Method for continuously rolling copper pipe through planetary pipe mill

A planetary tube rolling mill, copper tube technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of rolling tube quality, different feeding force and speed, and larger pitch, etc. The effect of increasing production and facilitating technological transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

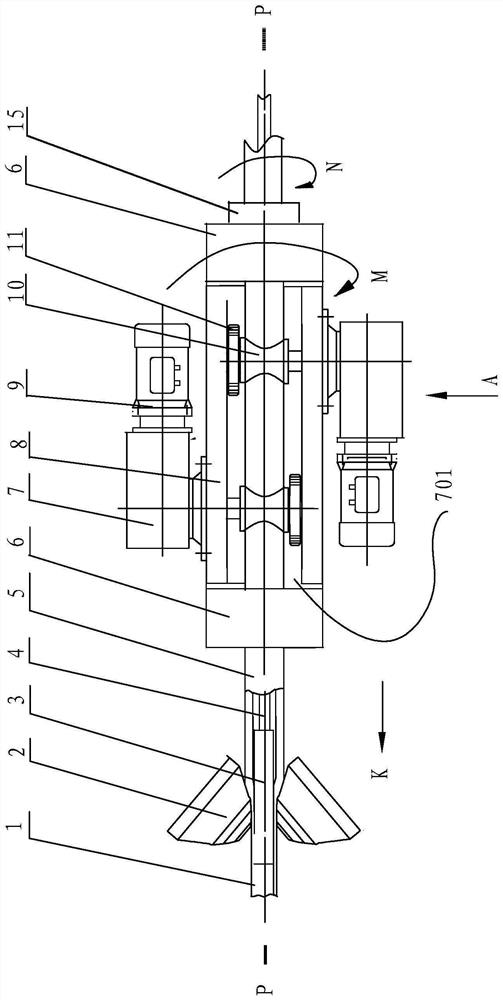

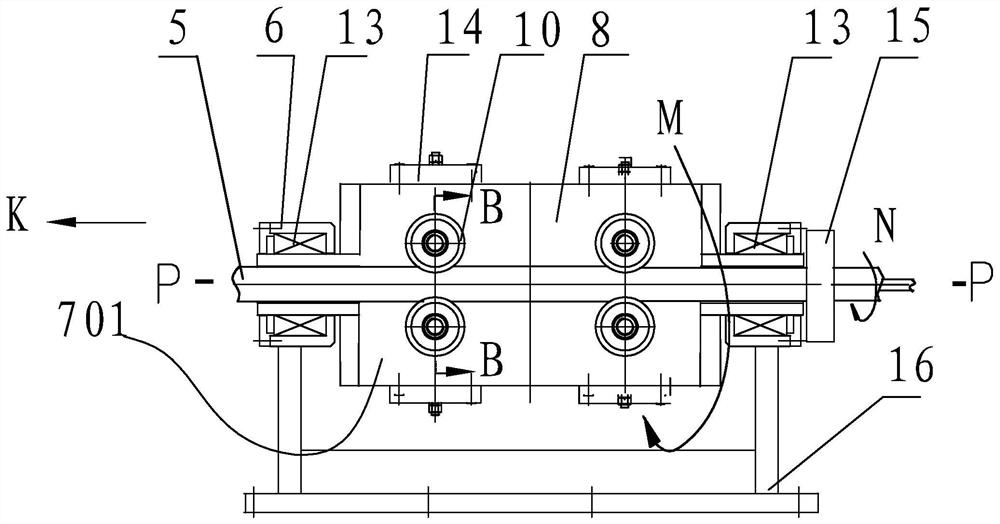

[0045] figure 1 It is a schematic diagram of the principle of the top view of the planetary pipe rolling mill for continuously rolling copper pipes in Embodiment 1 of the present invention, figure 2 for figure 1 A-direction view, image 3 for figure 2 The B-B view.

[0046] Embodiment 1 adopts a roller feeder as a tube billet feeder, figure 1The middle roll feeding machine 701 is placed at the entrance of the planetary rolling mill 2, and its structure is a two-stand pair-roll feeding structure. The motor 9 , the reducer 7 and the gear 11 drive the respective feed rollers 10 to rotate, and the conductive slip ring 15 transmits power to the motor 9 . The outer diameter of the feeding roller 10 is processed with a semicircular pass, so that it can fit closely with the outer diameter of the tube blank. A set of pressing device 14 compresses the feeding roller 10 and the tube blank 5, so that the roller feeder 701 can continuously feed the tube blank 5 one by one into the ...

Embodiment 2

[0054] Figure 4 It is a schematic diagram of the principle of the top view of the planetary pipe rolling mill for continuously rolling copper pipes according to the second embodiment of the present invention, Figure 5 for Figure 4 A-direction view, Image 6 for Figure 5 C-C view of . Embodiment 2 uses a crawler feeder as the billet feeder. The crawler feeder 702 plays the same role as the roller feeder 701. The feeder 702 can continuously and stably provide the feeding force for the billet 5, and also It can be passively rotated around the center line P-P driven by the tube blank.

[0055] First, the crawler feeder 702 is also placed at the entrance of the rolling mill, and there is only one feeder. Two chains (tracks) 53, two main sprockets 51, and two auxiliary sprockets 55 are installed on the crawler belt rotating frame 56 to form the main structure of the crawler belt feeding machine. Two chains have respective drive unit motor 9 and speed reducer 7. A briquett...

Embodiment 3

[0057] Figure 7 It is a schematic diagram of continuous feeding of tube blanks at the foreground of a three-roll planetary tube mill in Example 3 of the present invention. Wherein it comprises a material storage feeding rack 71, a fixed feeder 72, a front mandrel holder 73, an intermediate feeder 74, a rear mandrel holder 75, a planetary pipe mill 2 and a roller feeder 701. Among them, the roller feeding machine adopts a double pair of roller structure, the power between the pair of rollers is transmitted by gears, and the butterfly spring is adjusted to control the pressing force of the tube blank. The feeder controls the torque of the motor 9 through the conductive slip ring 15, and the motor 9 applies a constant feed force to the feed roller 10 through the reducer 7, and the feed force is adjustable within 0-30KN.

[0058] For convenience of description, the Figure 7 The key positions in the length direction of the planetary pipe mill are marked as D, E, F, G, H, I, J. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com