Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Effectively usable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

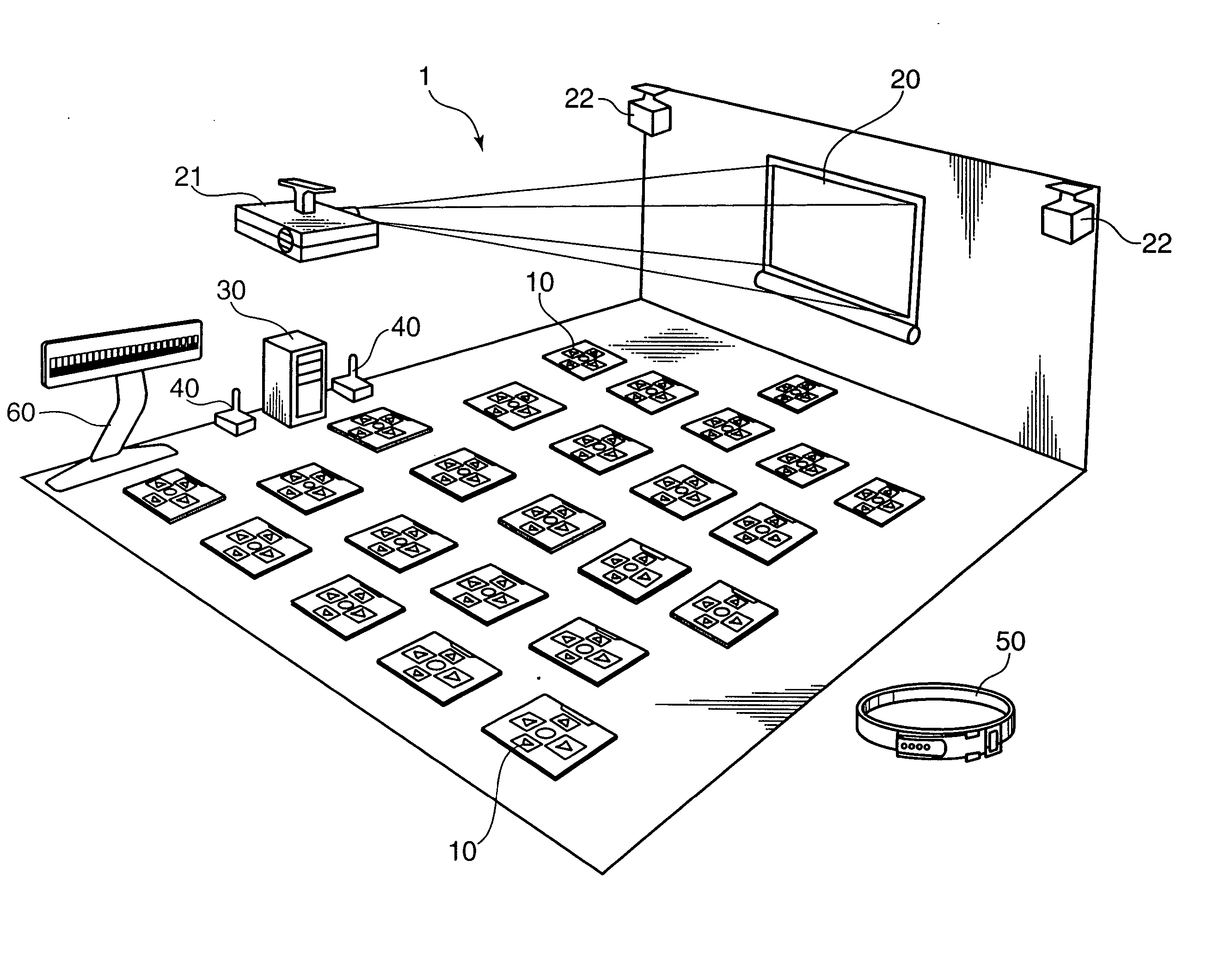

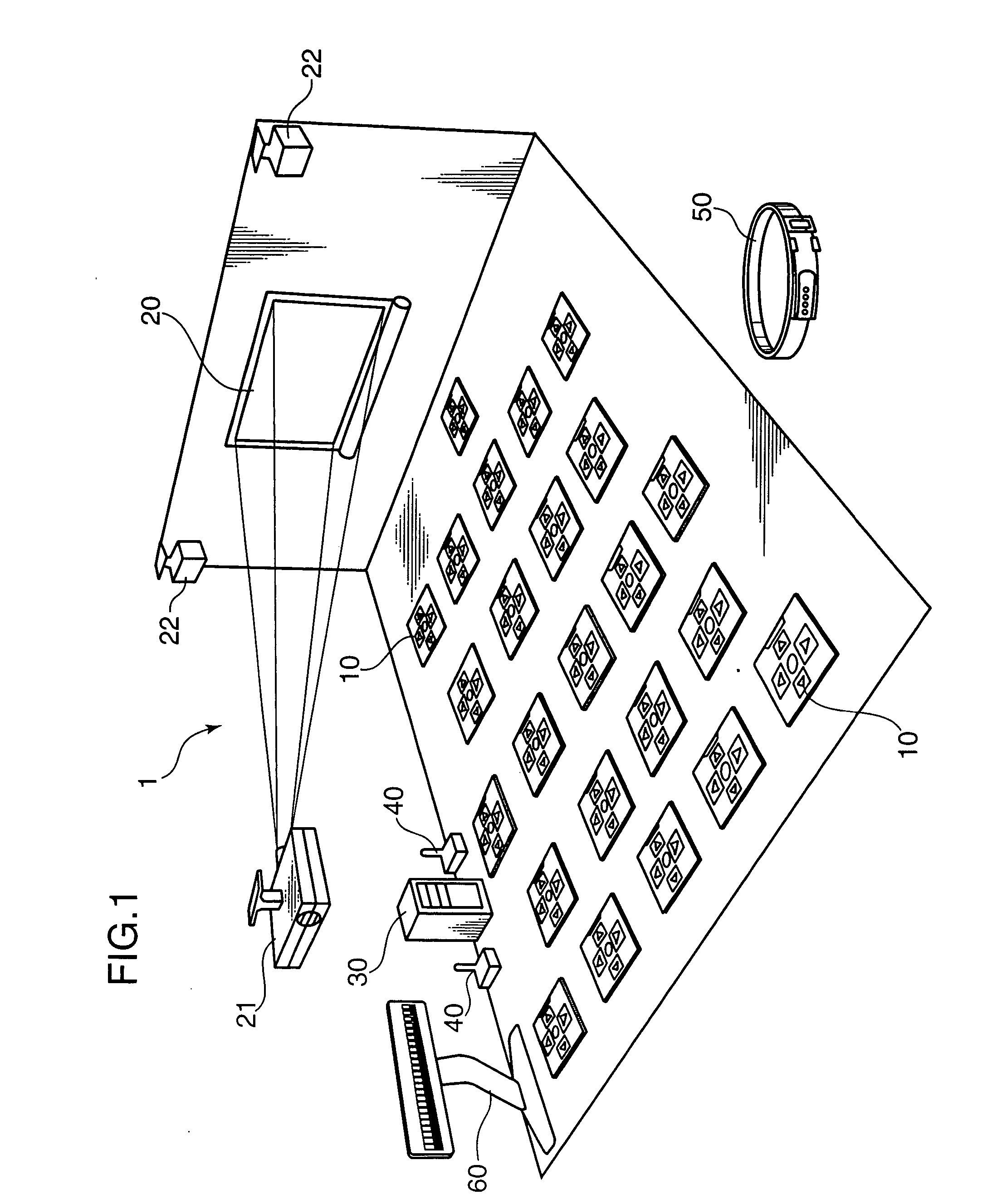

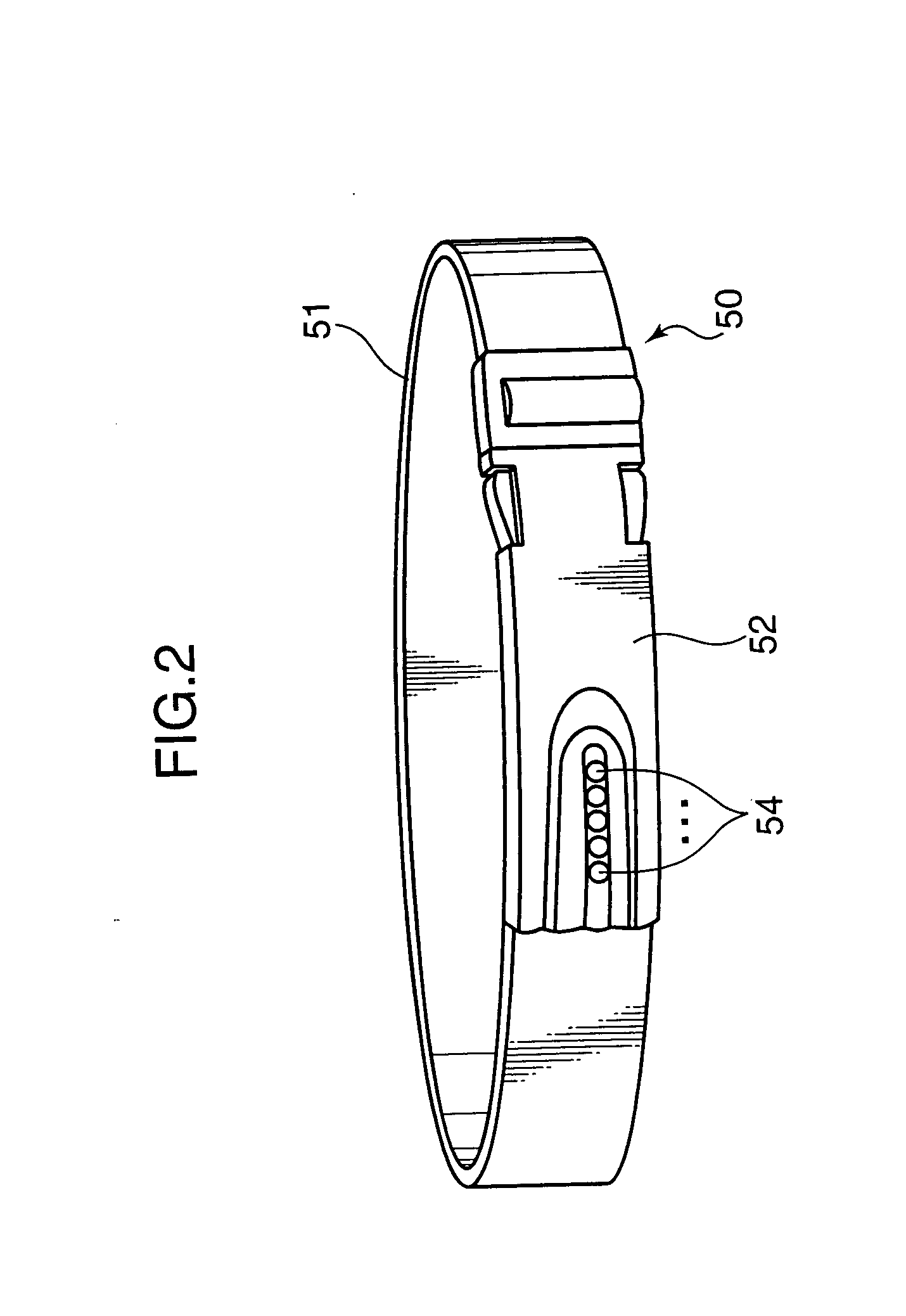

Movement-information processing system, terminal unit for use in the system, and battery recharging unit for use with the terminal unit

InactiveUS20070105629A1Increase awarenessEffectively usableVideo gamesSpecial data processing applicationsInformation processingElectrical battery

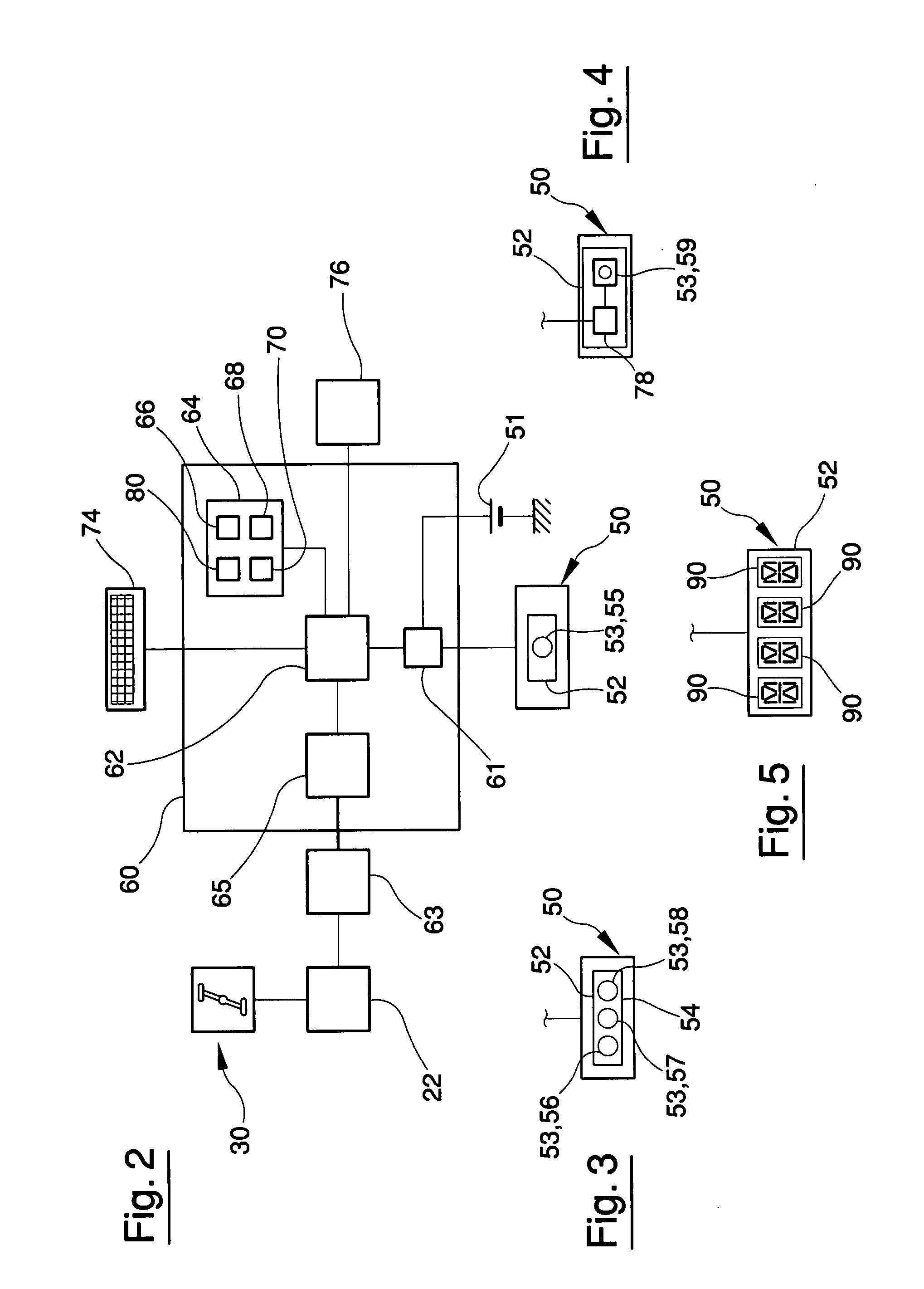

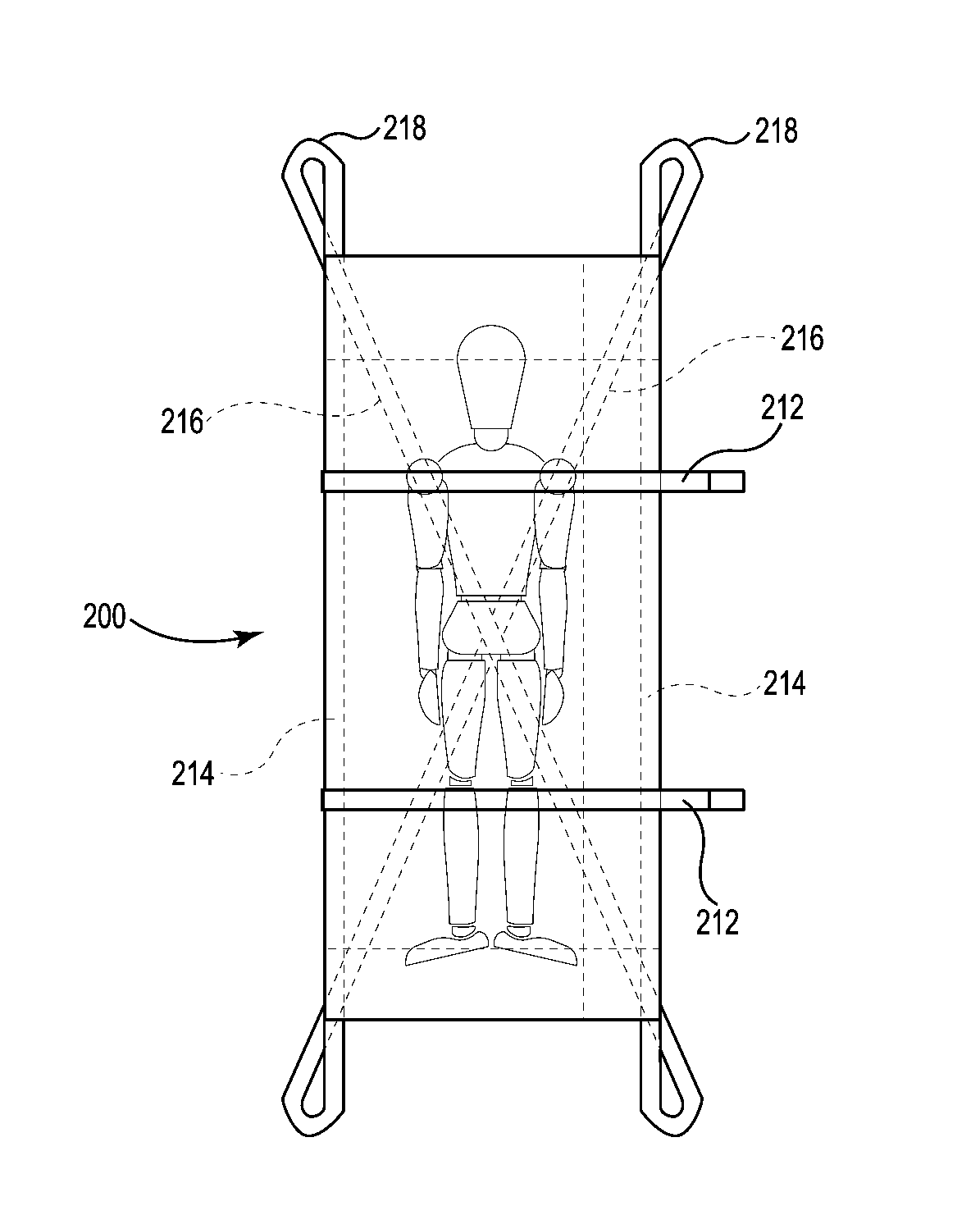

Disclosed is a movement-information processing system, which comprises a control unit 30 including an image display control section 312 adapted to allow a guide image for instructing a plurality of players to perform a physical training consisting of plural types of body movements to be displayed on a projection screen 20, and a plurality of terminal units each formed in a belt-like configuration and provided with a movement detection device 53 operable, when the terminal unit is worn on a body of either one of the players, to detect body movements of the player. Each of the terminal unit includes a communication processing section 533 for transmitting a detection signal representing the body movements detected by the movement detection device 53 to the control unit 30. The control unit 30 includes a communication processing section 313 for receiving the detection signal from the communication section 533 of the terminal unit 50, a calorie consumption calculation section 322 for evaluating an exercise quality of the player wearing the terminal unit 50, based on the received detection signal and a content of the guide image, and an image display control section 312 for announcing the evaluation result of the exercise quality through an announcement section.

Owner:KONAMI SPORTS & LIFE

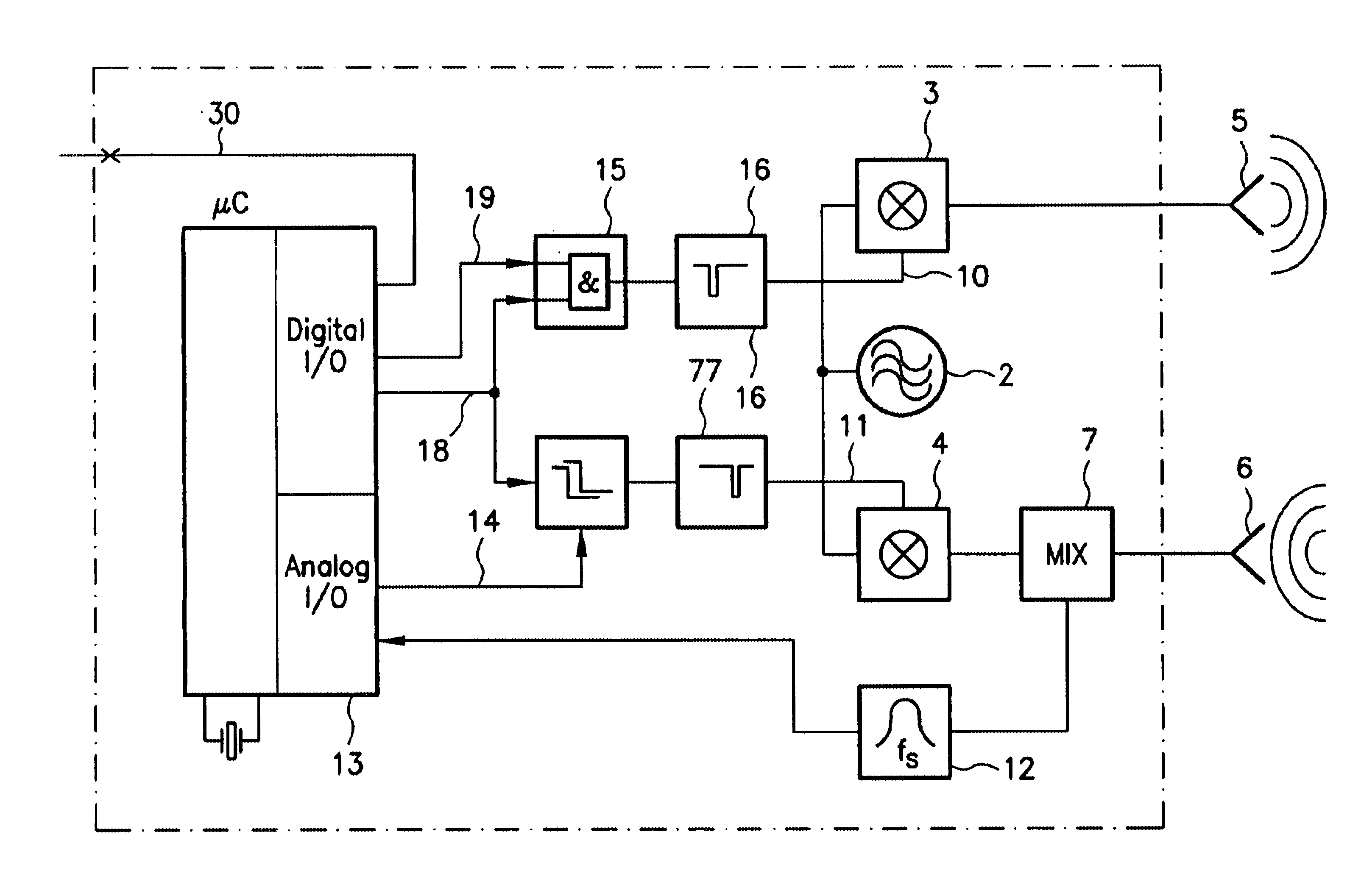

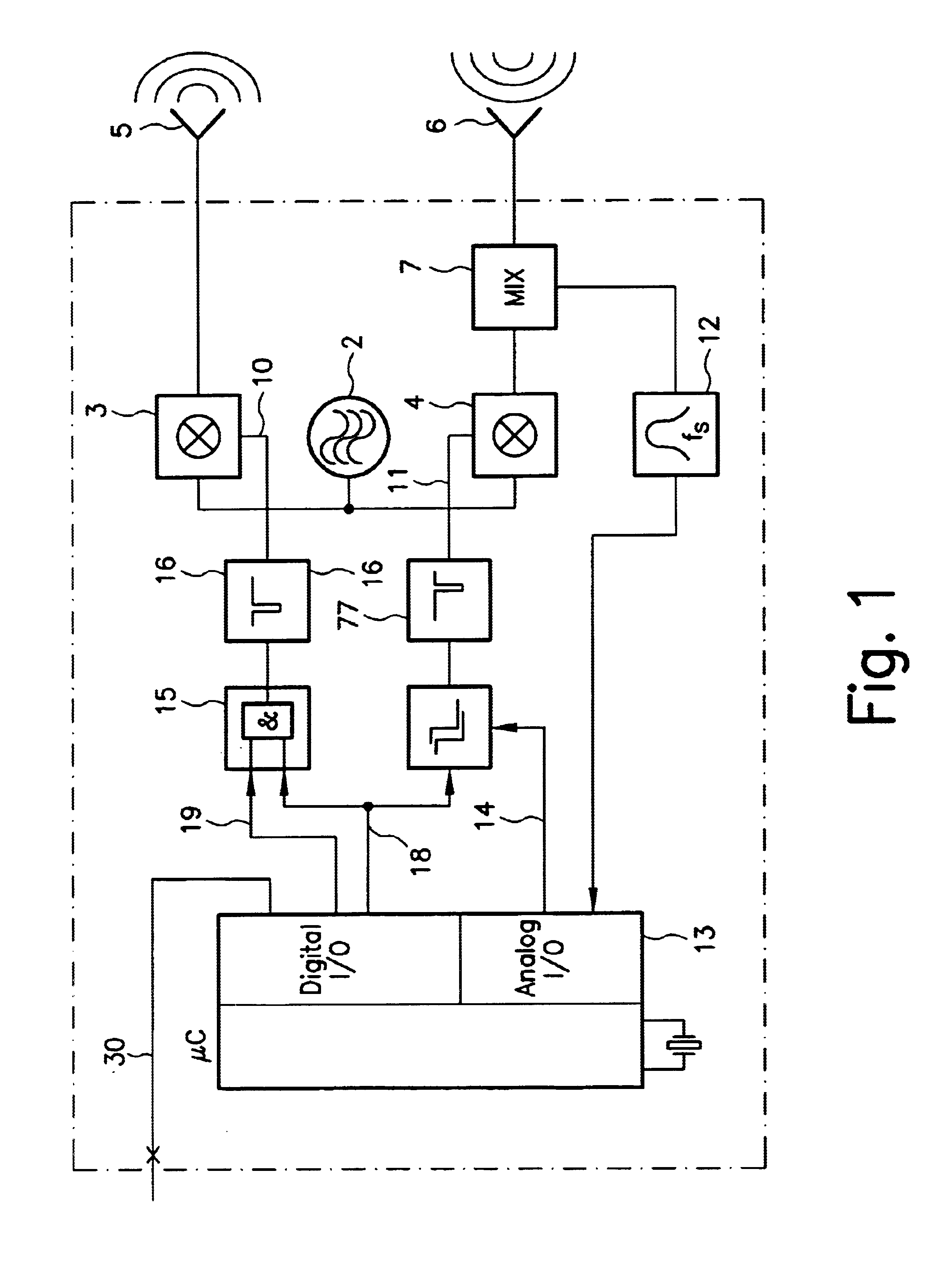

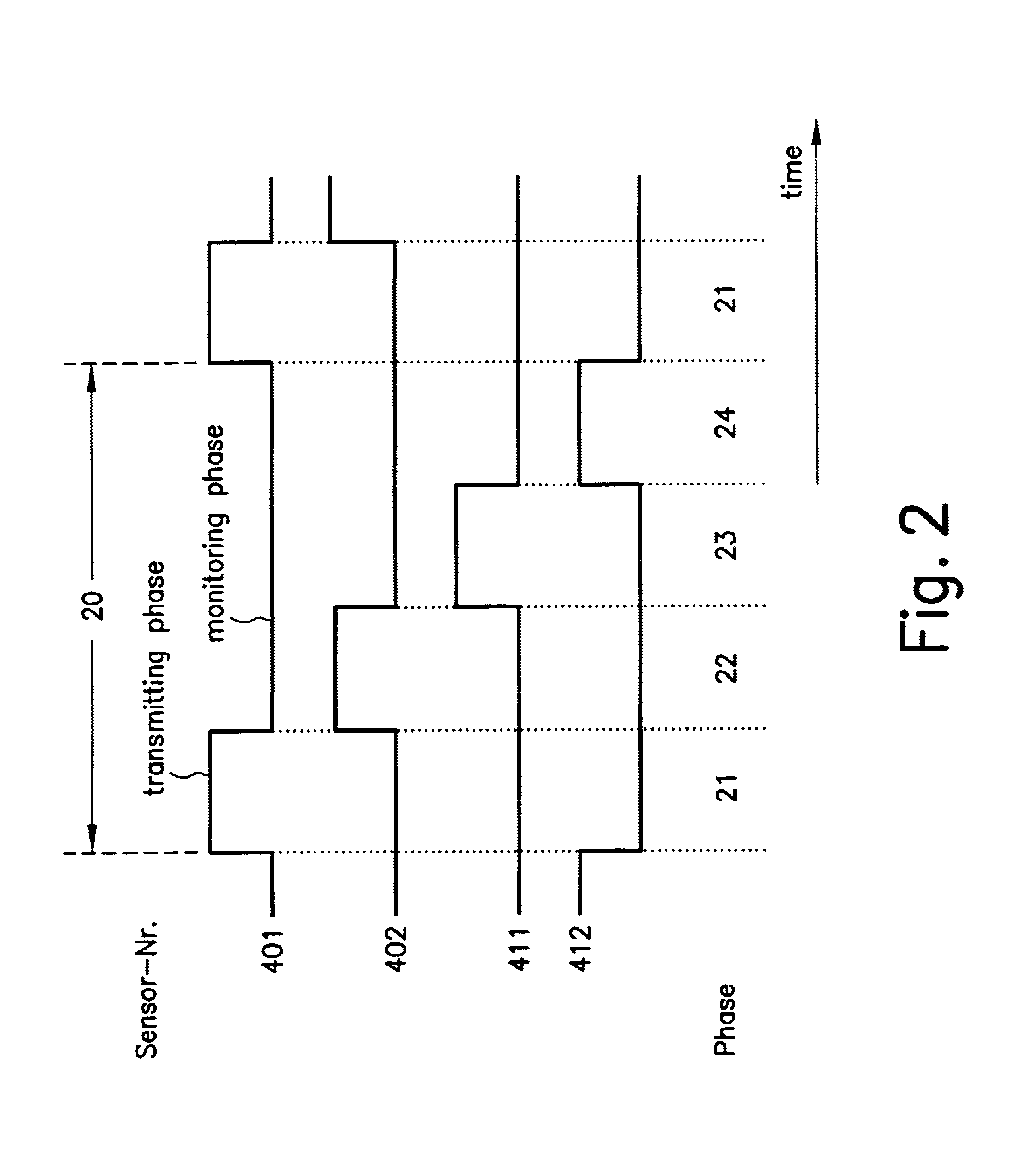

Pulse-radar method and pulse-radar sensor and system

InactiveUS6888491B2Effectively usableReduce mutual interferenceRadio wave reradiation/reflectionMobile vehicleMotorized vehicle

In a pulse-radar method, in particular for motor vehicles, different time slots of a time frame are predefined. During one time slot, a radar sensor emits at least one radar pulse and receives the echo signal(s). During the remaining time slots the radar sensor monitors whether interference signals occur. On the basis of the interference signals occurring per time slot, a decision is made whether the radar sensor should continue its transmitting and receiving operation in the predefined time slot or should switch to one of the remaining time slots of the time frame. The method is suited for the concurrent operation of a plurality of radar sensors, without this causing interference.

