Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about How to "Avoid processing failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

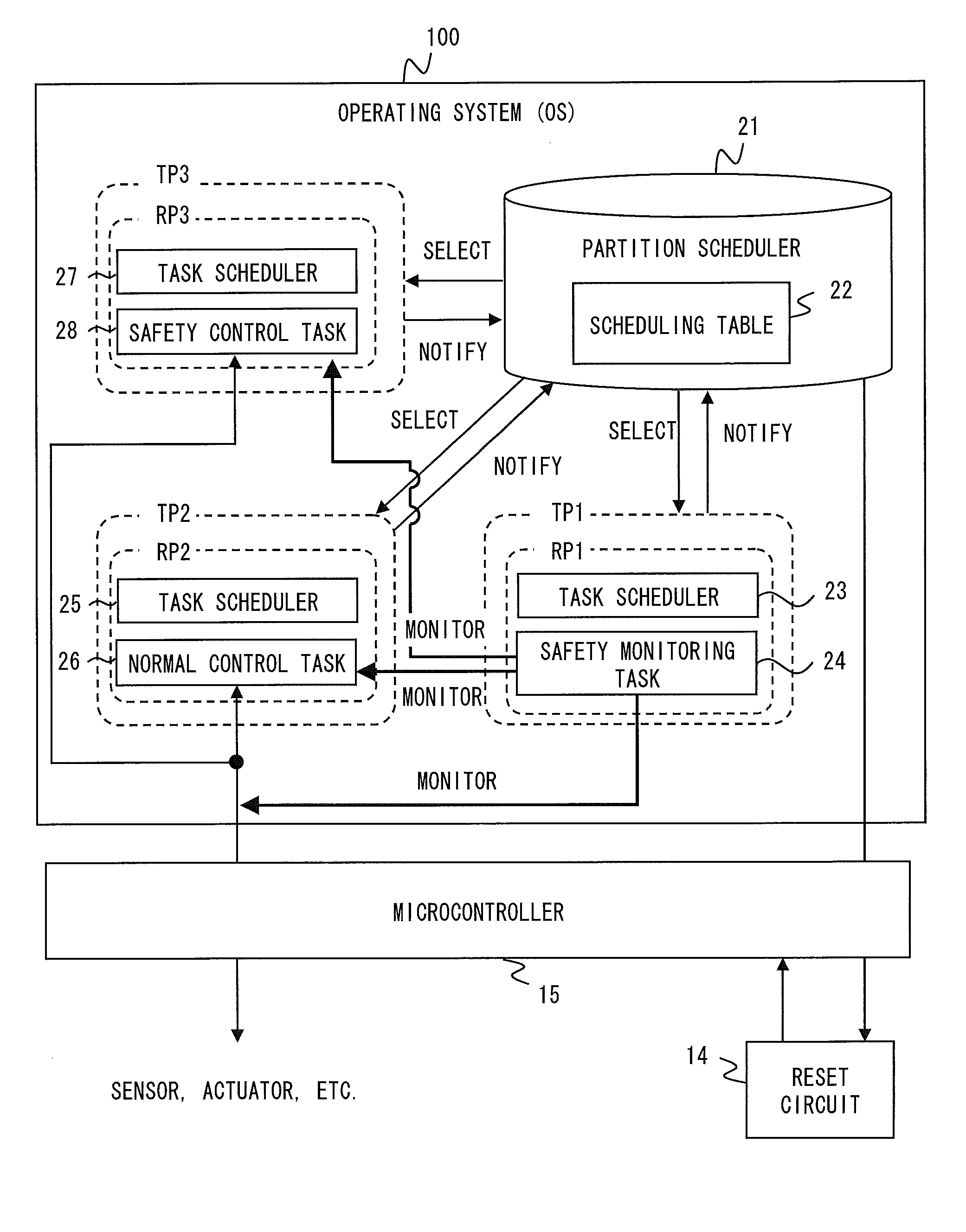

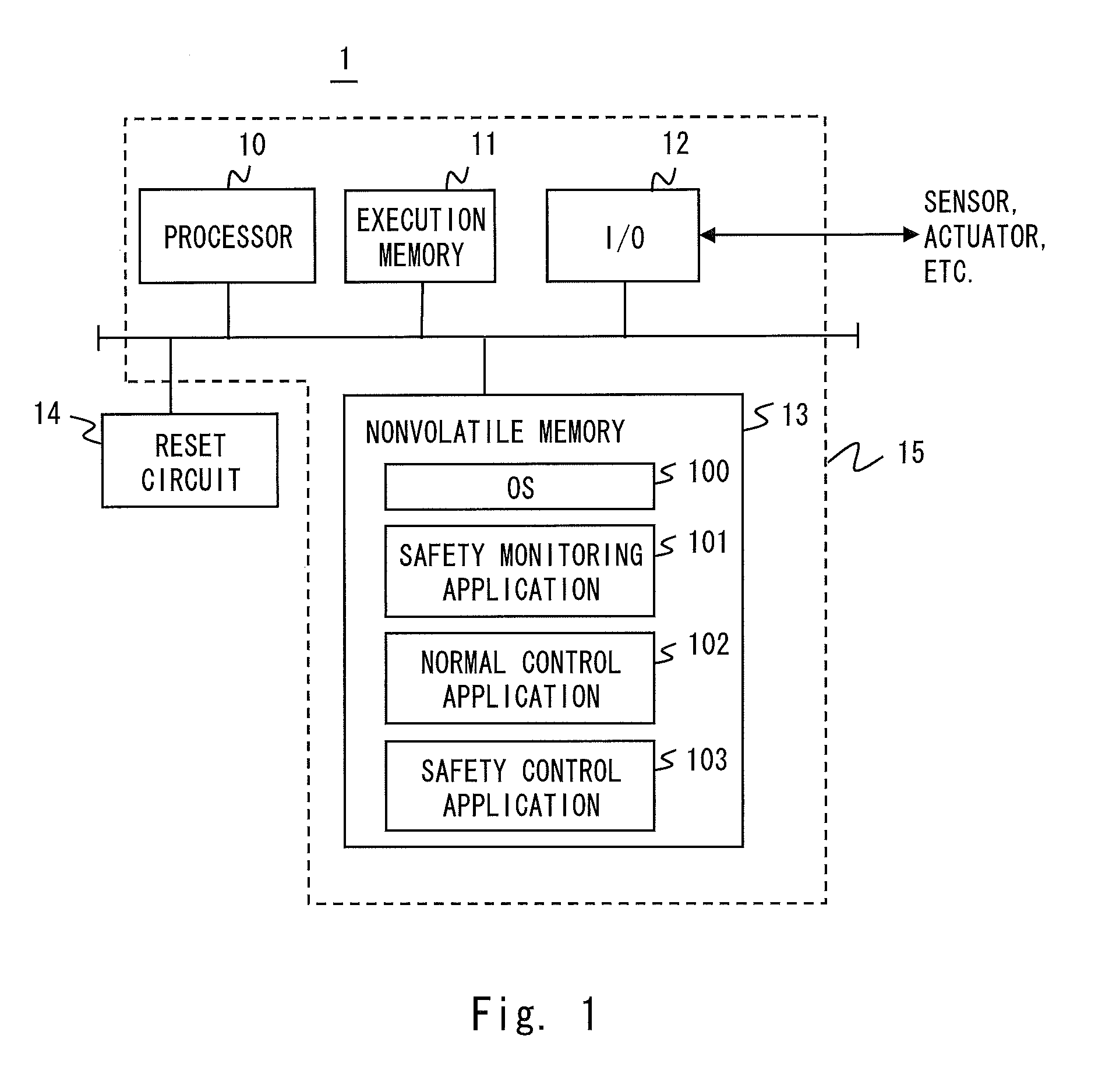

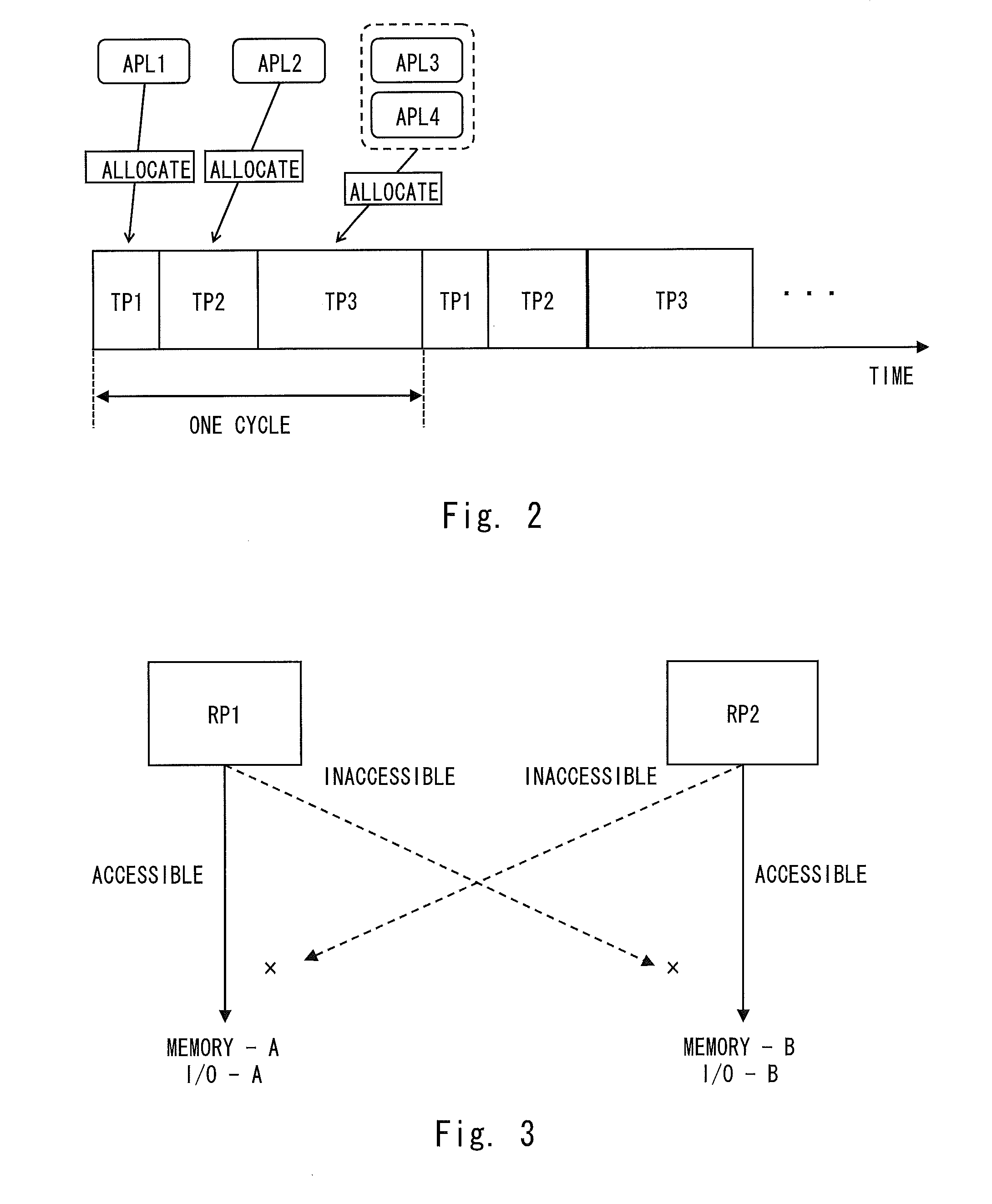

Safety controller and safety control method

InactiveUS20120198464A1Prevent failureSuppress execution delayProgramme controlSafety arrangmentsOperating systemExecution time

The present invention relates to time partitioning to prevent a failure of processing while suppressing execution delay of interrupt processing even when the interrupt processing is executed. A safety controller includes: a processor; a system program for controlling allocation of an execution time of the processor to a safety-related task, a non-safety-related task, and an interrupt processing task; and an interrupt handler. Upon generation of an interrupt, the processor executes the interrupt handler to reserve execution of the interrupt processing task as an execution reserved task, and executes the system program to schedule the tasks in accordance with scheduling information on a safety-related TP to which the safety-related task belongs, a non-safety-related TP to which the non-safety-related task belongs, and a reservation execution TP to which the execution reserved task belongs. When execution of a task in a previous TP is finished before the period of the previous TP prior to the execution reservation TP has expired, the execution time in the previous TP is allocated to the execution reserved task.

Owner:TOYOTA JIDOSHA KK

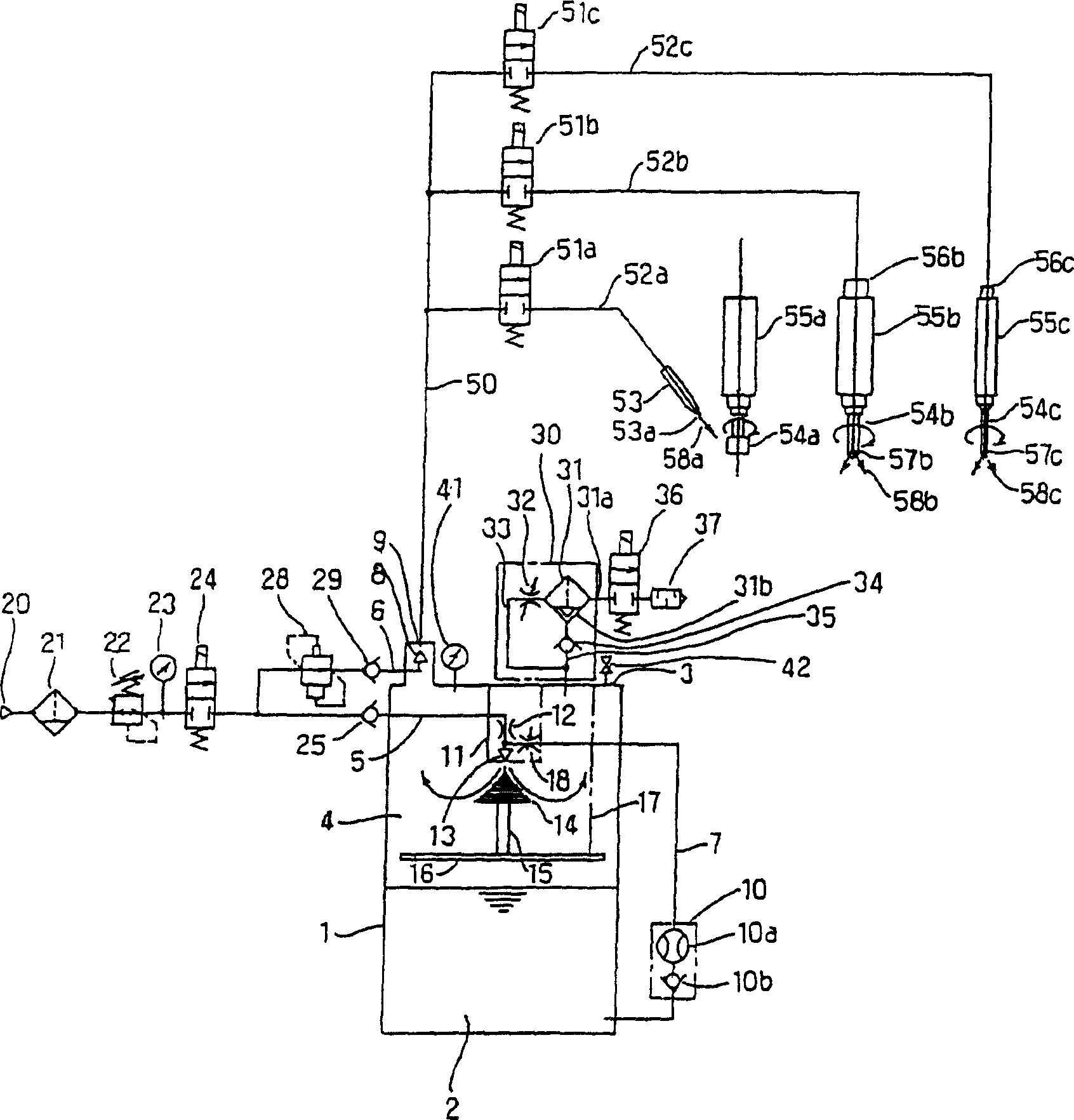

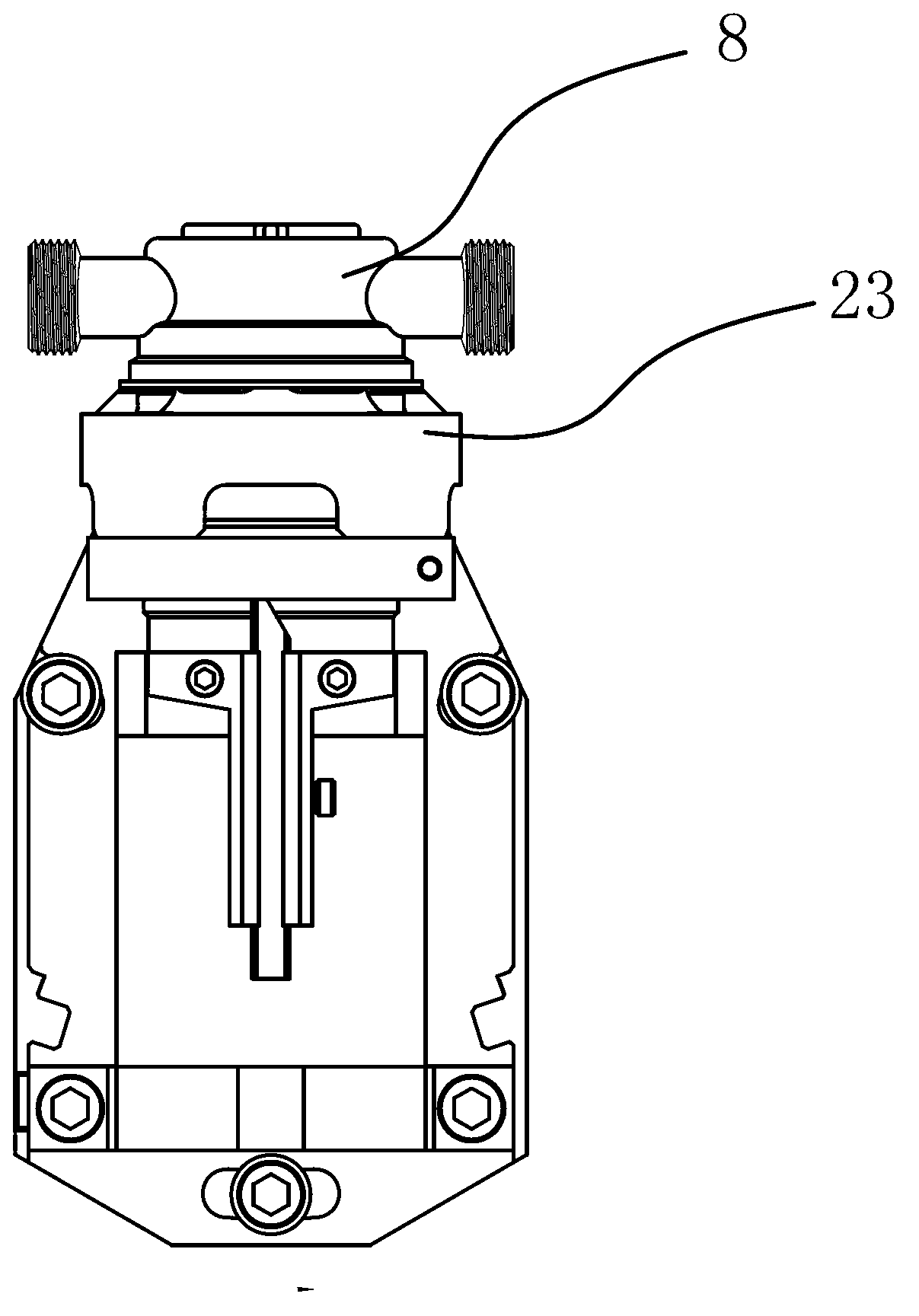

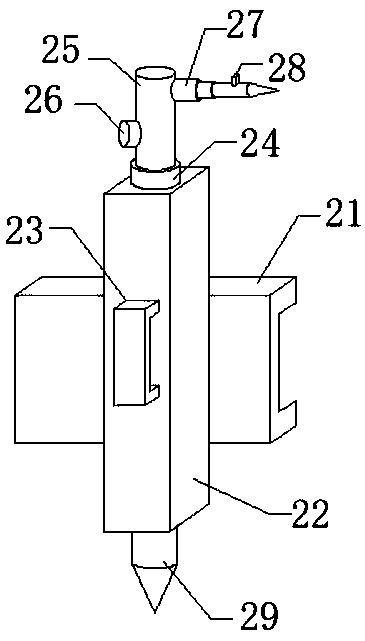

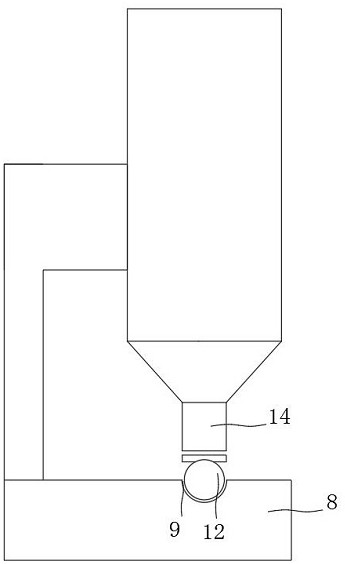

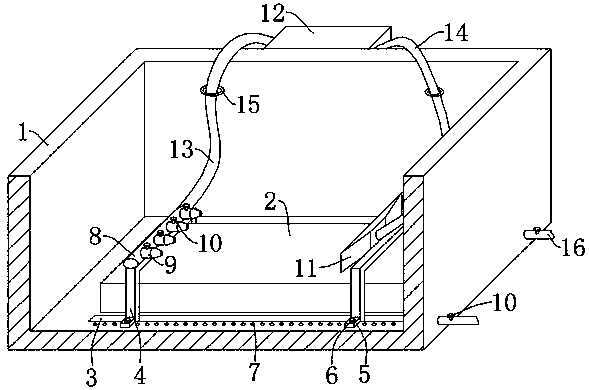

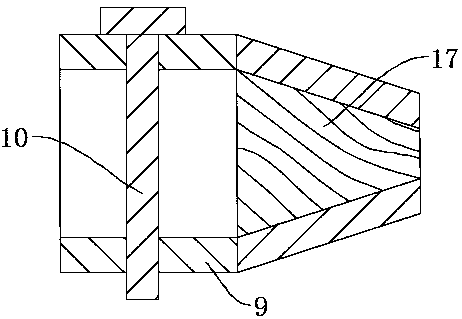

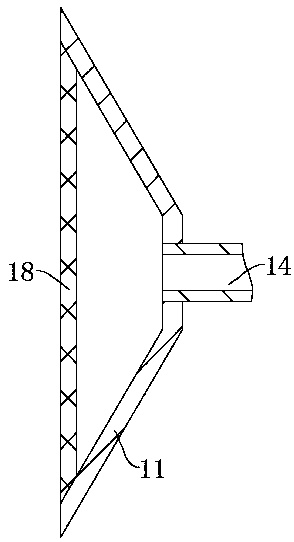

Gas apray generating apparatus

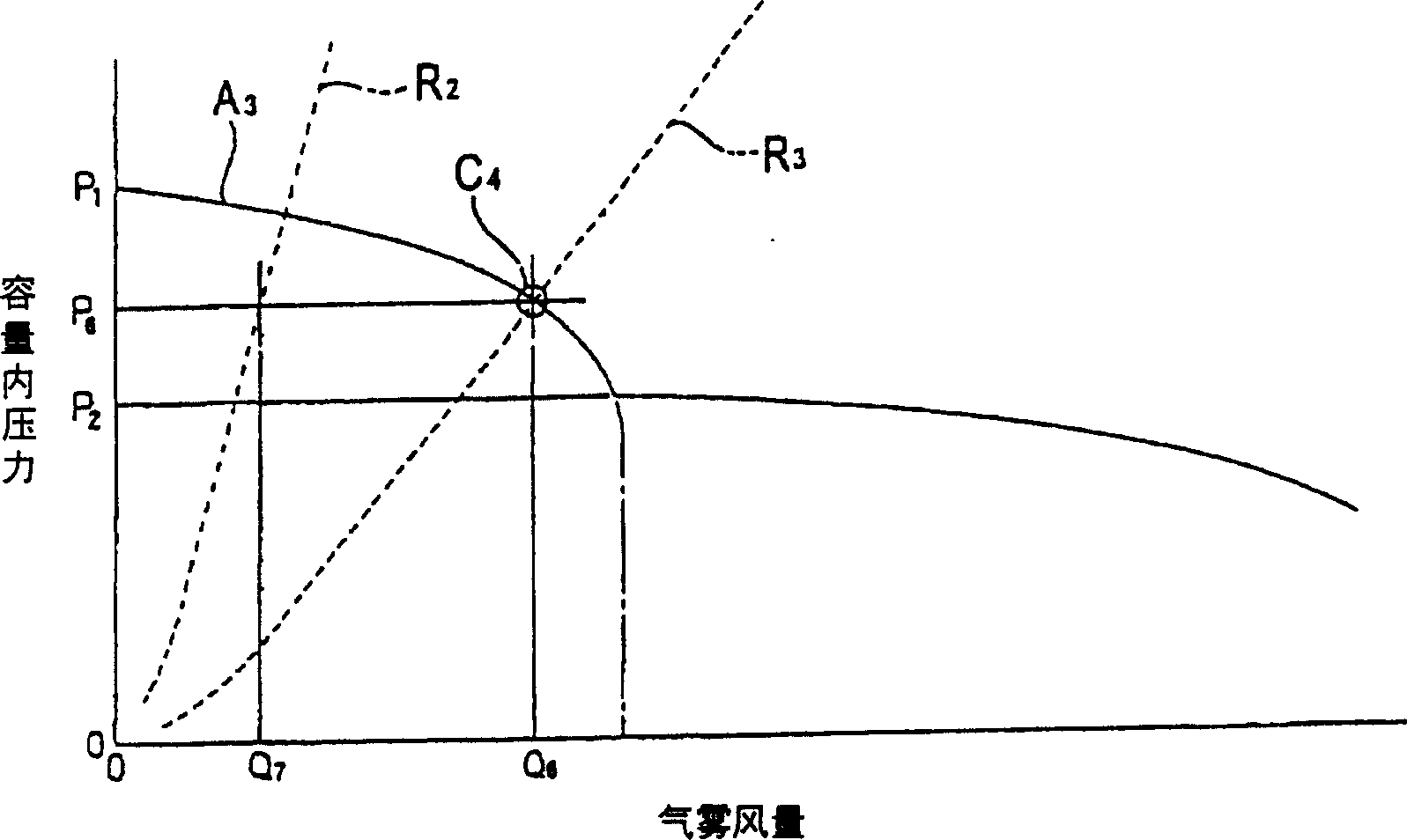

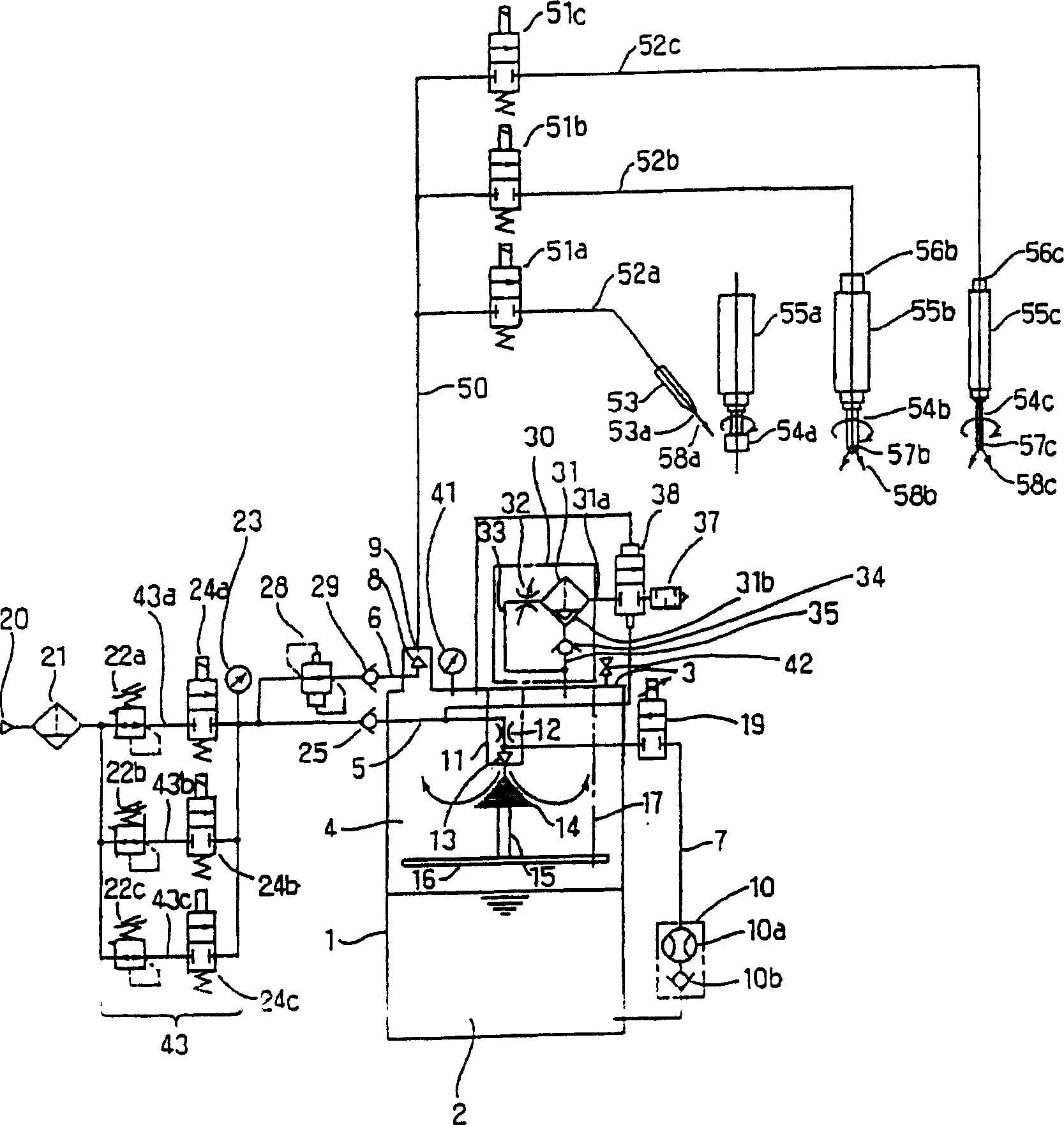

InactiveCN1524626AImprove convenienceAvoid processing failureLiquid spraying apparatusMaintainance and safety accessoriesEngineeringProduct gas

A mist generator is provided to avoid pressure adjustment in carrier gas supply to a carrier gas jet and to make MQL(Minimum Quantity Lubricant) processing possible. A mist generator comprises an injector(11) generating mist by receiving the liquid in a container(1) and the gas from a gas supply resource(20) and injecting the mist into the container, a duct(9) taking the mist in the container out of the container, and a carrier gas jet(8) communicated with the duct. A first pressure control unit(22) is installed in a gas supply passage(5) for supplying gas to the injector from the gas supply resource. A second pressure control unit(28) installed in a carrier gas supply passage(6) controls the secondary pressure of the first pressure control unit at a specific rate.

