Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Easy to elute and regenerate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microporous aluminum-salt lithium adsorbent, preparation method therefor, filler and lithium ion enriching method

ActiveCN106076243AOvercome the problem of high dissolution rateControl areaOther chemical processesAlkali metal oxides/hydroxidesLithiumSorbent

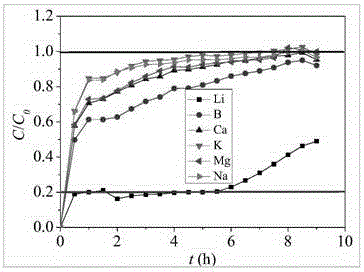

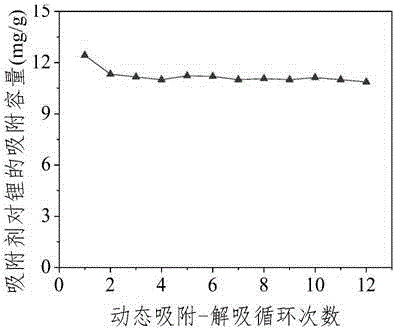

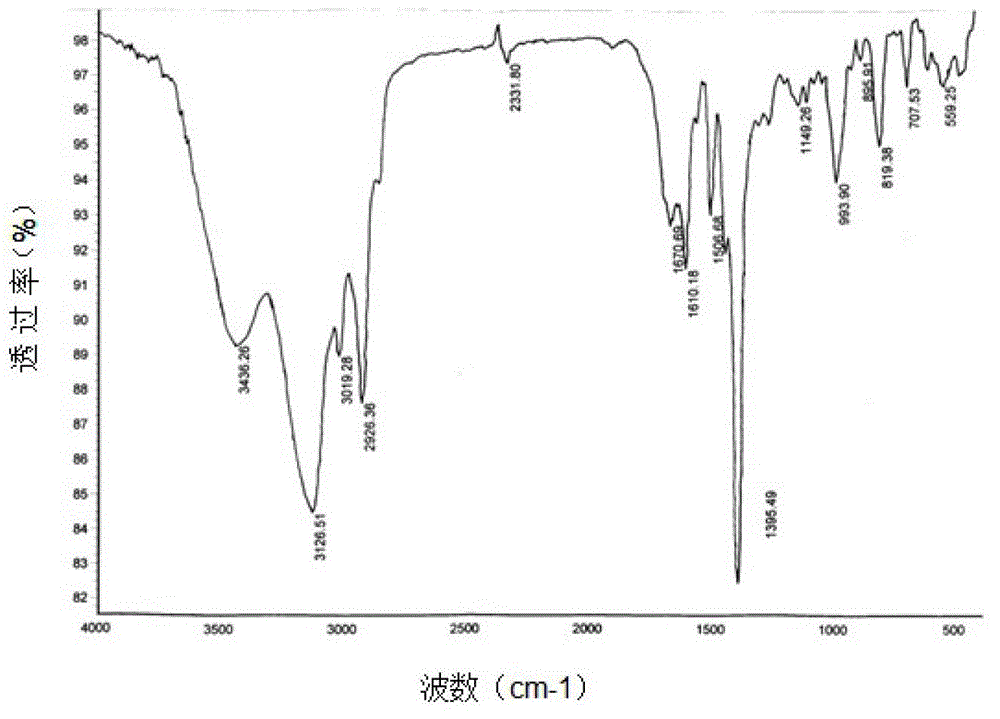

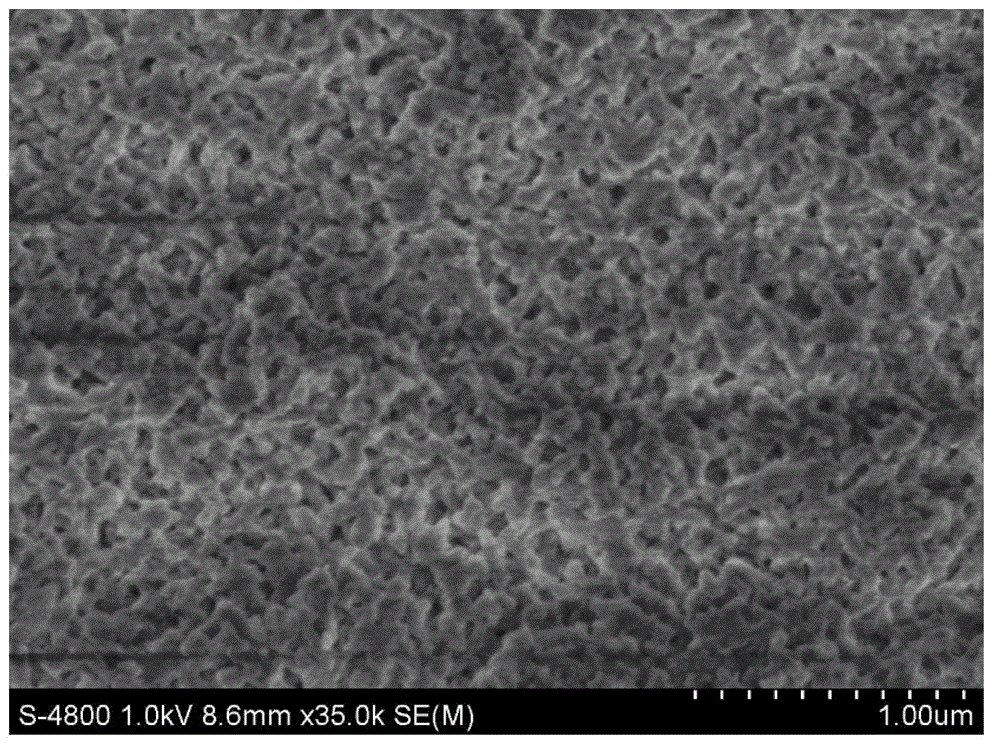

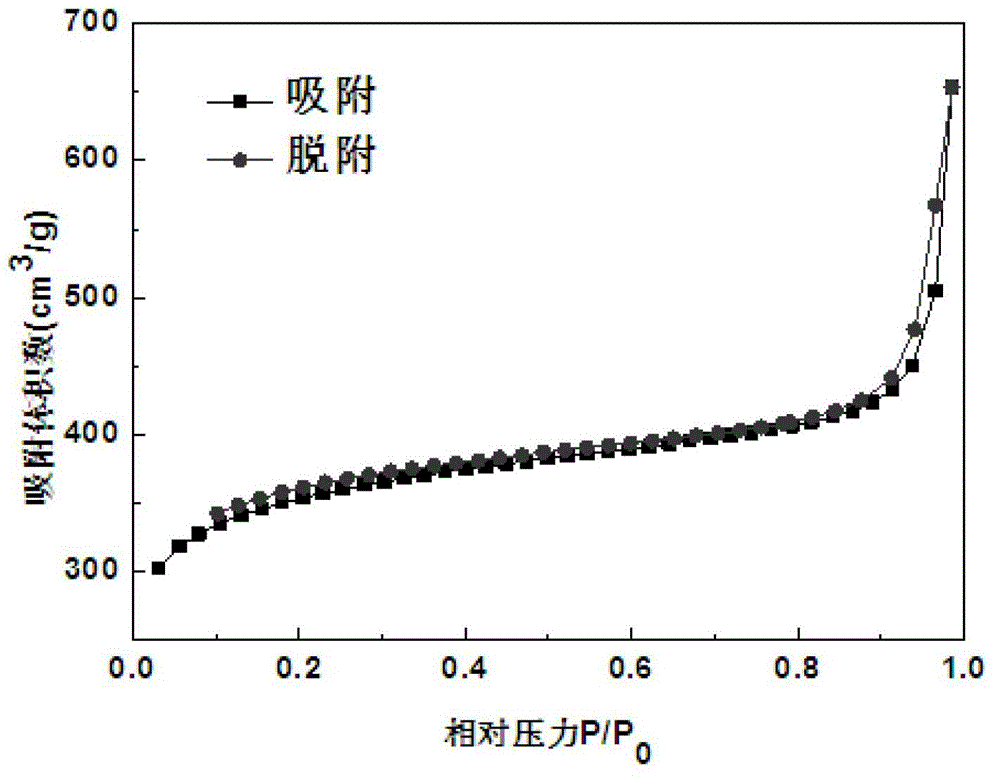

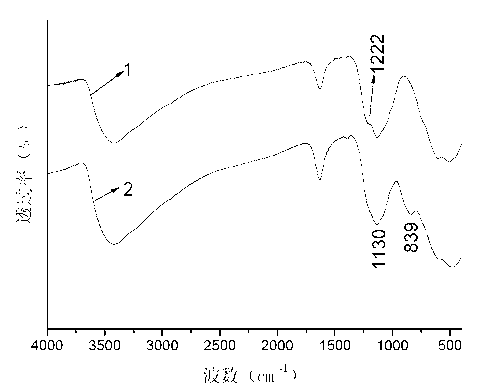

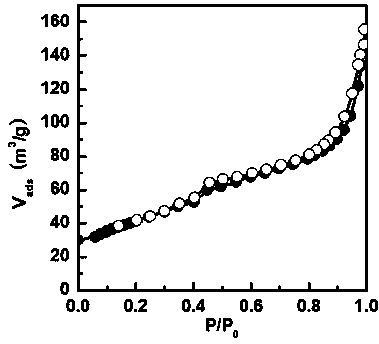

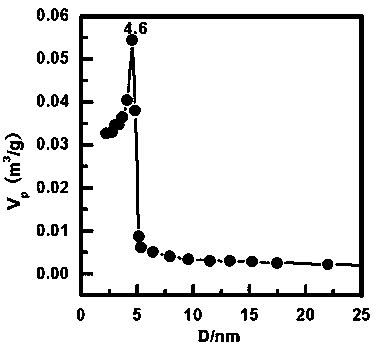

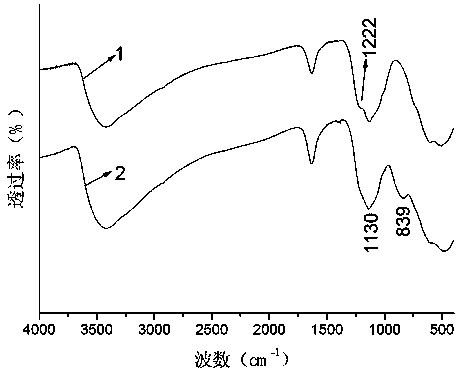

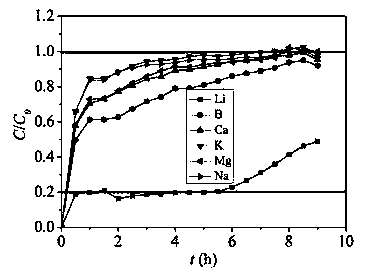

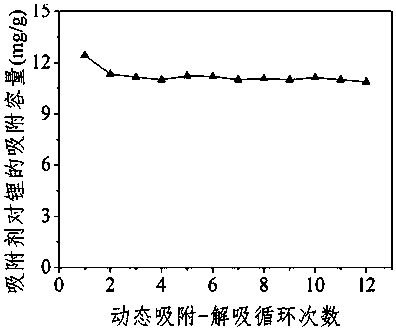

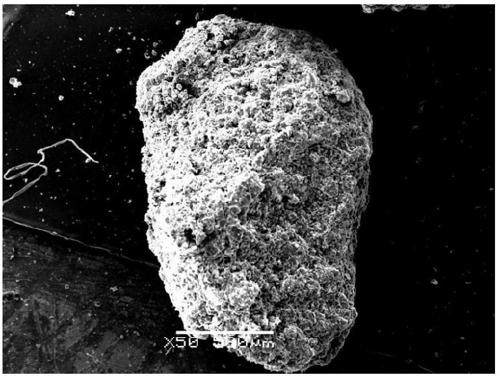

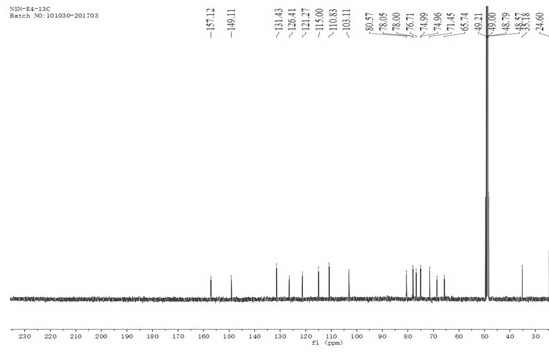

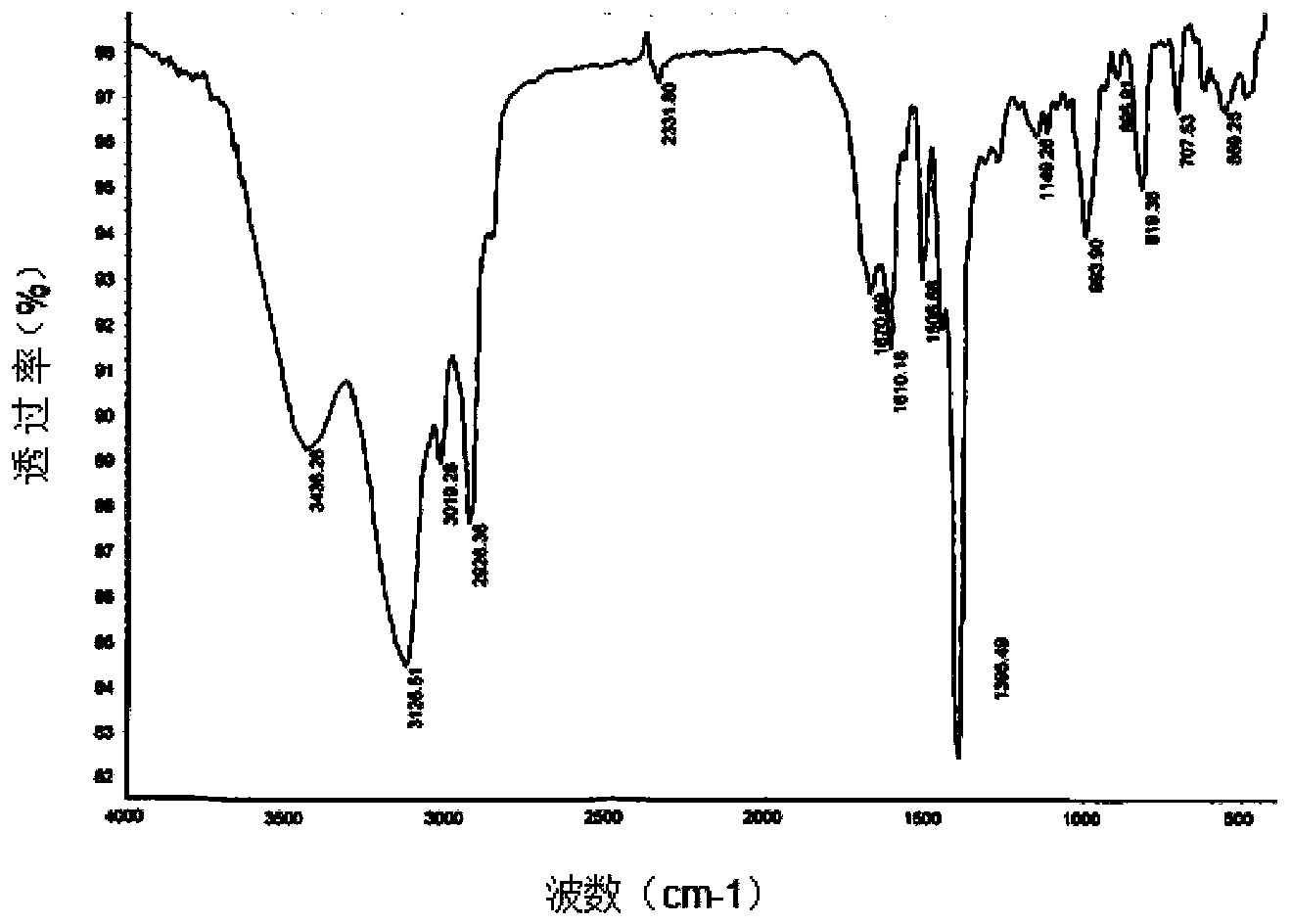

The invention discloses a microporous aluminum-salt lithium adsorbent, a preparation method therefor, filler containing the microporous aluminum-salt lithium adsorbent and a lithium ion enriching method. The microporous aluminum-salt lithium adsorbent disclosed by the invention has the molecular formula of LiCl.aAl(OH)3.bH2O and has micropores, of which the average pore size is smaller than 2nm, wherein a is greater than 1 and smaller than 3, and b is greater than 0.5 and smaller than 2. The preparation method disclosed by the invention is simple, and the obtained adsorbent is large in lithium ion adsorption capacity, high in selectivity, simple in eluting regeneration and long in cycle life and can be applied to the separation and extraction of lithium from lithium-containing saline lake brine, salt-field concentrated lithium-containing senescent brine, lithium-containing medicinal wastewater and a lithium-containing solution with the mineralization degree lower than 50g / L.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method for preparing hydroxyl carthamus tinctorius yellow color A

