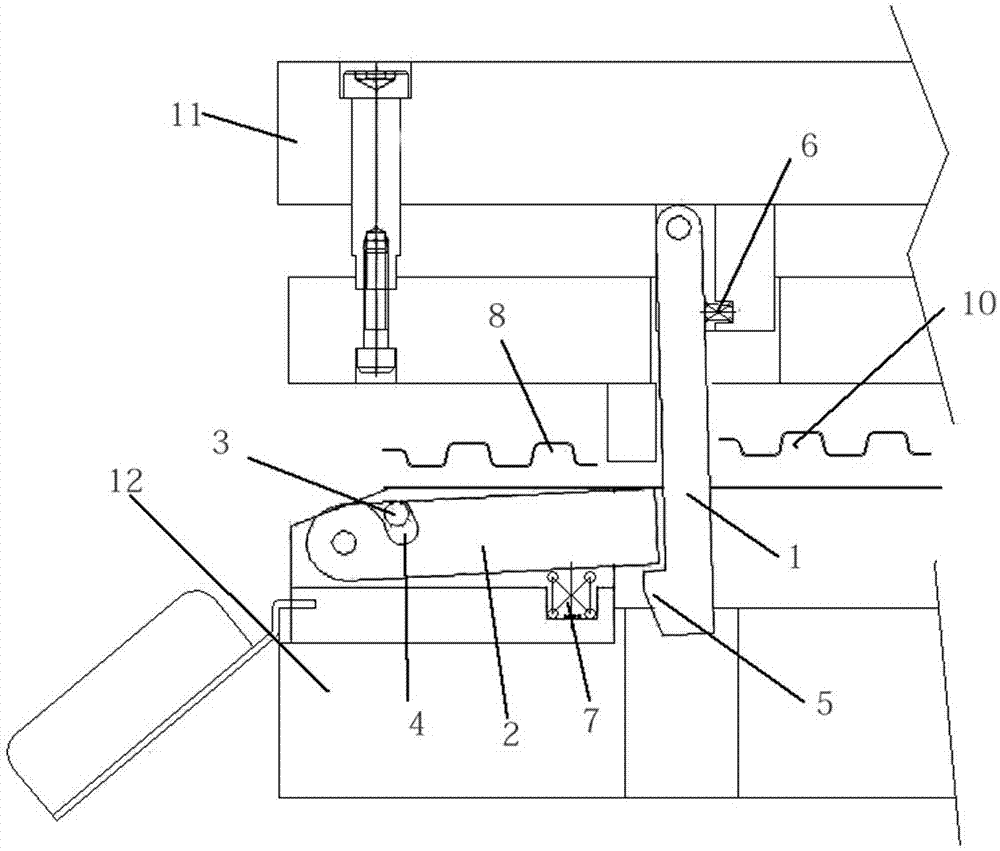

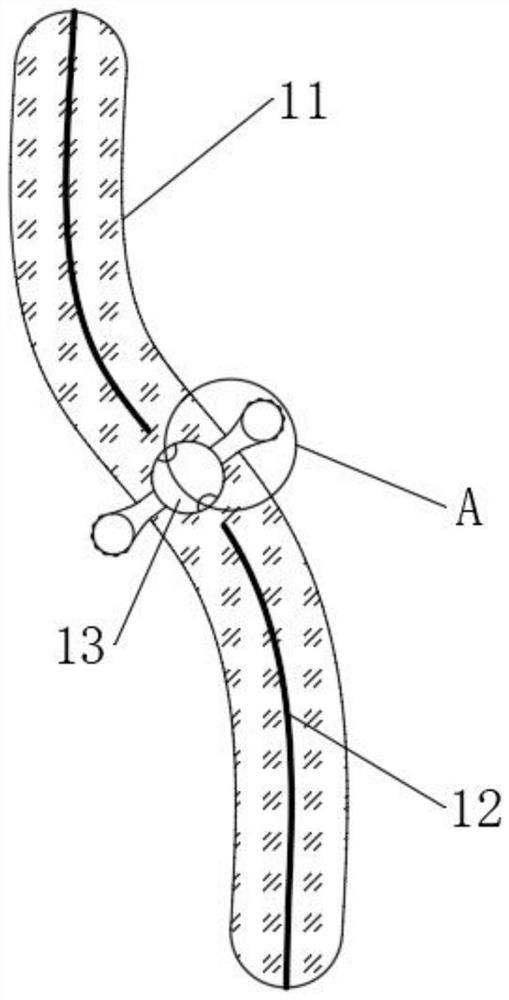

Auxiliary stripping mechanism in continuous die

InactiveCN103752718AEfficient continuous productionSafe continuous productionEjection devicesEngineeringMechanical engineering

The invention discloses an auxiliary stripping mechanism in a continuous die. The mechanism comprises a swinging rod, a stripping rod and a limit column. The upper end of the swinging rod is vertically installed in an upper die plate of the continuous die through a rotating shaft, the swinging rod can swing freely with a certain angle in the upper die plate, and the swinging rod is inserted into a lower die plate. The upper portion of the swinging rod is in contact matching with a swinging rod resetting spring fixedly installed in the upper die plate, and a protrusion with a straight side and an inclined corner is transversely extended from the lower end of the swinging rod, and a right-angle hook is formed by the protrusion and the swinging rod. The tail end of the stripping rod is installed in the lower die plate of the continuous die through a rotating shaft to enable the stripping rod to be transversely arranged in the lower die plate. The swinging rod is matched with the stripping rod. The auxiliary stripping mechanism is simple in structure and reasonable in design, overcomes the shortcoming of a traditional stripping mechanism in the continuous die, and enables the continuous die to conduct efficient safe continuous production.

Owner:XIANGXIN AUTOMOTIVE COMPONENT TOOL & DIE

Vertical full-automatic continuous-boiling granulator and sugar alcohol granulation method

ActiveCN106179114ATo achieve the effect of continuous mixingReasonable boiling heightSugar productsGranulation by powder suspensionBiochemical engineeringAlcohol sugars

The invention discloses a vertical full-automatic continuous-boiling granulator and a sugar alcohol granulation method. The granulator comprises a control unit, a granulation chamber, an air inlet unit, an air outlet unit, a feeding unit, a liquid spraying unit and a discharging unit, wherein the discharging unit comprises a discharging rotating valve for controlling the output of granules from the granulation chamber, and is characterized in that the discharging unit further comprises a discharging pressure difference sensor, the control unit receives a pressure signal output by the discharging pressure difference sensor and controls the size of the discharging rotating valve according to the pressure signal. According to the granulator, the equipment energy consumption can be greatly reduced, continuous feeding and discharging at the same time can be achieved, the production efficiency can be improved, the operation of workers can be simplified through automation, and the situation of flying dust can be reduced due to continuous production, furthermore, the vertical boiling granulator has natural advantages, the volume of equipment is small, and the area occupation is small, thus being beneficial to large-scale production.

