Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Torque amplifier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A torque amplifier is a mechanical device that amplifies the torque of a rotating shaft without affecting its rotational speed. It is mechanically related to the capstan seen on ships. Its most widely known use is in the power steering on automobiles. Another use is on the differential analyzer, where it was used to increase the output torque of the otherwise limited ball-and-disk integrator. The term is also applied to some gearboxes used on tractors, although this is unrelated. It differs from a torque converter, in which the rotational speed of the output shaft decreases as the torque increases.

Mechanical torque amplifier

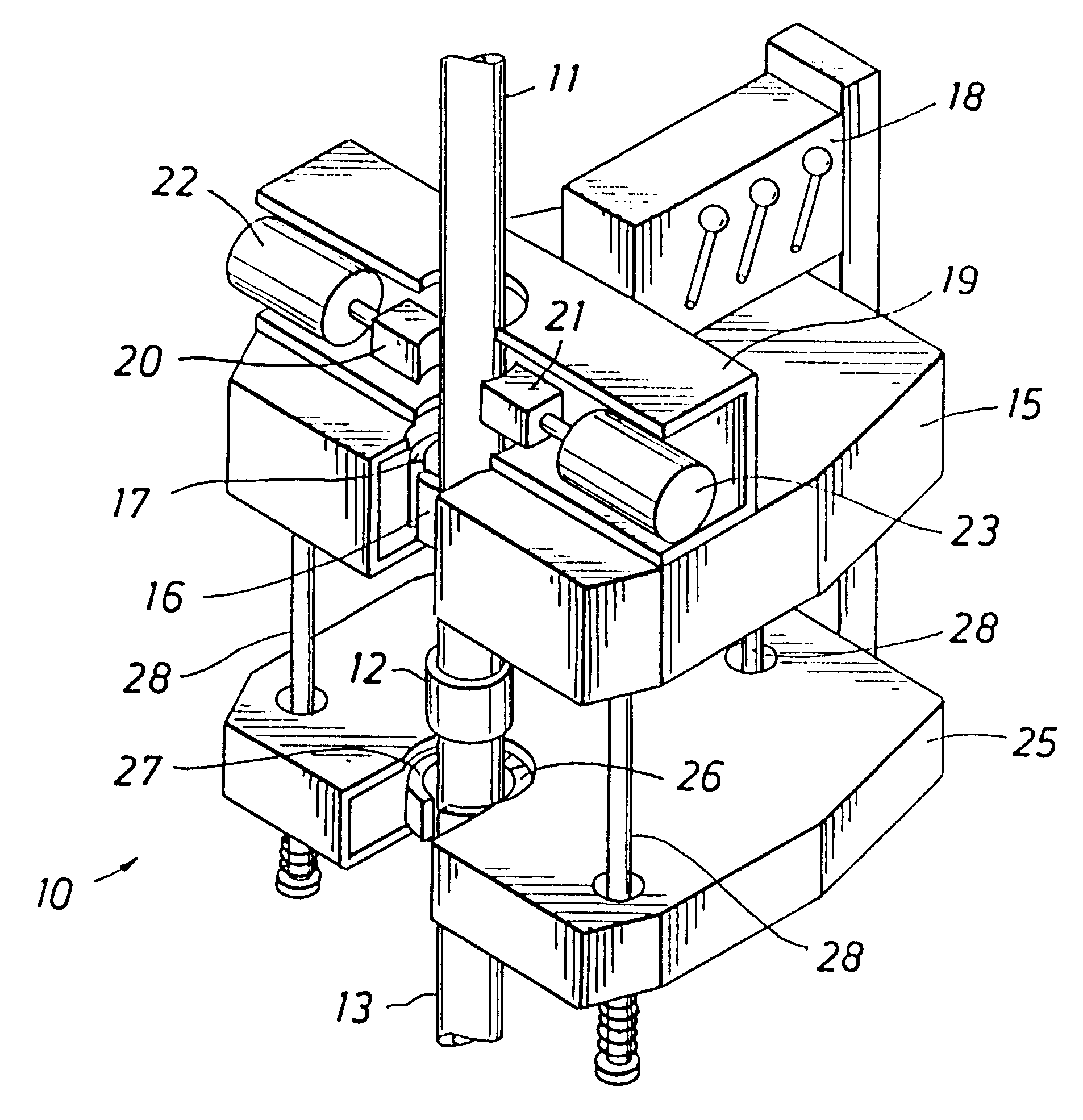

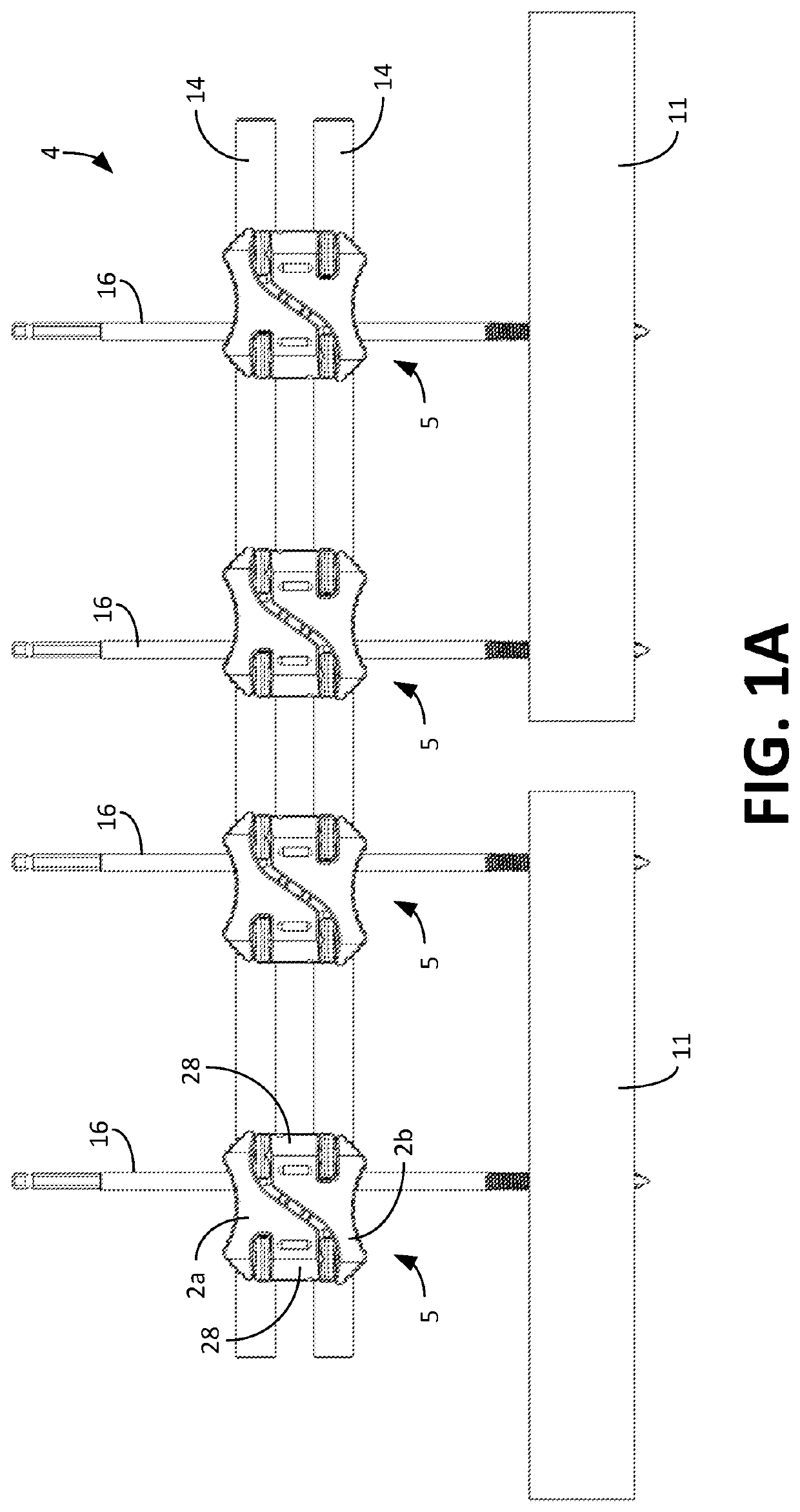

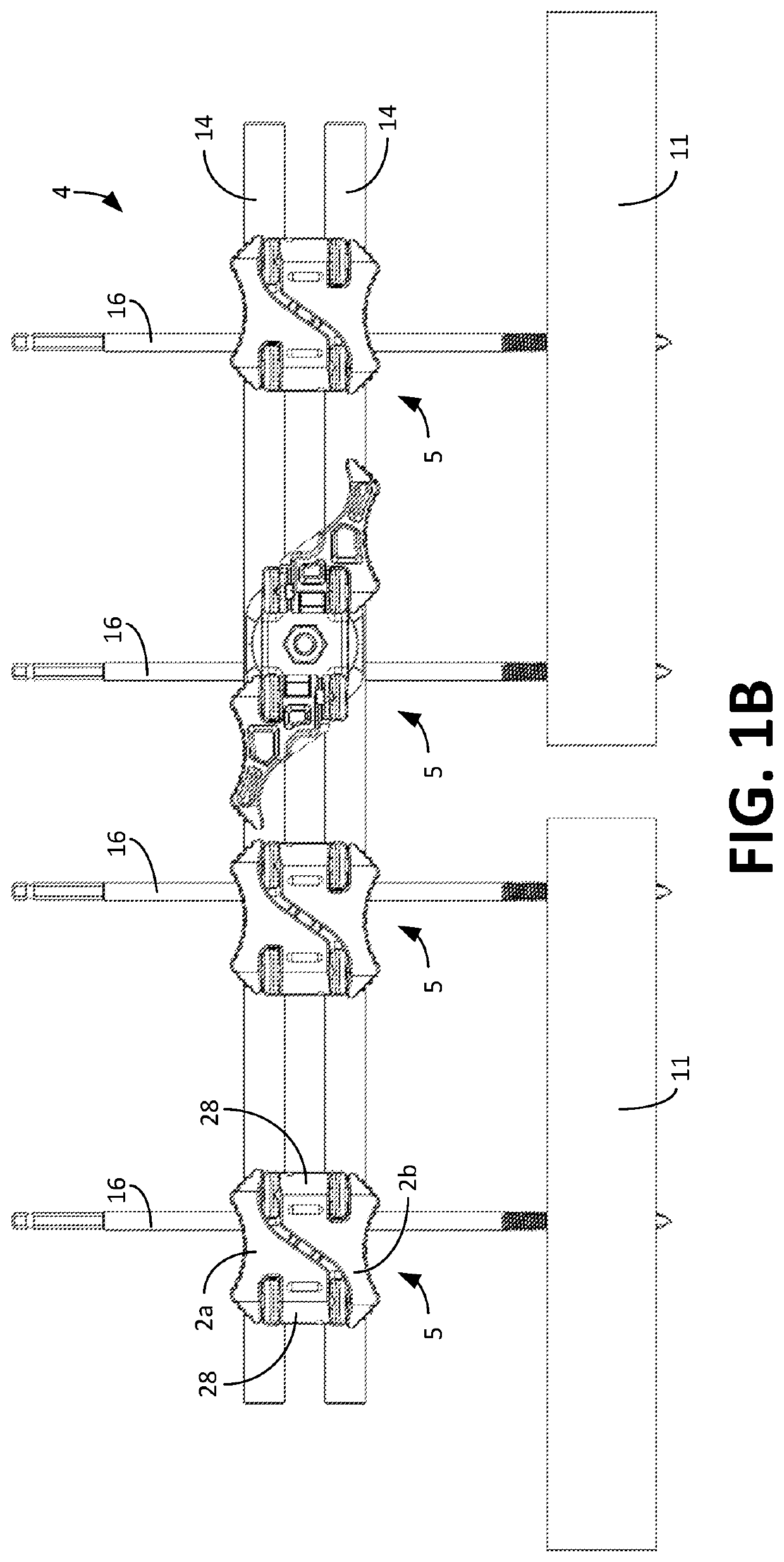

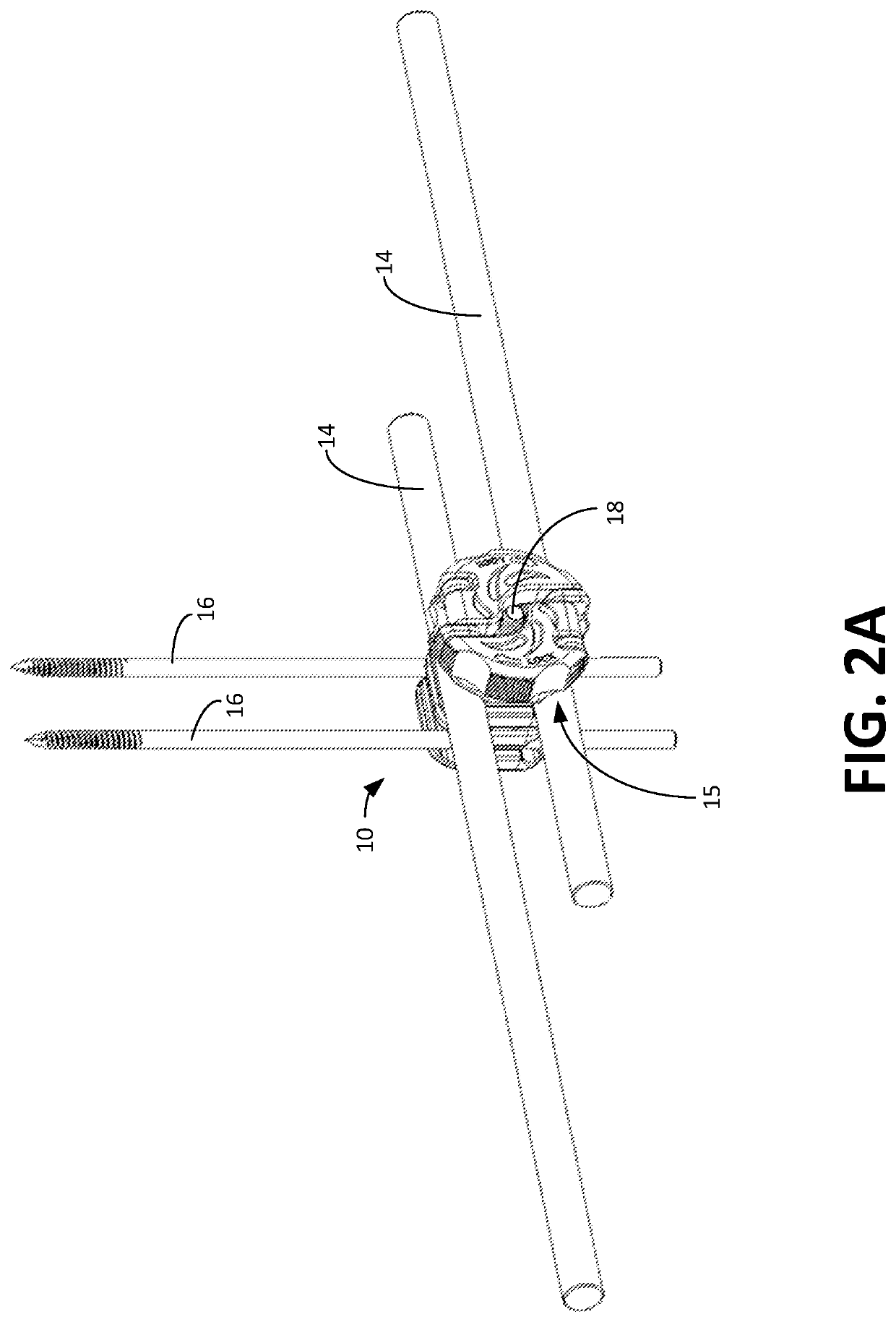

A power tong system is used to make up and break out threaded pipe connections. Rotary power tongs are connected to an integral backup tong through an extendable hydraulic cylinder and rod. A brake is secured to the rotary tong to selectively hold the pipe stationary relative to the rotary tong. When rotation of the pipe by the rotary tong ceases, the brake is applied, and the cylinder and rod are actuated to angularly displace the power tongs and the backup tong to apply a torque force to the pipe connection disposed between the power tongs and the backup. A resulting torque force is obtained that is greater than the maximum torque that can be exerted by the rotary tong acting alone. The system may also be deployed to apply and hold precise torque forces on the pipe connections. When used to obtain a makeup torque below the maximum rated rotary tong output, the rotary tong is regulated to limit its torque output. When the limited torque is reached, the brake is applied and the cylinder and rod are actuated to apply a smooth, closely controlled increase in torque to the connection. The final torque level may be held constant for a desired length of time. In both the high and low torque applications, the brake prevents the rotary tong from being turned backwardly by the increased torque force applied by actuation of the rod and cylinder assembly. Operation of the system may be manually or automatically controlled.

Owner:TESCO HLDG I

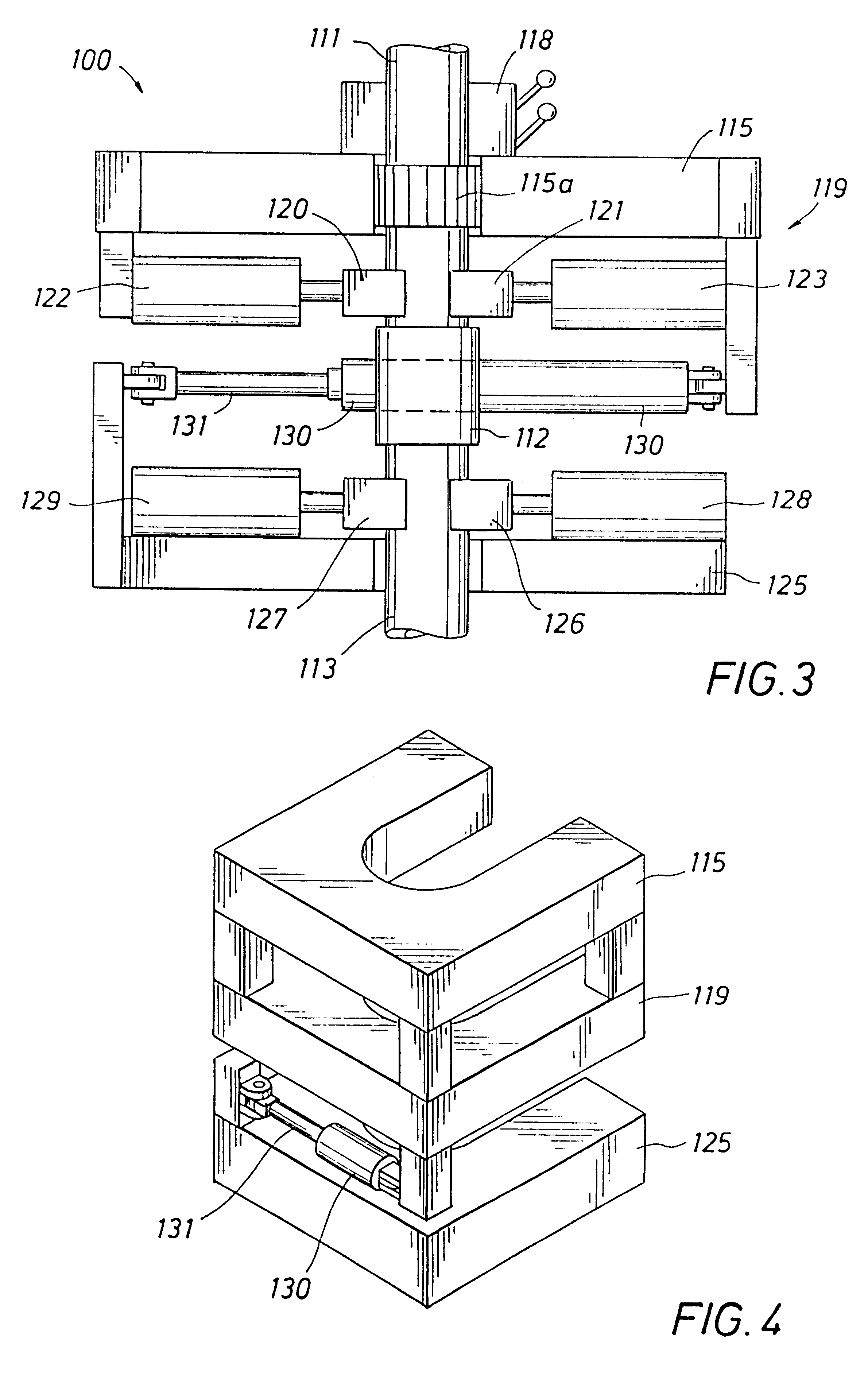

Power generator and torque amplifier

InactiveUS20050140231A1Simple structureEfficiently obtainedMagnetic circuit rotating partsAC/DC convertorsRotational axisAudio power amplifier

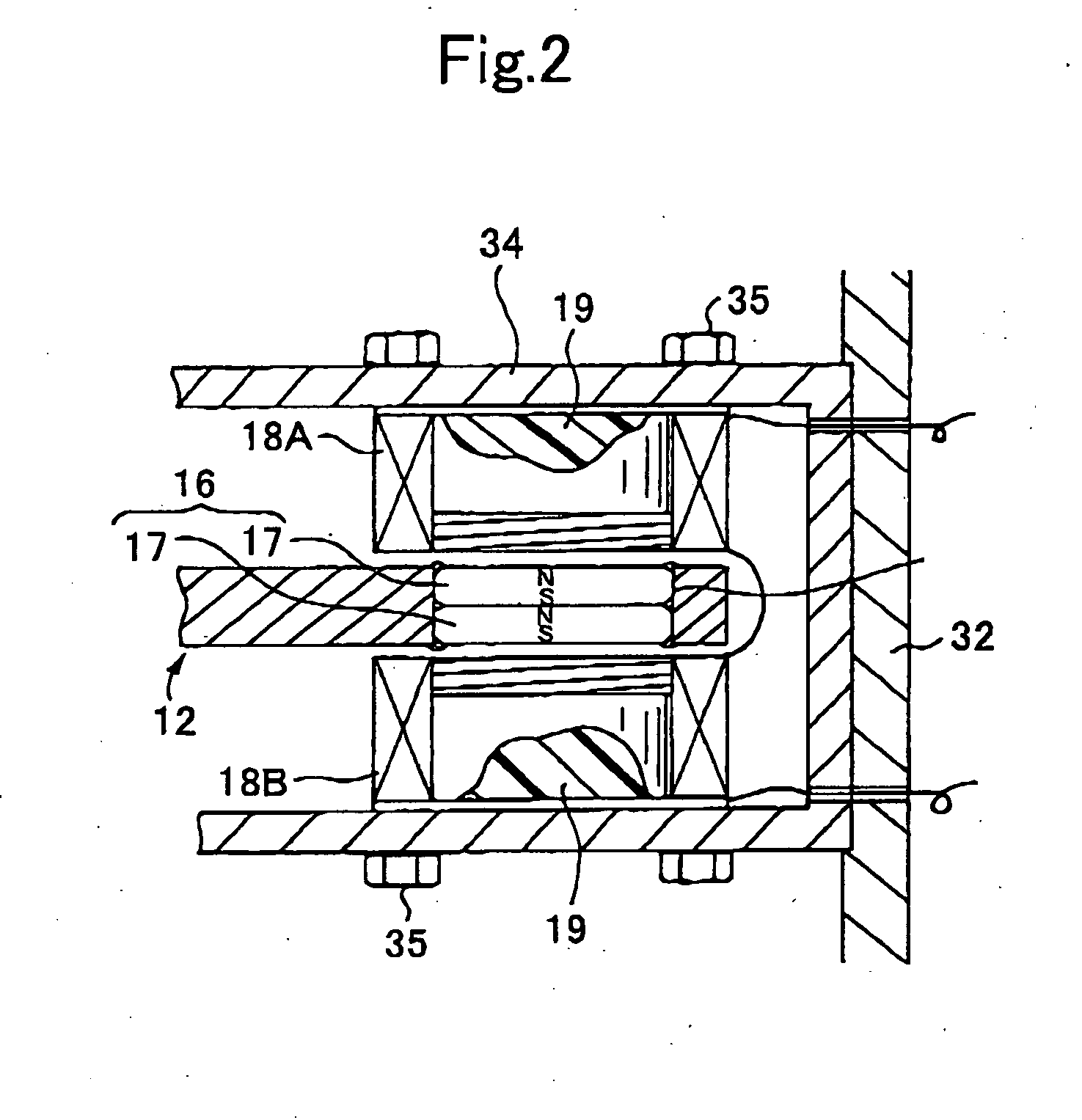

Disclosed is a power generator adapted to provide an electrical power greater than an input power by means of a permanent magnet. The power generator 10 comprises a rotatable rotor 12, a plurality of permanent magnets 16, and a plurality of coreless coils 18. The rotor 12 has a surface including an annular zone 14 formed around the rotational axis 13 thereof. The permanent magnets 16 are disposed along the annular zone 14 at constant intervals in the circumferential direction of the rotor 12 to form an annular array, while uniformly orienting their polarities in a direction orthogonal to the annular zone 14. The coreless coils 18 are supported by a stationary member 11 and disposed along the annular zone to form an annular array, while allowing the respective axes 19 of the coils to intersect with the annular zone 14. The permanent magnets 16 are moved along the coreless coils 18 in conjunction with the rotation of the rotor 12 induced by a rotational force supplied through a center shaft 22 from a torque amplifier 20 disposed below the rotor 12, so as to obtain an output power from the coreless coils 18.

