Spherical/special-shaped product all-print printing process and apparatus

A kind of printing equipment and special-shaped technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of small and difficult printing area, and achieve the effect of efficient continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

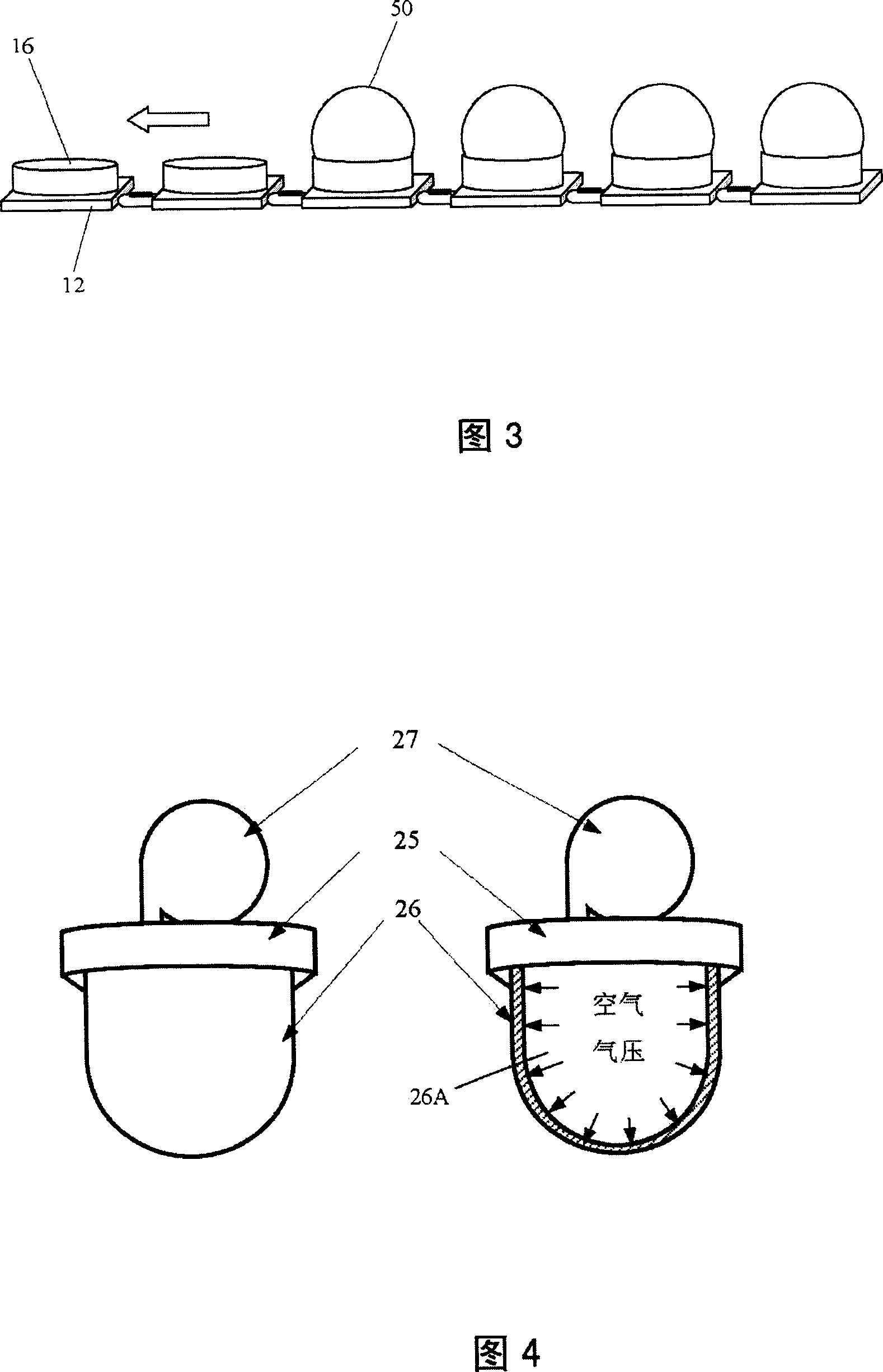

[0033] Please refer to FIG. 2 . FIG. 2 shows a schematic structural view of an embodiment of the all-print printing equipment for spherical / special-shaped products according to the present invention. The full-print printing equipment for spherical / special-shaped products of the present invention includes a transmission system frame 10 , an O-shaped conveyor belt 12 , an upper half surface printing area 20 and a lower half surface printing area 30 , and a turning mechanism 40 . Wherein the O-shaped conveyor belt 12 is arranged on the frame 10, and is used for conveying spherical / special-shaped products 50 during overprinting. The right side of the O-shaped conveyor belt 12 is also provided with an input and output channel 14, from which the spherical / special-shaped product 50 enters the O-shaped conveyor belt 12, and is sent out of the conveyor belt 12 after printing. The curved arrow in Figure 1 is the transmission direction of the spherical / special-shaped product 50 . The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com