Owner:ZHEJIANG HUAKANG PHARMA

Glass compositions for fiber formation

Provided is a range of glass compositions and glass fiber products made therefrom that show a unique combination of properties for both discontinuous fiber manufacturing and end use service. The glass compositions are particularly useful in high volume, high throughput, economical processes such as rotary spinning.

Owner:JOHNS MANVILLE CORP

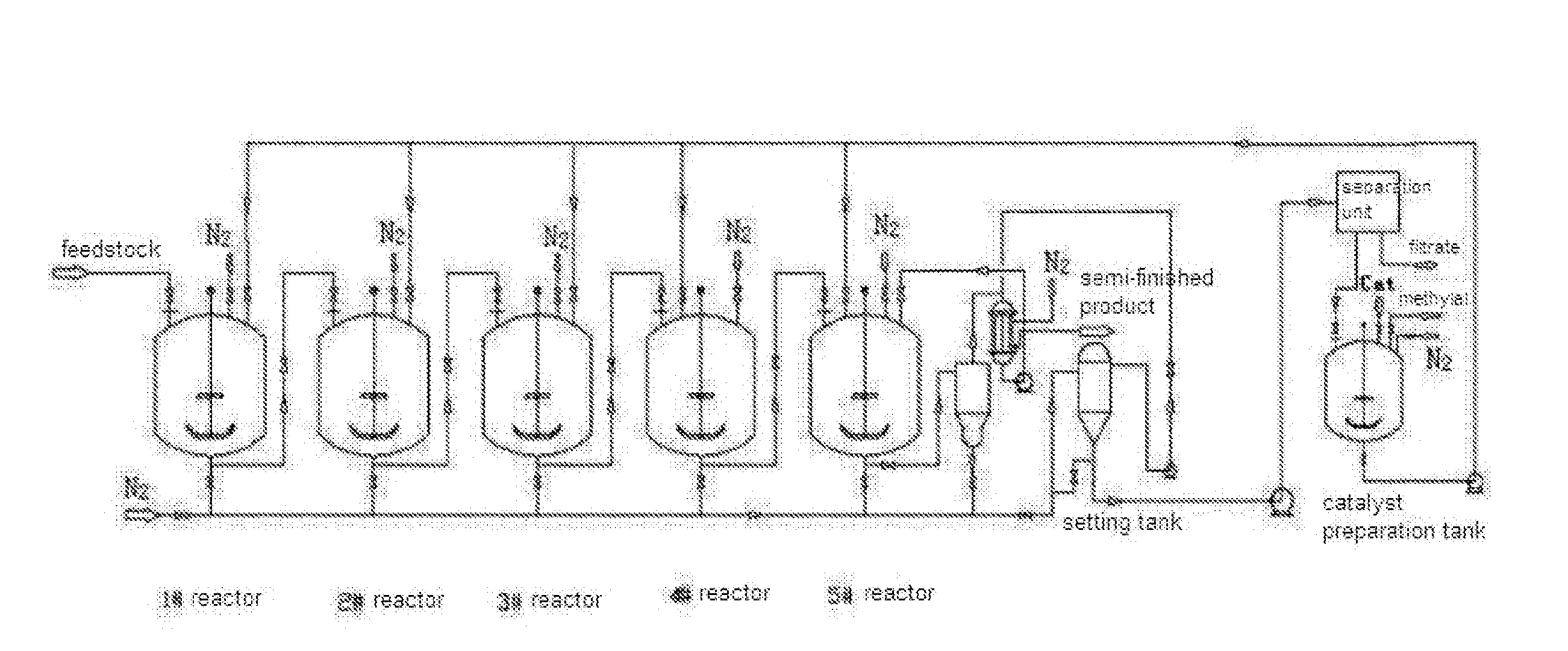

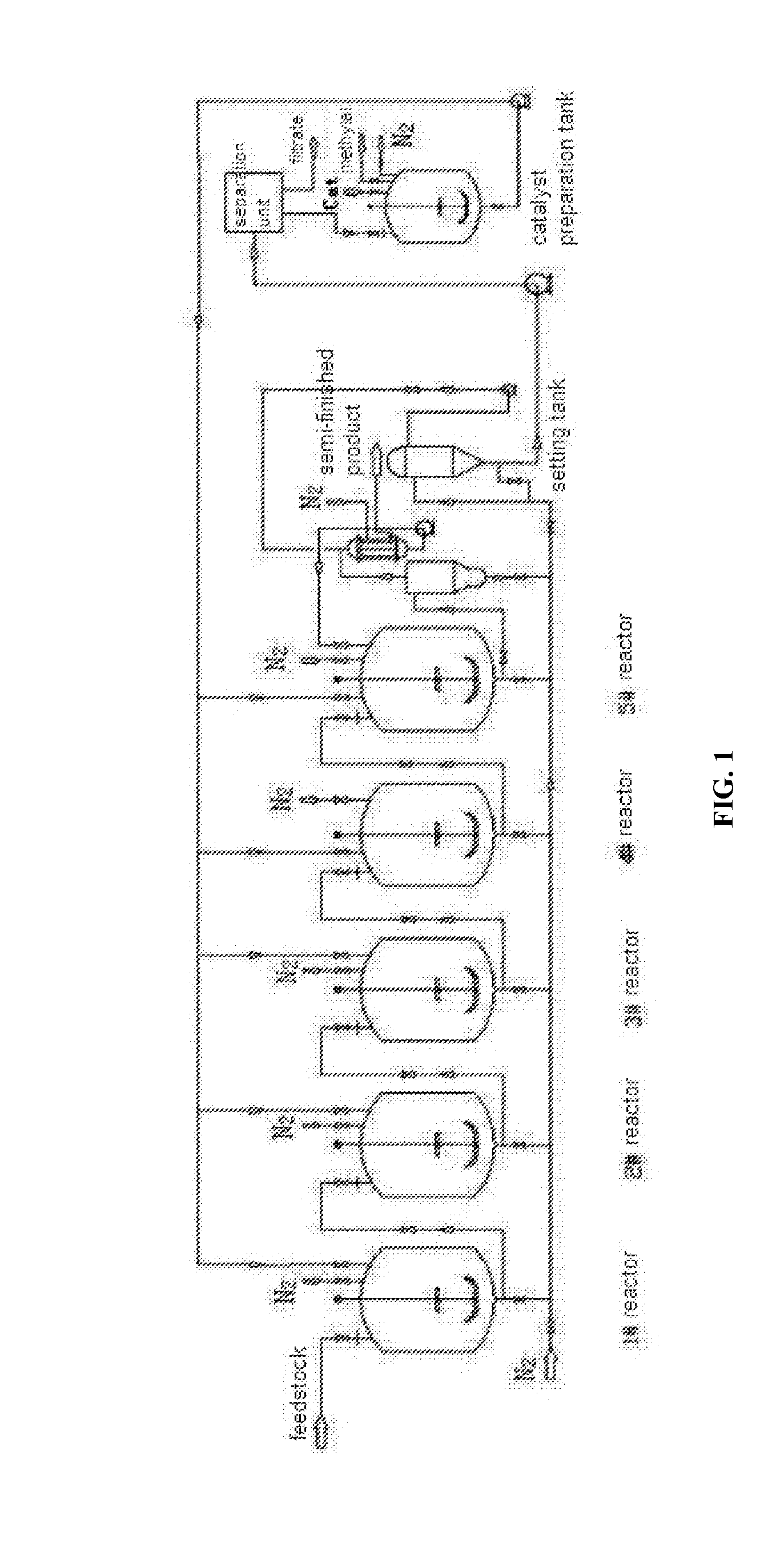

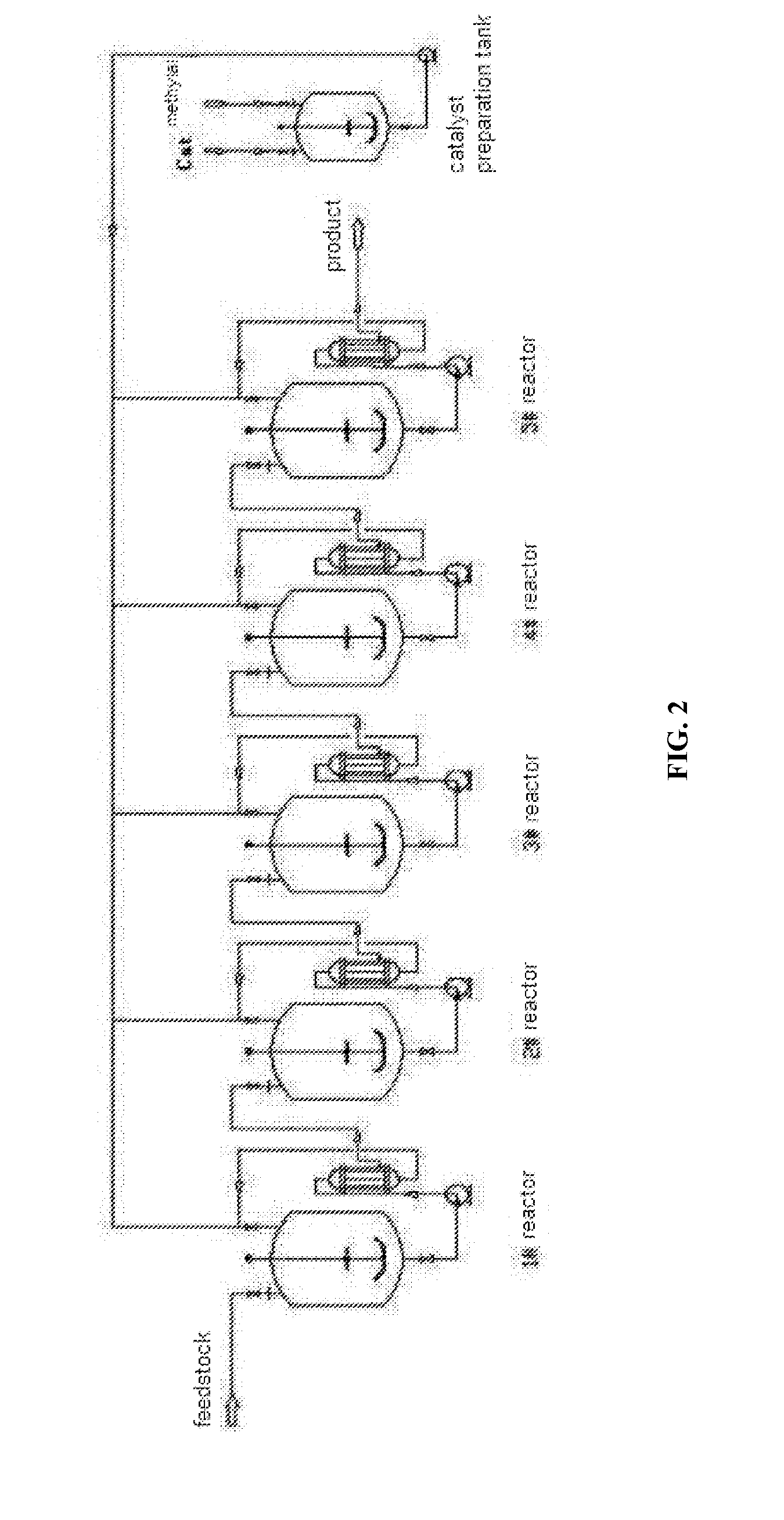

Continuous reaction device for synthesizing polyoxymethylene dimethyl ethers

InactiveUS20160185902A1Improve mixing efficiencySave energyOrganic chemistryOrganic compound preparationChemical industryReaction temperature

The present invention pertains to the technical field of energy resource chemical industry, and in particular relates to a continuous reaction device and process for synthesizing polyoxymethylene dimethyl ethers by using paraformaldehyde and methylal as feedstock or using trioxane and methylal as feedstock in the presence of an acidic catalyst. The continuous reaction device comprises multiple slurry bed stirred tank reactors connected in series or in combination of series connection and parallel connection, and also comprises an on-line solid-liquid separation device to perform separation of the reaction mixture from the catalyst. Each of the tank reactors is provided with an axial-flow stirring paddle having 2-6 blades per layer, to ensure sufficient mixing of the reactants with the catalyst. By using a distributed control pattern of reaction temperature and feedstock supplying to enhance the process and to optimize the operation, the reaction device of the present invention can effectively achieve large-scale continuous production of polyoxymethylene dimethyl ethers, and both the yield rates and the distribution of the reaction product are better than those of prior art.

