Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about "Temperature-sensitive devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

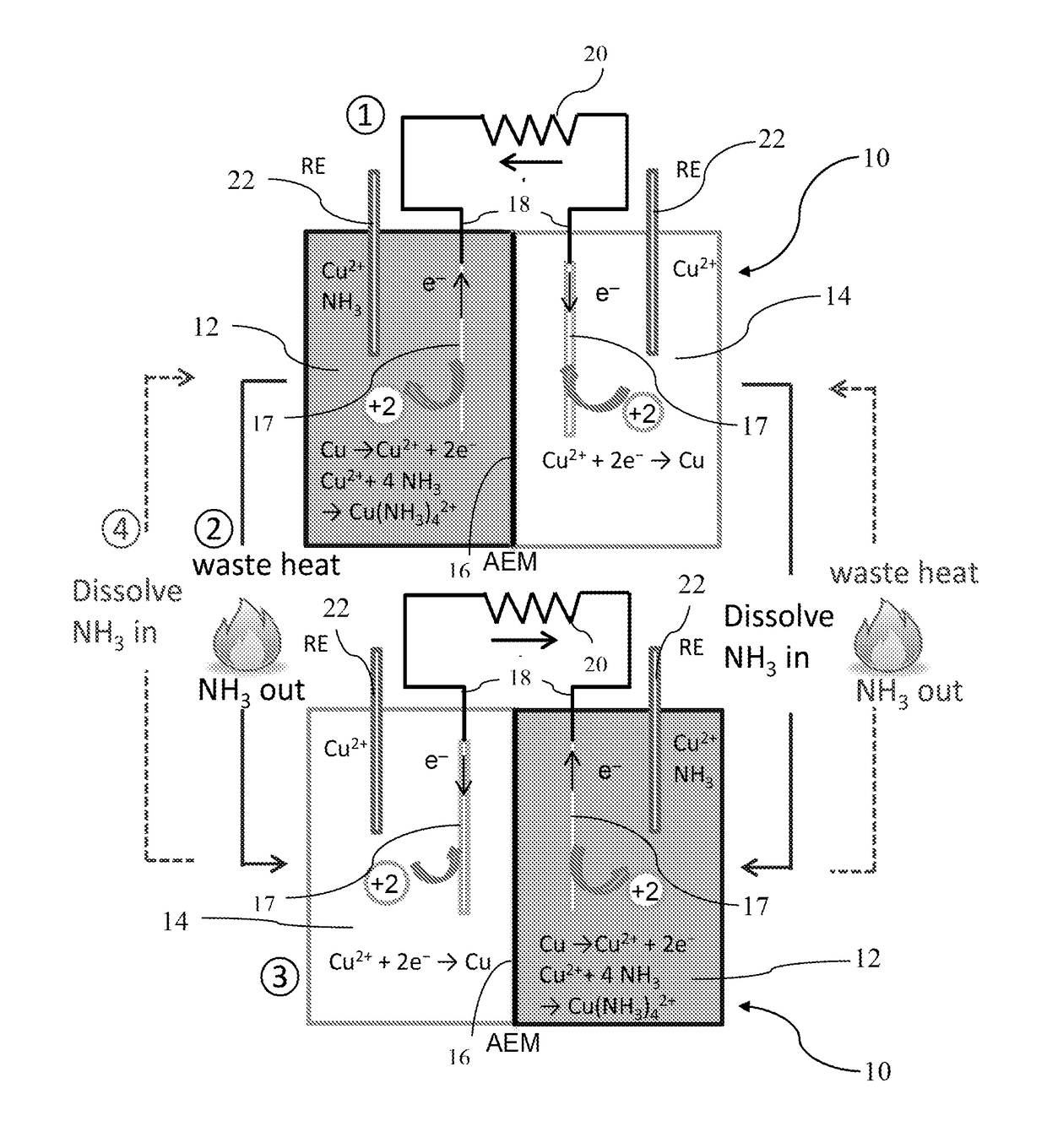

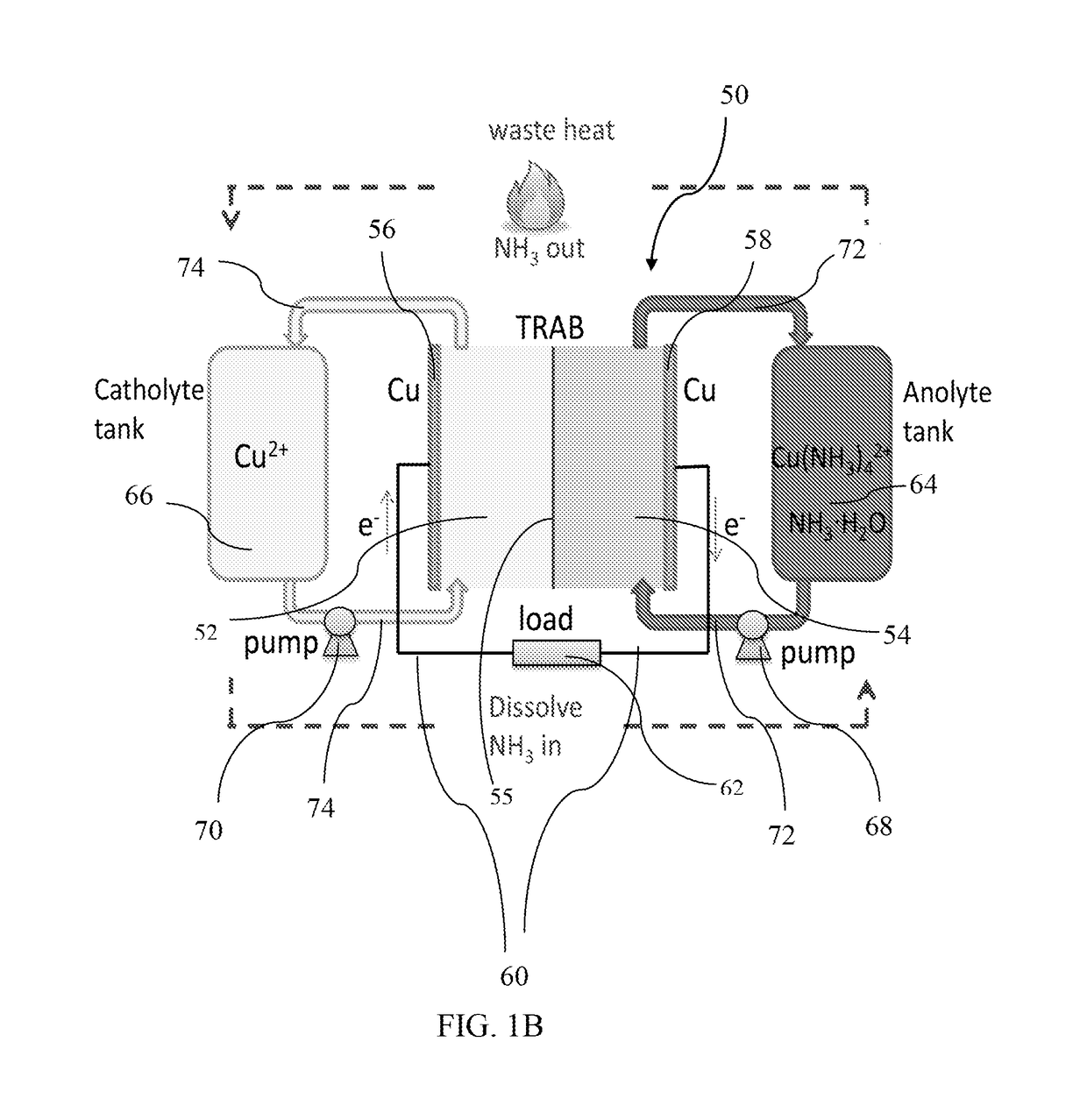

Ammonia-based thermoelectrochemical systems and methods

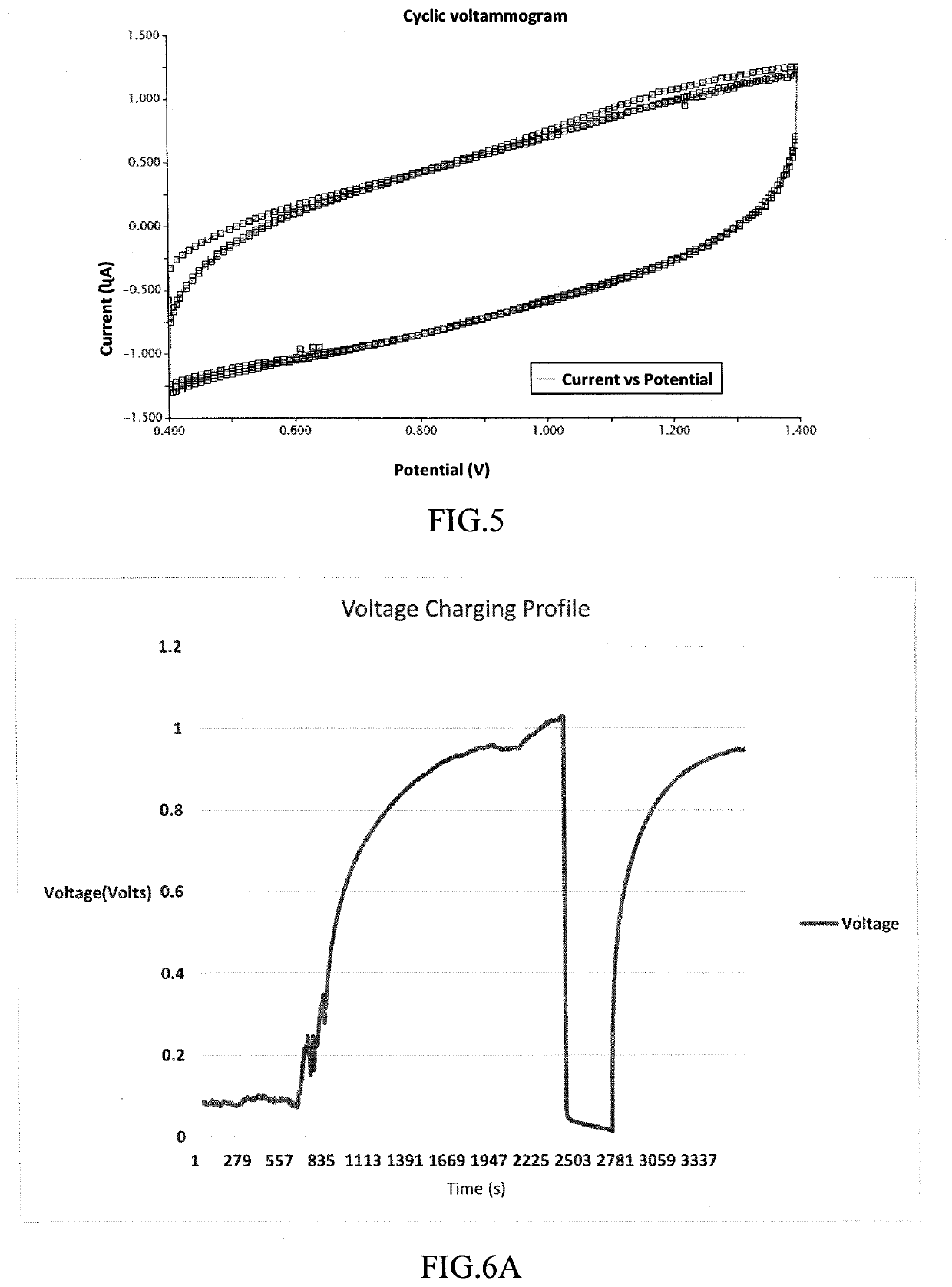

ActiveUS20170250433A1Avoid corrosionCell electrodesRegenerative fuel cellsThermal energyDistillation

Thermally regenerative ammonia-based battery systems and methods of their use to produce electricity are provided according to aspects described herein in which ammonia is added into an anolyte to charge the battery, producing potential between the electrodes. At the anode, metal corrosion occurs in the ammonia solution to form an ammine complex of the corresponding metal, while reduction of the same metal occurs at the cathode. After the discharge of electrical power produced, ammonia is separated from the anolyte which changes the former anolyte to catholyte, and previous anode to cathode by deposition of the metal. When ammonia is added to the former catholyte to make it as anolyte, the previous cathode becomes the anode. This alternating corrosion / deposition cycle allows the metal of the electrodes to be maintained in closed-loop cycles, and waste heat energy is converted to electricity by regeneration of ammonia, such as by distillation.

Owner:PENN STATE RES FOUND

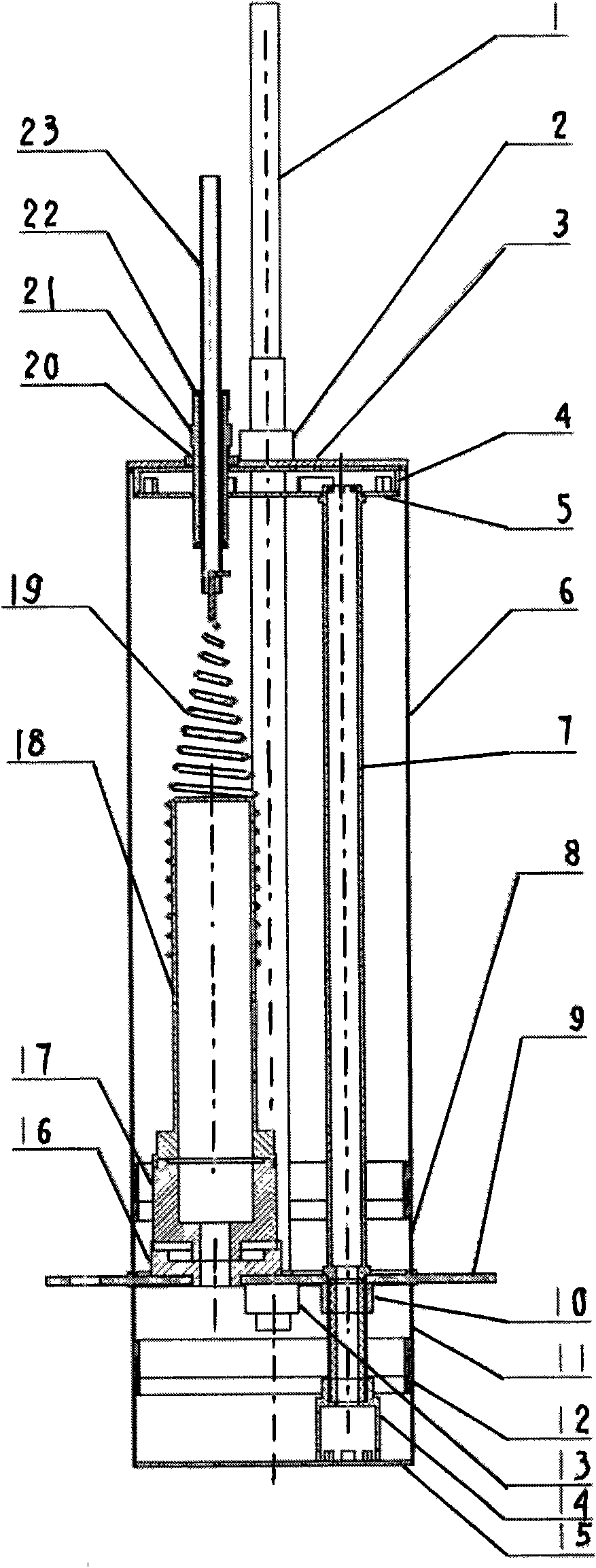

Alkali metal thermo-electric direct converter

InactiveCN101604931ATemperature-sensitive devicesKinetic-electric generatorElectrical conductorEngineering

The invention provides an alkali metal thermo-electric direct converter, which comprises an exhaust tube (1), a supporting seat (2), an upper cover (3), a condenser (4), a condenser sealing cover (5), an upper cavity I (6), a capillary core (7), an upper cavity II (8), a base (9), a capillary core nut (10), a lower cavity I (11), a lower cavity II (12), an exhaust tube nut (13), a capillary core base (14), a lower cover (15) and a ceramic base I (16). The alkali metal thermo-electric direct converter is an energy conversion device in the field of power energy conversion and renewable energy utilization, and uses a BASE (beta''-Al2O3 solid electrolyte) selective permeable membrane, namely the beta'-Al2O3 is an excellent conductor of ions, and by using the characteristics of defective conductors of electrons and atoms, the heat energy absorbed by the alkali metal steam is converted into electric energy to be used by users.

Owner:HARBIN ENG UNIV

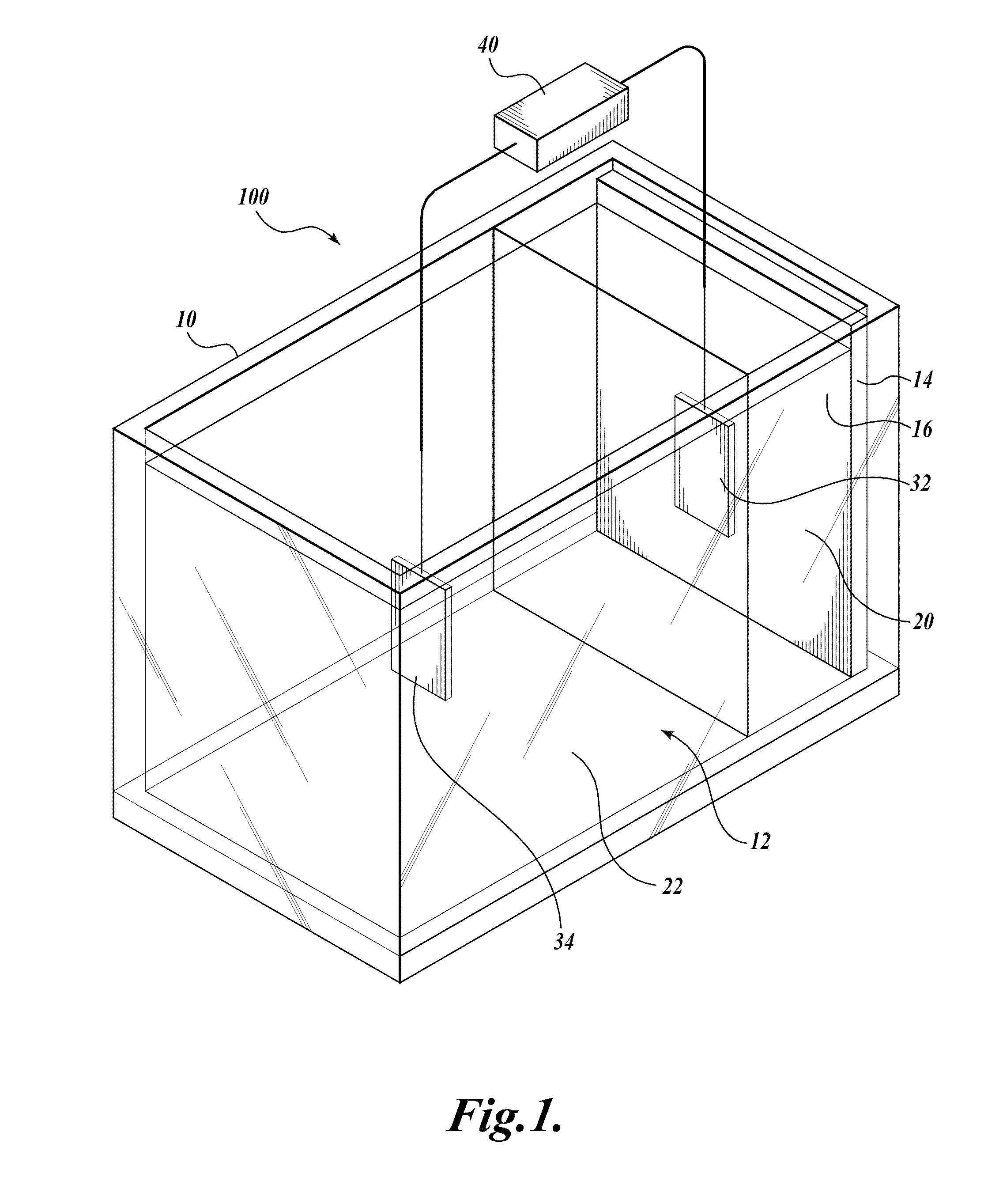

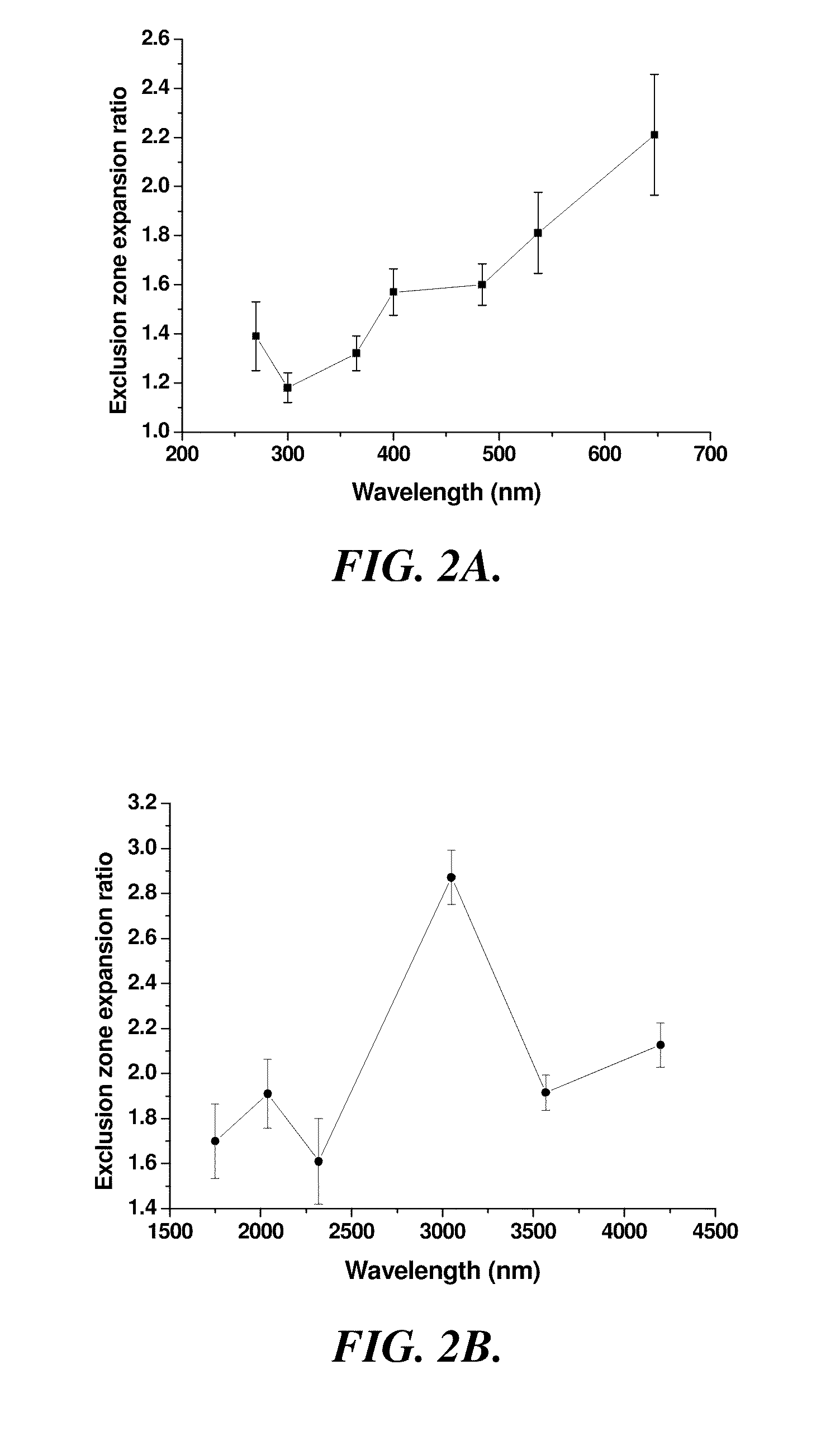

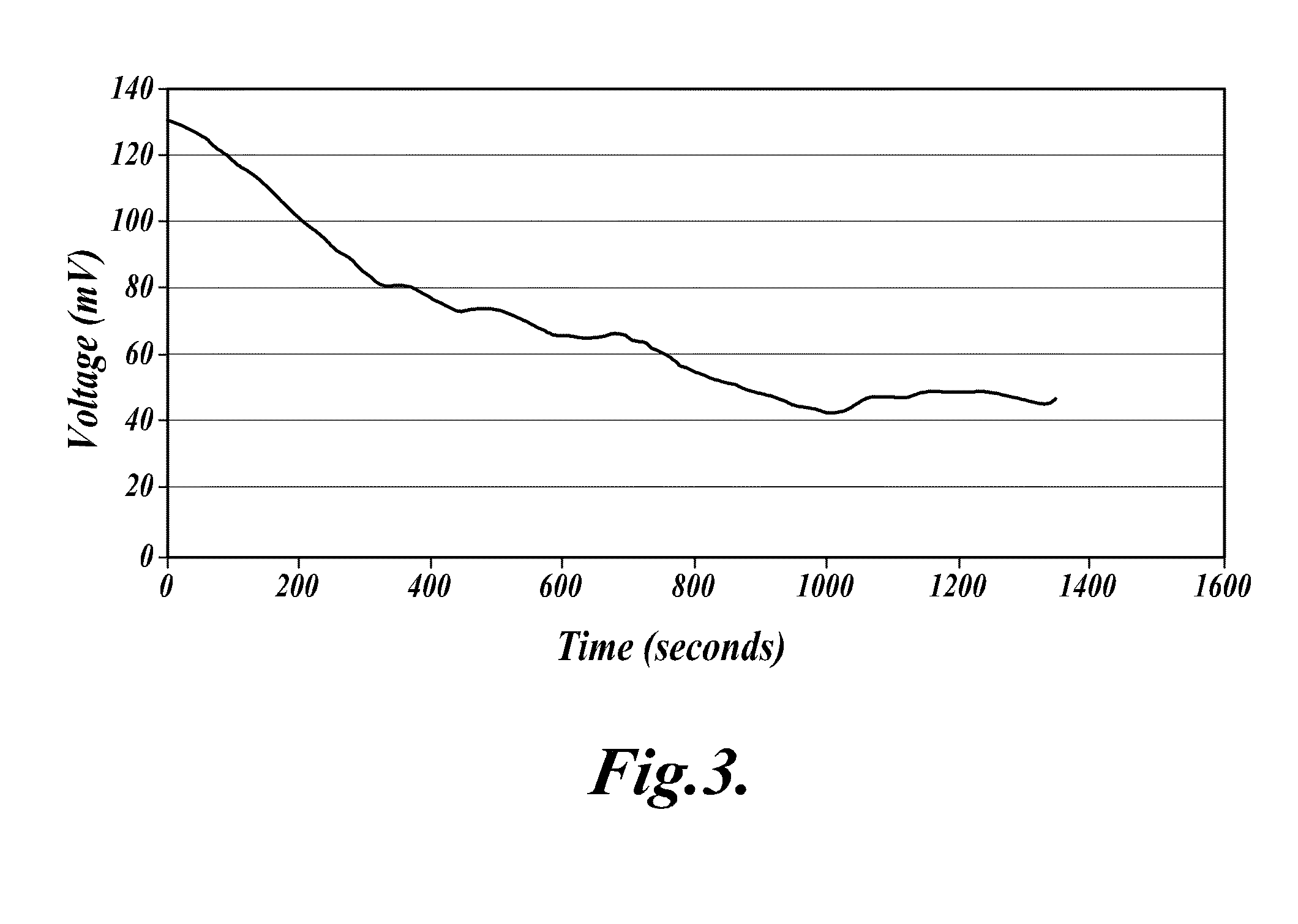

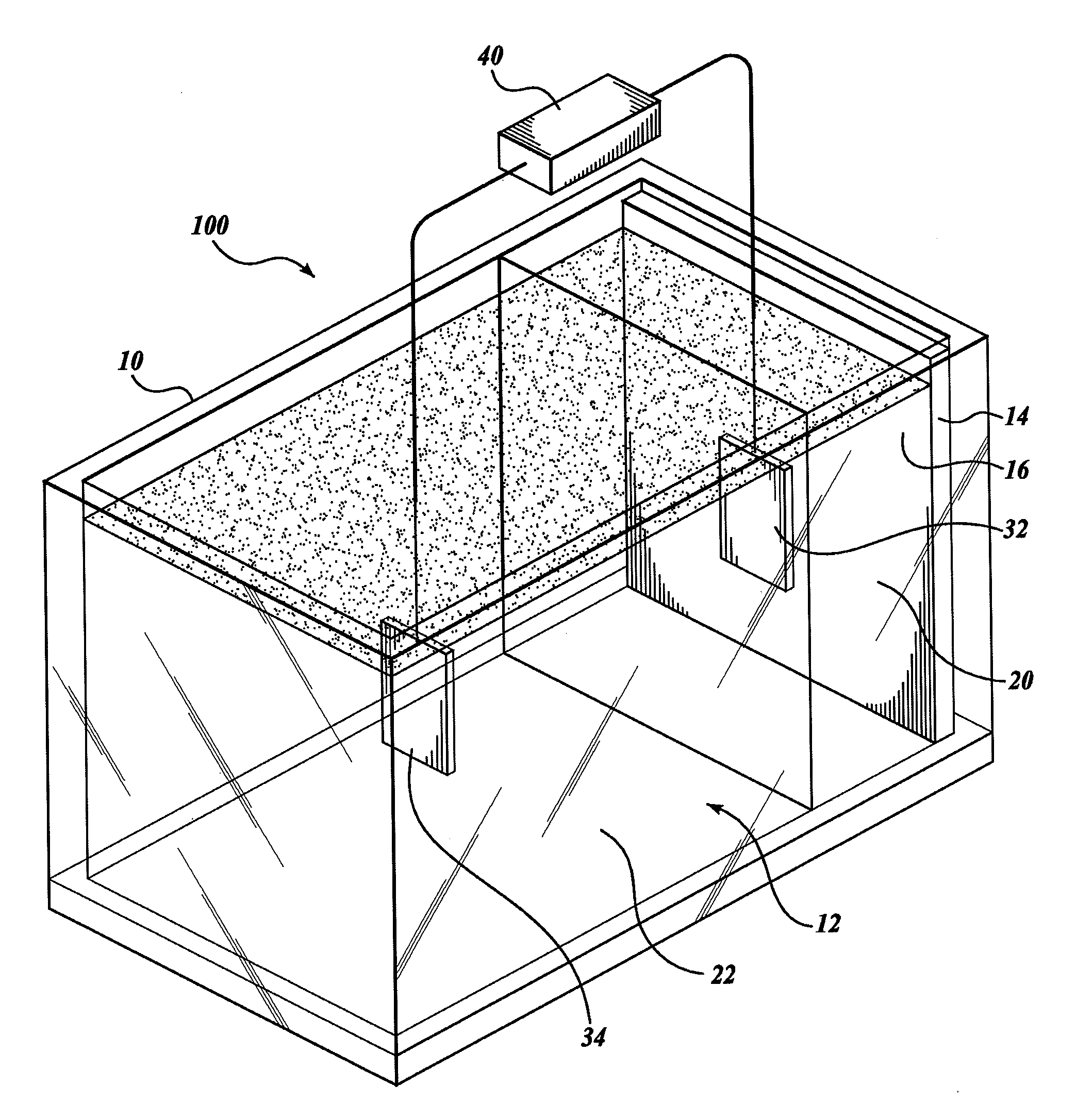

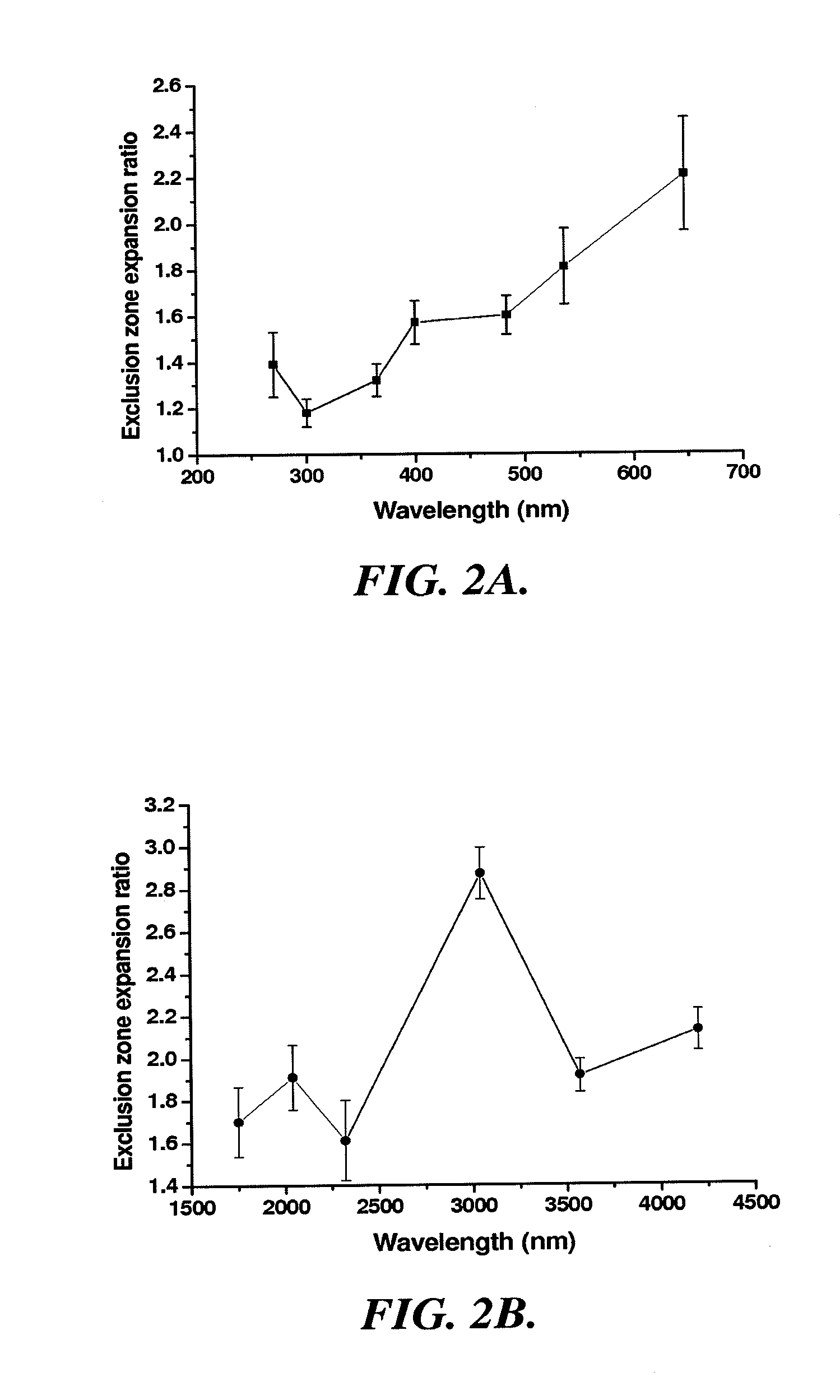

Method and system for generating electrical energy from water

InactiveUS20090226798A1High pH levelElectrolysis componentsLight-sensitive devicesElectric energyAutomotive engineering