Owner:ROBERT BOSCH GMBH

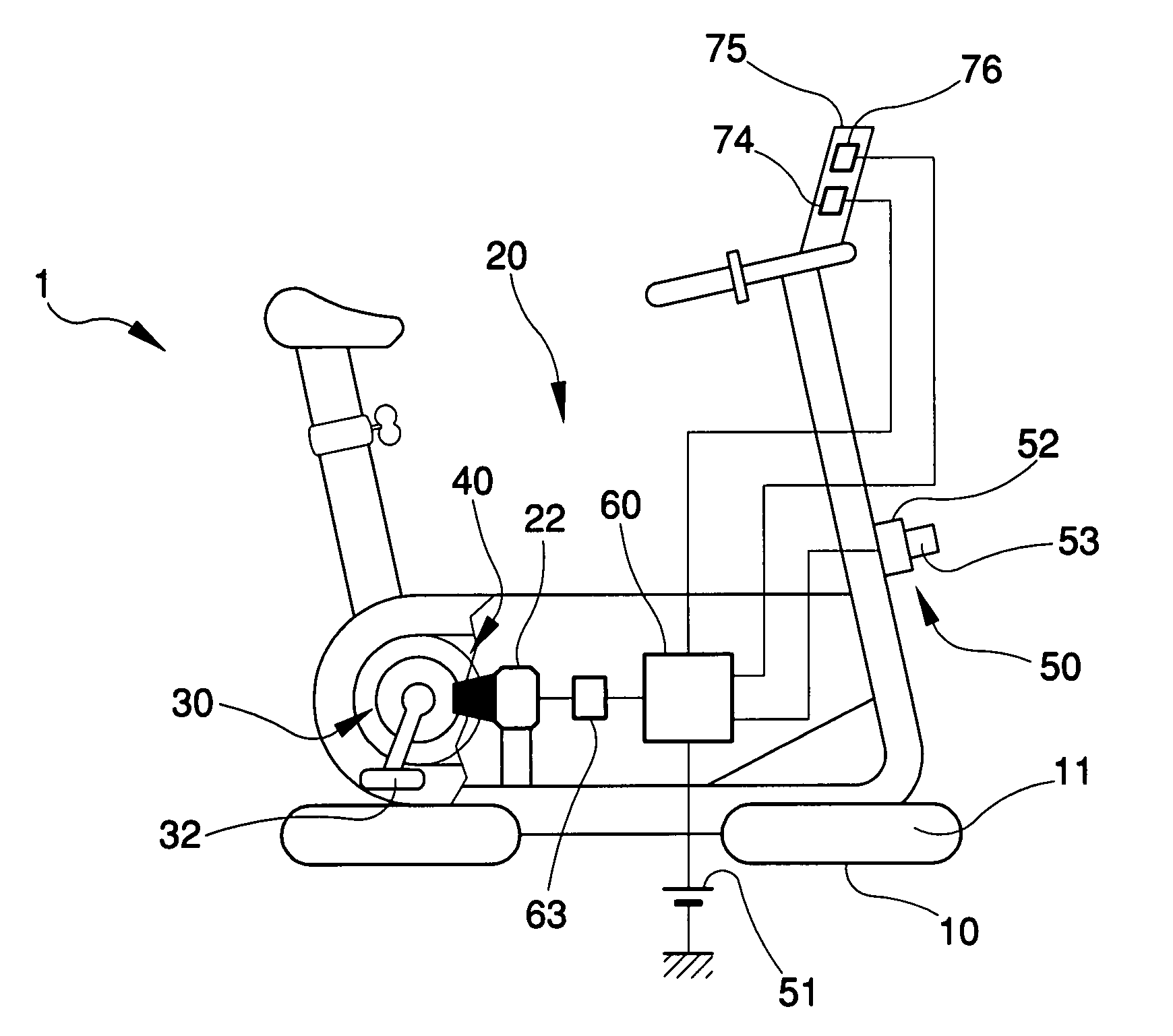

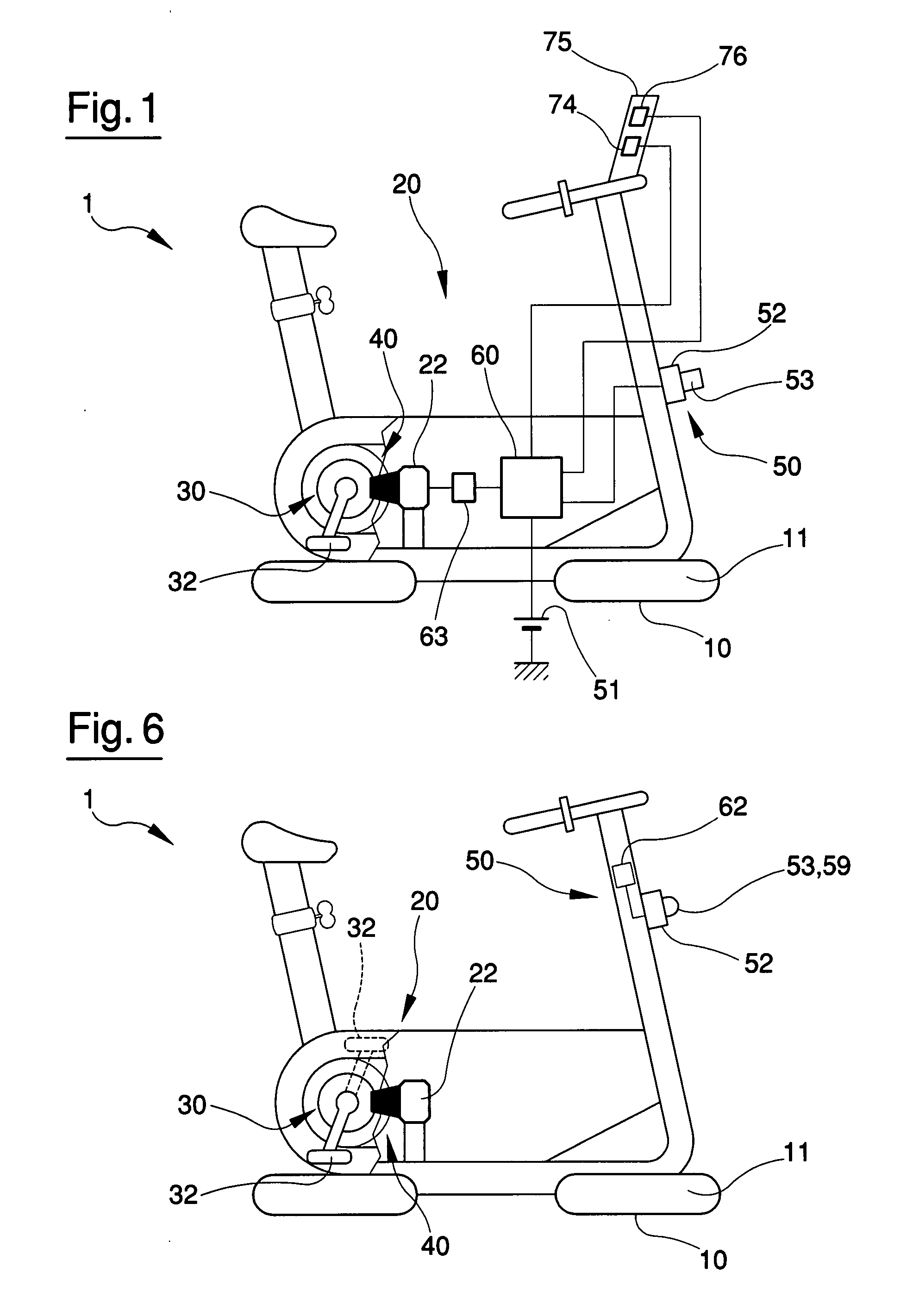

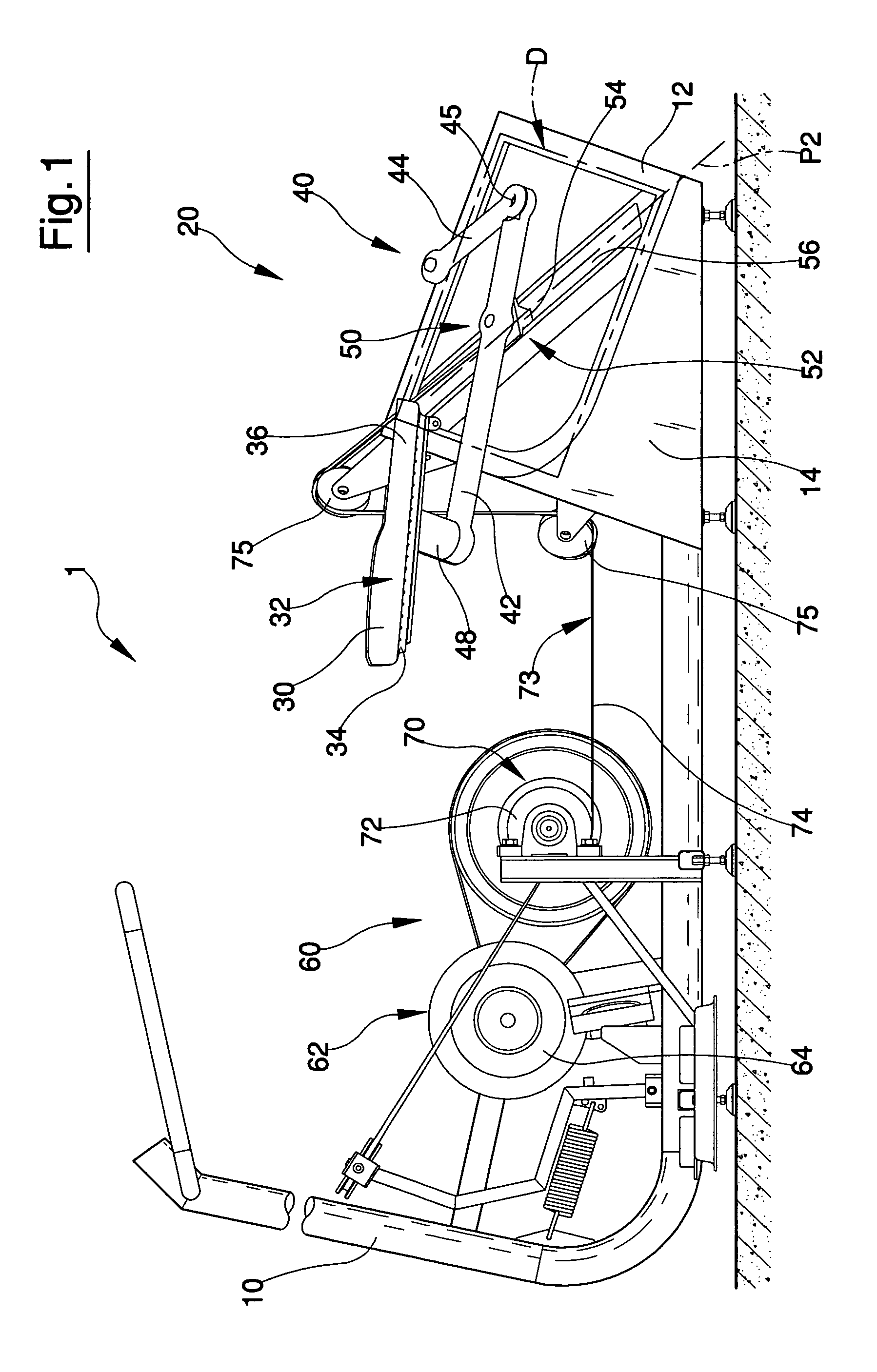

Gymnastic machine

InactiveUS20080015088A1Reduce waiting timeEnhancing customer loyaltySignalling system detailsStiltsPhysical medicine and rehabilitationContinuous use

Gymnastic machine (1) includes a frame (10), an exercise station (20) associated with the frame (10), at least a gymnastic implement (30) usable within the exercise station (20) for the execution of a training session, load group (40) supported by the frame (10) and coupled to each gymnastic implement (30), and a signaling device (50) which is provided, so predisposed as to give information on the use status of the implement (30) outside exercise station (20), in such a way as to reduce waiting times between two successive uses.

Owner:TECHNOGYM SPA

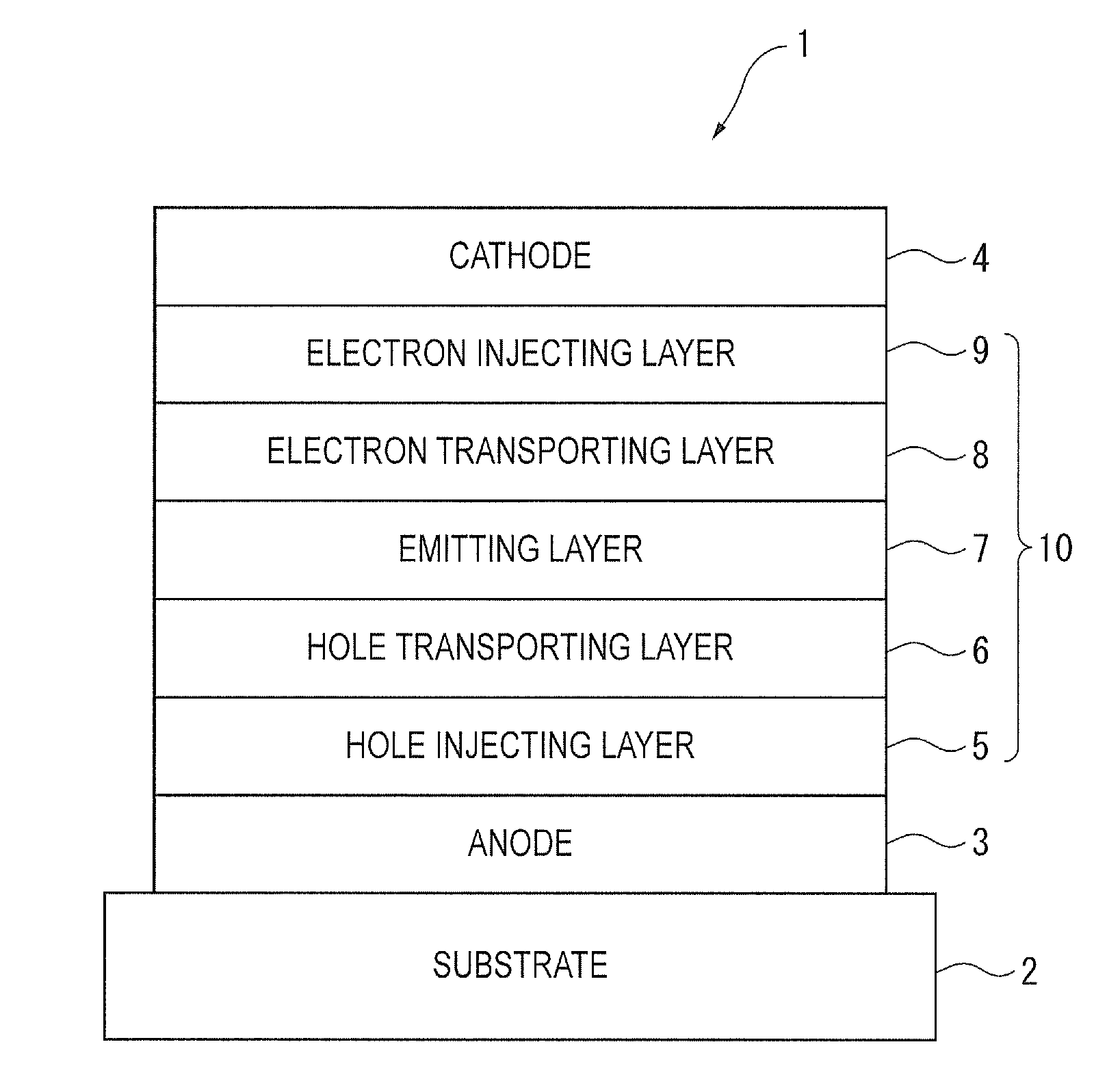

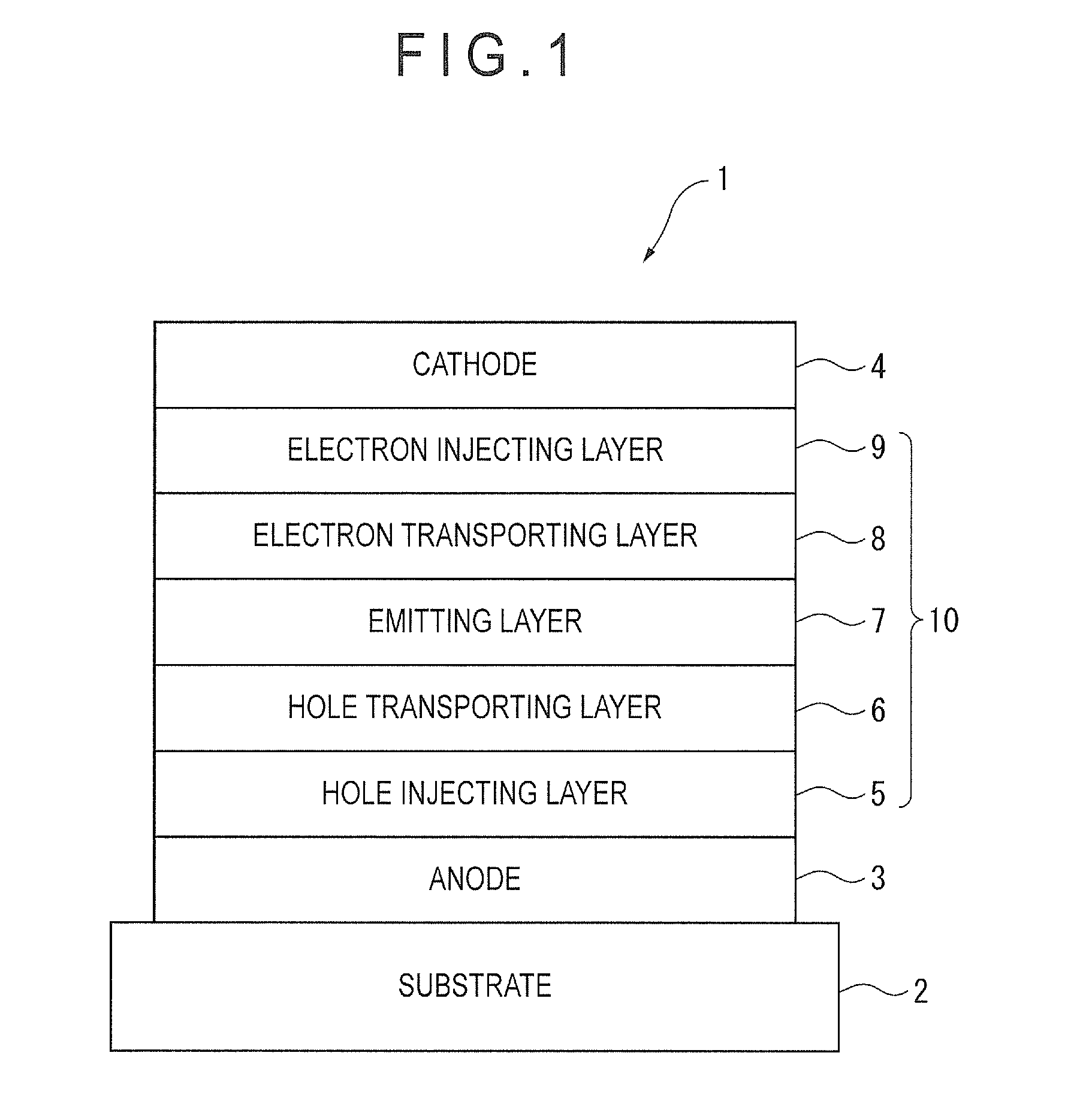

Light-emitting device and its production

InactiveUS20040046496A1Increased durabilityIncrease brightnessDischarge tube luminescnet screensFinal product manufactureOrganic layerOxygen

A light-emitting device comprises a laminate structure having an anode substrate, an anode, at least one organic layer comprising a light-emitting layer, a cathode and a cathode substrate in this order, wherein a water- and / or oxygen-absorbing layer is located between the cathode substrate and the cathode.

Owner:UDC IRELAND

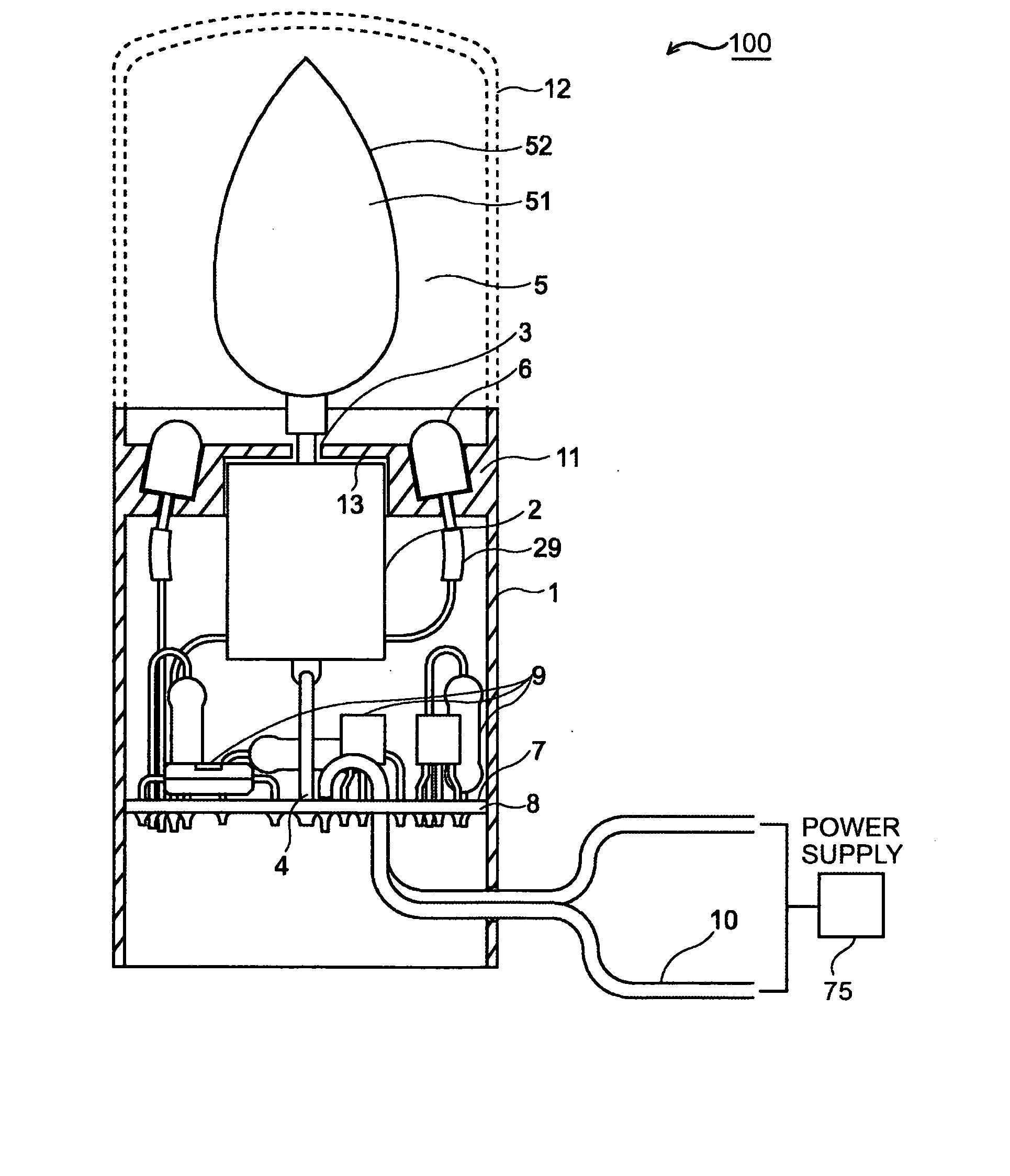

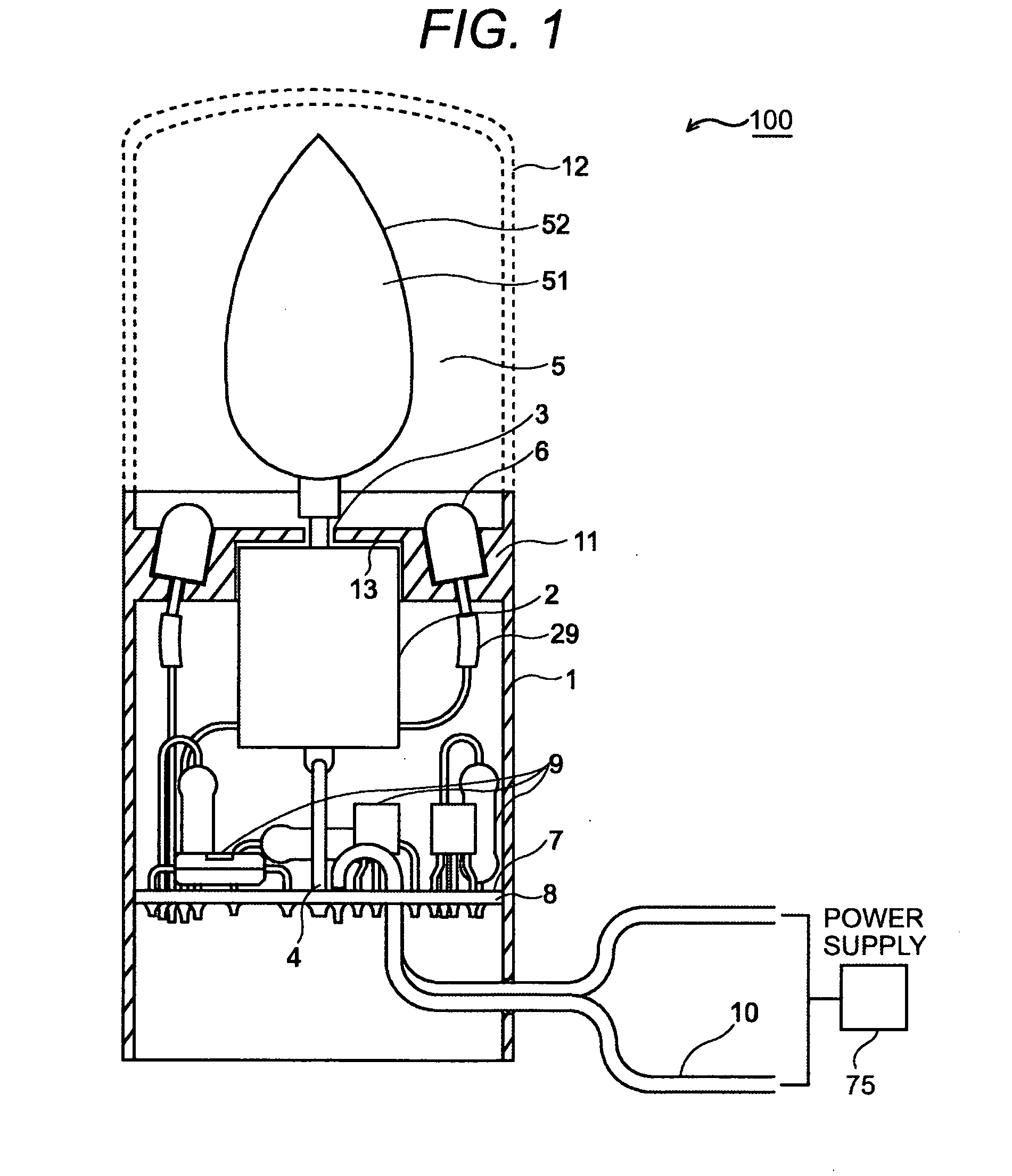

Three-dimensional pseudo-image presenting apparatus, method therefor and three-dimensional pseudo-image presenting system

InactiveUS20070242259A1Improve visual effectsEfficient processLight effect designsElectric lightingComputer graphics (images)