Owner:DONGFANG HONGSHENG NEW ENERGY APPL TECH RES INST +1

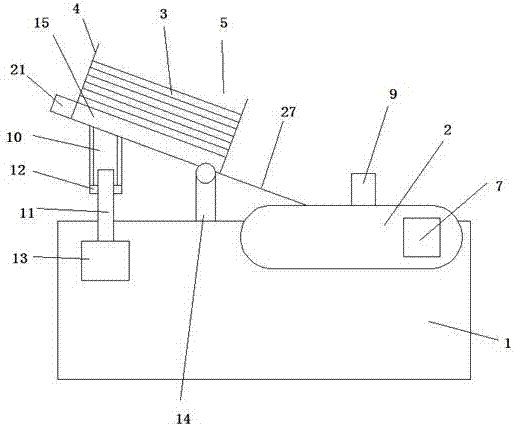

Coating, gold blocking and embossing continuous production and processing technology for papermaking

ActiveCN109334125AIncrease productivityRealize continuous productionMechanical working/deformationDecorative surface effectsPapermakingBronzing

The invention relates to the field of papermaking production, in particular to a coating, gold blocking and embossing continuous production and processing technology for papermaking. According to thecoating, gold blocking and embossing continuous production and processing technology, coating, gold blocking and embossing of paper can be achieved on the same equipment, and thus the papermaking efficiency is improved; the papermaking continuous production equipment adopted in the technology comprises a supporting platform, a feeding mechanism, a first fixing shell, a second fixing shell, a thirdfixing shell, a conveying mechanism, a collecting mechanism, a coating mechanism, an embossing mechanism, a gold blocking mechanism and a drying mechanism; the feeding mechanism is arranged on the top face of one end of the supporting platform; the conveying mechanism is arranged on the supporting platform; the coating mechanism is arranged in the first fixing shell; the drying mechanism is arranged in a ventilating hole in the first fixing shell; the gold blocking mechanism used for gold blocking of paper raw materials is arranged in the second fixing shell; and the embossing mechanism usedfor embossing the paper raw materials is arranged in the third fixing shell. According to the coating, gold blocking and embossing continuous production and processing technology, coating, gold blocking and embossing integrated papermaking is achieved, and the coating effect is better.