ActiveCN101215307ASimple refining processImprove extraction efficiencySugar derivativesSugar derivatives preparationAlcoholSolvent

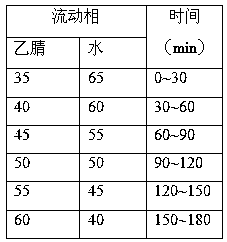

A process for preparing hydroxyl carthamus tinctorius yellow color A comprises using dry carthanus tinctorius as raw material, using deionized water and water alcohol as extracting solution, passing through preliminary separating column and refining column, using deionized water and water alcohol as eluent, and then obtaining hydroxyl carthamus tinctorius yellow color A after frozen and dried, and the content can reach 85%-99%. The invention uses cheap material, no toxic and safe solution, and has simple technology, high carthamus tinctorius usage and low cost, which is suitable to the industrialized industry, and the extracting rate is 0.8%-1.5% according to different purify requests of hydroxyl carthamus tinctorius yellow color A for various applications.

Owner:山西华卫药业有限公司

Process for extracting folium mori flavone

InactiveCN1683360ANo pollution in the processLow priceSugar derivativesMetabolism disorderAlcoholSolvent

The mulberry leaf flavone extracting process adopts mulberry leaf powder material, alcohol and water as extracting solvent and eluant and macroporous resin as separating material. The extract has mulberry leaf flavone content over 50 %. The present invention has the advantages of non-toxic cheap recoverable solvent, no environmental pollution, great extracted amount, capacity of industrial production and high extracting efficiency.