Owner:FLAP +2

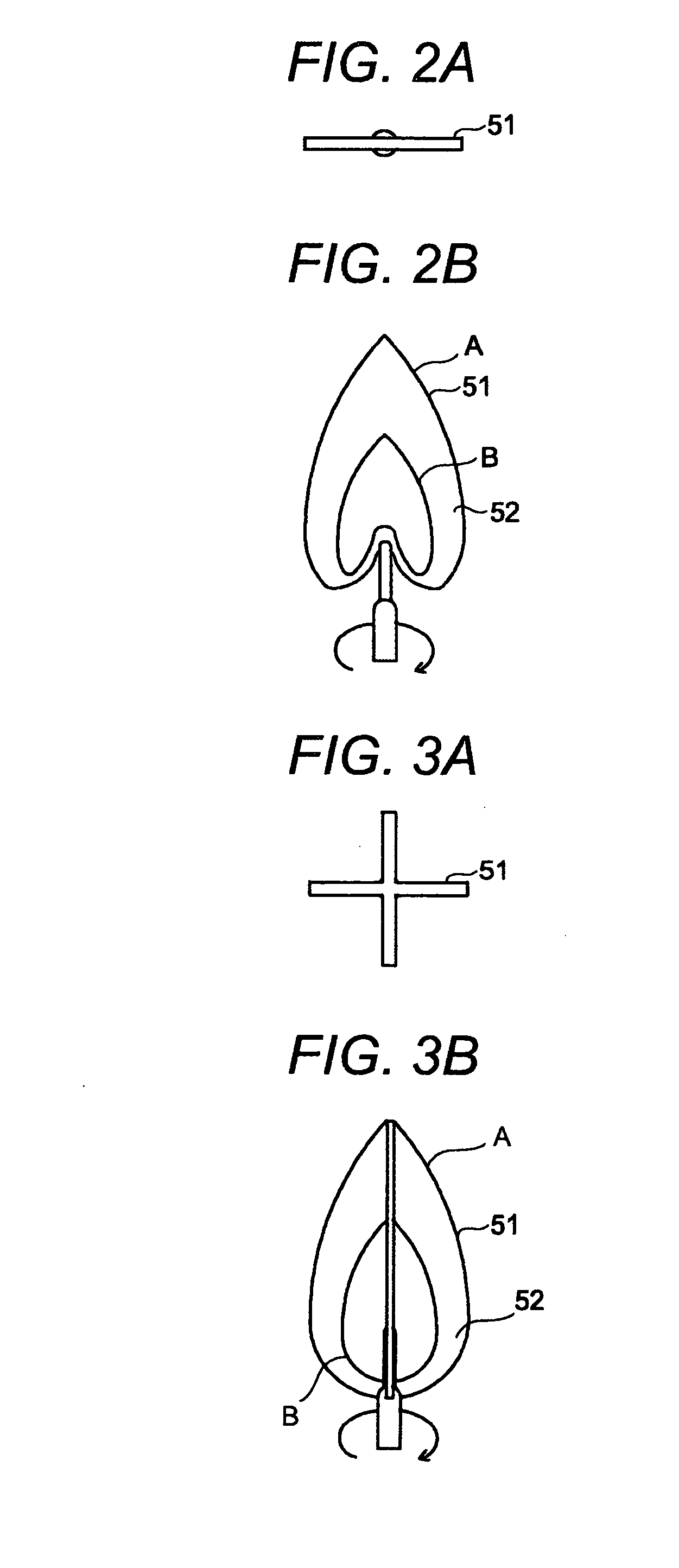

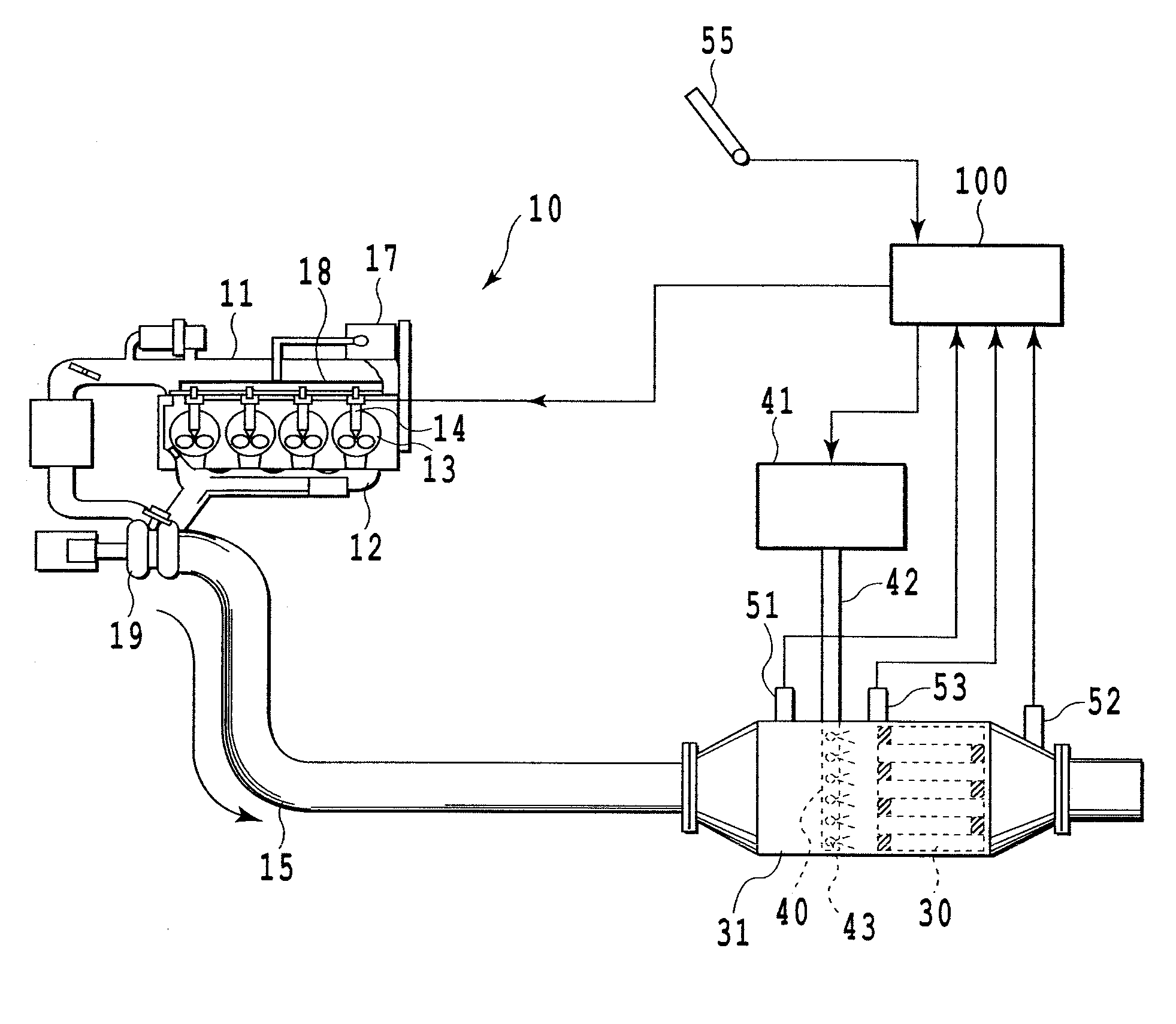

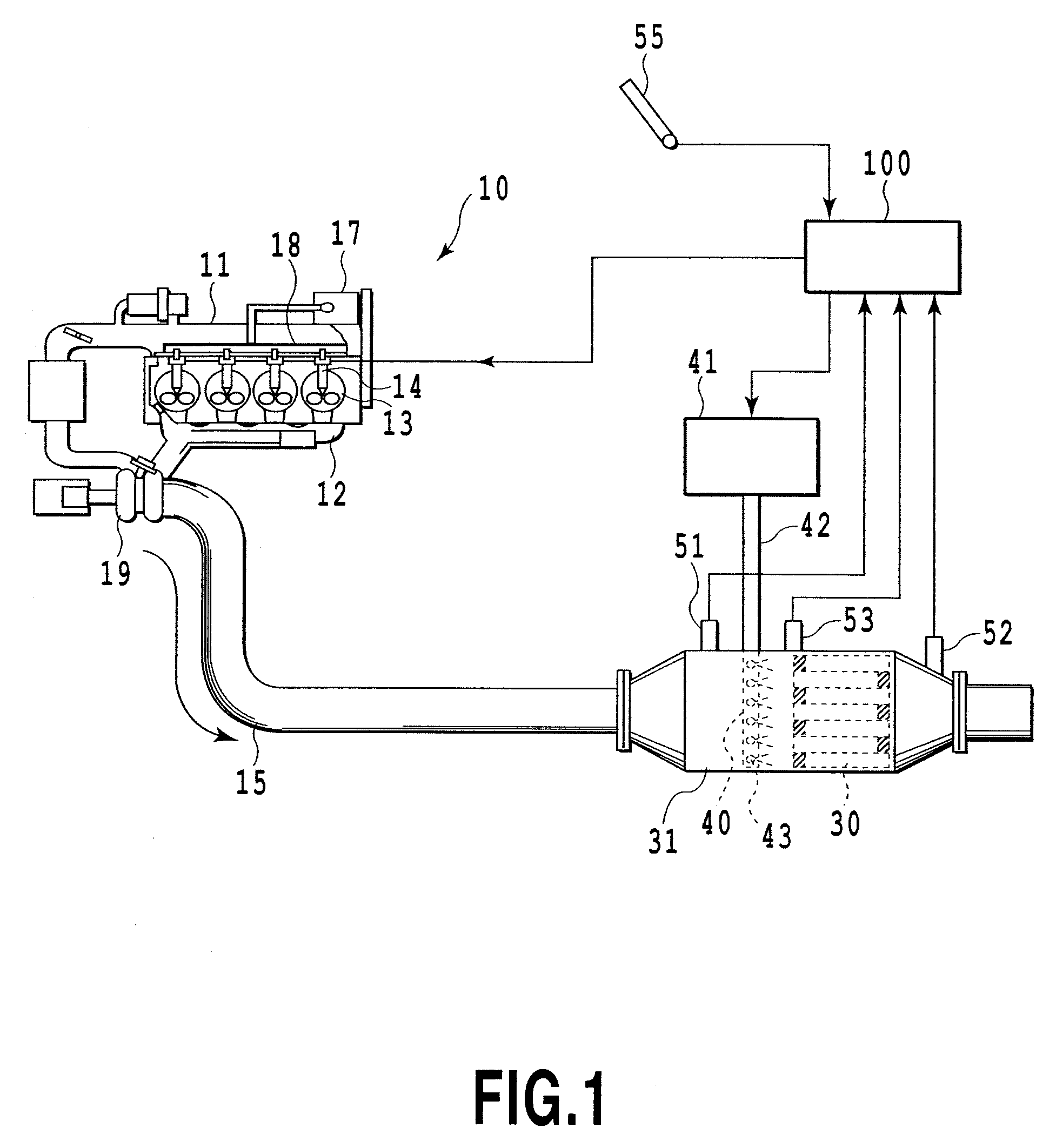

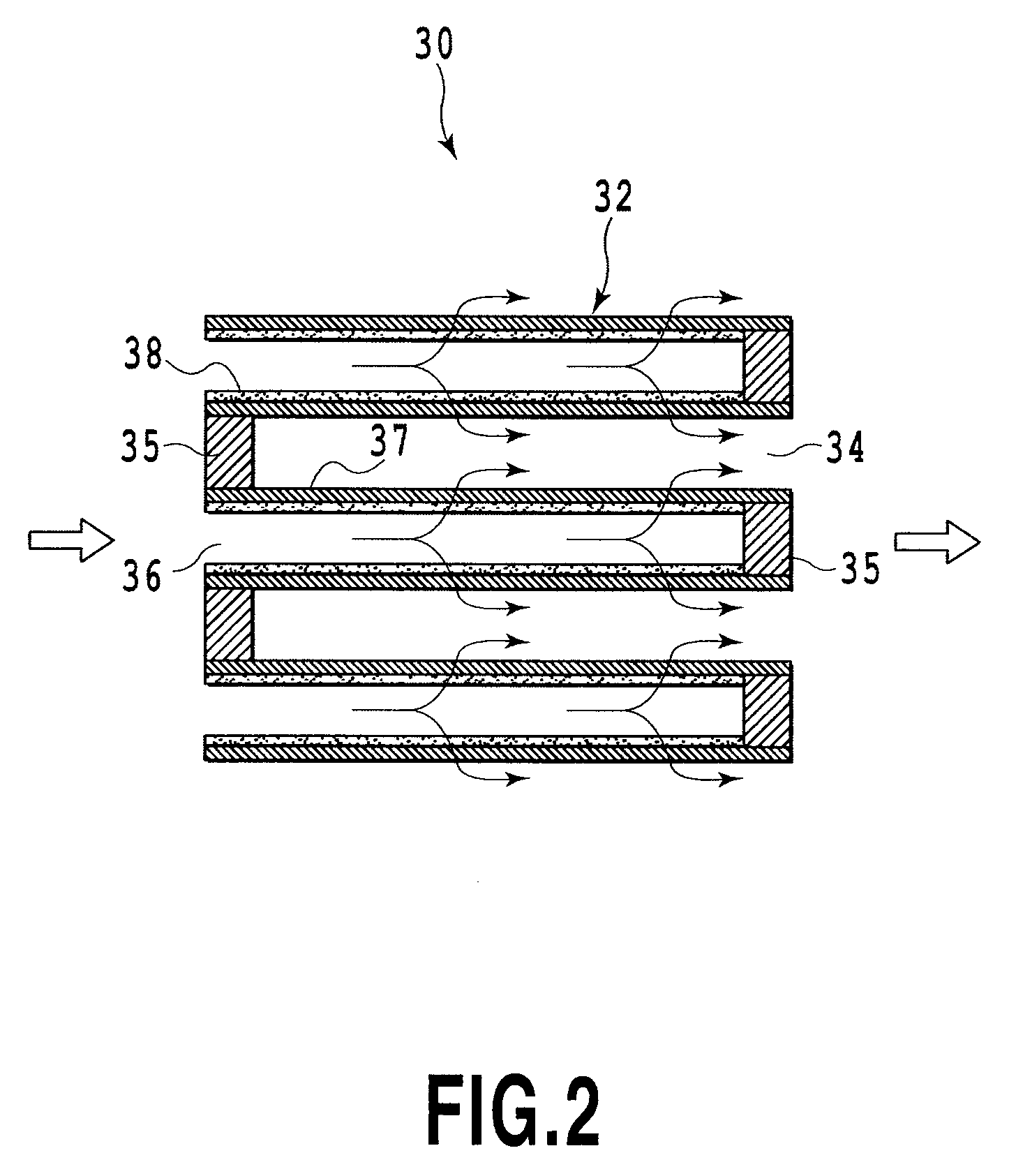

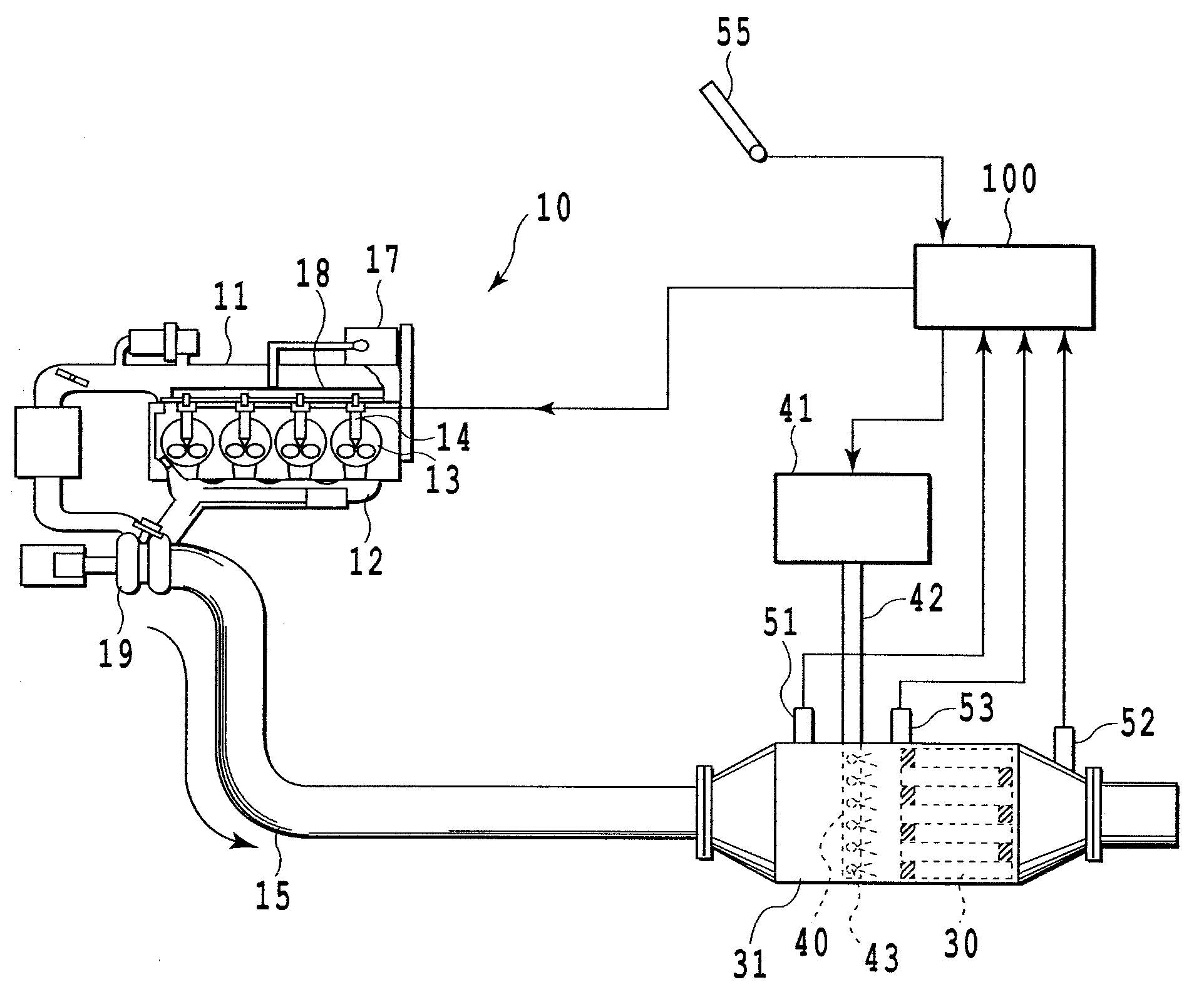

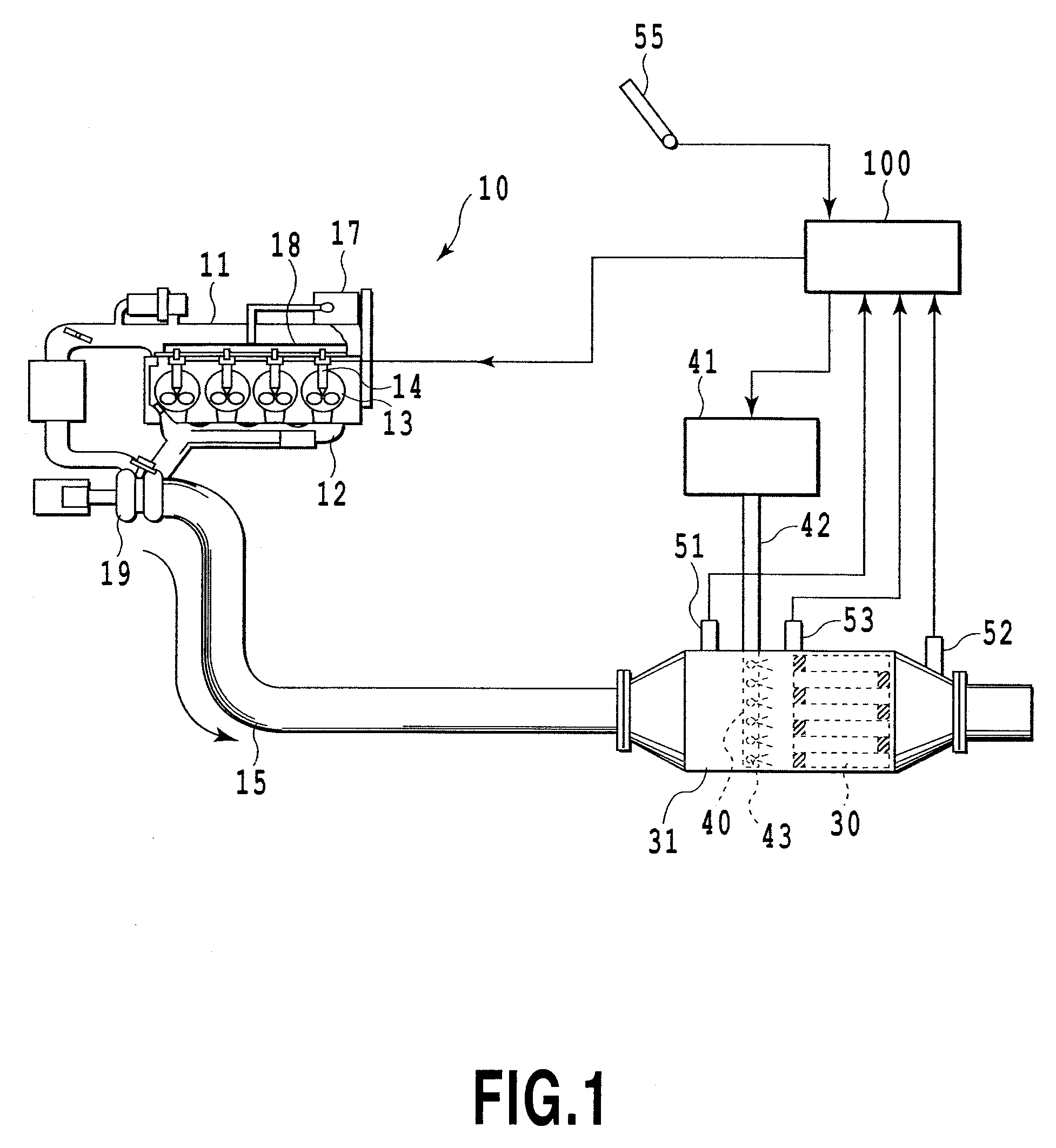

Device for Cleaning Exhaust Gas of Internal Combustion Engine

InactiveUS20090064664A1Good effectEffectively usableInternal combustion piston enginesExhaust apparatusParticulatesExhaust fumes

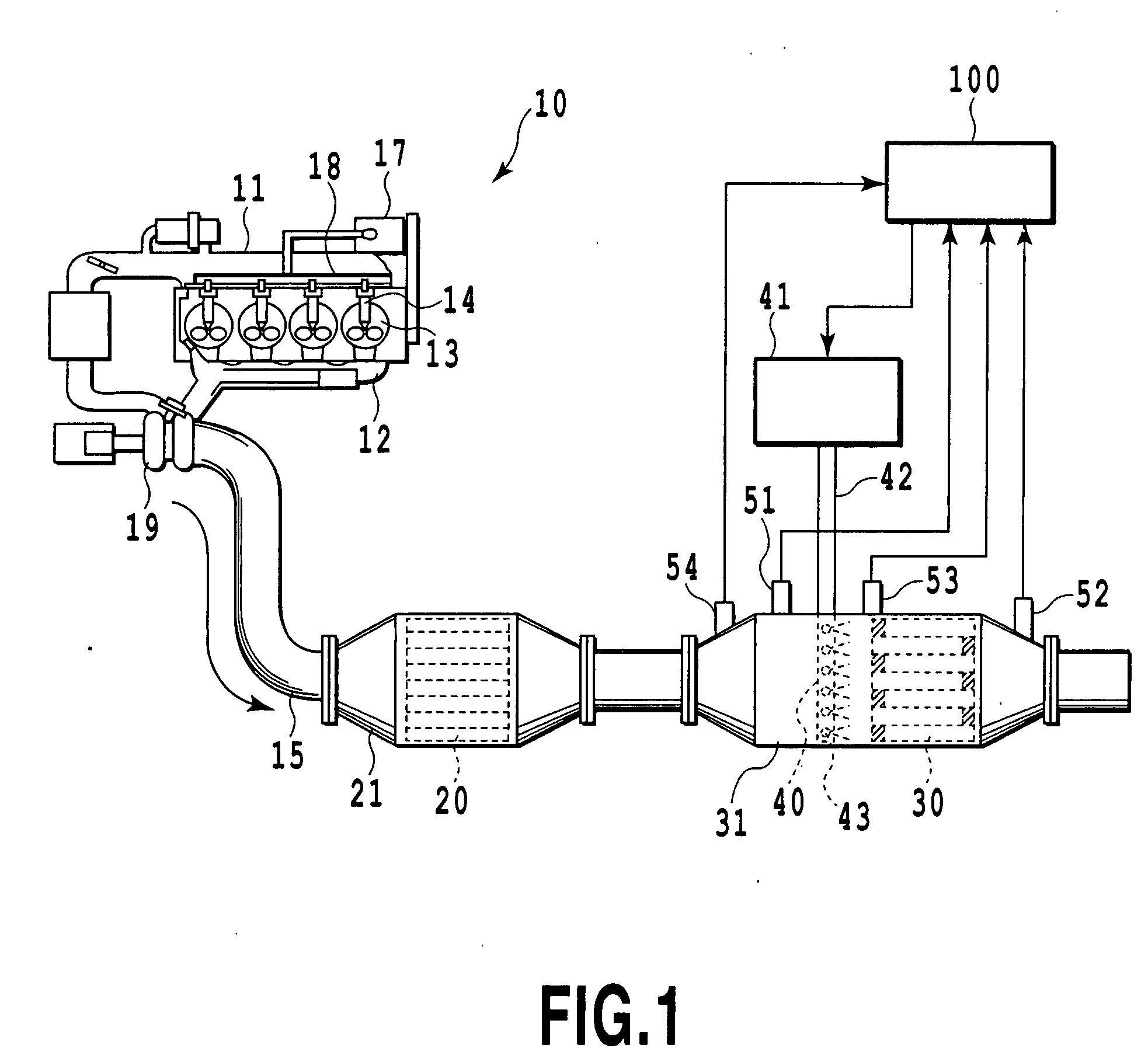

A device for cleaning exhaust gas of an internal combustion engine according to the present invention includes a device (30) for collecting particulate matter from exhaust gas in an exhaust gas passage (15), ozone feeding device (40) capable of feeding ozone to the device (30) for collecting particulate matter from upstream thereof, and an NOx catalyst (20) disposed upstream from the ozone feeding device (40), for cleaning NOx in the exhaust gas. Since NOx is preliminarily removed by the NOx catalyst (20) at apposition upstream from the ozone feeding device (40), the consumption of ozone due to the reaction with NOx is prevented, whereby it is possible to effectively use ozone for the purpose of oxidizing and removing PM in the device (30) for collecting particulate matter.

Owner:TOYOTA JIDOSHA KK

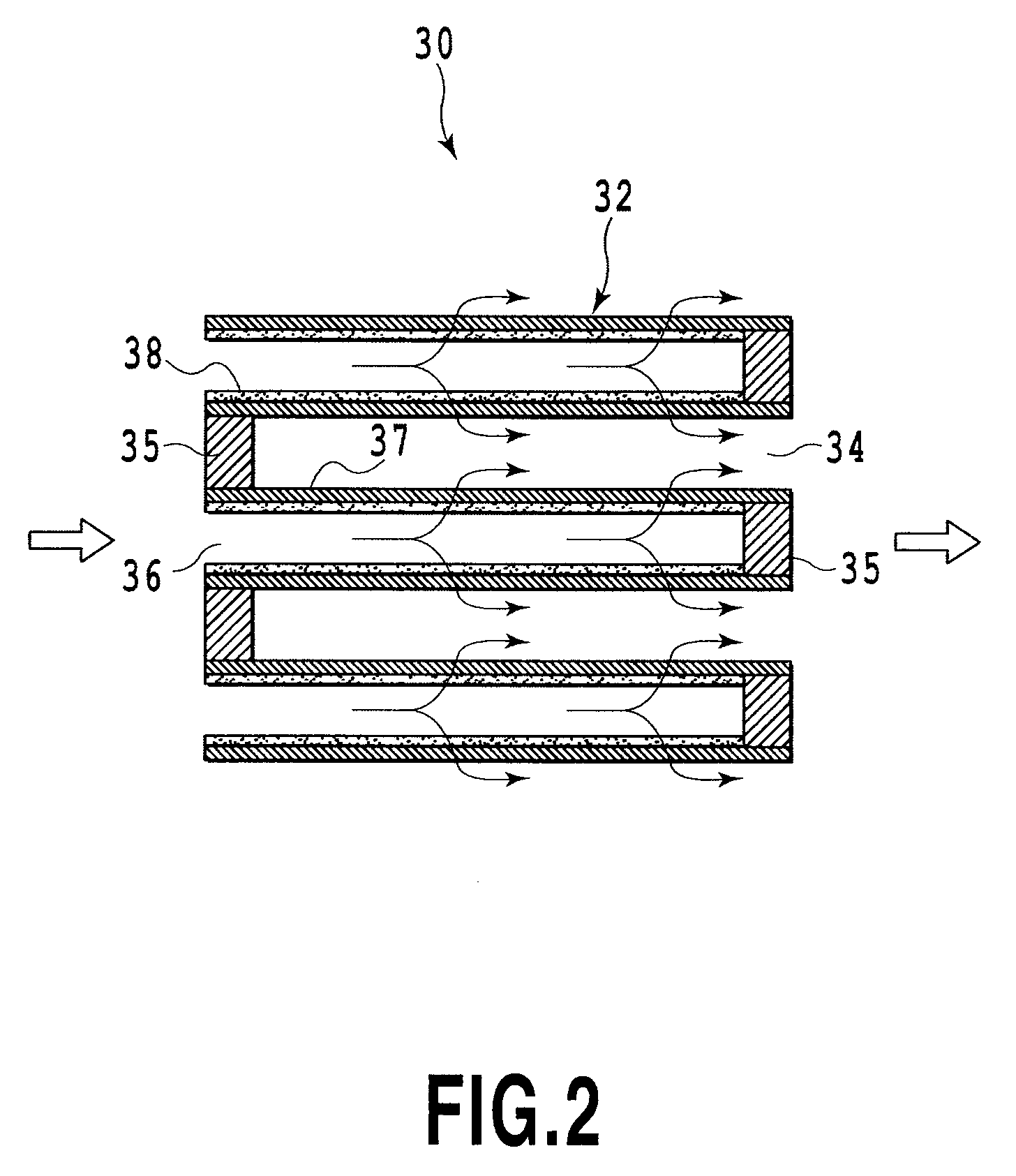

Exhaust cleaner for internal combustion engine

InactiveUS7954313B2Control consumptionImprove purification efficiencyGas treatmentInternal combustion piston enginesParticulatesEnvironmental engineering

