Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1605 results about "Three phase windings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

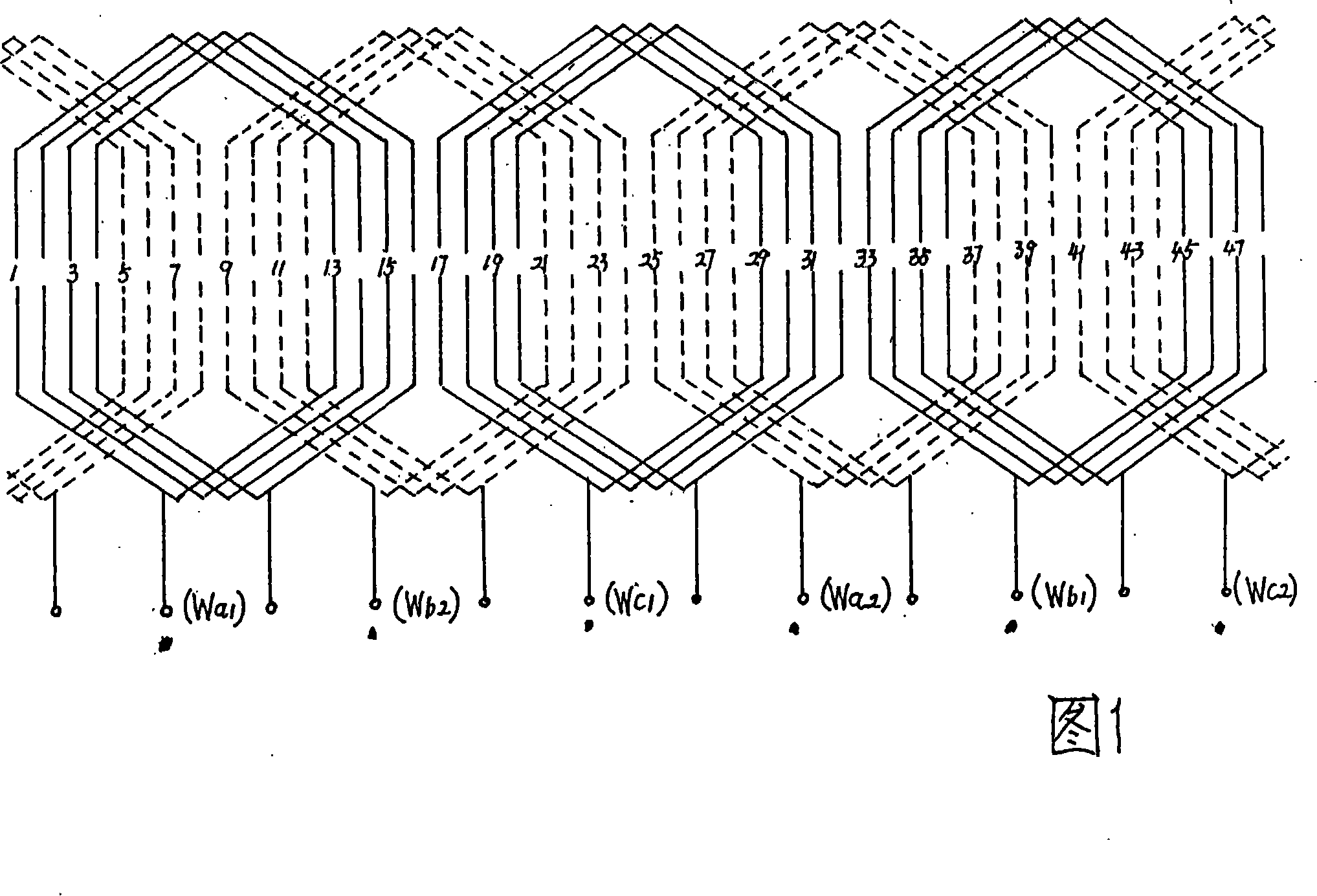

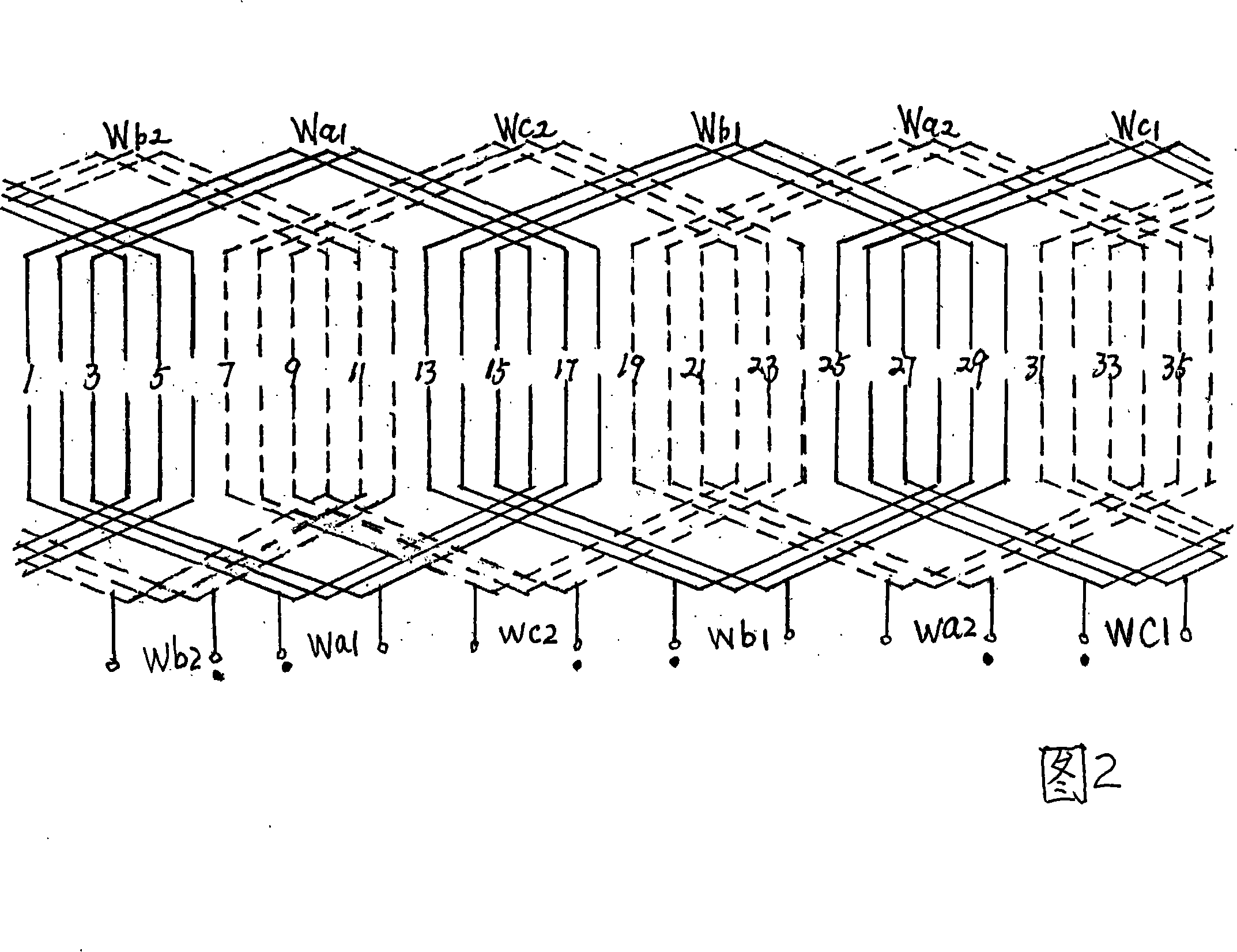

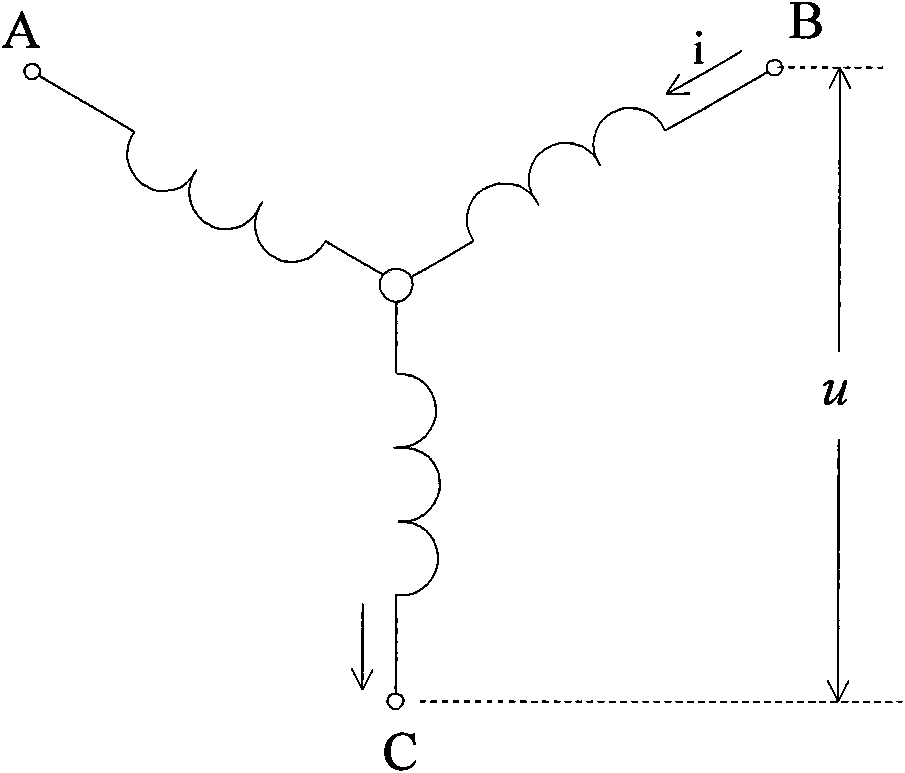

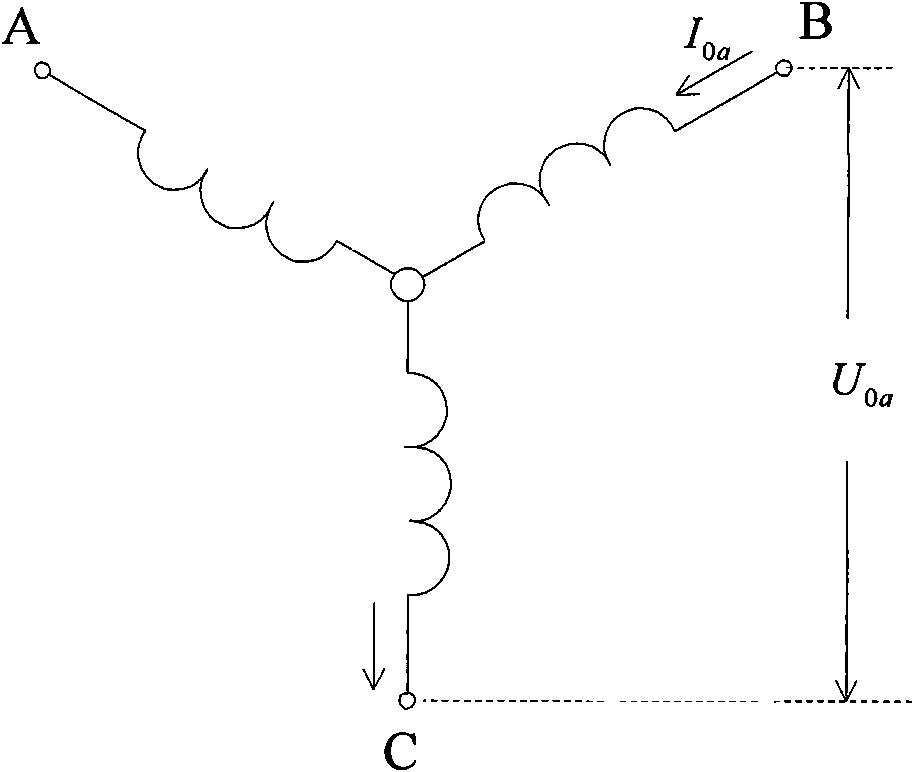

Three-Phase Transformer Windings and Connections. A three-phase transformer is made of three sets of primary and secondary windings, each set wound around one leg of an iron core assembly. Essentially it looks like three single-phase transformers sharing a joined core as in Figure below. Three phase transformer core has three sets of windings.

