Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Turbulent heat flux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

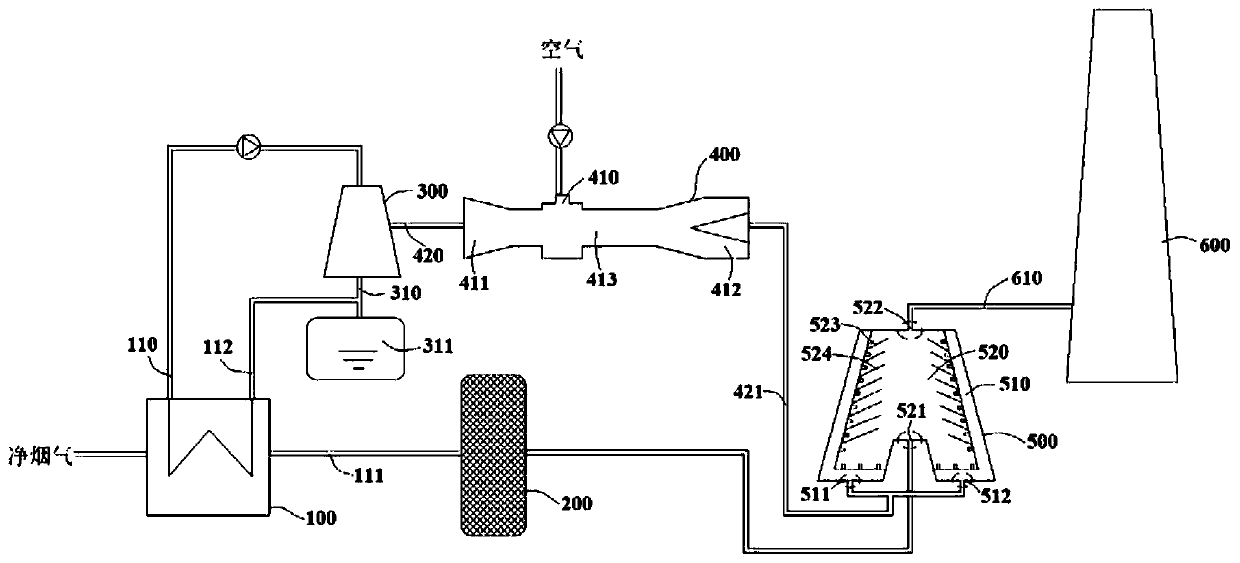

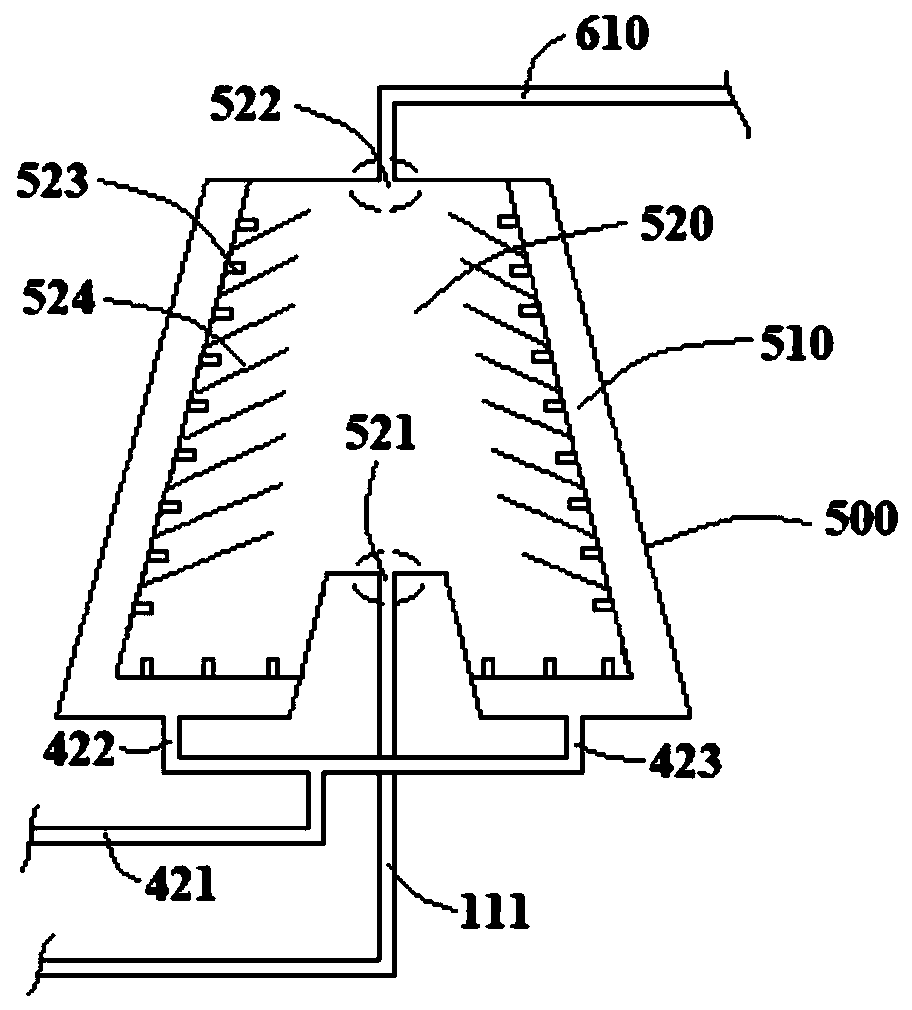

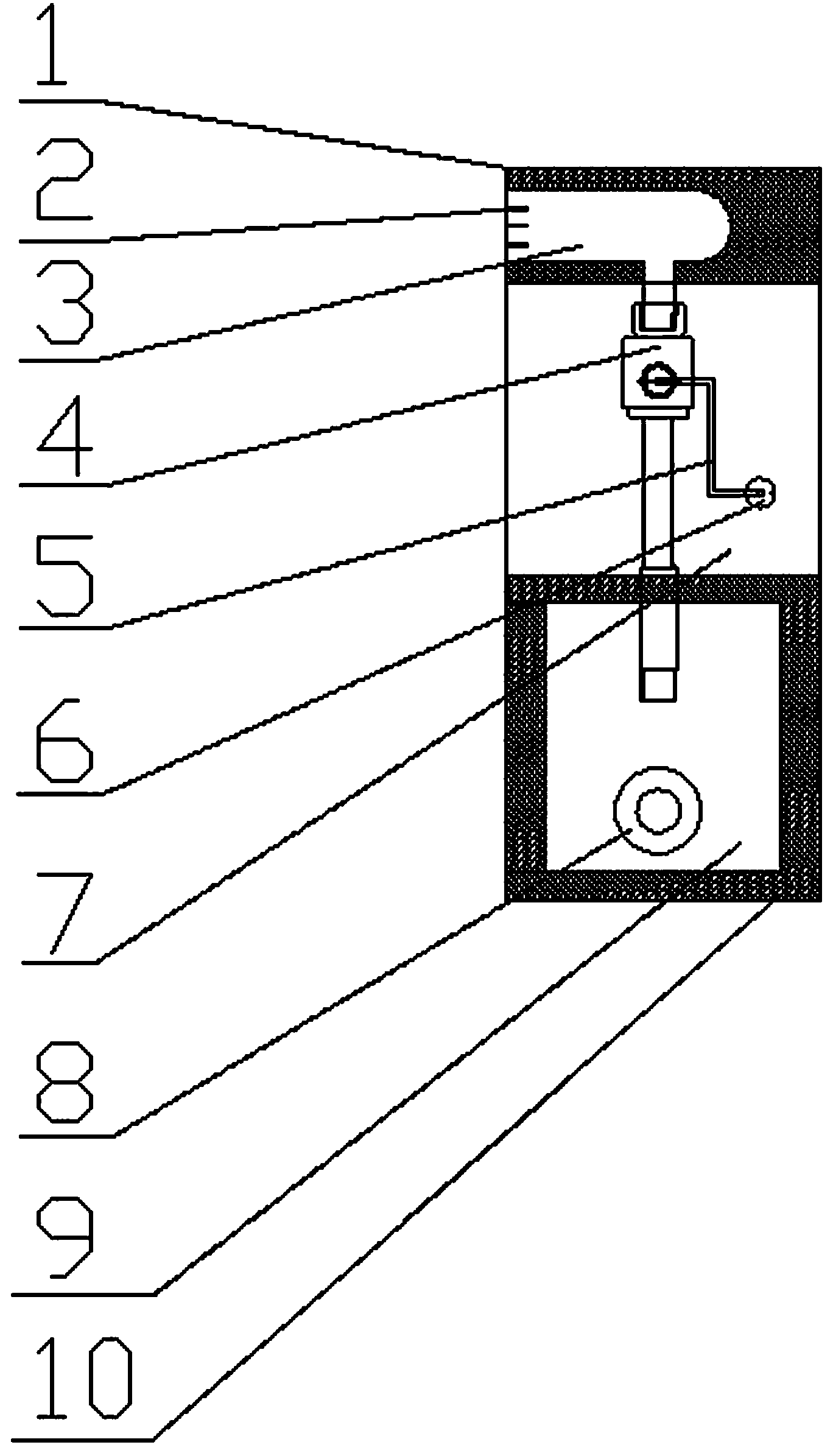

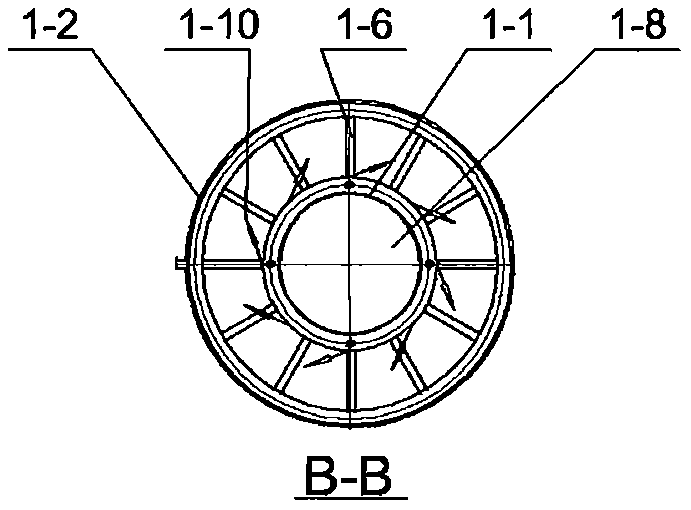

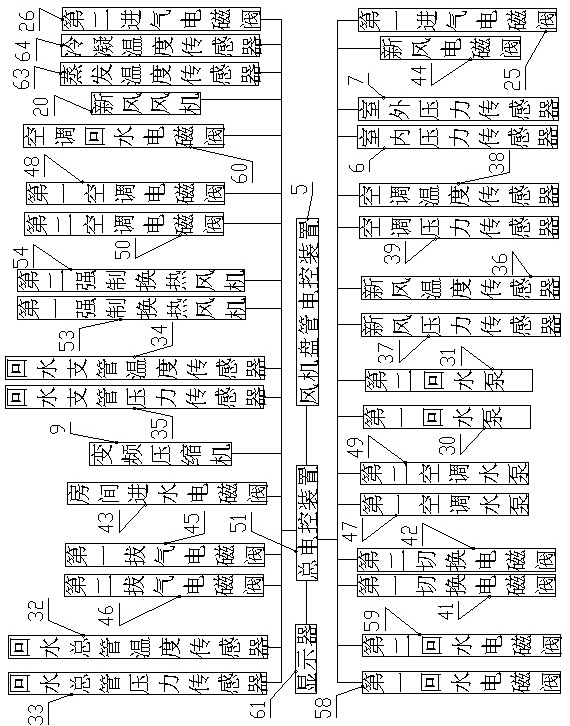

Boiler flue gas white smoke removal system

PendingCN110882611AHeating evenlyEduce condensation efficiencyGas treatmentDispersed particle separationCold airCooling tower

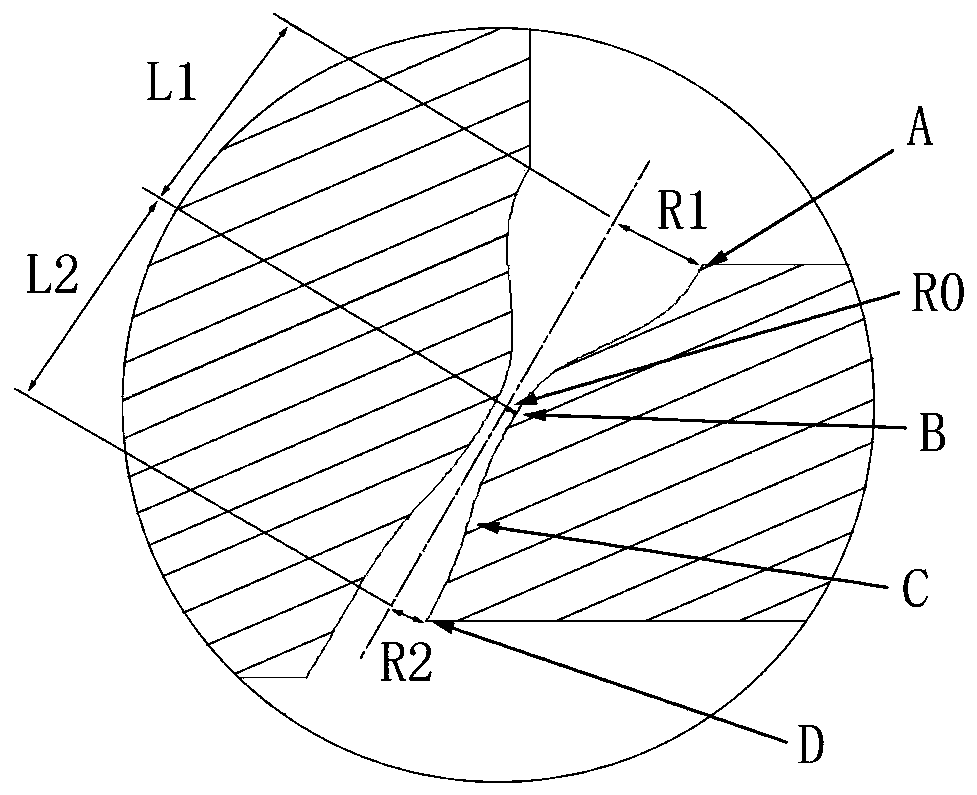

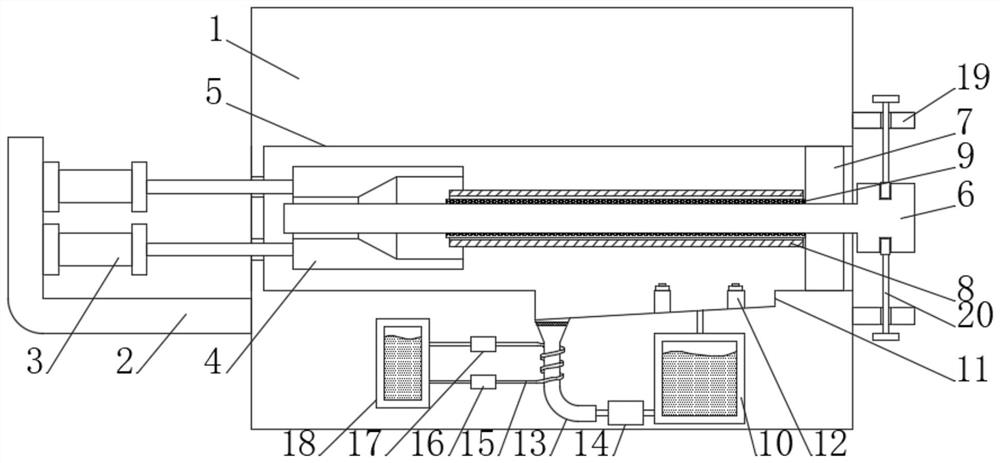

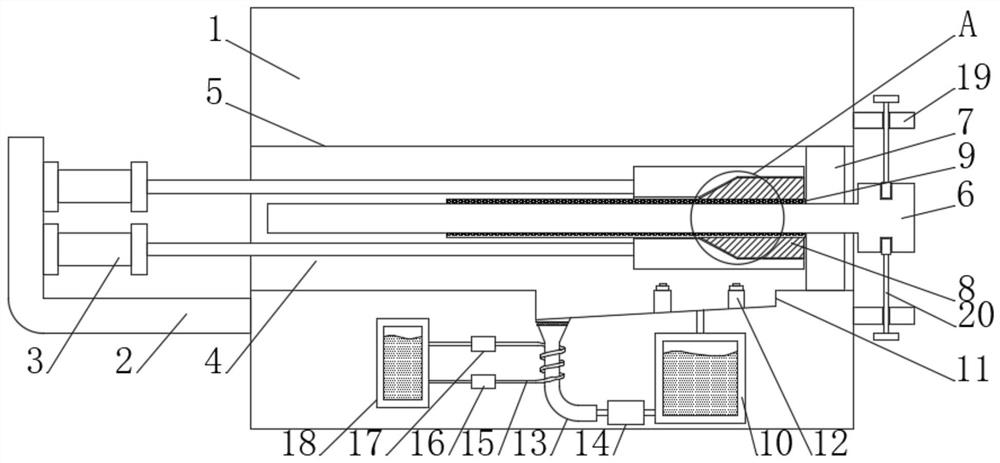

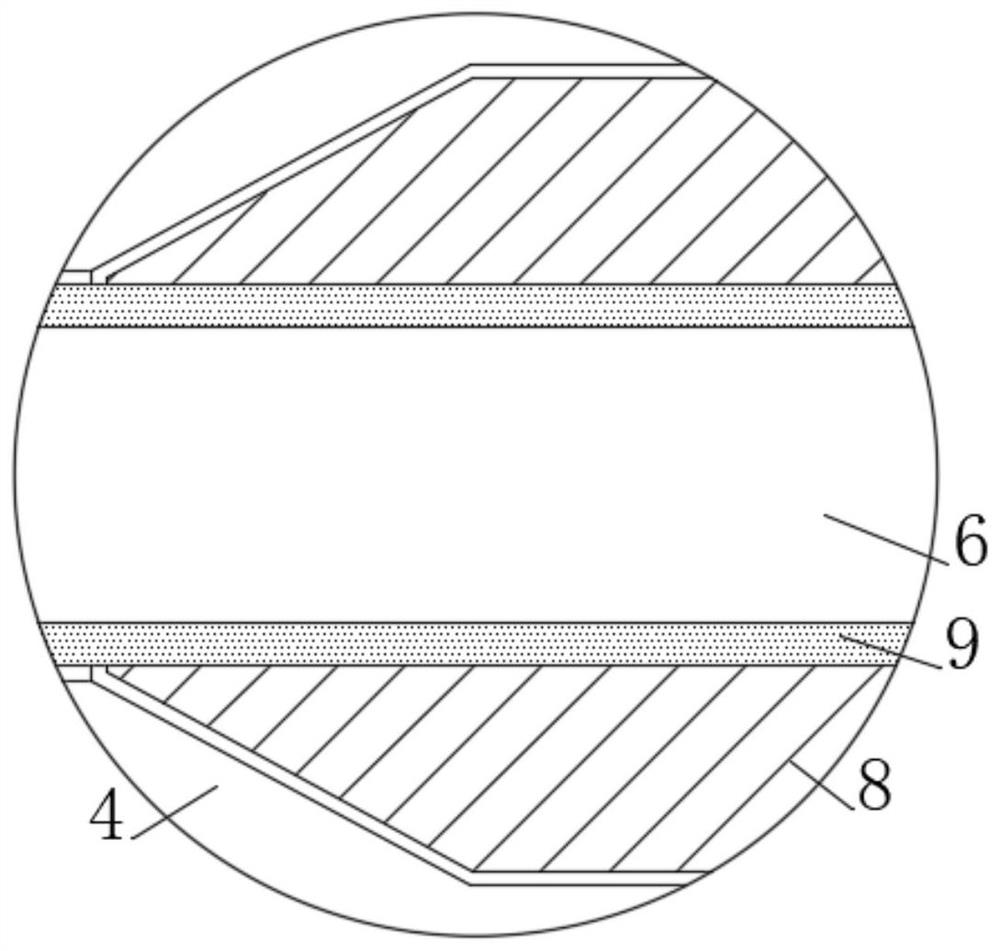

Belonging to the technical field of environmental protection, the invention discloses a boiler flue gas white smoke removal system. According to the boiler flue gas white smoke removal system, a cooling tower and a vortex tube are arranged between a flue gas condenser and a flue gas heater, and the flue gas condenser and the vortex tube are separated by the cooling tower, thus preventing reductionof flue gas condensation efficiency and heat exchange efficiency caused by mixing of cold air flow and hot air flow. A flow splitting chamber on the outer layer of the flue gas heater is arranged along the circumferential direction of an mixing chamber on the inner layer, the mixing chamber is communicated with the flow splitting chamber through flow guide pipes arranged on the surface of the mixing chamber, under the flow splitting effect of the flow guide pipes, the hot air flow generates uniform and stable thermal shunts, thus achieving uniform heating of flue gas in the mixing chamber; and the thermal shunts cannot press flue gas into a flue gas inlet pipeline due to too large air pressure, thus effectively preventing backflow of flue gas and improving the white smoke removal effect.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

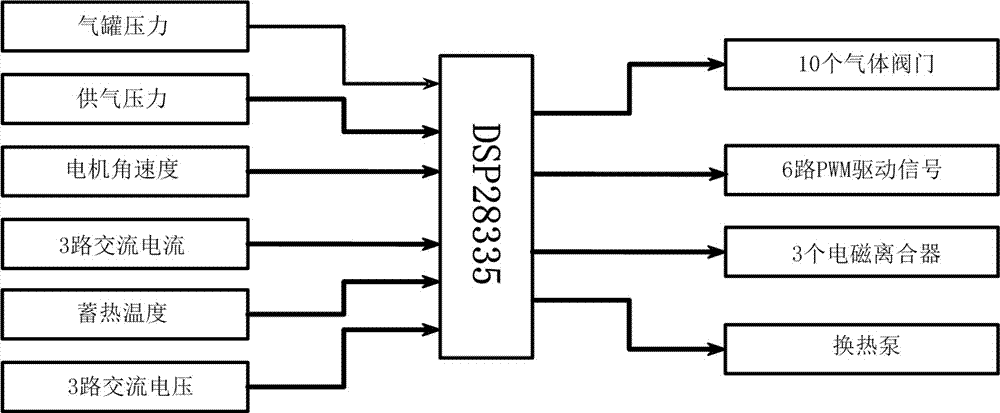

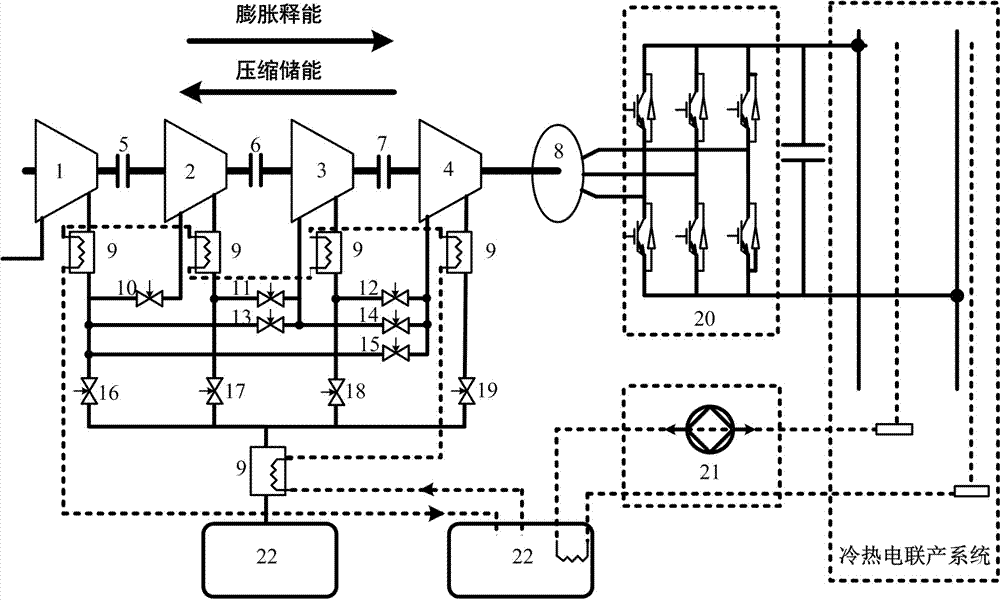

Flexible structure-variable compressed air energy storage system with vortex machines

ActiveCN103925216AImprove performance dropSolve power fluctuationsRotary/oscillating piston combinations for elastic fluidsCompression machines with non-reversible cycleNew energyPermanent magnet synchronous motor

The invention discloses a flexible structure-variable compressed air energy storage system with vortex machines, which is applied to a cold-thermo electric micro-grid system and provided with two electric heating connectors. The compressed air energy storage system comprises the vortex machines, clutches, air circuit valves, an air storage tank, a heat storage tank, a heat exchanger, a heat exchange pump, a permanent magnet synchronous motor and a bidirectional converter. The multiple vortex machines are optimized by the clutches and the air circuit valves to form multiple energy storage system structures which are optimally selected in combination with the air pressure of the air storage tank and the dispatching power of a micro-grid. To be specific, a series structure is determined according to the ratio of inner pressure to outer pressure of the vortex machines, and a parallel structure is determined according to the dispatching power of the micro-grid and the power of the energy storage system. According to the invention, energy generated by compression and expansion is recycled to the heat storage tank by the heat exchanger, and compression energy storage capacity is improved in combination with heat exchange between the heat exchange pump and a thermal loop of the micro-grid; the compression energy storage capacity and the short-time quickly changing fluctuating power adjusting capacity can be effectively improved, and the development of new energy industry and the optimizing and upgrading of the energy structures can be greatly promoted.