Owner:OGOSHI MAKOTO

Positioning servocontroller

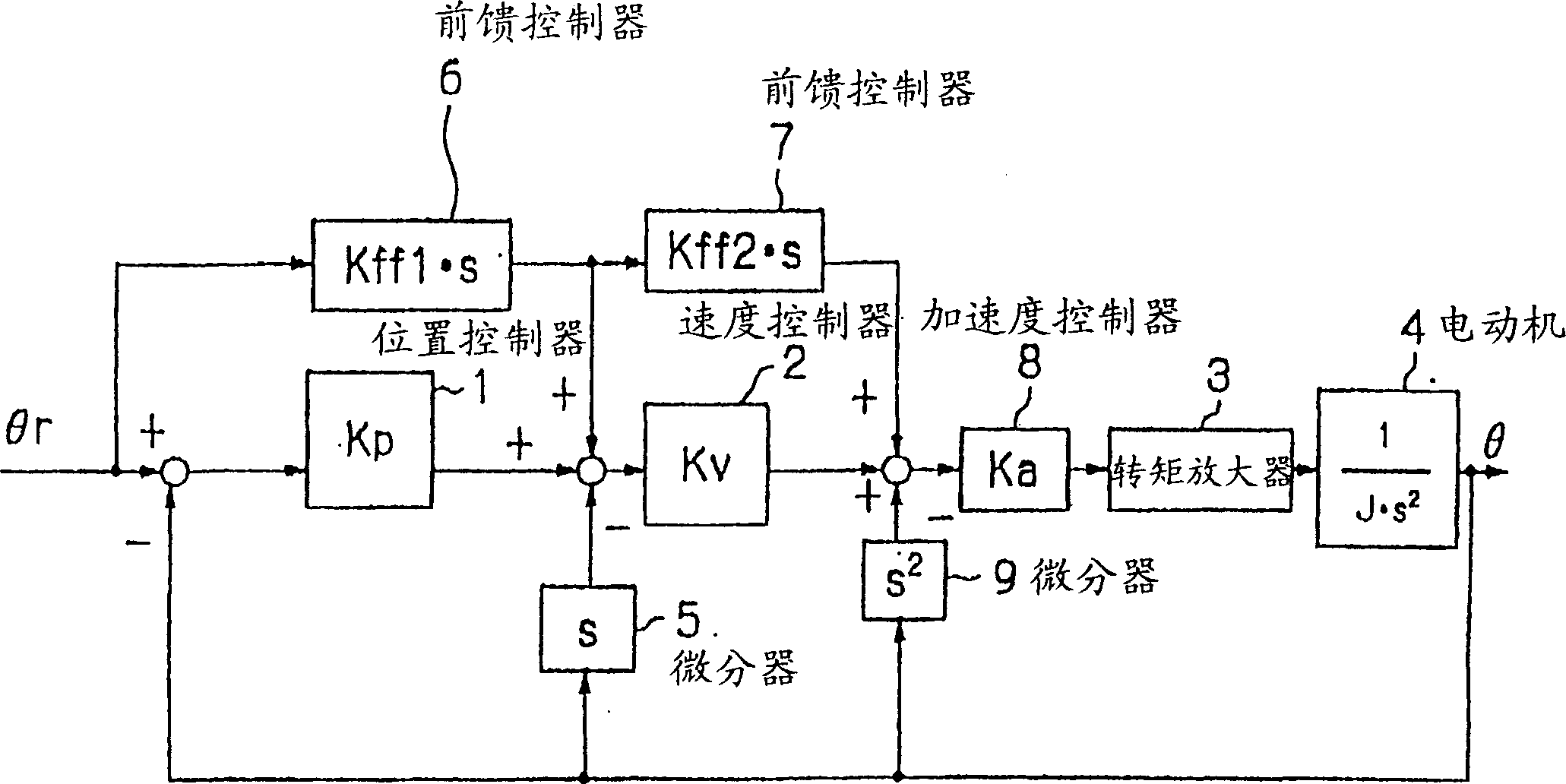

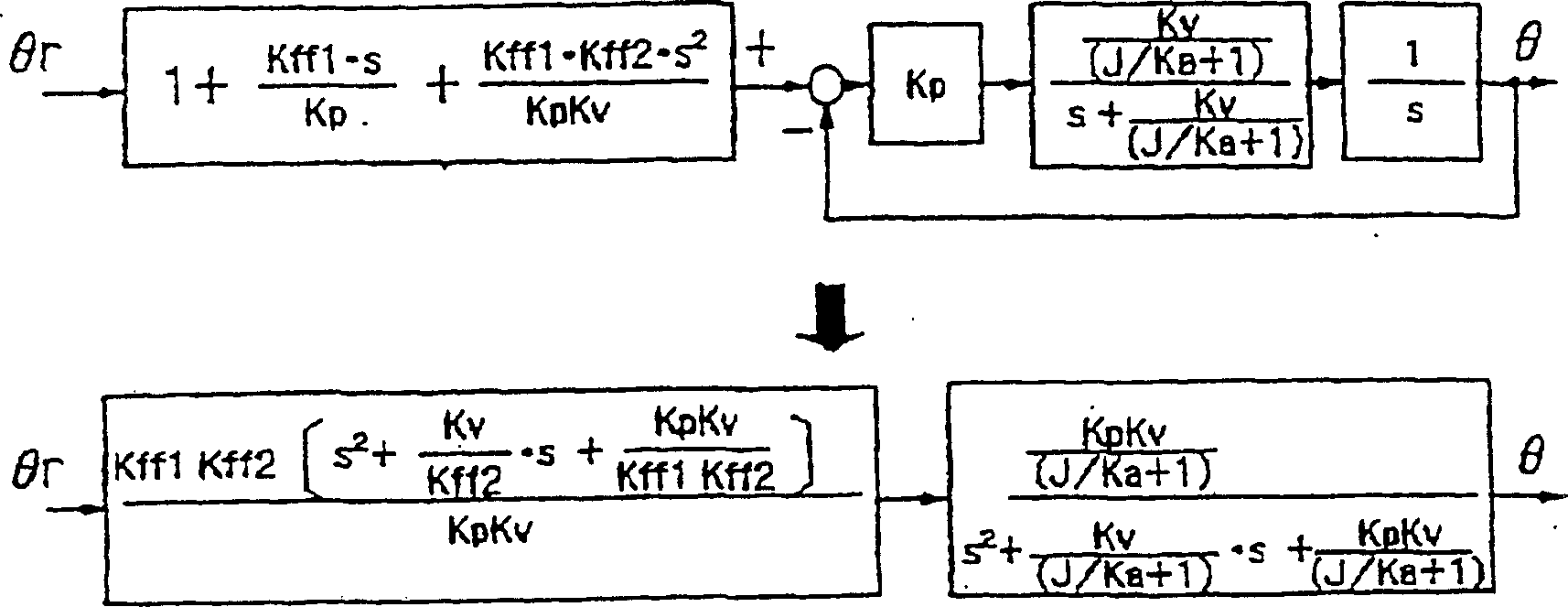

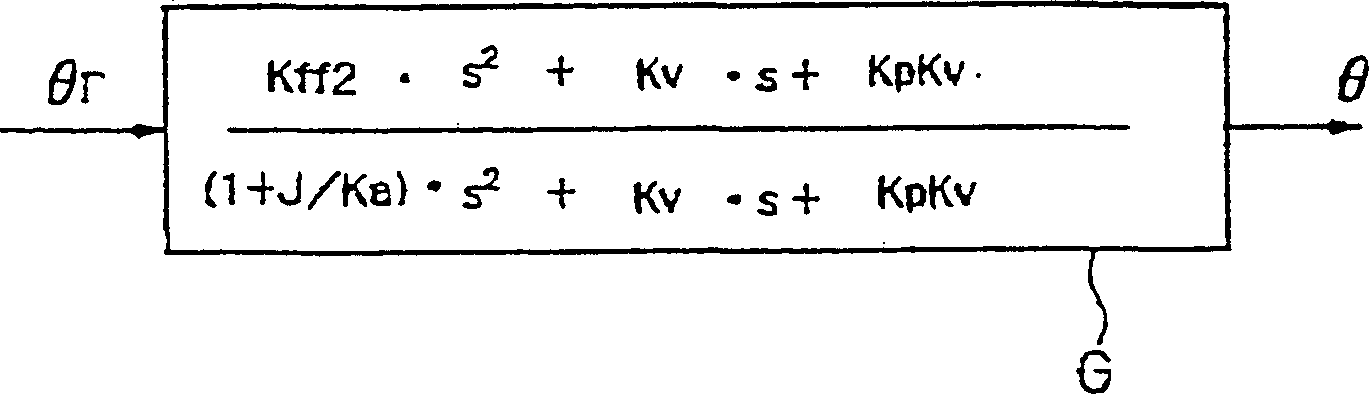

A positioning servocontroller performs optimum positioning simply by adjusting control gain. A positioning servocontroller comprises speed feedforward control means (22) that uses a speed command corresponding to the sum of a position deviation and a first feedforward compensation; acceleration feedforward means (23) that uses an acceleration command corresponding to the sum of a speed deviation and a second feedforward compensation obtained by amplifying and differentiating the first feedforward compensation amount; and a torque amplifier (3) that drives an object based on an acceleration deviation as a torque command. The first feedforward gain and the second feedforward gain are derived from a function that uses the values of control gain as arguments.

Owner:YASKAWA DENKI KK

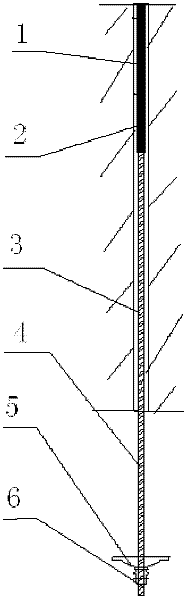

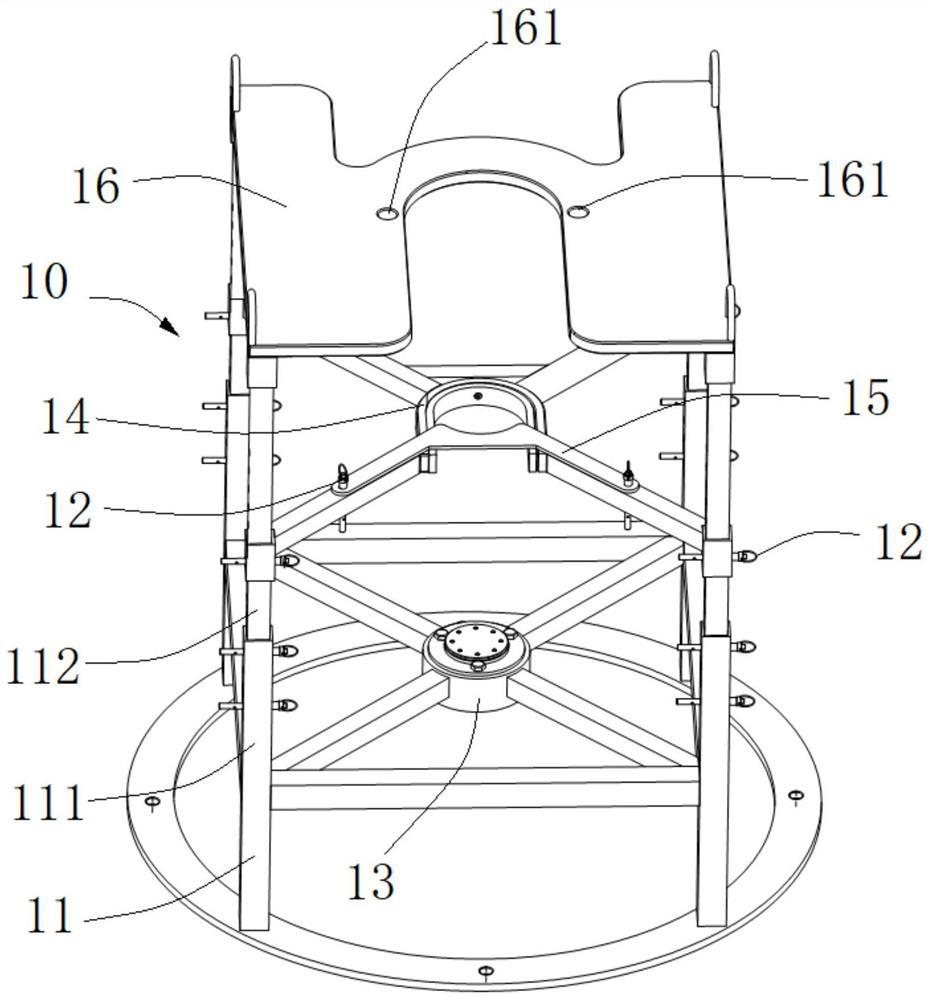

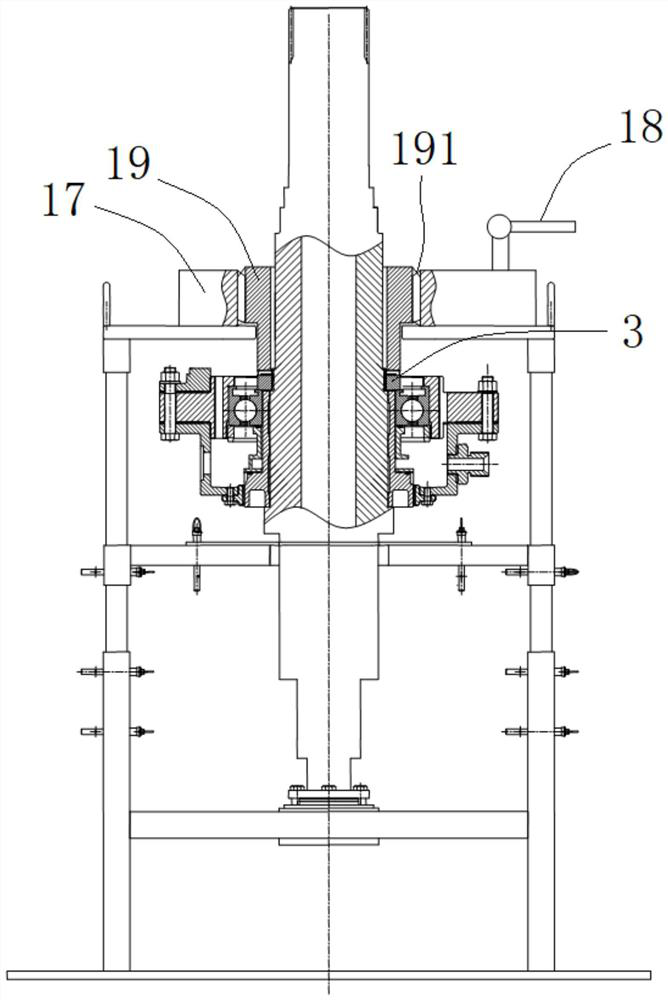

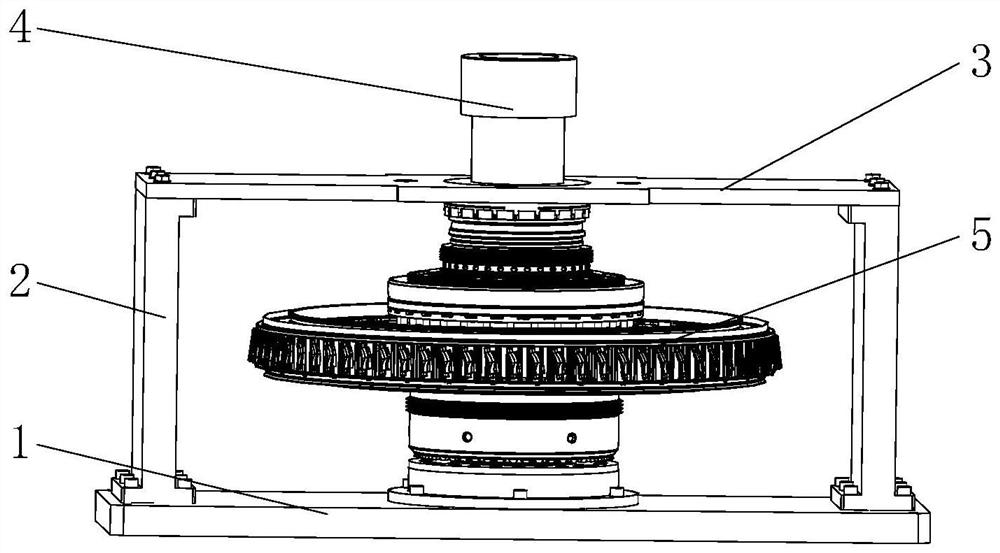

Disassembling and assembling device for high-pressure turbine front baffle

ActiveCN106217298AAvoid damageEliminate discomfortMetal-working hand toolsTorque amplifierEngineering

The invention relates to design of auxiliary equipment for high-pressure turbines of aircraft engines, in particular to a disassembling and assembling device for a high-pressure turbine front baffle. The disassembling and assembling device comprises an assembling and disassembling ring, a supporting frame, a connecting seat, an axial load pull rod, a spline shaft, a torque amplifier, a spline transition section and an axial load nut, wherein the assembling and disassembling ring is arranged on one side of the front baffle in a sleeving mode; the supporting frame is coaxially fixed to one side of the assembling and disassembling ring; the connecting seat is located in an inner cavity of the supporting frame and fixedly connected with a high-pressure turbine disc through a fixing part of the connecting seat; one end of the axial load pull rod coaxially penetrates through a through hole of the fixing part; the axial load pull rod is coaxially sleeved with the spline shaft, the outer ring face of the spline shaft is arranged at one end of the supporting frame through a thrust ball bearing, and one end of the spline shaft is arranged in an accommodating part of the connecting seat in a matched mode through splines; the torque amplifier is coaxially and fixedly arranged at the end, away from the assembling and disassembling ring, of the supporting frame; the spline transition section is arranged between the spline shaft and the torque amplifier; and the axial load nut is arranged at one end of the axial load pull rod. By means of the disassembling and assembling device for the high-pressure turbine front baffle, torque required for assembling and disassembling of the front baffle can be stably loaded.

Owner:AECC SHENYANG ENGINE RES INST

Rapid anchoring method for coal mine roadway anchor rod

InactiveCN102337912AImprove installation efficiencyShort head timeAnchoring boltsEngineeringMechanical engineering

The invention discloses a rapid anchoring method for a coal mine roadway anchor rod. The method mainly comprises the following steps of: filling two resin capsules with different solidifying times in turn when the anchor rod is installed, wherein one of the resin capsules is a rapidly-solidified resin capsule of which the solidifying time is not more than 10 seconds, and the other of the resin capsules is a common resin capsule; filling the rapidly-solidified resin capsule into the position at the bottom of a hole; after clamping a screw cap of the anchor rod by using a drilling machine with a special sleeve, continuously pushing rotation in the torque of 150 N.m; stirring the two capsules to the bottom at one time, still continuously rotating after stirring to the bottom until the rapidly-solidified resin capsule is solidified within 10 seconds; after the rapidly-solidified resin capsule is solidified, not rotating the anchor rod, but continuously rotating the screw cap until a screw nut damping plug is opened, and removing the drilling machine; and tightening the screw cap by using the drilling machine and a torque amplifier in the torque of 400 N.m to finish installation. By the method, the stirring and the installation of the drilling machine of the anchor rod are finished at one time, so that installation time is shortened, headspace time for tunneling a working surface is reduced, and the installation efficiency of the anchor rod is improved.

Owner:新汶矿业集团有限责任公司华丰煤矿

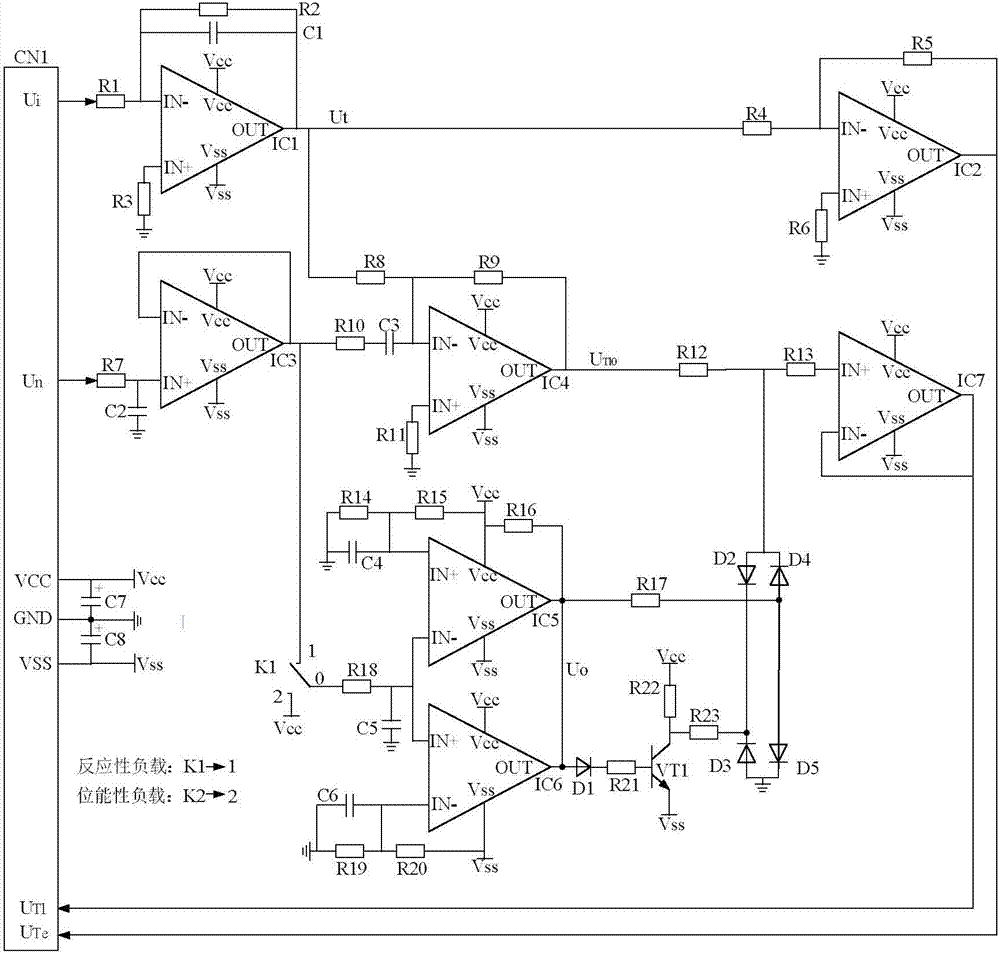

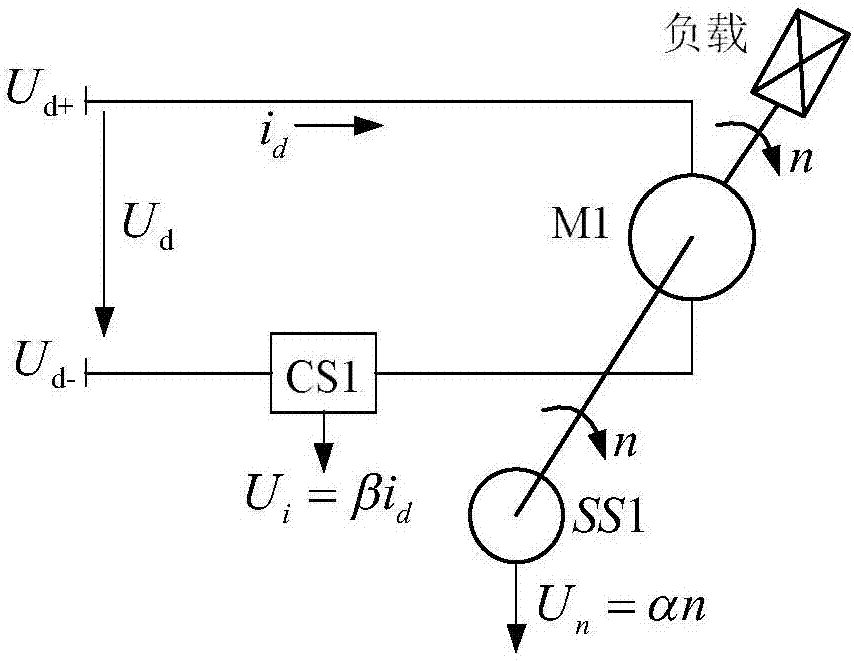

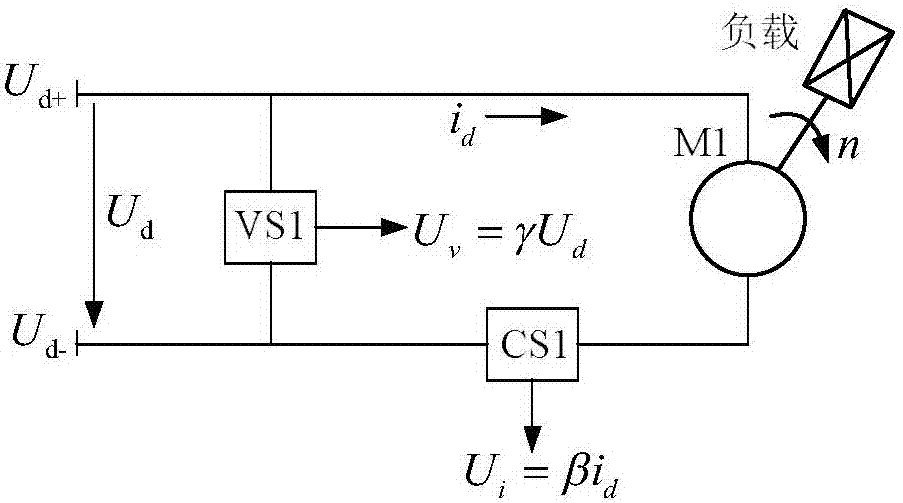

Load torque detection circuit based on armature current and rotation speed signal

ActiveCN107490762ARealize real-time detectionImprove versatilityElectrical measurement instrument detailsDynamo-electric machine testingSignal processing circuitsLoad torque

The invention relates to a load torque detection circuit based on armature current and a rotation speed signal. The circuit comprises a torque signal processing circuit and a load selection circuit. Specifically, a current detection signal end of a connector is connected to one end of an upper input resistor, the other end of the upper input resistor is connected to a negative input end of a current amplifier, an output end of a torque amplifier is connected to an electromagnetic torque signal end of the connector, a rotation speed detection signal end of the connector is connected to one end of a lower input resistor, the other end of the lower input resistor is connected to a positive input end of a rotation speed follower, an output end of a differential amplifier is connected to one end of a current limiting resistor, an output end of a forward comparator is connected to an output end of a reverse comparator, and an output end of a load follower is connected to a load torque signal end of the connector. The circuit is suitable for an application occasion of carrying out real-time detection of a mechanical load torque of a DC motor. The circuit has the advantages of high real-time performance, a small volume, low cost, good universality, high reliability, and easy implementation in a chip.