Owner:上海祥天纸业有限公司

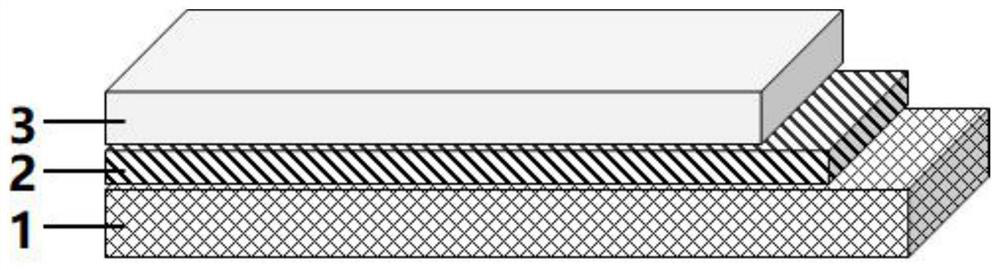

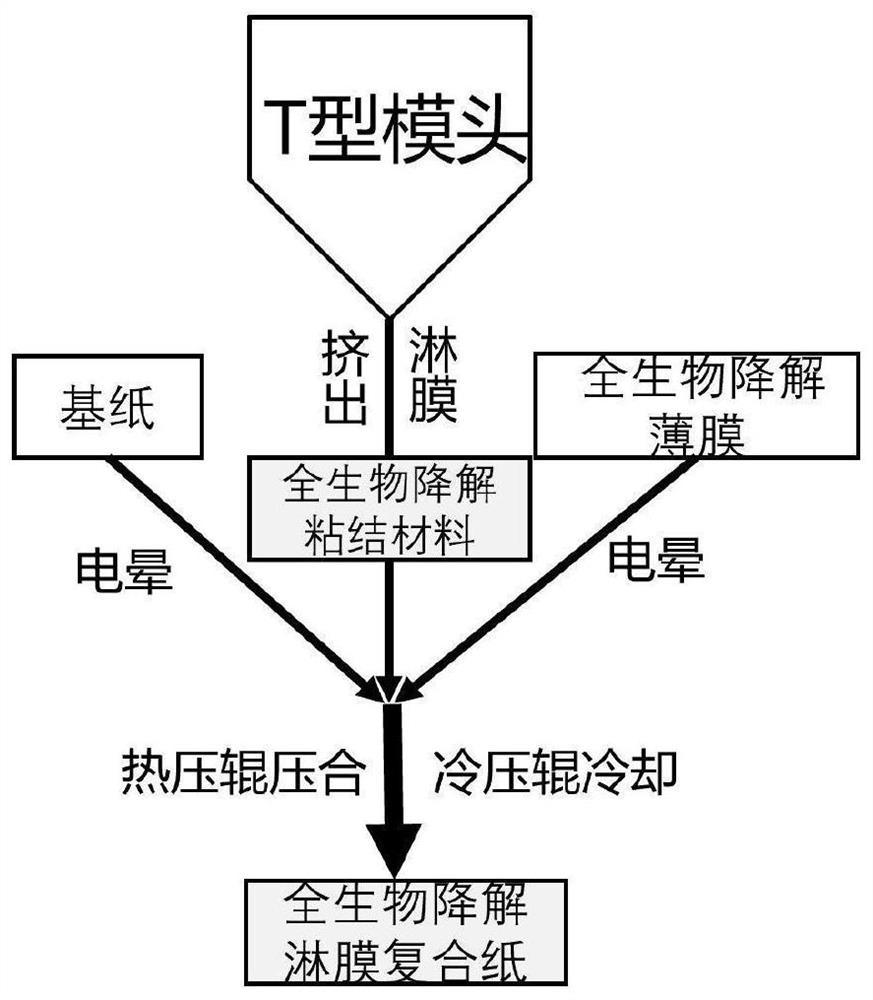

Full-biodegradable lamination composite paper material and preparation method thereof

ActiveCN113355950AImprove performanceBrown sports strongCoatings with pigmentsSpecial paperPolymer scienceAdhesive

The invention discloses a full-biodegradable lamination composite paper material and a preparation method thereof. According to the full-biodegradable composite paper material disclosed by the invention, the biodegradable binding material is used for replacing a traditional chemical adhesive to be applied to compounding of laminated composite paper so as to reduce residues of toxic and harmful substances; and through a mode of compounding the paper and the film, the defects of easiness in roll sticking, low production efficiency and poor material barrier property caused by laminating PBAT resin on a single paper surface are overcome. According to the invention, all the parts are made of full-biodegradable materials, so that the whole body has good biodegradability. After being discarded, the material can be fully biodegraded in the natural environment and does not pollute the environment. The relative biological decomposition rate is greater than or equal to 90%.

