Turbulence-inducing devices for tubular heat exchangers

a technology of turbulence-inducing devices and heat exchangers, which is applied in the direction of heat exchange apparatus, fluid heaters, lighting and heating apparatus, etc., can solve the problems of increasing heat transfer resistance, lowering the heat transfer coefficient, and heating or cooling fluids in the tubes to foul, so as to enhance the heat transfer coefficient and enhance the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

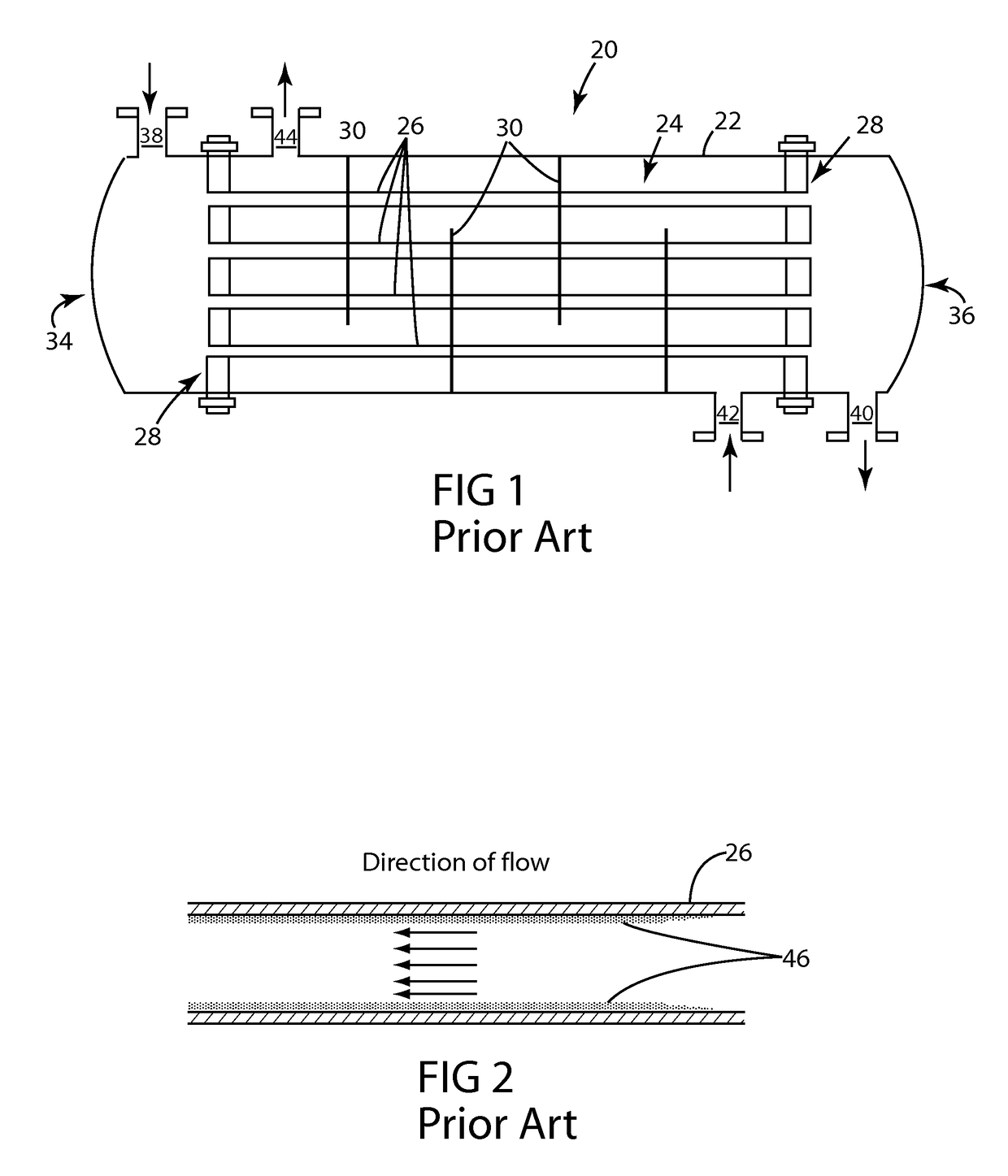

[0046]Referring to FIG. 1, there is shown a longitudinal cross-sectional view schematically depicting the arrangement of elements in a typical shell-and-tube heat exchanger 20 of the prior art. A bundled tube heat exchanger is a well known configuration of a type of heat transfer equipment in which a plurality of tubes convey a heat transfer fluid. By means of the thermal conductivity of the tubes, heat is transferred to a receiving fluid that contacts the exterior surface of the tubes.

[0047]Exchanger 20 includes a shell 22 and a tube set 24 having a plurality of tubes 26. The tubes 26 are supported at their ends by tube sheets 28, also known as end plates. In the typical construction of a bundled tube heat exchanger, a series of baffles 30 are provided through which the plurality of parallel tubes 26 pass.

[0048]In operation, heat transfer fluid is introduced via a tube set inlet 38 proximate to the first end 34 of the shell-and-tube heat exchanger 20, passes through the tubes 26, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com