Owner:北京中知中科技术开发有限公司

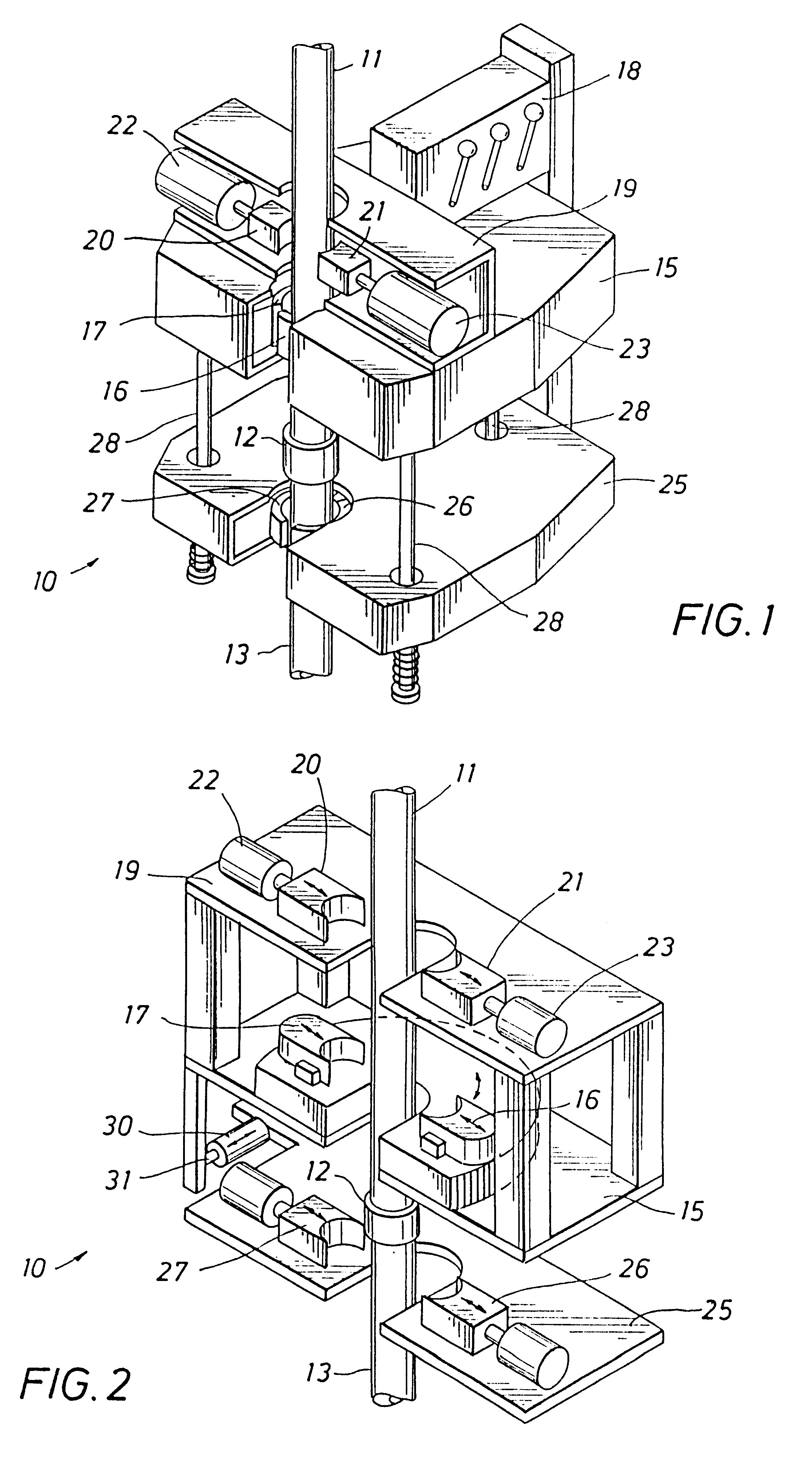

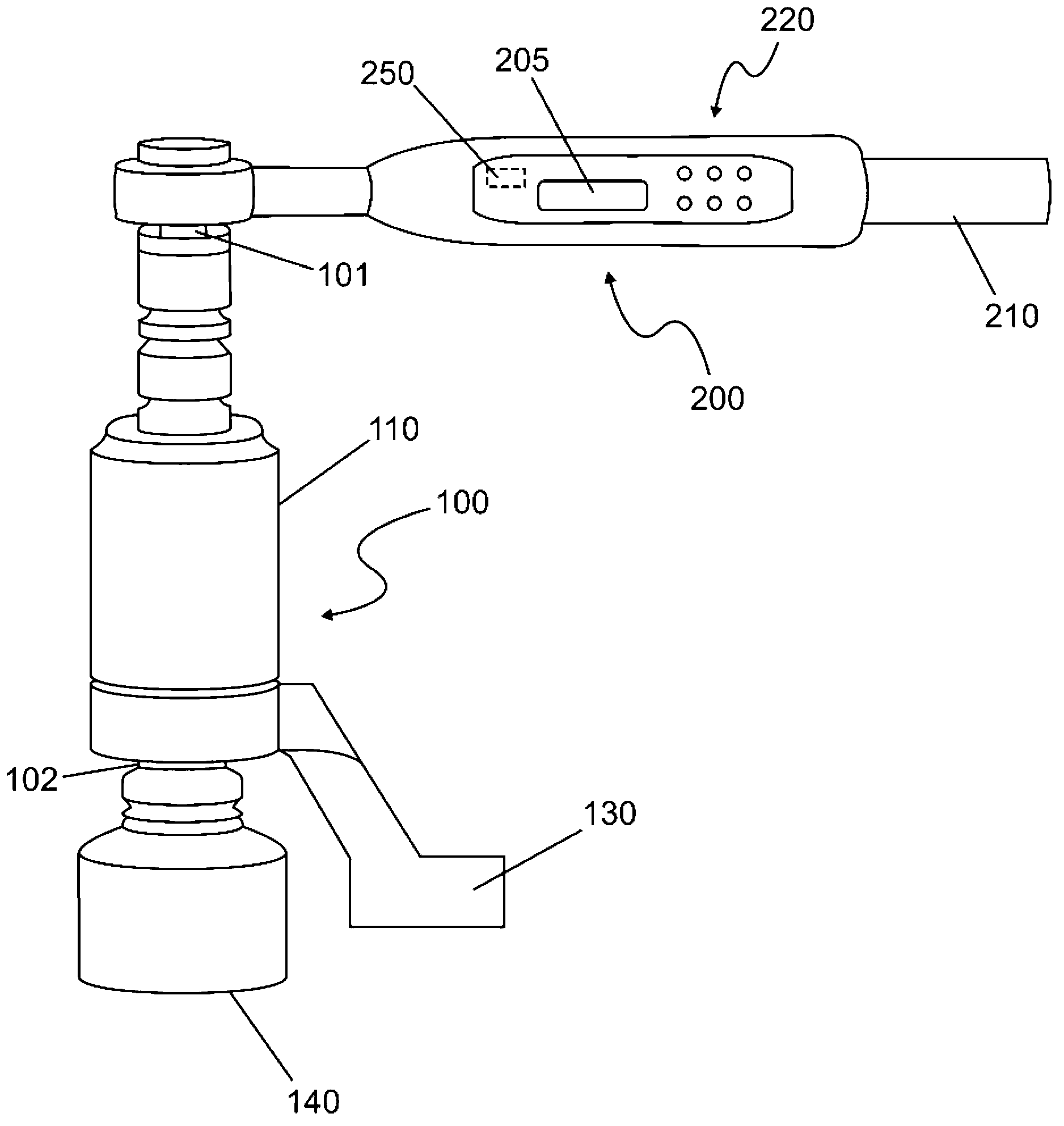

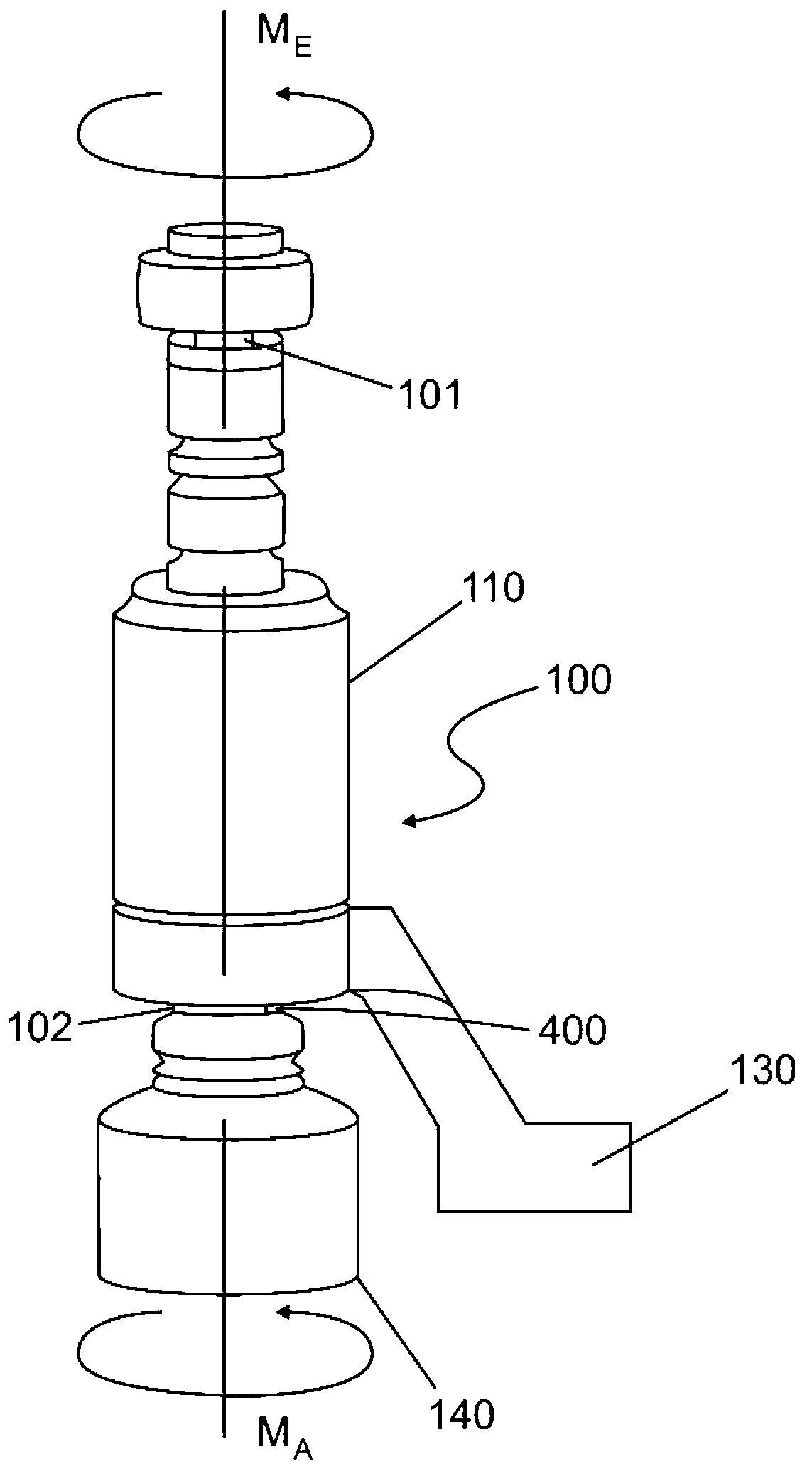

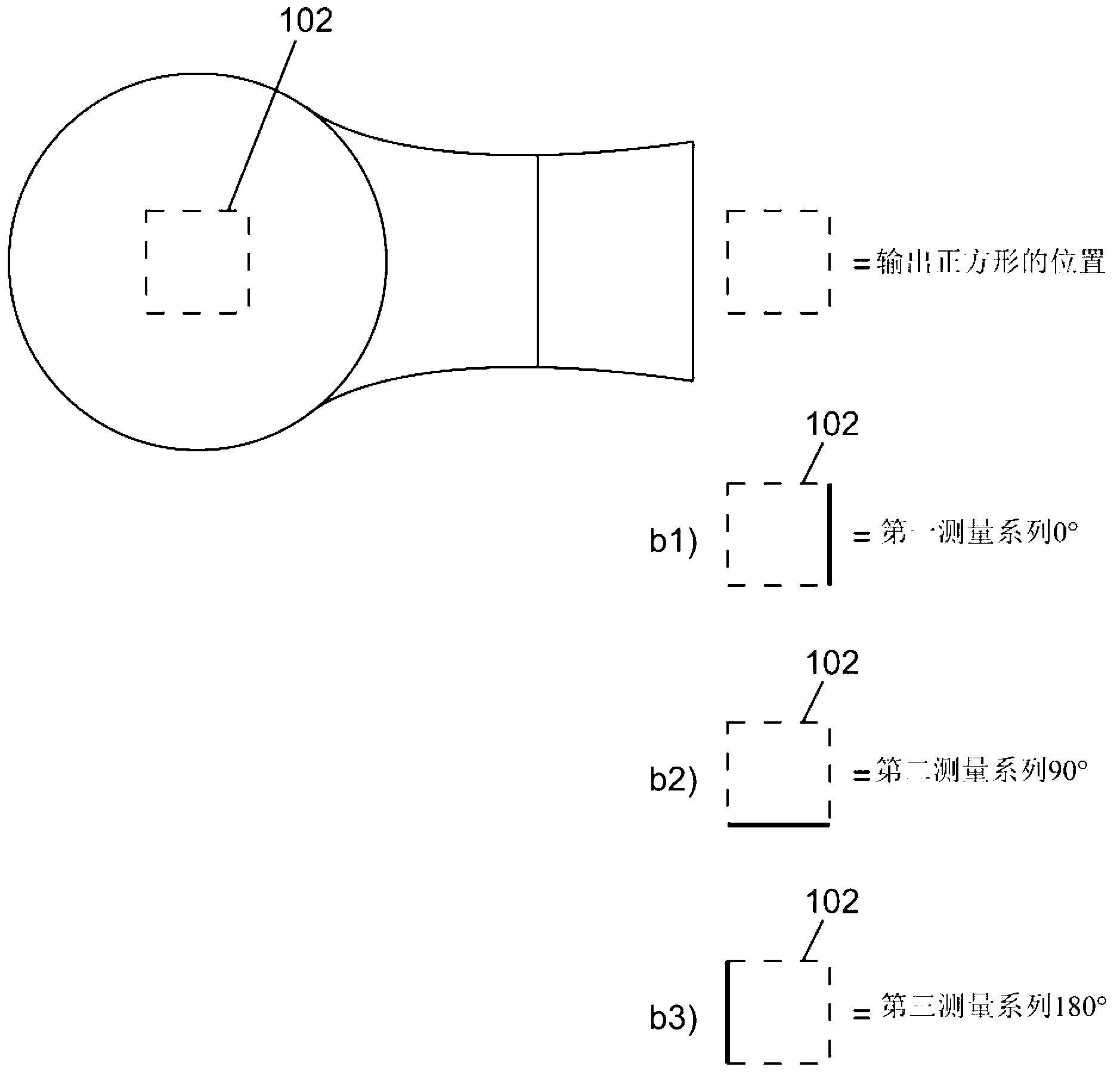

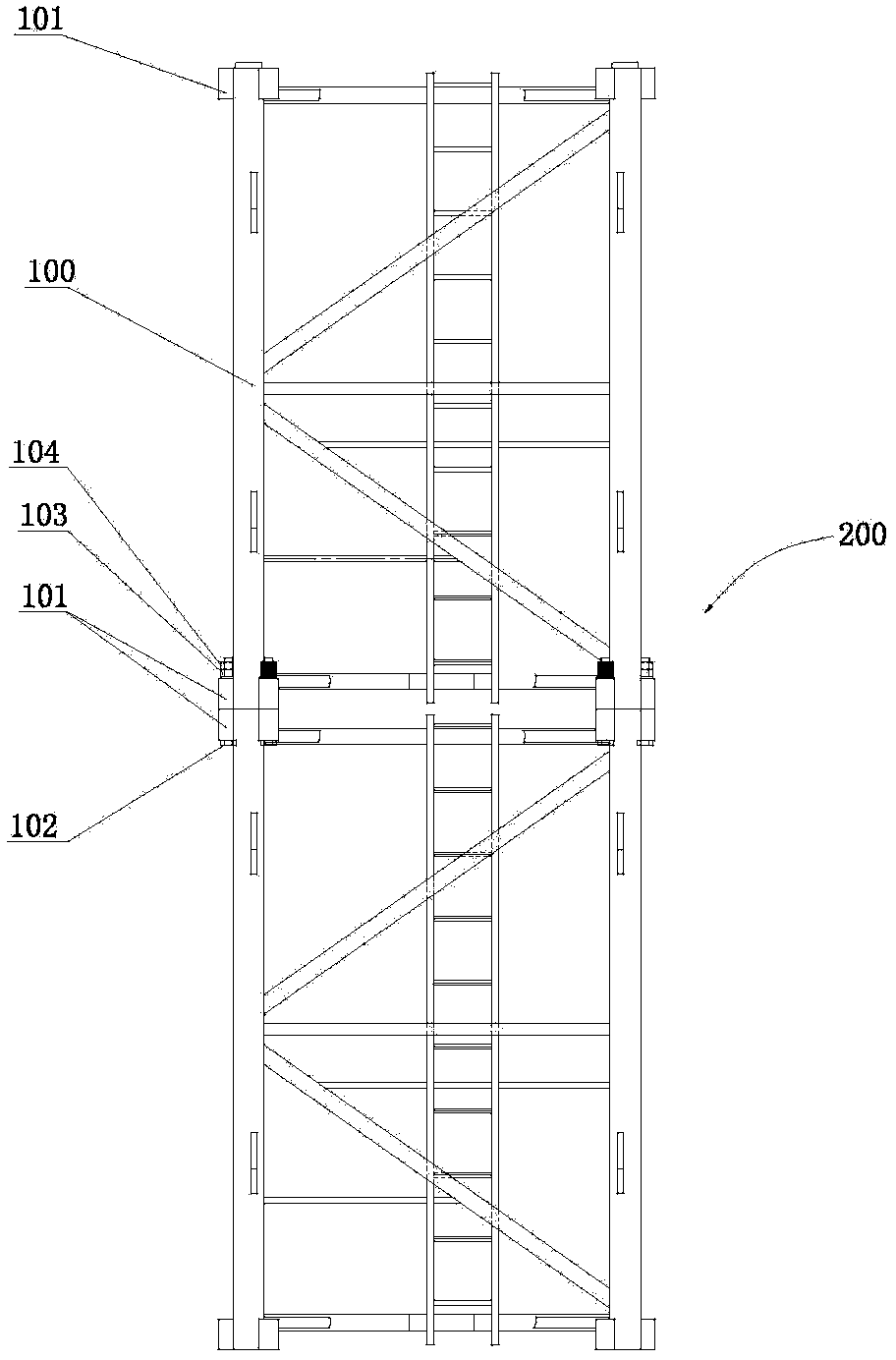

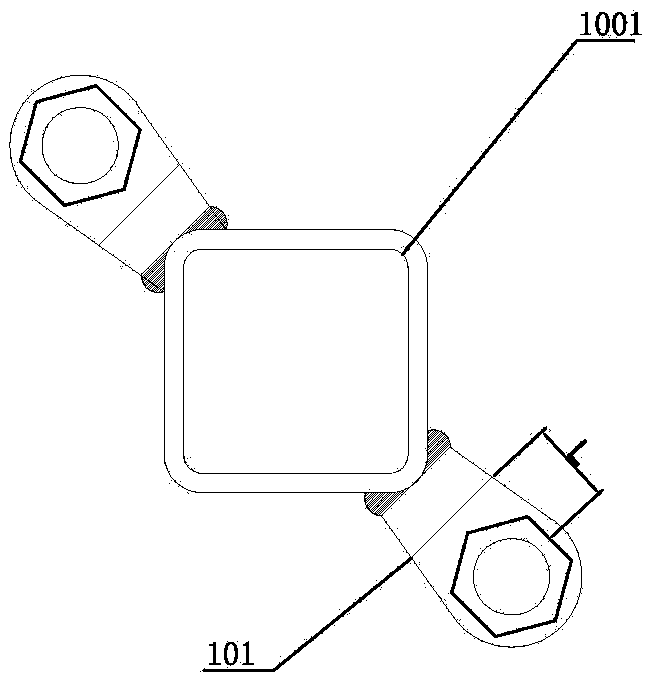

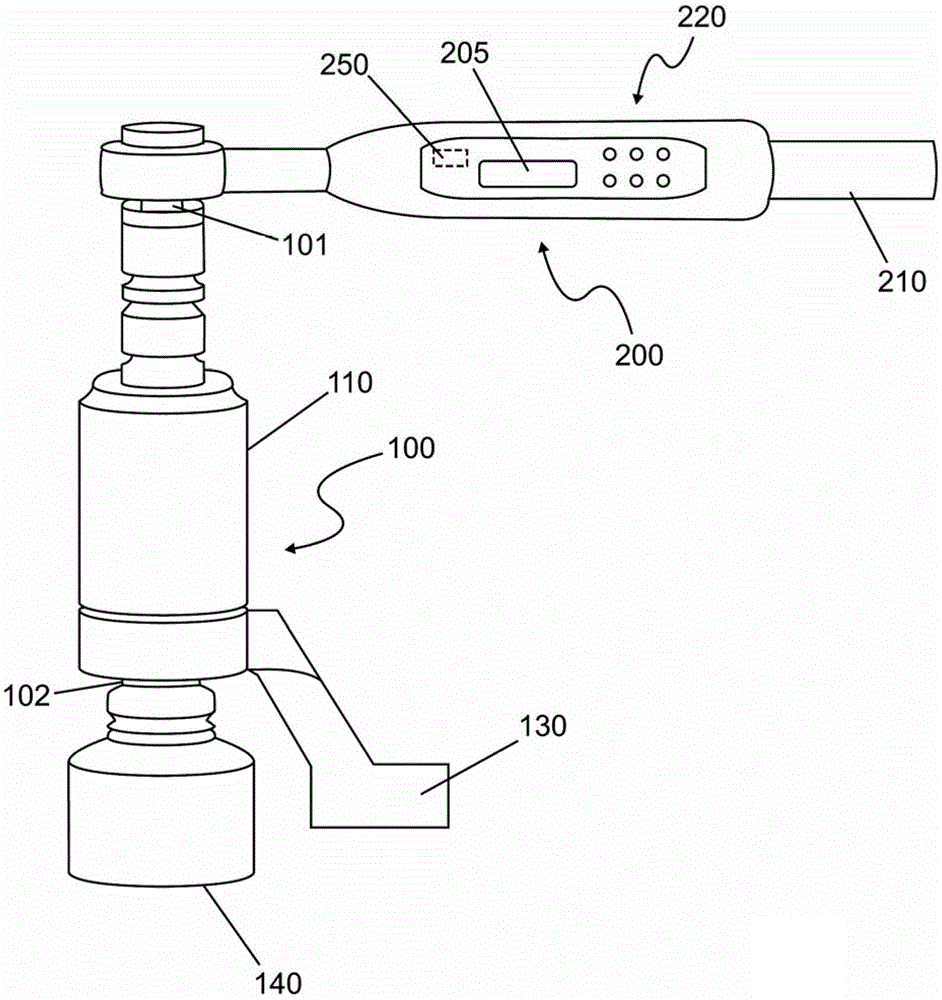

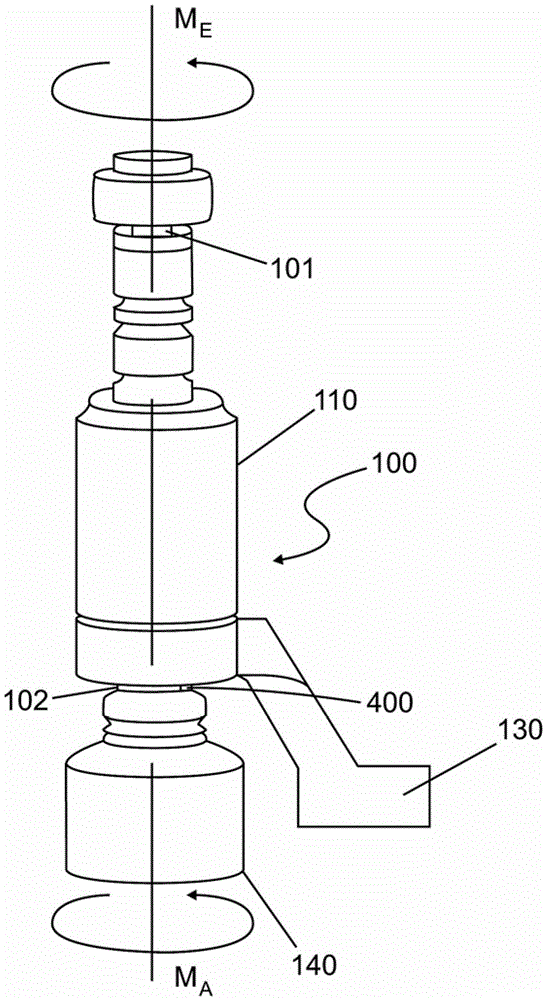

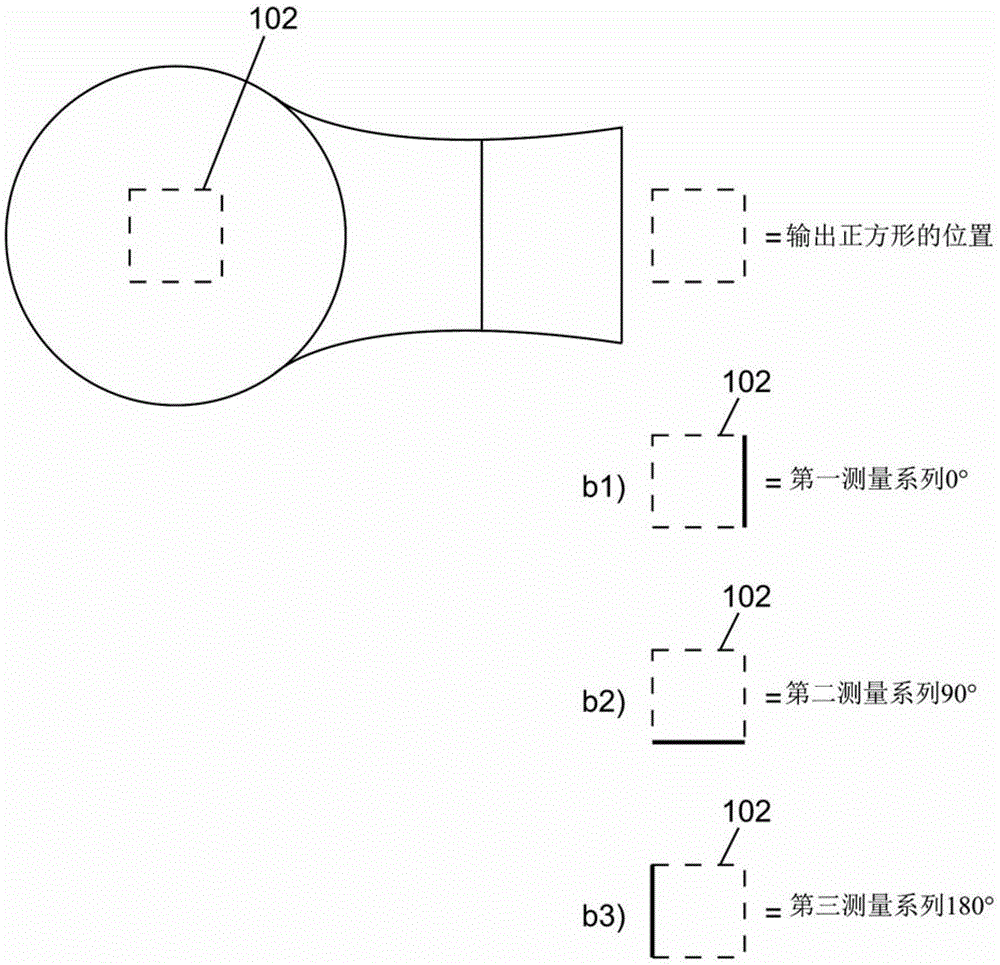

Device for producing precise tightening torque for screw connections

The invention relates to a device for producing precise tightening torque for screw connections characterised by the combination of a torque multiplier (100) and a torque wrench (200) which is adapted to said torque multiplier and calibrated therewith. The invention also relates to a method for calibrating said type of device.