Owner:EBARA CORP

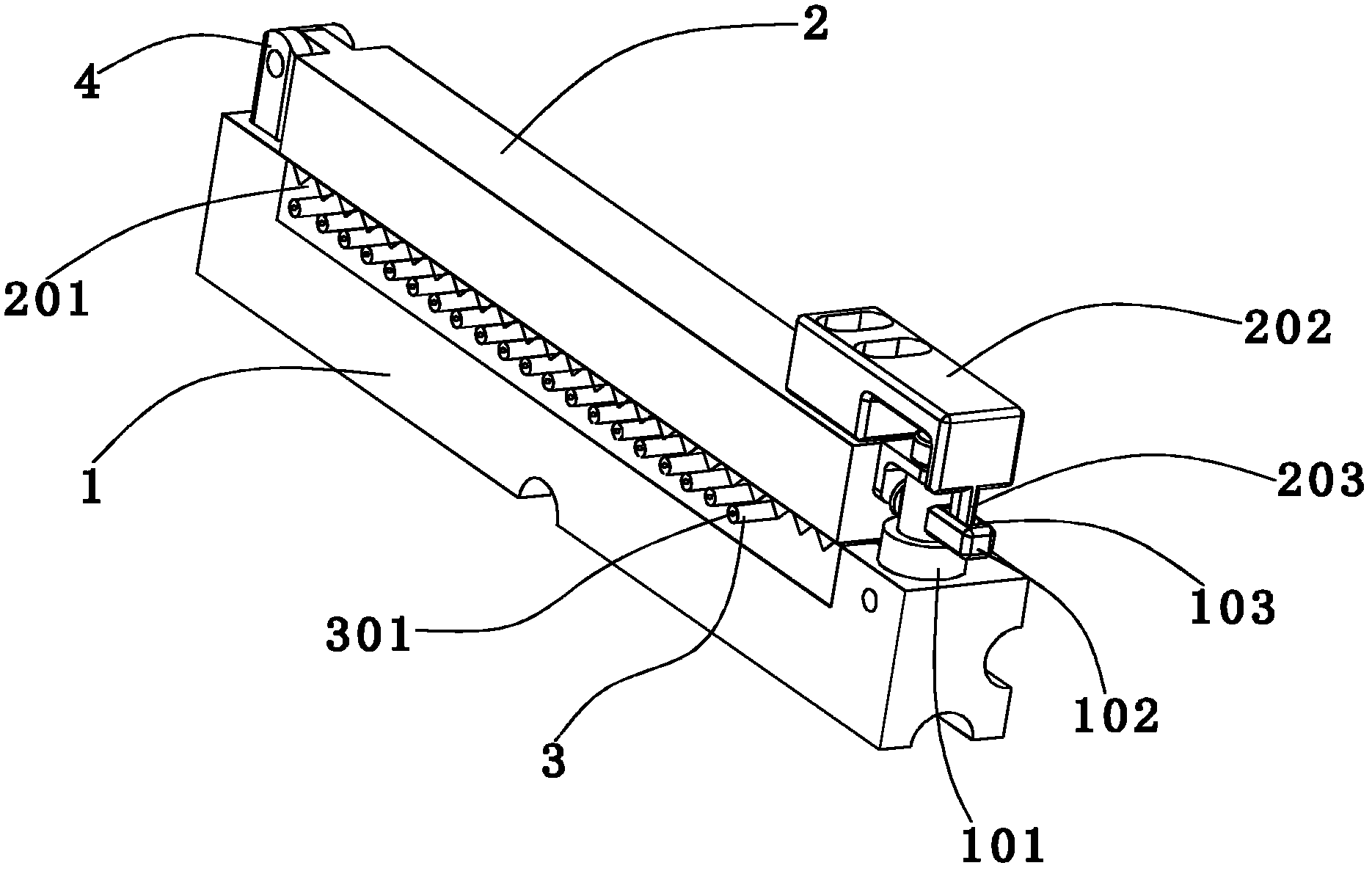

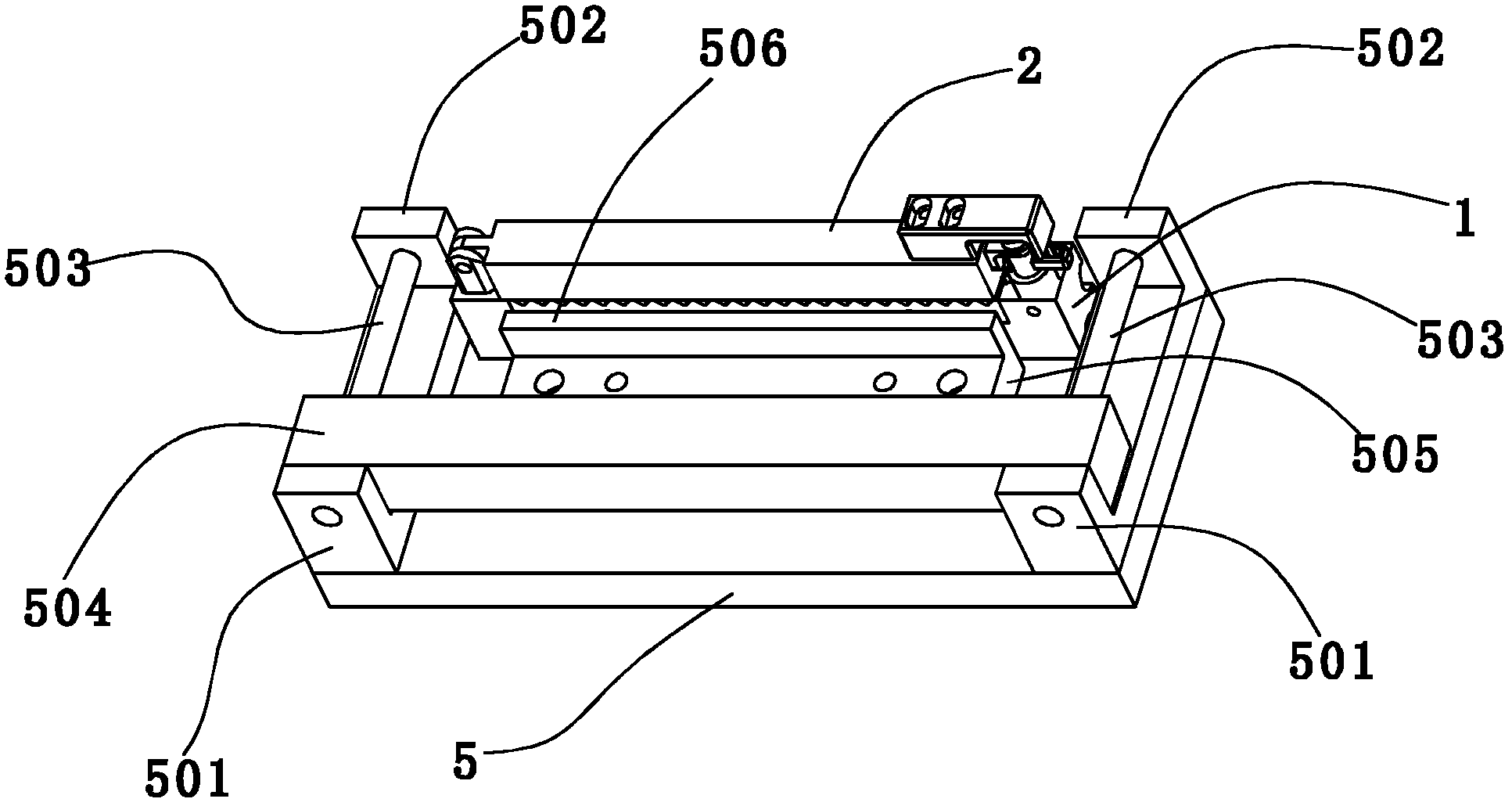

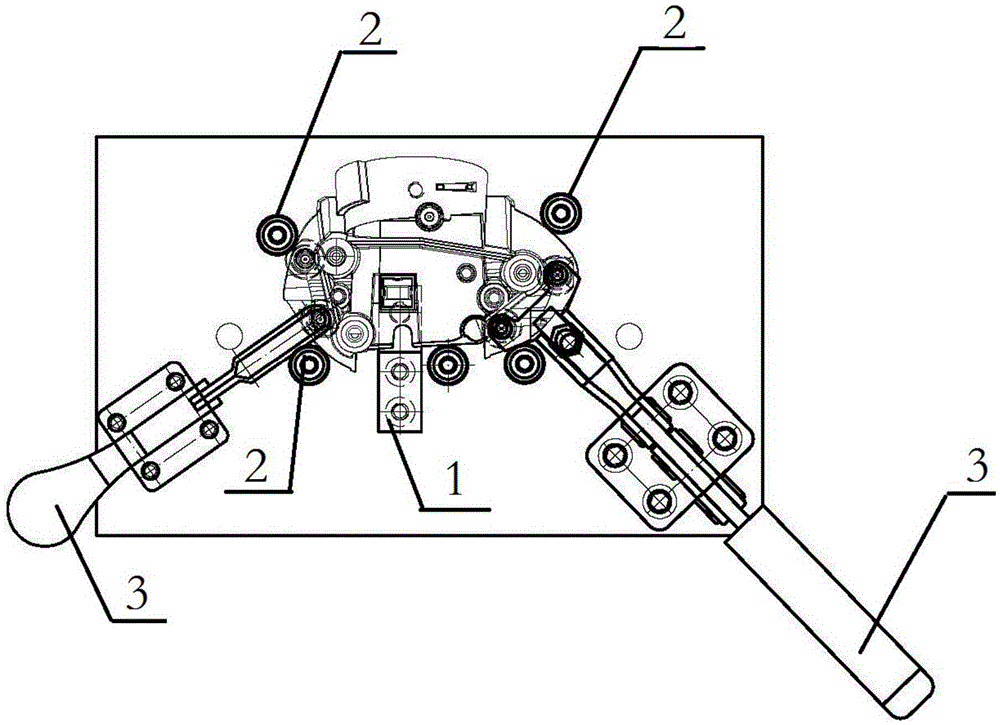

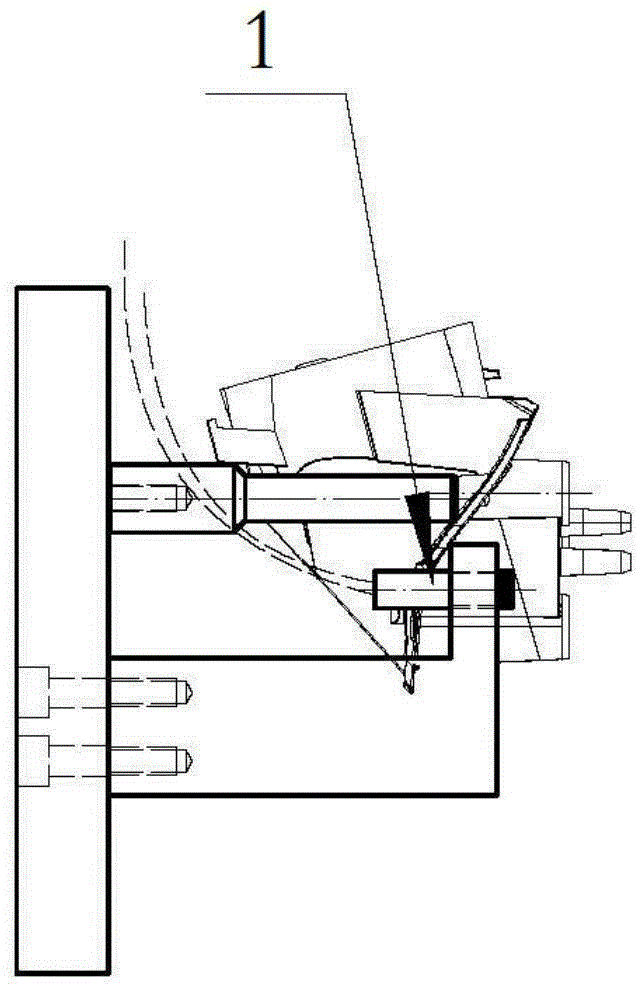

Production jig of optical fiber rapid connector and production method of optical fiber rapid connector

InactiveCN103185929AAvoid processing failureSolve labor intensityCoupling light guidesEngineeringFailure causes

The invention discloses a production jig of an optical fiber rapid connector and a production method of the optical fiber rapid connector. Inserting cores are fixed on an inserting core positioner, glue water is filled into the inserting cores, and the optical fibers are successively inserted into the inserting cores, then an optical fiber length fixing appliance fixes the length of each optical fiber which is inserted into the inserting core and enables the length of each optical fiber which is inserted into the inserting core to be the same, then the optical fibers which are inserted into the inserting cores are solidified to coagulate in the inserting core through the glue water, finally the inserting core positioner is installed on a protective cover fixture, protective covers are prefixed through a protective cover fixator, the number of the protective covers is the same as the number of the inserting cores, the positions of the protective covers correspond to the positions of the inserting cores, a handle is controlled to rotate to enable the protective cover fixator to correspond to and to be close to the inserting core positioner, finally corresponding inserting of the inserting cores into the protective covers are achieved, and production and manufacturing of the optical fiber rapid connector are completed. Compared with the prior art, the production jig of the optical fiber rapid connector and the production method of the optical fiber rapid connector can achieve manufacturing of a plurality of inserting cores, avoid problems of processing failure caused by excessively small inserting cores and optical fibers in manufacturing, solve the problems that labor intensity is high and production efficiency is low in manual manufacturing, and improve production efficiency by five time compared due to the adoption of the manufacturing method.

Owner:SHENZHEN HPN COMM TECH

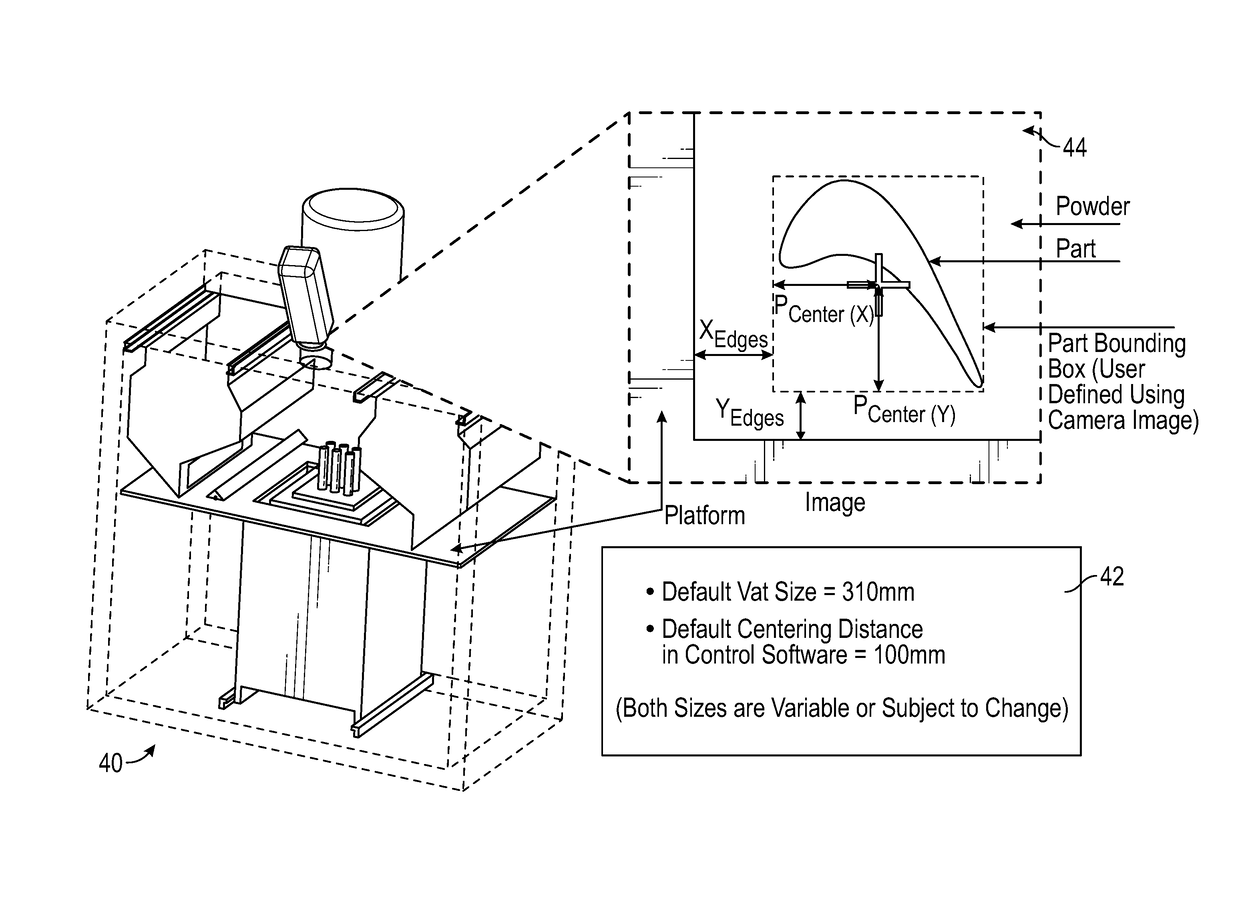

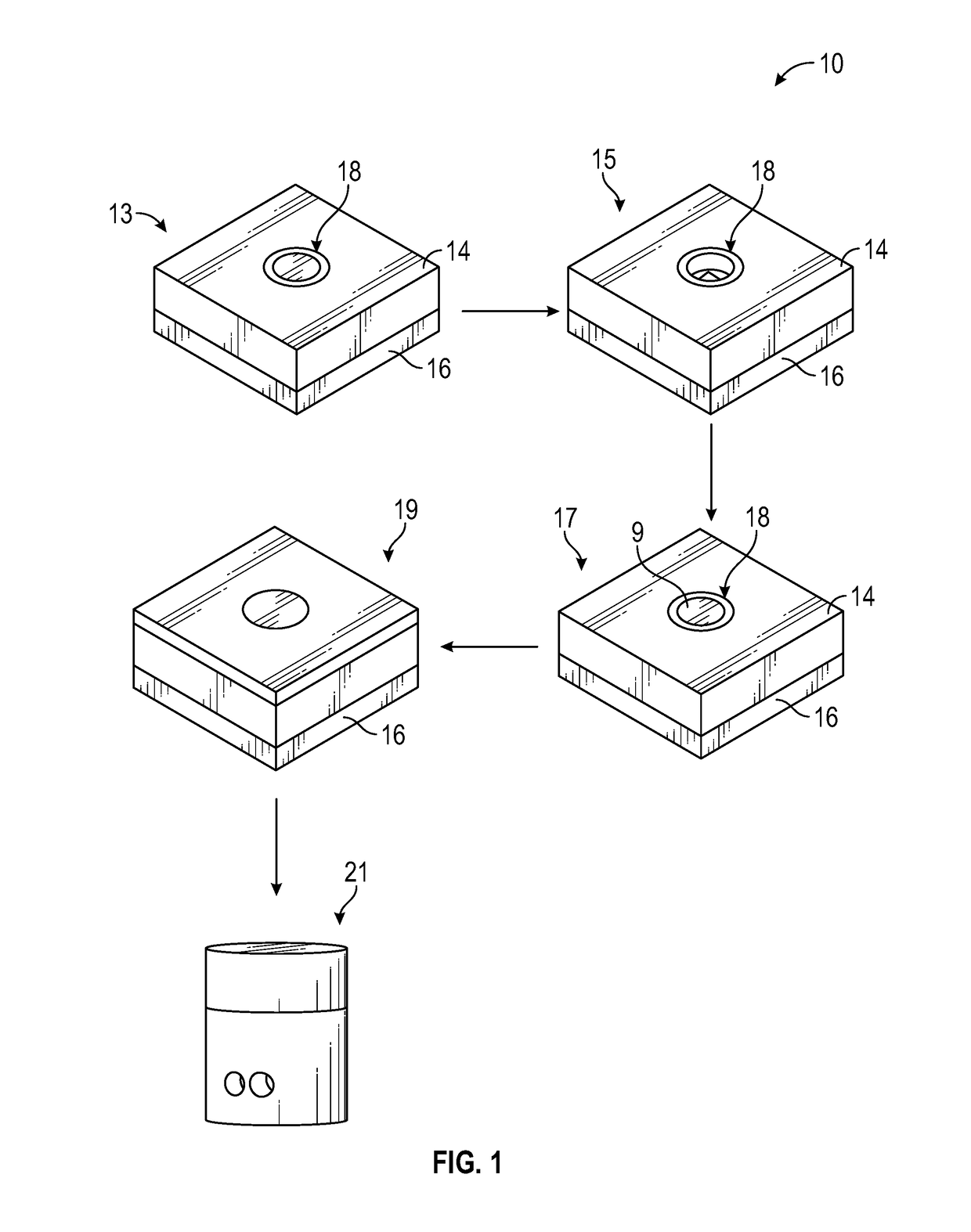

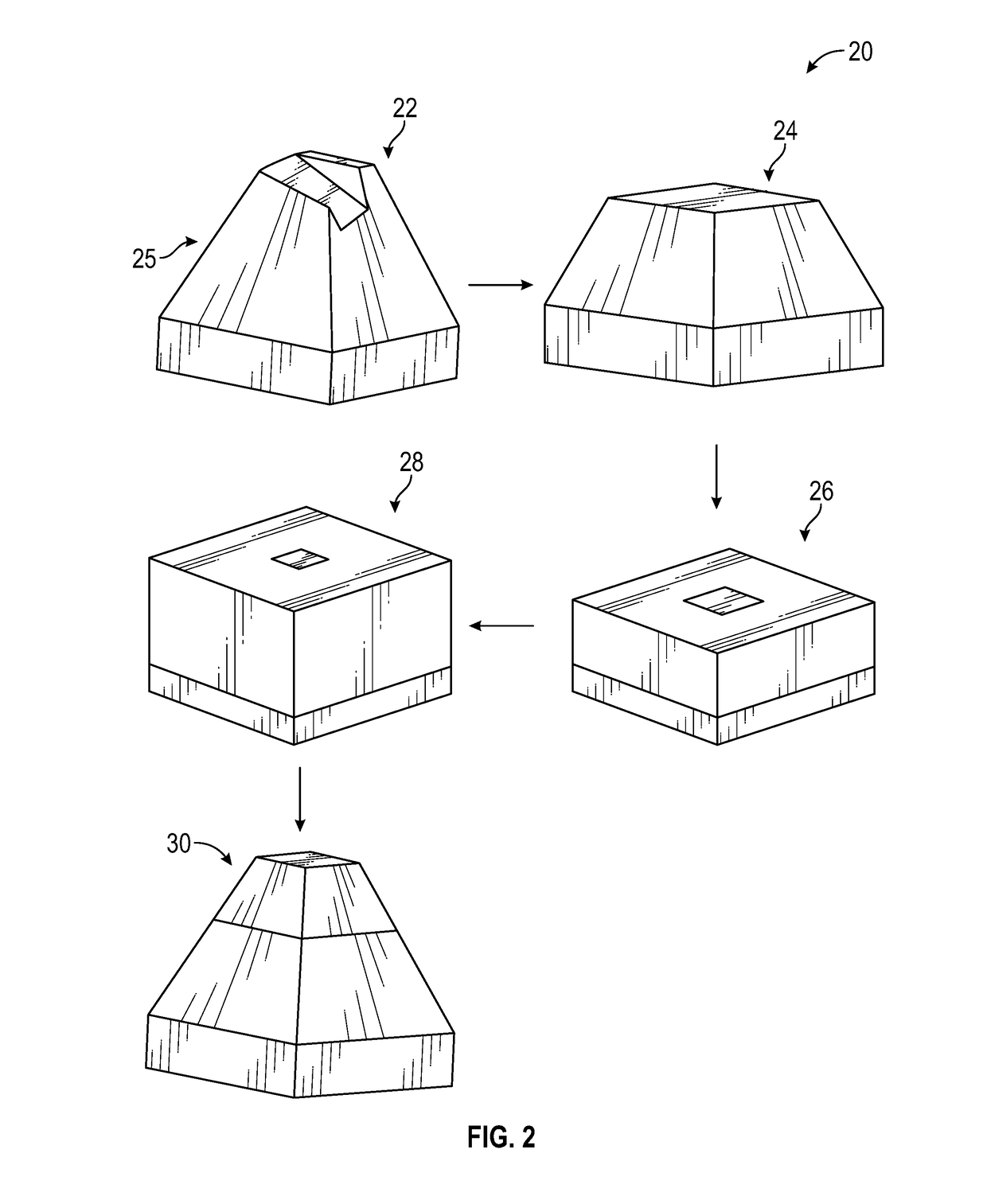

Method of fabrication for the repair and augmentation of part functionality of metallic components

ActiveUS20170095882A1Avoid processing failureAvoid smokingAdditive manufacturing apparatusIncreasing energy efficiencyRoom temperatureCooling down

Methods and systems for manufacturing a three-dimensional product. Fabrication of a three-dimensional part from a powder spread over a work table as a powder bed can be initiated. The fabrication process can be paused to cool down the work table to room temperature to obtain access to the three-dimensional part for post-processing operations such as, for example, embedding external artifacts. Fabrication can continue by preheating the powder rather than the work table until fabrication of the three-dimensional part is complete. A damaged part may be placed within the powder bed, wherein the fabrication process can be directly initiated to achieve part repair. Additionally, a material of the same part's composition can be used or a different material utilized to render the part better than new. Access to the three-dimensional part allows embedding of a foreign object in the three-dimensional part within the powder bed while the three-dimensional part remains non-finished.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

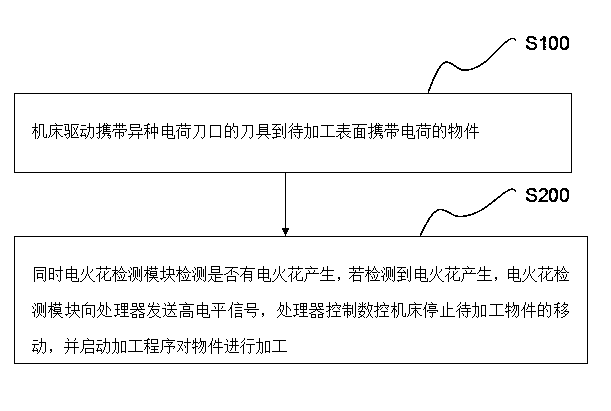

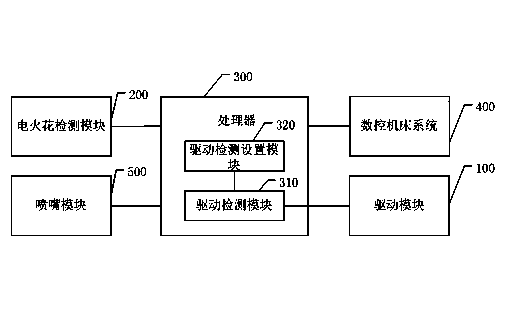

Accurate tool-setting method of numerical control machine tool and numerical control machine tool

InactiveCN103737423ALiberate human laborPrevent eye strainAutomatic control devicesMeasurement/indication equipmentsEngineeringMachine tool

The invention discloses an accurate tool-setting method of a numerical control machine tool and the numerical control machine tool. The accurate tool-setting method of the numerical control machine tool comprises the steps that A, the machine tool drives a tool provided with an opposite charge tool edge to a workpiece to be machined, wherein the surface of the workpiece carries a charge; B, an electric spark detection module detects whether an electric spark is generated at the same time, wherein if an generated electric spark is detected, the electric spark detection module sends a high level signal to a processor, and the processor controls the numerical control machine tool to stop the movement of the workpiece to be machined and starts a machining program to machine the workpiece. According to the numerical control machine tool, whether the workpiece and the tool edge are aligned is judged according to whether an electric spark is generated between mutually exclusive charges carried by the workpiece to be machined and the tool edge, and then the workpiece machining method is implemented; since the numerical control machine tool can conduct tool setting automatically and accurately, more labor is liberated, and full automation is realized; the problem that fatigue of human eyes causes unqualified machining of the workpiece can also be effectively prevented, and the intelligent demand for numerical control is met.