Owner:SHANXI UNIV

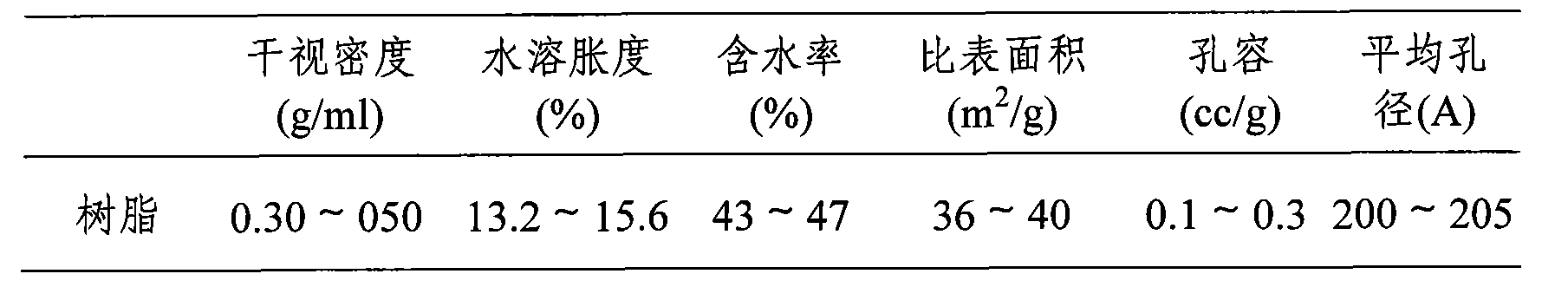

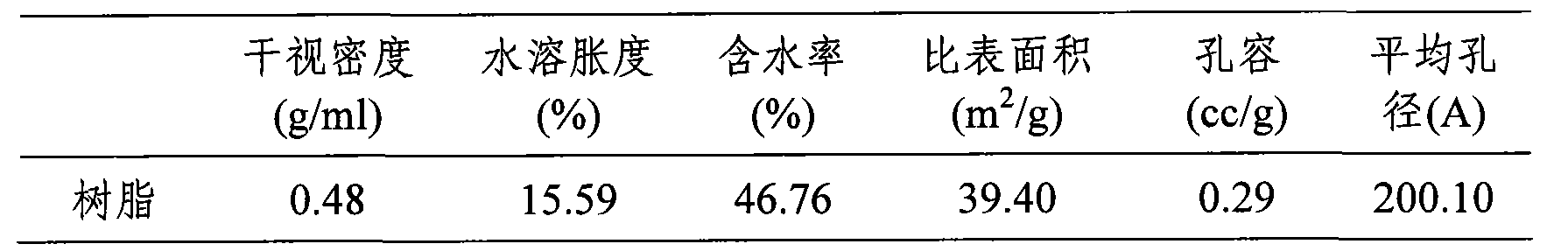

Modified styrene adsorption resin, preparation method of modified styrene adsorption resin and application of modified styrene adsorption resin to refining of lignocellulose hydrolysate

ActiveCN108355626AImprove hydrophilicityImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesCross-linkCellulose

The invention provides modified styrene adsorption resin, a preparation method of the modified styrene adsorption resin and application of the modified styrene adsorption resin to refining of lignocellulose hydrolysate. The preparation method of the modified styrene adsorption resin comprises the following steps: sequentially adding an acrylate monomer, a styrene monomer, a cross-linking agent, aninitiating agent a pore-forming agent to an aqueous solution containing a dispersing agent, and performing suspension polymerization reaction to obtain precursor resin; and performing Friedel-Craftsreaction on the precursor resin under the action of Lewis acid as a catalyst to obtain the modified styrene adsorption resin. By modifying the acrylate unit in the styrene adsorption resin, the acrylate unit contains an ester group which can form intermolecular hydrogen bonding with water molecules, thereby greatly improving the hydrophilicity of the modified styrene adsorption resin and being favorable for adsorbing hydrophilic fermentation inhibitors in the lignocellulose hydrolysate.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Method for decolorizing nucleotide enzymatic hydrolysate

InactiveCN103331035AIncrease throughputHigh loss rateSugar derivativesSolid sorbent liquid separationNucleotidaseHydrolysate

The invention relates to a method for decolorizing nucleotide enzymatic hydrolysate. The method comprises the following steps of: performing pigment adsorption on the nucleotide enzymatic hydrolysate through hyper-crosslinked resin SX-01; and after adsorption is saturated, and regenerating the hyper-crosslinked resin SX-01 by using a regenerant, wherein the hyper-crosslinked resin SX-01 has the following structure units: the skeleton of the resin is polystyrene, the average grain size is 0.3 to 1 mm, the water content is 32 to 49 percent, the aperture is 1.5 to 4 nm, the most probable aperture is 1.8 nm, the average specific surface area is 950 to 1,800 m<2> / g, and the average pore volume is 0.54 to 0.82 cm<3> / g. By adoption of the method, the decolorization ratio of the enzymatic hydrolysate reaches over 80 percent, the treatment quantity reaches 11 times of bed volume (BV), the loss ratio of four kinds of nucleotides is lower than 5 percent, and the consumption quantity of the regenerant is 5 BV.

Owner:NANJING TECH UNIV

Method for preparing arsenic adsorbent and method for treating waste water

InactiveCN102698703AImprove adsorption capacityThe synthesis method is simpleOther chemical processesWater/sewage treatment by sorptionSorbentWastewater

The invention provides a method for preparing an arsenic adsorbent. The arsenic adsorbent has zirconium oxide of nano-pore structure. The material can effectively treat arsenate and arsenite in the waste water, and can be recycled after waste water treatment. Another objective of the invention is to provide a method for treating waste water containing arsenate or arsenite ions by the arsenic adsorbent prepared by the method. The method contains a 'regeneration' step, so that the arsenic adsorbent can be reused cyclically.

Owner:CHONGQING THREE GORGES UNIV

Forsynthigenol extracting process

InactiveCN1148375CNo pollution in the processLow priceSugar derivativesGlycosidesSolventRaw material

A forsythigenol extracting process uses forsythia shell and leaf powder as raw material, ethanol and water as solvent and eluting agent, macroporous adsorbing resin as separating material, and active carbon as decoloring agent. The extracted forsythigenol product has forsythigenol content over 40%. The process of the present invention has the advantages of safe and non-toxic, cheap and reusable solvent, no environmental pollution, great extracting amount, high extracting efficiency, and being capable of being used in industrial production.

Owner:SHANXI UNIV

Method for separating iron and zinc in iron-containing waste acid

ActiveCN110841331AEasy to elute and regenerateAchieve separationCation exchanger materialsOrganic anion exchangersZinc ionChloride

The invention discloses a method for separating iron and zinc in iron-containing waste acid. The method comprises the following steps: S1, pretreating to remove suspended matters and impurities in theiron-containing waste acid; S2, carrying out water washing activation treatment on a 1 # resin and a 2 # resin; S3, carrying out column filing of the 1 # resin column and the 2 # resin column and connection in series, enabling the iron-containing waste acid pretreated in the step S1 sequentially flowing through a 1 # resin column and a 2 # resin column, so that zinc ions are adsorbed by resin, and a ferrous acid solution is collected at a liquid outlet position of the resin columns; and S4, eluting the zinc ions adsorbed by the 1 # resin column and the 2 # resin column with running water to obtain a low-acidity zinc chloride solution. Zinc ions in the waste acid are adsorbed by the activated amphoteric resins; the adsorption columns are washed with water to obtain the low-acidity zinc chloride solution through recovery; meanwhile, a solution obtained after adsorption is a recyclable ferrous acid solution, and can be used for preparing a water purifying agent after being oxidized; thetechnological process is simple, the resins are convenient to elute and regenerate, the usable period is long, no secondary is generated in the process, and separation and resource utilization of ironand zinc elements in the iron-containing waste acid are realized to the greatest extent.

Owner:CHANGZHOU WUJIN YOUBANG WATER PURIFICATION MATERIALS

Solidify tannin large hole adsorption resin and method of preparing the same

InactiveCN101249424AImprove adsorption capacityEasy to elute and regenerateOther chemical processesMannich reactionElution

The invention provides solidified tannin macroporous adsorptive resin containing 0.25-1% vegetable tannin and preparation method thereof. The Mannich reaction is adopted to solidify vegetable tannin on styrene-divinylbenzene copolymer to preparing a kind of novel solidified tannin macroporous adsorptive resin. The obtained solidified tannin macroporous adsorptive resin has the advantages of good absorbability to phenols substances in aqueous solution, easy elution and regeneration, and good reutilization effect. The resin has a satisfied result for enriching and recovering practical phenols substances-containing waste water and can overcome toxic chemical substances of synthetic resin.