Owner:RACHEM CHINA CO LTD +1

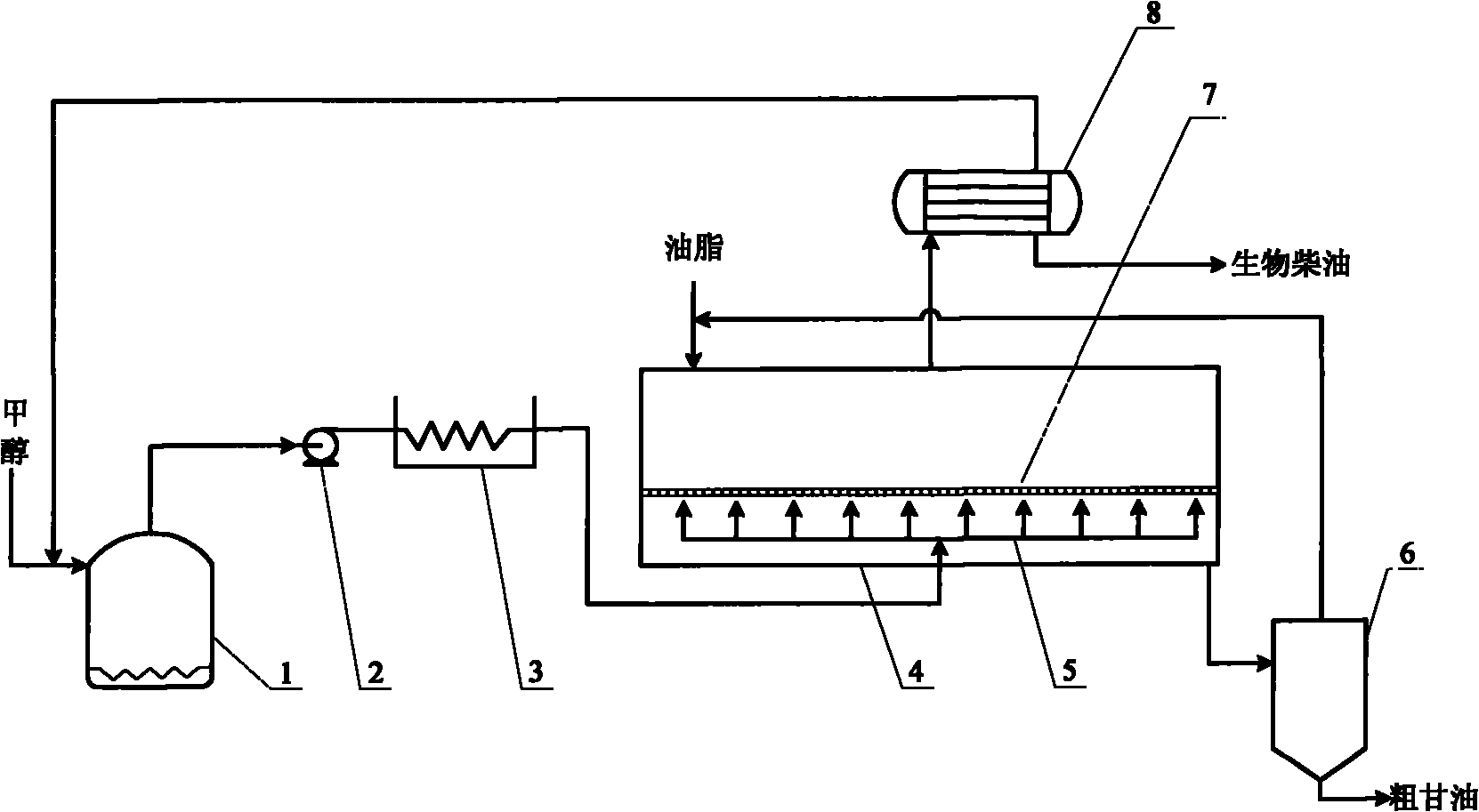

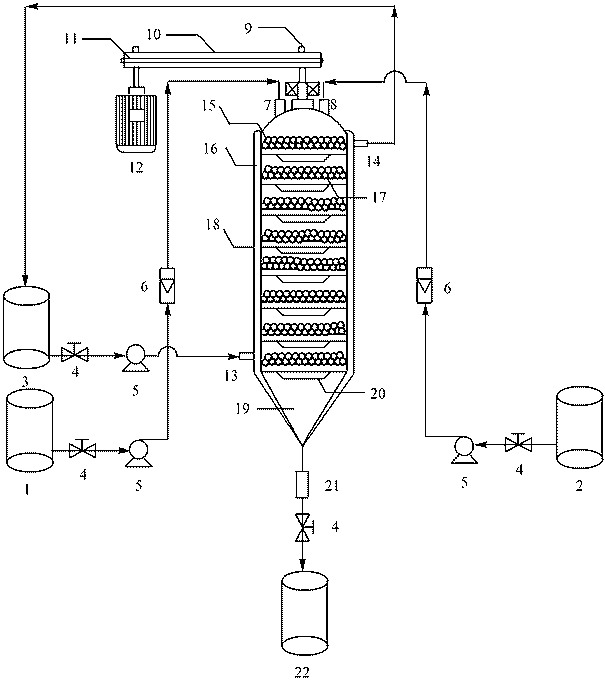

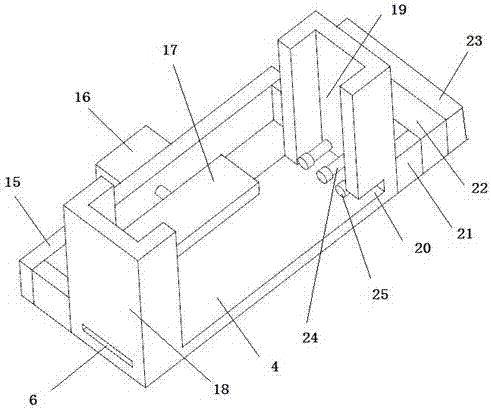

Device and method for preparing biodiesel through rotary fixed bed fast reaction

ActiveCN105713734AAvoid the uneven distribution of rotation and centrifugal forceAvoid uneven distributionFatty acid esterificationBiofuelsAlcoholCentrifugation

The invention provides a device and method for preparing biodiesel through a rotary fixed bed fast reaction. The device is mainly composed of a fixed bed reactor with a rotary shaft (9). Firstly, the fixed bed reactor filled with a solid catalyst is added to reactant methyl alcohol, and meanwhile a motor (12) is started to enable a reaction still to rotate. The dropping speed of raw material oil is controlled, and the oil and excessive methyl alcohol are subjected to the fast reaction. The contact chance of the reactant and the catalyst can be increased through rotating, more active point locations can be occupied, and sinking and separation of fatty acid methyl ester can be promoted. By means of a liquid redistributor, the phenomenon that liquid is unevenly distributed due to rotary centrifugation is avoided. The layering condition of sight glass (21) is observed, and products are removed in time. A forward reversible reaction can be accelerated through excessive methyl alcohol, timely removal of the products and the rotary reaction still. The advantages of being easy to operate, high in raw material utilization rate, high in esterification efficiency and the like are achieved, and the device and method can be used for fast and continuous preparation of the biodiesel.

Owner:SHANDONG UNIV OF TECH

Novel catalytic process for arylamine aromatic hydrocarbon alkylation

ActiveCN112225631AFast conductionEvenly distributedMolecular sieve catalystsMolecular sieve catalystChemical synthesisMolecular sieve

The invention discloses a novel catalytic process for arylamine aromatic hydrocarbon alkylation, belongs to the technical field of chemical synthesis, and can realize innovative introduction of a novel catalyst. The novel catalyst comprises a molecular sieve catalyst and a heat transfer catalytic fiber rod, an acidic center formed by protonic acid and aprotic acid is attached to the surface of a molecular sieve to form the catalyst with high activity and long service life, the catalyst is applied to a fixed bed reactor, the reaction process and the catalyst are fluoride-free and chlorine-free,and repeated utilization can be realized without backwashing. The introduced heat transfer catalytic fiber rod can improve the problem of poor heat transfer performance in the fixed bed reactor, notonly can realize rapid conduction and uniform distribution of heat, but also can trigger expansion and contraction actions of the fiber rods by the heat, so that reactant gas flows in a local range, and the reaction efficiency is improved. The catalytic reaction effect is improved through contact of the extruded gas and the molecular sieve catalyst, so that efficient and continuous production of alkylbenzene is realized.

