Alkali metal thermo-electric direct converter

An alkali metal, converter technology, used in electrical components, generators/motors, generators that convert kinetic energy into electrical energy, etc., and can solve problems such as harsh energy conversion conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

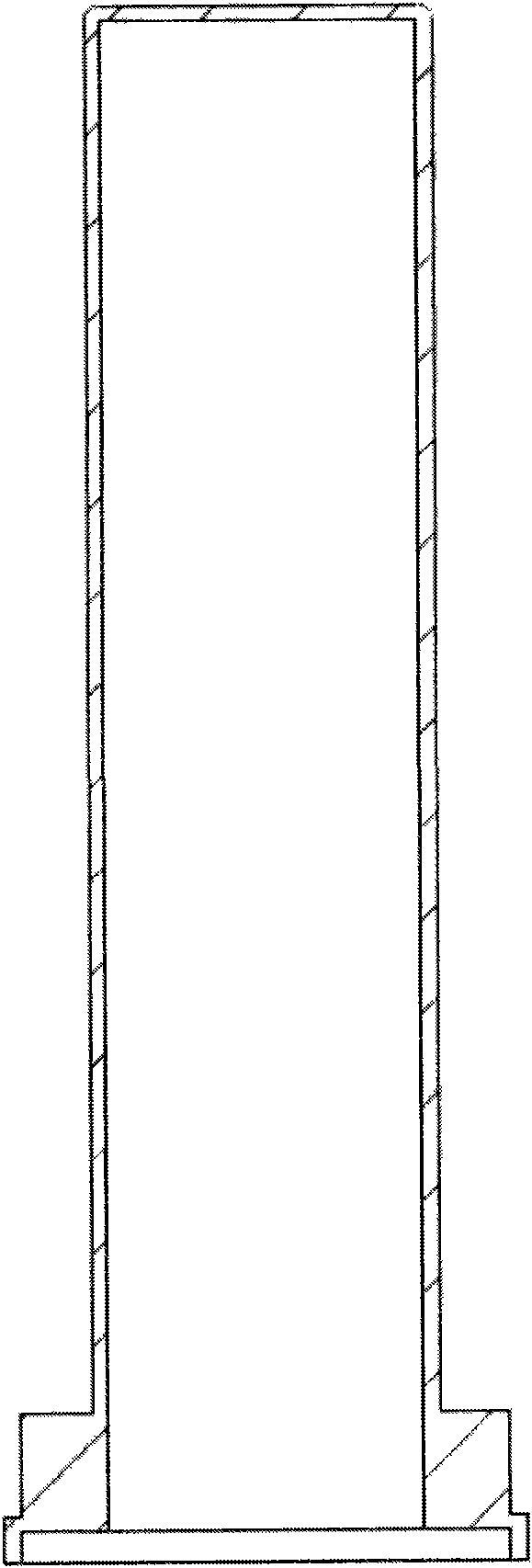

Image

Examples

Embodiment Construction

[0023] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0024] combine Figure 1-Figure 6 , the symbol "||" in the figure means welding. The composition of the alkali metal thermoelectric direct converter includes: exhaust pipe 1, support base 2, upper cover 3, condenser 4, condenser cover 5, upper chamber I 6, capillary core 7, upper chamber II 8, base 9 , capillary core nut 10, lower cavity body I 11, lower cavity body II 12, exhaust pipe nut 13, capillary core base 14, lower cover 15, ceramic base I 16; ceramic base II 17, solid electrolyte with electrodes inside and outside 18. Spring 19, support seat 20, ceramic tube 21, metal cover 22, metal tube 23, evaporator 25, the exhaust pipe 1 is connected to the support seat 2, the support seat 2 is located outside the upper cover 3, and the condenser 4 is located on the upper cover 3 on the back side; the condenser cover 5 is covered on the condenser 4, and the capilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com