Owner:BEIJING FORESTRY UNIVERSITY

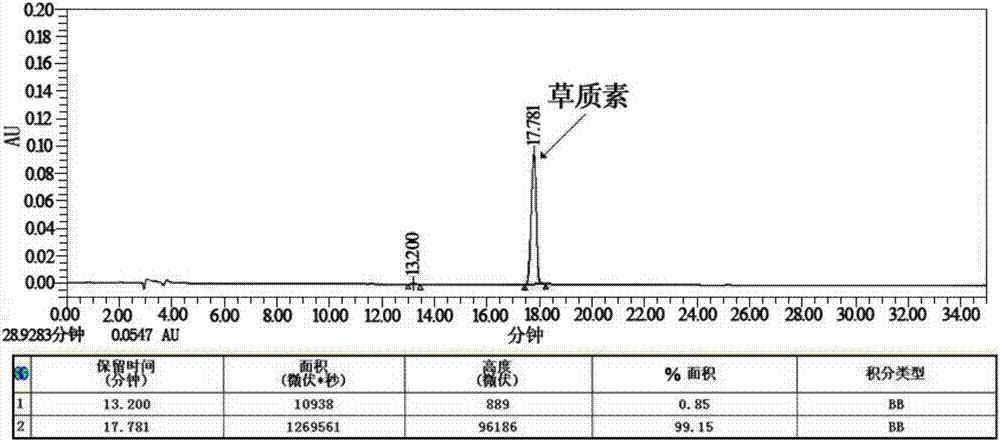

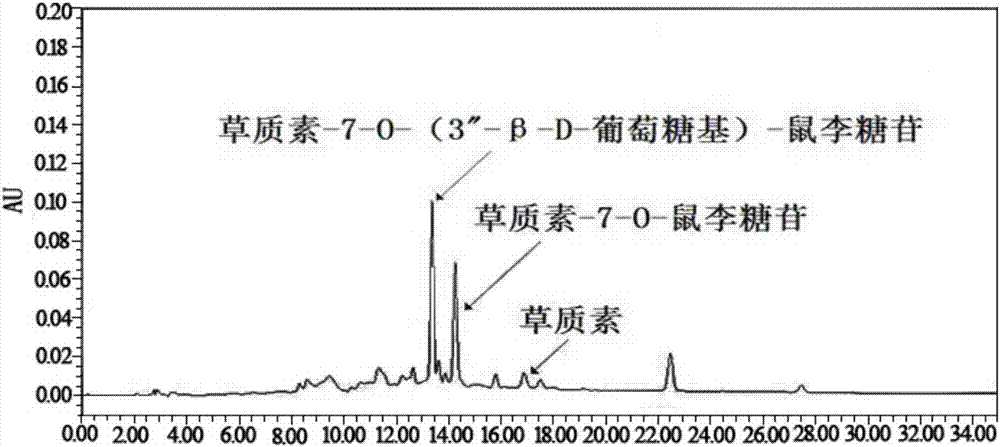

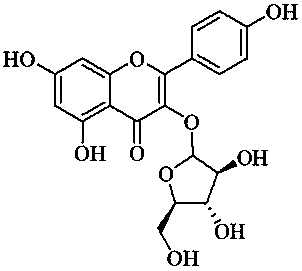

Method for preparing high-purity scutellarin

ActiveCN101747395ASimple processLow costSugar derivativesSugar derivatives preparationAlkaline waterElution

The invention provides a method for preparing high-purity scutellarin, which solves the problem that the prior preparation method is high in pollution, low in yield and high in cost. The method comprises the following: (1) a dissolution step, which is to take commercially available breviscapinun of which the scutellarin content in percentage by weight is 85 percent, dissolve the breviscapinun in alkaline water which is 5 to 10 times the weight of the breviscapinun and has a pH of 7 to 9 and filter the obtained product, and (2) a separation step, which is to use chromatography material to perform column chromatography on filtrate of which the sample loading amount is 1:1-3, elute the obtained product with elution water 8 to 10 times the volume of a column, collect the obtained product part by part, combine eluent of which the purity is greater than weight percentage by 98 percent, regulate pH to 2, precipitate, stand and filter the obtained product, wash precipitate with deionized water to be neutral, dry the obtained product and obtain the high-purity scutellarin.

Owner:CHENGDU UNIV

Method for preparing arsenic adsorbent and method for treating waste water

InactiveCN102698703BImprove adsorption capacityThe synthesis method is simpleOther chemical processesWater/sewage treatment by sorptionSorbentWastewater

The invention provides a method for preparing an arsenic adsorbent. The arsenic adsorbent has zirconium oxide of nano-pore structure. The material can effectively treat arsenate and arsenite in the waste water, and can be recycled after waste water treatment. Another objective of the invention is to provide a method for treating waste water containing arsenate or arsenite ions by the arsenic adsorbent prepared by the method. The method contains a 'regeneration' step, so that the arsenic adsorbent can be reused cyclically.

Owner:CHONGQING THREE GORGES UNIV

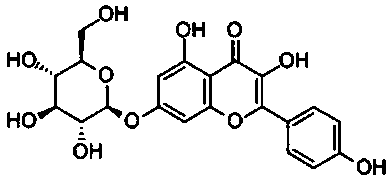

Apple flower effective part and preparation method thereof, and method for extracting kaempferol glucoside by apple flower effective part

InactiveCN107746419APromote development and utilizationBroad biological activitySugar derivativesSugar derivatives preparationN-ButanolSilica gel

The invention discloses a preparation method of an apple flower effective part, wherein the preparation method comprises the following steps: crushing apple flowers, carrying out heating extraction with ethanol, concentrating the extract liquid, then dispersing in water, and successively extracting with petroleum ether, ethyl acetate and n-butanol, to obtain an ethyl acetate extract. The inventionalso discloses a method for extracting kaempferol glucoside from the apple flower effective part; the apple flower effective part is treated by a silica gel column, a gel column, a preparative high performance liquid phase and other separation methods. The invention provides the method for extracting and separating kaempferol glucoside from the apple flowers, better development and utilization ofthe medicinal plant of the apple flowers are facilitated, kaempferol glucoside is studied deeply, the time and the labor are saved, and the yield of the sample can be greatly improved.

Owner:李昱珩

Method for preparing forsythiaside A

InactiveCN101215302BSimple refining processImprove extraction efficiencyEsterified saccharide compoundsSugar derivativesAlcoholSolvent

Owner:SHANXI UNIV

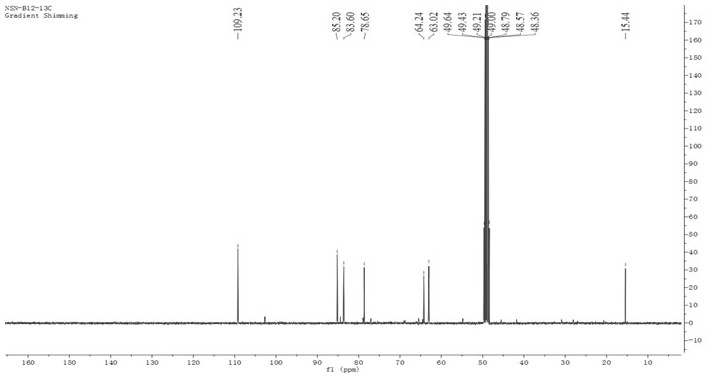

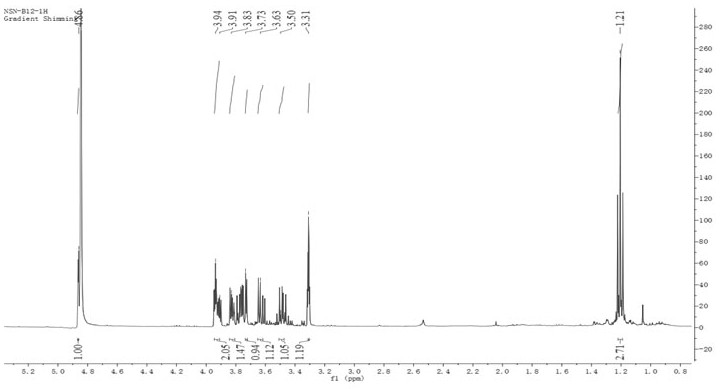

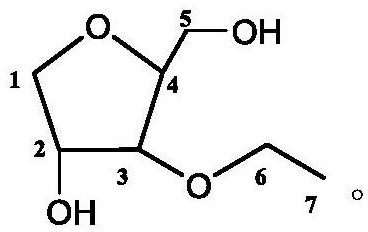

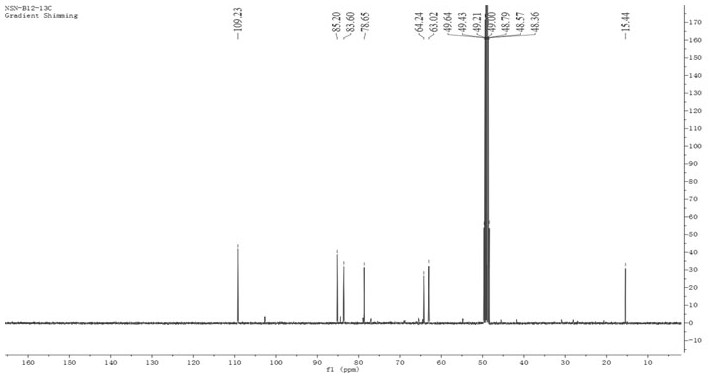

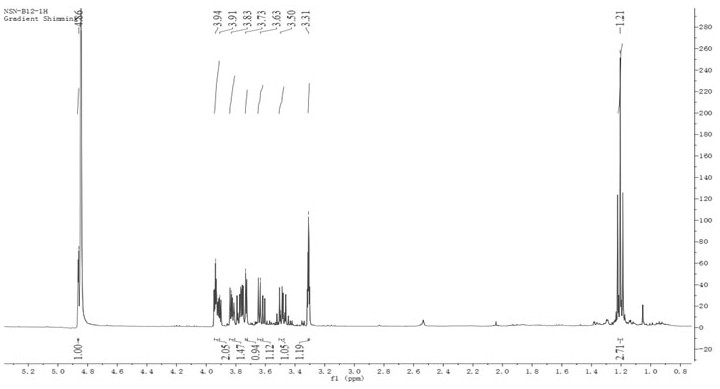

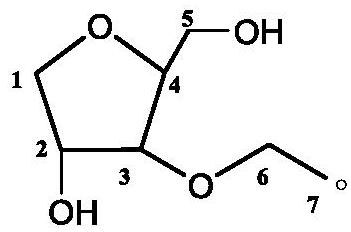

Method for extracting ethyl-alpha-D-furan arabinose from Nigella sativa seeds.

