Absorption-stabilization technique capable of enhancing absorption by using complementary energy

A stable absorption and enhanced absorption technology, applied in the petroleum industry, liquid hydrocarbon mixture recovery, hydrocarbon oil treatment products, etc., can solve the problems of limited improvement of absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Taking the absorption and stabilization unit of the 3 million tons / year coking unit as an example, the process simulation software ProⅡ is used for simulation calculation.

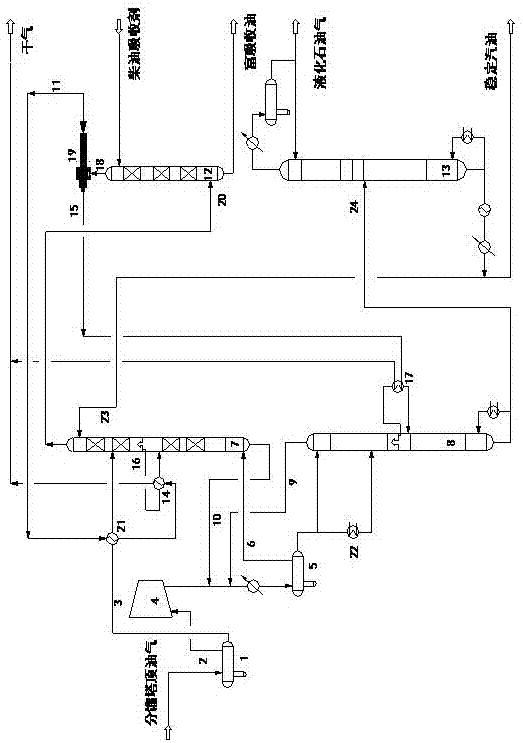

[0075] Simulation process such as figure 1 shown. The oil and gas from the top of the coking fractionation tower are separated into rich gas 2 and naphtha 3 in the gas-liquid separation tank 1 at the top of the tower. The rich gas 2 is boosted by the rich gas compressor 4 and mixed with the part of the absorption tower bottom oil 10 and desorbed gas 9 from the absorption tower 7 to cool down and enter the rich gas balance tank 5 . The gas phase 6 balanced by the rich gas balance tank 5 enters the bottom of the absorption tower 7; the liquid phase enters the upper part of the desorption tower 8 after being heated by the liquid phase heater 22 of the rich gas balance tank. The deethanized gasoline 24 at the bottom of the desorption tower 8 is sent to the stabilizing tower 13 for rectification, and t...

Embodiment 2

[0086] Taking the absorption and stabilization unit of the 3 million tons / year coking unit as an example, the process simulation software ProⅡ is used for simulation calculation.

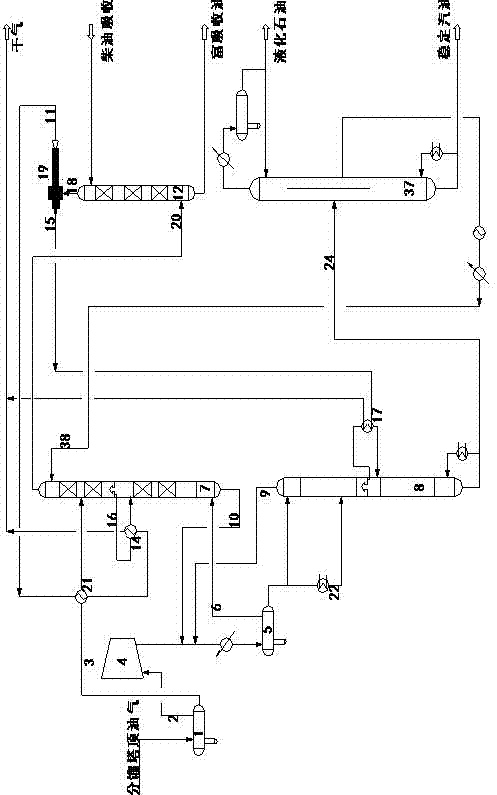

[0087] Simulation process such as figure 2 . The oil and gas from the top of the coking fractionation tower are separated into rich gas 2 and naphtha 3 in the gas-liquid separation tank 1 at the top of the tower. The rich gas 2 is boosted by the rich gas compressor 4 and mixed with the part of the absorption tower bottom oil 10 and desorbed gas 9 from the absorption tower 7 to cool down and enter the rich gas balance tank 5 . The gas phase 6 balanced by the rich gas balance tank 5 enters the bottom of the absorption tower 7; the liquid phase enters the upper part of the desorption tower 8 after being heated by the liquid phase heater 22 of the rich gas balance tank. The deethanized gasoline 24 at the bottom of the desorption tower 8 is sent to the stabilizing tower 13 for rectification, and the l...

Embodiment 3

[0098] Taking the absorption and stabilization unit of the 3 million tons / year coking unit as an example, the process simulation software ProⅡ is used for simulation calculation.

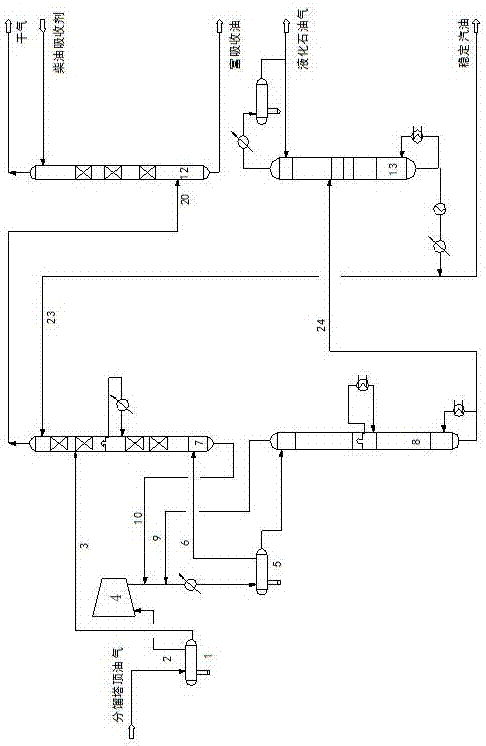

[0099] Simulation process such as image 3 . The oil and gas from the top of the coking fractionation tower are separated into rich gas 2 and naphtha 3 in the gas-liquid separation tank 1 at the top of the tower. The rich gas 2 is boosted by the rich gas compressor 4 and mixed with the part of the absorption tower bottom oil 10 and desorbed gas 9 from the absorption tower 7 to cool down and enter the rich gas balance tank 5 . The gas phase 6 balanced by the rich gas balance tank 5 enters the bottom of the absorption tower 7; the liquid phase enters the upper part of the desorption tower 8 after being heated by the liquid phase heater of the rich gas balance tank. The deethanized gasoline 24 at the bottom of the desorption tower 8 is sent to the partition tower 37 for rectification, and the liquefi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com