Owner:QUFU NORMAL UNIV +1

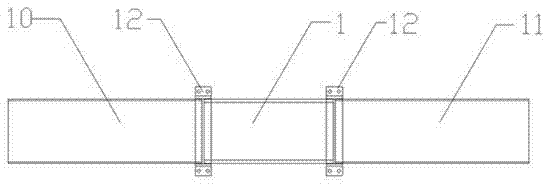

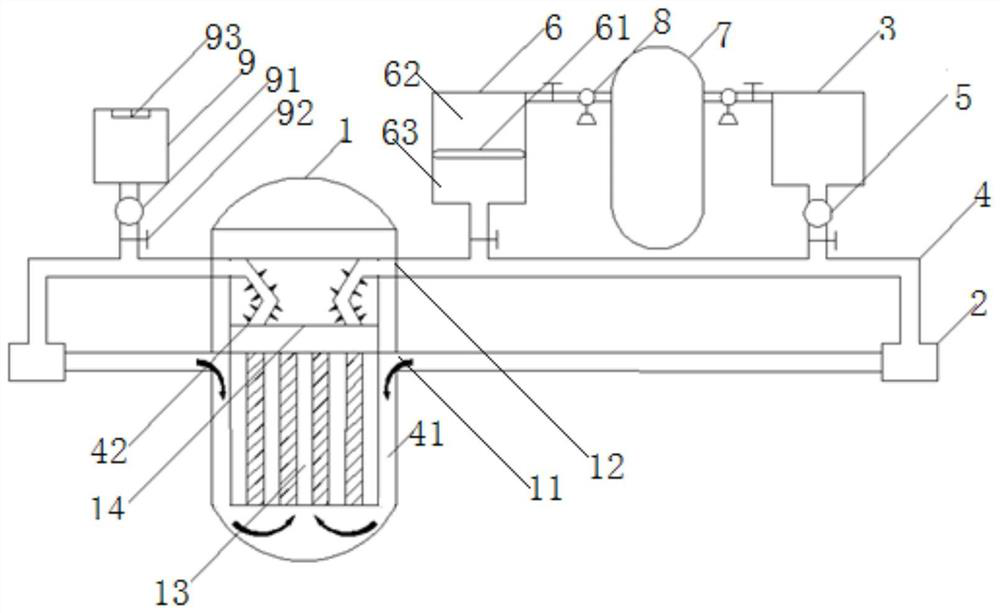

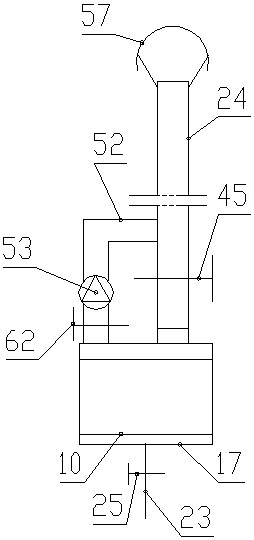

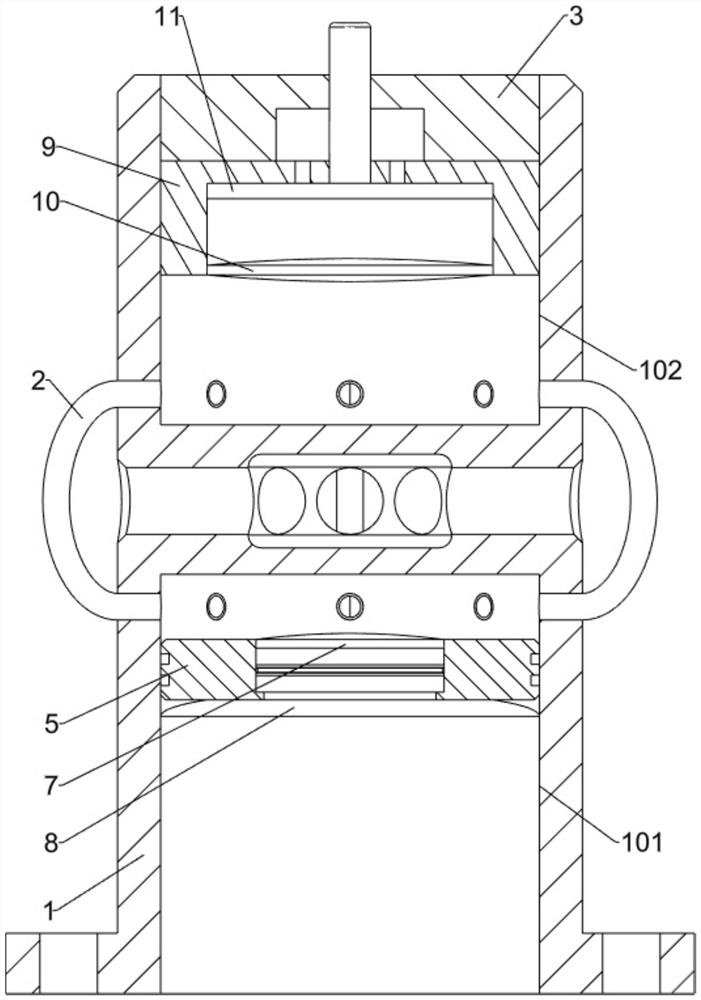

Experimental device for measuring periodical heat transfer coefficient

InactiveCN103792256AAvoid deformationEnables periodic cooling testsMaterial heat developmentTurbulent heat fluxEngineering

The invention discloses an experimental device for measuring a periodical heat transfer coefficient, which is used for measuring heat transfer coefficients of different heat transfer periods. The device comprises a steel cylinder rotating system, an air channel, a water channel system, a heating system, a temperature collecting system, nozzles and a regulating system thereof as well as a box body of the experimental device. The experimental device provided by the invention can regulate the revolving speed of a rotating steel cylinder so as to change the moving speed of a cooling surface, so that different heat transfer periods are realized, different nozzles are changed to realize different cooling manners, air pressure and water pressure are regulated, and the cooling intensity is changed; regulating devices of the nozzles can change a spraying angle and a spraying height of each nozzle, and the experimental device also can simulate the periodical cooling radiating process of an inner heat source.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

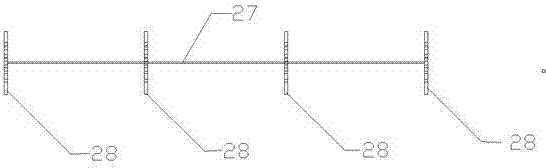

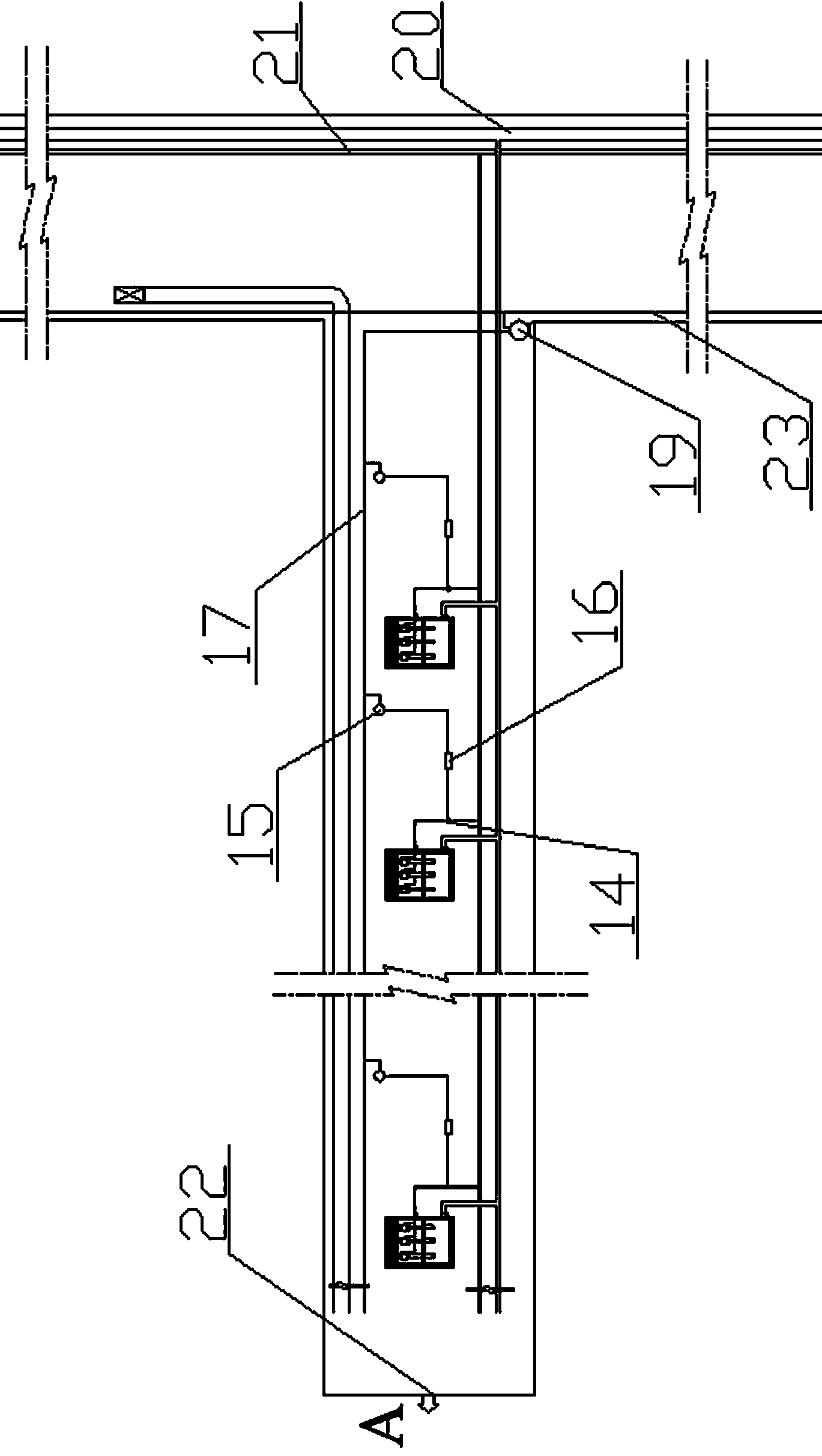

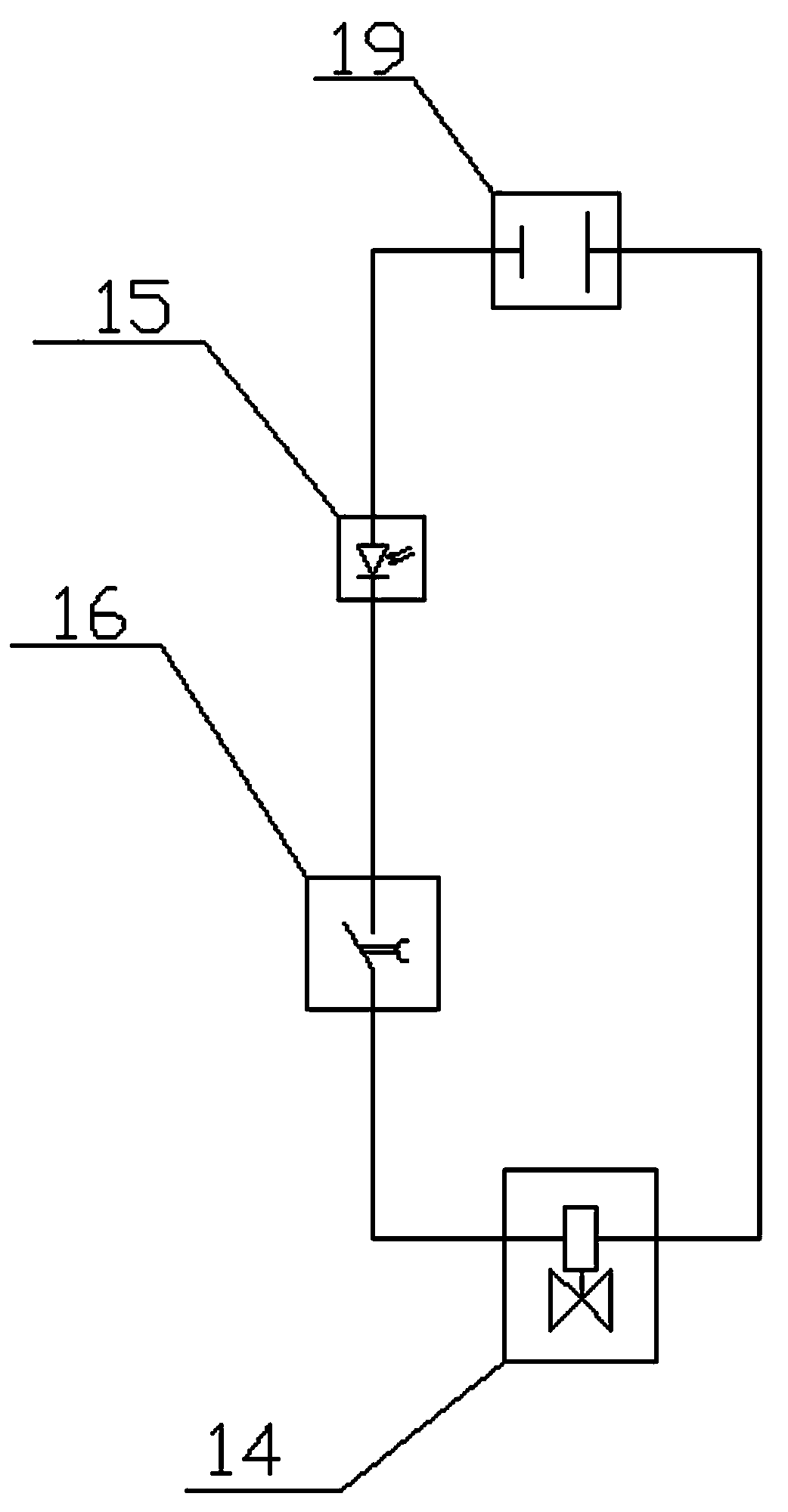

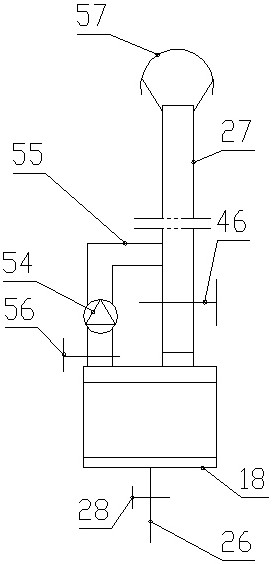

Coal mine high-temperature tunneling roadway sectional cooling device and method

ActiveCN104018871ALarge air volumeReduce consumptionTunnel/mines ventillationCold airTurbulent heat flux

The invention discloses a coal mine high-temperature tunneling roadway sectional cooling device and method. The device comprises a box, wherein the interior of the box is sequentially divided into a hot air recycling bin, an air inlet bin and a cold air exhausting bin from bottom to top, a vortex tube is arranged in the air inlet bin, the cold air flow end of the vortex tube is connected with the cold air exhausting bin, and the hot air flow end of the vortex tube is connected with the hot air recycling bin; the air inlet bin is provided with an air inlet connection port, an air pressure tube is arranged between the vortex tube and the air inlet connection port, the air inlet bin is connected with a compressed air pipeline through the air inlet connection port, the compressed air pipeline is provided with a pressure regulating valve, and the hot air recycling bin is connected with a hot air exhausting pipeline through an air exhausting hole connection port formed in the hot air recycling bin. Compared with the prior art, the device and method have the advantages of being free of moving parts, compact in structure, light, low in cost and long in service life; cold air can be produced timely without Freon refrigerants, refrigerating efficiency and speed are high, refrigerating can be performed on the underground work surface timely by introducing compressed air.

Owner:山西中科赛德能源科技有限公司

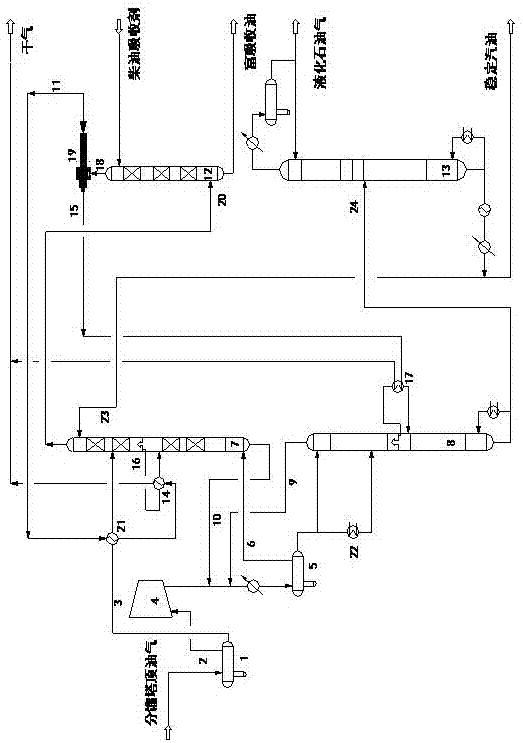

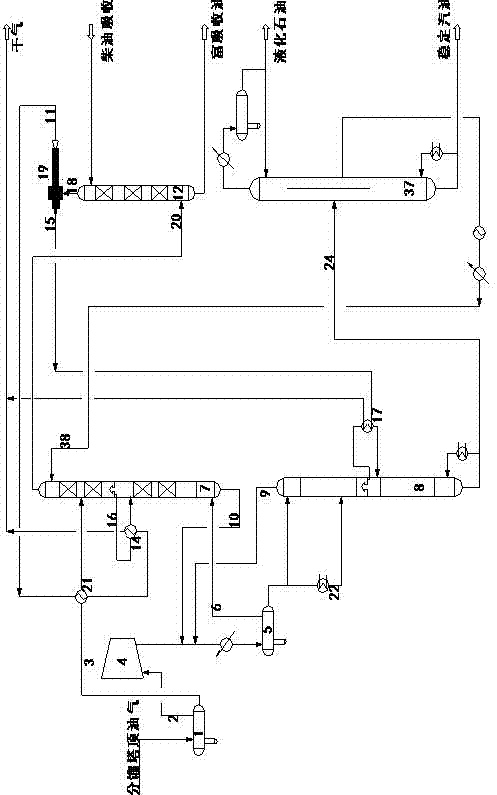

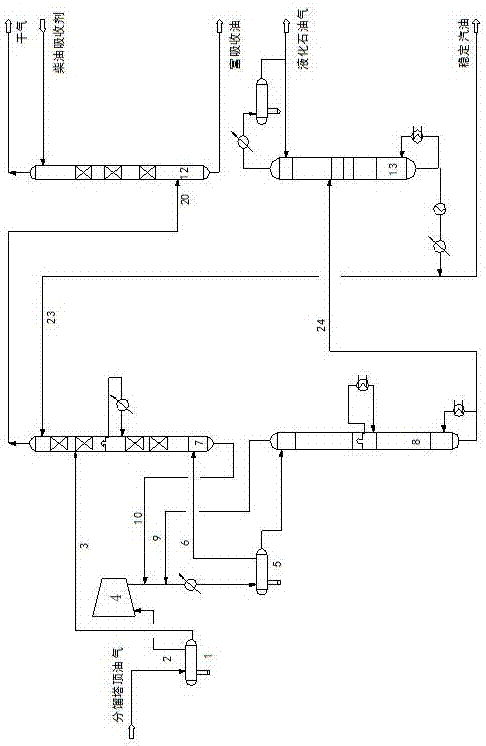

Absorption-stabilization technique capable of enhancing absorption by using complementary energy

ActiveCN107338068AGuaranteed uptimeReduce loadLiquid hydrocarbon mixture recoveryHydrocarbon oils treatment productsAbsorption ratioHeat flow

The invention discloses an absorption-stabilization technique capable of enhancing absorption by using complementary energy. A stabilized gasoline absorption packing section and a gasoline absorption packing section are arranged in a coking absorption tower from top to bottom; and crude gasoline and stabilized gasoline sectionally enter packing bed layers of the gasoline absorption section and stabilized gasoline absorption section. Preferably, the tower top of a reabsorbing tower is provided with a shell-and-tube vortex tube buncher, thereby converting the pressure energy of dry gas on the tower top into a cold flow and a heat flow. A dividing wall column is used for sharp separation to obtain the component with better absorbing capacity, thereby enhancing the absorption effect. The method disclosed by the invention can maximally display the absorbing capacity of stabilized gasoline for C3 and C4, enhance the absorption effect of the absorption tower and greatly lower the circulating volume of the stabilized gasoline complementary absorbent, thereby lowering the energy consumption of the system. The vortex tube buncher can recover the pressure energy formed by the dry gas pressure difference and convert the pressure energy into cold energy and heat energy, and can also optimize the absorption-stabilization technique, thereby implementing the dual effects of lowering the process energy consumption and enhancing the absorptivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