Owner:4TH PHASE INC +1

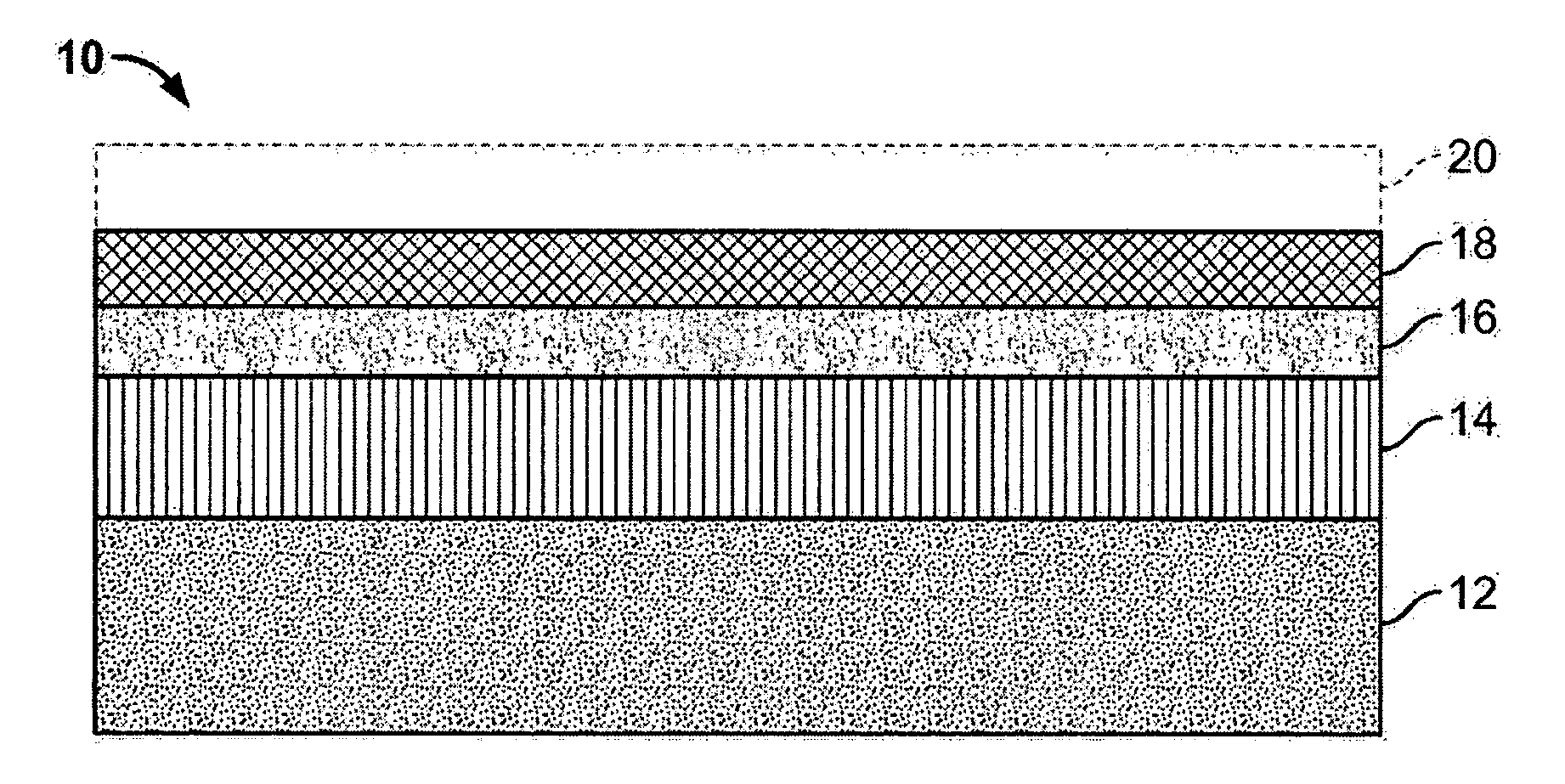

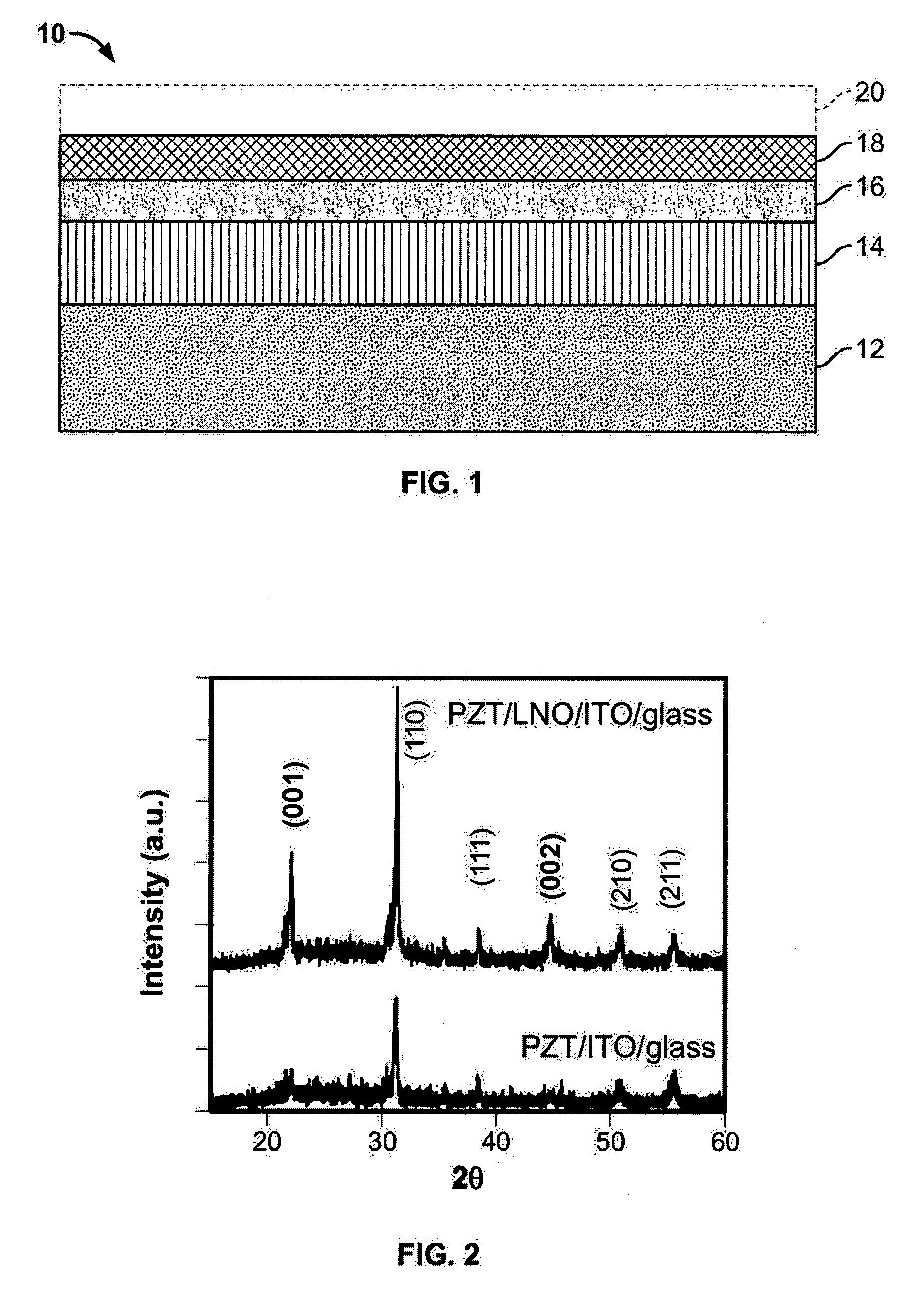

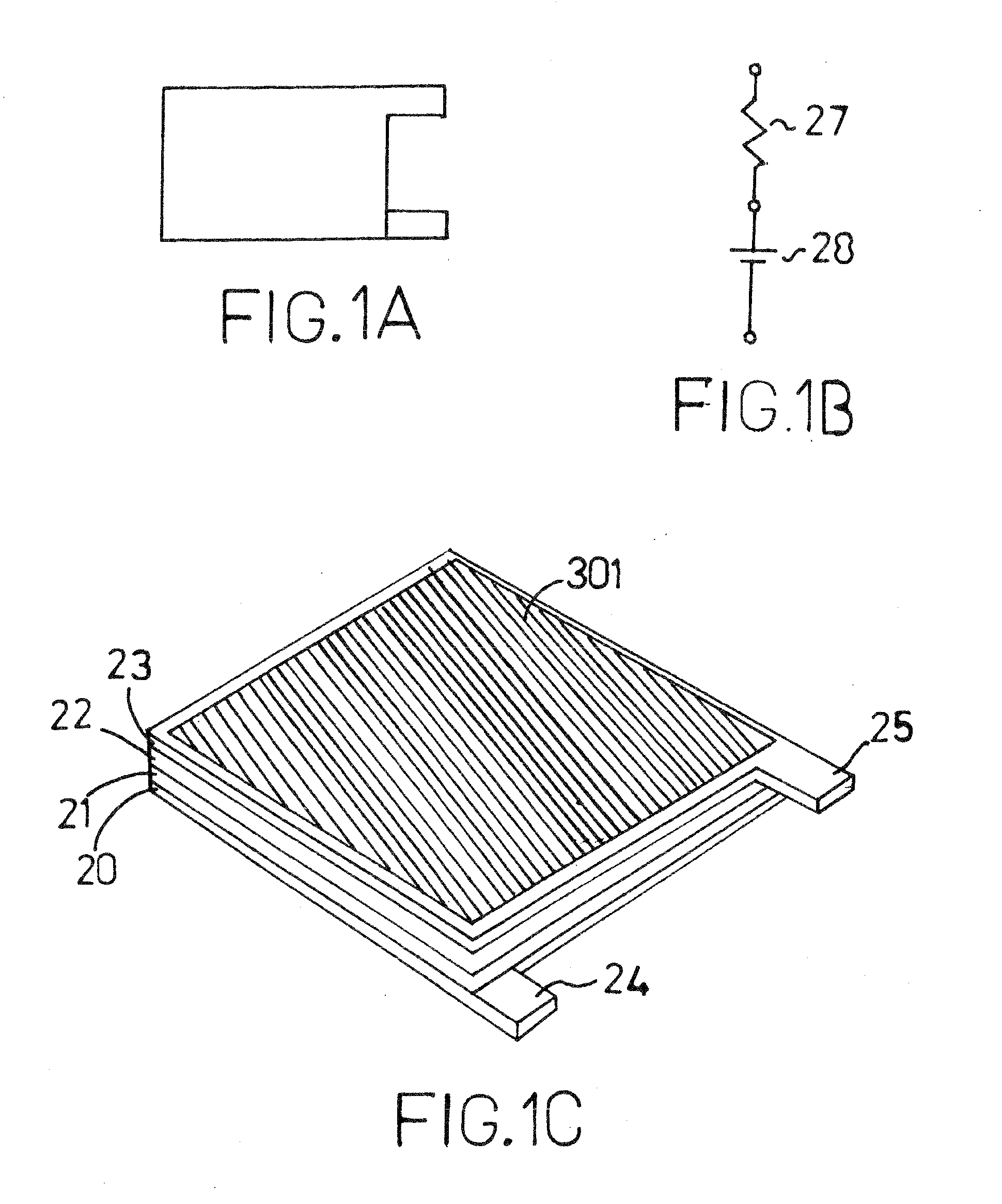

Transparent oxide capacitor structures

InactiveUS20080204970A1Optimized high polarizationLess and high conductivityFixed capacitor electrodesFixed capacitor dielectricCapacitanceLanthanide

A ferroelectric capacitor structure having a lattice matched lanthanide oxide film intervening layer for providing a high polarization state. The capacitor structure includes a glass substrate, a transparent electrode layer disposed on the glass substrate, a lanthanide oxide film disposed on the transparent layer and a ferroelectric perovskite layer disposed on the lanthanide oxide film. The claim also encompases semi-transparent applications where one conductive electrode (top or bottom) is not transparent.

Owner:UCHICAGO ARGONNE LLC

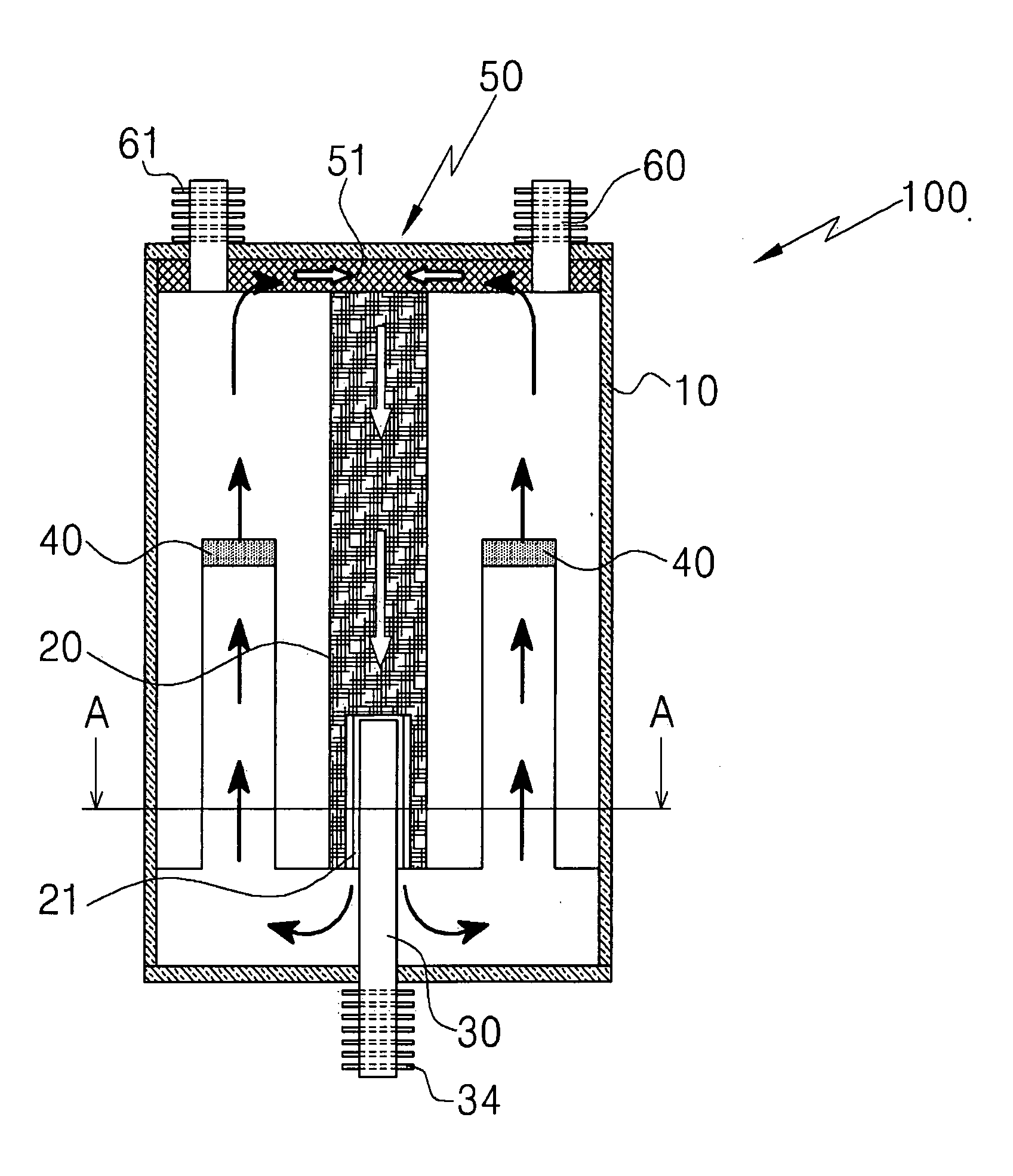

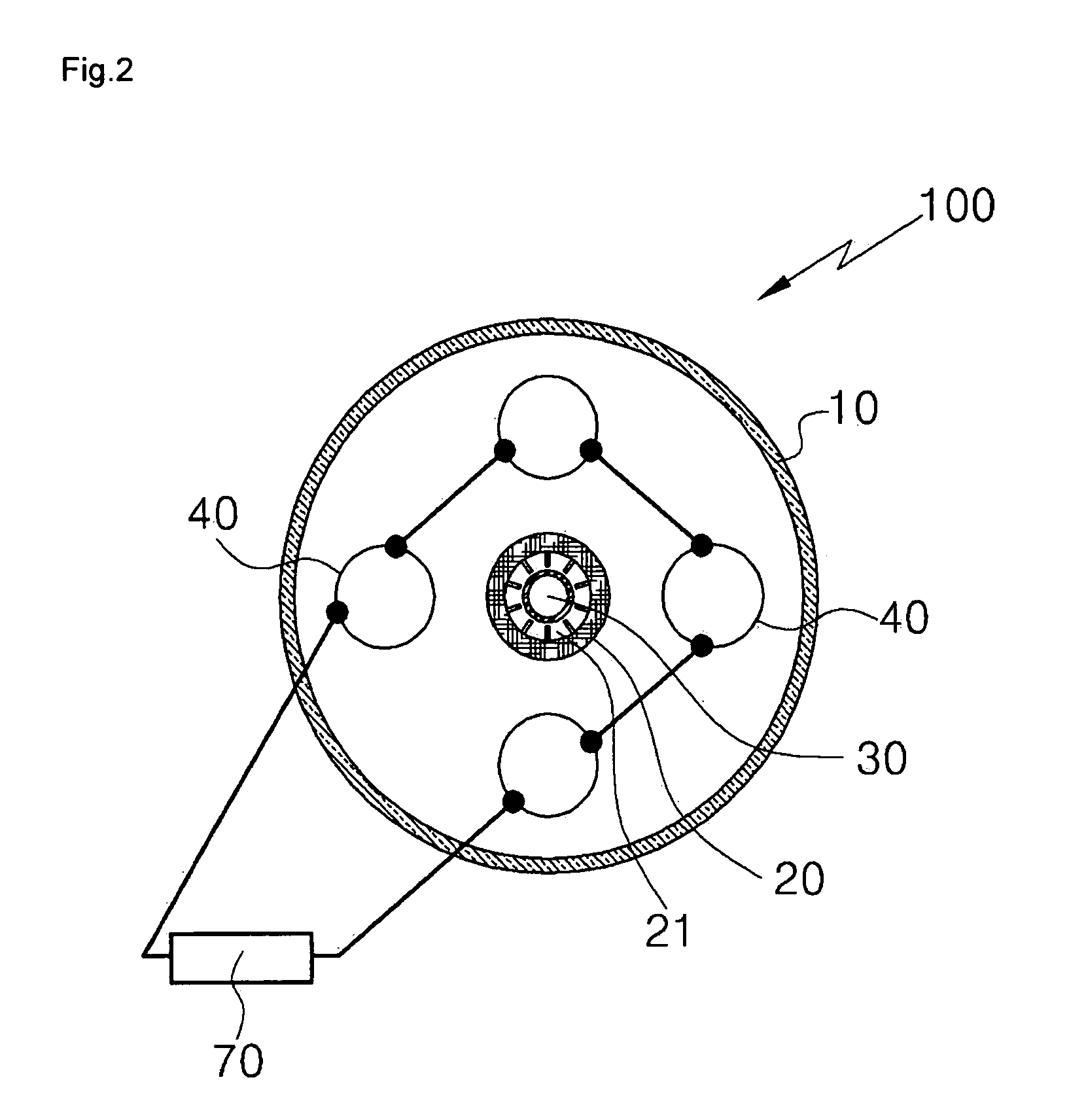

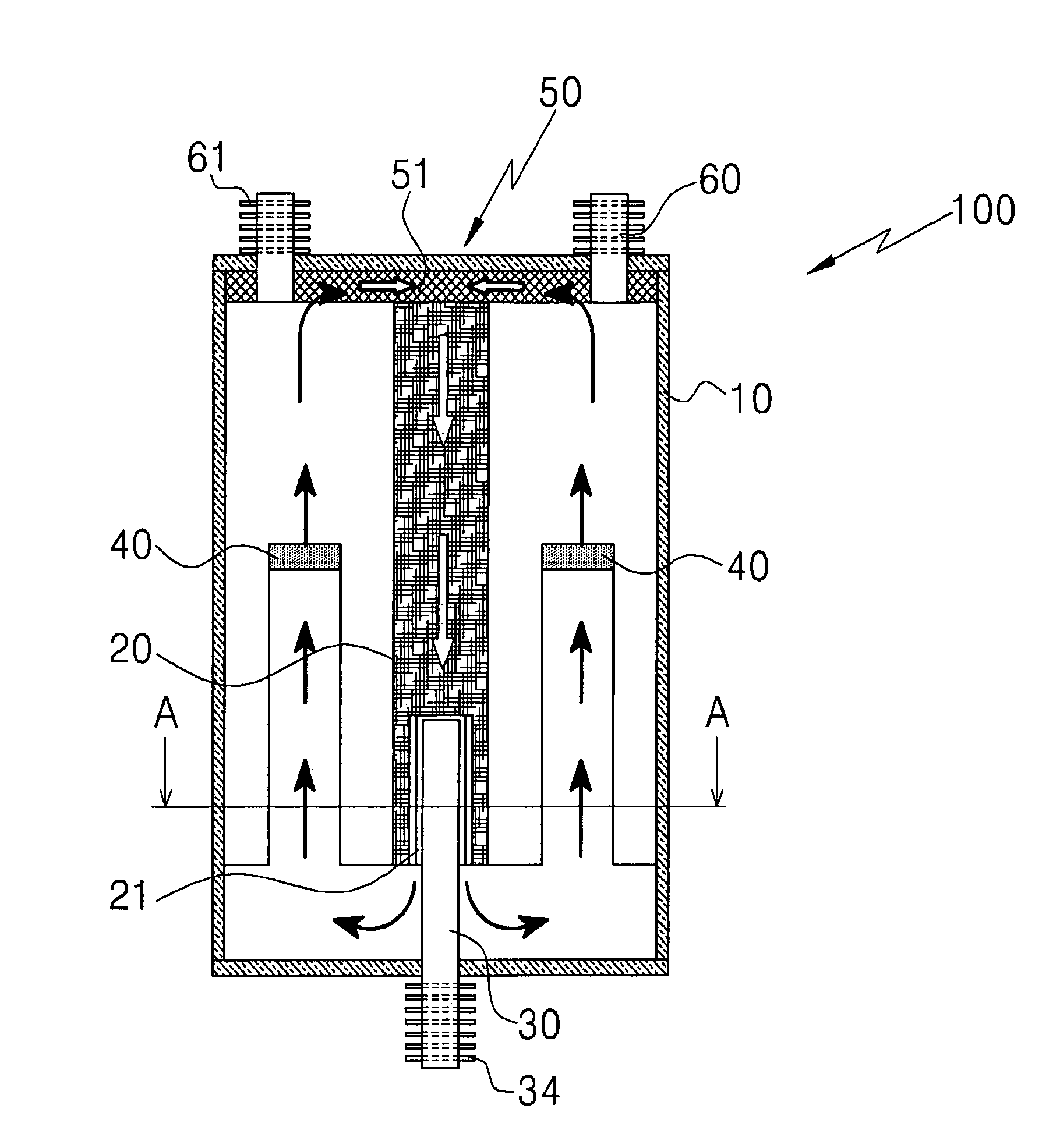

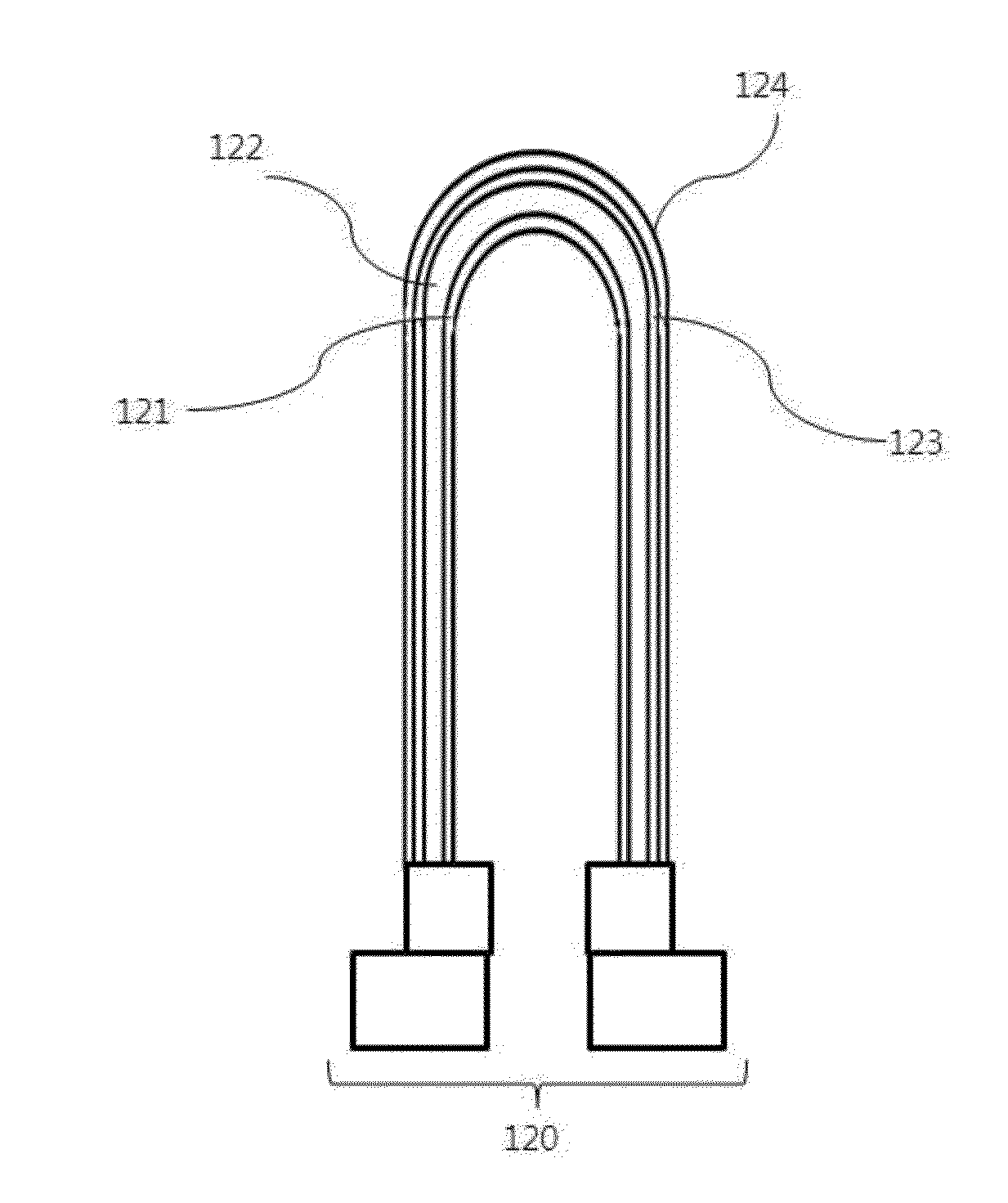

Amtec with heat pipe

ActiveUS20110168222A1Improve thermal efficiencySmall sizeDeferred-action cellsThermoelectric device with peltier/seeback effectEngineeringTemperature difference

There is provided an AMTEC (alkali metal thermal-electric converter) with a heat pipe and more particularly, to an AMTEC with a heat pipe minimized a heating part and a condensation part of the AMTEC and improved in efficiency of thermal to electric conversion through installing the heating and cooling heat pipes in the AMTEC, in which a metal fluid is heated by latent heat of an operating fluid of the heat pipe, instead of the heat conduction from a heat source, thereby reducing a temperature difference needed for heat transfer to vaporize the metal fluid even by a heat source of a lower temperature than a conventional heat source; improving a cooling performance in a condensation part to result in the high efficiency of thermal to electric conversion; using no additional driving components for driving the heat pipe.