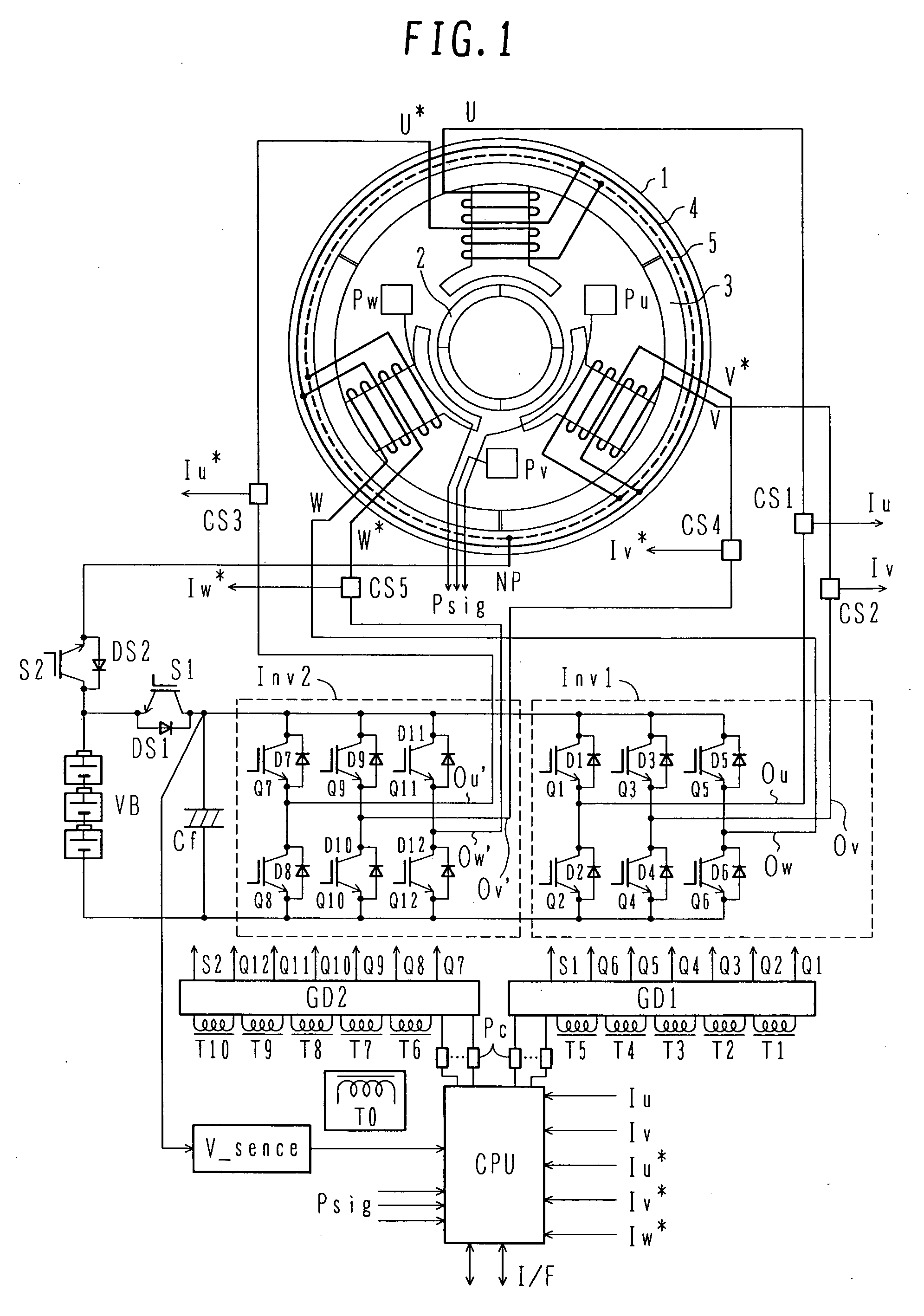

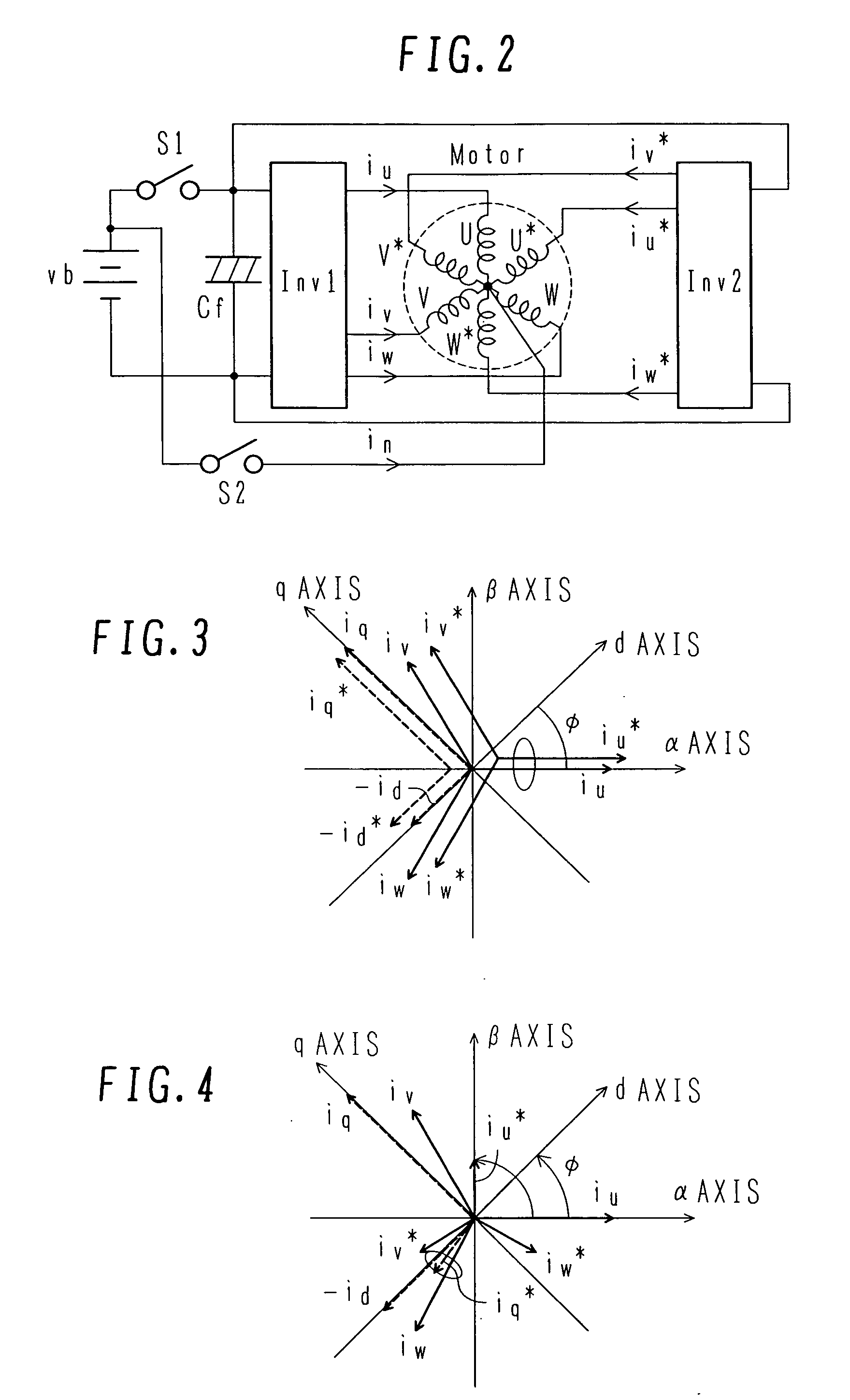

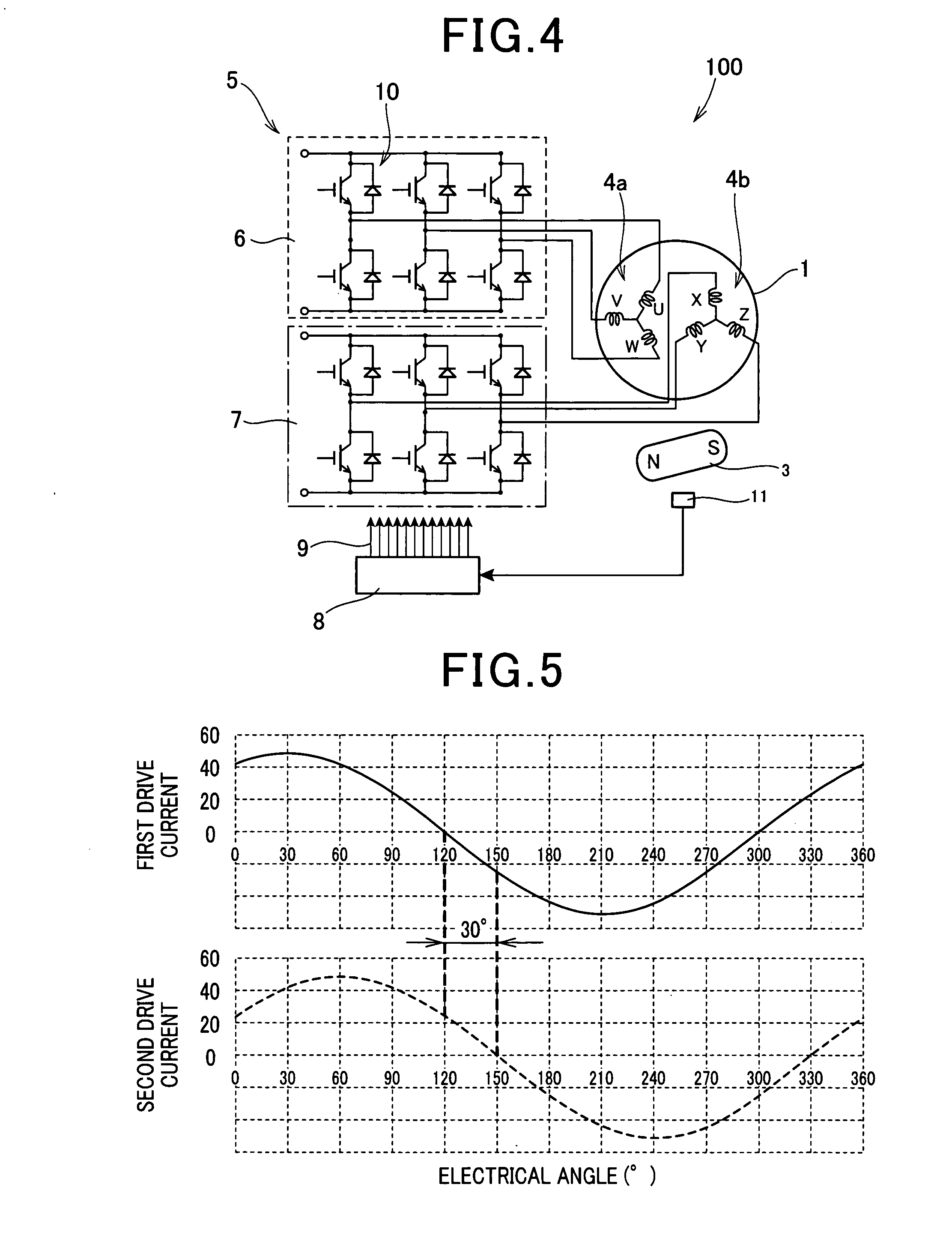

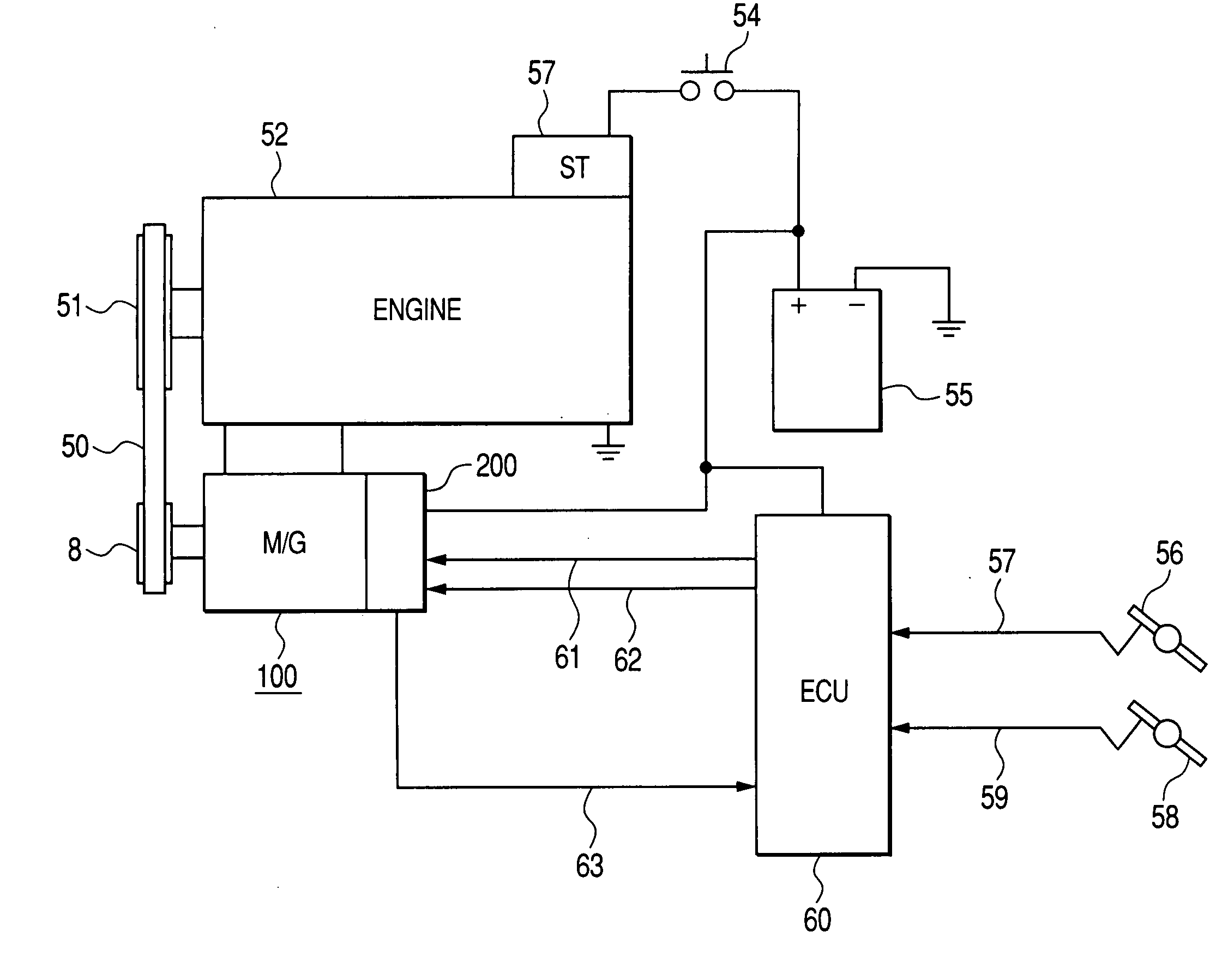

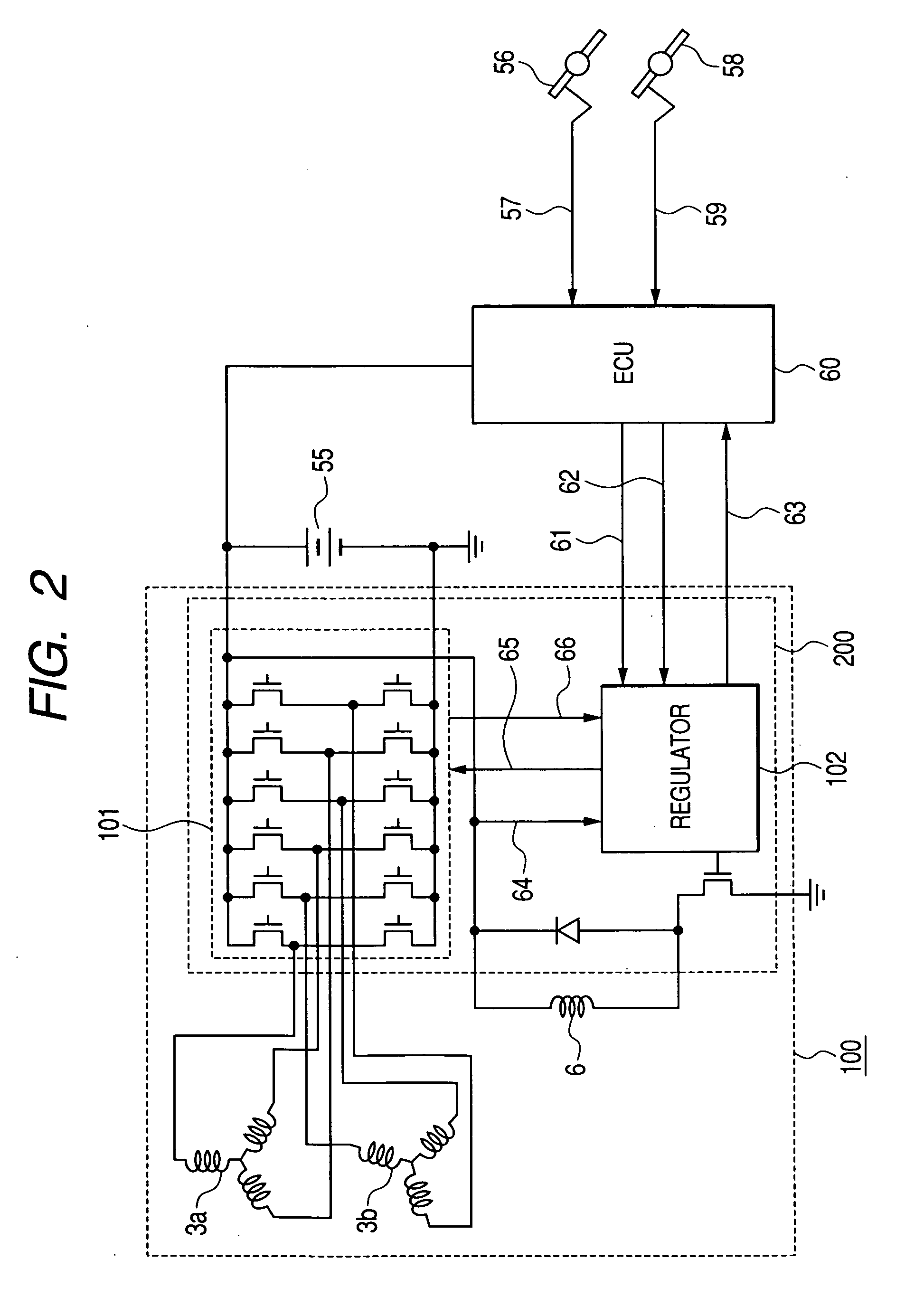

Motor driving device and automobile using the same

InactiveUS7439697B2Reduce lossesLoss generated in the first inverter can be reducedVehicular energy storageMechanical energy handlingMotor driveHigh voltage battery

