Pipeline connecting piece manufacturing and forming method

A technology of pipe connection and forming method, applied in the direction of manufacturing tools, metal processing mechanical parts, clamping, etc., can solve the problems of pipe shaking, blade offset, position offset during internal thread processing, etc. Guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

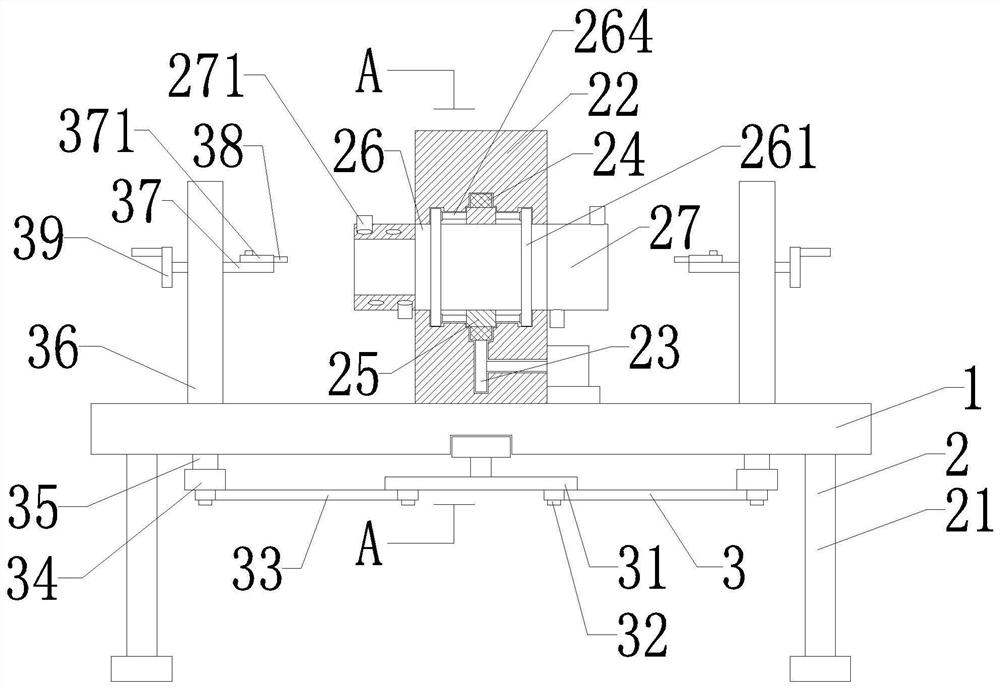

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

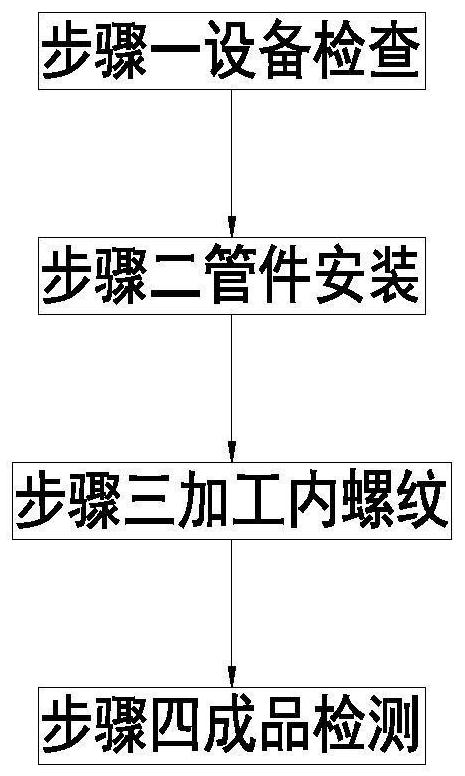

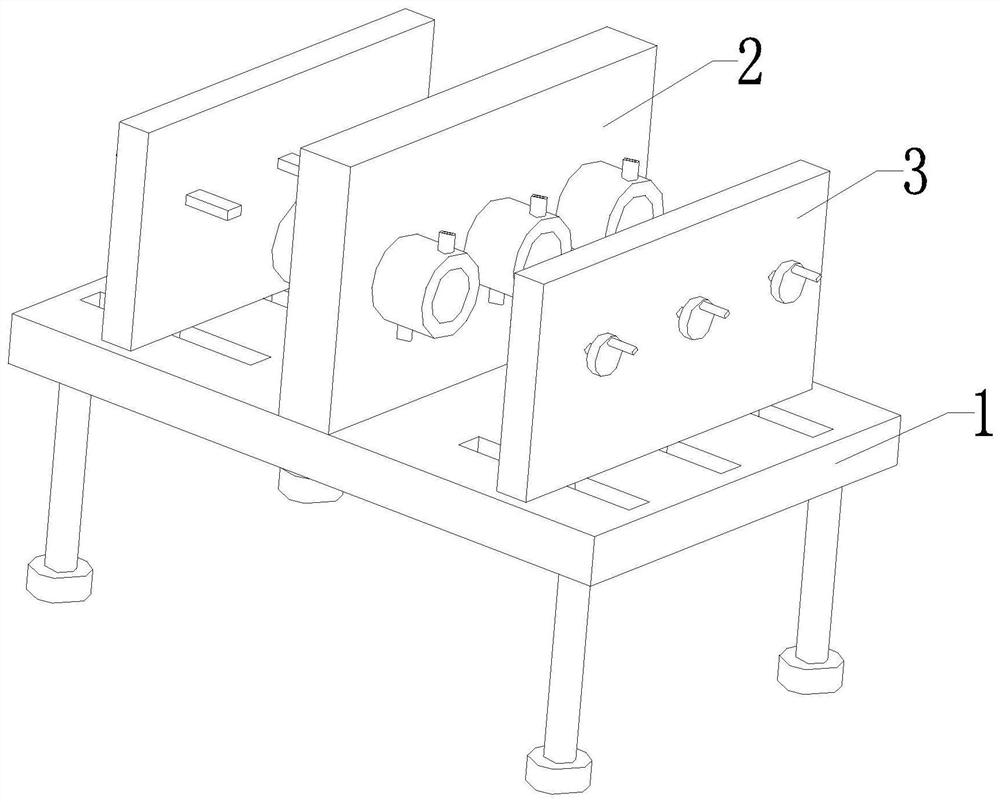

[0030] Such as Figure 1 to Figure 7 As shown, a method for manufacturing a pipe connector mainly includes the following steps:

[0031] Step 1: Equipment inspection: Check the operation of the equipment before using the internal thread processing equipment for pipe fittings to process the internal threads at both ends of the pipe connection;

[0032] Step 2: Fitting installation: Manually insert the fittings that need internal thread processing into the charging barrel 26, then manually rotate the adjusting wheel 39 to drive the cutting knife 38 against the inner wall of the fittings, and then the No. 1 motor works to drive The driving gear 23 rotates, thereby driving the transmission toothed belt 24 to move through the meshing action of the gears...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com