Owner:KOREA INST OF ENERGY RES

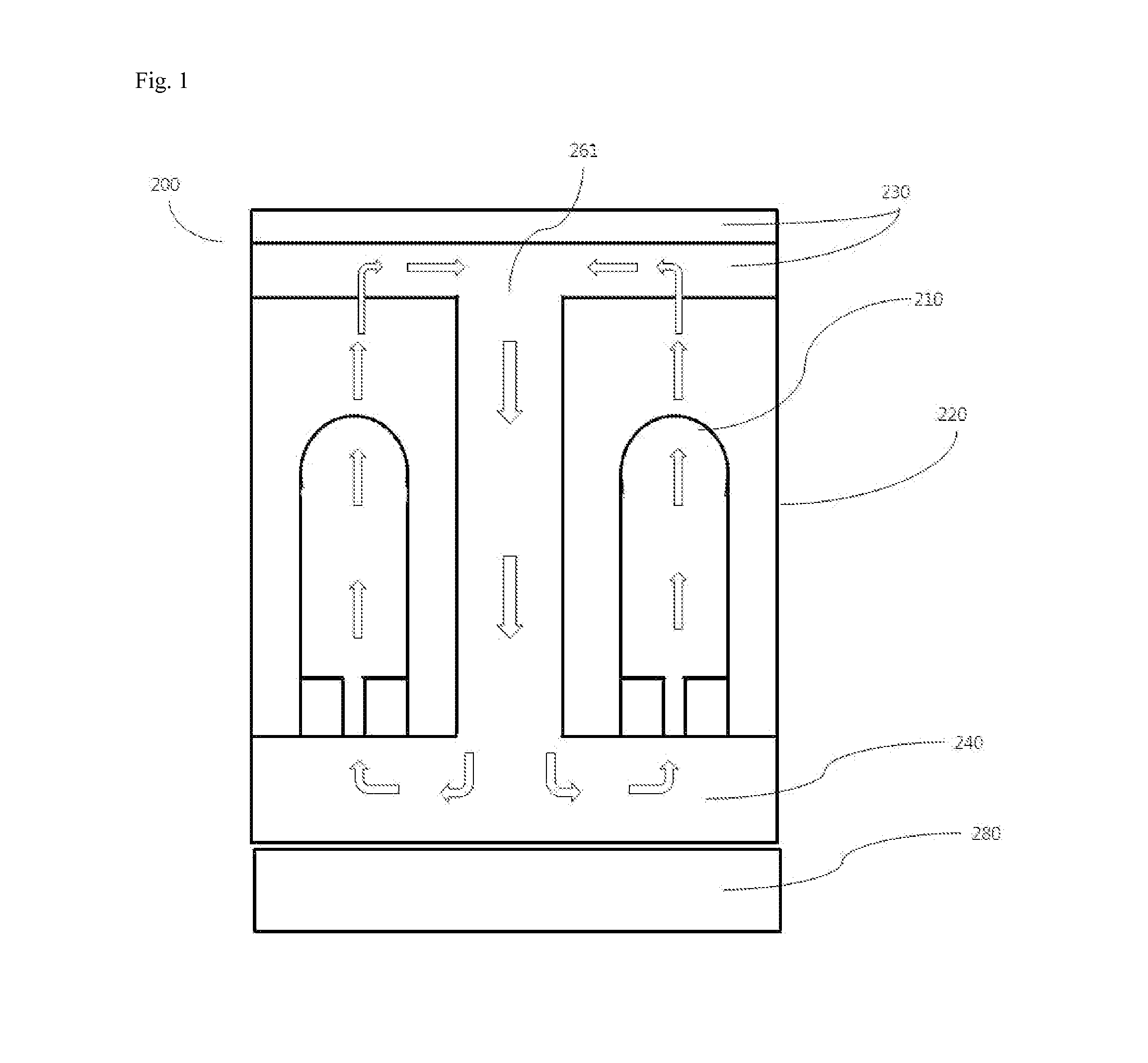

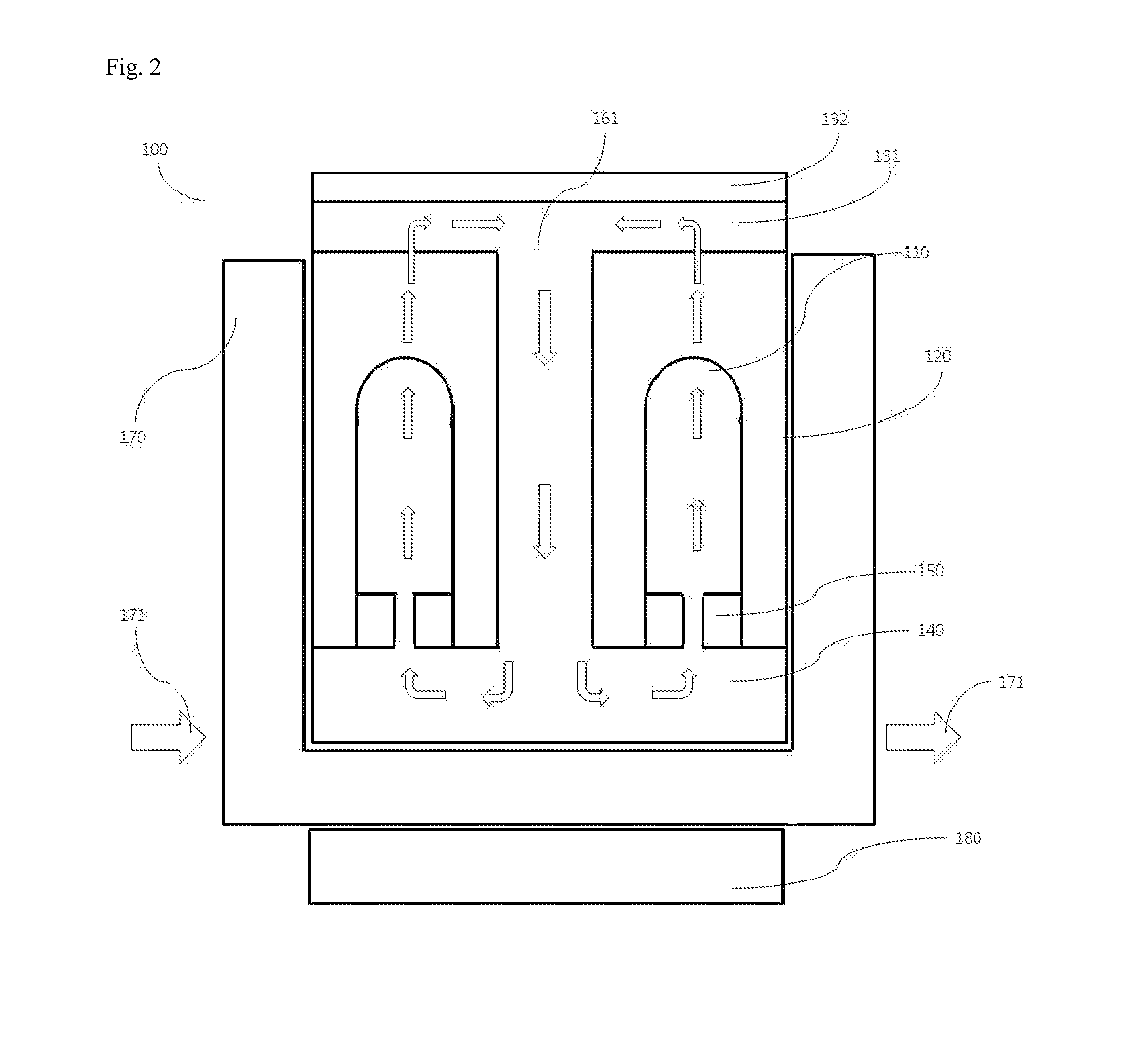

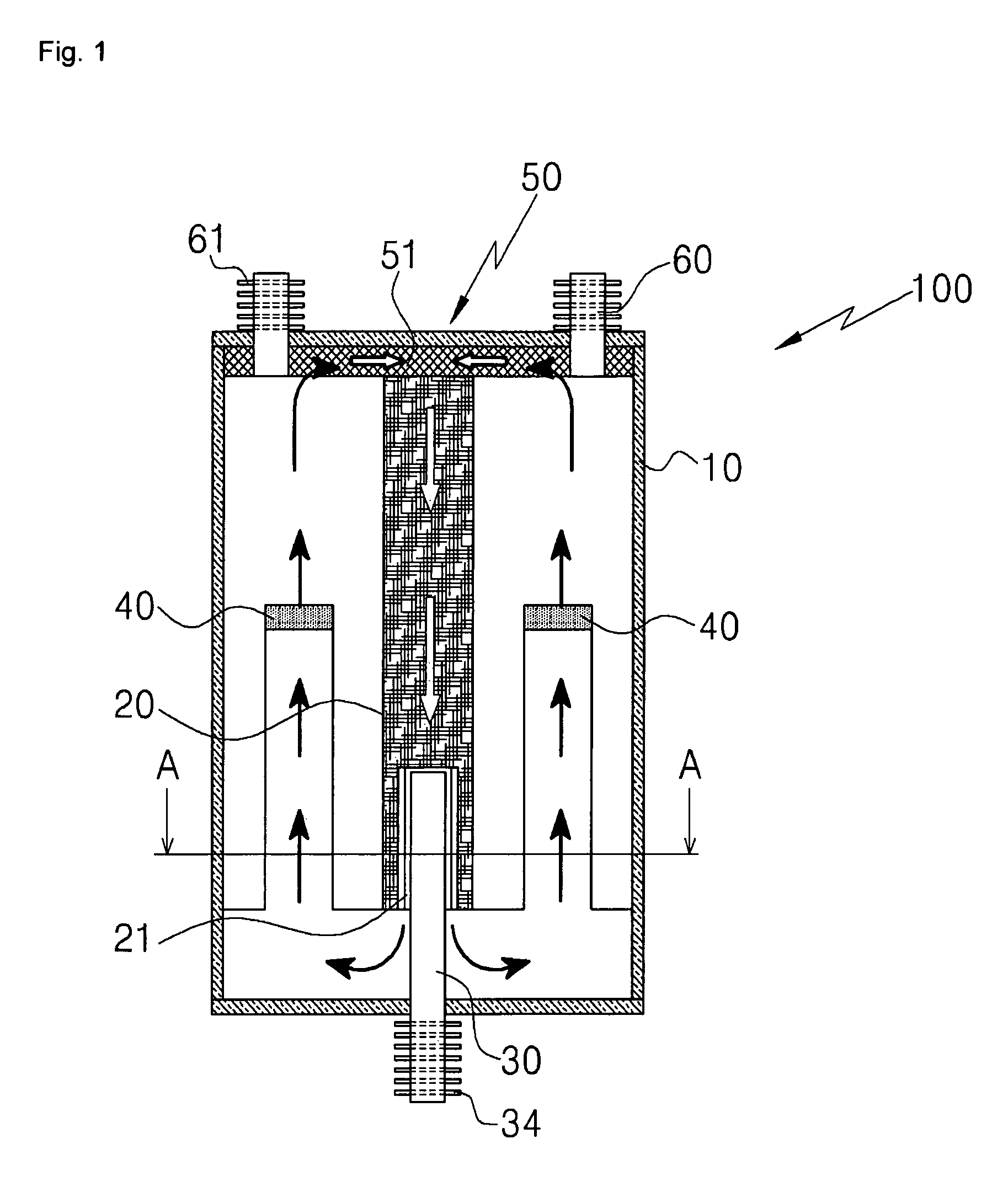

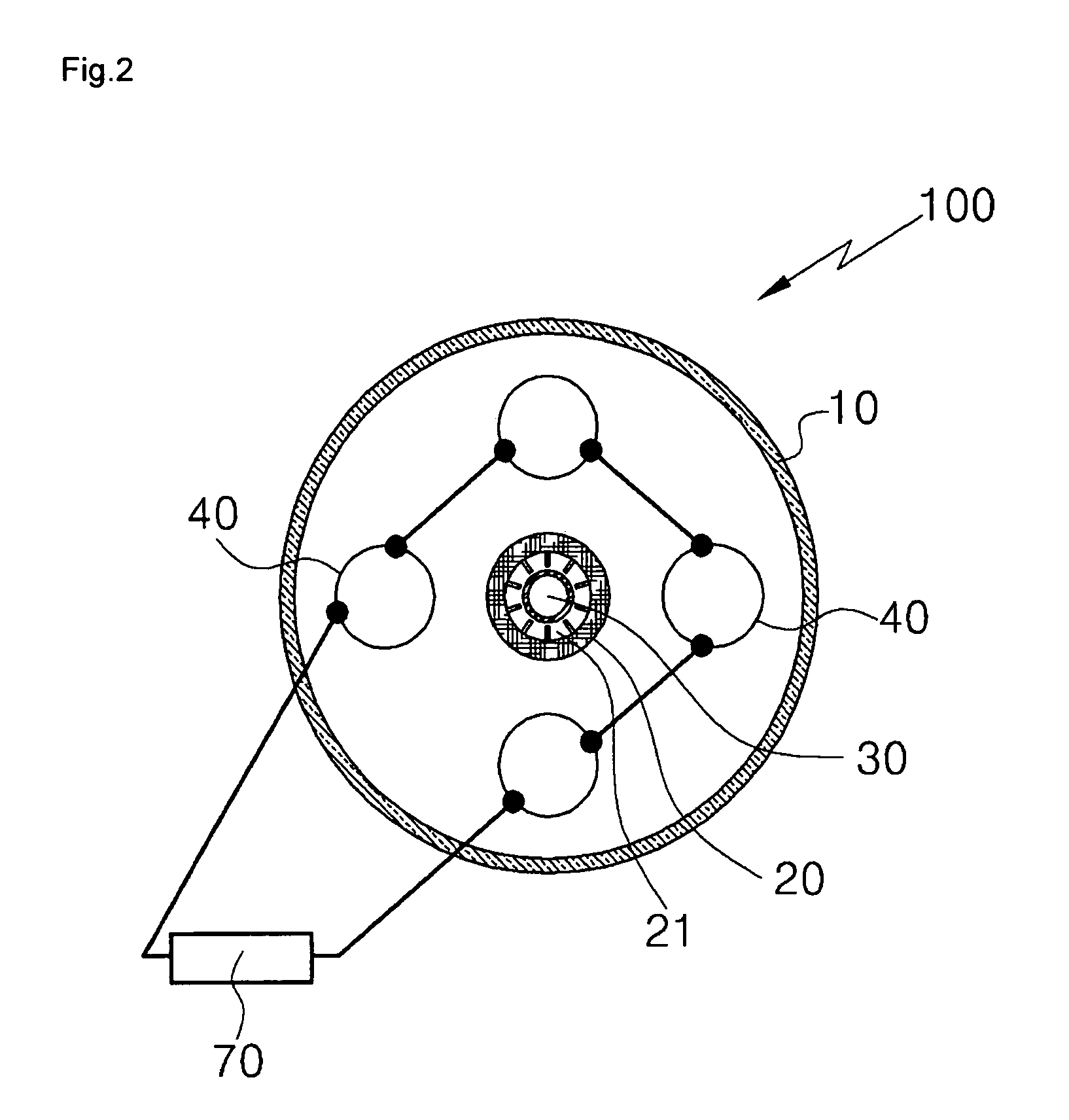

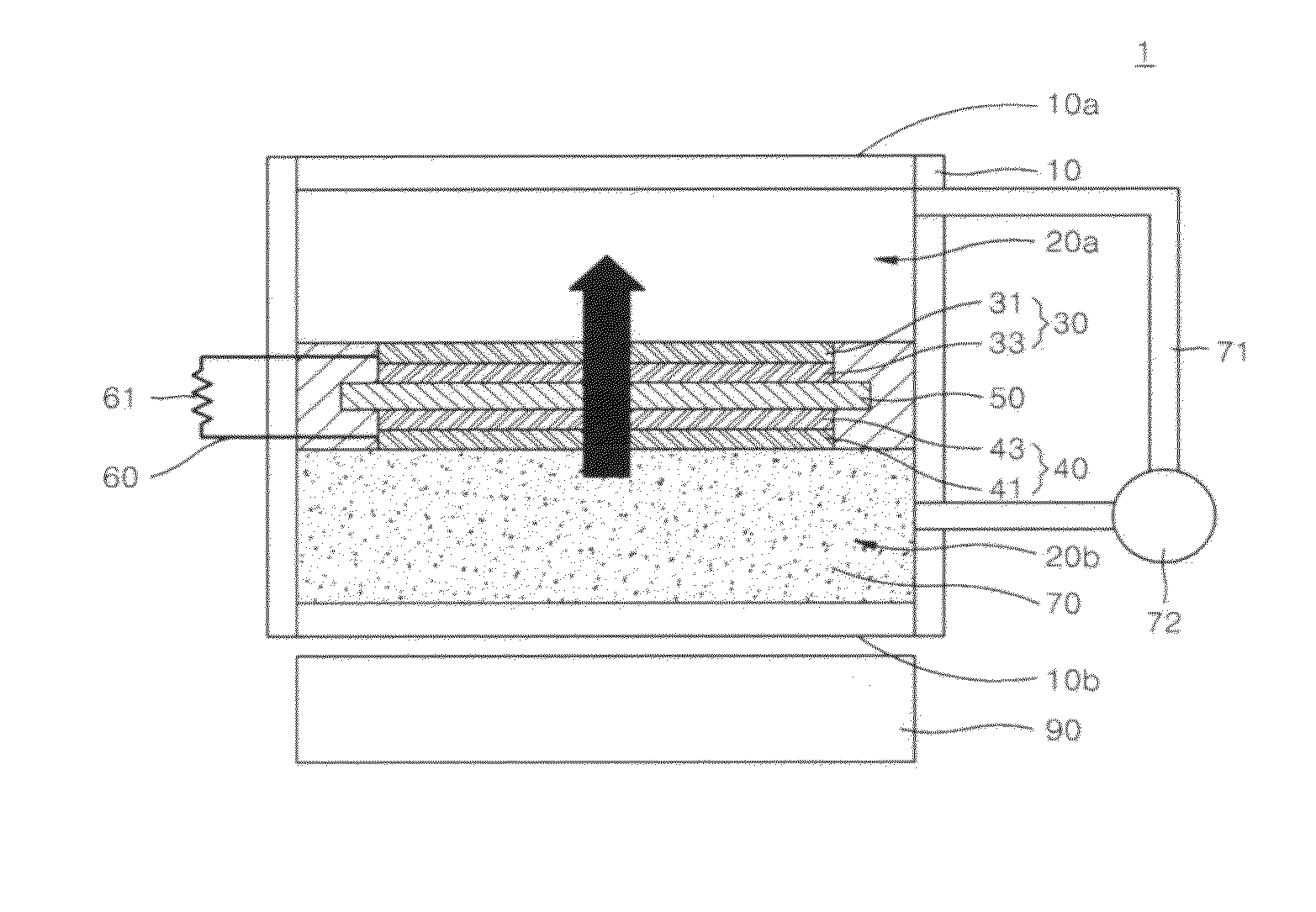

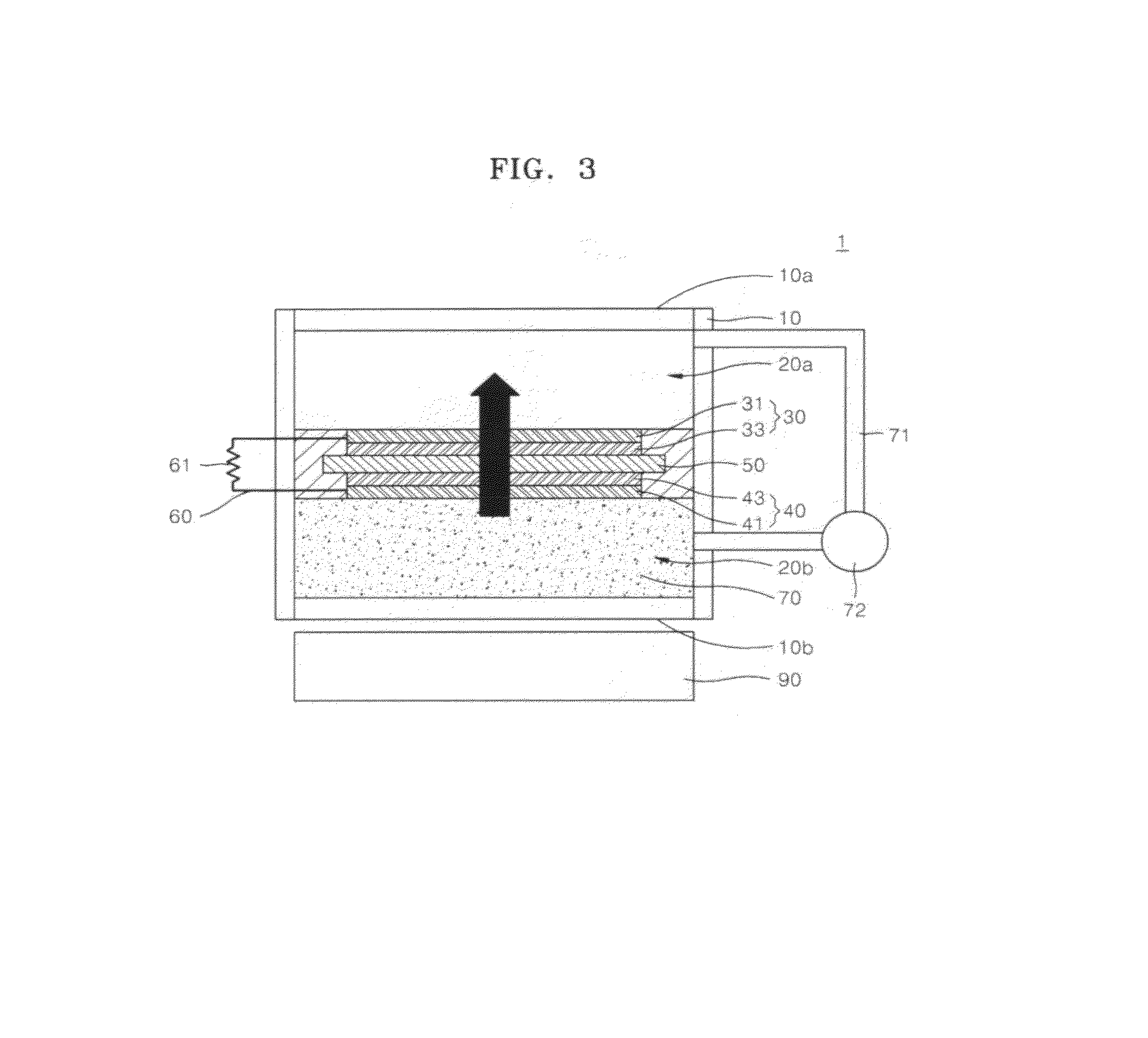

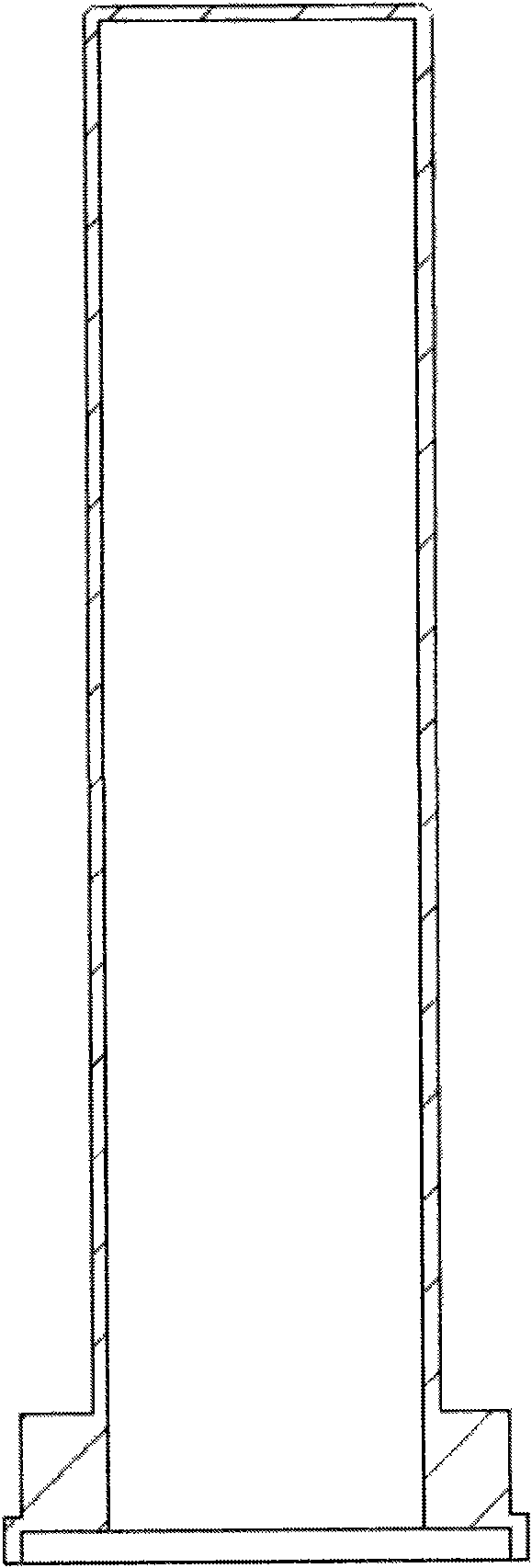

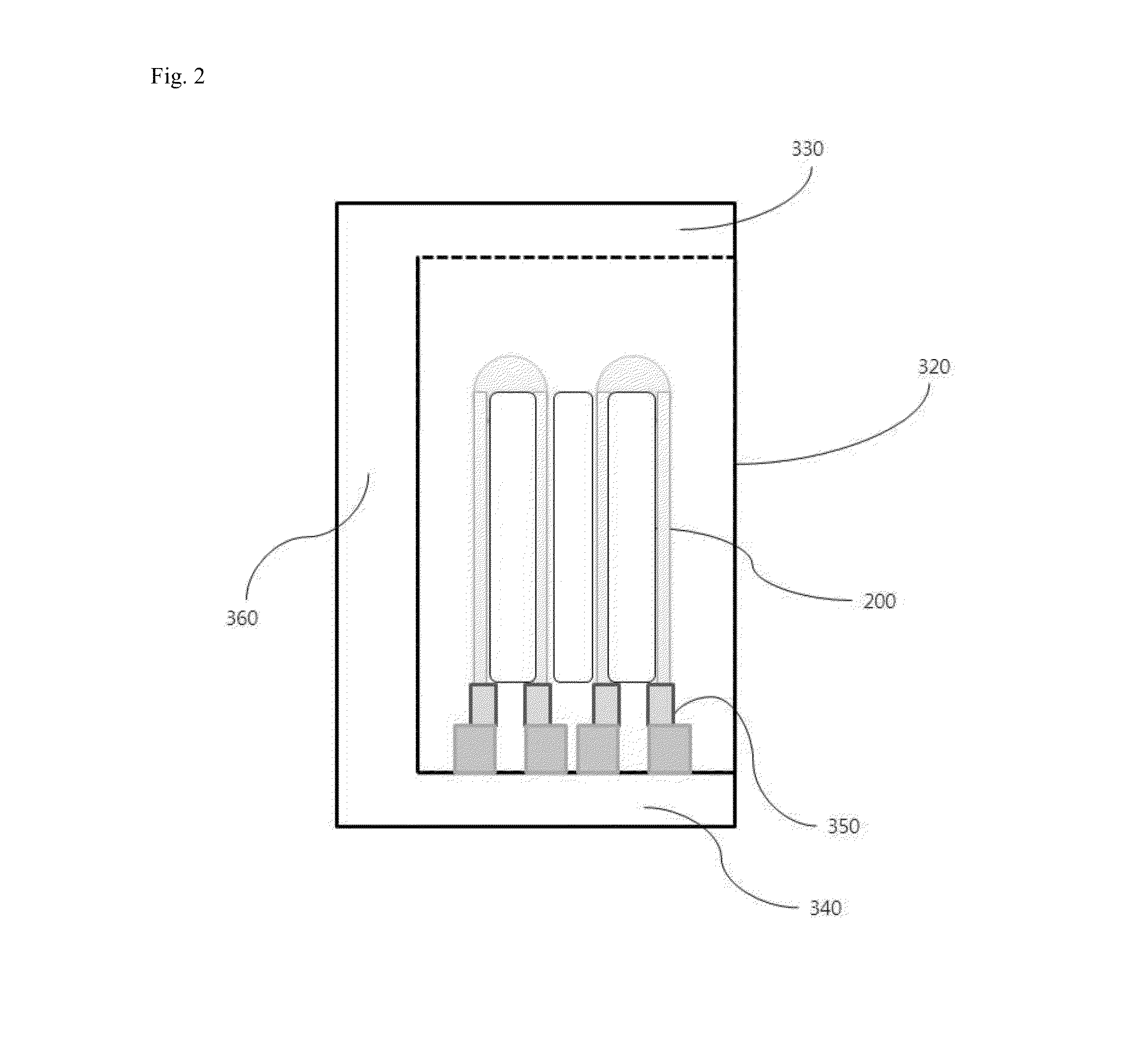

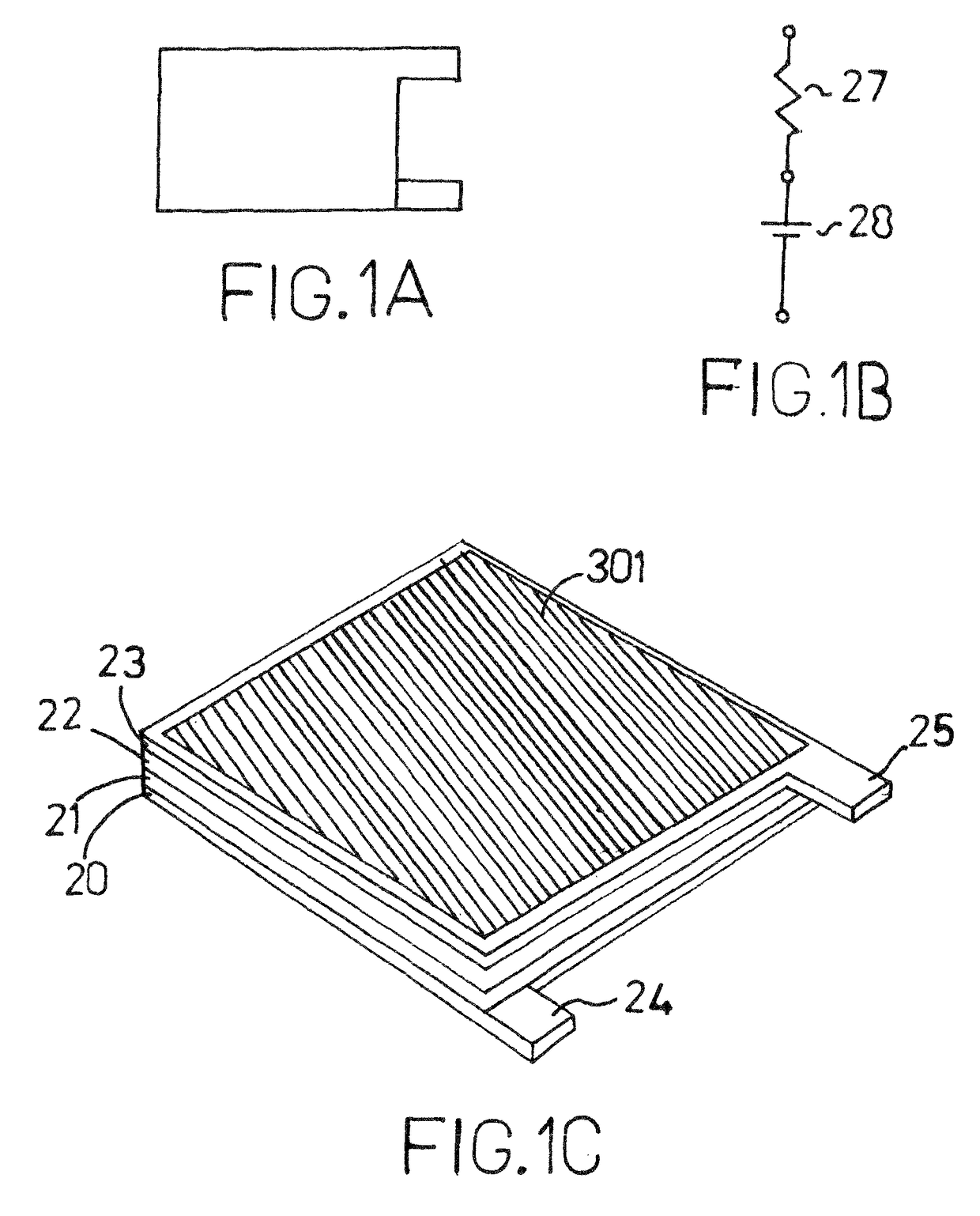

Alkali metal thermal to electric converter system including heat exchanger

InactiveUS20140332046A1Improve efficiencyAchieve recyclingThermoelectric device with peltier/seeback effectIndirect heat exchangersWorking fluidCase contact

Disclosed is a thermal to electric power generator comprising: a plurality of thermal to electric power generation cells; a case in which the plurality of the thermal to electric power generation cells are placed; a condensing unit which is disposed on an upper portion of the case and collects and condenses a working fluid which has passed through the plurality of the thermal to electric power generation cells; an evaporator which is disposed on a lower portion of the case, converts the working fluid into vapor by transferring heat to the working fluid; a heat exchanger which is placed on a surface other than an upper surface of the outside of the case contacting with the condensing unit; a circulator which connects the condensing unit and the evaporator; and a joiner which joins the evaporator to the plurality of the thermal to electric power generation cells.

Owner:KOREA INST OF ENERGY RES

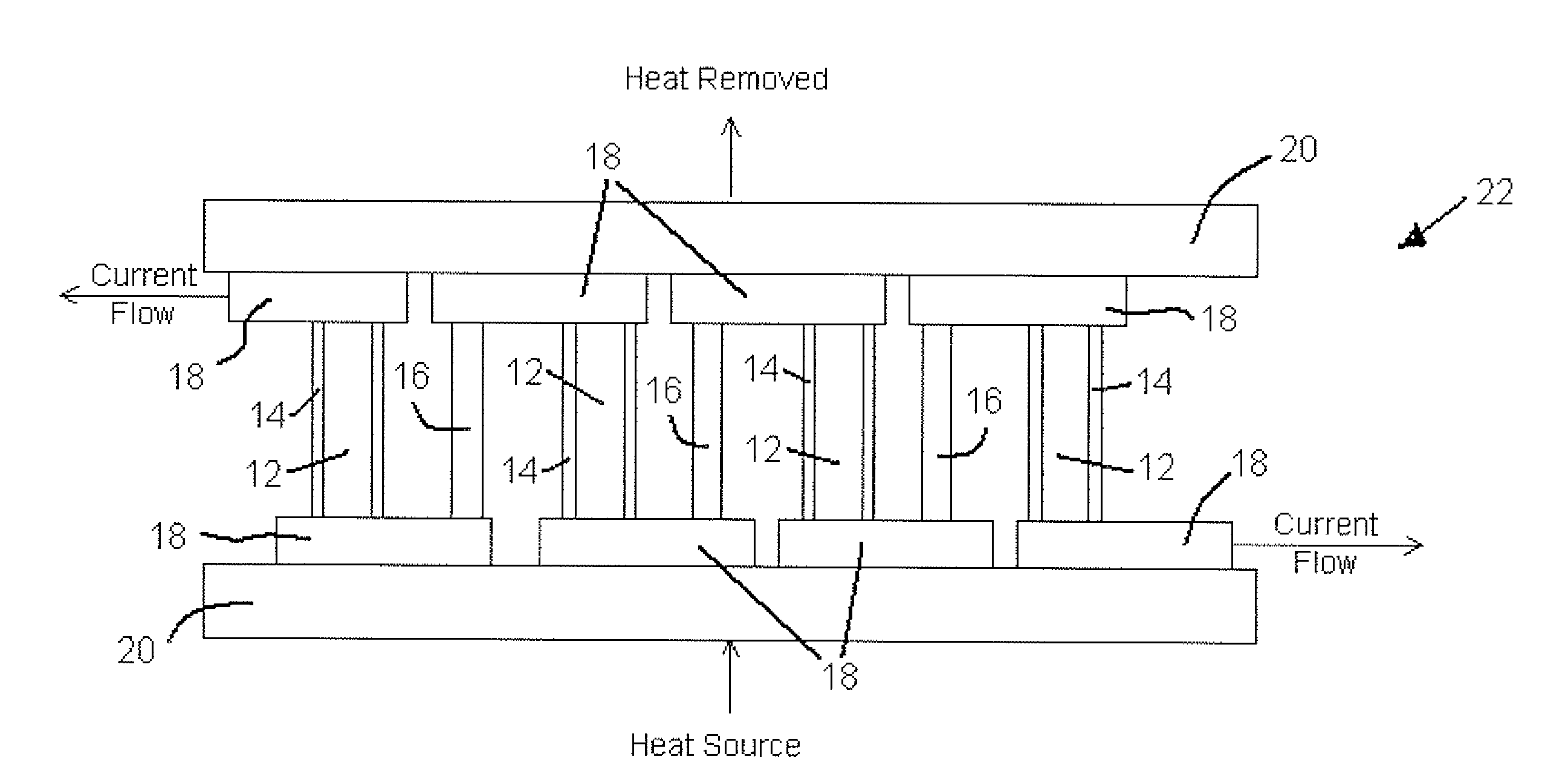

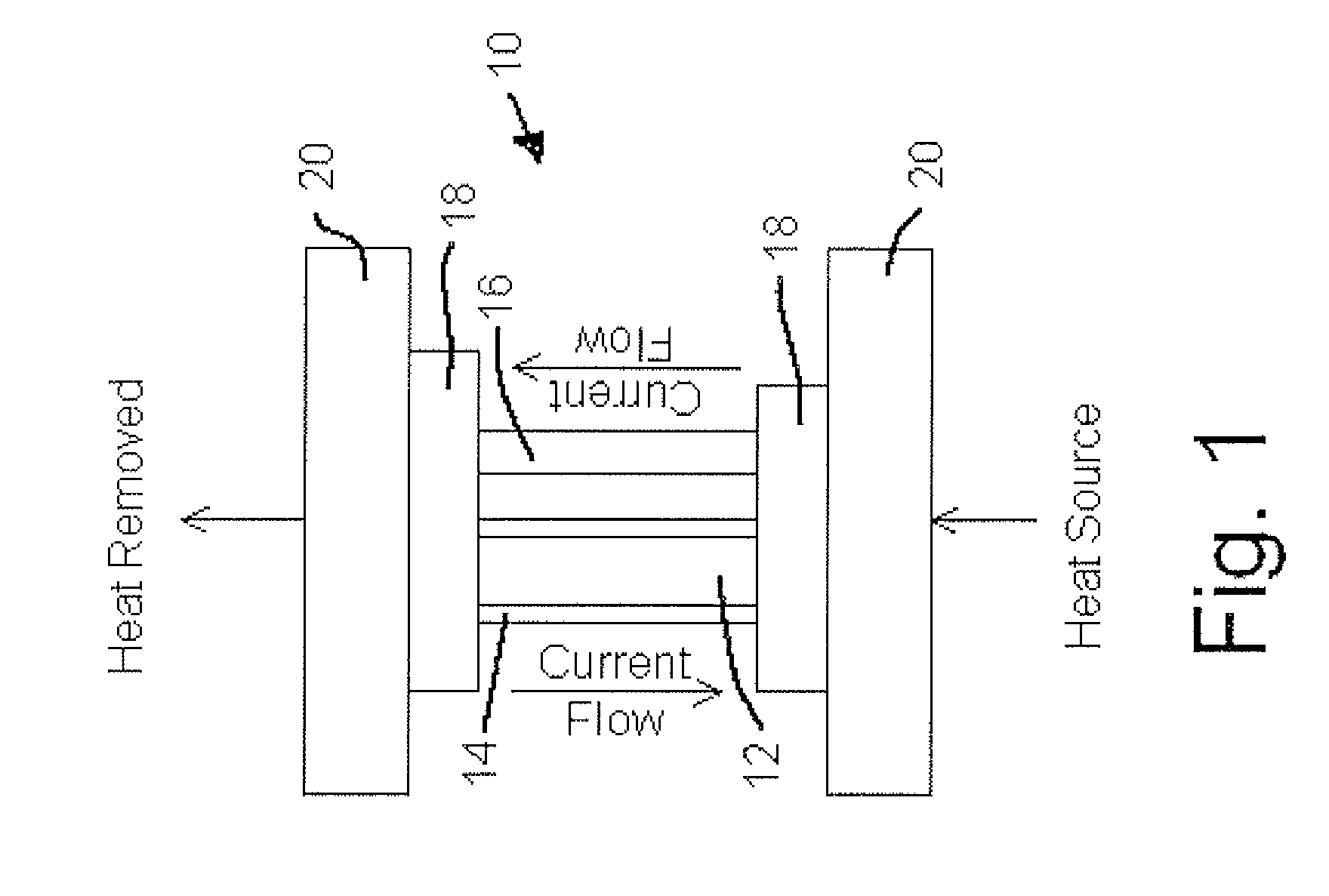

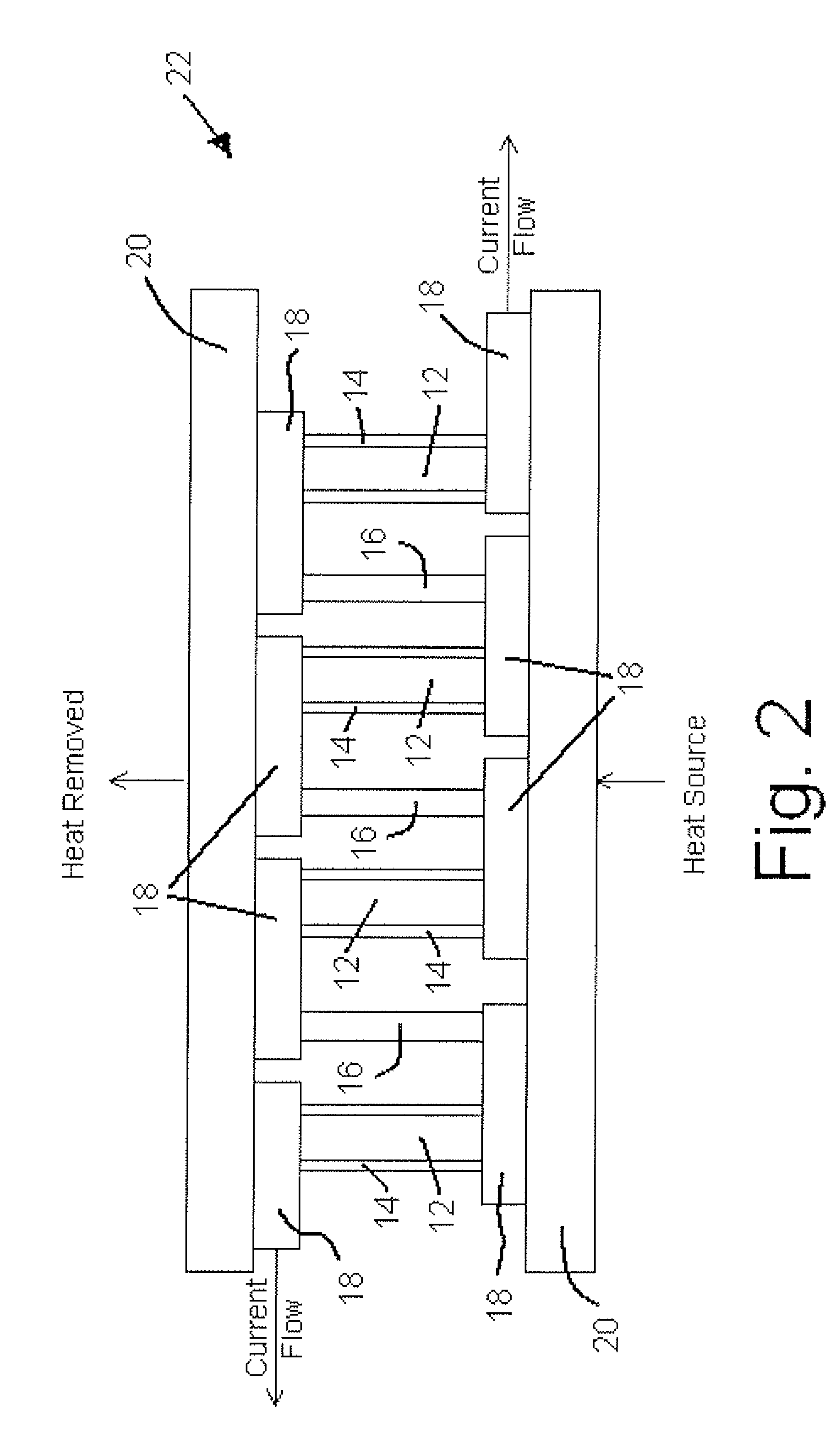

Thermoelectric conversion using metal-ion solutions

InactiveUS20110186101A1Improve equipment efficiencyDifficult and expensive to manufactureThermoelectric device with peltier/seeback effectTemperature-sensitive devicesPower flowLithium

A thermoelectric conversion device may be made of a pair of dissimilar materials conductively joined at opposite sides, wherein at least one of said materials is a metal ion liquid solution. A thermal differential between the opposite sides creates an electric current flow and the liquid metal ion solution resists thermal equilibrium. The liquid metal ion solution may be contained by a substantially nonconductive material, such as vinyl tubing. A plurality of pairs of these dissimilar materials may be joined in series to increase the current output. The metal ion of the liquid solution may be selected, for example, from a group consisting of Lithium (Li), Sodium (Na), and Potassium (K).