Owner:TIANSHUI SPARK MACHINE TOOL

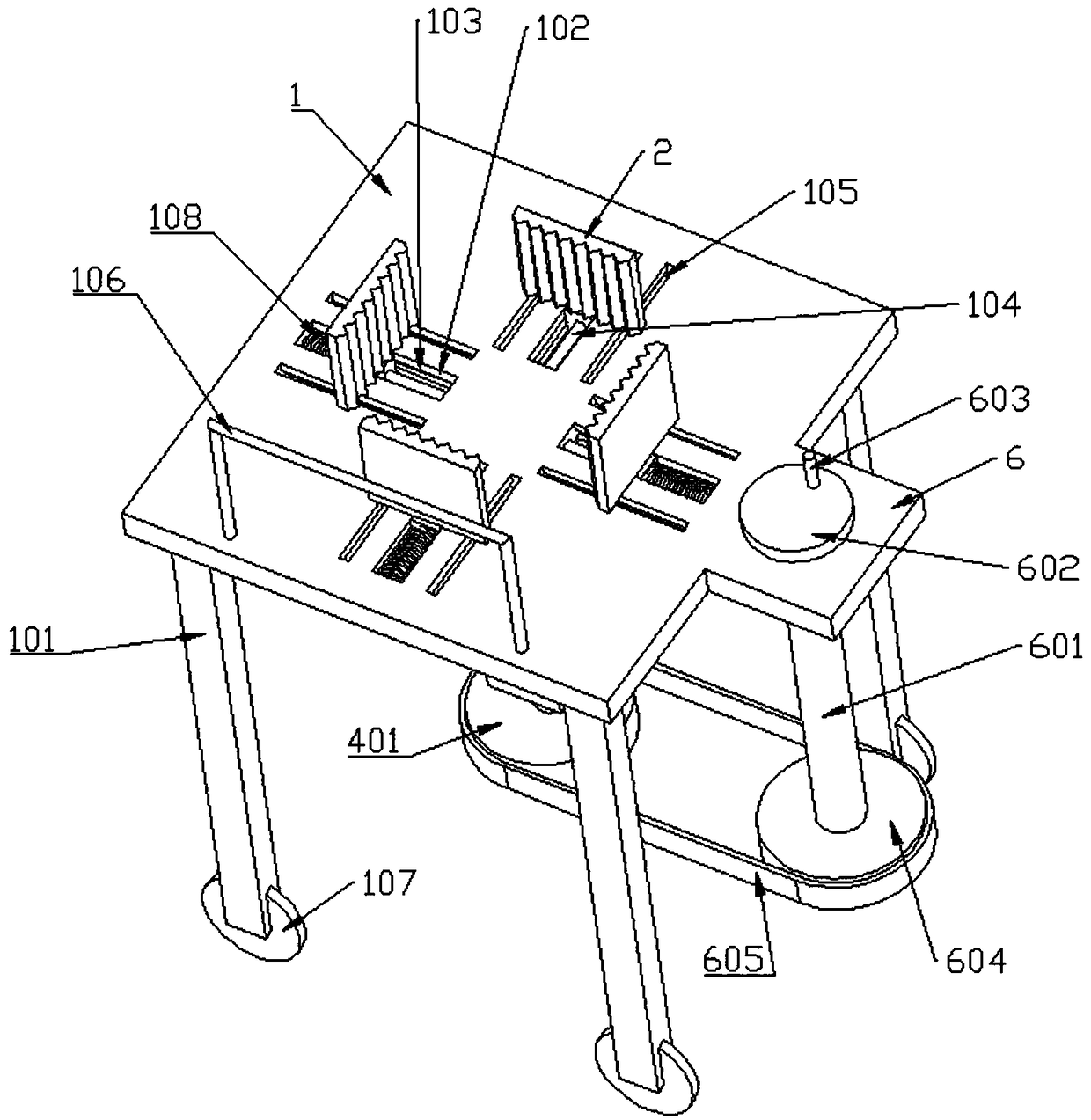

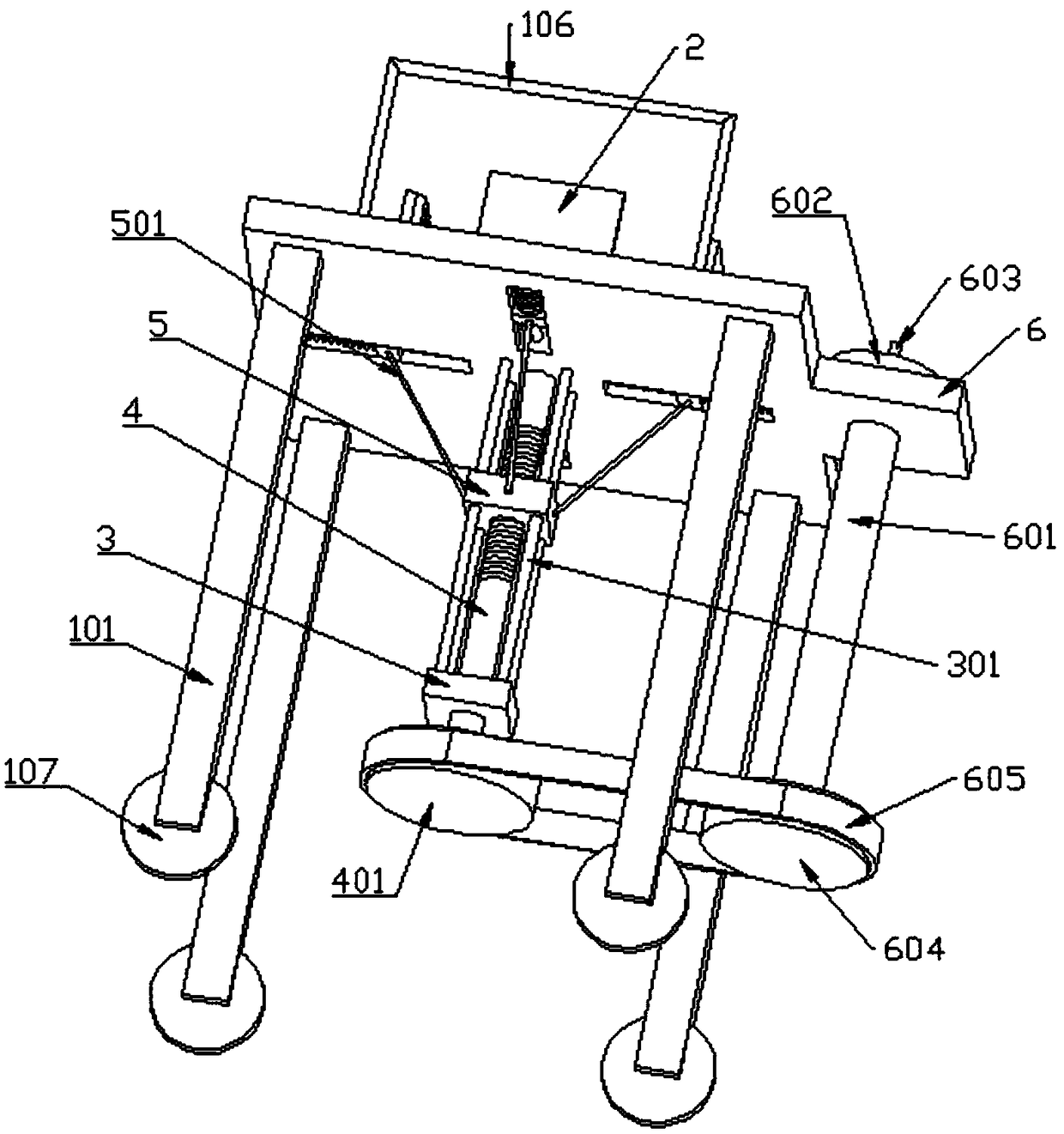

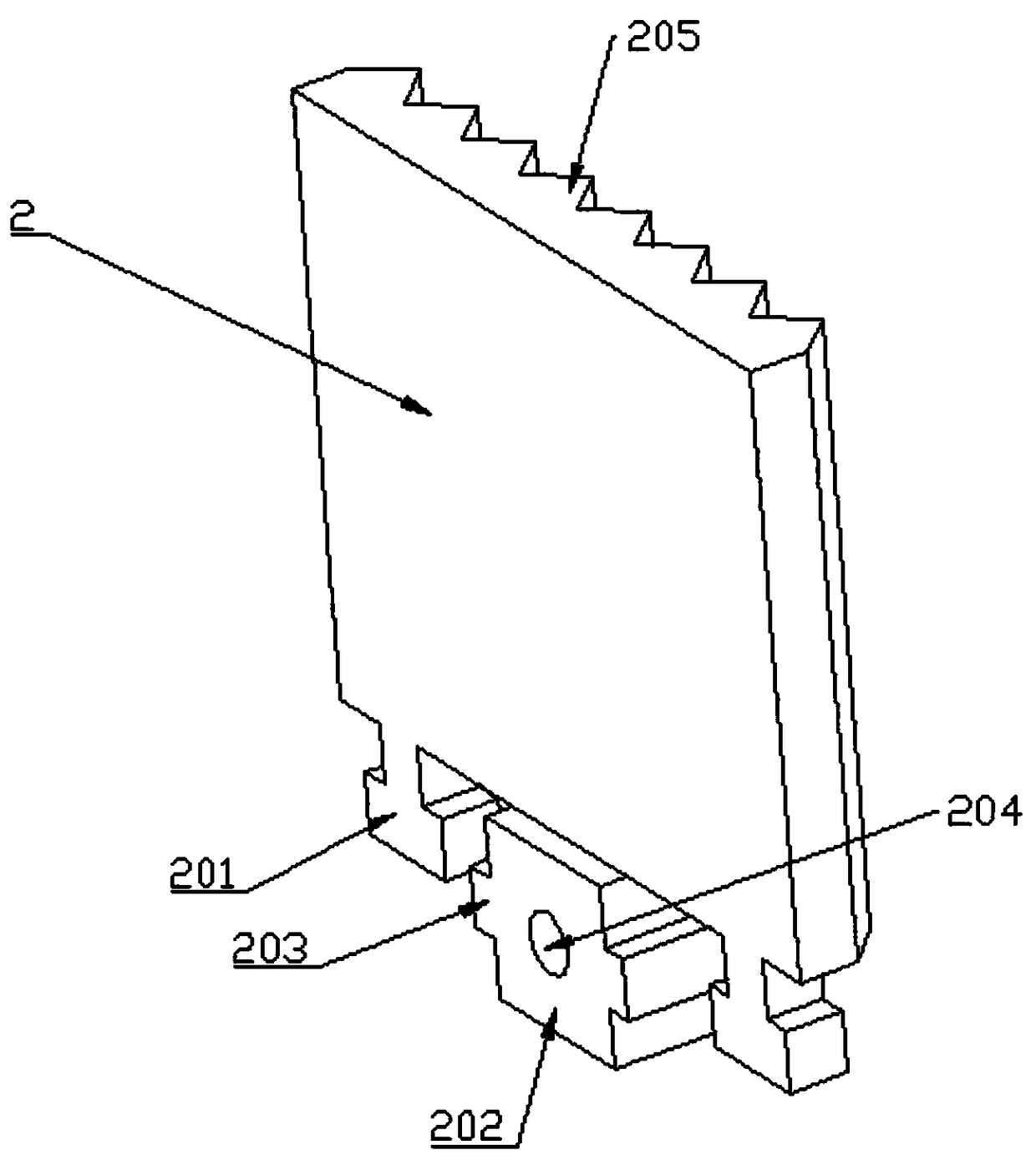

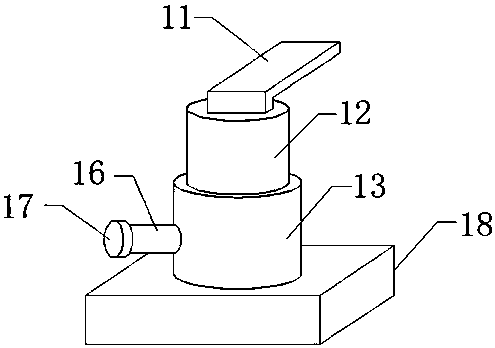

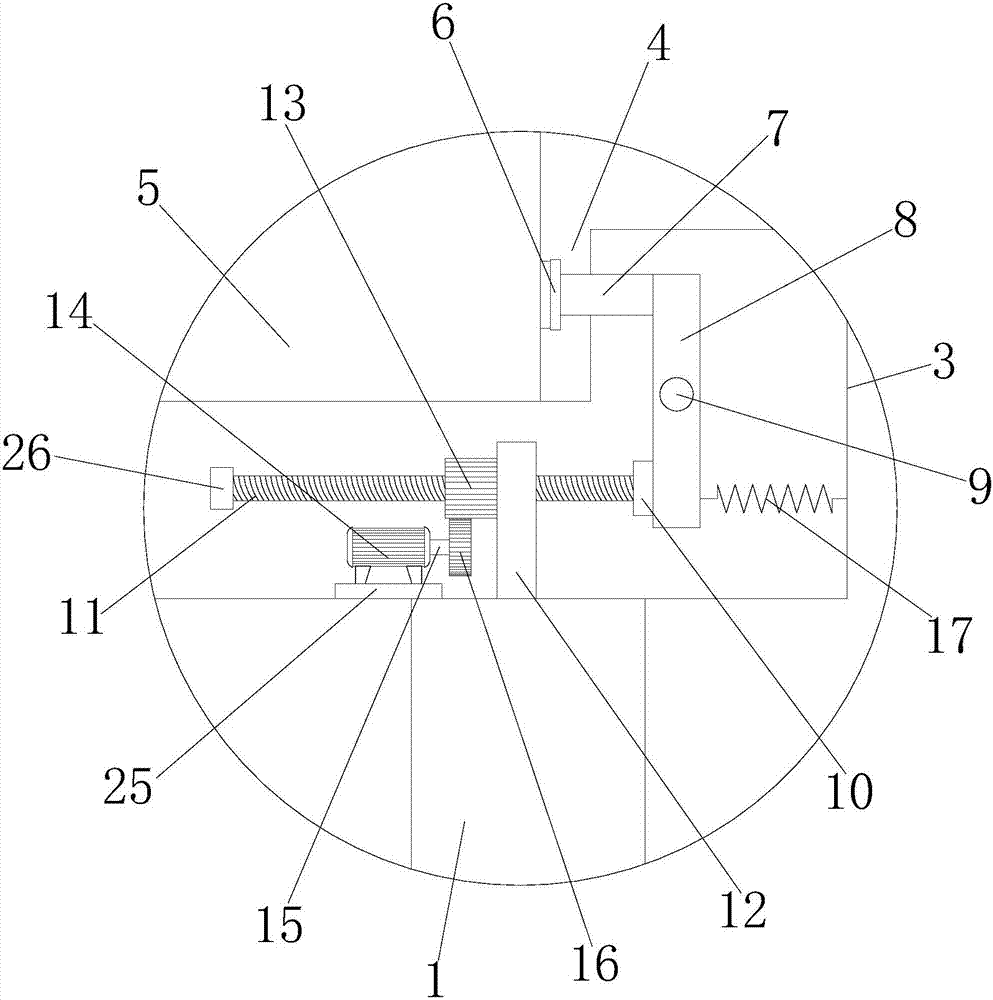

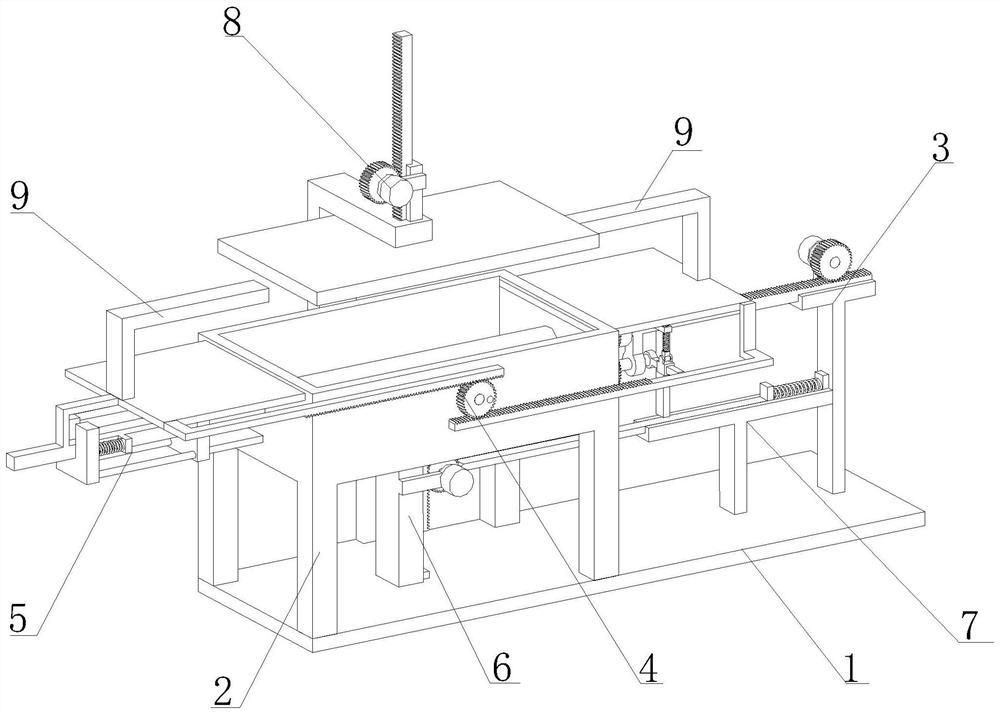

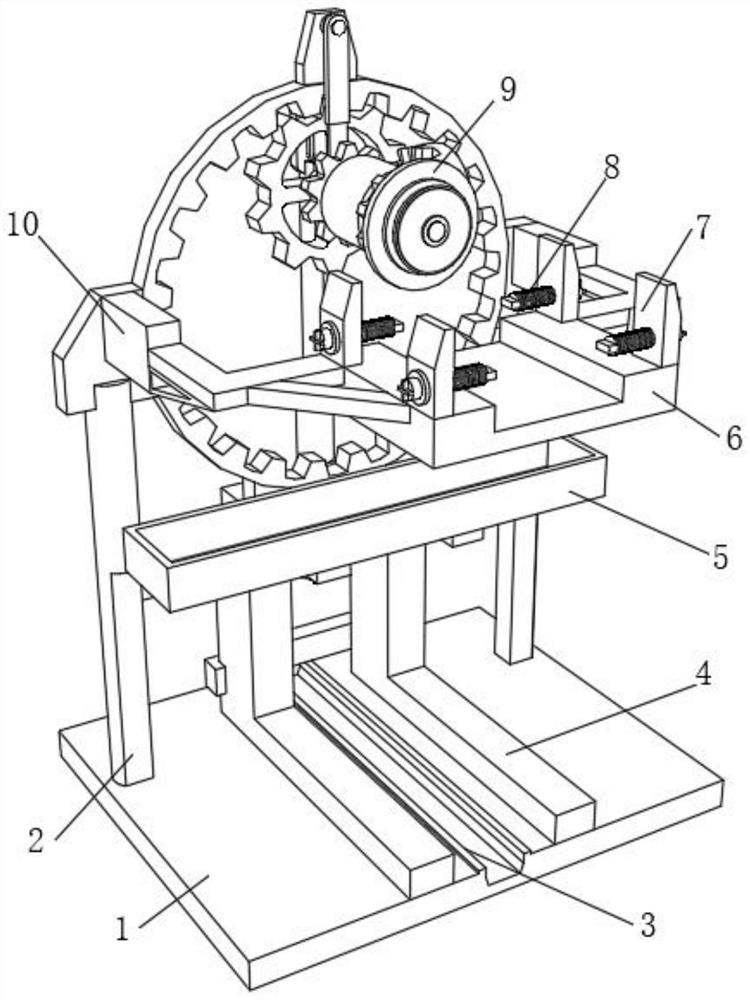

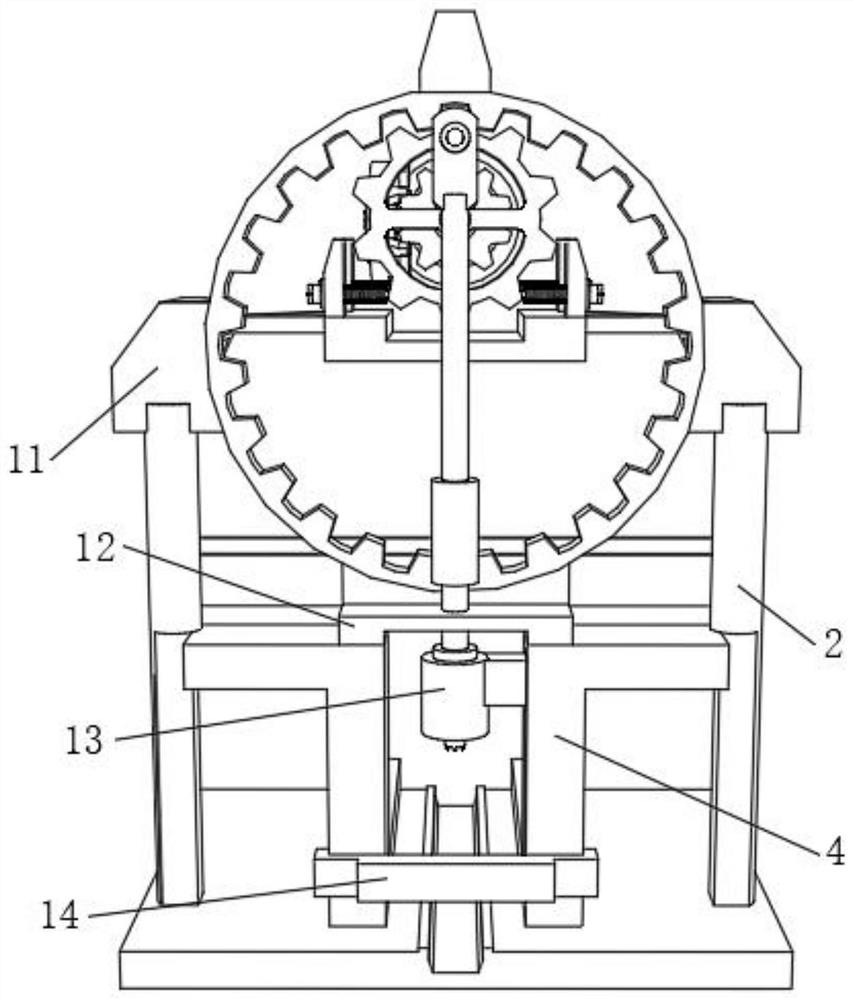

Mould processing workbench

InactiveCN108637993AImprove work efficiencyAvoid processing failureWork benchesFailure causesThreaded rod

The invention discloses a mould processing workbench. The mould processing workbench comprises a deck plate, clamping plates, a base plate, a threaded rod, a lifting block and a lug plate. The mould processing workbench is novel in structure, and is practical in function; the threaded rod rotates to drive the lifting plate to lift, and the lifting block lifts to drive the clamping plates to get close to each other or get away from each other; when the clamping plates get close to each other, a mould placed on the deck plate is clamped; and when the clamping plates get away from each other, clamping on the mould is loosened. The mould processing workbench is convenient in clamping way, can greatly improve mould processing working efficiency, is firm in clamping, and can avoid processing failure caused by clamping loosening.

Owner:HEFEI DINGXIN MOLD

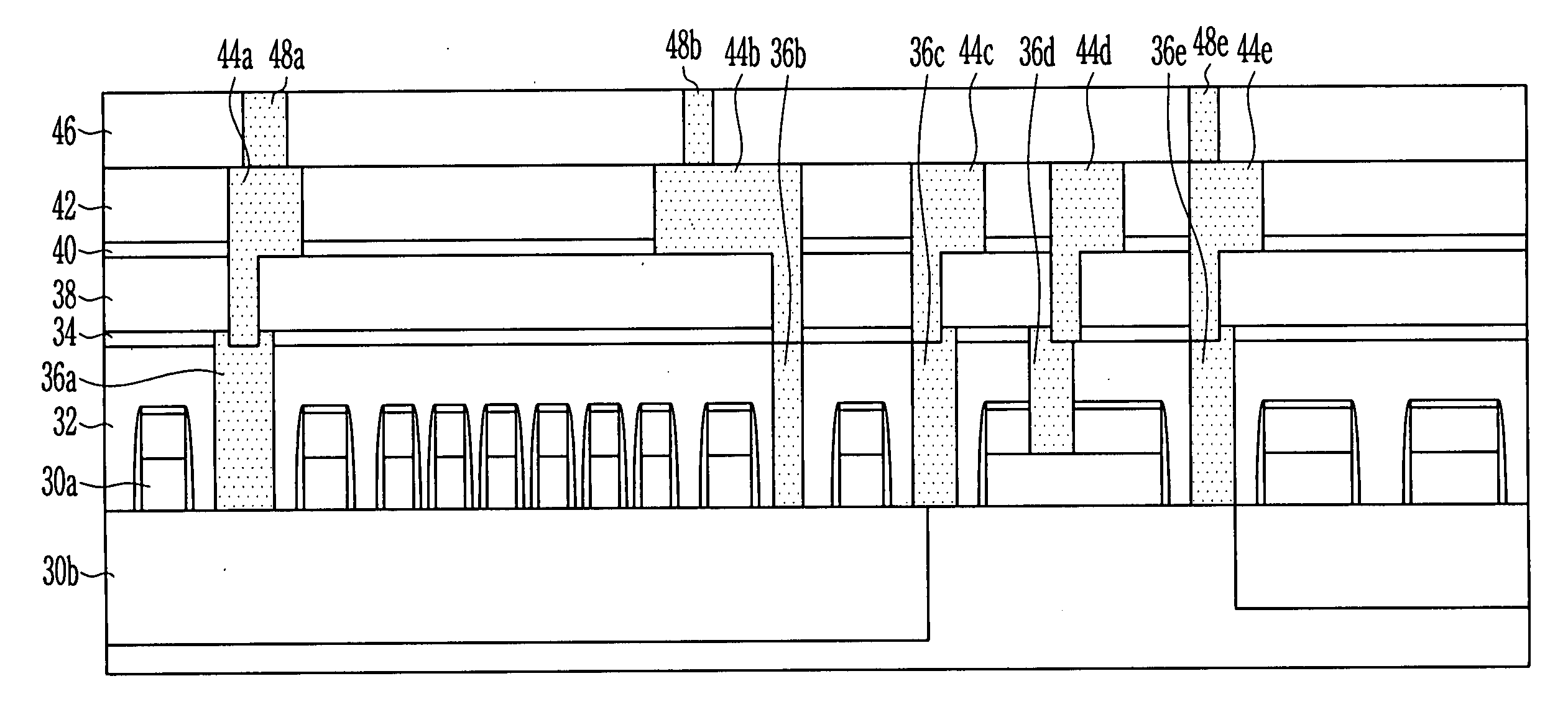

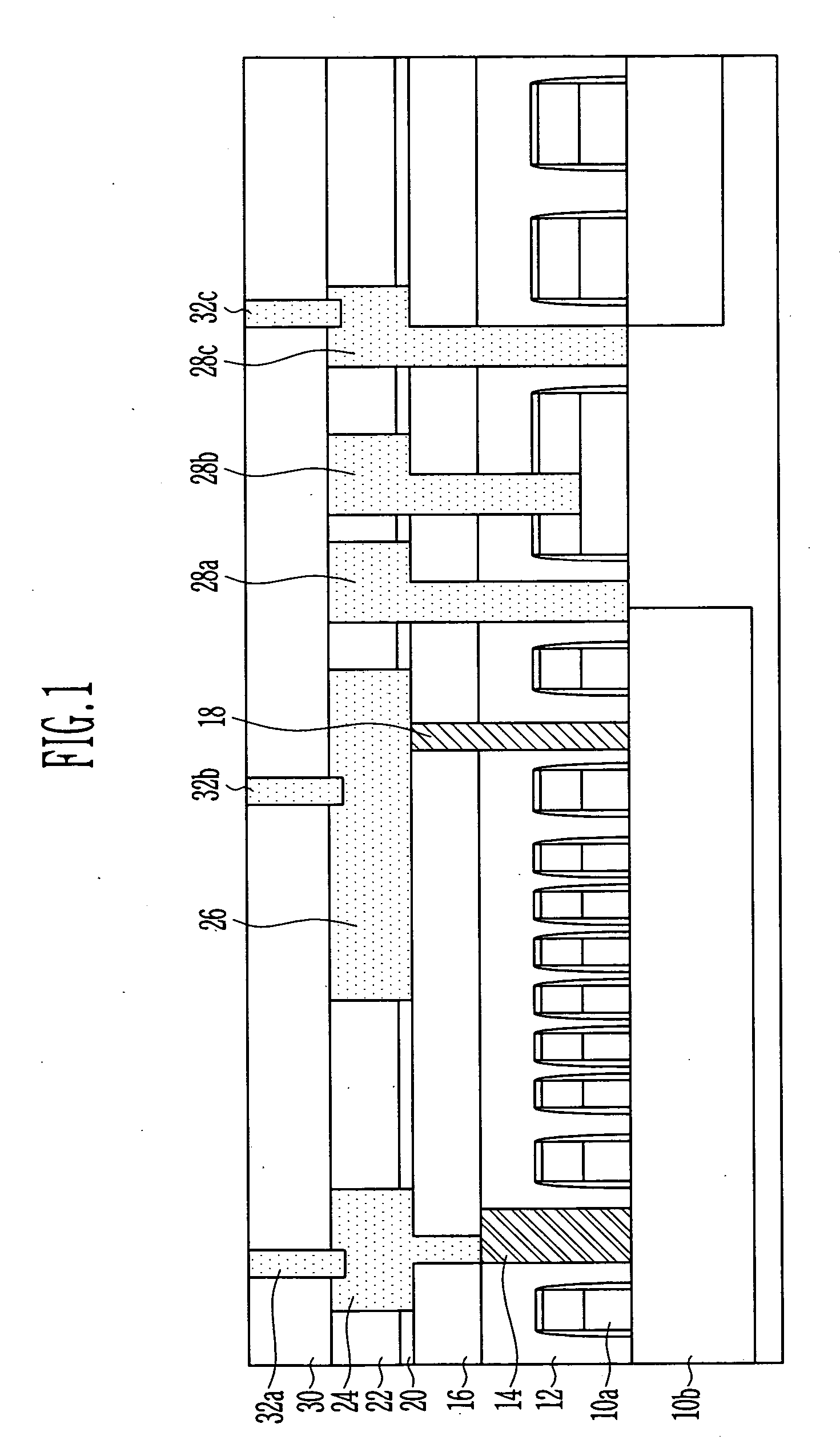

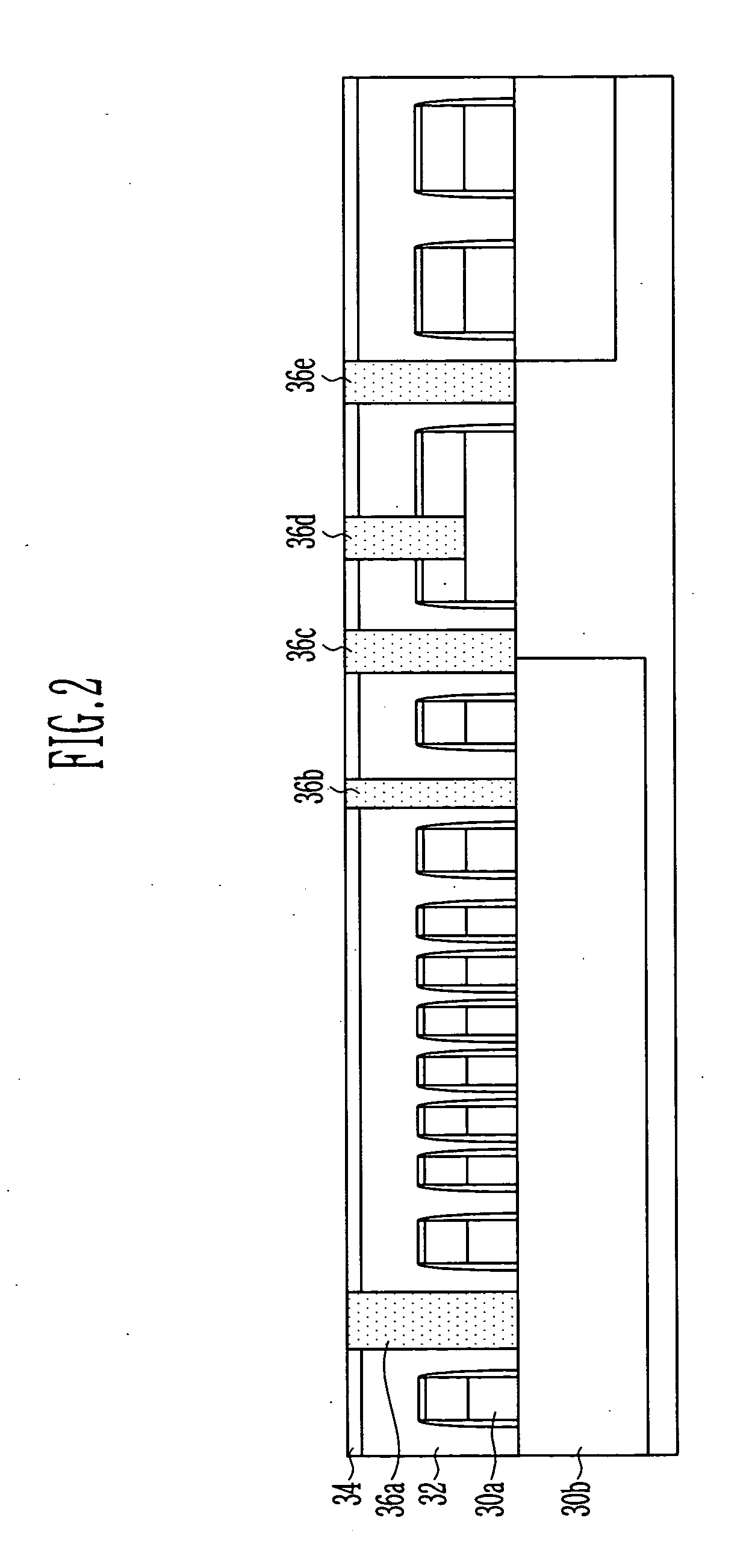

Method for manufacturing semiconductor device

InactiveUS20050095838A1Efficient fillingReduce in quantitySolid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering

The present invention discloses a method for manufacturing a semiconductor device, comprising the steps of: providing a semiconductor substrate on which cell strings are formed and in which a plurality of conductive regions are formed; sequentially forming a first interlayer insulation film and a first etch barrier film on the semiconductor substrate; forming a plurality of contact holes by exposing the plurality of conductive regions formed in the semiconductor substrate, wherein an impurity concentration of the conductive regions is reduced due to the process for forming the contact holes; filling a metal material in the contact holes and forming a plurality of contact plugs; sequentially forming a second interlayer insulation film, a second etch barrier film and a third interlayer insulation film over a resulting structure including the contact plugs; forming a plurality of metal line patterns, wherein the metal line patterns pass through the third interlayer insulation film, the second etch barrier film and the second interlayer insulation film and contact to the contact plugs; forming a fourth interlayer insulation film over a resulting structure including the plurality of metal line patterns; forming a plurality of metal line contact holes by patterning the fourth interlayer insulation film; and forming a plurality of metal line contact plugs in the plurality of metal line contact holes by filling a metal material in the metal line contact holes.

