Once molding processing device and technology for precision optical element

A technology of precision optics and molding processing, applied in glass molding, glass remolding, manufacturing tools, etc., can solve the problems of the failure of precision optical components, increase the burden and pressure of enterprises, limit the growth and development of enterprises, etc., to avoid processing The effect of failure, promotion, smooth operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

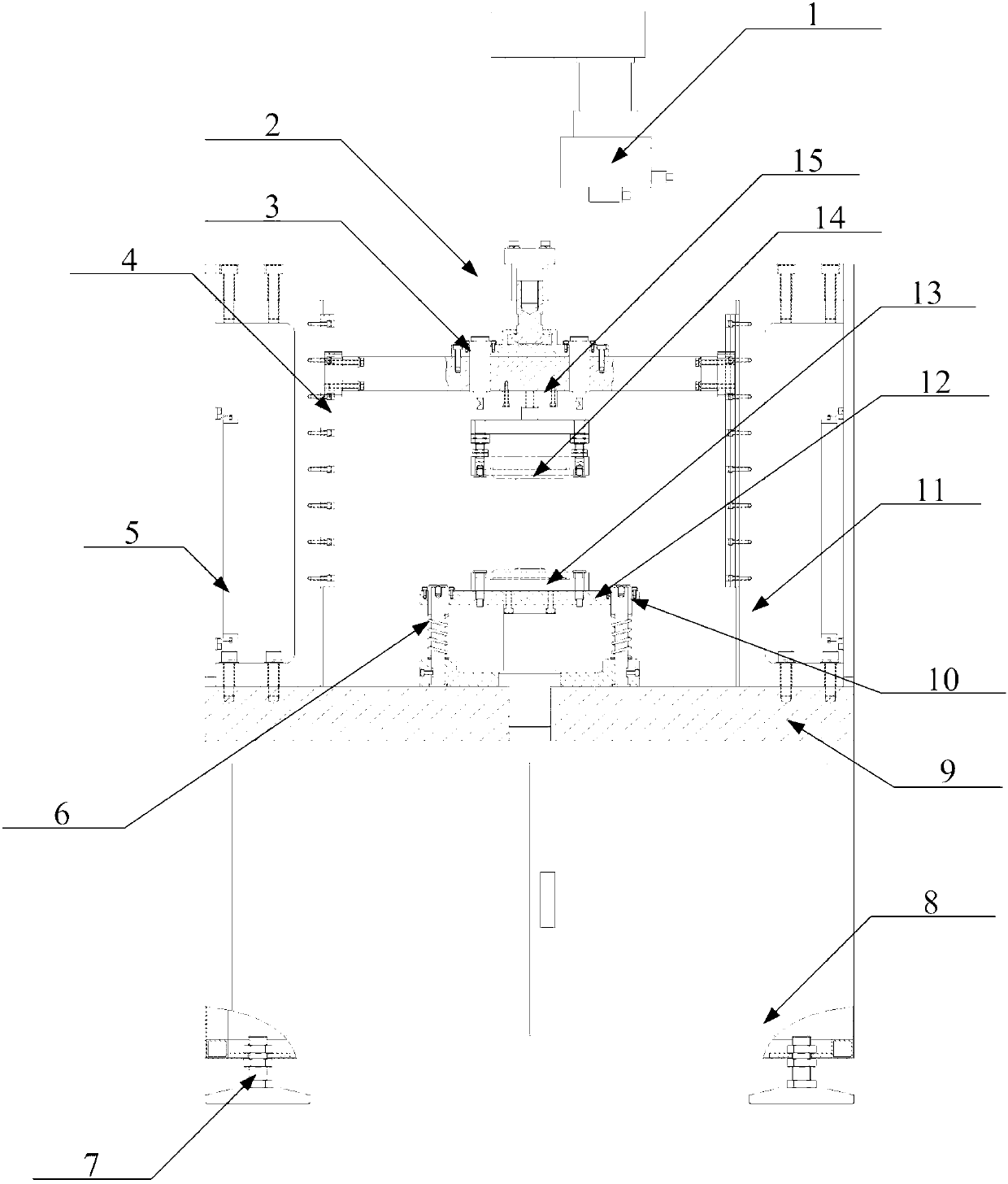

[0036] Such as figure 1 As shown, the precision optical element one-time molding processing device includes a frame 8, an adjustable support foot 7 is arranged at the lower end of the frame 8, a workbench 9 is arranged at the upper end of the frame 8, and a workbench 9 is also arranged on the workbench 9. A lower mold device and a column 11 are provided, and an upper support plate 2 is arranged on the top of the column 11. An upper mold device and a servo electric cylinder 1 are also arranged on the upper support plate 2. At the same time, the servo electric cylinder 1 is also connected There is a control cabinet.

[0037] Above-mentioned lower mold device comprises lower floating support frame 12, and this lower floating support frame 12 is provided with the support bar that is fixed on the workbench 9, and this support bar is covered with spring 6, and between the lower floating support frame 12 and the support bar A lower linear bearing 10 is provided, and a mold lower mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com