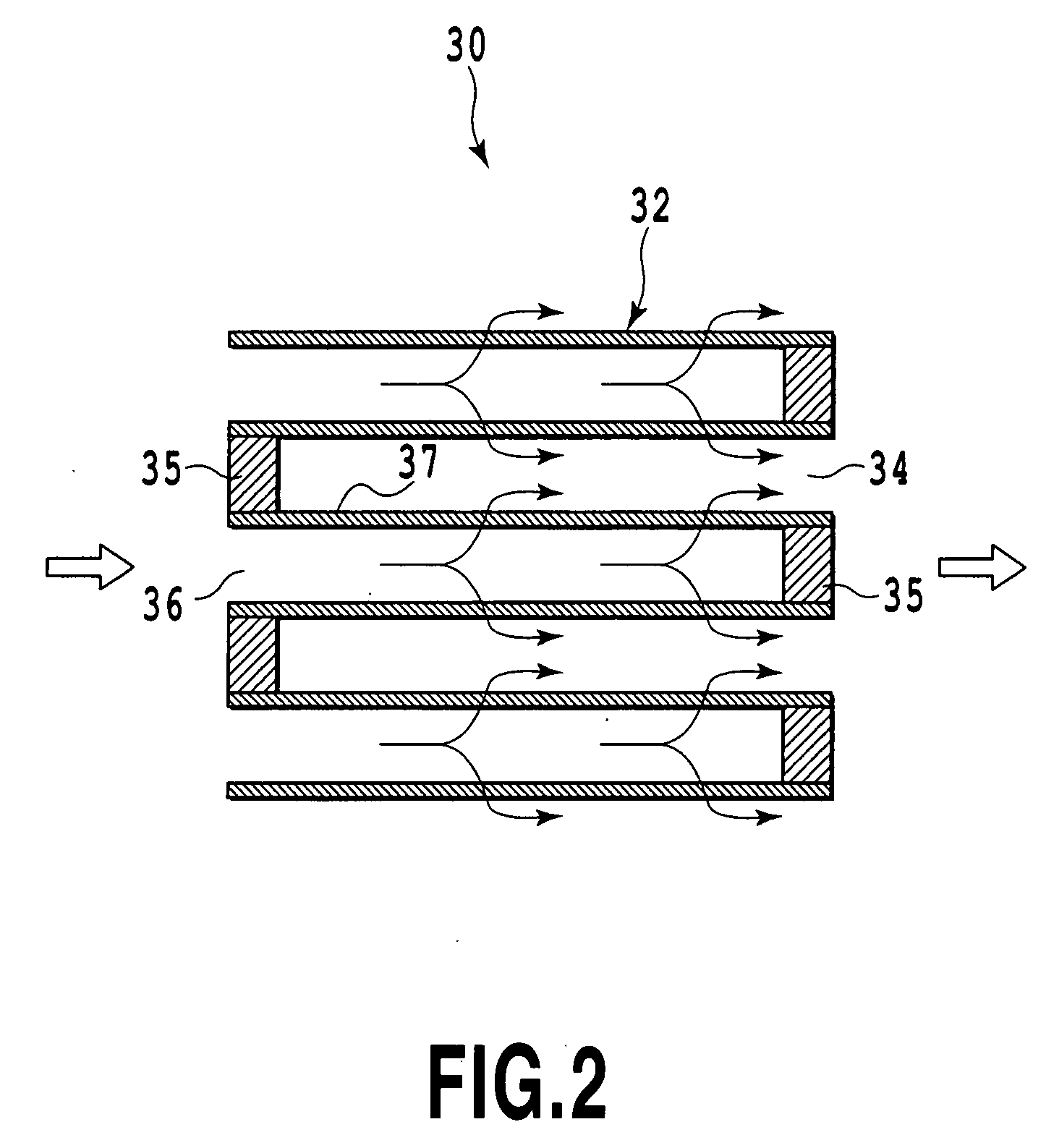

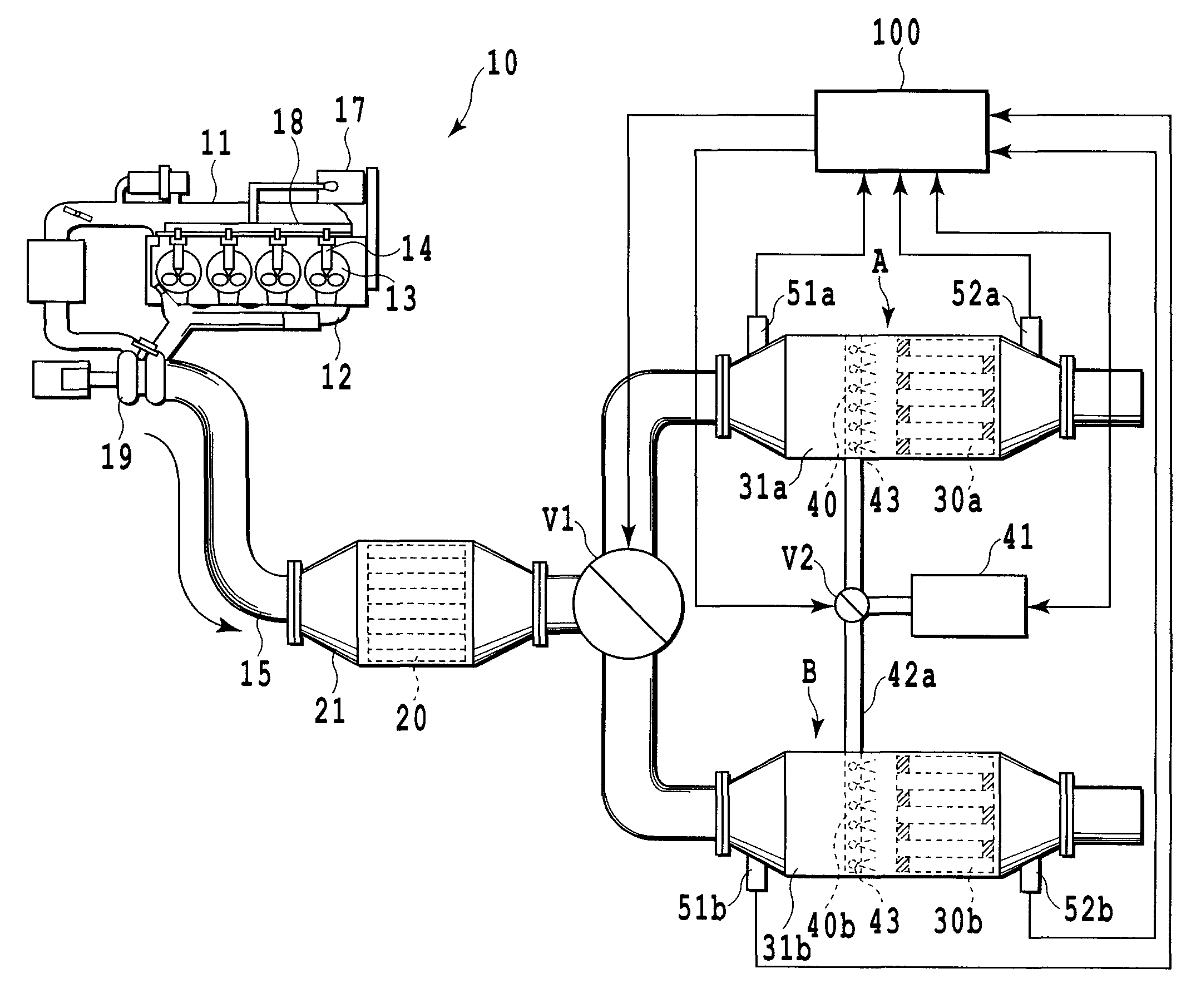

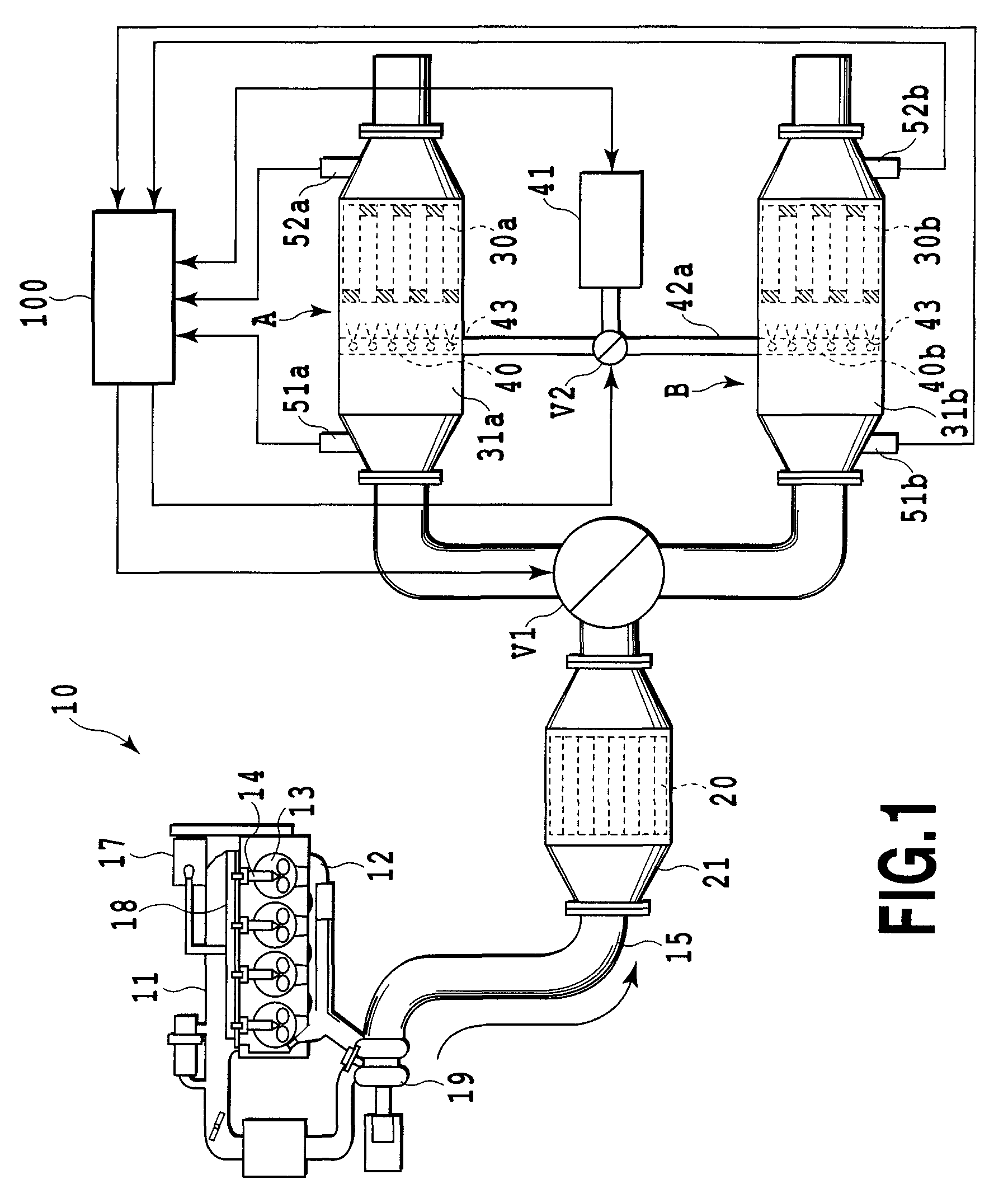

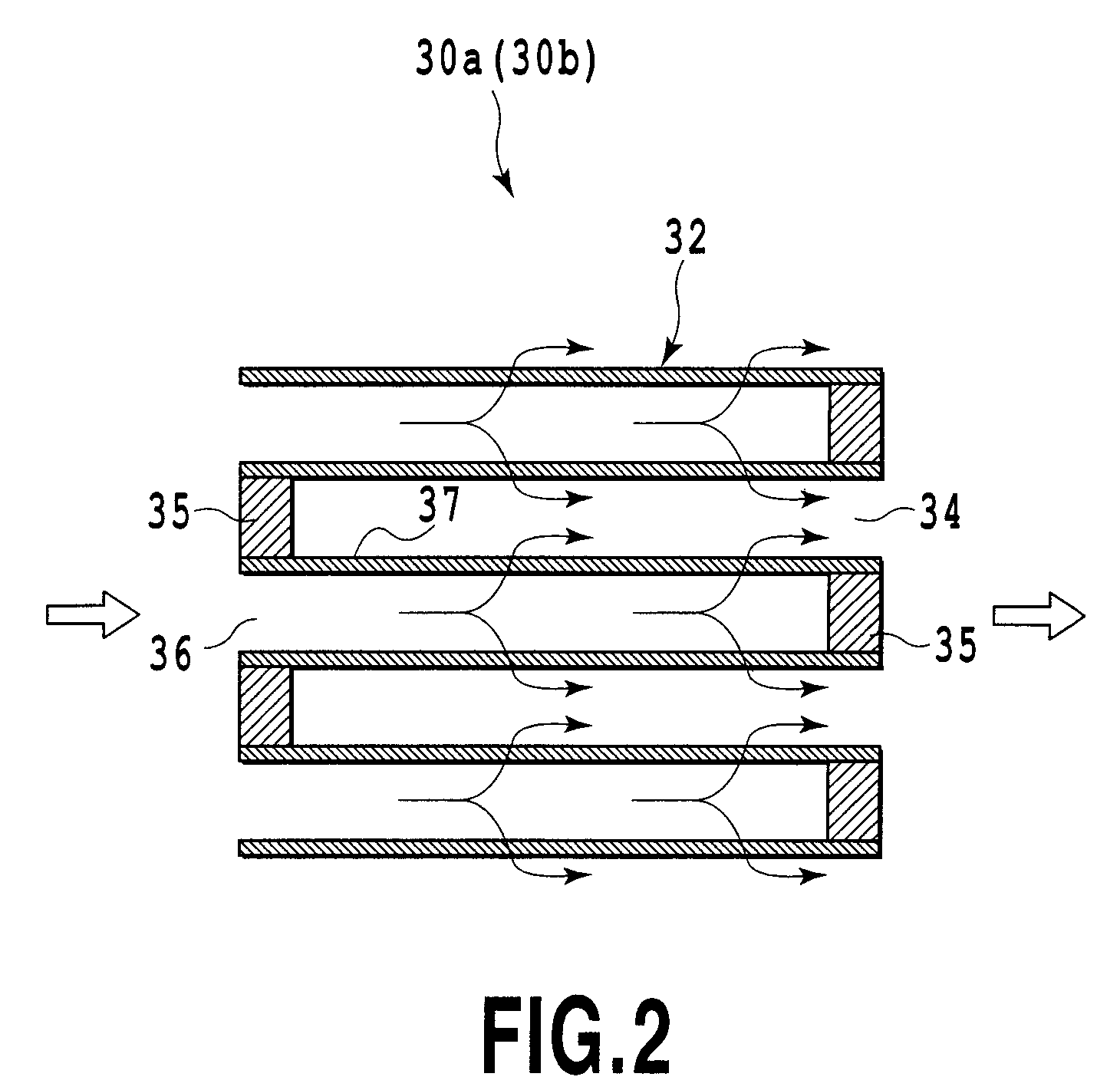

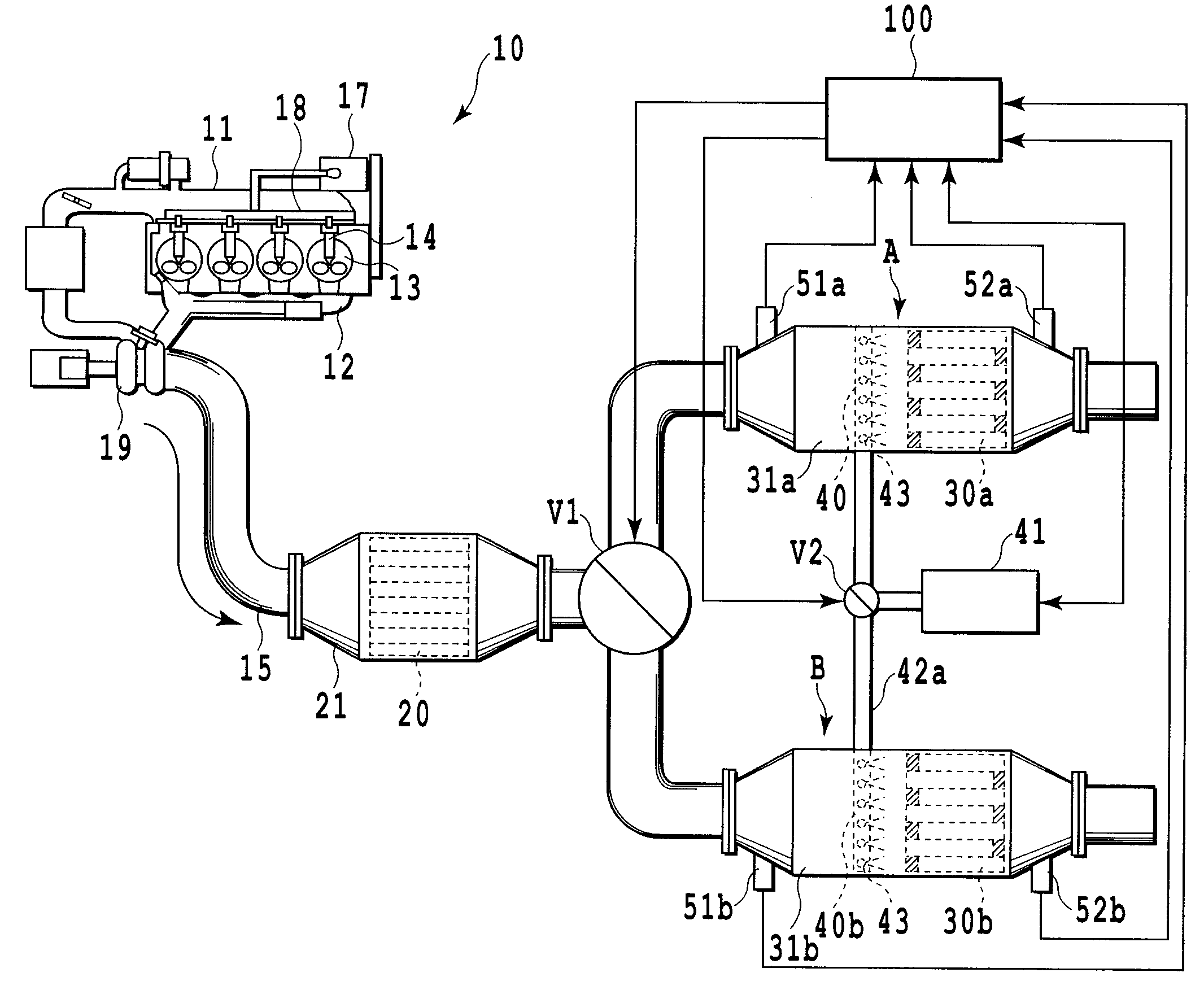

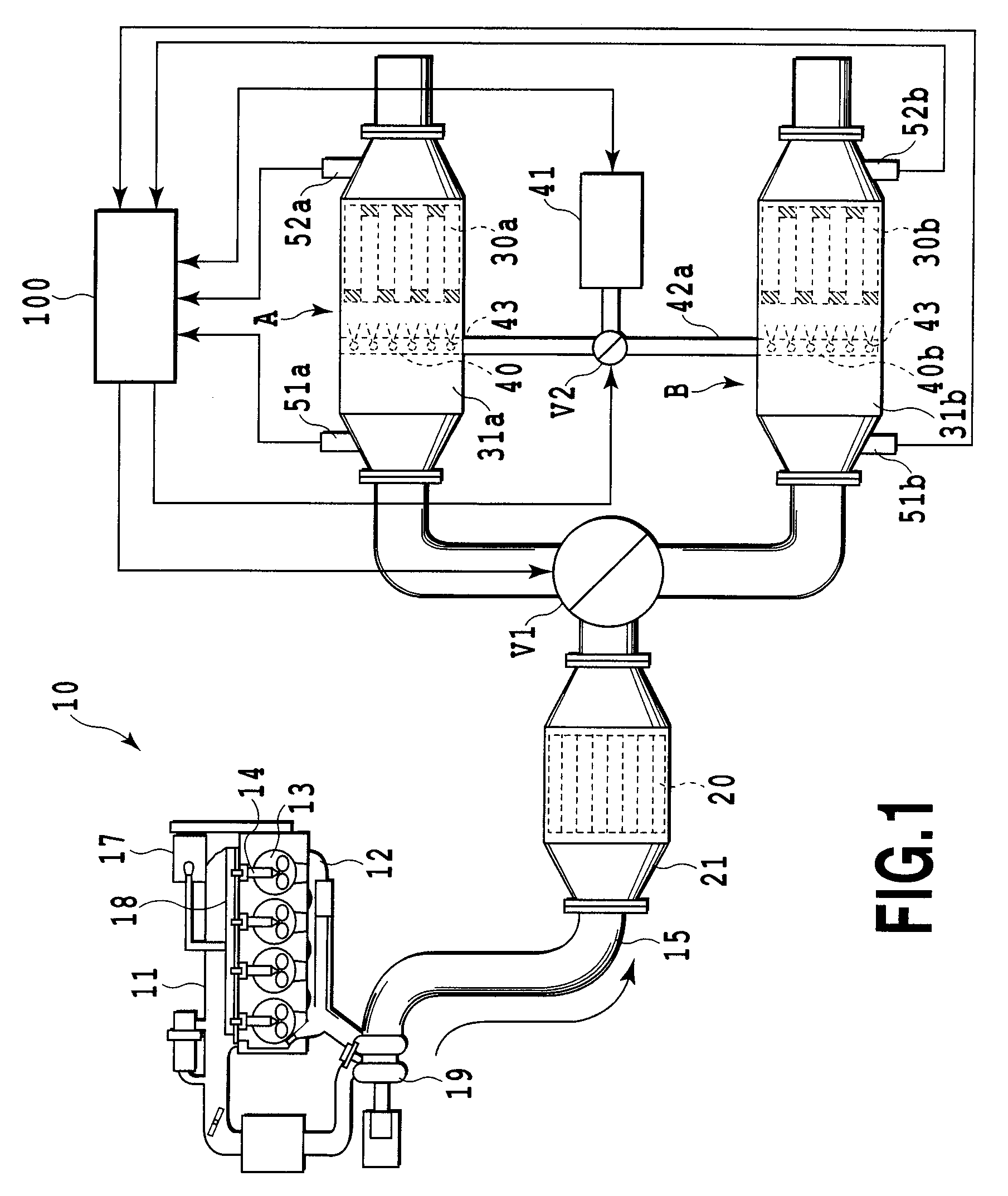

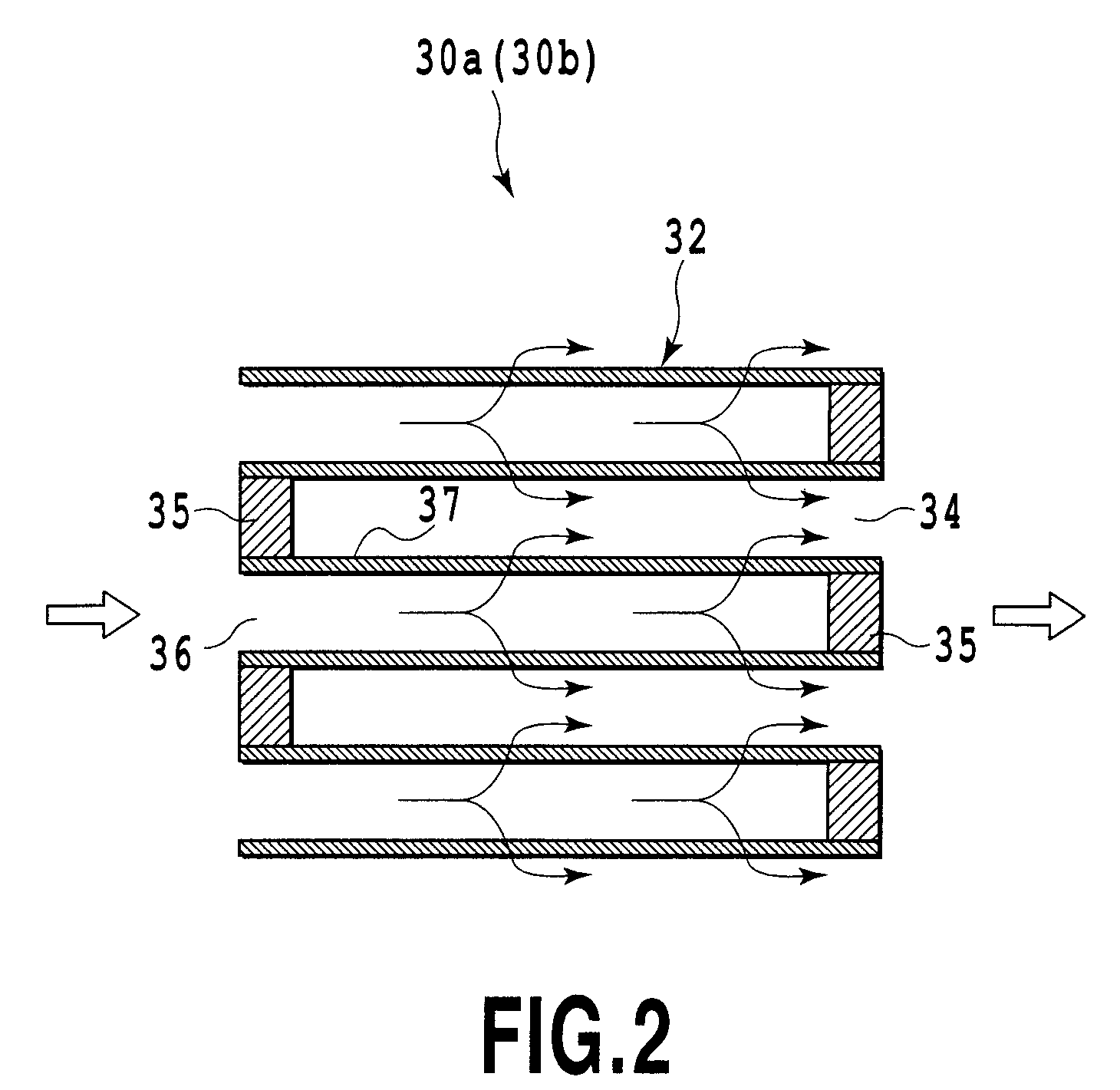

An exhaust purifying system for an internal combustion engine is provided with a plurality of DPFs (30a and 30b) branched and connected to an exhaust passage (15) for collecting particulate matter in an exhaust gas and an ozone supplier for supplying ozone to the upstream side of each of the plurality of DPFs (30a and 30b). The system respectively changes a ratio of a supply amount of the exhaust gas and a ratio of a supply amount of the ozone between the plurality of DPFs (30a and 30b).

Owner:TOYOTA JIDOSHA KK

Method for manufacturing formed honeycomb structure

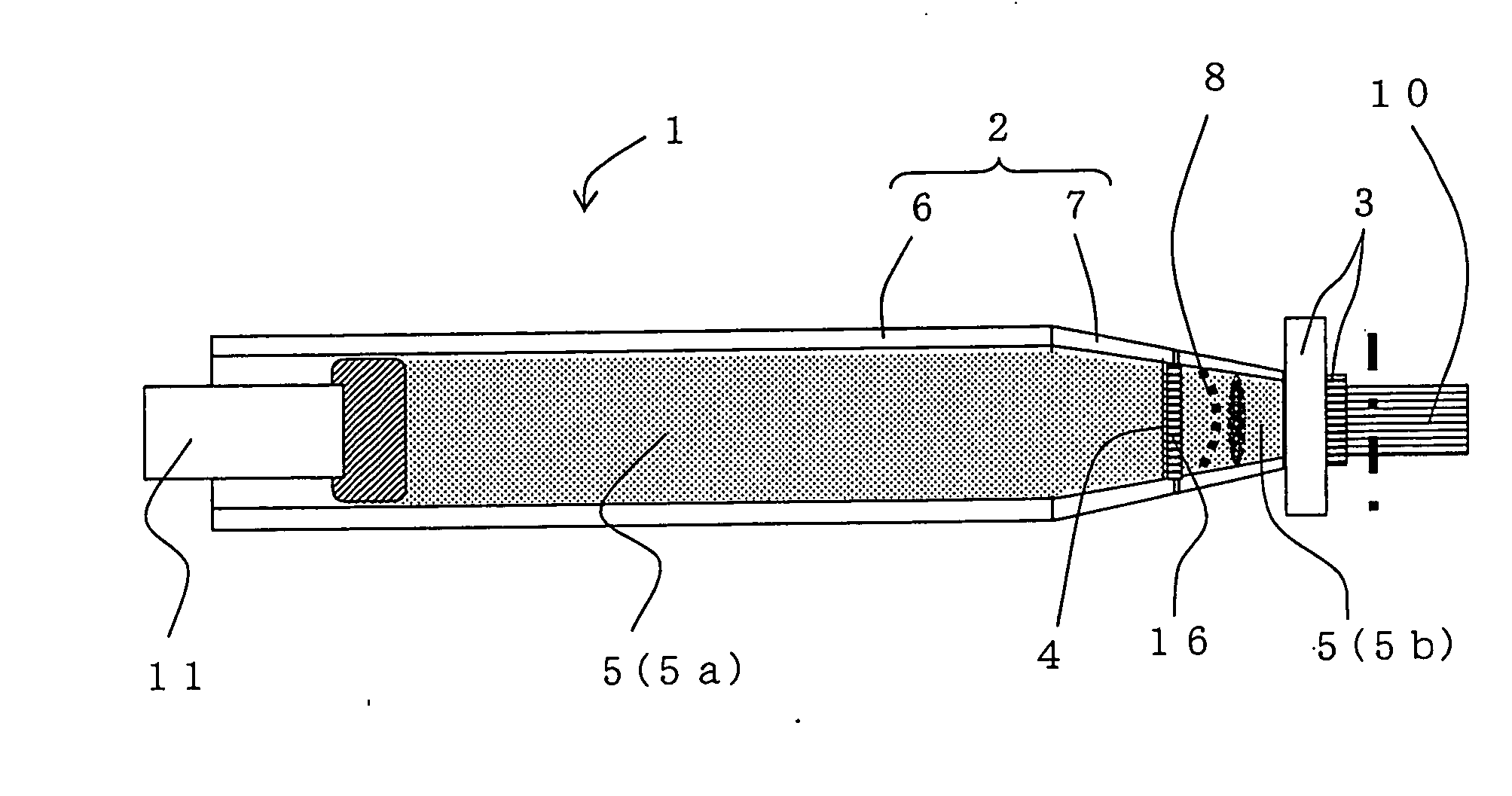

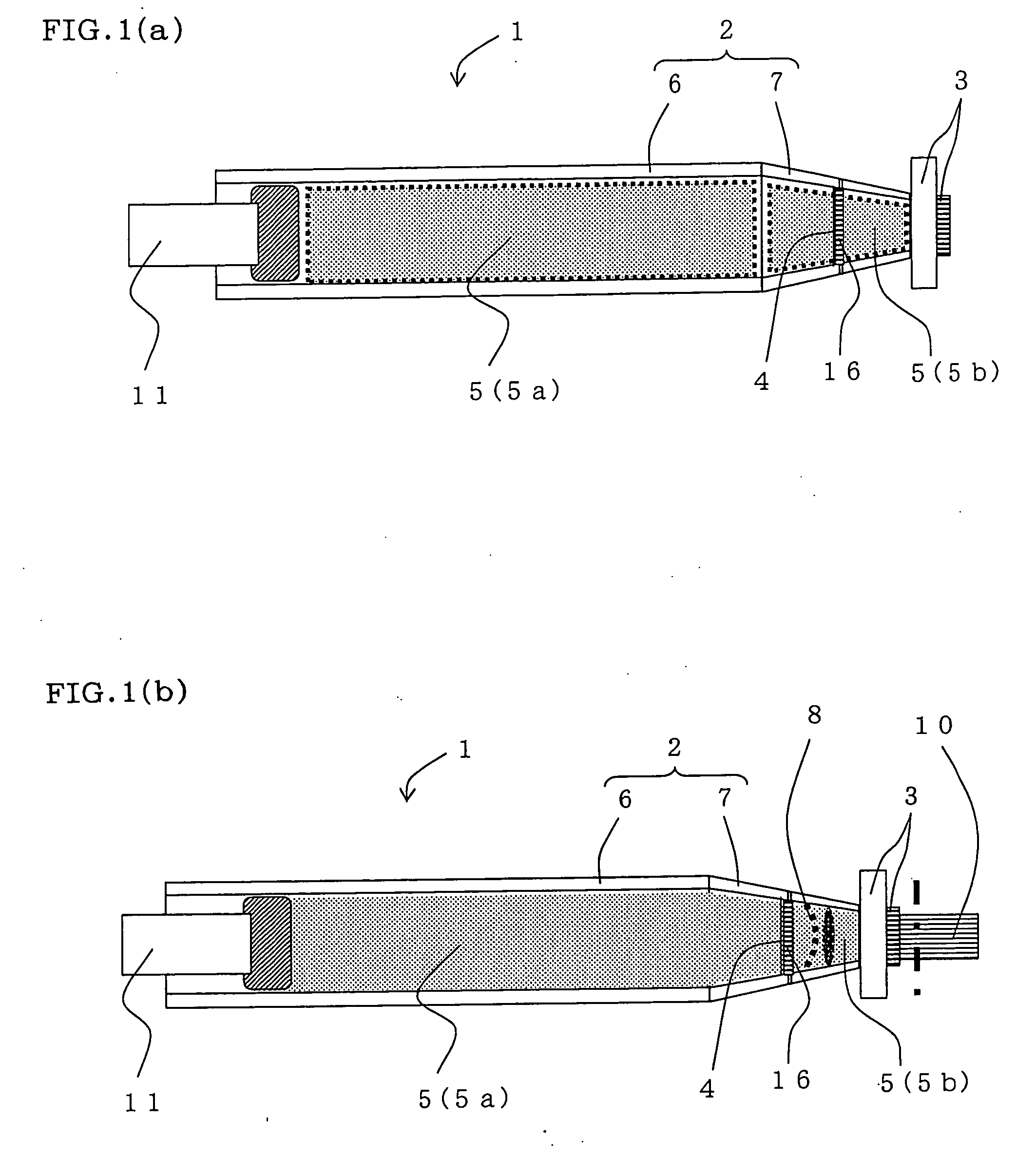

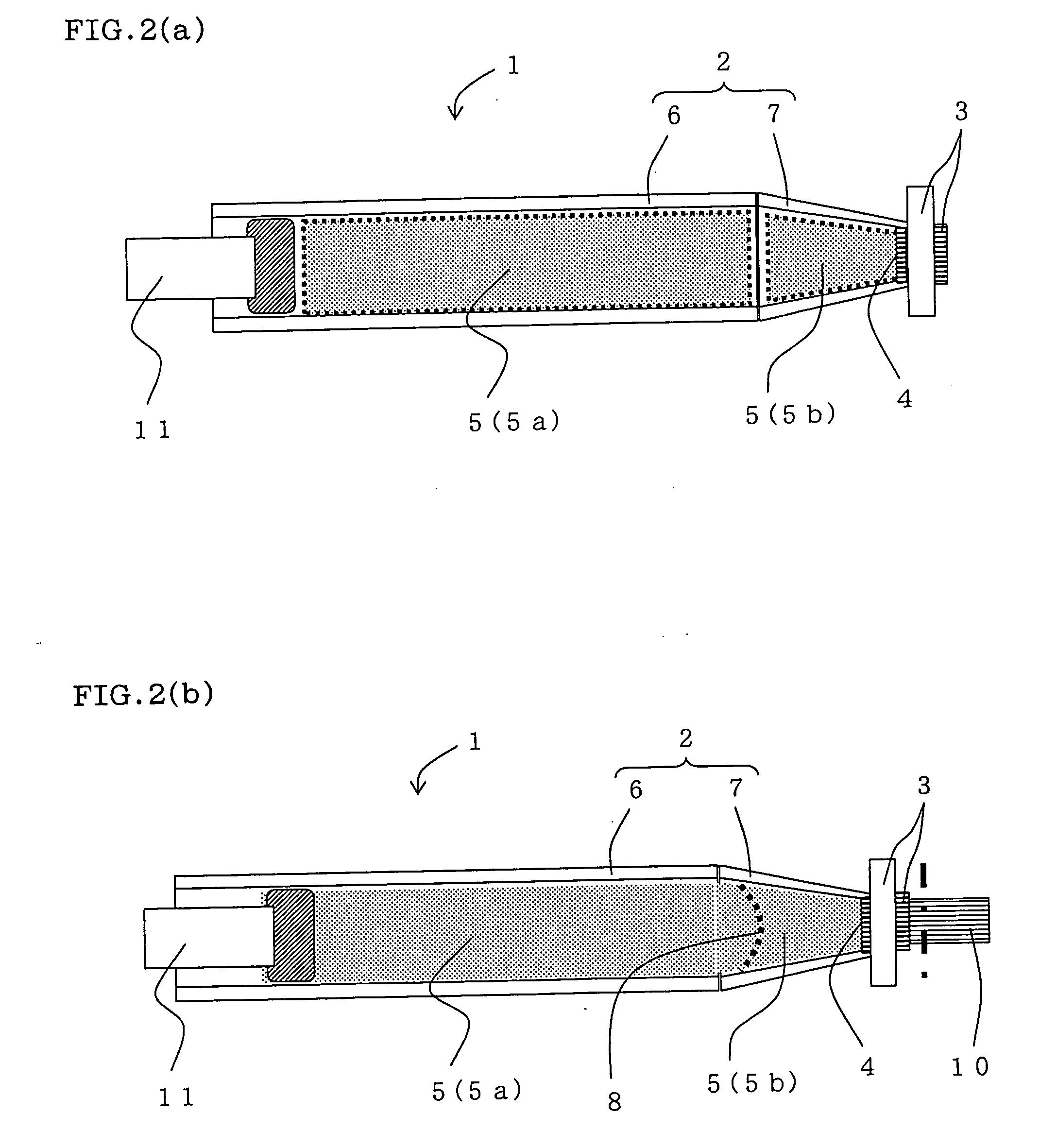

InactiveUS20060208397A1Reduce influenceEffectively usableCeramic extrusion diesFilament-forming treatmentHoneycomb structureForeign matter

A method for manufacturing a formed honeycomb structure in an efficient manner which comprises the steps of: charging a material for forming a honeycomb structure 5 into a passage 22 for preform material for a honeycomb structure whose one end portion is provided with die 3 for forming a formed honeycomb structure; and extruding the charged preform material for a honeycomb structure 5 from the die 3 to form a formed honeycomb structure 10 while passing it through the passage, wherein a screen 4 for filtering foreign matters included in the preform material for a honeycomb structure 5 is disposed in the vicinity of the die 3, and wherein an operation for reduction of frictional resistances between an inner face of the passage 22 for preform material for a honeycomb structure and the preform material for a honeycomb structure 5 which passes the passage is employed.

Owner:NGK INSULATORS LTD

Exhaust cleaner for internal combustion engine

InactiveUS20090120070A1Efficient oxidationReduce the temperatureGas treatmentInternal combustion piston enginesExhaust gasInternal combustion engine

An exhaust purifying system for an internal combustion engine is provided with a plurality of DPFs (30a and 30b) branched and connected to an exhaust passage (15) for collecting particulate matter in an exhaust gas and an ozone supplier for supplying ozone to the upstream side of each of the plurality of DPFs (30a and 30b). The system respectively changes a ratio of a supply amount of the exhaust gas and a ratio of a supply amount of the ozone between the plurality of DPFs (30a and 30b).

Owner:TOYOTA JIDOSHA KK

Method of treating by-product salt yielded with polyarylene sulfide

InactiveUS6939942B2Good water solubilityEffectively usableDrying solid materials without heatSolubilityOrganic solvent

There is disclosed a process for treating a by-product salt of a polyarylene sulfide which comprises subjecting solid matter containing an aprotic organic solvent and the by-product salt that is formed in the case of producing a polyarylene sulfide by polymerization condensation reaction of an alkali metal sulfide and a dihalogenated aromatic compound in the aprotic organic solvent to a drying treatment followed by a firing treatment of the resultant dryingly treated matter at a temperature in the range of 500 to 1000° C. The above process is capable of enhancing the solubility in water, of the by-product salt comprising sodium chloride as the principal component in the production of polyarylene sulfide, and affording waste water which is lowered in SS and COD in the case where the by-product salt is dissolved in water and is discharged as waste water.

Owner:GASOLINEEUM ENERGY CENT FOUND +1

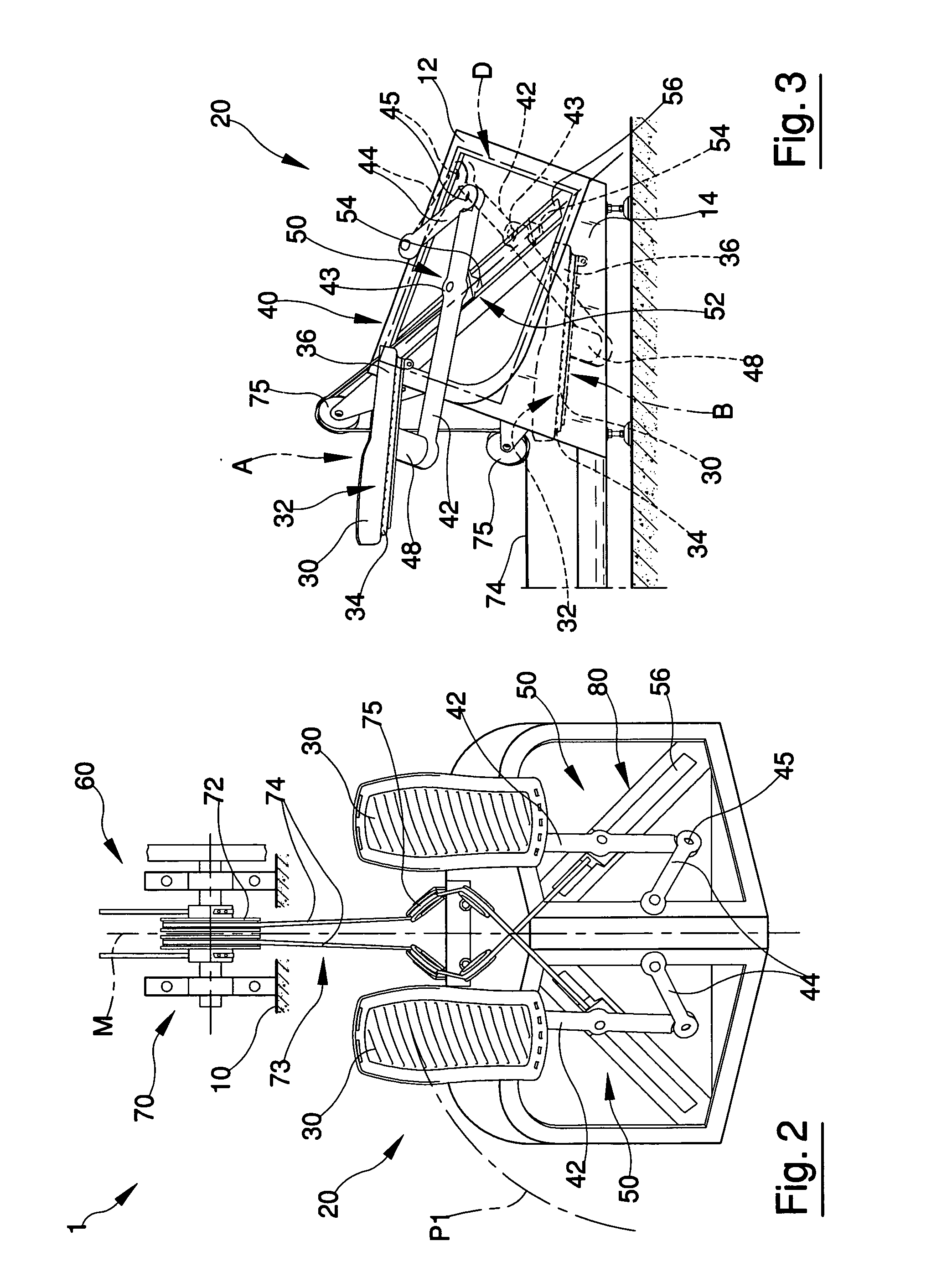

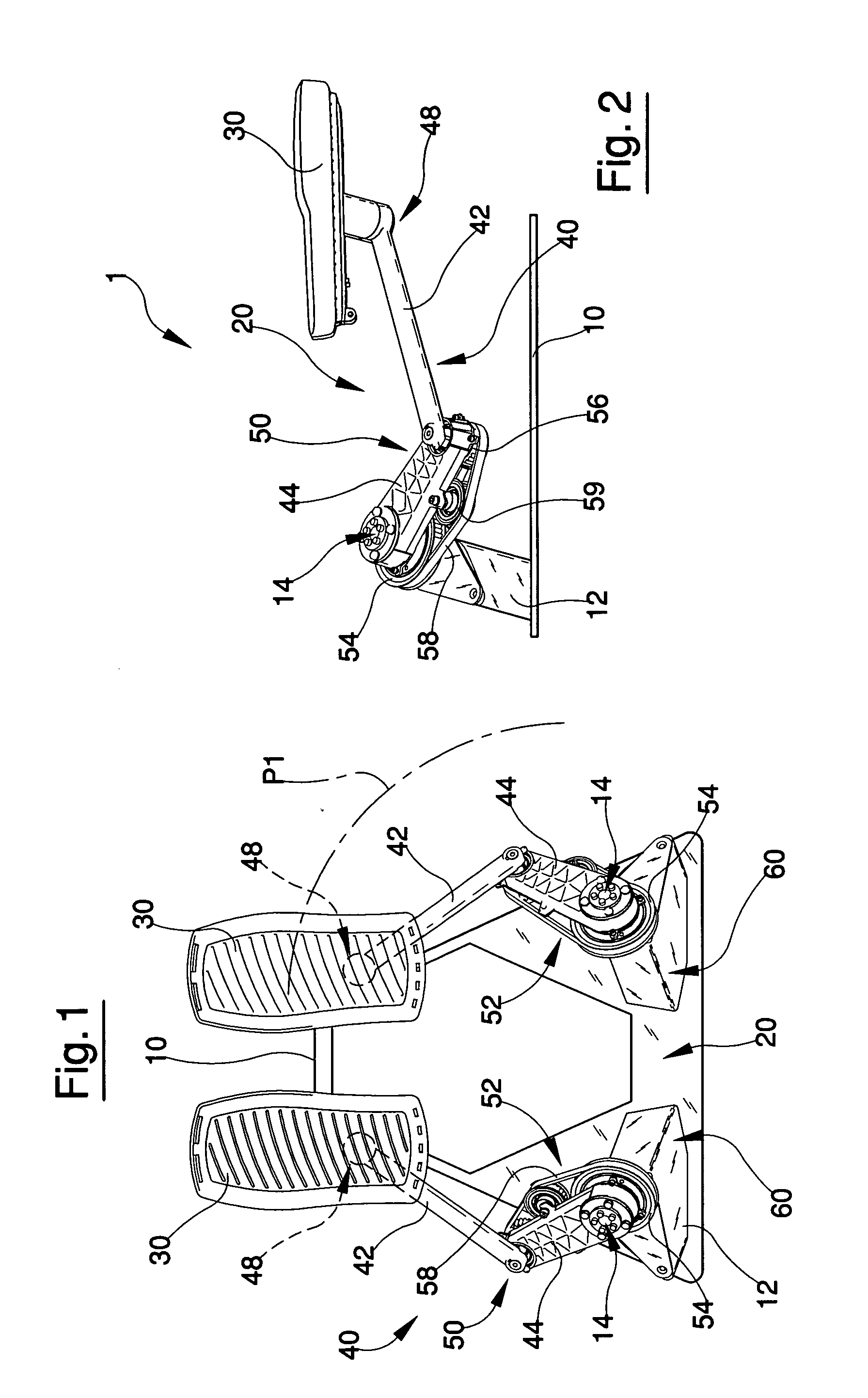

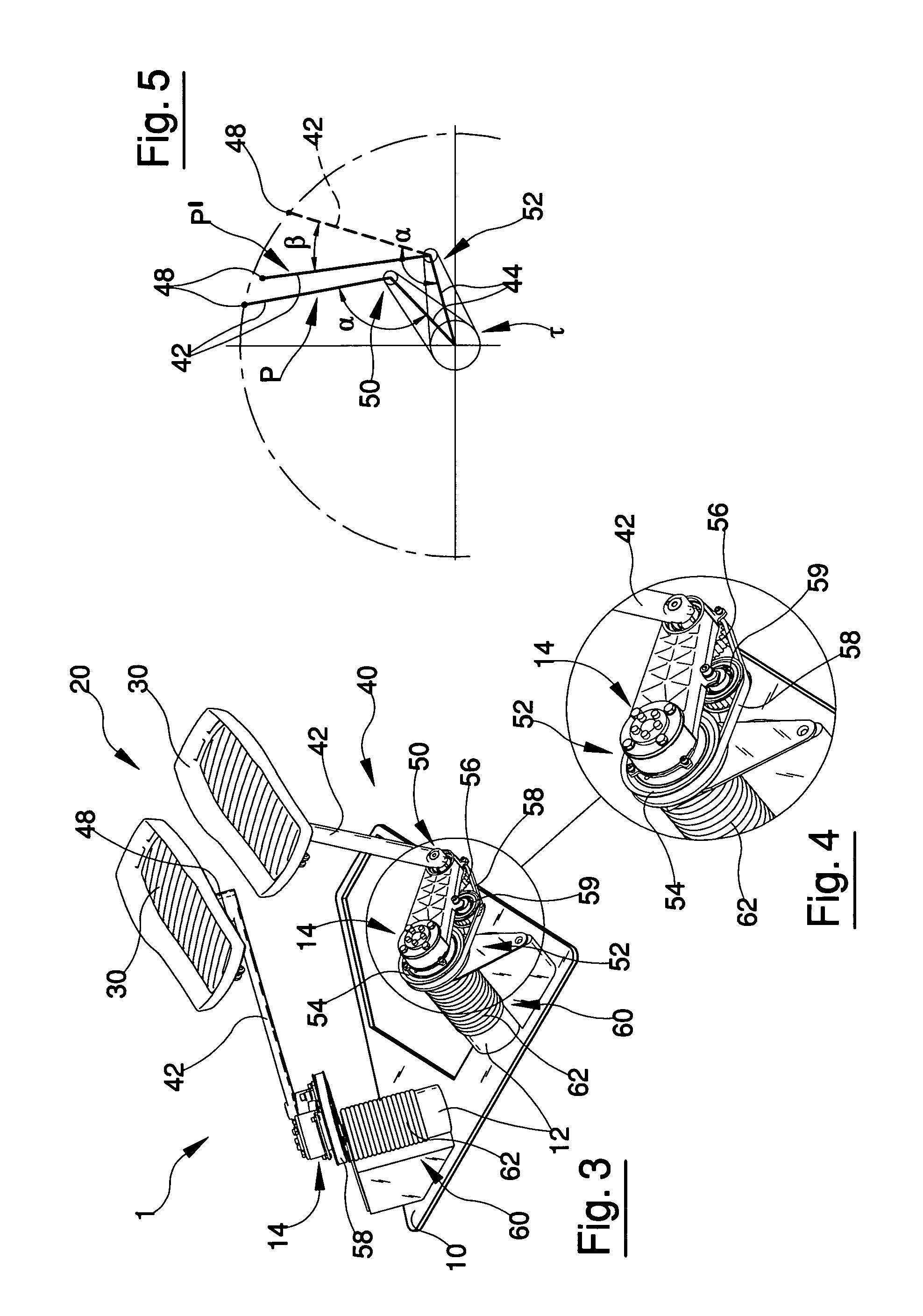

Gymnastic machine

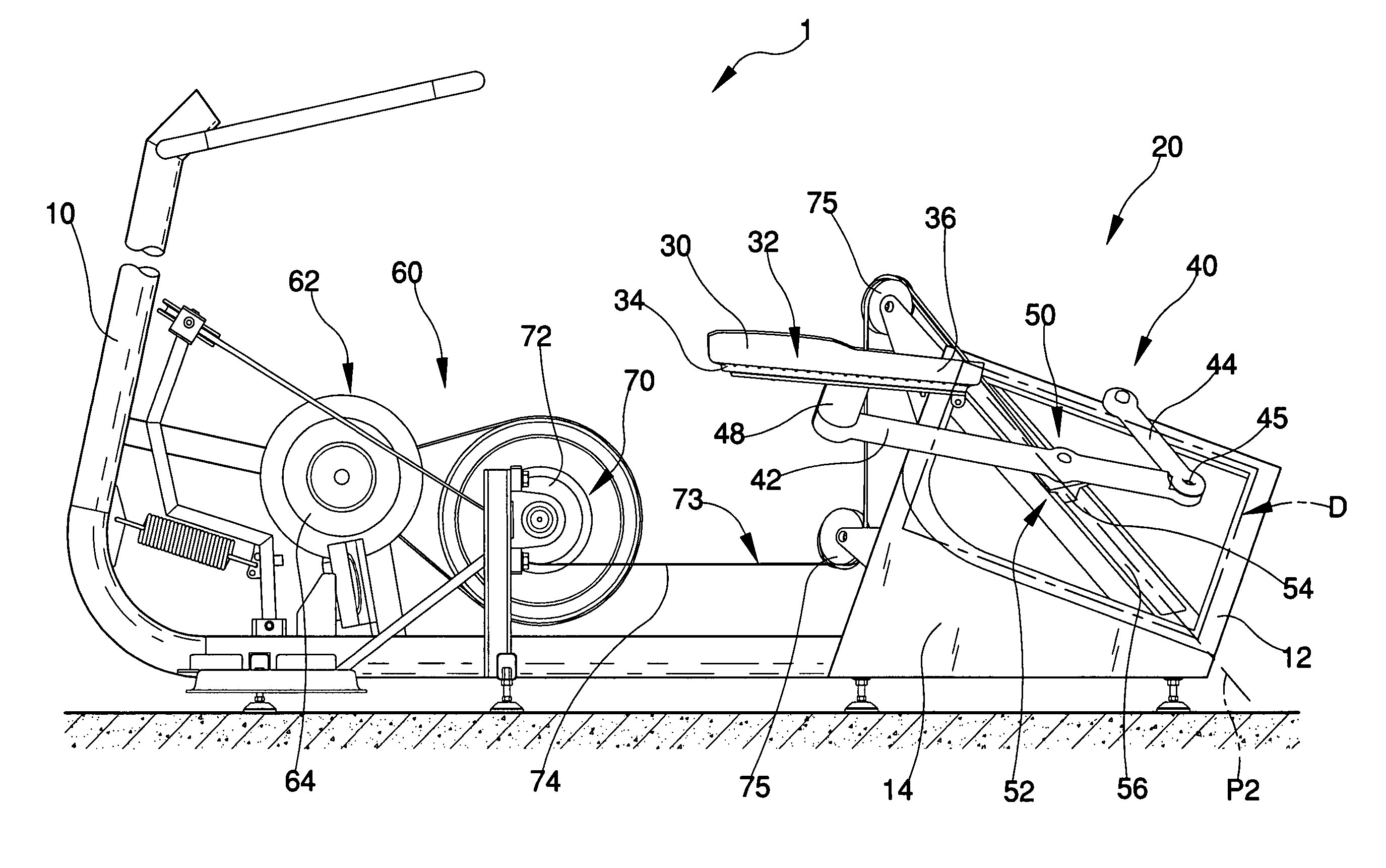

InactiveUS20070167289A1Effectively usableEffective applicationMovement coordination devicesCardiovascular exercising devicesSimulationFoot boards

Gymnastic machine having a frame (10) and an exercise station (20) provided with at least one footrest (30) movable with respect to the frame (10) along a first open trajectory (P1) and carried by a first rocker arm (42) supported in a cantilevered fashion by the frame (10) by means of at least one turning pair (45); the exercise station (20) being provided with a supporting device (50) associated with the first rocker arm (42) to minimise the amount of stress that can be transmitted to said footboard (30).