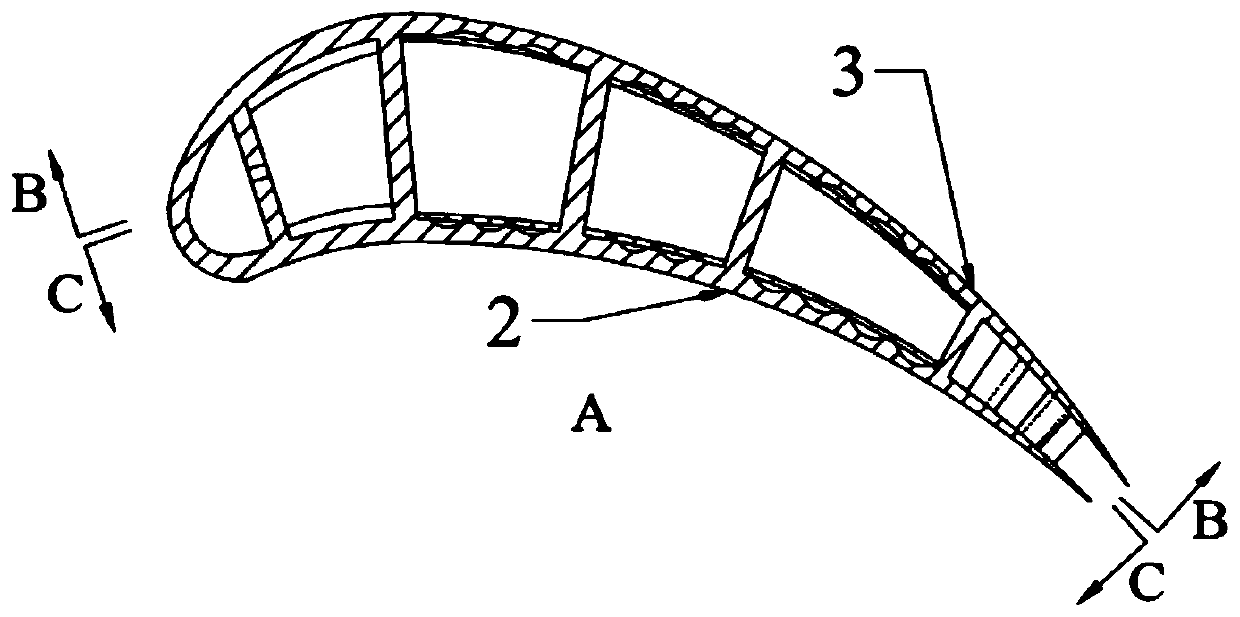

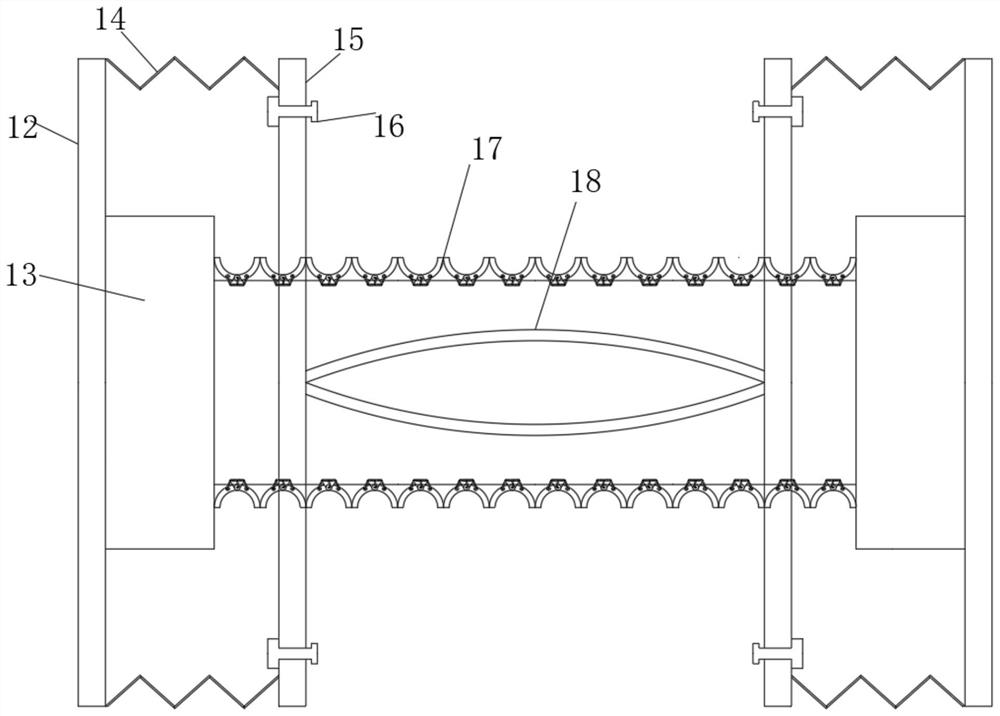

Gas turbine blade comprising V rib-pit composite cooling structures

InactiveCN110700893AIncrease the heat exchange areaImprove heat transfer effectEngine fuctionsBlade accessoriesThermodynamicsSuction force

The invention provides a gas turbine blade comprising V rib-pit composite cooling structures. The gas turbine blade comprises an upper wall and a lower wall, wherein the upper wall is a suction surface, the lower wall is a pressure surface, the V rib-pit composite cooling structures are arranged on the inner walls of the upper wall and the lower wall, each V rib-pit composite cooling structure comprises a composite cooling unit, wherein the composite cooling unit comprises a right-angle V-rib and a circular pit behind the right-angle V-rib. The gas turbine blade has the advantages that the heat exchange area of the whole structure is increased, the heat exchange effect is improved, a fracture between the adjacent V-shaped ribs enhances the turbulent flow generated by the gas flow, so thatthe gas flow is separated to a large extent, and then is attached to the wall surface, so that the boundary layer is damaged in a large extent, the turbulence degree of the fluid is greatly enhanced,the heat exchange is greatly enhanced, the rib are interrupted, so that the blockage ratio is reduced, the pressure loss is reduced, the disturbance is enhanced while the front and rear air pressure of the rib is balanced, and the heat exchange is greatly enhanced.

Owner:HARBIN ENG UNIV

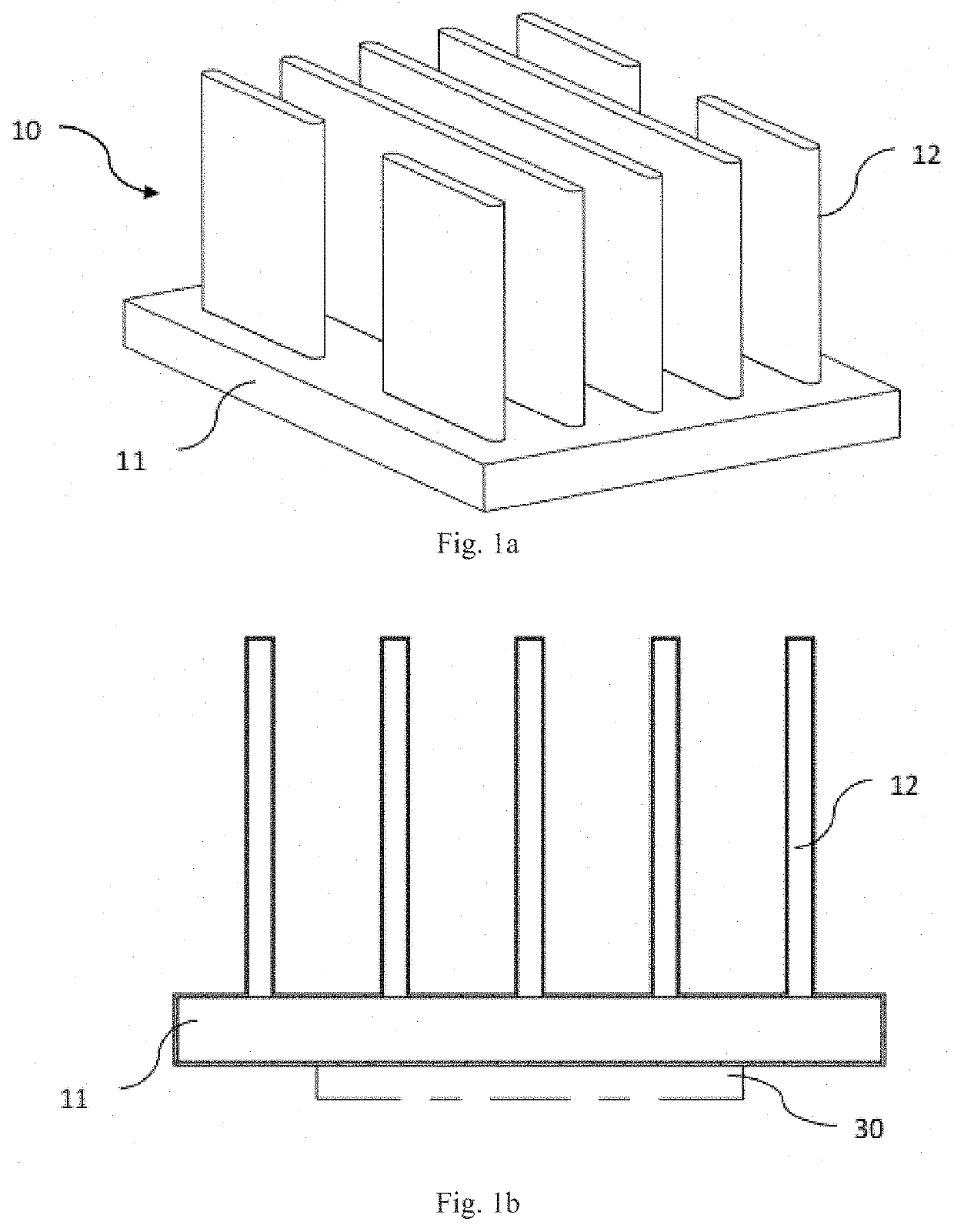

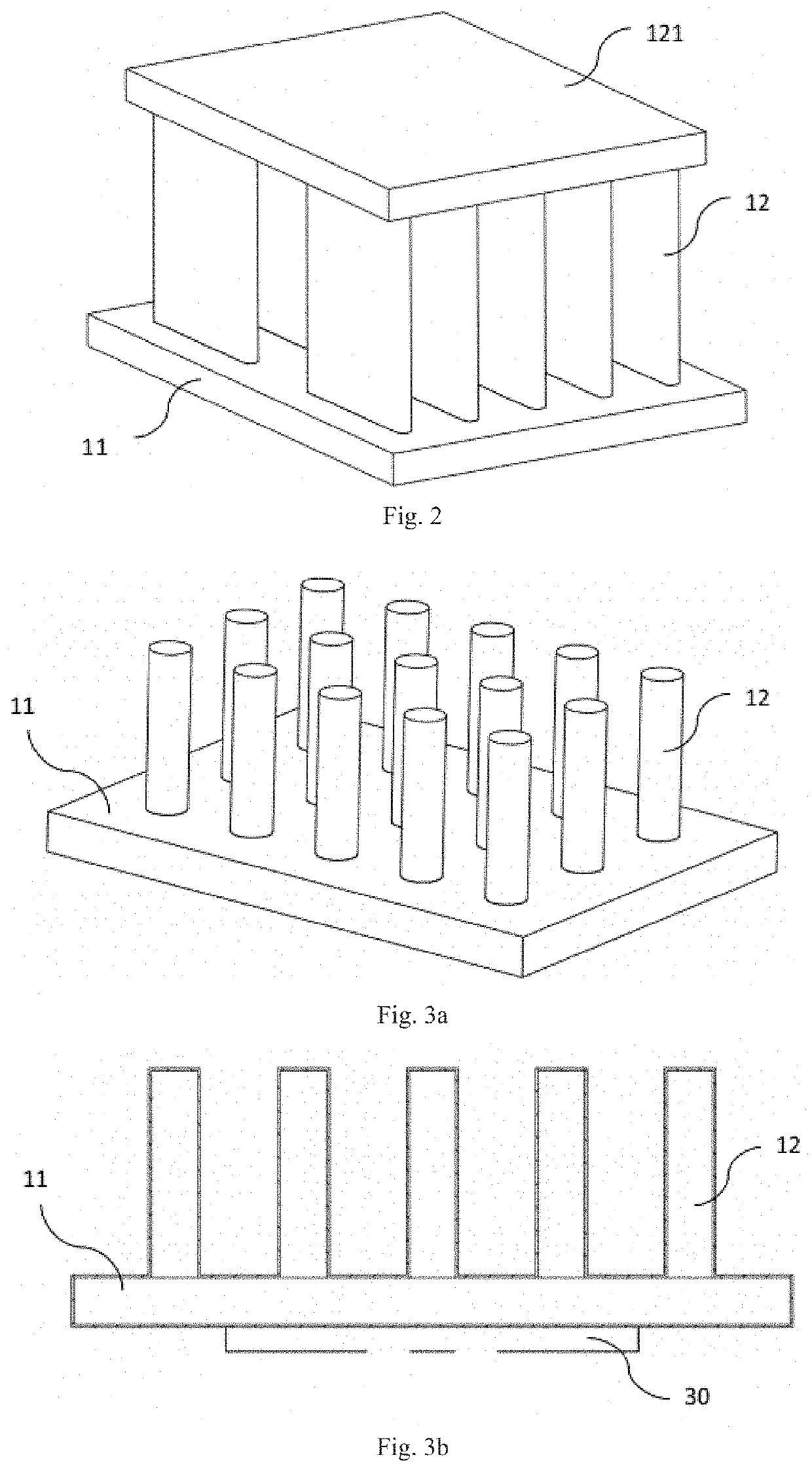

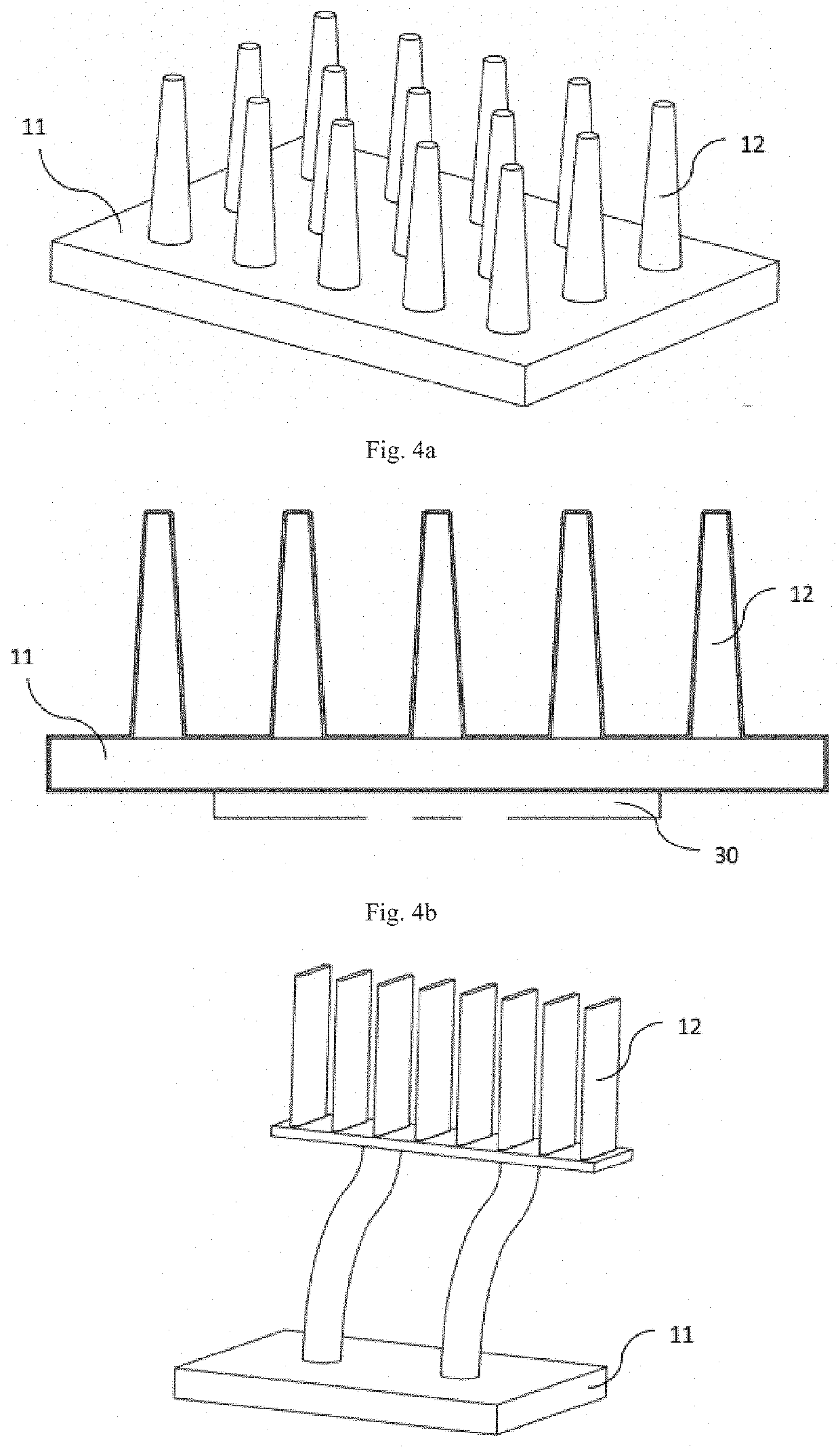

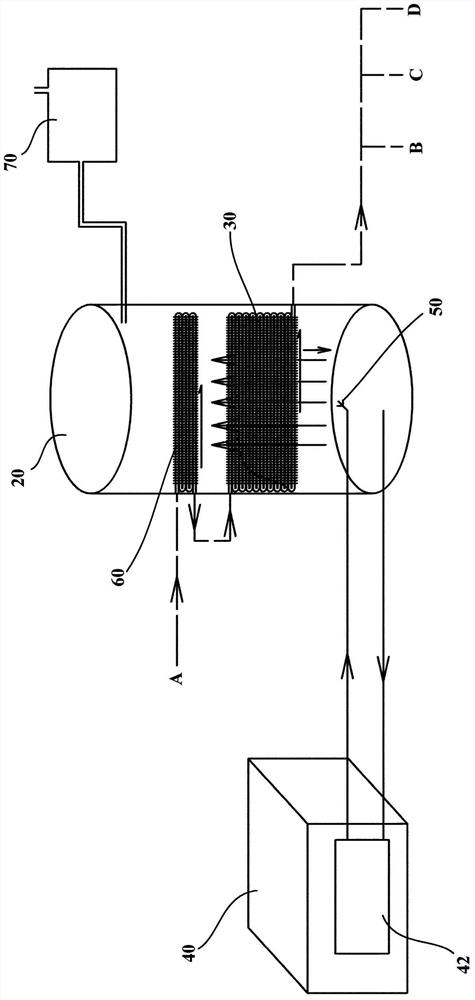

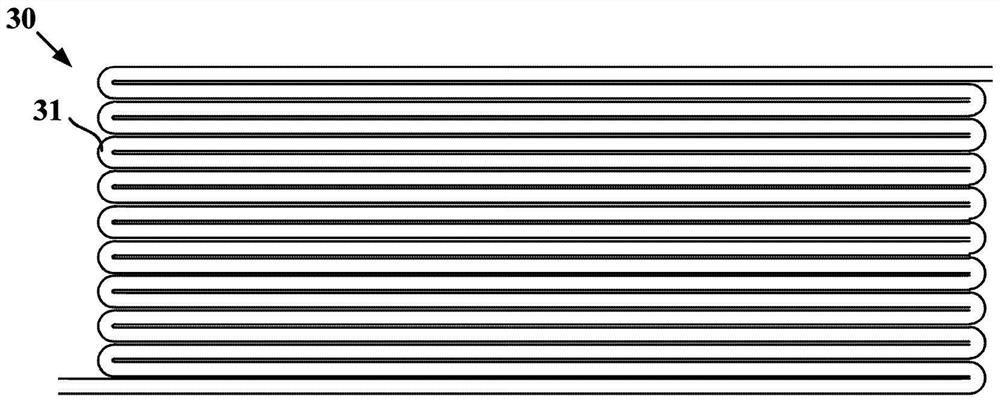

Phase-change heat dissipation device

PendingUS20210392783A1Improve heat transfer efficiencyHeat dissipation fastIndirect heat exchangersModifications using liquid coolingInternal pressureHeat flow

The present invention discloses a phase-change heat dissipation device comprising a phase-change assembly internally provided with a phase-change heat exchange medium, and the phase-change heat exchange medium provided in the phase-change assembly is configured such that, in an operating state of the phase-change heat dissipation device, an air pressure within the phase-change assembly is greater than 0.15 MPa. When the phase-change heat dissipation device of the present invention works in a working temperature range of 30-80° C., the internal pressure is far greater than the standard atmospheric pressure, the internal of the phase-change heat dissipation device is in a positive-pressure non-vacuum environment, the heat flux density of the heat source is high, the absolute pressure in the evaporator part of the phase-change assembly is high, the relative pressure difference between different parts of the phase-change assembly under the same temperature difference condition is large, and the pressure difference can drive more phase-change medium. Therefore, the heat exchange capacity is enhanced, the fluidity of the internal phase-change heat exchange medium is improved, which improves the heat flux density of heat transfer and makes it easier to achieve efficient heat dissipation.

