Preparation method of porous TiN electrode material of AMTEC

An electrode material and raw material technology, applied in the field of porous TiN electrode material preparation, can solve problems such as poor practicability, and achieve the effects of good practicability, guaranteed activity and stability, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 20ml of the raw material butyl titanate and dissolve it in 200mL of absolute ethanol to prepare a solution with a concentration of 10vol%. Add this solution dropwise to vigorously stirred distilled water. The molar ratio of butyl titanate to distilled water is: Ti:H 2 O=1:150, butyl titanate is hydrolyzed to generate TiO 2 Precipitate.

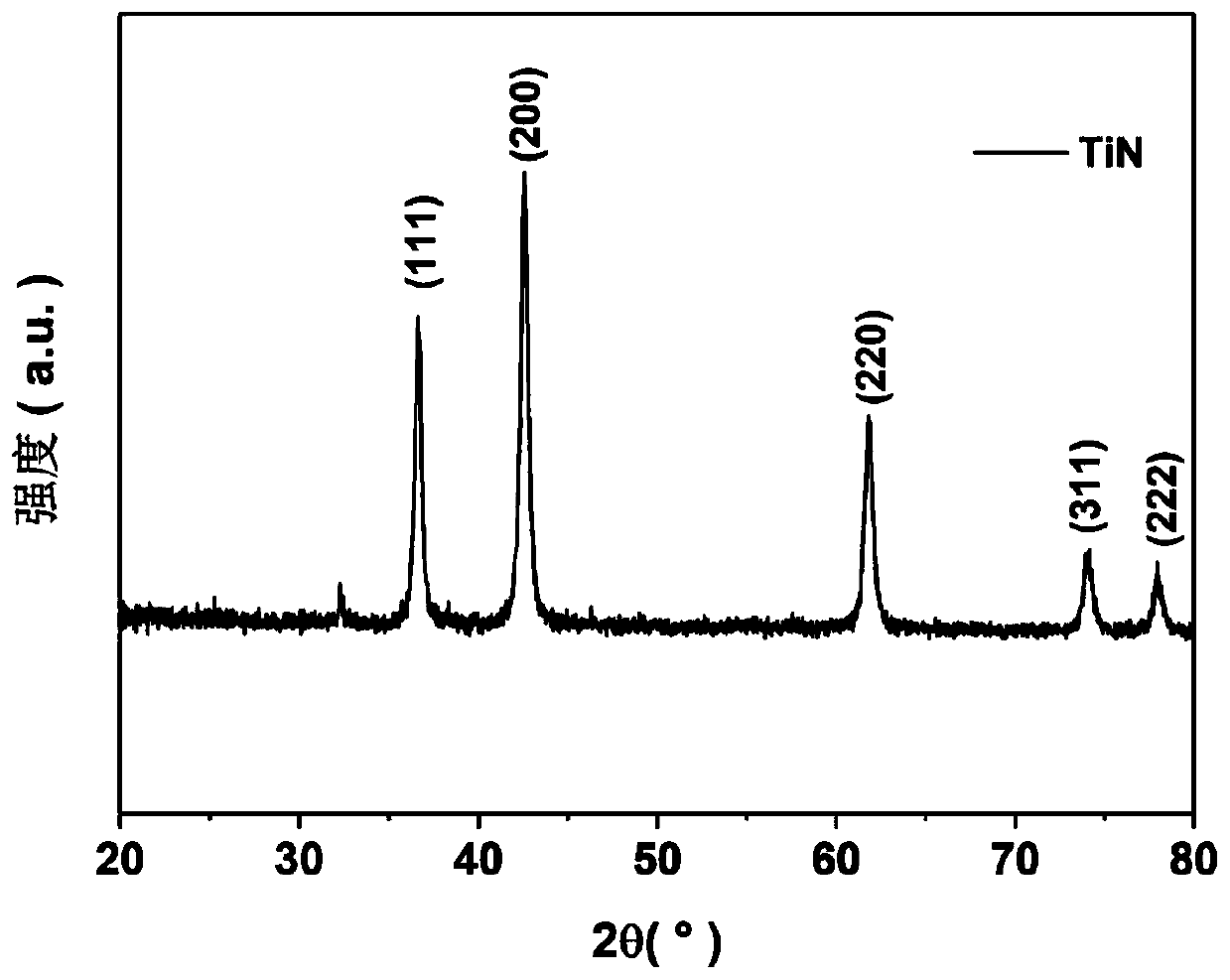

[0028] (2) TiO generated by filtration 2 The precipitate was washed twice with distilled water and then twice with absolute ethanol, and then dried in a drying oven at 120° C. for 12 hours. After drying, the precipitate was calcined in a calcination furnace at a temperature of 700°C and a calcination time of 6 hours to obtain anatase nano-TiO 2 Powder. The obtained powder was placed in a quartz boat and nitrided in a tube furnace with a nitriding temperature of 1000°C and a nitriding time of 5 hours. After nitriding the powder, it was cooled to room temperature under the protection of ammonia gas to obtain nano-TiN powder...

Embodiment 2

[0037] (1) Weigh 25ml of the raw material butyl titanate and dissolve it in 200mL of absolute ethanol to prepare a solution with a concentration of 12.5vol%. Add this solution dropwise to vigorously stirred distilled water. The molar ratio of butyl titanate to distilled water is: Ti:H 2 O=1:150, butyl titanate is hydrolyzed to generate TiO 2 Precipitate.

[0038] (2) TiO generated by filtration 2 The precipitate was washed 5 times with distilled water and then 5 times with absolute ethanol, and then dried in an oven at 80°C for 8 hours. After drying, the precipitate was calcined in a calcination furnace at a temperature of 300°C and a calcination time of 2 hours to obtain anatase nano-TiO 2 Powder. The obtained powder was placed in a quartz boat and nitrided in a tube furnace at a nitriding temperature of 800° C. and a nitriding time of 2 hours. After nitriding the powder, it was cooled to room temperature under the protection of ammonia gas to obtain nano-TiN powder.

...

Embodiment 3

[0047] (1) Weigh 30ml of the raw material butyl titanate and dissolve it in 200mL of absolute ethanol to prepare a solution with a concentration of 15vol%. This solution was added dropwise to vigorously stirred distilled water, and butyl titanate was hydrolyzed to generate TiO 2 , finally controlling the molar ratio of butyl titanate to distilled water: Ti:H 2 O=1:150.

[0048] (2) After filtering the precipitate generated by hydrolysis, wash twice with distilled water, then wash twice with absolute ethanol, then dry at 100°C for 10h, and finally burn at 500°C for 4h in a calciner to obtain anatase Nano-TiO 2 Powder. Nano TiO 2 Put the powder into a quartz boat, and use ammonia as a reducing agent in a tubular atmosphere furnace at 1500°C for 3 hours of nitriding. Under the protection of ammonia, cool to room temperature to obtain nano-TiN powder.

[0049] (3) Use 400 mesh, 800 mesh, 1200 mesh, and 2000 mesh sandpaper to treat the surface of the BASE tube uniformly. A BA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com