Coal mine high-temperature tunneling roadway sectional cooling device and method

A technology of segmented cooling and roadway, which is used in mine/tunnel ventilation, mining equipment, earth-moving drilling and other directions, can solve the problems of scattered workers' workplaces, weakening of the effect of increasing air and cooling, and increasing the humidity of inlet air flow. Cooling cost, improving cooling effect, increasing the effect of air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

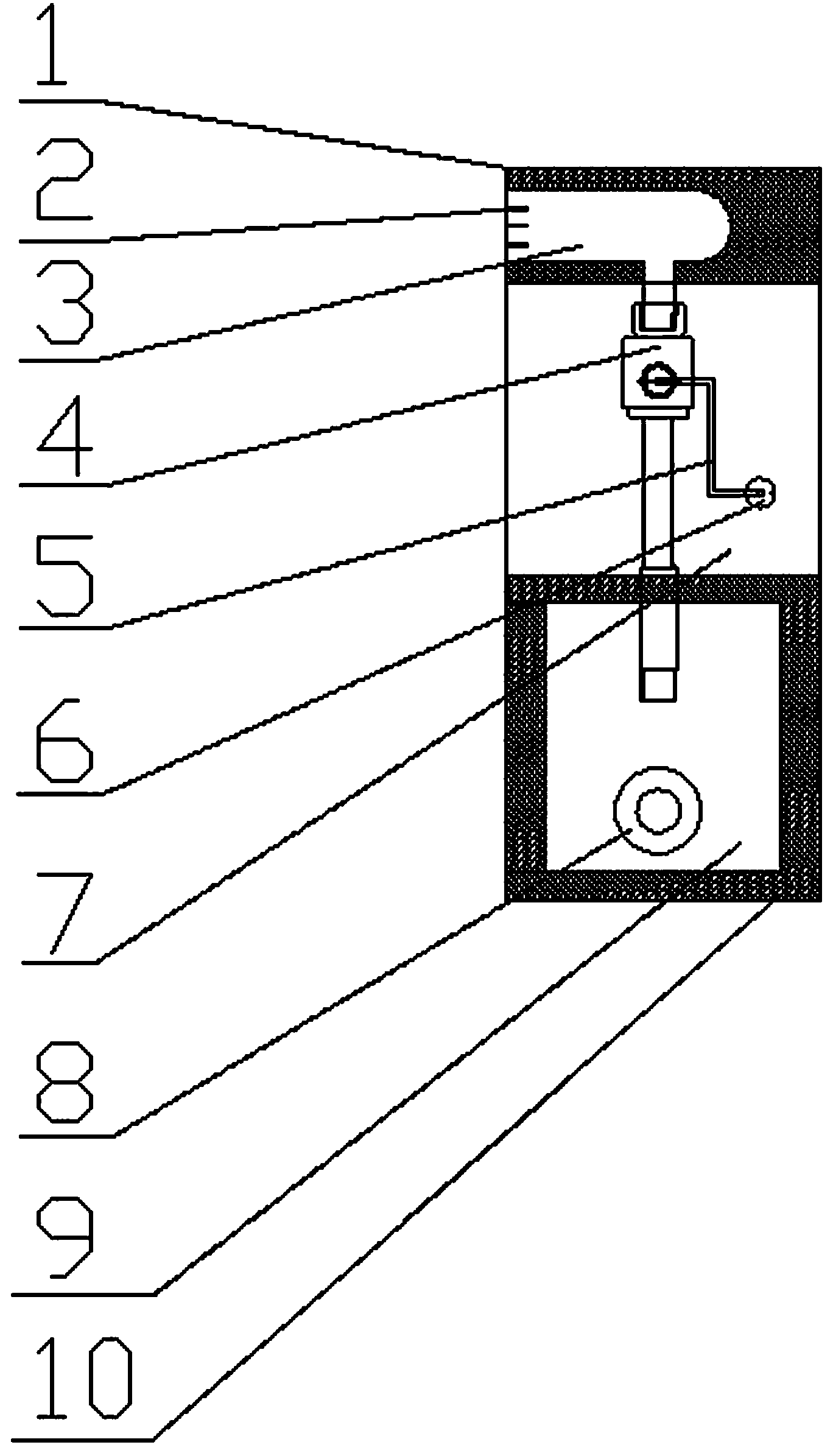

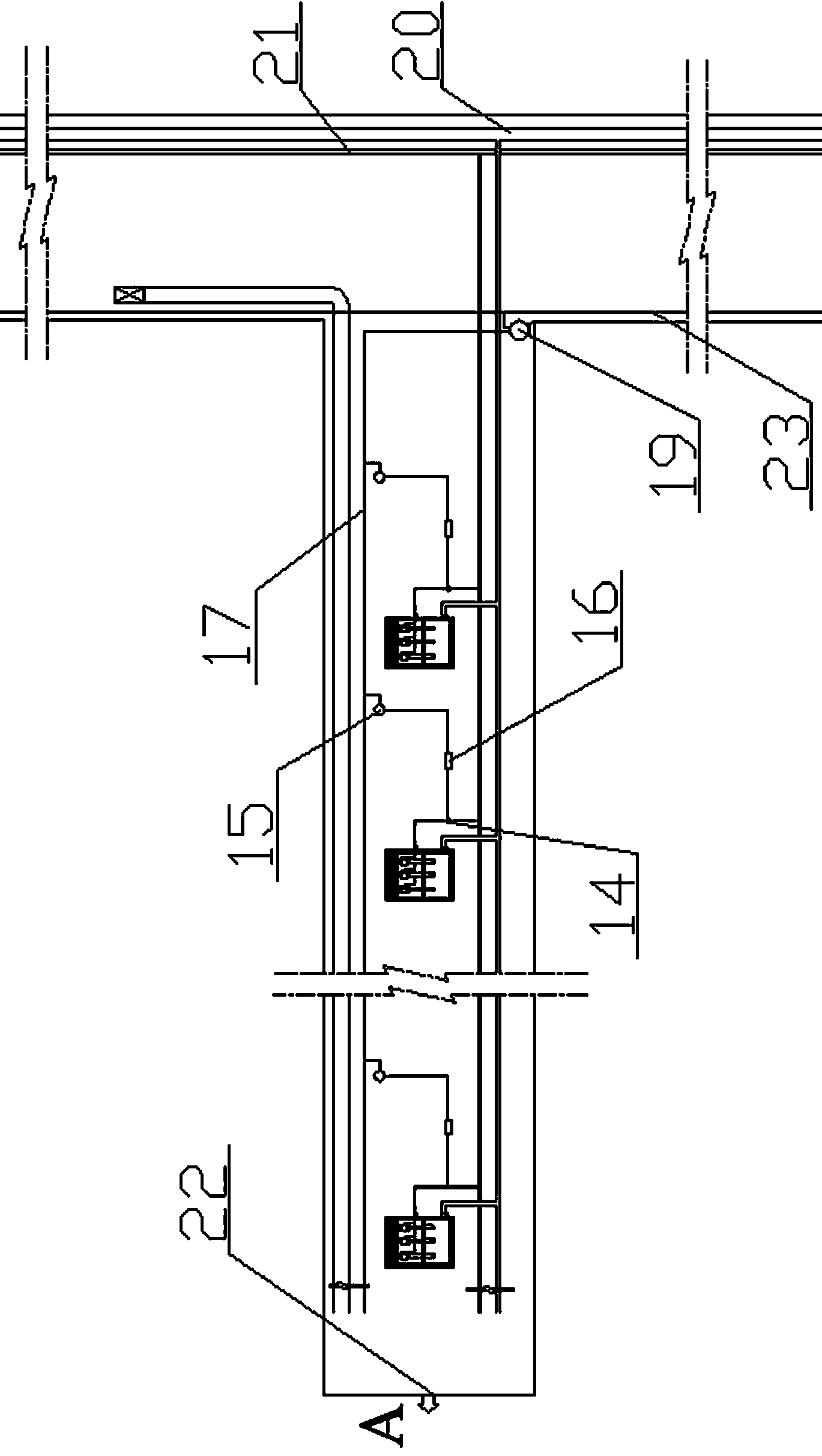

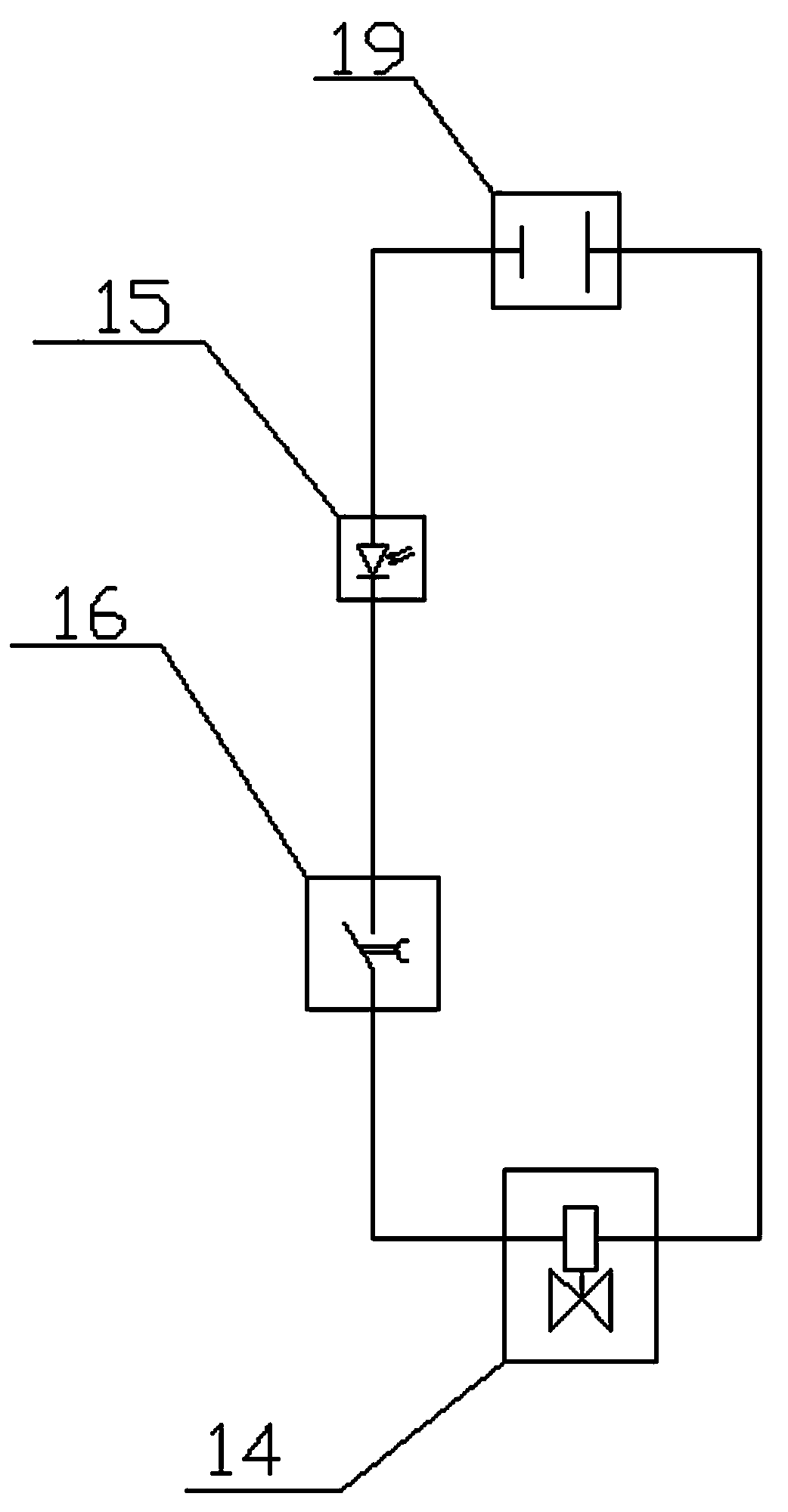

[0026] Such as figure 1 and figure 2 As shown, the cooling device for the underground working face of this embodiment includes a box body 1, and the hot gas recovery bin 9, the air intake bin 7 and the cold air discharge bin 3 are arranged in the box body