Temperature-control high-speed large-strain membrane two-way stretching device and experimental method thereof

A technology of two-way stretching and experimental methods, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of undeveloped two-way stretching technology, and achieve continuous adjustment of stretching rate and stretching ratio. Small size, precise control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and embodiment further illustrate the present invention.

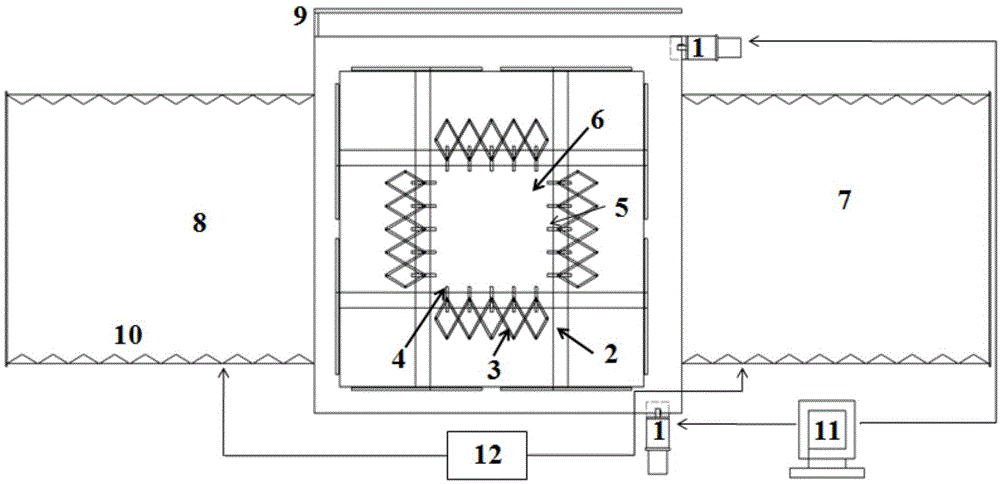

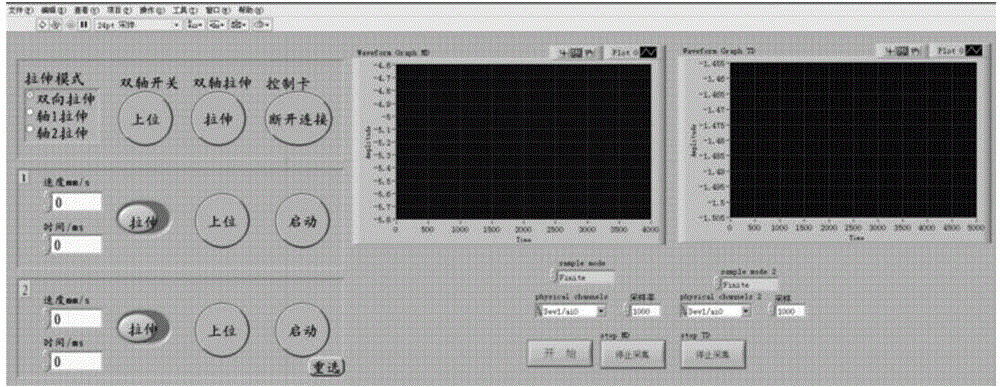

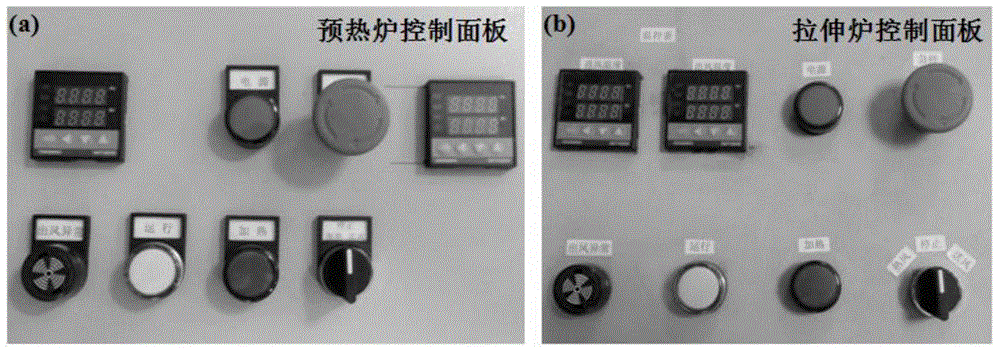

[0042] A temperature-controlled high-speed and large-strain film biaxial stretching device, see attached figure 1 , including high-precision servo motor 1, "well"-shaped guide rail 2, scissor mechanism 3, high-pressure pneumatic clamp 4, tension sensor 5, film sample 6, preheating furnace 7, stretching furnace 8, and is a high-precision ball screw 9. "Organ-style" protective cover 10, strain and stretching speed control system 11, hot air circulation system 12; high-precision servo motor 1 drives "well"-shaped guide rail 2 to move independently, so that scissor mechanism 3 completes telescopic movement, scissors The fork mechanism 3 realizes the stretching of the film sample 6 through multiple high-pressure pneumatic clamps 4. The stretching method can be selected as one-way or two-way stretching, and the running speed is continuously adjustable, which can well matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com