Owner:TECHNOGYM SPA

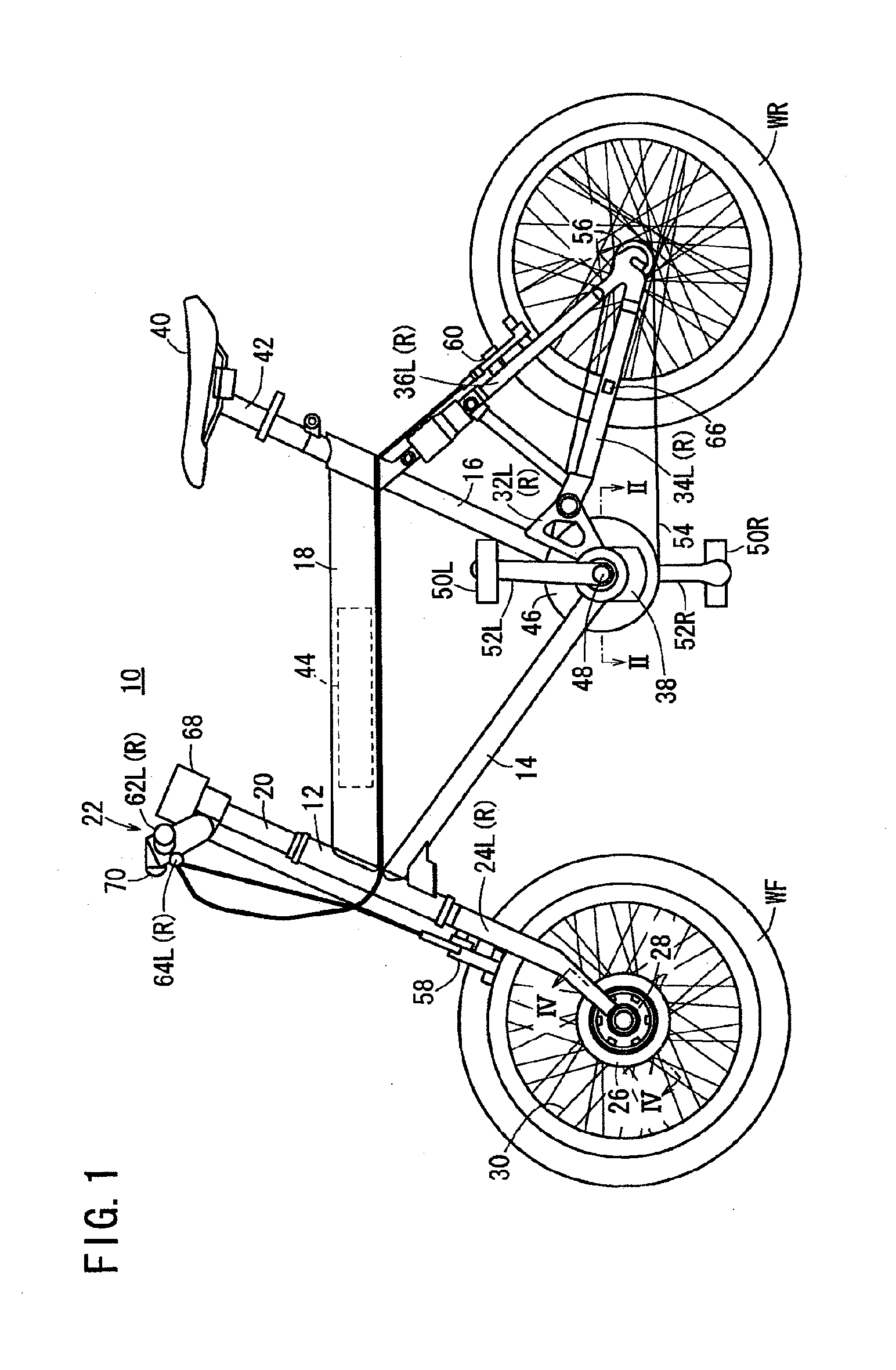

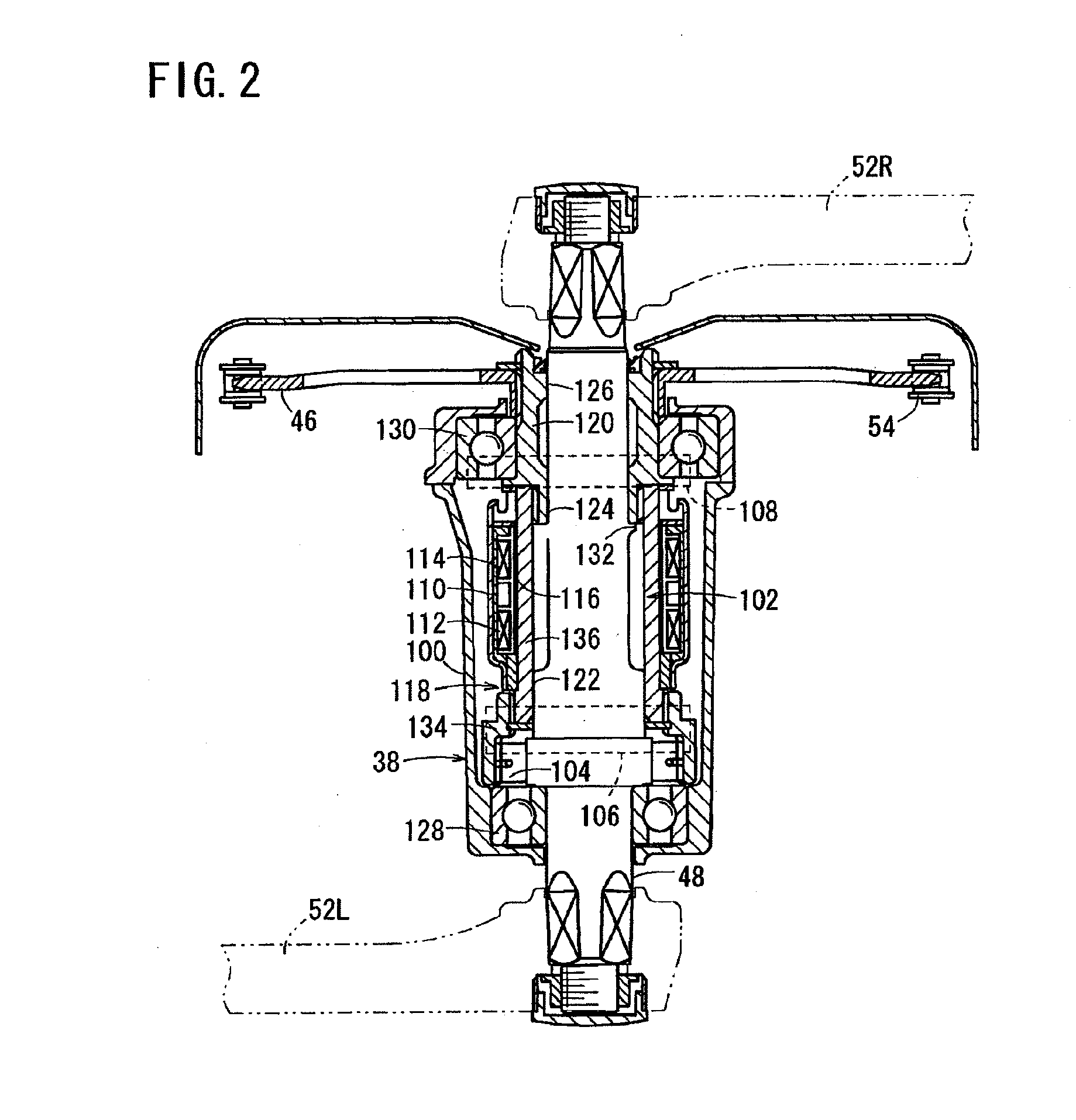

Control apparatus for motor-assisted bicycle

InactiveUS20120083956A1Improve drivabilityIncrease loadDigital data processing detailsVehicle position/course/altitude controlEngineeringControl theory

A control apparatus for a motor-assisted bicycle detects a pedaling torque applied to a crankshaft with a pedaling force sensor, controls a motor unit of the motor-assisted bicycle in a regenerative control process to charge a battery, if the torque value of the detected pedaling torque is equal to or smaller than a predetermined level, and controls the motor unit in an assistive control process, if the torque value is greater than the predetermined level. The control apparatus performs an assistive transient control process with an assistive ratio lower than in the assistive control process while the crankshaft makes a predetermined number of revolutions and thereafter performs the regenerative control process, if the torque value detected by the pedaling force sensor has a peak equal to or smaller than the predetermined level.

Owner:HONDA MOTOR CO LTD

Turning tool for grooving polishing pad, apparatus and method of producing polishing pad using the tool, and polishing pad produced by using the tool

InactiveUS7017246B2Small widthHigh dimensional accuracyPrecision positioning equipmentMilling cuttersWedge angleMechanical engineering

Disclosed is a turning tool for cutting circumferential grooves into a surface of a polishing pad formed of a resin material and utilized for polishing semiconductor devices. The turning tool comprising a cutting part arranged to have a tooth width within a range of 0.005–1.0 mm, a wedge angle within a range of 15–35 degrees, and a front clearance angle within a range of 65–45 degrees. A polishing pad effectively formed by using the turning tool, and an apparatus and a method of producing such a polishing pad by utilizing the turning tool are also disclosed.

Owner:TOHO ENG CO LTD

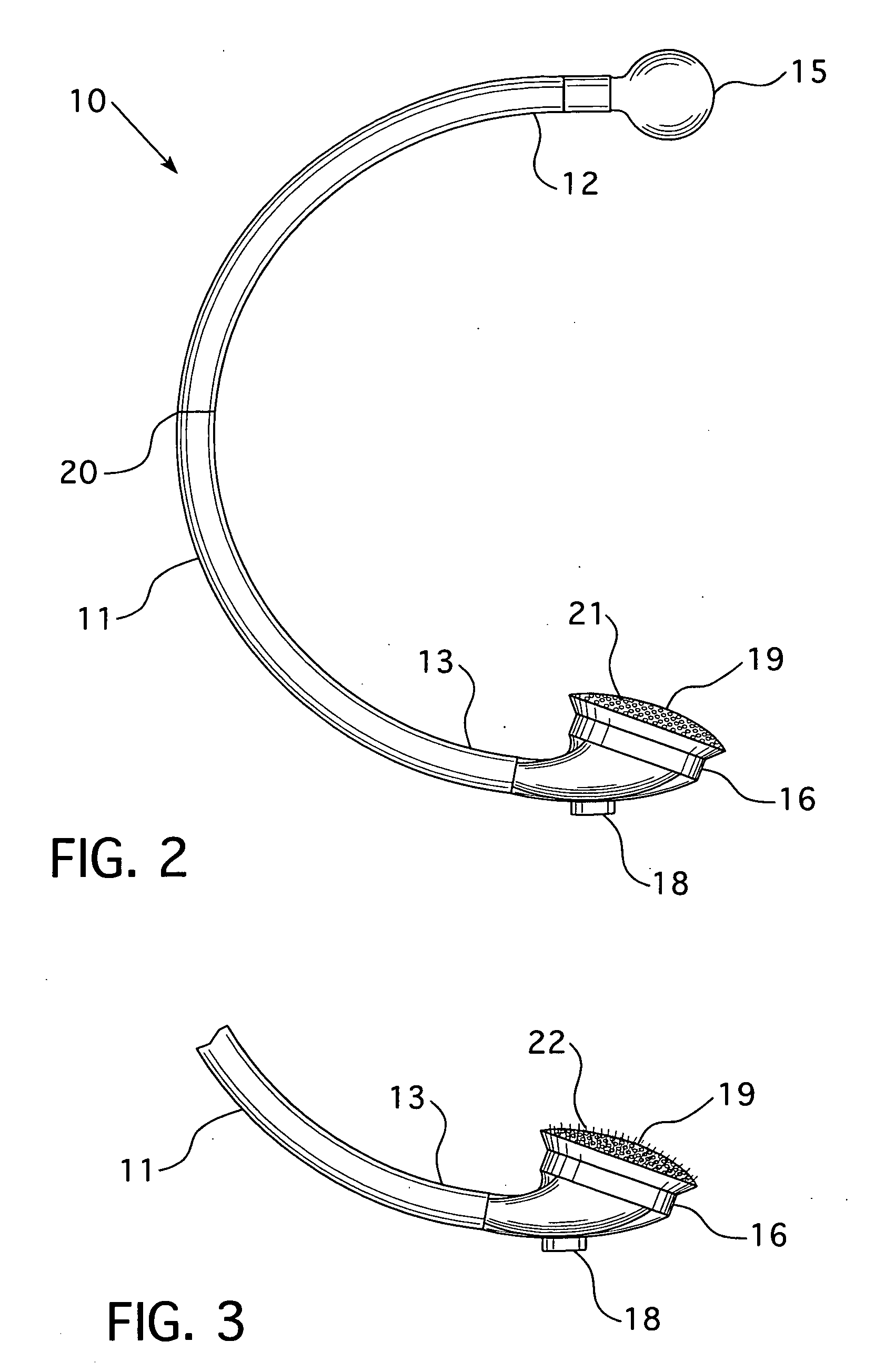

Liquid soap or lotion applicator

InactiveUS20090092435A1Efficiently usableEffectively usableCarpet cleanersBrush bodiesLiquid soapBiomedical engineering

A liquid soap or lotion applicator for hard to reach areas of the body which includes in combination a substantially rigid elongated tubular handle with a low pressure squeeze bulb secured to one end of the tubular handle for forcing air under low pressure through the tube handle, and a hollow head connected to the opposite end of the tubular handle. The head is provided with a reservoir that communicates with the hollow interior of the tubular handle and is further provided with a removable access for pouring liquid soap or lotion into the reservoir. A porous applicator is removably secured to head with the interior surface of the applicator exposed to the reservoir whereby liquid in the reservoir will be forced through the porous applicator for application to the body when the bulb is squeezed. The tubular handle has a fixed arcuate shape which extends through a curvature of 90° to 180°, and the exterior face of the porous applicator faces anywhere in the range from in line with the tube end to a direction facing the squeeze bulb.

Owner:STEVENS JAMES H

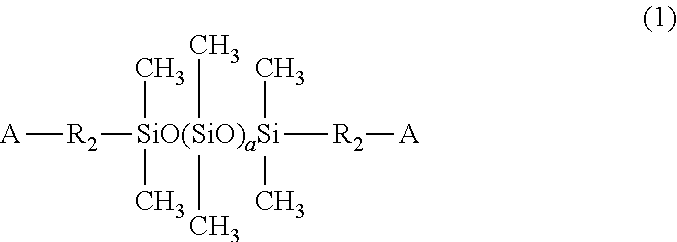

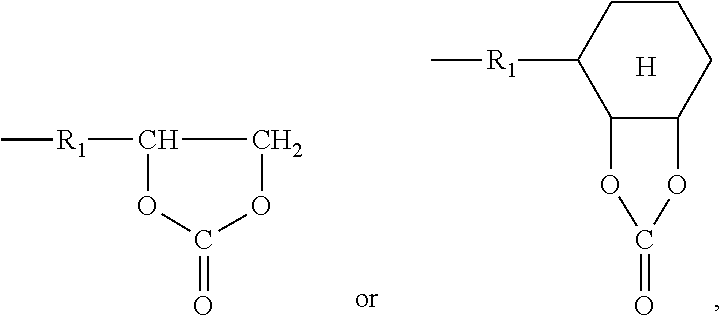

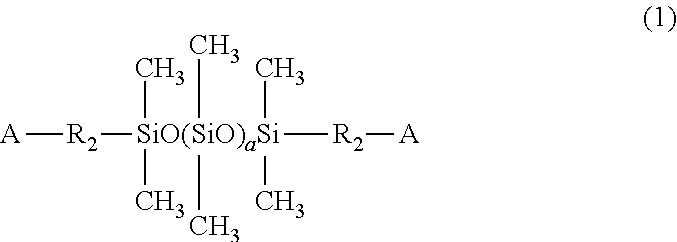

Self-crosslinking polysiloxane-modified polyhydroxy polyurethane resin, resin material containing same, method for producing same, artificial leather comprising same, and thermoplastic polyolefin skin material comprising same

ActiveUS20130171896A1Satisfactory performanceEffectively usableSynthetic resin layered productsAnimal housingPolymer sciencePolyolefin

Provided are a self-crosslinking polysiloxane-modified polyhydroxy polyurethane resin derived from a reaction of a 5-membered cyclic carbonate polysiloxane compound represented by the following formula (1) and an amine compound and having polysiloxane segments and masked isocyanate groups in its structure:wherein A meansand its production process. The present invention can provide a polyhydroxy polyurethane resin, the development of applications of which has not moved ahead in the prior art, as a novel self-crosslinking polyhydroxy polyurethane resin that enables to provide products excellent in lubricity, abrasion resistance, chemical resistance, non-tackiness, heat resistance and the like, is useful from the viewpoint of the reduction of warming gas, and is responsive to the environment.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD +1

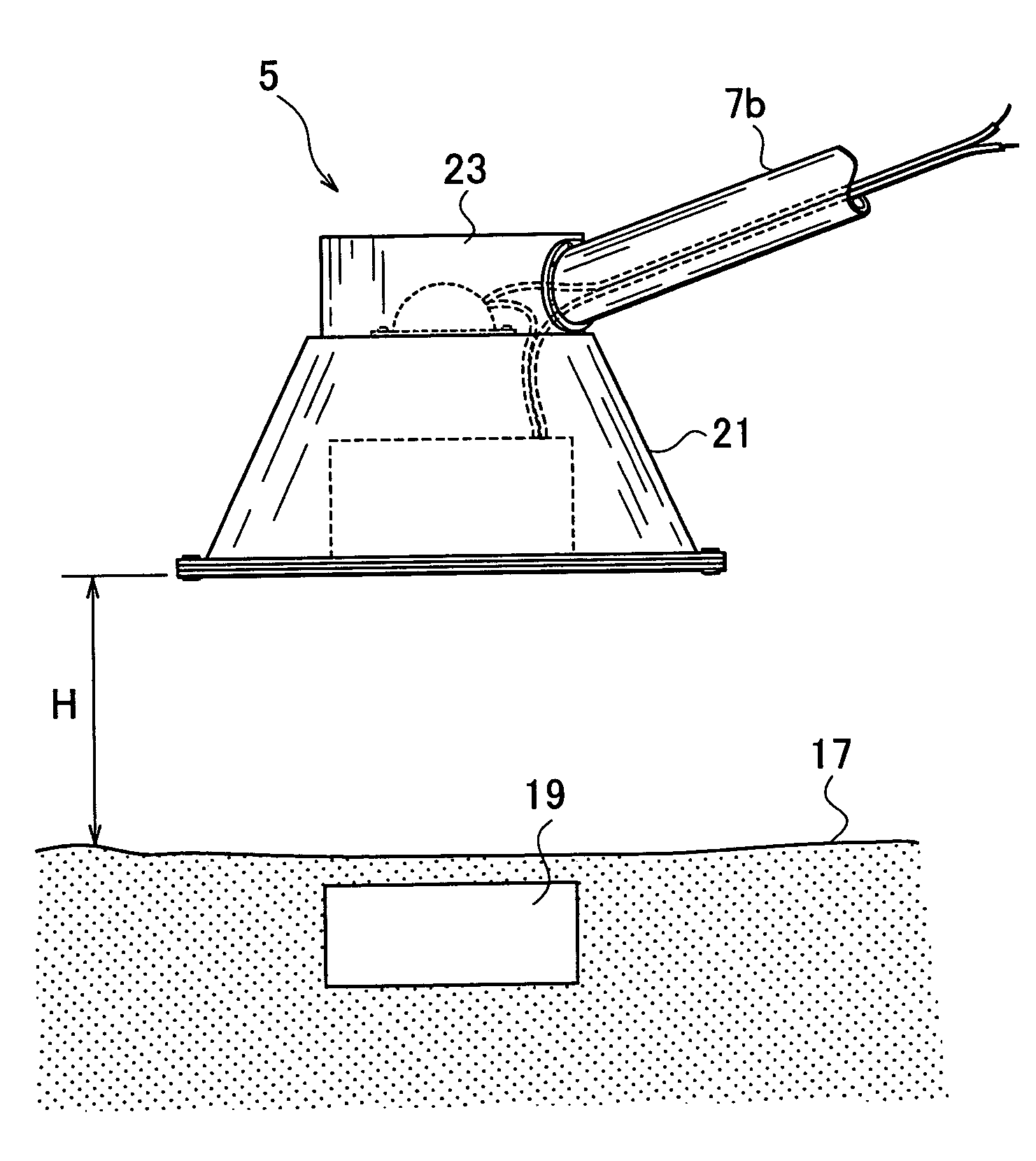

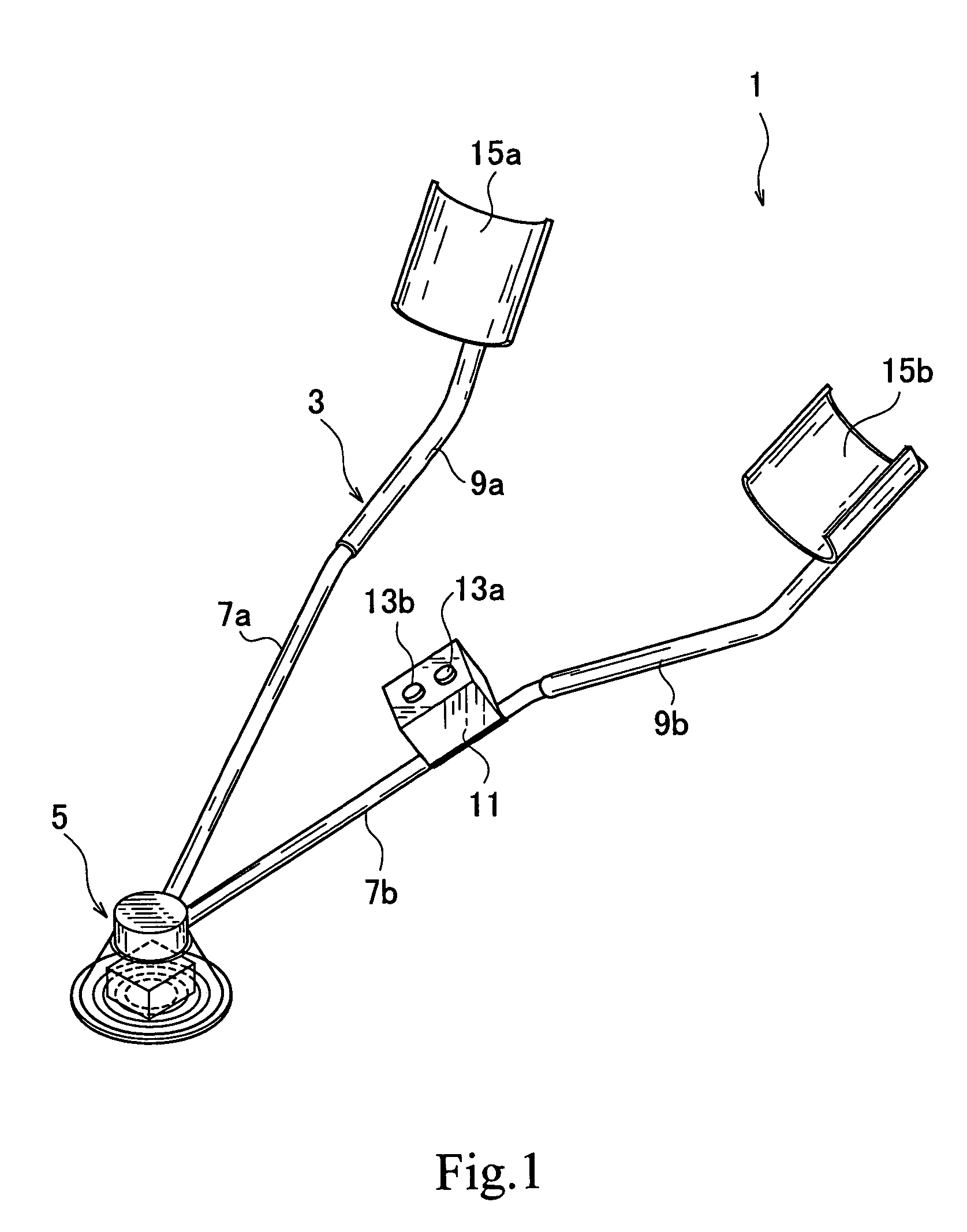

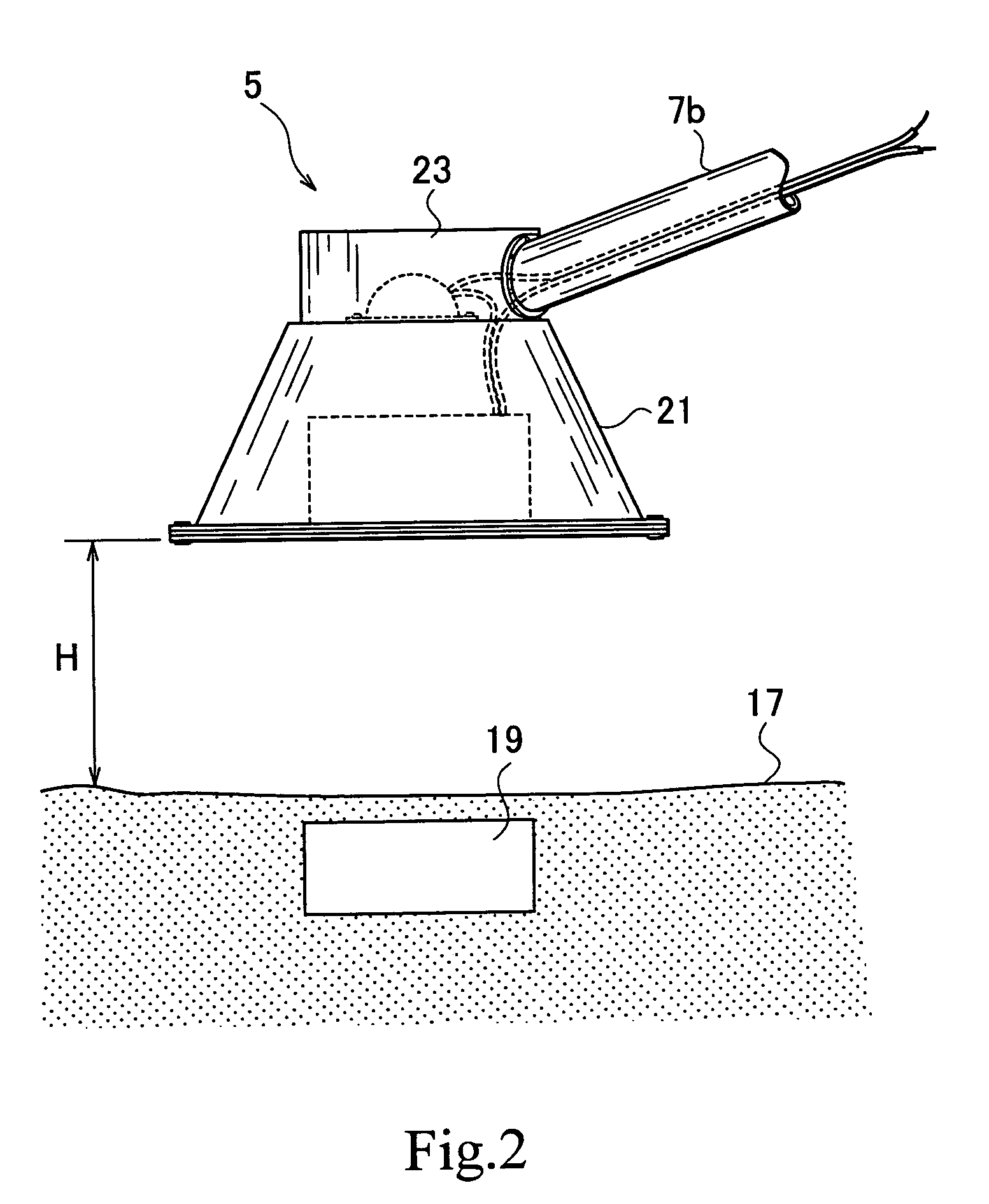

Buried structure detection device

InactiveUS6998854B2Accurate detectionEffectively usableDefence devicesResistance/reactance/impedenceEngineeringCapacitance transducer

An underground buried object detecting apparatus has a capacitance sensor attached to a base plate to be faced to the ground, to detect an underground capacitance change, a stored value of a reference capacitance corresponding to the absence of a buried object, a comparing operation device for comparing detected capacitance with the stored capacitance value, and a buzzer for receiving a signal from the operation device and indicating presence of a buried object.

Owner:UNIREC

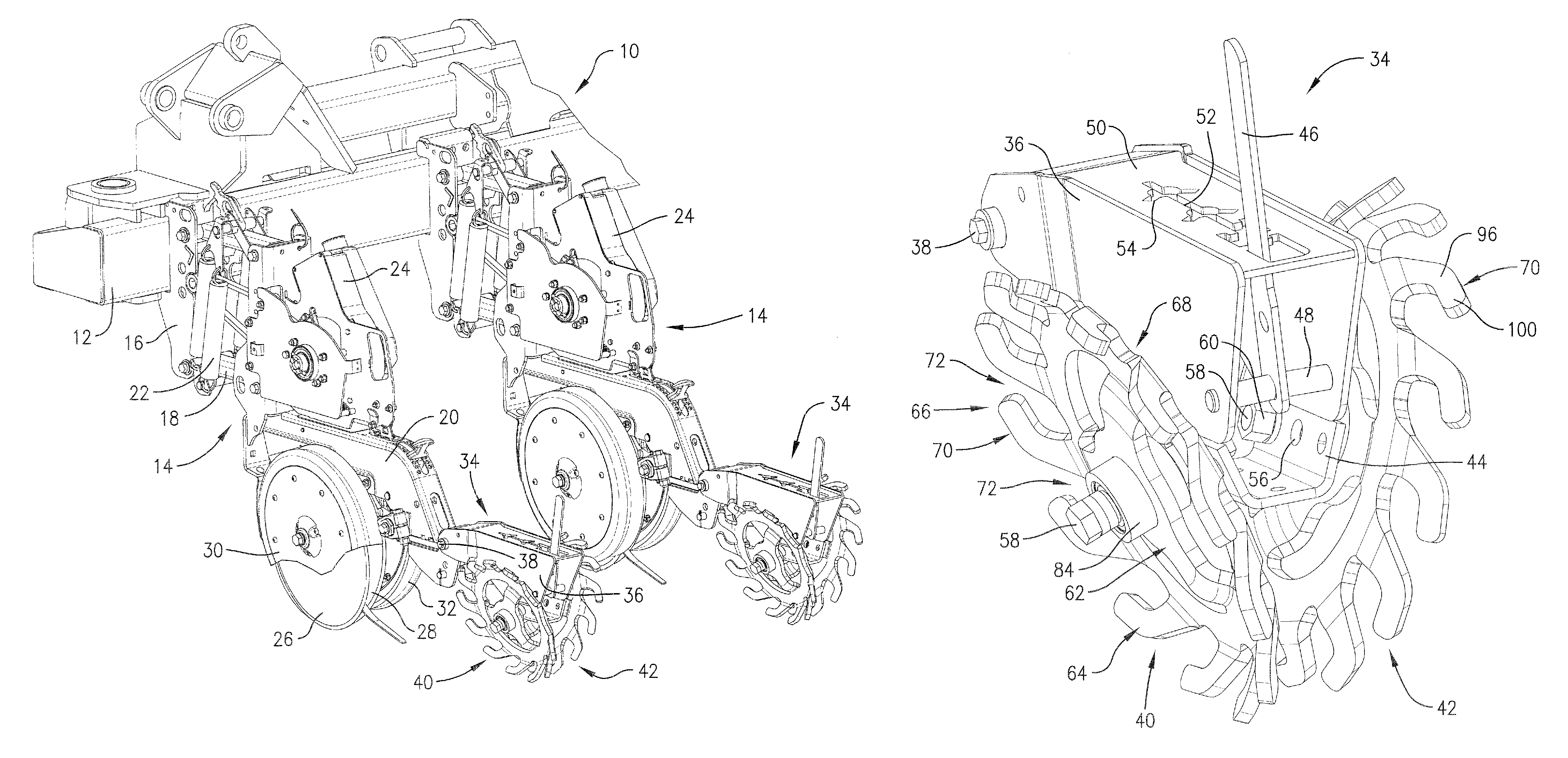

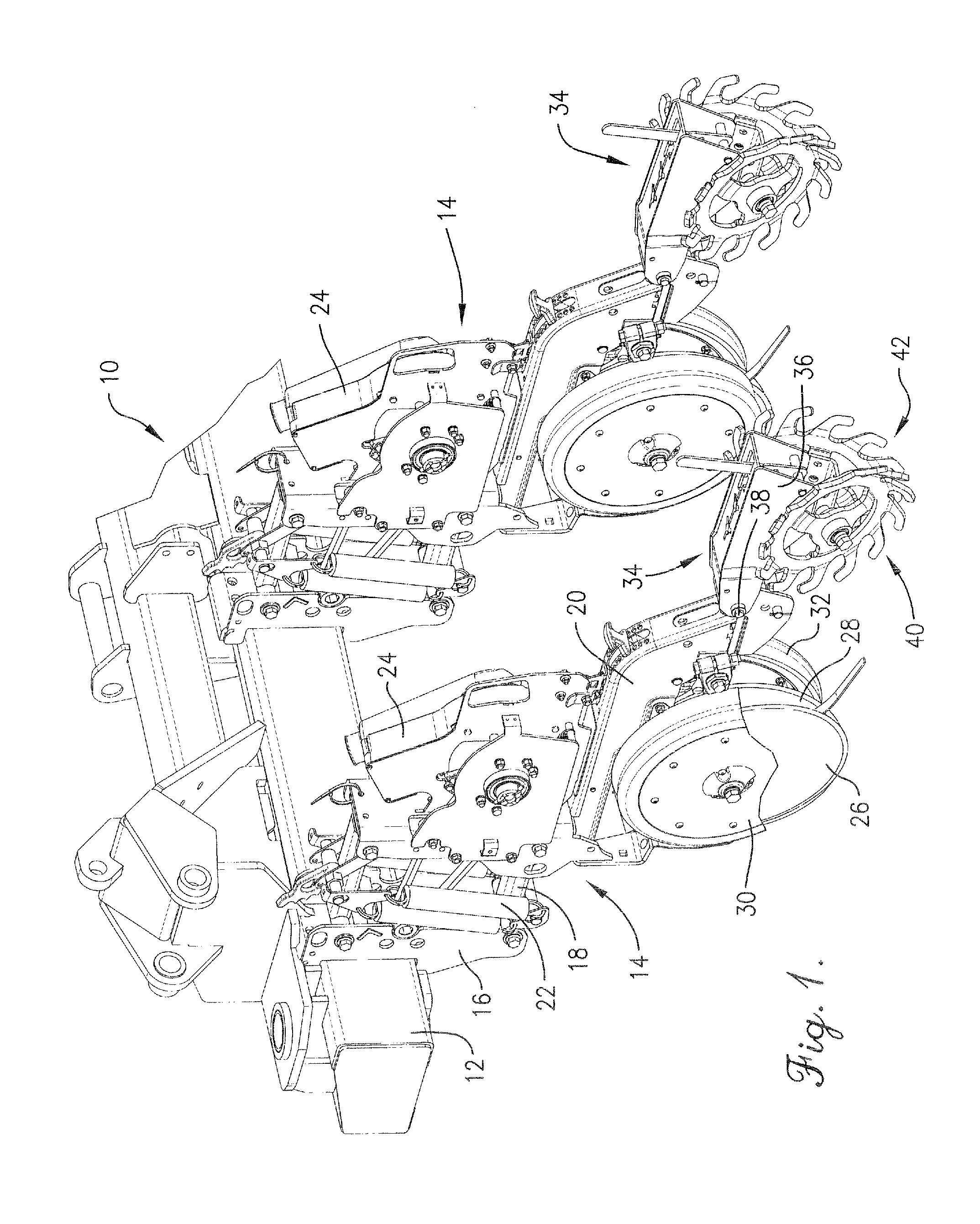

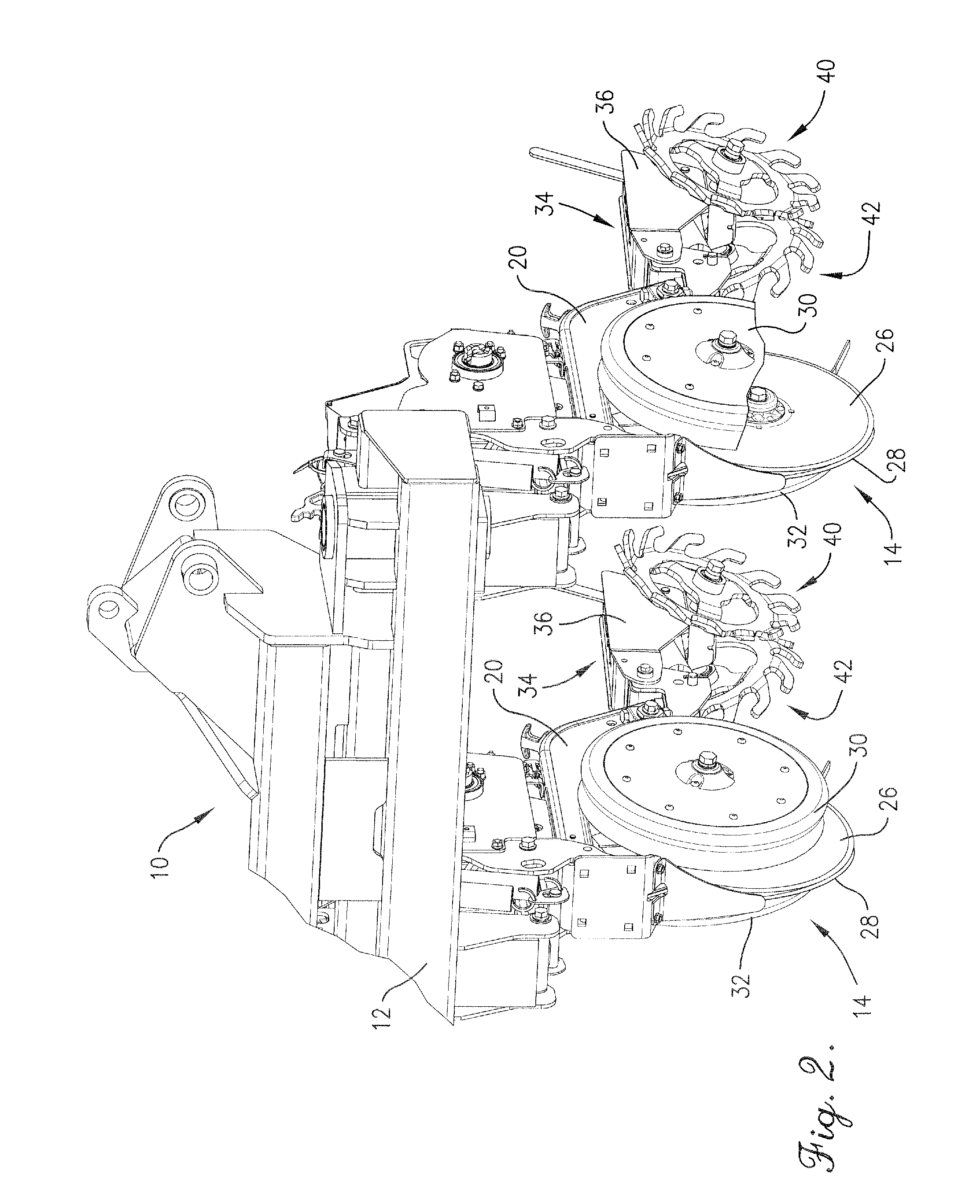

Seed furrow closing apparatus

ActiveUS8333161B2Effectively usableAvoiding time-consuming and laborious taskPlantingSoil-working equipmentsEngineeringFlange

A seed furrow closing wheel has a generally dish-shaped body defined by a central portion and a notched outer flange portion that circumscribes the central portion and projects obliquely outwardly from the plane thereof. The notched flange portion is configured to present a series of circumferentially spaced, non-radial, obliquely projecting teeth that function to fragment and squeeze together opposite sidewalls of the seed furrow when a pair of the wheels are rolled along opposite sides of the furrow outboard of the furrow itself, crumbling the sidewalls and covering the seeds.