Owner:HART INFO

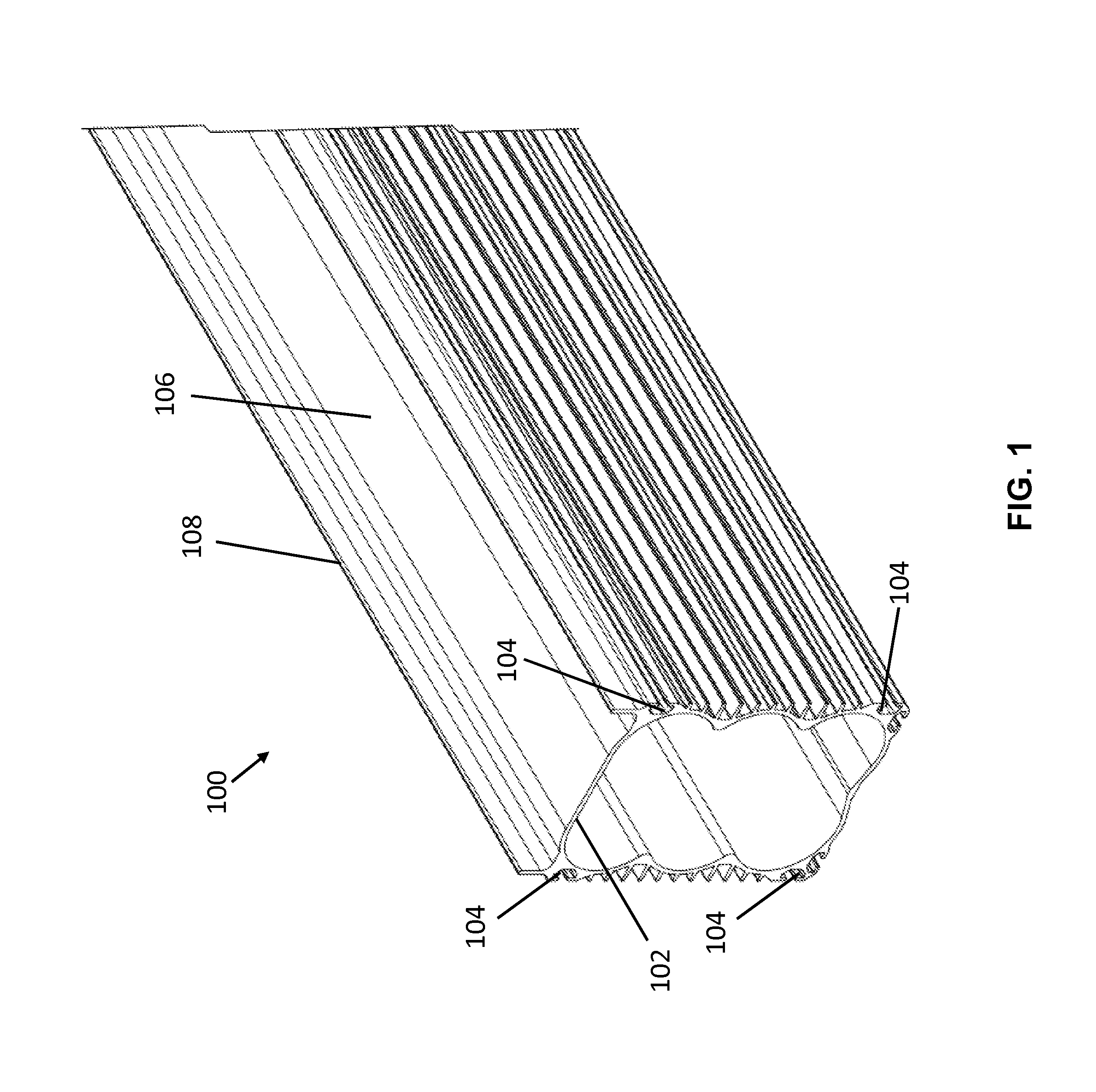

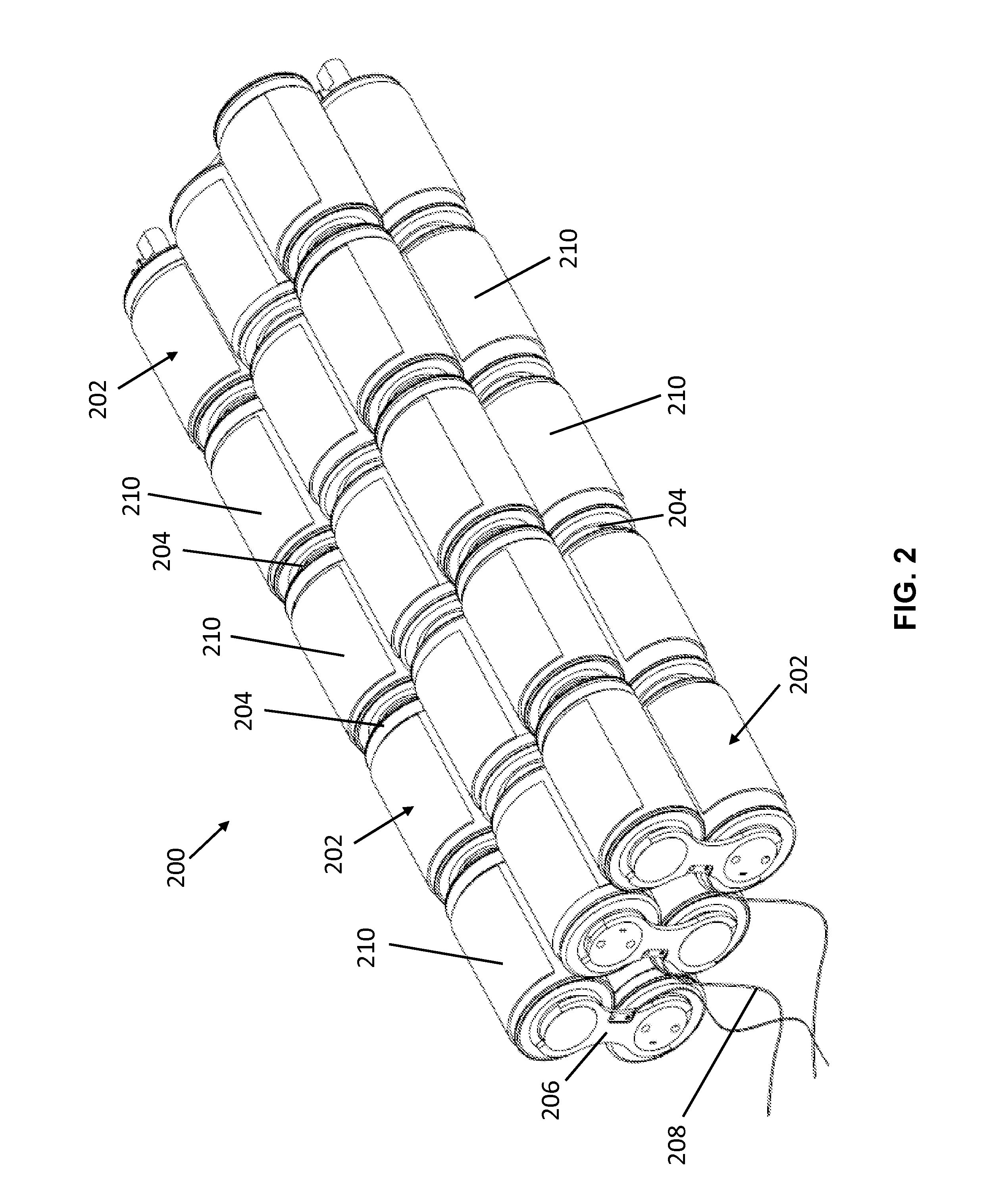

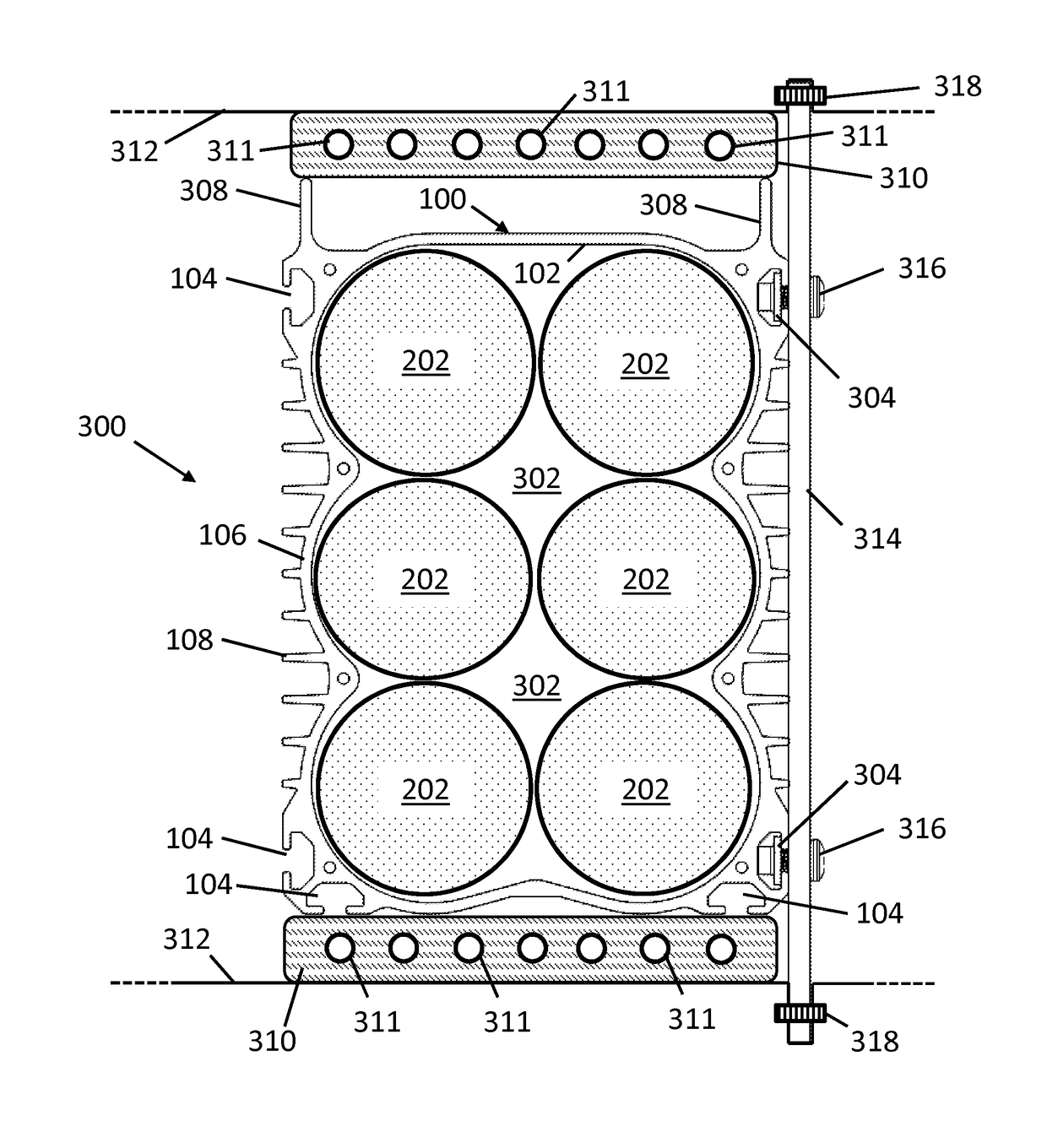

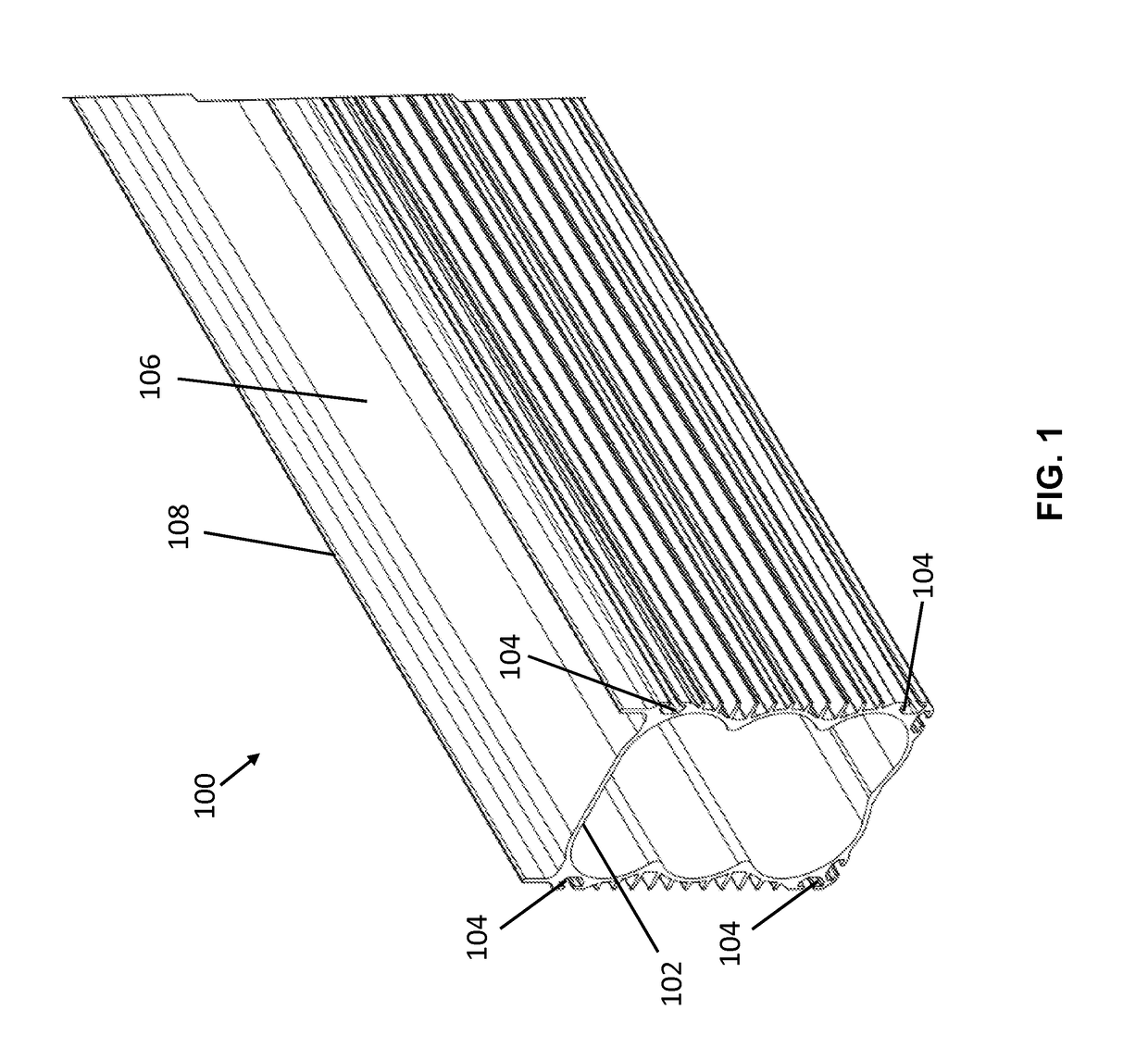

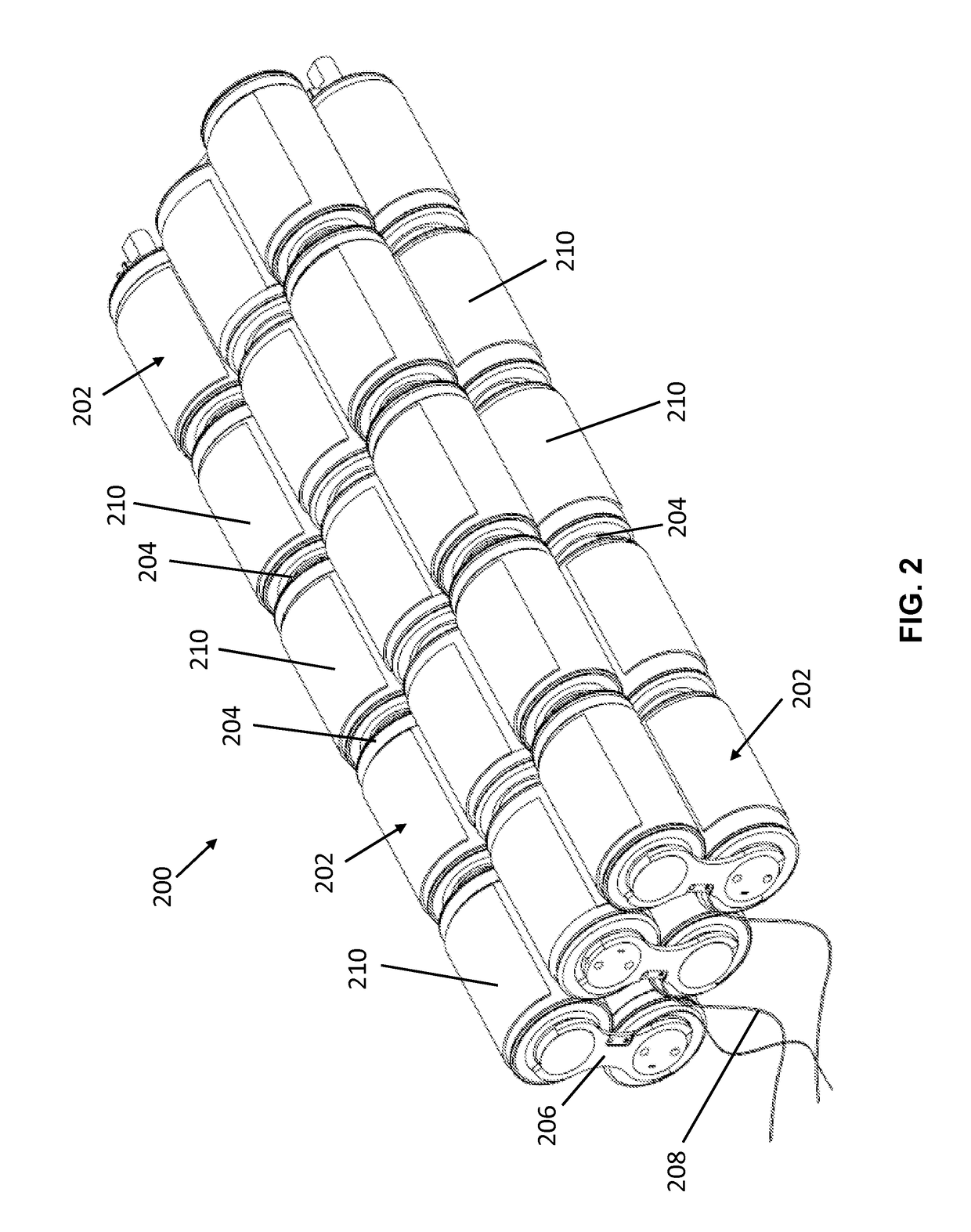

Apparatus for enclosing energy storage devices

ActiveUS20160211086A1Capacitor collector combinationsTransformers/inductances coils/windings/connectionsEngineeringConductive materials

Embodiments of the present disclosure include an apparatus for enclosing energy storage devices. An apparatus according to the present disclosure can include: an elongated sleeve having a contoured interior configured to enclose each of a plurality of energy storage devices, wherein the elongated sleeve is composed at least partially of a thermally conductive material; and at least one slot disposed on an exterior surface of the elongated sleeve, wherein the at least one slot is configured to receive for mechanically coupling a mounting rail to the elongated sleeve.

Owner:IOXUS INC +1

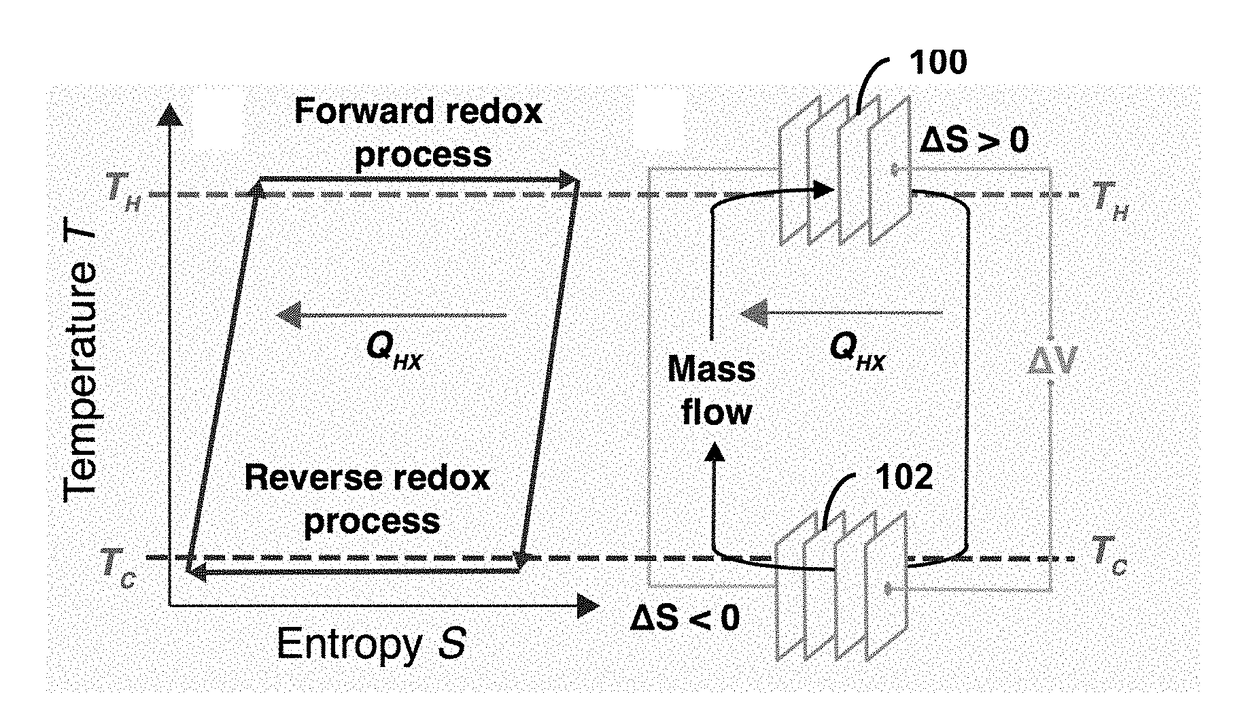

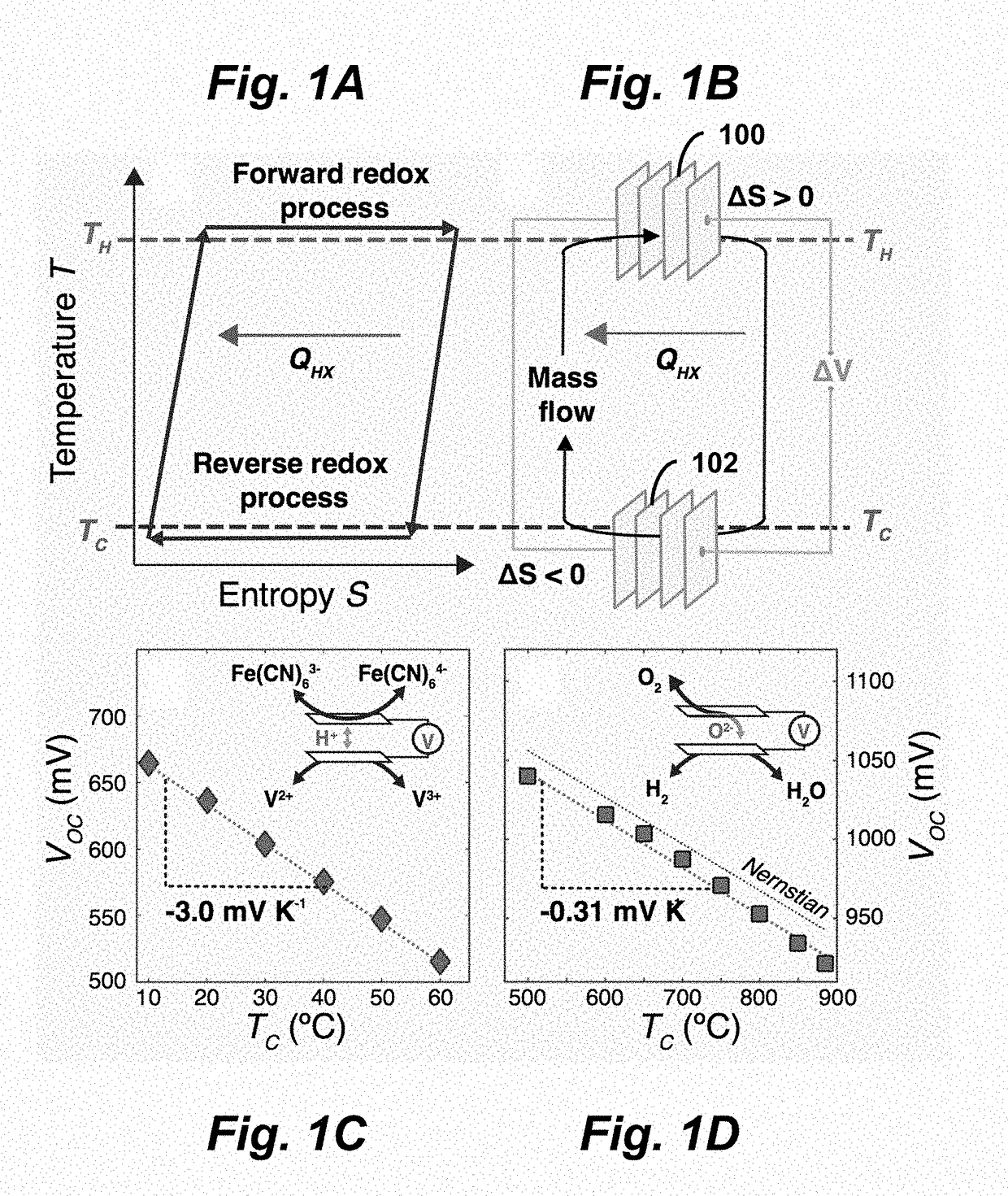

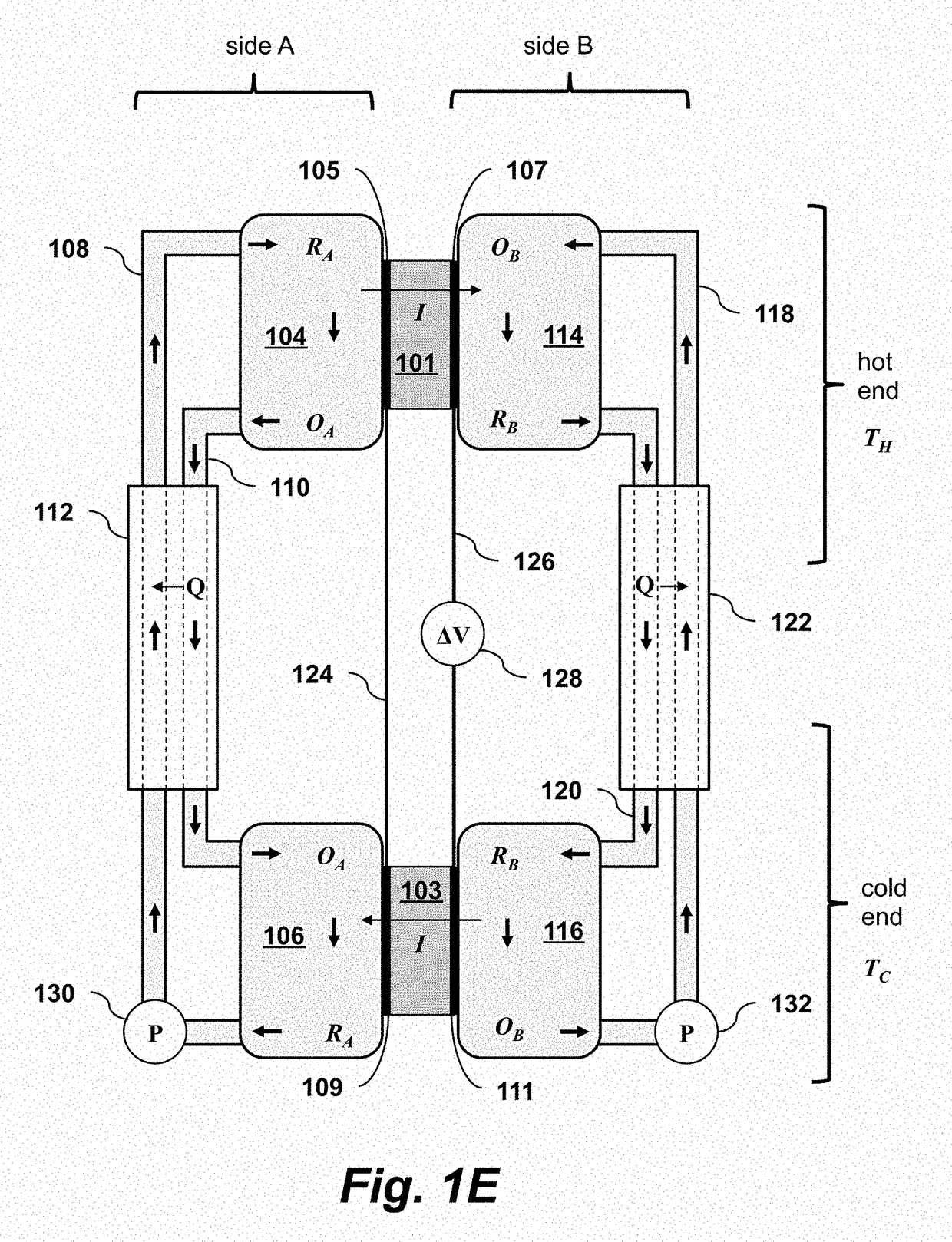

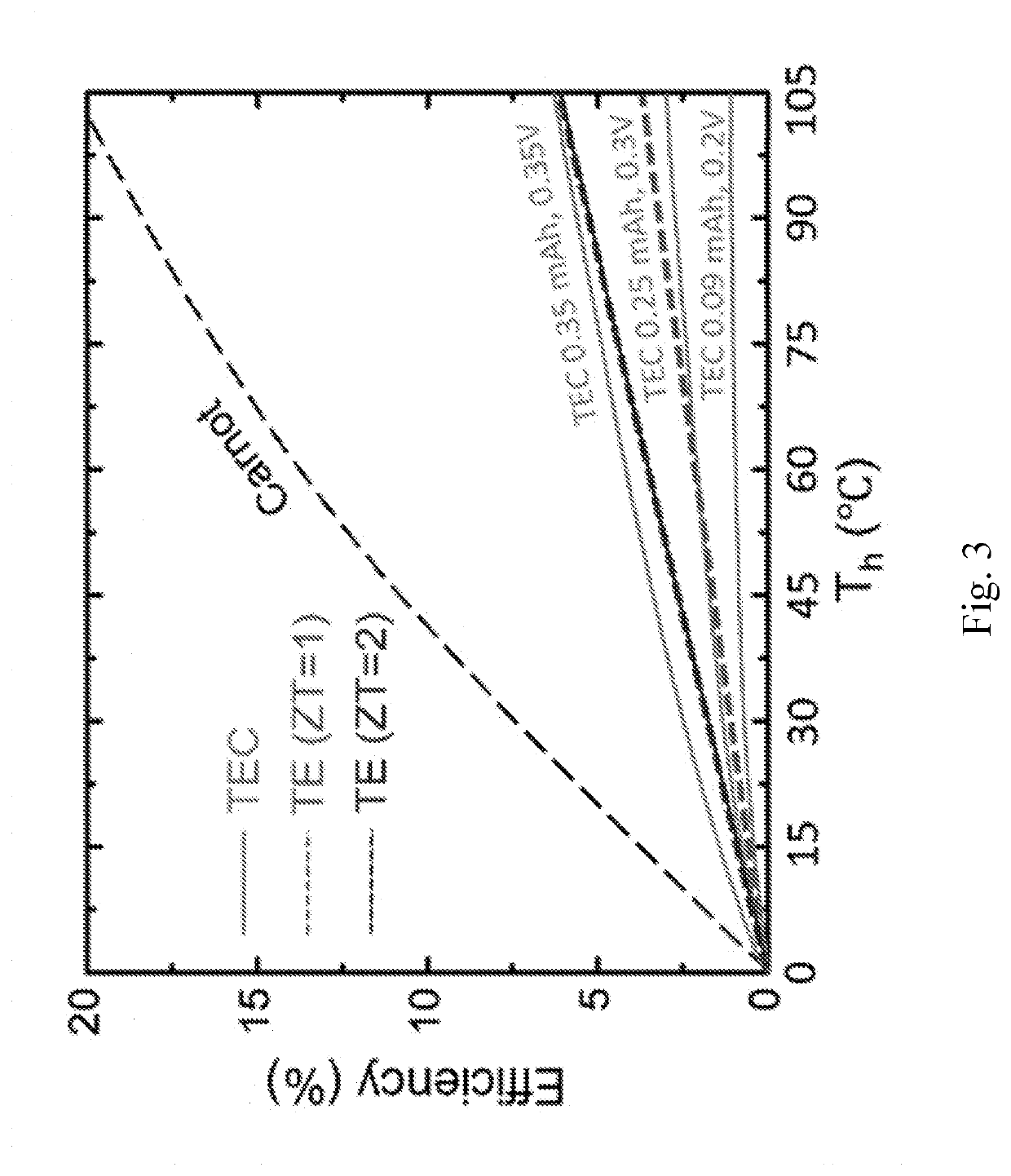

Thermoelectrochemical Heat Converter

InactiveUS20170288253A1Improvement in heat conversion efficiency and temperature range and power per unit weightEasy to useCell electrodesRegenerative fuel cellsElectricityWorking fluid