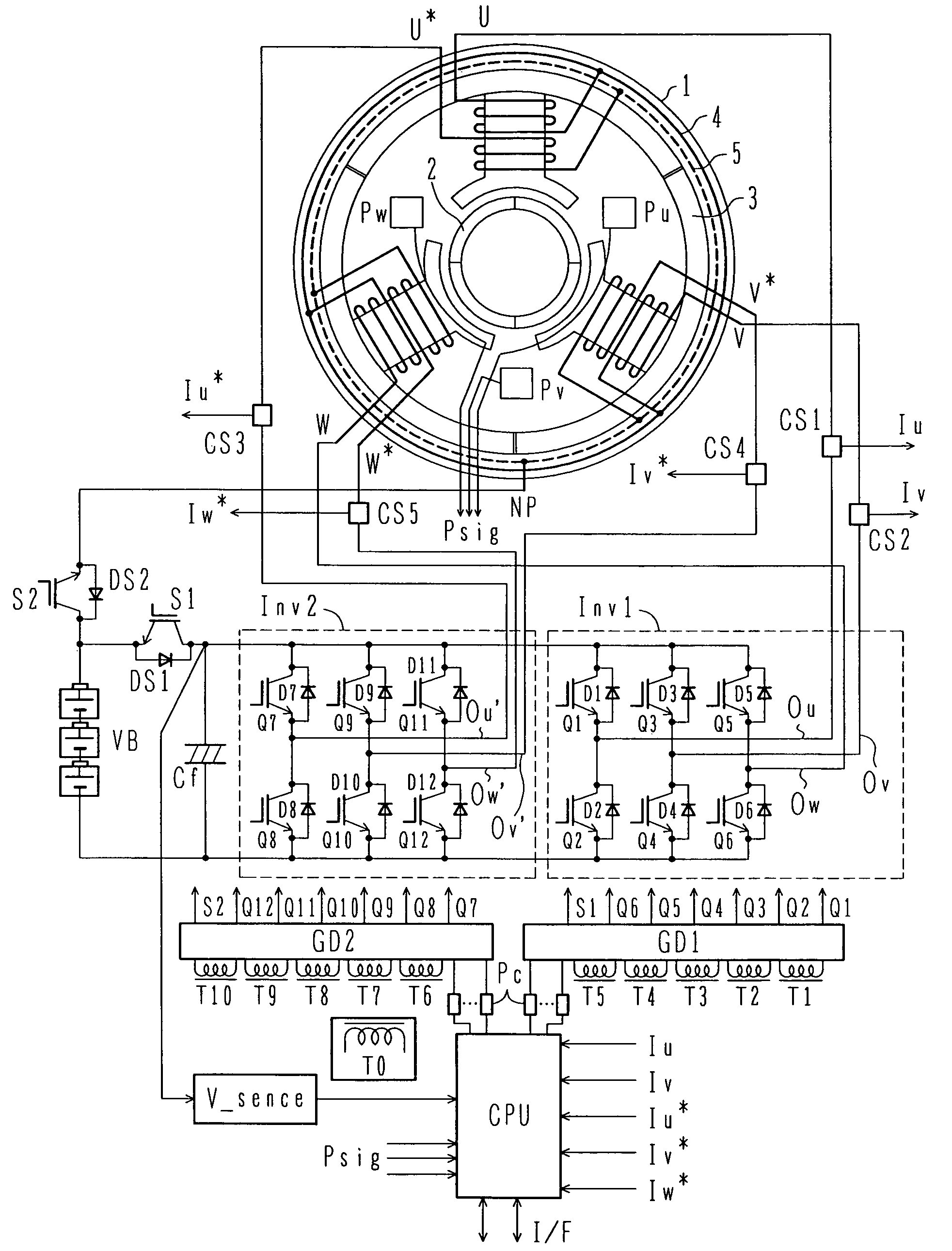

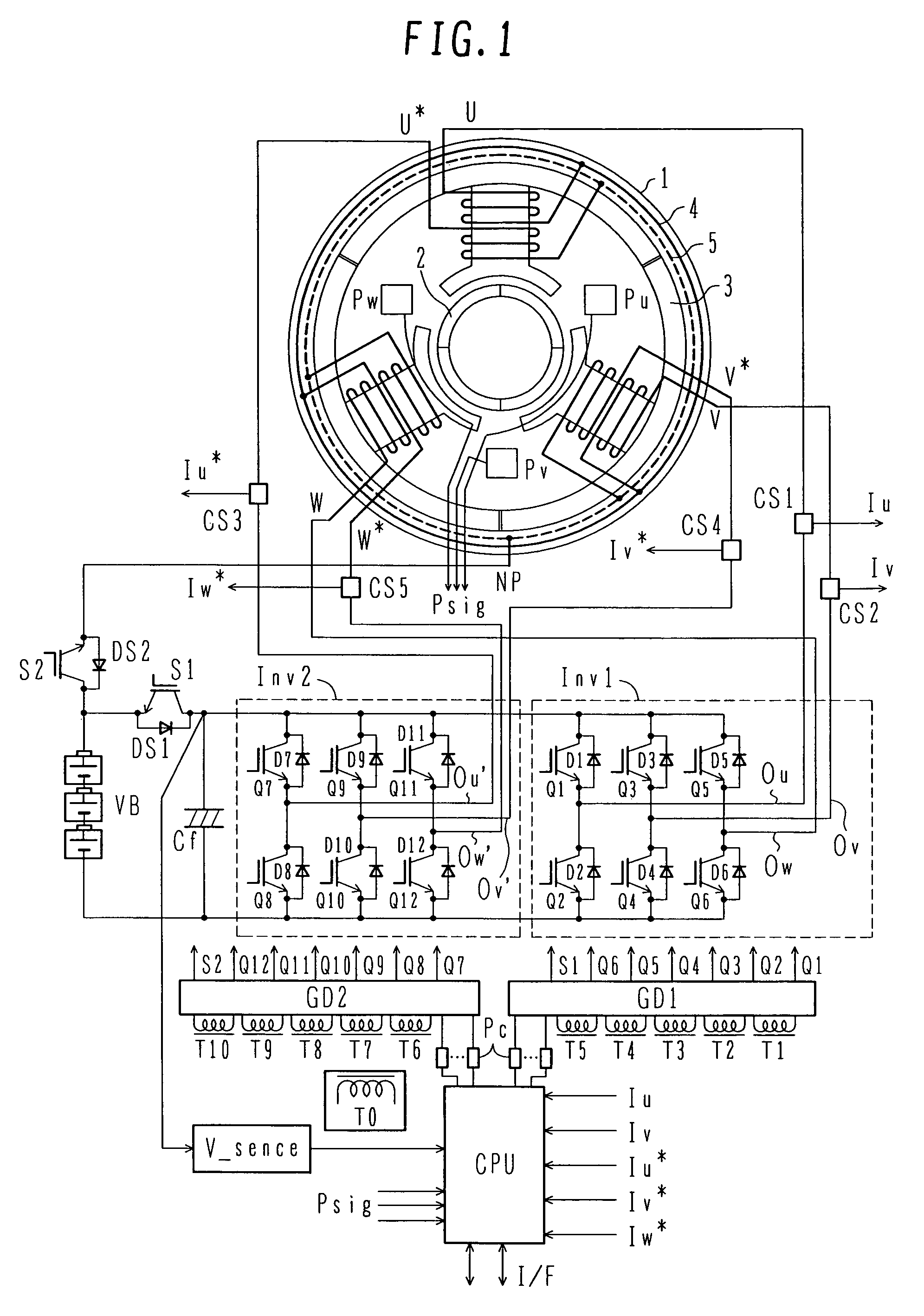

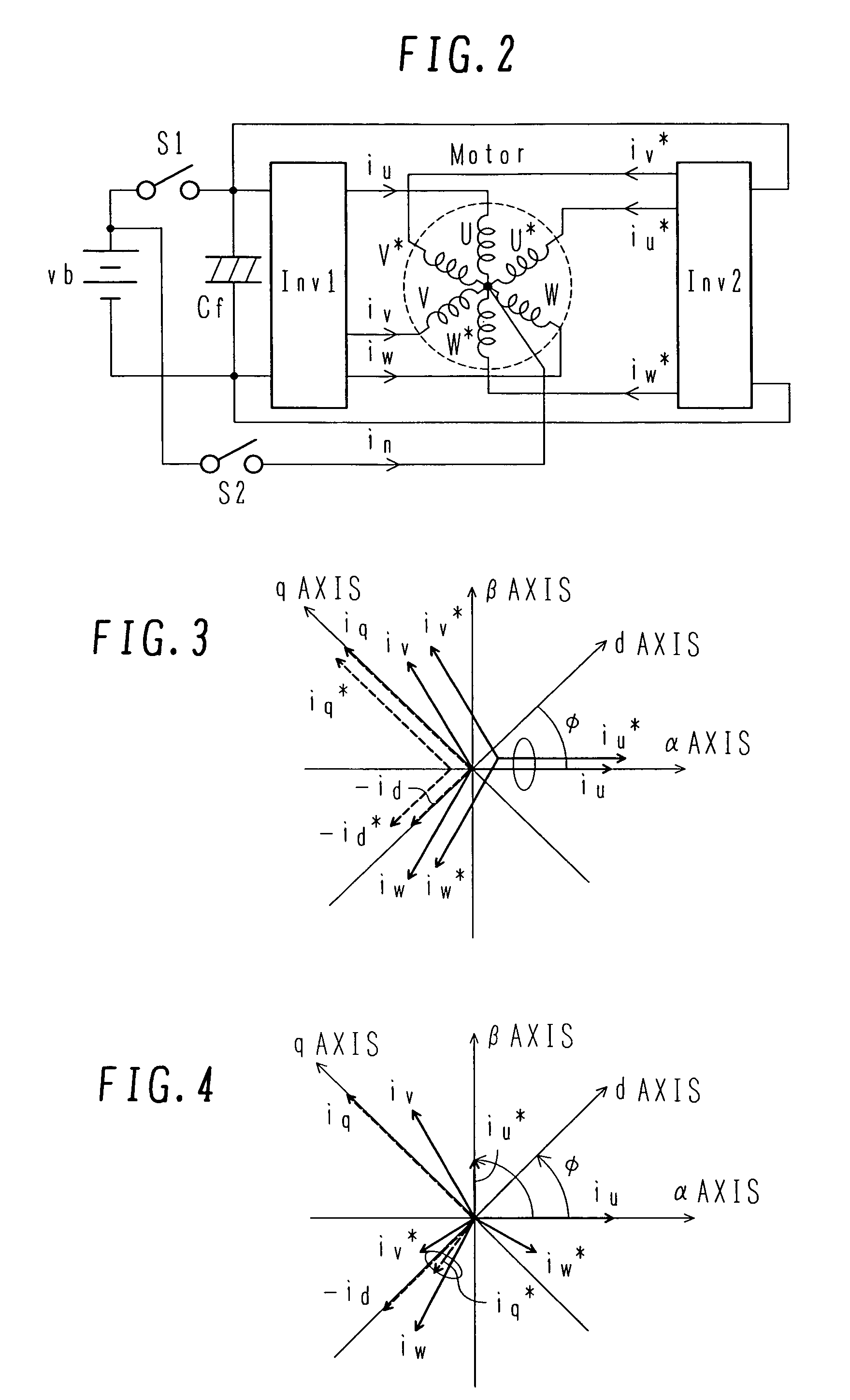

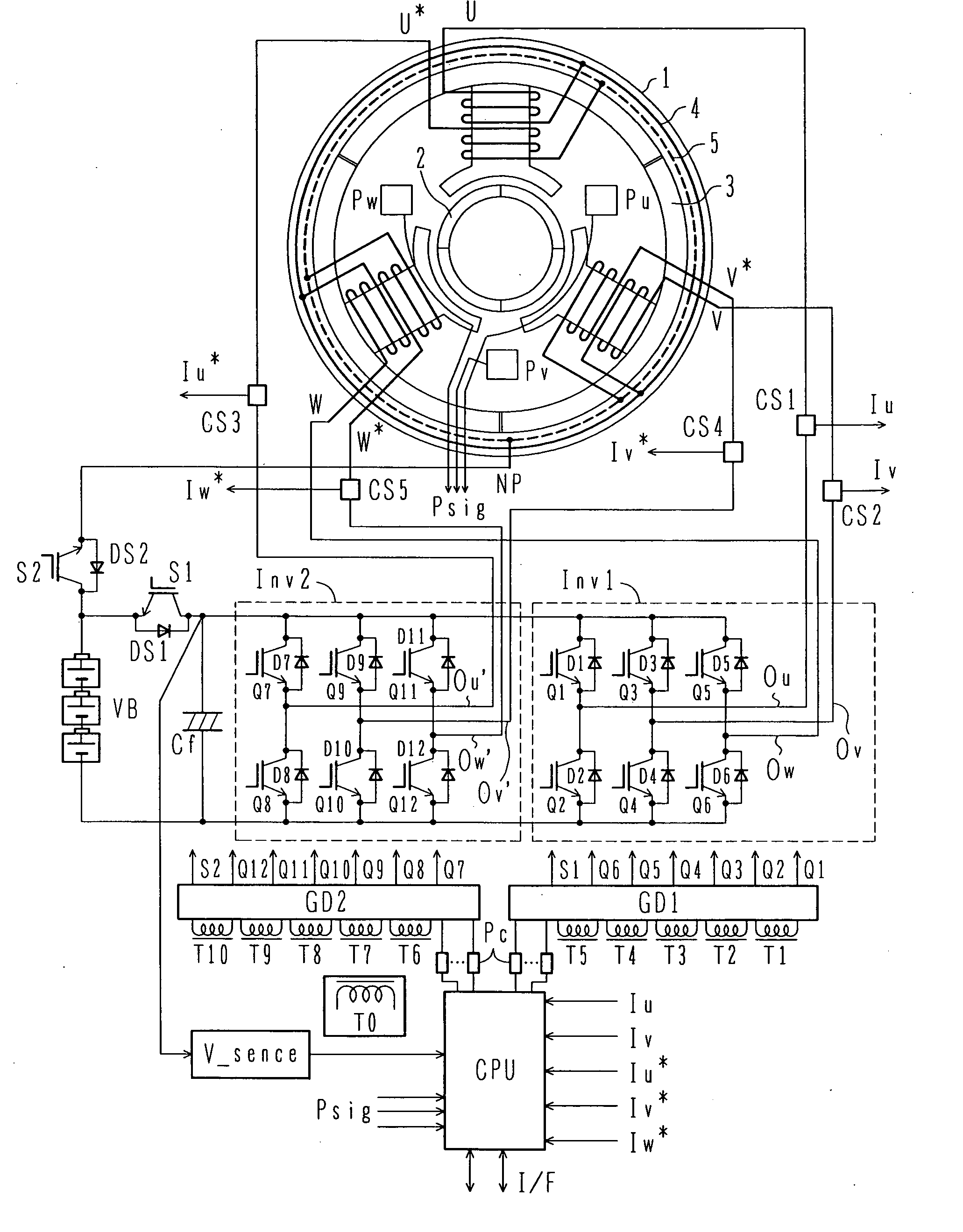

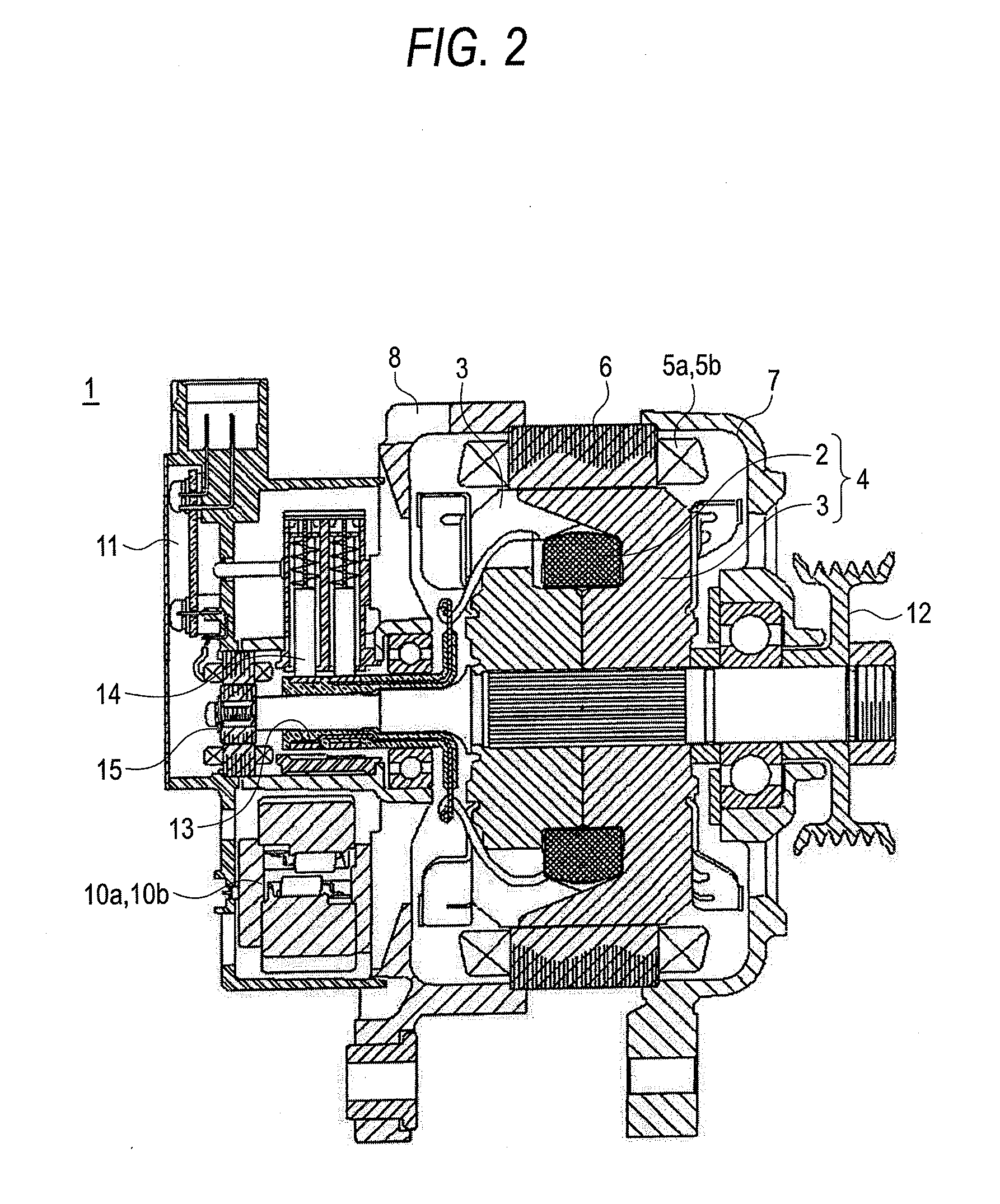

As a boosting-type motor driving device using no reactor, a motor driving device capable of controlling boosting operation and motor driving at the same time is provided, and an automobile using the motor driving device is also provided. The motor driving device is used for driving a motor with a double-winding structure having a first set of three-phase windings and a second set of three-phase winding which are wound over a stator, and includes first and second inverters, which are connected respectively to the first set of three-phase windings and the second set of three-phase windings, thereby controlling the first and second inverters to control a driving force of the motor with the double-winding structure. The first and second inverters have positive and negative terminals which are connected respectively in common to a high-voltage battery. The motor driving device further includes a first switch unit connected between the positive terminals of the first and second inverters connected in common and a positive pole of the high-voltage battery, and a second switch unit connected between a neutral point of the second set of three-phase windings and the positive pole of the high-voltage battery.

Owner:HITACHI LTD

Motor driving device and automobile using the same

InactiveUS20070120520A1Reduce lossesLoss generated in the first inverter can be reducedVehicular energy storageMechanical energy handlingMotor driveHigh voltage battery

As a boosting-type motor driving device using no reactor, a motor driving device capable of controlling boosting operation and motor driving at the same time is provided, and an automobile using the motor driving device is also provided. The motor driving device is used for driving a motor with a double-winding structure having a first set of three-phase windings and a second set of three-phase winding which are wound over a stator, and includes first and second inverters, which are connected respectively to the first set of three-phase windings and the second set of three-phase windings, thereby controlling the first and second inverters to control a driving force of the motor with the double-winding structure. The first and second inverters have positive and negative terminals which are connected respectively in common to a high-voltage battery. The motor driving device further includes a first switch unit connected between the positive terminals of the first and second inverters connected in common and a positive pole of the high-voltage battery, and a second switch unit connected between a neutral point of the second set of three-phase windings and the positive pole of the high-voltage battery.

