Milling cutter head for milling steel rails

A milling cutter and milling technology, which is applied to milling cutters, milling machine equipment, metal processing machinery parts, etc., can solve the problems of no milling cutter condition monitoring, failure to prevent milling cutter machining failures, etc., and achieve the effect of preventing machining failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

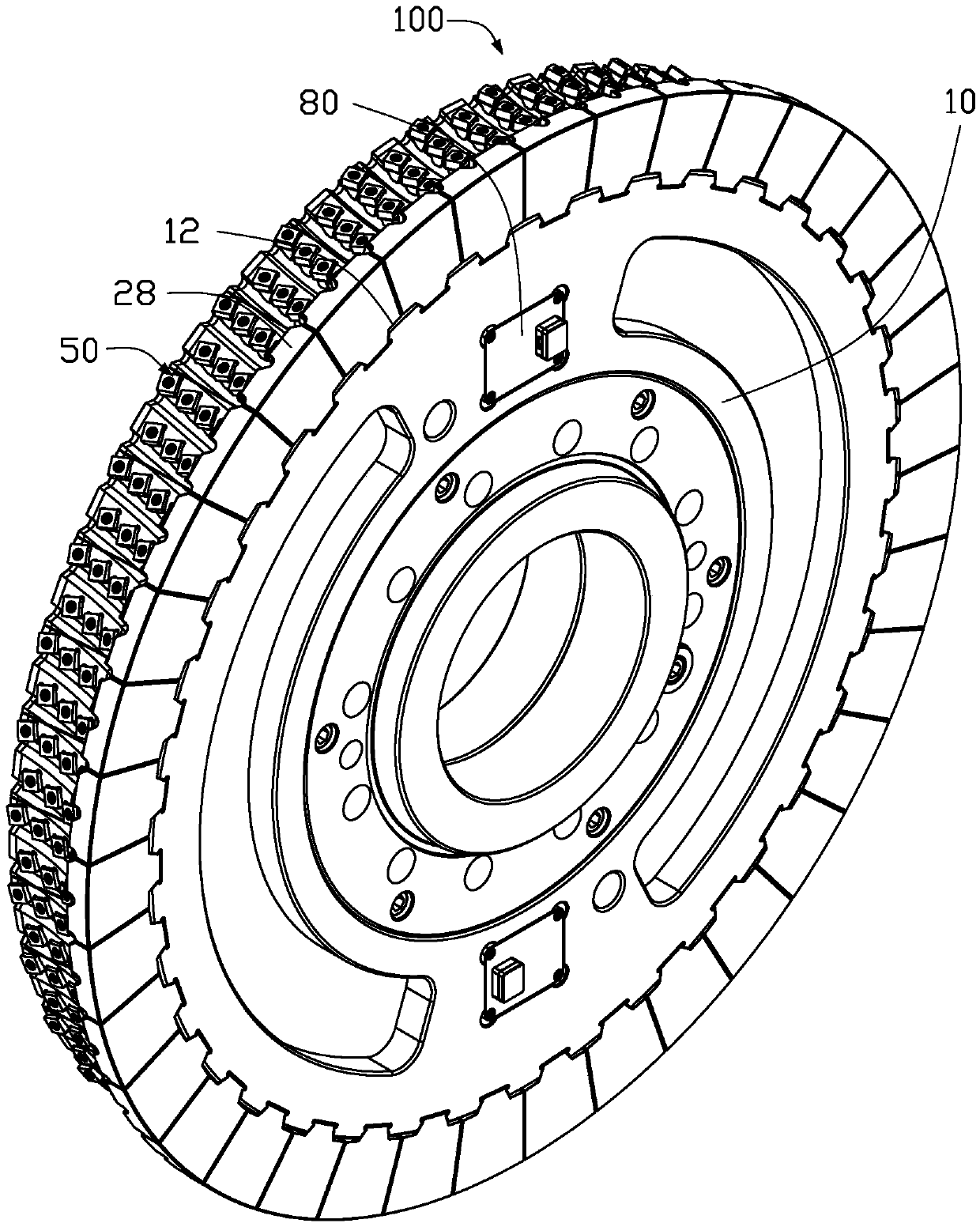

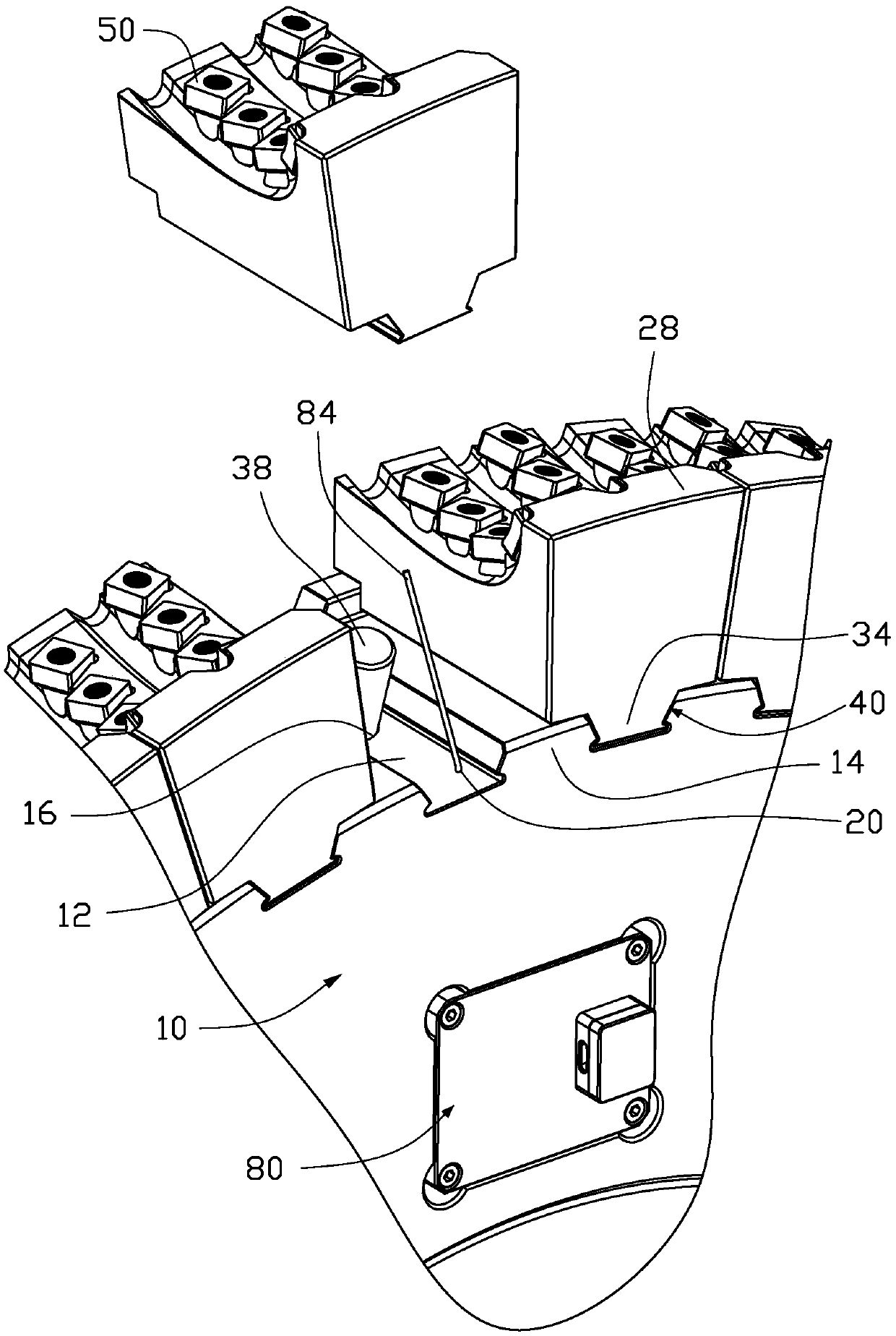

[0020] see Figure 1 to Figure 3 , the present invention provides a milling cutter head 100 . The milling cutter head 100 is used for milling rails. The milling cutter head 100 includes a cutter head 10 , a plurality of tool holders 28 and a plurality of sets of blades 50 . The plurality of tool holders 28 are fixed on the cutter head 10 , and the plurality of sets of blades 50 are fixed on the plurality of tool holders 28 .

[0021] The cutter head 10 includes a circumferential hub 12 and a plurality of uniformly spaced teeth 14 formed on the circumferential direction of the hub 12 . The part of the hub 12 between two adjacent teeth 14 forms a through hole 16 . A slot 36 is formed between every two adjacent teeth 14 . The tool holder 28 includes a clip body 32 and a protruding key 34 protruding from the middle of the bottom surface of the clip body 32 . A threaded hole (not shown) is formed on the side of the protruding key 34 facing the hub 12 . The protruding key 34 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com