A direct thermoelectrochemical heat-to-electricity converter includes two electrochemical cells at hot and cold temperatures, each having a gas-impermeable, electron-blocking membrane capable of transporting an ion I, and a pair of electrodes on opposite sides of the membrane. Two closed-circuit chambers A and B each includes a working fluid, a pump, and a counter-flow heat exchanger. The chambers are connected to opposite sides of the electrochemical cells and carry their respective working fluids between the two cells. The working fluids are each capable of undergoing a reversible redox half-reaction of the general form R→O+I+e−, where R is a reduced form of an active species in a working fluid and O is the oxidized forms of the active species. One of the first pair of electrodes is electrically connected to one the second pair of electrodes via an electrical load to produce electricity. The device thereby operates such that the first electrochemical cell runs a forward redox reaction, gaining entropy, and the second electrochemical cell runs a reverse redox reaction, expelling entropy.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

AMTEC with heat pipe

ActiveUS8253008B2Small sizeImprove efficiencyDeferred-action cellsThermoelectric device with peltier/seeback effectEngineeringTemperature difference

There is provided an AMTEC (alkali metal thermal-electric converter) with a heat pipe and more particularly, to an AMTEC with a heat pipe minimized a heating part and a condensation part of the AMTEC and improved in efficiency of thermal to electric conversion through installing the heating and cooling heat pipes in the AMTEC, in which a metal fluid is heated by latent heat of an operating fluid of the heat pipe, instead of the heat conduction from a heat source, thereby reducing a temperature difference needed for heat transfer to vaporize the metal fluid even by a heat source of a lower temperature than a conventional heat source; improving a cooling performance in a condensation part to result in the high efficiency of thermal to electric conversion; using no additional driving components for driving the heat pipe.

Owner:KOREA INST OF ENERGY RES

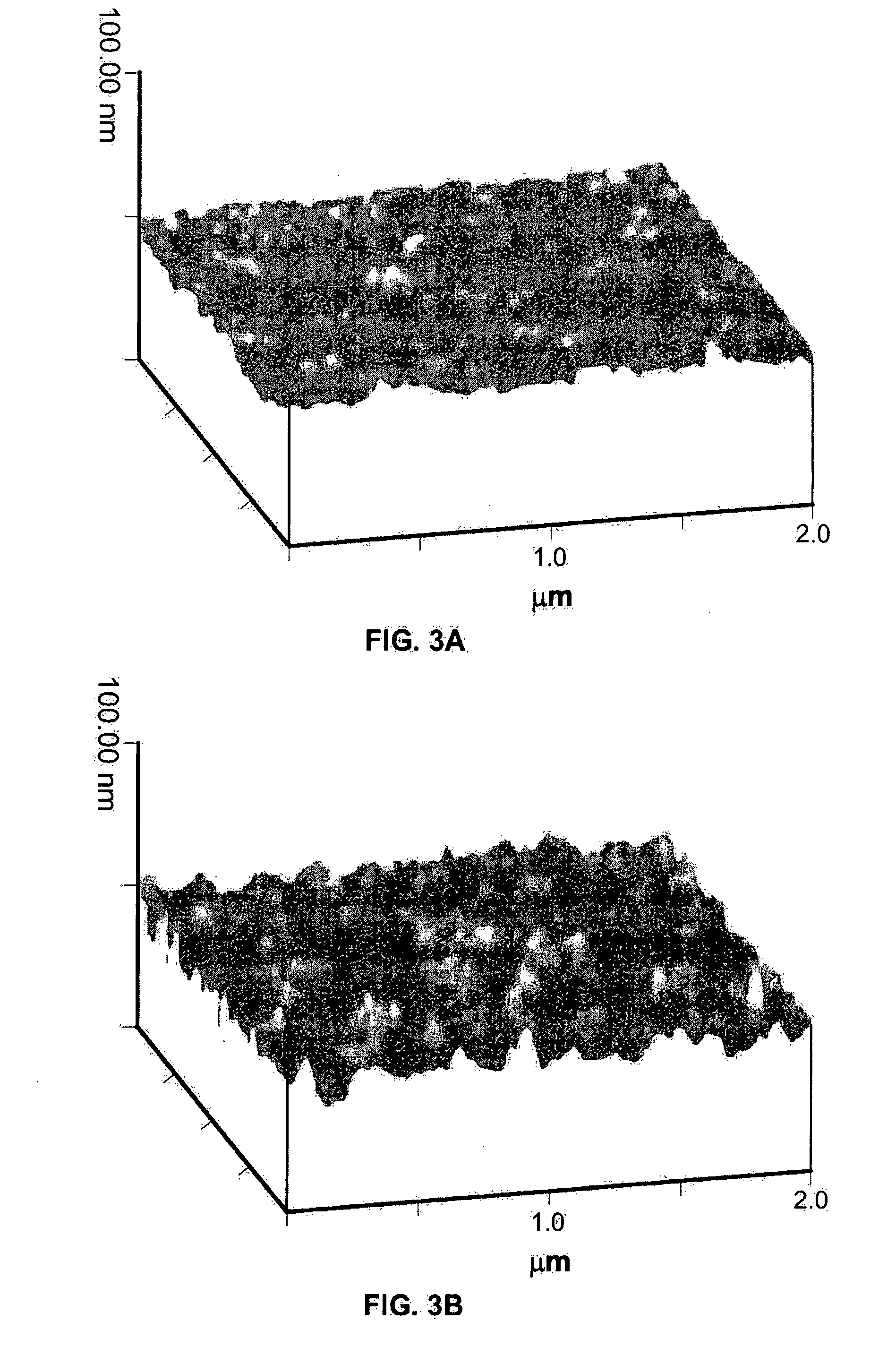

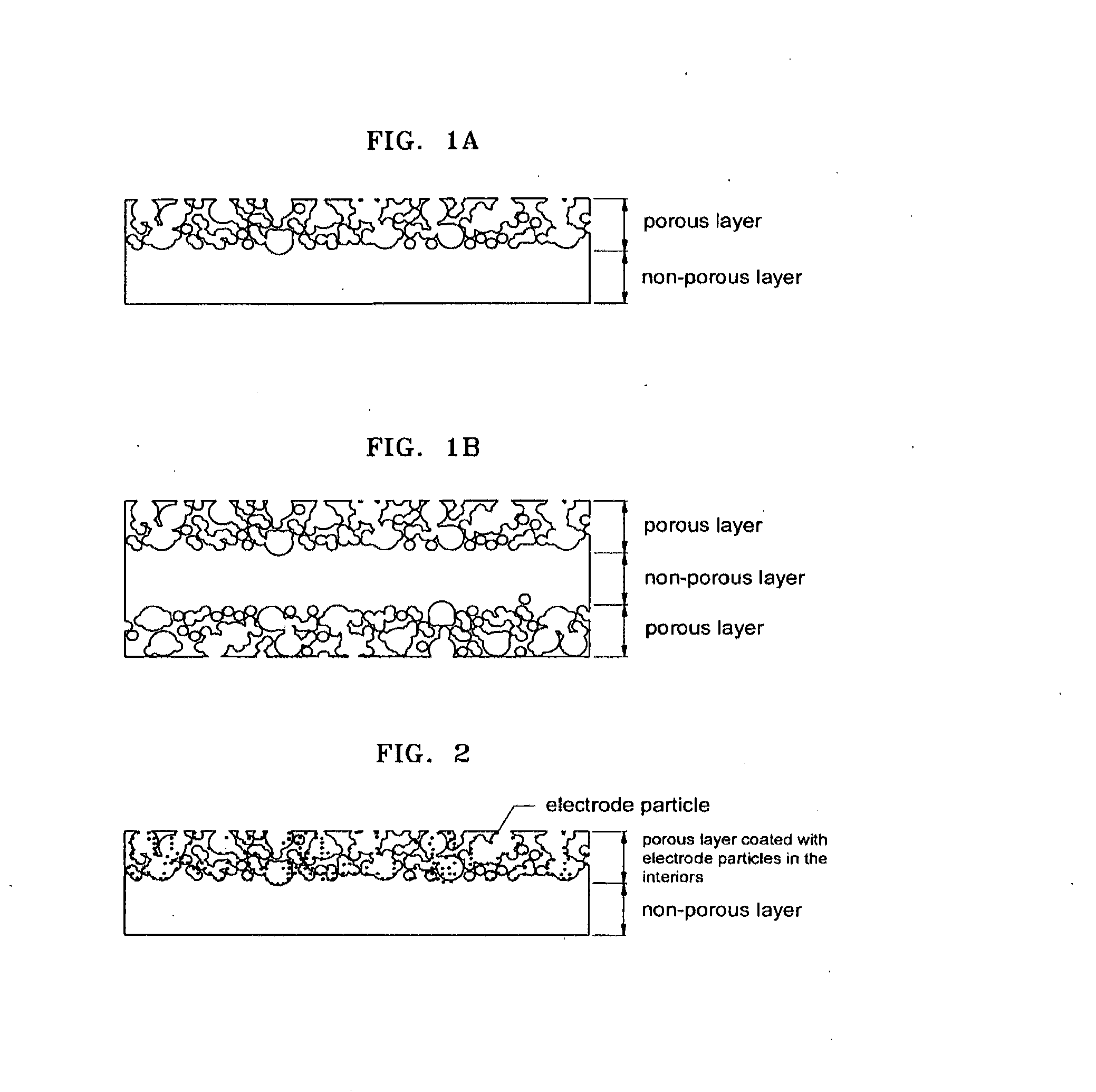

Solid electrolyte and thermoelectric converter including same

A solid electrolyte and a thermoelectric converter including the same. A solid electrolyte includes a non-porous layer and a first porous layer on a first surface of the non-porous layer.

Owner:SAMSUNG SDI CO LTD

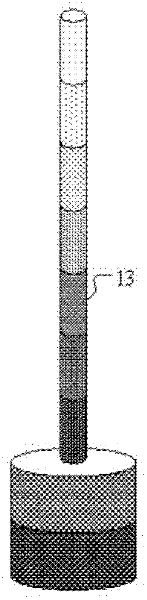

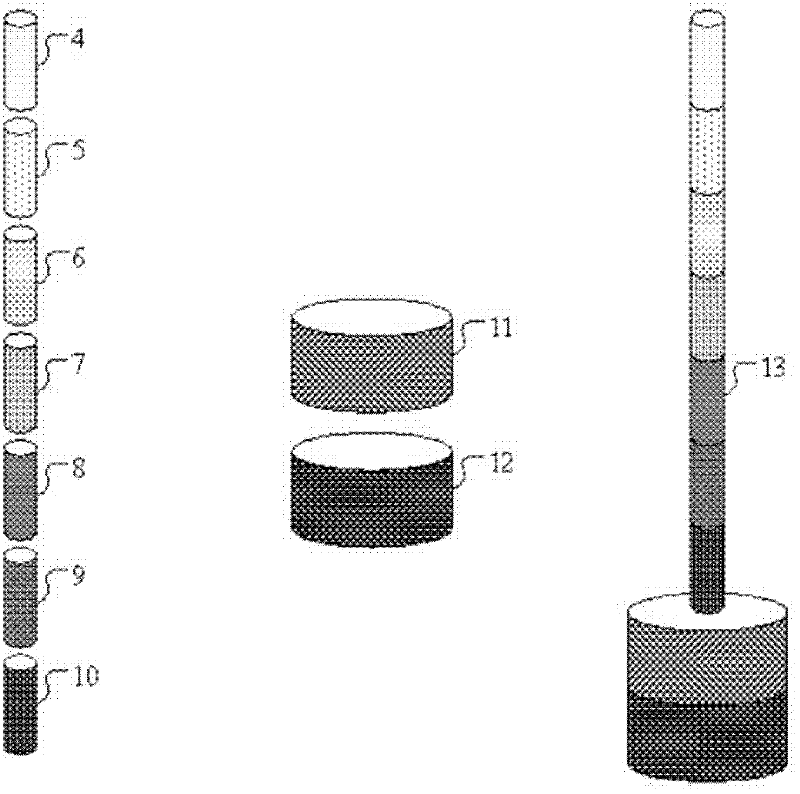

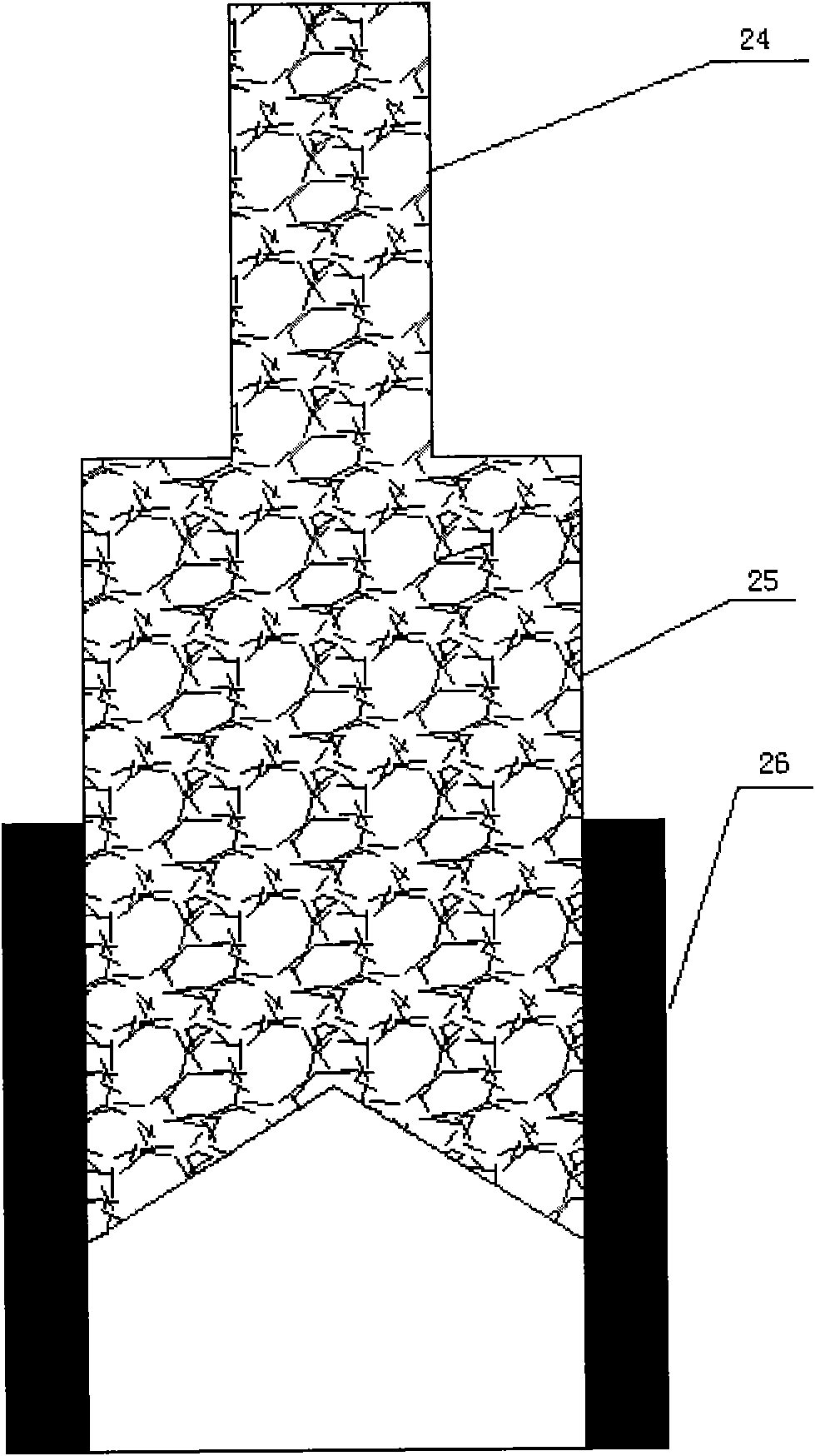

Liquid sucking core component of AMTEC (alkali metal thermoelectric converter) and manufacturing method thereof

InactiveCN102306556AReduce production processAvoid cut-offTemperature-sensitive devicesCapacitor detailsCore componentMetal powder

The invention discloses a liquid sucking core component of an AMTEC (alkali metal thermoelectric converter) and a manufacturing method thereof. In the method, metal powder blocks with multiple different apertures are sintered and molded together so as to manufacture the liquid sucking core component for one time, wherein the number of metal powder blocks used for manufacturing a liquid sucking core and evaporators is more than two, and the apertures of the metal powder blocks for manufacturing the liquid sucking core component are successively decreased from the top of the liquid sucking coreto the bottom of the evaporator. By adopting the manufacturing method provided by the invention, the manufacturing process of the traditional liquid sucking core component can be greatly reduced, thus the on-way resistance can be effectively reduced and the situation of the alkali metal cutoff can be avoided happening.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Alkali metal thermo-electric direct converter

InactiveCN101604931BTemperature-sensitive devicesThermoelectric devicesElectrical conductorEngineering

The invention provides an alkali metal thermo-electric direct converter, which comprises an exhaust tube (1), a supporting seat (2), an upper cover (3), a condenser (4), a condenser sealing cover (5), an upper cavity I (6), a capillary core (7), an upper cavity II (8), a base (9), a capillary core nut (10), a lower cavity I (11), a lower cavity II (12), an exhaust tube nut (13), a capillary core base (14), a lower cover (15) and a ceramic base I (16). The alkali metal thermo-electric direct converter is an energy conversion device in the field of power energy conversion and renewable energy utilization, and uses a BASE (beta''-Al2O3 solid electrolyte) selective permeable membrane, namely the beta'-Al2O3 is an excellent conductor of ions, and by using the characteristics of defective conductors of electrons and atoms, the heat energy absorbed by the alkali metal steam is converted into electric energy to be used by users.

Owner:HARBIN ENG UNIV

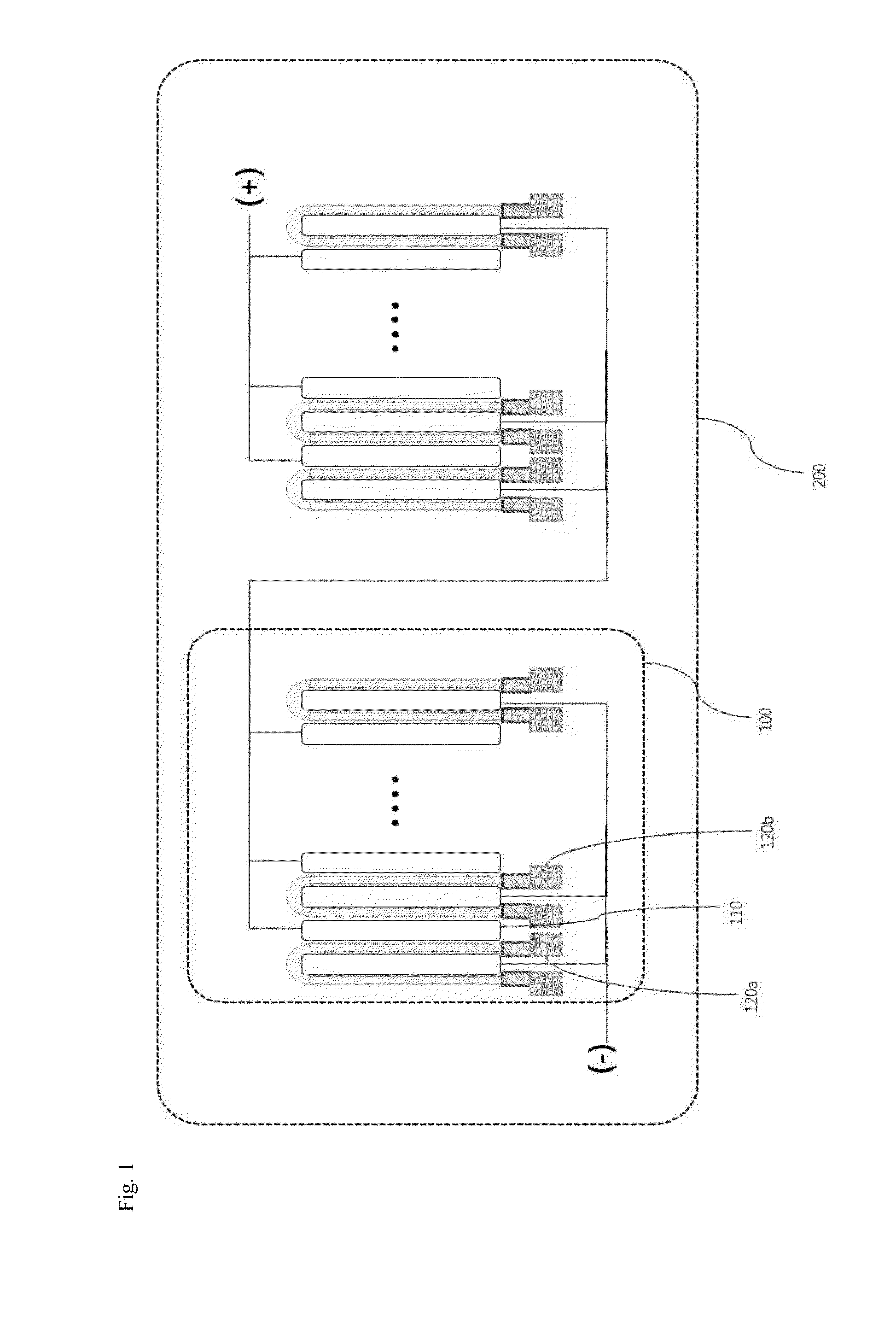

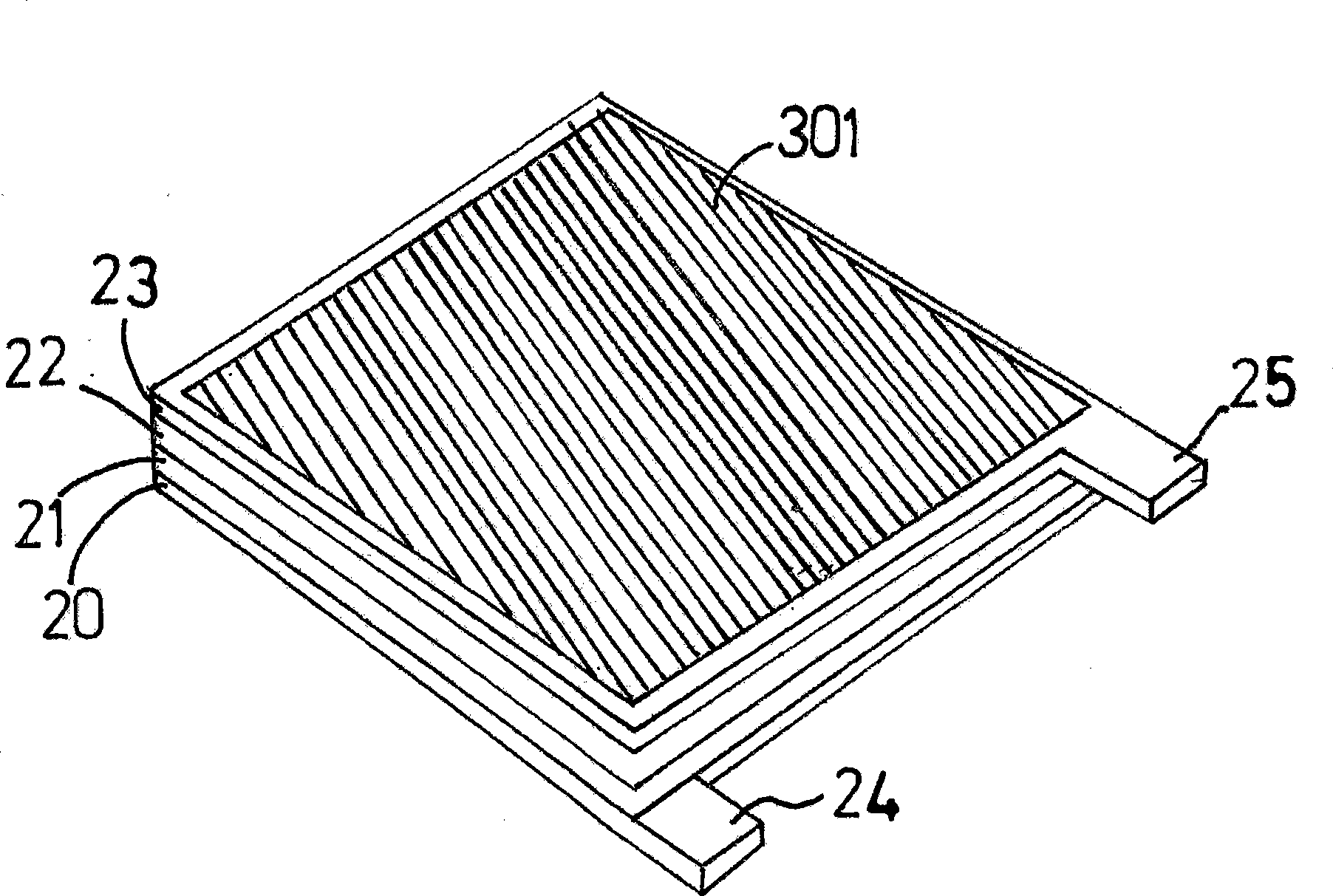

Serial and parallel connection structures of thermal to electric converting cells using porous current collecting material and application of the same

InactiveUS20140332047A1High propertyInterfacial resistanceDeferred-action cellsThermoelectric device with peltier/seeback effectWorking fluidPower flow

Disclosed is a method for collecting current by using a liquefied or gaseous working fluid present inside an electric power generator system. Through the method, a porous structure like a metal felt capable of infusing the liquefied working fluid is inserted and connected to the cell, and then the working fluid present around the cell is naturally infused, so that current is collected. For this purpose, a current collector is provided, which is located between adjacent thermal to electric power generation cells among a plurality of the thermal to electric power generation cells.

Owner:KOREA INST OF ENERGY RES

Method and system for generating electrical energy from water

InactiveUS20120067390A1Electrolysis componentsLight-sensitive devicesElectric energyAutomotive engineering