Owner:JIANGSU FEIYA CHEM IND

Polyurethane thermal panel and production process thereof

The invention discloses a polyurethane thermal panel and a production process thereof. The panel comprises composite polyether and isocyanate. The composite polyether comprises compound polyhydric alcohols, an amine catalyst, a foam stabilizer, a foaming agent, a flame retardant and modified graphene. The ratio of raw materials is strictly controlled in the production process, the mixing ratio ofthe raw materials is accurately measured, and the efficiency and stable-quality continuous production of the polyurethane thermal panel is realized through mixing, casting and foaming of a quick spraying gun of a foaming machine.

Owner:广西鸿匠保温材料有限公司

Method of preparing ethyl benzene by saparating ethene and benzene under dry gas of catalysis

InactiveCN1315761CReduce energy consumptionSimple structureHydrocarbonsHydrocarbon preparationSaturated water vaporVaporization

This invention is a process for preparing ethyl benzene through the phase-changing catalytic separation of benzene and ethylene in the dry catalytic cracking gas. Benzene and the dry catalytic cracking gas enter the reaction column from the upper and the lower portion, respectively. The temperature of the reaction section is close to the boiling temperature of benzene under the operation conditions. In the reaction section the heat needed for the vaporization of the liquid benzene is utilized to absorb the heat released during the reaction of benzene with ethylene in the dry catalytic cracking gas. The upper and lower effluents are utilized for heating benzene and the dry gas, respectively. The dry catalytic cracking gas comprises 10-60 vol. % of ethylene, 100-500ppm of H2S, 1.0-5.0 vol. % of COx, 0.1-1.5 vol.% of oxygen and saturated water vapor at 20-40 deg.C. The conditions for the hydrocarbonylation reaction are: the pressure is 1.0-3.5MPa, the temperature is 150-260 deg.C, the molar ratio of benzene to ethylene in the dry catalytic cracking gas is 1-10, and the weight flow rate of ethylene in the dry catalytic cracking gas is 0.05-1.5h-1.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Full-automatic workpiece assembling system

PendingCN106925989AGood slide outStable processingMetal working apparatusMotor driveTransmission belt

The invention discloses a full-automatic workpiece assembling system. The full-automatic workpiece assembling system comprises a feeding part and an assembling part arranged at the rear end of the feeding part. The feeding part comprises a rack, a feeding mechanism arranged at the front end of the rack, and a conveying belt arranged at the rear end of the rack, and the conveying belt is connected with a driving motor used for driving the conveying belt to operate. The assembling part comprises a case and a turntable rotatably arranged on the case. A stepping motor driving the turntable to rotate is arranged in the case. A plurality of mounting bases are annularly arranged on the turntable at equal angles. A nut feeding mechanism used for embedding nuts into the mounting bases, a taking mechanism used for taking material strips to the mounting bases, a safety braking mechanism used for embedding accessories into the mounting bases manually, a screw locking mechanism used for locking screws to corresponding positions, and a discharging mechanism used for discharging assembled pieces out of the mounting bases are arranged on the case around the turntable.

Owner:HUIZHOU ZHONGBANG ELECTRONICS

A vertical fully automatic continuous boiling granulator and sugar alcohol granulation method

ActiveCN106179114BTo achieve the effect of continuous mixingReasonable boiling heightSugar productsGranulation by powder suspensionBiochemical engineeringAlcohol sugars

The invention discloses a vertical full-automatic continuous-boiling granulator and a sugar alcohol granulation method. The granulator comprises a control unit, a granulation chamber, an air inlet unit, an air outlet unit, a feeding unit, a liquid spraying unit and a discharging unit, wherein the discharging unit comprises a discharging rotating valve for controlling the output of granules from the granulation chamber, and is characterized in that the discharging unit further comprises a discharging pressure difference sensor, the control unit receives a pressure signal output by the discharging pressure difference sensor and controls the size of the discharging rotating valve according to the pressure signal. According to the granulator, the equipment energy consumption can be greatly reduced, continuous feeding and discharging at the same time can be achieved, the production efficiency can be improved, the operation of workers can be simplified through automation, and the situation of flying dust can be reduced due to continuous production, furthermore, the vertical boiling granulator has natural advantages, the volume of equipment is small, and the area occupation is small, thus being beneficial to large-scale production.

