Auxiliary clamp for machining

An auxiliary fixture and machining technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of processing material movement, processing failure, processing inaccuracy, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

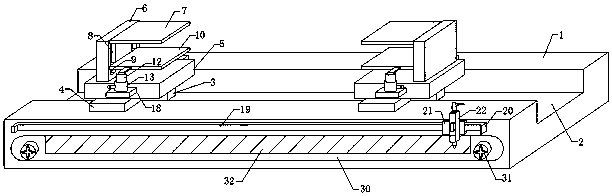

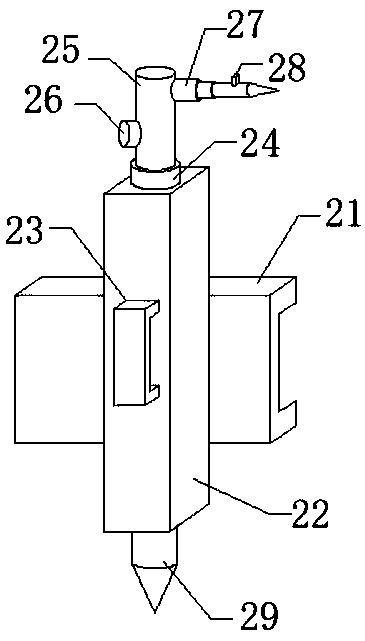

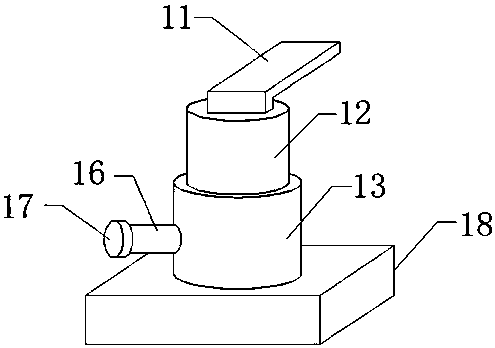

[0021] Such as Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: an auxiliary fixture for mechanical processing, including a base 1, a No. block 3, the two sides of the No. 1 slider 3 are fixedly connected with a slide plate 4, and the slide plate 4 can play the role of auxiliary movement when the No. 1 slider 3 moves, and a bottom plate 5 is connected above the No. 1 slider 3, so A riser 6 is fixedly installed on the bottom plate 5, a fixed plate 7 is connected to one side above the riser 6, and a number of No. 2 chutes 8 are arranged below the fixed plate 7. No. 2 slider 9, one side of the No. 2 slider 9 is connected with a splint 10, and the splint 10 moves freely on the No. 2 chute 8 through the No. 2 slider 9, thereby changing the distance between the splint 10 and the fixed plate 7 , to fix the processing material, one side of the splint 10 is connected with the inner rod 12 through the connecting plate 11, the inner rod 12 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com