Owner:STMICROELECTRONICS SRL +1

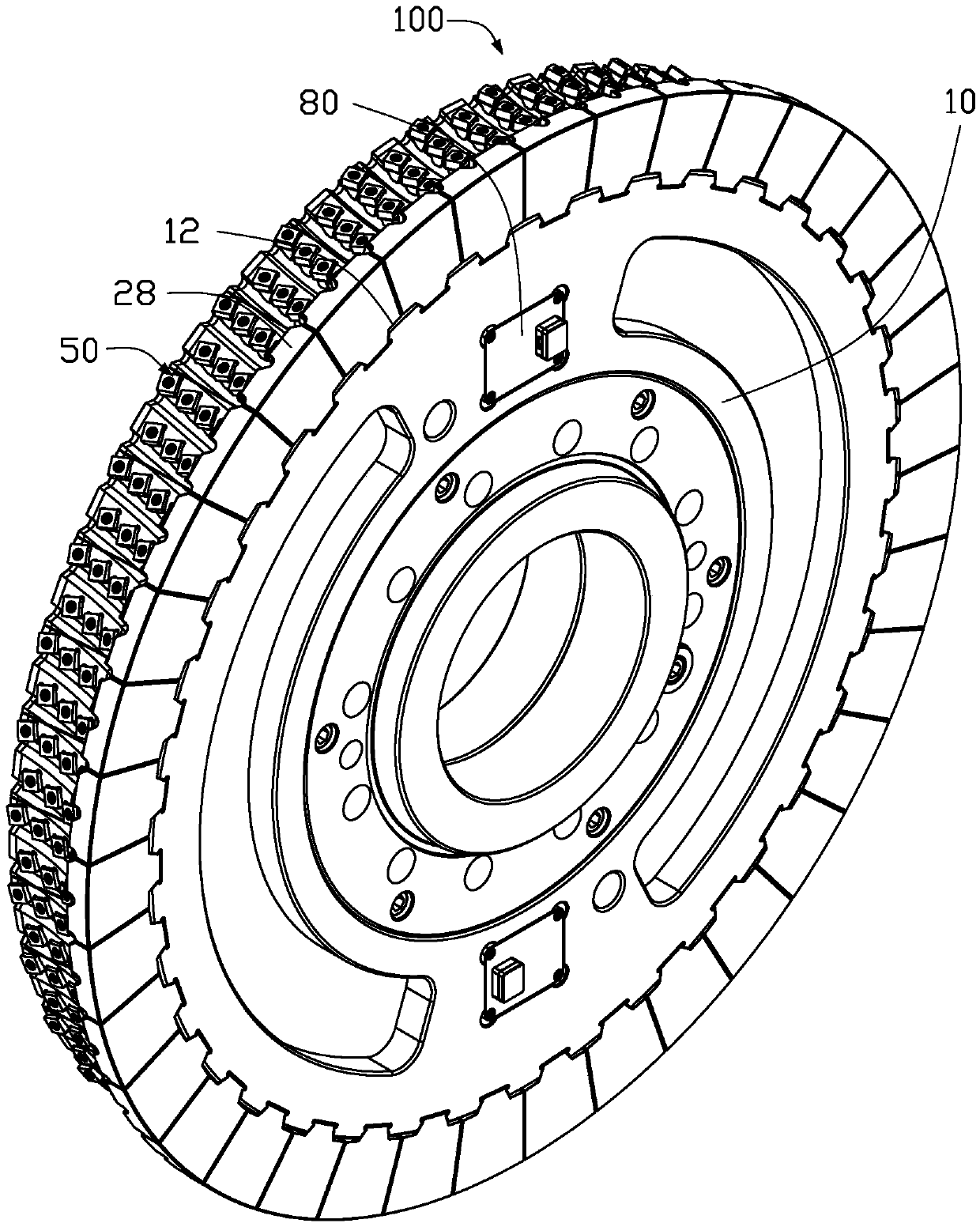

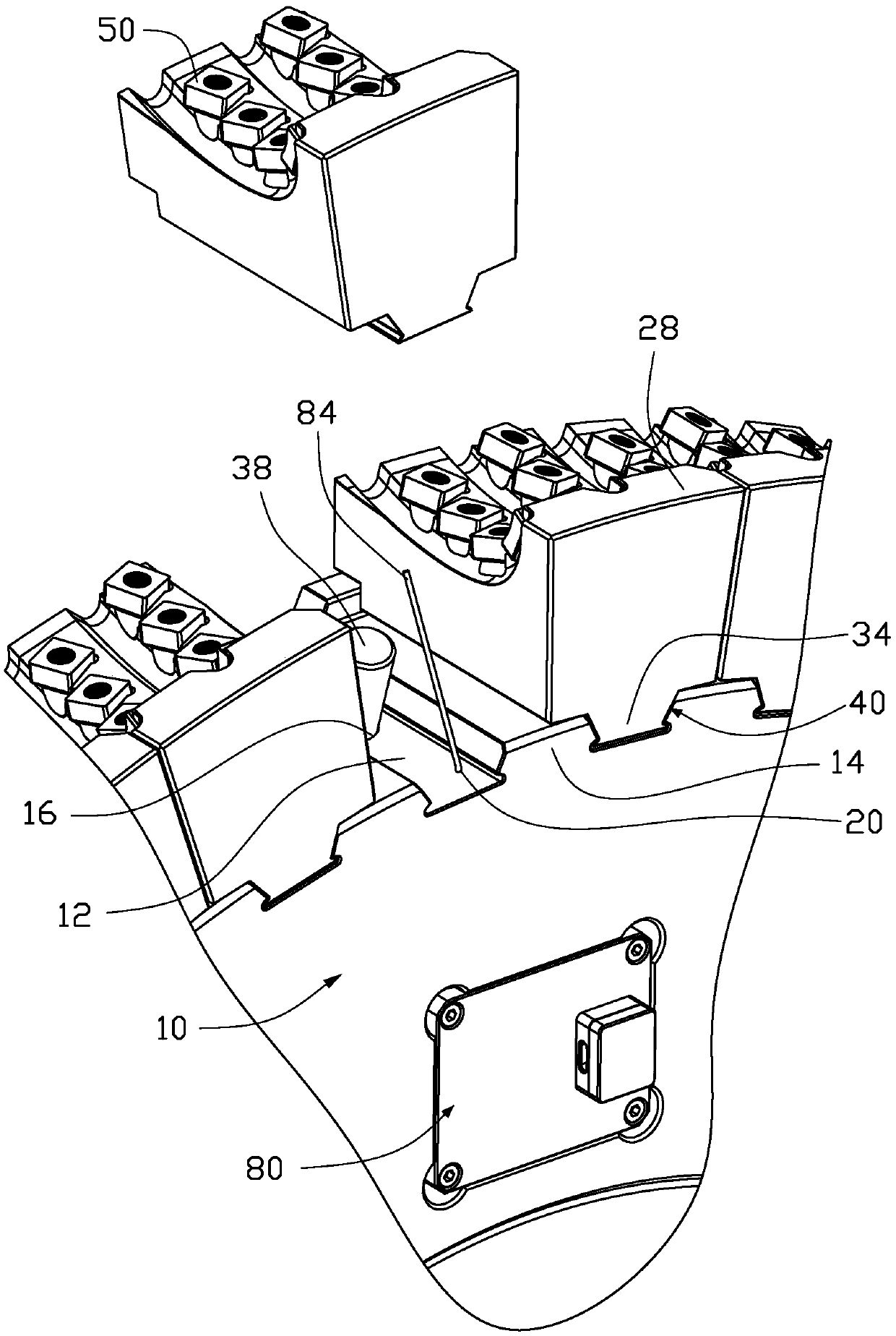

Milling cutter head for milling steel rails

PendingCN109604696APrevention of machining failuresAvoid processing failureMilling cuttersMeasurement/indication equipmentsEngineeringMilling cutter

The invention provides a milling cutter head for milling steel rails. The milling cutter head comprises a cutter head body, multiple cutter clamps and multiple sets of blades. The cutter head body comprises a hub, the multiple cutter clamps are fixed to the hub, the multiple sets of blades are fixed to the multiple cutter clamps, at least one chip module is fixed to the cutter head body, the at least one chip module is in communication connection with a server, the at least one chip module is connected with at least one sensor, the at least one sensor acquires at least one piece of milling state information of the milling cutter head during milling of the steel rails, and the at least one chip module transmits the at least one piece of milling state information to the server.

Owner:JIZHUN PRECISION IND HUIZHOU

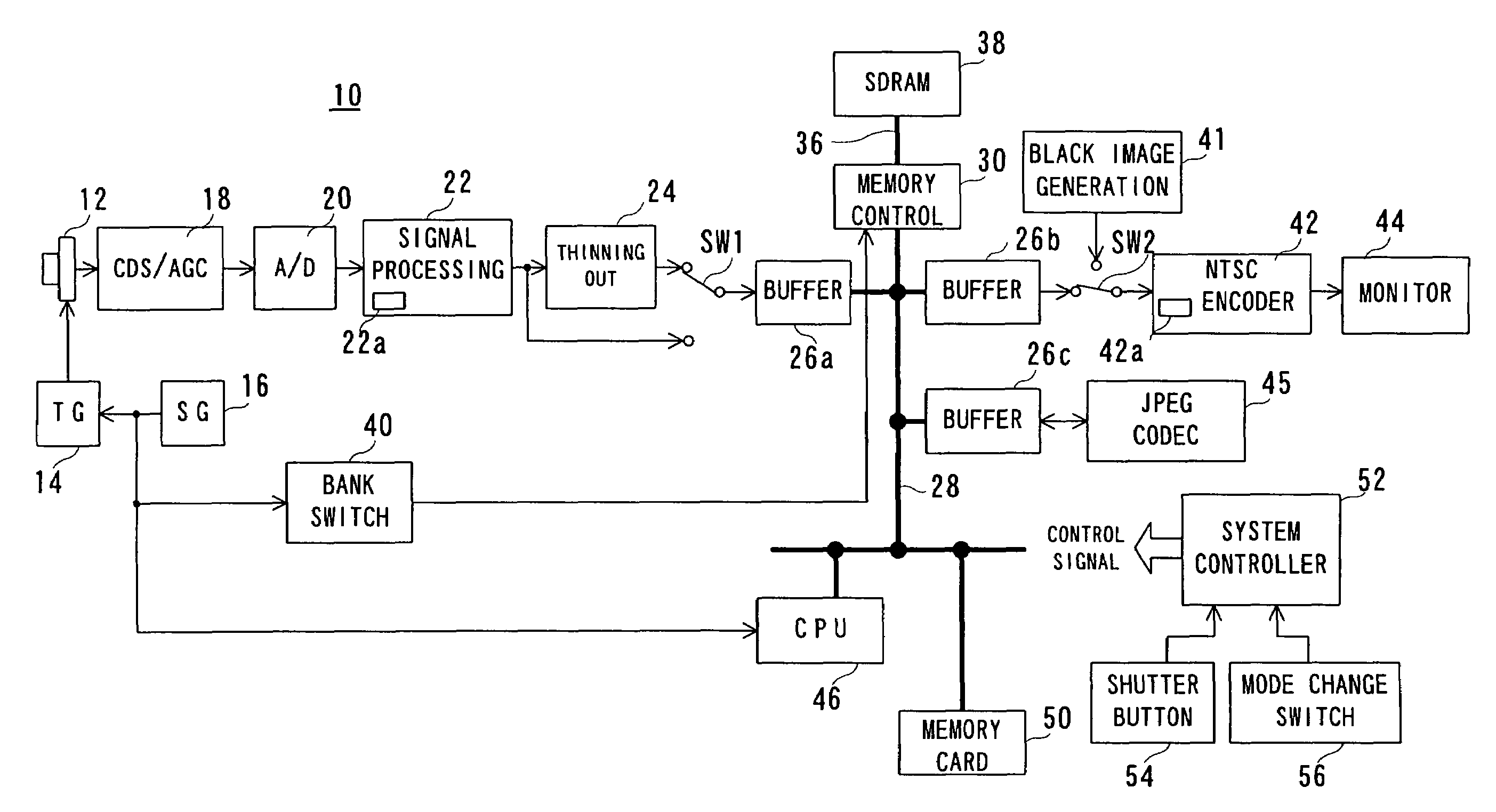

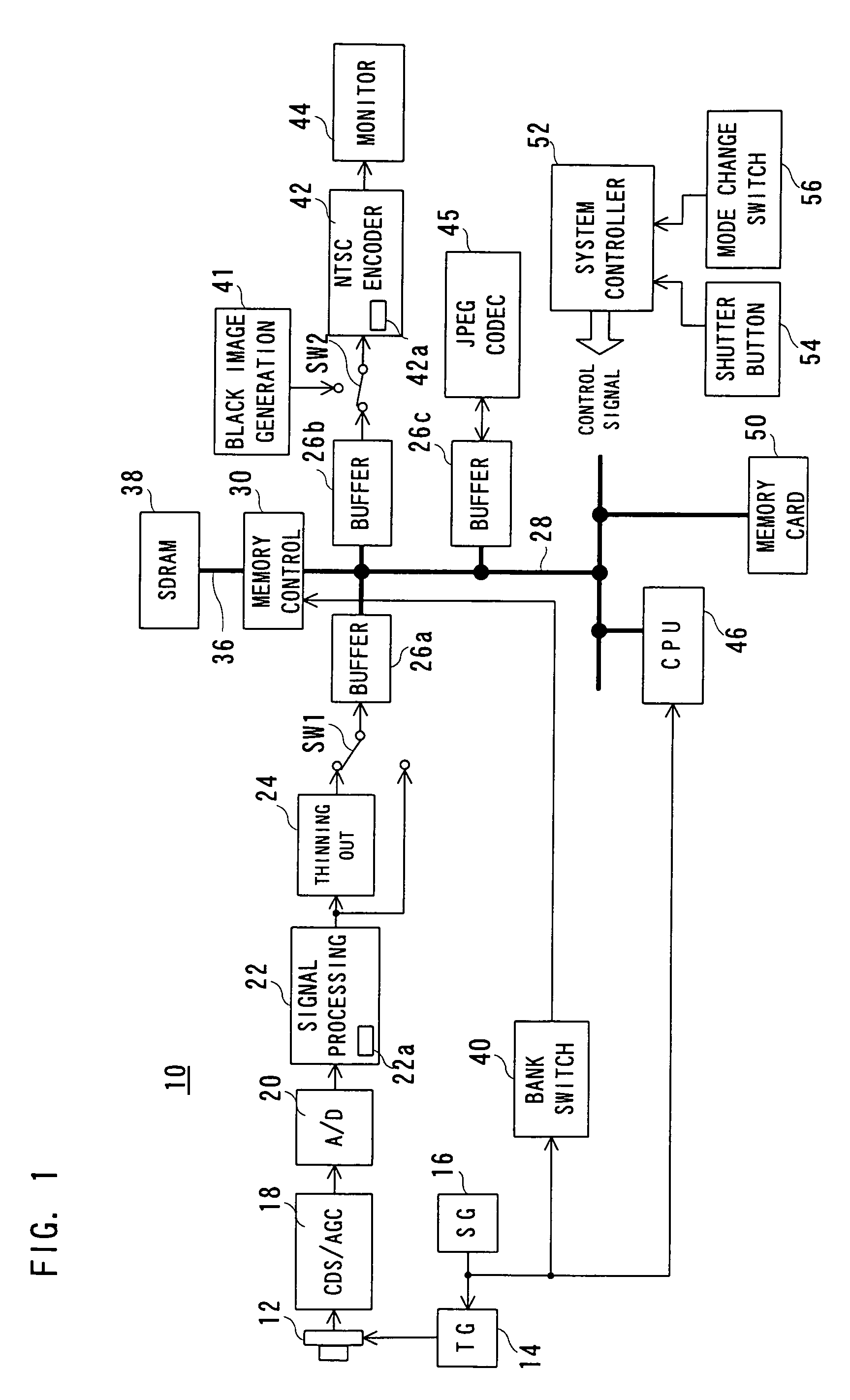

Digital camera

InactiveUS7295231B1Avoid processing failureHigh resolutionTelevision system detailsColor television detailsSignal processing circuitsImage resolution

A digital camera includes a monitor. When outputting through-images on the monitor, high-resolution YUV data outputted from a signal processing circuit is thinned out and created into low-resolution YUV data. The low resolution YUV data of a current frame is written to one of banks formed within an SDRAM in 1 / 15 second. On the other hand, the low resolution YUV data of the preceding frame is read out of the other bank in 1 / 30 second. That is, reading is made twice within 1 / 15 second. The low resolution YUV data thus read is thereafter processed by an NTSC encoder and outputted onto the monitor.

Owner:XACTI CORP

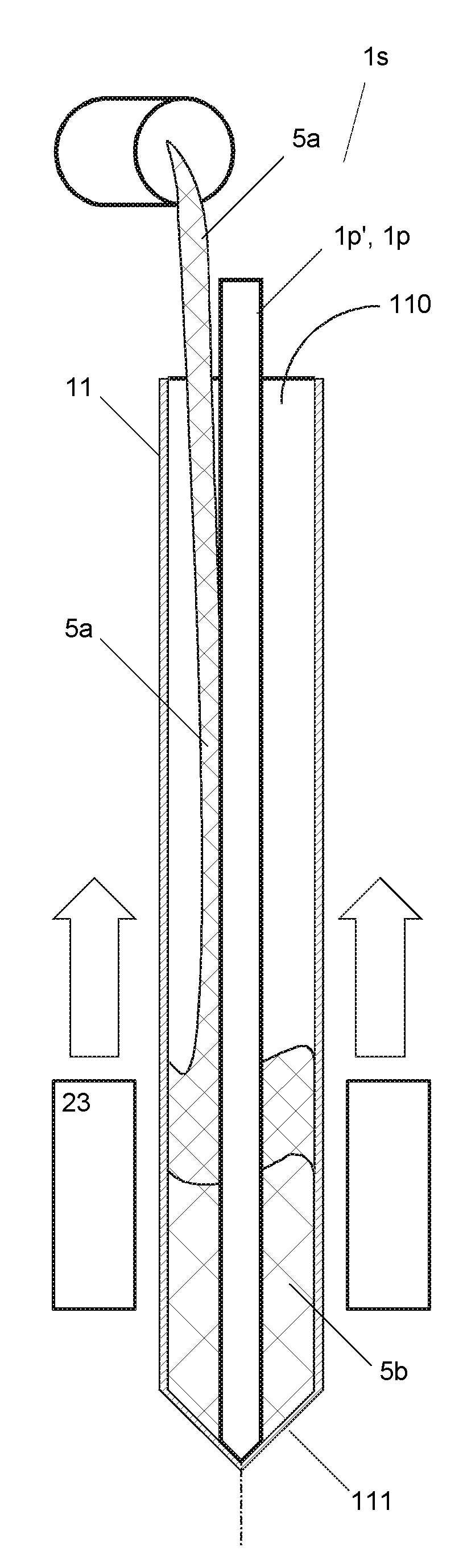

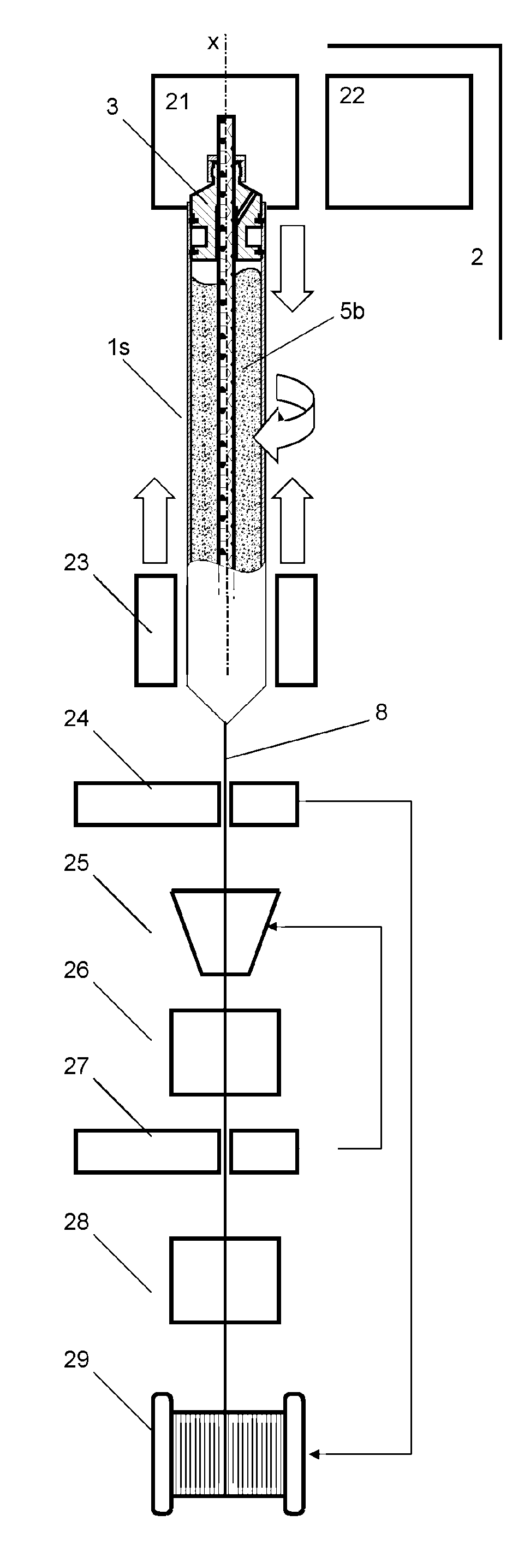

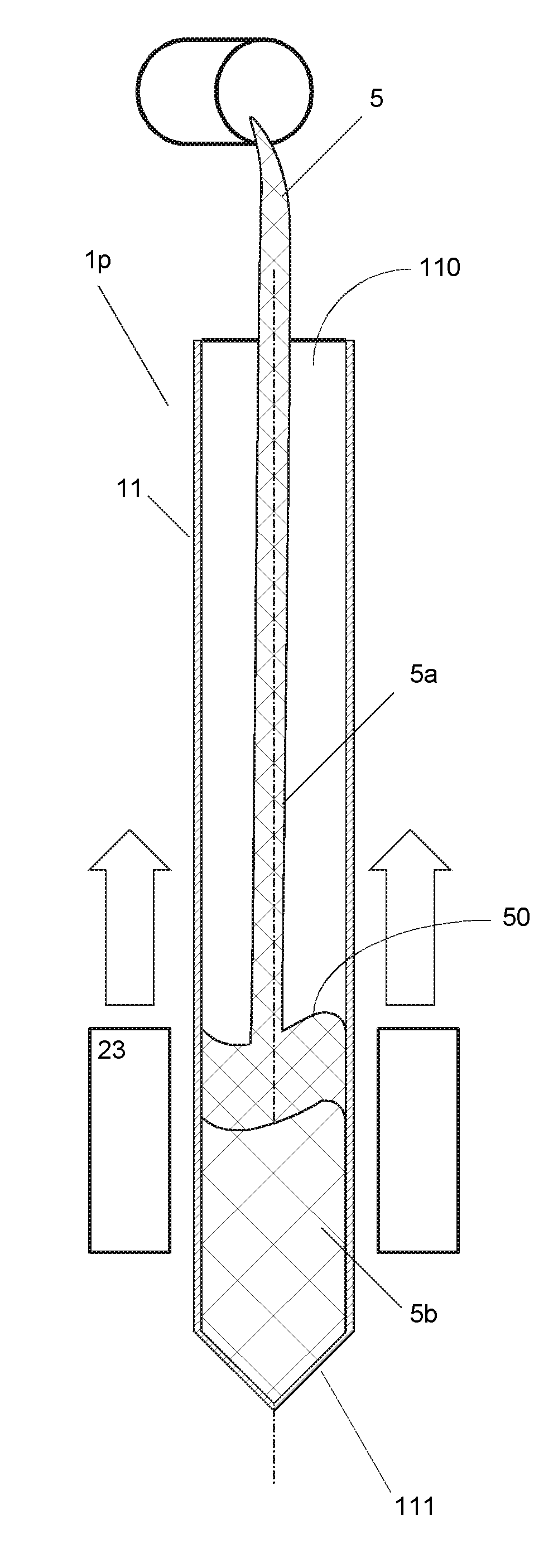

Method for producing and processing preform, preform and optical fiber

ActiveCN102325730AIncreased process reliabilityAvoid processing failureGlass fibre drawing apparatusGlass fibre productsSilica particleInterior space

The method for producing and processing a preform (1p, 1s) comprises a preliminary process phase, in which silica grain (5a; 5b) is supplied into the interior space (110) of a silica tube (11) having an open upper end and a closed lower end (111), in order to obtain an unprocessed preform (1p, 1s ), and comprises a final process phase, in which the interior space (110) of the silica tube (11) is closed, a condition of reduced pressure is generated, the unprocessed preform (1p, 1s ) is heated with a final process temperature in order to fuse the silica tube (11) and the silica grain (5b). According to the invention the silica grain (5a; 5b) entering the interior space (110) is thermally treated during the preliminary process phase with an intermediate process temperature that lies under the melting point of the silica grain.

