Multi-station rotating tooling device for plasma physical vapor deposition

A physical vapor deposition, multi-station technology, applied in metal material coating process, fusion spraying, coating, etc., can solve complex profiles and shielding parts, uneven connection of transition areas, excessive heat flow input, etc. problems, to achieve the effect of ensuring the uniformity of the organizational structure, reasonable and appropriate station settings, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation of the present invention is described in detail below, and described description implements under the technical solution that the present invention proposes, provides detailed implementation and specific operation process, but protection scope of the present invention is not limited to following examples.

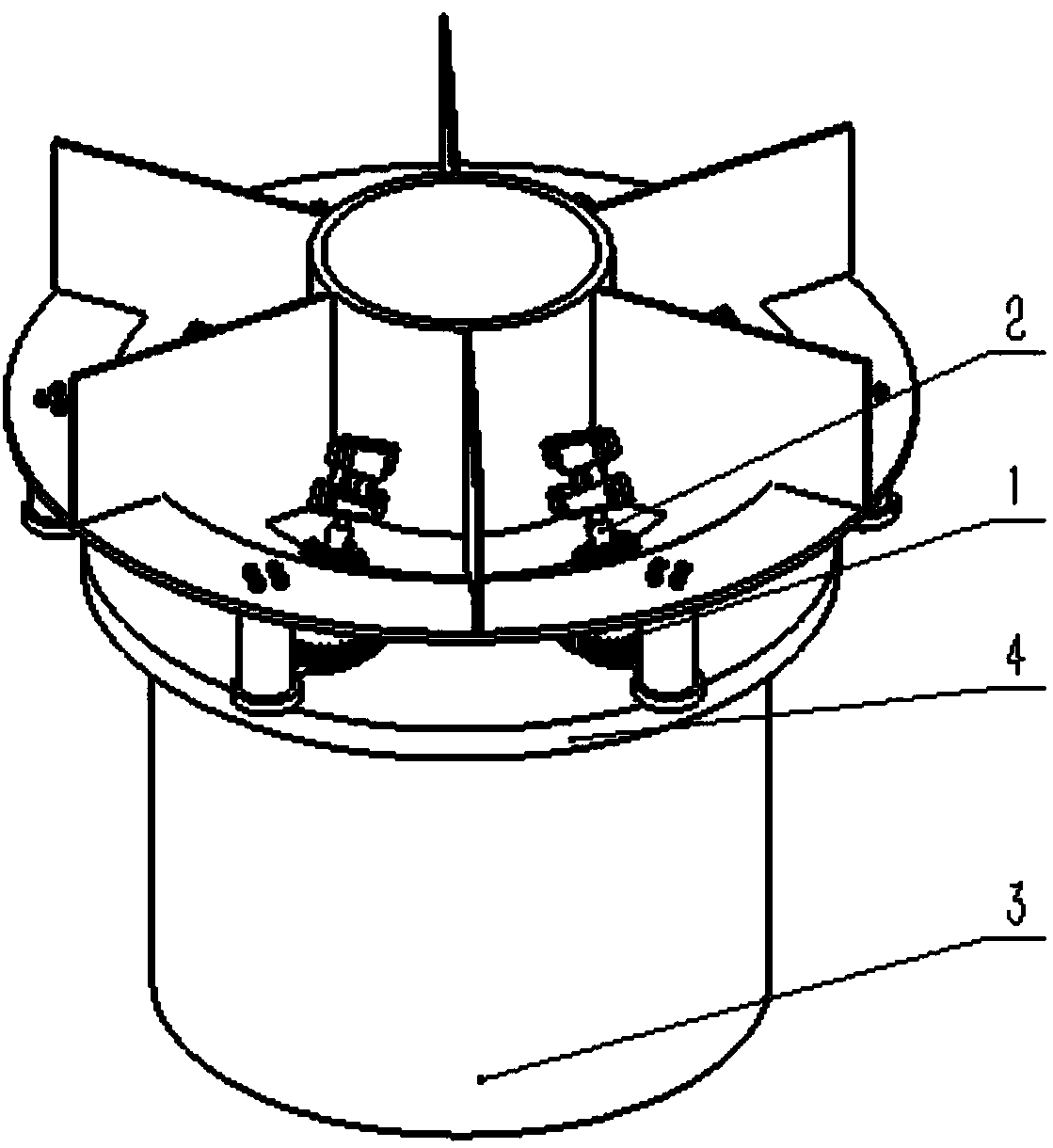

[0047] like figure 1 As shown, the present invention designs a multi-station rotary tooling device in the field of plasma spraying. The multi-station rotary tooling device is composed of four parts: a revolution system, an autorotation system, a control system, and a support frame; the revolution system is installed on the support frame On the top, revolution and rotation are realized. The autorotation system is installed on the high-precision mounting surface of the revolution system to realize self-propagation rotation. The control system realizes single-axis input and multi-axis output by controlling the motor speed of the electric spind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com