Owner:罗素麦特拧紧技术公司

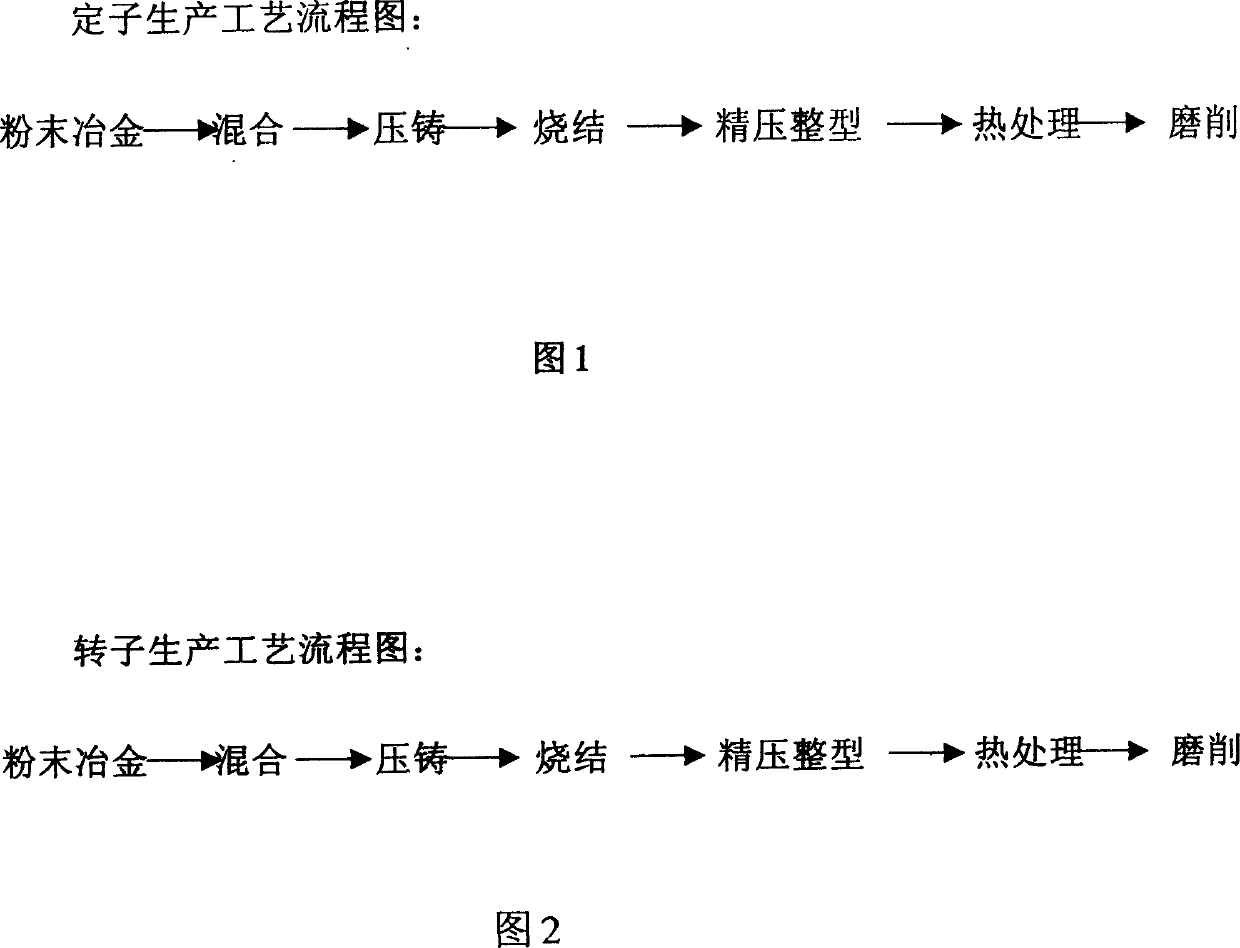

Method for mfg. rotor-stator pair of cycloid device

InactiveCN1451503AImprove wear resistanceIncrease productivityMagnetic circuitFinal product manufactureWork in processCycloid

A method for manufacturing the rotor-stator pair of cycloidal apparatus includes preparing cast dies and shaping dies, die pressing of powder metallurgy material to obtain stator and rotor, sintering, precisely die pressing for precise shaping, turning, heat treating, drilling and plain grinding. Its advantages are high fit precision and antiwear performance, low cost and high productivity.

Owner:张勇

General operation method for reaching given pre-tightening torque of high-strength bolt for tower crane

ActiveCN104192734AAdapt quicklyImprove construction efficiencySpannersWrenchesEngineeringTower crane

The invention discloses a general operation method for reaching the given pre-tightening torque of a high-strength bolt for a tower crane. The general operation method comprises the following steps: firstly, using a climbing frame to lift a tower crane rotating assembly and a part above the tower crane rotating assembly; secondly, placing additional standard sections at the top of a crane body; thirdly, penetrating each high-strength bolt; screwing a lower nut on the corresponding high-strength bolt, screwing each lower nut to be in the place with hands and preliminarily applying pre-tightening force by using a general wrench; fourthly, clamping a first open sleeve on the corresponding lower nut, rocking a torque wrench back and forth by using special tools until the pre-tightening torque is reached; fifthly, repeating the fourth step, wherein the special tools comprise the first open sleeve, a torque amplifier and the torque wrench; the first open sleeve comprises a first lower sleeve and a first panel; an opening which can be clamped on the lower nuts is formed in the first lower sleeve. By using the operation method disclosed by the invention, the determined pre-tightening force can be given for each high-strength bolt, the operation is convenient, both labor are saved in operation, the application range is wide, mounting persons can quickly adapt the high construction efficiency is high and the safety performance is high.

Owner:DONGGUAN YIXIN QINGJIANG MACHINERY MFG

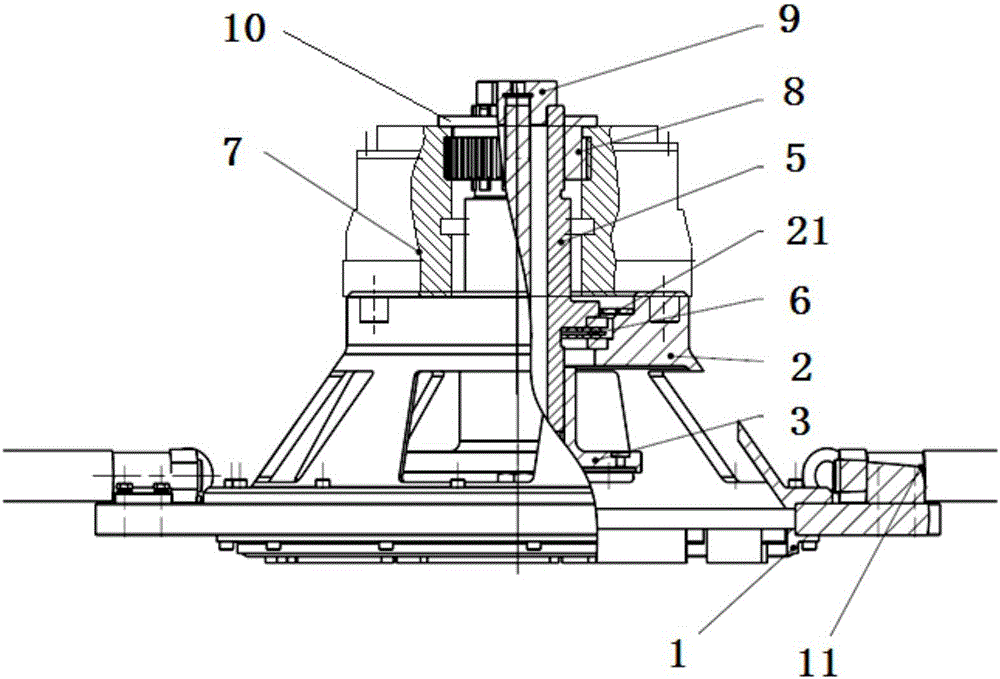

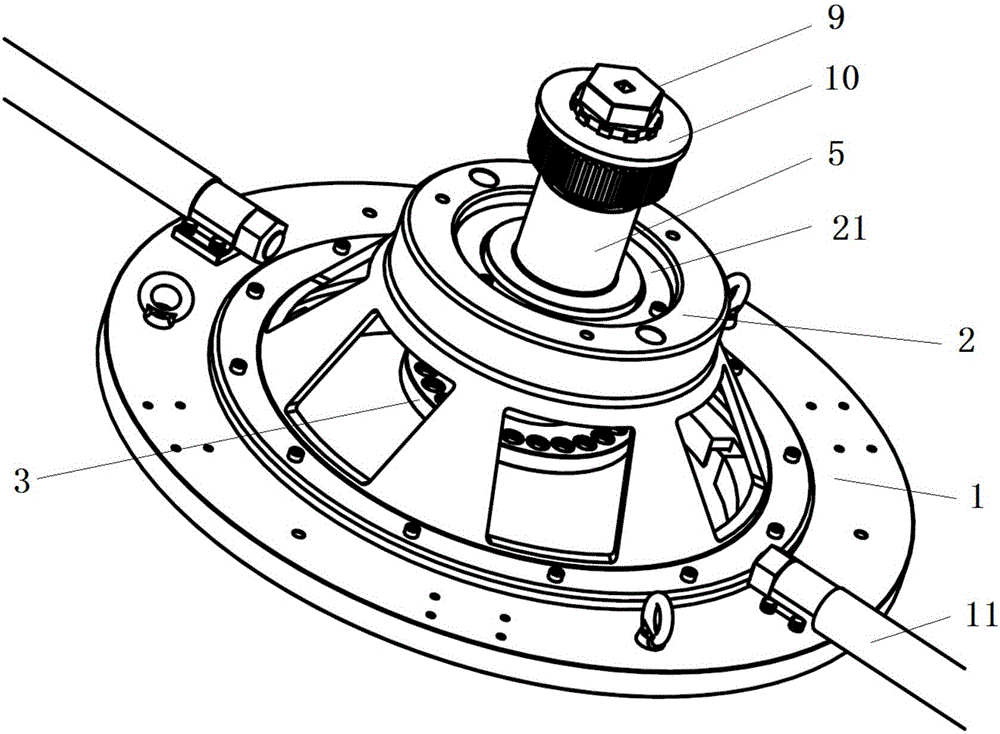

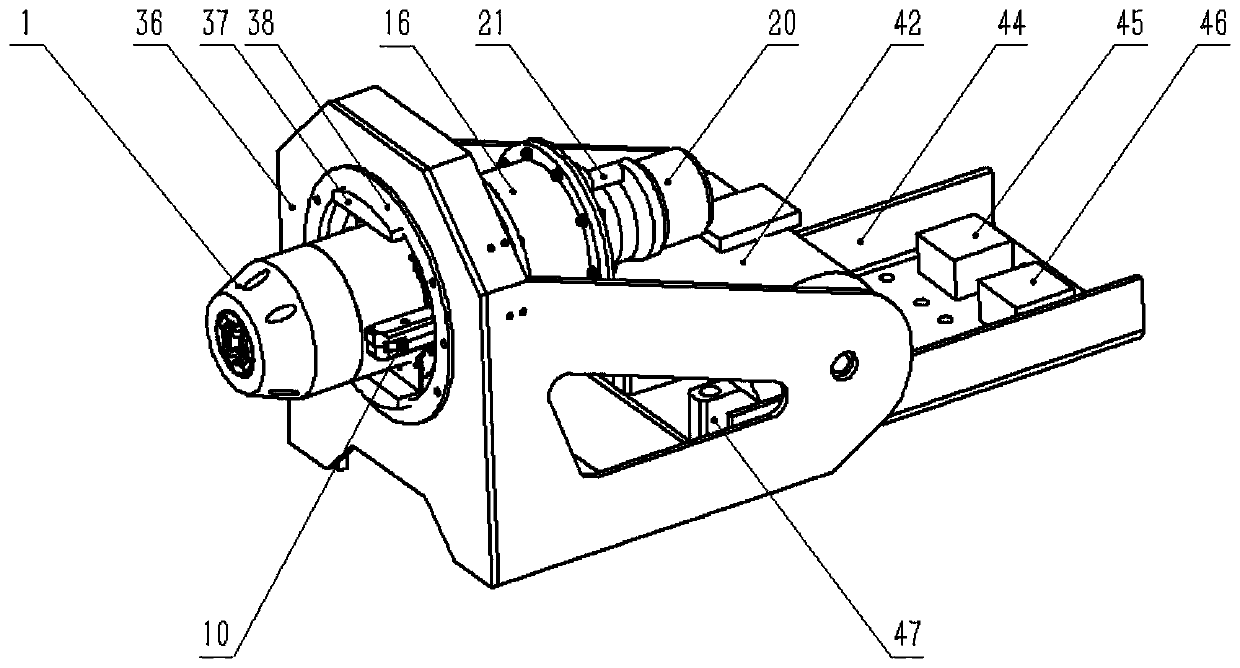

Posture-adjustable multifunctional ROV torque wrench

ActiveCN109944976AFlexible adjustmentQuick dockingOperating means/releasing devices for valvesUnderwater equipmentTorque amplifierEngineering

The invention provides a posture-adjustable multifunctional ROV torque wrench. The posture-adjustable multifunctional ROV torque wrench comprises a torque wrench interface, a locking device, a hydraulic driving mechanism, a torque switching mechanism, a guide base and a torque wrench control monitoring system. Torque is provided by a hydraulic motor, an appropriate torque gear is switched by the torque switching mechanism, and the torque is amplified by a torque amplifier and then transmitted to the torque wrench interface. The torque switching mechanism can switch the gear of the output torque, and the torque gear can be displayed by an indicating needle. The torque wrench interface can be in but connection with a rotary butt joint interface meeting the Class I-IV grade in SO 13628-8 interface standards, the locking device can lock the rotary butt joint interface, and connection stability in the rotating process is ensured. The guide base can be mounted on an ROV and finely adjusts the posture of the torque wrench. The torque wrench control monitoring system can control the torque wrench by controlling the actions of the hydraulic cylinder and the hydraulic motor, and feeds the operation state back to a control interface in real time. The posture-adjustable multifunctional ROV torque wrench is convenient and fast to operate, stable and reliable.

Owner:HARBIN ENG UNIV

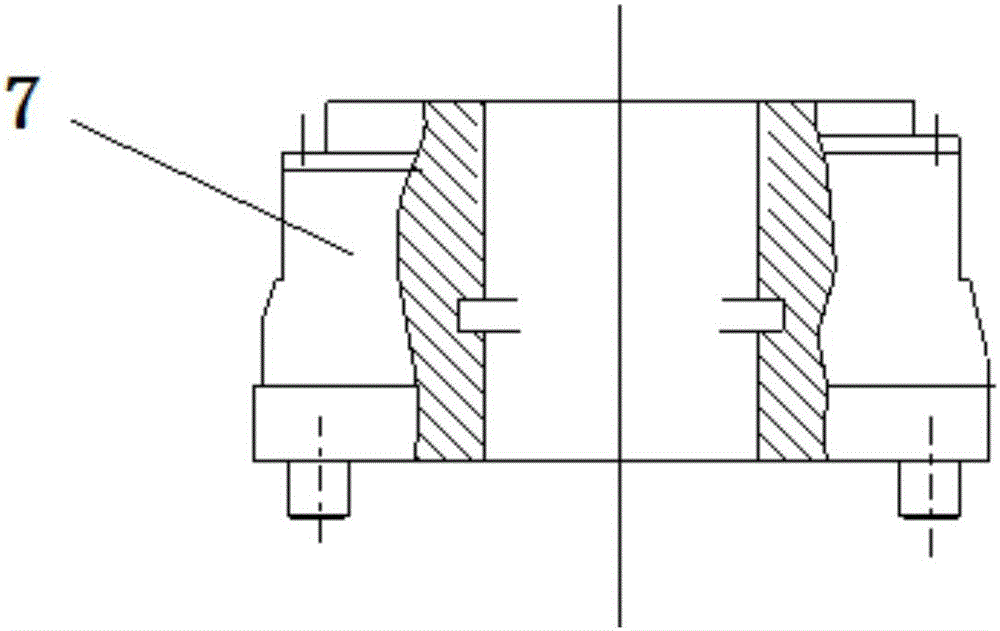

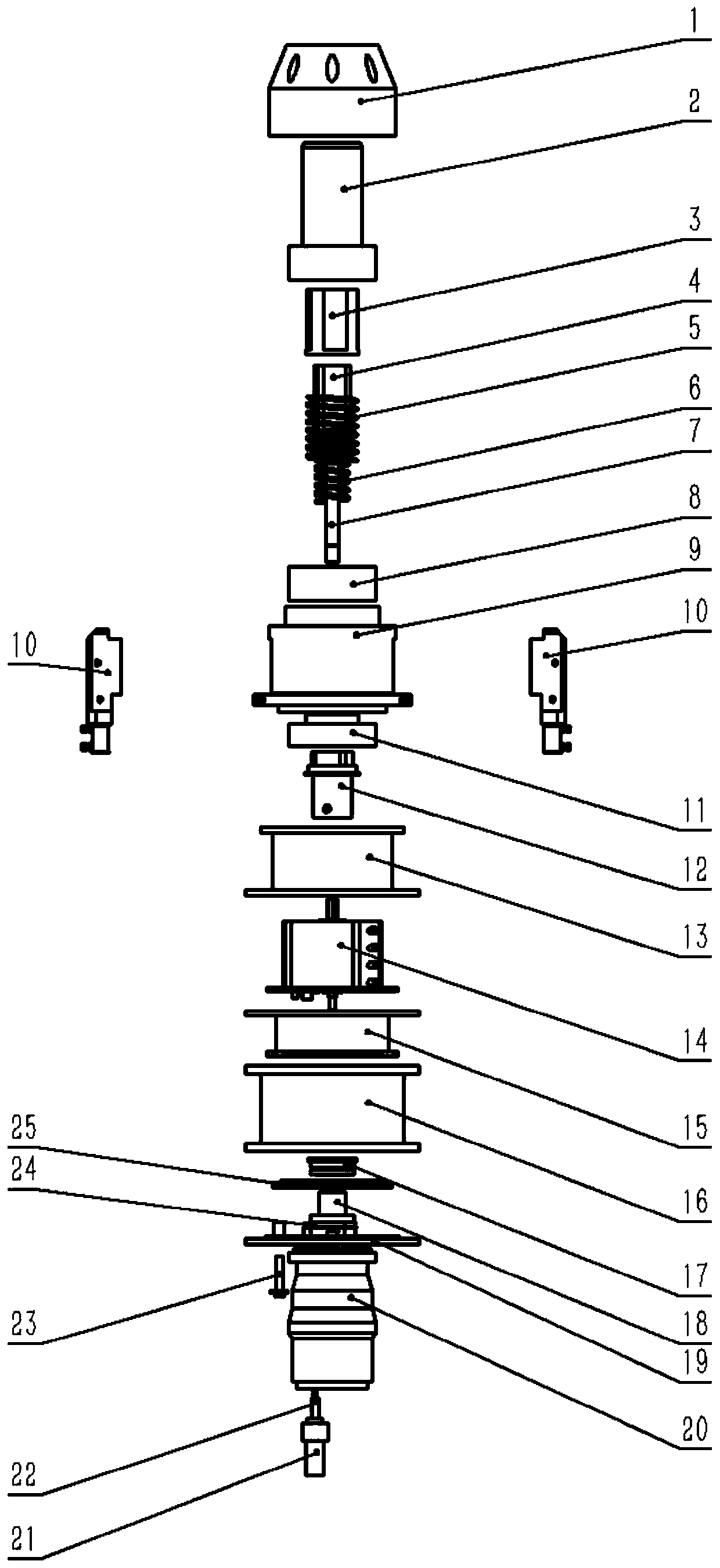

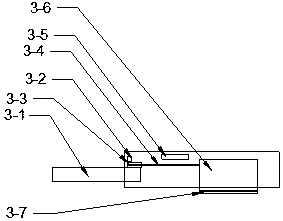

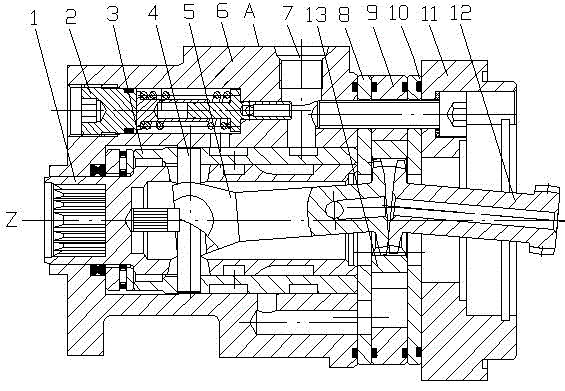

Torque amplifier for jumbolter

InactiveCN102494082AHigh torqueReduce labor intensityToothed gearingsAnchoring boltsAudio power amplifierControl theory

The invention relates to a torque amplifier, particularly to a torque amplifier for the jumbolter, and solves the problem that when an anchor rod nut of the conventional jumbolter is installed, the pre-tightening force cannot meet the requirement and influences the supporting effect. The torque amplifier includes a stepped sleeve with the diameter on the right side smaller than the diameter on the left side, wherein a transmission gear ring is arranged on the inner wall on the left side of the sleeve; an input shaft is arranged on the left side of the sleeve; a driving gear positioned in the sleeve is fixed on the input shaft; a plurality of planetary gears meshed with the driving gear and the transmission gear ring are arranged between the driving gear and the transmission gear ring; shaft pins penetrate the shaft centers of the planetary gears; and an output shaft is fixed at the shaft center on the right side of the sleeve. The torque amplifier for the jumbolter has a reasonable and reliable structural design, meets the requirement for pre-tightening force and improves the efficiency for two to three times as the torque of the jumbolter is greatly amplified, is particularly suitable for work places with smaller space, and has the advantages of light weight, simplicity in operation, as well as convenience for use and maintenance, thereby effectively reducing the labor intensity of employees and improving the labor efficiency.