Owner:HITACHI LTD

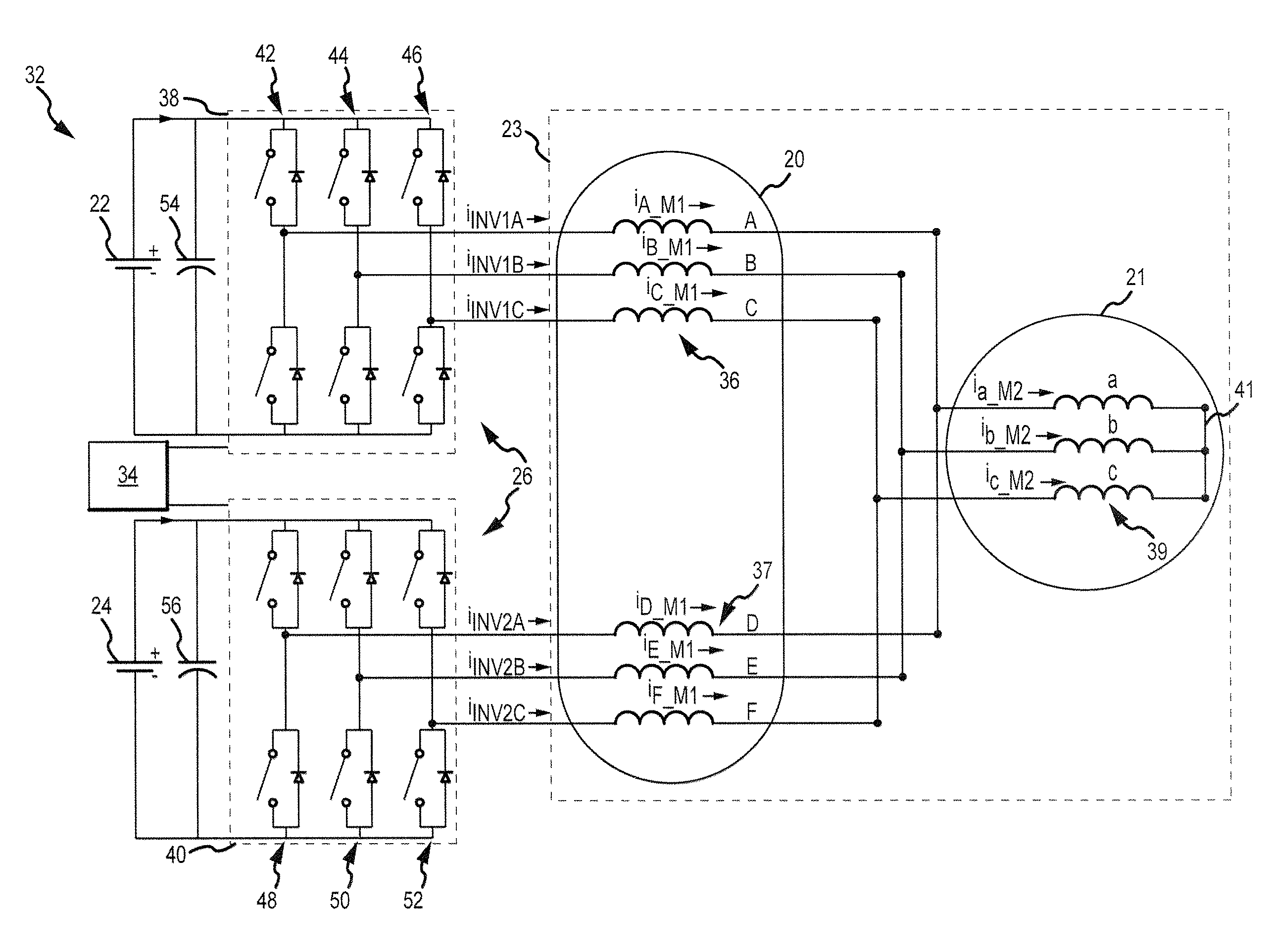

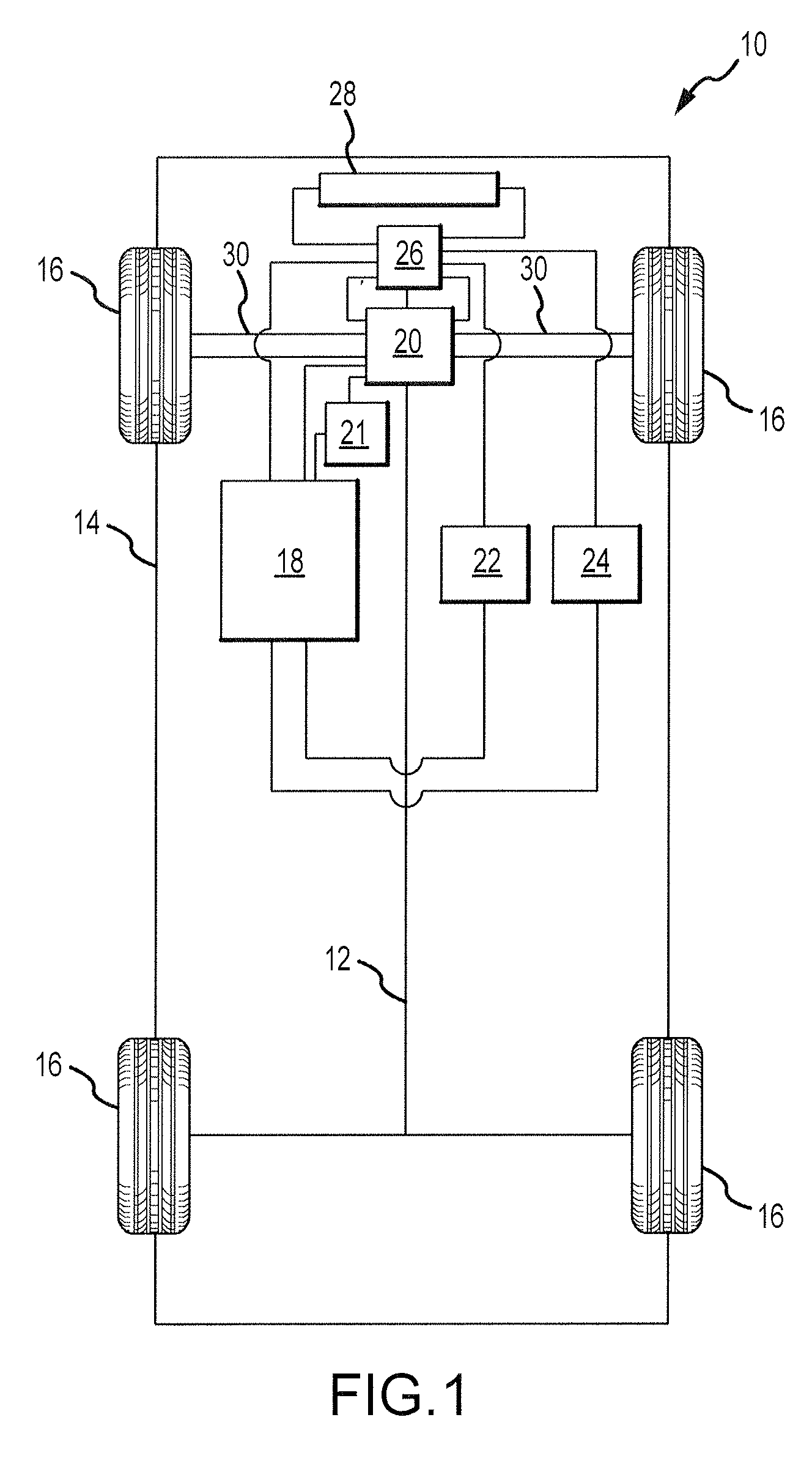

Series-coupled two-motor drive using double-ended inverter system

ActiveUS20090033251A1Well formedHybrid vehiclesDC motor speed/torque controlMotor driveMotor Drive Unit