Owner:ZHUZHOU ZHIRE TECH

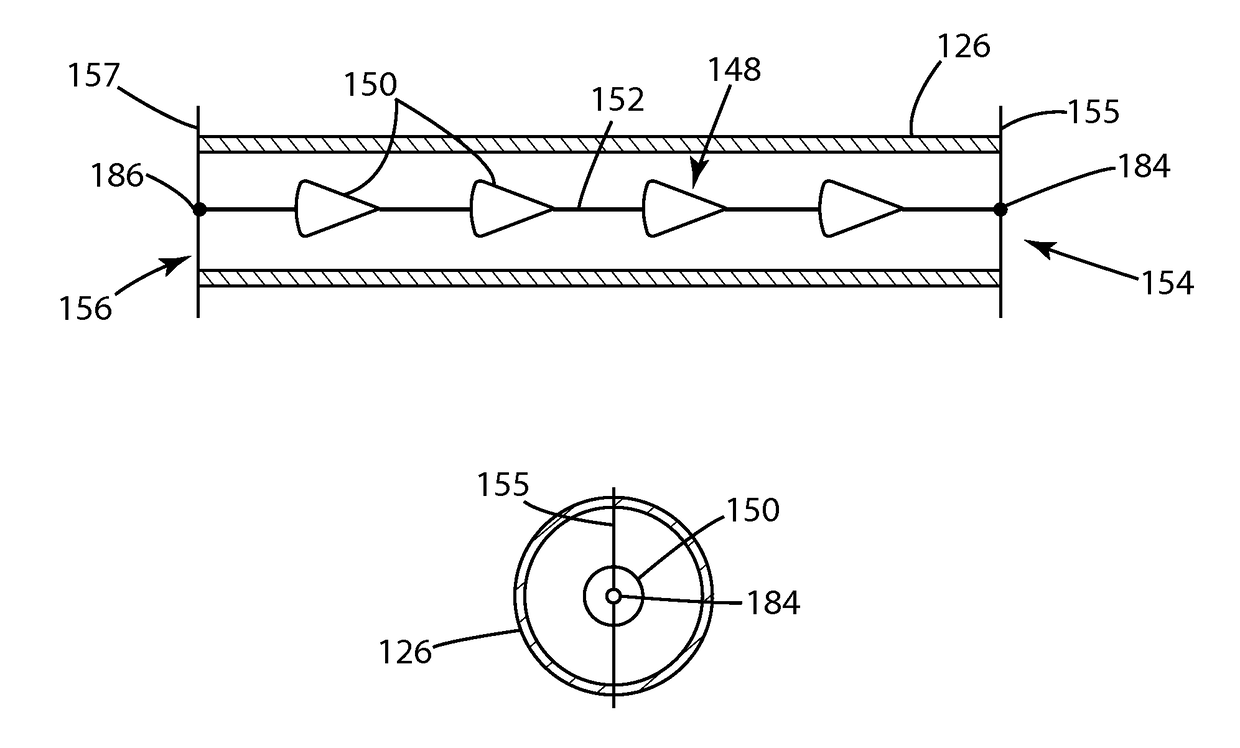

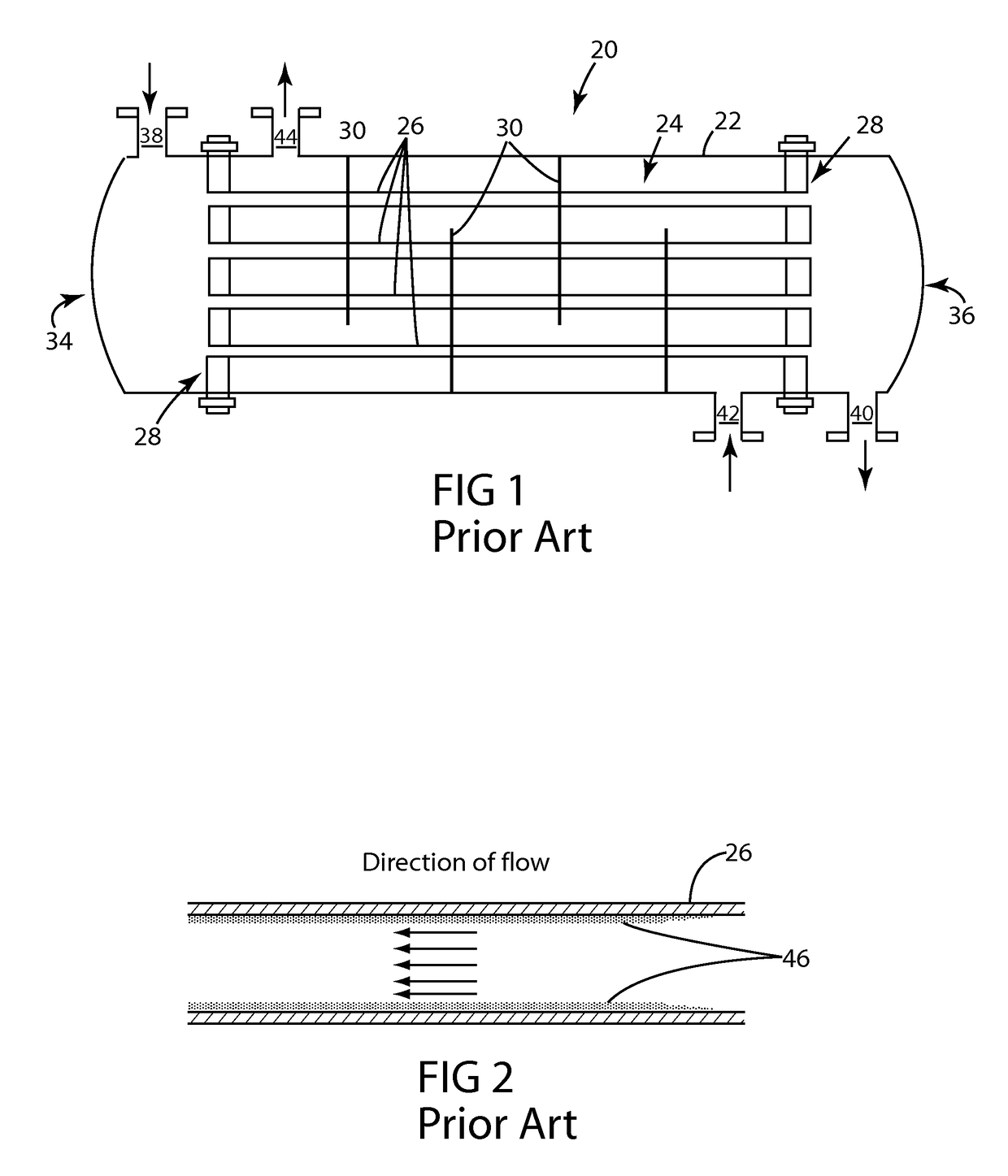

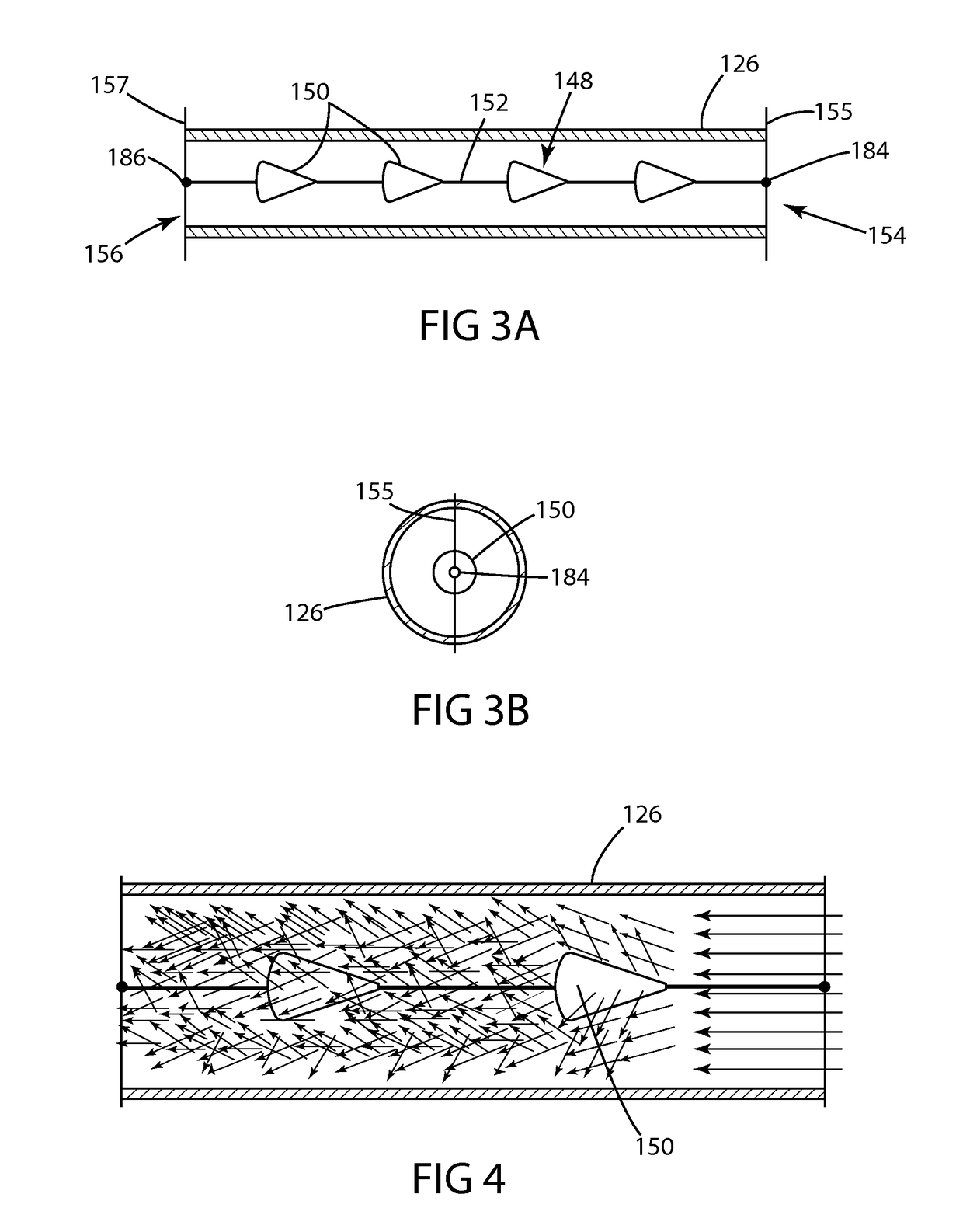

Turbulence-inducing devices for tubular heat exchangers

ActiveUS9605913B2Promote turbulenceAvoid accumulationFluid heatersHeat transfer modificationPlate heat exchangerTurbulent heat flux

A heat exchanger tube for conveying a heat transfer fluid, into which one or more turbulence-inducing elements are fixedly positioned on a supporting member extending in spaced relation along the central axis of the tube. The turbulence-inducing elements have a first portion facing upstream and a second portion facing downstream. The entire exterior surface of the first portion forms a continuous solid surface that blocks and deflects the path of the flowing fluid.

Owner:SAUDI ARABIAN OIL CO

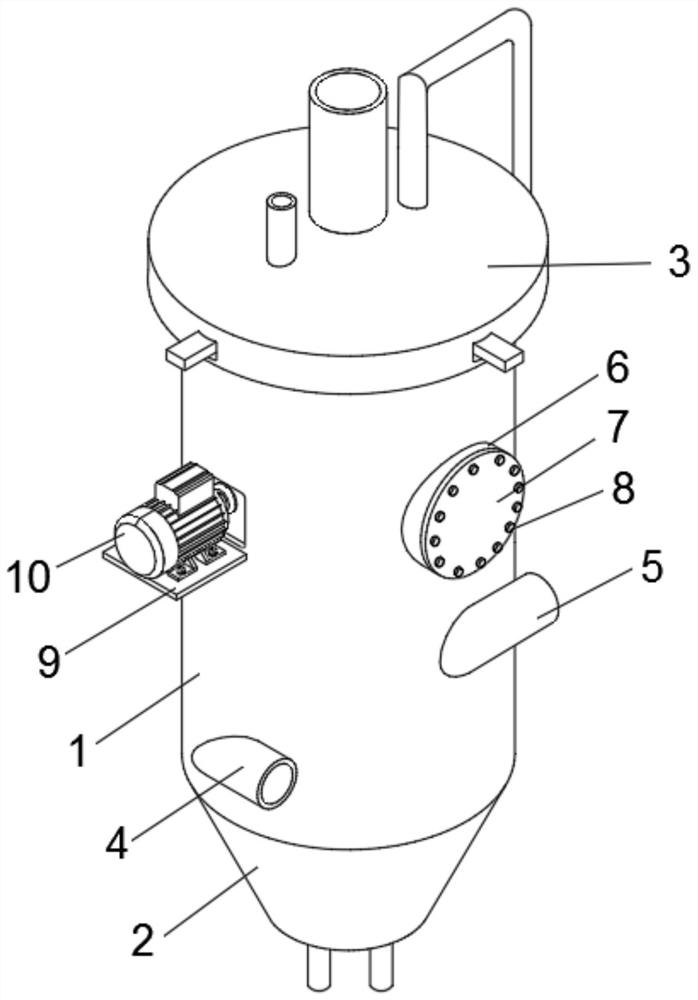

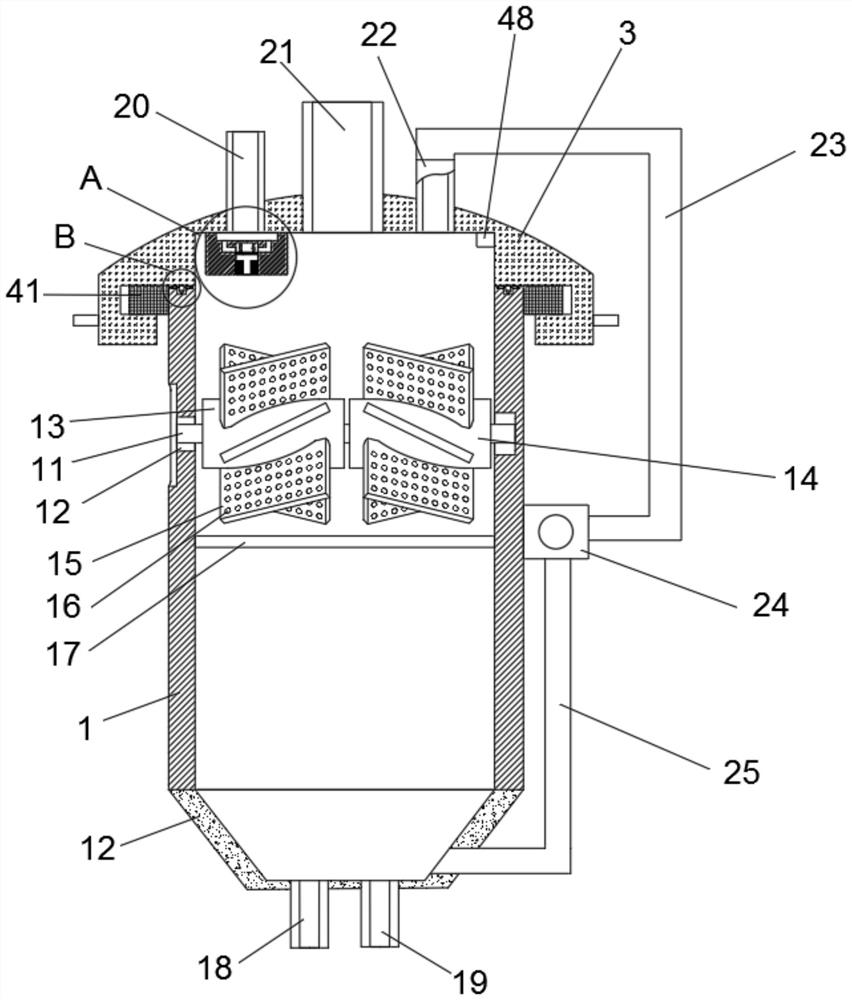

Swirling type combustible gas control even-mixing device

PendingCN111974234AImprove combustion efficiencyFull mixing effectRotary stirring mixersTransportation and packagingThermodynamicsAutomatic control

The present invention discloses a swirling type combustible gas control even-mixing device. The swirling type combustible gas control even-mixing device comprises a rotating tank body, a cooling tankbody and a tank cover, the cooling tank body is arranged under the rotating tank body, the cooling tank body is fixedly connected with the rotating tank body, a top part of the rotating tank body is fixedly connected with the tank cover, a turbulence plate is arranged, and a plurality of turbulent flow plates are symmetrically arranged above the turbulence plate to mix mixed gas twice to achieve asufficient even-mixing effect, combustion efficiency of the mixed gas is improved, production costs are reduced, and resource utilization is improved; and a movable block in a floating arrangement isused to automatically control air pressure of the rotating tank body to avoid excessive high pressure in the rotating tank body leading to leakage or more serious safety accidents, a temperature sensor is used to monitor the temperature of the mixed gas in the rotating tank body in real time, cooling is conducted when the temperature is too high, temperature of gas in the rotating tank body is controlled, and safety and reliability of the whole device are improved.

Owner:西安石大能源股份有限公司

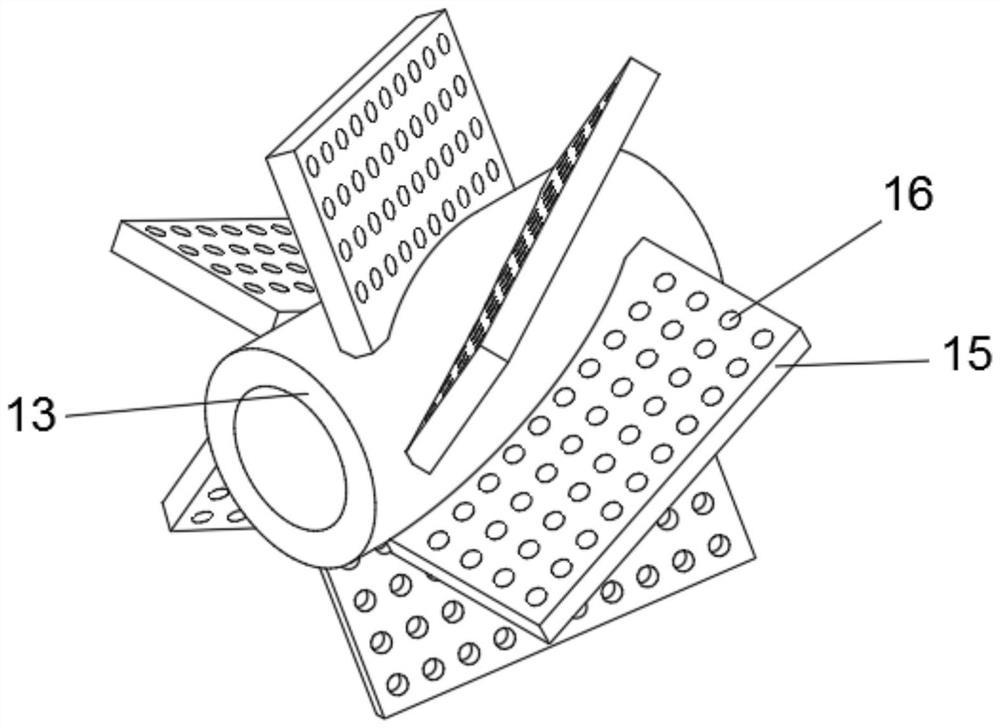

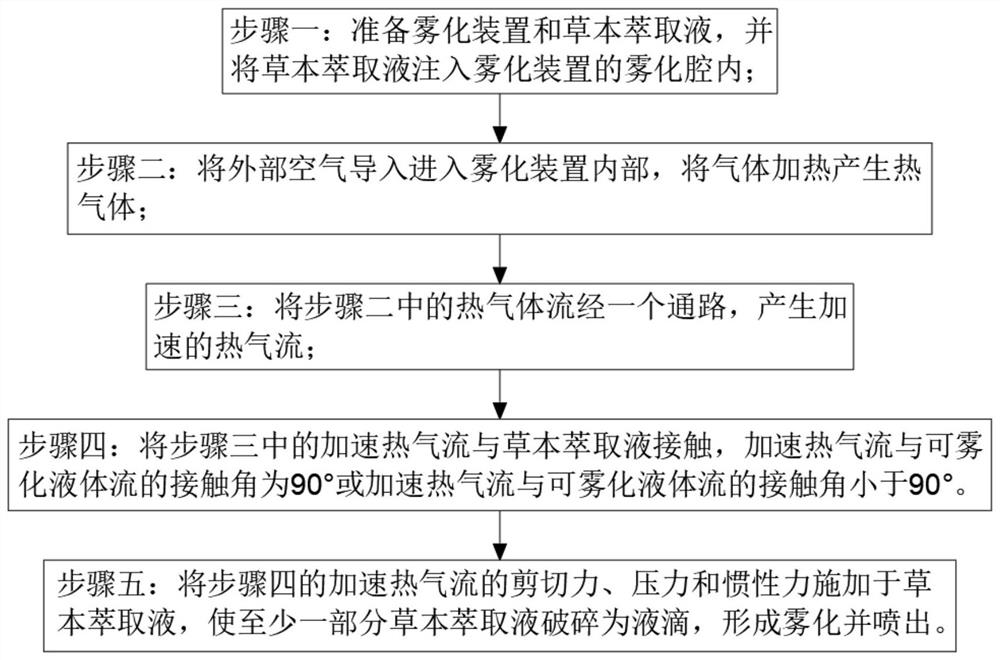

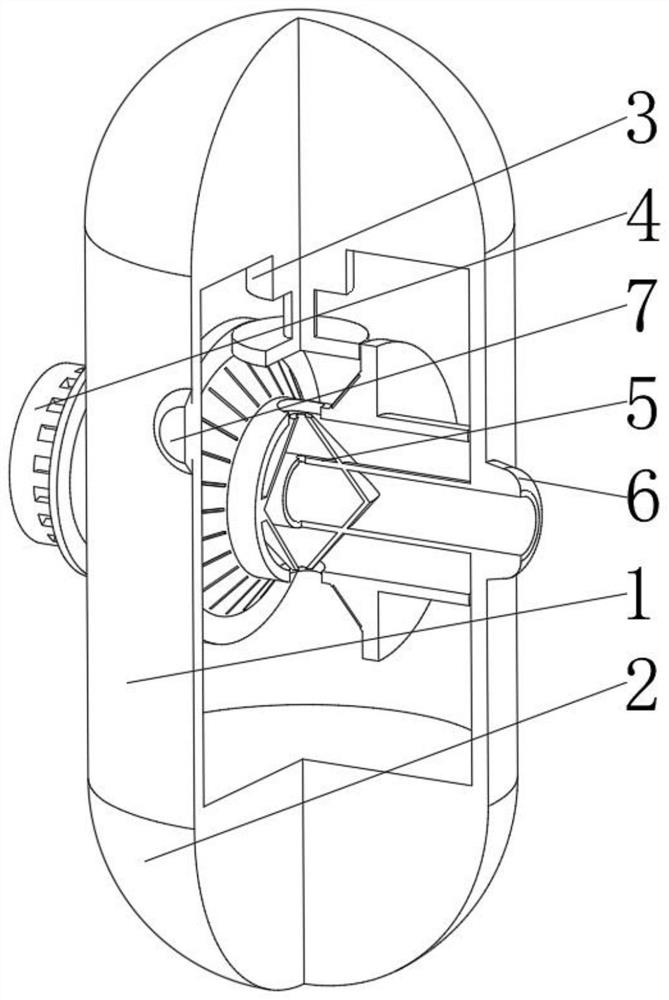

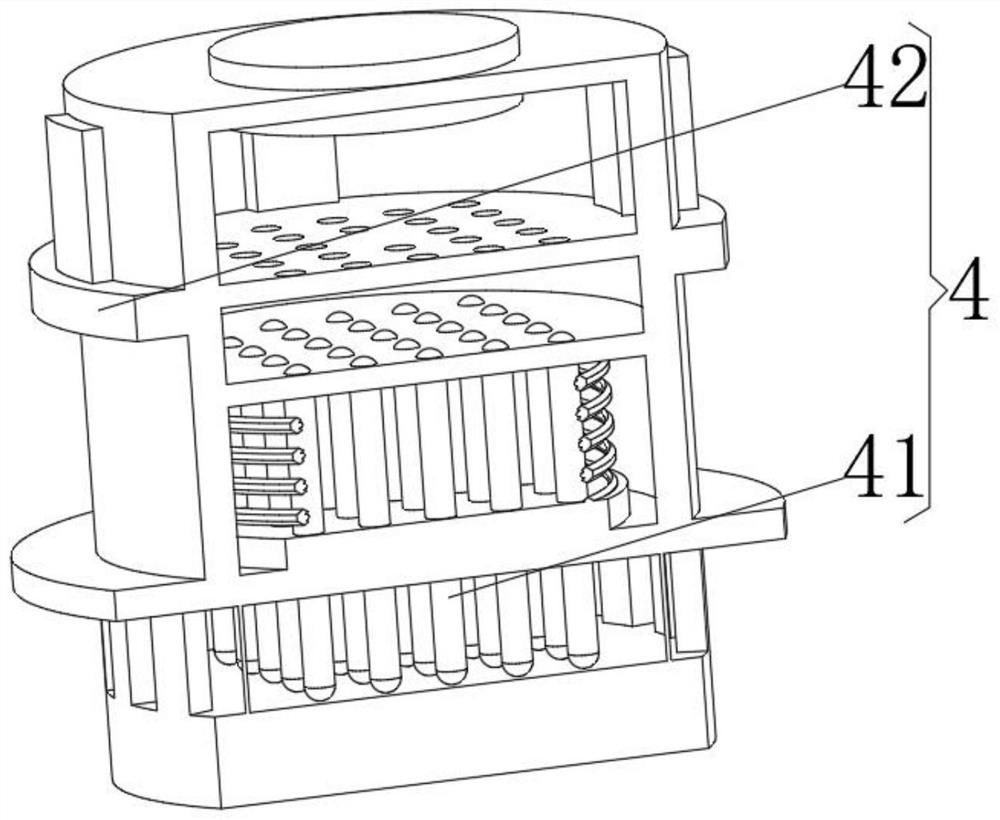

Herbal extract atomization method and atomization device

ActiveCN113182108AEasy temperature controlControl flow rateLiquid spraying apparatusThermodynamicsTurbulent heat flux

The invention discloses a herbal extract atomization method. The method comprises the following steps that secondly, outside air is introduced into an atomization device, and the air is heated through a plasma and vortex heating dual-heating mechanism to generate hot air; thirdly, the hot air in the second step flows through a channel, and accelerated hot air flow is generated; and fourthly, the accelerated hot air flow in the third step makes contact with a herbal extract, the contact angle between the accelerated hot air flow and liquid flow capable of being atomized is 90 degrees or the contact angle between the accelerated hot air flow and the liquid flow capable of being atomized is smaller than 90 degrees. The invention relates to the technical field of atomization. Plasma and vortex heating dual-heating methods can be mutually replaced during use, so that the temperature of atomized air can be conveniently regulated and controlled, air expansion is controlled through heat, the air pressure of the air is regulated and controlled, the flow speed of the air is conveniently controlled, the impact force of the air after atomization is changed through wires, and an atomization receptor is protected.

