Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Continuously adjustable speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

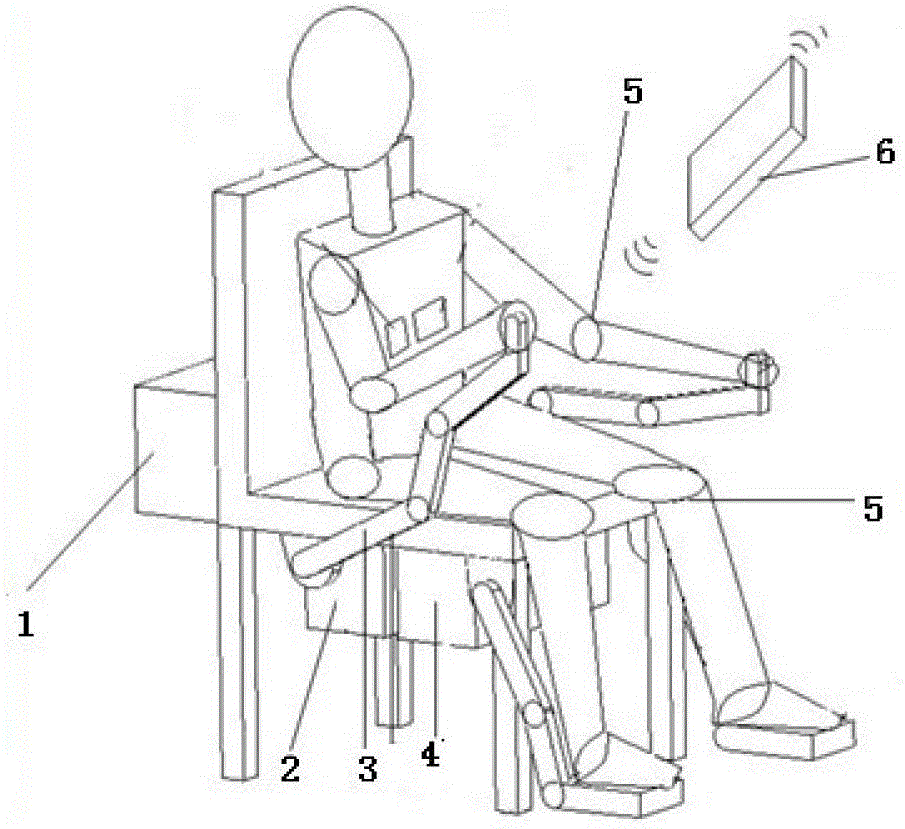

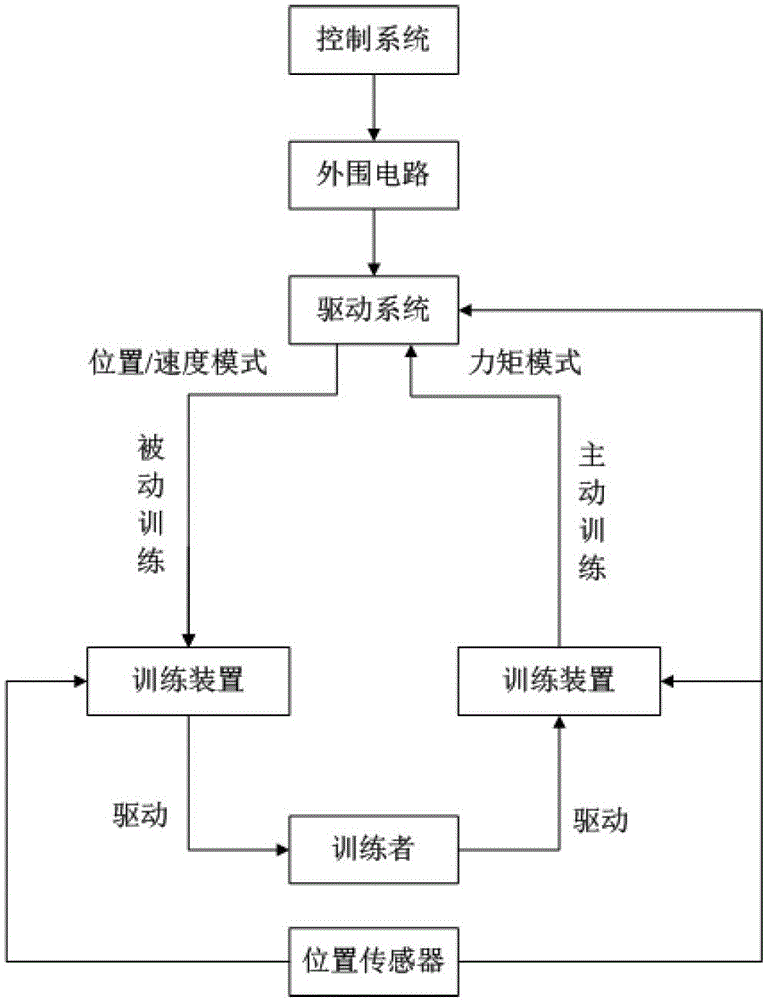

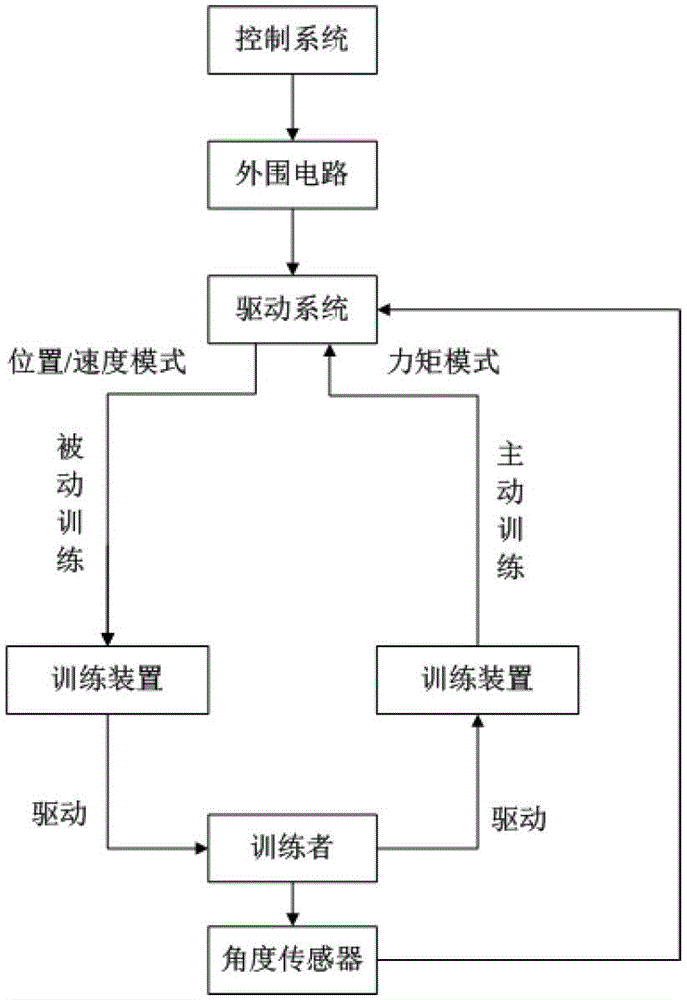

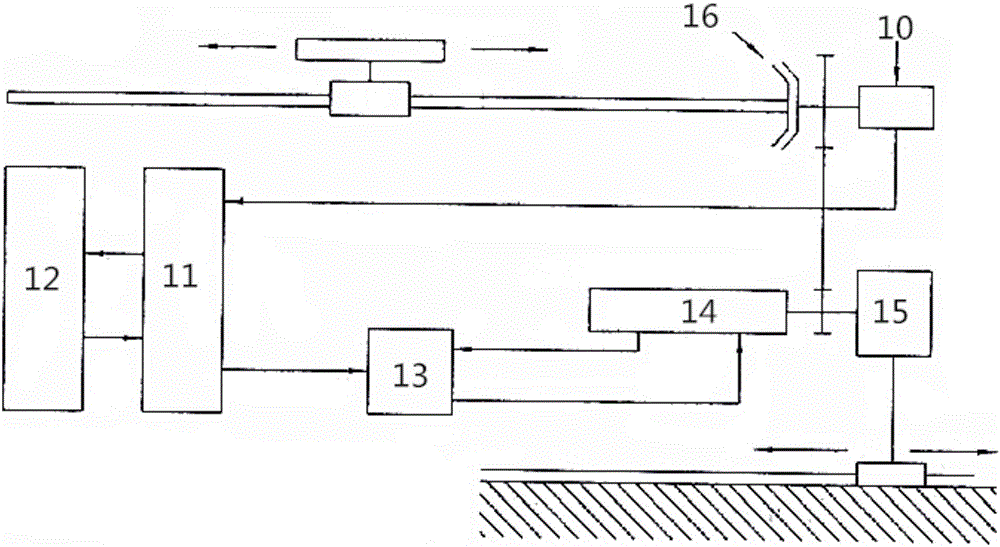

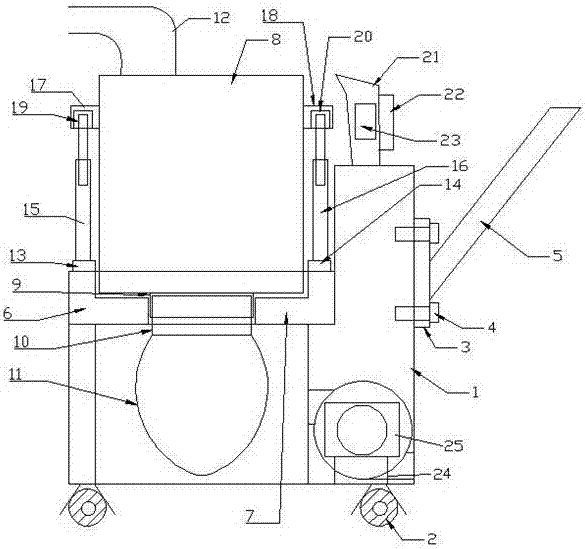

Active and passive realizing method of healthy exercise trainer

ActiveCN103142383ASensitive resistance changesSoft resistanceChiropractic devicesMuscle exercising devicesTime switchingPhysical exercise

The invention discloses an active and passive realizing method of a healthy exercise trainer. When a trainer is in passive training, a control motor is in either a position mode or a speed mode, and upper and lower limbs are driven to exercise to finish the passive training through a training device; when the trainer is in active training, the upper and lower limbs of the trainer exert strength, the motor is set to be in a torque mode, and the motor is driven to rotate through the training device; and the trainer is in assisted training, a working mode of the motor is a combination of the torque mode and the position mode or the speed mode in the different time periods, the active and passive trainings can be achieved through the real-time switching of the control motor between the position mode or the speed mode and the torque mode. According to the active and passive realizing method of the healthy exercise trainer, the initiatives of the trainers who take part in the training can be improved, and either body builders or patients can autonomously regulate the training mode, speed and intensity according to their own physical conditions and physical abilities, so that the active and passive realizing method of the healthy exercise trainer can be suitable for the healthy training of different recovery stages and different psychologic statuses.

Owner:WUHU TIANREN INTELLIGENT MACHINERY

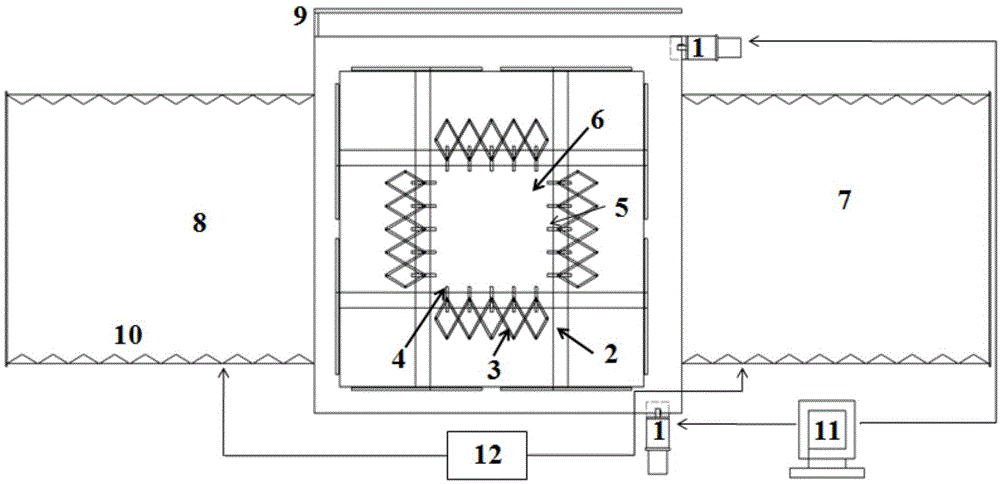

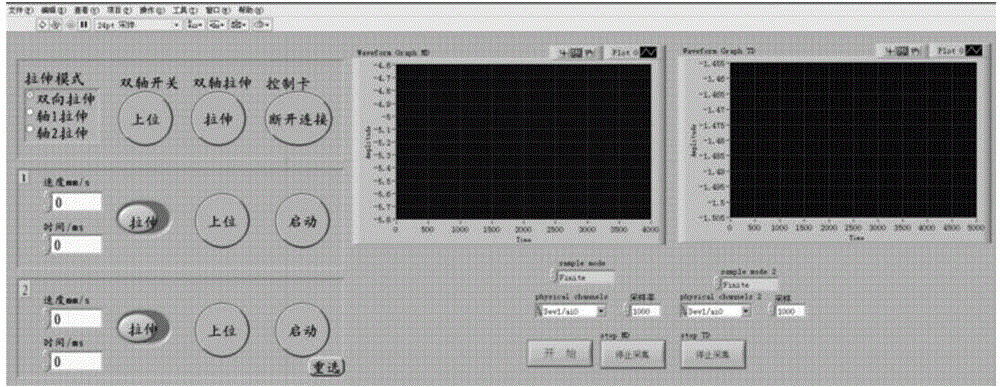

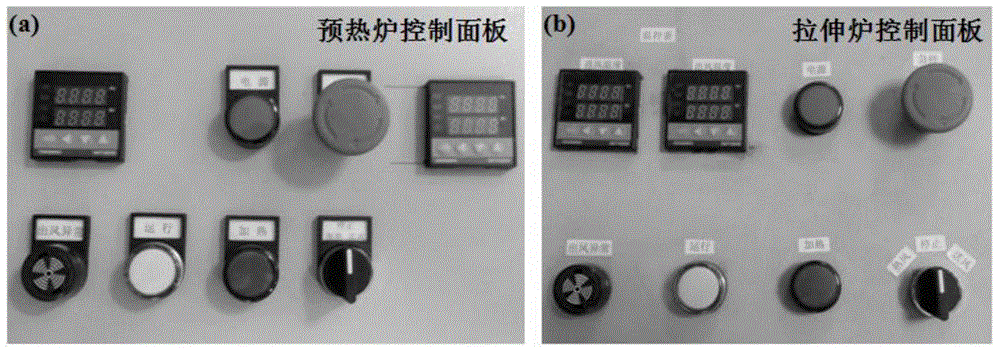

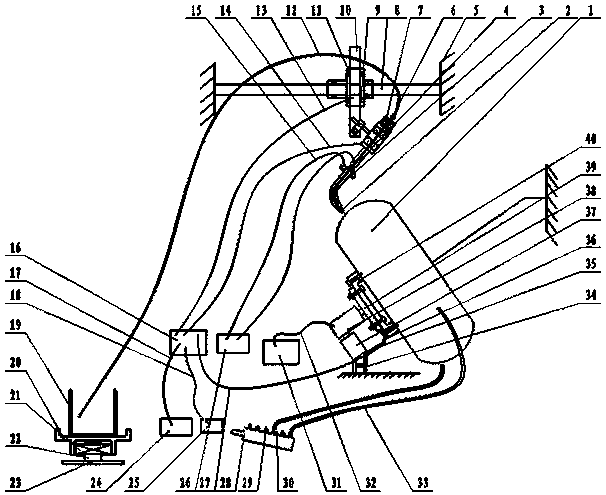

Temperature-control high-speed large-strain membrane two-way stretching device and experimental method thereof

InactiveCN104132853AAchieve stretchPlay the role of sealing cavityMaterial strength using tensile/compressive forcesTemperature controlMembrane stretch

The invention provides a temperature-control high-speed large-strain membrane two-way stretching device and an experimental method thereof. A servo motor drives four #-shaped guide rails to move, and a membrane sample is stretched through a scissors mechanism. A high-pressure pneumatic clamp quickly clamps the sample and can realize pressure compensation. Two independent temperature control furnaces are respectively used for preheating the device and stretching the sample. A hot air circulating system can be adopted to realize rapid temperature rise of the control furnaces and also can ensure the temperature uniformity of cavities. Tension sensors are respectively mounted in two stretch directions and used for collecting stress-strain information in the membrane stretching process. The servo motor drives a ball screw so as to enable a stretch part to be switched among different stations. The temperature-control high-speed large-strain membrane two-way stretching device can realize two-way synchronous stretching, two-way asynchronous stretching, limited one-way stretching and unlimited one-way stretching, thus being a good device for simulating industrial membrane stretching processing and establishing the relationship between processing parameters and the membrane structure performance.

Owner:UNIV OF SCI & TECH OF CHINA

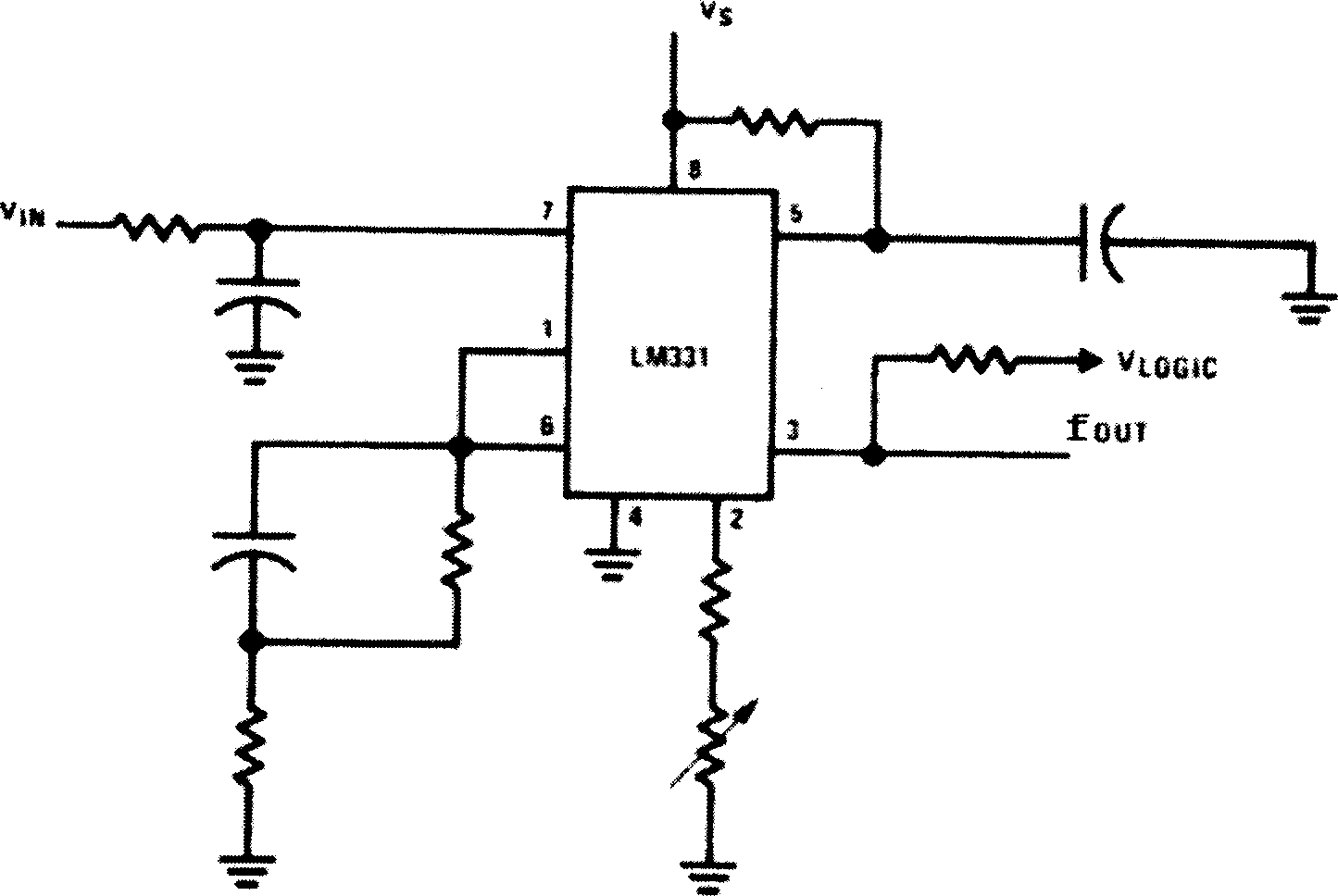

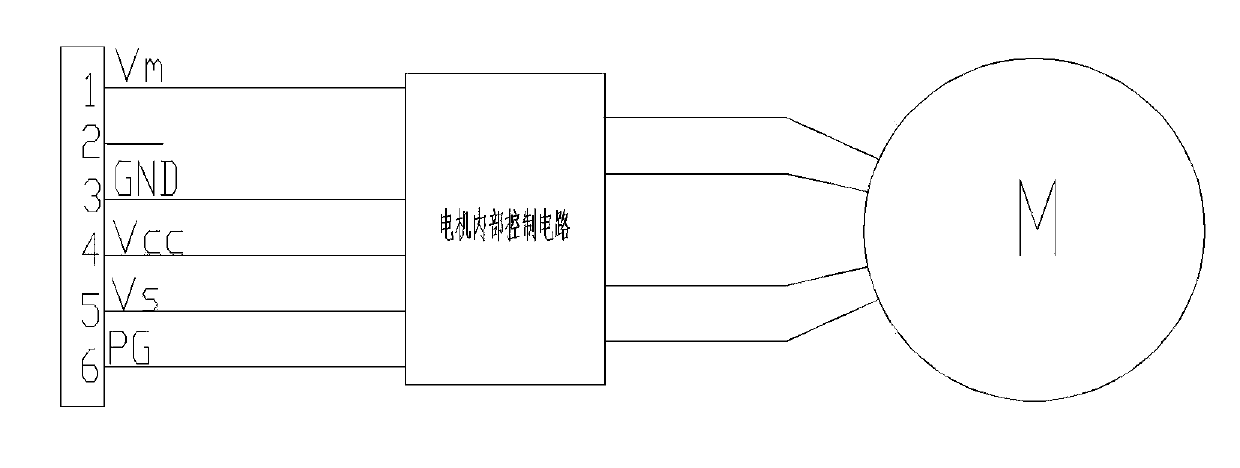

Speed regulating fan system with fault-tolerant capacity

ActiveCN1913334AReduce power consumptionReduce noiseElectric motor controlField or armature current controlElectricityControl signal

This invention relates to a fan regulation system with an error-tolerance ability including an input voltage testing circuit, a PWM circuit, a switch supply circuit and a fan set, in which, the control signal of rotation speed of the system and tested voltage signal control the output of the PWM waveforms, control the switch devices of a switch supply circuit and output a suitable voltage to the fan set, when the fan is tested to be faulty, the duty ratio of the PWm waveform can be adjusted.

Owner:ZTE CORP

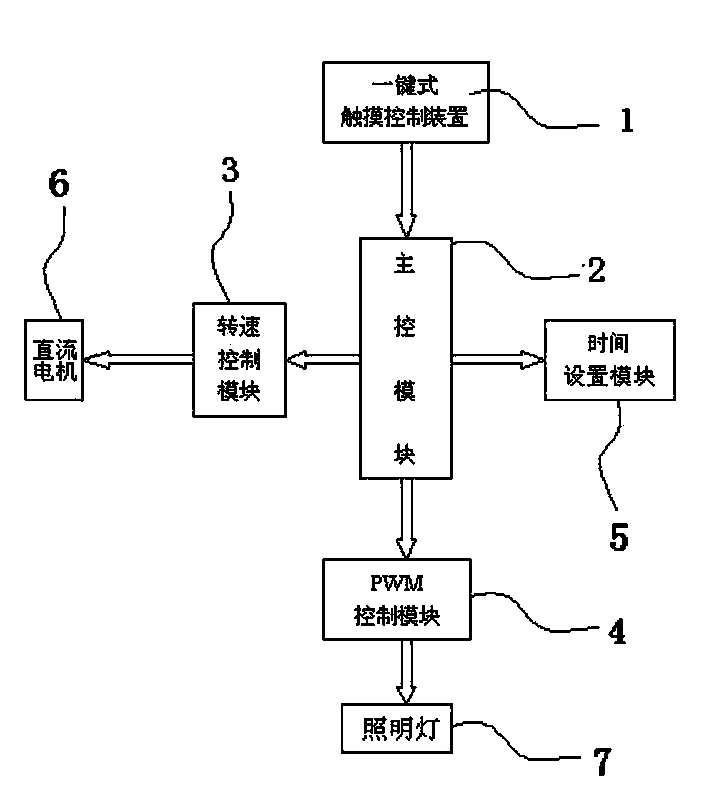

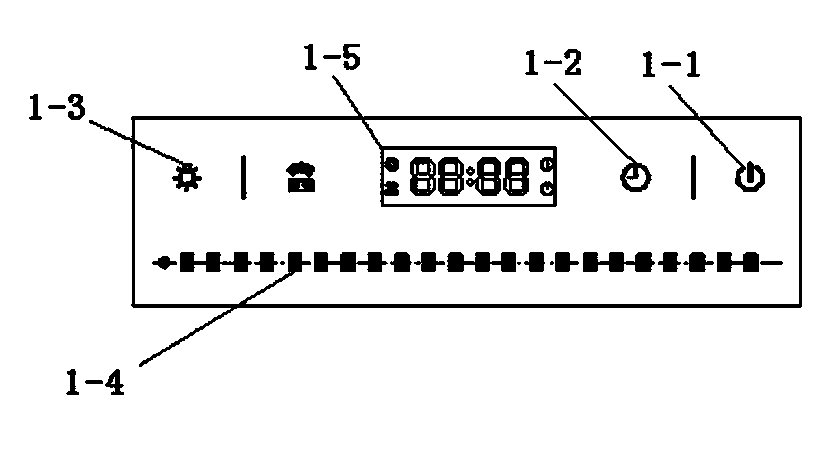

Range hood intelligent control system and one-key type range hood

InactiveCN103868119ASimple operation and controlGood practicalityDomestic stoves or rangesLighting and heating apparatusIntelligent control systemControl function

The present invention relates to the technical field of control of fume exhaust parts in household kitchen, and especially relates to a range hood intelligent control system. The system includes a one-key type touch control device, a main control module, a rotating speed control module, a PWM control module and a time setting module. The main control module is in signal connection with the one-key type touch control device, and is used for receiving operation command from the one-key type touch control device; the main control module is in control connection with the rotating speed control module, the PWM control module and the time setting module; and the rotating speed control module and the PWM control module are respectively electrically connected to a DC motor and a lighting lamp. The one-key type touch control device is provided with a switch button, a time setting button, a illumination brightness touch button, a touch sliding control strip and a display screen. Compared with the prior art, the invention has the advantages of simple structure, convenient operation, various control functions and good appearance. The invention also provides a one-key type range hood with the intelligent control system.

Owner:GUANGDONG MACRO GAS APPLIANCE

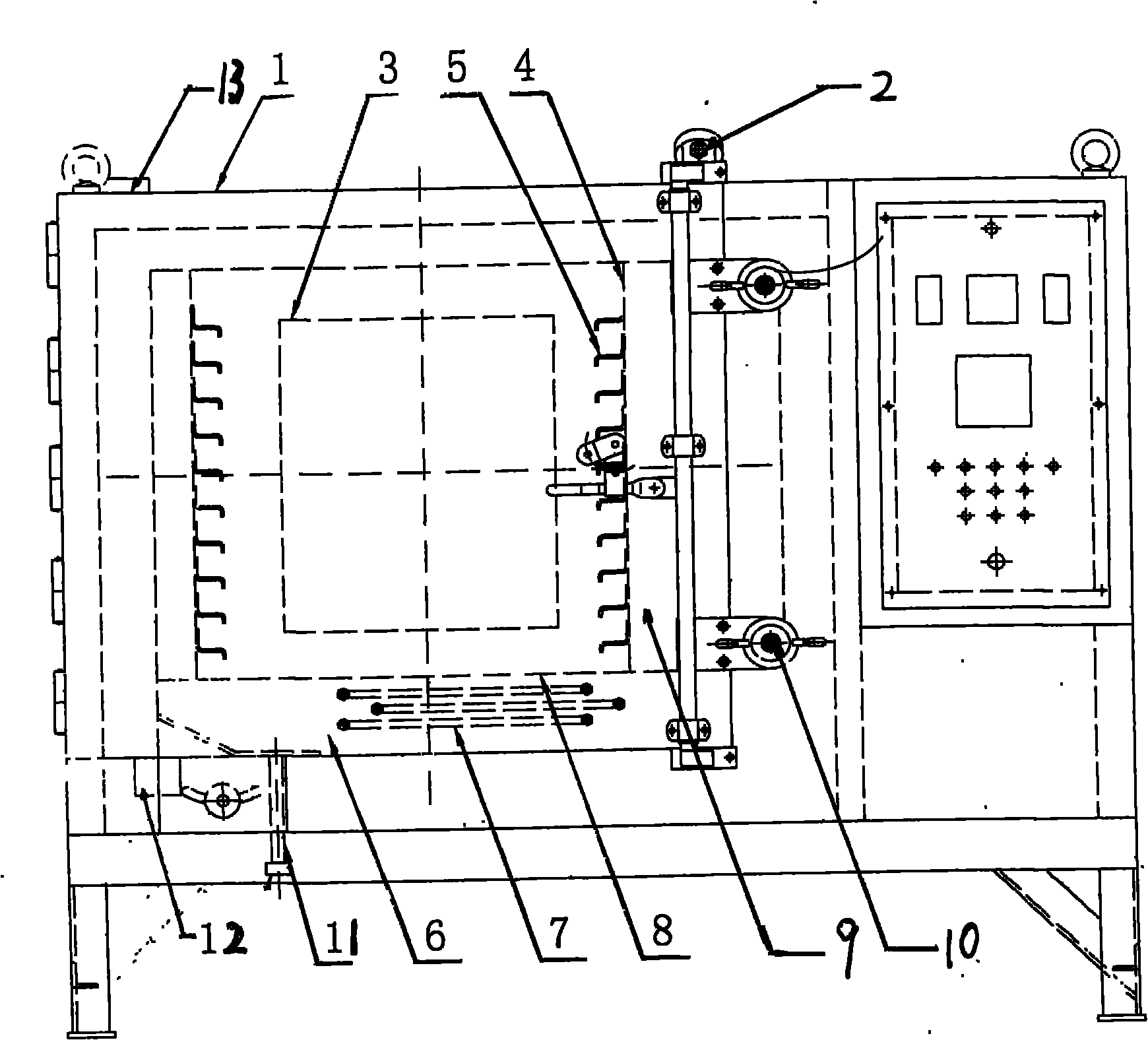

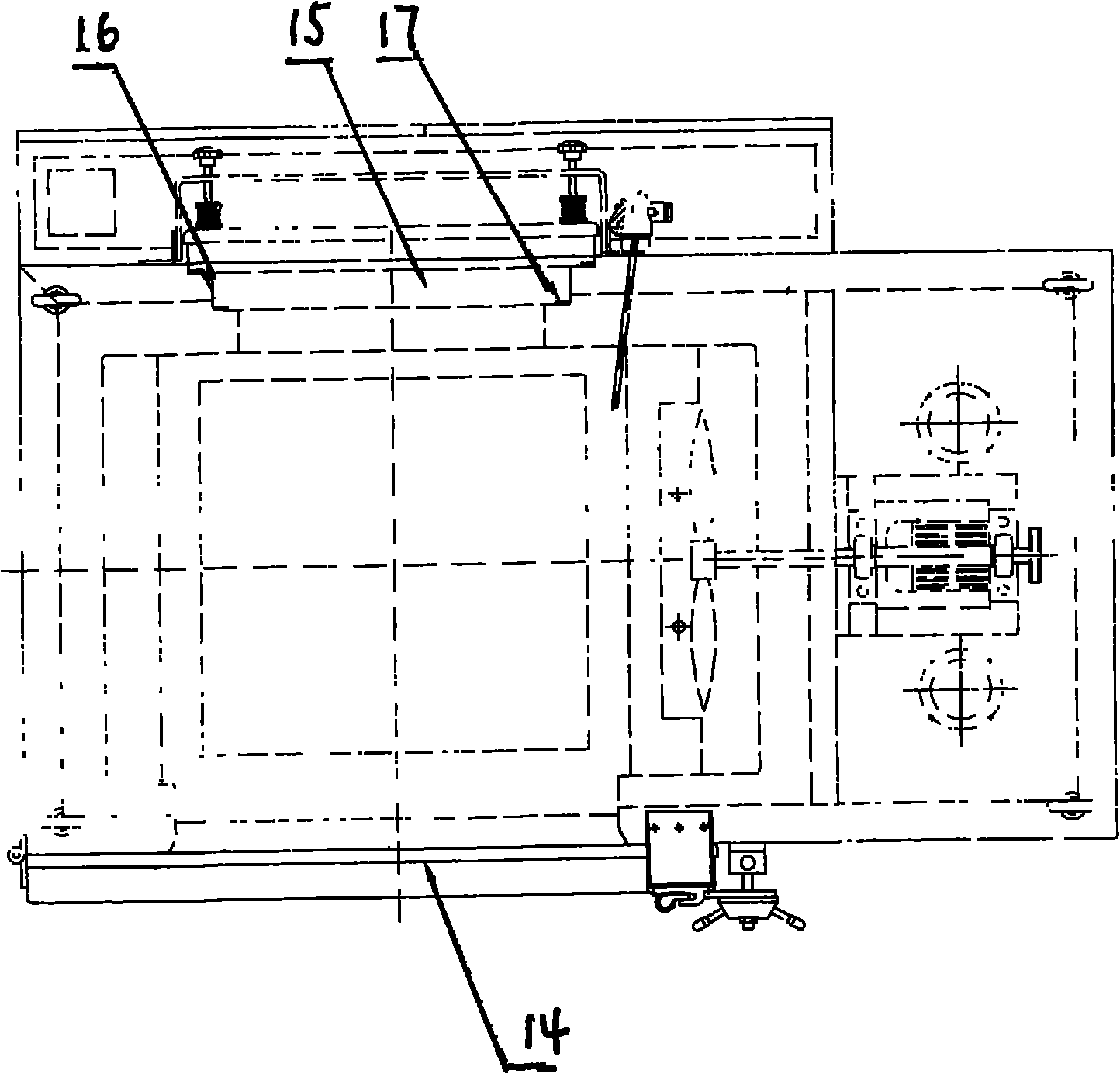

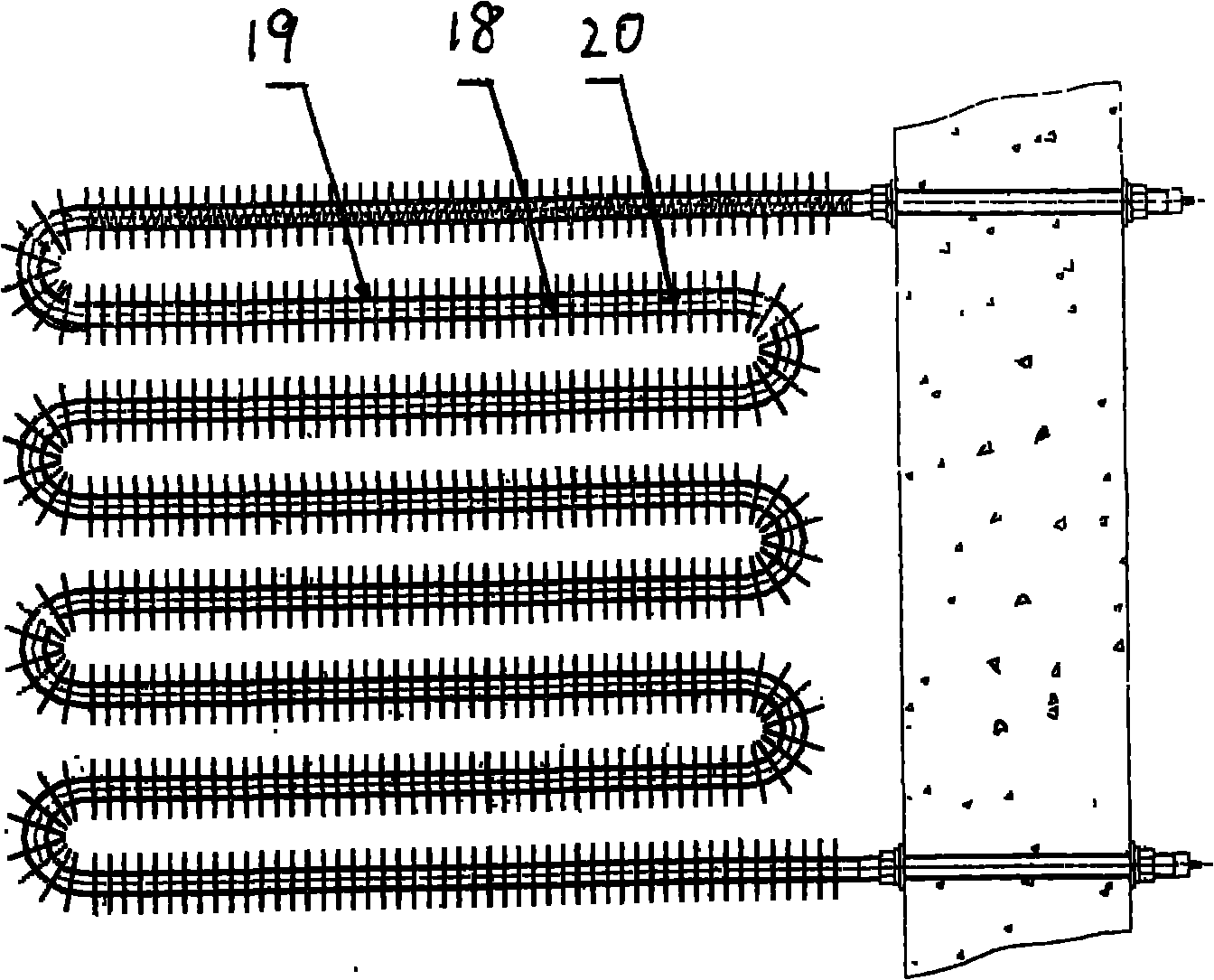

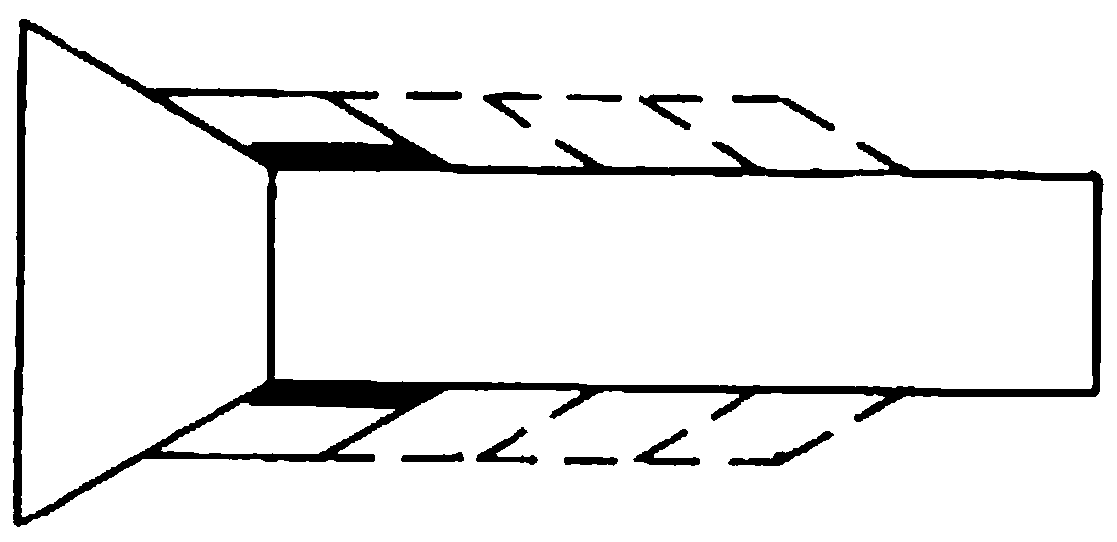

Debinding furnace

The invention discloses a debinding furnace and relates to the field of industrial furnaces, in particular to a drying debinding furnace for a ceramic ferrule for a photo-communication passive device. A hearth and a heating cavity welded by heat-resistant stainless steel plates are respectively formed in a mechanical frame; the hearth, the heating cavity, a hearth bottom plate and mesh plates on left and right sides of the hearth form an entire circulating air duct; an axial flow circulating fan is arranged inside the circulating air duct and is arranged on the right side of the hearth; and hot wind in the circulating air duct enters the hearth through the mesh plate on the right side of the hearth. The mesh plates are fixed on the left and right sides of the hearth; a slideway is fixed on a vertical steel bar of each mesh plate; the hearth bottom plate, the mesh plates on the two sides and the slideway are detachable; a hot-wind circulating system adopts an extremely-unique and timely air quantity-adjustable hot-wind circulating mode; the axial flow circulating fan regulates the speed by frequency conversion, the speed is continuously adjustable, the heat efficiency is greatly improved and the dead-space region is effectively reduced. A resistance wire has the characteristics of high material purity, stable performance, longer service life, high temperature resistance and corrosion resistance.

Owner:合肥高歌热处理应用技术有限公司

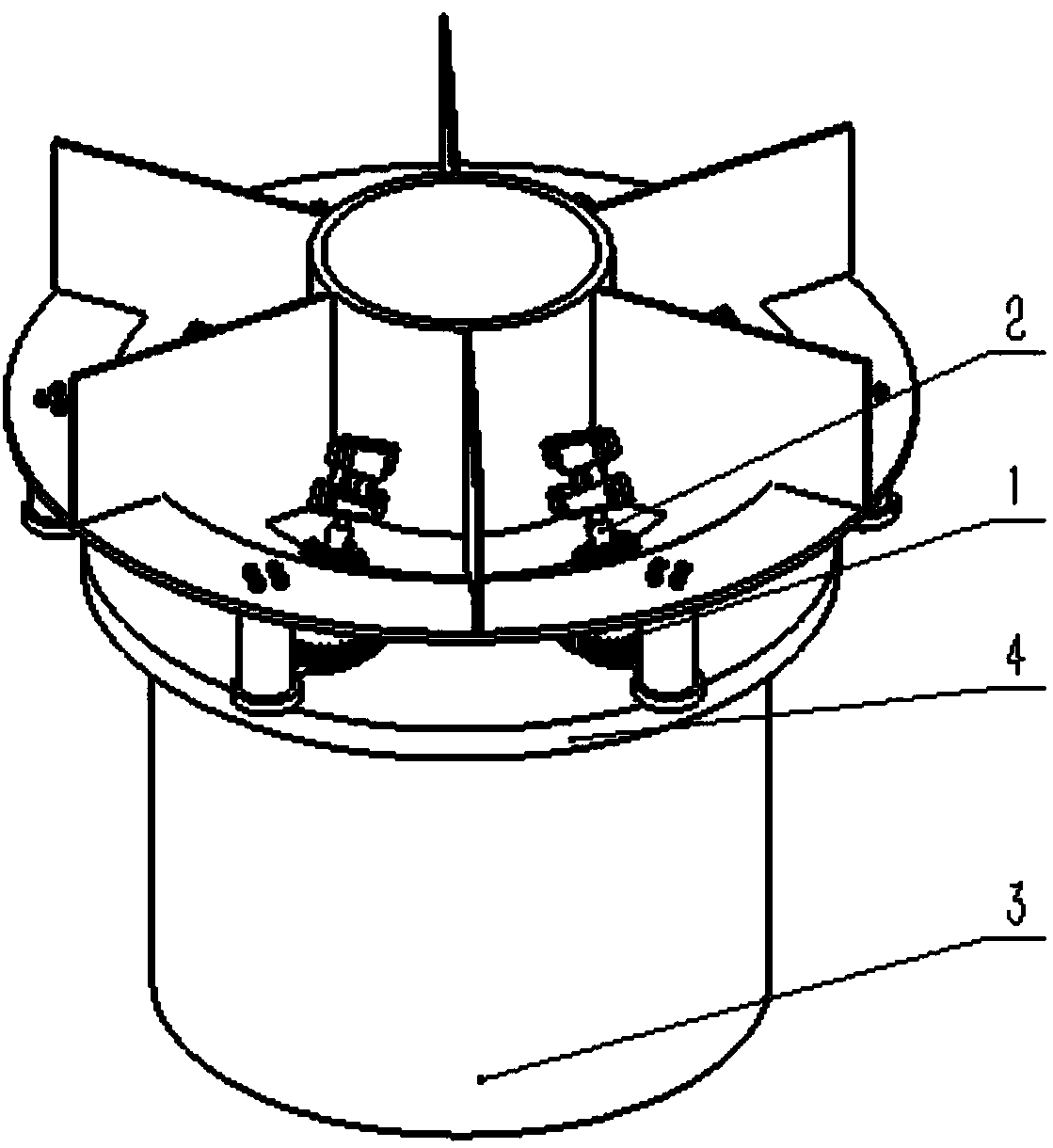

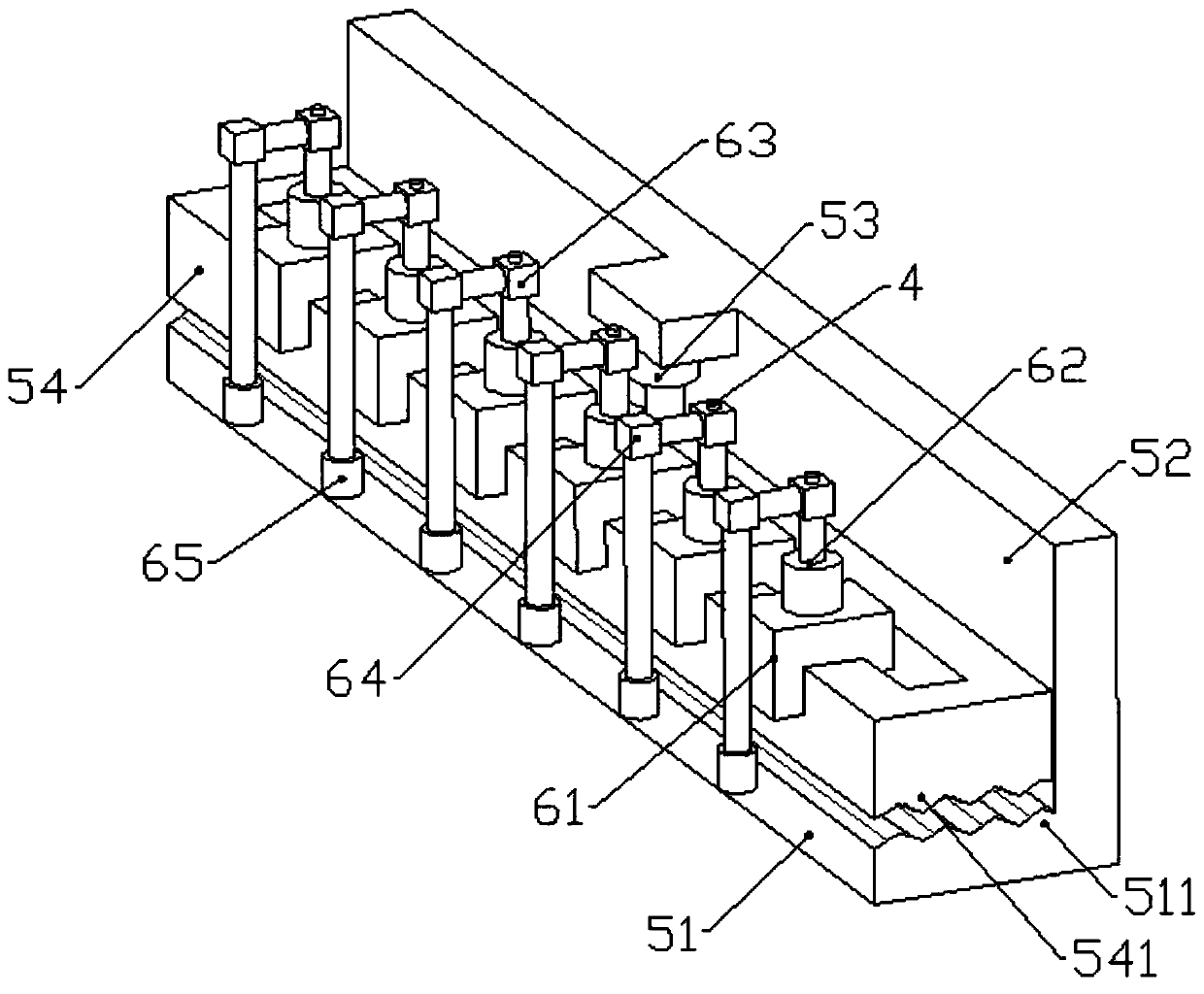

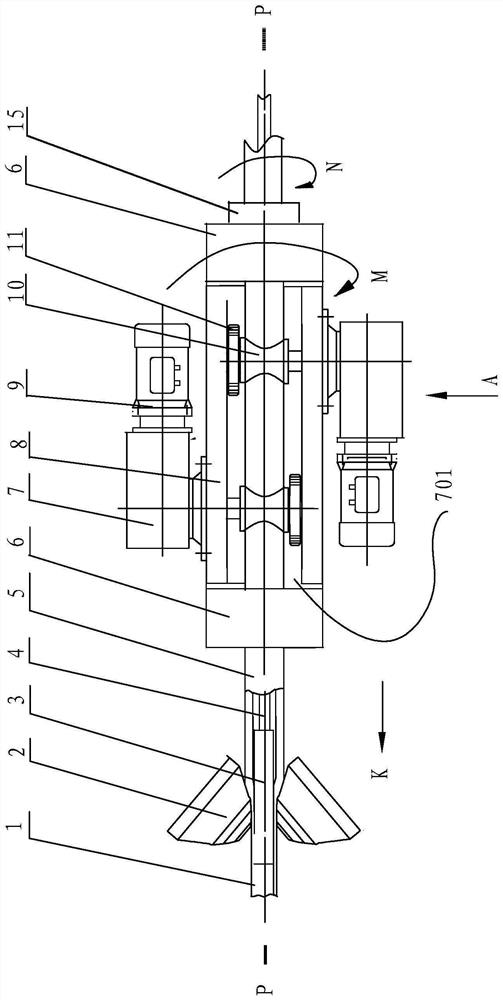

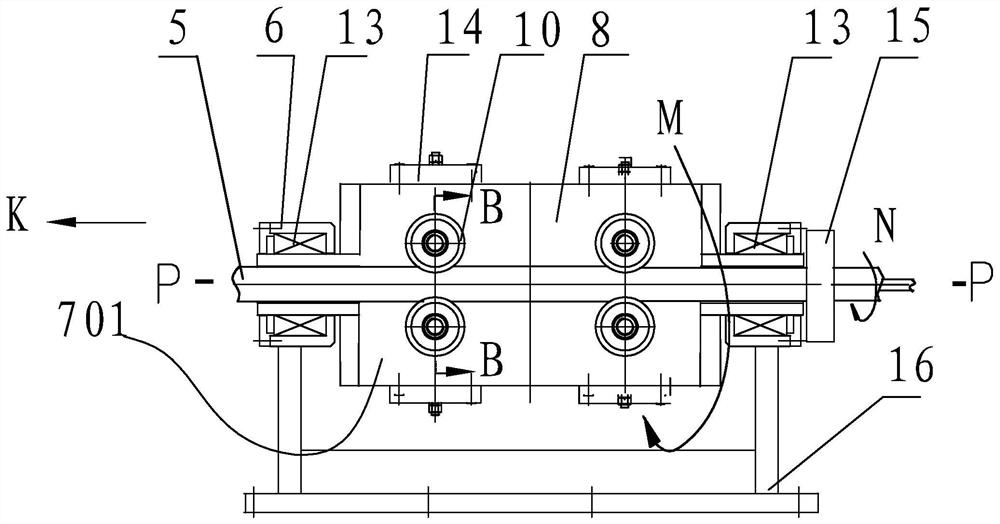

Multi-station rotating tooling device for plasma physical vapor deposition

PendingCN108531847AUniform rotation speedAdjustable rotation speedMolten spray coatingRotation functionGas phase

The invention discloses a multi-station rotating tooling device for plasma physical vapor deposition, and relates to the field of plasma spraying. The multi-station rotating tooling device consists four parts, including a revolution system, a rotation system, a control system and a supporting rack, wherein the revolution system consists of three parts, including an electric main shaft mechanism, arevolution frame mechanism and a revolution gear mechanism; the rotation system consists of two parts, including a universal joint mechanism and a rotation shaft mechanism. The device can implement single-shaft inputting and multi-shaft outputting, has revolution and rotation functions and can meet the use requirements for preparation of rotating surface coating layers of multiple rotating body parts; through the adoption of the tooling device with an angle, the spraying thickness of a workpiece is substantially improved, and uniform transition of a coating layer of a workpiece having a severely covered region or a region with a relatively large bending moment is achieved; the station setting of the device is reasonable and proper, and the mechanisms work stably and reliably; the thickness uniformity and consistency of a coating layer of a product can be strictly controlled; the multi-station rotating tooling device is particularly applicable to preparation of a coating layer on the surface of a turbine blade of a gas turbine engine; the production efficiency and the productivity are improved.

Owner:BEIJING GOLDEN WHEEL SPECIAL MACHINE +1

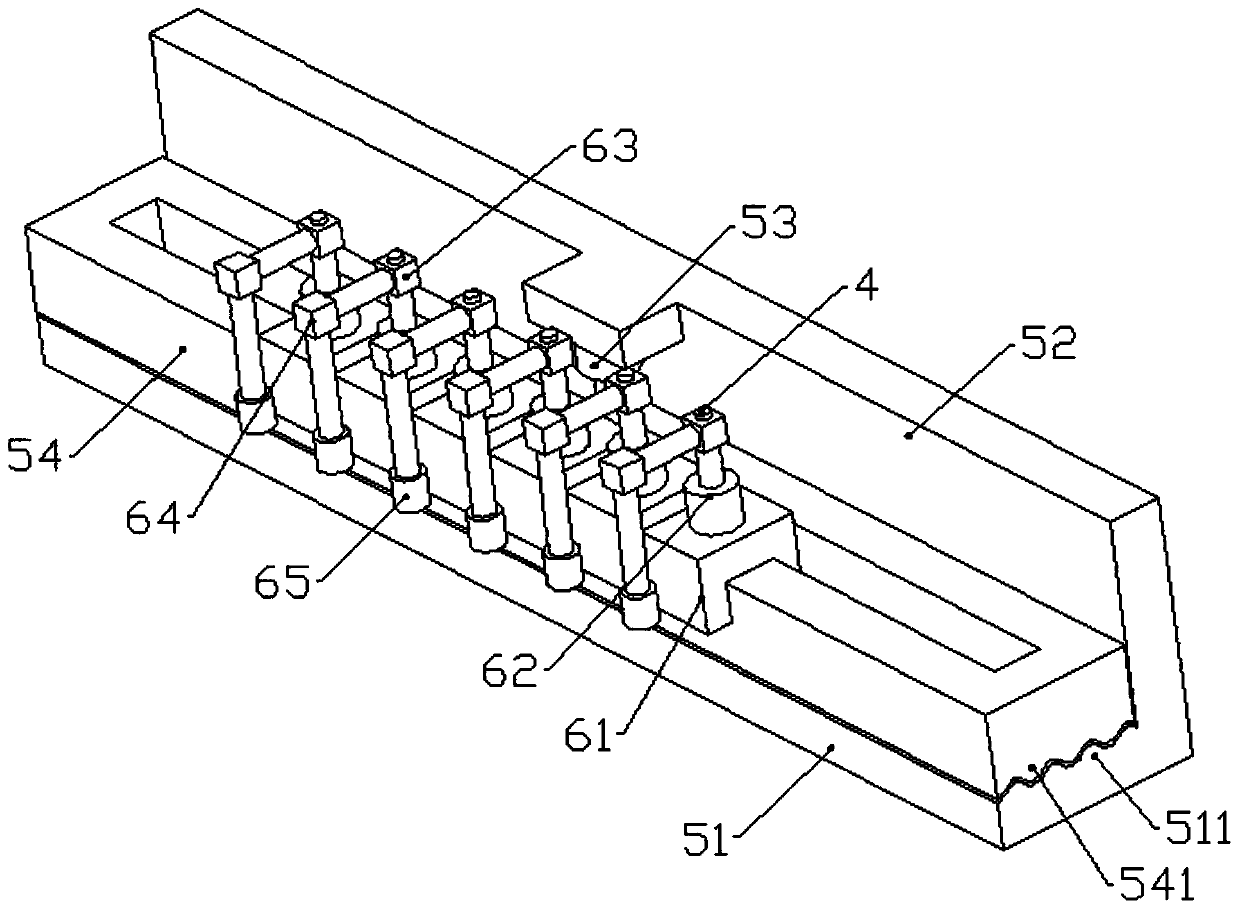

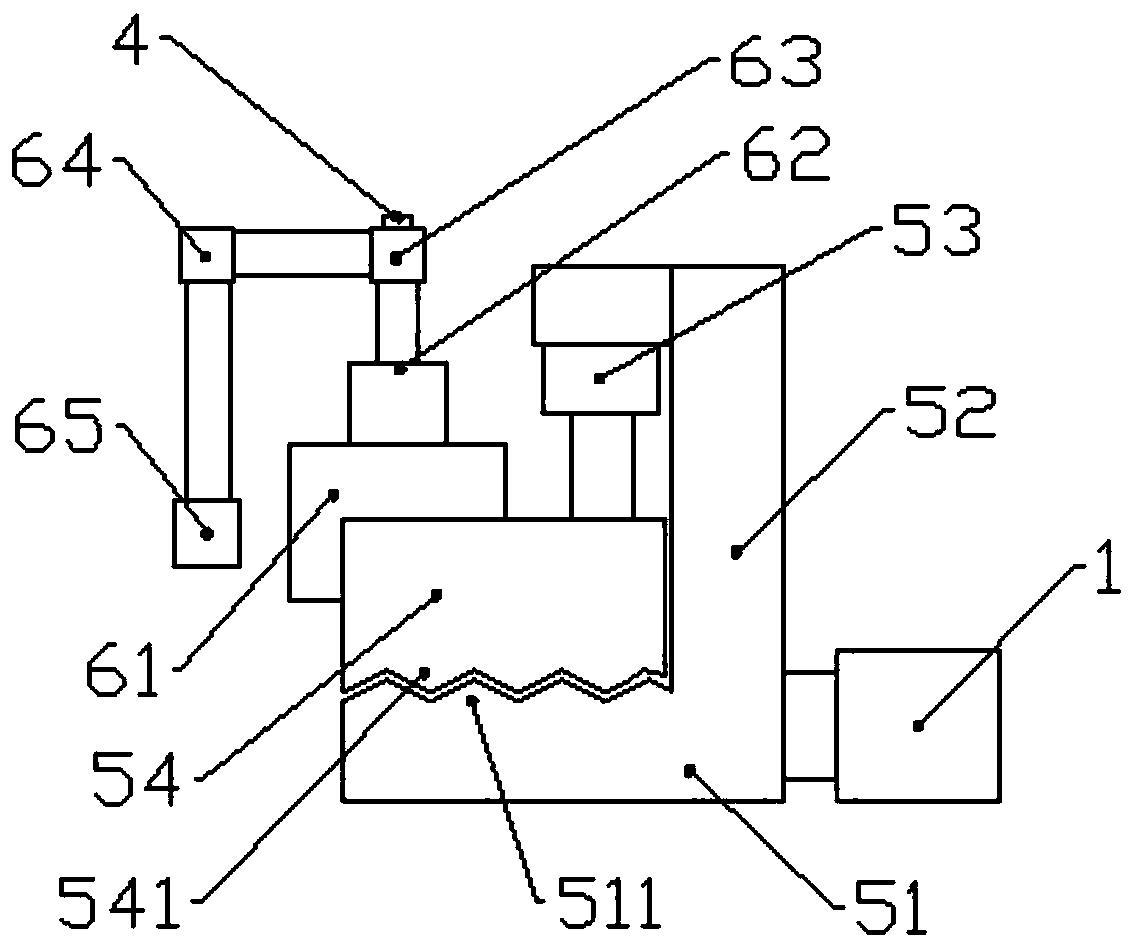

Film bidirectional accurate stretching device

InactiveCN110480996AAvoid the disadvantages of uneven thicknessGuaranteed stretching effectEngineering

Owner:合肥蒲亮科技有限公司

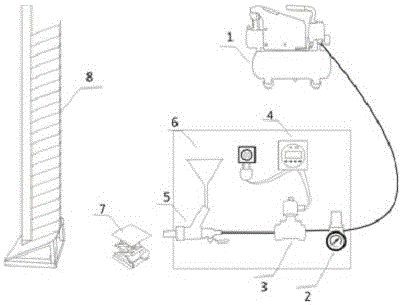

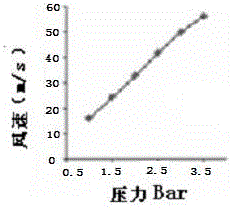

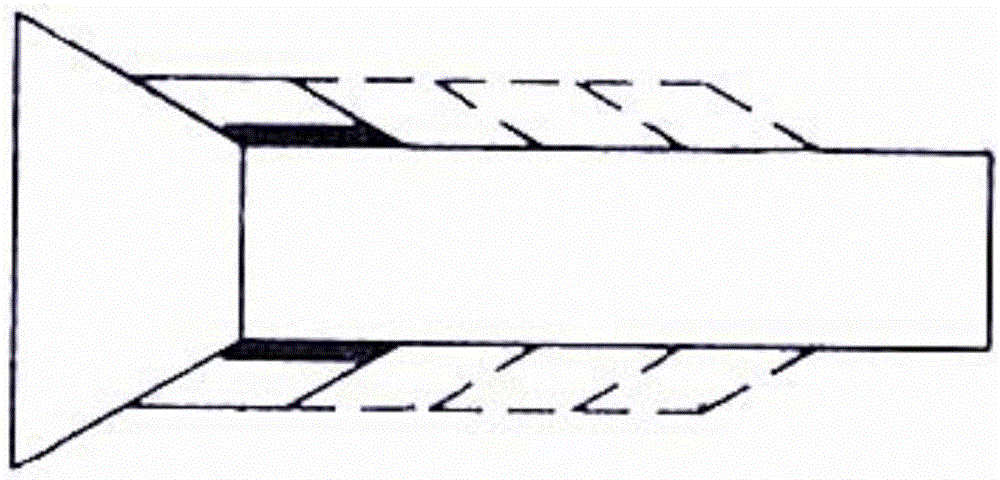

High speed dust storm saltation test observation system

InactiveCN105758610AContinuously adjustable speedAccurate jump observationAerodynamic testingSediment transportEngineering

The invention relates to a high speed dust storm saltation test observation system, characterized in that a pressure regulating valve, an electromagnetic switch valve, a time control switch, a sand blasting gun and a sand supply device are commonly fixed on a work panel; a power device is successively in connection with the pressure regulating valve, the electromagnetic switch valve and the sand blasting gun through a flexible pipe; the time control switch is in connection with a power supply, and is respectively in connection with the power supply and the electromagnetic switch valve through leads; the sand port of the sand supply device is in connection with the sand supply device; a test platform is located between a saltation dust collector and the sand blasting gun. The system can simulate continuously adjustable stable wind conditions with a wind speed greater than 150 m / s, and accurately control wind speed and effect time, and has the characteristics of convenient operation, easy control, portable equipment, simple disassembly and convenient transfer; the system is suitable for test observation such as dust storm saltation observation, wind speed wind pressure, wind erosion and polishing, sediment transport, etc. under heavy wind conditions, and microscopic research such as particle speed, concentration, etc., and provides basic test equipment for dust storm motion rules and process research under special conditions.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

Control method of sectional warping machine

ActiveCN107523914APrecise positioningPrecise shiftWarping machinesTextiles and paperYarn tensionPosition control

The invention relates to a control method of a sectional warping machine. The method comprises the steps that a positioning control module, a speed control module and a tension control module are included, the positioning control module detects position information of a shaft through a shaft encoder on a drum shaft, and a central controller controls the rotation speed of a control servo motor according to the position information; the speed control module detects speed information through a thickness measuring sensor and the shaft encoder, the linear speed of warping is calculated according to the speed information, the linear speed is compared with a preset linear speed, and according to a numerical value obtained after comparison, the rotating speed of a direct-current drum motor is controller by triggering a pulse module. According to the method, accurate positioning and displacement and automatic adjustment of speed and tension can be achieved, fluctuation of yarn tension is lowered, and the phenomenon that due to the fact that warp yarns are mutually wound into knots and the pressure is unbalanced, the yarn quality is affected is avoided.

Owner:江西诚鑫实业有限公司

Method for continuously rolling copper pipe through planetary pipe mill

PendingCN114054506AEnough feed forceNo feeding synchronization issuesMetal rolling arrangementsFeeding forceControl theory

The invention relates to a method for continuously rolling a copper pipe through a planetary pipe mill, which is characterized in that a roller type feeder or a crawler type feeder is arranged at an inlet of a three-roller planetary pipe mill and is driven by a pipe blank rolled by the three-roller planetary pipe mill to be in a passive rotating state; the roller type feeder or the crawler type feeder passively rotates and continuously provides a feeding force for the pipe blanks at the same time, and the pipe blanks are continuously fed into the three-roller planetary pipe mill one by one in an end-to-end connection mode to be rolled. By the adoption of the technical scheme, the structure is simple, reliable and practical, the requirement for continuously rolling copper pipes is met, the defects in the prior art are overcome, and production efficiency is improved.

Owner:JIANGSU XINGRONG HI TECH

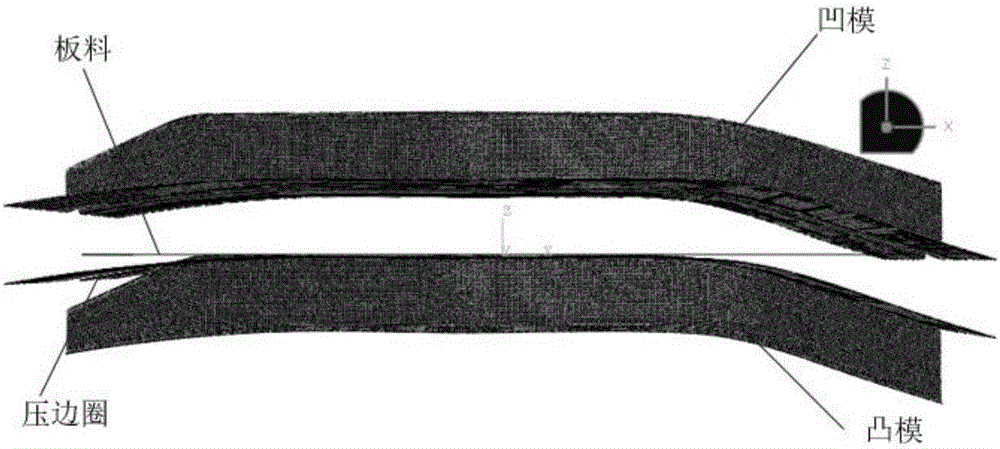

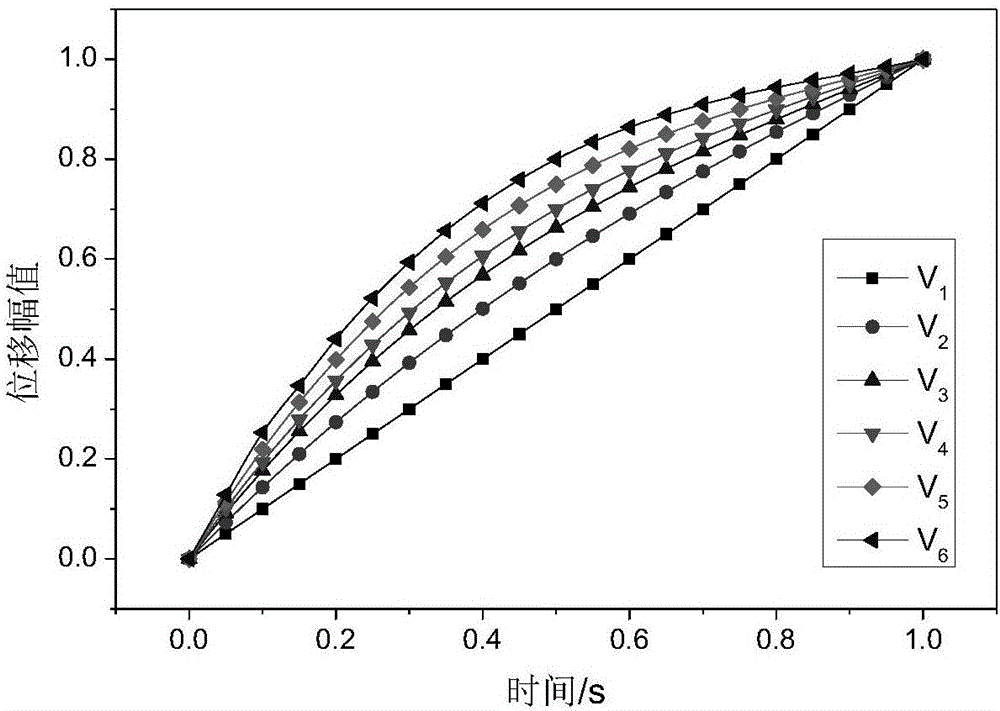

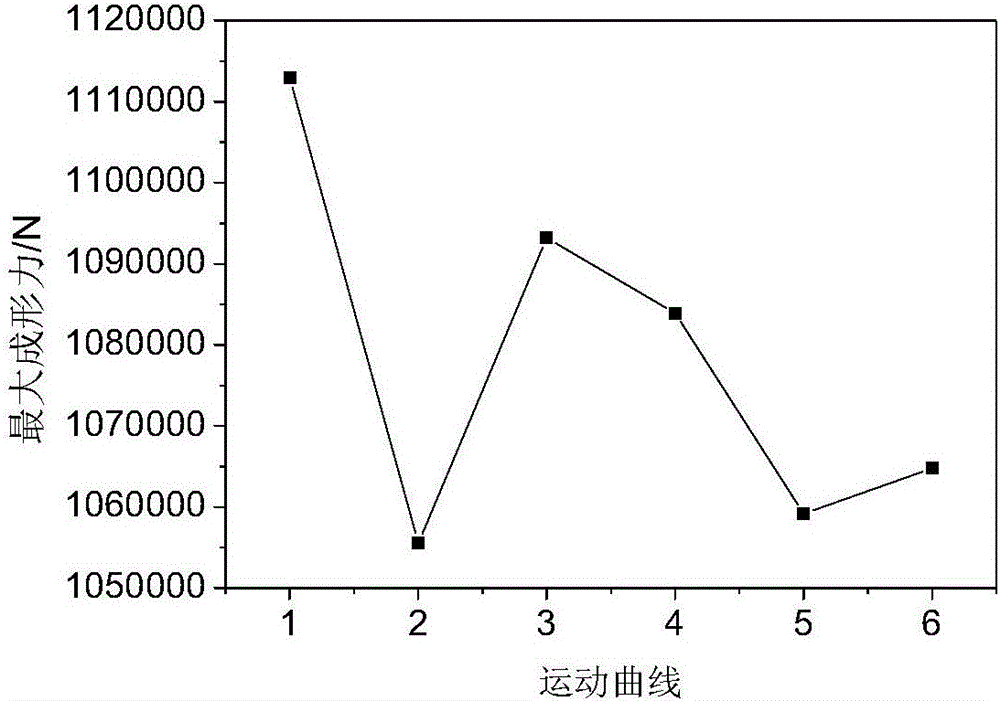

Servo stamping speed control method based on jerking movement degree

ActiveCN106739128AImprove forming qualityExtend your lifePressesFinite element analysis softwareFinite element analyse

The invention discloses a servo stamping speed control method based on a jerking movement degree. The method comprises the following steps of S1, building a three-dimensional model of a component to be stamped and introducing the model into finite element analysis software; S2, setting a material parameter, a boundary condition and a contact condition, and dividing grids; S3, setting a displacement amplitude mathematical expression to be X=At3+Bt2+Ct+D, and determining an initial value range of A to be 0 to 1, the initial value range of B to be 0 to -3, the initial value range of C to be 1 to 3, and the initial value of D to be 0; S4, selecting different values within the initial value ranges of A, B and V to set different displacement amplitude curves, and submitting for computation; and S5, extracting data from computation results for comparative analysis, and determining the optimized value ranges of A, B and C. According to the method provided by the invention, the displacement, speed, acceleration jerking movement degree can be continuously adjustable, and shaping quality of the complex components and the components difficult to shape is enhanced.

Owner:WUHAN UNIV OF TECH

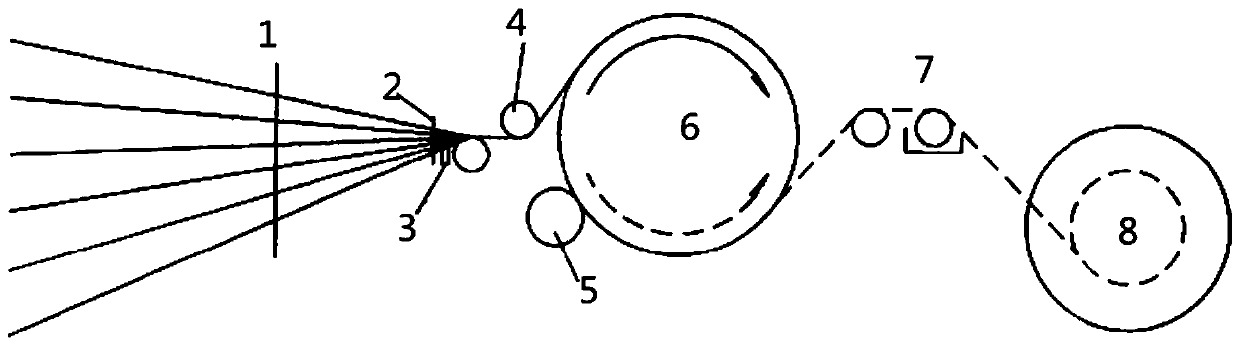

Speed simulator of train

ActiveCN101966852AContinuously adjustable speedGuaranteed uptimeVehicle route interaction devicesElectric machineSpeed test

The invention provides a speed simulator of a train, which comprises a bracket, a motor, a protective cover, a rotating disk, a flange, a speedometer and two shielding sheets, wherein the protective cover is horizontally arranged on the upper part of the bracket; the motor is arranged on the lower part of the bracket; an output shaft of the motor is vertically connected with the middle part of the rotating disk through the flange; the rotating disk is horizontally arranged in the protective cover; the two shielding sheets are symmetrically arranged on the lower side of the rotating disk; and the speedometer is arranged on the rotating disk and the protective cover. The invention provides a device for simulating the train to pass through a magnetic head in a speed of 0 to 350 km / h, which ensures that a quantitative test of the speed of the magnetic head in axle counter equipment is realized; the train speed simulated by the device is continuous and adjustable; the device can safely and stably simulate the constant speed running of the train at any speed point in 0 to 350 km / h; and the difficulty that the speed test of the magnetic head in the axle counter equipment in railway cannot be carried out is solved.

Owner:HENAN SPLENDOR SCI & TECH

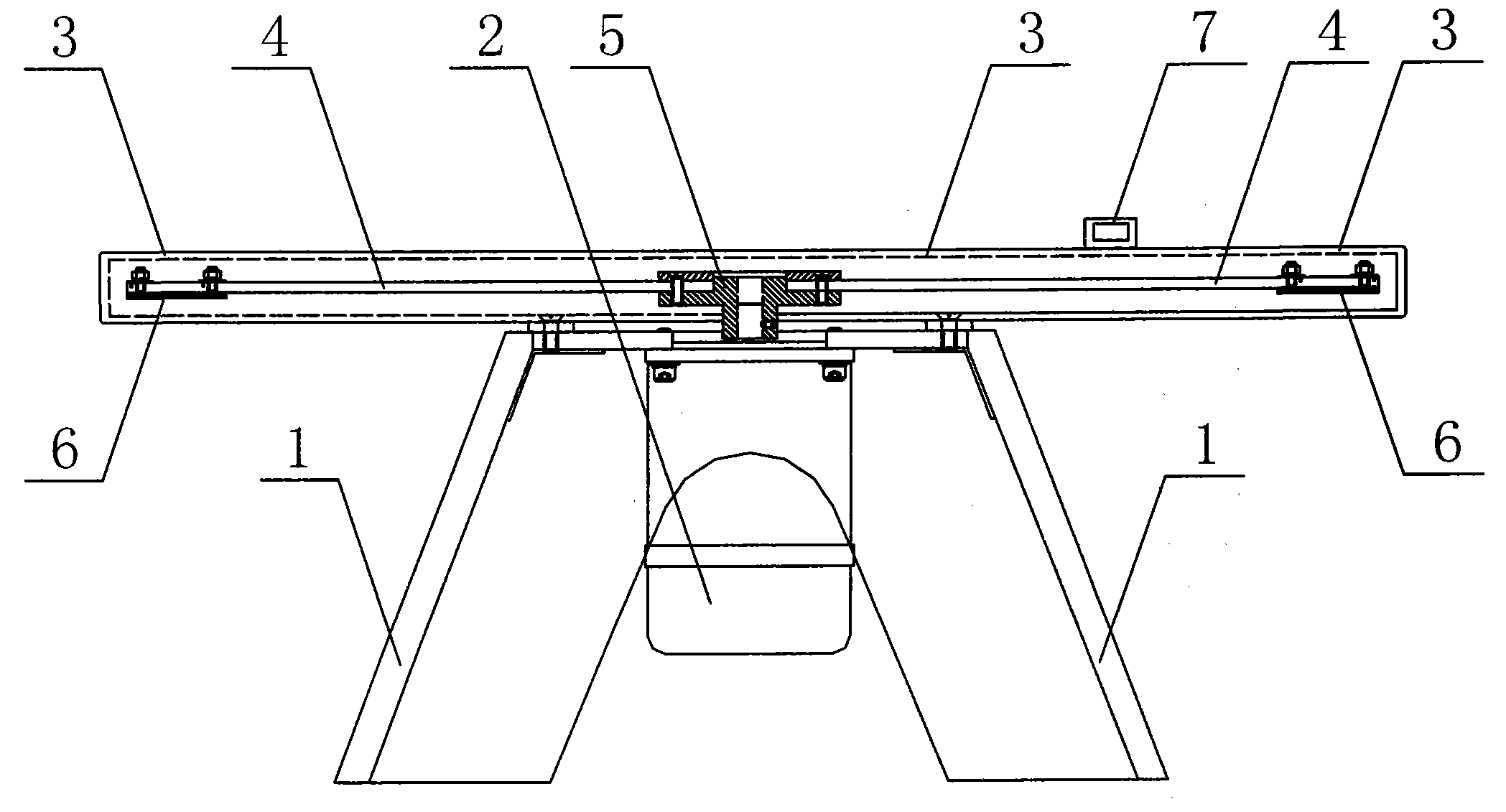

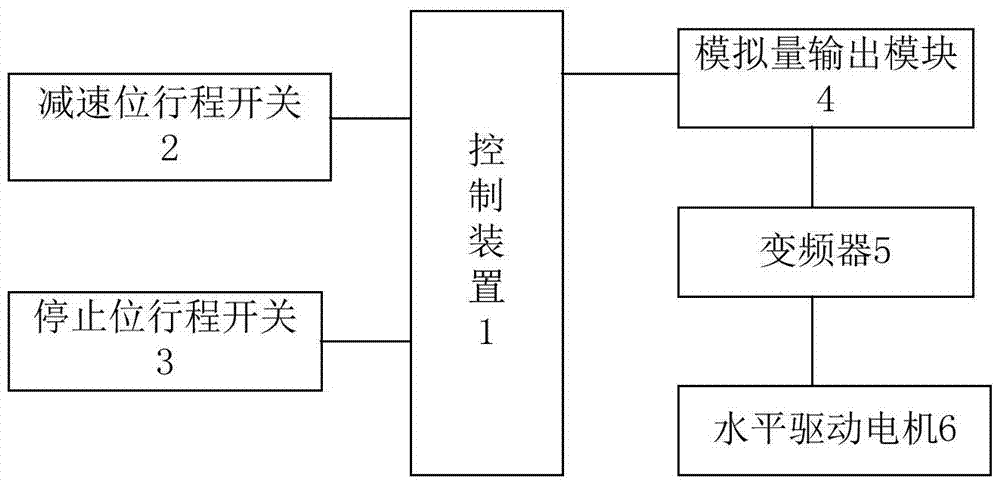

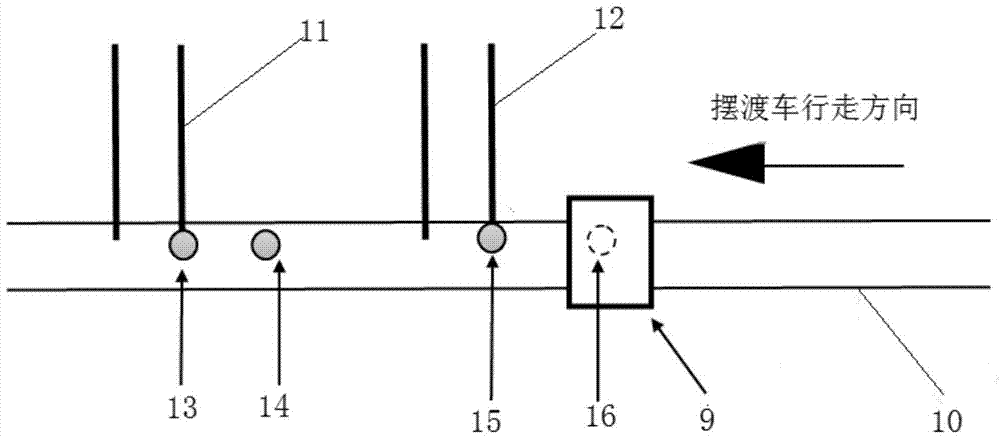

A Material Transportation Control System for a Curing Kiln

ActiveCN105173608BContinuously adjustable speedHigh degree of automationControl devices for conveyorsMechanical conveyorsAutomatic controlControl system

The invention discloses a material transportation control system of a curing kiln. The material transportation control system comprises a control device, a speed reduction position travel switch, a stop position travel switch and a horizontal drive motor. When receiving the signal which is sent by the speed reduction position travel switch and indicates that a ferry vehicle is detected, the control device controls the horizontal drive motor to reduce the rotation speed; when receiving the signal which is sent by the stop position travel switch and indicates that the ferry vehicle is detected, the control device controls the horizontal drive motor to stop rotating, and therefore the ferry vehicle can be aligned to a curing kiln chamber in the curing kiln. According to the invention, detection switches are installed at the positions needing speed reduction or stop, the ferry vehicle is automatically controlled to reduce the speed or stop when the switches sense that the ferry vehicle reaches the positions, the speed of the ferry vehicle can be regulated continuously, and therefore the ferry vehicle can be accurately aligned to a curing kiln rail when stopping. The automation degree is improved, and the production efficiency is improved.

Owner:ZHUO DA NEW MATERIAL TECH GRP

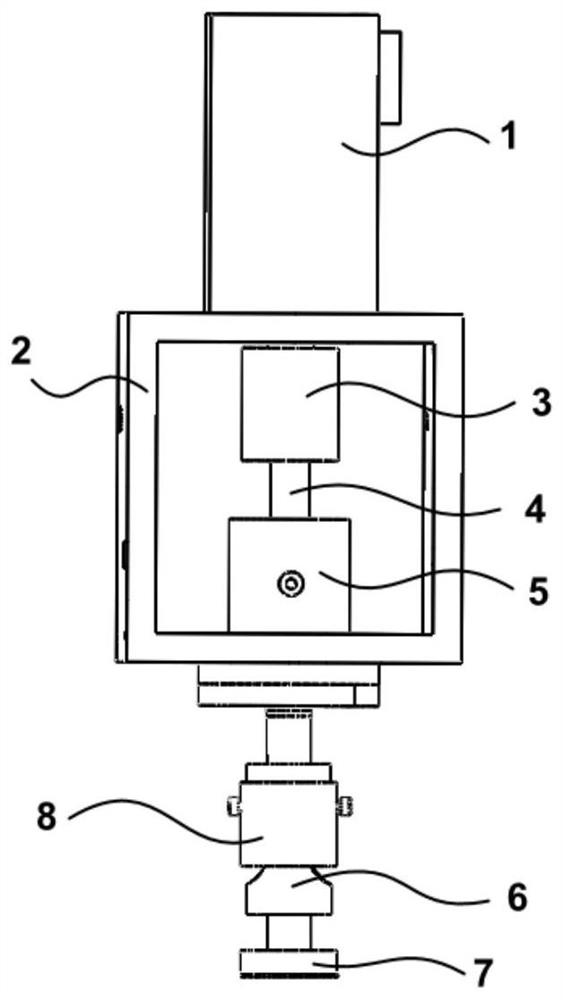

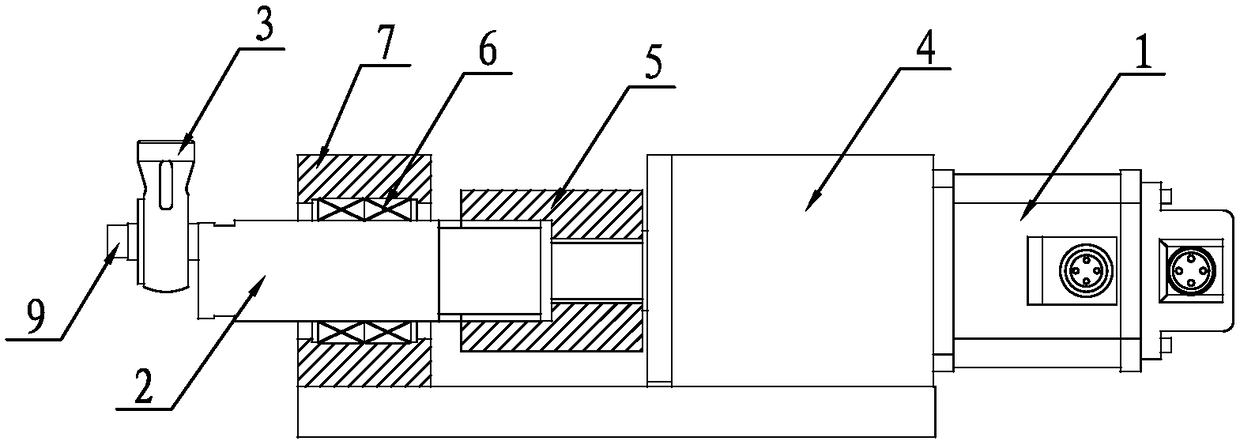

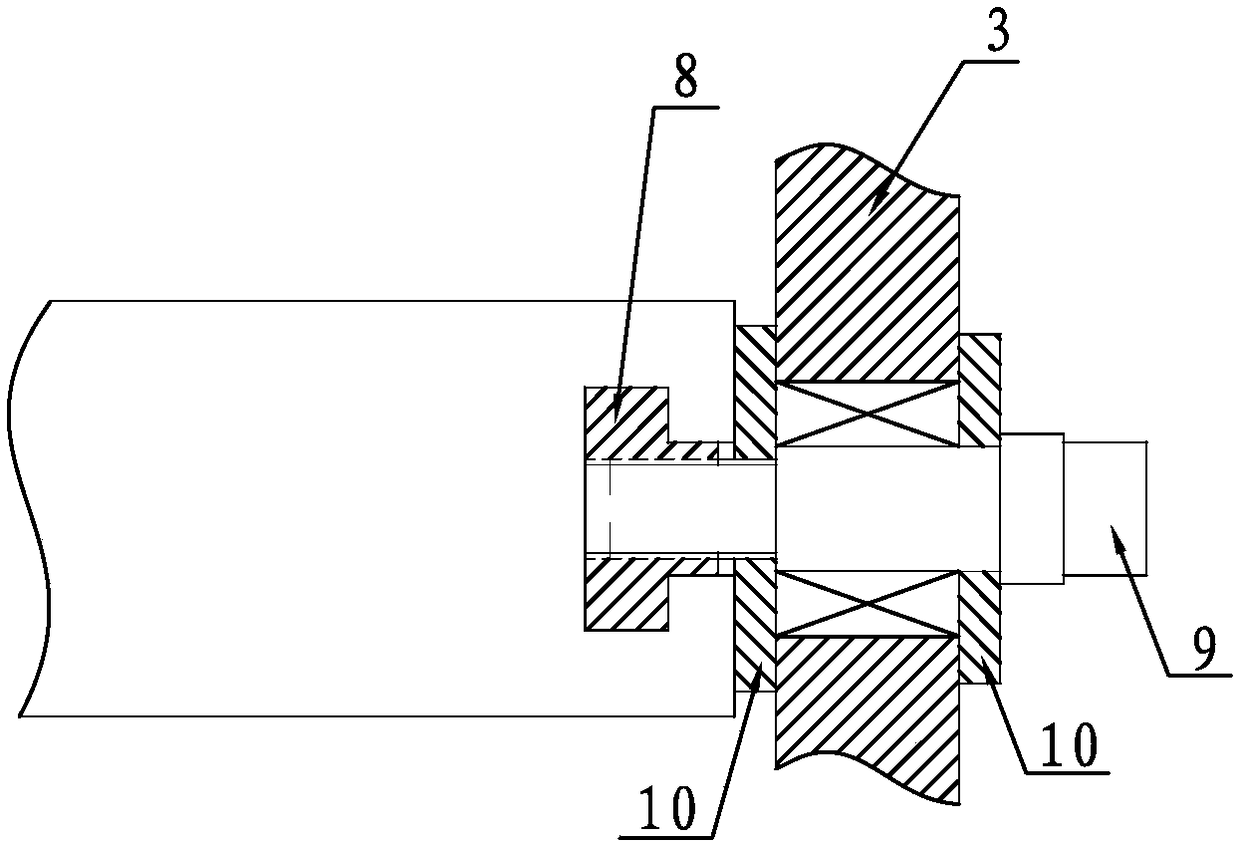

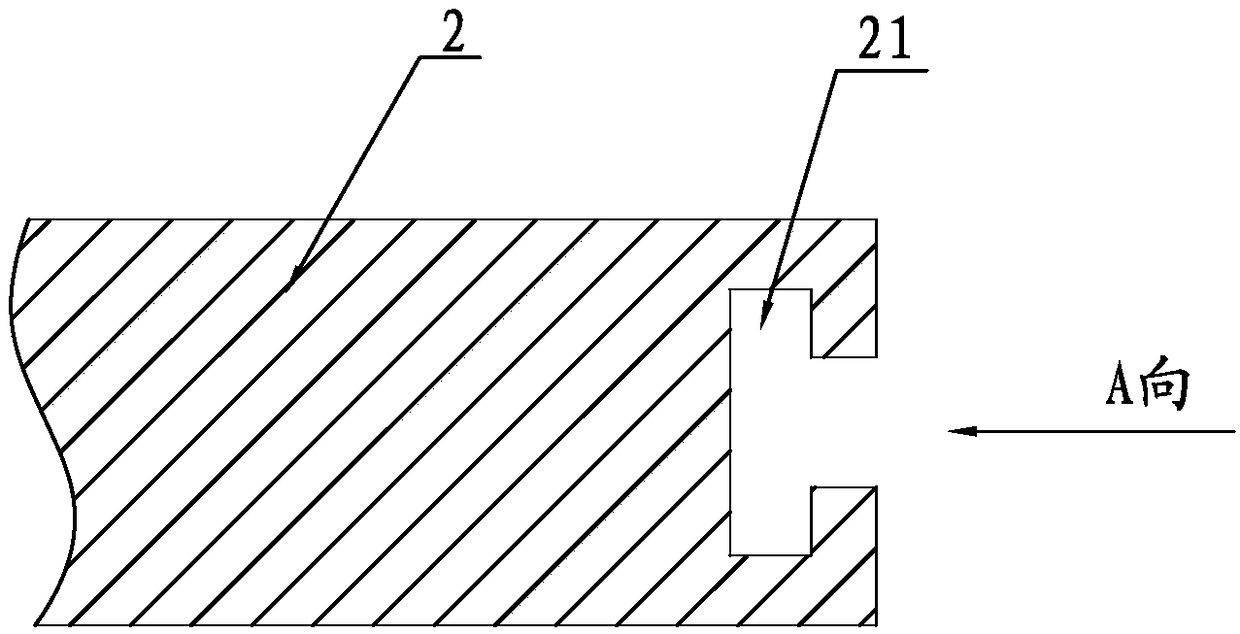

Optical element grinding and polishing device and machining method

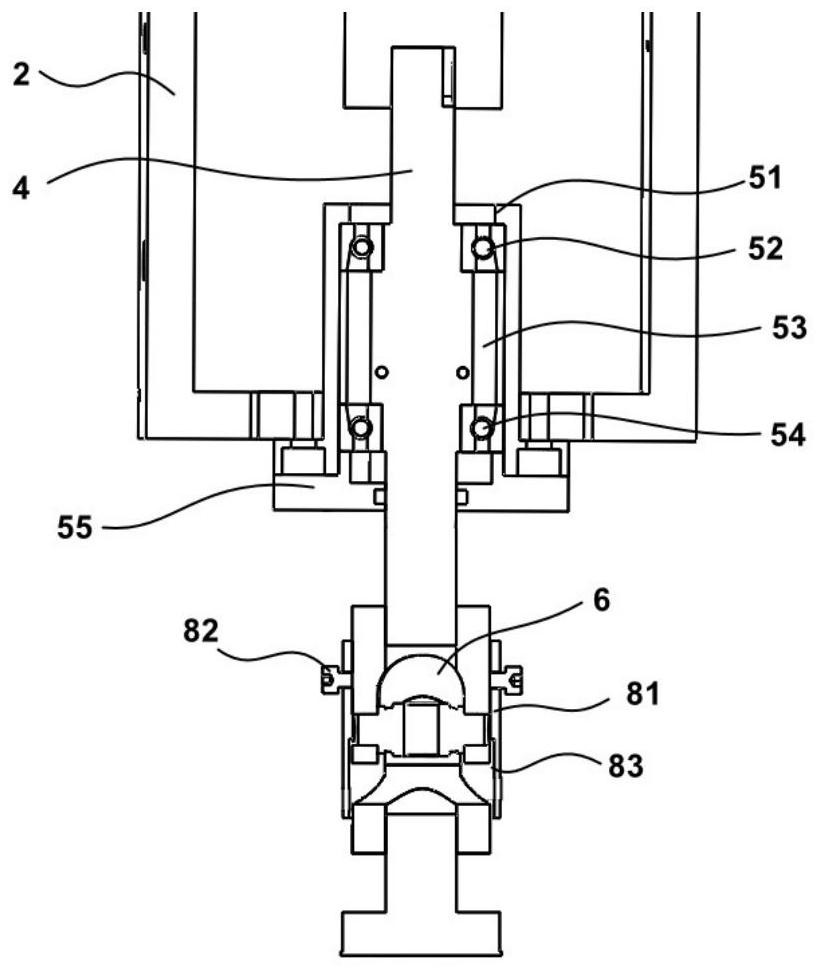

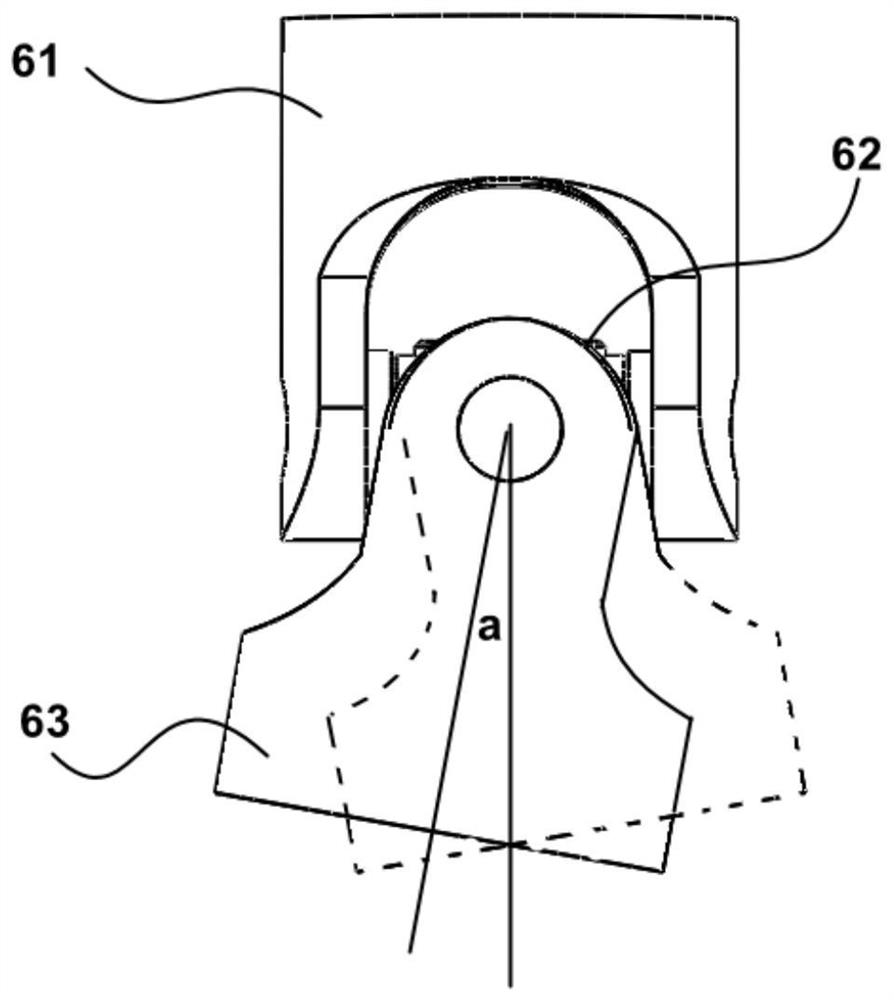

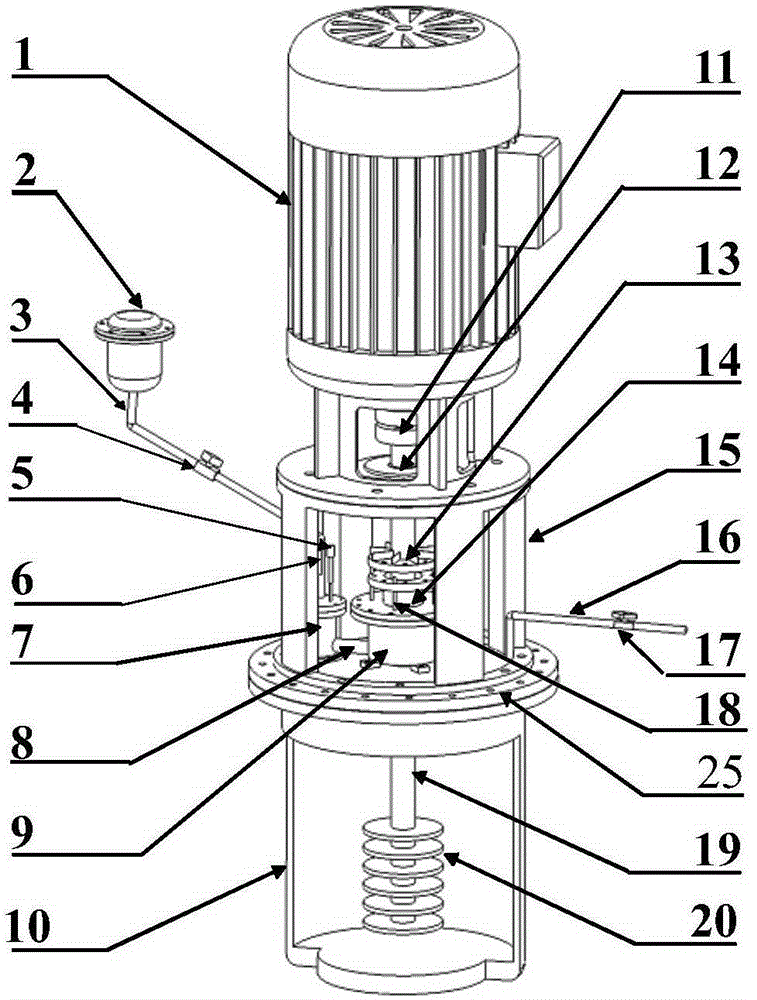

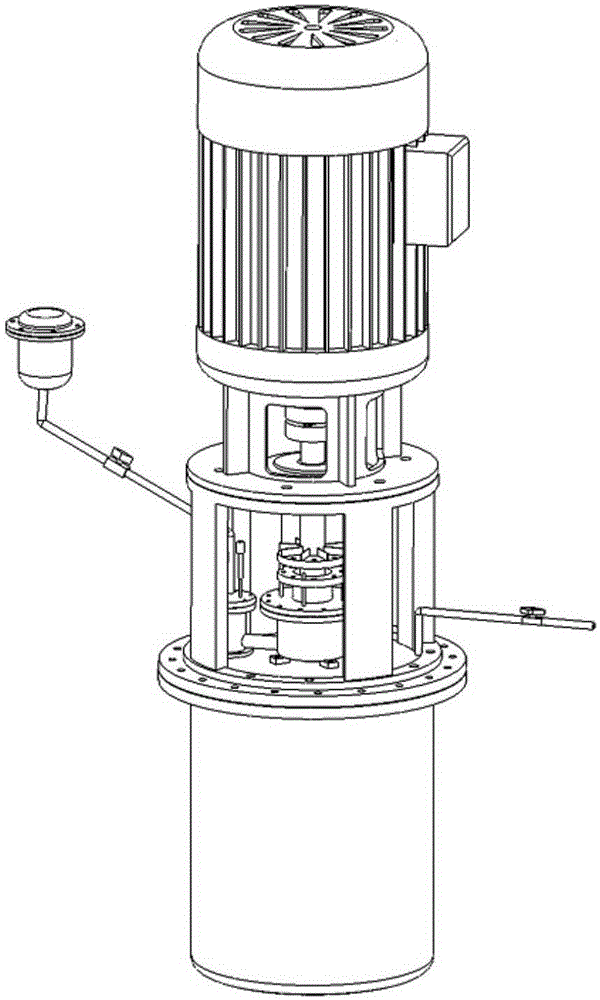

PendingCN113953932APrecise deliveryThe removal function is stableGrinding machine componentsOptical surface grinding machinesUniversal jointPolishing

The invention discloses an optical element grinding and polishing device and a machining method. The grinding and polishing device comprises a driving motor, a support, a coupler, a center rotating shaft, a rotating mechanism, a universal joint and a grinding and polishing tool from top to bottom. The device has the characteristics of being simple in structure, flexible to install and convenient to operate, the grinding and polishing tool makes contact with the surface of an optical element all the time in the lifting and descending process of the grinding and polishing tool, a grinding and polishing tool shaft is perpendicular to the surface of the optical element all the time, precise transmission of rotating speed loads is guaranteed, the removal amount of grinding and polishing materials of the optical element is precisely controlled, the grinding and polishing surface shape is stable, and the machining efficiency is improved.

Owner:恒迈光学精密机械(杭州)有限公司

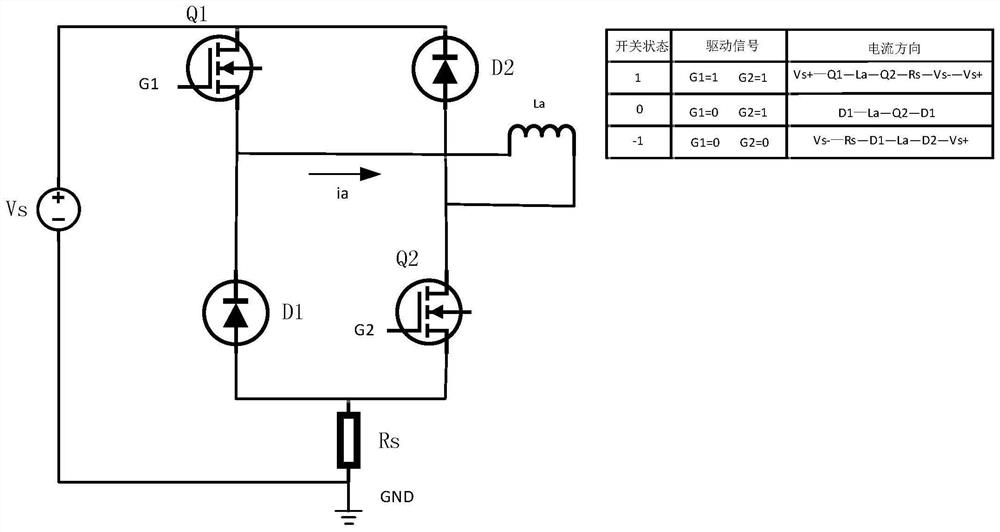

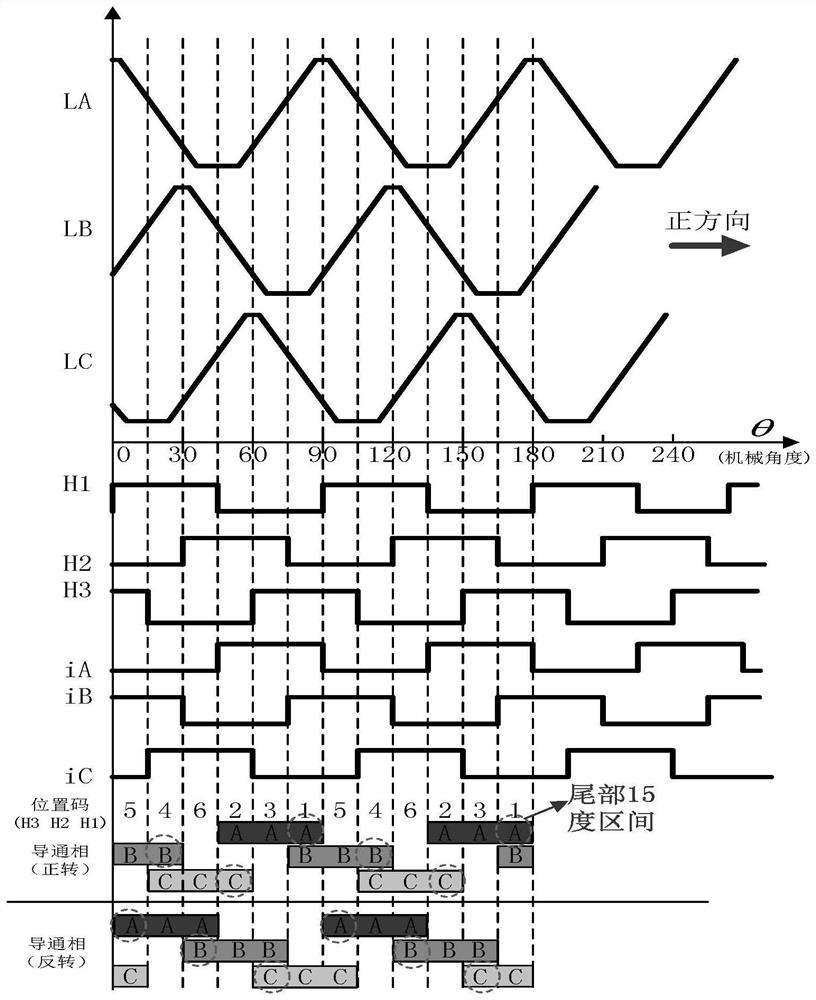

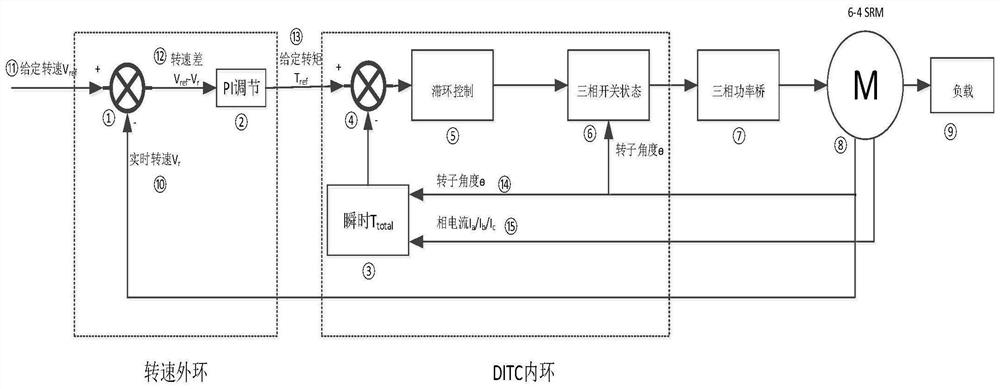

Noise reduction control method and system for switched reluctance motor

PendingCN114826037AEasy maintenanceImprove general performanceTorque ripple controlAC motor controlCommutation torque rippleElectric machinery

The invention discloses a switched reluctance motor noise reduction control method and system, and the method comprises the steps: controlling the operation of a switched reluctance motor through adjusting a commutation angle and voltage; a mode of combining torque control and commutation control of the switched reluctance motor is adopted, and the switch excitation state of each phase of the switched reluctance motor is dynamically adjusted by controlling the total torque output by the switched reluctance motor in real time; the dynamically adjusted commutation torque ripple of each phase switch is reduced, and the air noise and mechanical vibration of the operation of the switched reluctance motor are reduced accordingly, so that the total torque ripple is in a preset range. According to the scheme, the torque control characteristic of the switched reluctance motor is optimized aiming at the inherent commutation torque pulsation problem of the switched reluctance motor, so that the air noise of the operation of the switched reluctance motor is reduced, and the high-frequency mechanical jitter of the operation of the switched reluctance motor is reduced.

Owner:甄鹏 +1

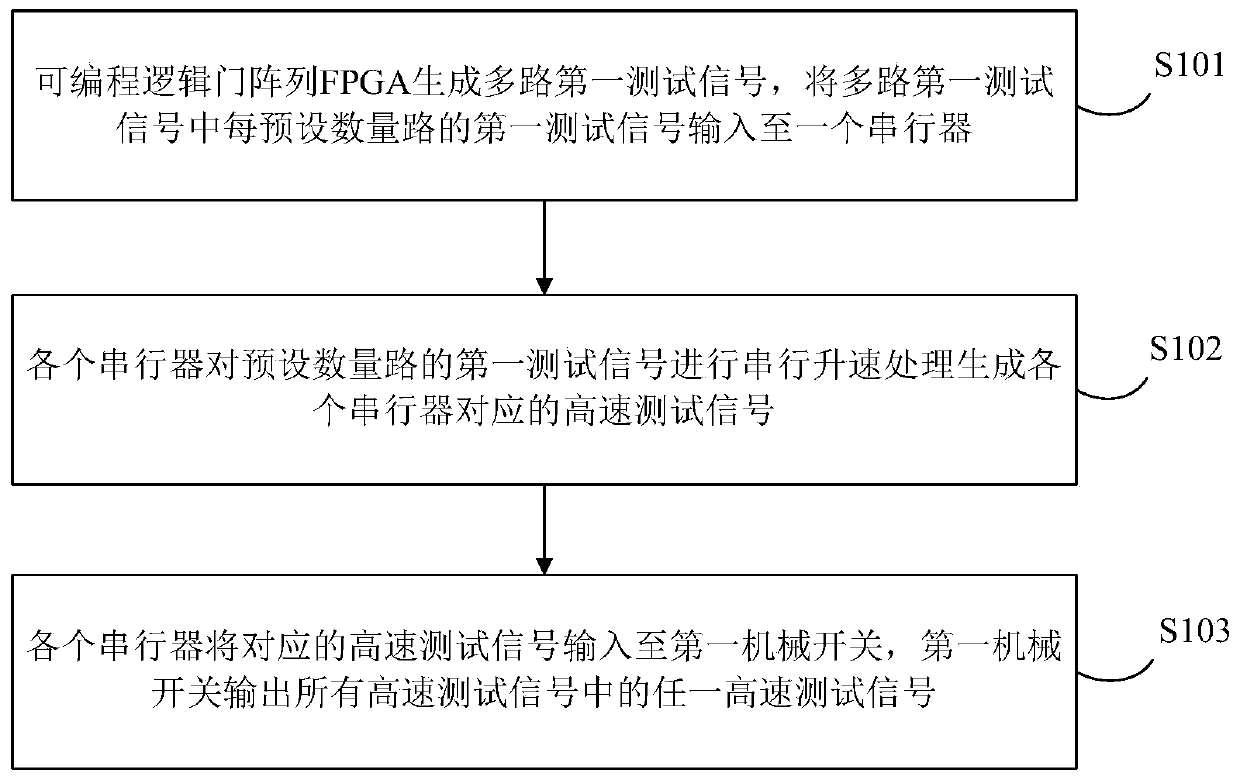

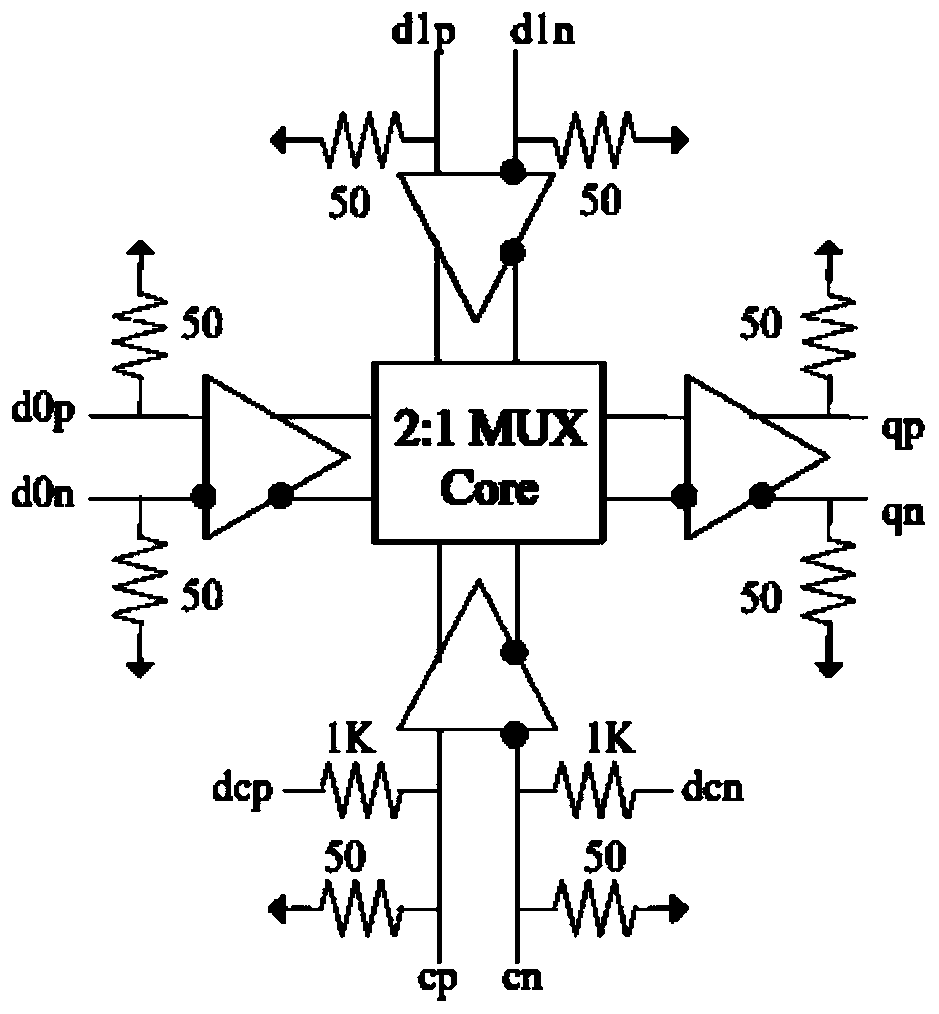

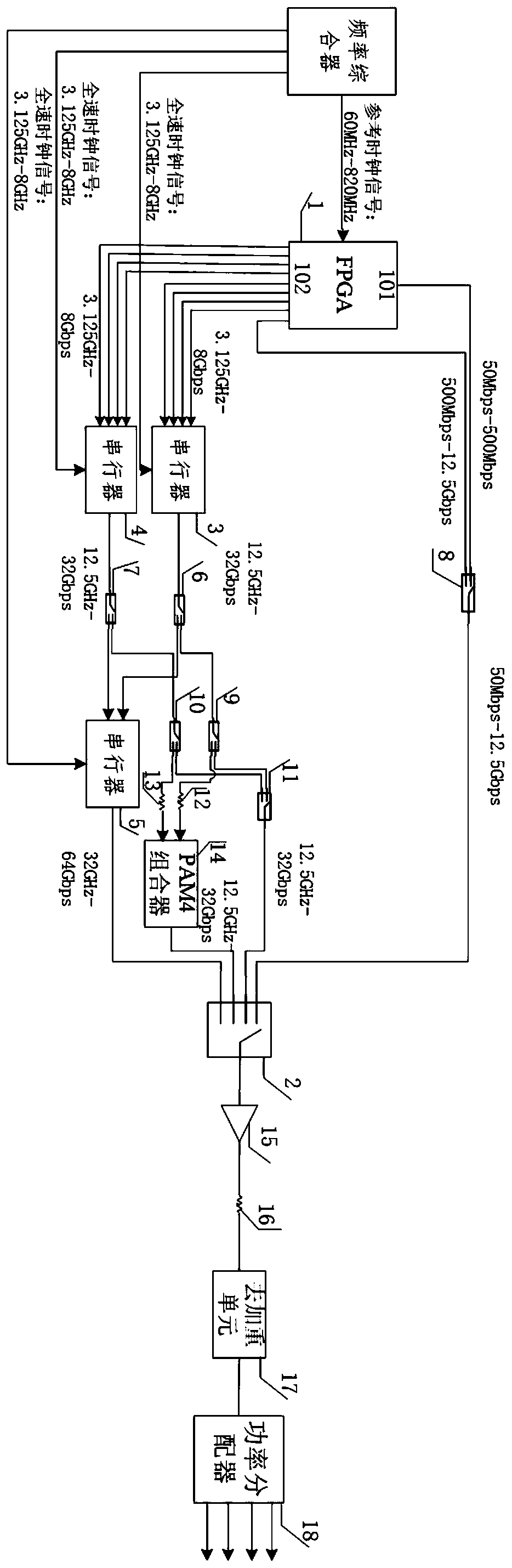

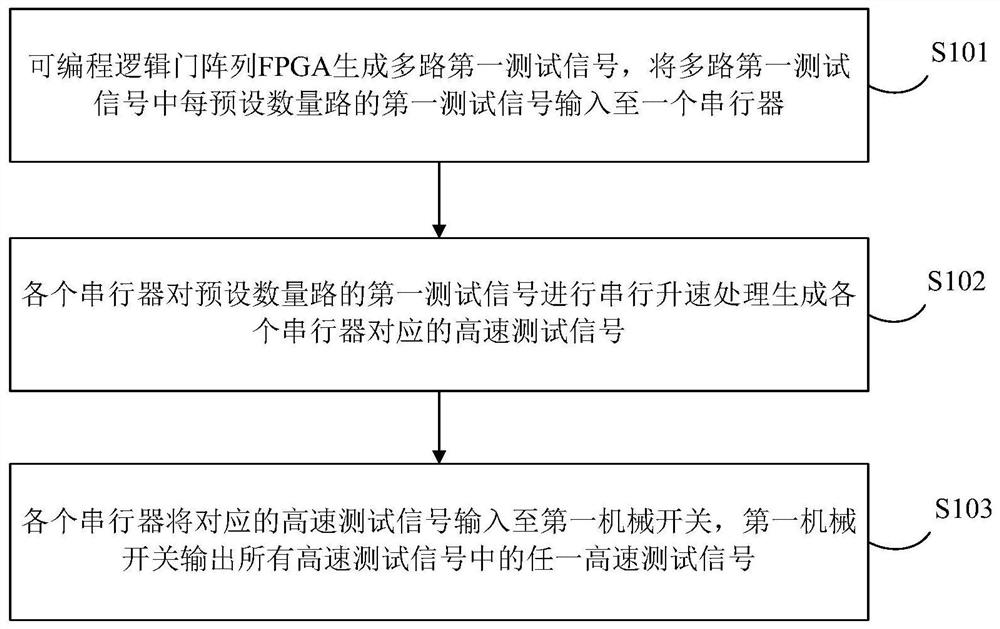

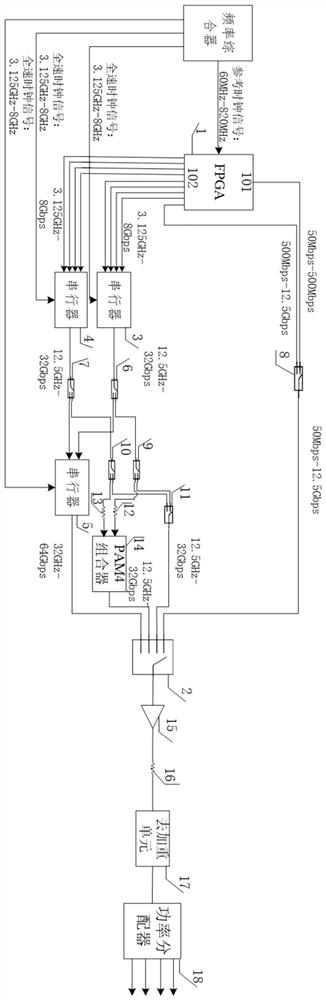

Signal acceleration method and circuit

ActiveCN111431596AHigh Signal Rate CapContinuously adjustable speedClose-range type systemsElectric digital data processingGate arrayHemt circuits

The embodiment of the invention discloses a signal acceleration method and circuit, and the method comprises the steps that a programmable logic gate array (FPGA) generates a plurality of paths of first test signals, and inputs each preset number of paths of first test signals in the plurality of paths of first test signals to a serializer; each serializer performs serial acceleration processing on the preset number of paths of first test signals to generate high-speed test signals corresponding to each serializer; each serializer inputs a corresponding high-speed test signal to the first mechanical switch, and the first mechanical switch outputs any one high-speed test signal in all high-speed test signals. By the adoption of the signal acceleration method, the speed range capable of being tested based on the signal acceleration method can be larger.

Owner:ZHONGXING LIANHUA TECH BEIJING CO LTD

Speed regulating fan system with fault-tolerant capacity

ActiveCN100440718CReduce power consumptionReduce noiseElectric motor controlField or armature current controlElectricityControl signal

This invention relates to a fan regulation system with an error-tolerance ability including an input voltage testing circuit, a PWM circuit, a switch supply circuit and a fan set, in which, the control signal of rotation speed of the system and tested voltage signal control the output of the PWM waveforms, control the switch devices of a switch supply circuit and output a suitable voltage to the fan set, when the fan is tested to be faulty, the duty ratio of the PWm waveform can be adjusted.

Owner:ZTE CORP

Movable pharmaceutical dust collection structure and operating method thereof

PendingCN107282546AEasy to unloadEfficient unloading operationsCleaning using gasesLow noiseRational use

The invention belongs to the technical field of application of tablet and chemical production machinery, and particularly discloses a movable pharmaceutical dust collection structure. The movable pharmaceutical dust collection structure is composed of a box frame, universal wheels, a hand push rod positioning plate, an inclined hand push rod, a dust collection assembly and a lifting assembly, wherein the universal wheels are arranged at four corners of the bottom of the box frame, the hand push rod positioning plate is arranged on one side of the box frame, the inclined hand push rod is arranged on the hand push rod positioning plate, the box frame is fastened with the hand push rod positioning plate by a positioning bolt, and the dust collection assembly and the lifting assembly are arranged on the box frame. The movable pharmaceutical dust collection structure has the beneficial effects of reasonable structural design, long service life, small vibration and low noise generated during use, convenience in efficiently discharging dust collection bags by virtue of the lifting of an air cylinder, excellent anti-explosion performance, high safety factor, high efficiency, energy conservation, closeness in operation, standardability and safety in use, attractive appearance, practicability, convenience in flushing, corrosion resistance, low noise, flexibility in movement and continuous adjustability and continuity of the rotating speed, the intelligent control production requirements are met, and the whole structure is made of stainless steel materials.

Owner:江苏贝力机械制造有限公司

A bell type sealed liquid heavy metal rotating device

ActiveCN103398941BSimple structural designImprove securityWeather/light/corrosion resistanceIndustrial equipmentMolten salt

The invention discloses a bell jar seal liquid heavy metal rotating device which flexibly utilizes a bell jar principle to replace the conventional easy-to-wear mechanical seal, packing seal and a rotating mode driven by a high-temperature demagnetizing electrode magnet rotor, can achieve long-time running under a condition that a shaft seal system is not worn, prevents air due to the fact that equipment is run in a long-term high-temperature environment and subjected to shaft seal wear from entering a polluted experimental area, and avoids changing the shaft seal system regularly. The device comprises a fused salt thawing box, a liquid collecting box, a variable-frequency motor, a bell jar, a support and a shaft sample experimental section, and is simple in structure and easy to operate. The device is in a unique bell shaft seal structure, is provided with the rotating speed-adjustable variable-frequency motor, combines an auxiliary heating and warm-keeping system, and is matched with the replaceable sample experimental section, so that the device can carry out corrosion mechanism researches of structural materials in different speed fields and temperature fields. In addition, the device can be widely applied to the field of industrial equipment corrosion tests and fundamental scientific research projects, and has important scientific research values and engineering application values.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

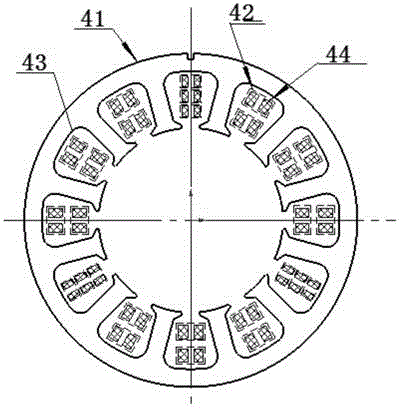

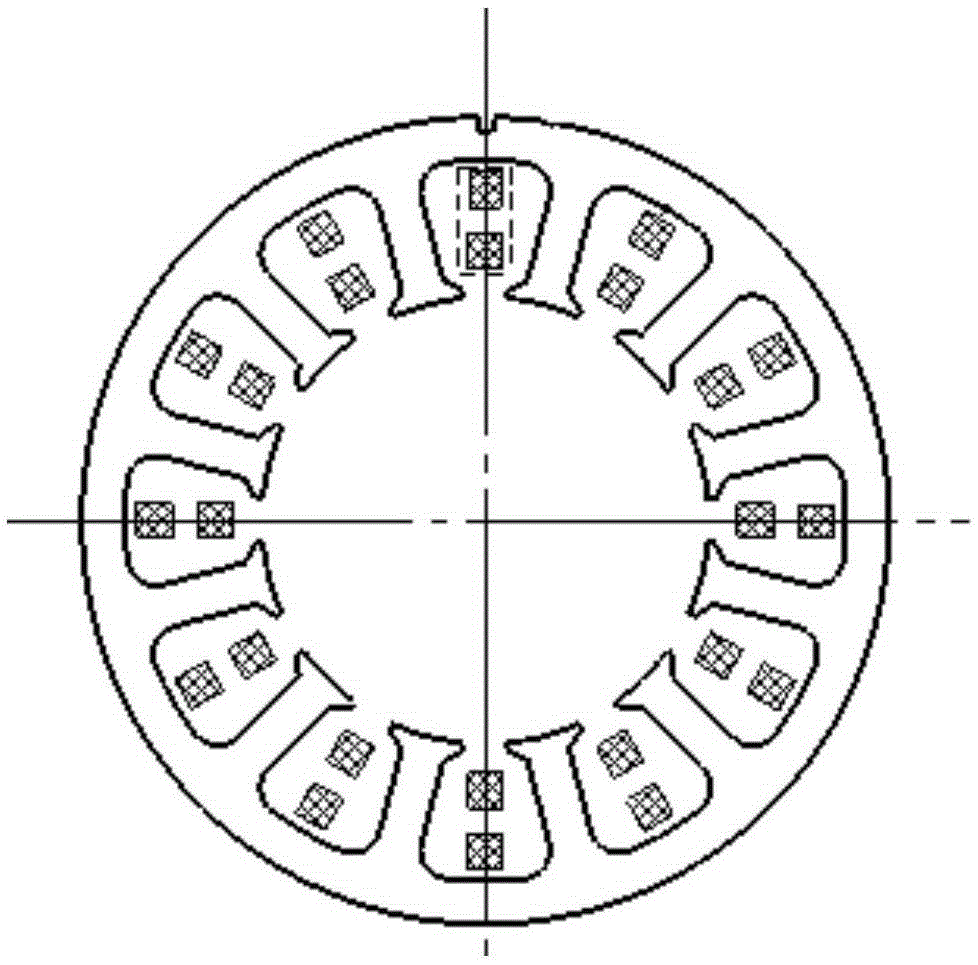

Brushless DC motor with asymmetric winding

ActiveCN105262260AHigh currentAchieve volume constantWindings conductor shape/form/constructionSmall amplitudeElectric machine

The invention discloses a brushless DC motor with an asymmetric winding. The brushless DC motor with the asymmetric winding comprises the components of a housing, a front end cap, a back end cap, a stator, a rotor, a circuit board assembly, a sensor rotor, a sensor back cover, a connector base and an electric connector. The stator is bonded in the housing. The stator comprises a stator core and a winding. The stator core is provided with stator trough structures. The winding is inlayed in the stator trough structures asymmetrically. According to the stator winding of the brushless DC motor with the asymmetric winding, a parallel winding manner of a plurality of enameled wires is adopted, thereby greatly enlarging a motor current. Under a precondition that the motor size is unchanged, motor power is remarkably improved. For realizing small-amplitude adjustment on the working rotating speed of the motor in a certain range, the numbers-of-turns of the winding in the troughs are different from one another. The asymmetric winding is equivalent with a fractional number-of-turns winding, thereby realizing continuous and adjustable rotating speed of the motor, and ensuring a fact that the motor satisfies a technical requirement.

Owner:沈阳兴华航空电器有限责任公司

Open arc on-line surfacing repair device and method for grinding roller of medium-speed mill

PendingCN110539124ASave human effortSave moneyCooled electrode holdersWelding accessoriesSurface layerMaterial resources

The invention relates to an open arc on-line surfacing repair device and method for a grinding roller of a medium-speed mill. The open arc on-line surfacing repair device comprises a PLC welding control box, and an electric welding machine, a welding trolley, a double-drive wire feeder and a limit switch which are connected with the PLC welding control box. A grinding roller driving device is arranged at the bottom of the grinding roller; a welding gun is arranged on the surface of the grinding roller; the rear end of the welding gun sequentially communicates with the double-drive wire feederand a welding wire straightening mechanism through a connecting rod; a welding wire placed on a wire feeding device penetrates into a wire inlet of the welding wire straightening mechanism; and the double-drive wire feeder is mounted on the welding trolley through a welding gun angle adjusting mechanism. On-line surfacing repair is carried out on the grinding roller without disassembling the grinding roller, so that a large amount of manpower and material resources are capable of being saved and the repair period is capable of being shortened. The open arc on-line surfacing repair method mainly ensures that each performance of a surfacing layer meets repair requirements by selecting welding parameters and welding modes.

Owner:甘肃酒钢集团西部重工股份有限公司

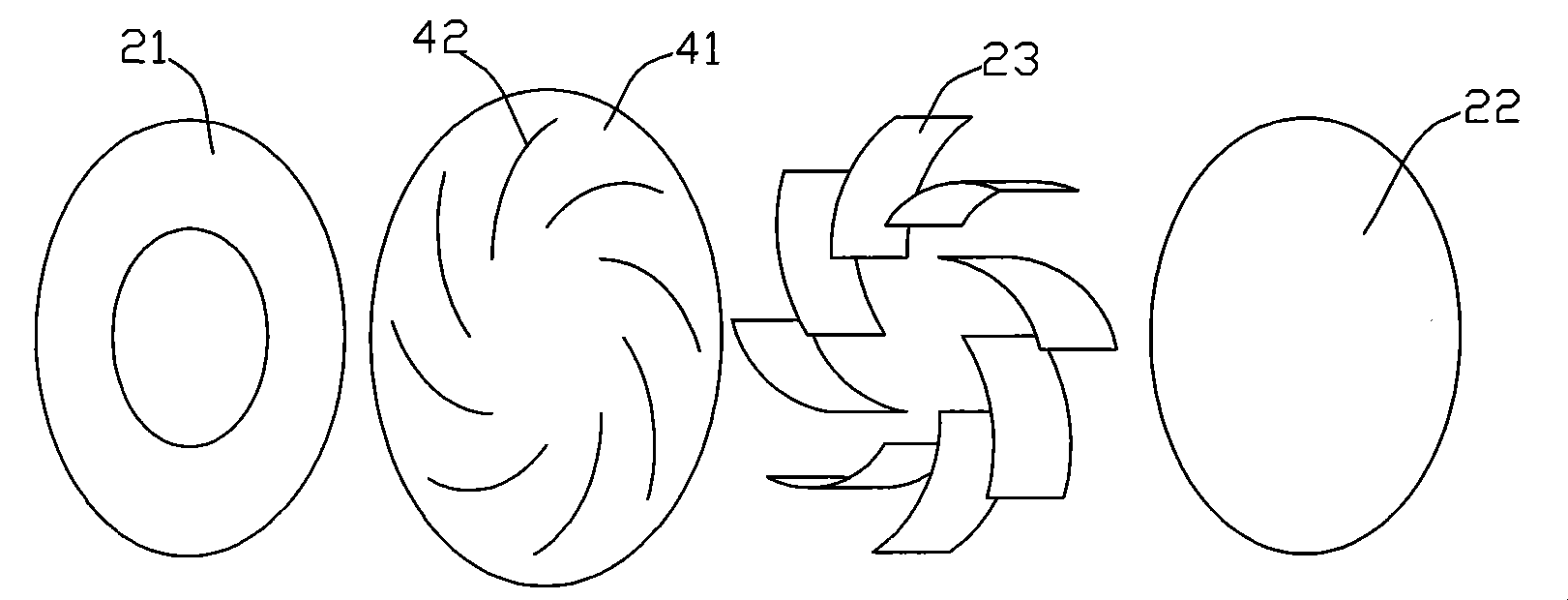

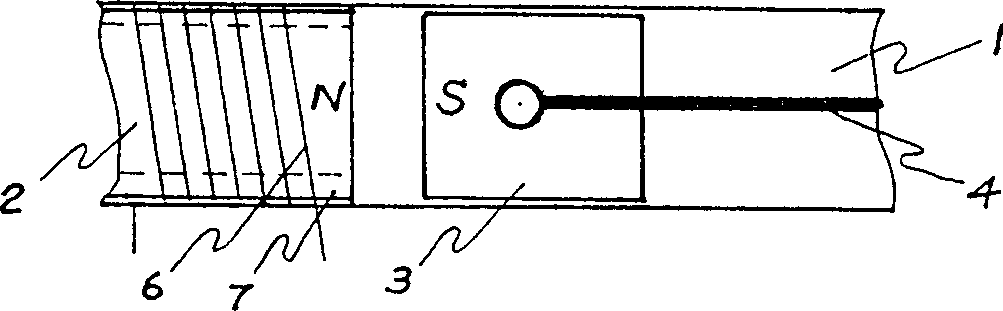

Speed variator with variable flow impeller

InactiveCN101413513BReduce resistanceAvoid disturbancePump componentsPump controlImpellerEngineering

The invention relates to a variable flow impeller comprising a sealed pump shell, a main impeller and an output impeller respectively arranged in the left and right side of pump shell cavity. The main impeller is a variable flow impeller having a restrictor, the pump shell cavity is a ring cavity, and the main impeller and the output impeller have arc shape adaptive to the ring cavity shape. C shape cavities with opposite openings are respectively arranged on front disks of the main impeller and the output impeller. The main impeller and the output impeller are arranged in the pump shell, and the main impeller is controlled by the restrictor. The rotation speed of the output impeller can be changed as long as adjusting the flow of the variable flow impeller during work, thereby realizing the continuous adjustment of the rotation speed, effectively reducing the flow resistance during flow and improving work efficiency.

Owner:林英燮

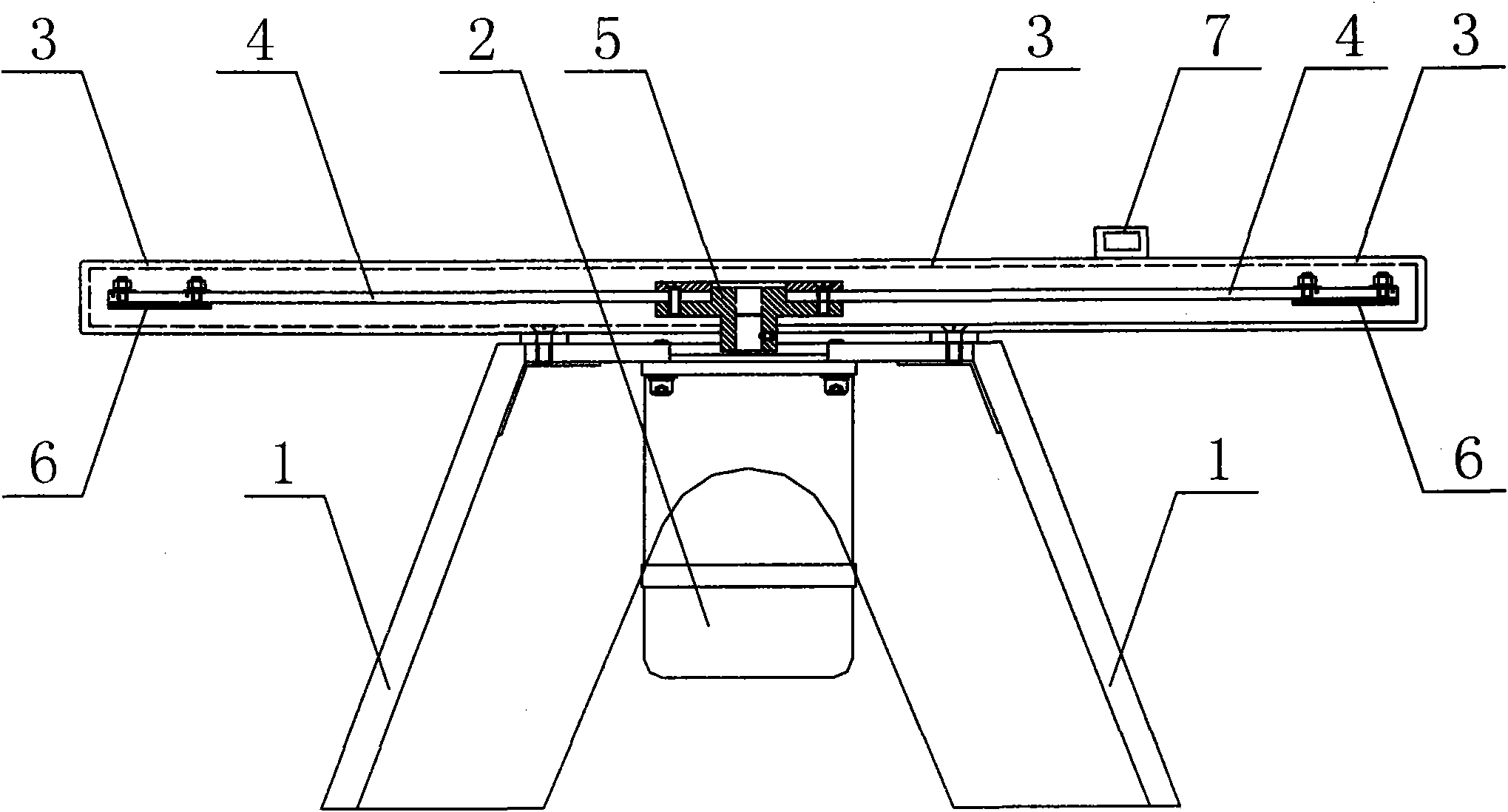

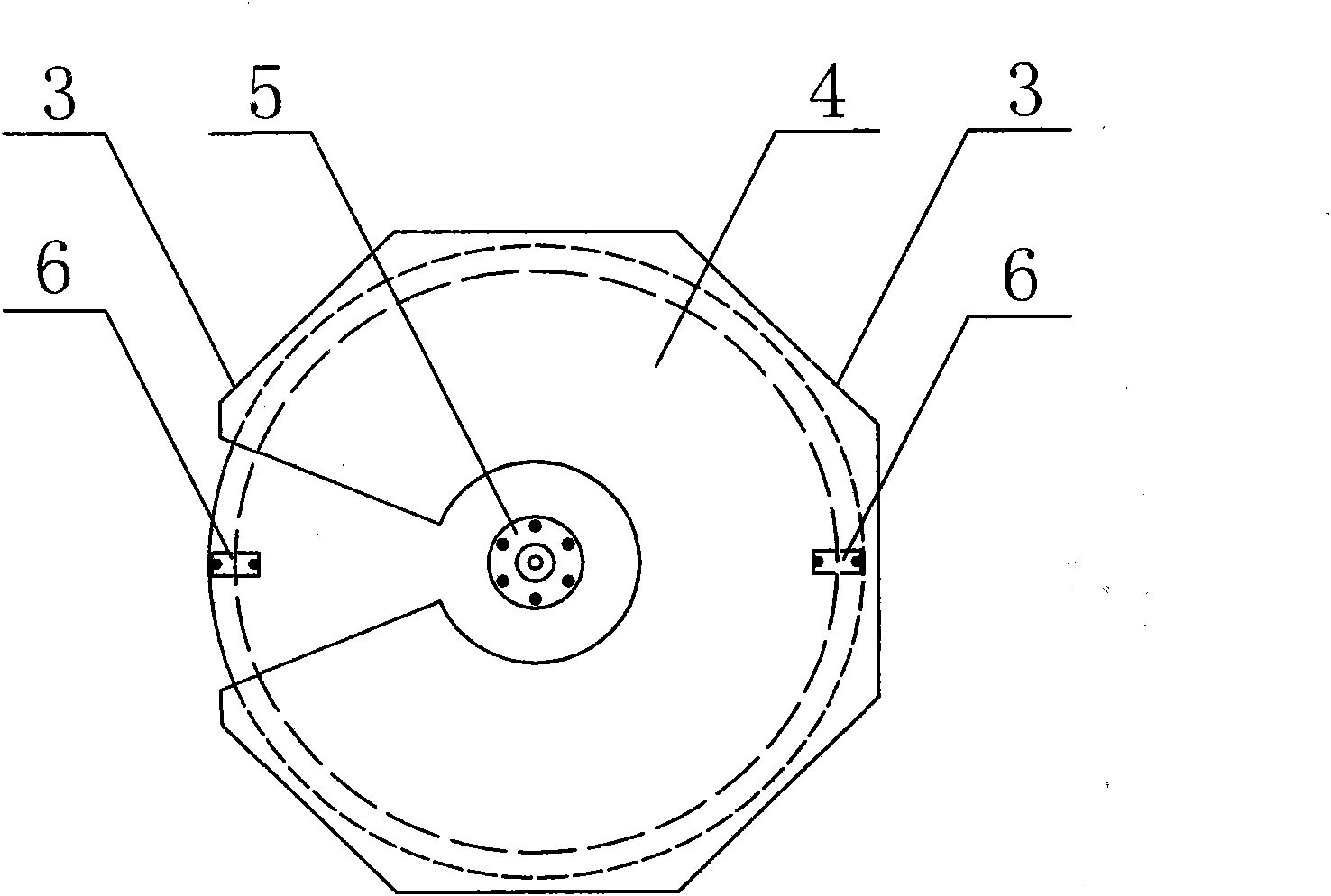

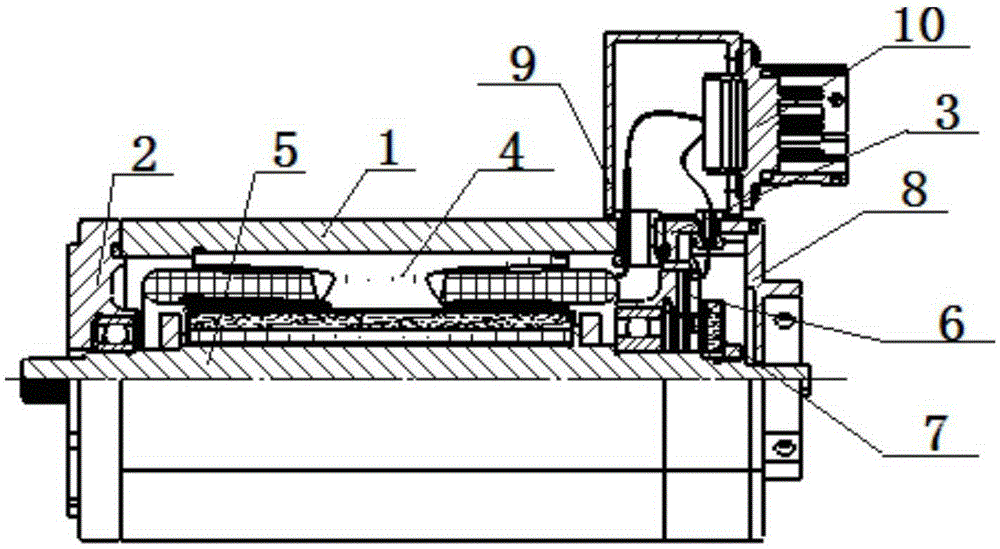

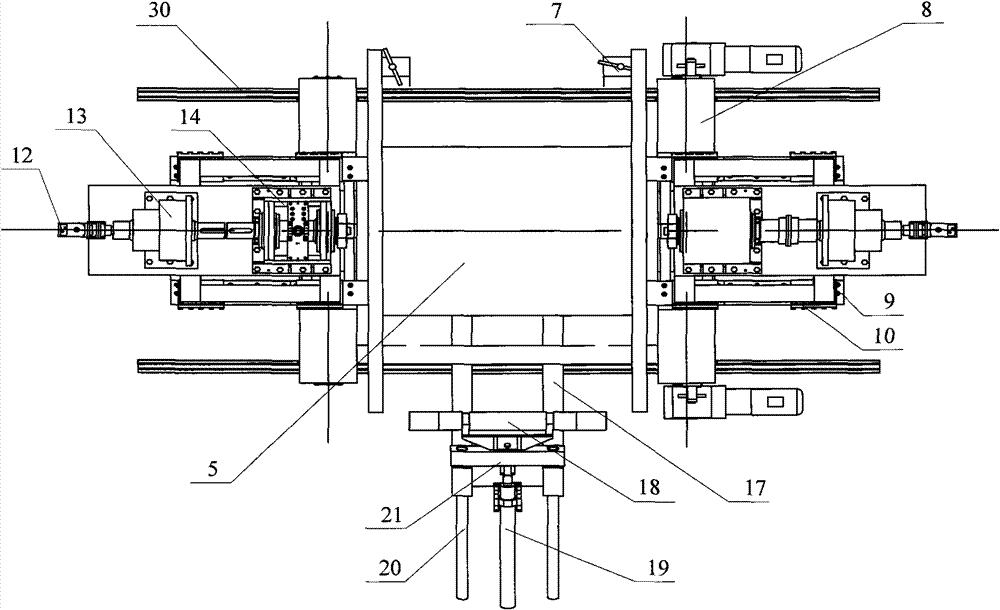

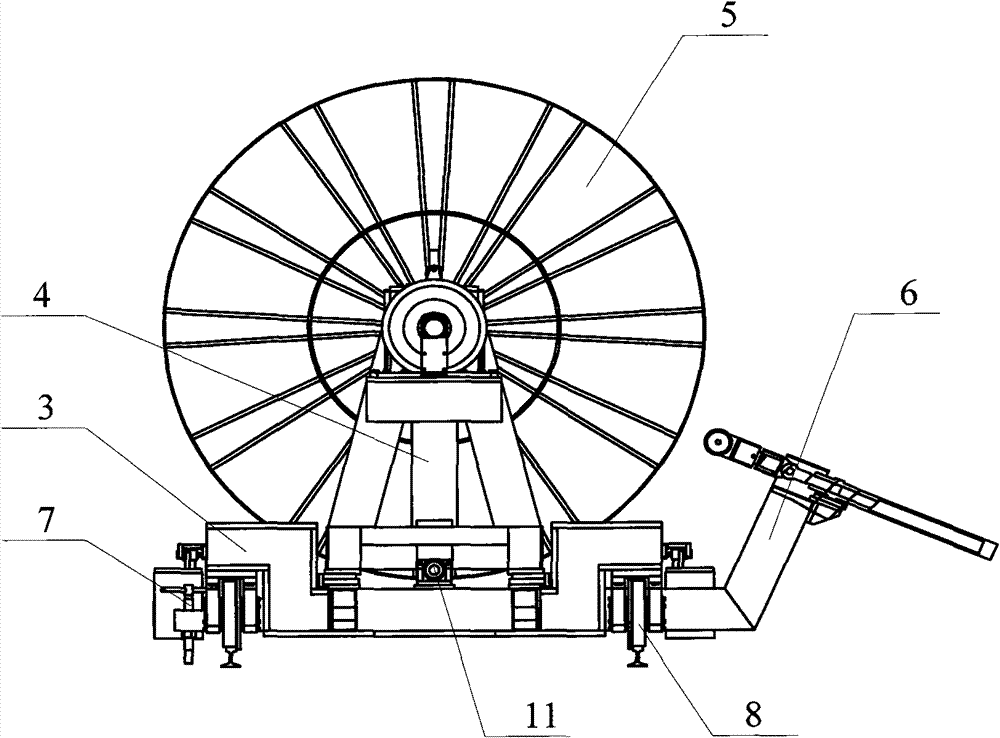

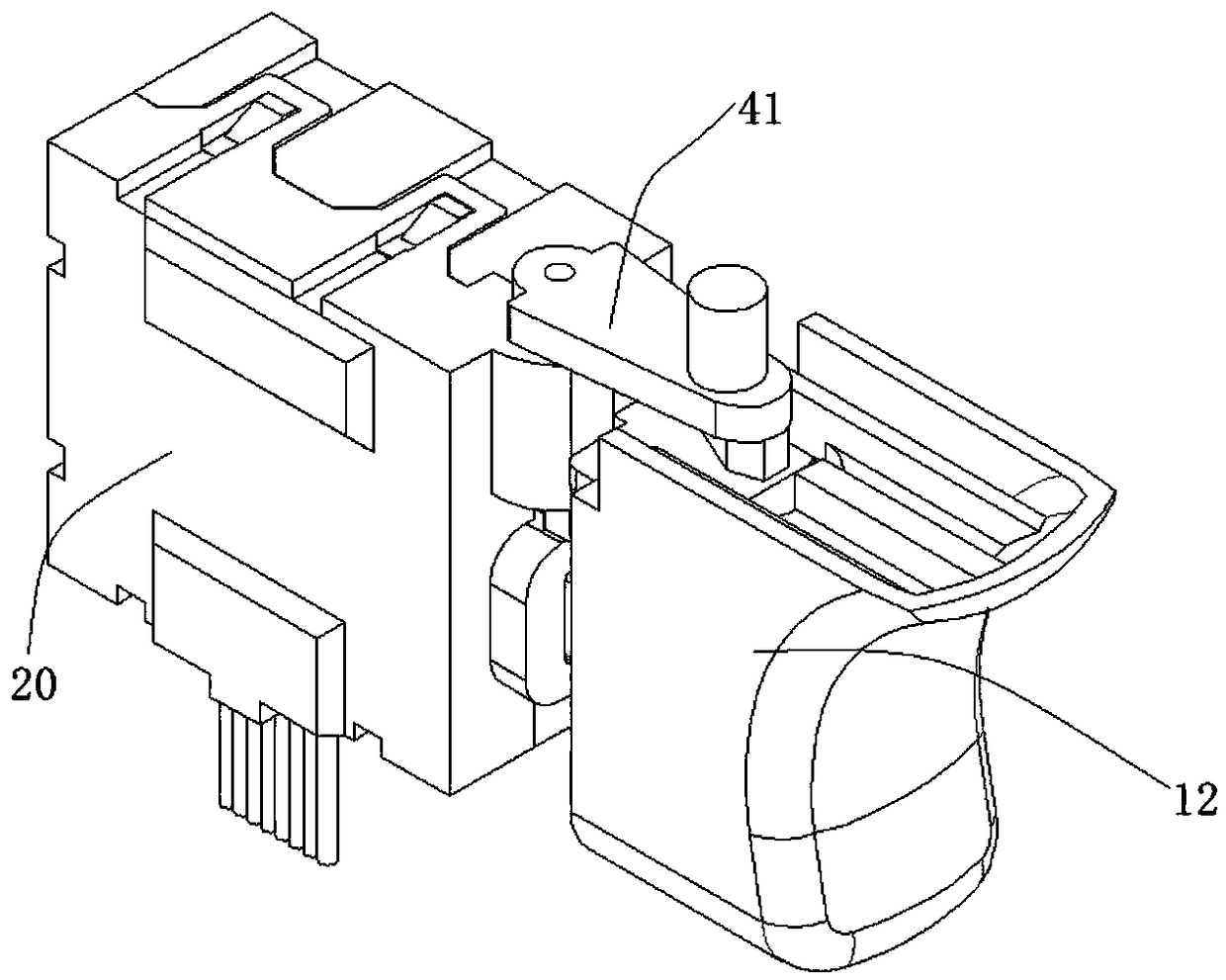

Continuous oil pipe reeling machine

The invention relates to a continuous oil pipe reeling machine, which is composed of a vehicle body (3), machine frames (4), a running mechanism (8) and transmission gears (2), wherein the vehicle body (3) is fixed on the running mechanism (8); the vehicle body is provided with slide rails (9); the two machine frames (4) are symmetrically positioned on the slide rails (9); the two transmission gears (2) are symmetrically arranged on the upper end faces of the two machine frames (4); a reel (5) is arranged in the middle of the vehicle body and positioned between the two machine frames (4); andboth ends of the main shaft of the reel (5) are respectively connected with the power output shafts of the two transmission gears (2). In the invention, the continuous oil pipes are wound on the reelto be stored on site; and thus, the invention is convenient to store, and meets the requirements on production, transportation and user operation of continuous oil pipes. The invention has the functions of transverse running, locking in place, continuous adjustable speed, automatic variable speed, adjustable opening of the machine frame, oil pipe bounce compacting resistance after completing reeling, rotation prevention of automatic braking after completing the reeling operation, and the like, and is safe and reliable in production operation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Front demounting conveying system for scrapped automobile demounting line

InactiveCN102442365BGuaranteed uptimeStable storageVehicle dissasembly recoverySolid waste disposalProgrammable logic controllerComputer module

The invention discloses a front demounting conveying system for a scrapped automobile demounting line, which comprises a supporting bottom frame, a conveying plate chain, a driving mechanism and a PLC (programmable logic controller) module, wherein the conveying plate chain is mounted on the supporting bottom frame, the driving mechanism and the PLC module are connected with the conveying plate chain, and the driving mechanism is connected with the PLC module. By means of the technical scheme, completely automatic operation is realized, conveying efficiency is high, operation is table, storing stability of a demounted vehicle body can be guaranteed to meet requirements of dynamic demounting, and further, the speed of the conveying system is continuously adjustable by means of a frequency-variable motor.

Owner:安徽韦尔汽车科技有限公司

A multi-parameter metal corrosion device for gap flow field

InactiveCN104729983BEffectively fixedAvoid affecting the experimental resultsWeather/light/corrosion resistanceAuxiliary electrodeWorkstation

Owner:DALIAN UNIV OF TECH

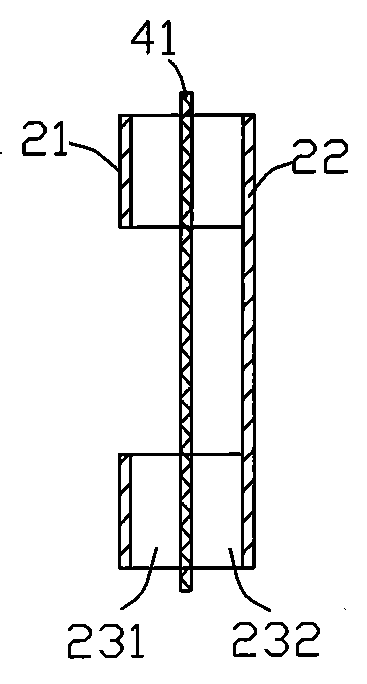

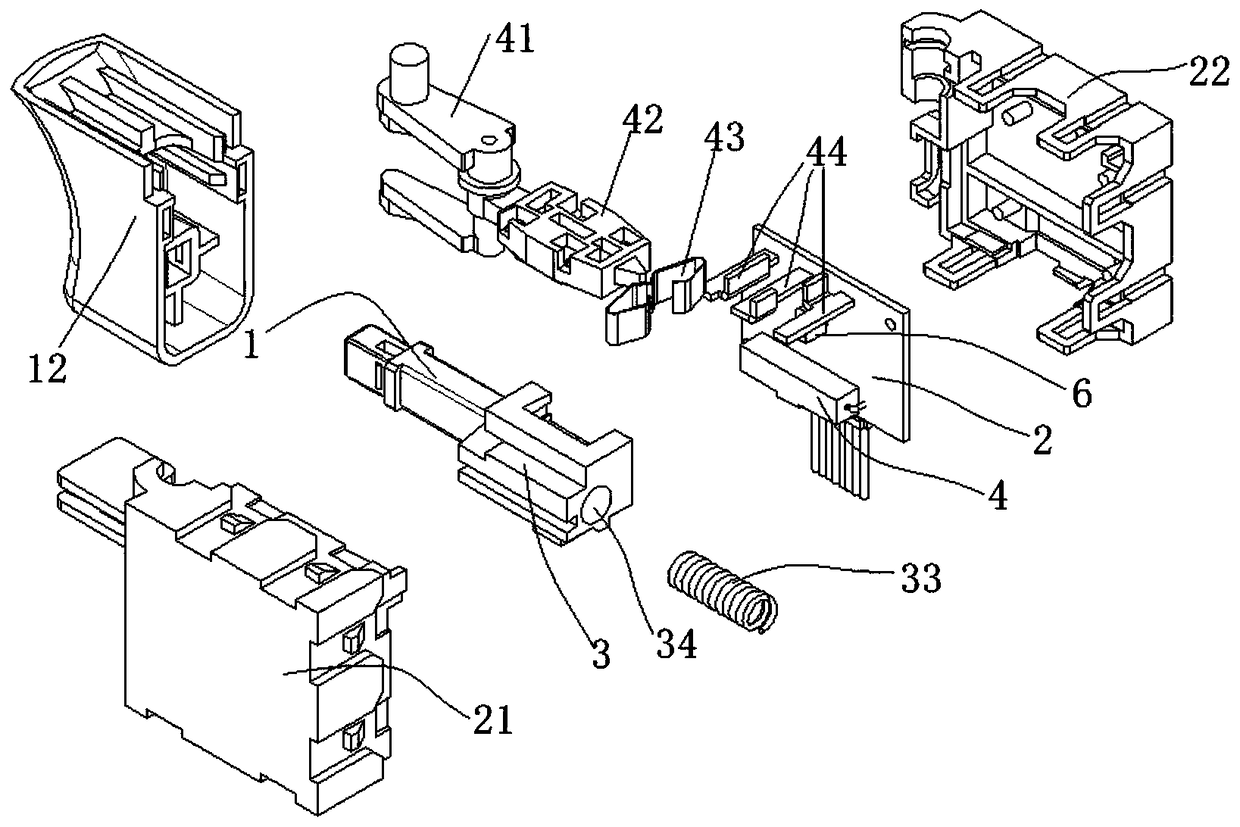

Speed-control switch with function of continuously adjusting speed

PendingCN108899233AImprove reliabilityExtended service lifeElectronic switchingMagnetic/electric field switchesEngineeringControl switch

The invention discloses a speed-control switch with function of continuously adjusting speed. The speed-control switch comprises a shell, and a circuit board, a push rod, a speed adjustment sliding block, a dry reed tube and a Hall sensor which are arranged in the shell, wherein the dry reed tube and the Hall sensor are separately and electrically connected with the circuit board; the push rod makes elastic sliding and passes through the shell; the speed adjustment sliding block is arranged at the end, positioned in the shell, of the push rod; the speed adjustment sliding block is arranged atone side of the circuit board in a way of clearance sliding; the speed adjustment sliding block comprises a first magnetic field and a second magnetic field; the dry reed tube is positioned in the first magnetic field, and the Hall sensor is arranged in the second magnetic field; the speed adjustment sliding block makes sliding motion relative to the circuit board; a reed in the dry reed tube is connected or disconnected by sensing the intensity of the first magnetic field; the Hall sensor outputs corresponding Hall voltage by sensing the intensity of the second magnetic field. The normal useof the switch can be effectively guaranteed, contact wear and failure can be prevented, and the speed can be continuously adjusted.

Owner:WUXI CITY LINGHONG ELECTRIC

A signal speed-up method and circuit

ActiveCN111431596BHigh Signal Rate CapContinuously adjustable speedClose-range type systemsElectric digital data processingGate arrayHemt circuits

The embodiment of the invention discloses a signal acceleration method and circuit, and the method comprises the steps that a programmable logic gate array (FPGA) generates a plurality of paths of first test signals, and inputs each preset number of paths of first test signals in the plurality of paths of first test signals to a serializer; each serializer performs serial acceleration processing on the preset number of paths of first test signals to generate high-speed test signals corresponding to each serializer; each serializer inputs a corresponding high-speed test signal to the first mechanical switch, and the first mechanical switch outputs any one high-speed test signal in all high-speed test signals. By the adoption of the signal acceleration method, the speed range capable of being tested based on the signal acceleration method can be larger.

Owner:ZHONGXING LIANHUA TECH BEIJING CO LTD

A control method for a section warping machine

ActiveCN107523914BPrecise positioningPrecise shiftWarping machinesTextiles and paperComputer moduleElectric machinery

The invention relates to a control method of a sectional warping machine. The method comprises the steps that a positioning control module, a speed control module and a tension control module are included, the positioning control module detects position information of a shaft through a shaft encoder on a drum shaft, and a central controller controls the rotation speed of a control servo motor according to the position information; the speed control module detects speed information through a thickness measuring sensor and the shaft encoder, the linear speed of warping is calculated according to the speed information, the linear speed is compared with a preset linear speed, and according to a numerical value obtained after comparison, the rotating speed of a direct-current drum motor is controller by triggering a pulse module. According to the method, accurate positioning and displacement and automatic adjustment of speed and tension can be achieved, fluctuation of yarn tension is lowered, and the phenomenon that due to the fact that warp yarns are mutually wound into knots and the pressure is unbalanced, the yarn quality is affected is avoided.

Owner:江西诚鑫实业有限公司

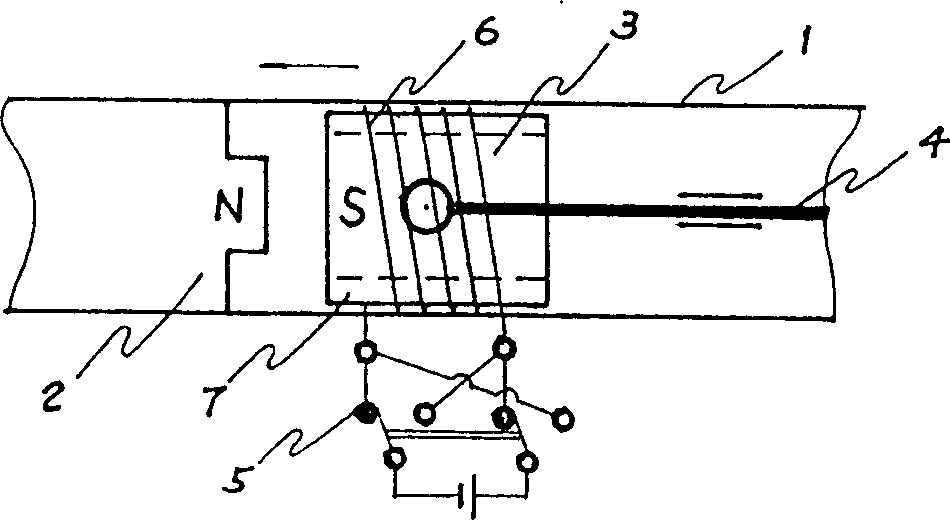

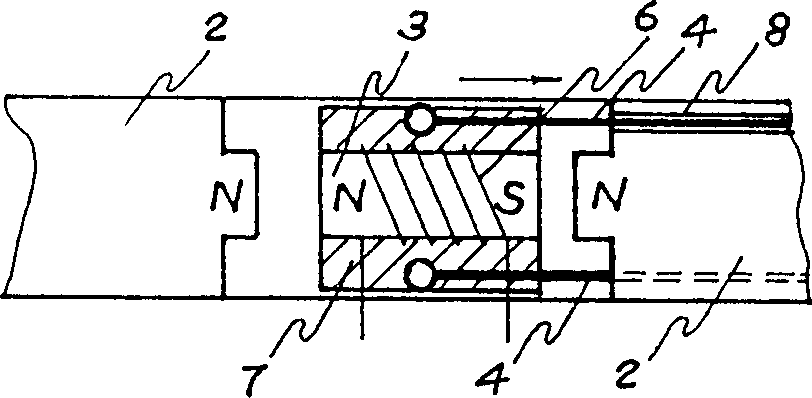

Permanent magnetic DC incremental motor

InactiveCN1123958CSimple structureSimple processDynamo-electric machinesElectric machineElectromagnet

The present invention relates to a permanent-magnet D.C. incremental motor, which comprises machine seat, stator, armature, output shaft and commutator, one of stator and armature is made of permanent-magnet, and its correspondent another component is made of electromagnet. The electromagnet is formed from coil frame and conductive coil, said conductive coil is connected with two poles of the commutator. Its ouput shaft can output linear movement, also can output rotary movement by means of crank-guide mechanism. The stator can be made of two permanent-magnets or electromagnets, and its correspondent armature comprises one electromagnet or permanent-magnet. Its structure is simple, output power and rotating speed can be continuously regulated so that it can be extensively used in the design and manufacture of electromechanical products.

Owner:邱兆云

Intelligent warp-knitting-machine needle-bed headstock speed-range variable motion system

InactiveCN108277575ALow movement resistanceEliminate Lube Oil Contamination ProblemsWarp knittingMotion resistanceRadial position

Disclosed is an intelligent warp-knitting-machine needle-bed headstock speed-range variable motion system which comprises a variable speed motor, a rotating shaft and a needle bed plunger cap. The variable speed motor drives the rotating shaft, the needle bed plunger cap is mounted on the extension end of the rotating shaft through a radial regulating device, and the needle bed plunger cap is radially adjustable along the rotating shaft. Output of kinetic energy is achieved in the motion mode that the variable speed motor drives an eccentric wheel with adjustable eccentric distance to move, sothat traveling trajectory of a needle bed swinging cam of a warp knitting machine is flexibly variable; driving on a plunger does not rely on the travelling cam, so that the plunger does not contactwith the cam directly; lateral force does not exist since the plunger is only subjected to axial force, motion resistance is greatly lowered, abrasion of the plunger is avoided, a plunger driving mechanism does not need to be dipped in an oil groove, and the problem about lubricant pollution commonly existing in the warp knitting machine is solved.

Owner:常州源通电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com