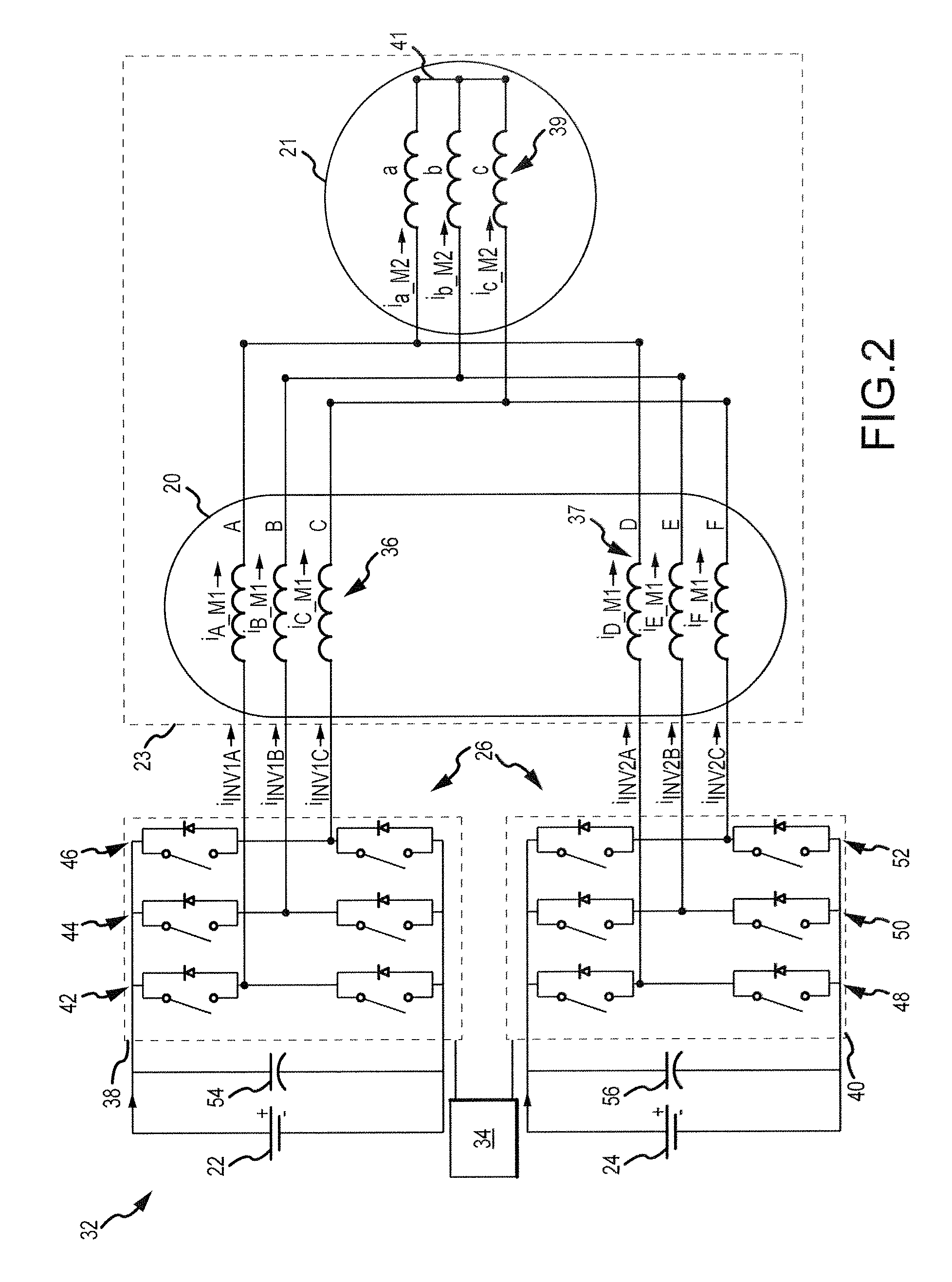

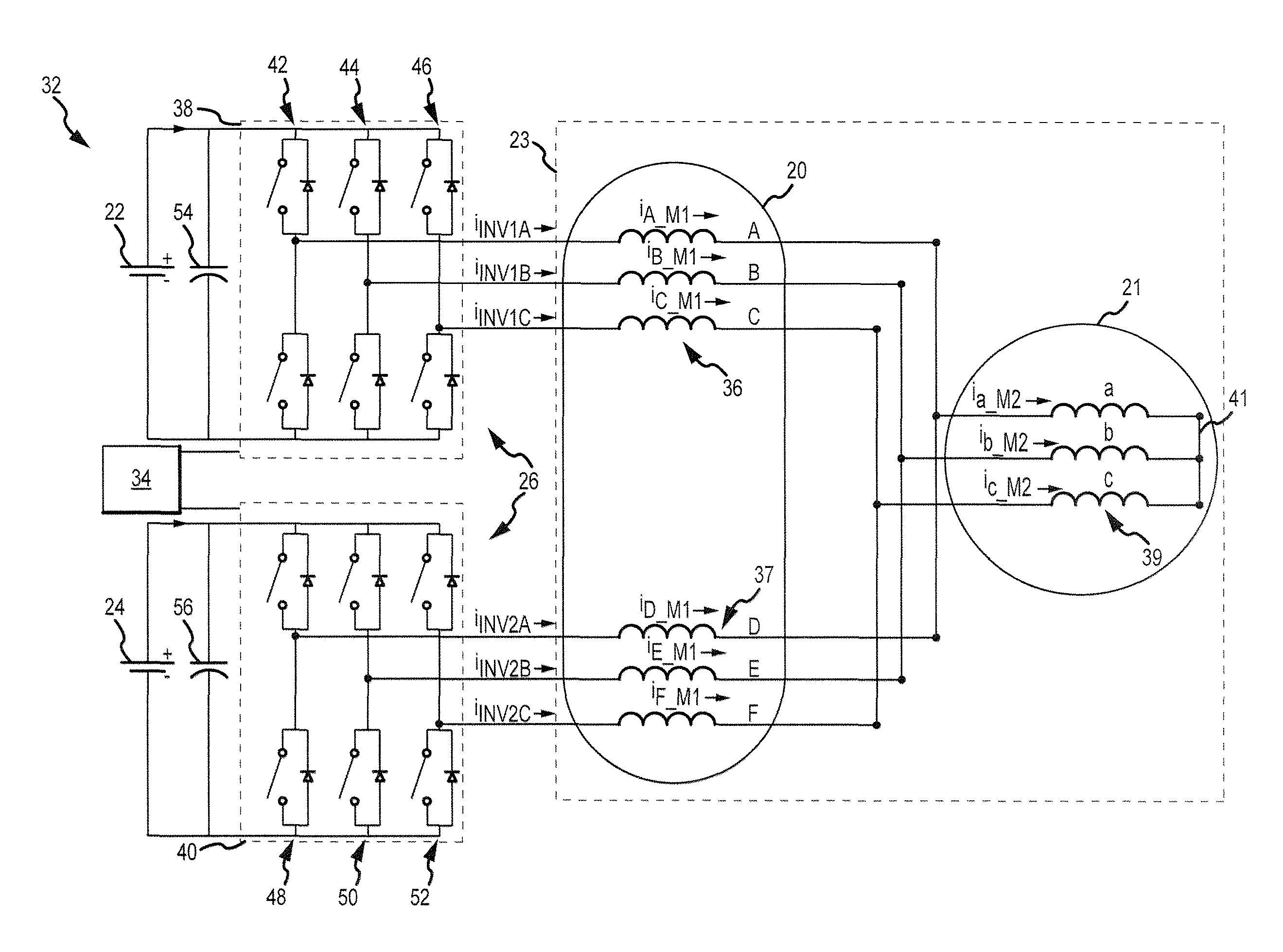

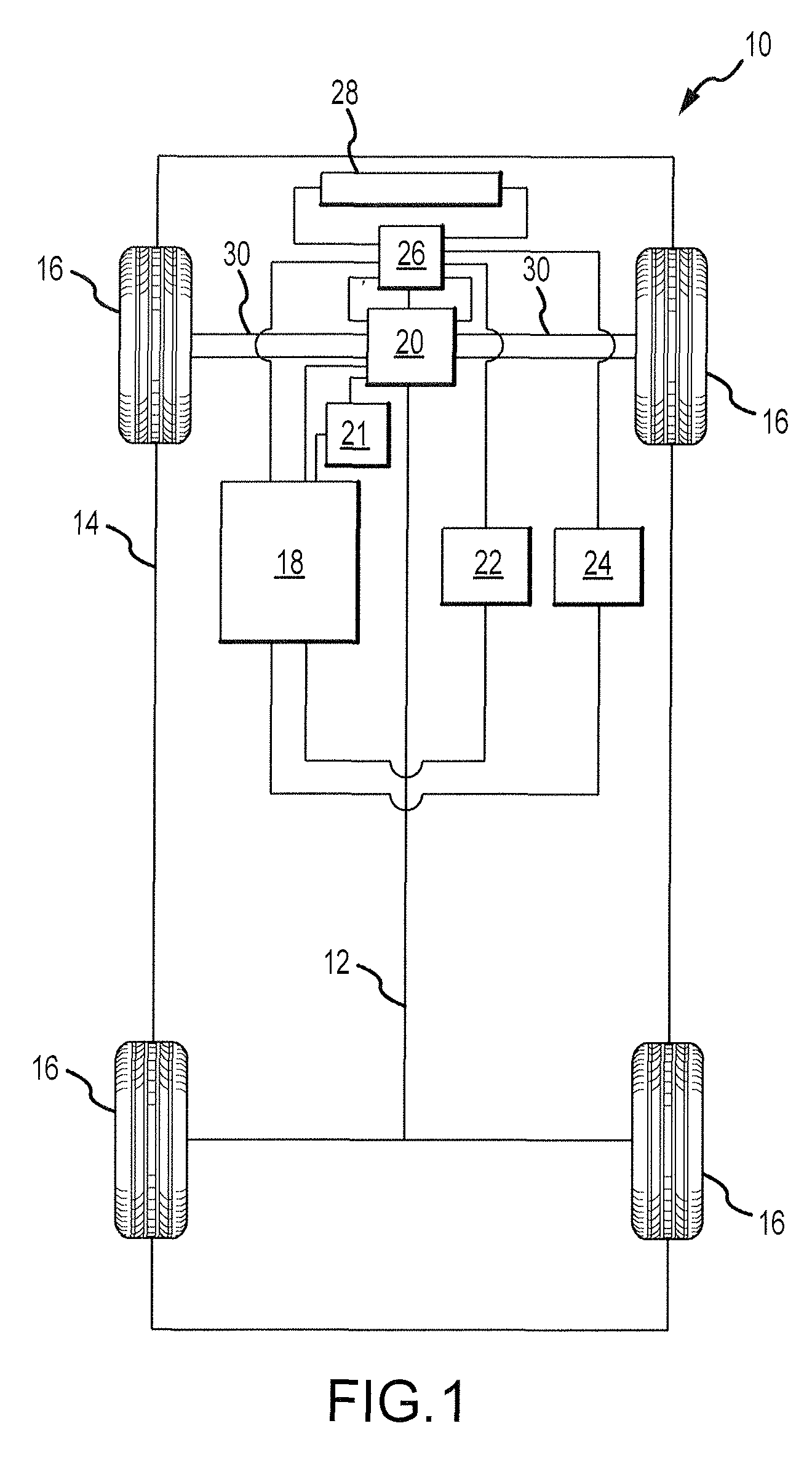

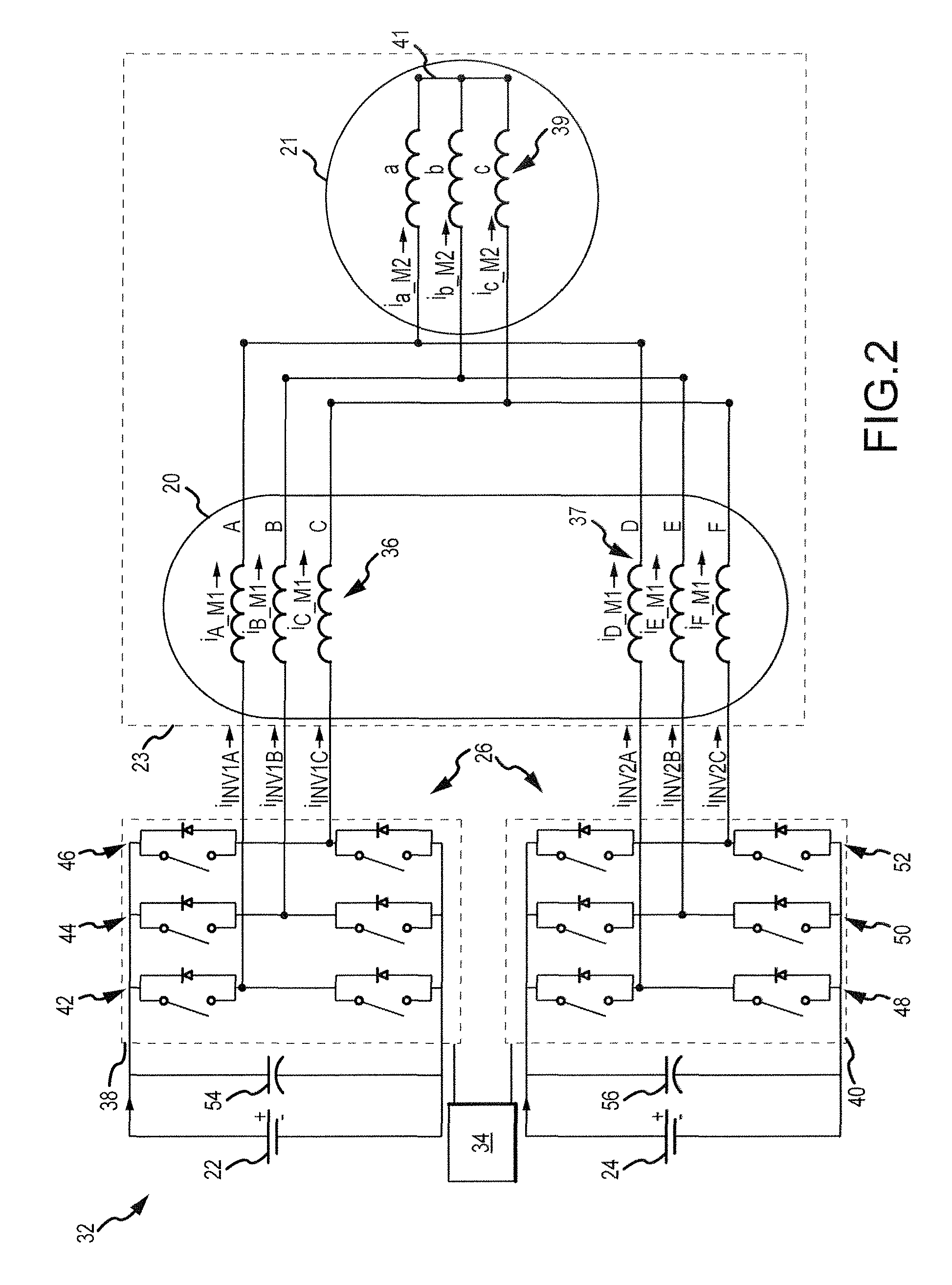

Systems and apparatus are provided for an inverter system for use in a vehicle. The inverter system comprises a six-phase motor having a first set of three-phase windings and a second set of three-phase windings and a three-phase motor having a third set of three-phase windings, wherein the third set of three-phase windings is coupled to the first set of three-phase windings and the second set of three-phase windings. The system further comprises a first energy source coupled to a first inverter adapted to drive the six-phase motor and the three-phase motor, wherein the first set of three-phase windings is coupled to the first inverter, and a second energy source coupled to a second inverter adapted to drive the six-phase motor and the three-phase motor, wherein the second set of three-phase windings is coupled to the second inverter. A controller is coupled to the first inverter and the second inverter.

Owner:GM GLOBAL TECH OPERATIONS LLC

Motor

InactiveUS20100327680A1Reduce motor sizeSmall sizeSynchronous generatorsAssociation with control/drive circuitsConductor CoilTransistor