Owner:POLLACK GERALD

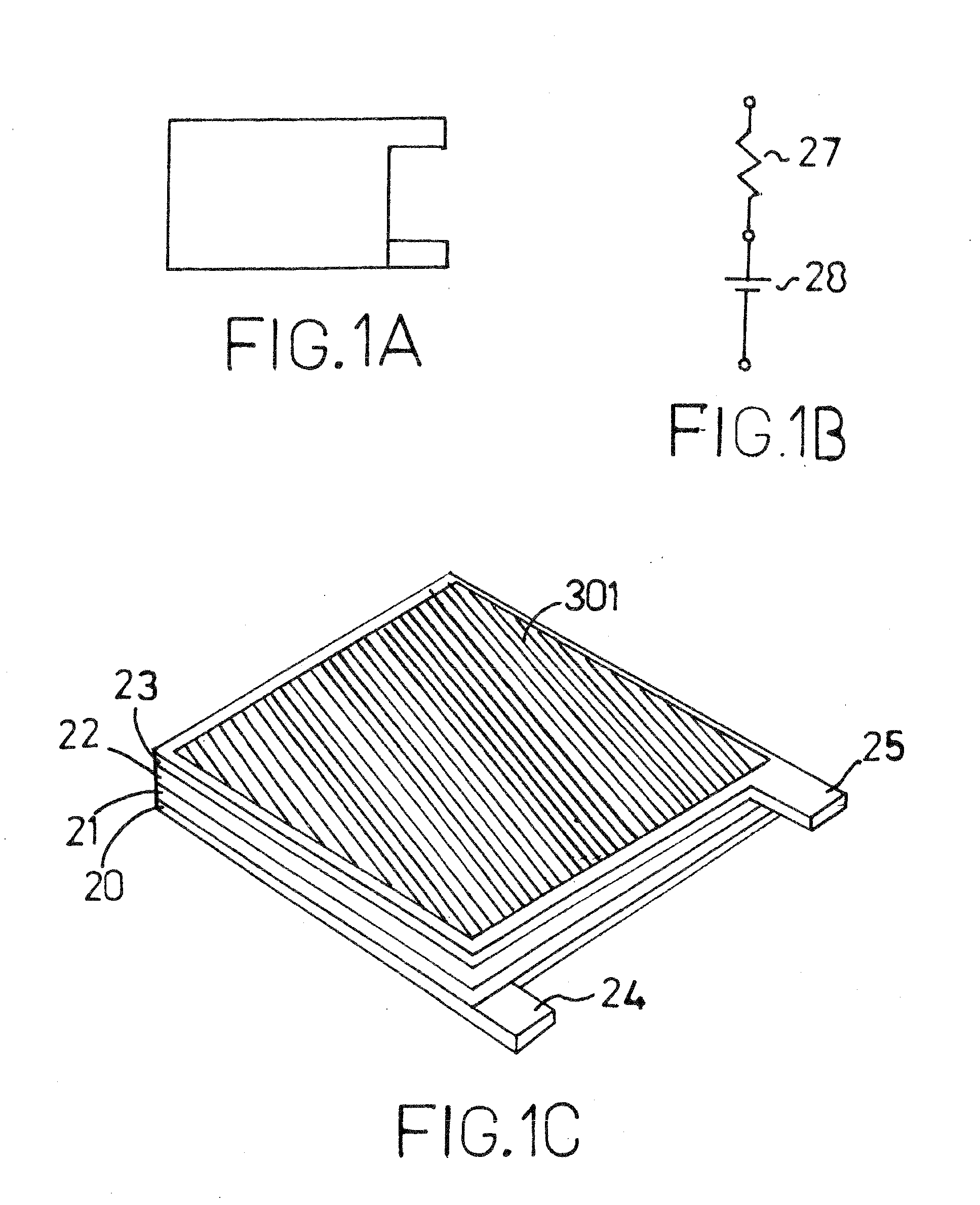

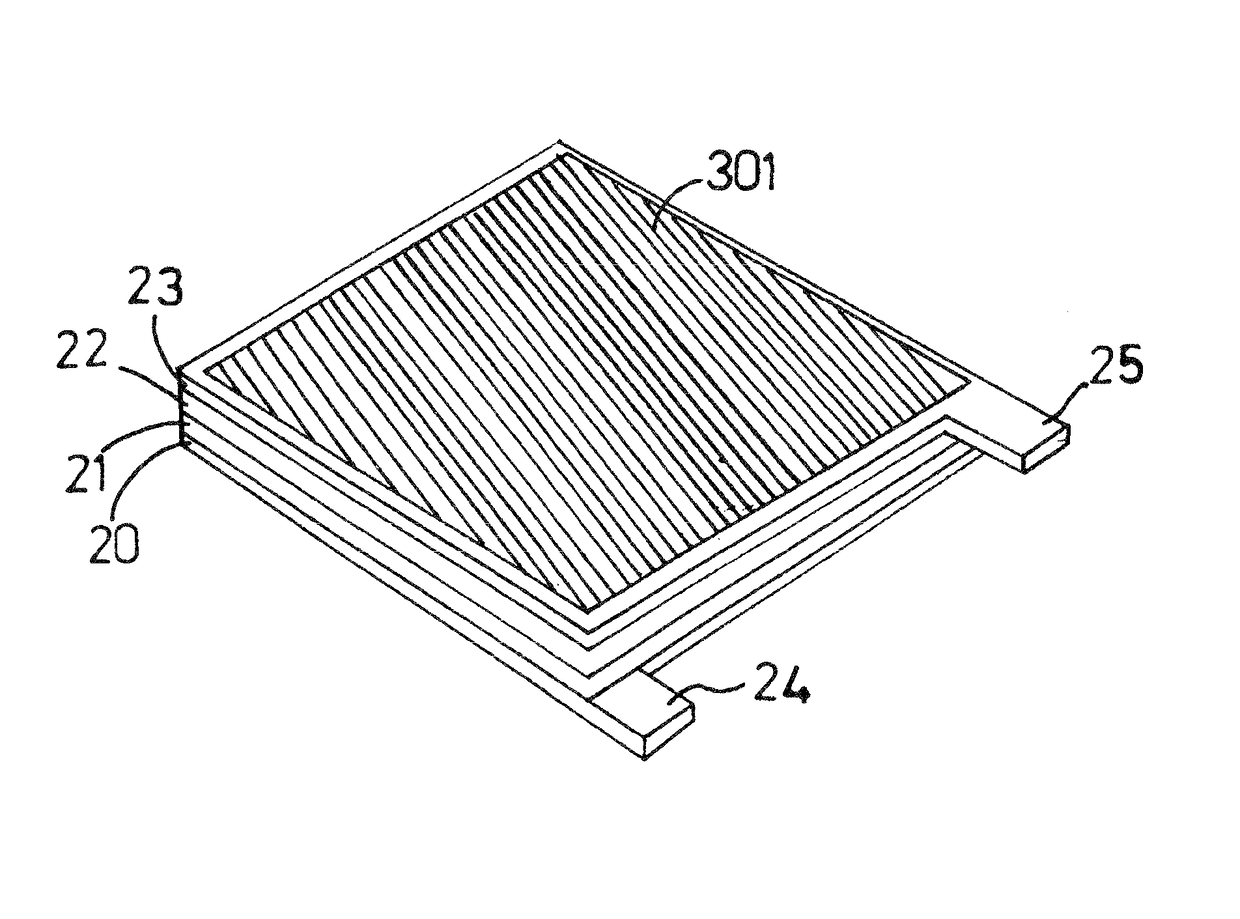

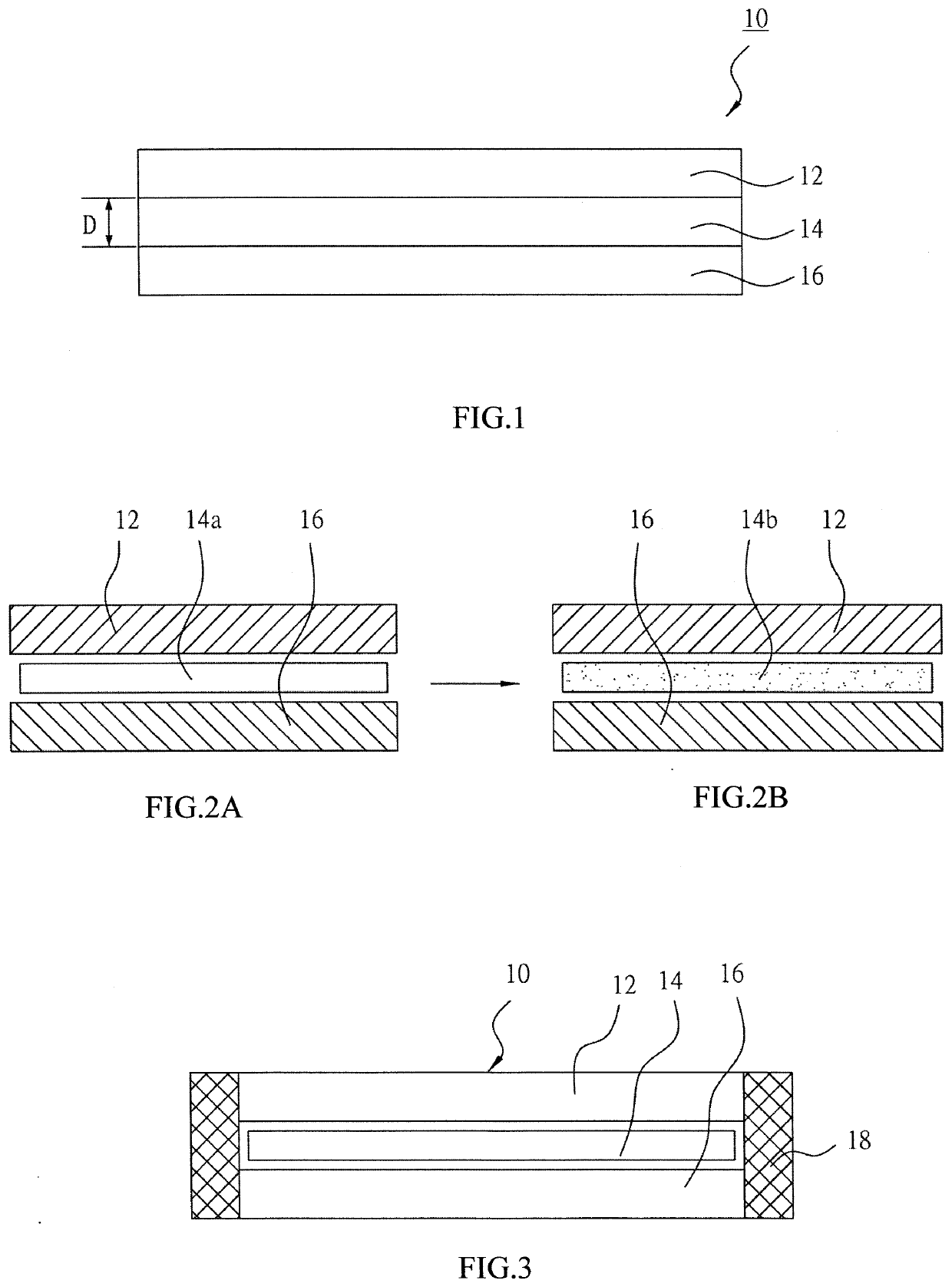

Manganese oxide and carbon combination generator battery

InactiveUS20130228206A1Easy to manufactureNeed expensiveDeferred-action cellsSolid electrolytic capacitorsManganese oxideElectron density

A solid state energy generator and storage device, comprising two layers, in contact with each other, of dissimilar materials in terms of electron density and configuration, sandwiched between an anode and a cathode. One of the layers is a stabilized mixture of carbon and an ionic material (carbon matrix) and the other layer is a stabilized manganese oxide mixed with an ionic material (oxide matrix). The built-in potential of the device is determined mathematically by integrating the electrostatic forces across the barrier and will rise or fall in direct proportion to the device temperature (in Kelvin). In addition the device can be charged and thus function as a charge storage device, with the rated voltage varying according to the temperature of the device. When a load is attached across the terminals of the device a current flows.

Owner:CONCEPTUAL WERKS LLC

Adverse event-resilient network system

ActiveUS20130263905A1Easy to manufactureNeed expensiveThermoelectric device with peltier/seeback effectReduction-oxidation hybrid capacitorsEngineeringElectromagnetic shielding

An adverse event-resilient network system consisting of autonomously powered and mobile nodes in communication with each other either through radio, light or other electromagnetic signals or through a physical connection such as through wiring, cables or other physical connected methods capable of carrying information and communication signals. The nodes powered by an energy generator comprising multiple data, information and voice gathering, receiving and emitting devices as well as mechanical, optical and propulsion devices.

Owner:CONCEPTUAL WERKS LLC

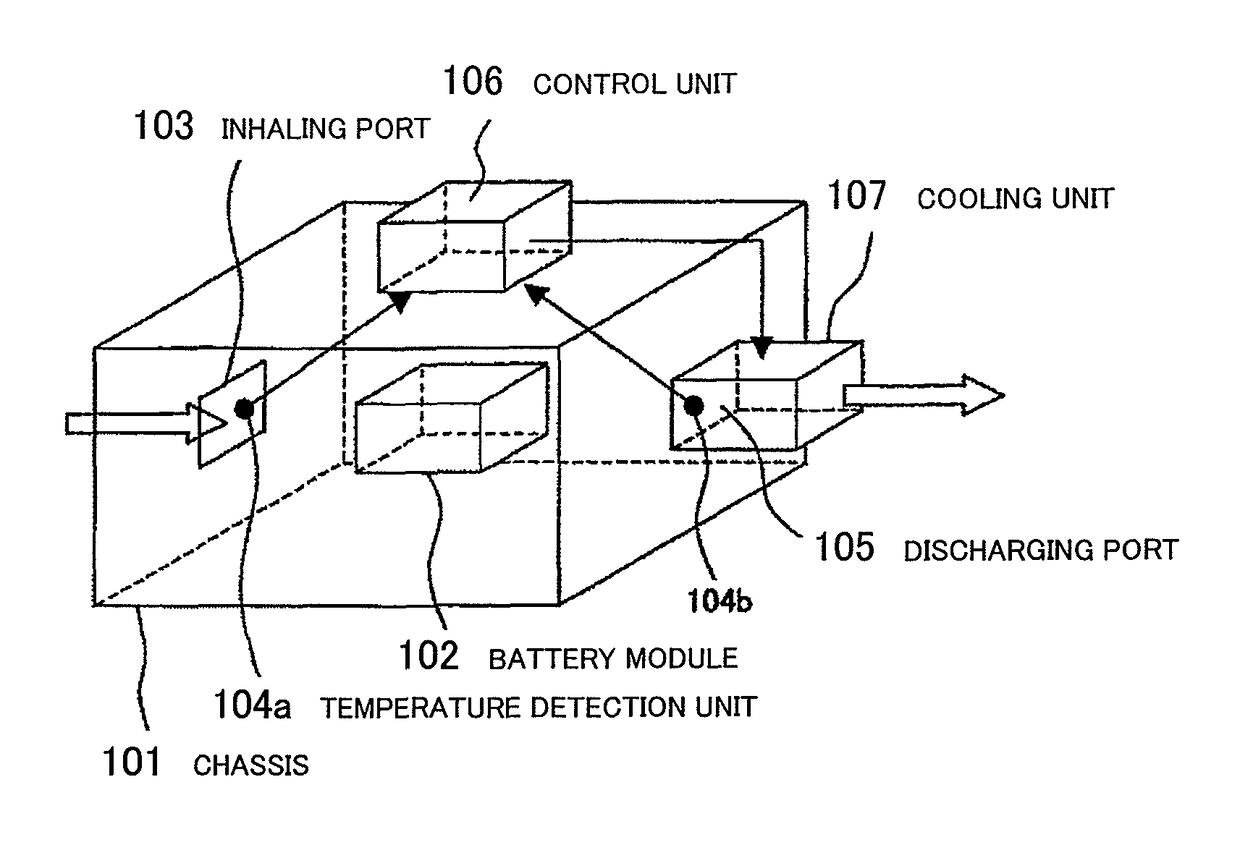

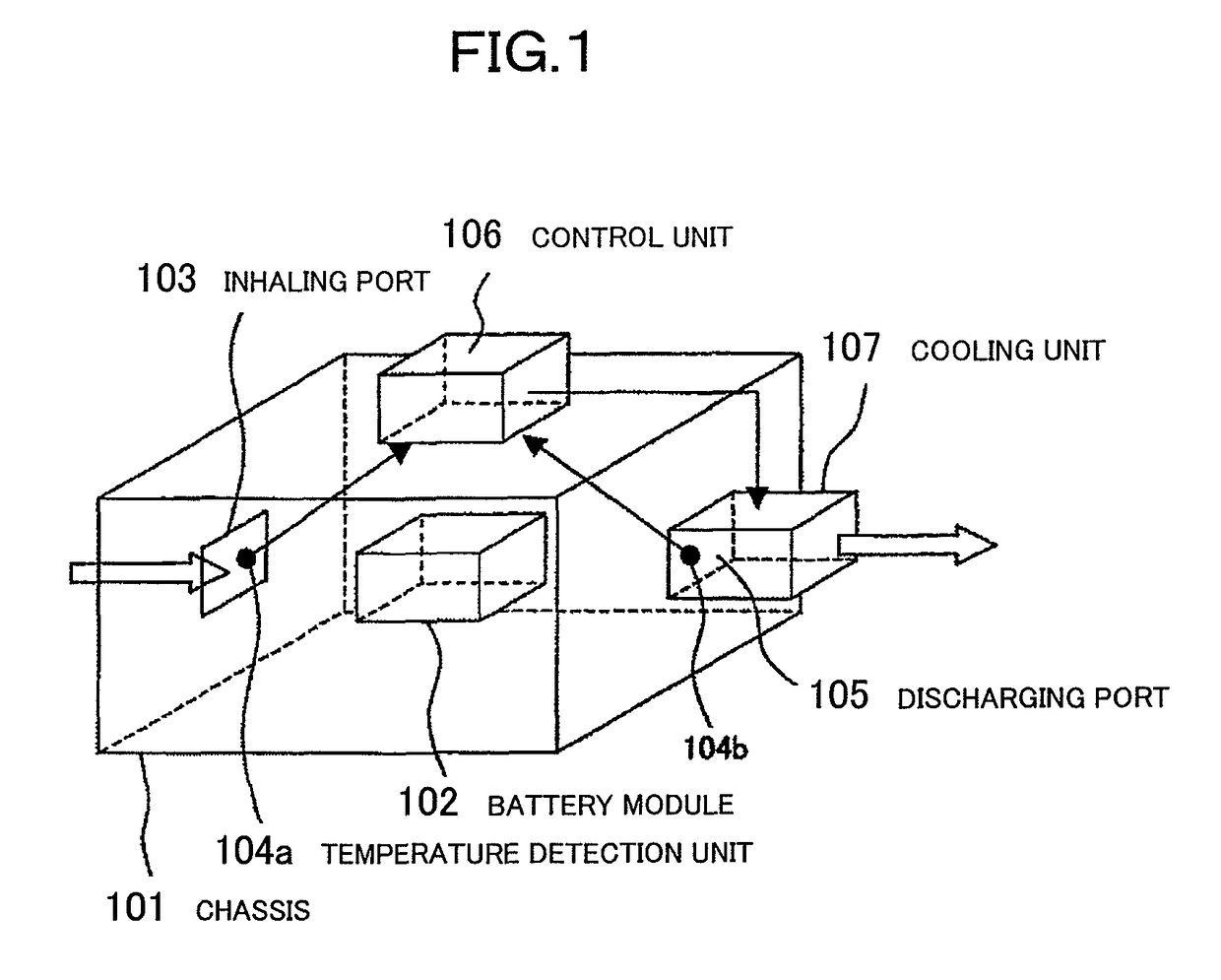

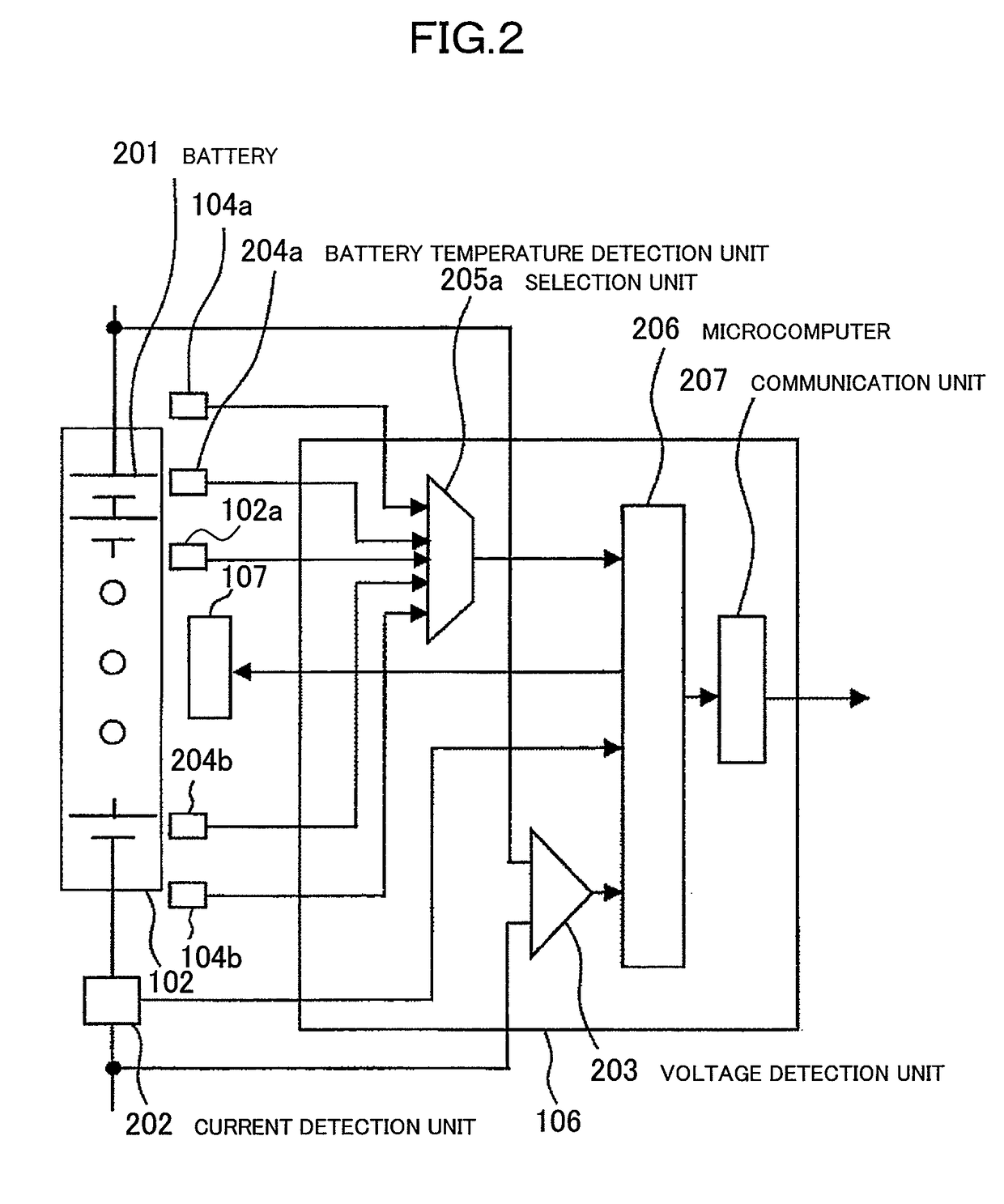

Storage battery apparatus

ActiveUS9748537B2Improve accuracyEasy to useBatteries circuit arrangementsCell temperature controlElectrical batteryComputer module

There is provided a highly reliable storage battery apparatus which can diagnose the status of a temperature detection unit and a cooling unit. In the storage battery apparatus comprising a battery module including one or more batteries, a plurality of temperature detection units and a cooling unit cooling the battery module, the temperature detection units measure, at least, the temperature of the cooling medium inputted to the storage battery apparatus, the temperature of the cooling medium outputted from the storage battery apparatus, and the temperature of at least one of the batteries and the battery module.

Owner:HITACHI ASTEMO LTD

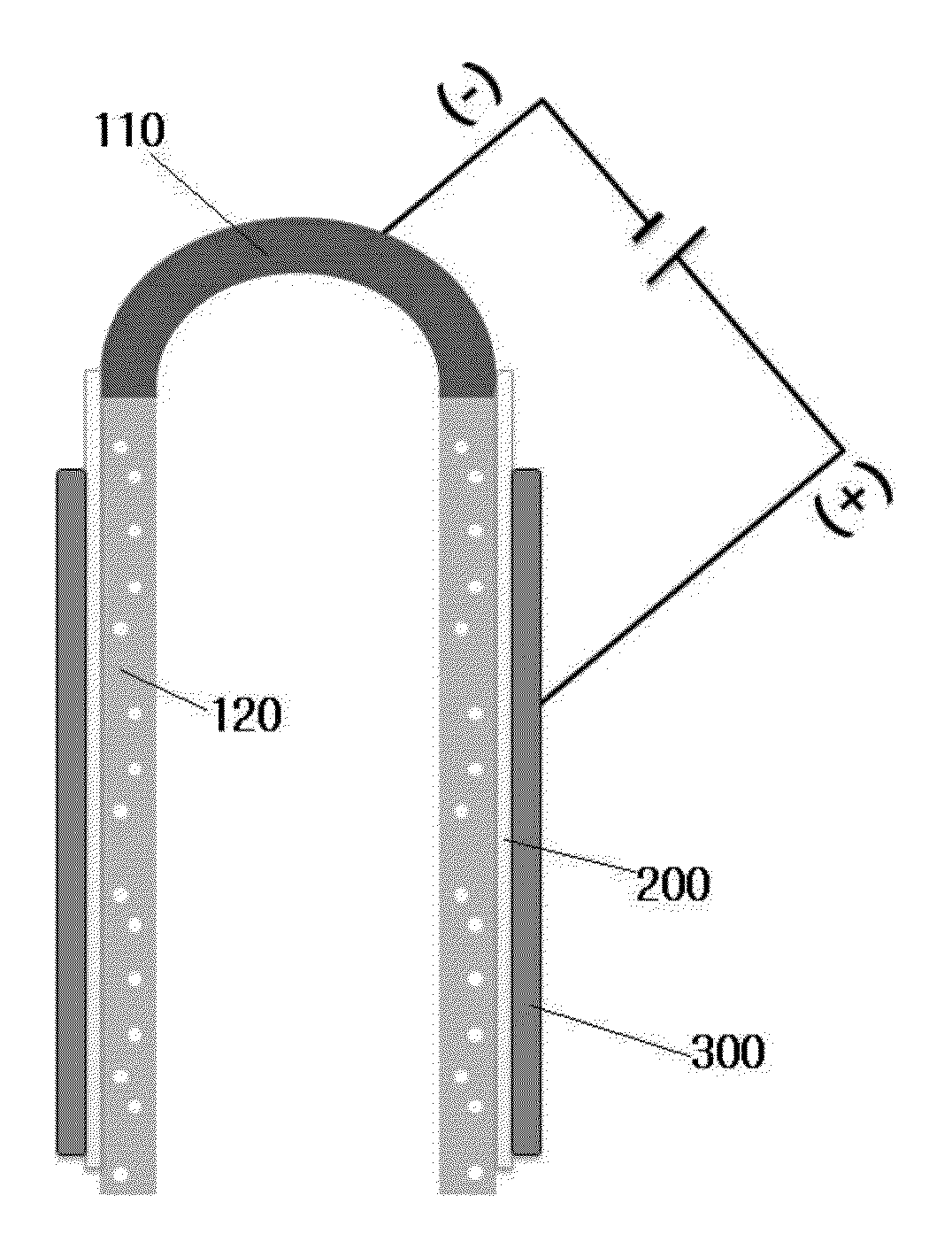

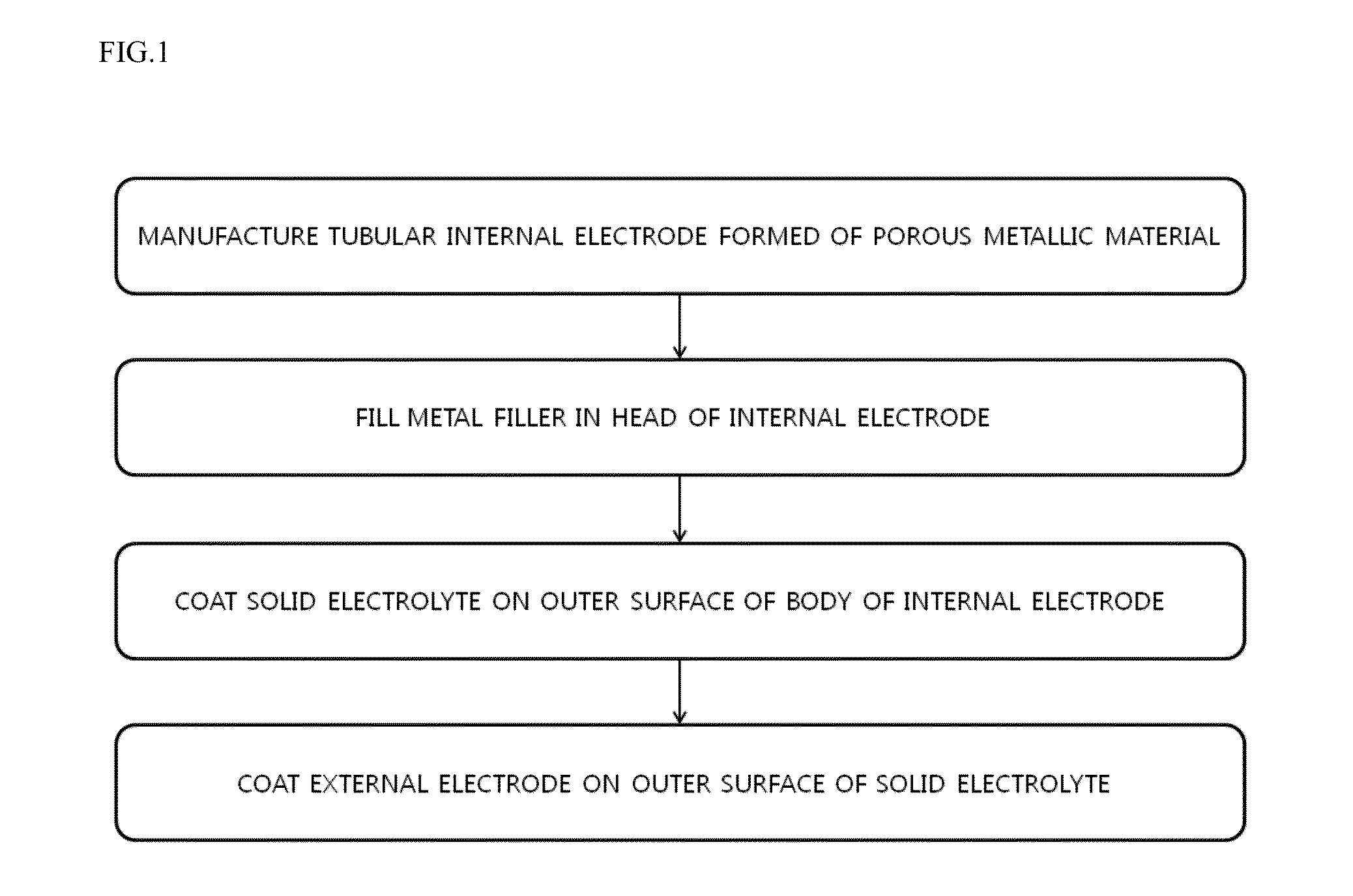

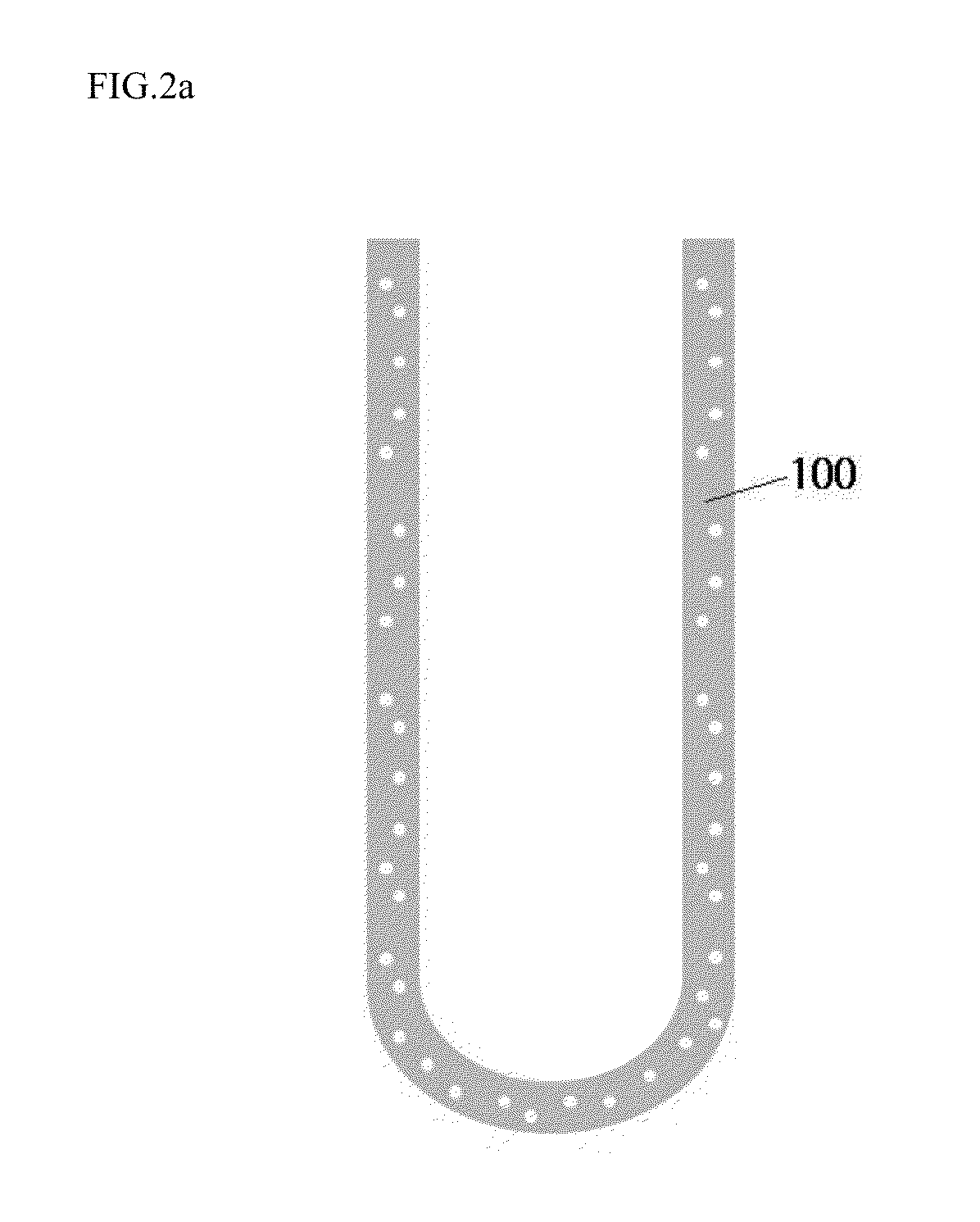

Amtec unit cell with partially opened internal electrode and method for manufacturing the amtec cell

ActiveUS20140202513A1Dense fine structureOvercome difficultiesMolten spray coatingThermoelectric device with peltier/seeback effectElectricityElectrical battery

Disclosed are an open internal electrode AMTEC unit cell, a method for manufacturing the same and a method for connecting circuits. In order to overcome the difficulty in collecting electricity within a conventional AMTEC unit cell, an internal electrode of which a portion is open to the outside, so that the internal electrode and an external electrode can be electrically connected to each other at the outside of the unit cell, and a metal support is used as the internal electrode, so that the internal electrode has durability and stability, and a solid electrolyte is formed in the form of a thin film, and as a result, the AMTEC unit cell has an improved efficiency and a simpler manufacturing process.