Owner:广州雾普康生物科技有限公司

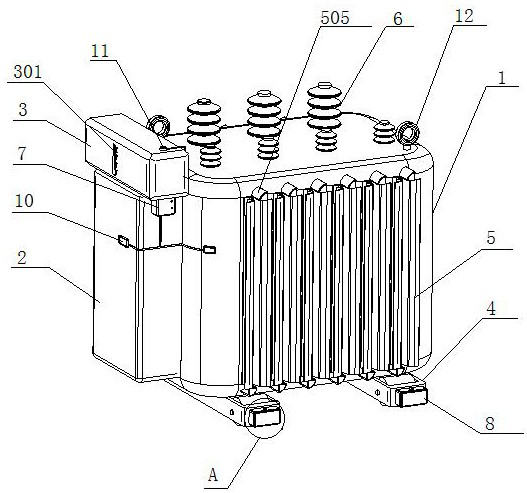

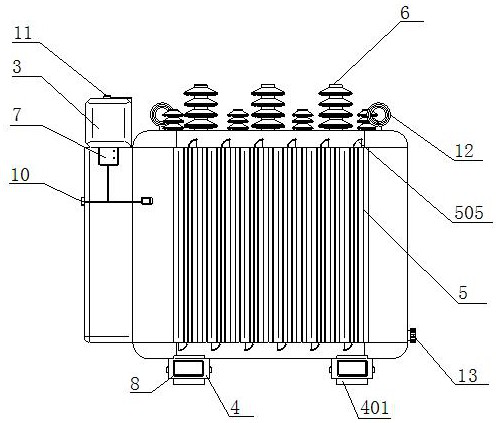

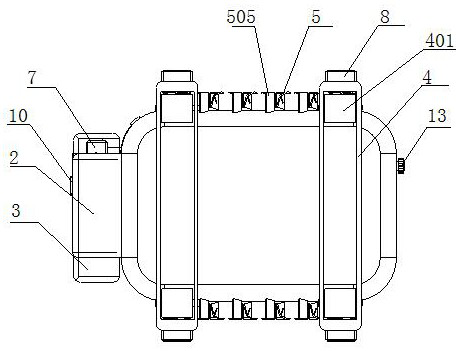

An oil-immersed three-phase transformer

InactiveCN112103030BSpeed up circulationImprove cooling effectTransformers/reacts mounting/support/suspensionTransformers/inductances coolingCooling effectTurbulent heat flux

The invention discloses an oil-immersed three-phase transformer, which includes a box body, the top of the box body is fixedly connected with a terminal group, and the outer walls of the front and back sides of the box body are fixedly connected with heat dissipation structures. The left end of the body is fixedly connected with an oil tank, and the top of the oil tank is fixedly connected with an oil conservator. Through the special structure of the air guide strip, according to the principle of aerodynamics, when the wind blows, the arc surface of the air guide strip away from the box will flow through the air at a faster speed, while the smooth surface of the air guide strip close to the box will flow through The airflow velocity is relatively slow, forming an air pressure difference, and the air near the box body of the air guide strip rushes toward the side of the arc of the air guide strip, forming a vortex, which accelerates the heat dissipation on the side of the heat sink close to the box body, and the two sides The guide directions of the two windshields are opposite, and the windshields in the opposite direction of the wind guide on both sides can guide the blown wind to the inside of the heat dissipation structure and lead it out from the other end, so that the wind can be guided up and down while forming a vortex, so that The cooling effect is better.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER

Vehicle power battery safety monitoring device

ActiveCN114572059AAchieve circular flowExpedite evacuationPropulsion by batteries/cellsVehicular energy storageControl theoryExhaust pipe

The invention relates to the technical field of automobile power battery protection, in particular to a vehicle power battery safety monitoring device which comprises a protection mechanism, a bottom transmission mechanism, a drum liquid cooling mechanism and a hot pressing mechanism. According to the monitoring device, when the temperature of the battery in the containing box is increased, heat energy generated by the inner cavity of the containing box is transmitted into the arc pipe through the inner cavity of the heat transfer top plate, expansion pressure is applied to cooling liquid in the inner cavity of the arc pipe, and the liquid level of the inner cavity of the arc pipe is increased and the inner side cavity of the inner pad is compressed; at the moment, an elastic part is pushed by air pressure of an exhaust pipe to be in contact with a conducting rod at the top of a base, a servo motor in a case can be controlled to control a plurality of air blowing parts and a chain, so that a plurality of first turbine parts and a plurality of second turbine parts are controlled to synchronously rotate, and circulating flow of cooling liquid in a cold flow pipe is realized; therefore, heat energy is dissipated.

Owner:江苏英拓动力科技有限公司

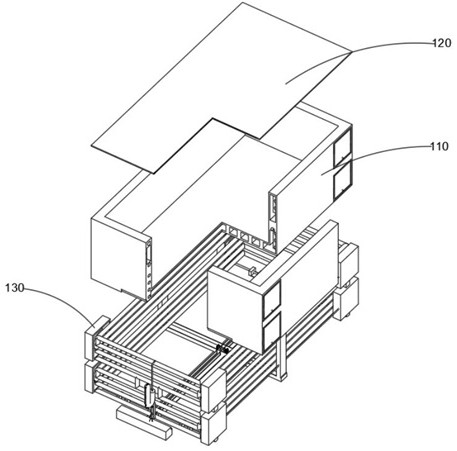

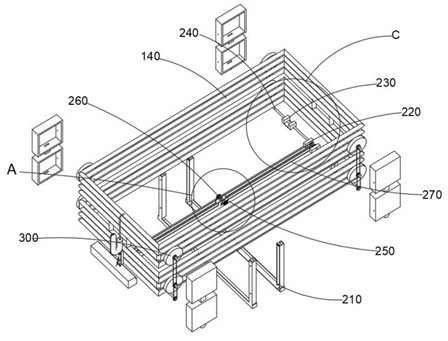

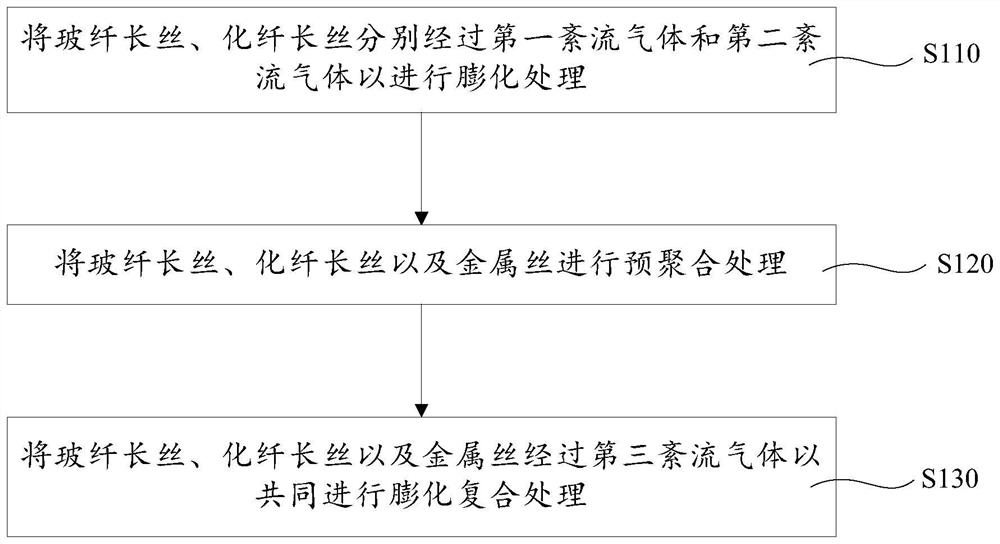

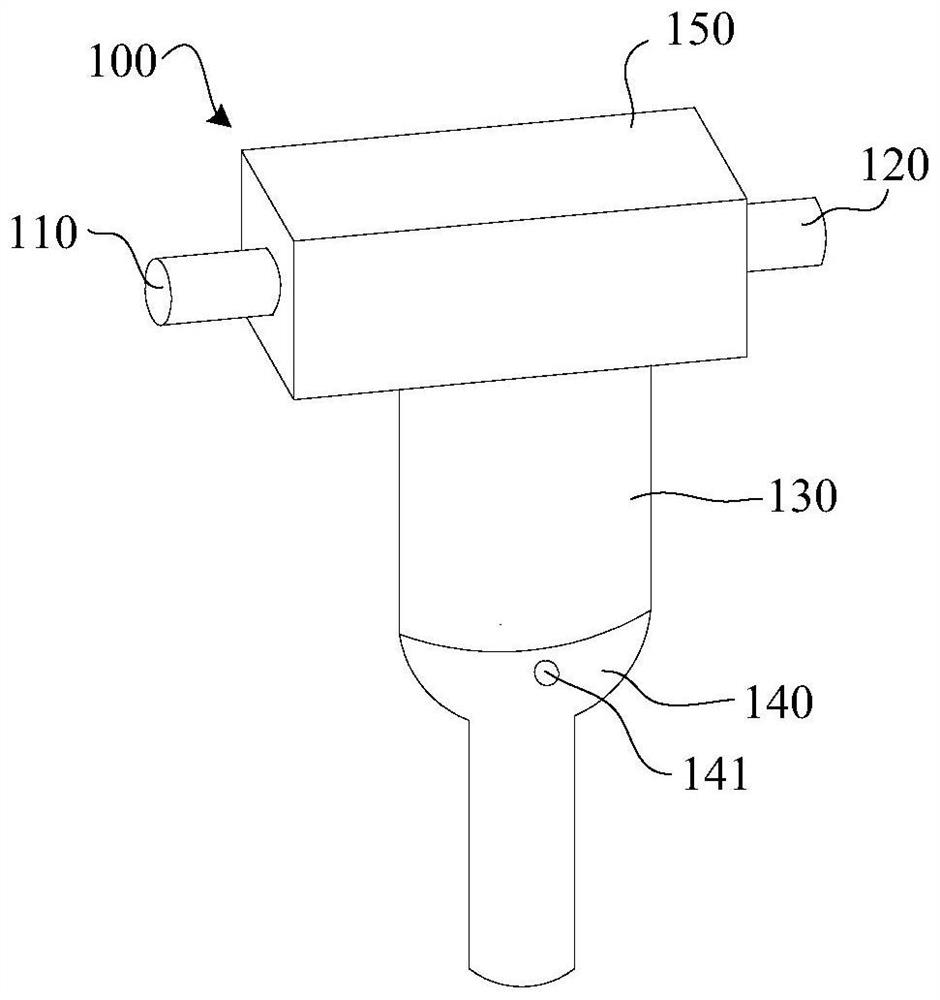

Puffing composite line for clutch facing and preparation method and processing equipment of puffing composite line

The invention discloses a puffing composite line for a clutch facing and a preparation method and processing equipment of the puffing composite line for the clutch facing. Glass fiber filaments and chemical fiber filaments are subjected to puffing treatment through first turbulent flow gas and second turbulent flow gas respectively, the first turbulent flow gas is formed in a first puffing cavity under the action of first high-pressure gas, the second flow gas is formed in the second puffing cavity under the action of second high-pressure gas; prepolymerization is carried out on the glass fiber filaments, the chemical fiber filaments and the metal wires; and the glass fiber filaments, the chemical fiber filaments and the metal wires are jointly subjected to puffing composite treatment through third turbulent flow gas, and the third turbulent flow gas is formed in a third puffing cavity under the action of third high-pressure gas. According to the puffing composite line for the clutch facing and the preparation method and the processing equipment of the bulking composite line, the composite uniformity of the prepared bulking composite line can be high, meanwhile, the requirement for the pressure stability of output gas of a high-pressure gas supply system is lowered, and the preparation cost of the bulking composite line is remarkably reduced.

Owner:NANTONG XINYUAN SPECIAL FIBER

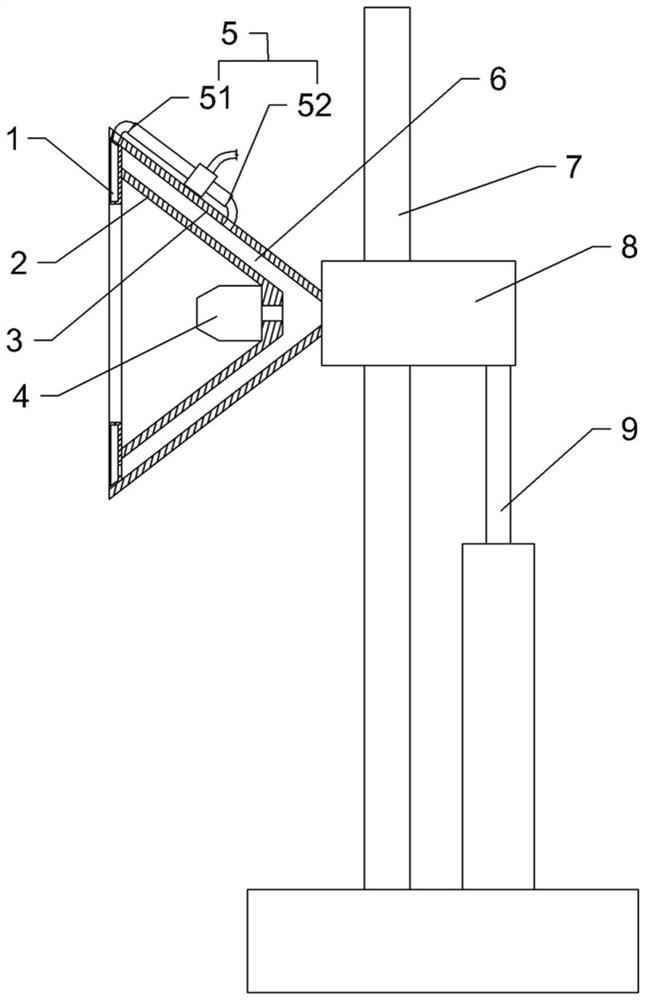

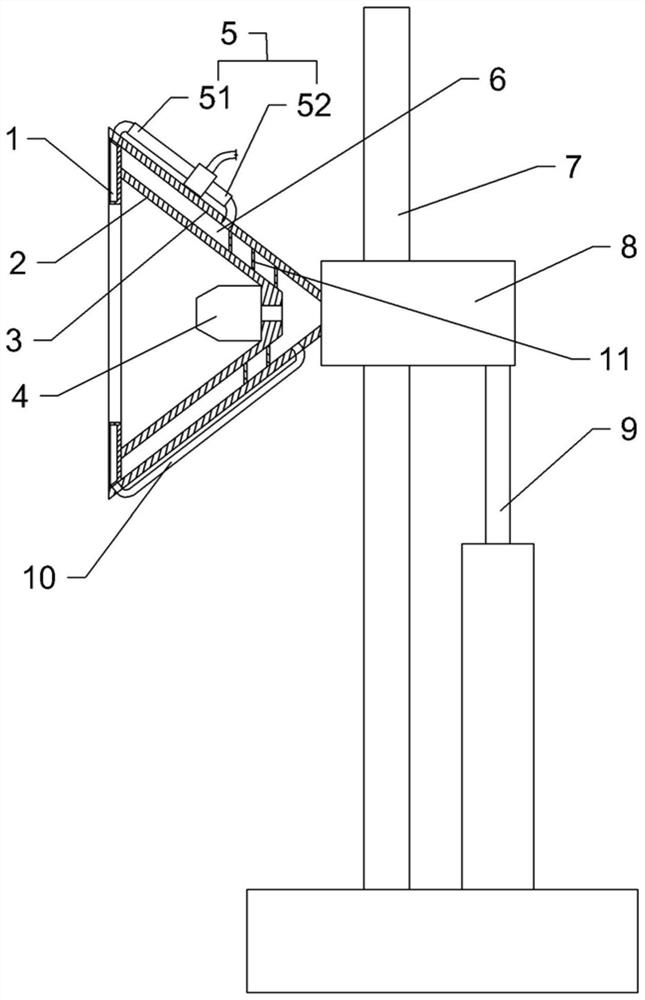

Spraying device for architectural decoration

ActiveCN111411762BSolve the problem of long drying timeSpraying apparatusPretreated surfacesAir compressionTurbulent heat flux

The invention belongs to the technical field of appliances for applying plasticizing substances on the building surface through the action of air pressure in building decoration engineering, and specifically relates to a spraying device for building decoration, which includes a bracket connected with a spray head and an air compression mechanism. There is a first cover set on the nozzle. The end of the first cover away from the support is connected with a ring-shaped heat pipe. The support is connected with a vortex tube. The air inlet of the vortex tube is connected with the air compression mechanism. The air outlet of the hot end is communicated with the inlet end of the heat conduction tube, and the air outlet of the heat conduction tube and the air outlet of the cold end of the vortex tube are jointly communicated with the nozzle. This solution solves the problem of relatively long drying time after the spraying operation of architectural decoration in the prior art.

