Optical element grinding and polishing device and machining method

A technology of optical components and polishing devices, which is applied in the direction of grinding devices, optical surface grinders, grinding/polishing equipment, etc., can solve the problems of small tool removal function changes, material removal instability, large and medium frequency ripple errors, etc., to achieve suppression Eliminate function instability and intermediate frequency ripple errors, improve component processing efficiency, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

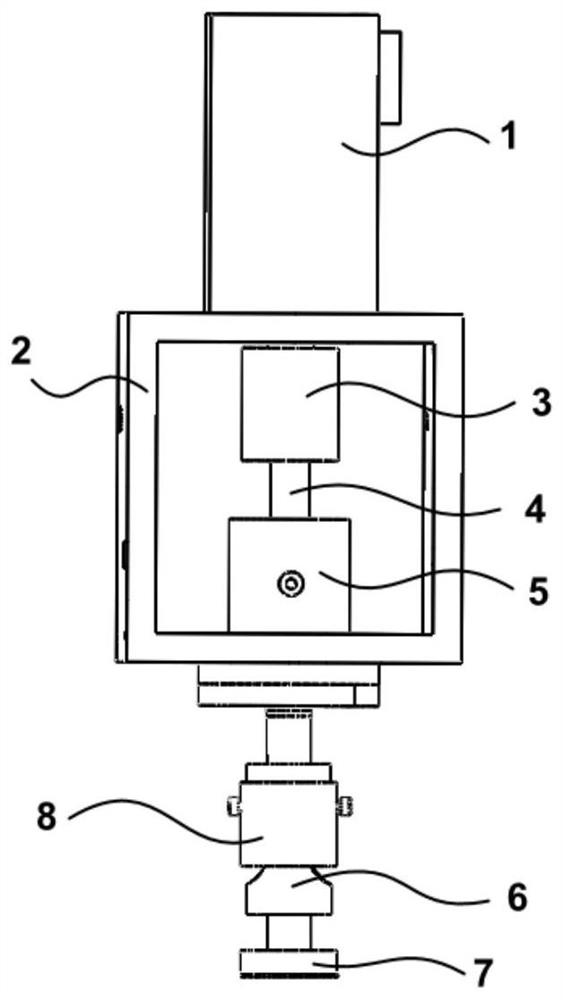

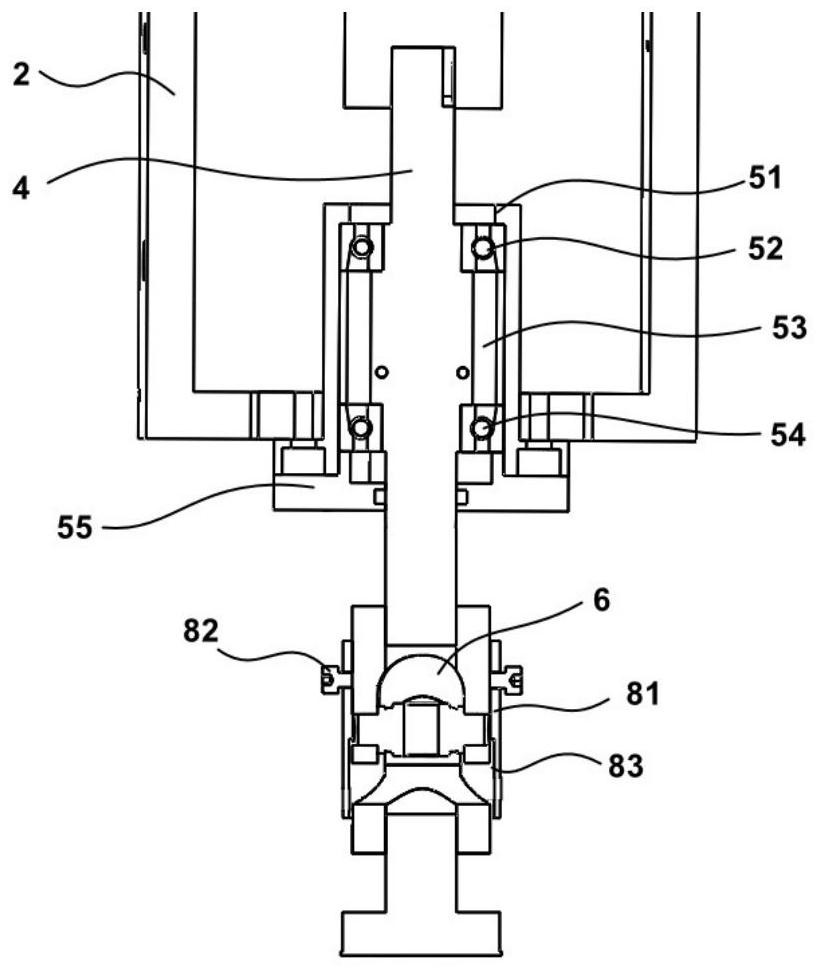

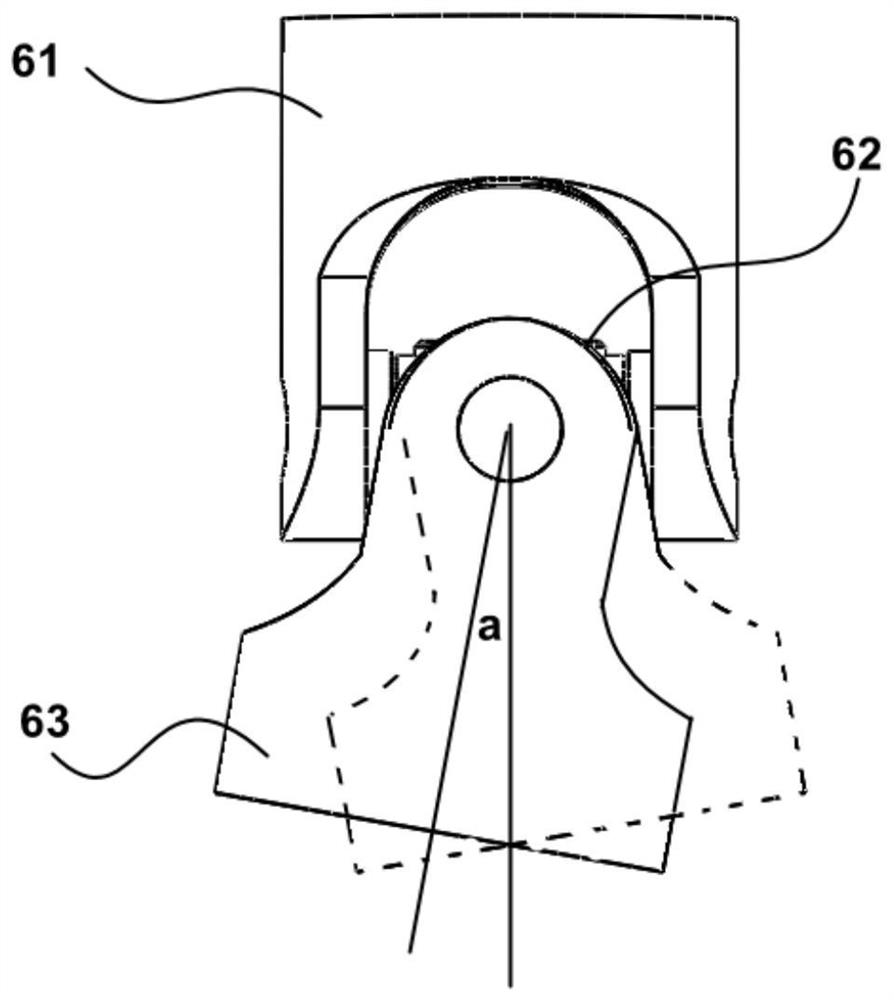

[0048] 1) The drive motor 1 is located at the top, and the grinding and polishing tool 7 is located at the bottom, and the bracket 2 of the grinding and polishing device is fixedly installed on the sixth axis flange end of the industrial robot 9 through the installation hole. The center line angle a of the input end sleeve fork 61 and the output end sleeve fork 63 is adjusted to be 0° (the deviation of the center line angle ≤ 1 ') by the limit sleeve 8. Adjust the sleeve fork 63 at the output end so that the lower surface of the grinding and polishing tool 7 is parallel to the reference plane 11-1 of the turntable (included angle≤10").

[0049] 2) The working turntable 10 is located in front of the robot 9 , and the optical element 11 to be processed is fixed on the working turntable 10 . It is stipulated that facing the industrial robot 9, the center point of the working turntable 10 is the origin, and the connection line between the industrial robot 9 and the working turntab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com