Owner:霍州煤电集团有限责任公司李雅庄煤矿

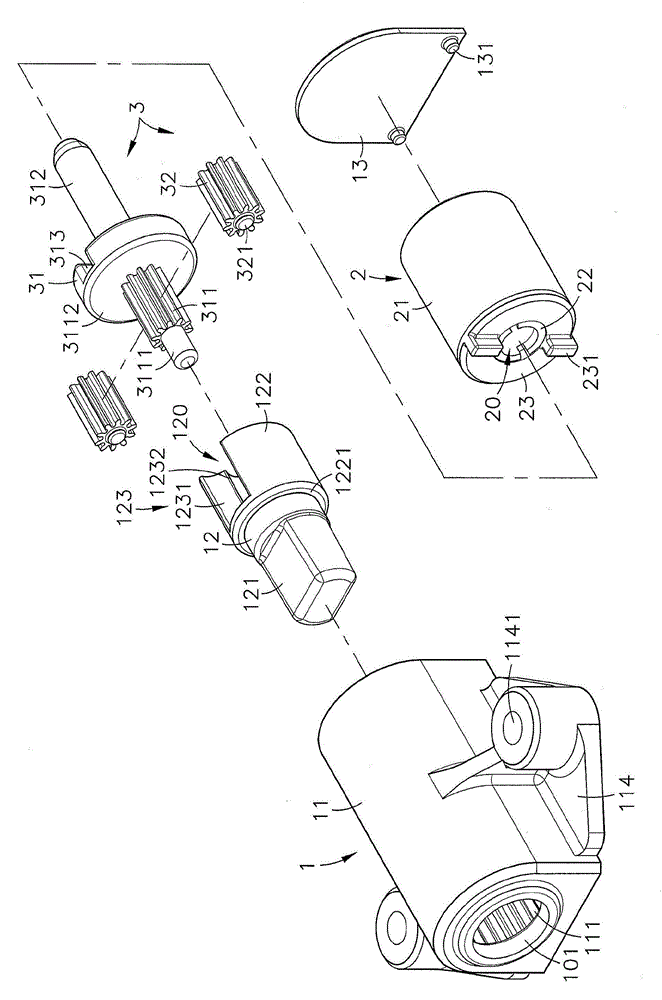

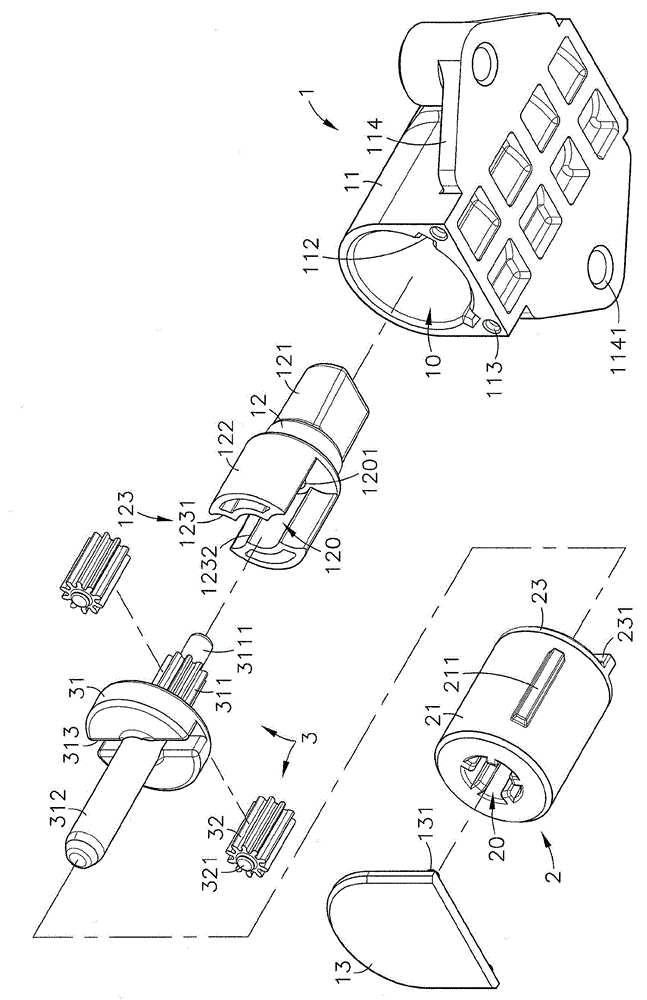

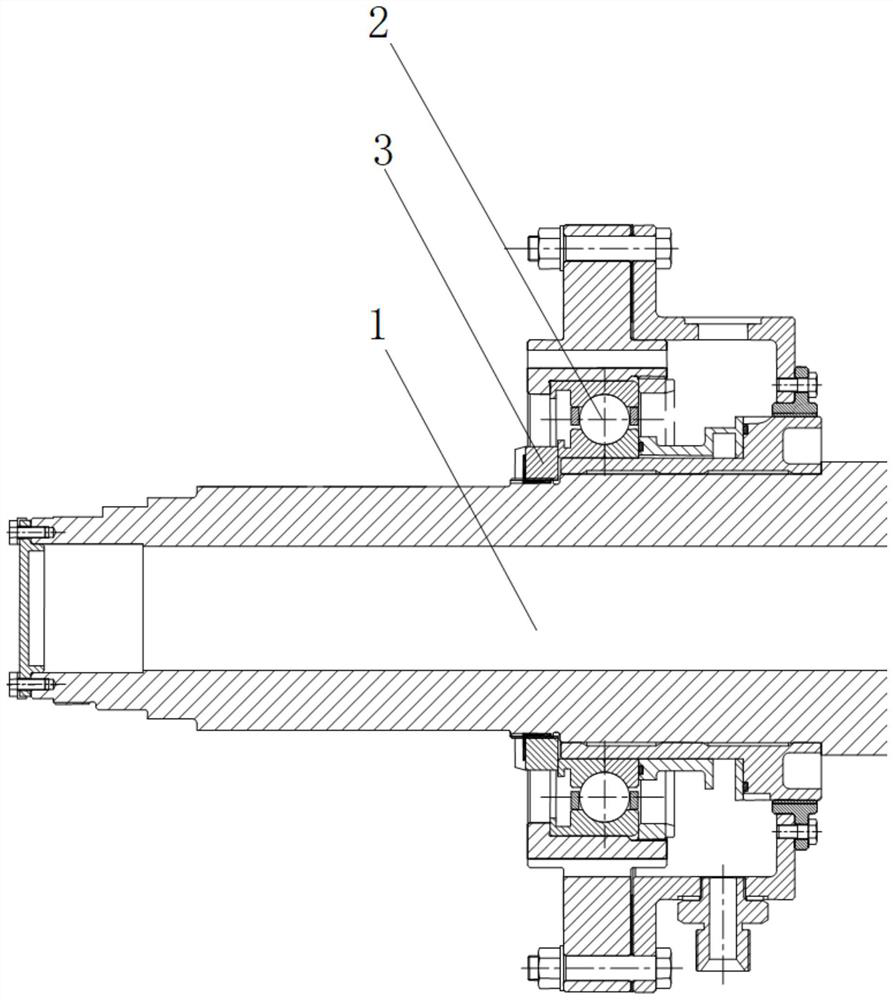

Torque amplifier for damper

The invention provides a torque amplifier for a damper. A damper and a torque amplifier are positioned in an accommodating space inside a base of a seat body; a rotating shaft penetrates through one side of the accommodating space and is provided with a connection part; at least two accommodating slots which are communicated to the inner accommodating space are formed in the actuation part on the other side of the connection part; an annular tooth part penetrating into the accommodating space is arranged on one side of the connecting shaft of the torque amplifier, and at least two planet gears positioned in the accommodating slots are engaged on the annular tooth part; each planet gear is engaged on an annular tooth slot in the inner wall surface of the base; and an axial rod which is arranged in the perforation of a damping part of the damper in a penetrating manner is arranged in the center, on the opposite side of the annular tooth part, of the connecting shaft. When the rotating shaft rotates, the actuation part can be used for pushing the planet gears to engage and drive the annular tooth part, the connecting shaft can simultaneously rotate according to a preset gear ratio, and the connecting shaft is linked with the damping part, so that the damper can achieve the effect of steppless multiple torque amplification.

Owner:NIFCO TAIWAN

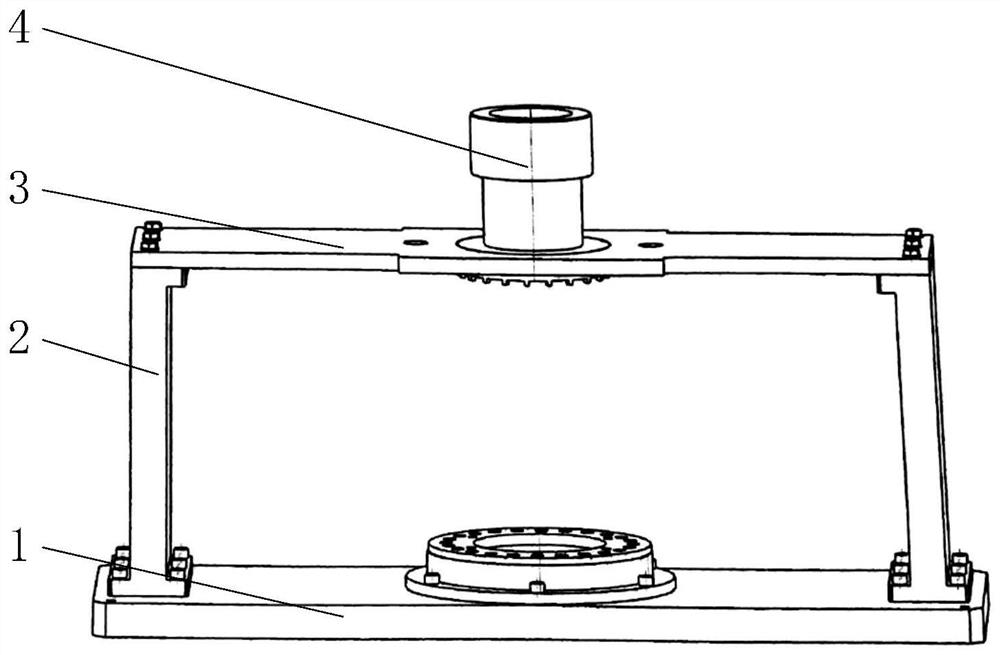

Assembling and disassembling device for bearing inner ring compression nut

ActiveCN112372582ASimplify assembly and disassembly processImprove operational safetyWork holdersMetal-working hand toolsClassical mechanicsTorque transmission

The invention provides an assembling and disassembling device for a bearing inner ring compression nut. The device comprises a main support, a fixing table, an operating table, a lifting clamp, a pressing plate, a torque amplifier and a bushing wrench, wherein the main support at least comprises a first support and a second support which can move relative to each other, the first support and the second support are connected through a connecting piece, height adjustment of the main support is achieved, the device adapts to rotor assemblies of various specifications, the fixing table and the operating table are fixedly arranged on the main support, the fixing table is used for fixing a rotor assembly bearing a bearing inner ring, the operating table is used for bearing the torque amplifier,the lifting clamp is arranged on the main support and can move relative to the main support, the pressing plate is connected with the lifting clamp, a rotor in the rotor assembly is limited through the pressing plate and the lifting clamp, the torque amplifier is mounted on the operating table, and the bushing wrench is arranged between the torque amplifier and the bearing inner ring compression nut, sleeves the rotor and is used for transmitting a torque of the torque amplifier to the bearing inner ring compression nut so as to tighten the bearing inner ring compression nut.

Owner:AECC SHENYANG ENGINE RES INST

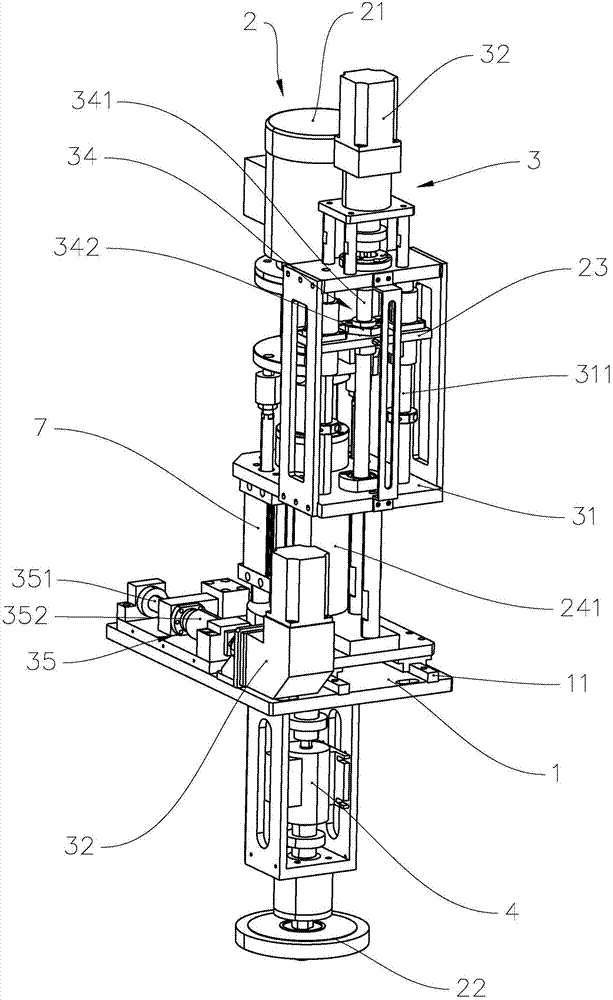

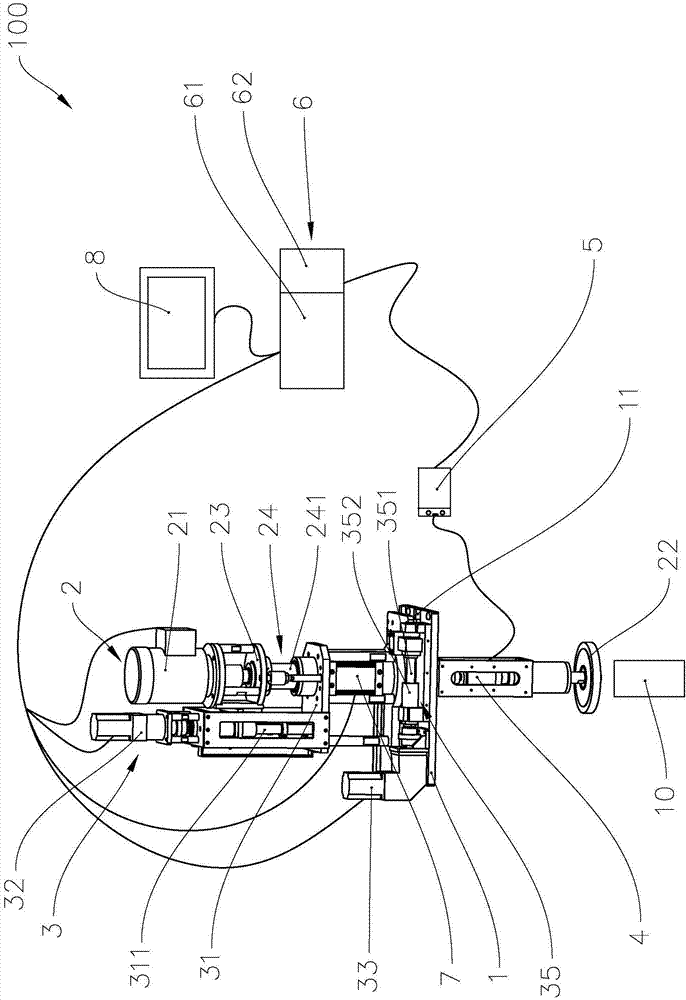

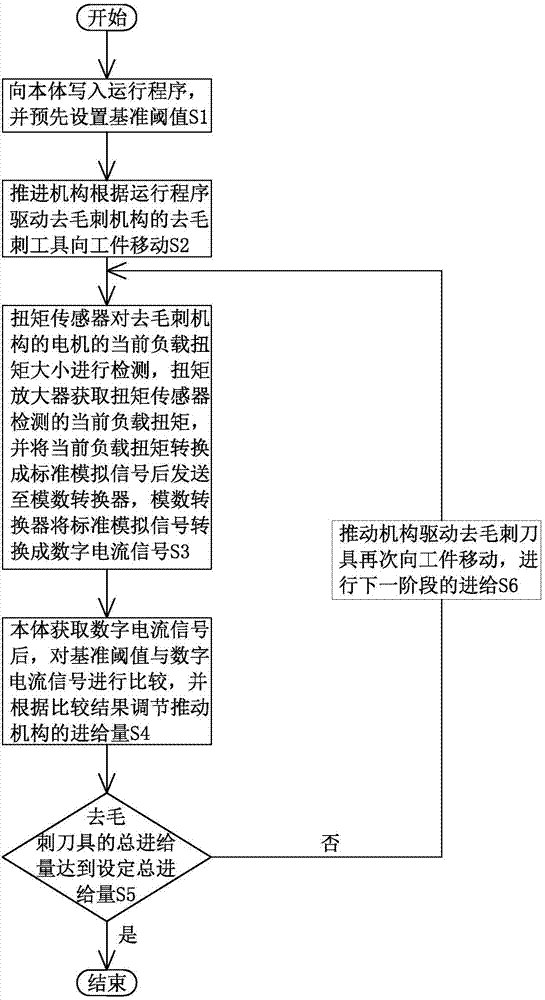

Burr removing machining method based on torque control and burr removing system

PendingCN107971858AGuarantee processing qualityEnsure processing consistencyEdge grinding machinesGrinding drivesCurrent loadLoad torque

The invention provides a burr removing machining method based on torque control and a burr removing system. The burr removing system comprises a pushing mechanism, a burr removing mechanism with a motor, a torque sensor, a torque amplifier and a controller with a body and an analog-digital converter. The burr removing machining method comprises the steps that a run program is written into the body, and a standard threshold value is set in advance; a burr removing tool is driven by the pushing mechanism according to the run program to move to a workpiece; the current load torque of the motor isdetected through the torque sensor, the current load torque is converted into standard analog signals through the torque amplifier, and the standard analog signals are converted into digital currentsignals through the analog-digital converter; and the digital current signals are obtained by the body, the standard threshold value is compared with the digital current signals, and the feeding amount of the pushing mechanism is adjusted according to the comparative result. By means of the burr removing device and the burr removing machining method, the burr removing tool feeding amount can be adjusted according to friction force borne by the burr removing tool, and the beneficial effects of being high in machining accuracy and good in machining quality are achieved.

Owner:GUANGDONG HESHI AUTOMATION TECH CO LTD

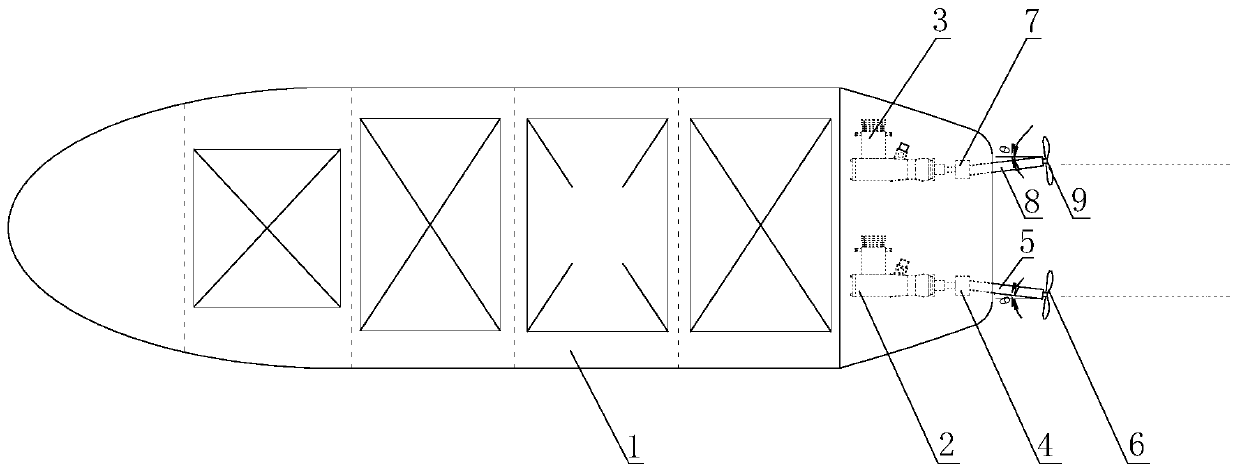

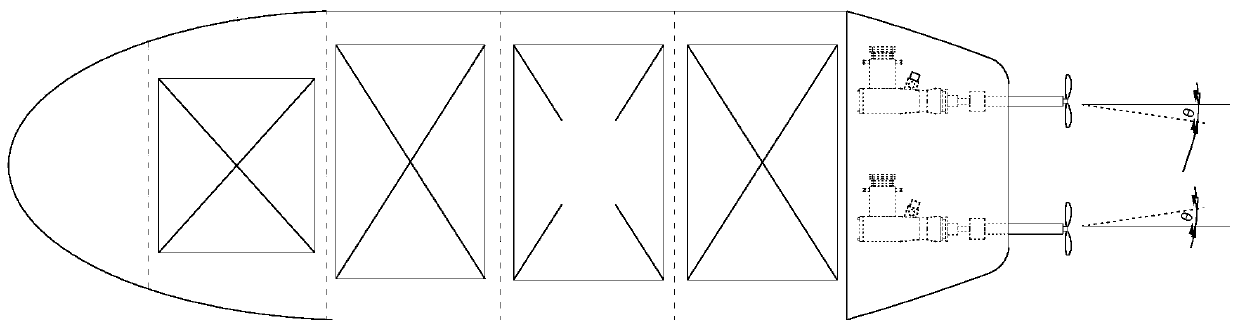

Efficient sailing propeller and force application pushing method

The invention discloses an efficient sailing propeller and a force application pushing method. The propeller comprises a hull; a first engine and a second engine are installed in the stern of the hull; a first propeller rod and a first torque amplifier are obliquely installed; a second propeller rod and a second torque amplifier are obliquely installed; and the included angle formed between the first propeller rod and the horizontal line of the hull and the included angle formed between the second propeller rod and the horizontal line of the hull are both theta. The method comprises the following steps that: the mounting and fixing modes of the first propeller rod and second propeller rod are changed, first propeller blades deviate from the horizontal line of the hull by 3 degrees; secondpropeller blades deviate from the horizontal line of the hull by 3 degrees; the first engine drives the first propeller rod and the first propeller blades to rotate; and the second engine drives the second propeller rod and the second propeller blades to rotate. Under the condition that engine power and extra power consumption are not increased, power pushing can be changed, so that sailing speedis effectively increased, and meanwhile, an energy-saving effect can be achieved.

Owner:邵定国

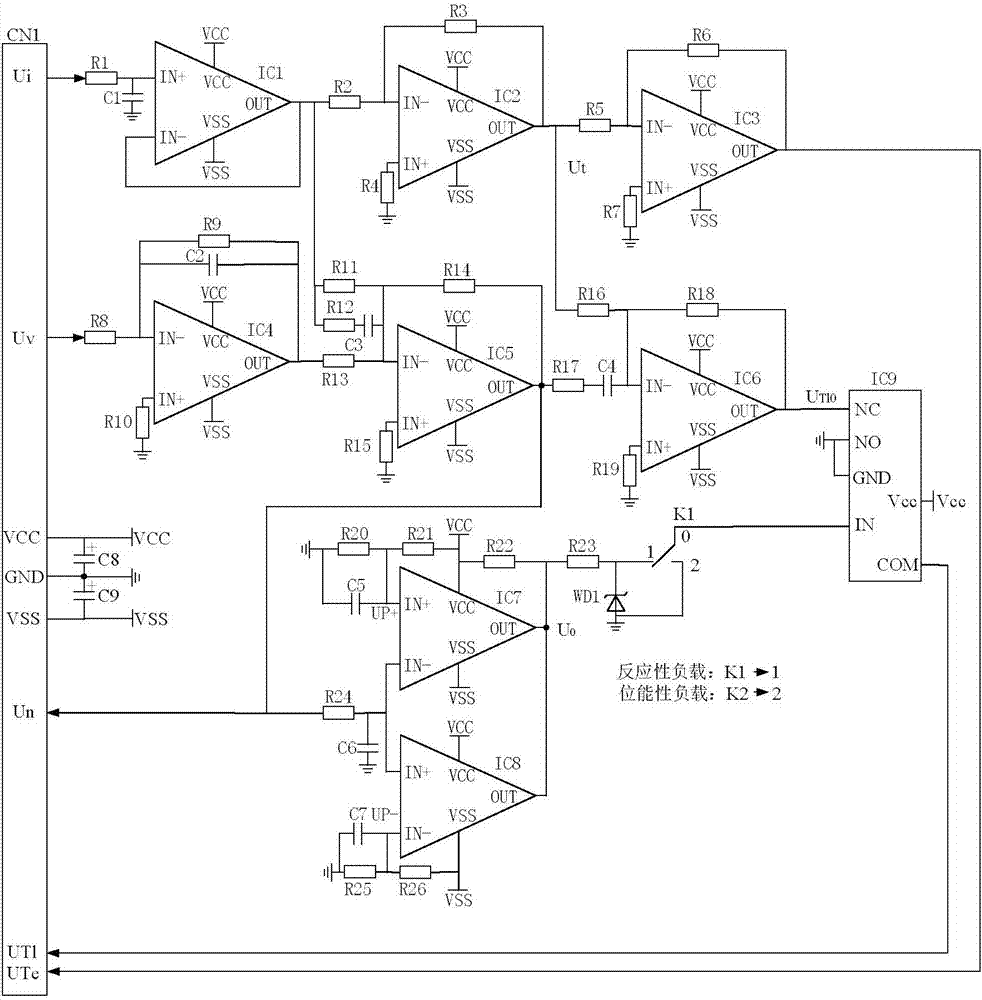

Integrated rotating speed-torque soft detection circuit based on armature voltage and current signal

ActiveCN107462281AImprove versatilityStrong real-timeMeasurement devicesSignal processing circuitsLoad torque

The invention discloses an integrated rotating speed-torque soft detection circuit based on an armature voltage and a current signal. The integrated rotating speed-torque soft detection circuit comprises a rotating speed signal processing circuit, an integrated torque signal processing circuit, and a load type selection circuit. A current detection signal terminal of a connection element is connected with one end of an upper input resistor; the other end of the upper input resistor is connected with a positive input terminal of a current follower; a voltage detection signal terminal of the connection element is connected with one end of a lower input resistor; the other end of the lower input resistor is connected with a negative input terminal of a voltage amplifier; an output terminal of an armature amplifier is connected with a rotational speed output signal terminal of the connection element; an output terminal of a torque amplifier is connected with an electromagnetic torque signal terminal of the connector; and an output terminal of an analog switch is connected with a load torque signal terminal of the connection element. The integrated rotating speed-torque soft detection circuit is suitable for an application occasion for real-time soft detection on the rotating speed and mechanical load torque of a direct-current motor. The soft detection circuit has advantages of good real-time performance, small size, low cost, and high universality and reliability and is easy to chip realization.

