Device for producing precise tightening torque for screw connections

A technology of threaded connectors and equipment, applied in the direction of screwdrivers, wrenches, manufacturing tools, etc., can solve the problems that need to be hung around the neck of the operator and hinder the operator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

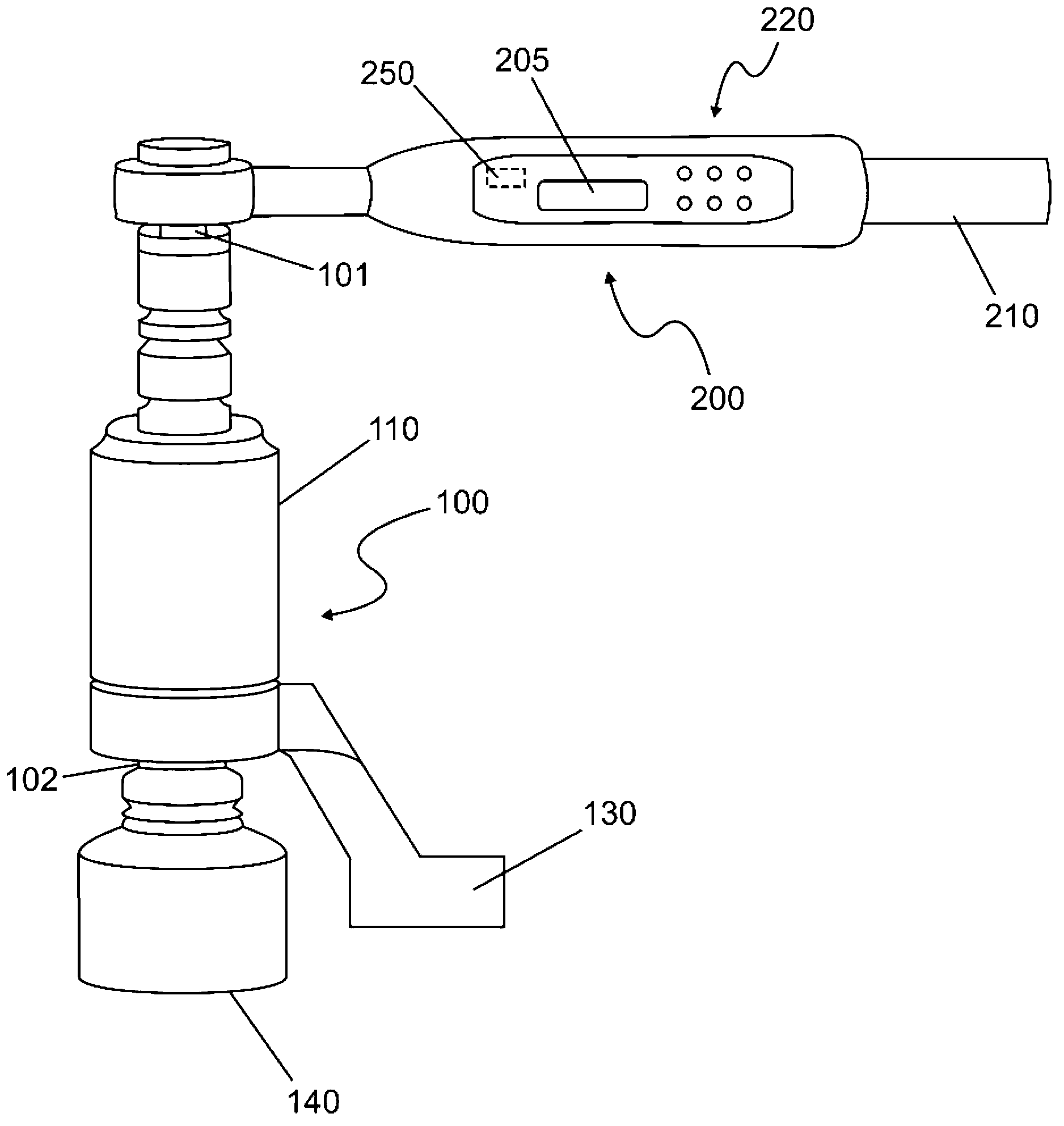

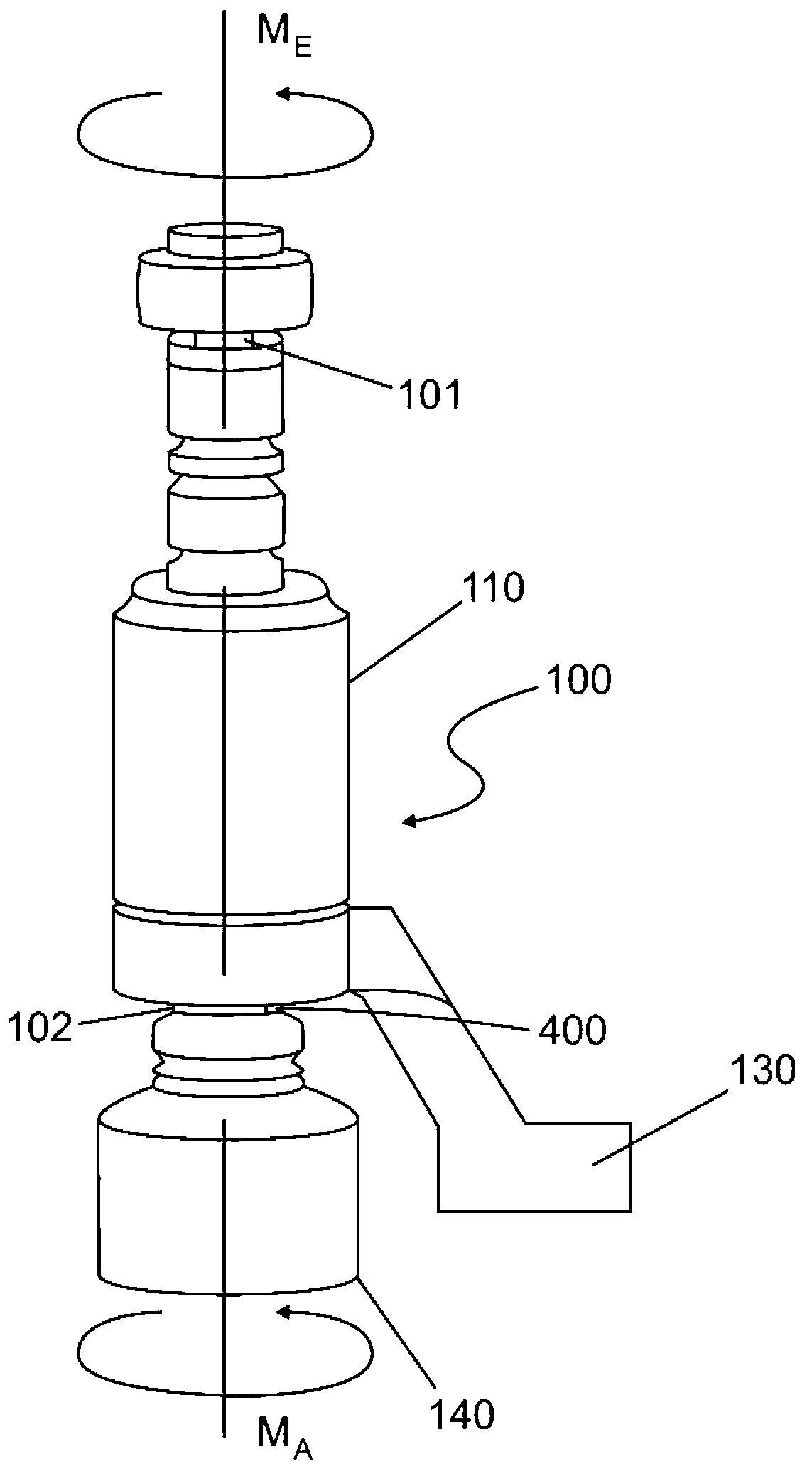

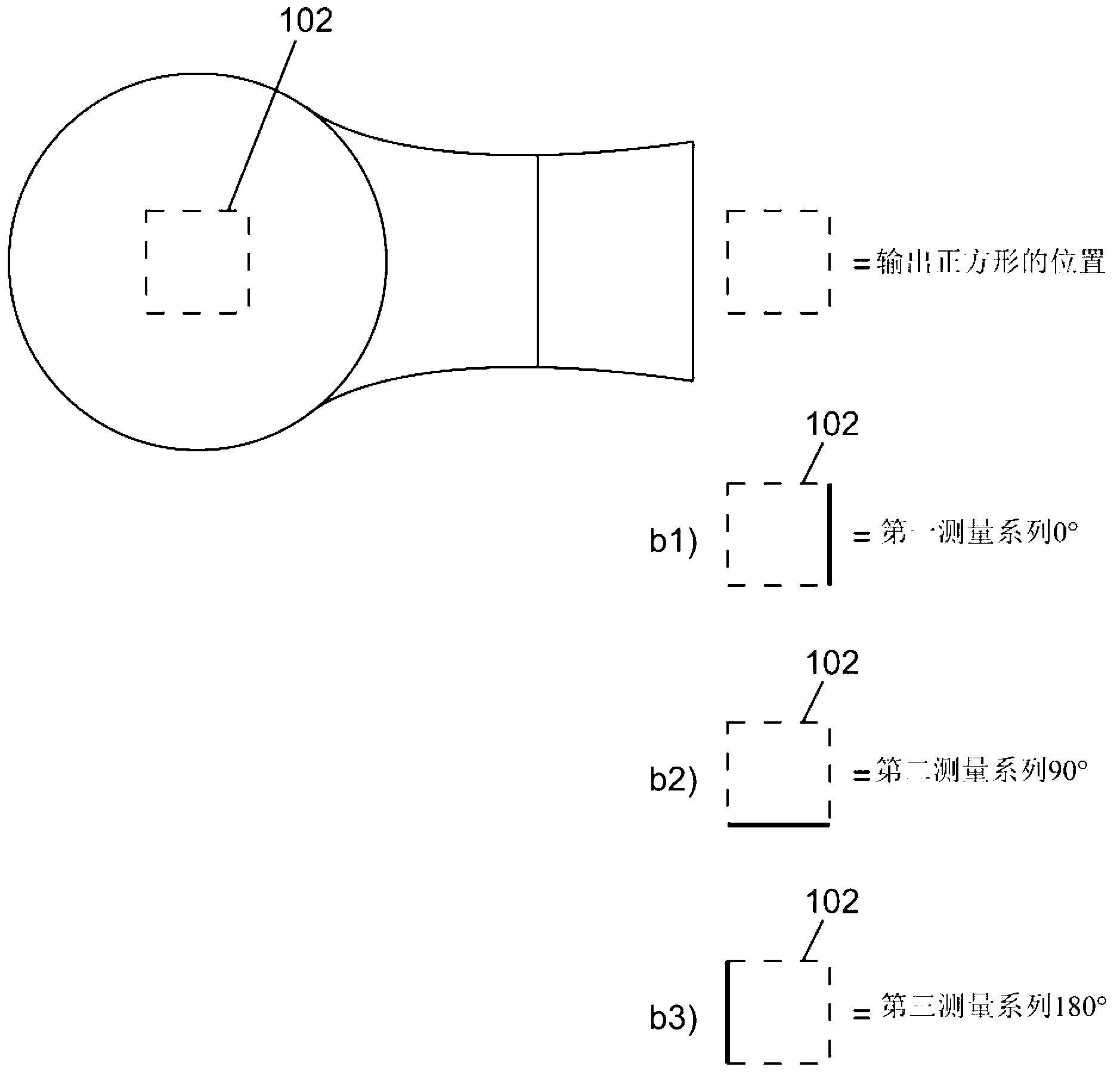

[0026] The apparatus for producing precise tightening torque shown in the drawings comprises a torque amplifier which will hereinafter be referred to and generally referred to as a power amplifier 100 comprising an input shaft 101 and an output shaft or driven shaft 102 . The input and output shaft ends are respectively square, for the input shaft the torque wrench 200 will act on said square, and for the output shaft 102 the output shaft 102 will engage in a so called "wrench socket" or just "socket" 140 . Torque is transmitted through socket 142 to a threaded connection (not shown). The torque amplifier 100 further includes what is generally known as a reaction arm 130 that prevents the torque amplifier from rotating by striking a stationary object during steering.

[0027] The torque amplifier 100 is manually actuated by a torque wrench 200 . To this end, the torque wrench 200 includes a handle 210 . The torque wrench 200 itself is an electronic torque wrench 200 with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com