ActiveCN112409422AFast extraction and separationEffective extraction and separationSugar derivativesSugar derivatives preparationBiotechnologyNIGELLA SATIVA SEED

The invention relates to a method for extracting and separating a compound ethyl-alpha-D-furan arabinose from a Nigella sativa seed, which comprises the following steps: selecting a dry Nigella sativaseed as a raw material, pulverizing, degreasing with petroleum ether, extracting with ethanol at room temperature, adding methanol into the extract, dissolving, stirring with silica gel, loading, eluting with dichloromethane and methanol to obtain seven components Fr1-Fr7, and continuously separating and purifying to obtain a compound pure product. The method disclosed by the invention is beneficial to better development and utilization of the medicinal plant, namely the Nigella sativa, and is beneficial to sustainable utilization of the plant; the extraction process is simple, the ethyl-alpha-D-furan arabinose compound monomer is easy to obtain, the solvent can be recycled, the extraction amount is large, and industrial production can be achieved.

Owner:HENAN UNIVERSITY

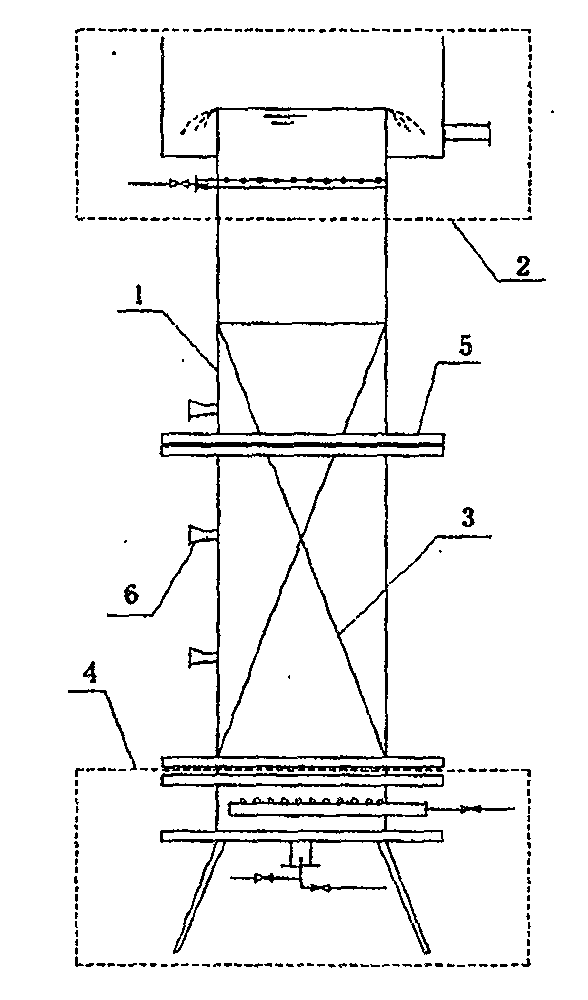

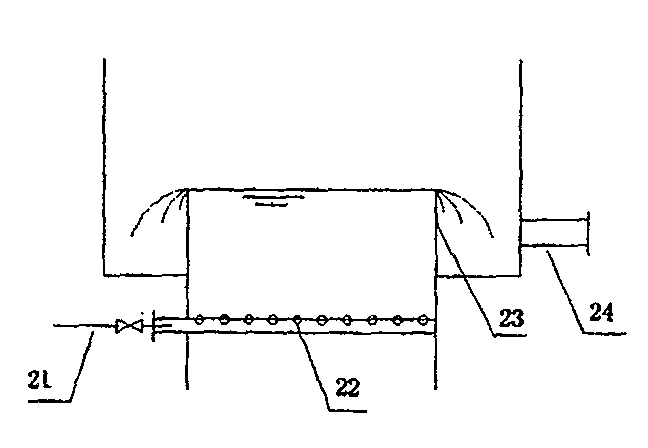

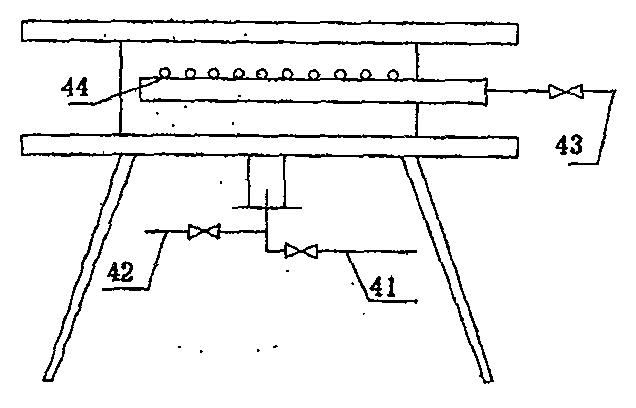

Continuous fiber agglomeration coarse-grain oil eliminator

InactiveCN100564269CAchieve demulsificationAchieve decentralizationFatty/oily/floating substances removal devicesLiquid separationFiber bundleWastewater

The long-fiber agglomeration coarse-grained degreaser enables oil droplets to float along the filter layer in time under the lift of air bubbles through a reasonable filter layer structure, achieving the dual goals of coarse-grained and filtered oil removal. The oil remover includes oil removal reactor column (1), water inlet and overflow device (2), modified fiber bundle assembly (3), water outlet and backwash device (4), oil removal column connector ( 5), sampling port (6); the deoiling reactor column (1) is divided into upper and lower parts, which are connected into one by the deoiling column connector (5), and the deoiling reactor column (1) A modified fiber bundle assembly (3) is installed inside, a sampling port (6) is provided on the side of the deoiling reactor cylinder (1), and a water inlet and overflow are provided on the upper part of the deoiling reactor cylinder (1). The flow device (2) is equipped with a water outlet and backwashing device (4) at the lower part of the oil removal reactor column (1); the upper part of the device is fed with water, and the lower part is aerated to realize the agglomeration of oil droplets in the oily wastewater, the coarse to achieve oil-water separation.

Owner:王世和

Method for extracting ursolic acid from vegetable Dian clove

InactiveCN101544679ABeautiful plant typeProlong flowering periodSteroidsPlant ingredientsSephadexUrsolic acid

The invention relates to a method for extracting ursolic acid from vegetable Dian clove. The method comprises the following steps that: (1) the dried Dian clove is picked up, crushed and undergoes repeated cold soaking by 10L of 95 percent ethanol for three times, seven days for each time, and the ethanol is filtered, decompressed and reclaimed to obtain a concentrated extractive; (2) the obtained ethanol extractive is tested; and (3) the extract obtained from the step(2) is subjected to Sephadex LH-20 gel column chromatography and is separated to obtain the finished product by taking methanol as an eluant and compare with the standard product. The separation materials used by the method include macroporous adsorptive resin and gel, so that the separation materials have stable physical-chemical properties, are not dissolved in acids, alkalis and organic dissolvants, have good selectivity on organic matters, and are not affected by existence of organic salts and strong-ion low-molecule compounds; and the separation materials are easily eluted and regenerated, thereby facilitating the cyclic utilization.

Owner:HENAN UNIVERSITY

Microporous aluminum salt lithium adsorbent and preparation method thereof, filler and method for enriching lithium ions

ActiveCN106076243BControl areaLarge specific surface areaOther chemical processesAlkali metal oxides/hydroxidesLithiumSorbent

The invention discloses a microporous aluminum-salt lithium adsorbent, a preparation method therefor, filler containing the microporous aluminum-salt lithium adsorbent and a lithium ion enriching method. The microporous aluminum-salt lithium adsorbent disclosed by the invention has the molecular formula of LiCl.aAl(OH)3.bH2O and has micropores, of which the average pore size is smaller than 2nm, wherein a is greater than 1 and smaller than 3, and b is greater than 0.5 and smaller than 2. The preparation method disclosed by the invention is simple, and the obtained adsorbent is large in lithium ion adsorption capacity, high in selectivity, simple in eluting regeneration and long in cycle life and can be applied to the separation and extraction of lithium from lithium-containing saline lake brine, salt-field concentrated lithium-containing senescent brine, lithium-containing medicinal wastewater and a lithium-containing solution with the mineralization degree lower than 50g / L.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method for separating and extracting chain ester compounds from Nigella sativa seeds

ActiveCN112299997AConducive to sustainable useBroad biological activityOrganic compound preparationCarboxylic acid esters preparationNIGELLA SATIVA SEEDChemistry

The invention relates to a method for separating and extracting chain ester compounds from Nigella sativa seeds, which comprises the steps of 1) pulverizing the dried Nigella sativa seeds, degreasingwith petroleum ether, extracting with 60-80% ethanol, and recovering the solvent under reduced pressure to obtain an extract; 2) dissolving the extract with methanol, mixing the extract with a silicagel column, and carrying out gradient elution with dichloromethane-methanol to obtain seven components Fr1-Fr7; 3) performing normal pressure silica gel column chromatography on the component Fr1 to obtain six components Fr1-1 to Fr1-6; and 4) performing gel column chromatography and silica gel column chromatography separation on the component Fr1-4 to obtain 9-decenoic acid-12-hydroxy ethyl ester, and performing gel column chromatography, silica gel column chromatography and reversed phase chromatography separation on the component Fr1-2 to obtain 9-undecylenic acid-1-(3-pentyloxy silane)-ethyl ester. The method has the advantages of simple extraction process, accessible product, recyclable solvent and large extraction amount, and can implement industrial production.

