Solidify tannin large hole adsorption resin and method of preparing the same

A pore adsorption and resin technology is applied in the field of macroporous adsorption resin containing tannin and its preparation, and achieves the effects of easy elution and regeneration, good repeated use effect and good adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

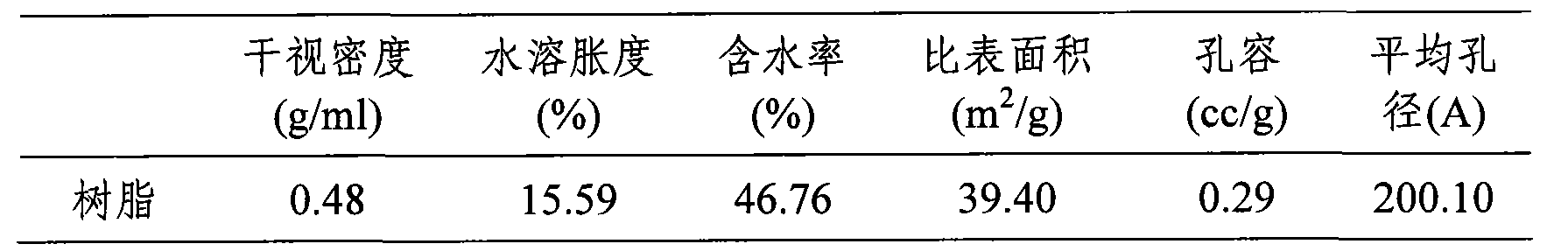

Embodiment 1

[0030] The cured tannin macroporous adsorption resin of this embodiment contains 0.5% plant tannin fixed on the styrene-divinylbenzene copolymer.

[0031] Concrete preparation process is as follows:

[0032] (1) Preparation of amino resin

[0033] Add 7.0g of chloromethylated polystyrene resin to a 250mL three-necked flask, add 10mL of dimethyl sulfoxide to swell for 1h, then add 20mL of ethylenediamine to react at 70°C for 24h, after the reactant is cooled, conduct Soxhlet extraction with ethanol Extract for 4 hours, wash with water, and then shake it with 5% NaOH solution for 3 hours, wash with water until neutral, and dry to obtain an amino resin.

[0034] (2) Mannich reaction to prepare resin

[0035] Take 2g of amino resin, add 5mL of tetrahydrofuran to swell for 2h, add 25mL of distilled water and 1mL of formaldehyde aqueous solution (mass concentration 37%), adjust the pH of the solution to 4 with hydrochloric acid, react at 99-100°C for 30min, and then add 25mL of ta...

Embodiment 2

[0040] The cured tannin macroporous adsorption resin in this embodiment contains 0.8% plant tannin fixed on styrene-divinylbenzene copolymer.

[0041] Concrete preparation process is as follows:

[0042] (1) Preparation of amino resin

[0043] Add 7.0g of chloromethylated polystyrene resin to a 250mL three-necked flask, add 10mL of dimethyl sulfoxide to swell for 0.5h, then add 40mL of ethylenediamine and react at 60°C for 12h. Extract for 6 hours, wash with water, and then shake it with 3% NaOH solution for 2 hours, wash with water until neutral, and dry to obtain an amino resin.

[0044] (2) Mannich reaction to prepare resin

[0045] Take 2g of amino resin, add 5mL of tetrahydrofuran to swell for 1.5h, add 30mL of distilled water and 1.5mL of formaldehyde aqueous solution (mass concentration 37%), adjust the pH of the solution to 3 with hydrochloric acid, react at 99-100°C for 20min, and then add 20mL of mono The tannin aqueous solution (adjusting the pH value to 4 in adv...

Embodiment 3

[0050] The cured tannin macroporous adsorption resin in this embodiment contains 1% plant tannin fixed on the styrene-divinylbenzene copolymer.

[0051] Concrete preparation process is as follows:

[0052] (1) Preparation of amino resin

[0053] Add 5.0g of chloromethylated polystyrene resin to a 250mL three-necked flask, add 20mL of dimethyl sulfoxide to swell for 1.5h, then add 50mL of ethylenediamine and react at 80°C for 36h. Extract for 5 hours, wash with water, and shake with 4% NaOH solution for 2 hours, wash with water until neutral, and dry to obtain an amino resin.

[0054] (2) Mannich reaction to prepare resin

[0055] Take 3g of amino resin, add 10mL of tetrahydrofuran to swell for 2.5h, add 40mL of distilled water and 2mL of formaldehyde aqueous solution (mass concentration 37%), adjust the pH of the solution to 4 with hydrochloric acid, react at 99-100°C for 40min, and then add 30mL of tannin The aqueous solution (adjusting the pH value to 4 in advance) makes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com