from bottom to top in sequence, and the air inlet bin is provided with Vortex tube 4, the vortex tube is installed in the intake compartment in parallel connection, the cold air flow end of the vortex tube is connected with the cold air discharge compartment, and the outer edge of the cold air discharge compartment is provided with a wind deflector 2 to guide the direction of the cold air flow in time; The hot gas flow end of the vortex tube is connected with the hot gas recovery bin; the air inlet port 6 is provided on the air inlet bin, and the vortex tube and the air inlet port are connected through the air pressure tube 5. The pressure regulating valve 11 on the gas port interface is connected to the compressed air pipe...

Embodiment 2

[0032] The cooling device for the underground working face of this embodiment includes a box body, and the box body is provided with a hot gas recovery bin, an air intake bin, and a cold air discharge bin in sequence from bottom to top. The connection method is installed in the intake chamber, the cold air flow end of the vortex tube is connected with the cold air discharge chamber, and the outer edge of the cold air discharge chamber is equipped with a wind deflector to guide the direction of the cold air flow in time; the hot air flow end of the vortex tube is connected to the hot air recovery The air intake chamber is connected with each other; the air inlet port is provided on the air intake chamber, and the air pressure pipe is provided between the vortex tube and the air inlet port. Pipes are connected, and the hot gas recovery bin is connected with the hot gas discharge pipe through the exhaust hole interface provided thereon.

[0033] The box body of this embodiment is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com