Owner:北京中知中科技术开发有限公司

Devices that generate precise tightening torques for threaded connections

The invention relates to a device for generating precise tightening torque for a threaded connection characterized by a torque amplifier (100) in combination with a torque wrench (200) adapted to said torque amplifier and calibrated together with said torque amplifier. The invention also relates to a method for calibrating such a device.

Owner:罗素麦特拧紧技术公司

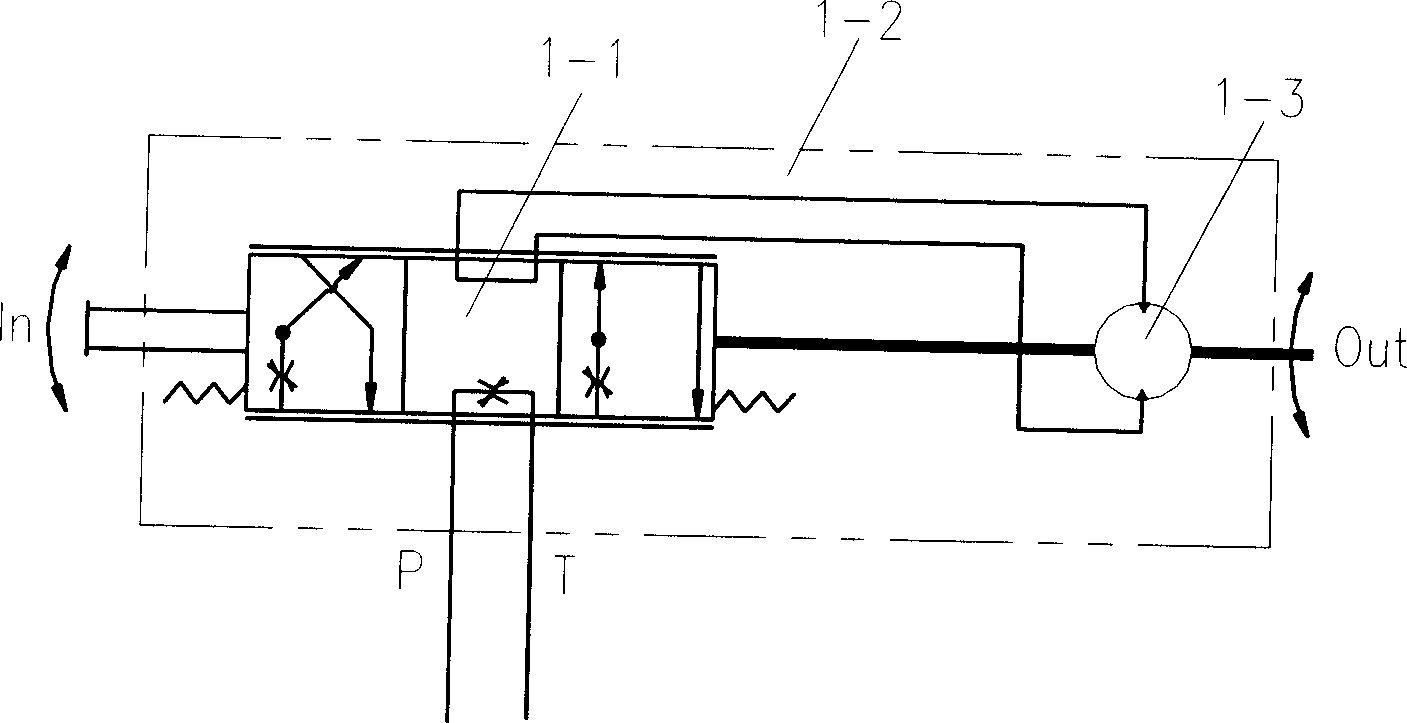

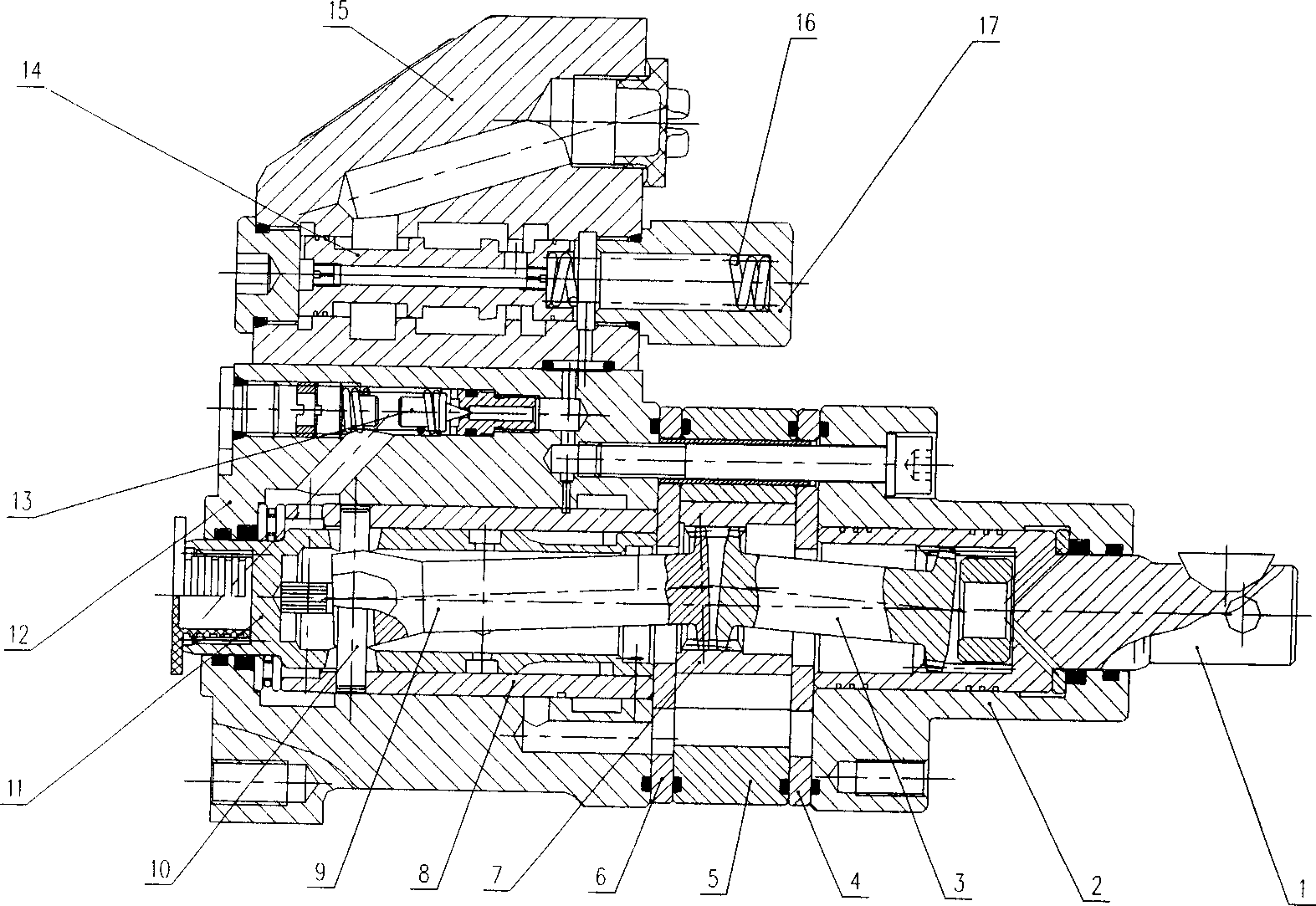

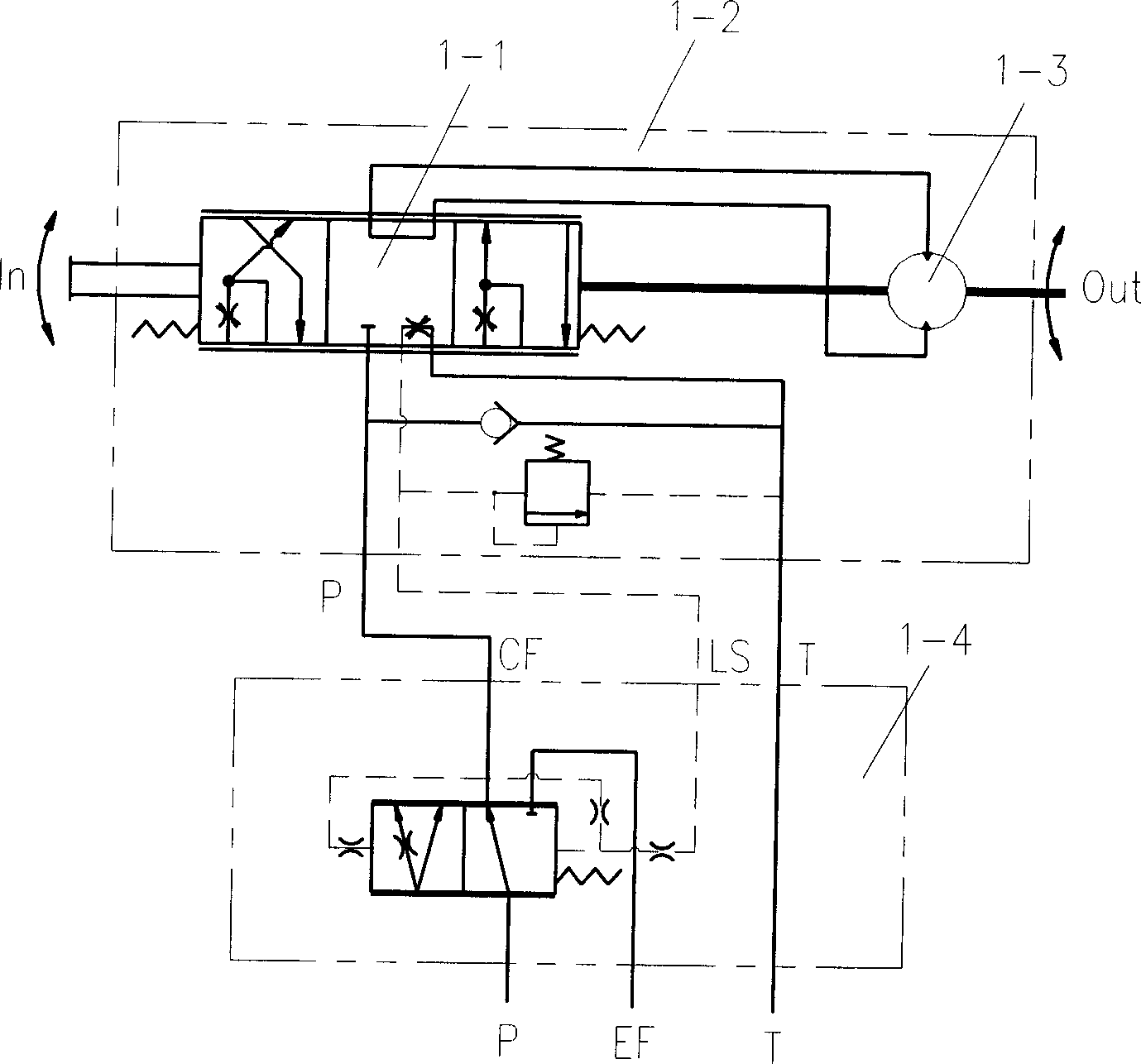

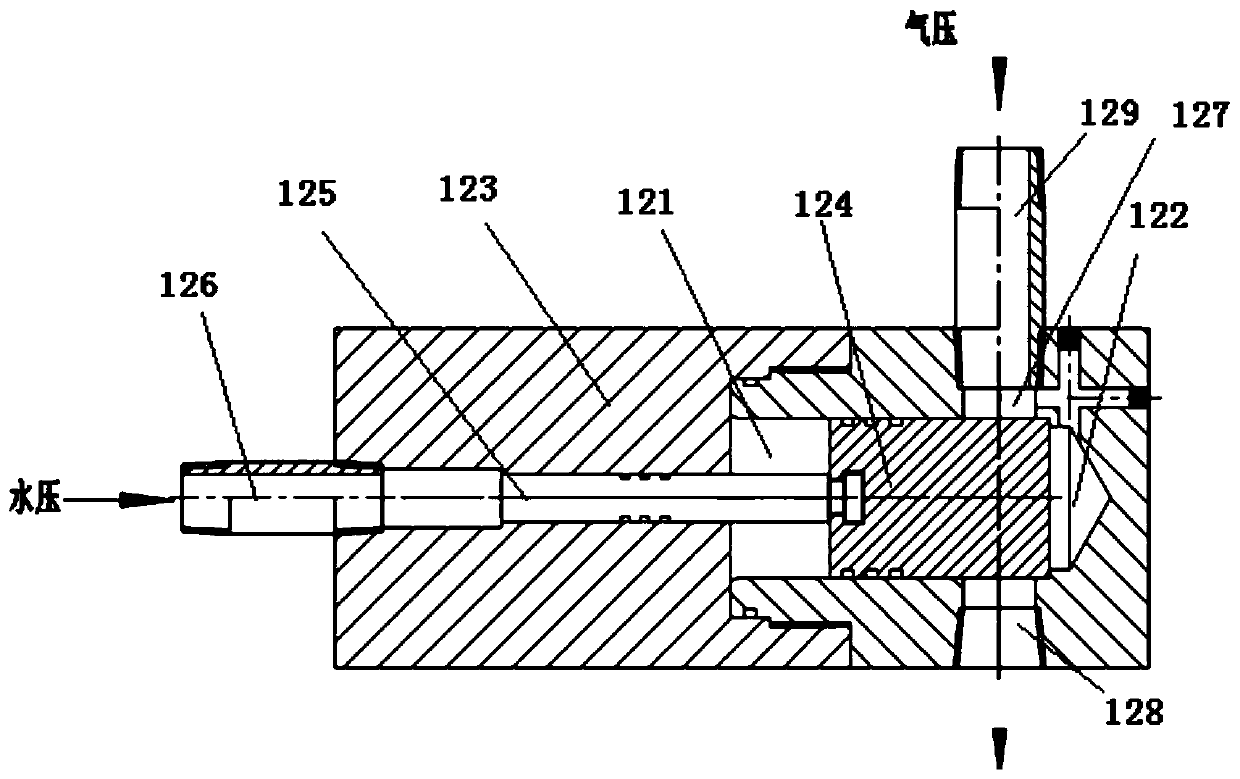

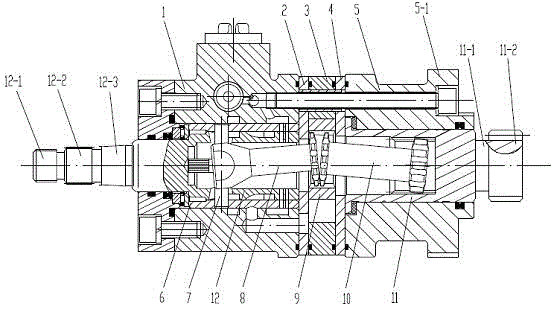

Combined dynamic load sensing torque amplifying and converting device

InactiveCN1865712ARealize a reasonable distributionAvoid ineffective energy consumptionServomotor componentsAudio power amplifierLoad sensing

The invention discloses a combine dynamic load sensitive torque amplifying converter, belonging to the hydraulic transmission technique. Wherein, said device comprises a torque amplifier and a dynamic priority valve; the dynamic priority valve comprises a flow inlet, a flow supply port, a diversion port and a flow channel, while it contains two valve pins that connecting the flow inlet and the flow supply port according to need; or the flow inlet is connected to the flow supply port and the diversion port at the same time; the valve of amplifier has a pressure control valve, a one-way valve and a signal output. When assembling, the flow supply port of dynamic priority valve is through to the inlet of amplifier, while one end of two-way valve pin via flow channel is connected to the signal output of amplifier. The invention can supplies the liquid flow to appointed system, when these systems works together; when appointed system do not work, and it supplies liquid flow to other working system, to distribute the hydraulic energy reasonably; when the system pressure is higher than the pressure of valve, the liquid flow is directly fed to the flux port, without energy consumption, to save energy.

Owner:ZHENJIANG HYDRAULICS

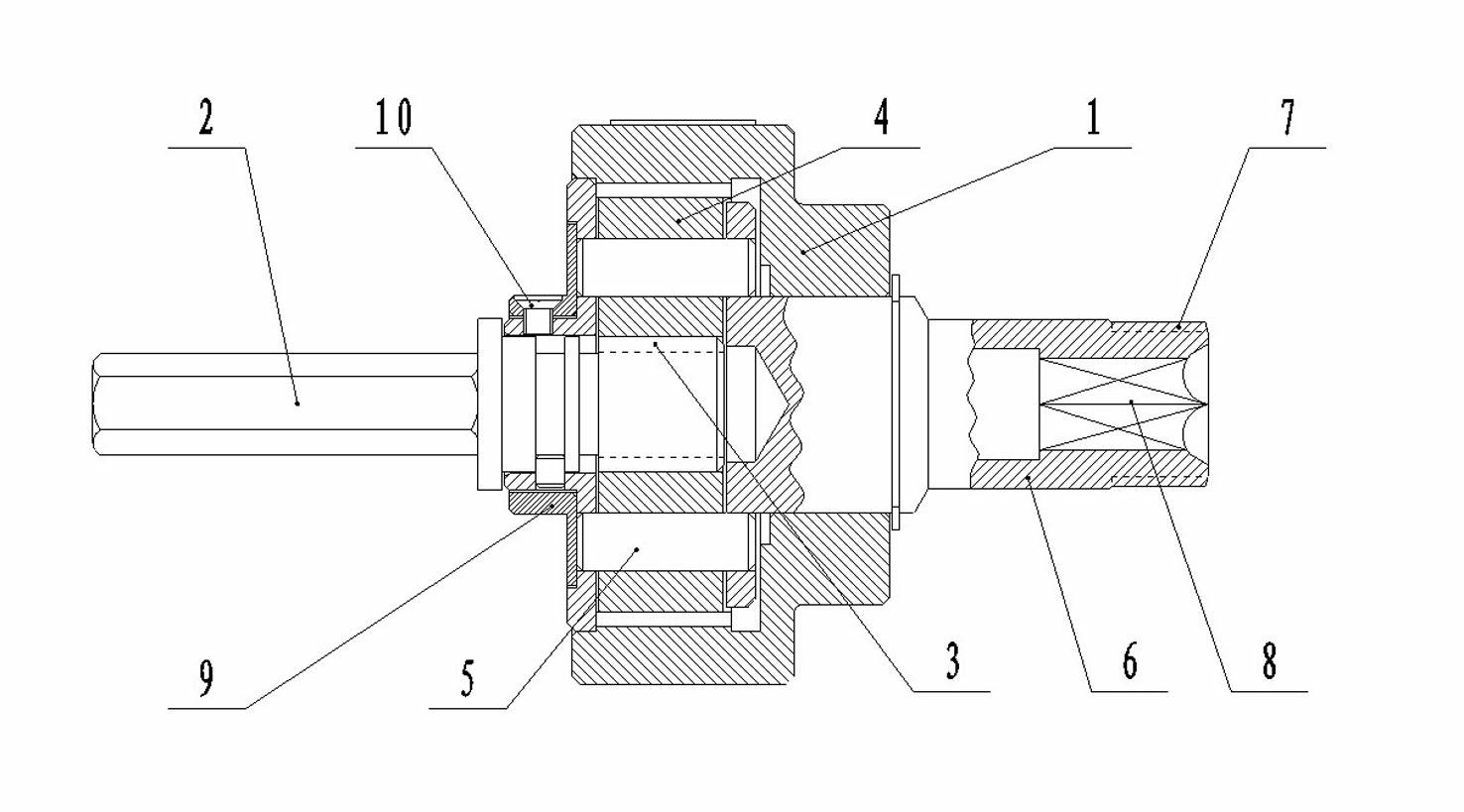

Anchor rod torque amplifier

The invention provides an anchor rod torque amplifier. The anchor rod torque amplifier comprises an input shaft, an output shaft and a speed changing transmission mechanism arranged between the input shaft and the output shaft. The speed changing transmission mechanism is composed of a planet gear speed reduction mechanism and a one-level gear speed reduction mechanism. The planet gear speed reduction mechanism comprises a tooth ring sleeve, three planet gears and a sun wheel which are engaged with one another. The sun wheel is connected with the input shaft. The planet gears are connected with a planet carrier. The one-level gear speed reduction mechanism comprises a drive wheel, a driven wheel and a wheel shaft carrying the driven wheel, the drive wheel is arranged at the output end of the planet carrier, and the wheel shaft is connected with the tooth ring sleeve through a spline bearing and extends out of the tooth ring sleeve. The wheel shaft is slid so that when the drive wheel and the driven wheel are engaged, the output end of the wheel shaft and the output shaft can be in threaded connection. The wheel shaft is slid so that when the drive wheel and the driven wheel are separated, the output end of the planet carrier and the output shaft can be connected. According to the anchor rod torque amplifier, the output torque can be adjusted, and adaptability is high.

Owner:长治市科力机械有限公司

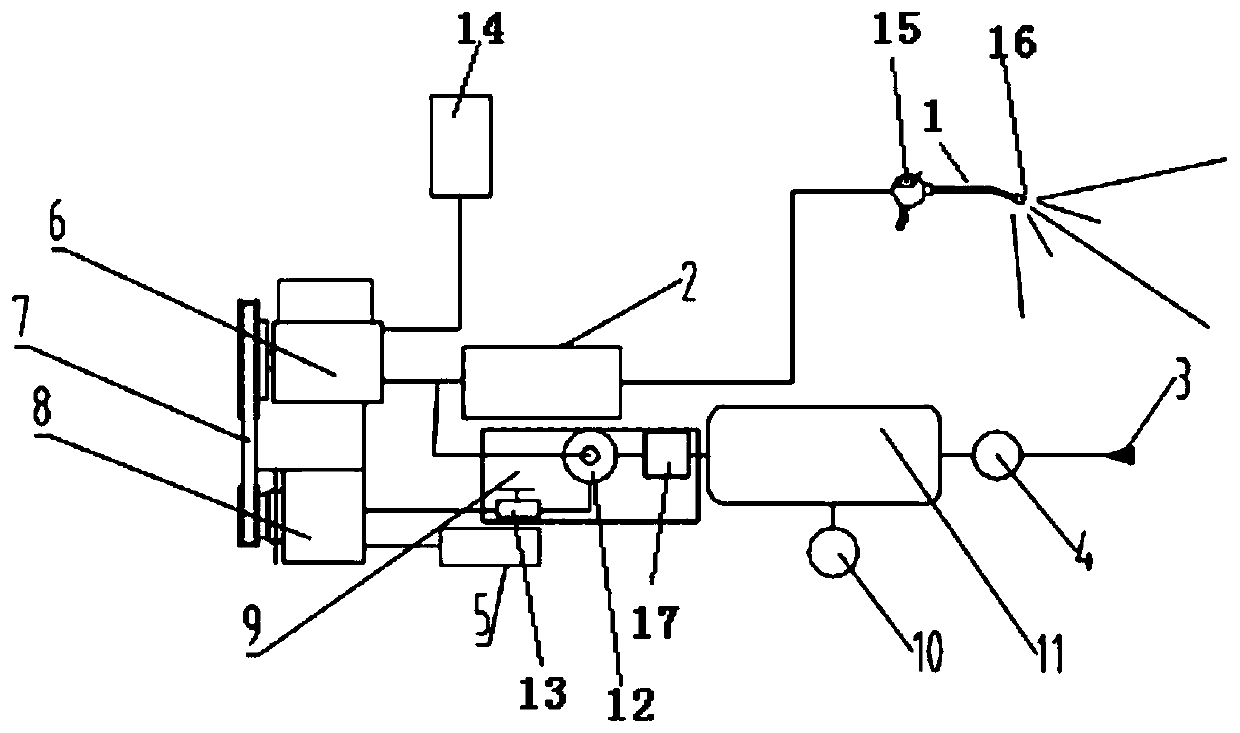

Gas-liquid driven cleaning device

A gas-liquid driven cleaning device comprises a gas power unit, wherein a gas buffer is connected with the gas power unit; an air filter is arranged between the gas power unit and the gas buffer; a gas-liquid indicator is arranged on the gas buffer; a gas flow controller is connected with the rear end of the gas buffer, and comprises an automatic liquid balancing device and a flow control valve; alower cavity of the automatic liquid balancing device is connected with a torque amplifier through the flow control valve; a gas noise reducer is arranged at a gas exhaust port of the torque amplifier; the torque amplifier is connected with a liquid-operated reciprocating supercharger through a synchronous driver; a liquid inlet of the liquid-operated reciprocating supercharger is connected witha water source through a water pipe; a liquid outlet of the liquid-operated reciprocating supercharger is connected with an upper cavity of the automatic liquid balancing device through one end of a tee; a liquid-operated pressure water drum is connected with the other end of the tee; the tail end of the liquid-operated pressure water drum is connected with a high-pressure injector; the high-pressure injector is equipped with an injector switch plate and a spray head; and the nozzle angle of the spray head is adjustable. The gas-liquid driven cleaning device is very high in operability, safety, economy and applicability.