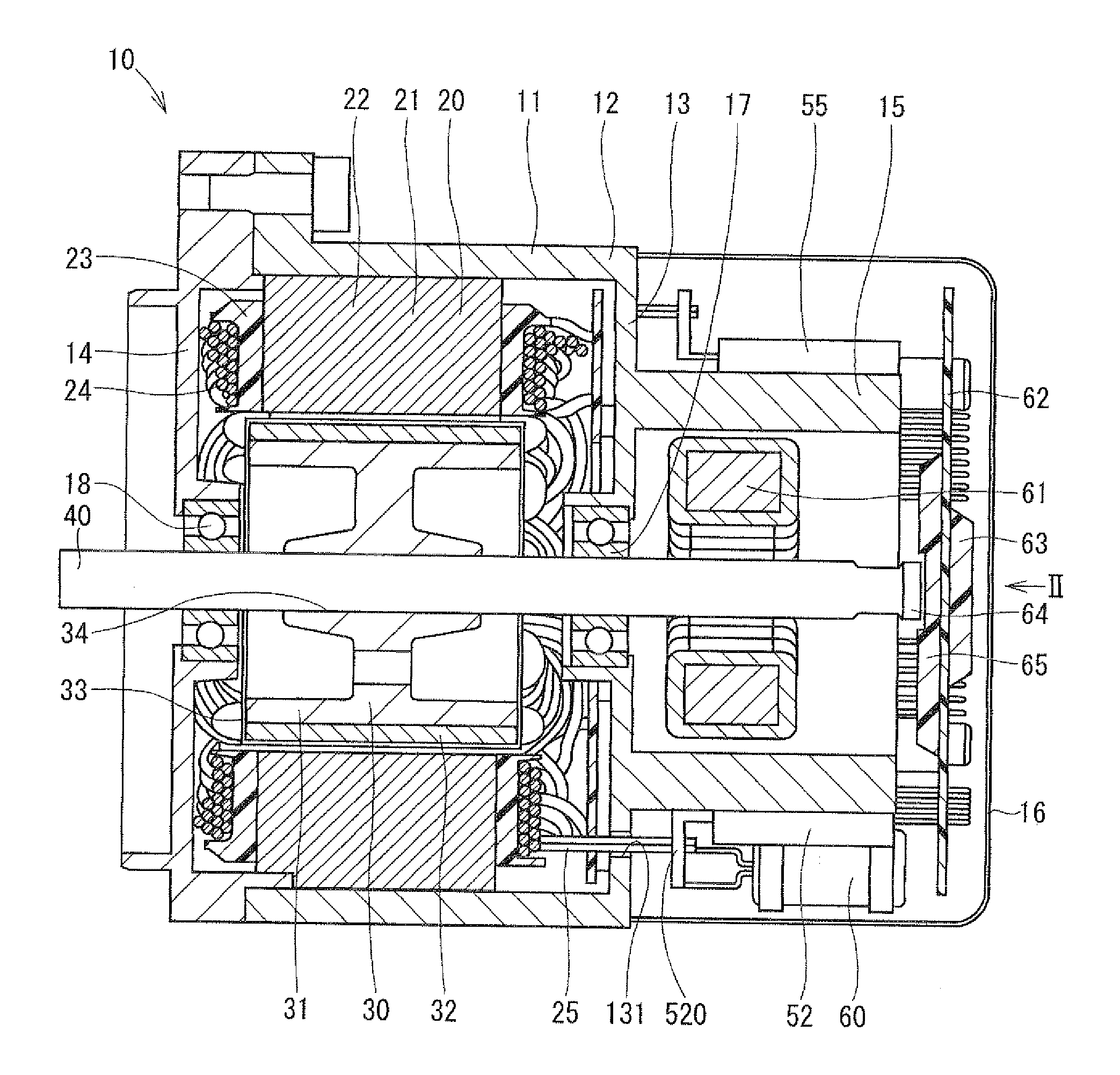

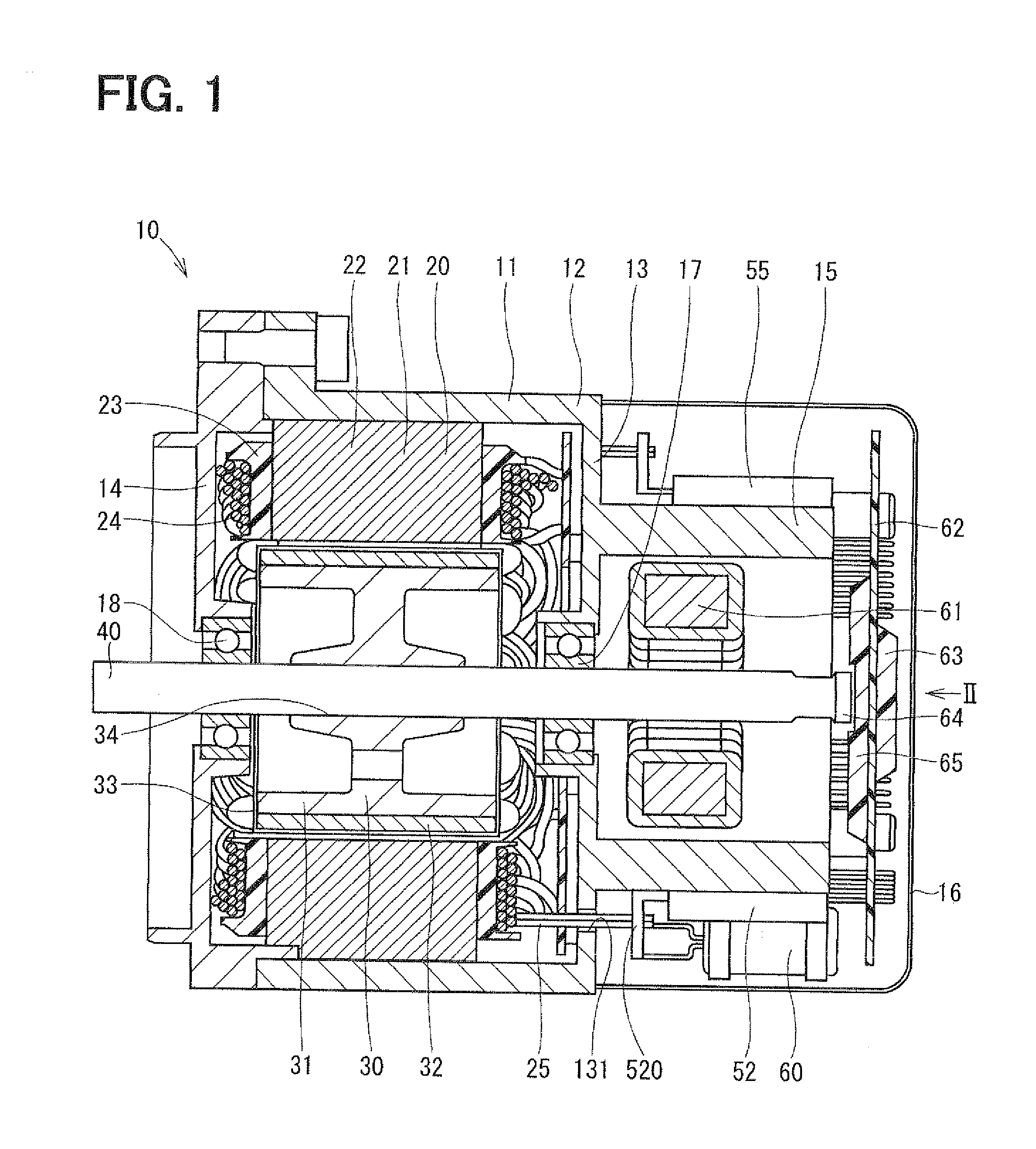

In a motor, a stator with a three-phase winding set and a rotor are located in an operation region of a motor casing having a side wall. An inverter circuit constructed with power modules is located in a control region that is located on the opposite side of the operation region across the side wall in an axial direction of the motor. Each power module has a pair of transistors and a common terminal connected to the pair of transistors. A lead of a winding corresponding to one phase and a lead of a winding corresponding to another phase extend in the axial direction to cross over from the operation region to the control region and are connected together to the common terminal of a corresponding power module.