Owner:ZHEJIANG HUAKANG PHARMA

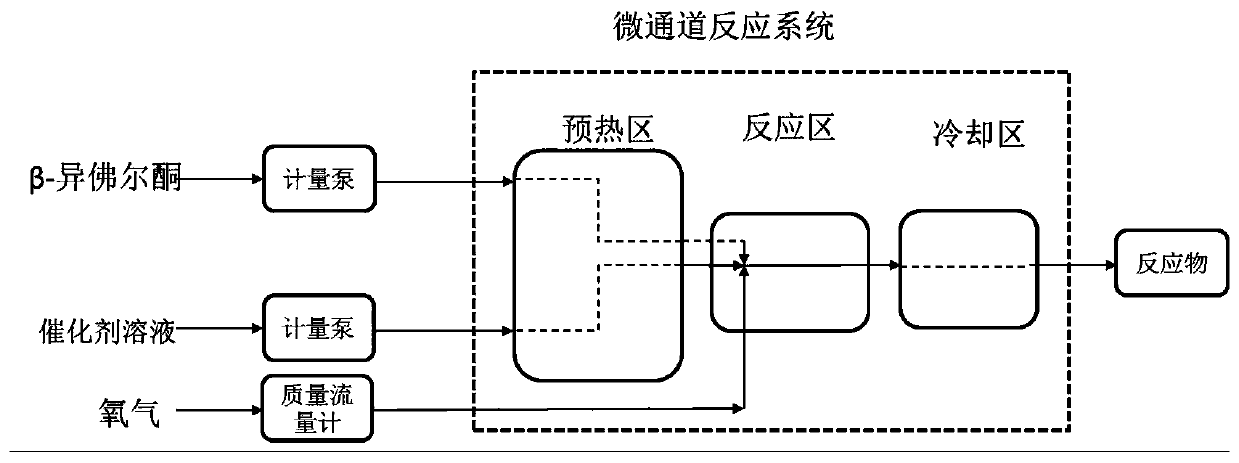

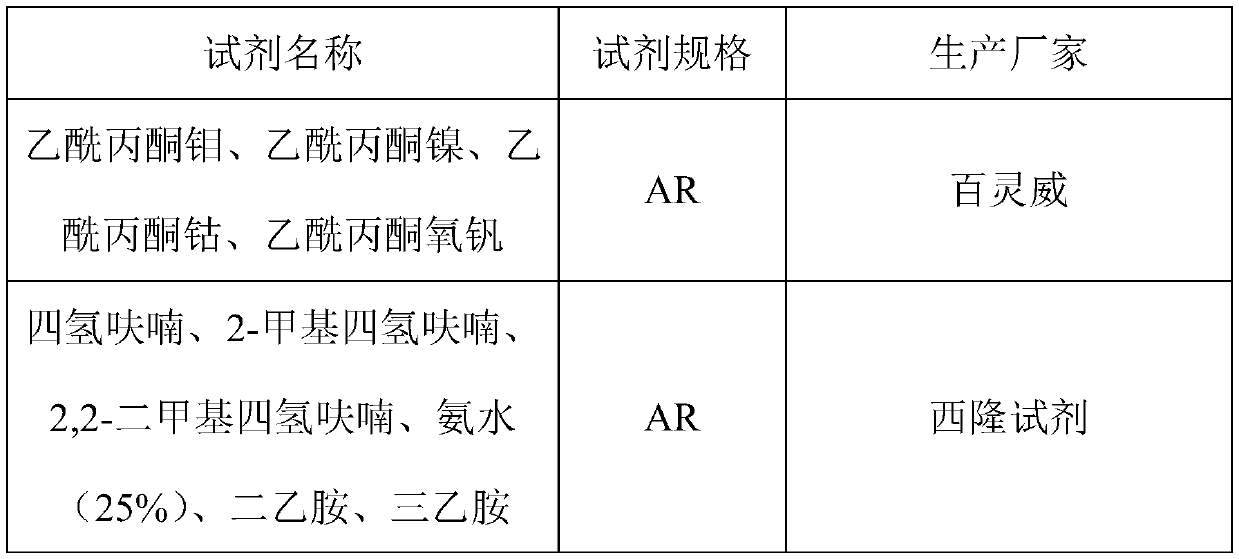

Method for continuously synthesizing 4-oxoisophorone in microchannel reactor

PendingCN110283056AHigh reaction mass transfer efficiencyStable reaction temperatureOrganic compound preparationChemical/physical/physico-chemical microreactorsIsophoroneReaction temperature

The invention discloses a method for continuously synthesizing 4-oxoisophorone in a microchannel reactor. The method comprises the following steps: feeding a metered catalyst solution, oxygen and beta-isophorone into the microchannel reactor in proportion, fully mixing and then reacting to obtain the 4-oxoisophorone. According to the process method disclosed by the invention, the microchannel reactor is utilized, so that the reaction mass-transfer efficiency is high, the reaction temperature is stable, and the experimental operability is greatly improved; the metered oxygen is used as an oxidant, the reactor volume is small, no waste gas is generated, the flash-explosion risk of a traditional kettle type gas-liquid two-phase reaction is effectively avoided, and the safety performance of the reaction is improved; a special system is adopted, so that a homogeneous catalyst is prevented from slagging during the reaction so as to plug the reactor, and the efficient continuous production of the 4-oxoisophorone becomes possible.

Owner:WANHUA CHEM GRP CO LTD

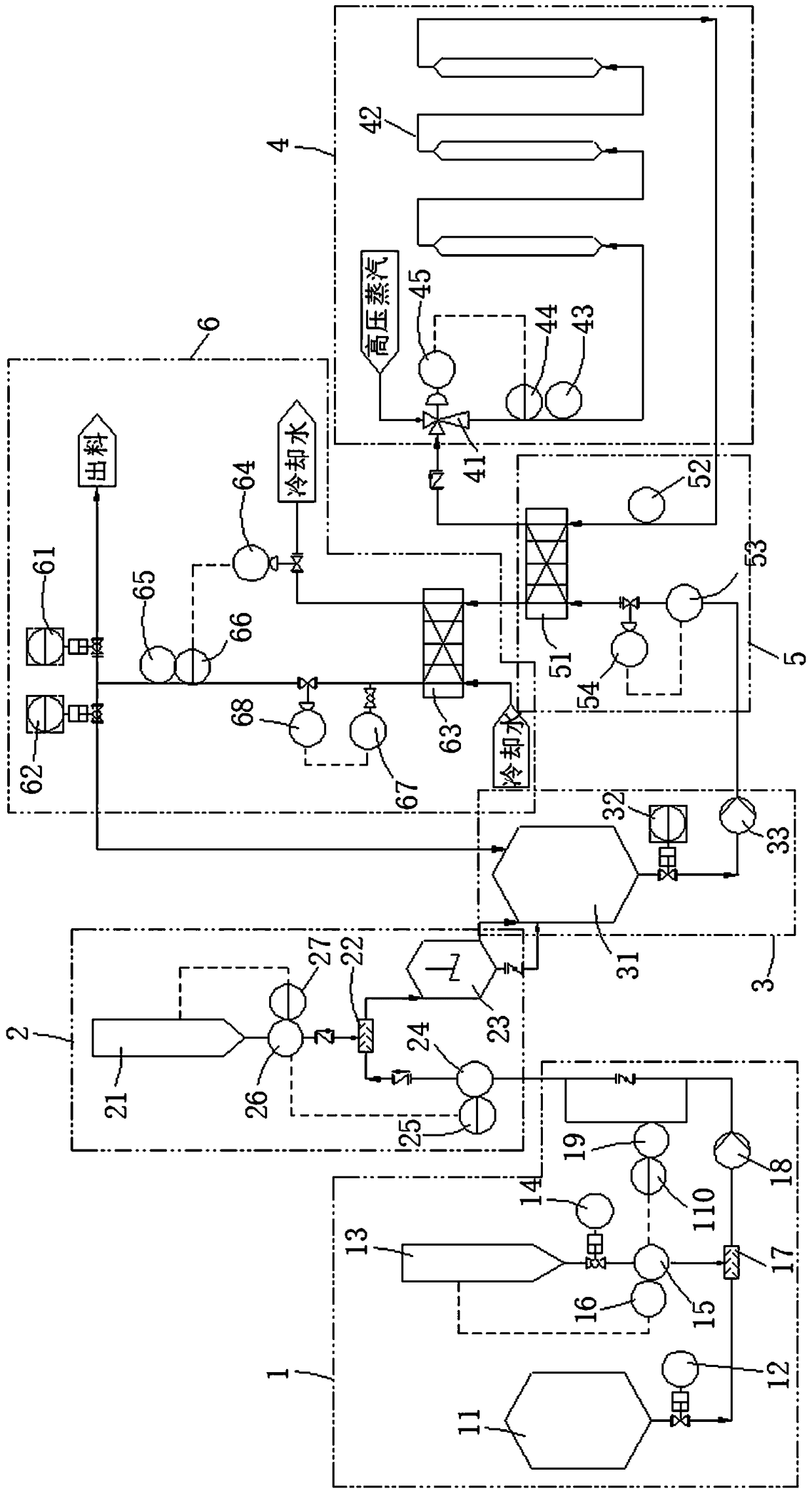

System and method for continuously hydrolyzing hemicellulose to prepare xylose liquid

ActiveCN109355443AContinuous hydrolysisHydrolytically stablePH-change processesXylose productionReflux valveHemicellulose