Owner:大庆义浦石油科技开发有限公司

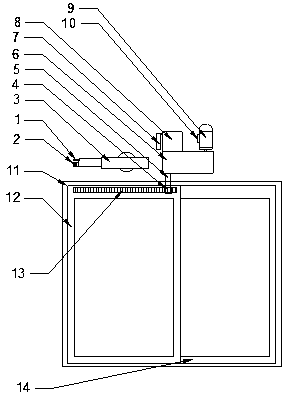

Automatic opening and closing window suitable for household

The invention provides an automatic opening and closing window suitable for household. The automatic opening and closing window comprises a photoelectric sensor module, a wind speed sensor, a sensor base seat, a window opening and closing transmission gear, a window opening and closing transmission shaft, a torque amplifier gear box, a wireless network module antenna, a controller, a motor, a motor resistance sensor, an aluminum alloy window frame, a main window, a main window toothed rail and a subsidiary window, wherein the aluminum alloy window frame is installed at a window position reserved in the wall face and is internally and fixedly provided with the subsidiary window, the inner side of the aluminum alloy window frame is provided with the main window through a rail, the surface ofthe upper portion of the main window is fixed with the main window toothed rail through screws, the main window toothed rail is engaged with the window opening and closing transmission gear, the surface of the window opening and closing transmission gear is connected with the window opening and closing transmission shaft in a welded manner, the surface of the torque amplifier gear box is providedwith a through hole to install the window opening and closing transmission shaft, the torque amplifier gear box is connected with the motor through a bearing, and the surface of the motor is providedwith the motor resistance sensor. By means of the automatic opening and closing window suitable for the household, the window can be automatically opened and closed to perform ventilation indoors, and meanwhile, equipment will close the window automatically once wind blows too fast or in rains.

Owner:徐州泰和门窗有限公司

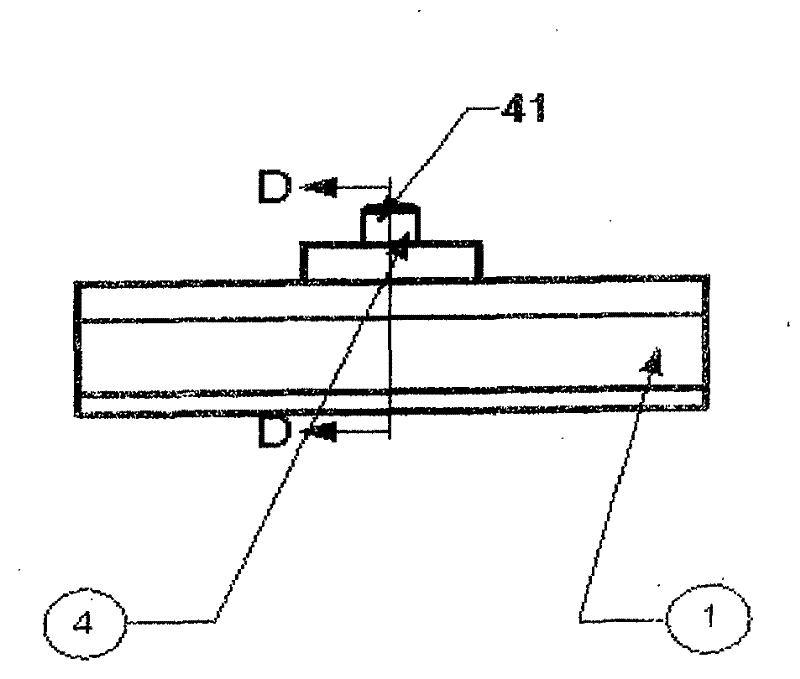

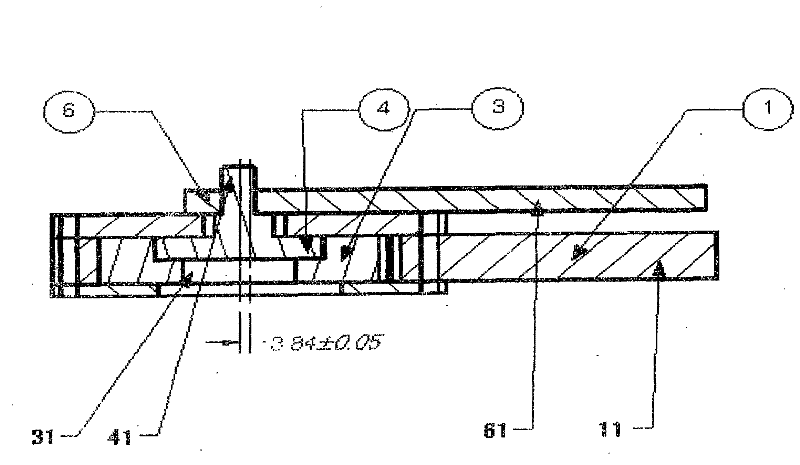

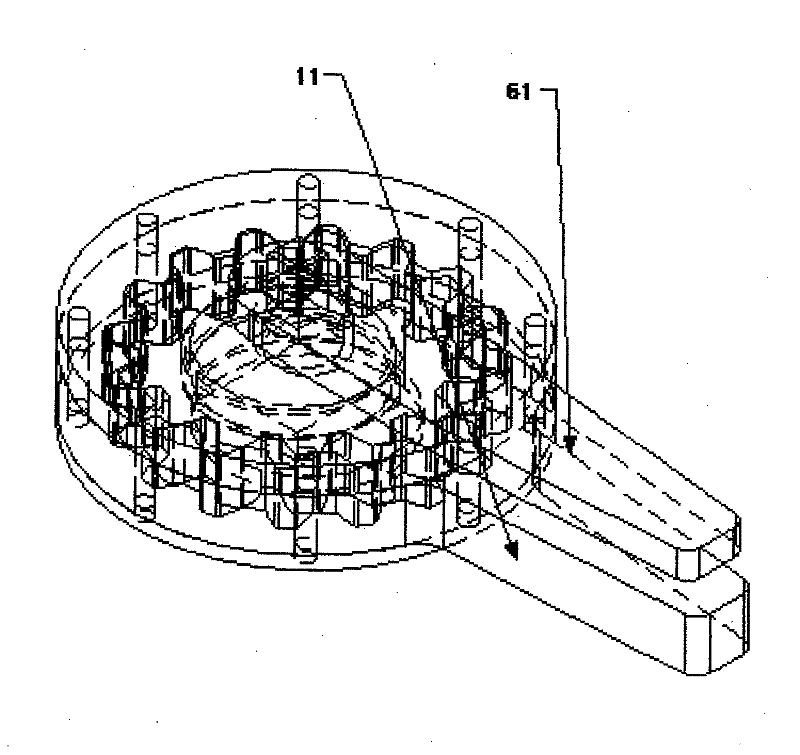

Labor-saving time-saving torque amplifier

The invention discloses a torque dupler that is both labor and time saving, which comprises an internal gear (1), a planetary gear (3) and an eccentric shaft (4) in a small-teeth-difference drive. In the internal gear (1), a wrench 11 is arranged; on the planetary gear (3), an output square hole 31 is arranged; on the ends of the eccentric shaft (4), a square end 41 is arranged; a wrench 61 with a square hole and looped on the square end 41 can rotate about the axial center. The internal gear (1) and the planetary gear (3) employ the gear pair of the small-teeth-difference drive. The gear ratio of the gear pair is equal to the magnification to be increased of the torque. As the torque dupler is provided with two wrenches 11 and 61, when the two wrenches rotate together, as the small-teeth-difference drive is locked into one part, the torque applied by the two wrenches on the places to be twisted is small, and the twisting time is fast; when one of the two wrenches is fixed and anotheris rotating, as the small-teeth-difference drive is developed into a reduction drive, the torque applied on the places to be twisted is bigger, and the twisting time is long. The torque dupler is both labor and time saving in operation.

Owner:王榕生

Method for mfg. rotor-stator pair of cycloid device '

InactiveCN1176767CImprove wear resistanceIncrease productivityFinal product manufactureMagnetic circuitWork in processCycloid

A method for manufacturing the rotor-stator pair of cycloidal apparatus includes preparing cast dies and shaping dies, die pressing of powder metallurgy material to obtain stator and rotor, sintering, precisely die pressing for precise shaping, turning, heat treating, drilling and plain grinding. Its advantages are high fit precision and antiwear performance, low cost and high productivity.

Owner:张勇

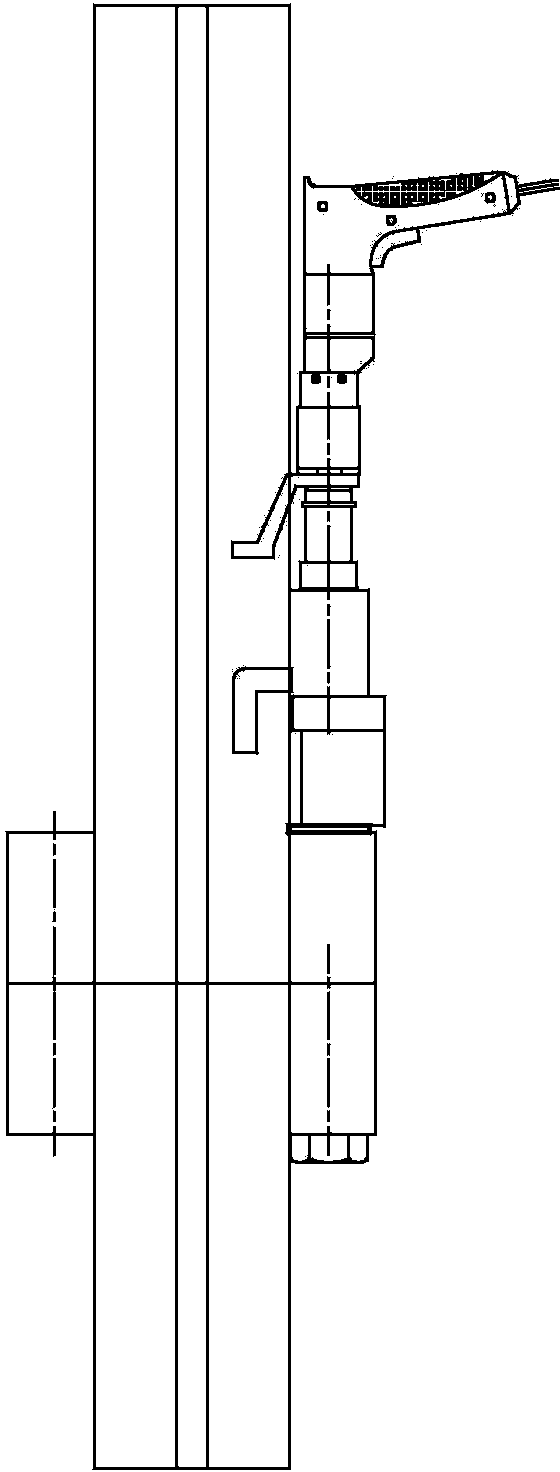

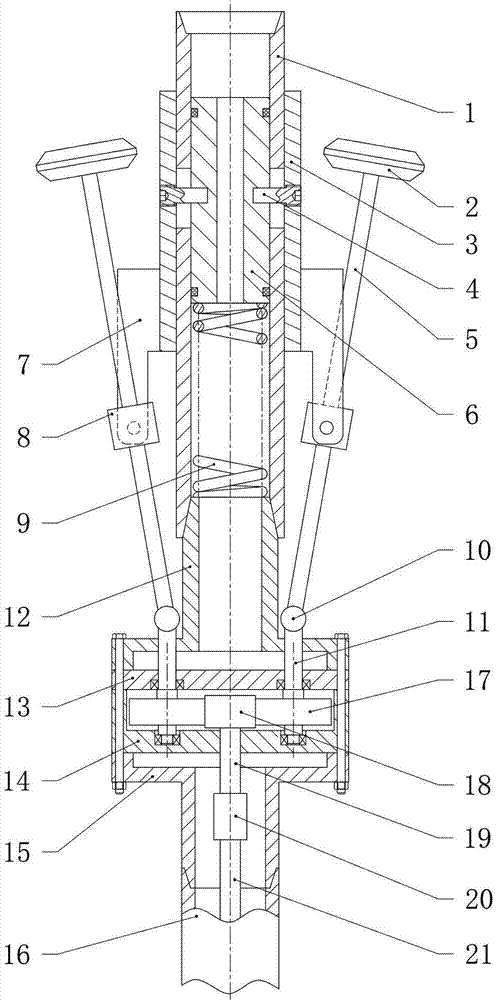

A Coiled Tubing Drilling Torque Booster

The invention relates to a drilling pressure and torque amplifier for a coiled tubing. By the adoption of the drilling pressure and torque amplifier for the coiled tubing, the torque of a turbine drill can be converted into the drilling pressure and torque of a front-end tool. According to the technical scheme of the drilling pressure and torque amplifier for the coiled tubing, a throttling cylinder is arranged in a central cylinder, the throttling pressure difference skews in the radial direction and deflects in the circumferential direction through sliding sleeve driving wheel shafts, the rotation and torque of the turbine tool are transmitted to rolling wheels by means of a transfer case through a big gear and a small gear, and a flow hole is formed in the transfer case. According to the drilling pressure and torque amplifier for the coiled tubing, the stretching angles of the wheel shafts can be adjusted automatically and steplessly, the adaptability to borehole diameter changes is high, and the torque of the turbine drill can be amplified through the transfer case, so that better conditions are provided for the front-end tool; and meanwhile, greater pulling force can be provided for the coiled tubing.

