Glass tube heating and firing device for manufacturing high borosilicate glass container

A high borosilicate glass and container manufacturing technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve problems such as low operating efficiency, achieve adjustment effects, improve heating and firing effects, and prompt adjustment flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

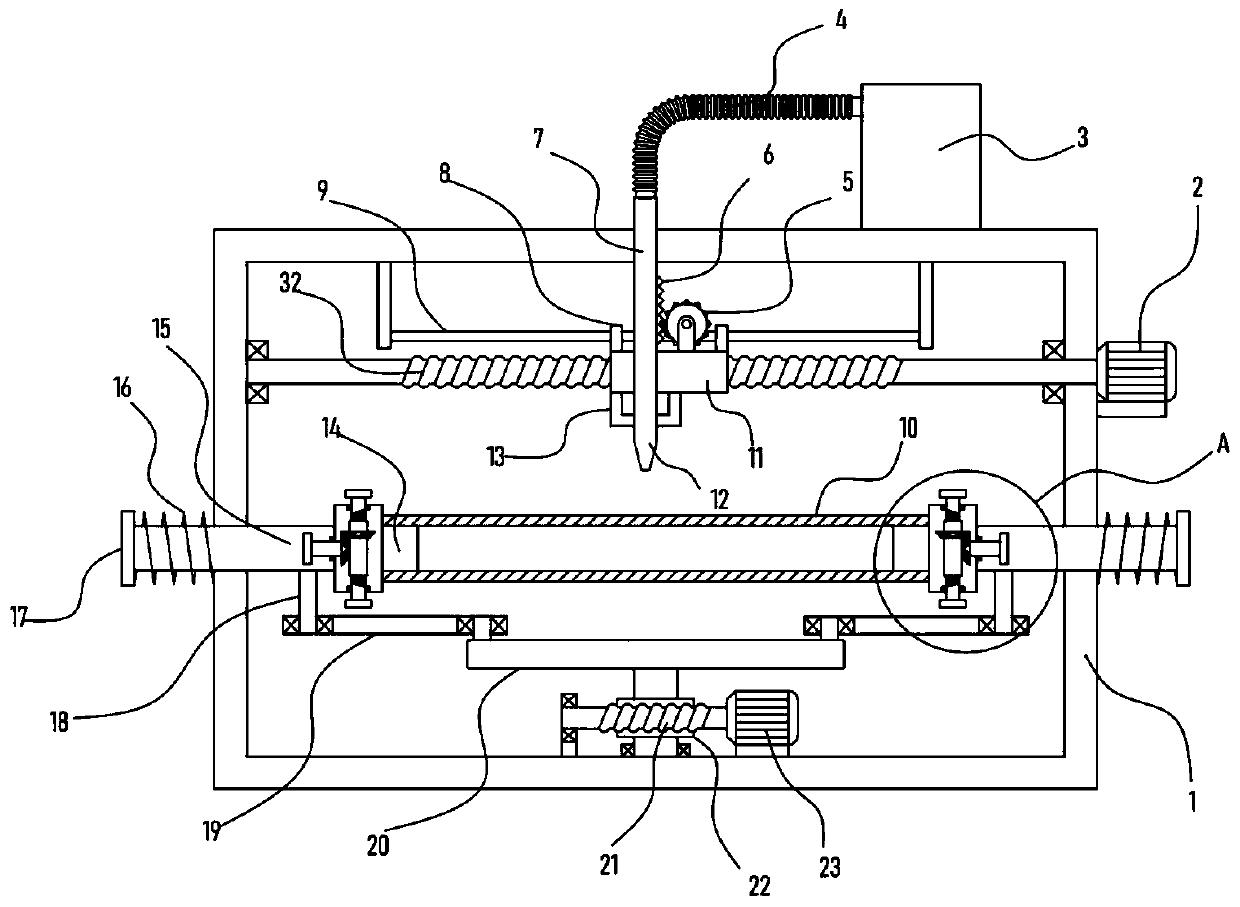

[0023] See Figure 1-4 , A glass tube heating and firing device for the manufacture of high borosilicate glass containers, comprising a fixing frame 1, a gas tank 3 is fixed on the fixing frame 1, and the fixing frame 1 is provided with a translation mechanism driven by a motor I2. A screw sleeve block 11 is provided. A limit frame 13 is fixed at the bottom of the screw sleeve block 11. A nozzle 12 connected to the gas tank 3 is slidably installed on the limit frame 13, and the screw sleeve block 11 is provided with a nozzle 12 for driving Vertically adjustable lifting mechanism, the fixed frame 1 is fixed with a motor II23, two symmetrically arranged guide rods 15 are slidably mounted on the fixed frame 1, and the guide rods 15 are fixed on the ends of the glass tube 10 A locking mechanism, a driving mechanism for driving the guide rod 15 to slide laterally is drivingly connected to the motor II23.