Owner:西里特克光纤公司

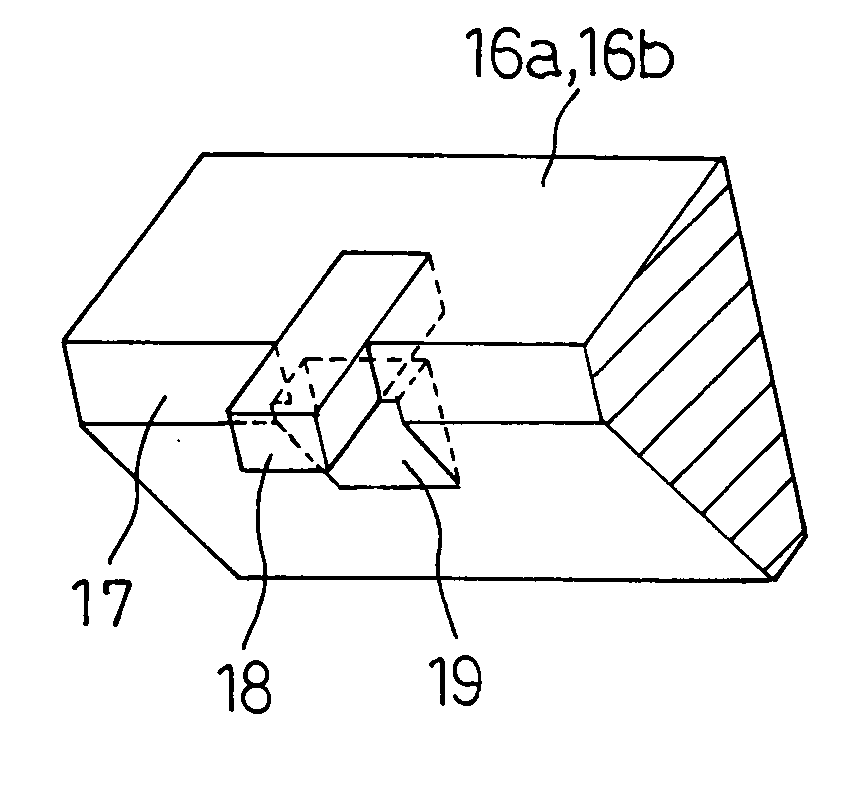

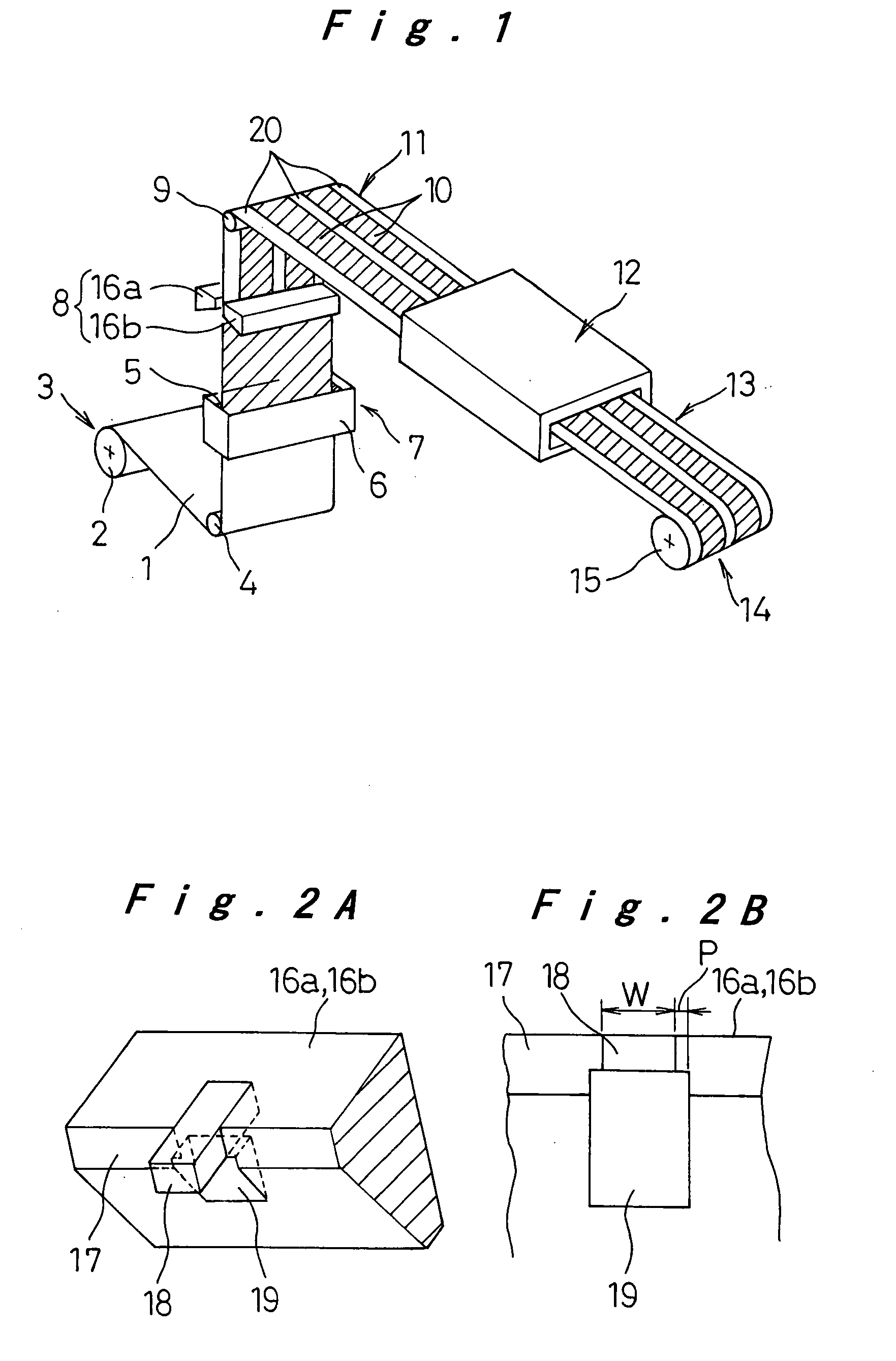

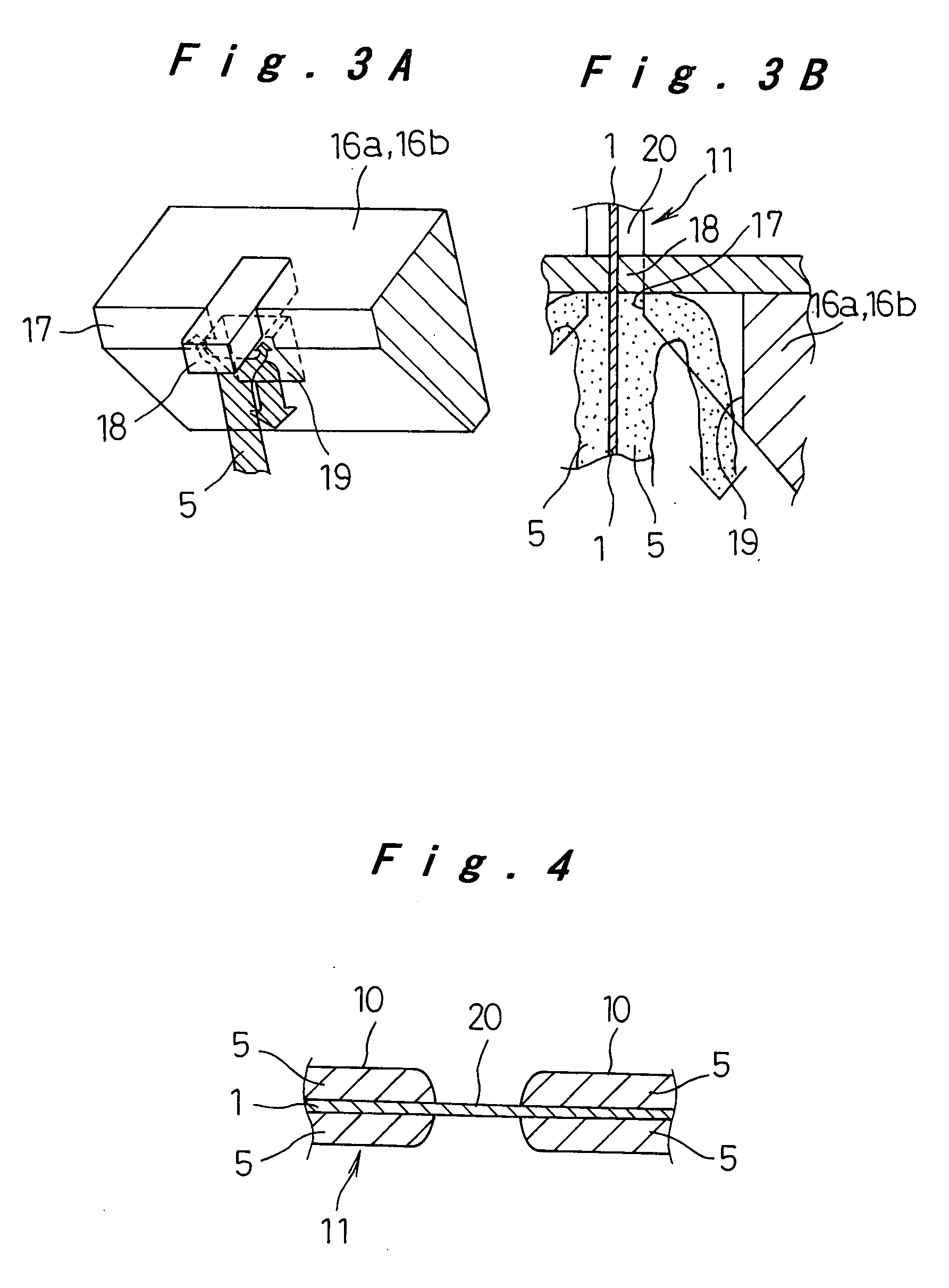

Method and apparatus for applying electrode mixture paste

InactiveUS20090053399A1Uniform coating thicknessAvoid deformationMechanical working/deformationPretreated surfacesProcess failureMaterials science

An electrode mixture paste (5) is applied on both sides of a strip of core material (1) as it runs along its lengthwise direction, and the coating thickness of the paste (5) is adjusted as the core material (1) coated with the paste (5) passes through a gap between a pair of scraper tools (16a, 16b). Tips (18) provided to the scraper tools (16a, 16b) scrape off the paste (5) to form a paste-coated portion of a predetermined width. The electrode mixture paste (5) scraped off with the tips (18) is returned through recesses (19) on the upstream side of the tips (18) in the running direction of the core material, so as to prevent the phenomenon where the coating thickness is increased at both side edges of the paste-coated portion. Thus, a method for applying electrode mixture paste is realized that can prevent the phenomenon where the coating thickness is increased at both side edges of the paste-coated portion and prevent process failures such as deformation of paste-coated sheet.

Owner:PANASONIC CORP

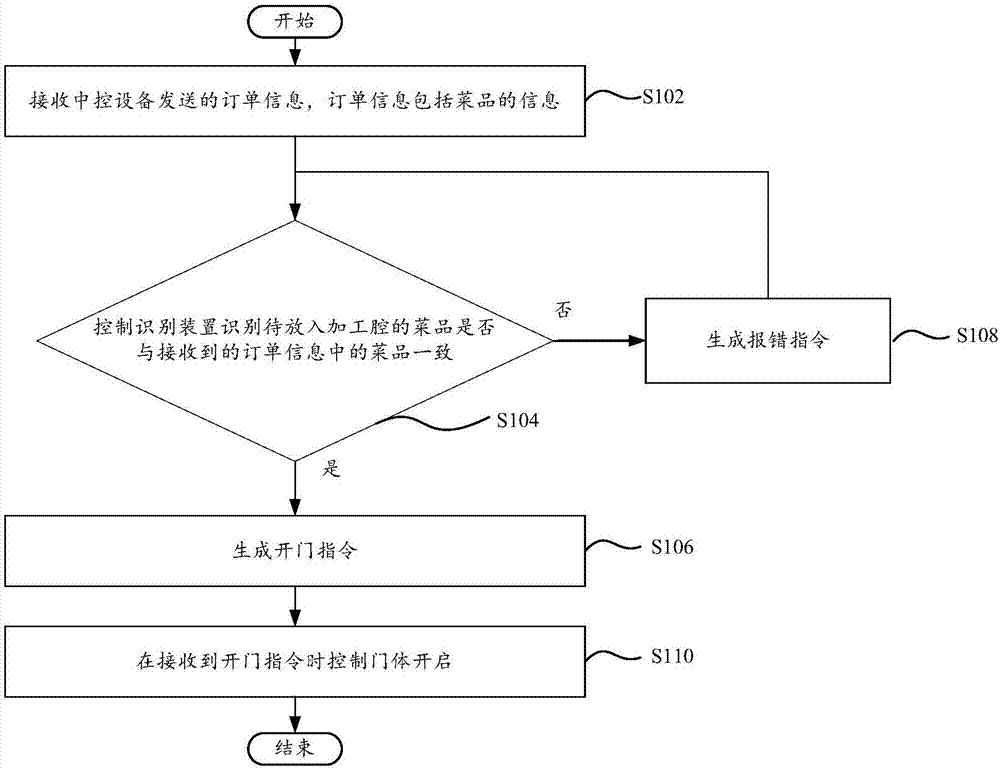

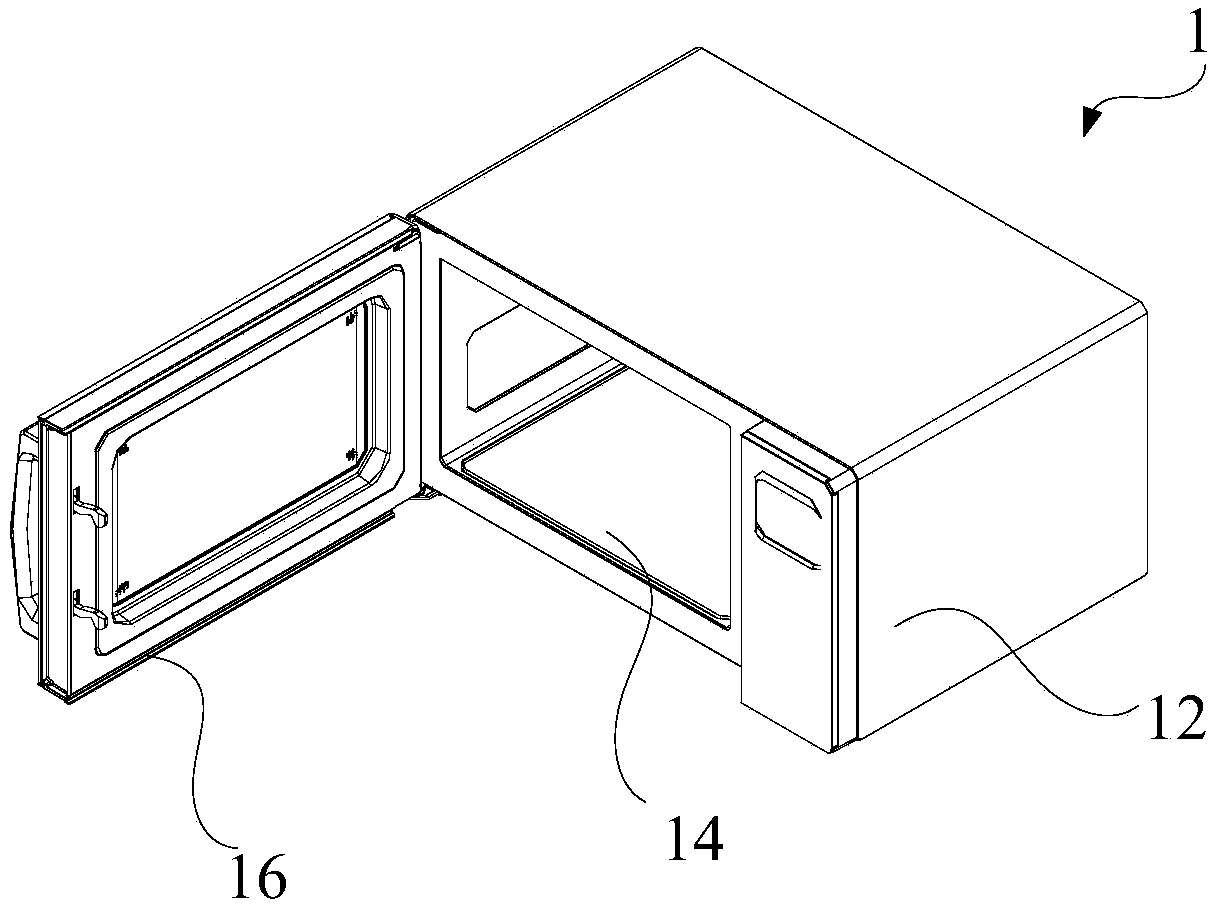

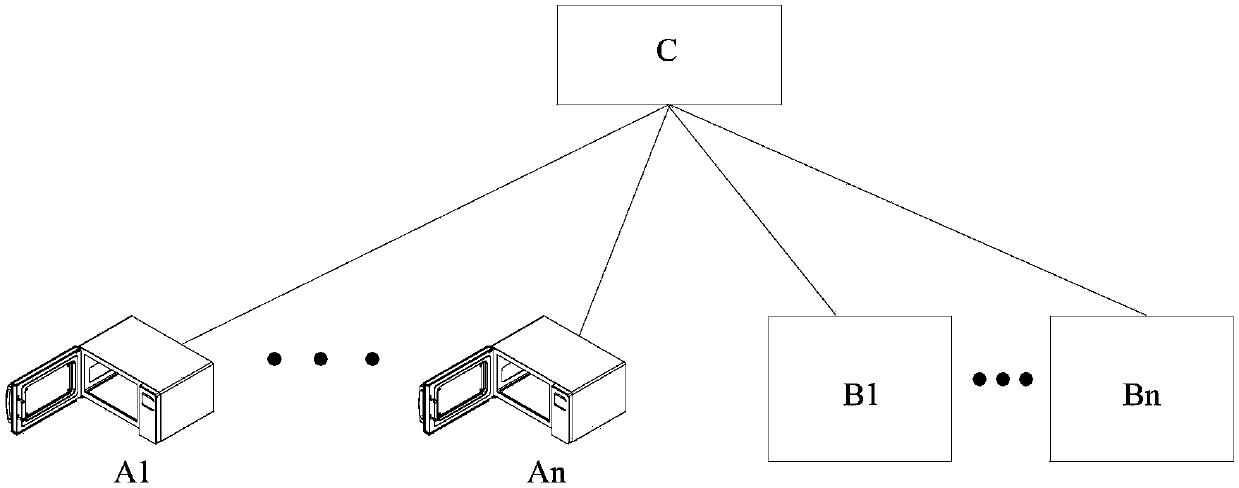

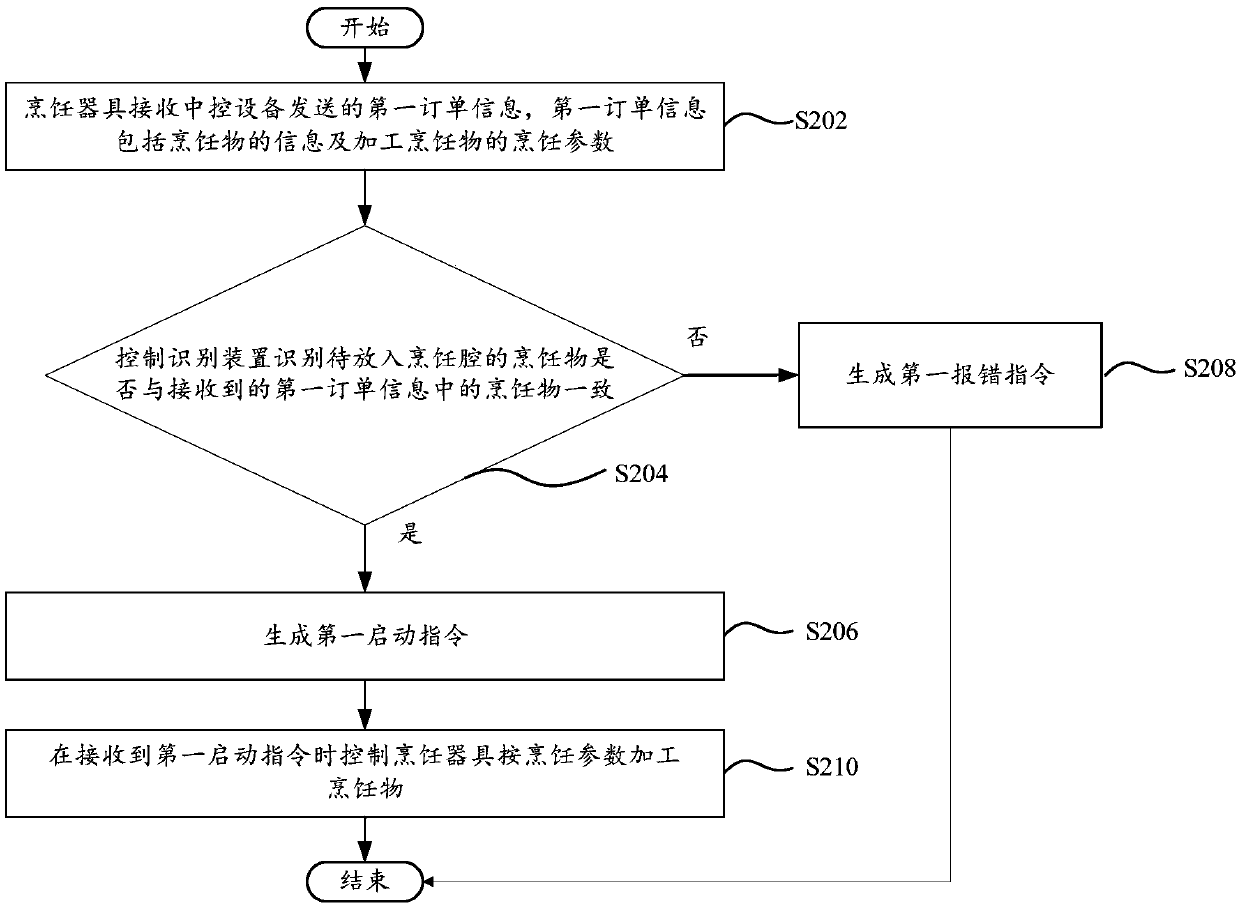

Control method and control system

ActiveCN107966932AImprove user experienceReduce stepsProgramme controlComputer controlControl systemError reporting

The invention provides a control method, a control system, a cooking appliance, computer equipment, a computer readable storage medium and a central control system. The cooking appliance comprises a cooking cavity and an identification device, wherein the cooking cavity is used for accommodating a cooking material. The control method is applied to the cooking appliance, and comprises the steps of:receiving order information transmitted by central control equipment, wherein the order information comprises the information of the cooking material; controlling the identification device to identify whether a cooking material to be placed in the cooking cavity is consistent with the cooking material in the received order information, if so, generating a door opening command, otherwise, generating an error reporting command; and controlling a door body to open when receiving the door opening command. The control method provided by the invention controls the identification device to identifythe cooking material, has few operations and high efficiency, timely and effectively avoids the problem of cooking processing failure caused by mismatching of the cooking material to be placed in andthe order information, and enhances the using experience of users.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

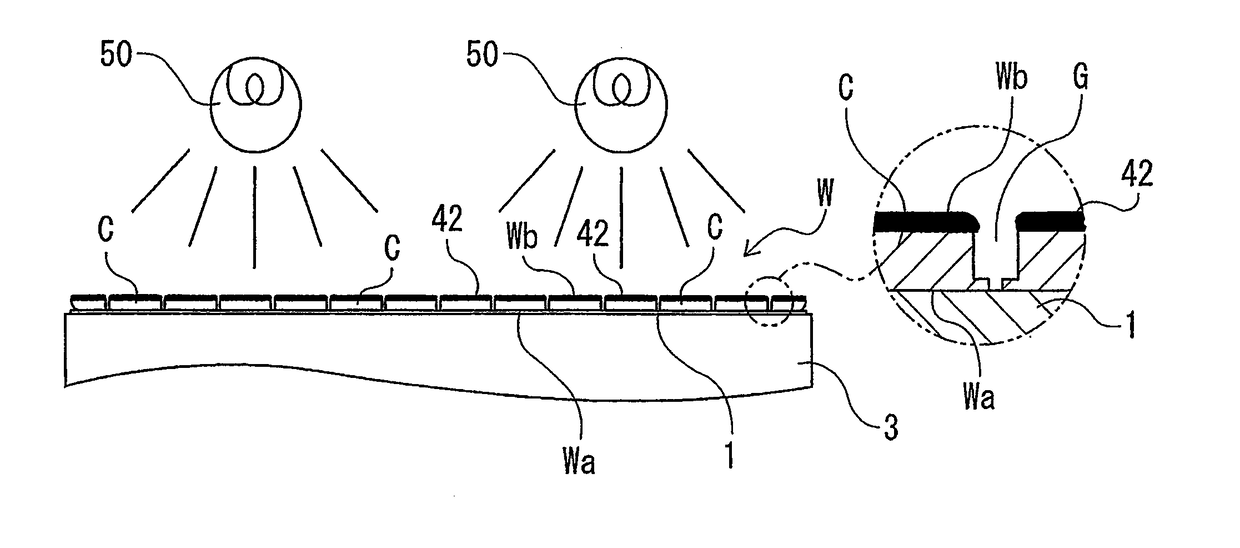

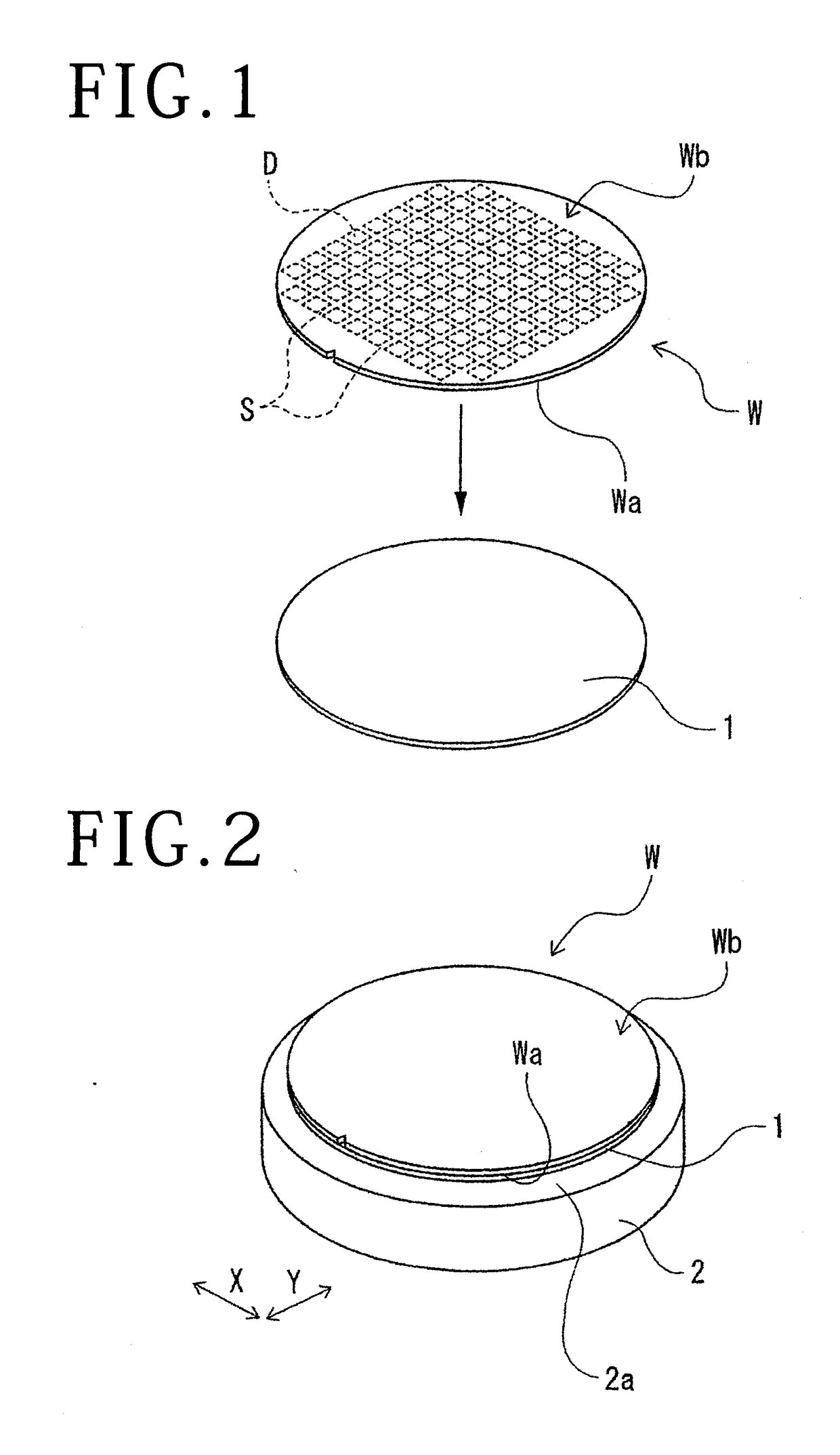

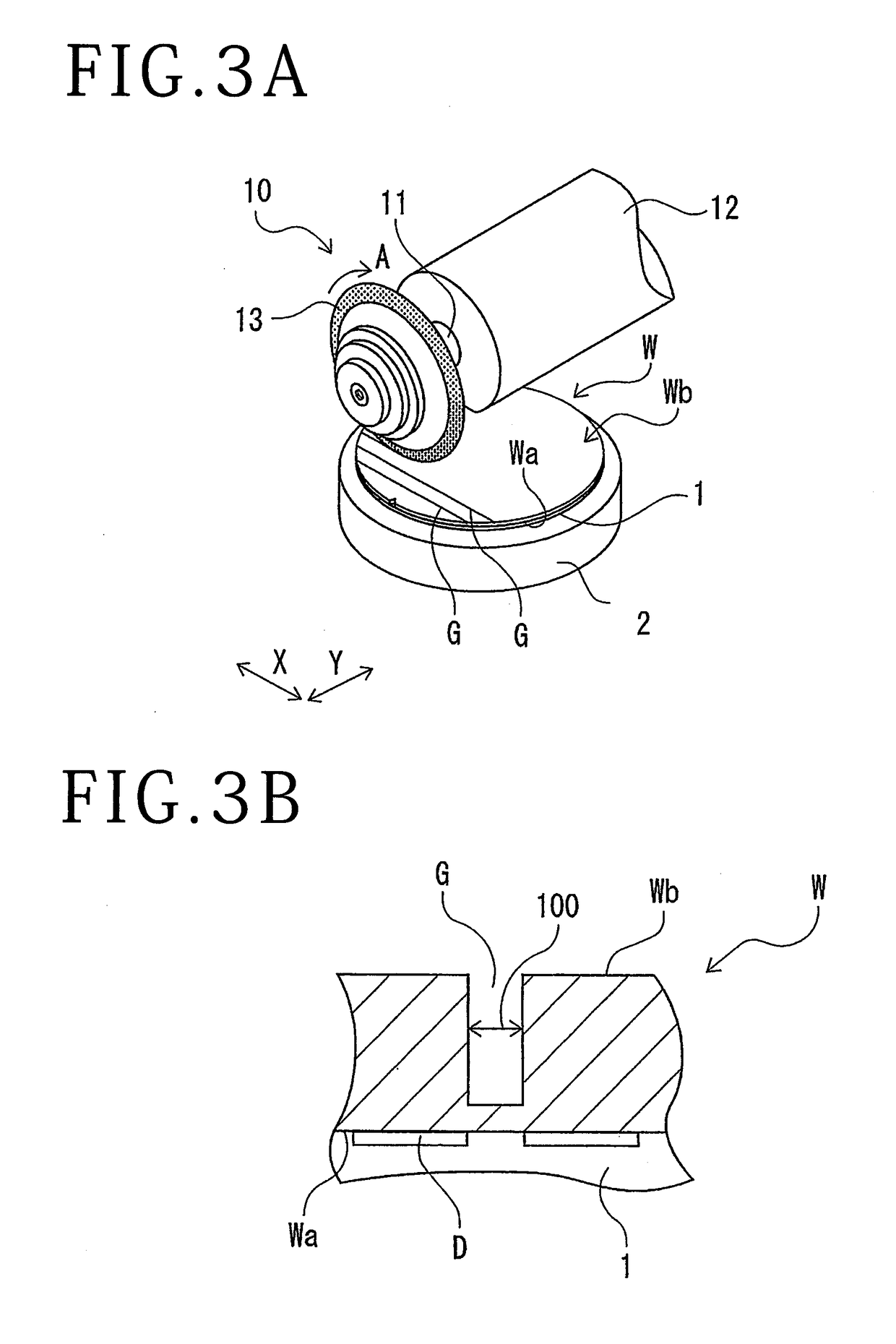

Processing method of wafer

ActiveUS20180226295A1Easy disposalAvoid it happening againSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringDie bonding

A processing method of a wafer includes a cut groove forming step of carrying out cutting with a cutting blade along streets from the back surface of the wafer to form cut grooves, a wafer dividing step of irradiating the wafer with a laser beam along the cut grooves and dividing the wafer into individual chips after the cut groove forming step is carried out, and a die bonding layer disposing step of applying a liquid die bonding agent on the back surface of the wafer and curing it to form the chips on which die bonding layers are formed on the back surface. According to the processing method of the present invention, the occurrence of clogging in the cutting blade and generation of a burr or the like in the die bonding layers can be prevented.