Owner:CHONGQING VOCATIONAL INST OF ENG

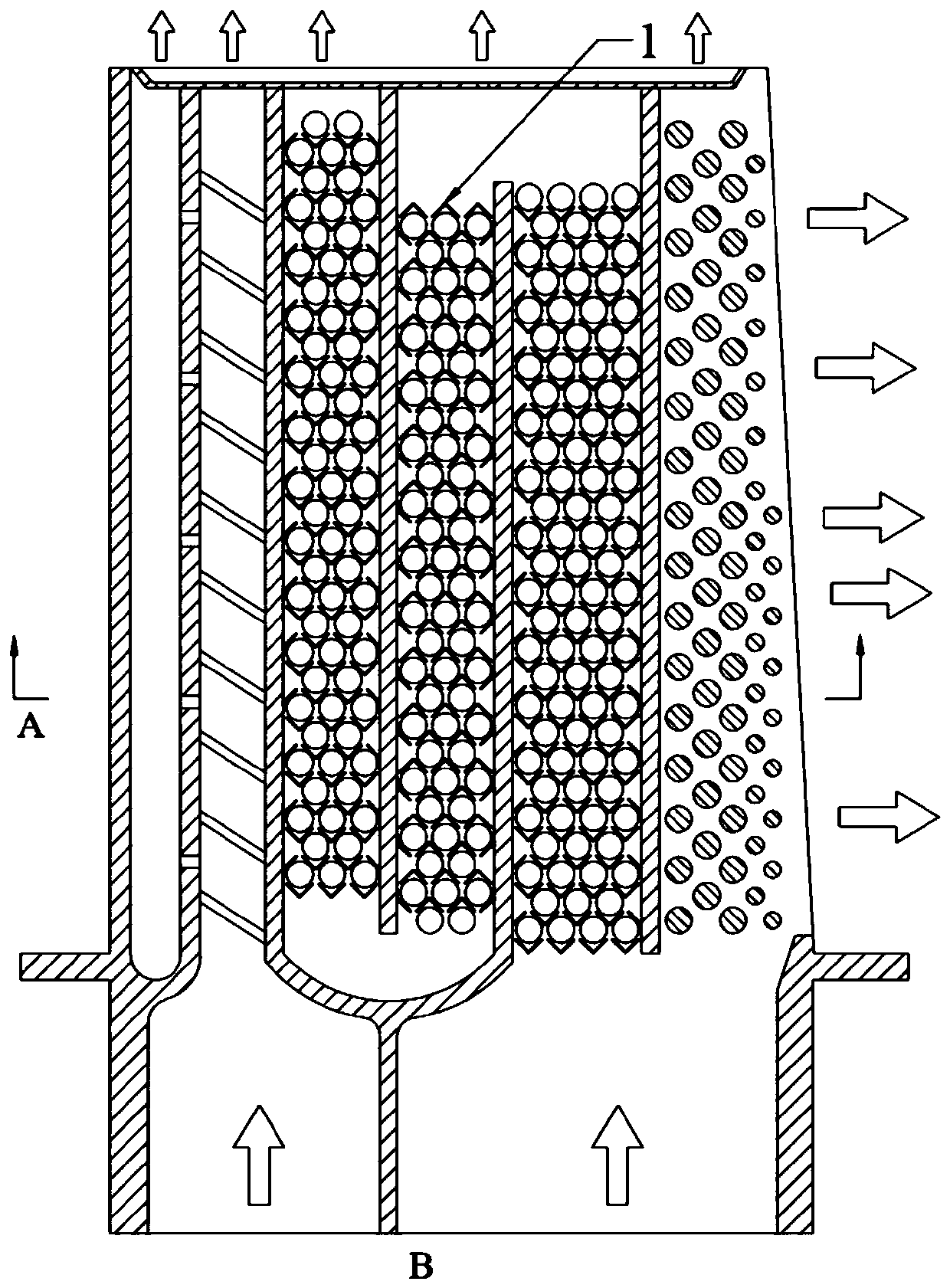

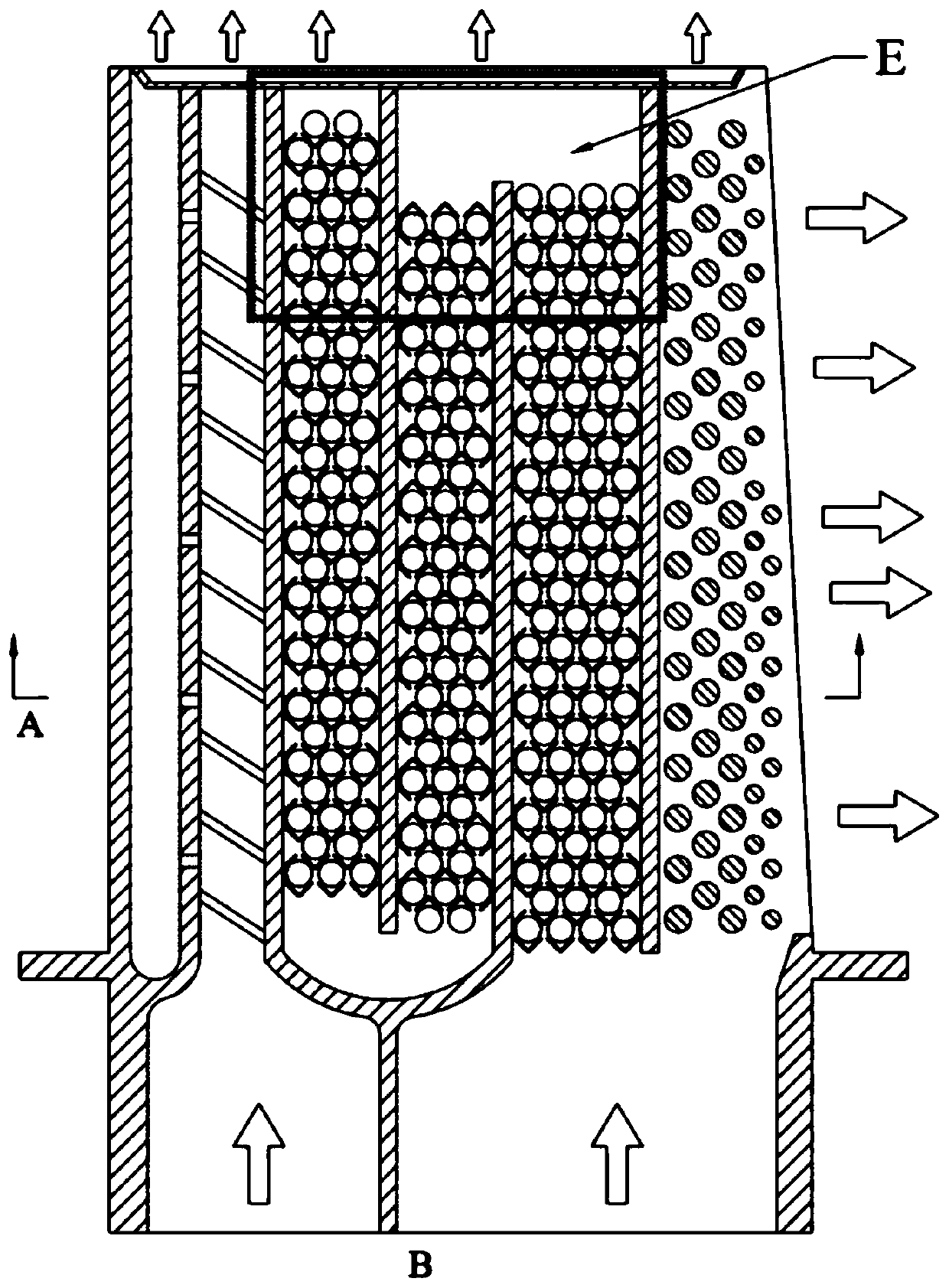

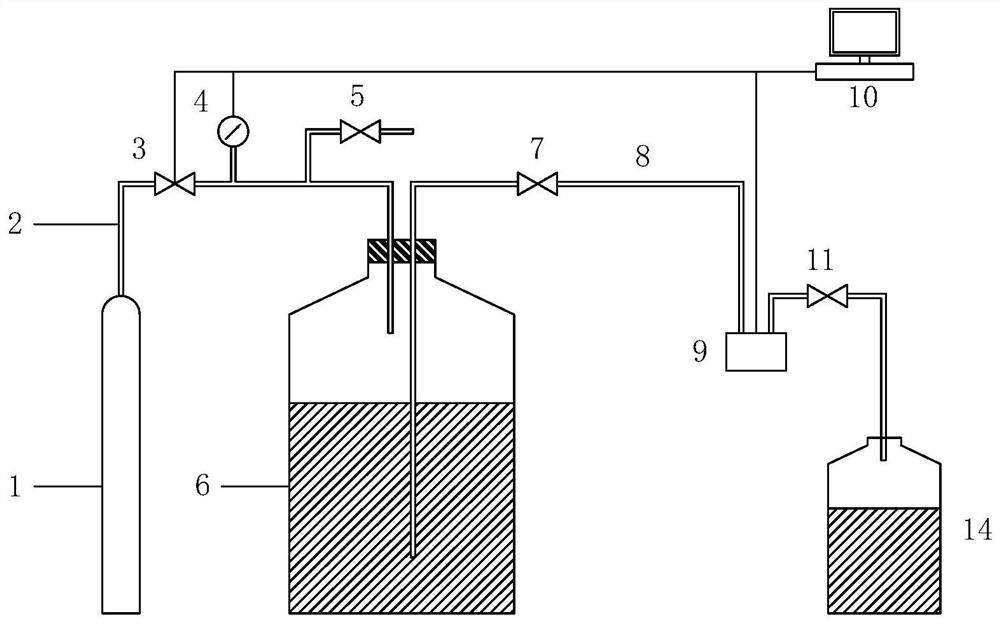

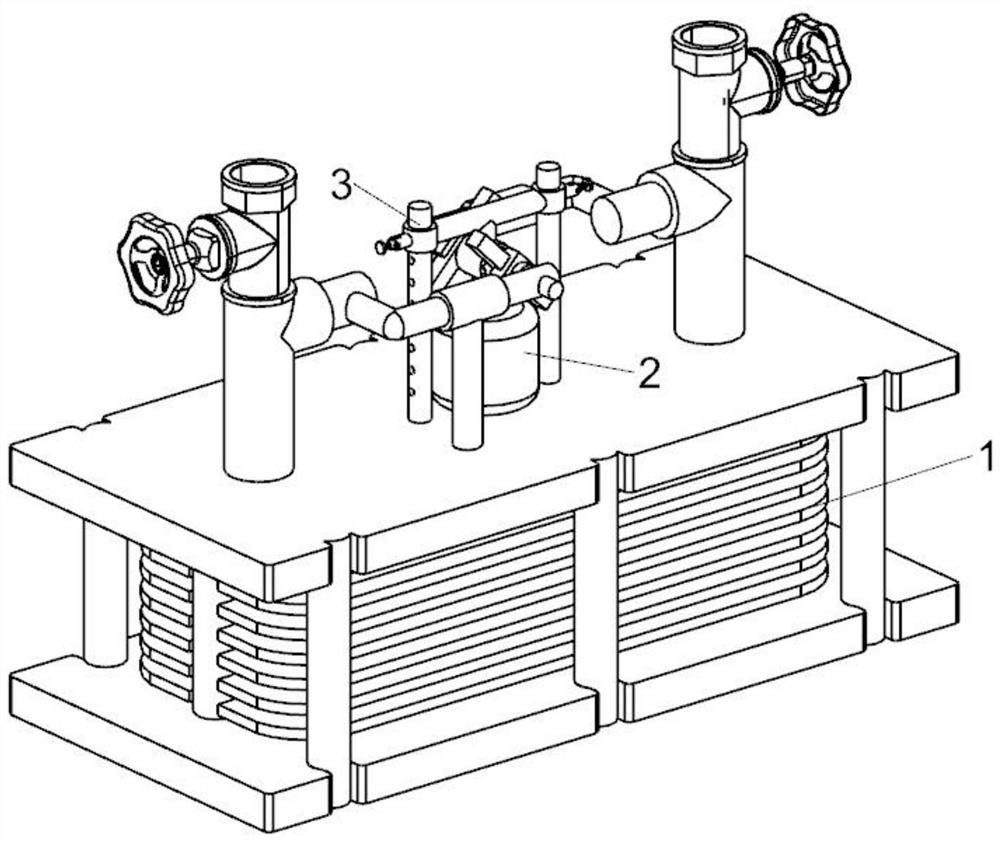

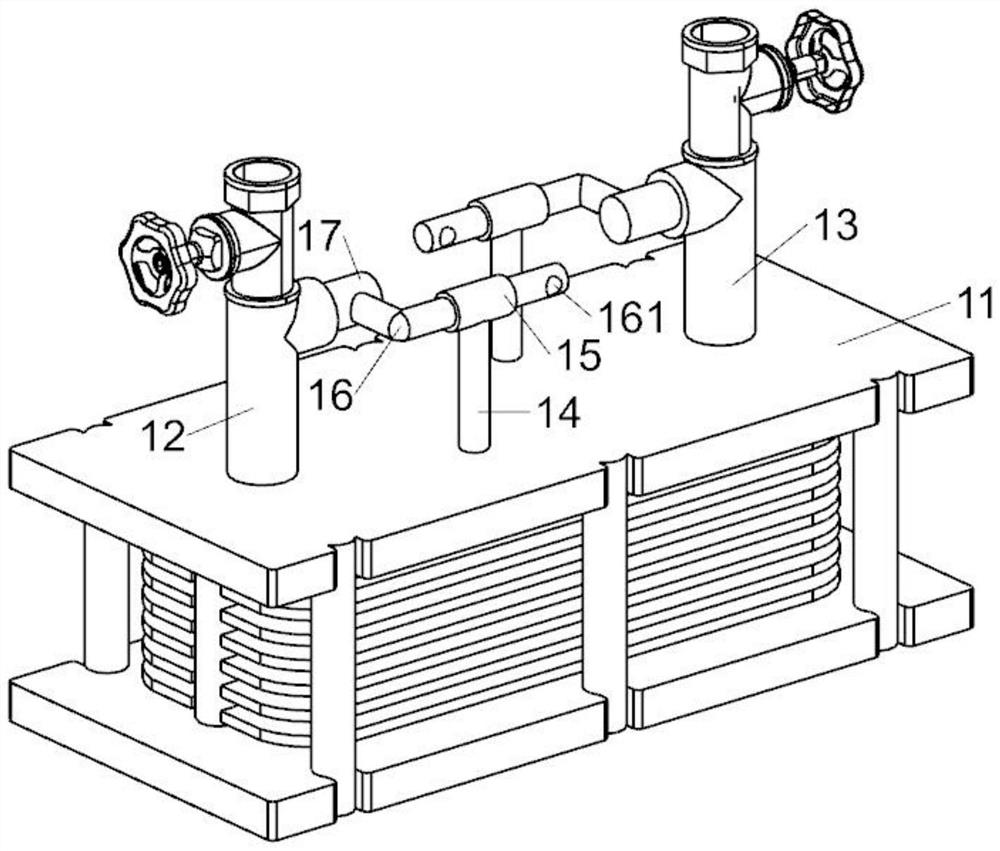

A small modular reactor coolant system and an experimental method using the same

ActiveCN111951987BImprove natural circulationIncrease disturbanceNuclear energy generationNuclear monitoringTurbulent heat fluxEngineering

The invention discloses a small modular reactor coolant system. In the system, liquid metal gallium is used as a coolant, a certain amount of gas is added to the coolant, and the natural circulation capacity of the liquid gallium metal is increased by the gas, which can also increase its Disturbance to enhance the heat transfer effect; through this system, the liquid gallium metal can be repeatedly increased or decreased, and the doped gas can also be arbitrarily increased or decreased, the air pressure can be adjusted, and the heat transfer capacity and natural circulation of the liquid gallium metal under various conditions can be recorded and analyzed. It provides basic data for building flexible and diverse small modular reactors.

Owner:SOUTHEAST UNIV +1

An intelligent heating device

ActiveCN109349933BIncrease profitEmission reductionSteam cooking vesselsWarming devicesThermodynamicsControl signal

The embodiment of the invention relates to an intelligent heating device. The intelligent heating device comprises a processing control module, a heating module, a steam cycle driving module, an air pressure control module, a power source module and a circuit module; the processing control module generates a heating control signal and a cycle driving control signal according to a starting command,and the heating control signal and the cycle driving control signal are sent to the heating module and the steam cycle driving module respectively; the heating module heats a liquid in a water tank to generate hot steam; the steam cycle driving module drives the hot steam to circulate to continuously and uniformly heat the to-be-heated object contained in the intelligent heating device; the processing control module obtains an air pressure value and a steam temperature value in the intelligent heating device; when the air pressure value reaches an air pressure threshold and the steam temperature value is lower than a preset temperature threshold, the processing control module generates an air pressure control signal and sends the air pressure control signal to the air pressure control module; the air pressure control module is started so that the hot steam is discharged from the intelligent heating device in a set volume.

Owner:因特厨供应链管理(深圳)有限公司 +1

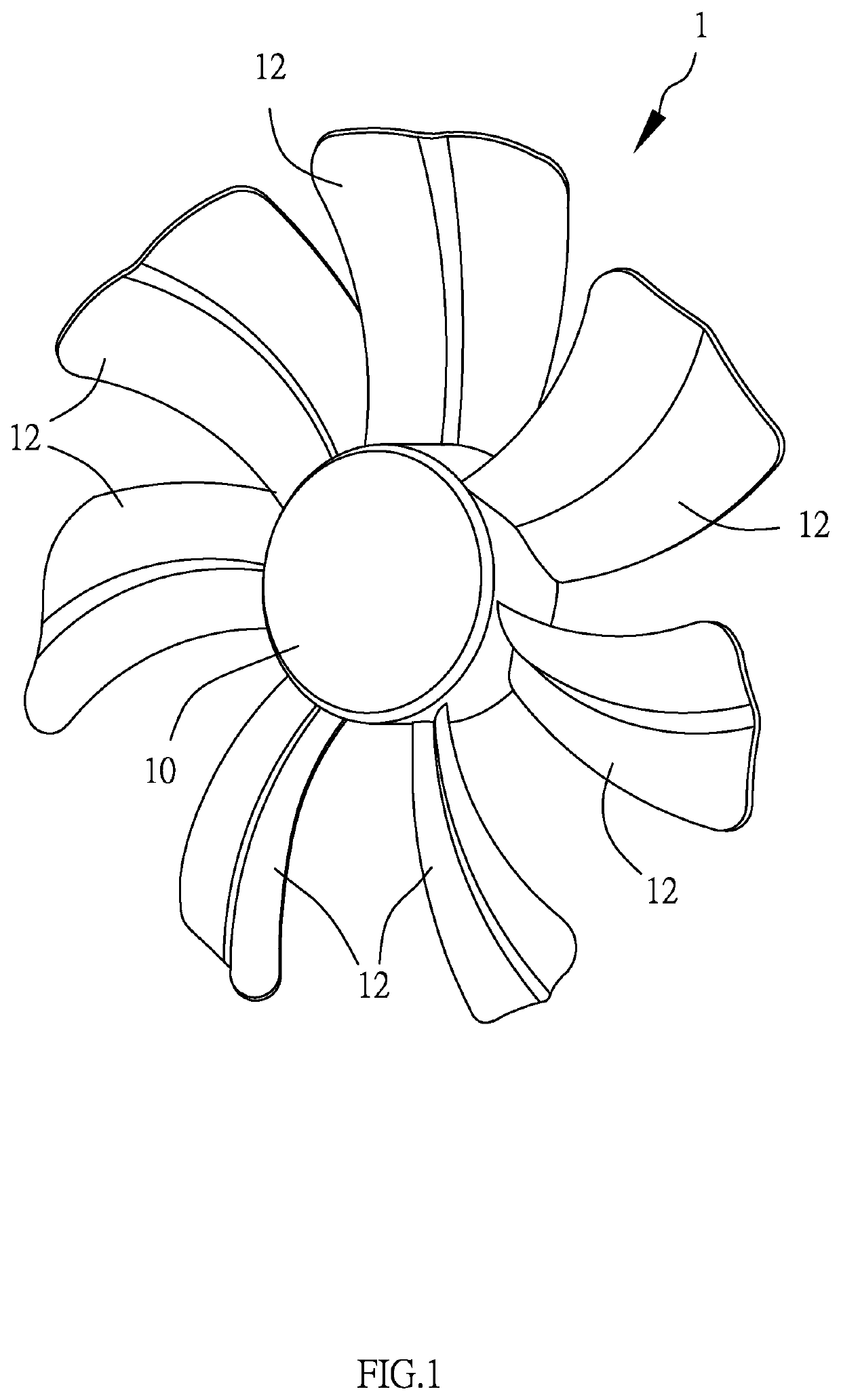

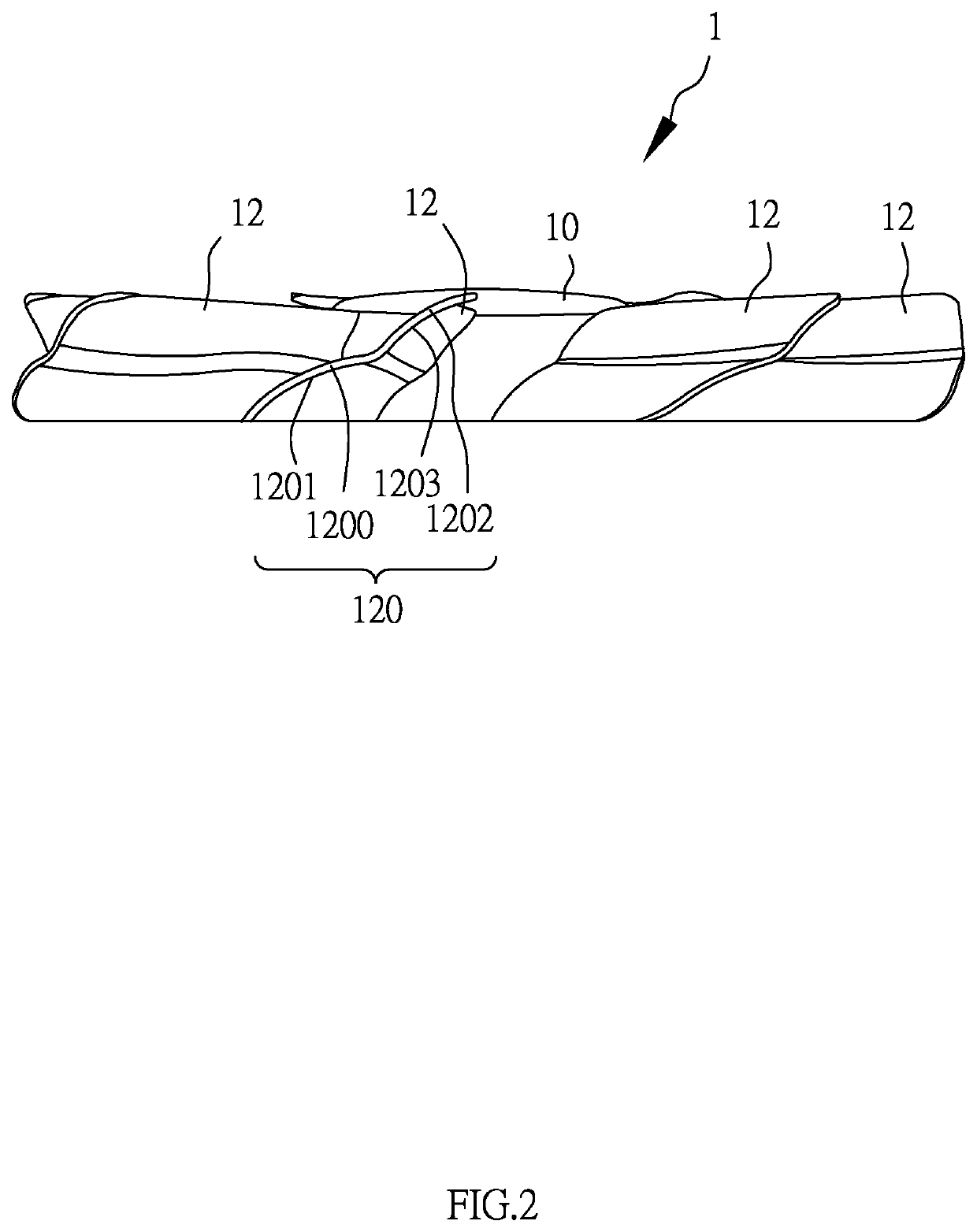

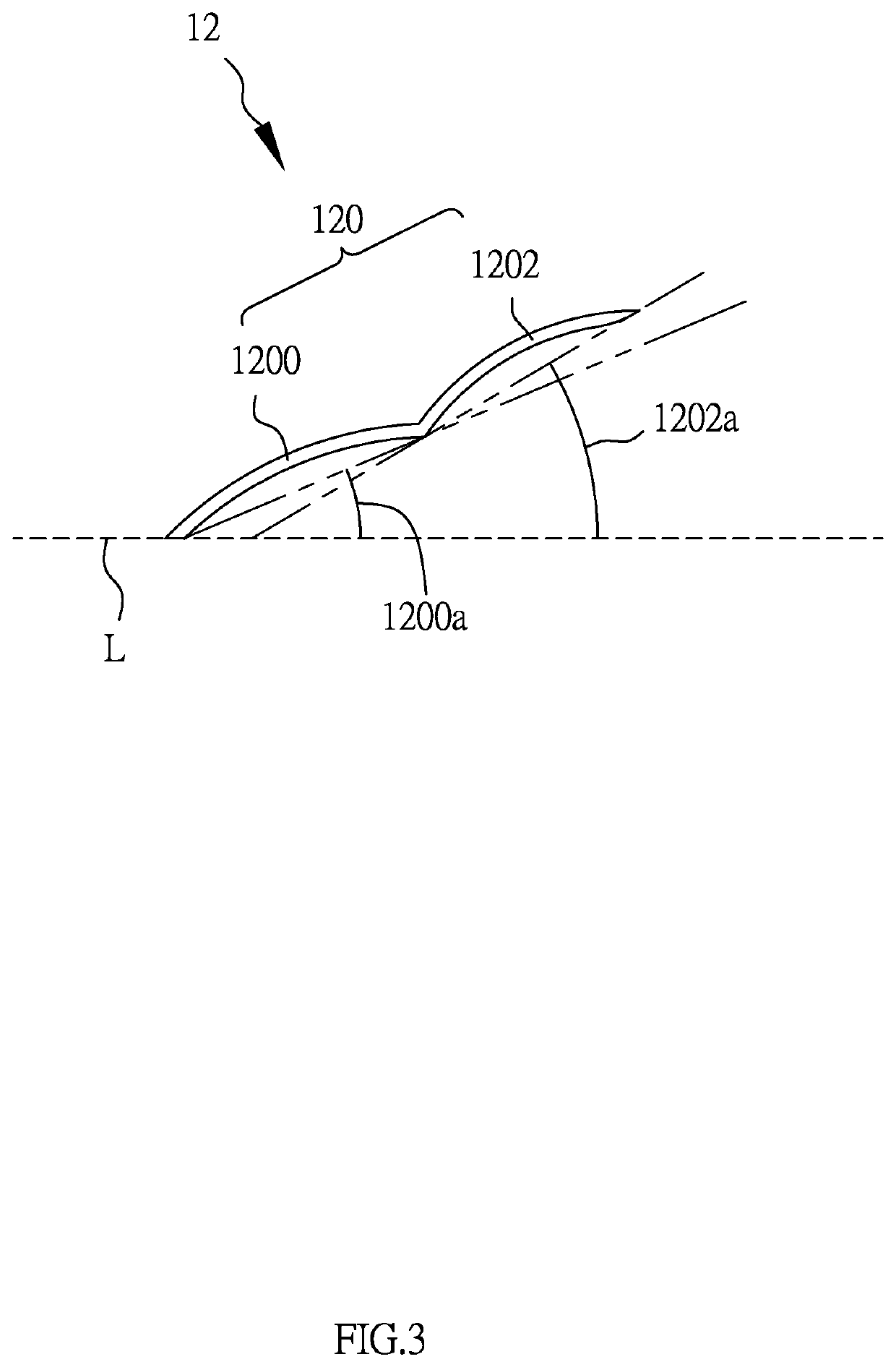

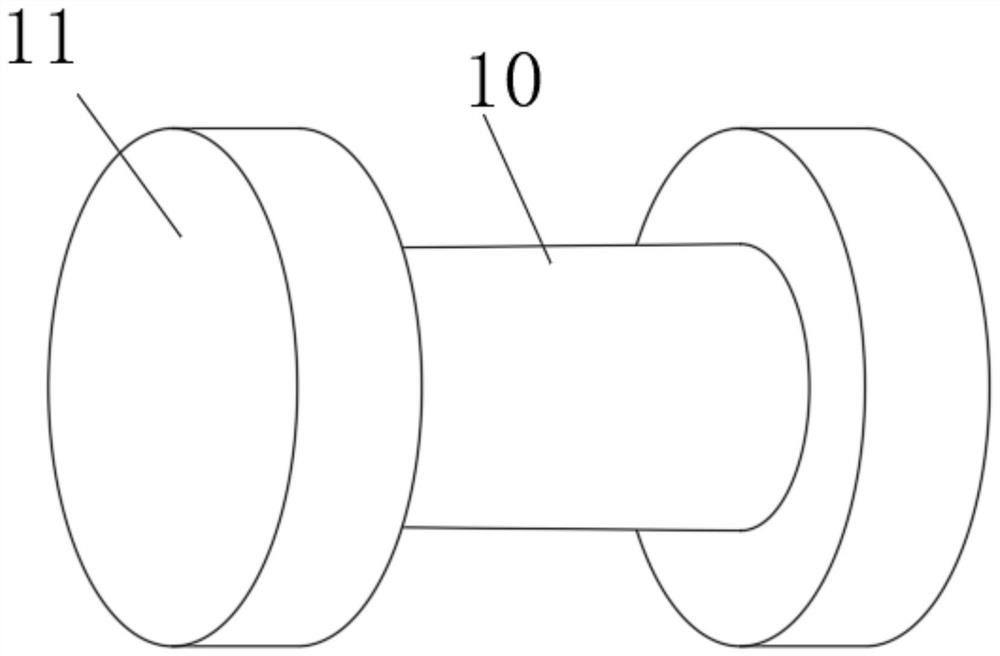

Fan blade structure

InactiveUS20210388846A1Increase rangeImprove cooling effectPump componentsPumpsTurbulent heat fluxEngineering

A fan blade structure comprises primarily an axle seat and plural vanes. Each vane is connected to the axle seat and includes a vane body. The vane body is provided an air pressure structure which is extended from the axle seat, and an air flow structure which is extended from an end of the air pressure structure. The angle of air pressure structure is smaller than that of air flow structure. By the air pressure structure, turbulent air can be pushed to a farther distance. On the other hand, as the tilt angle of air flow structure is larger than the angle of air pressure structure, the range of push to the turbulent aft can be increased, so as to improve the heat dissipation effect.

Owner:WANG TUNG MAO

Novel double-line winch

The invention discloses a novel double-wire winch which comprises a rack. A motor is fixedly connected to the upper surface of the rack, and a driving mechanism is rotatably connected to the left side of the motor; a winch body is rotatably connected to the right side of the driving mechanism, and located between the motor and the driving mechanism; and the winch body comprises a reel. According to the novel double-line winch, a turbulent flow mechanism, a sealing mechanism and a connecting rod are installed in a connecting wheel, when the connecting wheel is rotated, a clamping ball is driven by a convex block to extend outwards under the inertia effect; since the bottom stress of the sealing mechanism is not uniform, gas at the bottom is pushed upwards to the turbulent flow mechanism while inclined rotation is conducted, and then the gas is pushed out through the turbulent flow mechanism; a clamping plate is extruded by a limiting ball under the inertia effect, and the fitting degree between a spoiler and the sealing mechanism is increased; a movable plate is pushed to move under the air pressure effect, and the problem that gaps are generated when cables are wound since the size of a side wing baffle of a traditional winch is fixed is solved.

