Debinding furnace

A degreasing furnace and furnace technology, which is applied in the field of industrial furnaces, can solve the problems of easy generation of dead corners, low product quality, and failure to achieve mass production, and achieve the effects of reducing dead corner areas, high material purity, and improving thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

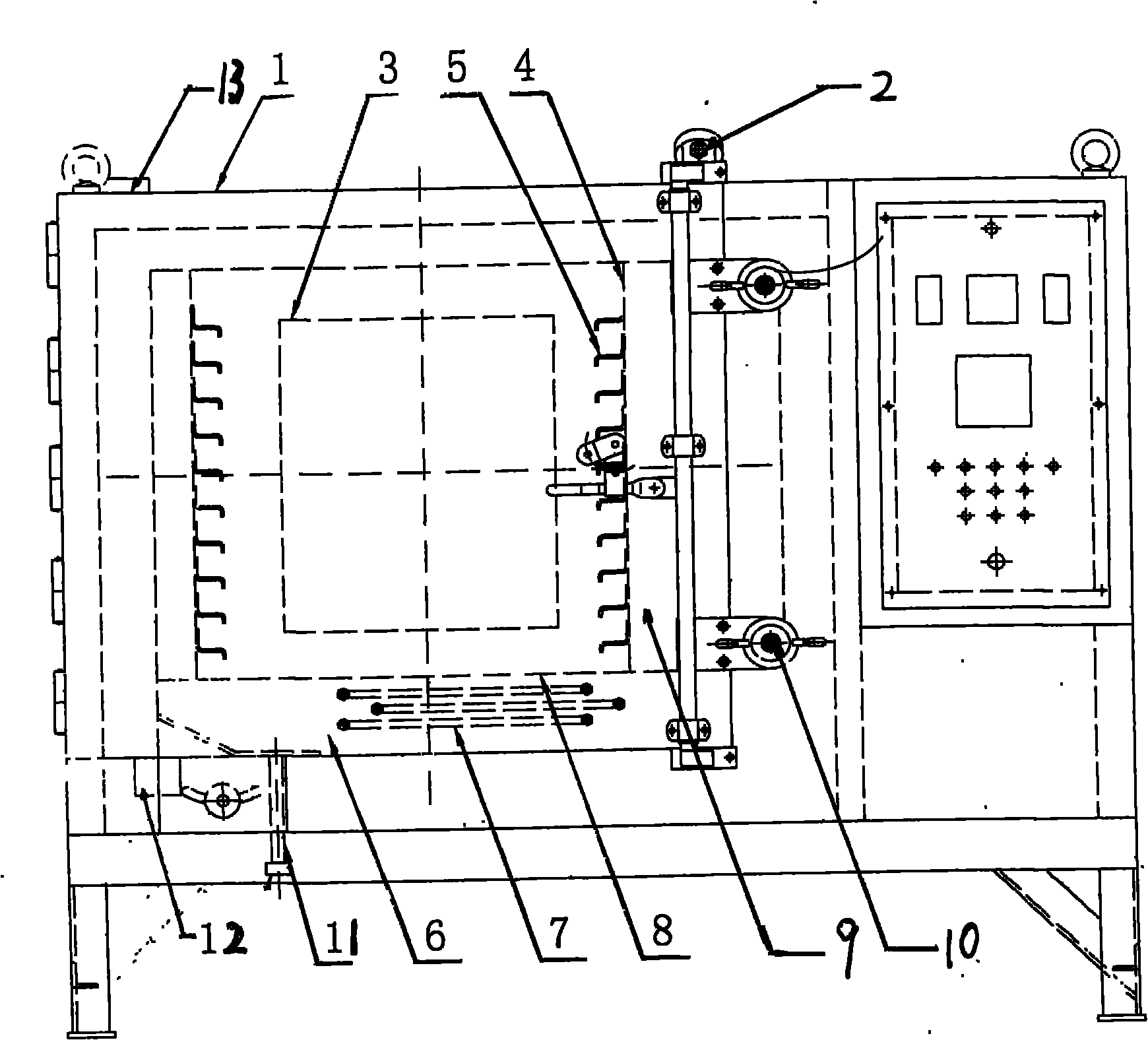

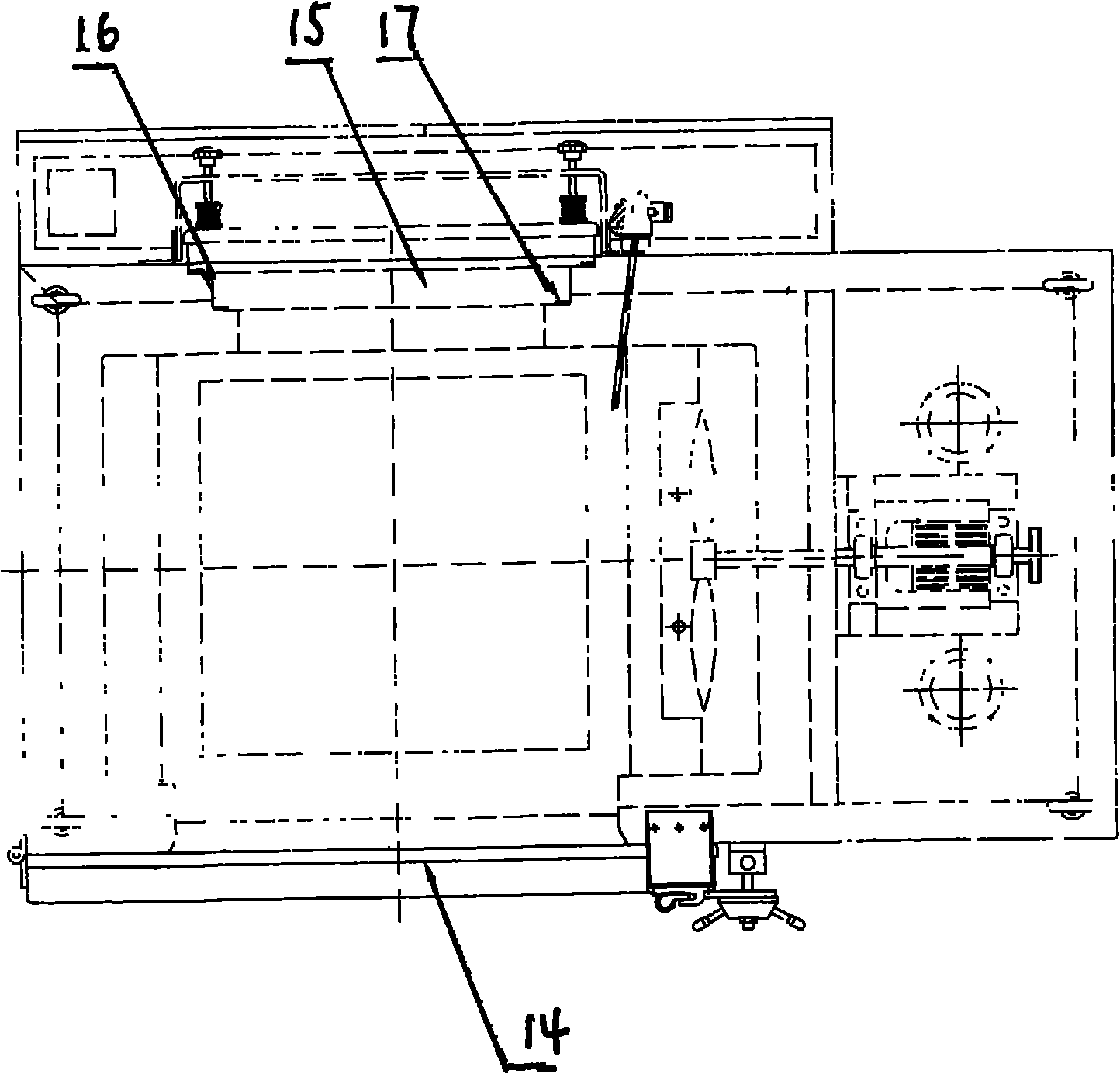

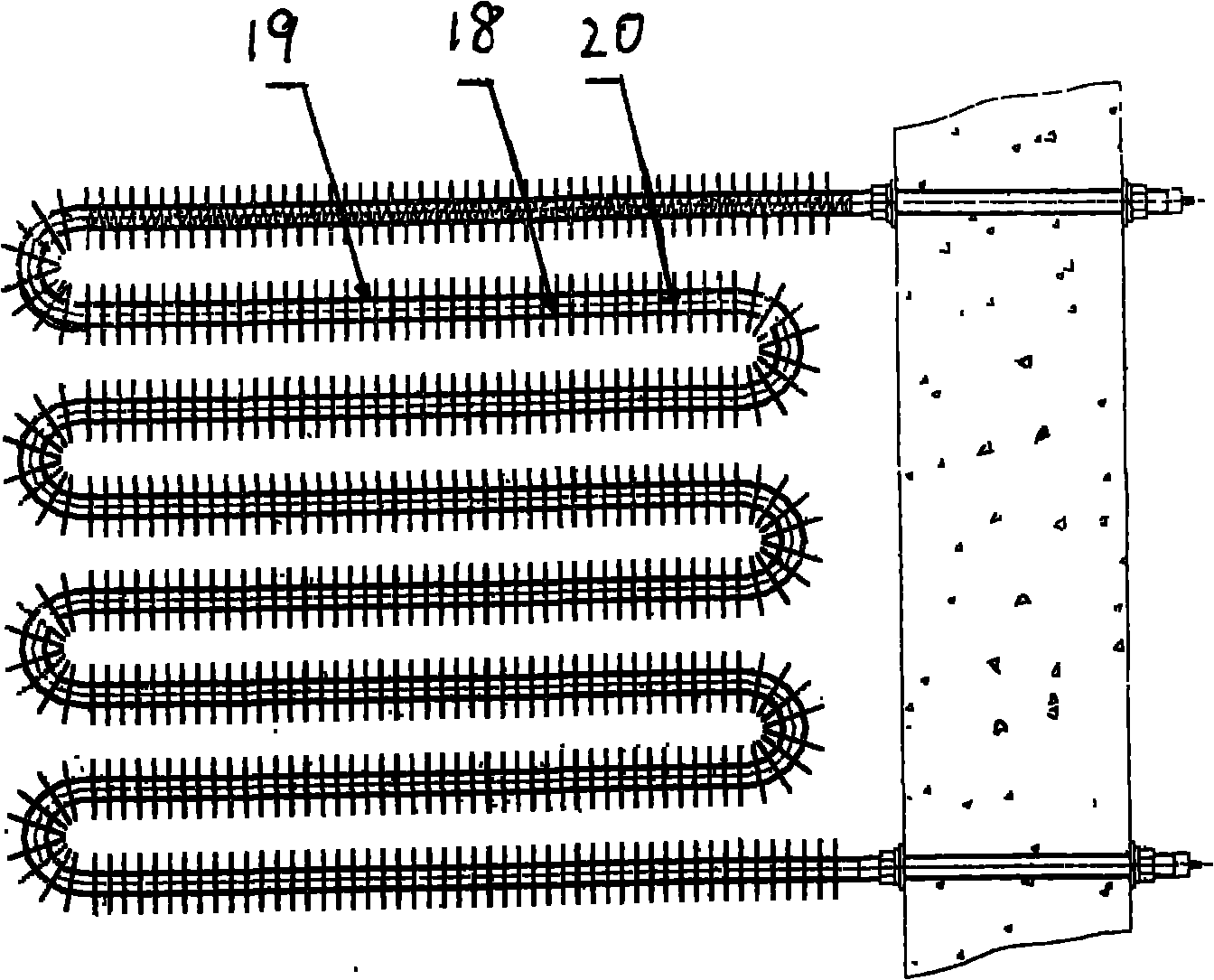

[0012] A degreasing furnace includes a mechanical frame 1, a furnace 3, a heating chamber 6, an axial circulation fan 10 and the like. Such as figure 1 The furnace 3 and the heating chamber 6 formed by welding heat-resistant stainless steel plates are respectively arranged in the mechanical frame 1, the left and right sides of the furnace 3 are fixed with mesh plates 4, the vertical ribs of the mesh plate 4 are fixed with slideways 5, and the bottom plate of the furnace 8. The mesh plates 4 and slideways 5 on both sides are detachable; the thermocouples 2 are respectively fixed on the top and the back of the mechanical frame 1 of the degreasing furnace, and extend into the furnace 3, using armored K graduations Thermocouple 2 temperature measuring elements, a total of 6 points for temperature measurement, 2 points are inserted into the fan from the top of the furnace 3, 3 points are inserted into the furnace 3 from the back of the furnace 3, 1 point is arranged near the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com