Owner:KOREA INST OF ENERGY RES

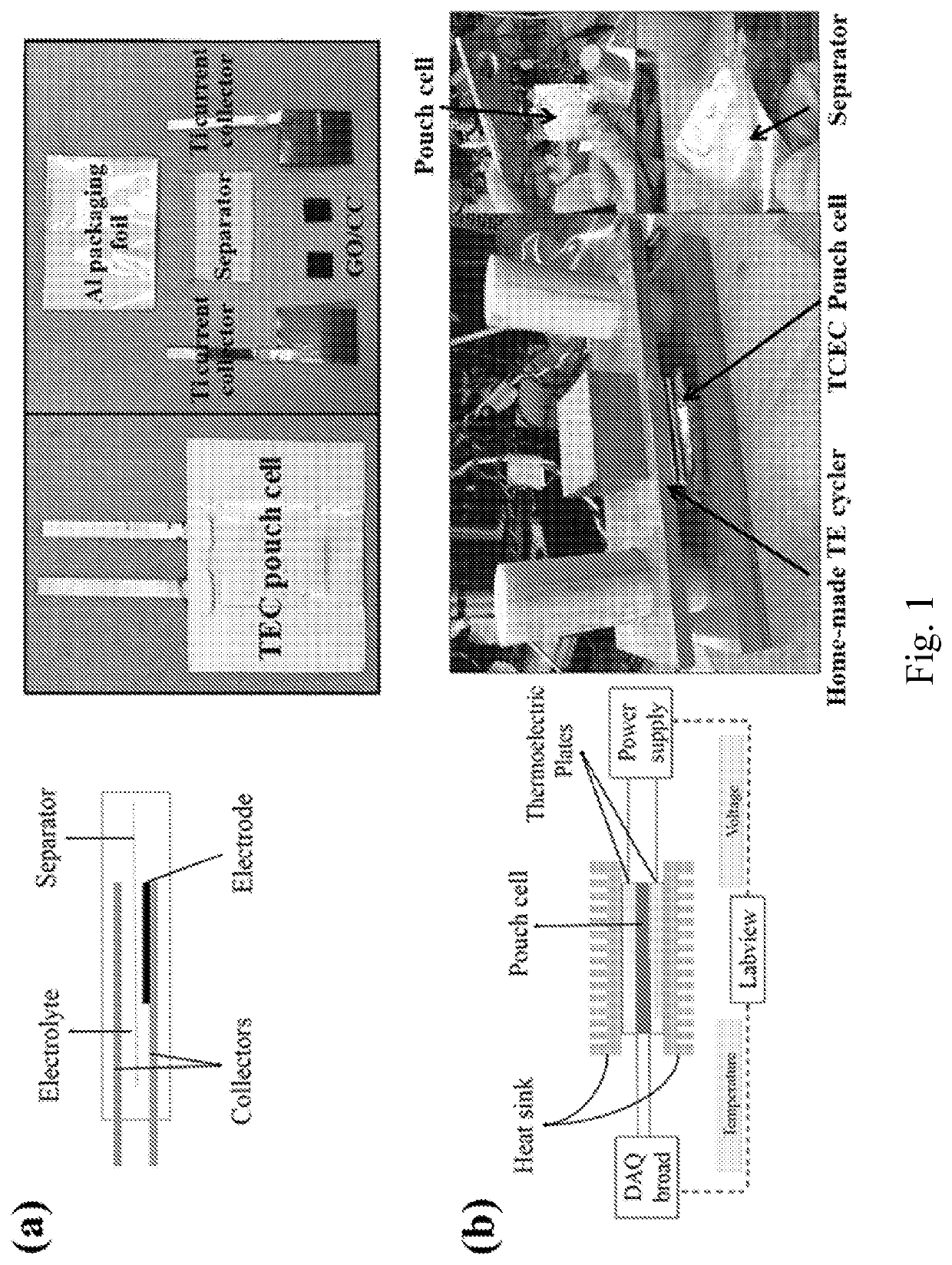

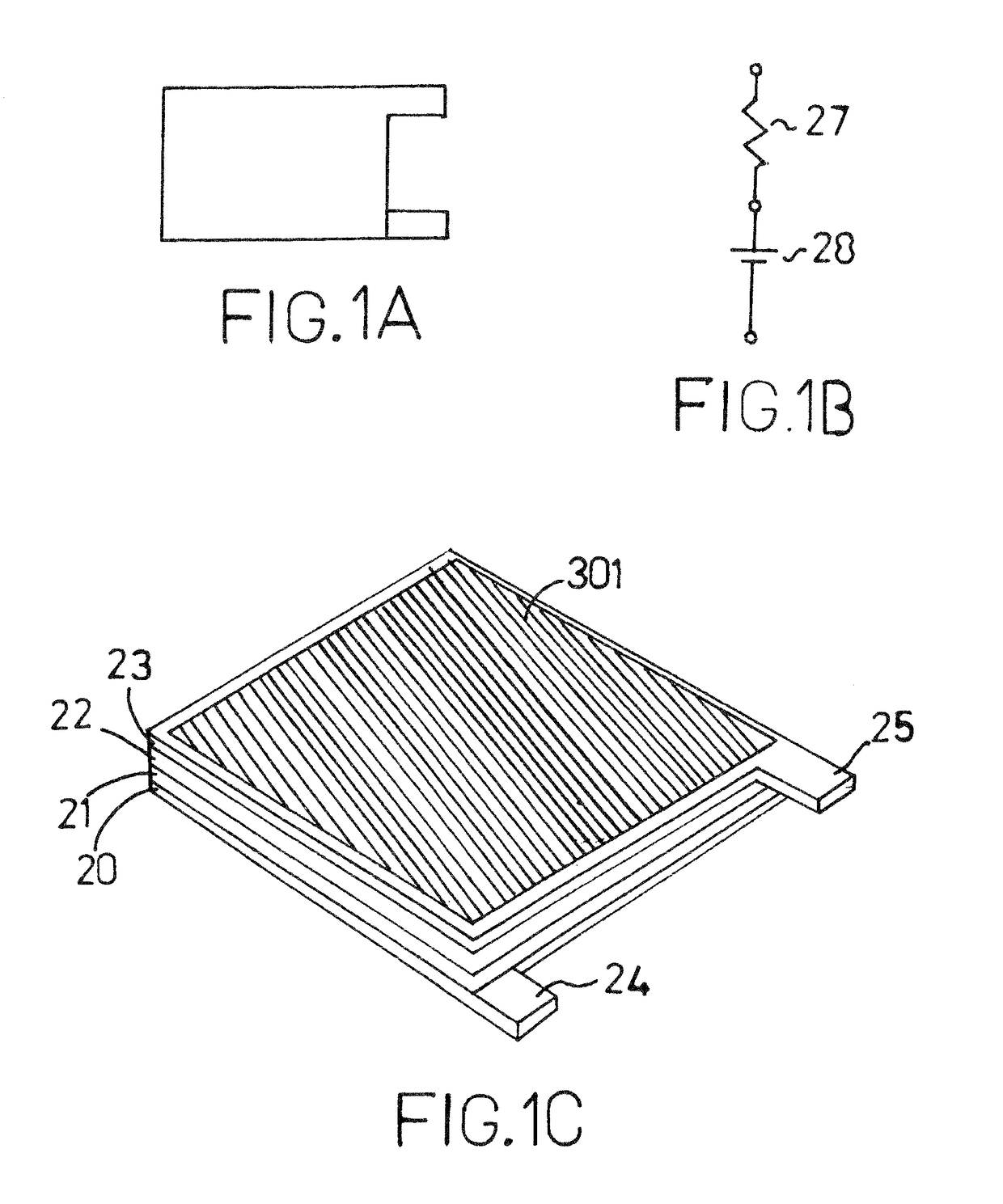

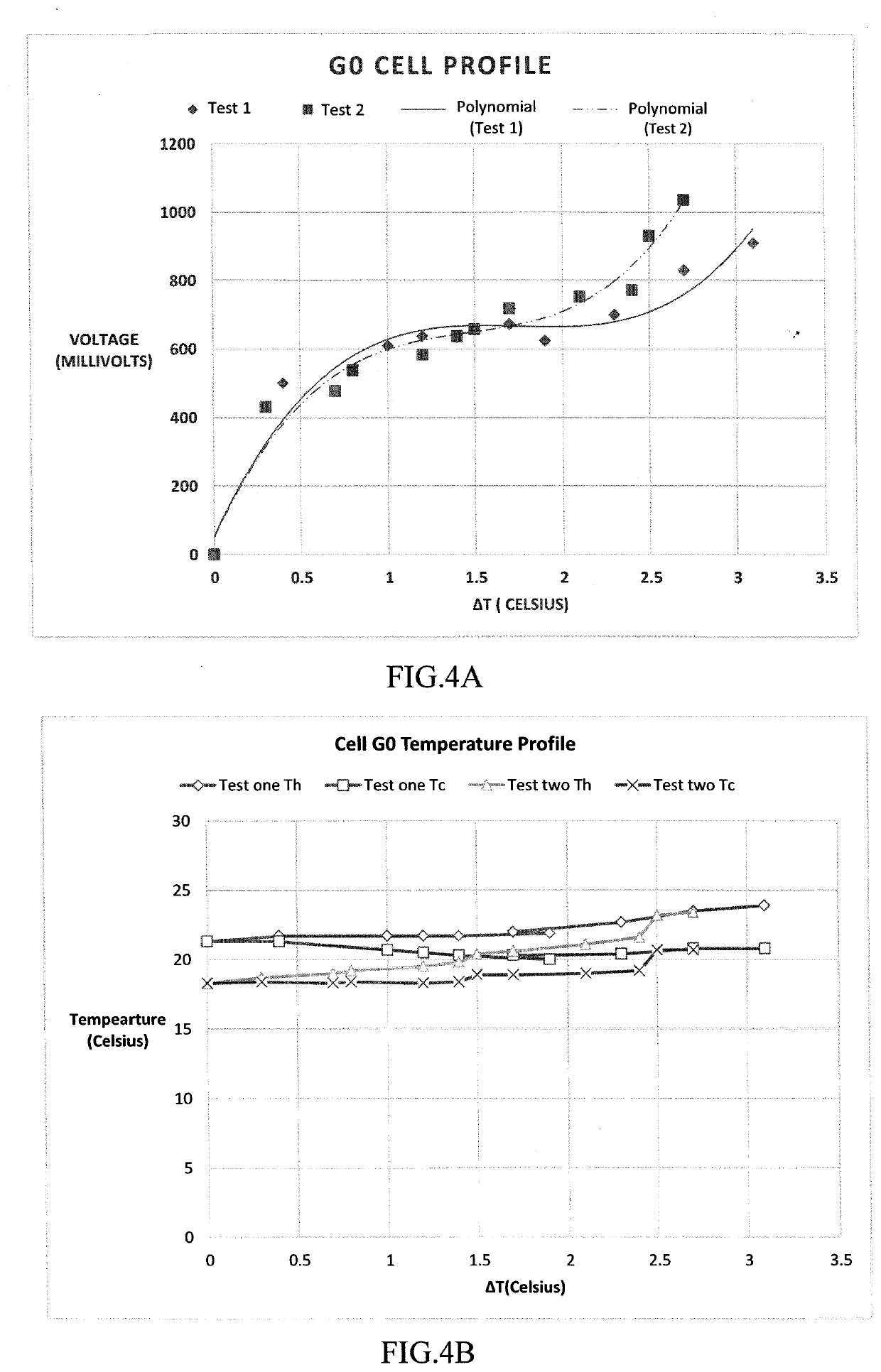

Thermo-electric capacitor

ActiveUS20210366659A1Improvement factorFast dynamicsCell electrodesCapacitor electrolytes/absorbentsConductive polymerElectrical battery

Devices that convert heat into electricity, and methods for a fabrication of the same are provided. The asymmetric thermo-electrochemical capacitor uses a GO-based positive electrode and a battery-type negative electrode to open up the operating voltage window and enhance the electrical discharge capacity for converting low-grade heat into electricity with excellent efficiency, fast thermo-charging time, and stable cycles. The thermo-electrochemical device includes a carbon-based positive electrode, a conductive polymer or a metal-organic framework as negative electrode, a current collector, and a porous separator.

Owner:VERSITECH LTD

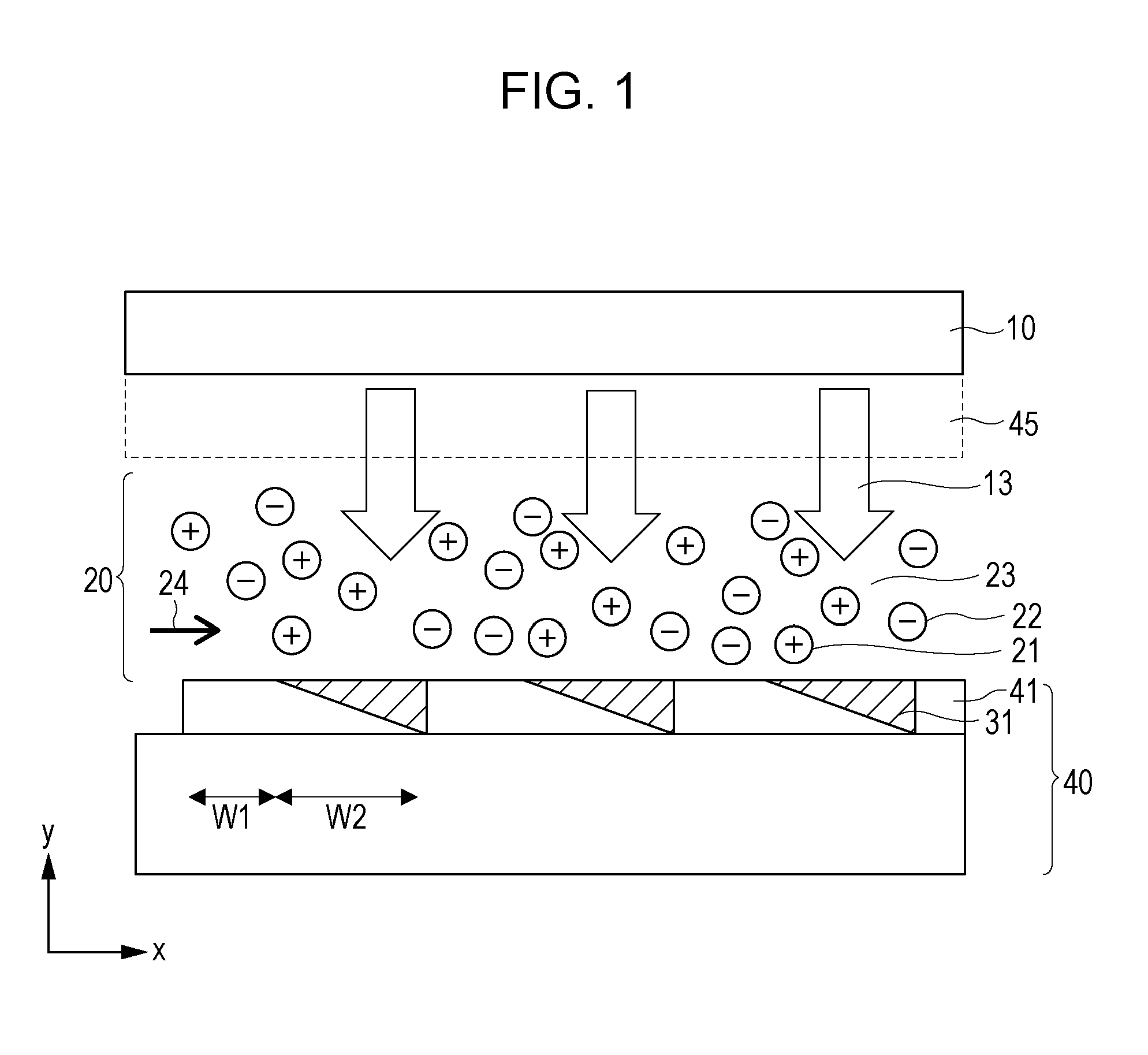

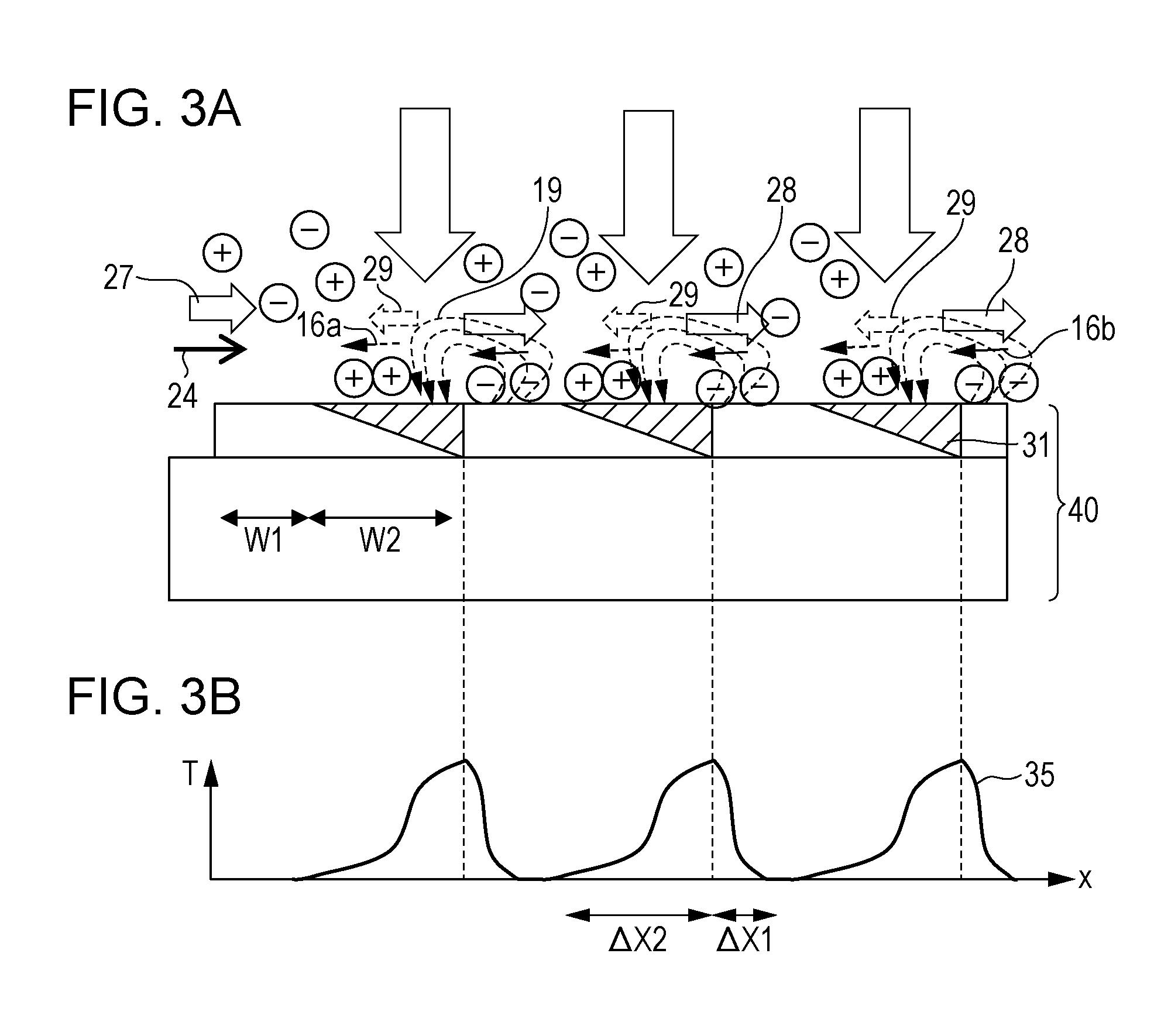

Liquid transport device

A liquid transport device includes a channel, a substrate, and a light radiation unit. A liquid containing ions is transported through the channel. The substrate is disposed at a position where the substrate is in contact with the liquid. The light radiation unit radiates light toward the substrate. In the liquid transport device, an asymmetrical temperature distribution in a direction in which the liquid is transported is produced on a surface of the substrate by the light radiated by the light radiation unit.

Owner:CANON KK

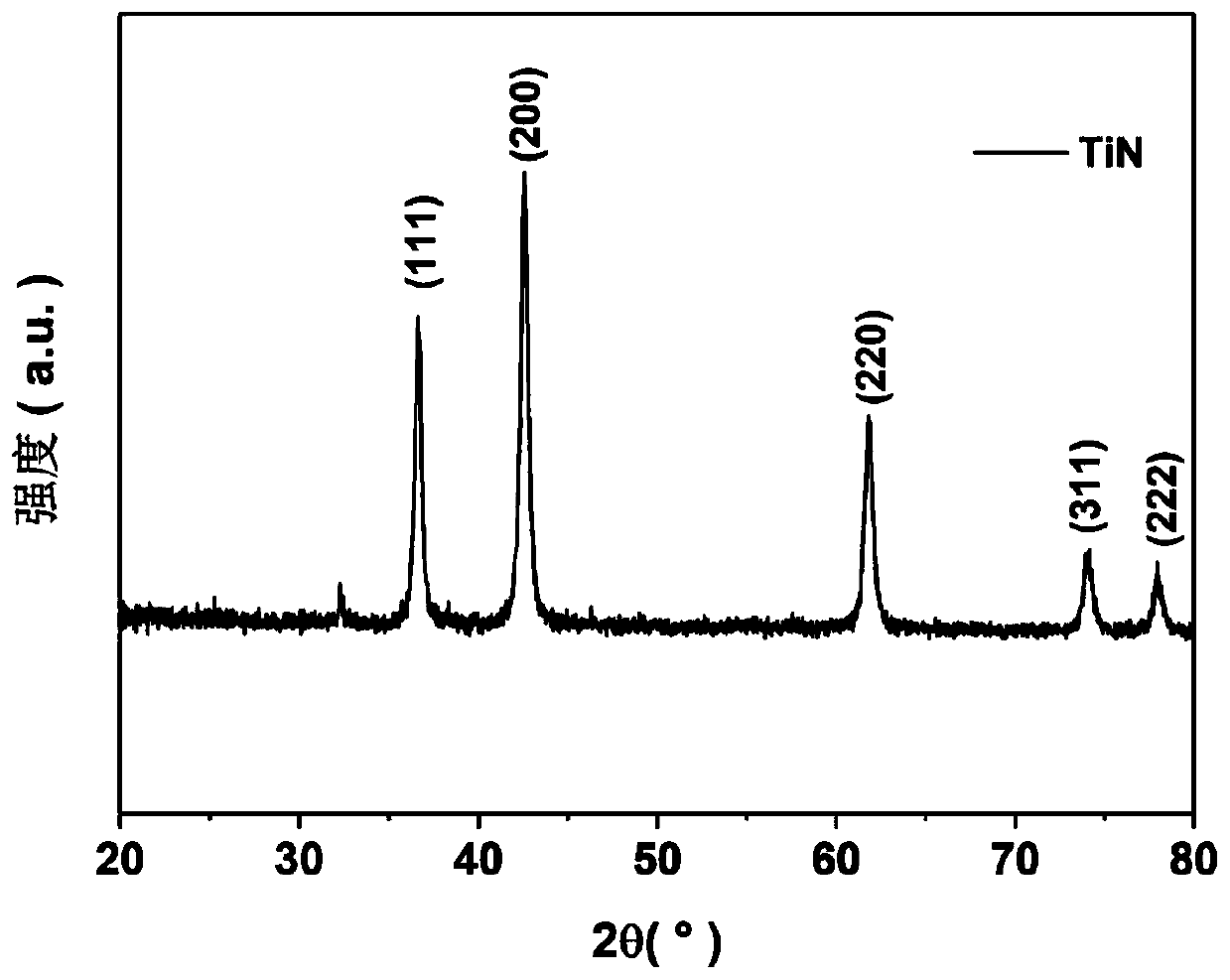

Preparation method of porous TiN electrode material of AMTEC

InactiveCN109950047AGuaranteed activityGuaranteed stabilityTemperature-sensitive devicesPorous electrodeMaterials science

The invention discloses a preparation method of a porous TiN electrode material of an AMTEC, and is used for solving the technical problem that an existing preparation method of the porous TiN electrode material is poor in practicability. According to the technical scheme, the method comprises the steps: dissolving butyl titanate in absolute ethyl alcohol, and adding the obtained mixed solution dropwise into distilled water which is stirred violently to generate precipitates; performing the washing, drying, calcining and high-temperature nitridation of the precipitates to obtain a nano TiN material; performing the surface treatment of a BASE tube, assembling TiN active electrode materials on a cathode and an anode of the BASE tube after surface treatment by adopting a silk-screen printingmethod, and finally heating the BASE tube to obtain the porous electrode of the AMTEC. According to the invention, the method does not employ hydrogen in the preparation process, is simple, is low inpreparation cost, achieves the safe preparation of large-batch coating materials, guarantees the activity and the stability of the electrodes, and is good in practicality.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