Owner:GREAT PLAINS MFG INC

Gymnastic machine

InactiveUS20070202994A1Effectively usableEffective applicationOperating chairsDental chairsEngineeringRocker arm

Gymnastic machine having a frame (10) and an exercise station (20) provided with at least one footrest (30) movable with respect to the frame (10) along a first open trajectory (P1); each footrest (30) being supported rotatably by a first rocker arm (42) in turn supported by a second rocker arm (44) coupled rotatably to the frame (10); a device (50) to control rotation of the first rocker arm (42) being carried on the second rocker arm (44) to minimise the size of the volumes engaged by movable masses in the exercise station (20) and around each footrest (30).

Owner:TECHNOGYM SPA

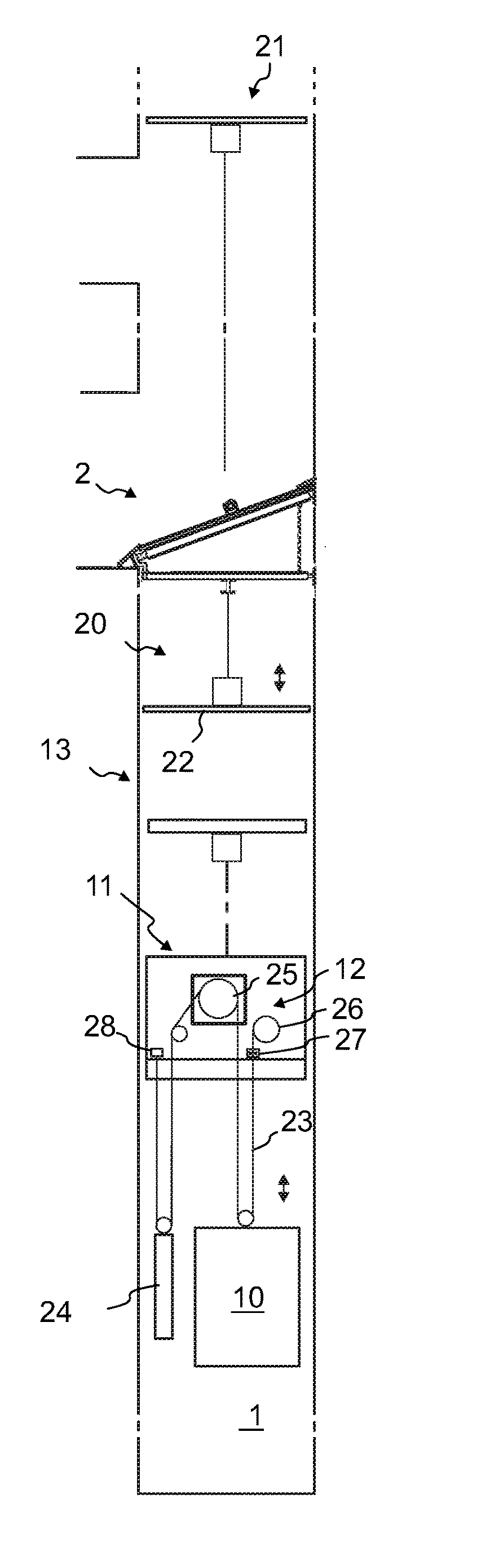

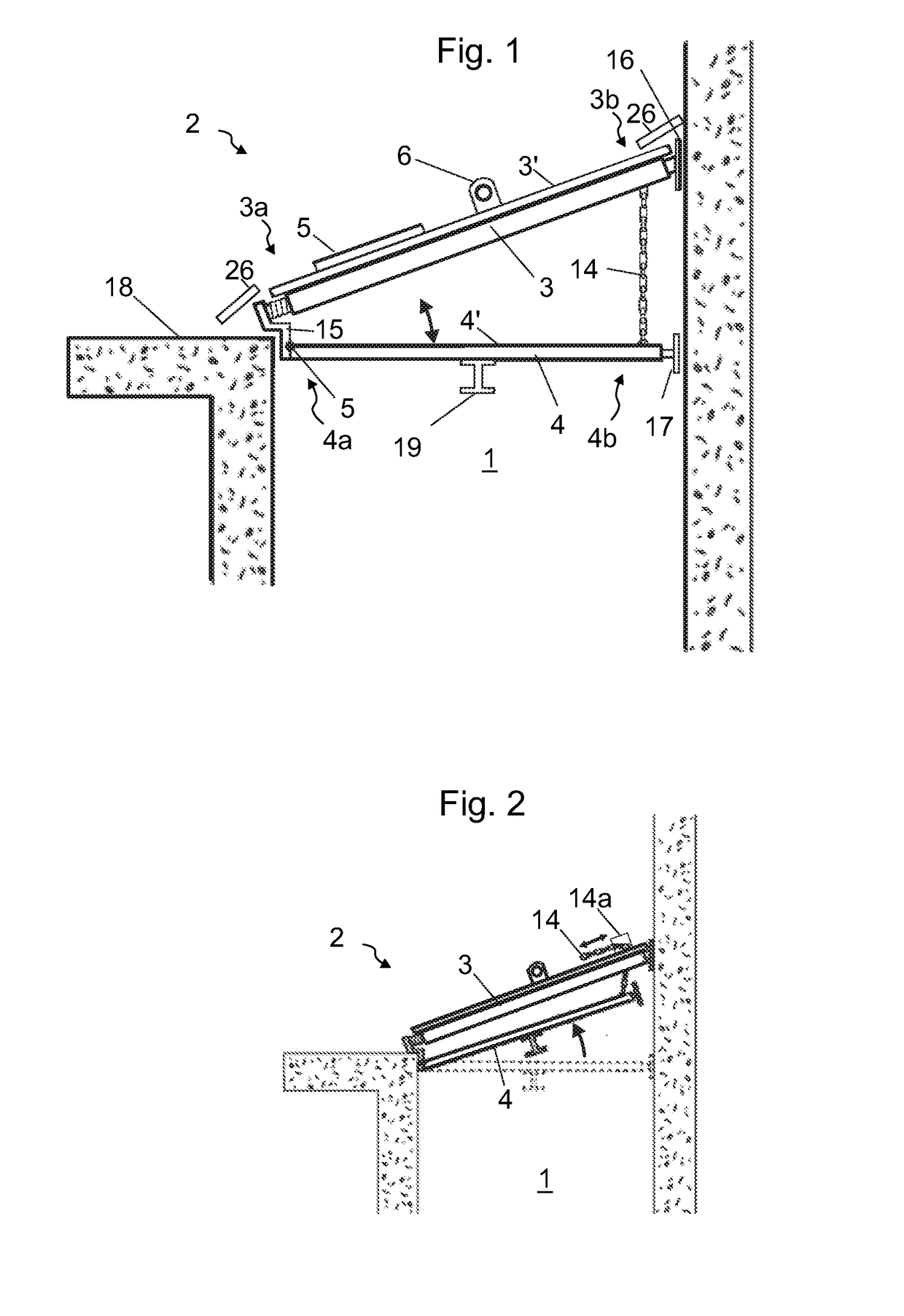

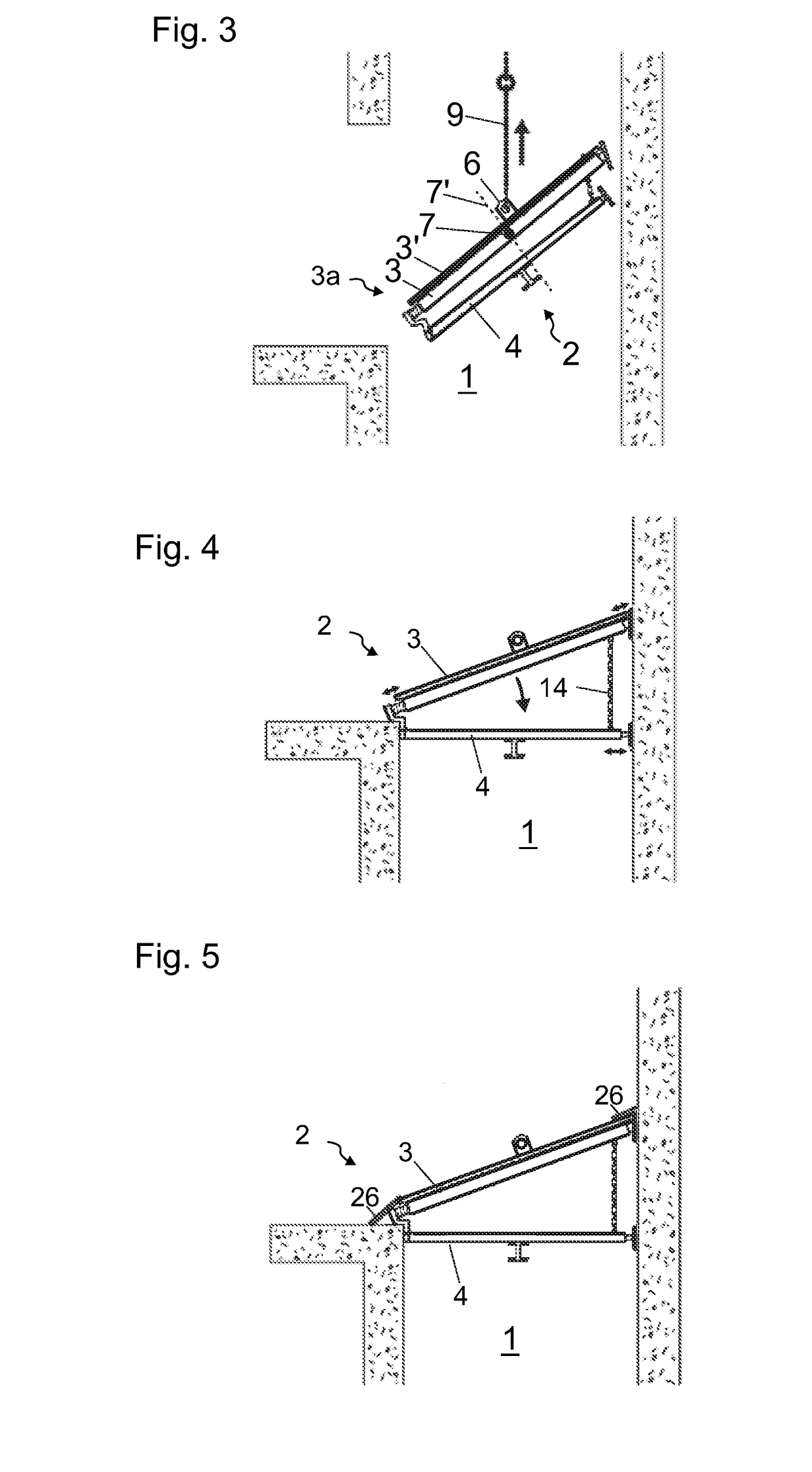

Elevator arrangement and method

ActiveUS20180290863A1Simple structureMaintaining ability to modify the configuration swiftlyElevatorsBuilding material handlingEngineeringMechanical engineering

The invention relates to a construction time elevator arrangement comprising a hoistway; a protection deck mounted within the hoistway for protecting the portion of the hoistway below it from falling objects; the protection deck comprising a roof member extending diagonally across the hoistway and covering the hoistway such that it blocks objects and / or water from falling into the hoistway below it; and a cross member extending in horizontal direction across the hoistway below the roof member. The cross member is pivotally connected with the roof member, the protection deck being collapsible into a transport state by pivoting the cross member and the roof member towards each other. The invention relates to a method implementing the construction time elevator arrangement.

Owner:KONE CORP

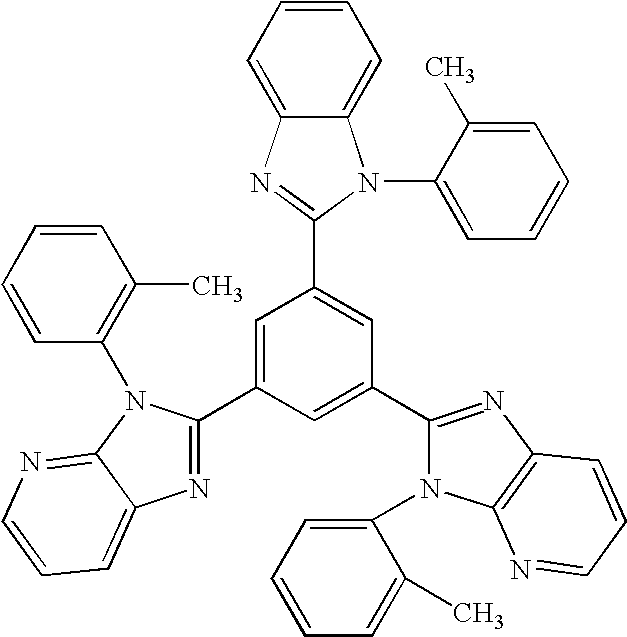

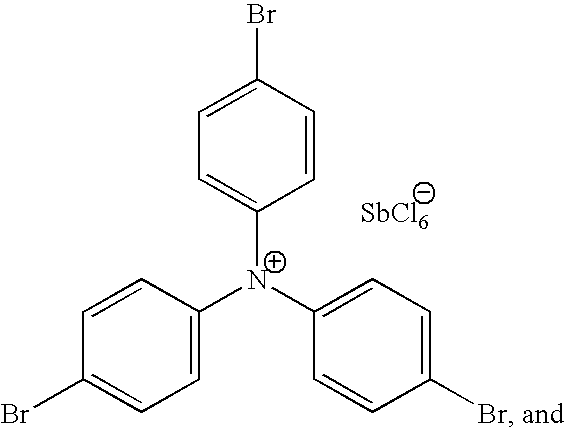

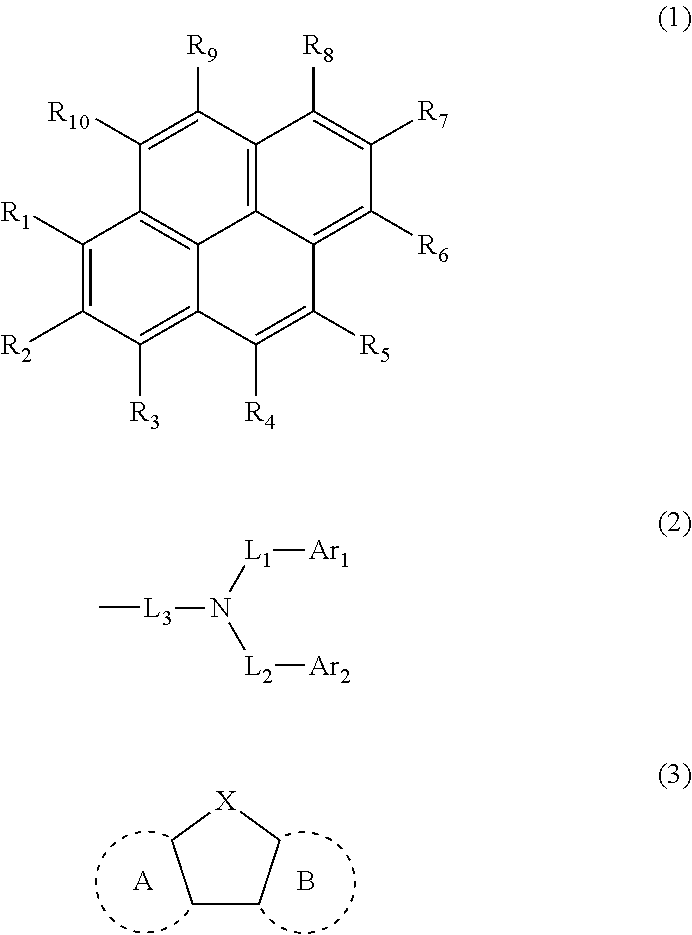

Aromatic amine derivative and organic electroluminescent element using same

InactiveUS20150014666A1Effectively usableSilicon organic compoundsElectroluminescent light sourcesArylPerylene derivatives

An aromatic amine derivative is represented by a formula (1) below. In the formula (1), R2, R3, R4, R5, R7, R8, R9 and R10 each independently represent a hydrogen atom and a substituent. In the formula (1), R1 and R6 are represented by a formula (2) below, and L1 to L2 are each independently a single bond, a divalent residue of an aryl group, and the like. L3 is a divalent residue of an aryl group and the like. In the formula (2); Ar1 is a monovalent substituent having a partial structure represented by the following formula (3); X represents an oxygen atom or a sulfur atom; and A and B represent a six-membered ring. In the formula (2), Ar2 is an aryl group, a monovalent substituent having a partial structure represented by the formula (3), and the like.

Owner:IDEMITSU KOSAN CO LTD

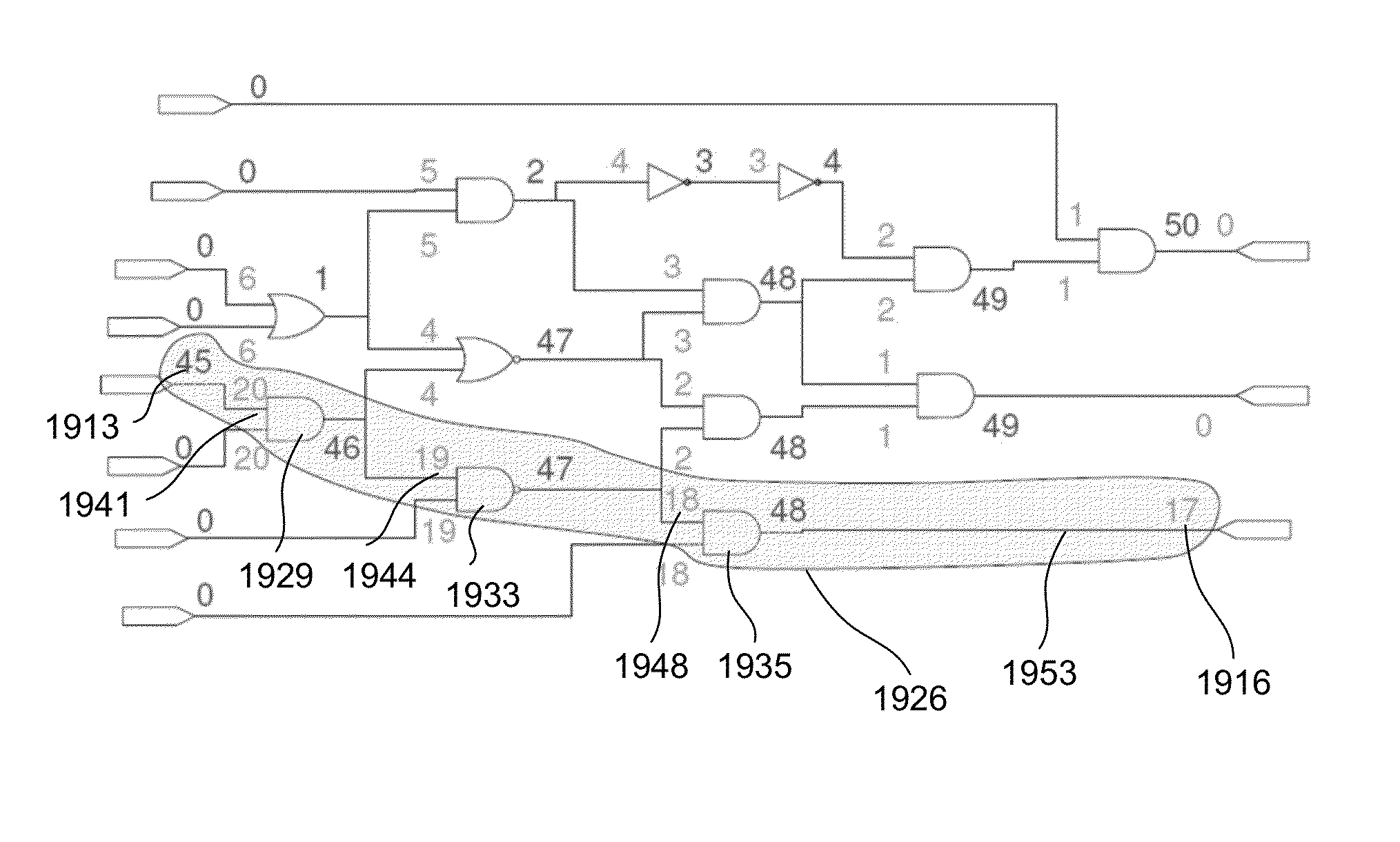

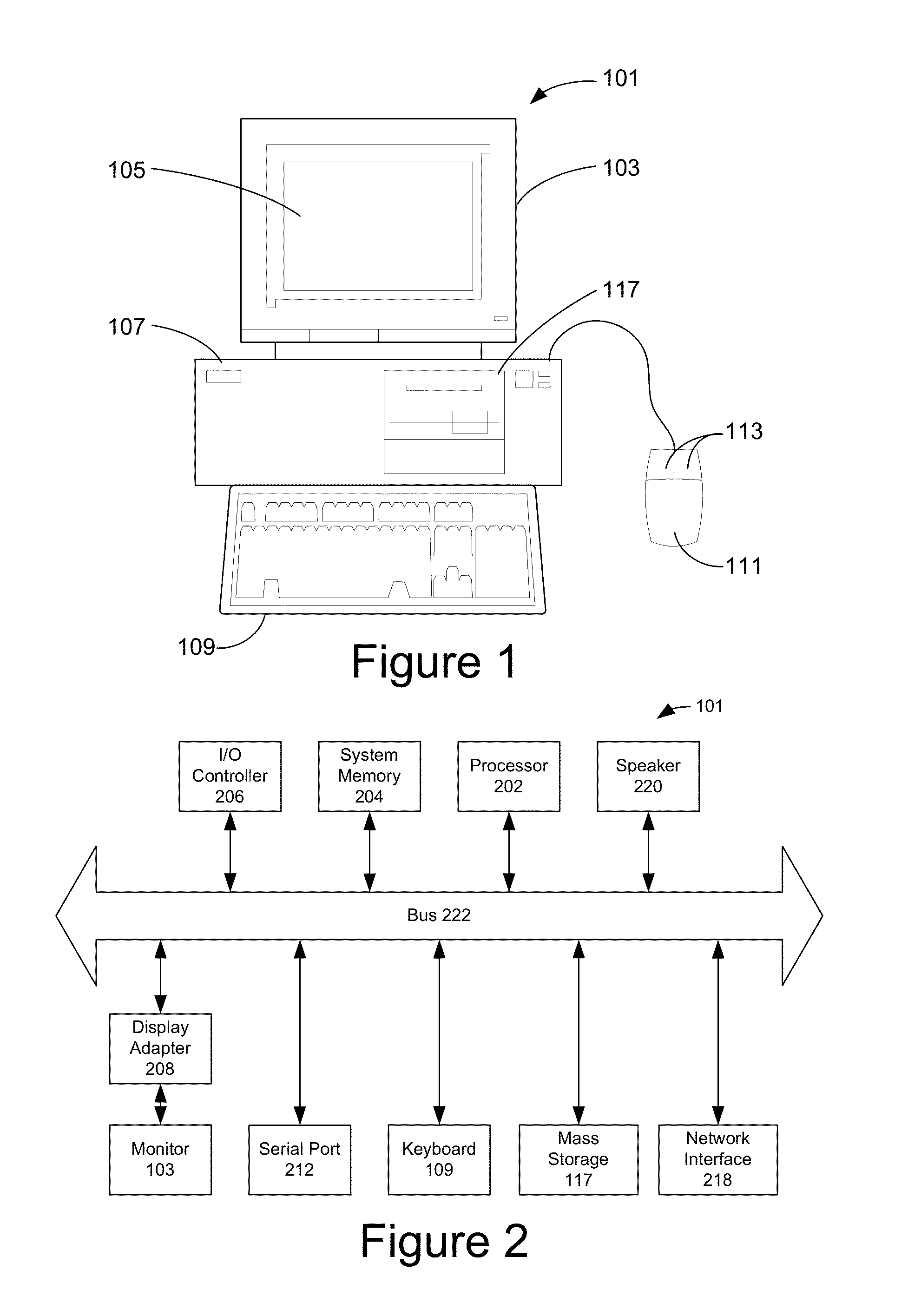

Creating cell libraries with a large number of cells

ActiveUS8898610B1Improve design qualityResult producedCAD circuit designSpecial data processing applicationsQuality by DesignLarge cell

Techniques for organizing a cell library permit a large number of cells. To improve design accuracy using cell libraries, very large cell libraries are needed. However, optimization tools are not able to use very large cell libraries directly, since their results suffer. Very large cell libraries are organized into sublibraries that are adapted to be processed by optimization tools. This allows improvement in the design quality of integrated circuits, while allowing the designs to be processed by optimization tools.

Owner:SILVACO INC

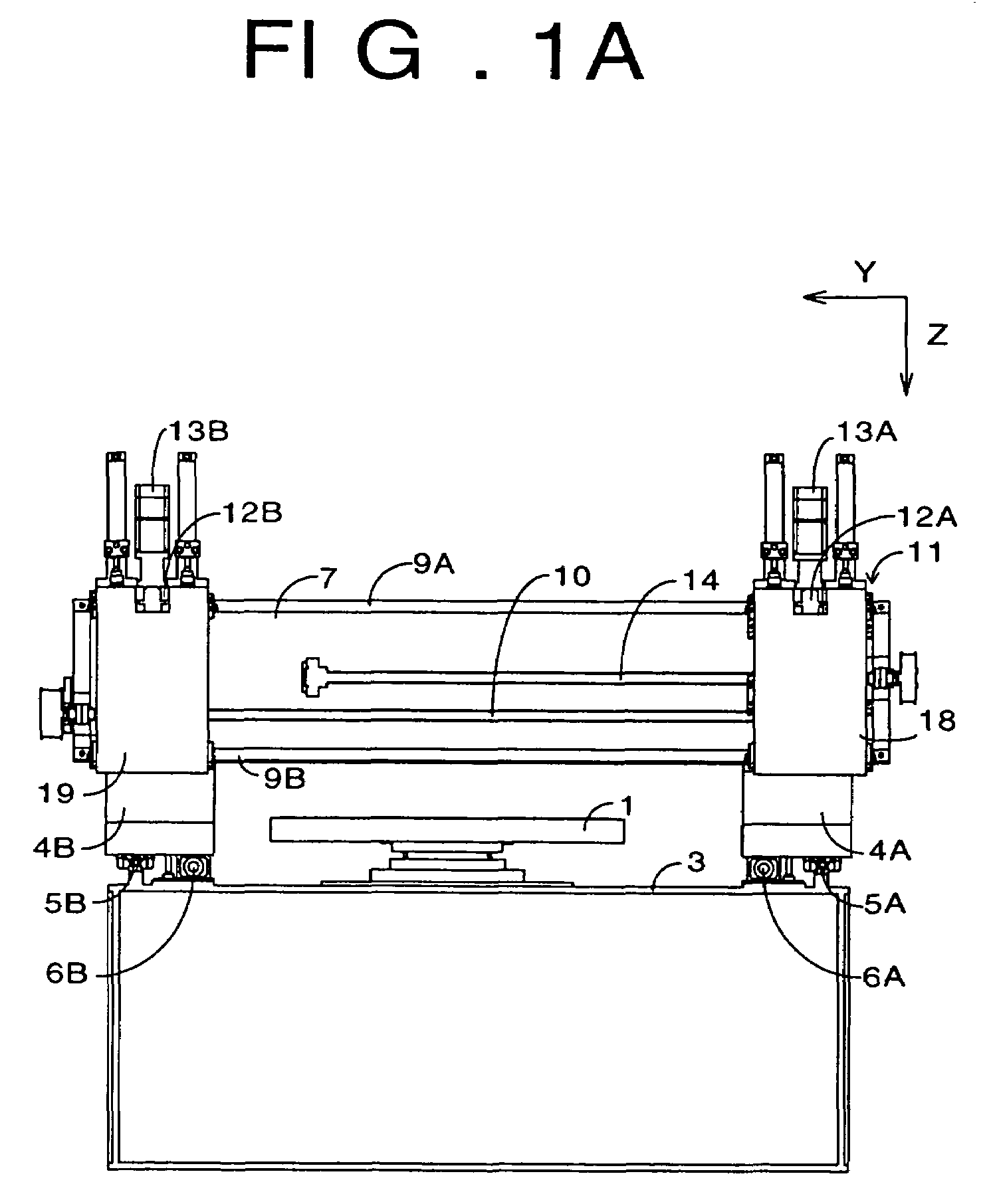

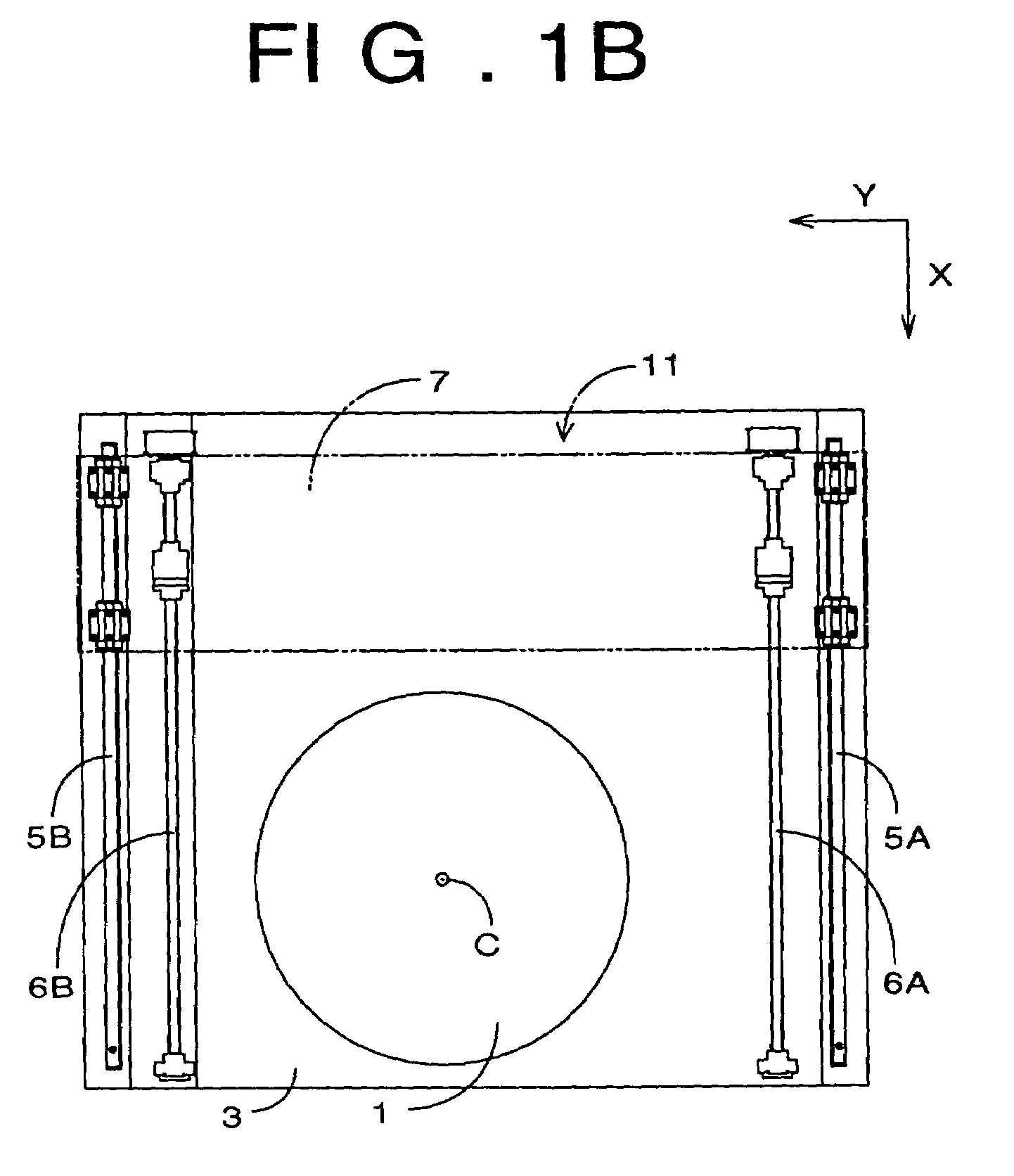

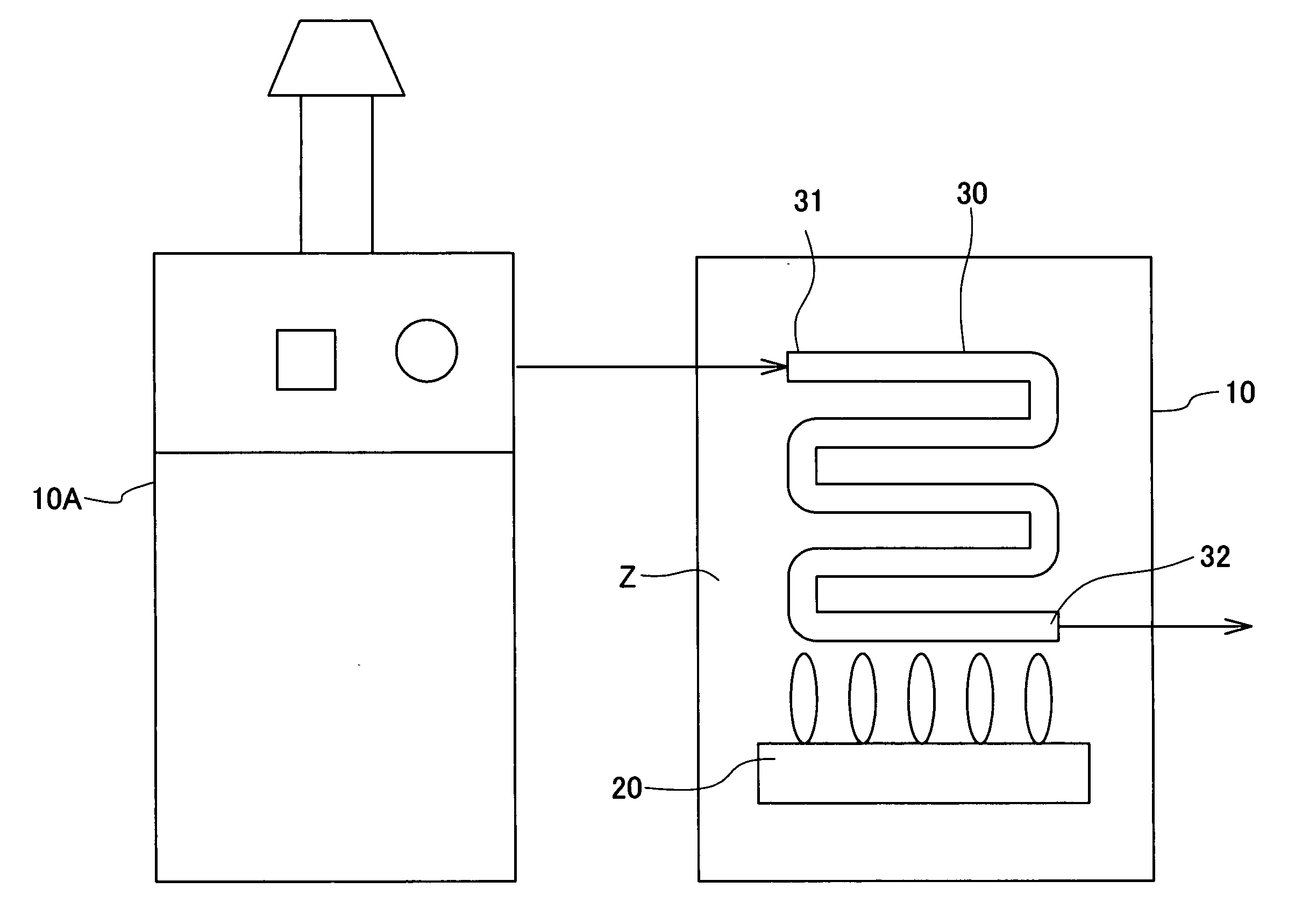

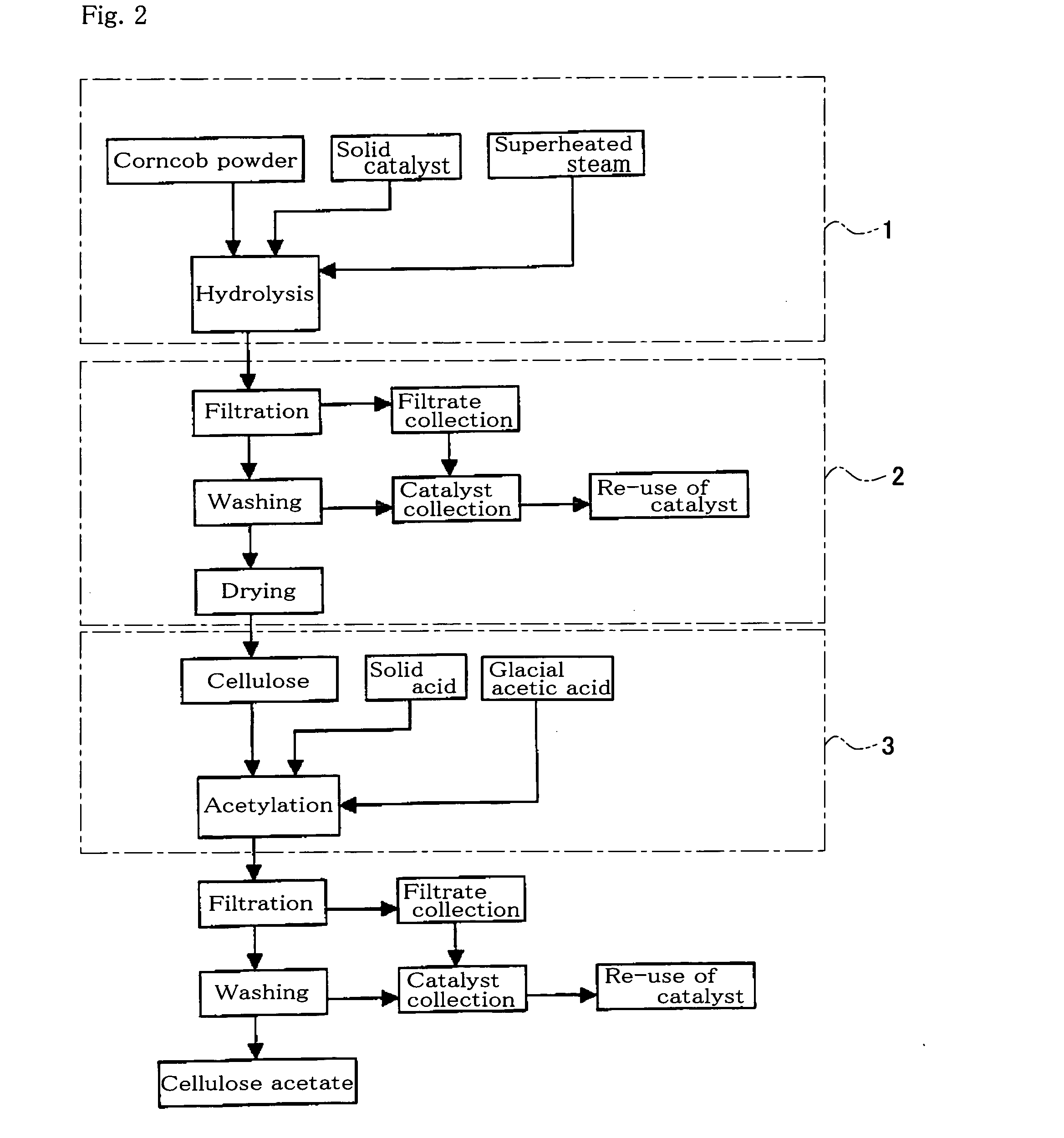

Method of manufacturing cellulose acetate, high temperature steam reactor vessel used in the same method, and superheated steam generator used in the same method