Owner:HENAN UNIVERSITY

A method for separating and extracting phenolic glycosides from nigella sativa seeds

ActiveCN112300230BConducive to sustainable usePromote development and utilizationSugar derivativesSugar derivatives preparationBiotechnologyNIGELLA SATIVA SEED

The present invention relates to a Nigella sativa Method for separating and extracting phenolic glycosides from seeds: drying Nigella sativa After the seeds are crushed, degrease with petroleum ether, extract with 60-80% ethanol, recover the solvent under reduced pressure, and obtain the extract extract; Eluted to obtain 7 components Fr1-Fr7; 3) The fourth component Fr4 was separated by silica gel column chromatography to obtain 5 components 4-1~4-5; 4) Component 4-3 was separated by gel column Chromatography, silica gel column chromatography separation, obtain 3,5 dihydroxyphenethyl alcohol-3- O - β ‑Pyranoside; Component 4‑2 was separated by reverse phase column chromatography and Sephadex LH‑20 dextran gel column chromatography to obtain broadbactin C. The extraction process of the invention is simple, the product is easy to obtain, the solvent can be recycled, the extraction amount is large, and industrial production is possible.

Owner:HENAN UNIVERSITY

Method for decolorizing nucleotide enzymatic hydrolysate

InactiveCN103331035BIncrease throughputHigh loss rateSugar derivativesSugar derivatives preparationHydrolysateNucleotidase

The invention relates to a method for decolorizing nucleotide enzymatic hydrolysate. The method comprises the following steps of: performing pigment adsorption on the nucleotide enzymatic hydrolysate through hyper-crosslinked resin SX-01; and after adsorption is saturated, and regenerating the hyper-crosslinked resin SX-01 by using a regenerant, wherein the hyper-crosslinked resin SX-01 has the following structure units: the skeleton of the resin is polystyrene, the average grain size is 0.3 to 1 mm, the water content is 32 to 49 percent, the aperture is 1.5 to 4 nm, the most probable aperture is 1.8 nm, the average specific surface area is 950 to 1,800 m<2> / g, and the average pore volume is 0.54 to 0.82 cm<3> / g. By adoption of the method, the decolorization ratio of the enzymatic hydrolysate reaches over 80 percent, the treatment quantity reaches 11 times of bed volume (BV), the loss ratio of four kinds of nucleotides is lower than 5 percent, and the consumption quantity of the regenerant is 5 BV.

Owner:NANJING TECH UNIV

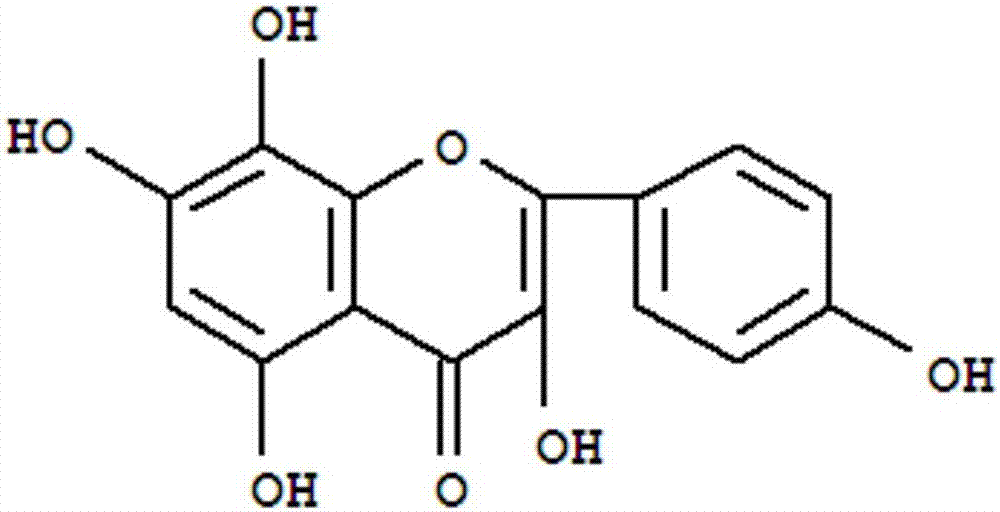

Method for extracting herbacetin from rhodiola rosea

ActiveCN107074798AHigh puritySatisfy industrial productionOrganic active ingredientsOrganic chemistryOrganic solventRHODIOLA ROSEA ROOT

A method for extracting herbacetin from rhodiola rosea comprises the steps of: 1) extracting a medicinal material by using an extraction solvent, and then concentrating to obtain an extract paste; 2) extracting the extract paste, and acid hydrolyzing an aqueous layer obtained from the extraction; 3) extracting a solution obtained from the acid hydrolysis with an organic solvent, combining with the extraction solution, concentrating under reduce pressure to obtain an extract of herbacetin; 4) treating the extract of herbacetin with polyamide column chromatography, collecting fractions containing herbacetin, concentrating till dry, and recrystallizing to obtain a pure product of herbacetin.

