A bolt torque amplifier

A technology of torque amplifiers and bolts, applied in the directions of transmission parts, gear transmissions, belts/chains/gears, etc., can solve the problems such as the inapplicability of mechanical multipliers without torque value adjustment of hydraulic wrenches, and achieve increased adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

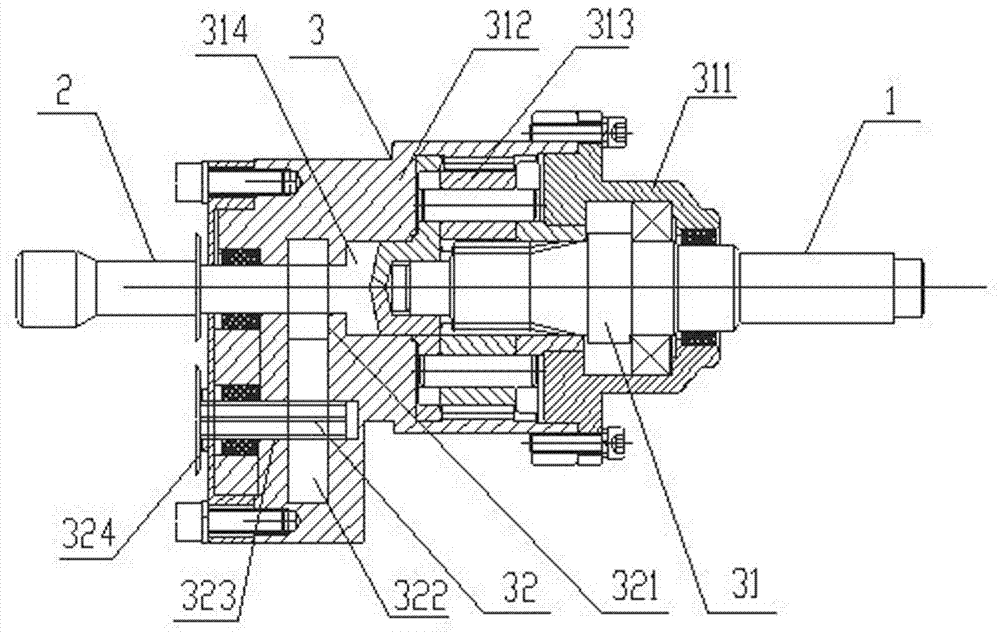

[0020] Example 1, such as figure 1 A bolt torque amplifier shown includes an input shaft 1, an output shaft 2, and a speed change transmission 3 arranged between the input shaft and the output shaft. The speed change transmission mechanism consists of a planetary gear reduction mechanism 31 and a primary gear reduction mechanism 32 The planetary gear reduction mechanism 31 includes a cover body 311, a ring gear sleeve 312 meshing with each other, three planetary gears 313 and a sun gear 315. One end of the ring gear sleeve 312 has an opening, and the cover body 311 is arranged at the opening and is connected with the The ring gear sleeve 312 is threaded to form a closed cavity in the ring gear sleeve, the sun gear is connected to the input shaft 1, and the three planetary gears 313 are connected to the planetary carrier 314, and the planetary carrier 314 is arranged in the closed cavity, and from It extends out and is threadedly connected with the output shaft 2; the first-sta...

Embodiment 2

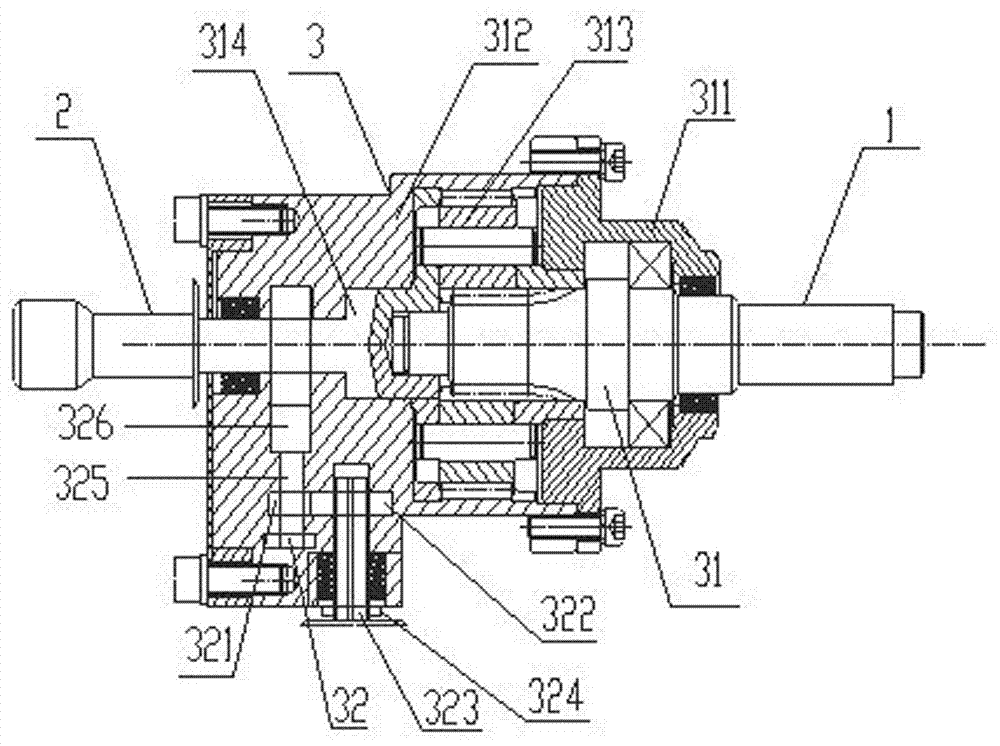

[0023] Example 2, such as figure 2 A bolt torque amplifier shown includes an input shaft 1, an output shaft 2, and a speed change transmission 3 arranged between the input shaft and the output shaft. The speed change transmission mechanism 3 consists of a planetary gear reduction mechanism 31 and a primary gear reduction mechanism 32. The planetary gear reduction mechanism 31 includes a cover body 311, a ring gear sleeve 312 meshing with each other, three planetary gears 313 and a sun gear 315. One end of the ring gear sleeve 312 has an opening, and the cover body 311 is arranged at the opening and is connected with the The ring gear sleeve 312 is threaded to form a closed cavity in the ring gear sleeve, the sun gear is connected to the input shaft 1, and the three planetary gears 313 are connected to the planetary carrier 314, and the planetary carrier 314 is arranged in the closed cavity, and from It extends out and is threadedly connected with the output shaft 2; the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com