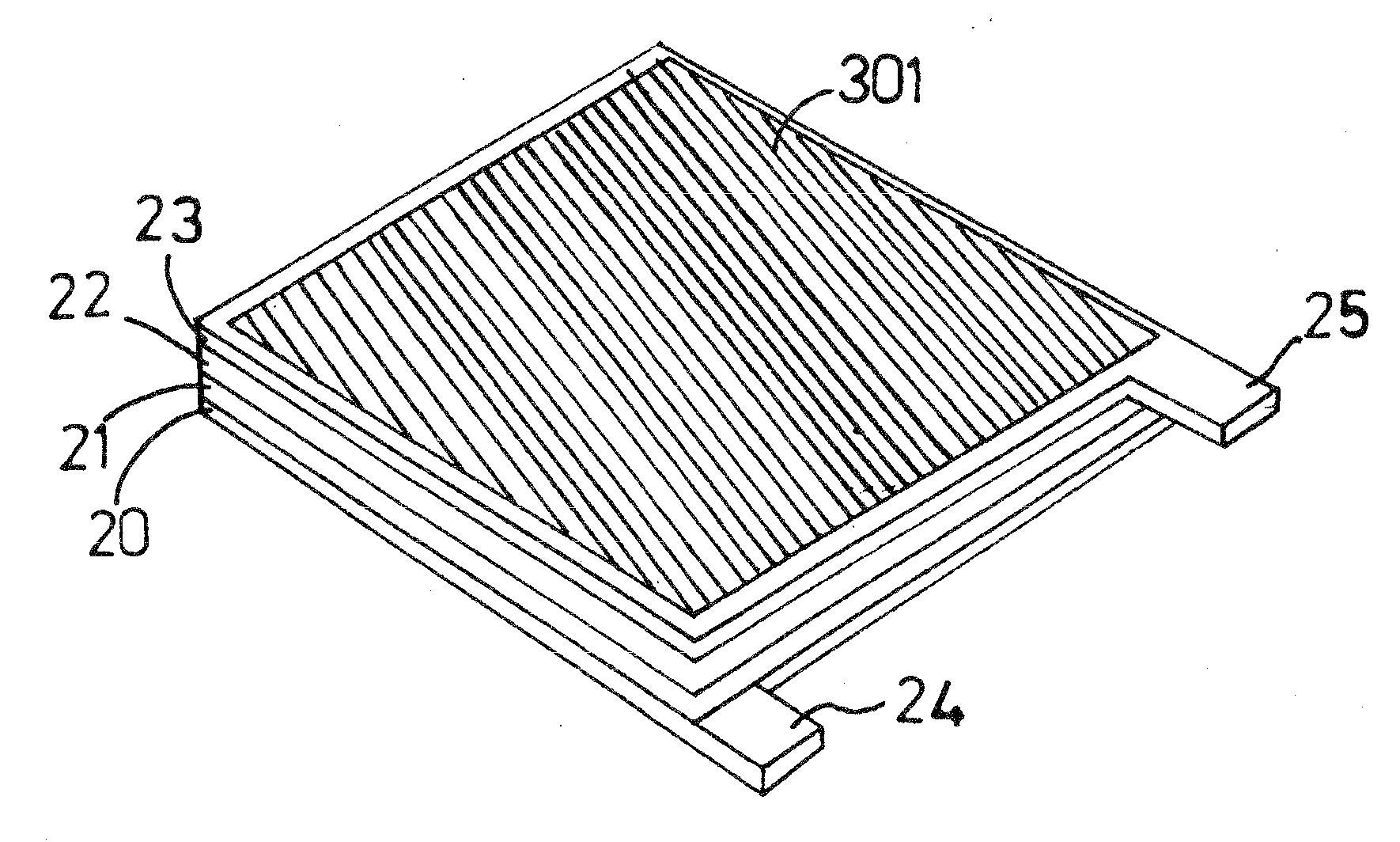

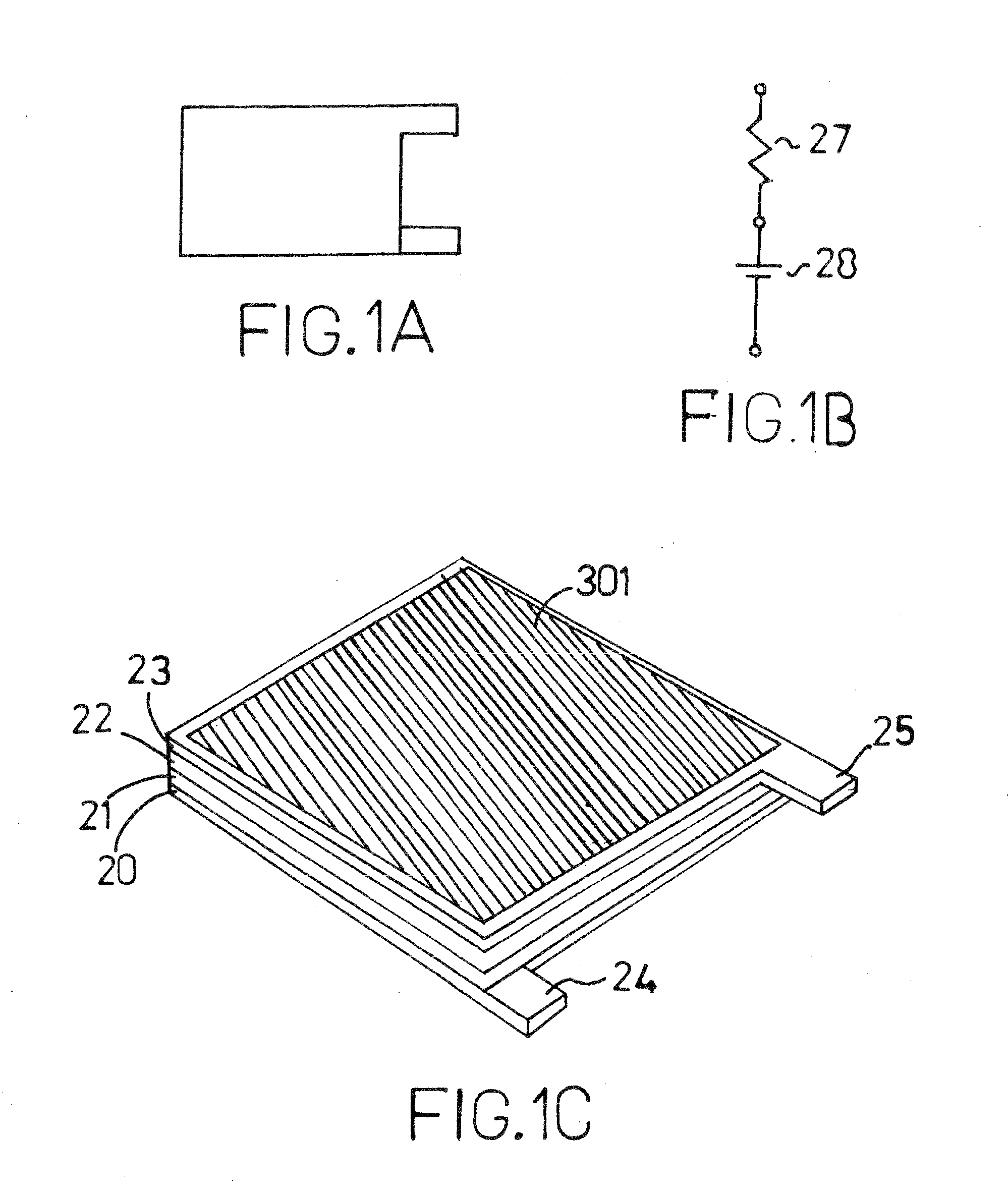

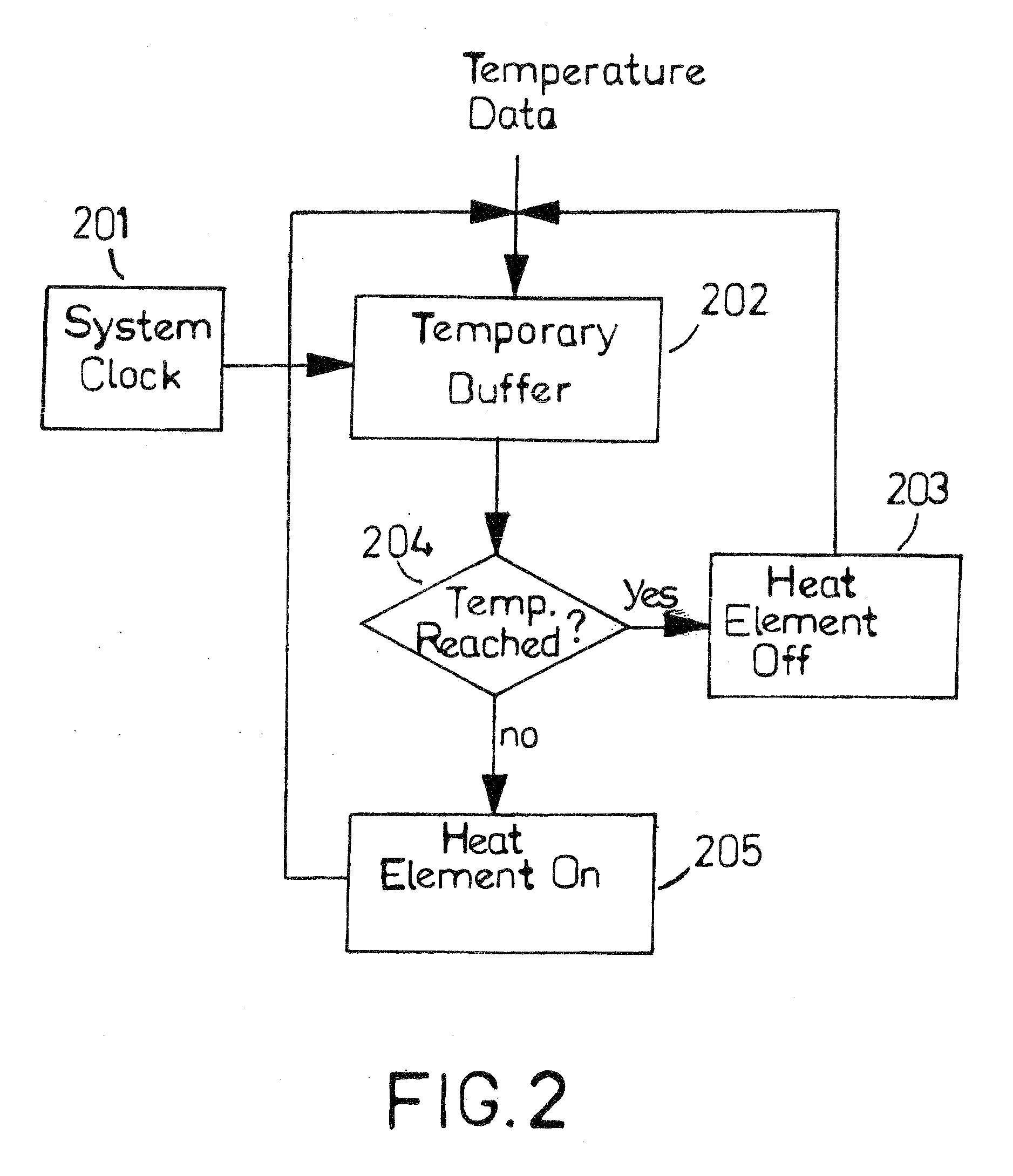

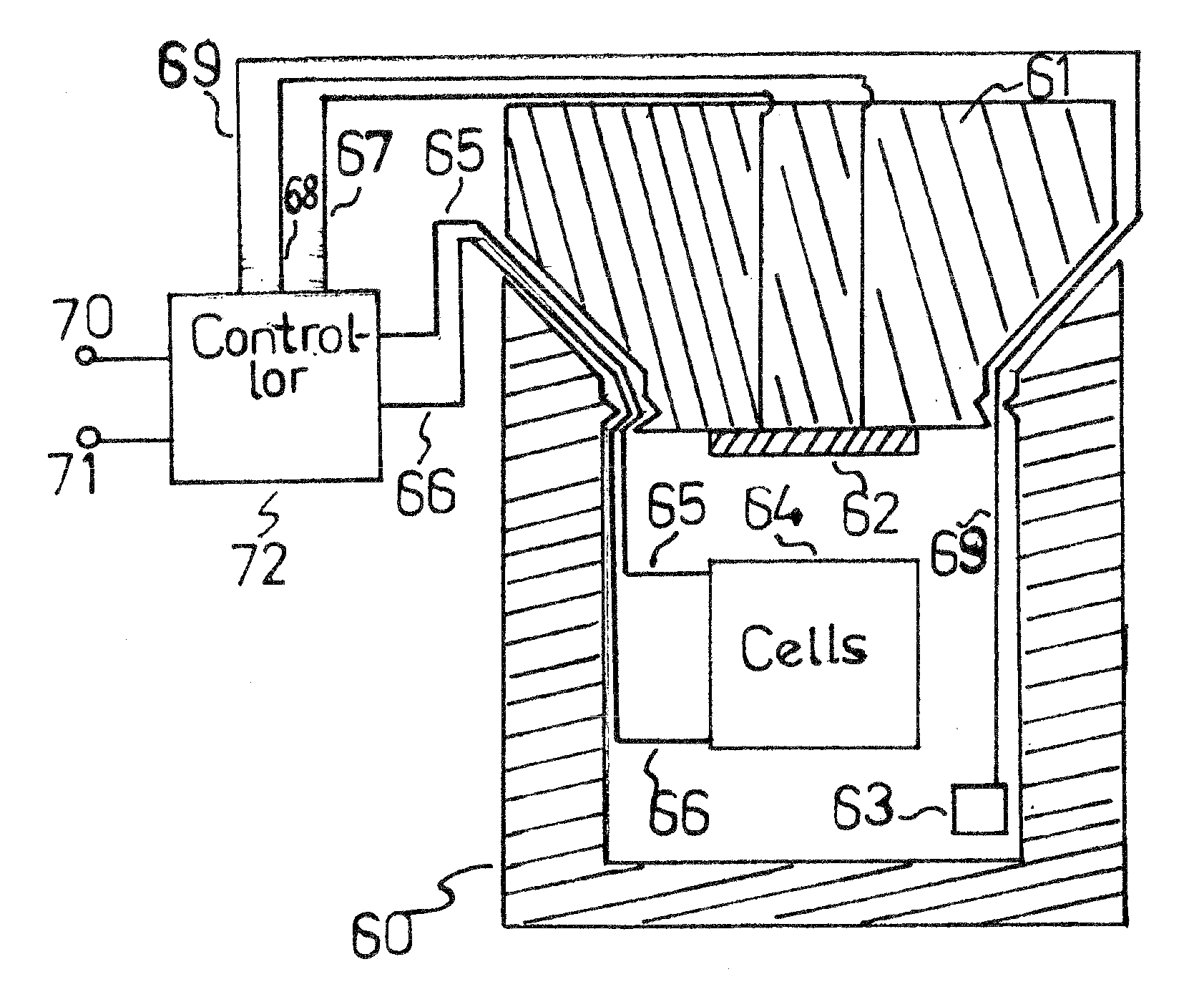

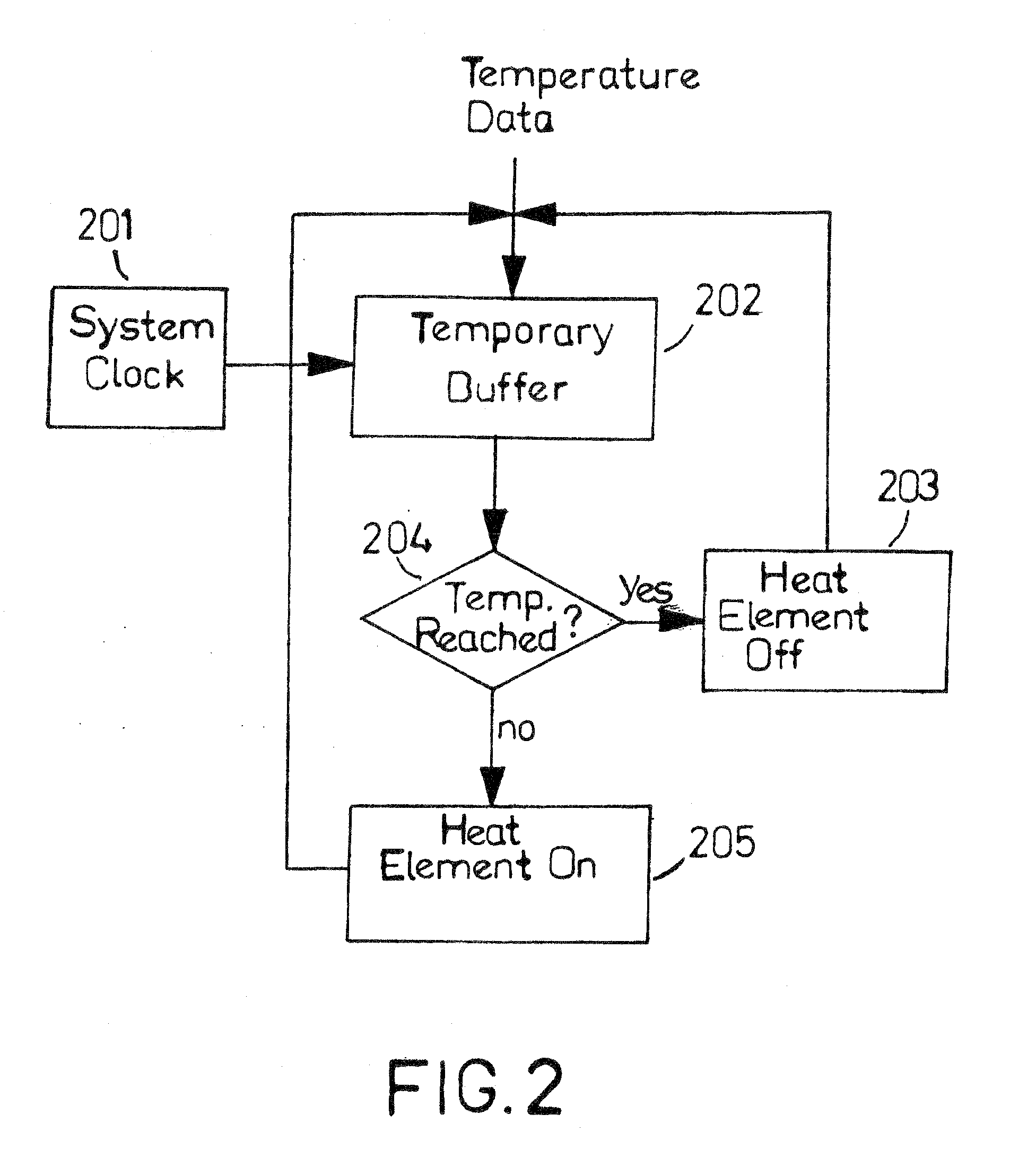

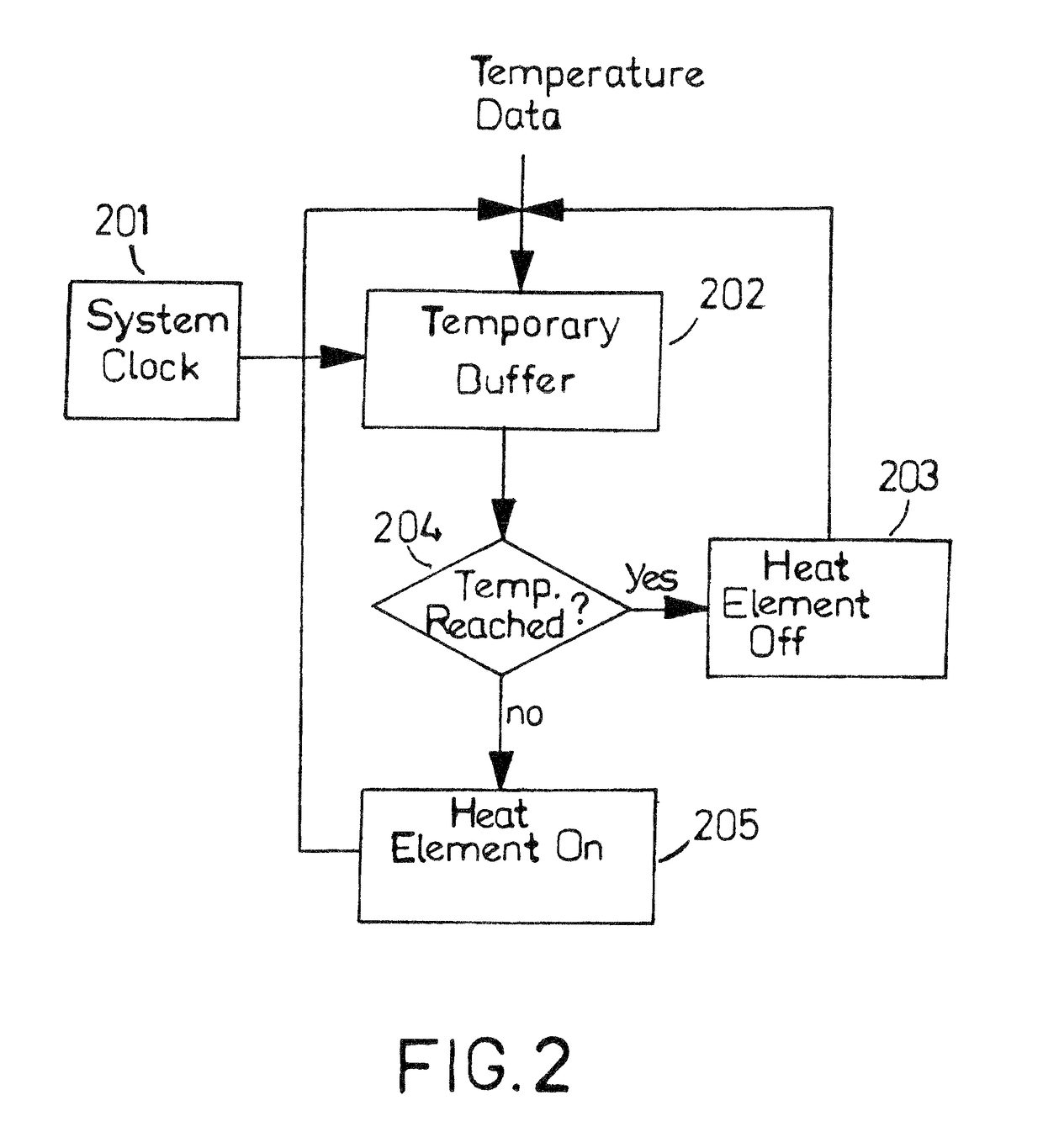

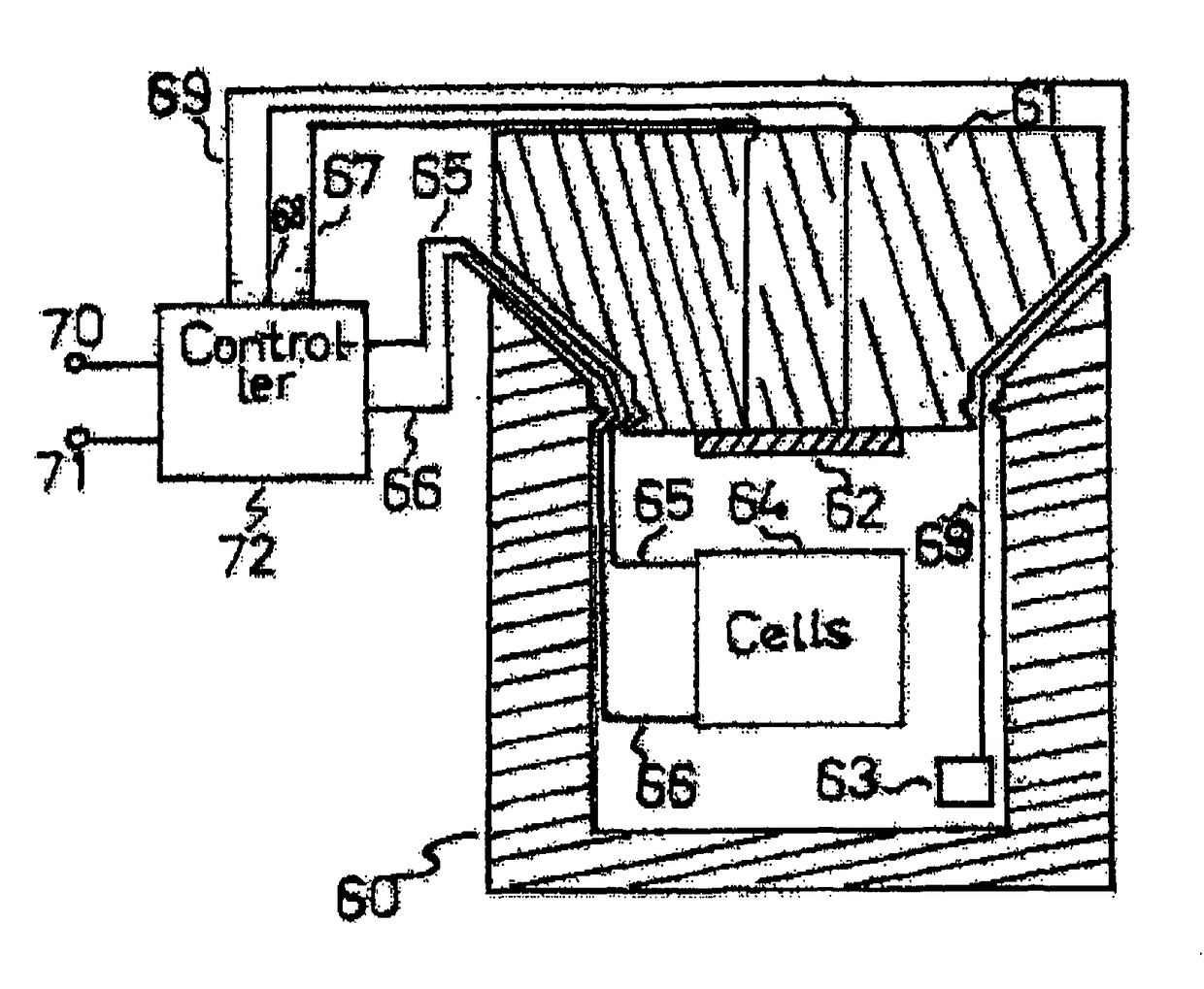

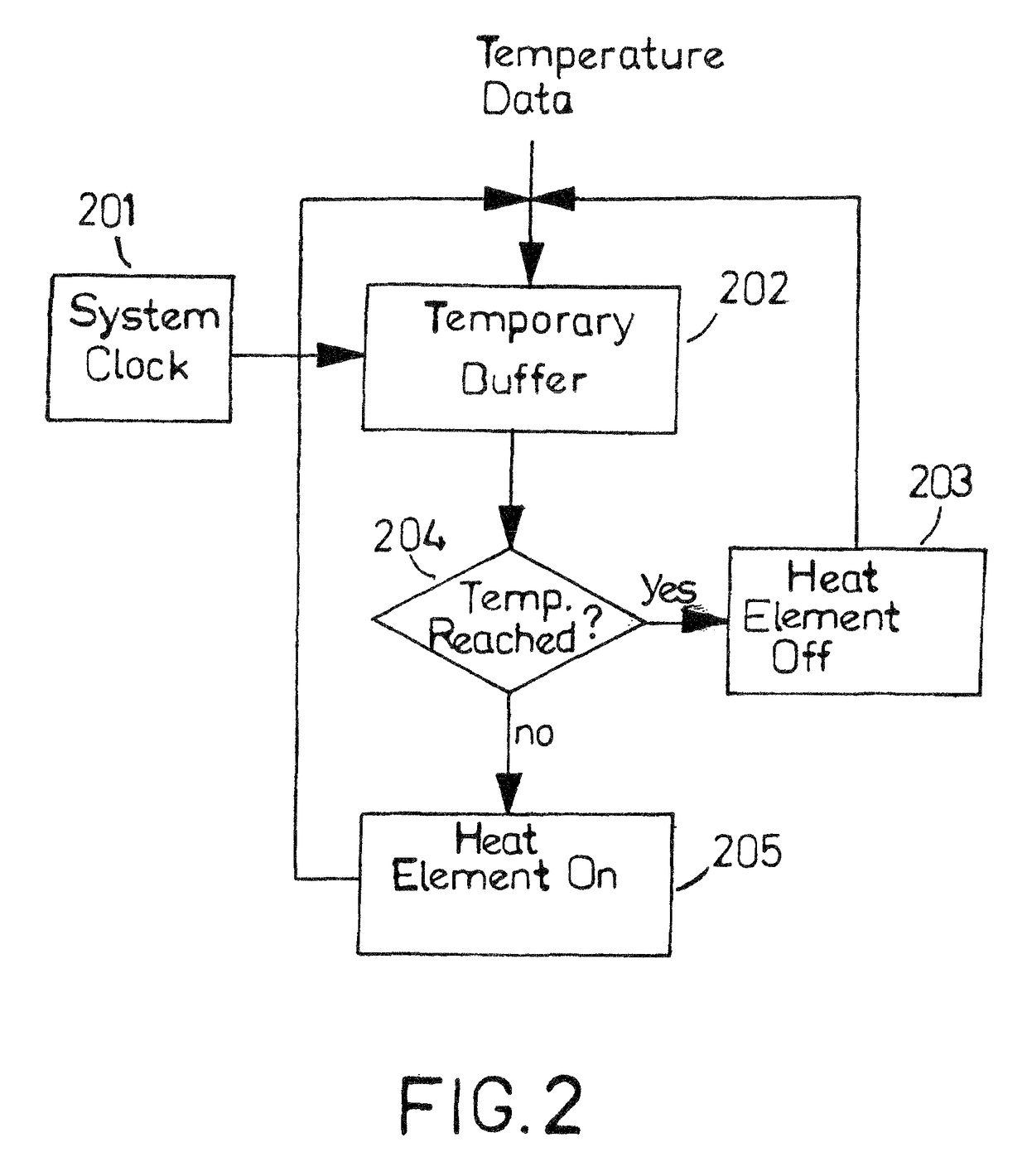

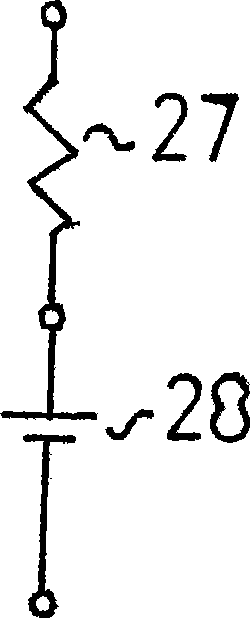

Thermally controllable energy generation system

ActiveUS20130263904A1Easy to manufactureNeed expensiveSolid electrolytic capacitorsThermoelectric device with peltier/seeback effectElectrical batteryHemt circuits

A thermally controllable energy generation system comprising an insulated, thermally-enhanced generator with a power circuit for conveying power. The thermally enhanced generator and its available voltage is controlled by a circuit which changes the ambient temperature of the generator through the use of a heating element and heating circuit. A controller circuit is in communication with the temperature sensor, the control circuit, the heating circuit and the power circuit. The thermally enhanced generator includes at least one cell, which comprises a layer of electron-rich donor material in contact with a layer of hole-rich acceptor material, sandwiched between an anode and a cathode. One of the layers is a stabilized mixture of carbon and an ionic material (carbon matrix) and the other layer is a stabilized oxide mixed with an ionic material (oxide matrix).

Owner:CONCEPTUAL WERKS LLC

Adverse event-resilient network system

ActiveUS9825346B2Easy to manufactureNeed expensiveThermoelectric device with peltier/seeback effectDouble layer capacitorsElectromagnetic shieldingElectromagnetic signal

An adverse event-resilient network system consisting of autonomously powered and mobile nodes in communication with each other either through radio, light or other electromagnetic signals or through a physical connection such as through wiring, cables or other physical connected methods capable of carrying information and communication signals. The nodes powered by an energy generator comprising multiple data, information and voice gathering, receiving and emitting devices as well as mechanical, optical and propulsion devices.

Owner:CONCEPTUAL WERKS LLC

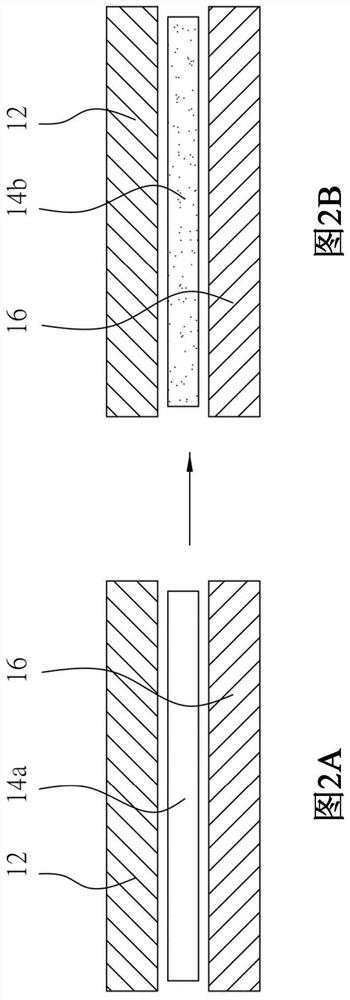

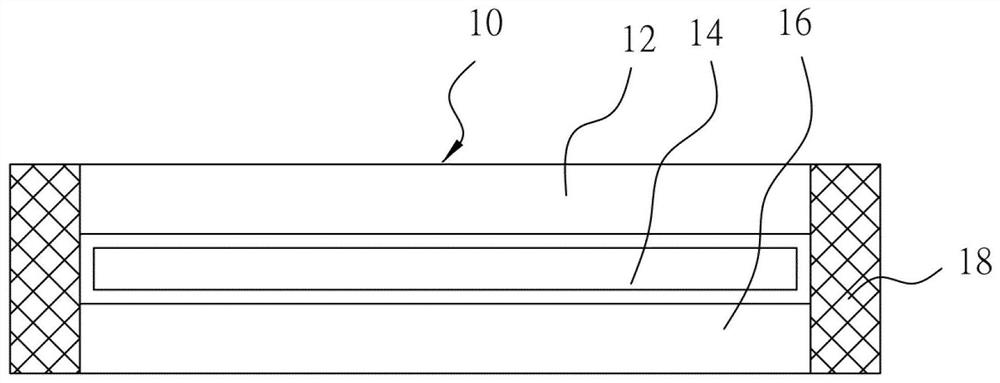

Heat capacitors

ActiveUS20210020362A1Easy to manufactureImprove thermoelectric conversion efficiencyMaterial nanotechnologyHybrid capacitor electrolytesEngineeringThermoelectric conversion

A heat capacitor with simple structure, easy to manufacture and high thermoelectric conversion efficiency is provided. The heat capacitor includes: a pair of electrodes, at least one said electrode being a carbonaceous electrode; and a thermoelectric electrolyte disposed between the pair of electrodes, wherein the distance between the pair of electrodes is at most 1 mm.

Owner:CHANG YU CHE

Thermally controllable energy generation system

ActiveUS9634217B2Easy to manufactureNeed expensiveSolid electrolytic capacitorsThermoelectric device with peltier/seeback effectOxide matrixPower circuits

A thermally controllable energy generation system comprising an insulated, thermally-enhanced generator with a power circuit for conveying power. The thermally enhanced generator and its available voltage is controlled by a circuit which changes the ambient temperature of the generator through the use of a heating element and heating circuit. A controller circuit is in communication with the temperature sensor, the control circuit, the heating circuit and the power circuit. The thermally enhanced generator includes at least one cell, which comprises a layer of electron-rich donor material in contact with a layer of hole-rich acceptor material, sandwiched between an anode and a cathode. One of the layers is a stabilized mixture of carbon and an ionic material (carbon matrix) and the other layer is a stabilized oxide mixed with an ionic material (oxide matrix).

Owner:CONCEPTUAL WERKS LLC

Thermally enhanced solid-state generator

ActiveCN101548350AEasy to manufacturePrimary cell maintainance/servicingFinal product manufactureElectron densityResistive load

A solid state energy conversion device along with its production methods and systems of use is provided. The device in its most basic form consists of two layers, in contact with each other, of dissimilar materials in terms of electron density and configuration, sandwiched between metal layers, which serve as the anode and cathode of the device. One of the inside layers is made of a stabilized mixture of carbon and an ionic material (carbon matrix). The other inner material consists of a stabilized oxide mixed with an ionic material (oxide matrix). This device takes advantage of the built-in potential that forms across the barrier between the carbon matrix and the oxide matrix. The built-in potential of the device (when not attached to a resistive load at the terminals), which is determined mathematically by integrating the electrostatic forces that have created themselves across the barrier, will rise or fall in direct proportion to the rise and fall of the device temperature (in kelvins). When a load is attached across the terminals of the device, current flows. Depending on the size of the load or the surface area of the device, a reduced current will allow sustained recombination such that the built-in potential and current remains steady overtime. Otherwise, the current curve will fall over time similar to a capacitor device. Experimentation shows that current rises by the fourth power of the temperature factor.

Owner:托马斯·贝雷蒂茨

Heat capacitors

PendingCN112234220ASimple structureEasy to manufactureMaterial nanotechnologyHybrid capacitor electrolytesEngineeringThermoelectric conversion

A heat capacitor with simple structure, easy to manufacture and high thermoelectric conversion efficiency is provided. The heat capacitor includes: a pair of electrodes, at least one said electrode being a carbonaceous electrode; and a thermoelectric electrolyte disposed between the pair of electrodes, wherein the distance between the pair of electrodes is at most 1 mm.

Owner:张宇彻

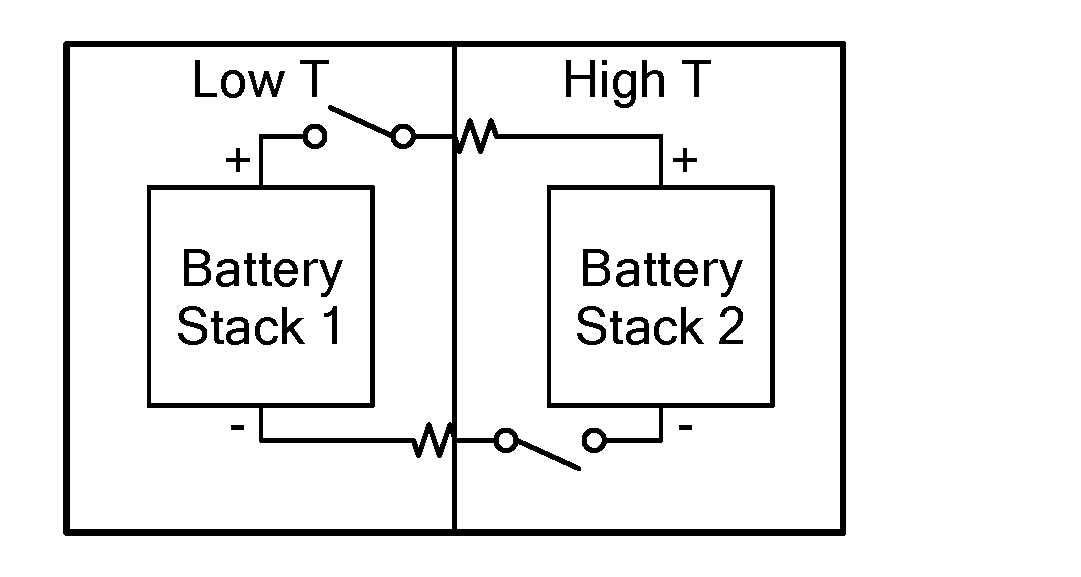

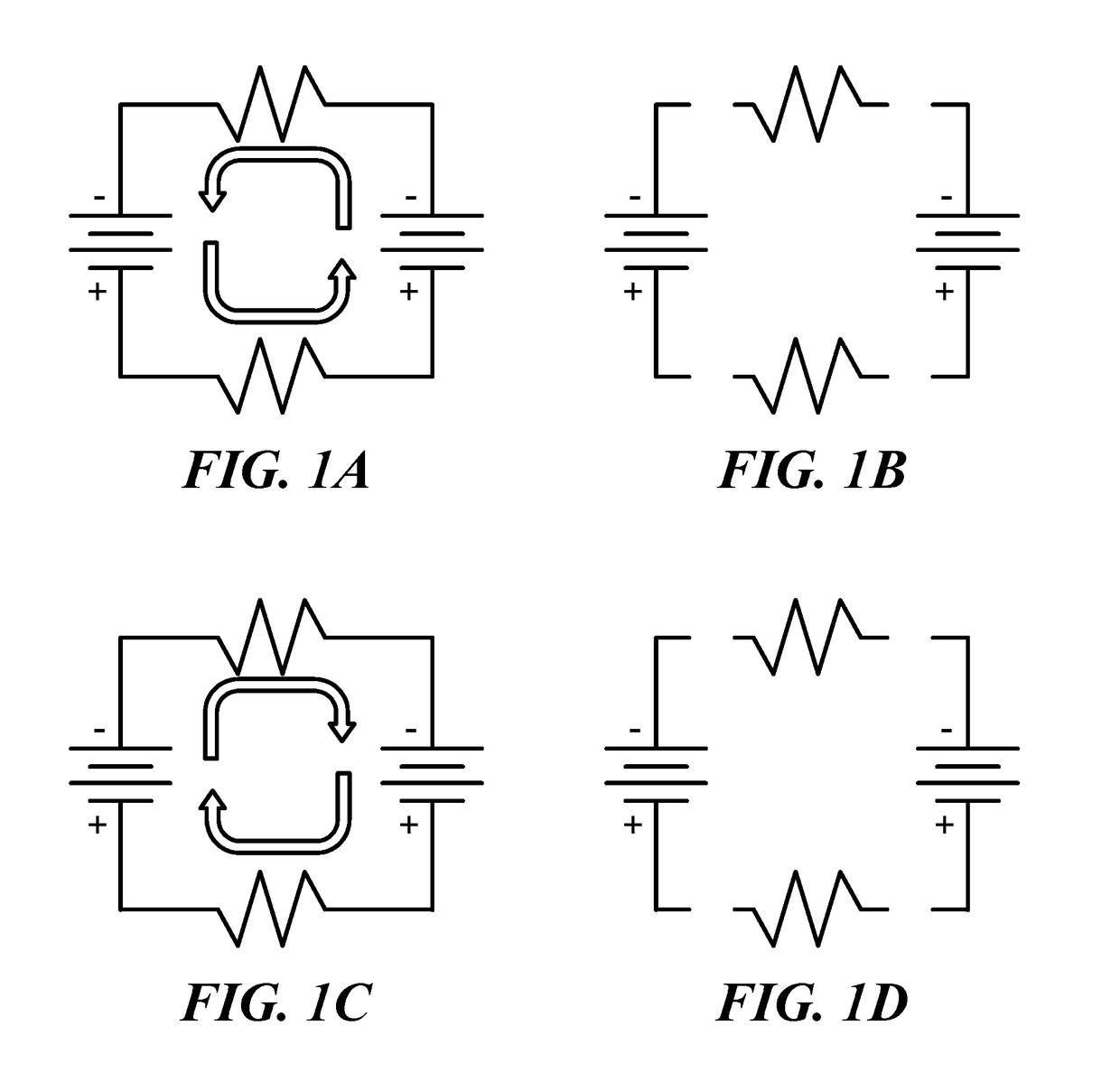

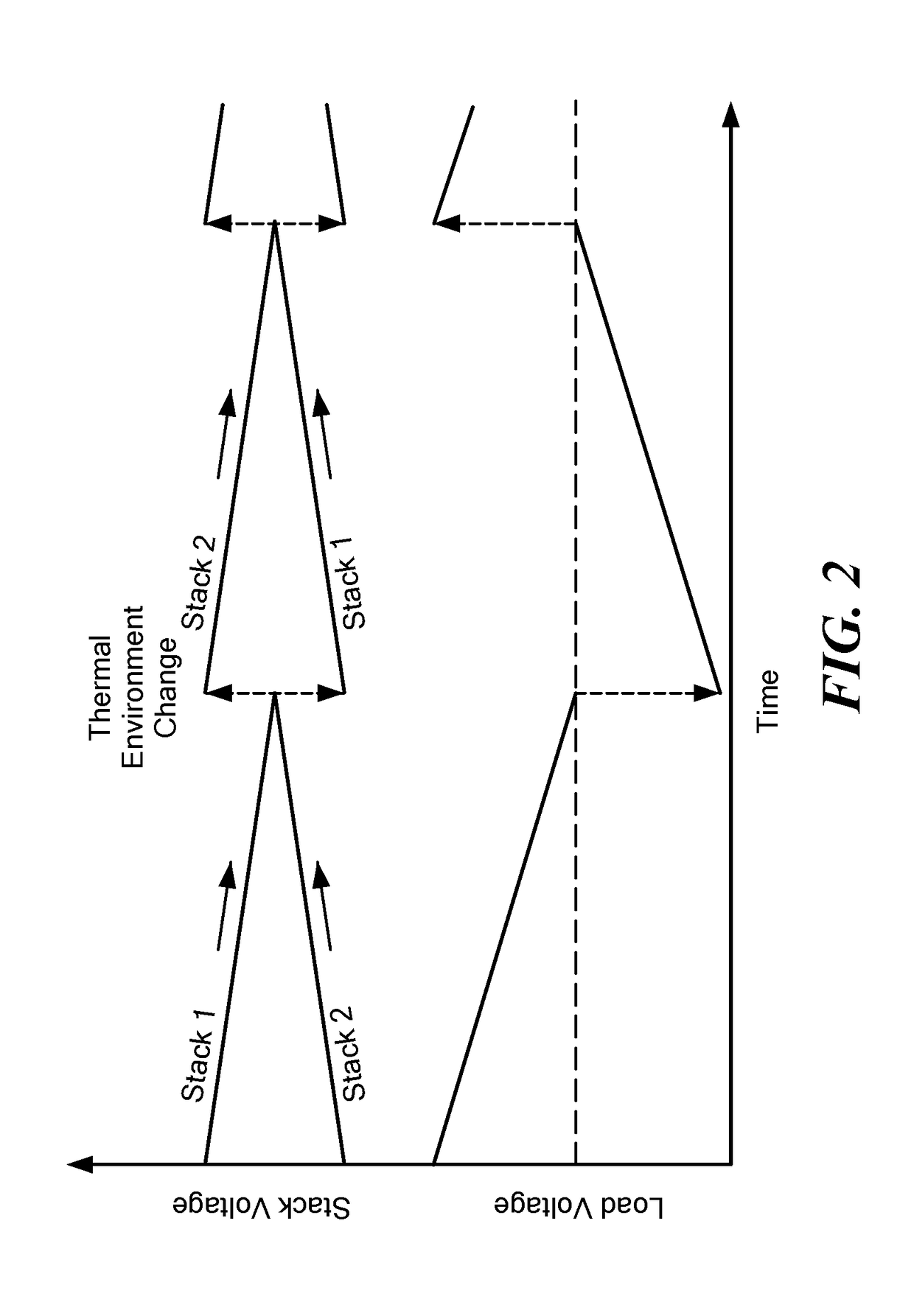

Electrochemical Stack Direct Heat To Electricity Generator

ActiveUS20180323480A1Cells structural combinationSecondary cells charging/dischargingElectrical batteryEngineering

A thermogalvanic electrochemical system includes two battery sources connected together in a switchable circuit to provide electric current to an electrical load in the circuit. The battery sources are located in a thermal environment having a varying temperature, and each battery source has a corresponding electrical potential that varies with temperature of the thermal environment. A power management processor operates the circuit to: form a closed circuit at a first temperature with current flow from a first battery source through the electrical load to a second battery source until reaching a first thermal equilibrium, and then form an open circuit, then form a closed circuit at a second temperature with current flow from the second battery source through the electrical load to the first current source until reaching a second thermal equilibrium, and then form an open circuit.

Owner:MASSACHUSETTS INST OF TECH

Apparatus for enclosing energy storage devices

ActiveUS9779887B2Capacitor collector combinationsMultiple hybrid/EDL capacitorsConductive materialsEngineering

Embodiments of the present disclosure include an apparatus for enclosing energy storage devices. An apparatus according to the present disclosure can include: an elongated sleeve having a contoured interior configured to enclose each of a plurality of energy storage devices, wherein the elongated sleeve is composed at least partially of a thermally conductive material; and at least one slot disposed on an exterior surface of the elongated sleeve, wherein the at least one slot is configured to receive for mechanically coupling a mounting rail to the elongated sleeve.

Owner:IOXUS INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com