Owner:TAIZHOU DANDING BIOTECH CO LTD

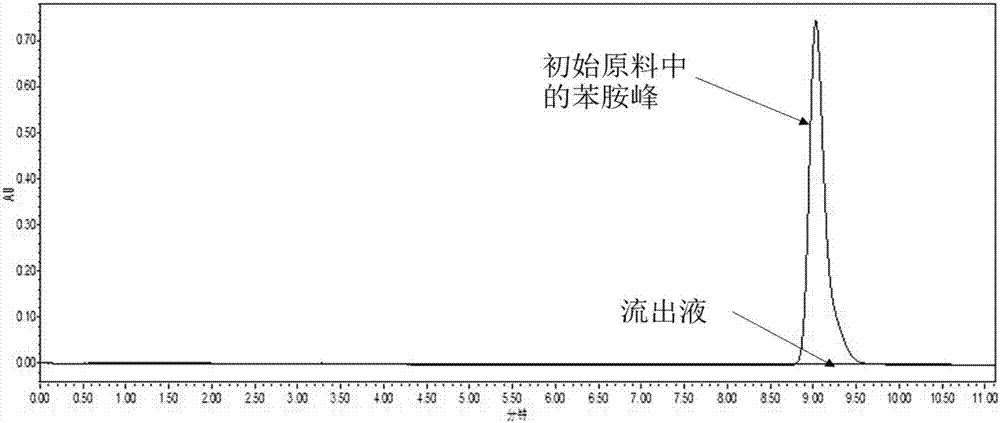

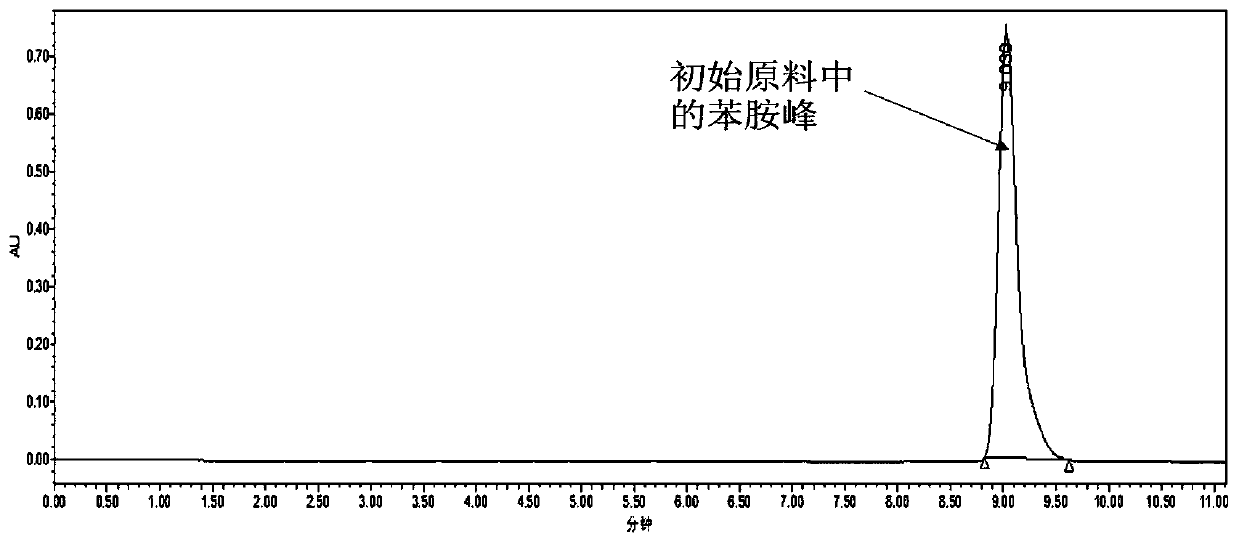

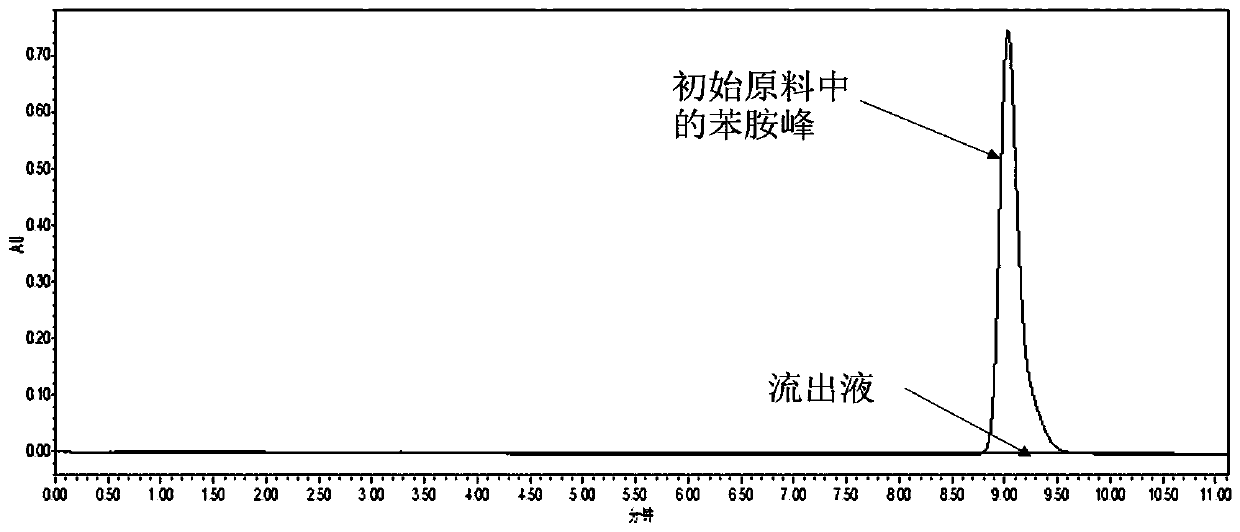

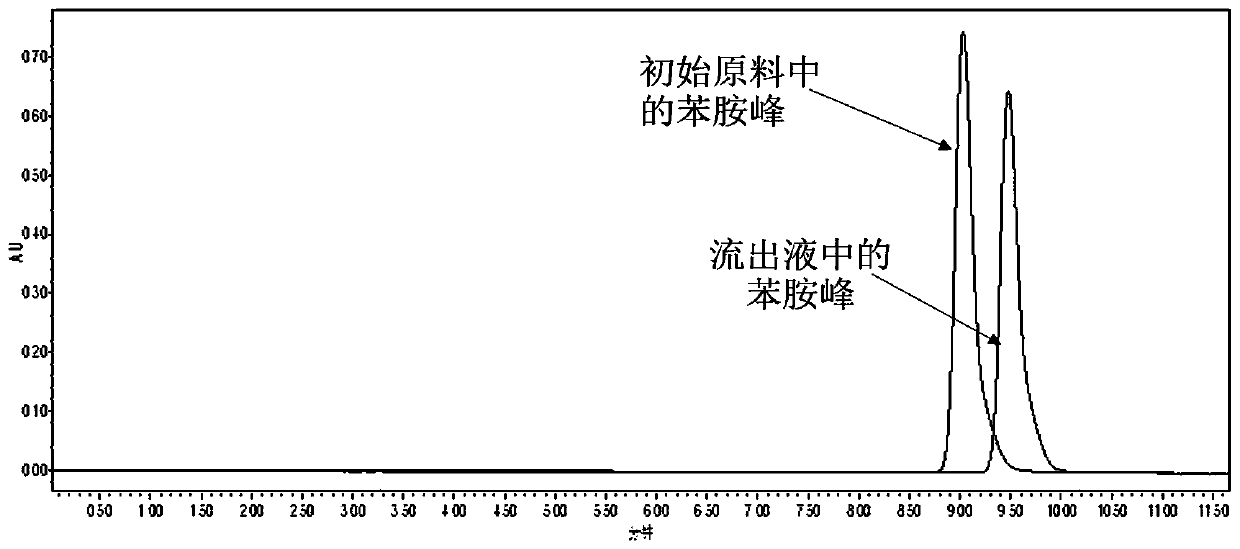

Adsorbing stuffing for treating aniline-containing wastewater and preparation method and application thereof

ActiveCN106944019AImprove adsorption capacityEasy to elute and regenerateOther chemical processesWater contaminantsEmulsion polymerizationOil phase

The invention belongs to the technical field of wastewater treatment and relates to adsorbing stuffing for treating aniline-containing wastewater and a preparation method and an application thereof. In particular, the preparation comprises the following steps: 1) preparing a mixed solution of a surfactant and water as an aqueous phase; 2) preparing a mixed solution of acrylate, styrene and amino styrene as an oil phase; 3) preparing an O / W emulsion; and 4) performing free radical emulsion polymerization. The preparation method is simple and feasible. The grain size of the adsorbing stuffing prepared by the method is 200-2000[mu]m, and the adsorbing stuffing can effectively adsorb and enrich aniline in water, is easily eluted and generated and is suitable for industrial treatment of aniline-containing wastewater.

Owner:微纯生物科技(广州)有限公司

Method for extracting dictyota dichotoma lactone

The invention discloses a method for extracting dictyota dichotoma lactone, which comprises steps of regarding dictyota dichotoma as a raw material, regarding 70%-90 % of alcohol as an extraction solvent, performing ultrasound extraction or reflux extraction for 2-4 times, performing filtration, filtrate combination and concentration, adding macroporous resin columns for absorption, using 50%-80% of alcohol to elute effective constituents, concentrating eluate, feeding the concentrated solution to a high-pressure silica gel column, using hexane-acetone for elution, enabling the eluate to subject to concentration and crystallization, enabling hexane to flow back and dissolve the crystal, performing recrystallization and obtaining the dictyota dichotoma lactone. The dictyota dichotoma lactone produced by the method is high in extraction rate, simple in process and specific.

Owner:NANJING ZELANG MEDICAL TECH

Method for extracting juglanin from apple flowers

ActiveCN107602645APromote development and utilizationBroad biological activitySugar derivativesSugar derivatives preparationBiotechnologyChromatographic separation

The invention discloses a method for extracting juglanin from apple flowers. The method comprises the following steps of (1) obtaining ethanol total extracts of dried apple flowers; (2) performing extraction on the ethanol total extracts to obtain apple flower normal butanol positions; (3) performing normal pressure column chromatography separation on the apple flower normal butanol positions through silica gel; performing gradient elution and TLC thin layer chromatography tracking detection merging to obtain six ingredients; performing normal pressure silica gel column chromatography separation on the fifth ingredient; performing gradient elution; collecting two ingredients; performing Sephadex LH-20 gel column chromatography separation and recrystallization on the first ingredient to obtain a pure ingredient of juglanin. The used separation materials include the silica gel and sol column chromatography, and cannot be dissolved in water and any solvents; no toxicity and no smell exist; the chemical properties are stable; the selectivity on organic matters is better; the influence by the existence of inorganic salts and strong ion low molecular compounds is avoided; in addition, the elution regeneration is easy; the benefits to multi-time utilization can be realized.