Owner:DISCO CORP

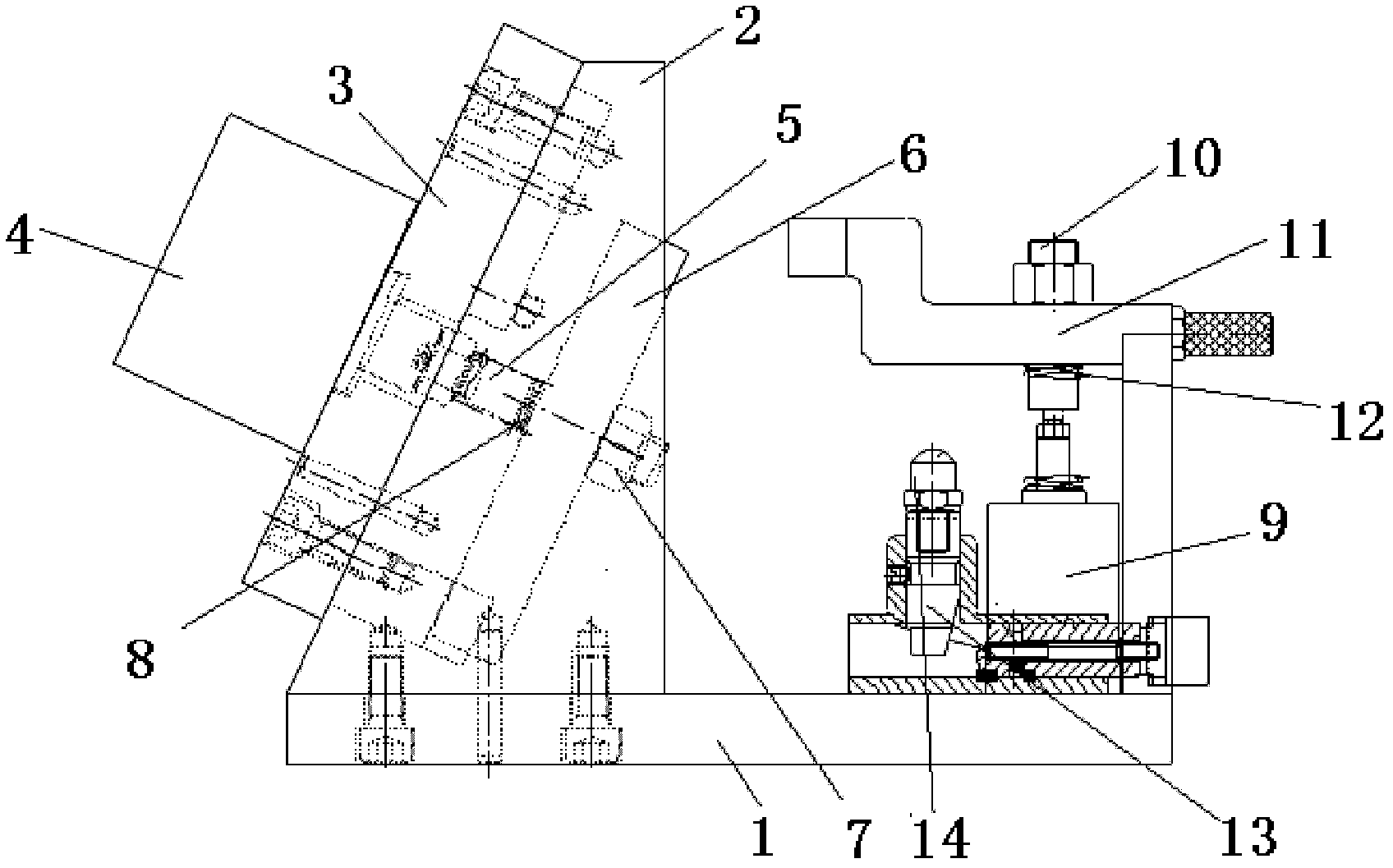

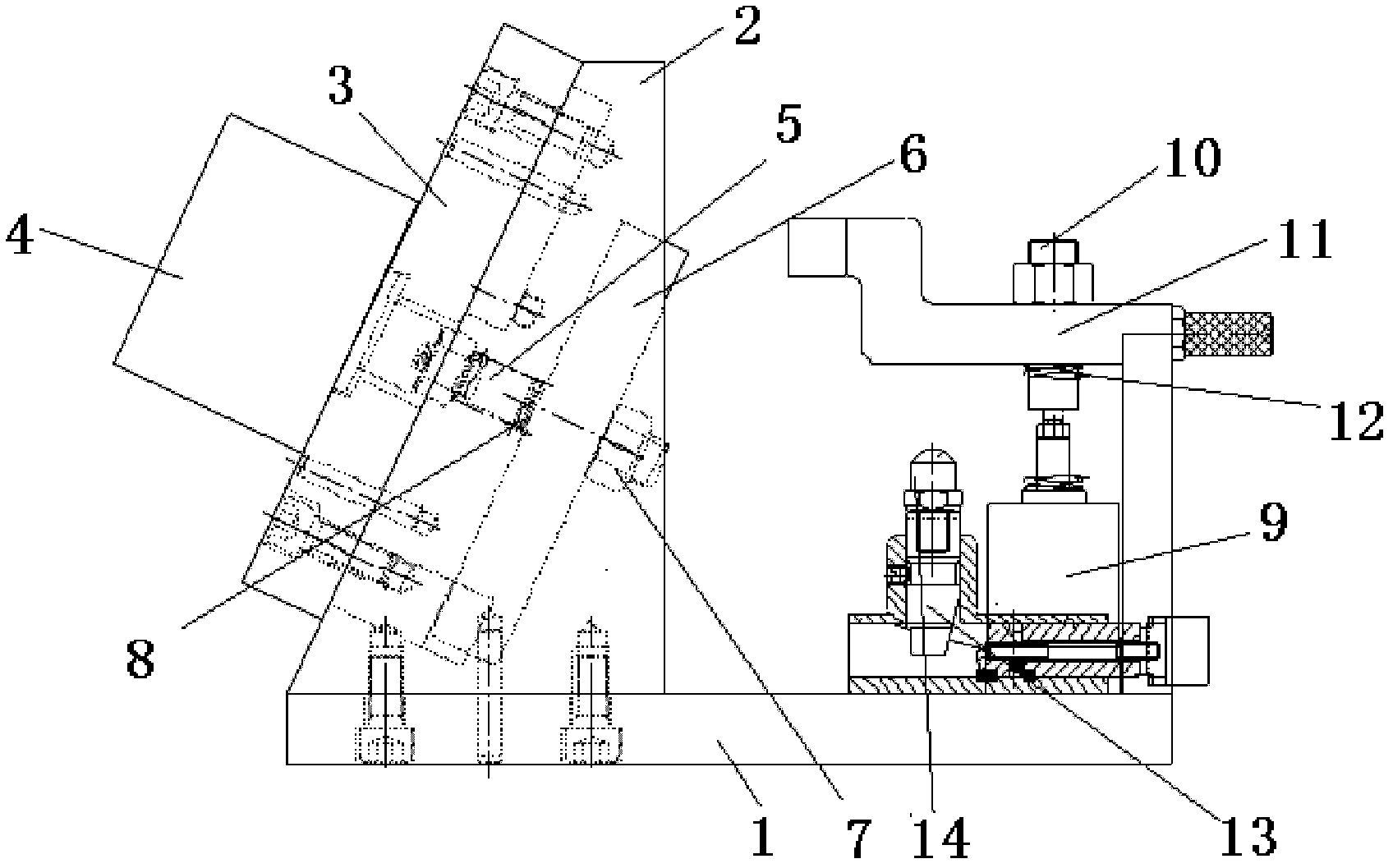

Exhaust pipe milling small-flange clamp

ActiveCN102441803AAvoid position shiftAvoid processing failurePositioning apparatusMetal-working holdersStructural engineeringMechanical engineering

The invention discloses an exhaust pipe milling small-flange clamp. The exhaust pipe milling small-flange clamp comprises a bottom plate, wherein supports are arranged at the front end and the back end of the left side of the bottom plate; inclined surfaces are arranged in the left upper directions of the left support and the right support; a clamp plate is fixedly installed between the right inclined surface and the right inclined surface; a thin-wall cylinder is fixedly installed on the outer surface of the clamp plate; a pull rod is fixedly installed at one end of a piston rod of the thin-wall cylinder; and one end of the pull rod penetrates through the clamp plate and is provided with a pressing plate. The exhaust pipe milling small-flange clamp can be used for mounting a flange accurately, and a flange installing bearing is guaranteed not to deflect.

Owner:如东县岔河污水处理有限公司

Once molding processing device and technology for precision optical element

InactiveCN103342454AGuaranteed uptimeRunning distance is accurateGlass reforming apparatusGlass productionBiochemical engineeringMachining

The invention discloses a once molding processing device and technology for a precision optical element. The device comprises a rack, wherein adjustable support legs are arranged at the lower end of the rack, a workbench is arranged at the upper end of the rack and is also provided with a lower die device and uprights, and an upper support plate is arranged at the top ends of the uprights and is also provided with an upper die device and a servo electric cylinder which is connected with a control cabinet. The technology comprises the following steps of: A. design, manufacture and installation of a die; B. preparation of materials; C. profiling through warming; D. annealing; E. examination; F. trimming; G. cold machining; and H. examination. According to the device and the technology, the production processes are simplified, the possibility of errors is lowered, manpower investment is lowered, the yield and production efficiency of the finished products is greatly improved, and the cost for production is saved.

Owner:雅安格纳斯光电科技有限公司

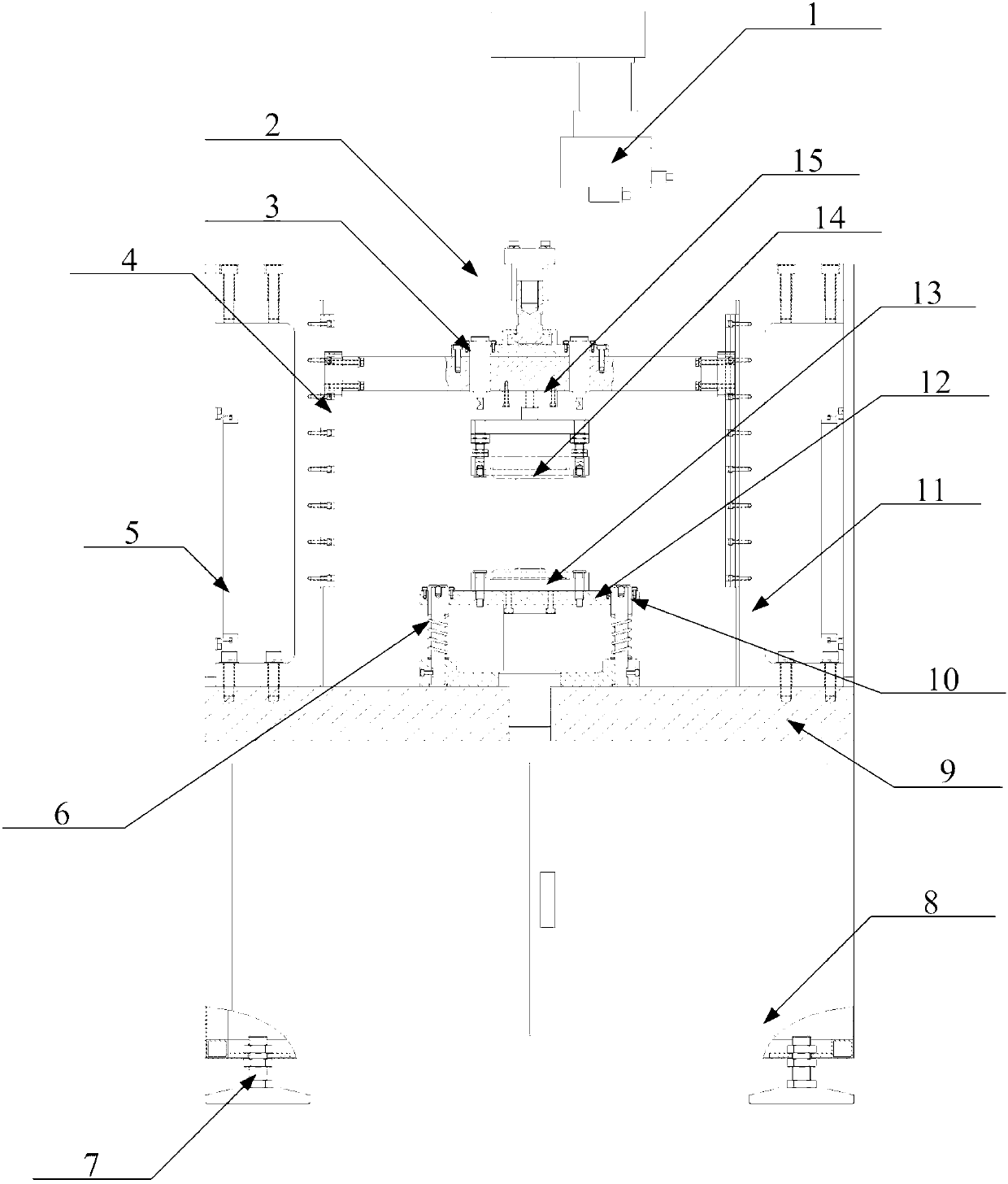

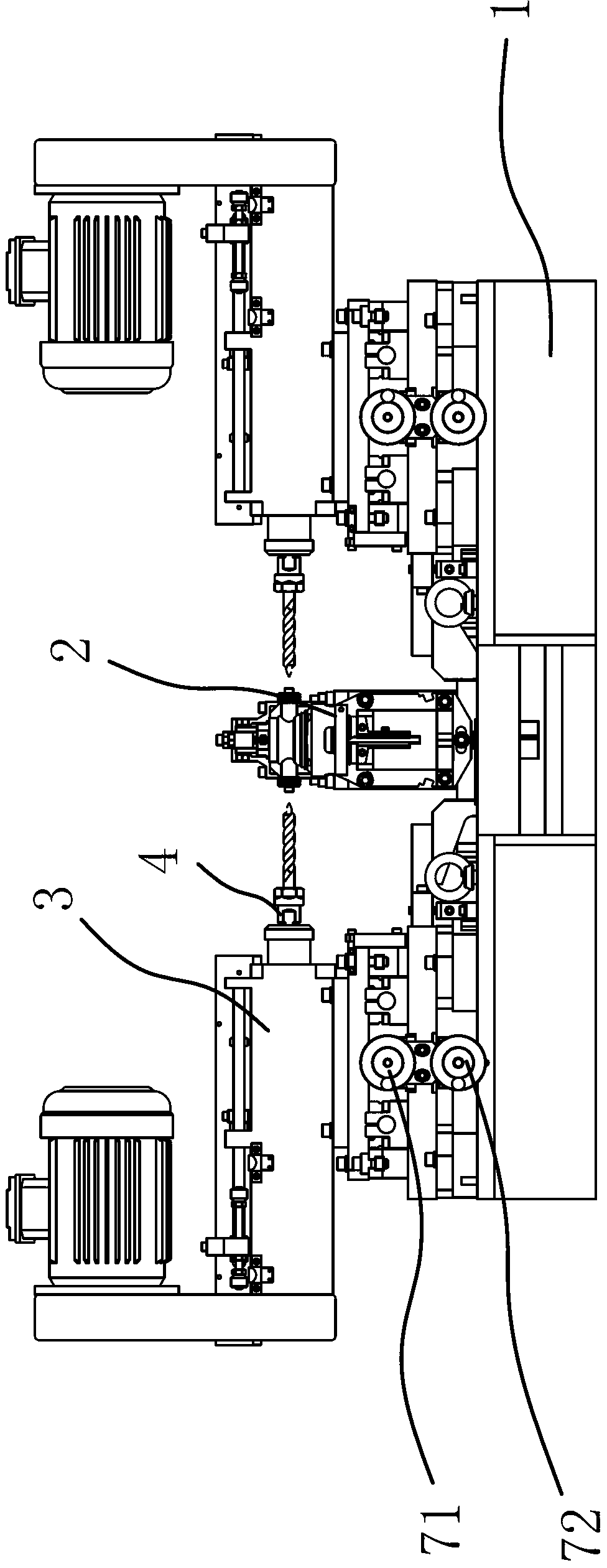

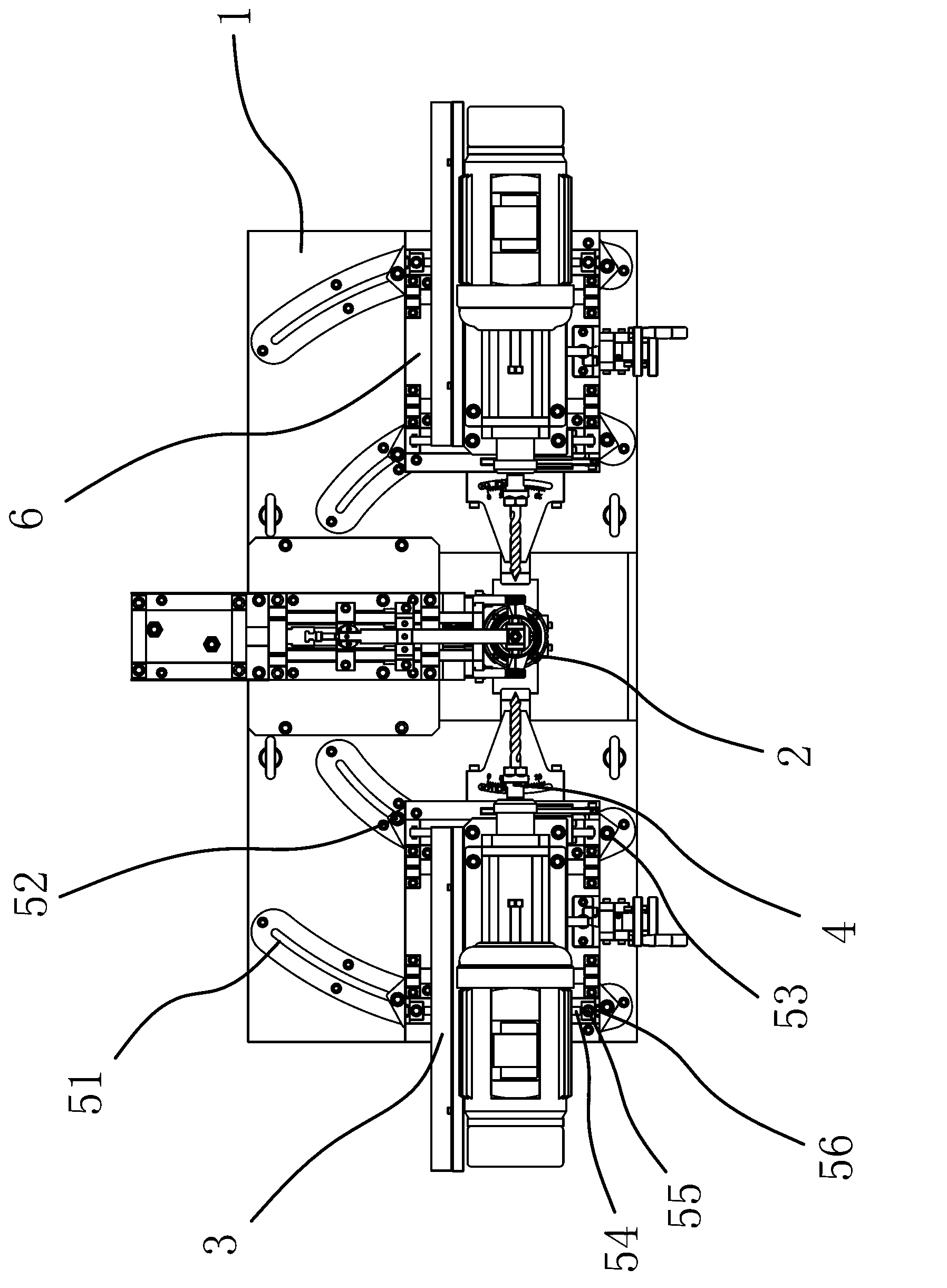

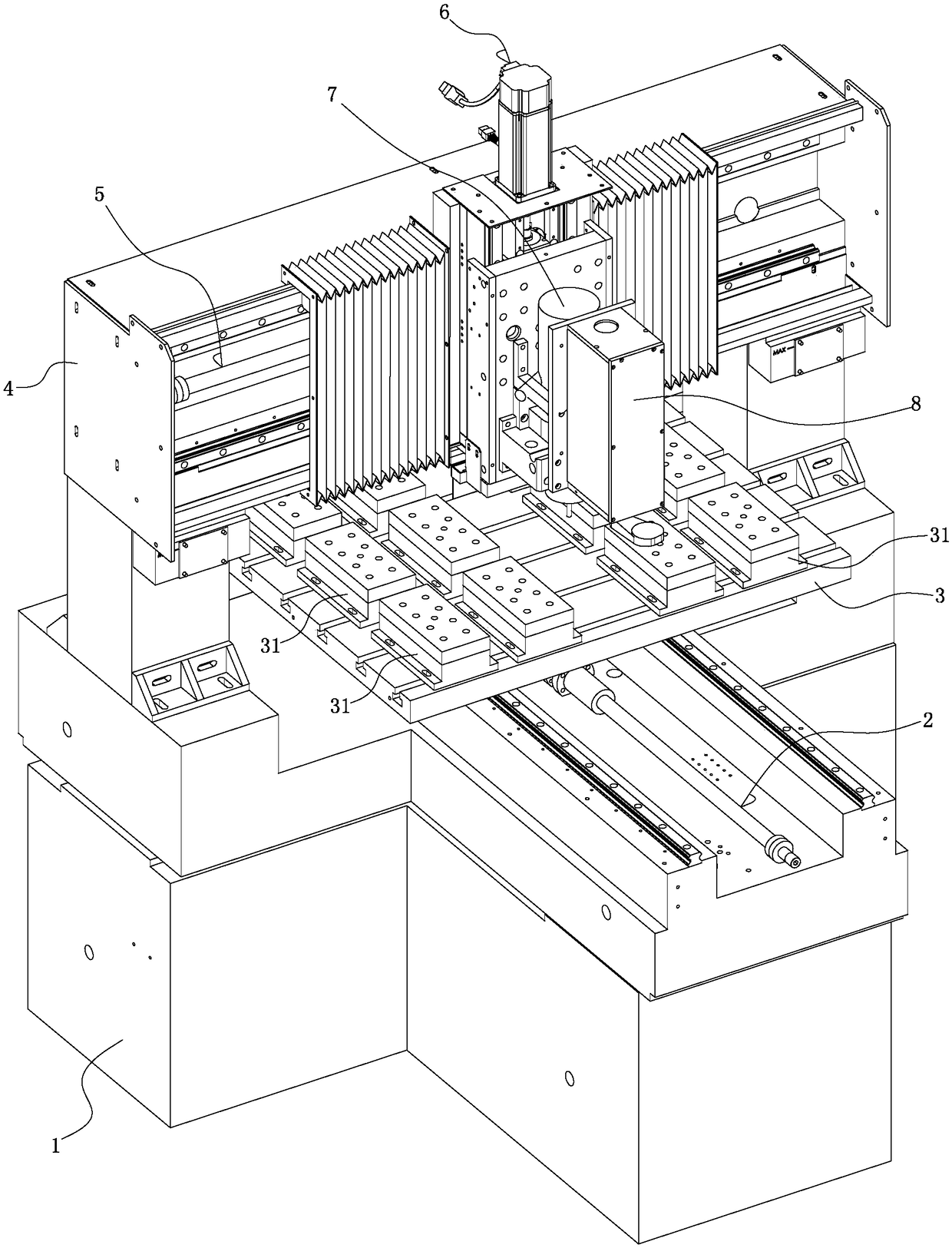

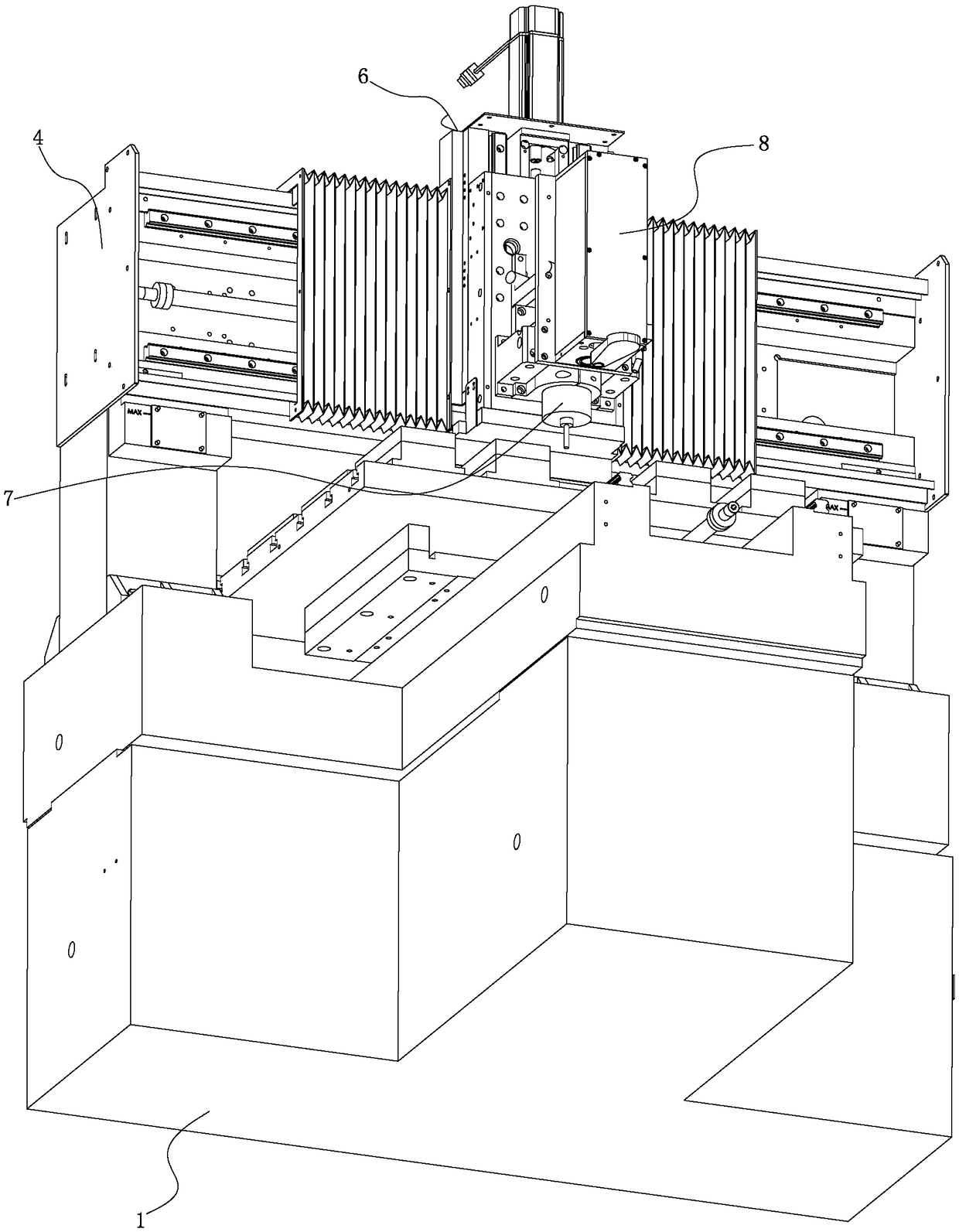

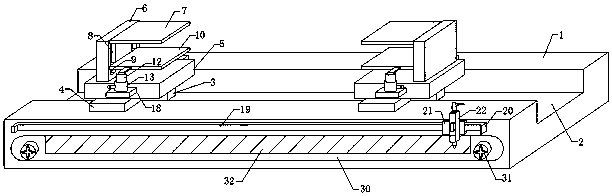

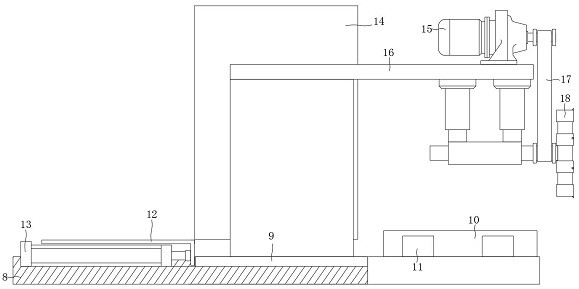

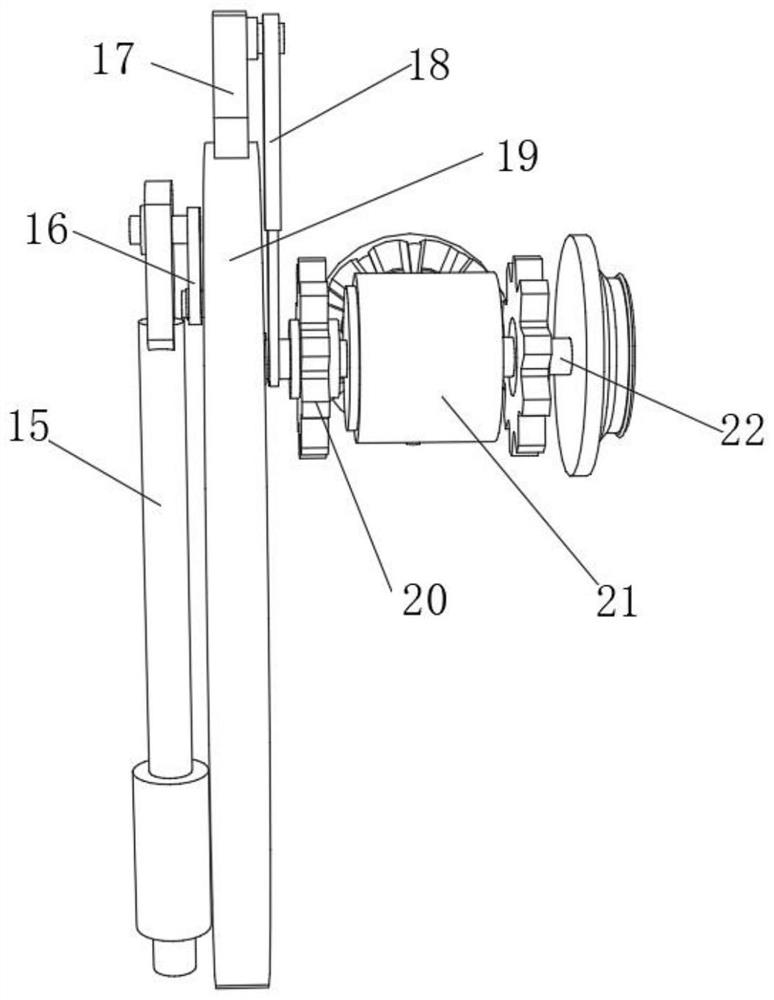

Machine tool for processing inlet/outlet water passages of water meter shell

ActiveCN103071828AImprove stabilitySimple and fast operationLarge fixed membersPositioning apparatusEngineeringRate curve

The invention provides a machine tool for processing inlet / outlet water passages of a water meter shell, which belongs to the field of mechanical technology, and solves the problems that inlet / outlet water passages of a water meter cannot be simultaneously processed by the existing machine tool, the production efficiency is low, the error is large, and the water meter flow rate curve obtained through processing is poor in stability. The machine tool for processing the inlet / outlet water passages of the water meter shell comprises a base and a clamp arranged at the middle part of the base, wherein the two sides of the clamp are respectively provided with a power head assembly which is provided with a power head seat and a rotating shaft, the rotating shafts are arranged towards the clamp, and an adjusting device which can at least adjust the rotating shaft to swing along the horizontal plane is arranged between each power head seat and the base. By the adoption of the machine tool for processing the inlet / outlet water passages of the water meter shell, the inlet / outlet water passages of the water meter shell on the same straight line or have a certain angle can be simultaneously processed, the consistency of the processed inlet / outlet water passages and the stability of the flow rate curve of the water meter are good, the yield is high, the cost is low, and the production efficiency is high.