The invention relates to a system for continuously hydrolyzing hemicellulose to prepare a xylose liquid. The system comprises a neutralization unit, an acid regulating unit, a feeding unit, a liquidation jet unit, a feeding and discharging heat exchange unit and a discharging control unit, wherein the neutralization unit comprises a raw material tank, a neutralizing concentrated sulfuric acid pumpand a neutralizing pipeline mixer, the acid regulating unit comprises an acid-regulating concentrated sulfuric acid pump, an acid-regulating pipeline mixer and an acid regulating tank, the feeding unit comprises a feeding tank, the liquidation jet unit comprises a liquidation injector and a liquidation maintainer, the feeding and discharging heat exchange unit comprises a feeding and dischargingplate type heat exchanger and a first discharging temperature sensor, and the discharging control unit comprises a discharging valve and a reflux valve. The prepared xylose liquid exchanges heat witha hemicellulose liquid in the feeding and discharging plate type heat exchanger, so that the temperature of the xylose liquid is reduced, and the temperature of the hemicellulose liquid is increased.The invention also discloses a method for using the system. The system for continuously hydrolyzing the hemicellulose to prepare the xylose liquid has the advantages that heat exchanging is performedon feeding and discharging simultaneously, thereby greatly reducing the energy consumption; feeding and discharging are performed continuously, thereby improving the production efficiency, and simplifying the workers' operation.

Owner:ZHEJIANG HUAKANG PHARMA +1

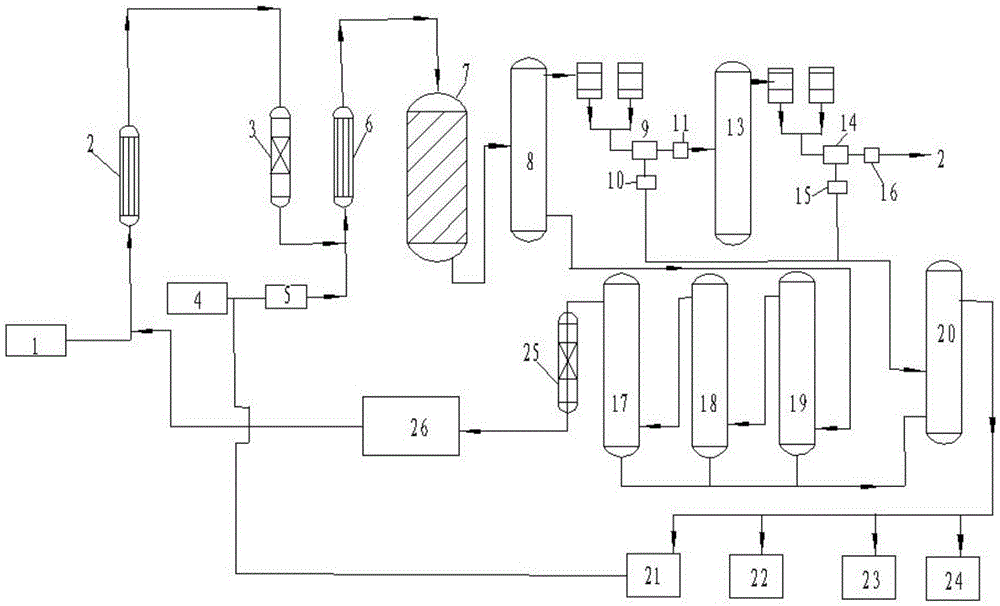

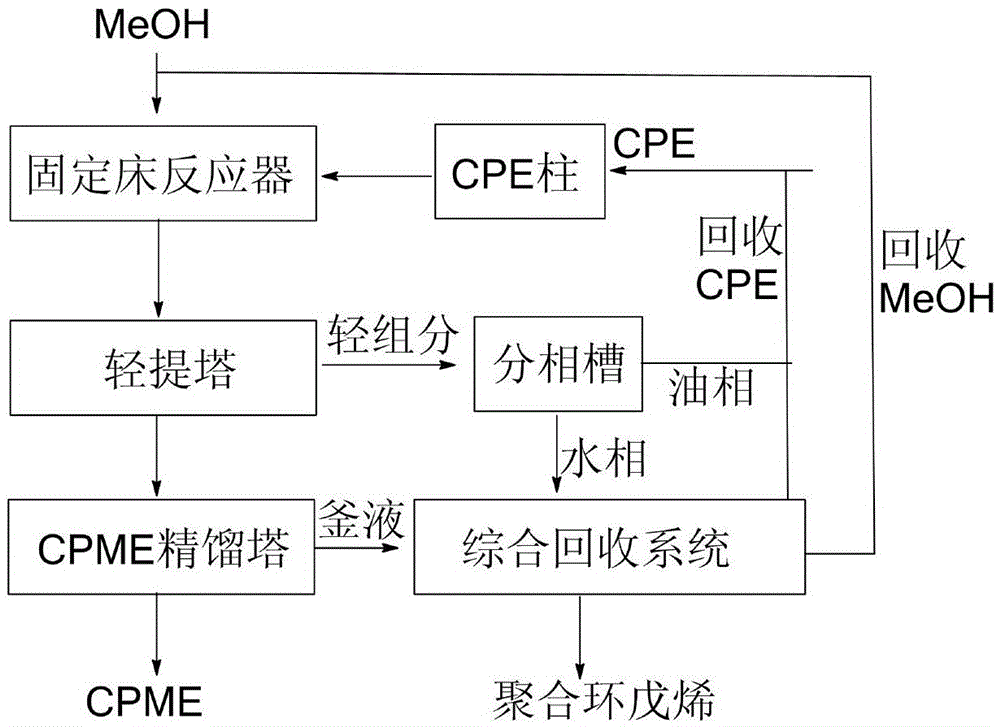

Continuous cyclopentylmethyl ether production process and production system

ActiveCN105481660AReduce poisonImprove conversion rateEther preparation by compound additionCyclopenteneDistillation

The present invention discloses a continuous cyclopentylmethyl ether production process and production system, the production process comprises vaporization of cyclopentene, filteration through an adsorption column, mixing with methanol and vaporization in a raw material vaporizer, catalytic addition reaction of the cyclopentene by entering a fixed bed reactor, distillation of the reaction solution by a light component removal tower, recovery and reuse of CPE and the methanol from light components, and rectification of a light component removal tower kettle liquid by a CPME rectification device to obtain cyclopentylmethyl ether, wherein the temperature of the catalytic addition reaction is 100-105 DEG C, the liquid hourly space velocity is 0.35-0.55hr<-1>, the gas hourly space velocity is 110-125hr<-1>, the pressure is 0.1-0.12Mpa. The conversion rate of the methanol is greater than 95%, the gas chromatography (GC) purity of a product in the reaction solution is greater than 90%, the purity of the cyclopentylmethyl ether prepared by refining is greater than 99.5% (the purity is detected by GC area normalization method), and the total yield of the cyclopentylmethyl ether is more than 80%.

Owner:ZHEJIANG ALPHARM CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com