InactiveUS20070249824A1Low pressure levelCheap sourceExhaust apparatusSilencing apparatusAcetic acidCellulose acetate

The present invention relates to a method of manufacturing cellulose acetate by use of a high temperature steam reactor vessel and a superheated steam generator. According to this method, a material to which solid catalyst added is subject to a steaming process so as to cause cellulose content to be separated from the material, followed by carrying out an acetylating process of the separated cellulose content together with solid acid in the state of being pressurized so as to obtain cellulose acetate. The high temperature steam reactor vessel employs a system that there is arranged in a reactor vessel body 1 a cartridge 2 filled with collective chips 100, whereby enabling the material subjected to the process to be readily handled and processed, and also resulting in that there is no need to carry out in a later process separation between useful content and residue produced in hydrolysis with high temperature steam. The superheated steam generator comprises a heat-exchange line 3 having line parts P1, P2, P3 sectioned into plural stages and so adapted that a sectional area of the line part on a stage at a downstream side is larger than that of the line part on a stage at an upstream side, whereby superheated steam having ultra high temperature is able to be generated while or although pressure proof properties can be designed to be relatively lower.

Owner:ITEF INC

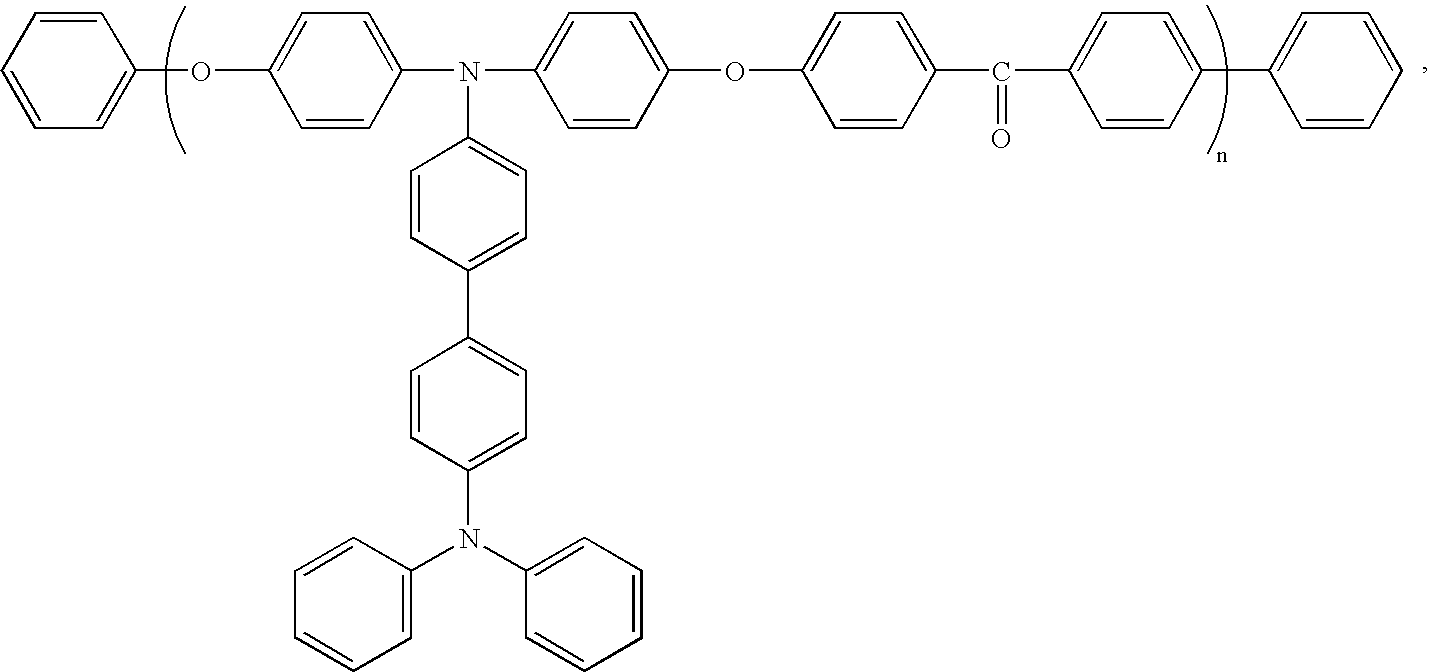

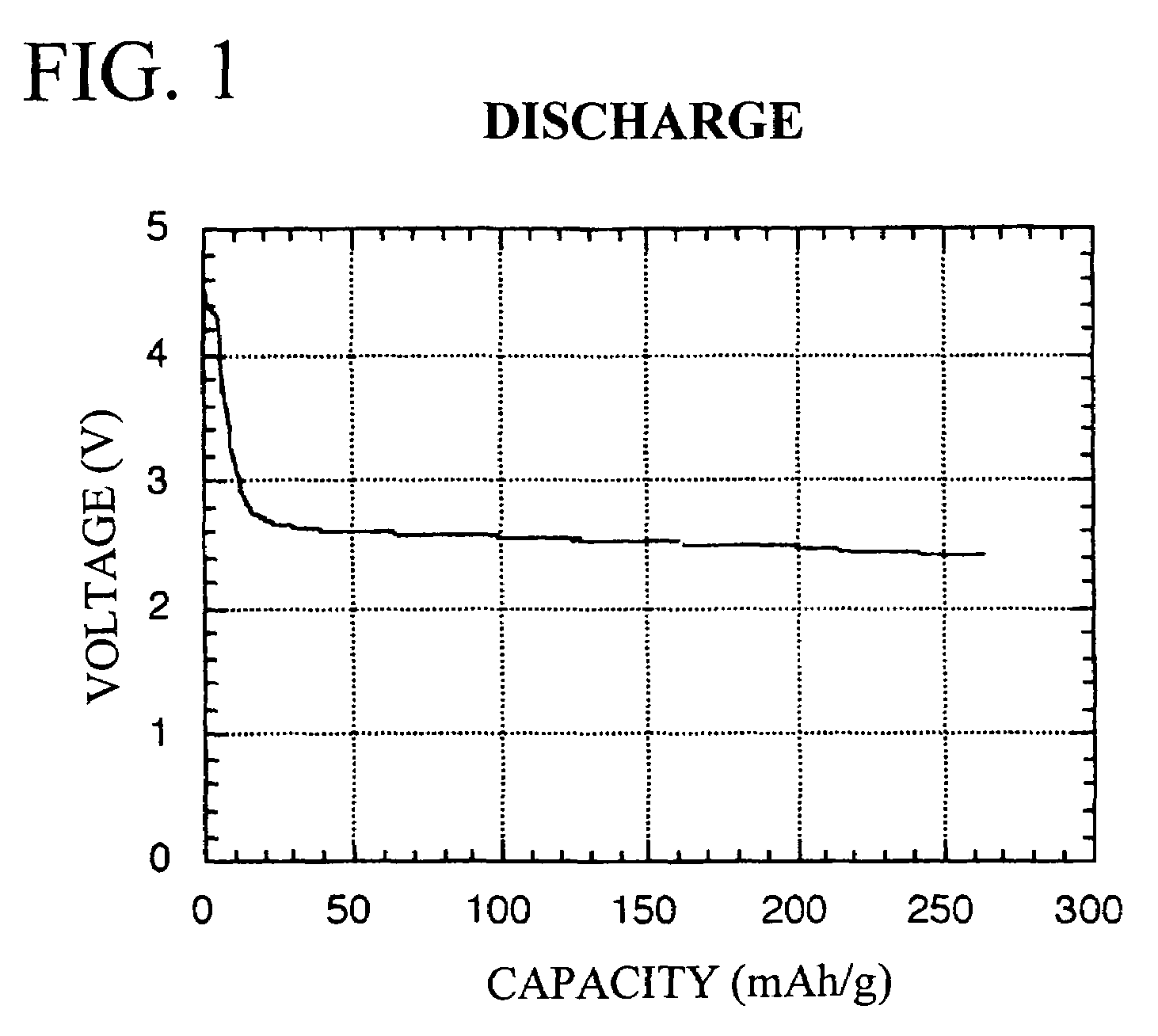

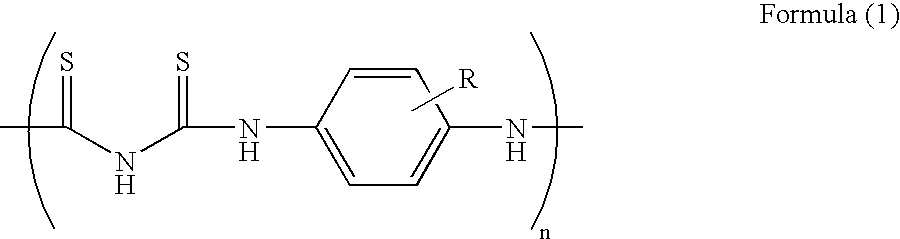

Redox-active polymer and electrode comprising the same

InactiveUS7214762B1High coloring/de-coloringHigh response rateSecondary cellsNon-aqueous electrolyte accumulator electrodesPolymer scienceThiourea

The present invention provides a new redox-active polymer capable of an adequate redox reaction even at low temperature and effectively usable as a high-capacity, high-energy density battery, a large-area electrochromic element, or a biochemical sensor using a microelectrode. This redox-active polymer is of being prepared by polymerizing an aromatic or heterocyclic compound having two or more thiourea groups with an aromatic or heterocyclic compound having two or more isothiocyanate groups. For example, The redox-active polymer may be of being prepared by polymerizing N,N′-1,4-phenylene-bis-thiourea with phenylene-1,4-diisothiocyanate. The redox-active polymer is suitable as an electrode material, particularly a cathode for lithium secondary batteries.

Owner:JAPAN SCI & TECH CORP

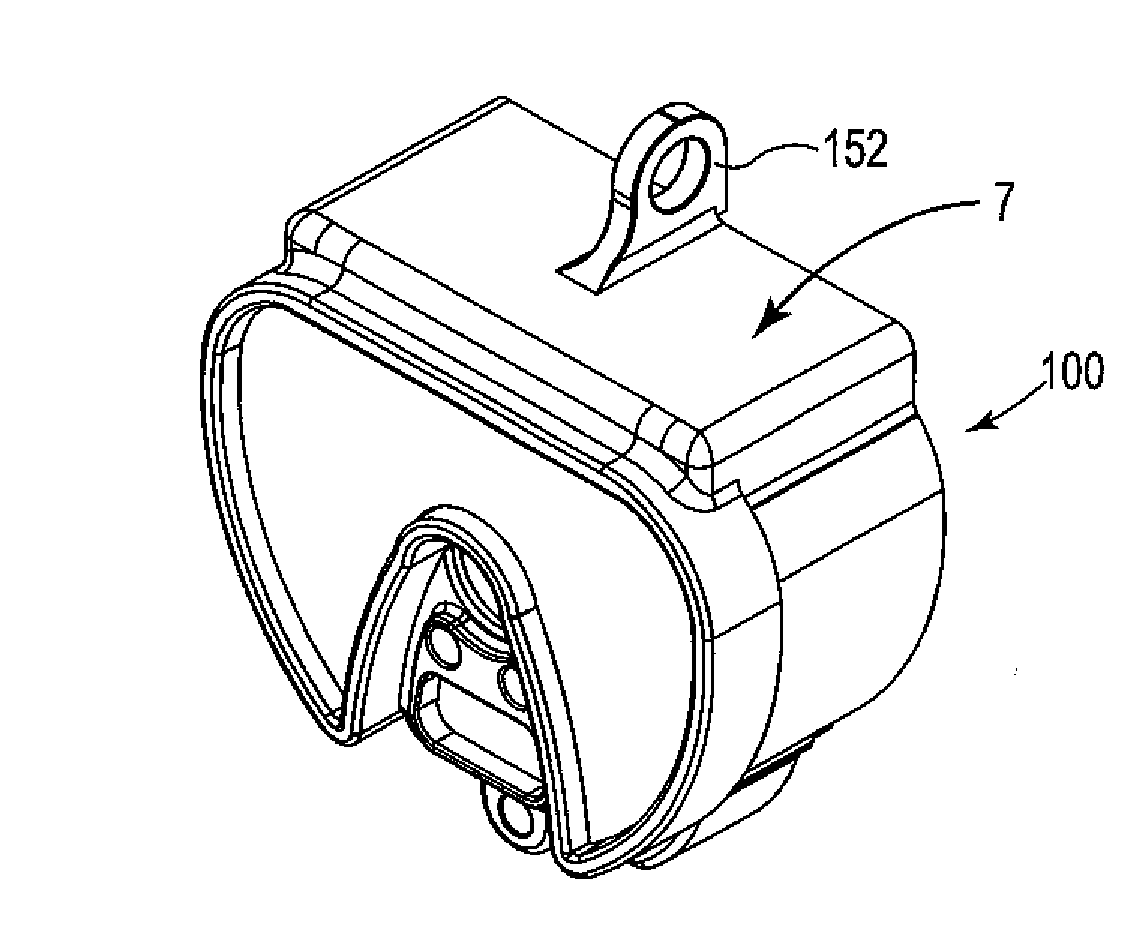

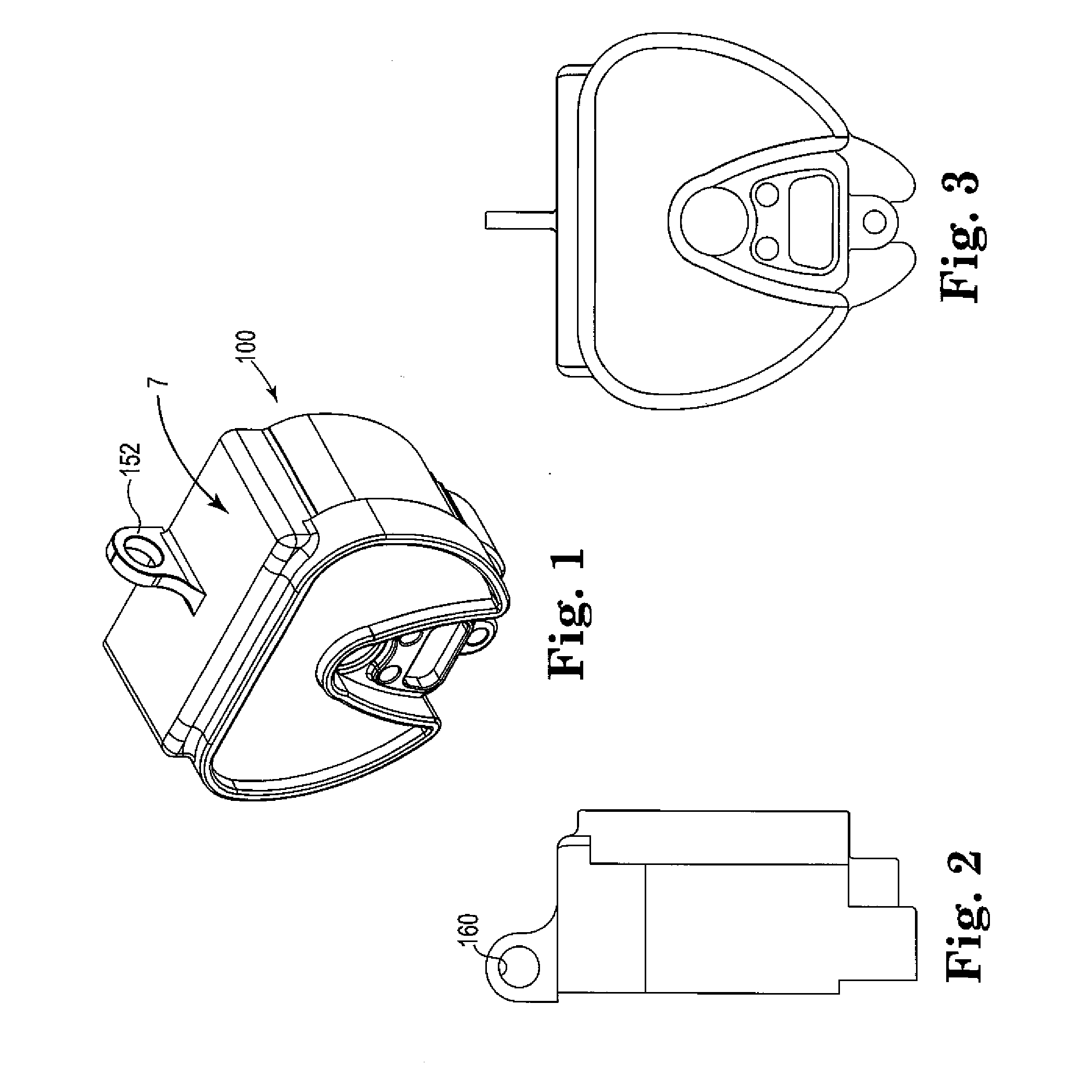

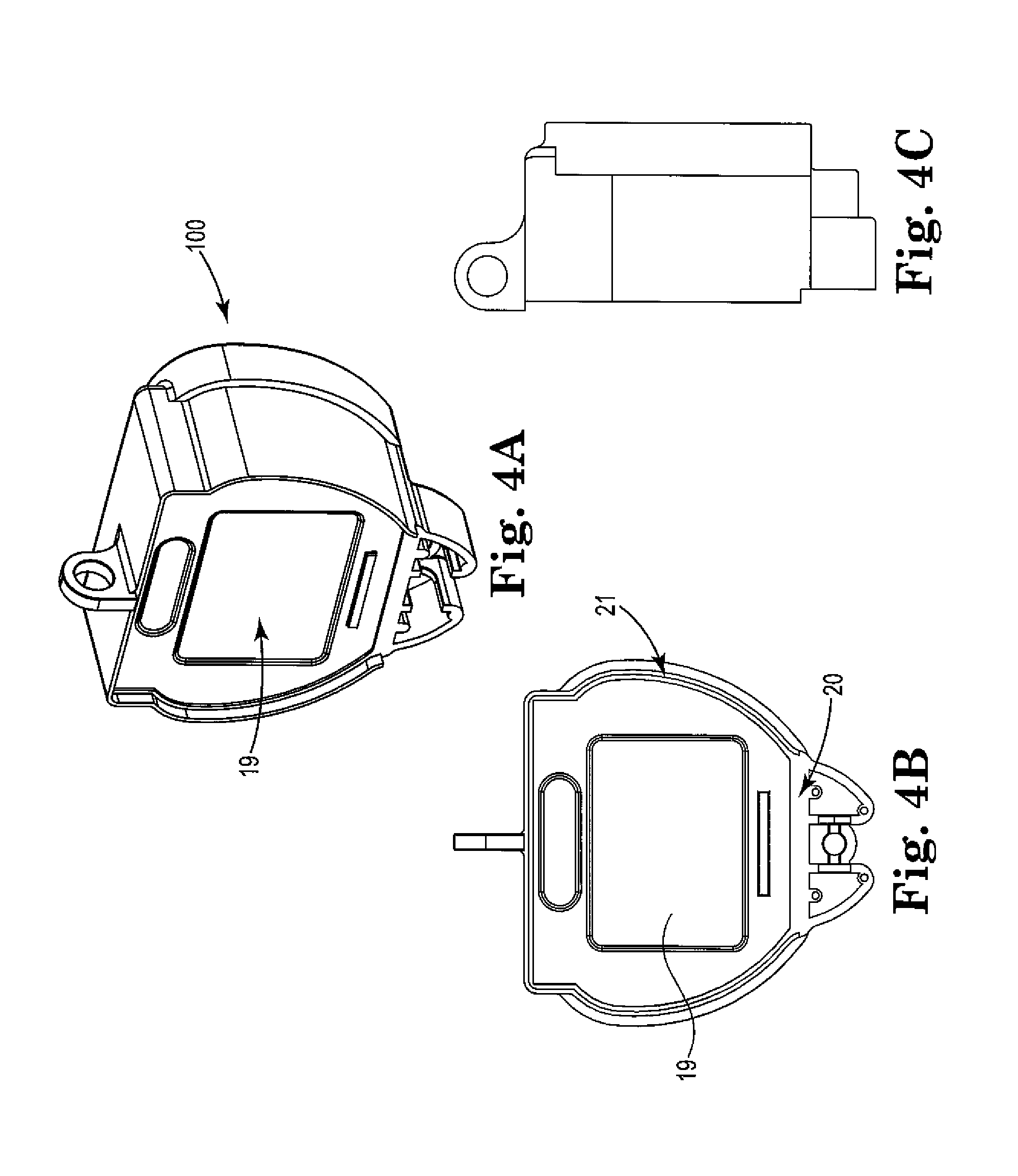

Multi-axis camera surveillance apparatus

ActiveUS20140015968A1Effectively usableColor television detailsClosed circuit television systemsPower cableEngineering

Remote usable surveillance apparatuses are provided with at least a single camera head and preferably with the ability to provide adjustment about one or more axis. The present invention also solves several other problems faced by designs with fixed (non-moveable) axis imaging systems. Those include but are not limited to supplying power to a camera head that tilts and rotates, particularly at a remote location. The ability of the user to interface with camera functions and setting using a tilting head, multiple power supplies and options built into a single housing without the addition of power cables or external jacks. The present invention provides a standalone concept without the aid of one or even more mounting apparatuses or devices which in turn sets it apart and creates a totally different multi-axis concept from prior art.

Owner:GOOD SPORTSMAN MARKETING LLC

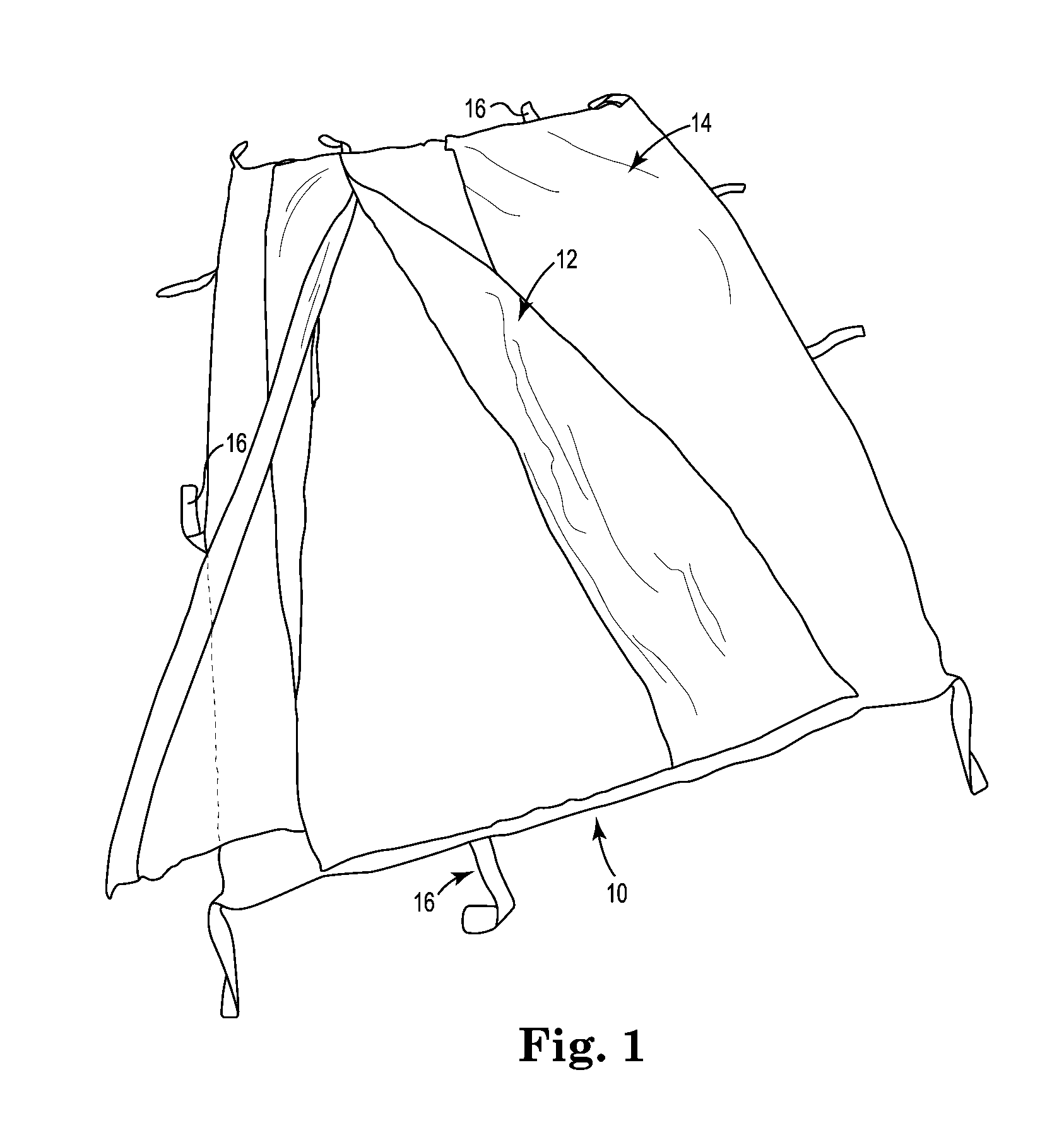

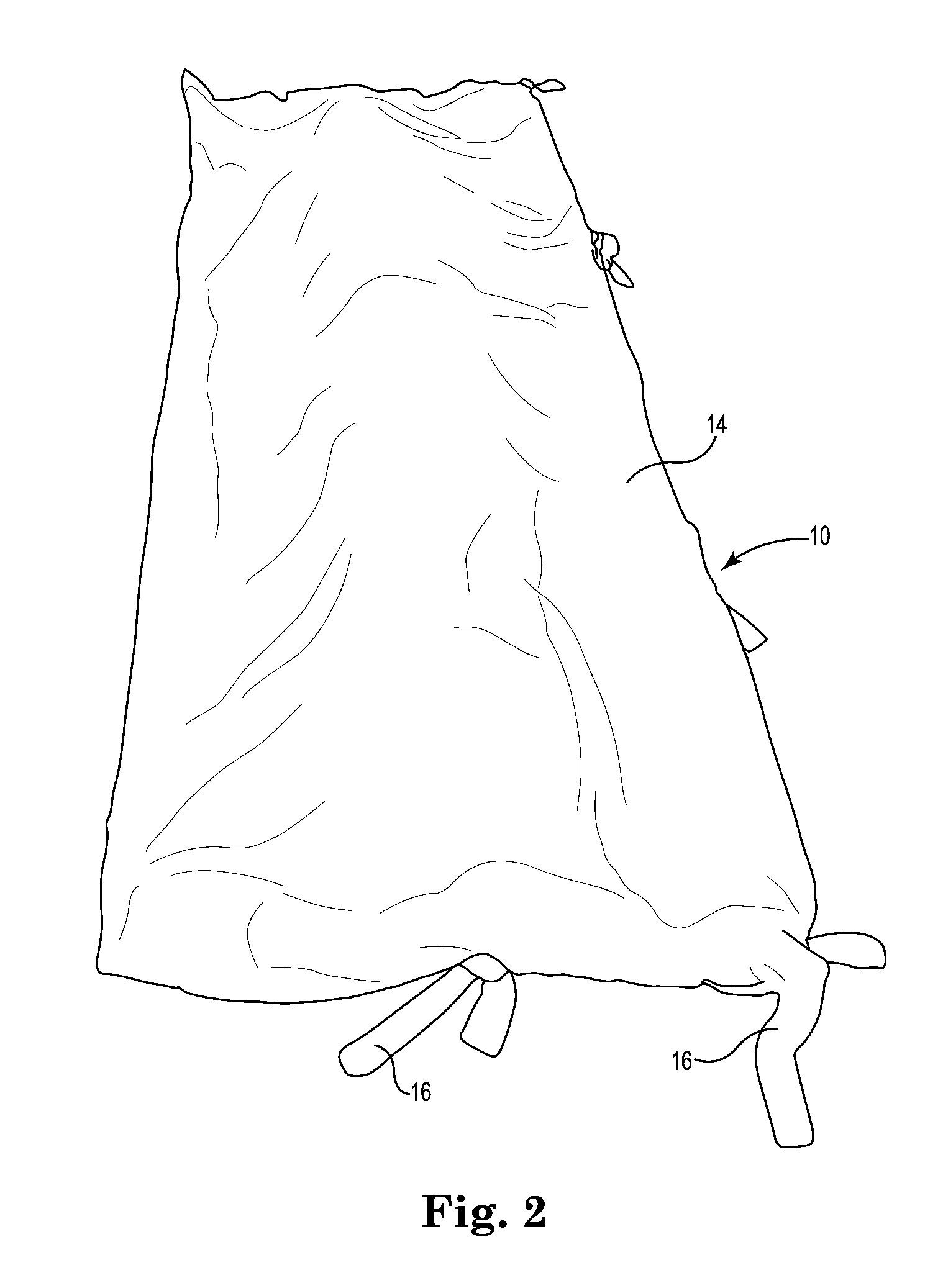

Body containment construction suitable for use within bio-cremation processes

ActiveUS20140366342A1Efficient decompositionEffectively usableCoffinsMetal working apparatusDecompositionEngineering

Body containment constructions, materials, and methods of use for bio-cremation processes are disclosed. Preferably, the containment constructions of the present invention provide the functionality of liquid containment and also the functionality of body presentment for viewing purposes, if desired, in addition to bio-degradability. Advantageously, liquid containment is provided in a body containment construction that is sufficiently liquid impervious, allows for body transport by sufficient structural support, and is decomposable within the time period for a bio-cremation process. More preferably, the containment construction will dissolve or decompose within a normal procedural time period without leaving any component remaining from the containment construction. According to an aspect of the present invention, a body containment bag is provided that is made from a structural material that is combined with a liquid containment material and one or more closures, wherein the body containment bag is effectively usable for bio-cremation during which all components of the body containment bag can effectively decompose by alkaline hydrolysis. Methods of making and of utilizing a body containment bag for decomposition are also disclosed.