Owner:WENLING YOUNIO WATER METER

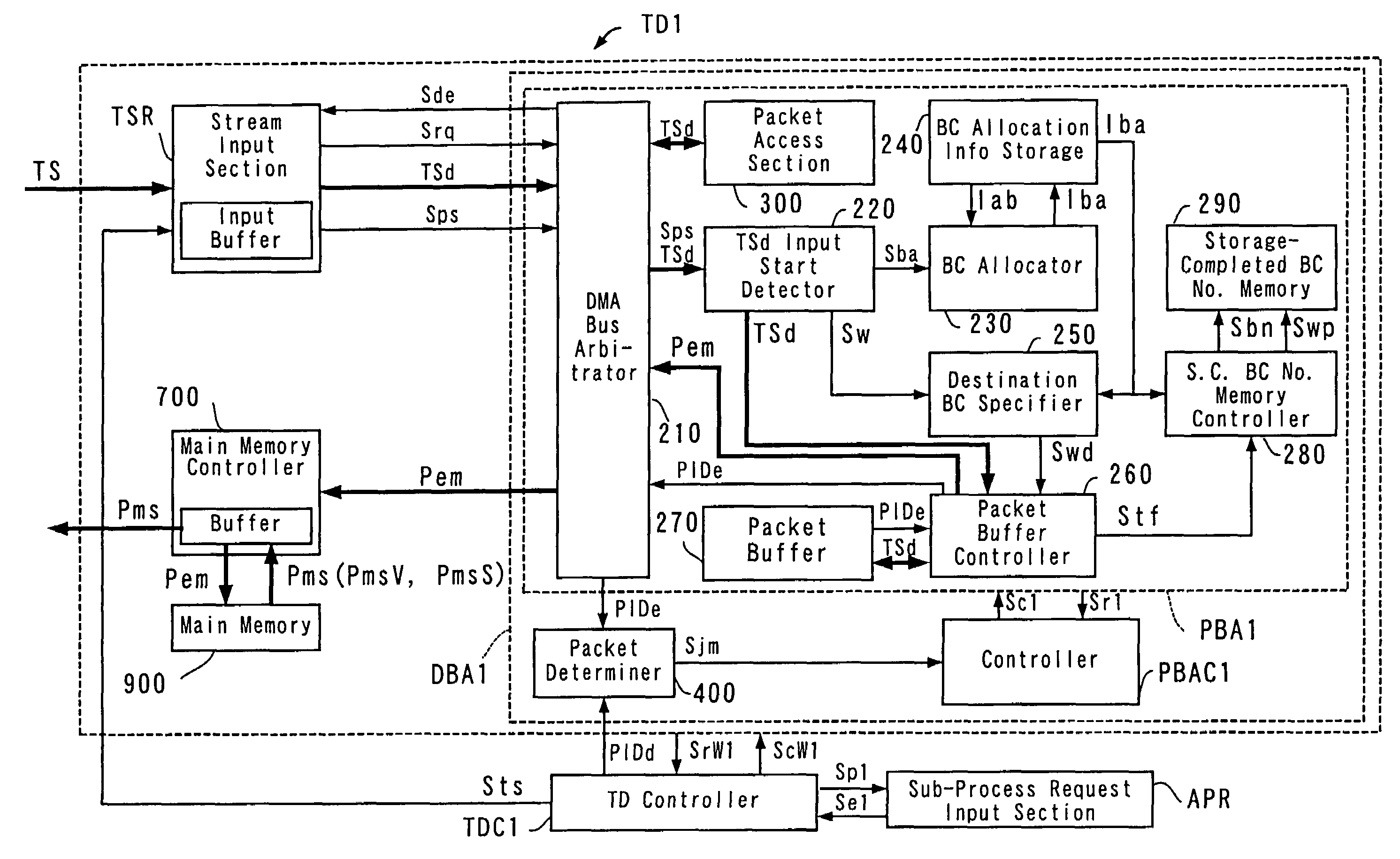

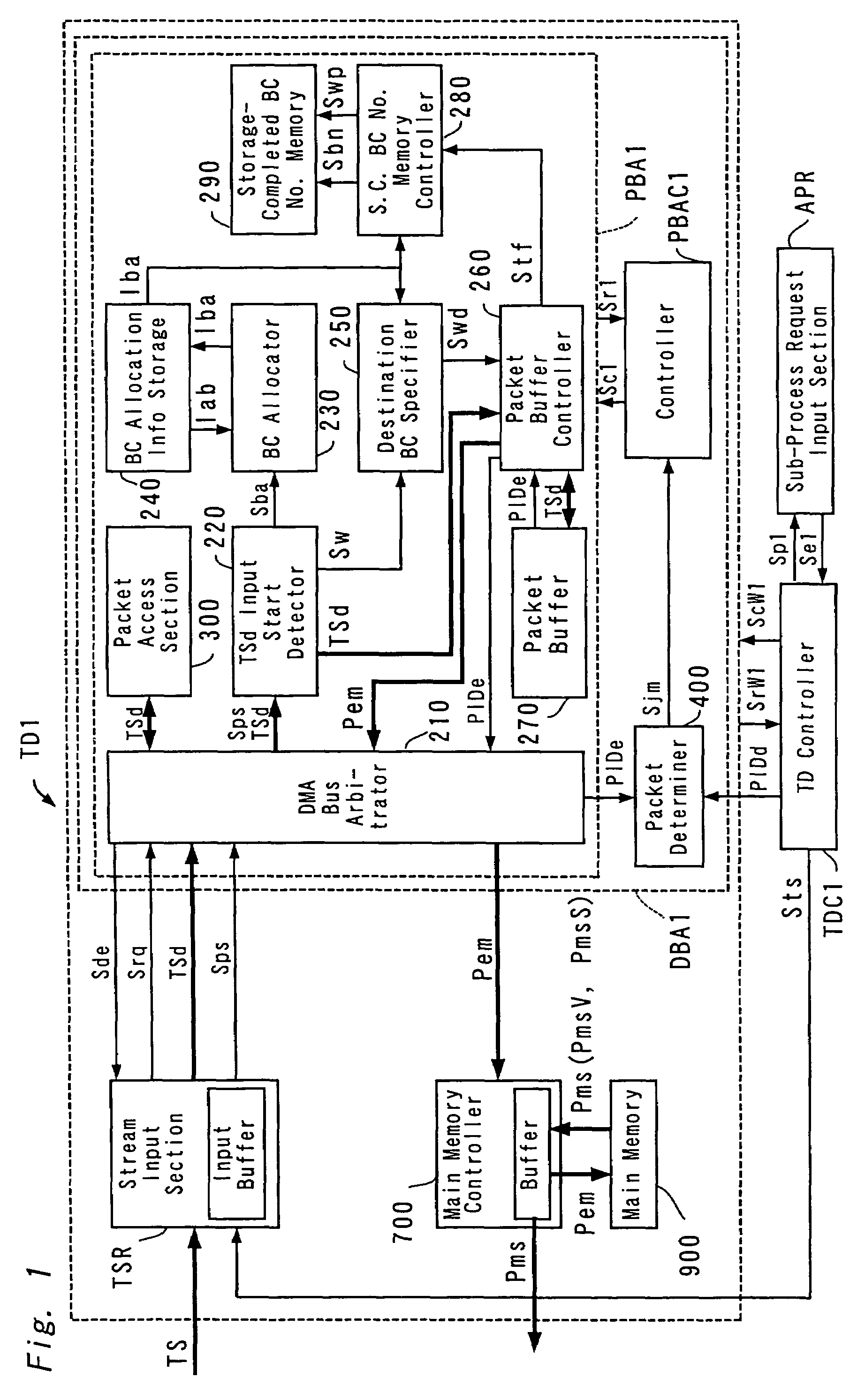

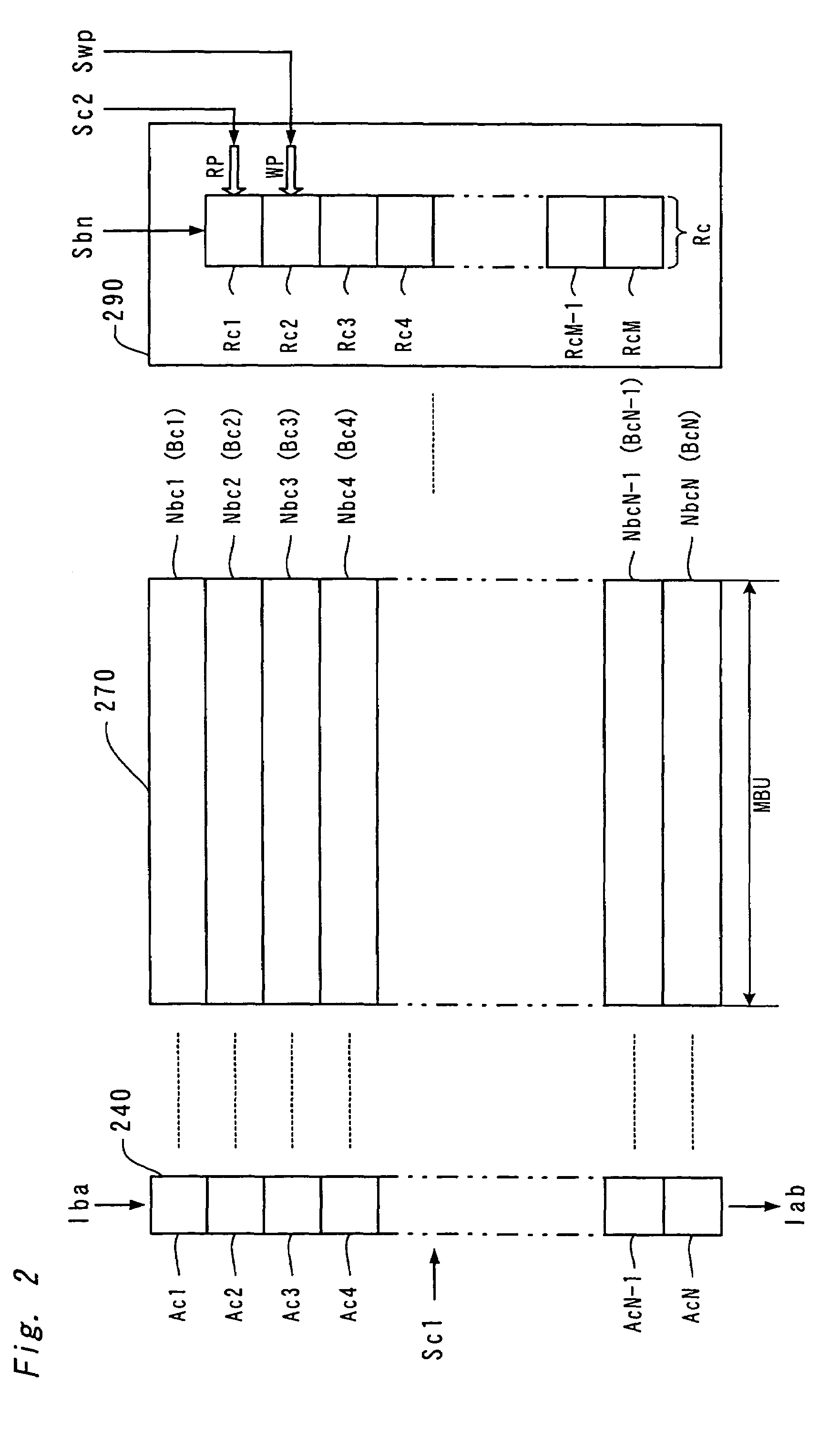

Packet data processing determination apparatus

InactiveUS7359441B2Minimize timeMinimize capacityTelevision system detailsPicture reproducers using cathode ray tubesProcess informationReal-time computing

In a packet data processing determination apparatus (DBA1) for respectively and sequentially determining a plurality of packet data (P) composing an inputted transport stream (TS), a packet data storage section (270) stores the packet data (P) for a predetermined time period in the order in which they came. A stored packet data identifying section (270, 260) reads identification information (PIDe) from the stored packet data (P). A target packet data determining section (400) compares the read identification information (PIDe) with predetermined process information (PIDd) to determine whether the packet data (P) is to be processed.

Owner:PANASONIC CORP

Intelligent single-spindle charge coupled device (CCD) engraving and milling machine

PendingCN108857576AIncrease the range of photos takenSave time for loading and unloadingTelevision system detailsMeasurement/indication equipmentsCcd cameraLinear drive

The invention discloses an intelligent single-spindle charge coupled device (CCD) engraving and milling machine which comprises a machine base, a Y-axis linear driving device arranged on the machine base, a working table arranged on the Y-axis linear driving device, a portal frame arranged on the machine base, an X-axis linear driving device arranged on the portal frame, a Z-axis linear driving device arranged on the X-axis linear driving device, and an engraving device arranged on the Z-axis linear driving device. A jig is arranged on the working table; a CCD camera assembly is arranged on the Z-axis linear driving device, is located at the front end of the engraving device, and comprises a base plate fixed onto the Z-axis linear driving device, and a CCD camera arranged on the base plate; a protection cover is arranged on the periphery of the base plate and covers the periphery of the CCD camera; a lens hole corresponding to the CCD camera is formed in the lower end of the protectioncover; a lens of the CCD camera faces the lens hole; the protection cover is provided with a lens cover matched with the lens hole, and a drive mechanism for controlling the lens cover to open or close the lens hole.

Owner:SHENZHEN JOJOY BEN MACHINERY EQUIP

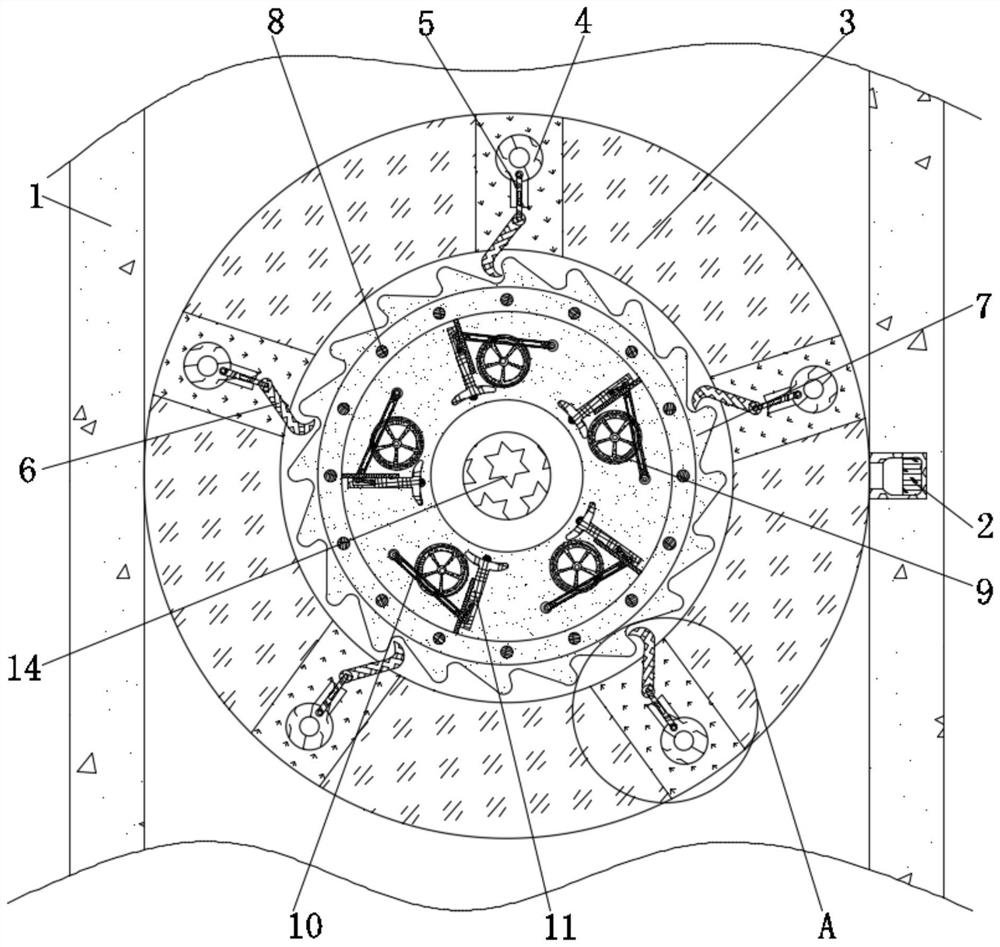

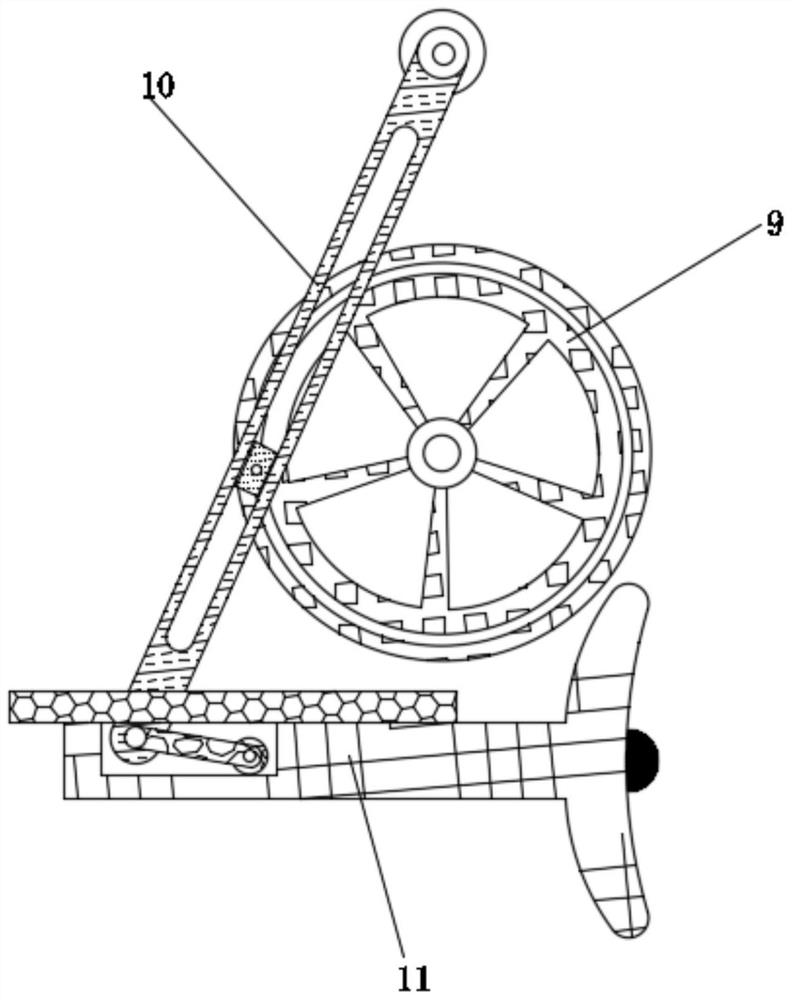

Positioning and punching protection device for automobile hub punching machine tool

InactiveCN112296199AProtect the effect of auto-fixTo achieve the effect of automatic fixationPerforating toolsMetal-working feeding devicesRatchetMotor vehicle part

The invention relates to the technical field of automobile part machining machine tools, and discloses a positioning and punching protection device for an automobile hub punching machine tool. The positioning and punching protection device comprises a shell, wherein a photosensitive component is fixedly connected to the interior of the shell, a supporting plate is fixedly connected to the interiorof the shell, a turntable is movably connected to the exterior of the supporting plate, and a connecting rod is movably connected to the exterior of the turntable. Under the interaction of all the structures of the device, when a wheel hub is machined, the circle center of the wheel hub can be the dead center, in this way, the situation that when an operator fixes the wheel hub, the center of thewheel hub deviates, and consequently the machined wheel hub is unqualified is avoided, machining precision is improved, and the percent of pass of products is guaranteed. A ratchet wheel disc can bedecelerated in time when the rotating speed of the ratchet wheel disc is too high, so that the effect of decelerating the ratchet wheel disc in time when the ratchet wheel disc stalls is achieved, thepersonal safety of an operator is protected, the machining efficiency is improved, and the device conforms to the design concept of intelligent manufacturing.

Owner:温州纽柏贸易有限公司

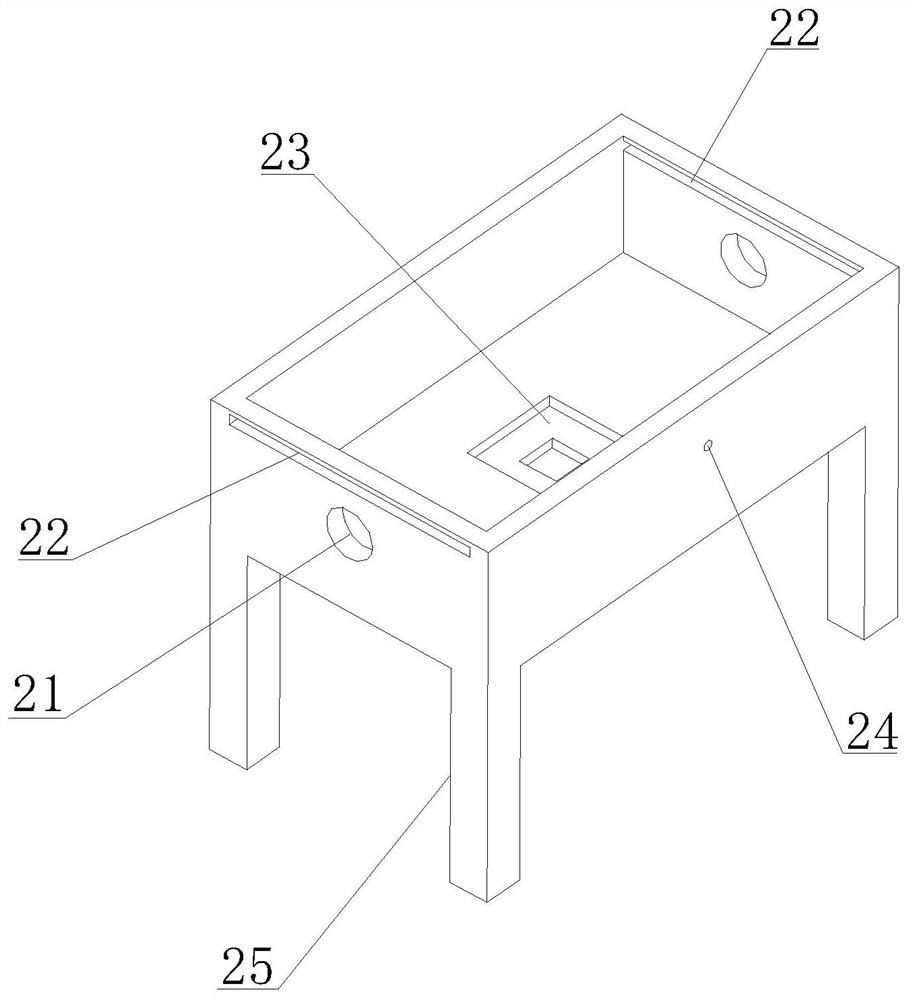

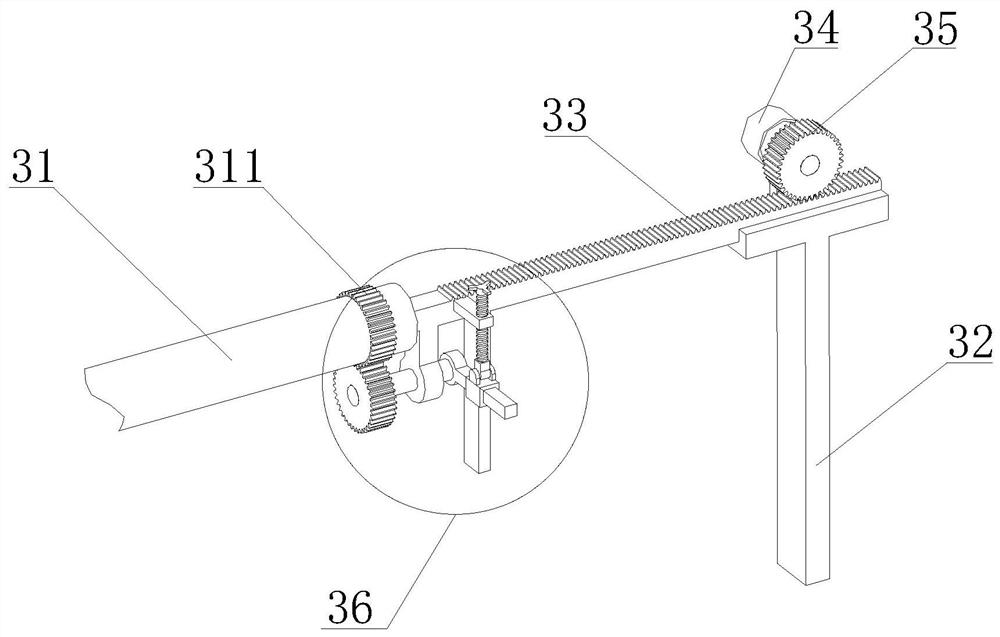

Auxiliary clamp for machining

InactiveCN108372413AAvoid processing failureAvoid damageMeasurement/indication equipmentsPositioning apparatusGear wheelSlide plate

The invention discloses an auxiliary clamp for machining. The clamp comprises a base, a first sliding groove is formed in the base, and multiple first sliding blocks are arranged in the first slidinggroove; sliding plates are fixedly connected to the two sides of each first sliding block, and baseplates are connected to the upper portions of the first sliding blocks. The auxiliary clamp for machining is provided with a scale ruler and pointers, clamping blocks can freely move on a sliding rail, and therefore the pointers can be freely moved through a first handle; a second rod is rotated through a second handle, the pointer at one end of each retractable rod and the pointer below the first rod form a right angle, and workers can more precisely conduct machining through scales of the scaleruler during machining; through arrangement of clamping plates and fixing plates, rotation rods can be rotated through rotation handles, gears at the peripheries of the rotation rods and a gear at one side of each inner rod are used for moving the inner rod up and down, connection plates drive the clamping plates to move up and down, the clamping plates and the fixing plates are used for fixing materials to be machined, and the situation is avoided that the materials are moved in the machining process, and accordingly the machining failure is caused.

Owner:龙岩丽荣电子科技有限公司

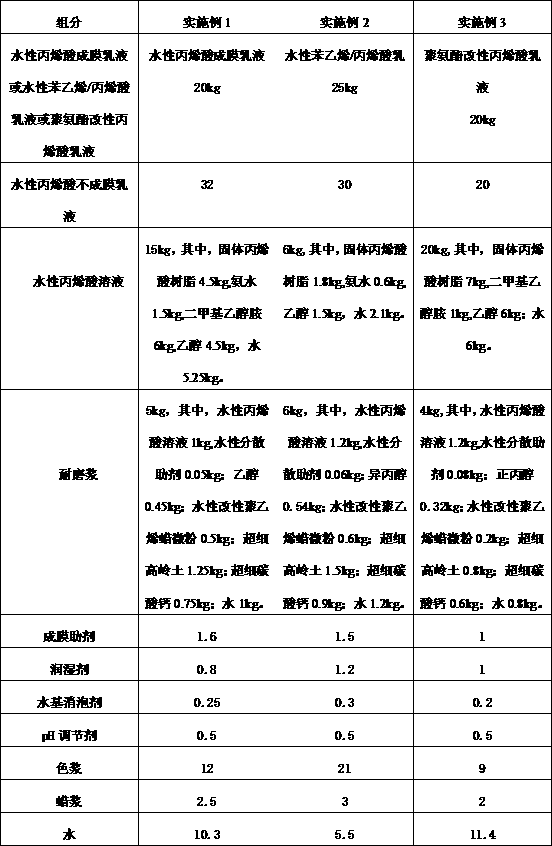

Overprint varnish-free high wear resistance aluminum foil lined paper water-based ink and preparation method thereof

This invention relates to the field of inks, and discloses an overprint varnish-free high wear resistance aluminum foil lined paper water-based ink. The overprint varnish-free high wear resistance aluminum foil lined paper water-based ink comprises 20-25 wt% of an aqueous acrylic film-forming emulsion or an aqueous styrene / acrylic emulsion or a polyurethane modified acrylic emulsion, 20-35 wt% ofan aqueous acrylic non-film forming emulsion, 2-25 wt% of an aqueous acrylic solution, 0.2-2 wt% of a wetting agent, 0.1-0.5 wt% of a defoamer, 0.4-0.6 wt% of a pH adjuster, 10-25 wt% of a color paste, 4-10 wt% of a wax paste, 4-10 wt% of a wear-resistant slurry, 5-15 wt% of water and 0.1-2 wt% of a film forming aid, wherein the wear-resistant slurry comprises 20-30 wt% of an aqueous acrylic solution, 20-25 wt% of water, 5-10 wt% of a water-modified modified polyethylene wax micro-powder, 1-2 wt% of an aqueous dispersion aid, 8-9 wt% of a cosolvent, 20-25 wt% of ultrafine kaolin and 10-15 wt%of ultrafine calcium carbonate. The ink has the adhesion of prime coating, also has the heatproof, waterproof, anti-slip, wear-resistant and scratch-resistant properties of a varnish, is convenient touse, and can simplify aluminum foil pre-coating, monochrome printing and three-time overprint varnish printing into one-time inking printing, so two printing processes are saved, and energy saving and environmental protection are achieved.