Owner:SOUTHWEST PETROLEUM UNIV

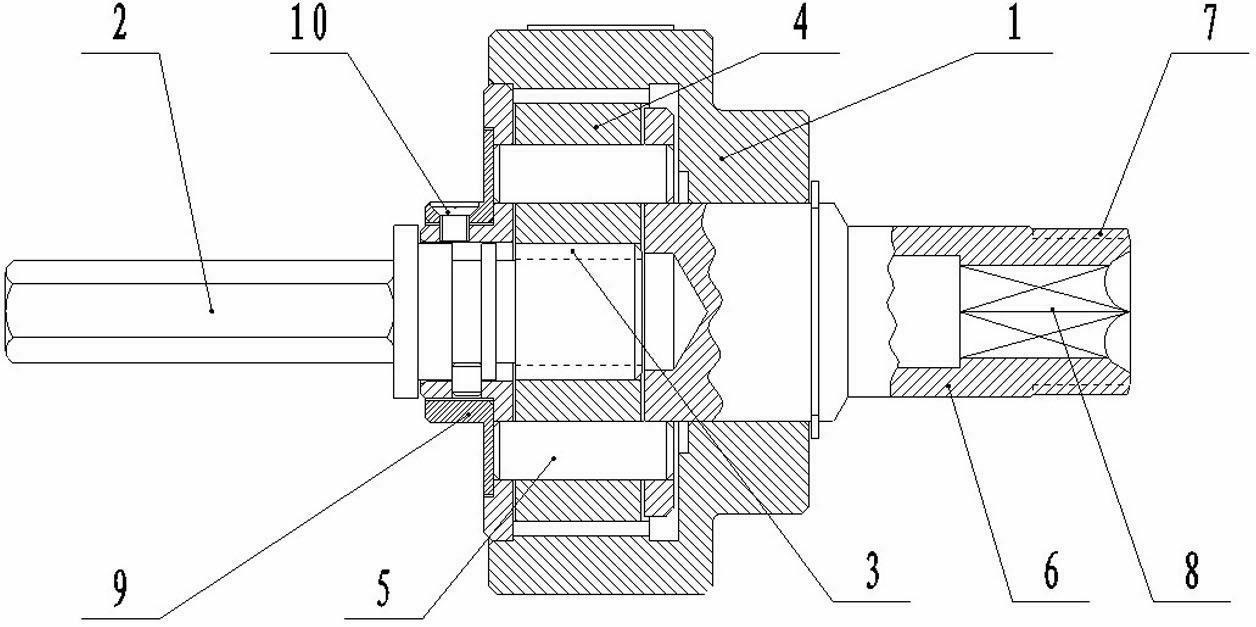

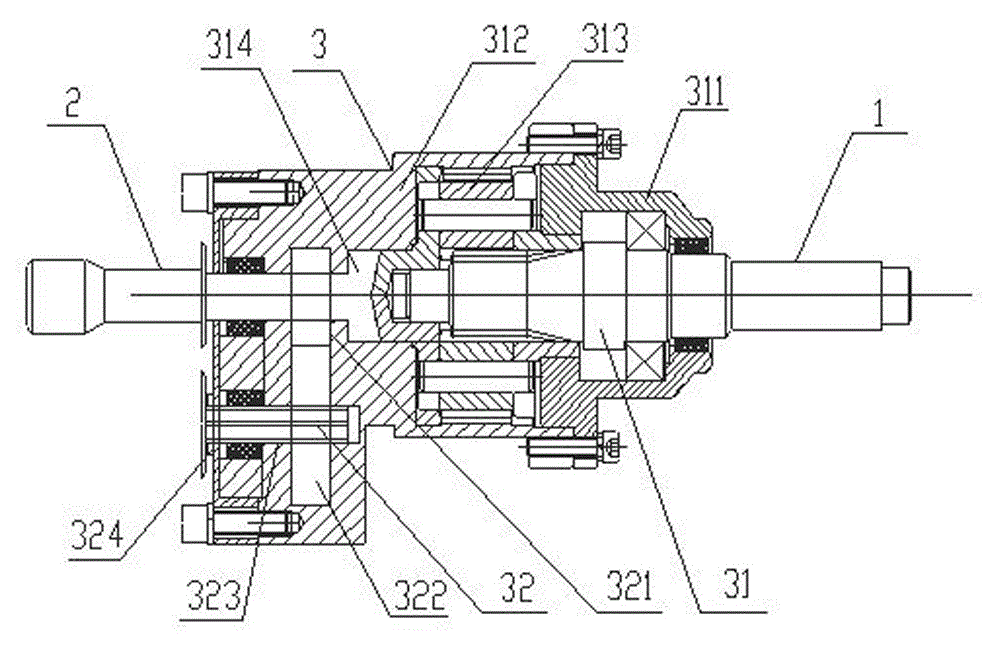

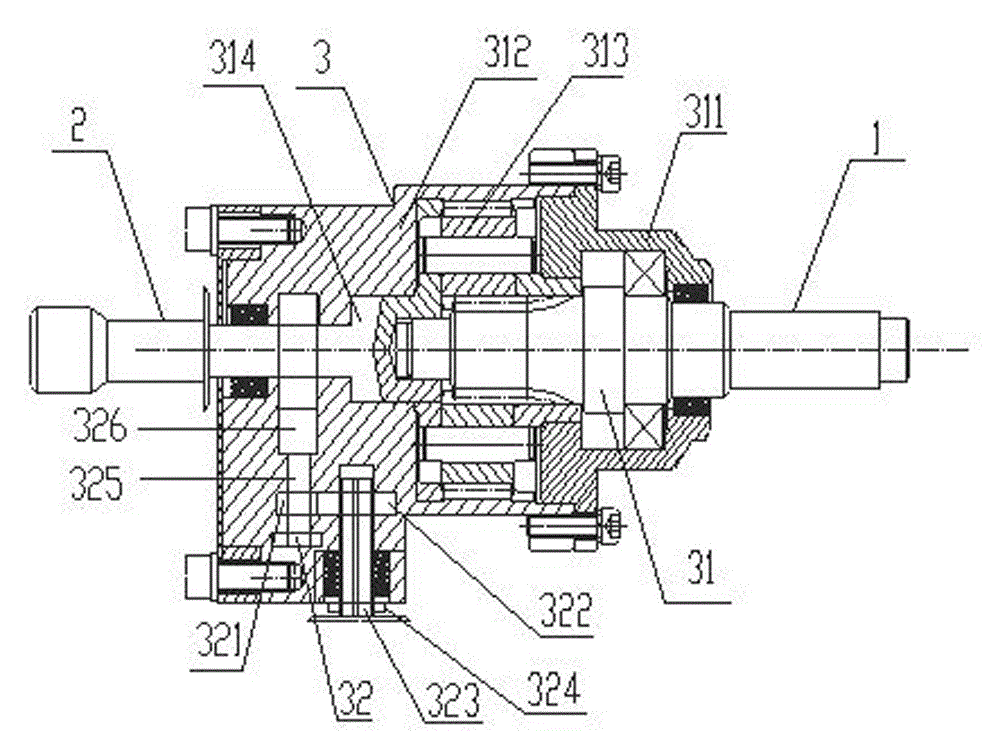

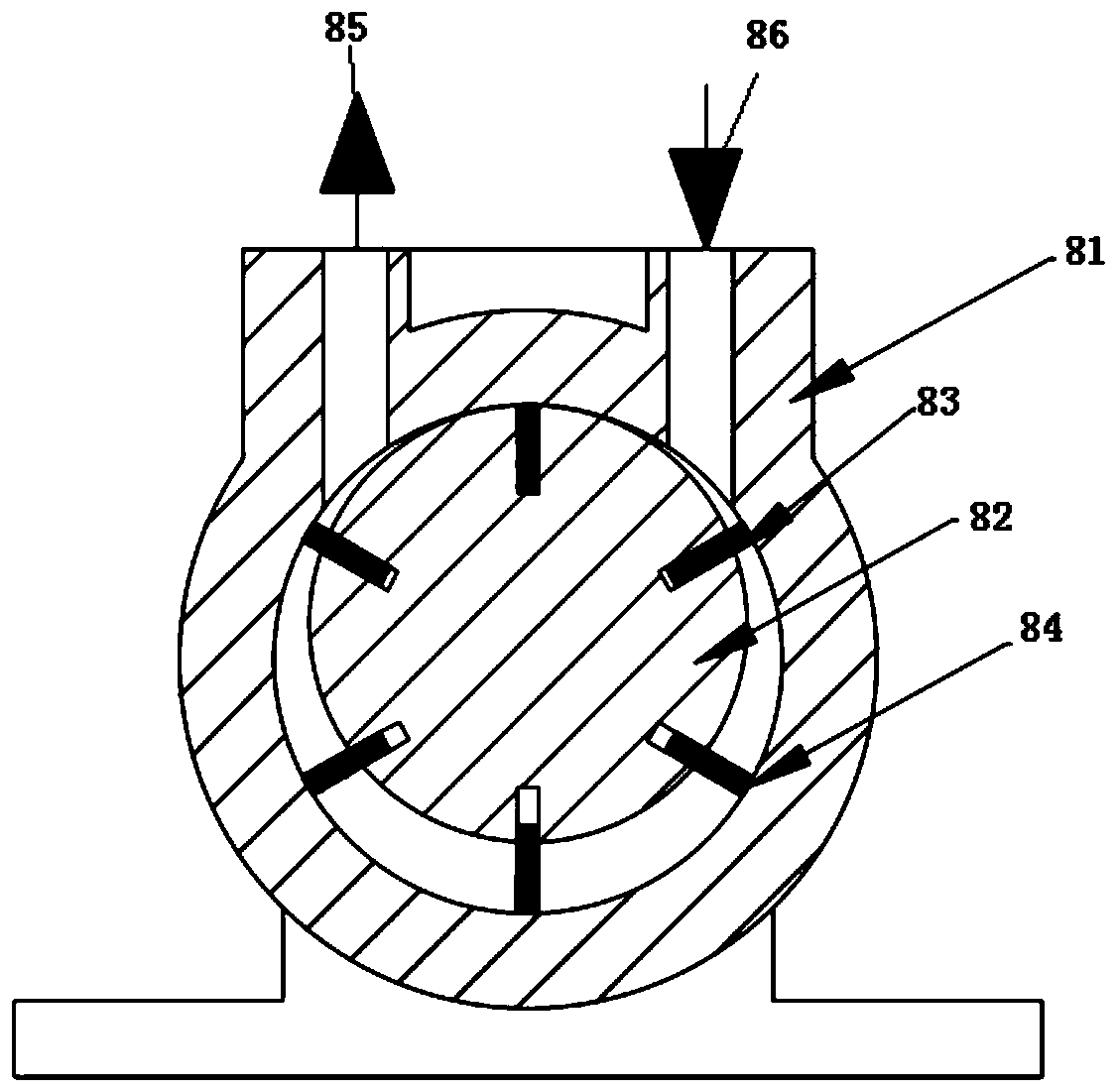

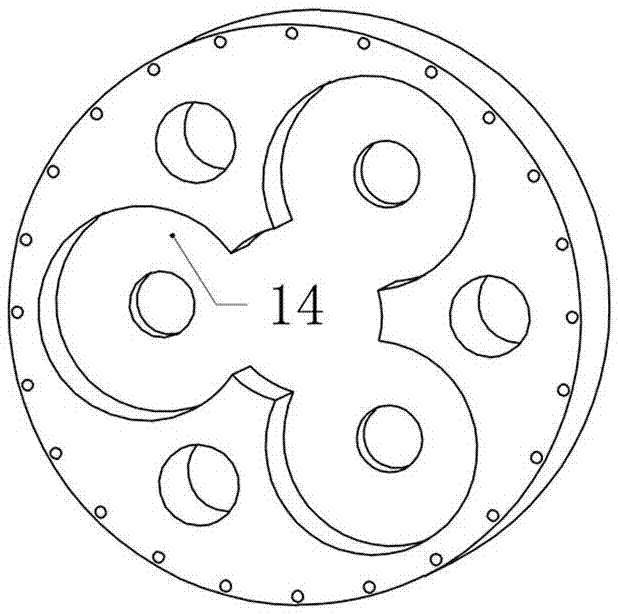

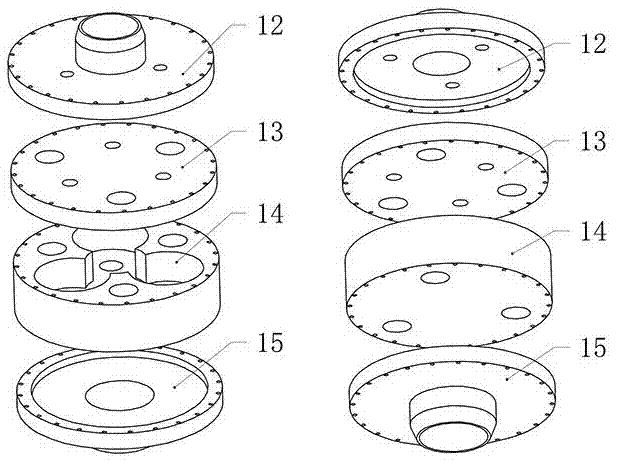

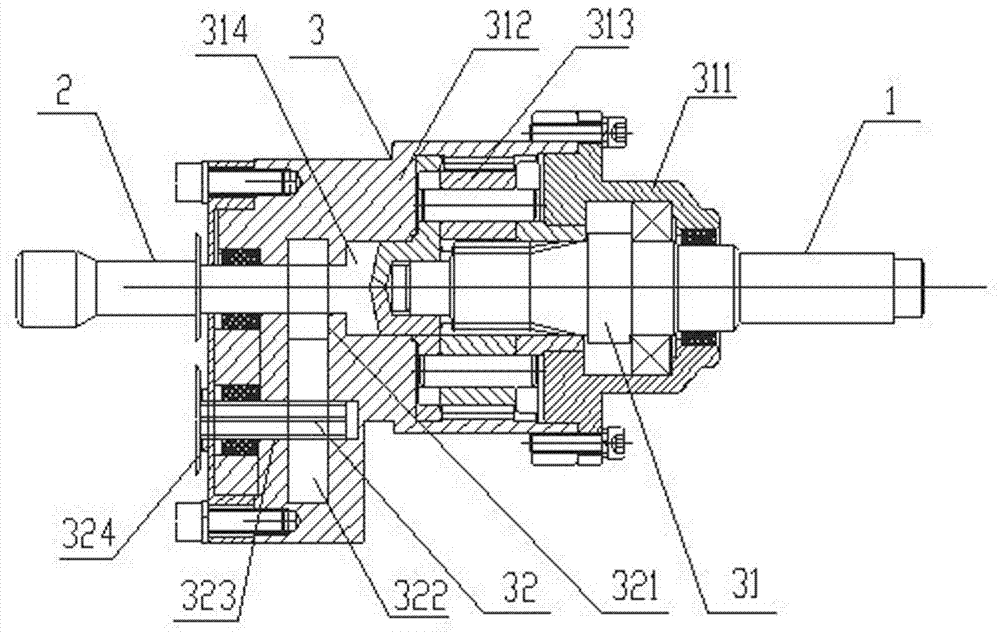

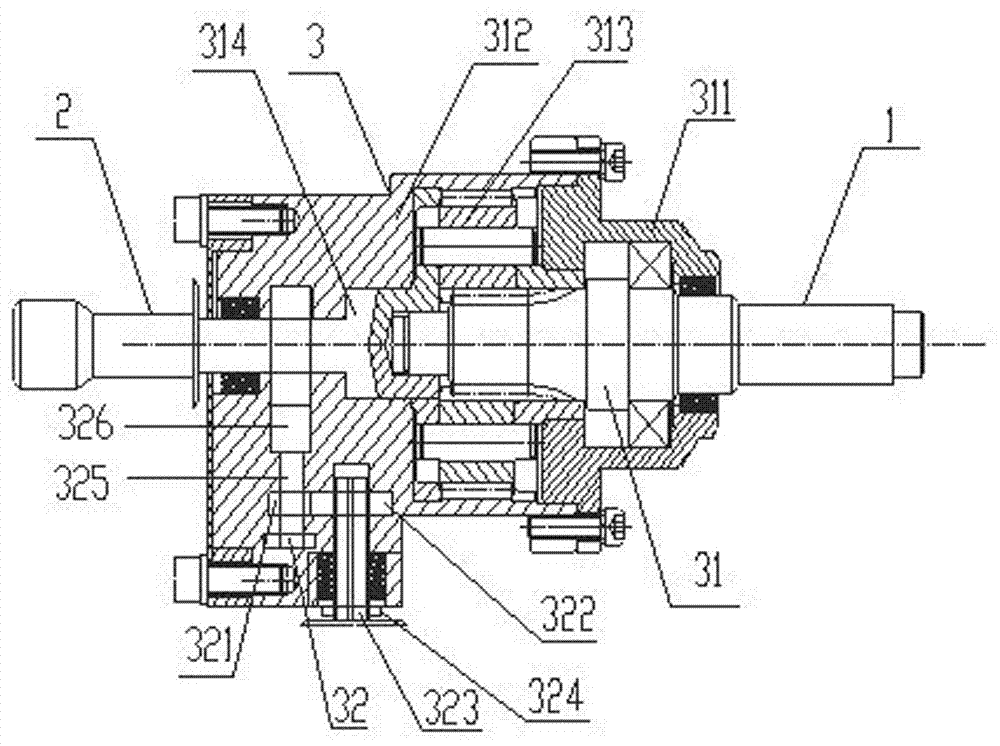

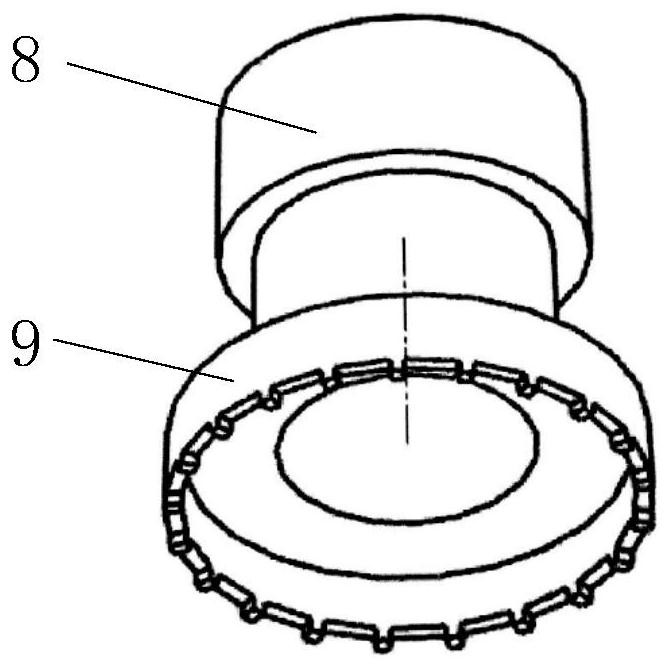

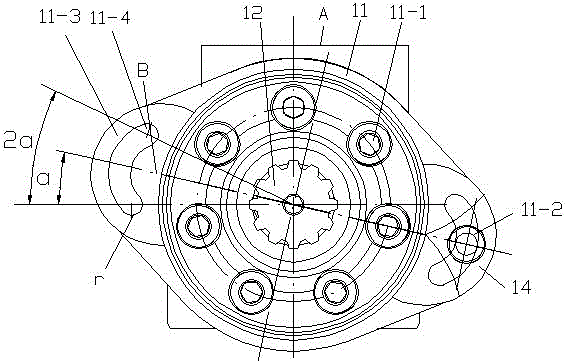

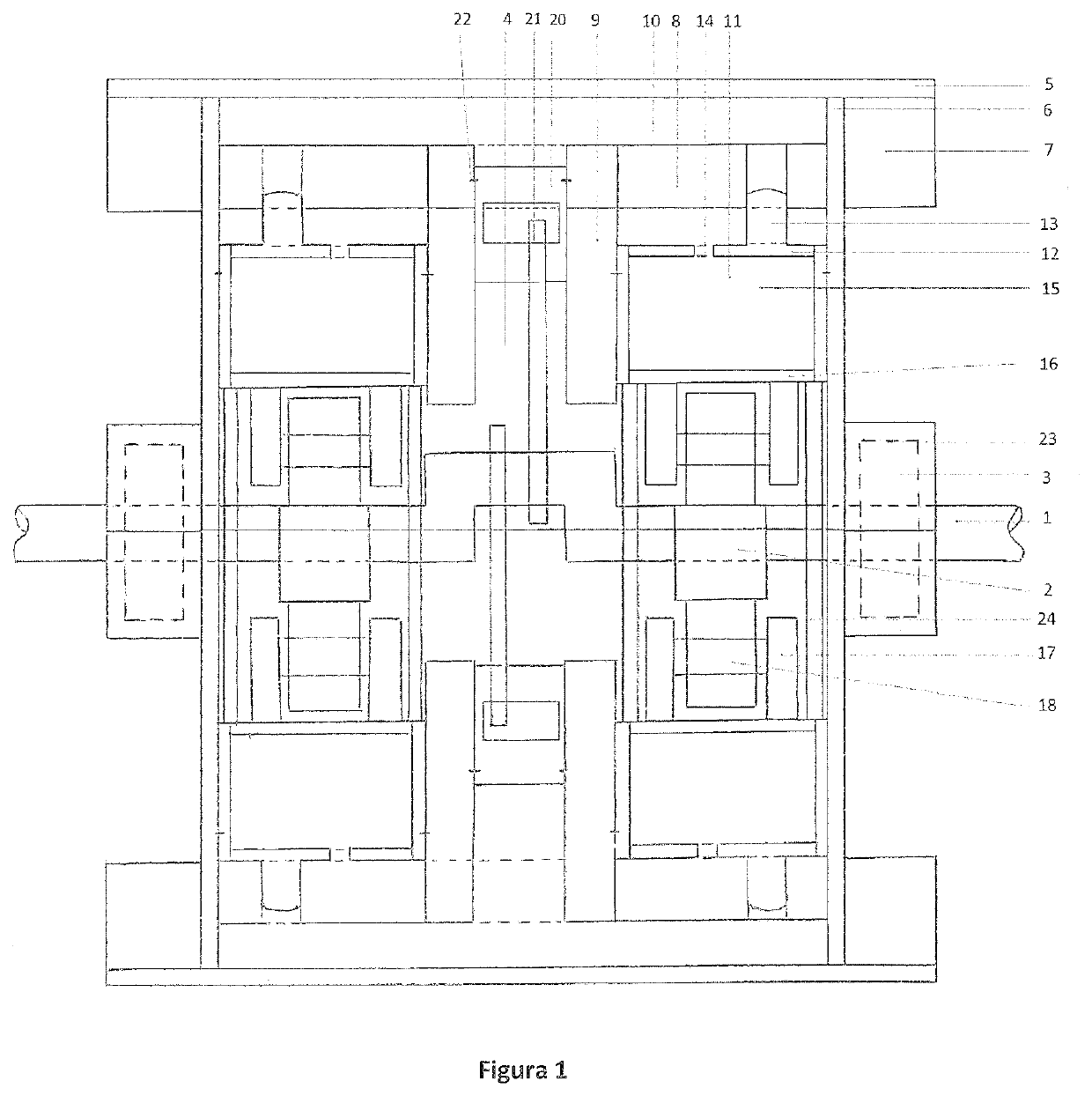

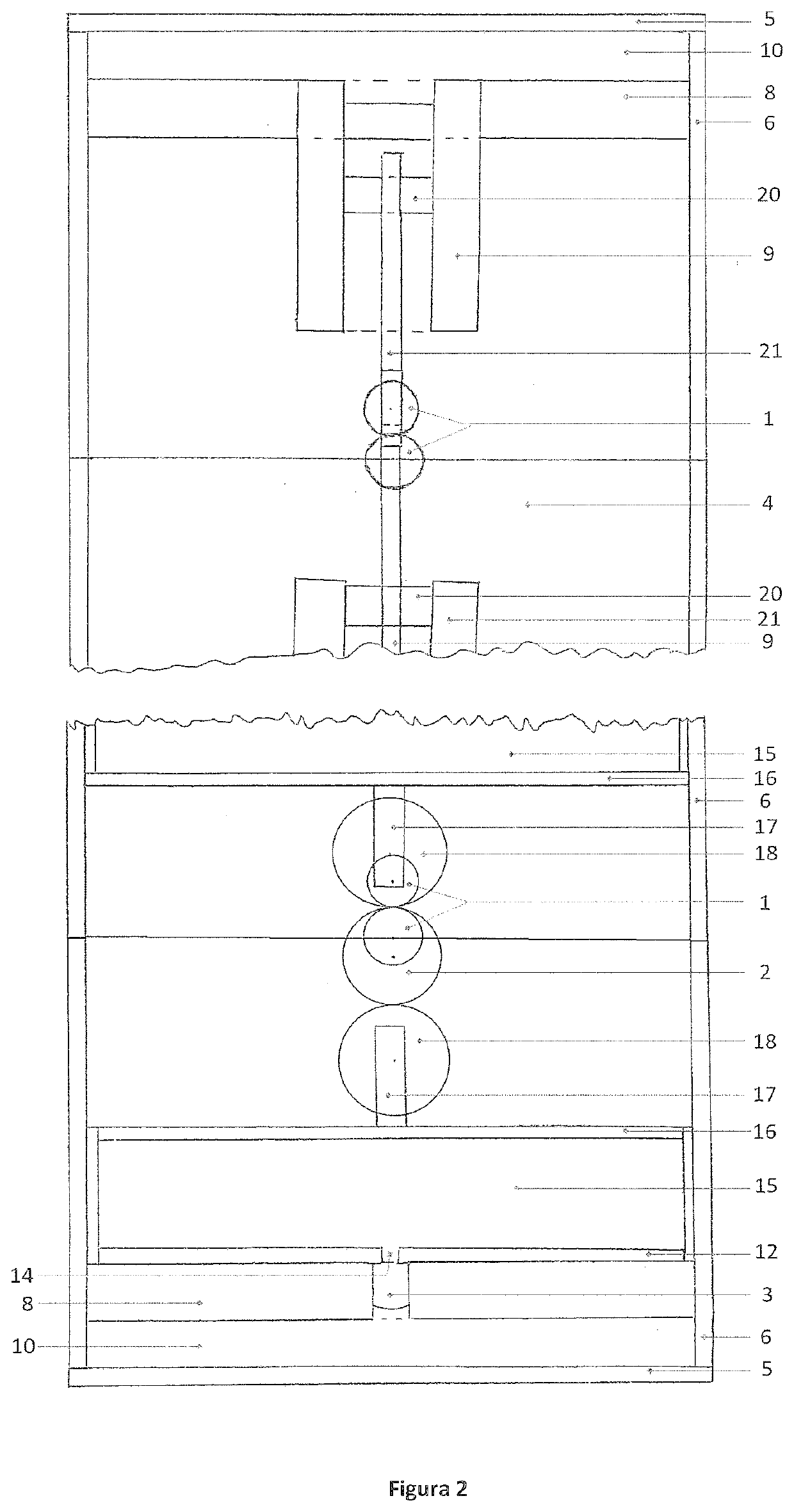

Integrated torque amplifier

The invention relates to an integrated torque amplifier, and belongs to the technical field of hydraulic pressure. The torque amplifier comprises an outer shell consisting of a housing, stators clamped by front and rear isolation disks and a rear cover, wherein the housing, the stators and the rear cover are fixedly connected in sequence along the direction of a main axial line; a valve core sleeve which supports an input valve core is arranged in the housing; rotors which form cycloid pin gear pairs together with the stators are arranged in the stators; an output shaft is supported in the rear cover; inner holes of the rotors are simultaneously connected with the opposite ends of an input linkage shaft and an output linkage shaft through inner splines in a meshing manner; the other end of the input linkage shaft is connected with the valve core sleeve through a shift pin; the other end of the output linkage shaft is connected with the output shaft through an inner spline in a transmission manner; the input valve core extends out of the input shaft with a connection structure. During use, the integrated torque amplifier can be directly connected with an external input device without a connection transitional piece, so that the connection structure is obviously simplified, and the integrated torque amplifier is very convenient to mount and connect.

Owner:ZHENJIANG HYDRAULICS

A bolt torque amplifier

The invention provides an anchor rod torque amplifier. The anchor rod torque amplifier comprises an input shaft, an output shaft and a speed changing transmission mechanism arranged between the input shaft and the output shaft. The speed changing transmission mechanism is composed of a planet gear speed reduction mechanism and a one-level gear speed reduction mechanism. The planet gear speed reduction mechanism comprises a tooth ring sleeve, three planet gears and a sun wheel which are engaged with one another. The sun wheel is connected with the input shaft. The planet gears are connected with a planet carrier. The one-level gear speed reduction mechanism comprises a drive wheel, a driven wheel and a wheel shaft carrying the driven wheel, the drive wheel is arranged at the output end of the planet carrier, and the wheel shaft is connected with the tooth ring sleeve through a spline bearing and extends out of the tooth ring sleeve. The wheel shaft is slid so that when the drive wheel and the driven wheel are engaged, the output end of the wheel shaft and the output shaft can be in threaded connection. The wheel shaft is slid so that when the drive wheel and the driven wheel are separated, the output end of the planet carrier and the output shaft can be connected. According to the anchor rod torque amplifier, the output torque can be adjusted, and adaptability is high.

Owner:长治市科力机械有限公司

Bearing gland nut tightening process device and method

PendingCN113635265AImprove assembly efficiencyShorten assembly cycleMetal-working hand toolsTurbineAero engine

The invention discloses a bearing gland nut tightening process device and method, and belongs to the technical field of aero-engine assembly. The bearing gland nut tightening process device comprises a base, a process stand column, a process baffle and a process wrench, wherein the process stand column is fixedly arranged above the base, the process baffle is detachably arranged at the top of the process stand column, and the process wrench penetrates through the process baffle to be connected with a gland nut in a clamped mode. The bearing gland nut tightening process method comprises the steps that a high-pressure turbine unit body is placed on the base, the process baffle is connected with the process stand column, the process wrench is connected with the gland nut in a clamped mode, the process wrench is connected with a torque amplifier, then the torque amplifier is connected with the torque wrench, and the gland nut is tightened through the torque wrench, the torque amplifier and the process wrench. According to the bearing gland nut tightening process device and method, the assembly efficiency of an engine is improved, and the assembly period is shortened.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

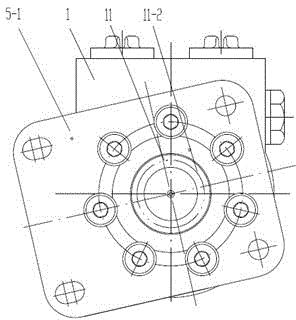

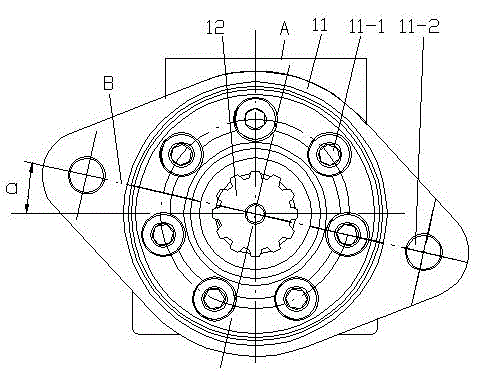

Back cover displacement type torque amplifier

InactiveCN105114375AMeet supporting installation requirementsSufficient connection strengthServomotor componentsServomotorsCycloidOil intake

The invention relates to a back cover displacement type torque amplifier, which belongs to the hydraulic technical field, which comprises a shell body with a datum plane provided with an oil inlet and an oil return port, wherein the shell body is fixedly connected to a stator clamped between front and back spacer discs and a back cover along the direction a main axis; a valve core sleeve used for supporting a valve core is mounted inside the shell body; a rotor that is used together with the stator to form a cycloid pin gear pair is mounted inside the stator; an inner hole of the rotor is simultaneously engaged with opposite ends of an input linkage shaft and an output linkage shaft through an internal spline; the other end of the input linkage shaft is connected to the valve core sleeve through a poke pin and the other end of the output linkage shaft penetrates out of the back cover; and the back cover is provided with seven through holes evenly distributed along main axis circumference and two opposite mounting holes at the outer side of the circumference on which the through holes are located. According to the invention, the torque amplifier has enough connection strength; the torque amplifier is matched with the number of teeth of the cycloid pin gear pair; and the mounting holes have more than seven directional assembly positions, thus the torque amplifier can be suitable for various main machines.

Owner:ZHENJIANG HYDRAULICS

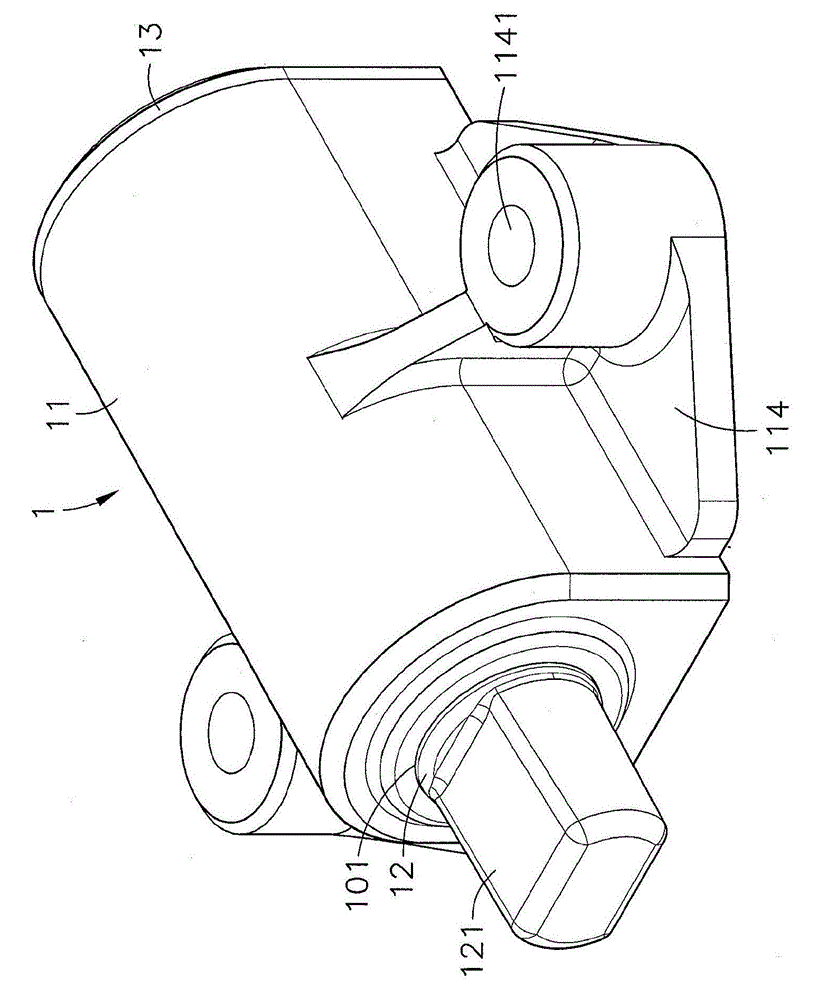

Universal clamp apparatus for bone fixation device

ActiveUS20220296278A1Extraordinary tightening precisionReduce riskExternal osteosynthesisRatchetBone splinters

Embodiments of a universal clamp apparatus for an orthopedic exterior fixator are disclosed. The universal clamp apparatus can be operated without the need for tools, with extraordinary tightening precision, and with low risk of losing stability. The universal clamp apparatus has at least one pin / rod clamp, but preferably two pin / rod clamps. Each clamp has seating grooves for snapping in and attaching to at least one of the following: a frame rod associated with a frame of the fixator and / or a bone pin for implantation in a bone fragment. A screw mechanism, such as a clamp screw, extends through and connects the first and second pin / rod clamps. An ergonomically designed knob having at least one collapsible or non-collapsible turn lever acts as a torque amplifier when rotated to tighten and untighten the pin / rod clamps to the frame rod and / or bone pin by movement along the clamp screw. A planar side of the pin / rod clamps that are contiguous each have radial ratchet grooves that are in mating engagement and that implement a ratcheting and securing mechanism so that the rotation of the pin / rod clamps relative to each other occurs in discrete incremental rotational steps.

Owner:INFIX INC

Drive-torque amplifier for a moving shaft

The invention relates to a machine that amplifies the drive torque of a moving shaft, which is formed by at least one pair of identical units facing a central shaft, each unit being formed by at least one mechanical actuator (cam), a hydraulic actuator (amplified linear force that provides the application of Pascal's law) and a mechanism comprising a piston, connecting rod and crankshaft. For mechanical considerations, the machine is a two-stroke engine (compression and intake) having at least two opposite horizontal pistons, that is, a 180° V engine.

Owner:ZOLLNER VALDETTARIO JOSE FELIPE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com