Owner:彭煜

Deep cryogenic temperature control system for power devices

ActiveCN112397466BControl flow rateControl cooling rateSemiconductor/solid-state device detailsSolid-state devicesTemperature controlControl system

Owner:无锡中科德芯感知科技有限公司

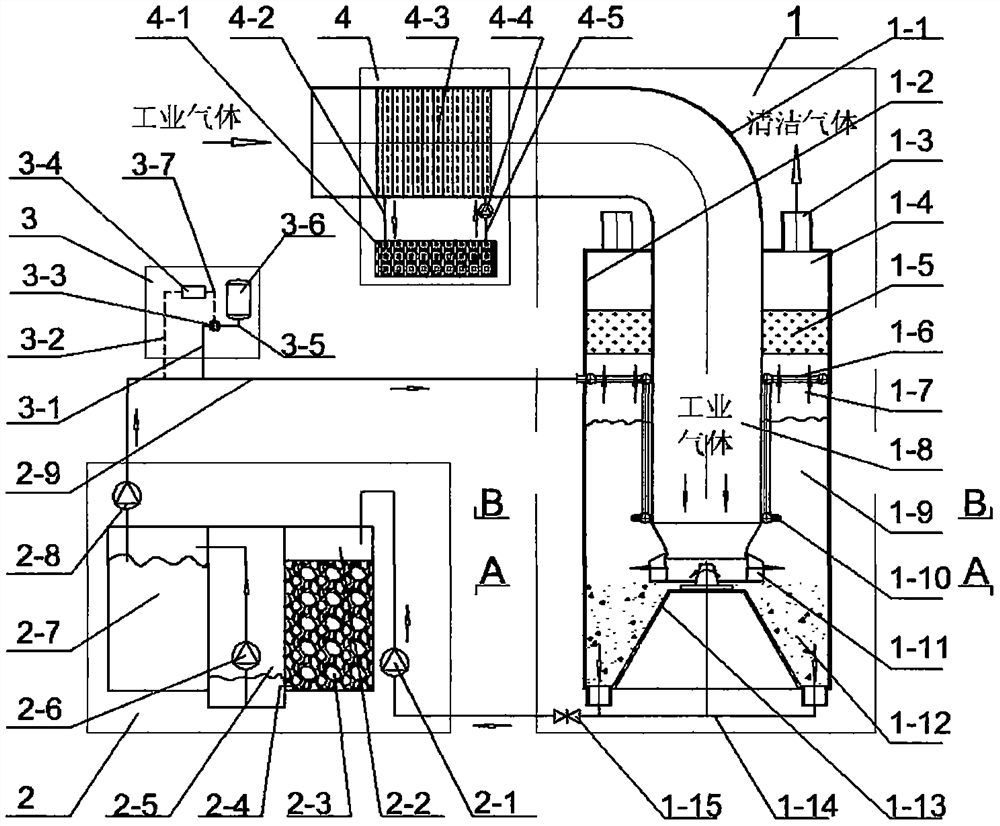

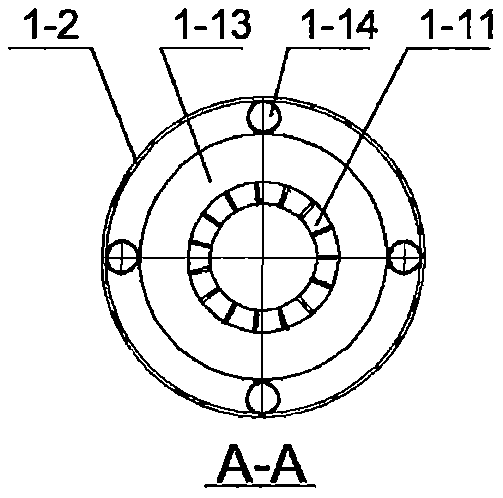

System and method for purifying industrial gas in gas explosion mode

The invention relates to the field of industrial gas purification treatment. Industrial gas is fed into turbulent flow water in a gas explosion bin by a foam maker to be converted into a plurality of bubbles with different sizes, the bubbles are impacted and extruded by the turbulent flow water, the air pressure in the bubbles is increased until the bubbles burst, namely gas explosion, and harmful substances in the gas are rushed into water along with gas explosion waves to be in strong contact with water, is instantly wrapped and stored by the water, enters a settling bin along with the spiral water flow and the gravity, and then is discharged from a blow-off pipe along with the water flow; the industrial gas purified in a gas explosion mode is converted into clean gas, the clean gas is separated from the gas explosion bin and enters a dehydration bin to be converted into mist, water molecules in the mist are gathered through a condenser and a drop catcher to be converted into water drops to be recycled, and the dehydrated gas enters a transition bin and then is exhausted through an exhaust pipe; sewage carrying harmful substances enters a liquid-sewage separation unit through a blow-off pipe to be subjected to sewage-liquid separation, the harmful substances are retained in a filter material, and the sewage is converted into clear water; and the clear water is fed into a gas explosion purification unit through a water supply pump for cyclic operation.

Owner:北京金熔节能环保科技有限公司

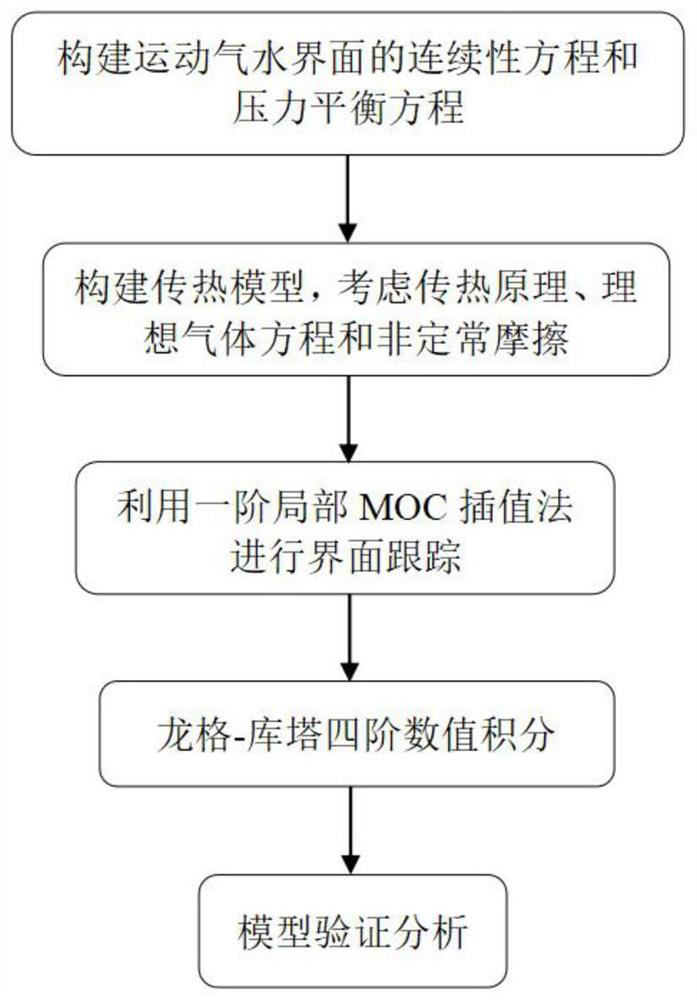

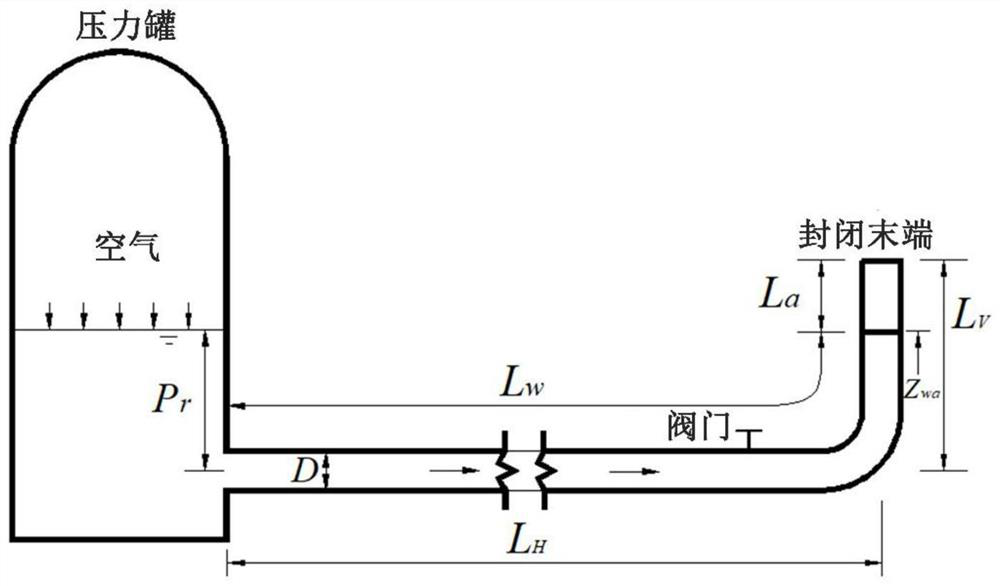

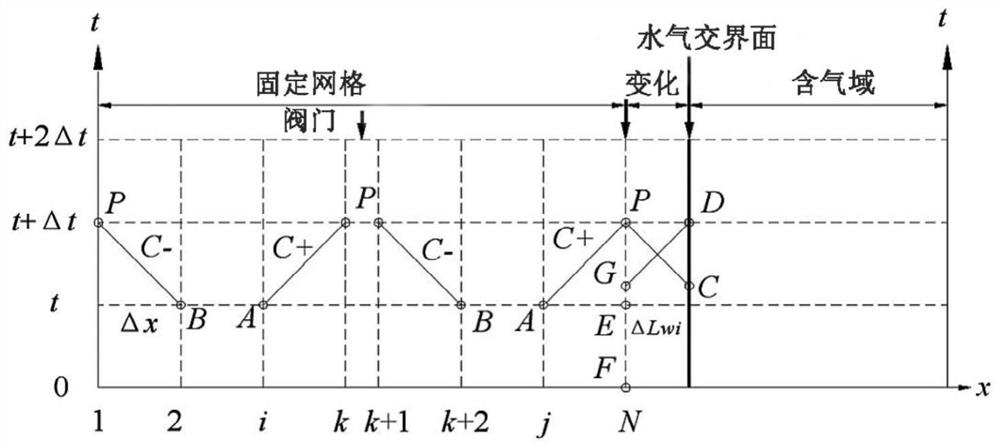

Quick filling vertical pipeline simulation method considering intercepted air energy dissipation

PendingCN114417749AExplain white fogExplain heat pipe wall phenomenaDesign optimisation/simulationCAD numerical modellingEngineeringWater hammer

The invention discloses a rapid vertical pipeline filling simulation method considering trapped air energy dissipation. The method comprises the steps that a continuity equation and a pressure balance equation of a moving air-water interface are established; constructing a heat transfer model by taking a water hammer theory as a basis and combining a heat transfer principle of a closed air bag and an equation of ideal gas; a first-order local MOC interpolation interface tracking method is adopted to solve the filling water column control equation and the air heat transfer equation considering the unsteady friction, and the air pressure, the speed and the position of the moving air-water interface are obtained through calculation; solving by using a Runge-Kutta four-order numerical integration method; and performing simulation according to the solving result to obtain a simulation result. The heat transfer model considering trapped air energy dissipation is researched, rime fog and heat pipe wall phenomena of related experiments can be explained, the accuracy problem of a traditional model is solved, and the method has important significance on heat transfer of trapped air pockets in actual rapid filling vertical pipelines and energy consumption simulation of violent air-water interaction.

Owner:HOHAI UNIV

Operation method of building cooling and heating system

InactiveCN108592185BReduce differential pressureSave electricityMechanical apparatusLighting and heating apparatusFrequency conversionFresh air

The invention discloses an operation method of a building cooling and heating system, including a cooling operation method and a heating operation method; the first step of the cooling operation method is to adjust the operation state; the second step is to start the operation through the general electric control device Frequency conversion compressor, first air-conditioning water pump and fresh air fan, the third step is to continuously carry out summer frequency conversion control, and the total electric control device performs air pressure adjustment and fresh air energy-saving adjustment; the heating operation method is carried out according to the following steps: The first step is to adjust the operating state The second step is that the staff start the frequency conversion compressor, the first air-conditioning water pump and the fresh air blower through the total electric control device, and the third step is to continue the winter frequency conversion control; at the same time, the total electric control device performs air pressure adjustment and fresh air energy-saving adjustment. The invention has simple steps, flexible control, is convenient to switch between the cooling operation method and the heating operation method, adopts various technical means to reduce energy consumption, can separately adjust each air-conditioned room, and the system runs very smoothly.

Owner:HENAN COLLEGE OF IND & INFORMATION TECH

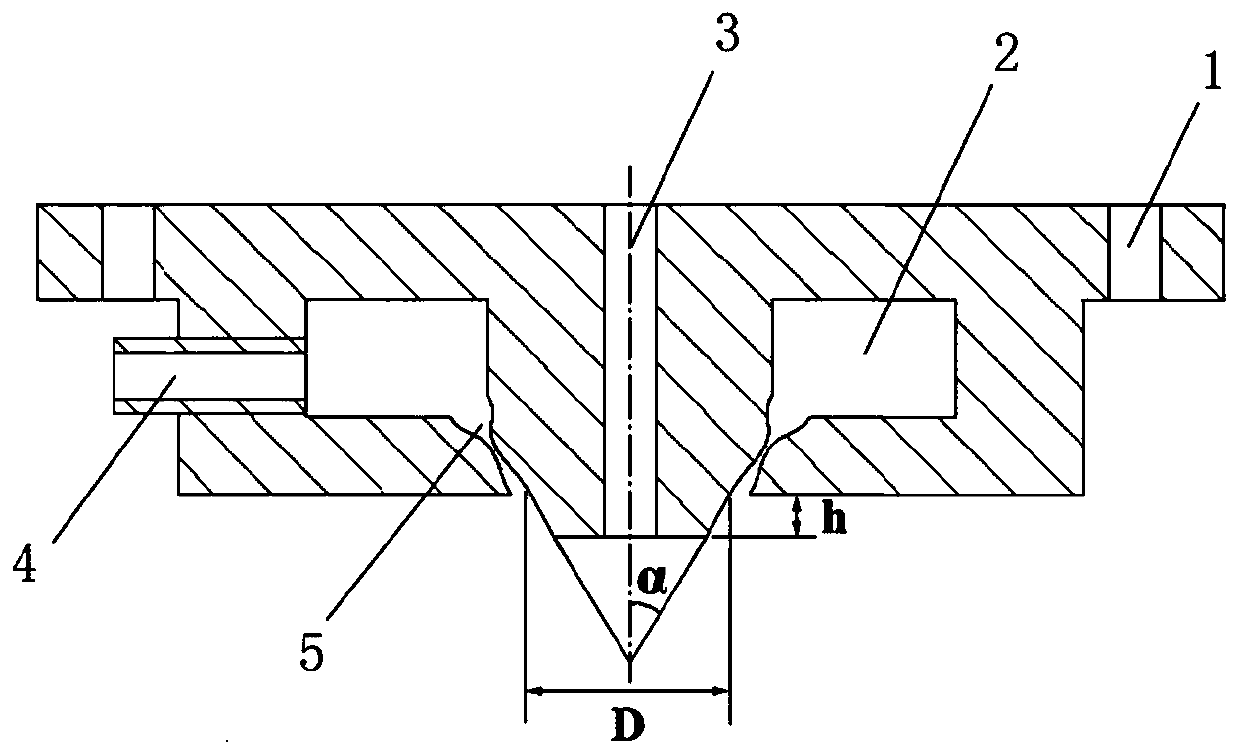

A Design Method for Alloy Melt Atomizer with Supersonic Laval Nozzle Structure

ActiveCN109570517BPrevent backflowPrevent blowbackGeometric CADSustainable transportationShock waveTurbulent heat flux

The invention relates to a design method of a supersonic laval nozzle structural alloy melt atomizer, and belongs to the field of alloy powder atomizing preparation. According to the design method, asupersonic laval wall curve is researched, the characteristic of close coupled atomization is combined, the supersonic laval nozzle structural atomizer is designed according to the suction pressure criterion, the close coupled criterion and the flow velocity criterion, and the influence of five main factors including the atomization gas pressure, the atomization gas temperature, the gas nozzle hole heart distance, the gas injection angle and the extended length of a diversion pipe on the flow field structure is simulated and researched by utilizing computational fluid dynamics software. Thus,structural parameters of a nozzle can be optimized, the phenomena of gas backflow and back spray are avoided, the atomizing efficiency is improved, and a guarantee is provided for the production of alloy powder. According to the atomizer, the phenomena of blockage of the diversion pipe, gas back spray and the like of the atomizer can be prevented, shock wave and turbulent flow are reduced, the flying distance of gas can be reduced, the flow velocity can be increased, and the loss of energy is reduced.

Owner:UNIV OF SCI & TECH BEIJING

An ultra-long pier thickening device for a large-wall-thick seamless steel pipe and its application method

ActiveCN111054870BEasy accessNot easy to bendForging/hammering/pressing machinesForging press detailsTurbulent heat fluxAlloy

The invention discloses an ultra-long thickening device for a large-walled seamless steel pipe and a method for using the same, and belongs to the technical field of thickening of steel pipes. This scheme makes the heating part of the seamless steel pipe difficult to Bending to reduce the folding phenomenon of the inner wall of the seamless steel pipe. After the seamless steel pipe pier is roughly formed, the cooling water in the water tank is sprayed out through the nozzle to form cooling water mist, which cools the moving mold and the seamless steel pipe. The water after heat exchange is collected, and the water is pumped into the water tank through the water pump, so that the water in the water tank is recycled, and the liquid nitrogen in the liquid nitrogen tank is circulated in the spiral tube through the air pump to cool down the high temperature water. The nitrogen gas formed after the heat exchange is pressurized by the suction pump, so that the nitrogen gas is pressurized and liquefied again. With the help of the easy deformation of the memory alloy ring at low temperature, the seamless steel pipe can be taken more easily after the forming is completed. convenient.

Owner:NANTONG YONGDA PIPE IND

A heat exchanger temperature control device

ActiveCN112880466BSolve the problem of declining yield rateHeat exchange apparatusTemperature controlWater flow