[0024] The locking mechanism of the device locks and fixes the two ends of the...

Embodiment 2

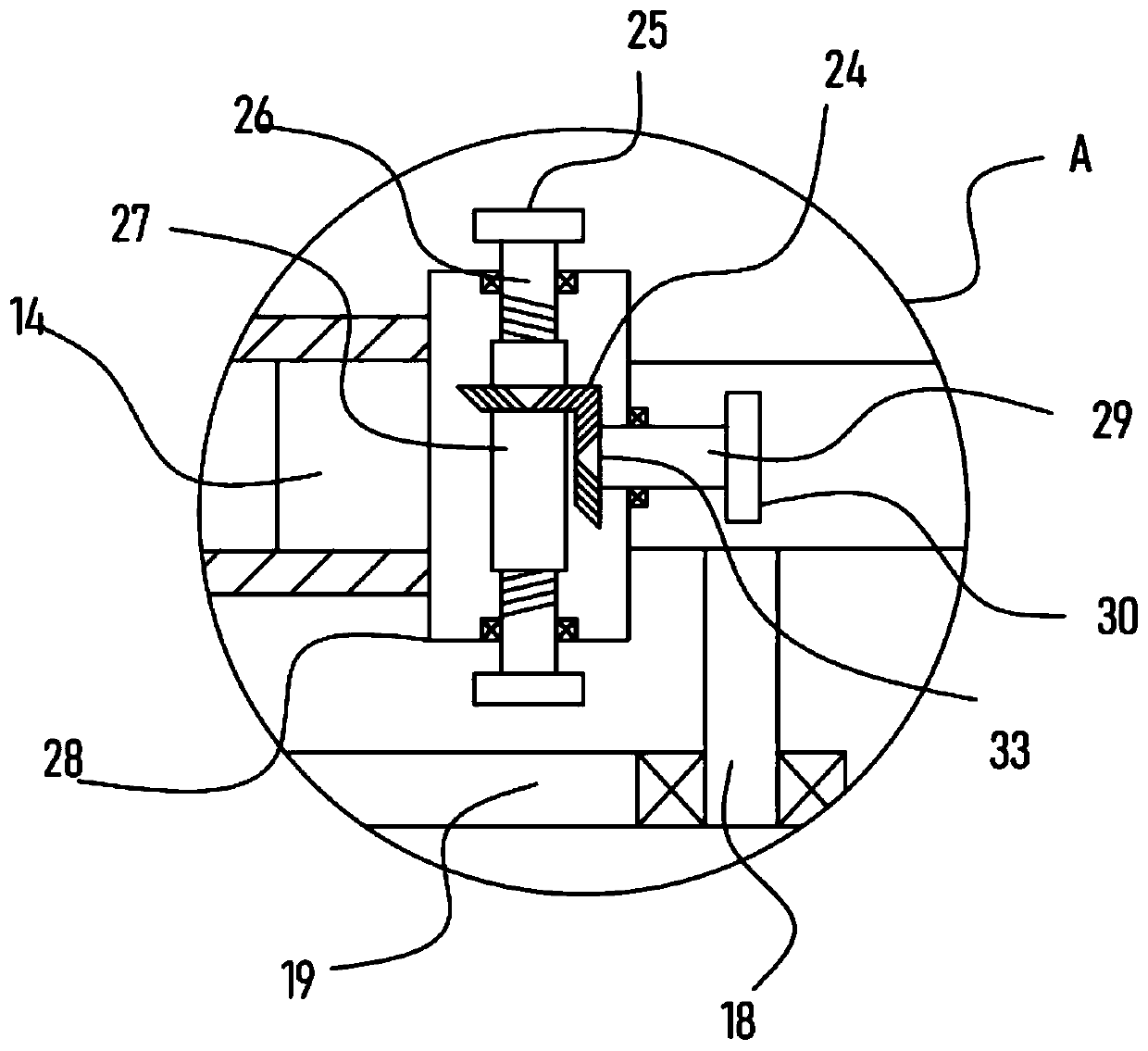

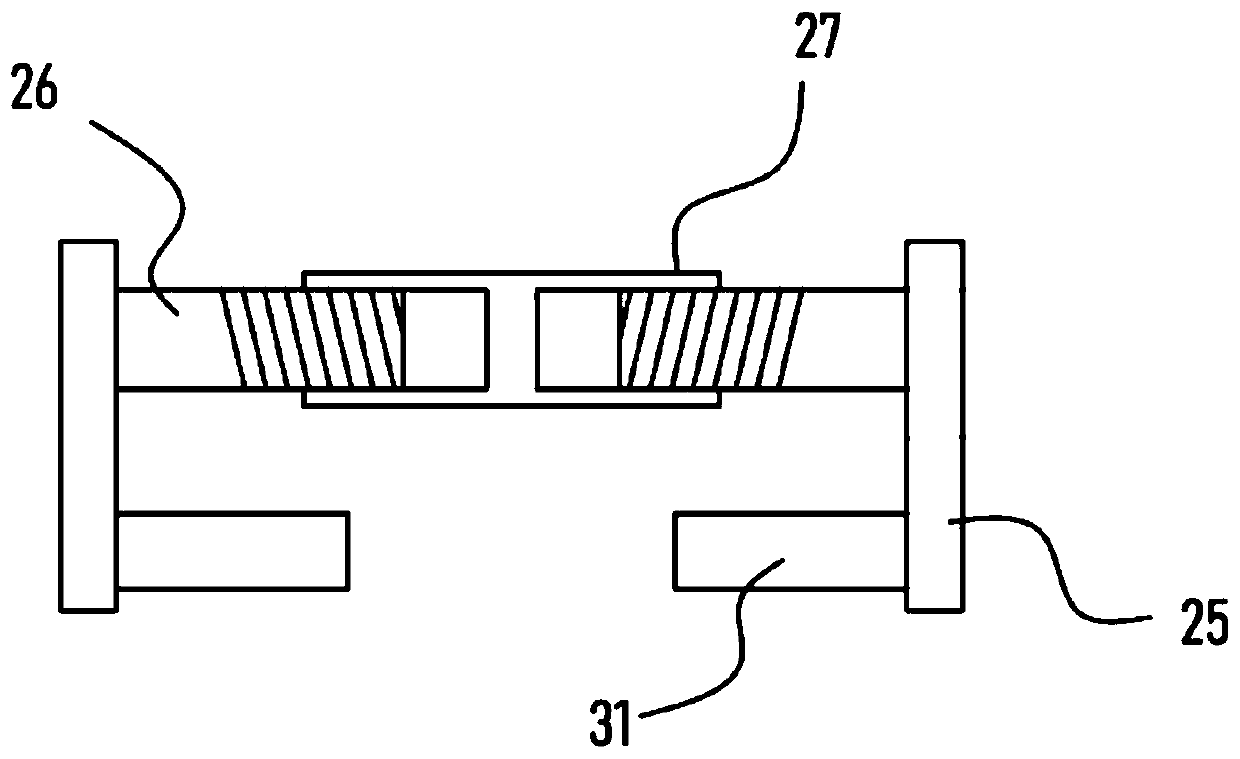

[0029] On the basis of embodiment 1, in addition, the locking mechanism of the device includes a clamping sleeve block 28 fixed at the end of the guide rod 15, and a clamping block 14 is fixed on the clamping sleeve block 28, the clamping sleeve block 28 A threaded sleeve 27 is installed on the upper rotation. Two screws 26 with opposite screw threads are connected in the threaded sleeve 27. The end of the screw 26 is fixed with a connecting plate 25, and the connecting plate 25 is fixed with a sliding block inserted into the clamping sleeve. 28, the locking mechanism also includes a rotating shaft 29 rotatably mounted on the clamping sleeve 28, a bevel gear II33 is coaxially fixed on the rotating shaft 29, and a bevel gear II33 is meshed and connected with a sleeve and fixed on the thread Bevel gear I24 on sleeve 27.

[0030] The two ends of the glass tube 10 are inserted into the clamping sleeve block 28, the set block 14 enters into the glass tube 10 for support, and the screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com