Owner:周静宜

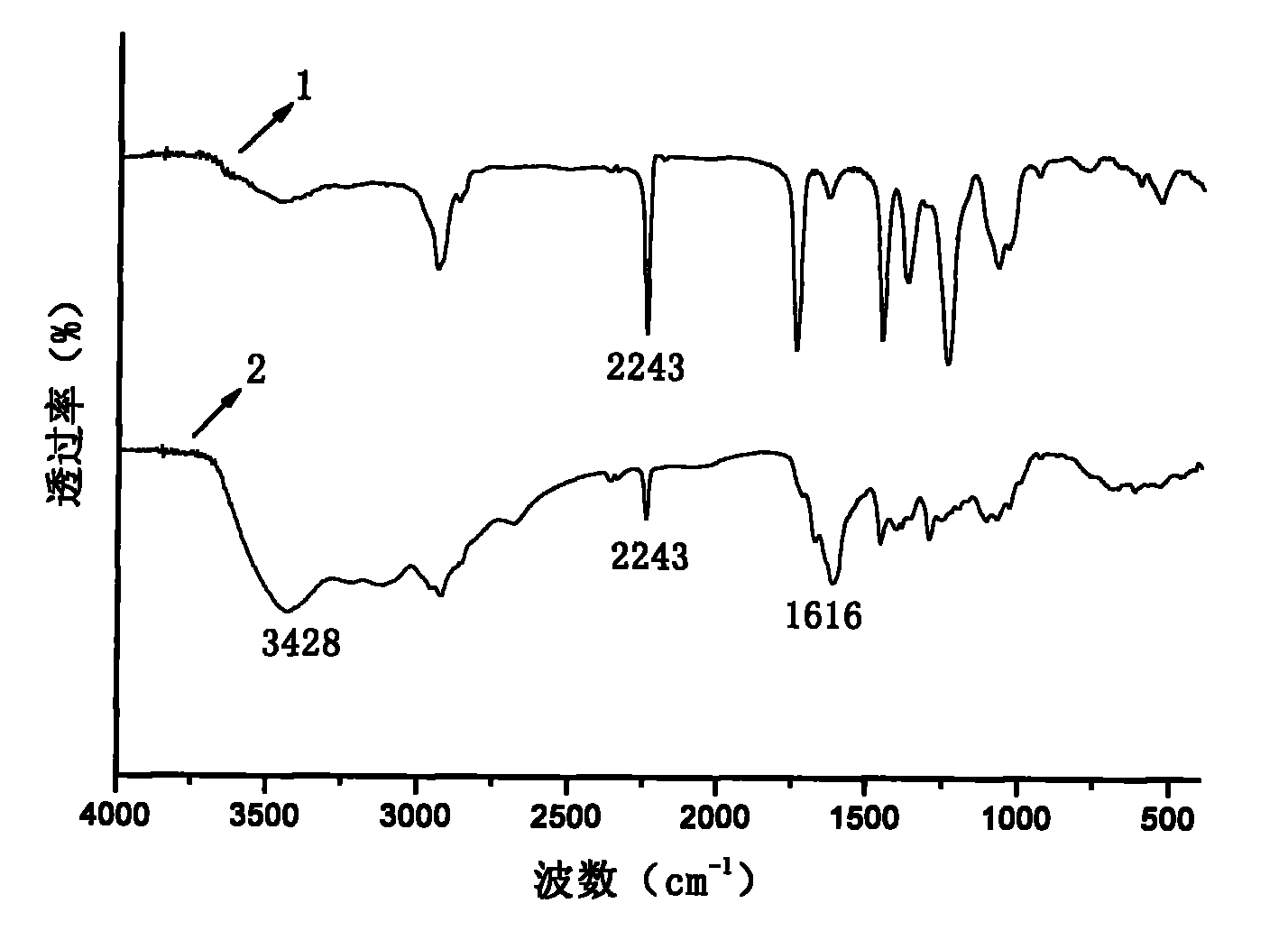

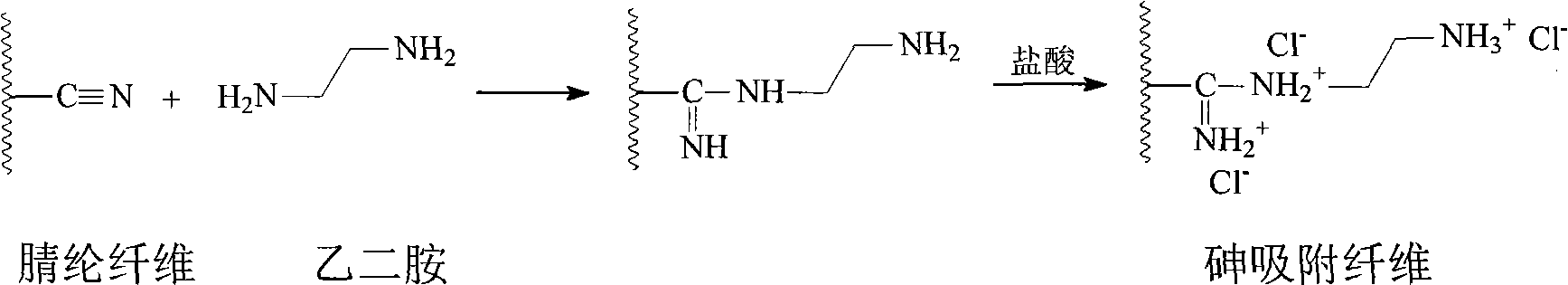

Arsenic adsorbing fiber and synthesizing method thereof

ActiveCN101569854BImprove adsorption capacityEffective absorptionOther chemical processesAlkali metal oxides/hydroxidesPolymer scienceSorbent

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

A method for separating iron and zinc in iron-containing waste acid

ActiveCN110841331BEasy to elute and regenerateAchieve separationCation exchanger materialsOrganic anion exchangersZinc ionChloride

The invention discloses a method for separating iron and zinc in iron-containing waste acid. The method comprises the following steps: S1, pretreating to remove suspended matters and impurities in theiron-containing waste acid; S2, carrying out water washing activation treatment on a 1 # resin and a 2 # resin; S3, carrying out column filing of the 1 # resin column and the 2 # resin column and connection in series, enabling the iron-containing waste acid pretreated in the step S1 sequentially flowing through a 1 # resin column and a 2 # resin column, so that zinc ions are adsorbed by resin, and a ferrous acid solution is collected at a liquid outlet position of the resin columns; and S4, eluting the zinc ions adsorbed by the 1 # resin column and the 2 # resin column with running water to obtain a low-acidity zinc chloride solution. Zinc ions in the waste acid are adsorbed by the activated amphoteric resins; the adsorption columns are washed with water to obtain the low-acidity zinc chloride solution through recovery; meanwhile, a solution obtained after adsorption is a recyclable ferrous acid solution, and can be used for preparing a water purifying agent after being oxidized; thetechnological process is simple, the resins are convenient to elute and regenerate, the usable period is long, no secondary is generated in the process, and separation and resource utilization of ironand zinc elements in the iron-containing waste acid are realized to the greatest extent.

Owner:CHANGZHOU WUJIN YOUBANG WATER PURIFICATION MATERIALS

An adsorption filler for treating aniline-containing wastewater, its preparation method and use

ActiveCN106944019BImprove adsorption capacityEasy to elute and regenerateOther chemical processesWater contaminantsEmulsion polymerizationOil phase

Owner:微纯生物科技(广州)有限公司

A method for extracting ethyl-α-D-arabinofuranofuranose from nigella sativa seeds

ActiveCN112409422BConducive to sustainable usePromote development and utilizationSugar derivativesSugar derivatives preparationNIGELLA SATIVA SEEDEthyl group

The present invention relates to a Nigella sativa Extracted from the seeds to isolate the compound ethyl‑ α ‑D‑Arabinofuranose Method: Choose Dried Nigella sativa Seeds are used as raw materials, crushed and degreased with petroleum ether, extracted with ethanol at room temperature, dissolved in methanol, mixed with silica gel and loaded, eluted with dichloromethane and methanol to obtain Fr1‑Fr77 components, and then through continuous separation and purification, the pure compound is obtained. The method of the present invention is conducive to better development and utilization Nigella sativa This medicinal plant is conducive to the sustainable utilization of plants; the extraction process of the present invention is simple, and it is easy to obtain ethyl- α ‑D‑arabinofuranose compound monomer, the solvent can be recycled, the extraction amount is large, and it can be produced industrially.

Owner:HENAN UNIVERSITY

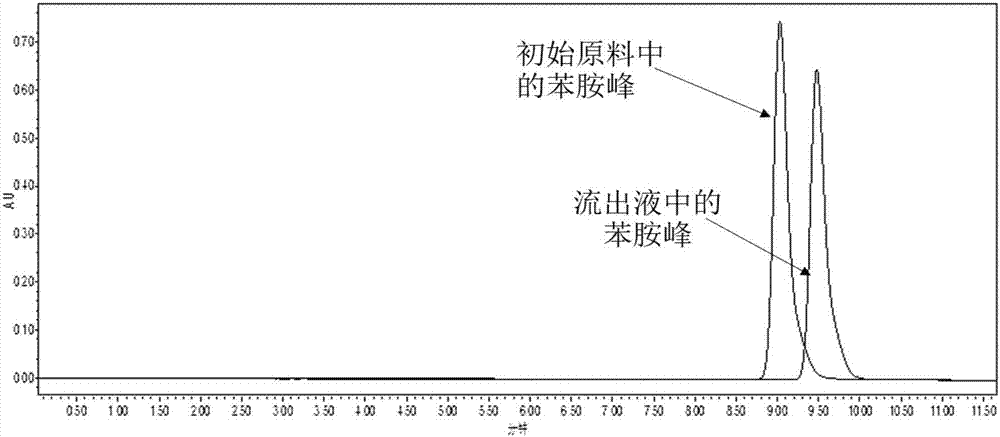

Extraction and separation method of nicotiflorin in rose flower

ActiveCN109956984AImprove extraction yieldFast extraction and separationSugar derivativesSugar derivatives preparationNicotiflorinGradient elution

The invention belongs to the technical field of plant extraction, and particularly relates to an extraction and separation method of nicotiflorin in rose flower. The method comprises the following steps: 1) taking dried rose flowers, pulverizing, degreasing the material with petroleum ether at room temperature, then adding ethanol to extract by cold soaking, and extracting an extract to obtain a total ethanol extract; 2) dissolving the total ethanol extract by methanol and mixing the materials, eluting a mixture through water, 20% ethanol, and 40% ethanol in order through a D101 macroporous resin column, and then drying a solvent to obtain a 40% ethanol elution component; 3) performing gradient elution on the 40% ethanol elution component with dichloromethane-methanol by normal pressure silica gel column chromatography, and combining the materials by silica gel thin layer chromatography to obtain 12 components which are marked as component Fr. 4-1 to Fr. 4-12 according to the polarityof the obtained components from small to large; and 4) obtaining the eleventh component Fr. 4-11 by gel column chromatography and high performance liquid chromatography. The method of the invention can quickly and effectively extract and isolate the nicotiflorin contained in the rose flower, and the extraction yield of the nicotiflorin is high.

Owner:HENAN UNIVERSITY

Method for preparing high-purity scutellarin

ActiveCN101747395BSimple refining processHigh yieldSugar derivativesSugar derivatives preparationAlkaline waterElution

The invention provides a method for preparing high-purity scutellarin, which solves the problem that the prior preparation method is high in pollution, low in yield and high in cost. The method comprises the following: (1) a dissolution step, which is to take commercially available breviscapinun of which the scutellarin content in percentage by weight is 85 percent, dissolve the breviscapinun in alkaline water which is 5 to 10 times the weight of the breviscapinun and has a PH of 7 to 9 and filter the obtained product, and (2) a separation step, which is to use chromatography material to perform column chromatography on filtrate of which the sample loading amount is 1:1-3, elute the obtained product with elution water 8 to 10 times the volume of a column, collect the obtained product part by part, combine eluent of which the purity is greater than weight percentage by 98 percent, regulate pH to 2, precipitate, stand and filter the obtained product, wash precipitate with deionized water to be neutral, dry the obtained product and obtain the high-purity scutellarin.

Owner:CHENGDU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com