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

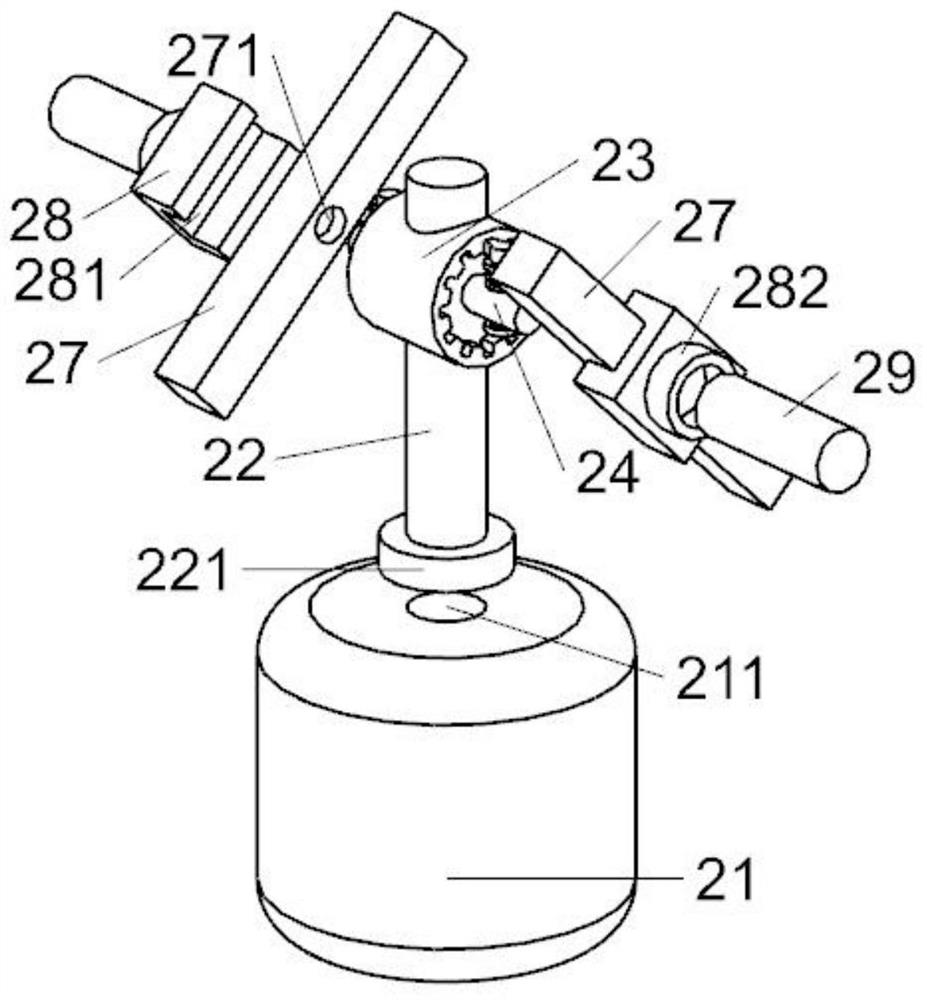

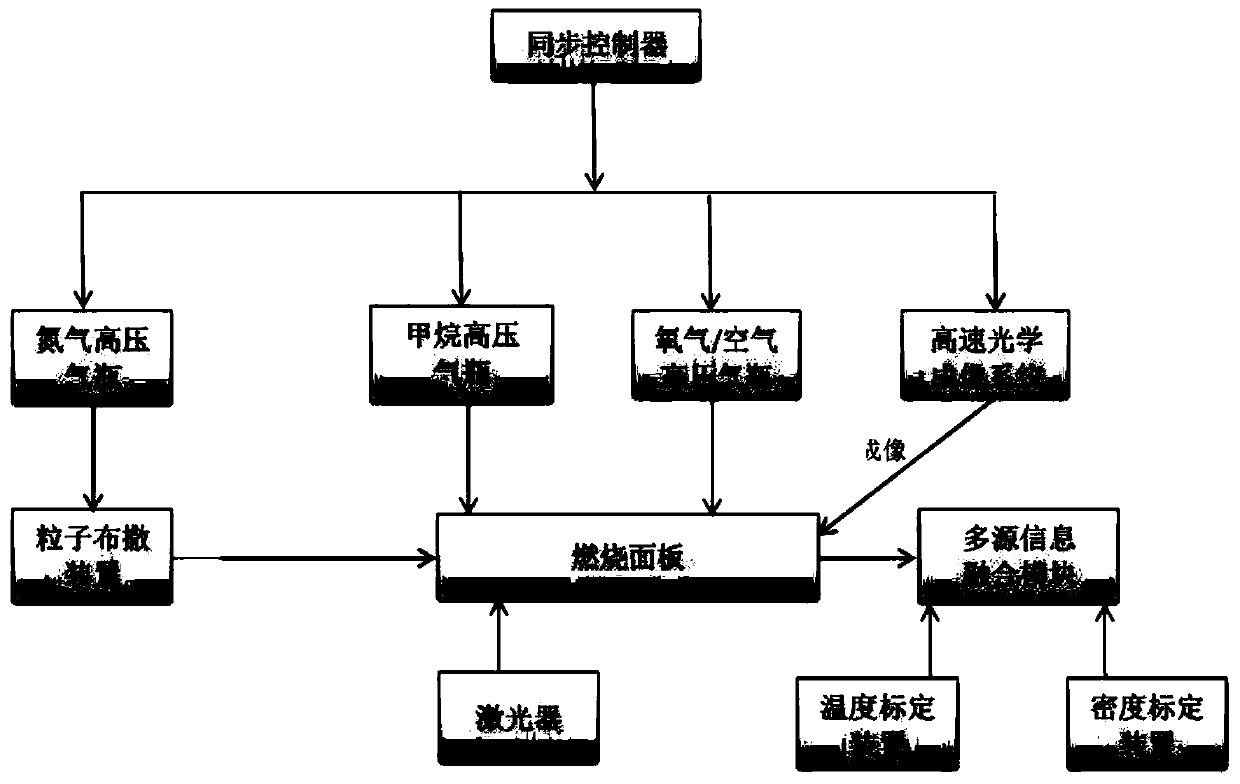

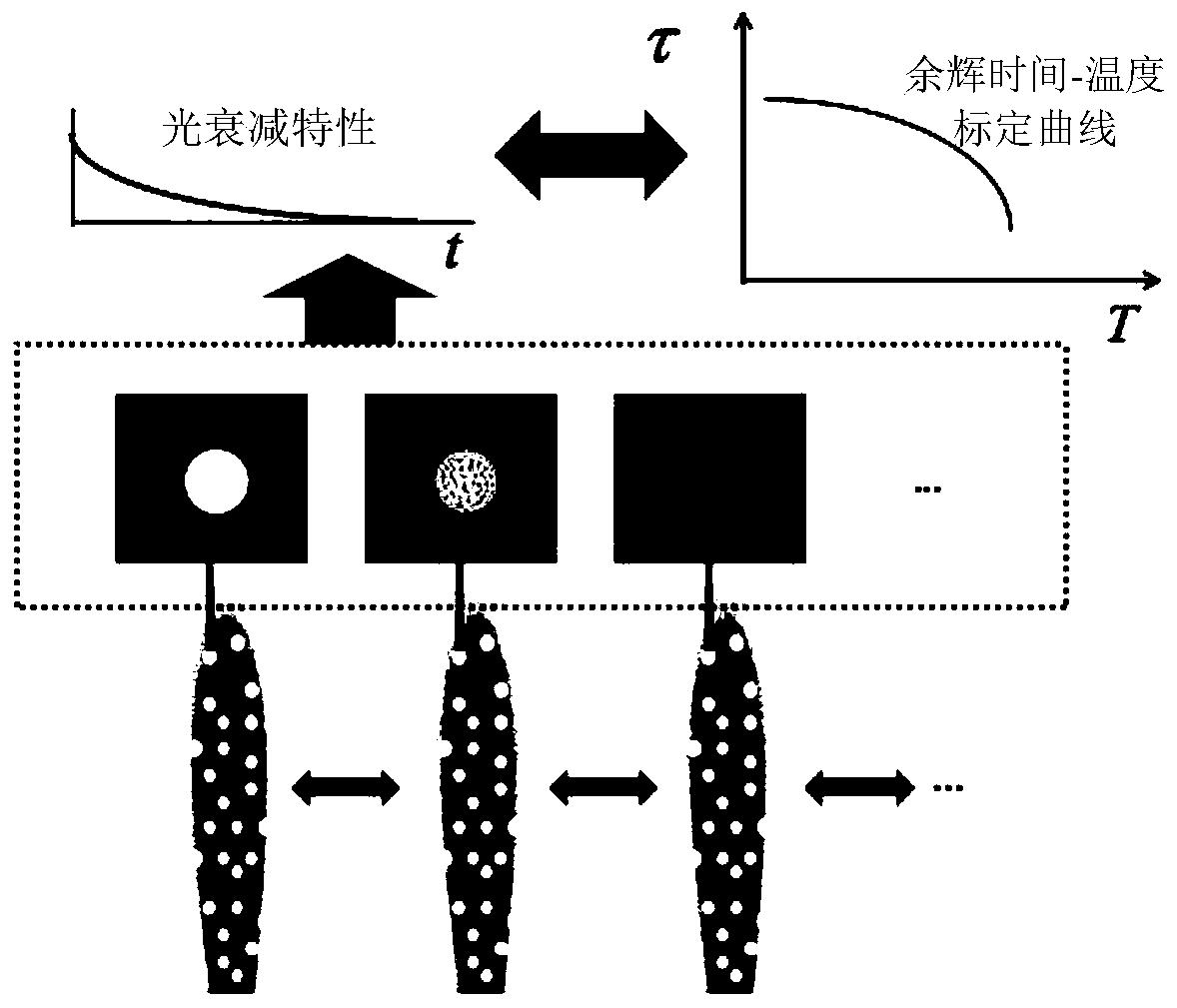

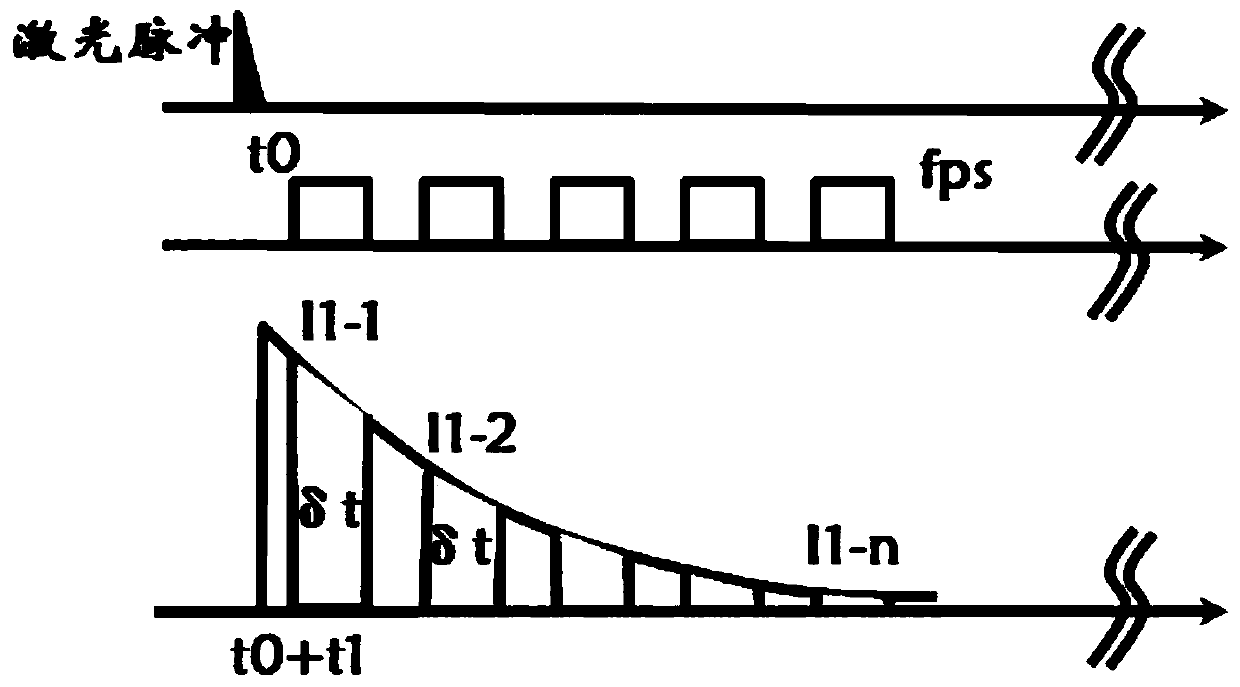

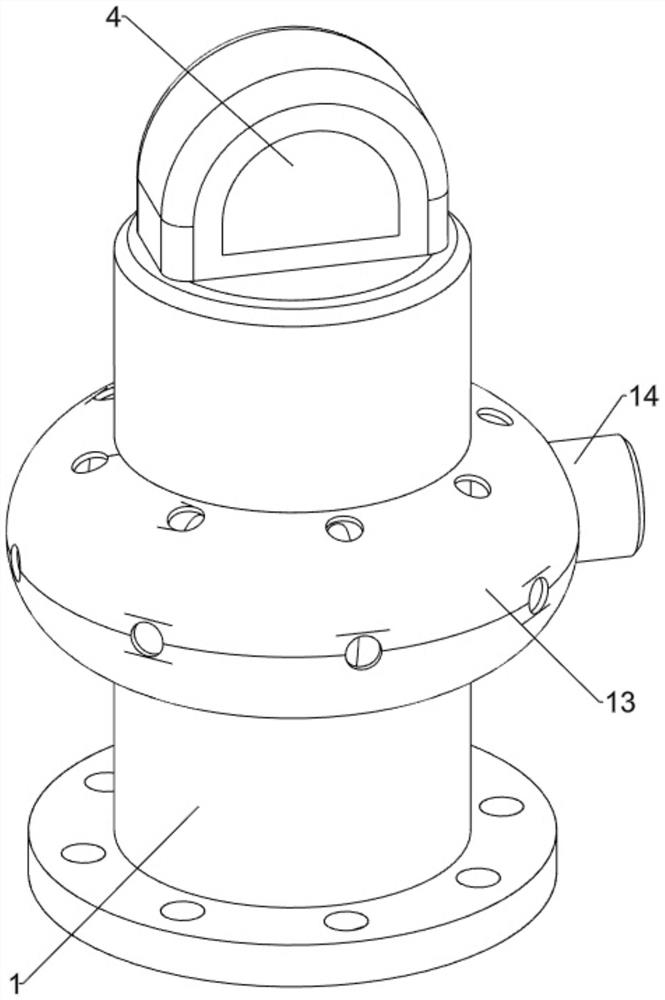

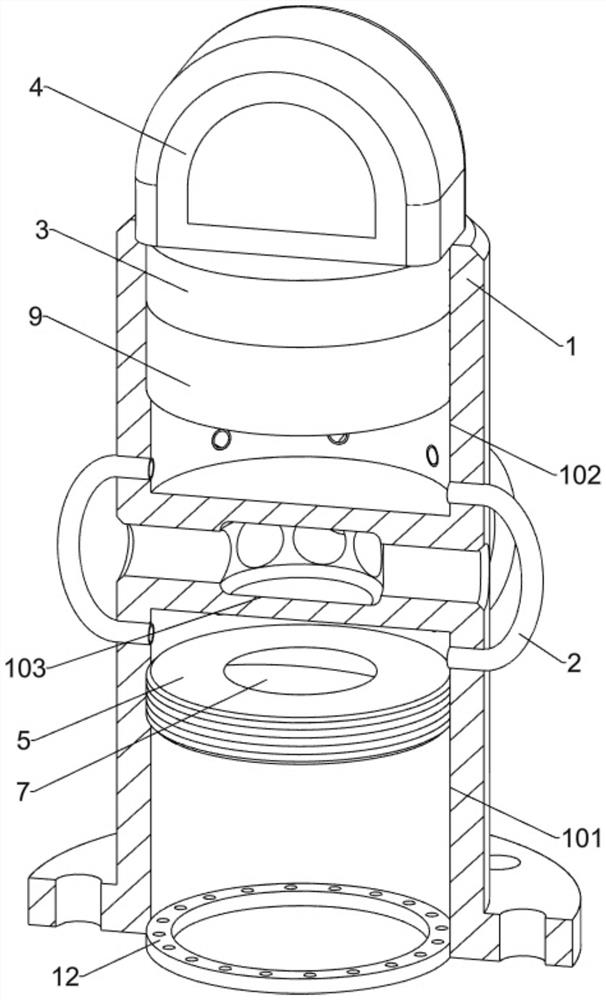

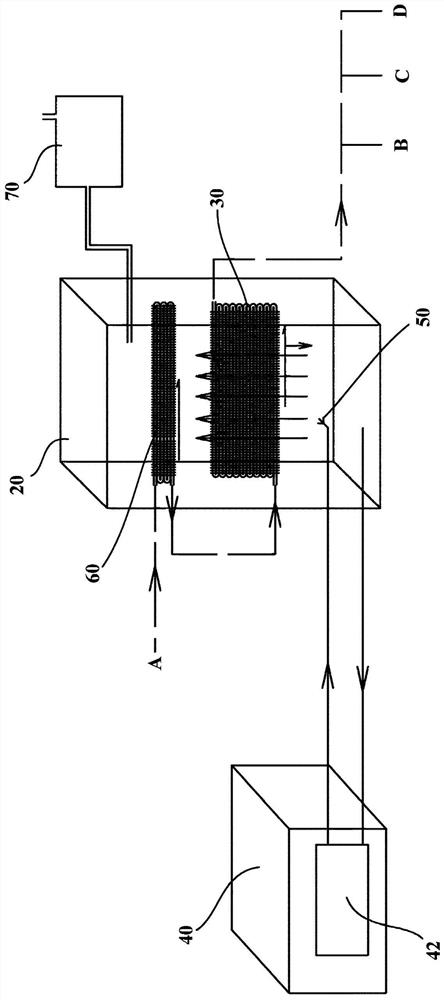

A full-field measurement system and method for high-temperature and high-speed turbulent heat flux

The invention relates to a full-field measuring system and a method for heat flux of a high-temperature high-speed turbulence. The system comprises a multi-source information fusion module, a synchronization controller, a dispenser of thermal long afterglow luminescent particles, a laser, a high-speed optical imaging system, and a combustion panel. Wherein the multi-source information fusion module performs complementary integration of the multi-source information for determining high-frequency information such as the density, velocity and temperature of a high-temperature and high-speed gaseous flow field characterized by a thermal tracer; the synchronization controller controls a supply of the combustion gas to the combustion panel, and controls the high-speed optical imaging system forimaging a time series long thermal afterglow image of the thermal tracer; the nitrogen gas is supplied to the particle dispenser to provide an input of the luminescent particle to the combustion panelas a tracer; the laser provides a laser light to the combustion panel. According to the full-field measuring system and the method for the heat flux of the high-temperature high-speed turbulence, themulti-source information fusion technology is fully utilized, the density, speed and temperature of the full field are synchronously measured, and the heat flux of the high-temperature high-speed turbulence is measured.

Owner:SHANGHAI JIAO TONG UNIV

Device and method for identifying, calculating and detecting vacuum of condenser of power plant

PendingCN114812925ALarge amount of displacement changePrecise deliveryFluid pressure measurement by electric/magnetic elementsVacuum gaugesMeasurement devicePressure transmission

The invention relates to the field of power plant auxiliary measuring instruments, in particular to a power plant condenser vacuum recognition calculation detection device and method. Technical problems to be solved are that steam turbulence in a condenser affects measurement, and a high-temperature and high-humidity environment and pressure fluctuation of a measurement device affect the measurement precision of the device. The invention provides a power plant condenser vacuum identification calculation detection device and method, and the device comprises a pressure transmission housing, the lower part in the pressure transmission housing is provided with a pressure buffer transmission assembly, and the upper part in the pressure transmission housing is provided with a pressure conversion transmission assembly. The influence of steam flow turbulence on pressure measurement is prevented through the first pressure transmission cavity, the pressure buffering transmission assembly is matched with transmission of pressure in the condenser and the first pressure transmission cavity in an induction mode, the pressure change in the second pressure transmission cavity is inducted through the pressure conversion transmission assembly, and the air pressure variation in the second pressure transmission cavity is transmitted through hydraulic change.

Owner:国电内蒙古东胜热电有限公司 +2

Fire-fighting waterway heating equipment for fire-fighting vehicles in cold regions

ActiveCN113457053BImprove heating efficiencyAvoid damageFire rescueWater heatersThermal insulationEngineering

The invention belongs to the technical field of fire protection, in particular to a fire-fighting waterway heating equipment for fire trucks in cold regions, which includes a plurality of waterway pipes. The joints are connected to form the whole fixed waterway in the fire truck. The outer wall of the waterway pipeline is fixed with a thermal insulation shell, and a heat exchange chamber is formed between the thermal insulation shell and the outer wall of the waterway pipeline, and a circulation cavity is arranged inside the waterway pipeline. The present invention makes the air flow in the middle of the circulation cavity recoil to both ends, so as to realize the rapid disturbance of the air flow in the flow cavity through the heat exchange rate difference and improve the actual heating efficiency, and cooperate with the air pressure difference caused by heating and the swaying of the fire truck when driving The resulting expansion and contraction of the first spring drives the reciprocating motion between the two piston rings, improving the actual heating efficiency of the water pipeline.

Owner:六安华晟智恒工业设计有限公司

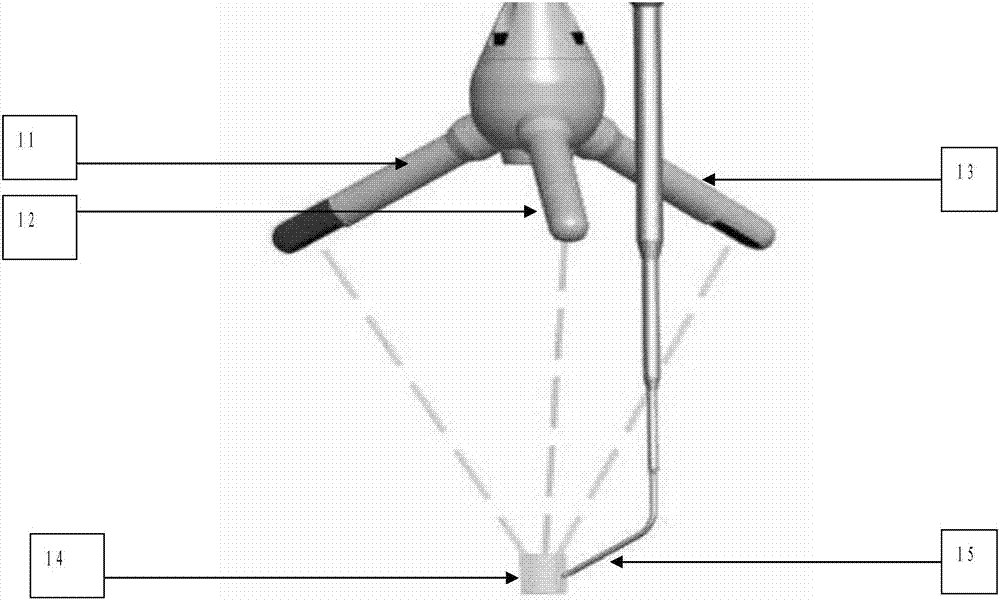

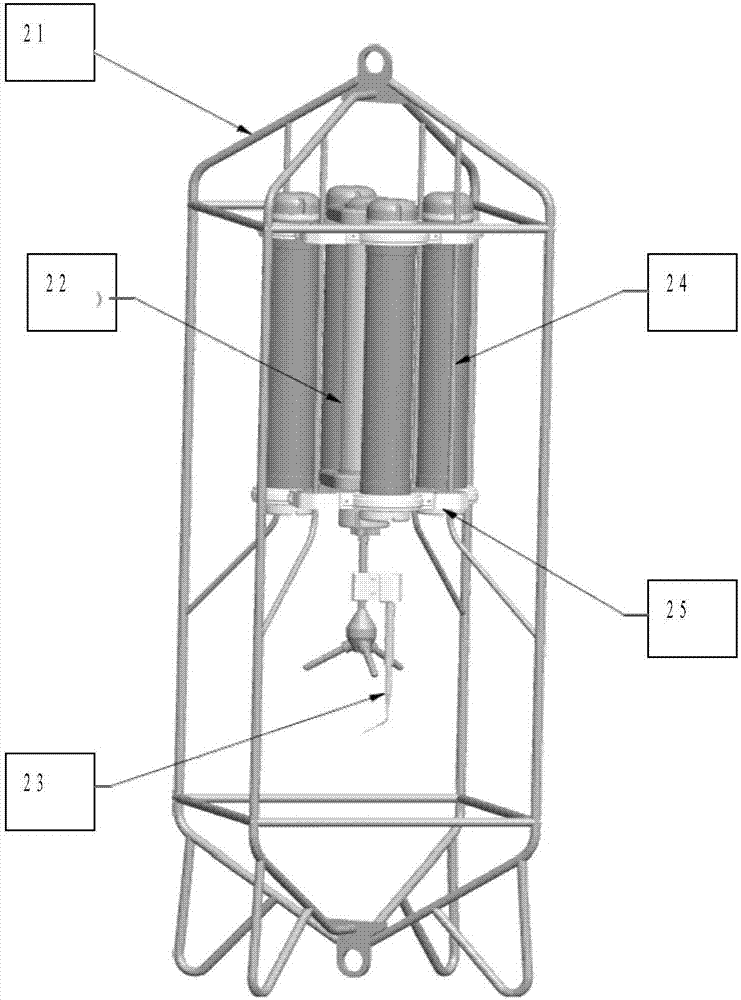

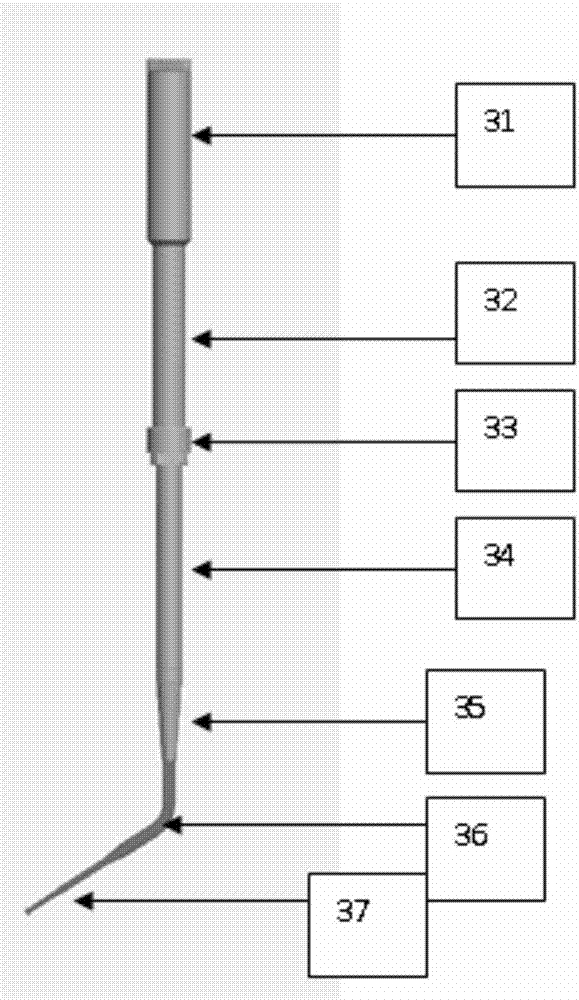

A kind of ocean turbulence heat flux instrument and using method thereof

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

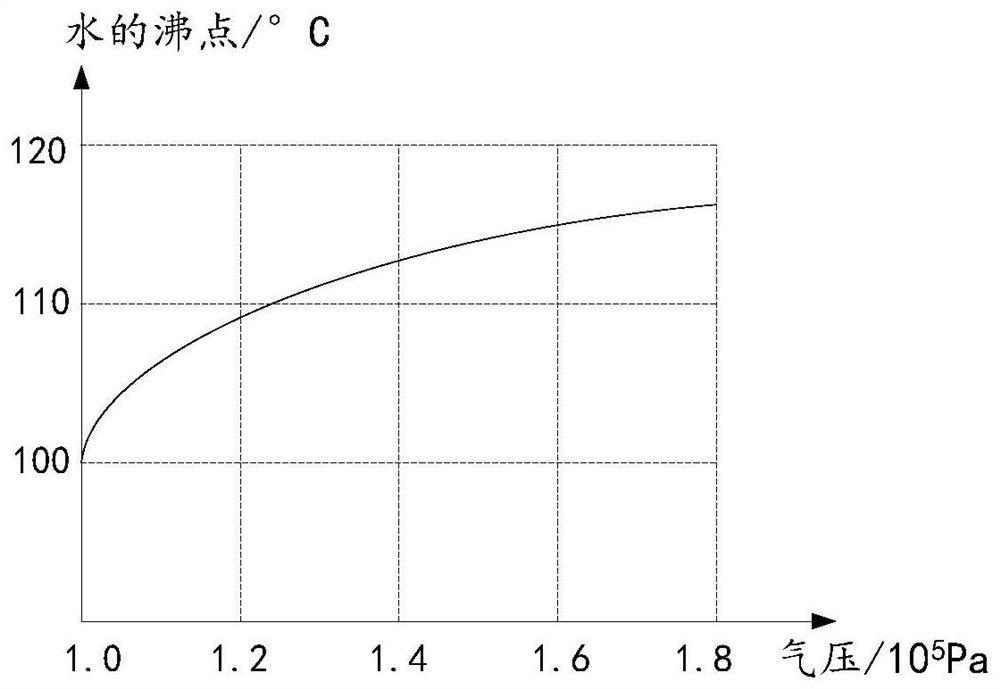

Heat pump water heater

ActiveCN106152505BImprove heating energy efficiency ratioTo achieve the purpose of energy savingFluid heatersTurbulent heat fluxEngineering

The invention relates to a heat pump water heater. Specifically, the heat pump water heating device of the present invention includes: a heating chamber configured to have a predetermined vacuum degree and used to accommodate a heat transfer medium, so that the heat transfer medium is in a low-pressure environment whose air pressure is lower than standard atmospheric pressure; the first heat exchange device , located in the heating chamber and above the highest heat transfer medium liquid level in the heating chamber, configured to accommodate heated water; and a heat pump circulation system configured to heat the heat transfer medium in the lower part of the heating chamber to boiling under a low pressure environment, so that The heat transfer medium vaporizes and rises to form a gaseous heat transfer medium. At least part of the gaseous heat transfer medium heats the heated water. In the heat pump water heater device of the present invention, because the heat transfer medium is in a low-pressure environment, the heat transfer medium can be vaporized at a lower temperature. It turns into a gaseous heat transfer medium, and uses the latent heat and sensible heat of the gaseous heat transfer medium to heat the heated water, which significantly improves the heating energy efficiency ratio of the heat pump water heater and achieves the purpose of saving energy.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com