Owner:HUIZHOU PERFECT CHEM IND CO LTD

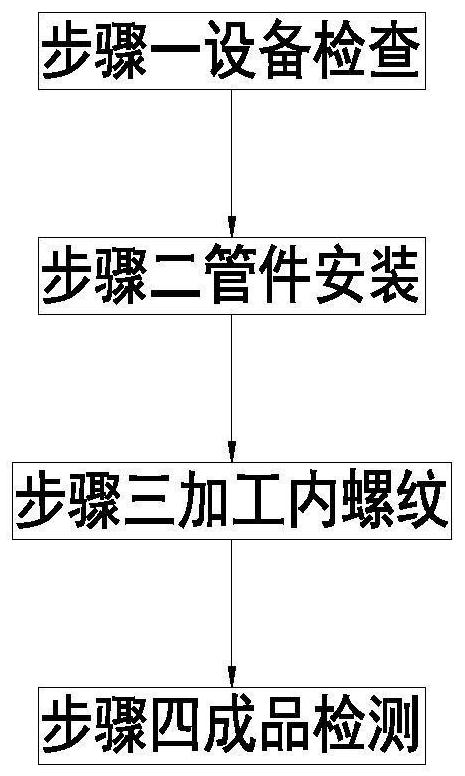

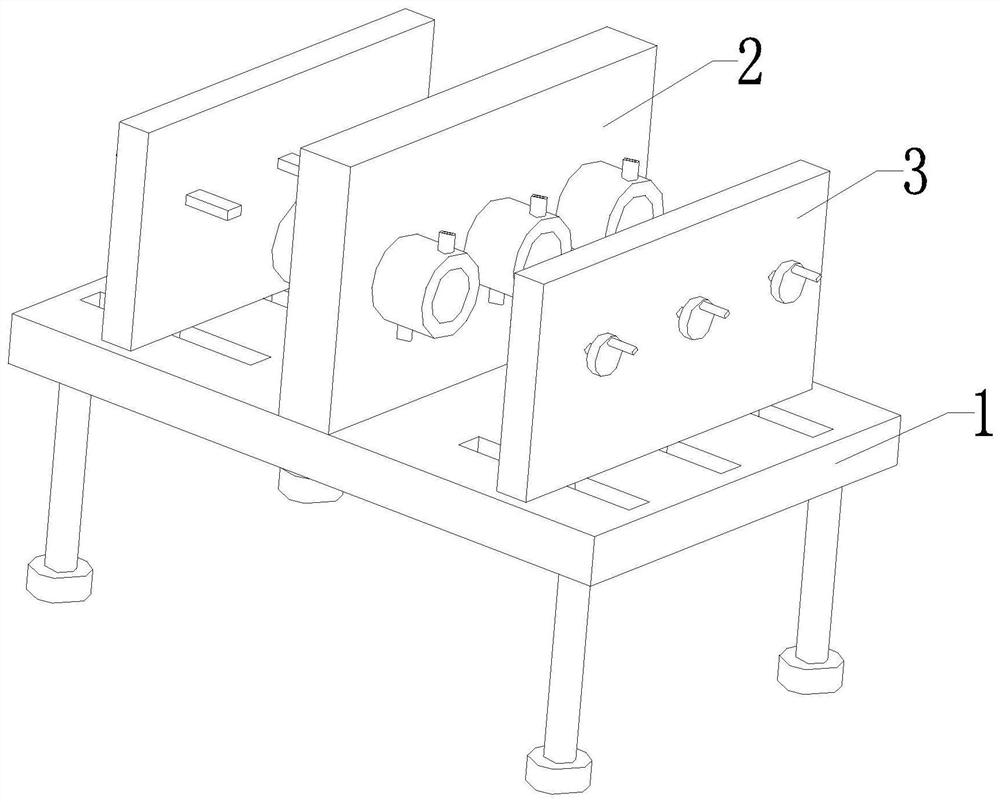

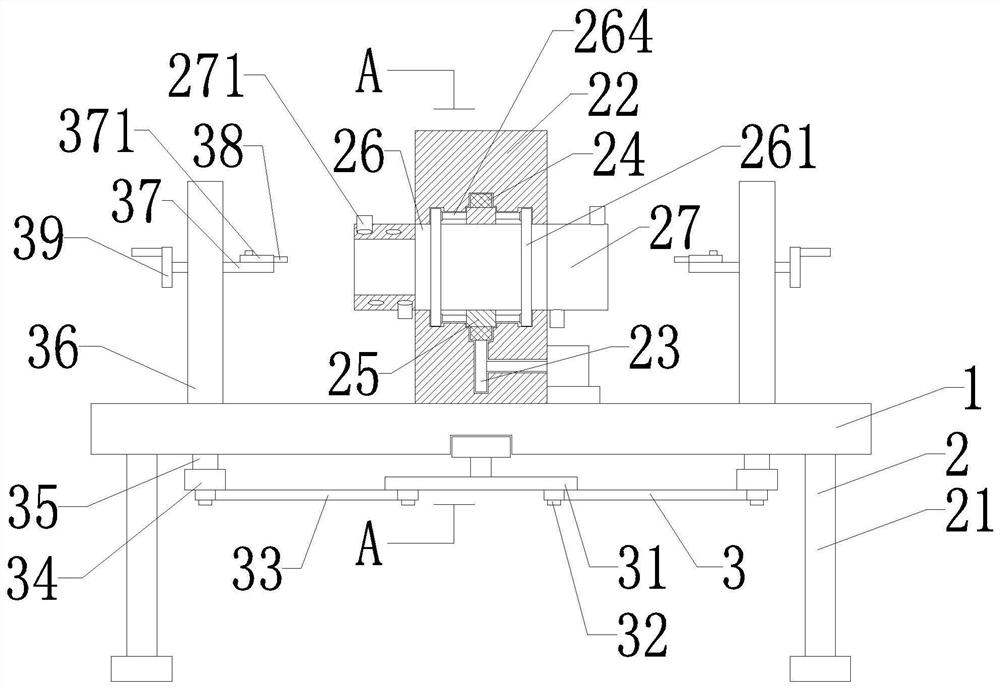

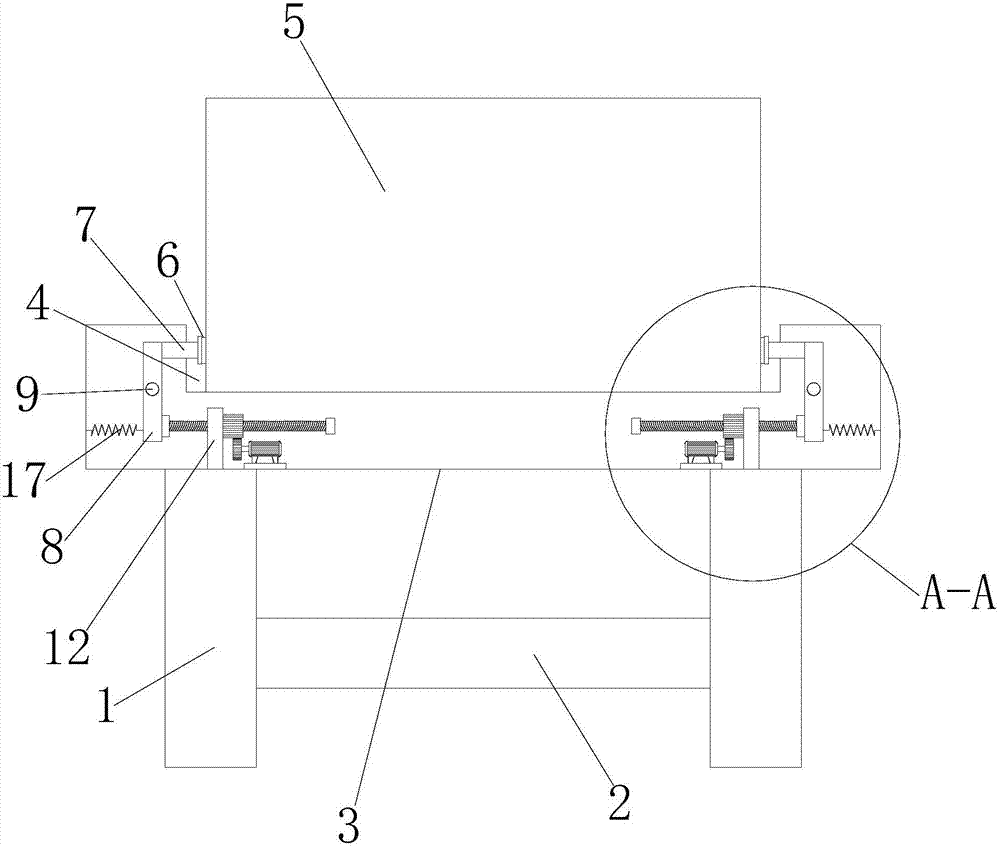

Pipeline connecting piece manufacturing and forming method

PendingCN112589211AEnsure stabilityEasy PickupThread cutting feeding devicesThread cutting machinesKnife bladesManufacturing engineering

The invention relates to a pipeline connecting piece manufacturing and forming method which mainly comprises the following steps of equipment inspection, pipe fitting installation, internal thread machining and finished product inspection. Pipe fitting connecting piece internal thread machining equipment comprises an installation frame, a fixing sleeve piece and forming sleeve pieces, the fixing sleeve piece is installed on the installation frame, and the forming sleeve pieces are symmetrically arranged at the two ends of the fixing sleeve piece. The pipeline connecting piece manufacturing andforming method can solve the following problems existing in internal thread machining forming of an existing pipe fitting connecting piece. The problems include that a, during internal thread machining forming of the existing pipe fitting, the pipe fitting often shakes, so that the position deviates during internal thread machining, the situation of internal thread machining failure is caused, the pipe fitting is scrapped, and raw materials are wasted; and b, when the existing pipe fitting is subjected to internal thread machining, an internal thread turning blade is often subjected to the action of large force, then the position of the blade deviates, the size of a thread is changed, and the product quality is affected.

Owner:陆红华

Welding table

InactiveCN107511620APrevent movementReduce the difficulty of operationWelding/cutting auxillary devicesAuxillary welding devicesRotational axisMachining

The invention discloses a welding table, which comprises four supporting legs, all of which are fixedly connected by connecting rods, and the tops of the four supporting legs are all fixedly connected with the fixed table, and the top of the fixed table is provided with Placement slot, the interior of the placement slot is fixed with a workpiece, both sides of the workpiece are provided with buffer blocks, the side of the buffer block away from the workpiece is fixedly connected with the locking rod, and the other end of the locking rod runs through the fixed table and Extending to the inside of the fixed table, the end of the locking rod extending to the inside of the fixed table is fixedly connected to the top of one side of the rotating plate, and the middle part of the rotating plate is movably connected to the fixed table through a rotating shaft. The welding table for electronic product production of the present invention effectively avoids the movement of the workpiece due to external factors during processing, thereby avoiding the occurrence of processing failure, improving the processing quality and processing efficiency, reducing the difficulty of operation for operators, and saving time and effort .

Owner:重庆文客巴科技有限公司

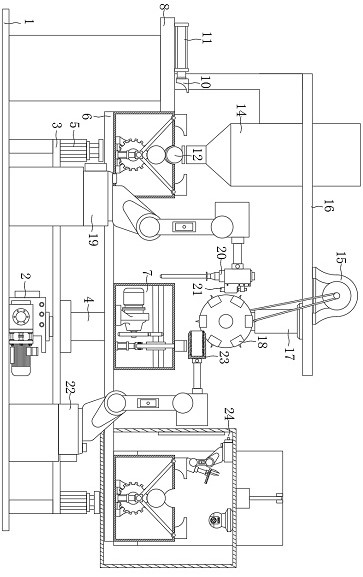

Machining equipment with hole diameter measuring function for hollow bolt

PendingCN113618169AGuaranteed qualifiedImprove detection efficiencyThread cutting machinesMeasurement/indication equipmentsElectric machineryCam

The invention discloses machining equipment with a hole diameter measuring function for a hollow bolt, which comprises a chassis; a cam divider is arranged above the chassis; a bottom plate is arranged above the cam divider; a main shaft is arranged above the bottom plate; a rotating disc is arranged above a supporting rod; a material placing plate is arranged on the left side of the rotating disc; a grinding tool is arranged on the left side of the material placing groove; a material pushing plate is arranged behind the material placing groove; a material storage bin is arranged above a material pushing rod; a transverse plate is arranged below a main motor; a screwer is arranged below a lifting rod; a first mechanical arm is arranged in front of the rotating disc; a positioning instrument is arranged on the right side of a drilling machine; a cylinder knife is arranged on the left end of a second mechanical arm; a detection box is arranged on the right side of the rotating disc; and the hollow bolt is provided with the processing equipment with the hole diameter measuring function. Compared with existing common bolt machining equipment, machining procedures are simplified; and machining efficiency and product quality are improved.

Owner:东莞市劲力机电科技有限公司

Machine tool with mistake-proofing system

InactiveCN106695453ANo special requirements for shapePrevent leavingMeasurement/indication equipmentsMachine instructionProduct processing

The invention relates to a machine tool with a mistake-proofing system. The machine tool comprises an instruction panel, a jig and the mistake-proofing system; the instruction panel is connected with the mistake-proofing system; the mistake-proofing system comprises a sensor (1), an alarm and a controller; the sensor (1) and the alarm are connected with the controller; the sensor (1) is arranged on the machine tool; a to-be-machined product enters a sensing area of the sensor (1) when put in place, when the controller receives a machining instruction of the instruction panel and the sensor (1) senses the to-be-machined product, the controller controls the machine tool to machine the product, and after the product leaves the sensing area, the sensor (1) is reset; and if the controller does not receive the machining instruction of the instruction panel in the period from the current reset action to the next reset action of the sensor (1), the alarm gives an alarm. Compared with the prior art, the machine tool not only can effectively prevent omissive machining but also can prevent unqualified machining, and is suitable for various products.

Owner:SHANGHAI CENSI AUTOMOBILE PARTS

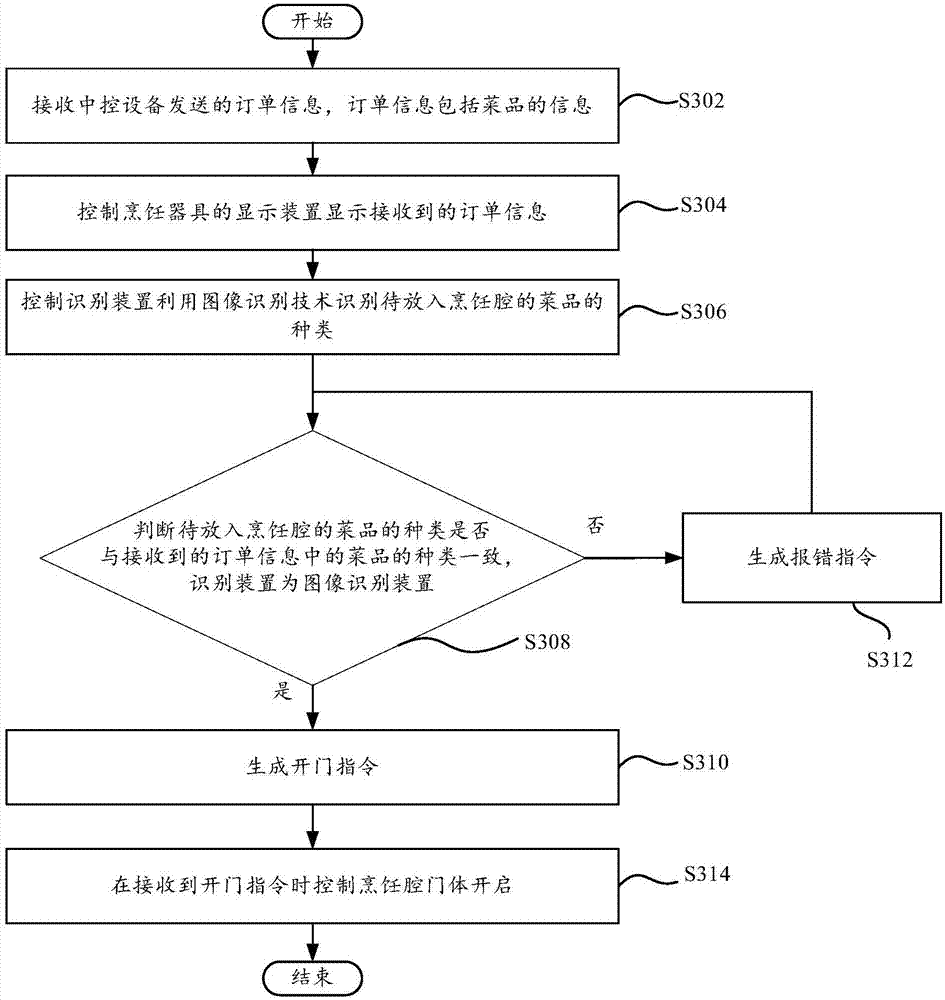

Control method and control system of cooking system

ActiveCN108013777AAvoid processing failureImprove user experienceSteam cooking vesselsMicrowave heatingControl systemError reporting

The invention provides a control method, control system of a cooking system and the cooking system, and is applied to the field of commercial cooking. The cooking method comprises the steps that a cooking utensil receives first order information send by center control equipment, wherein the first order information comprises information of cooked food and cooking parameters for processing cooked food; controlling a recognition device to recognize whether cooked food put into a cooking cavity is consistent with the cooked food in the received first order information or not, if yes, a first starting instruction is generated, and if not, a first error reporting instruction is generated; when the first starting instruction is received, the cooking utensil is controlled to process the cooked food according to the cooking parameters. By means of the control method, by controlling the recognition device to recognize the cooked food, the problem that the cooked food fails to be processed sincethe cooked food to be processed is unmatched with the first order information is timely solved, and the effect of solving the problem that the cooked food to be processed is unmatched with the first order information is achieved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

PC structure machining device

ActiveCN113858399AAchieve insertionRealize selectionMouldsAuxillary shaping apparatusStructural engineeringAxial strain

The invention discloses a PC structure machining device, and belongs to the field of PC structure machining. The PC structure machining device comprises a box body, a mold bar inserting and drawing mechanism, an opening and closing mechanism, a limiting mechanism, a jacking mechanism, a locking mechanism and a downward pressing mechanism. The mold bar inserting and drawing mechanism is arranged on the box body, and a rotating assembly is arranged in the mold bar inserting and drawing mechanism, so that the drawing action of a mold bar is smoother and simpler, and axial strain of an inner circle of a cylindrical hole is avoided when the mold bar is drawn; by arranging the opening and closing mechanism and the limiting mechanism, control over the opening time of the upper end of the box body is achieved, and the situation that when concrete is poured into the box body, the mold bar cannot be inserted into the box body, and machining fails is avoided; by arranging the jacking mechanism and the locking mechanism, control over the jacking time of the jacking mechanism is achieved, and deformation of the mold bar is avoided; and the downward pressing mechanism is arranged, so that discharging of gas in the concrete is accelerated while the concrete is flattened.

Owner:阜阳市晶宫工业科技有限公司

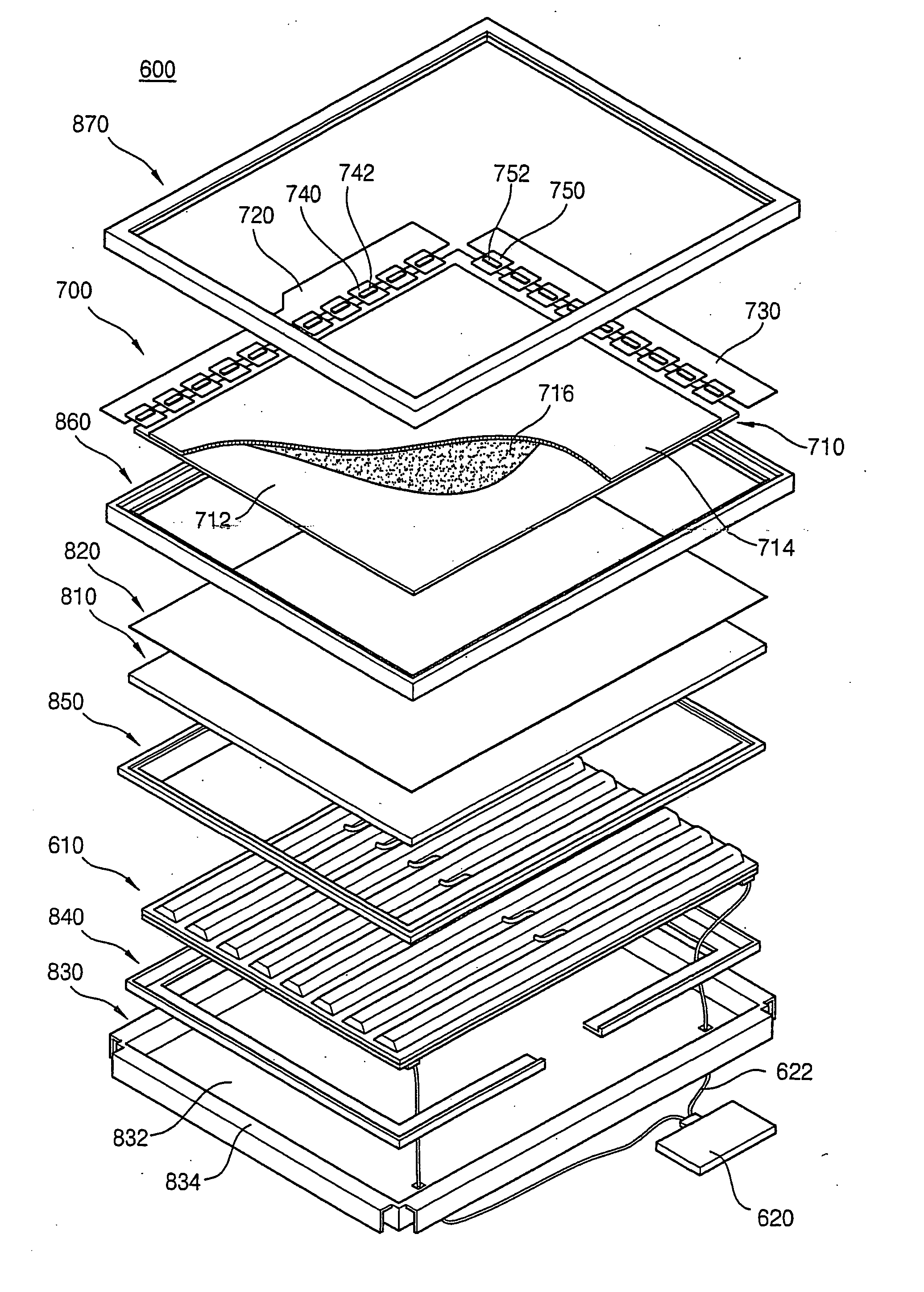

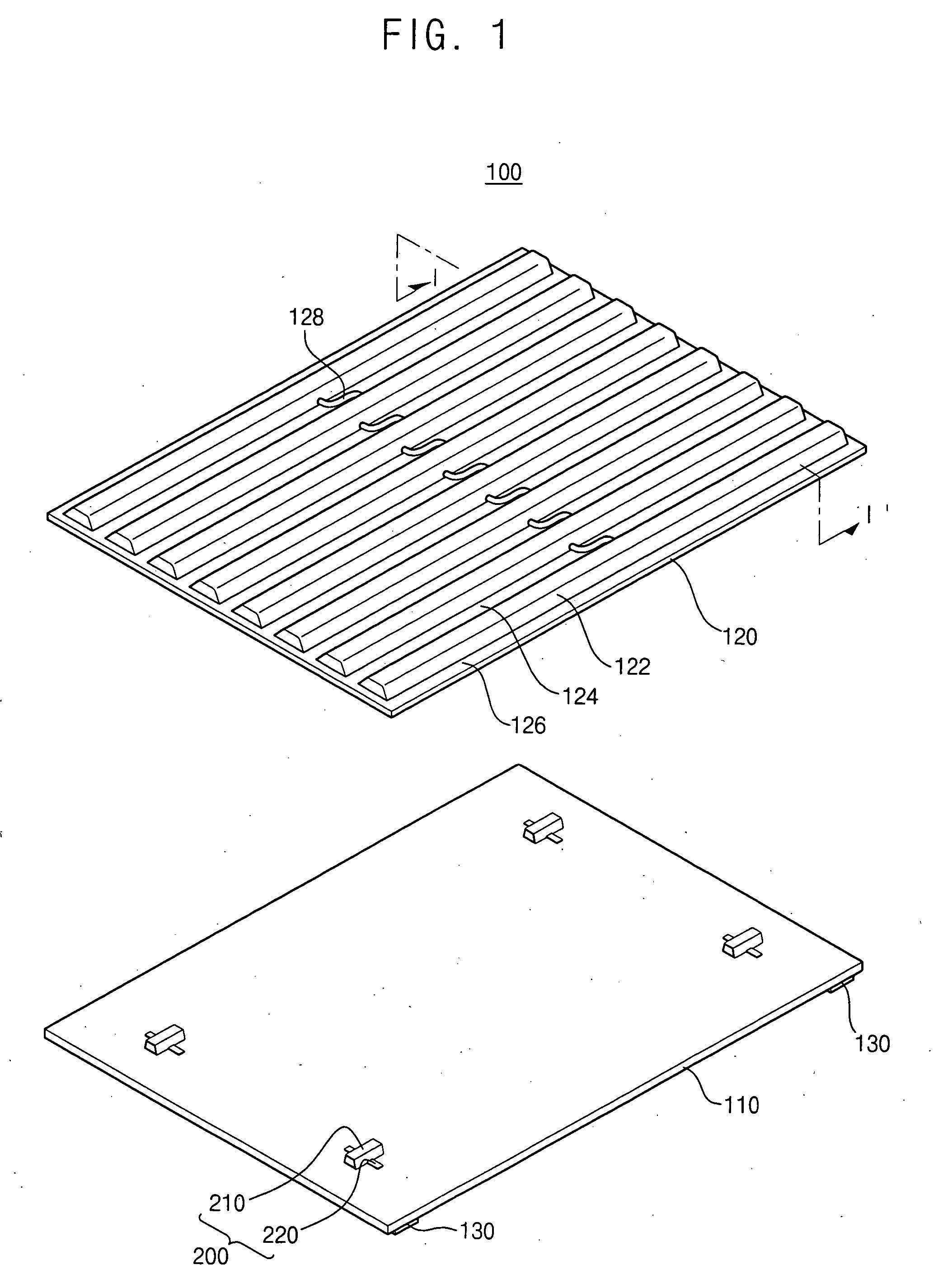

Flat fluorescent lamp and liquid crystal display apparatus having the same

InactiveUS20060119764A1Improve abilitiesMore stably securedOther domestic articlesWork tools storageLiquid-crystal displayEngineering

A flat fluorescent lamp and liquid crystal display apparatus having the same is provided. The flat fluorescent lamp includes a first substrate and a second substrate combined with the first substrate to form a discharge space between the first and second substrates. The flat fluorescent lamp also includes a getter disposed in the discharge space. The getter includes a body portion and a wing portion for securing the body portion.

Owner:SAMSUNG ELECTRONICS CO LTD

Redwood furniture tenon mortise cutting device

InactiveCN112356183AImprove efficiencyQuality improvementDovetailed workProfiling/shaping machinesStructural engineeringWaste material

The invention discloses a redwood furniture tenon mortise cutting device, and relates to the technical field of furniture cutting. The problem of synchronous cutting of tenons and mortised wood is solved. The device specifically comprises a base; supporting columns are arranged on the outer walls of the two sides of the top of the base correspondingly; mounting bases are arranged on the outer walls of the tops of the two supporting columns correspondingly; a same circumferential cutting mechanism is arranged on the opposite sides of the two mounting bases; a connecting plate is arranged on theouter wall of the bottom of the circumferential cutting mechanism; a waste groove is arranged on the outer wall of the top of the connecting plate; limiting plates are arranged on the outer walls ofthe two sides of the bottom of the connecting plate correspondingly; a same baffle is arranged on the outer walls of one sides of the two limiting plates; a first timber groove is arranged on the outer wall of the top, close to the position between the two limiting plates, of the base; and fixing plates are arranged on the outer walls of one sides of the front faces of the two mounting bases correspondingly. By means of the redwood furniture tenon mortise cutting device of the invention, manufacturing of a set of tenon and mortise wood can be synchronously completed at the same time, the woodmanufacturing efficiency is greatly improved, and time is saved for subsequent wood processing.

Owner:赵子淇

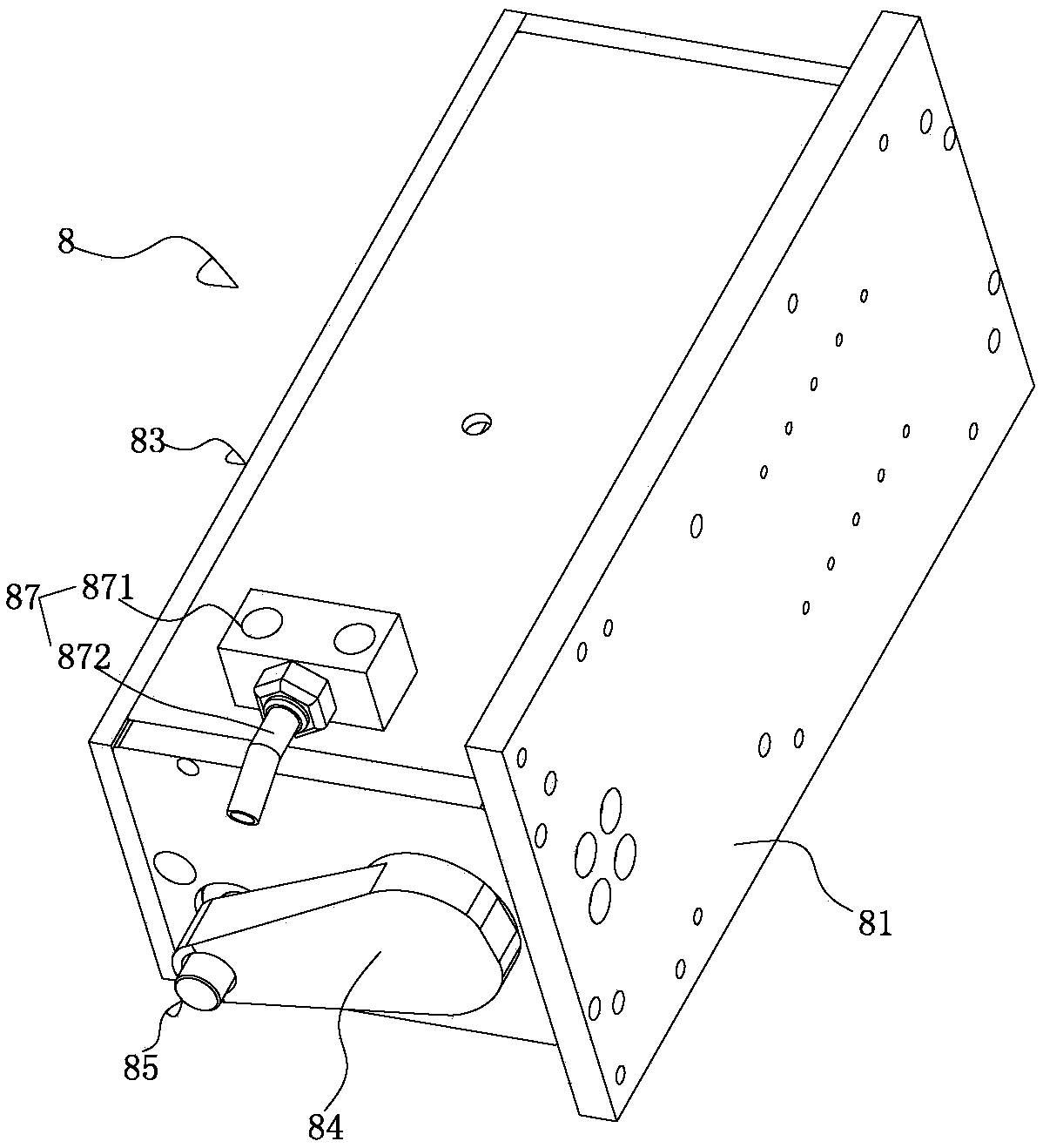

Carbon deposit suction device of electric spark forming machine

InactiveCN109570656APrevent disengagementAvoid processing failureElectrical-based auxillary apparatusMachine partsSlag

The invention discloses a carbon deposit suction device of an electric spark forming machine. The carbon deposit suction device of the electric spark forming machine comprises a working trough. A workbench is installed on a base plate in the working trough. Sliding grooves are formed in the base plate of the working trough and on the two sides of the workbench. Sliding racks are arranged at the ends of the sliding grooves in a clamping connection manner. A positioning plate is installed on the outer wall of each sliding rack. Multiple threaded holes are formed in the base plate of the workingtrough. Positioning bolts penetrate through the positioning plates. The positioning bolts are connected with the threaded holes through thread structures. An oil distribution tube and an oil suction disk are installed on the sliding racks respectively. The oil distribution tube is connected with multiple nozzles in a sleeving manner. An installation box is installed on the outer wall of the working trough. An oil pump is installed in the installation box. One end of the oil pump communicates with the oil distribution tube through an oil outlet tube, and the other end of the oil pump communicates with the oil suction disk through an oil suction tube. When one workpiece is fixed to the workbench, the sliding racks are enabled to slide to make the nozzles and the oil suction disk be located on the two sides of the part, to be machined, of the workpiece, and are fixed by the positioning bolts and the threaded holes, spark oil ejected out of the nozzles washes away electric slag and carbondeposit generated at the machined part of the workpiece, and the oil suction disk sucks the electric slag and carbon deposit away from the workpiece.

Owner:WUJIANG TIANLONG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com