Owner:KRS

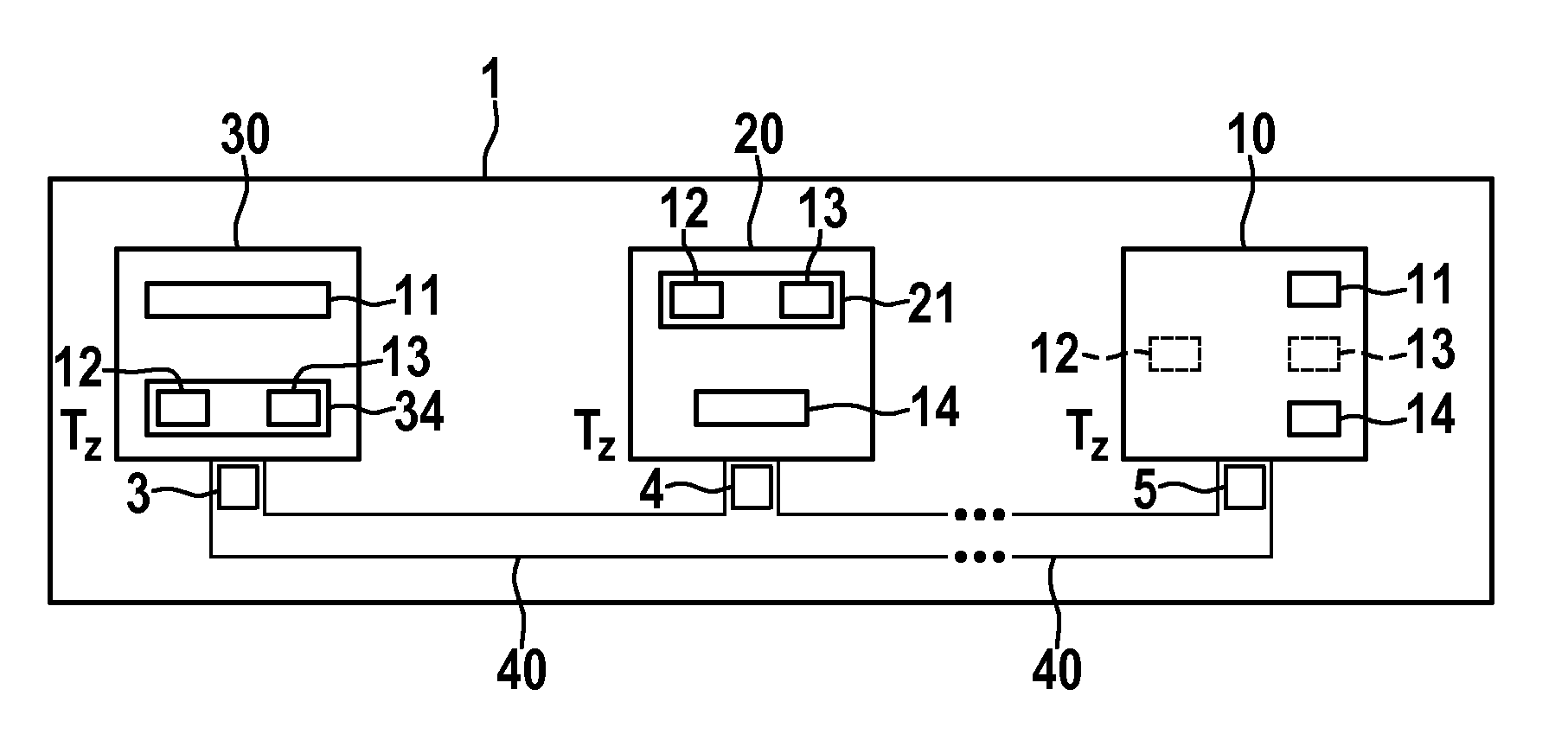

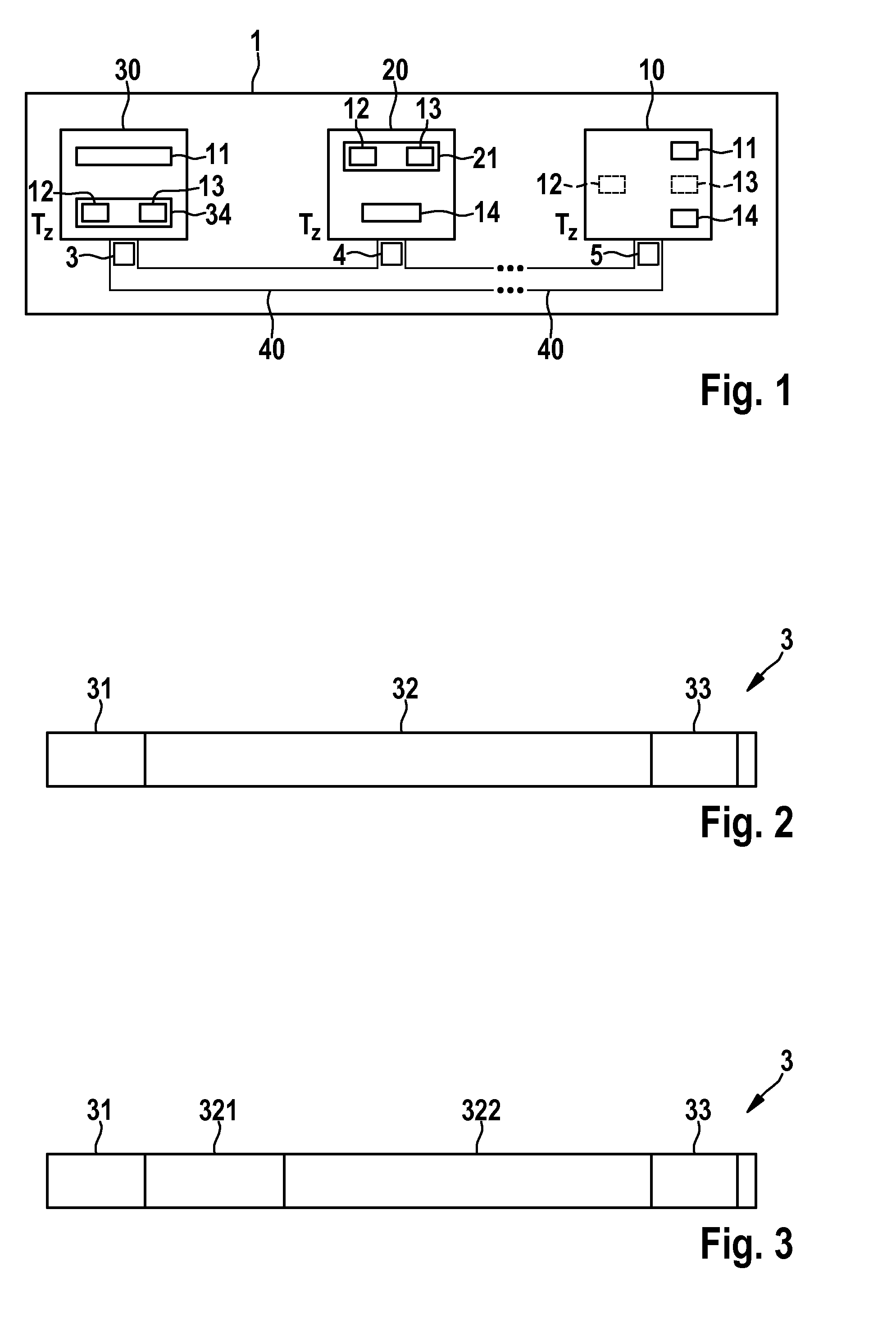

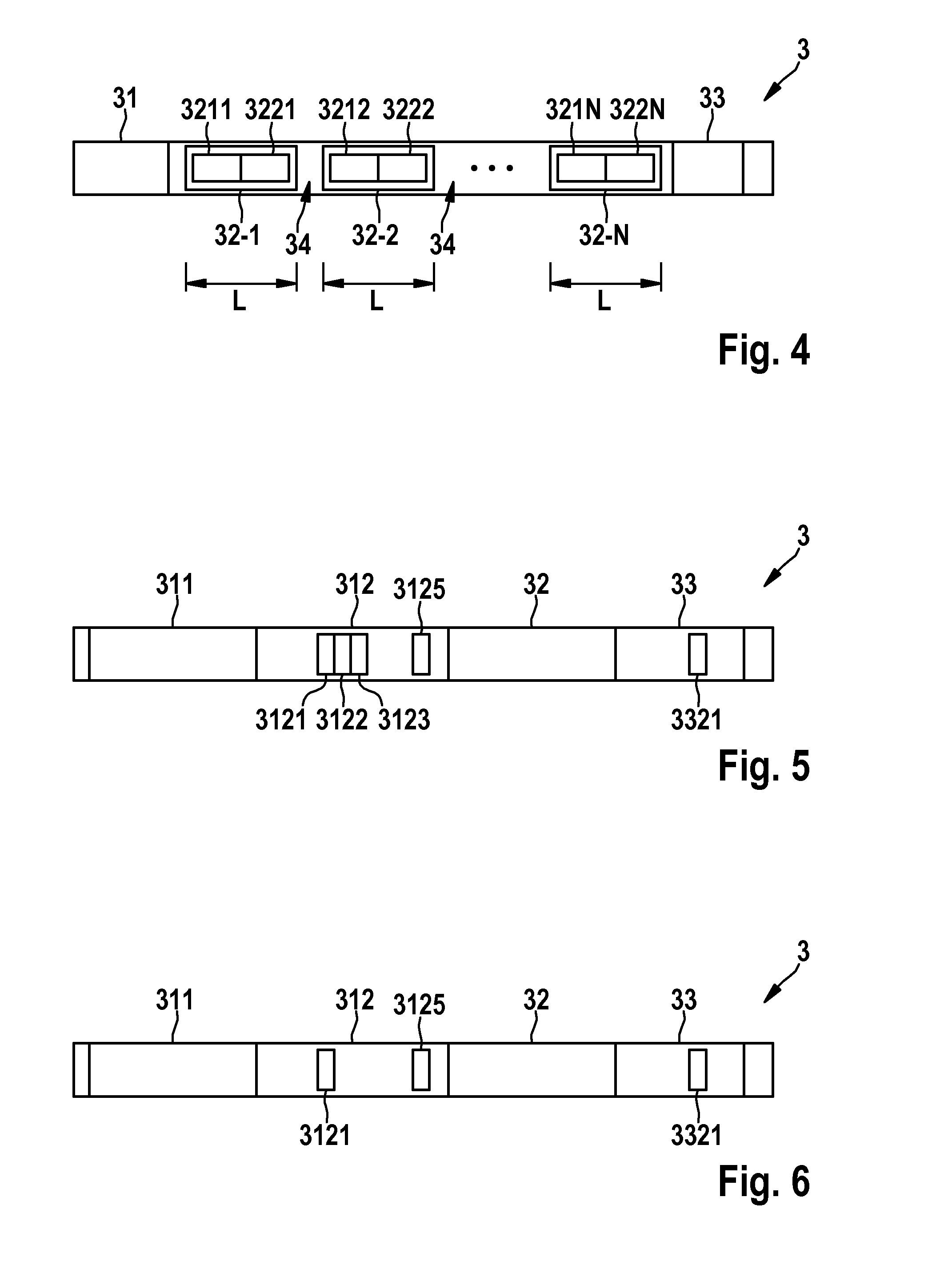

Subscriber station for a bus system and method for broadband can communication

ActiveUS20160043947A1High data rateEffectively usableData switching by path configurationBroadbandCollision free

A user station for a bus system implementing broadband CAN communication includes: a communication control device for creating or reading at least one message for / from at least one further user station of the bus system, in which exclusive, collision-free access of a user station to a bus of the bus system is ensured at least intermittently; and a data interleaving device for interleaving data packets of at least two messages into a single message, so that the data packets are situated in one data segment of the single message. The single message has a shared outer frame header for the data packets in front of the data segment and a shared outer frame end for the data packets after the data segment.

Owner:ROBERT BOSCH GMBH

Device and method for controlling internal combustion engine

InactiveUS8191353B2Easy to useEffectively usableElectrical controlExhaust apparatusParticulatesExternal combustion engine

A device for controlling an internal combustion engine comprises a device for trapping particulate matter (PM) in exhaust gas in an exhaust passage, means for supplying ozone to the particulate matter trapping device from the upstream thereof to oxidize and remove PM deposited in the device, and means for interrupting the fuel injection of the internal combustion engine upon the execution of ozone supply by the ozone supply means. It is possible to prevent components consuming ozone, such as NOx, from being contained in the exhaust gas of the internal combustion engine, whereby ozone is effectively usable.

Owner:TOYOTA JIDOSHA KK

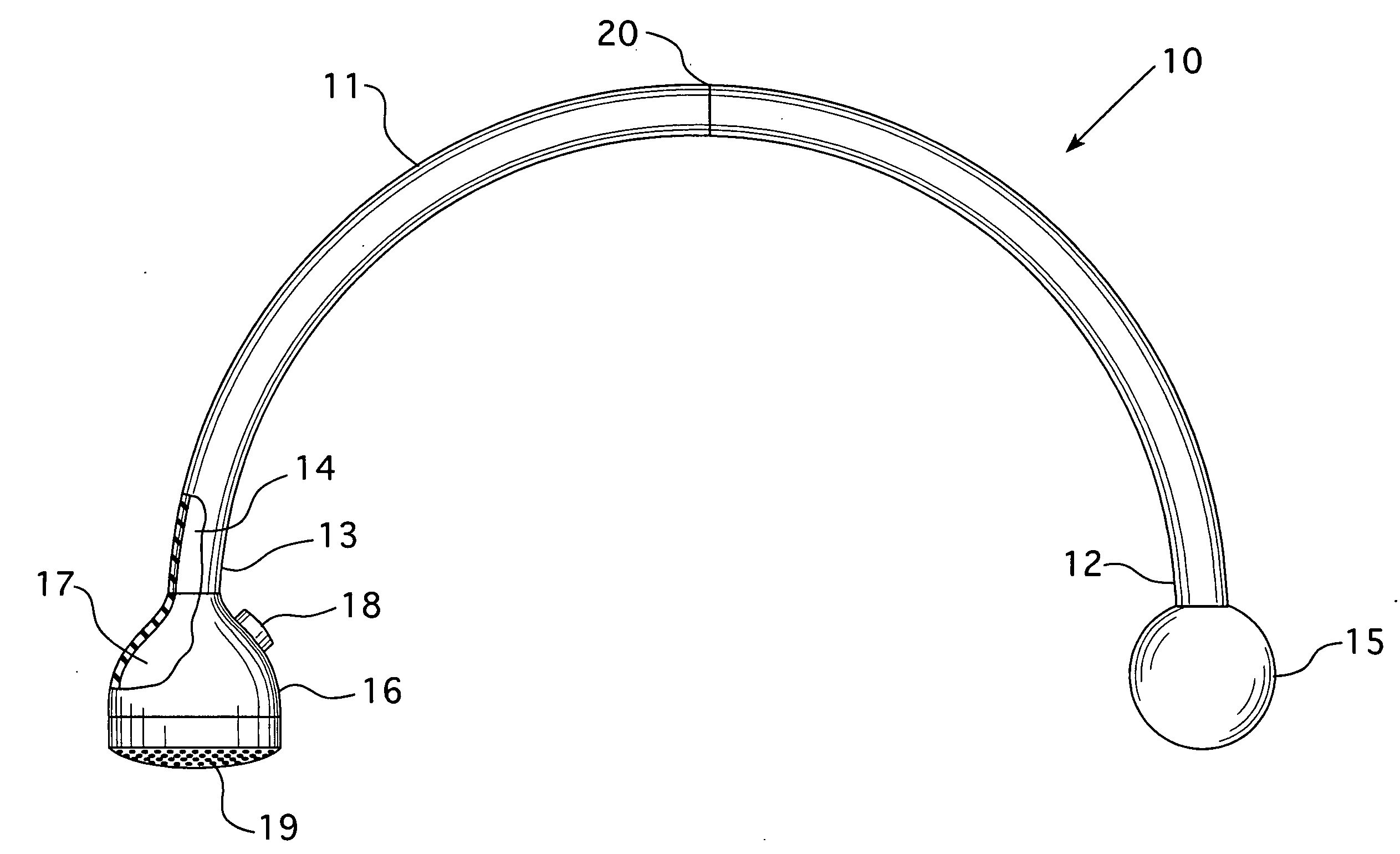

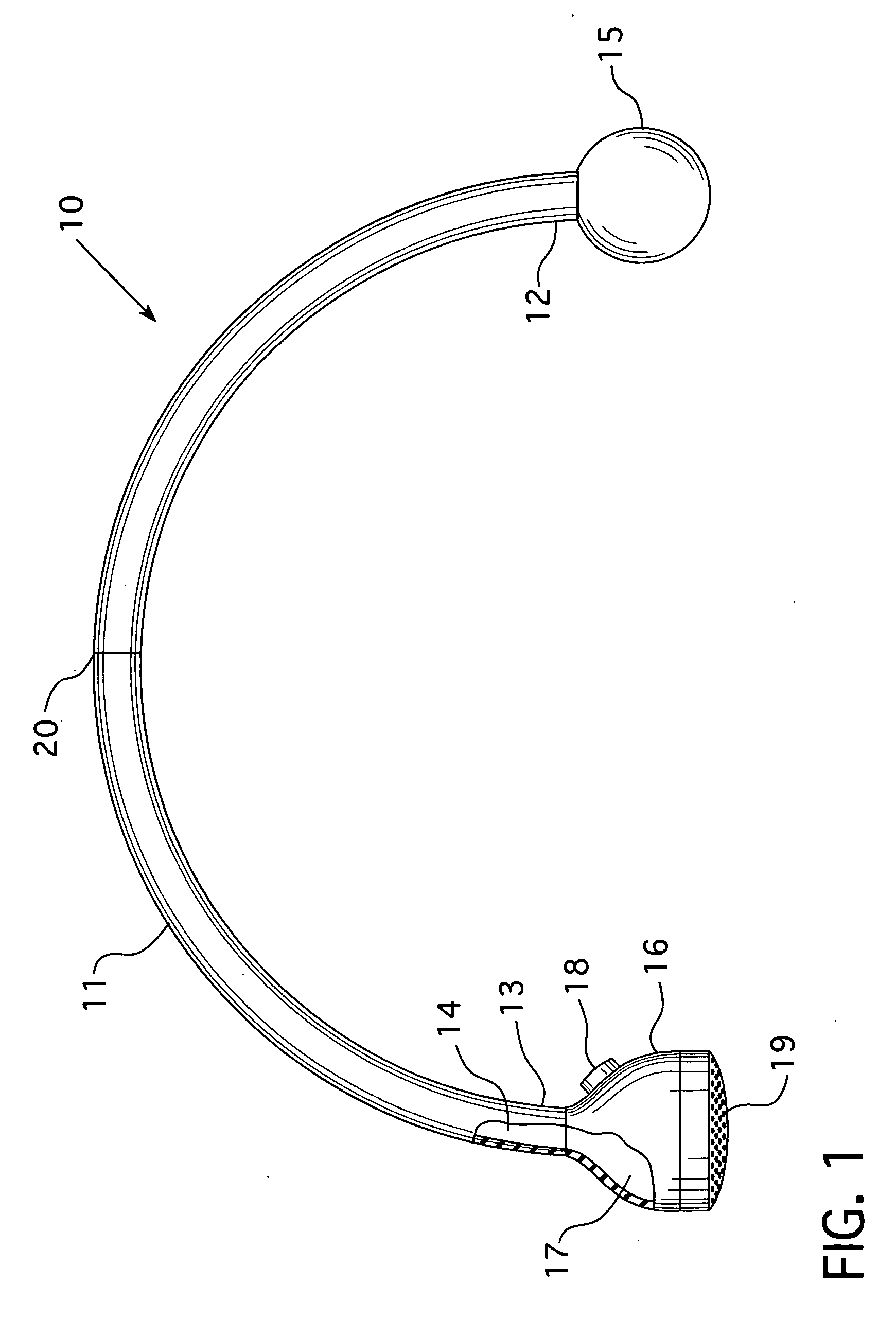

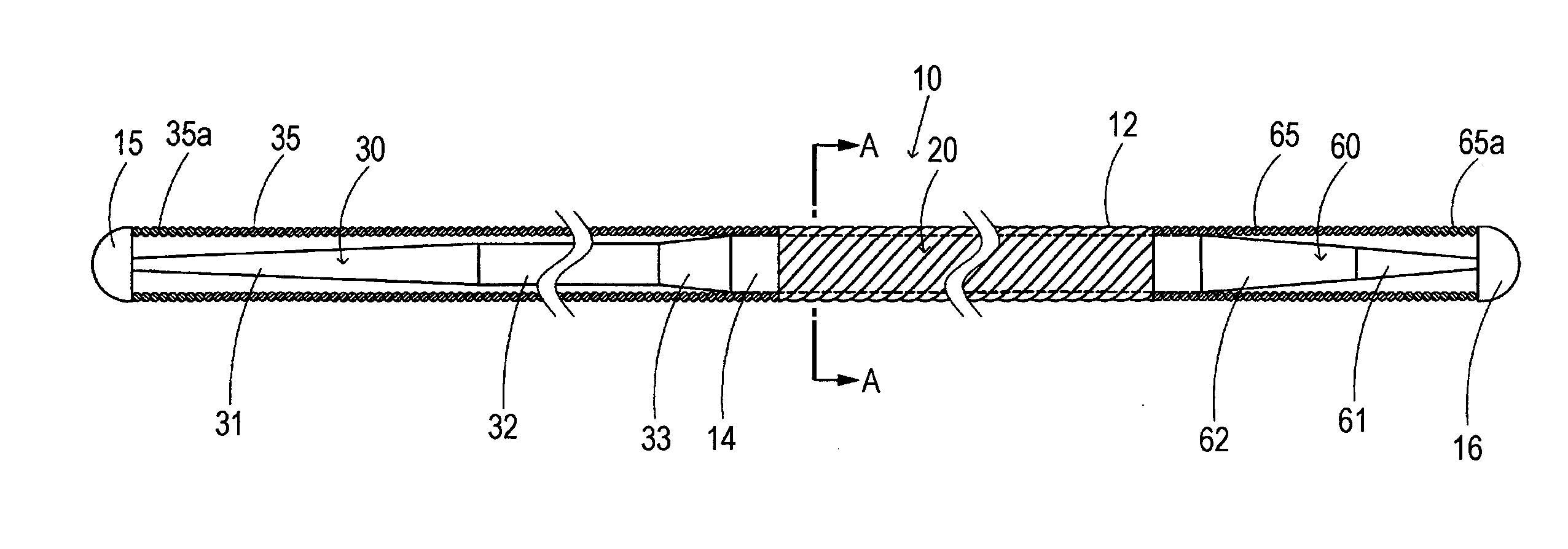

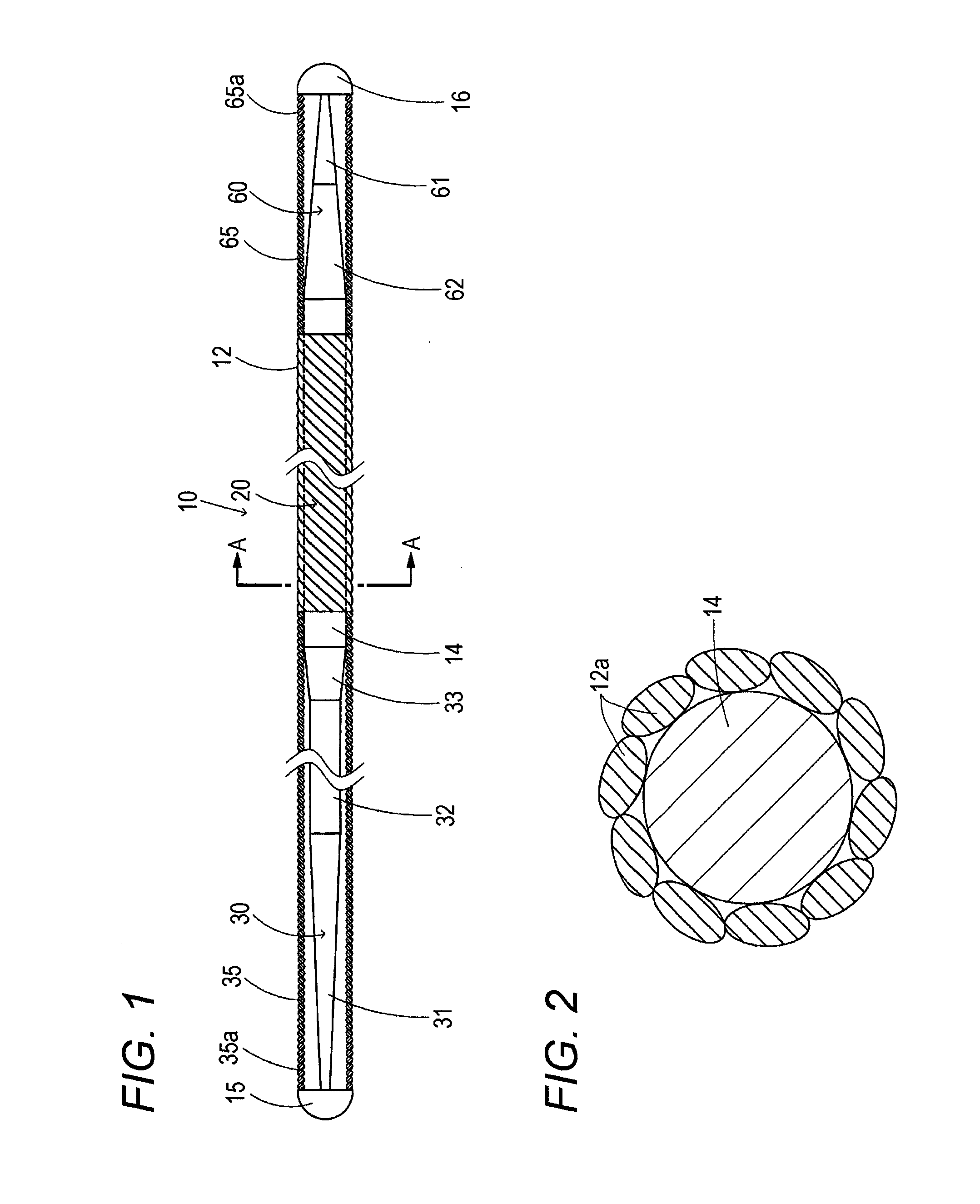

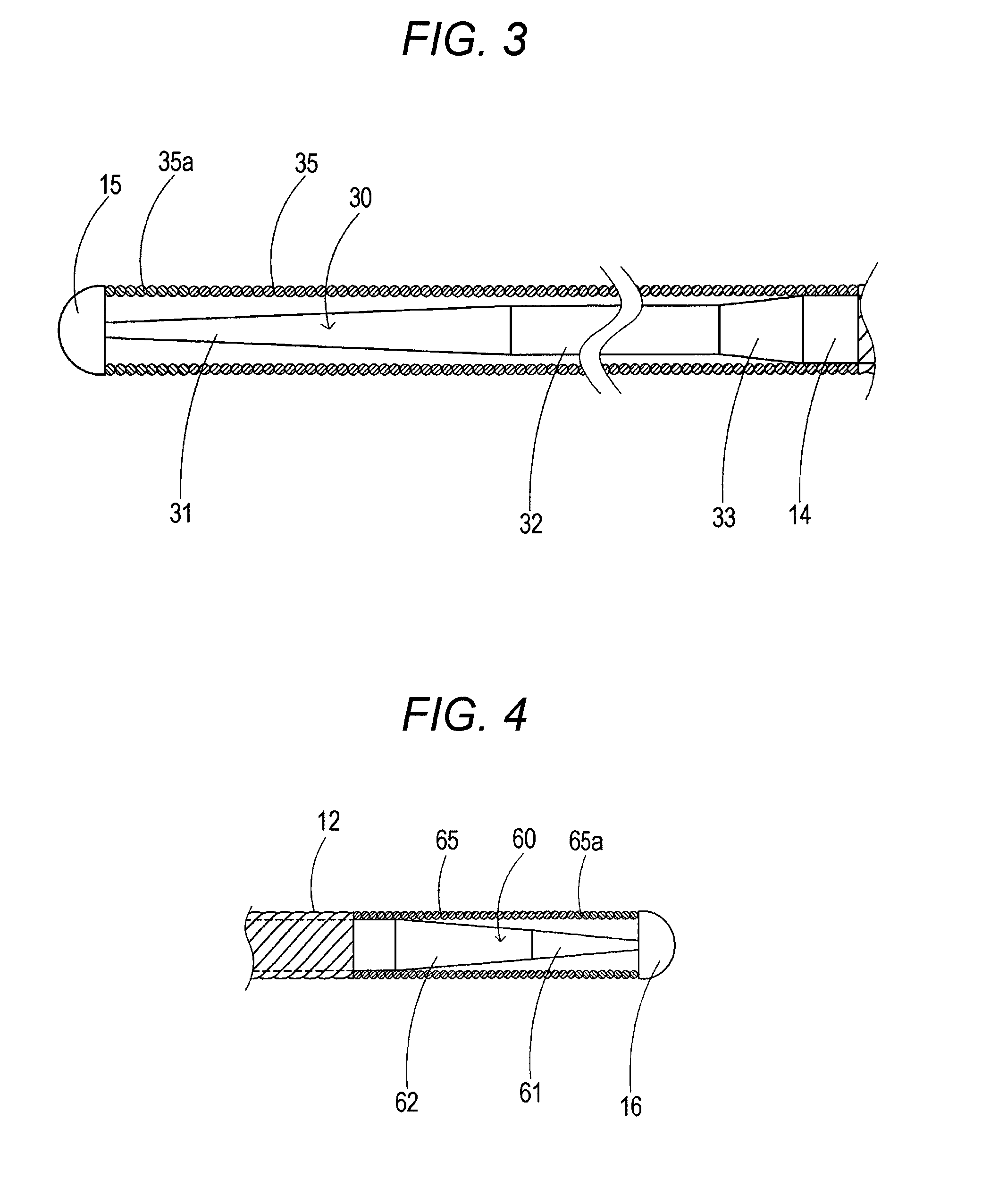

Guidewire

InactiveUS20110144538A1Effectively usableGuide wiresDiagnostic recording/measuringMedicineBending stiffness

Provided is a guidewire effectively usable for a retrograde approach. A guidewire has a body portion, and a first tip portion and a second tip portion provided at ends of the body portion. Flexural stiffnesses of the first tip portion and the second tip portion increase in a continuous or stepwise manner from the respective tips of the first and second tip portions toward the body portion. The flexural stiffness of the first tip portion is not smaller in value than the flexural stiffness of the second tip portion in first distance ranges from the respective tips of the first and second tip portions toward the body portion. The flexural stiffness of the first tip portion is smaller in value than the flexural stiffness of the second tip portion in second distance ranges beyond the respective first distance ranges of the first and second tip portions toward the body portion.

Owner:ASAHI INTECC CO LTD

Device and method for controlling internal combustion engine

InactiveUS20090235648A1Easy to useEffectively usableElectrical controlExhaust apparatusParticulatesExternal combustion engine

A device for controlling an internal combustion engine comprises a device for trapping particulate matter (PM) in exhaust gas in an exhaust passage, means for supplying ozone to the particulate matter trapping device from the upstream thereof to oxidize and remove PM deposited in the device, and means for interrupting the fuel injection of the internal combustion engine upon the execution of ozone supply by the ozone supply means. It is possible to prevent components consuming ozone, such as NOx, from being contained in the exhaust gas of the internal combustion engine, whereby ozone is effectively usable.

Owner:TOYOTA JIDOSHA KK

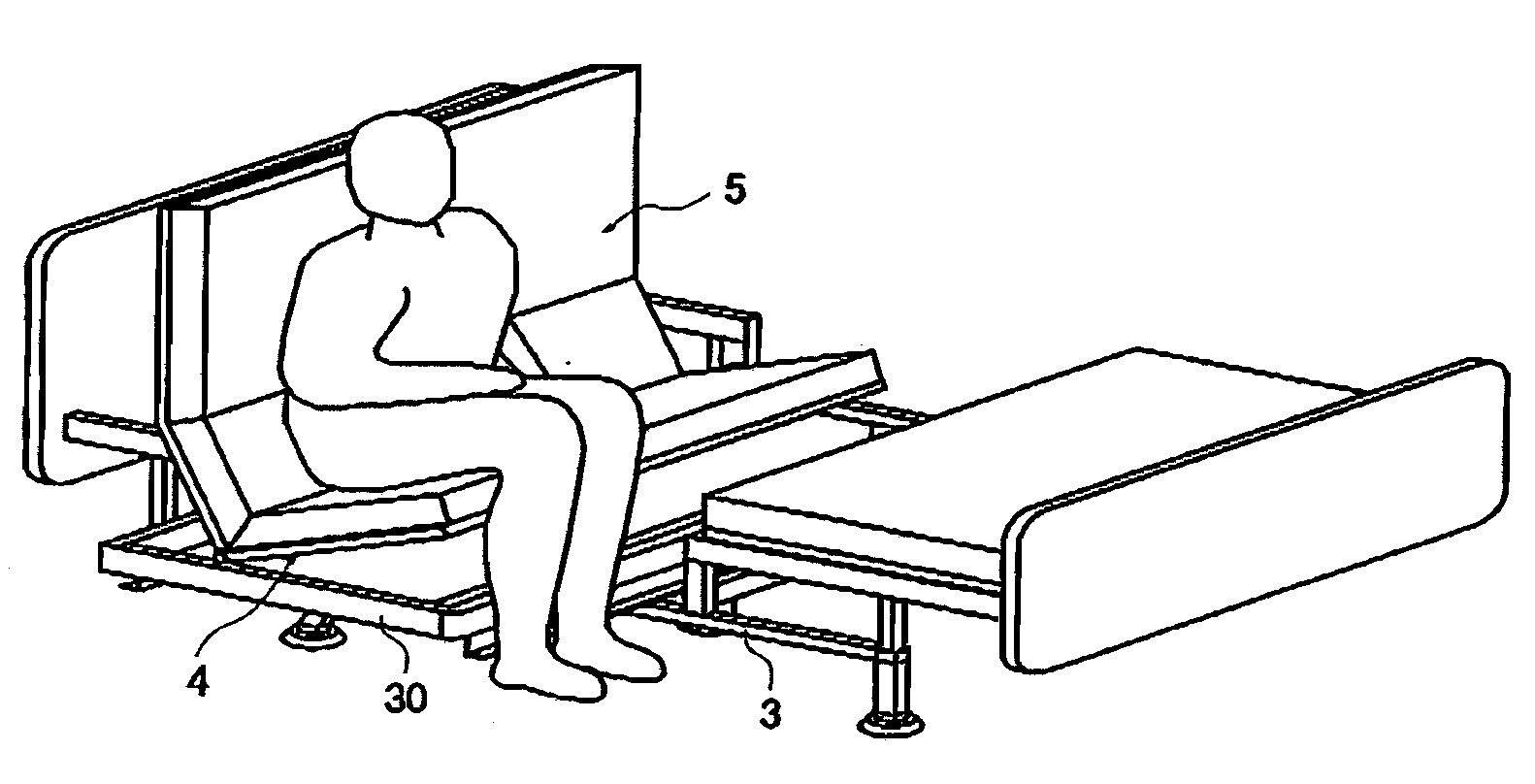

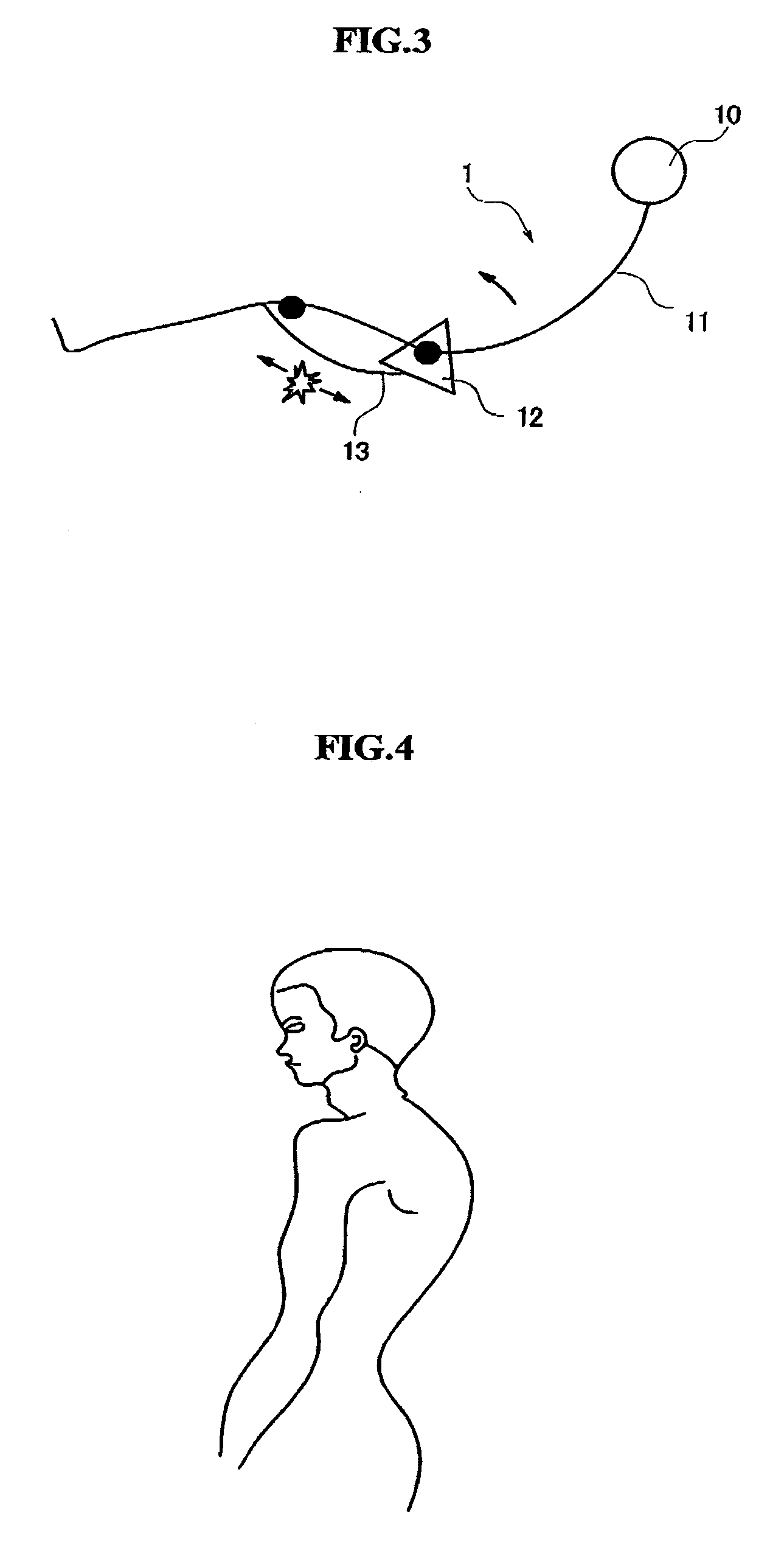

Bed for allowing posture for sitting on chair to be taken

The invention provides a bed on which a patient and so forth can take a posture for sitting on a chair, in particular, a bed for allowing the posture for sitting on a chair to be taken, effectively usable even by those having the back in the shape of the round back, Kyphosis or the like.

Owner:NOMURA KYOZO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com