Biodiesel preparation method

A biodiesel and oil technology, applied in the field of oleochemical industry, can solve the problems of complex post-processing, high equipment requirements, and many waste liquids, and achieve the effects of simple recovery and purification, wide applicability of raw materials, and efficient continuous production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: the preparation of jatropha biodiesel

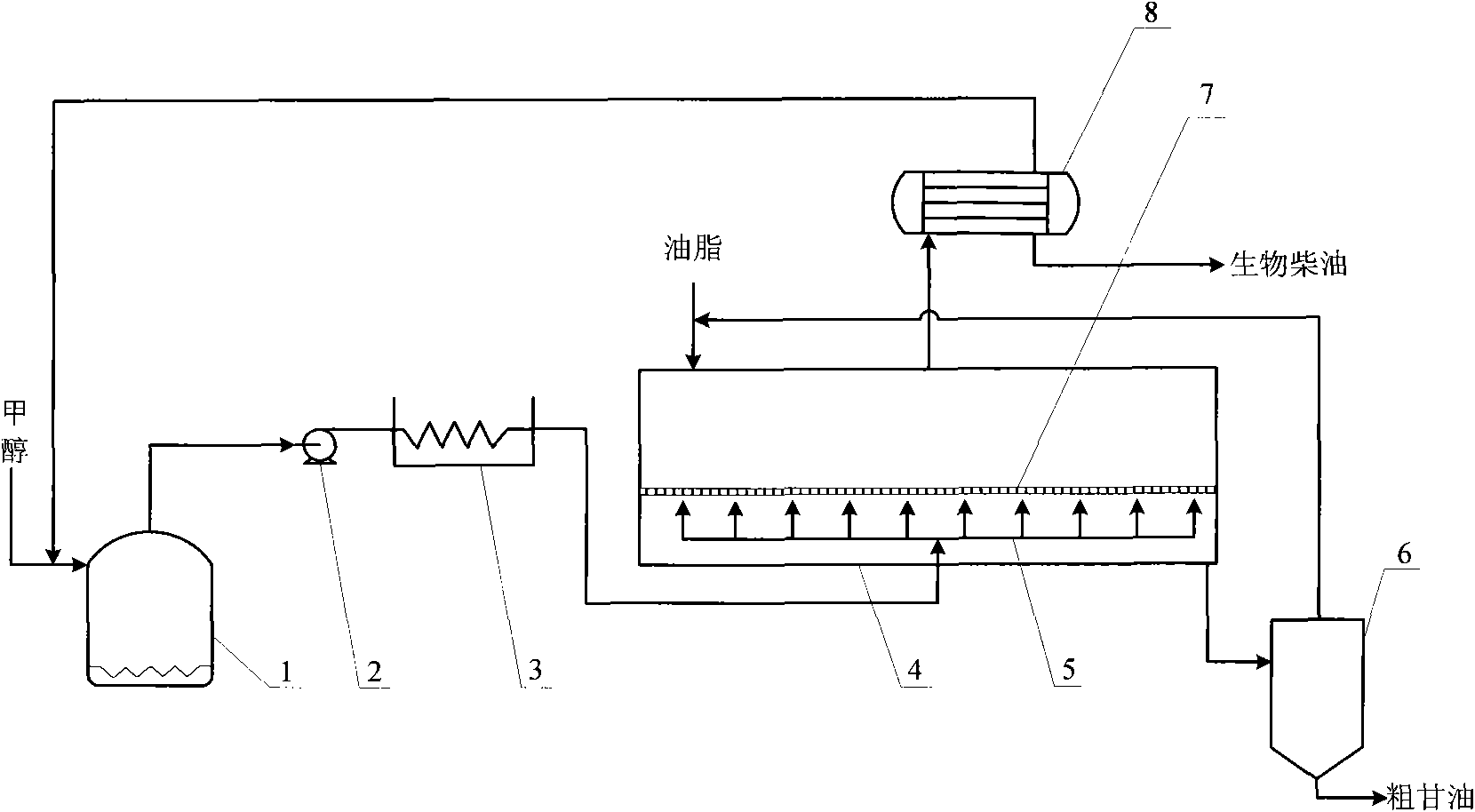

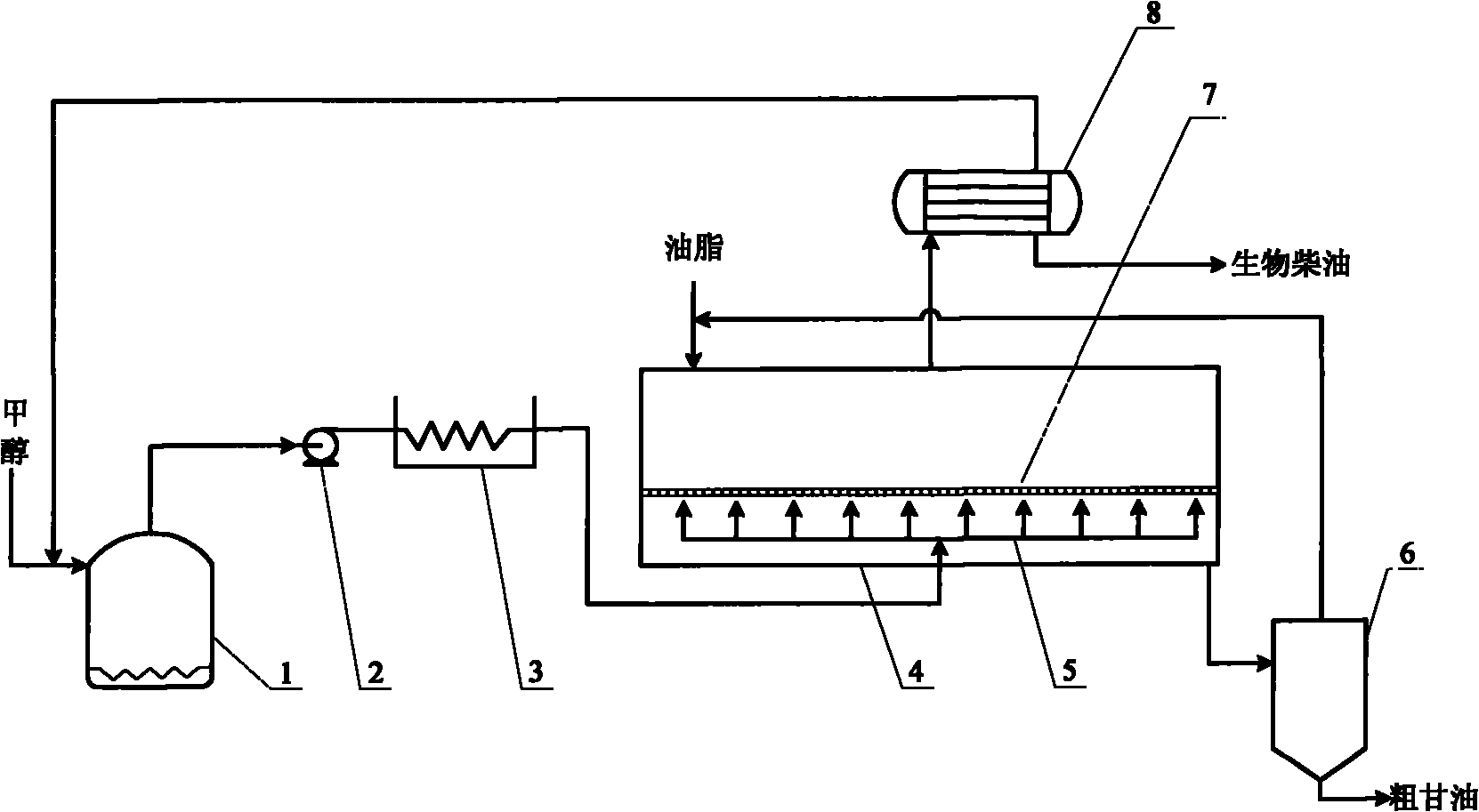

[0014] 1) Continuous transesterification and product refining: Jatropha oil is continuously added to the transesterification reactor 4, and the methanol vapor generated in the methanol gasification device 1 is heated by the heat bath 3 from the gas distribution plate installed at the bottom of the transesterification reactor 4 5 into the reactor equipped with mesoporous solid base catalyst (calcium oxide), under the action of the mesoporous solid base catalyst in the fixed bed 7, methanol vapor and jatropha oil undergo transesterification reaction, and the remaining methanol vapor is reacted The reaction product biodiesel is taken out of the reactor 4 and enters the condenser 8; after temperature control and condensation, the biodiesel is discharged from the bottom of the condenser 8 in liquid form to obtain the product Jatropha oil biodiesel, and methanol is in gas form in the gas circulation pump 2 Under the action...

Embodiment 2

[0020] Embodiment 2: the preparation of rapeseed oil biodiesel

[0021] 1) Continuous transesterification and product refining: rapeseed oil is continuously added to the transesterification reactor 4, and the methanol vapor generated in the methanol gasification device 1 is heated by the heat bath 3 from the gas distribution plate installed at the bottom of the transesterification reactor 4 5 into the reactor equipped with a mesoporous solid base catalyst (barium oxide), under the action of the mesoporous solid base catalyst in the fixed bed 7, methanol vapor and rapeseed oil undergo transesterification, and the remaining methanol vapor The reaction product biodiesel is taken out of the reactor 4 and enters the condenser 8; after temperature control and condensation, the biodiesel is discharged from the bottom of the condenser 8 in liquid form to obtain the product rapeseed oil biodiesel, and methanol is in the form of gas in the gas circulation pump 2 Under the action, return...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap