Continuous oil pipe reeling machine

A coiler and tubing technology, which is used in the transportation of filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of winding, coiled tubing cannot be stored, and achieve convenient storage, easy storage and transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

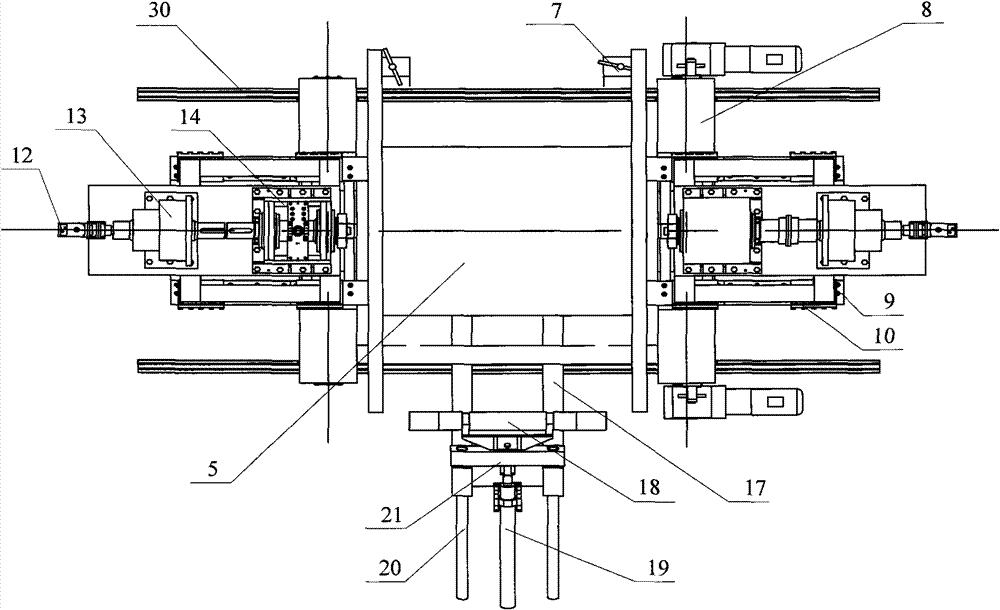

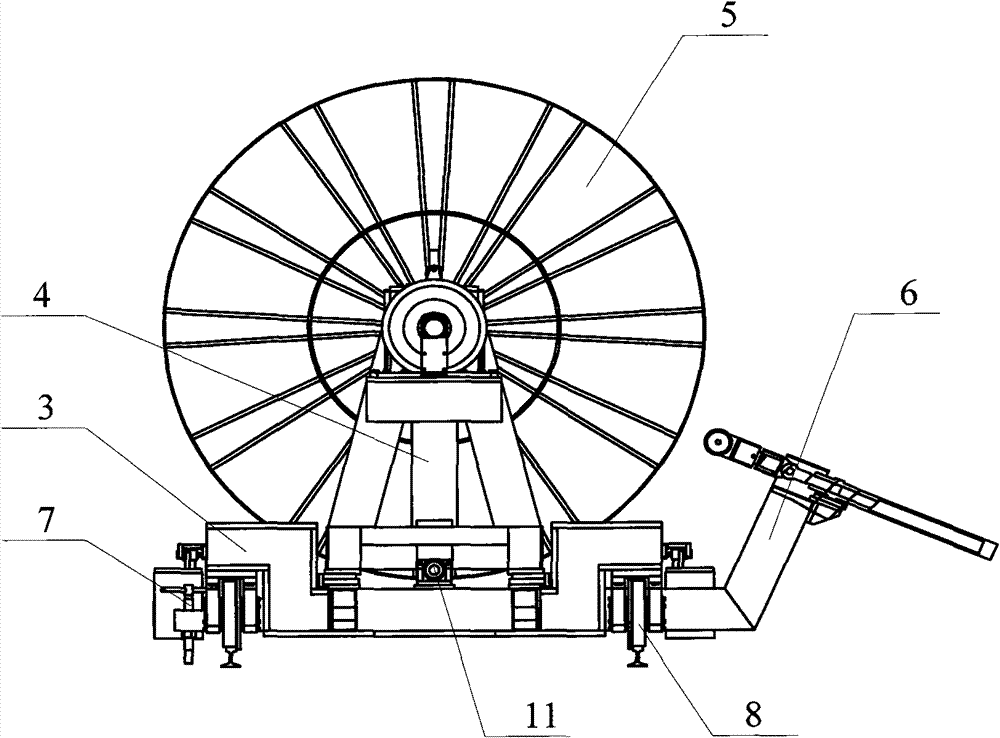

[0020] combined with figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9 describe an embodiment of the present invention.

[0021] A coiled tubing coiler is composed of a vehicle body 3 , a frame 4 , a traveling mechanism 8 and a transmission device 2 . The car body 3 is a rectangular frame structure, supported and fixed on the traveling mechanism 8. The car body 3 is provided with two parallel slide rails 9, and the two racks 4 are symmetrically arranged on the two parallel slide rails through the sliders 10 fixed on their lower end faces. The two ends of rail 9, two opening and closing oil cylinders 11 are fixed on the two ends of car body 3, and the piston end of two opening and closing oil cylinders 11 is hinged with the bottom of two frame 4 respectively. The two transmission devices 2 are arranged symmetrically on the upper end surfaces of the two frames 4, and the reel 5 is arranged in the middle of the car body 3 between the two frames 4, and the two ends of the main shaft of the ree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com