Owner:DENSO CORP

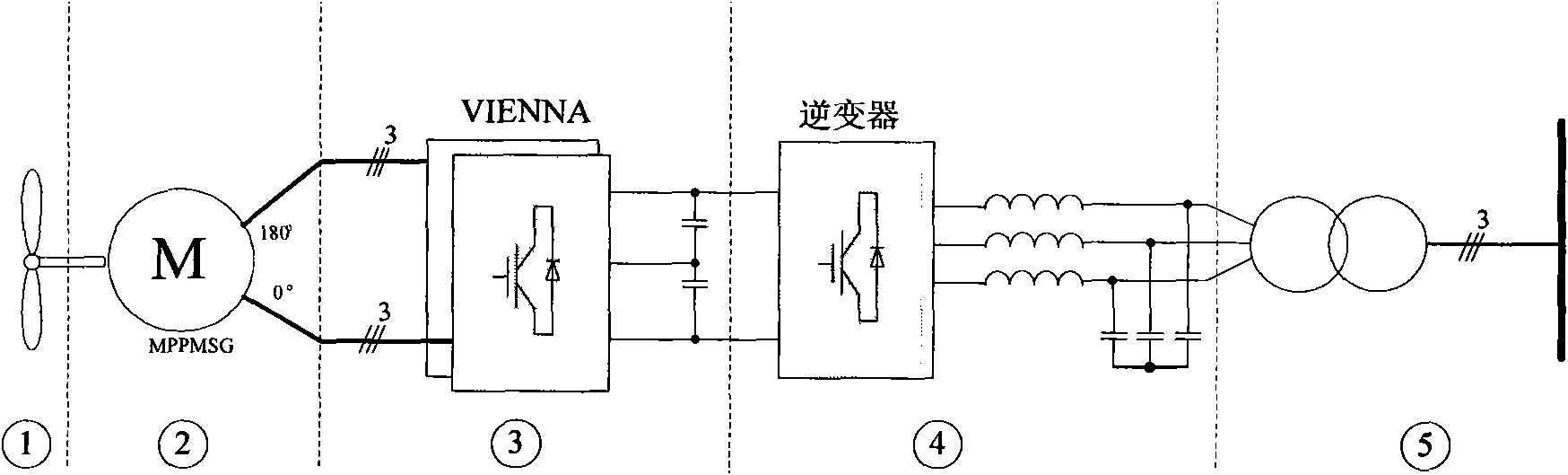

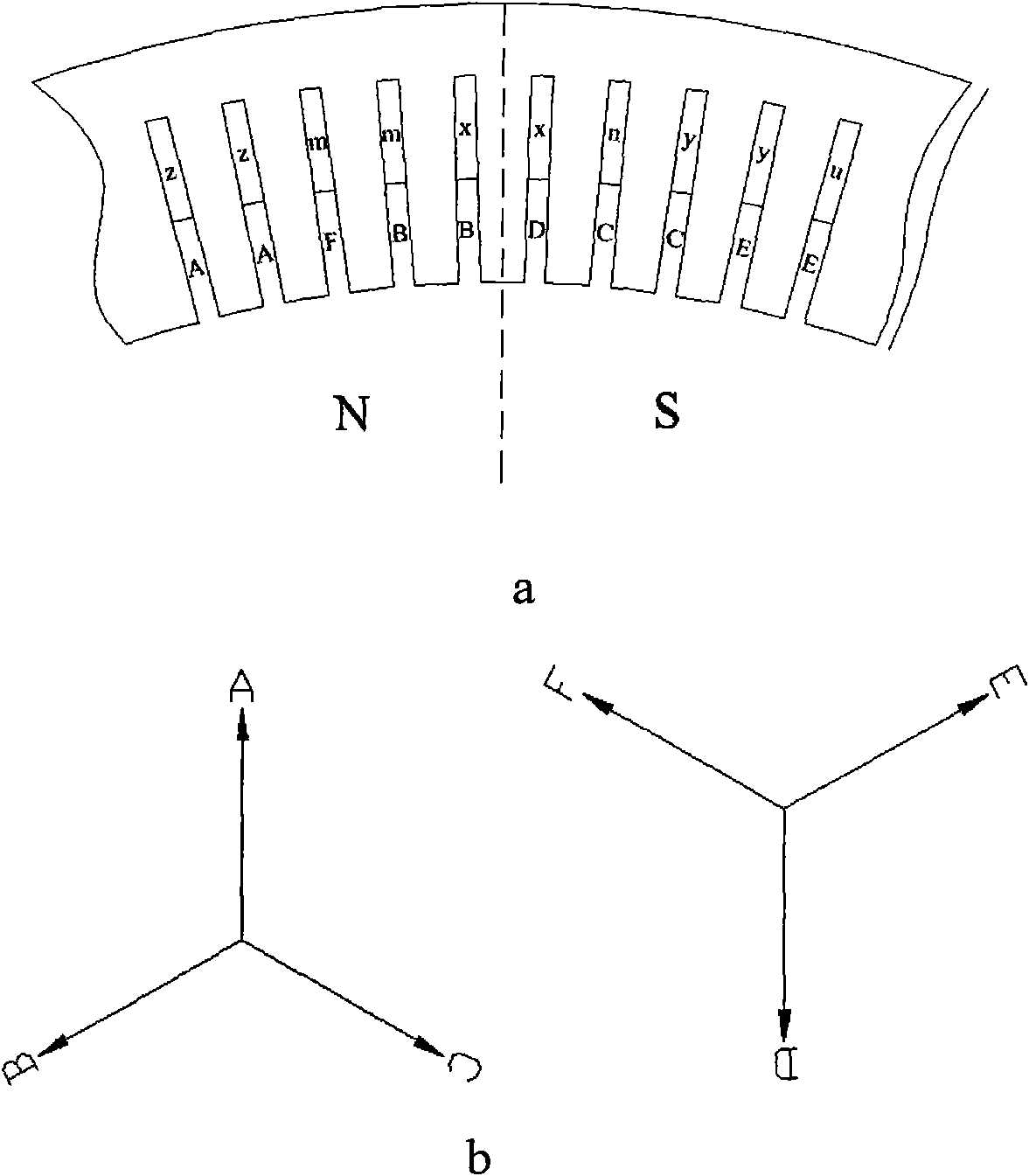

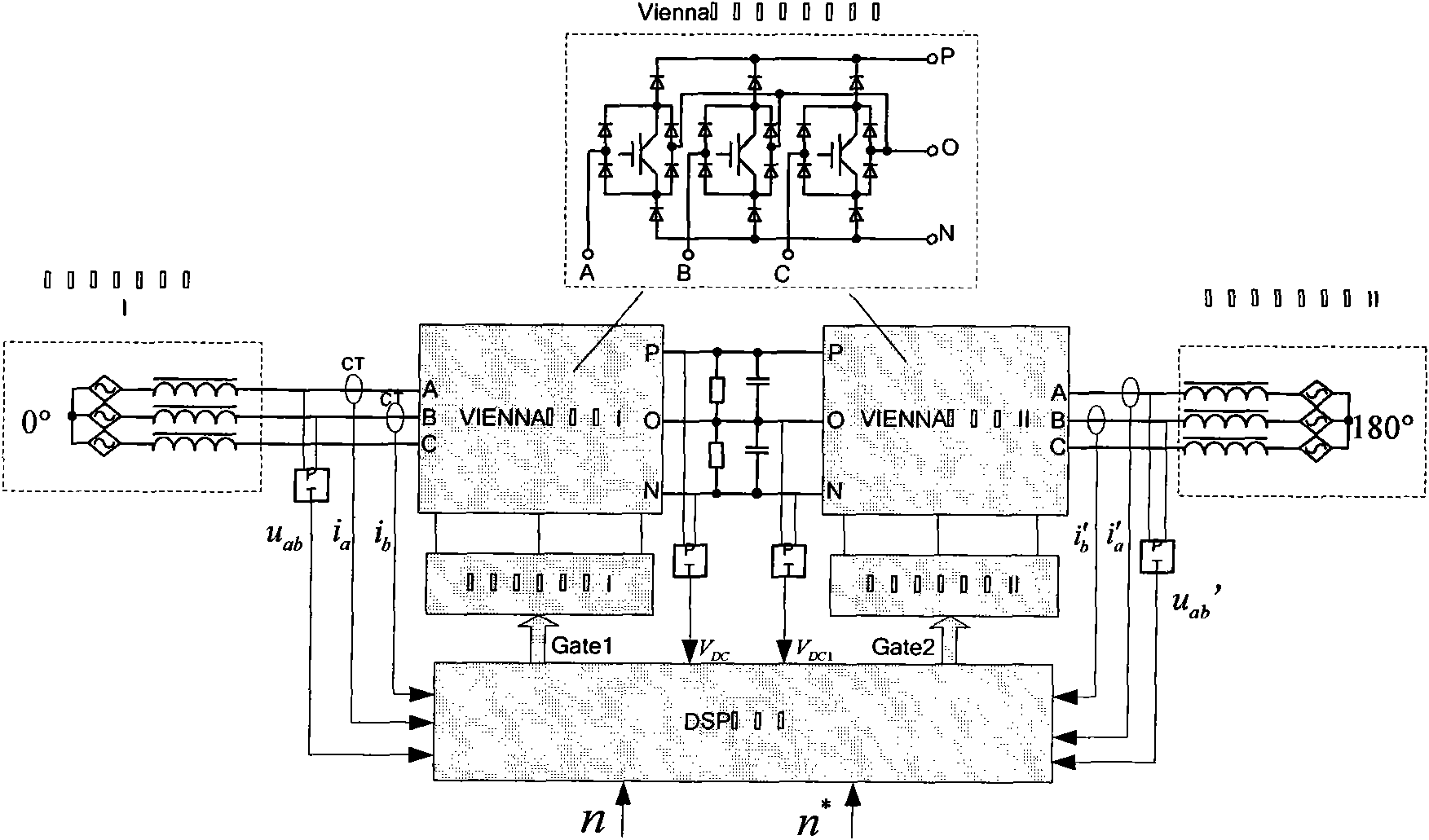

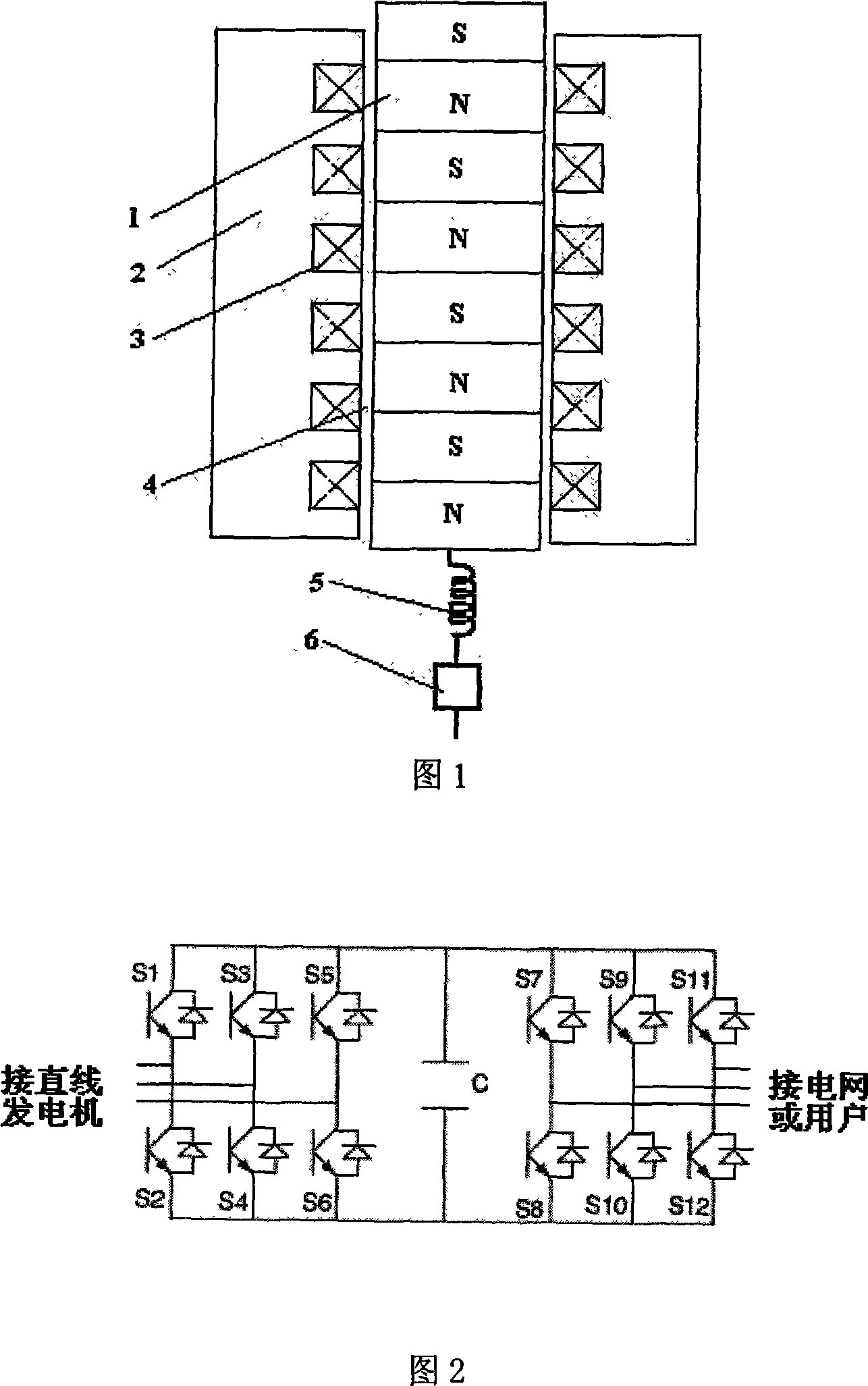

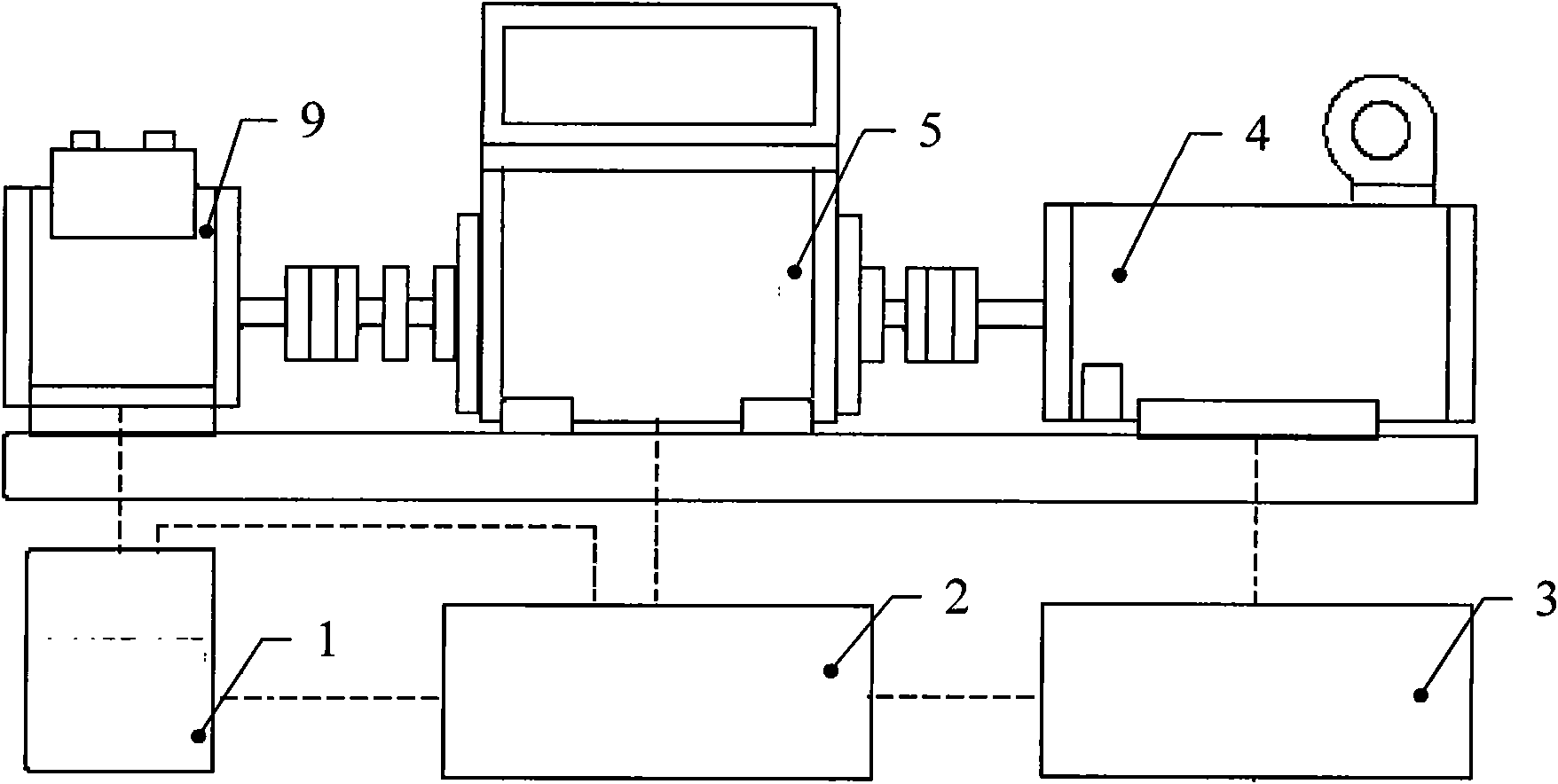

Generator system for wind power generation and variable speed control method

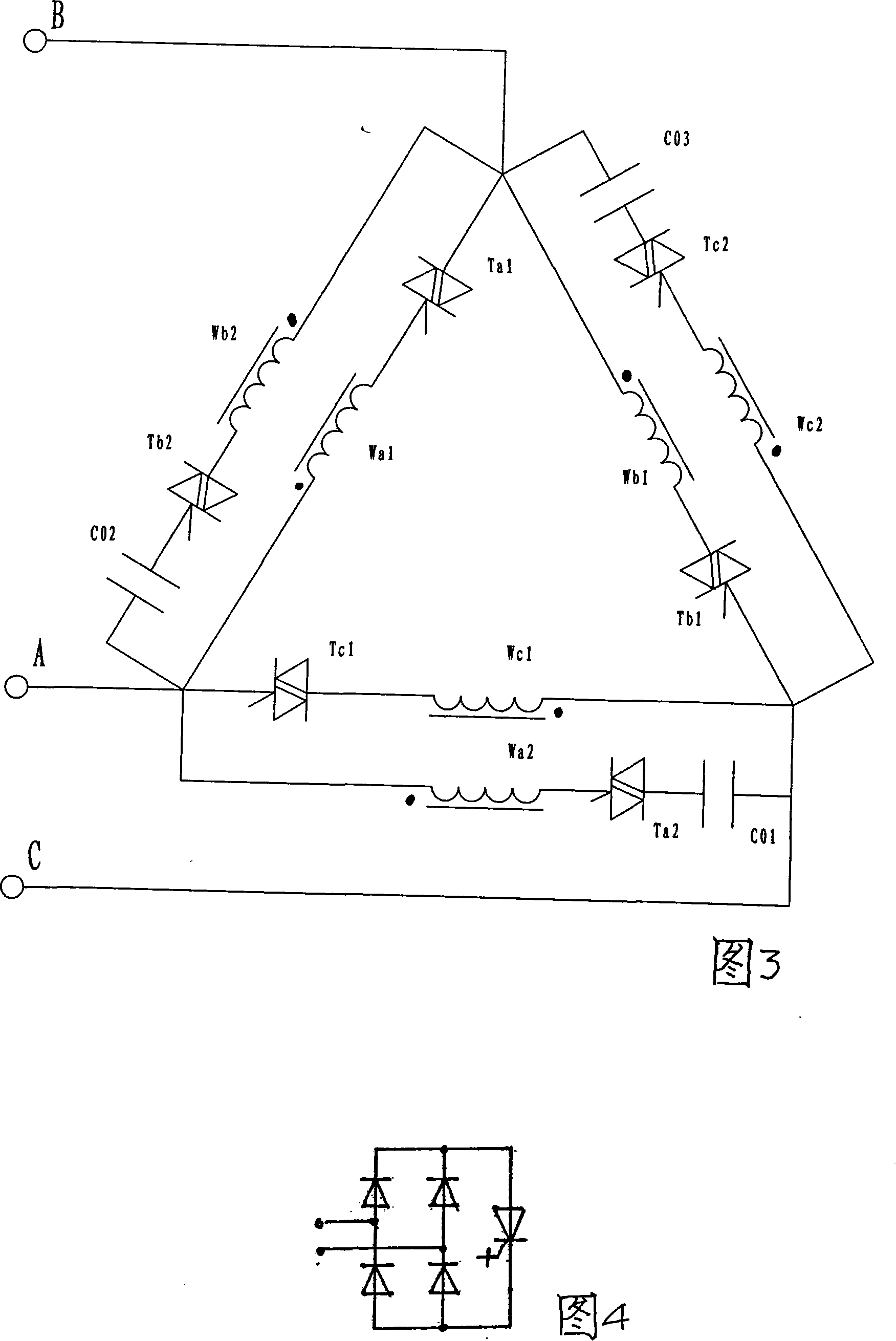

InactiveCN101640423ASimplify Parallel CombinationAutomatically eliminate voltage pulsationSingle network parallel feeding arrangementsWind energy generationPhase currentsCapacitance

The invention discloses a generator system for wind power generation and a variable speed control method; the system comprises a permanent magnetic synchronous generator of which the electrical energyoutput is connected with a Vienna rectifier device, and is characterized in that a stator winding of the permanent magnetic synchronous generator comprises two sets of triphase windings with electrical degree difference of 180 degrees and unconnected neutral points thereof; the Vienna rectifier device comprises two Vienna rectifiers with identical structure, which are in parallel connection withthe DC side with a central point O connected with a DC bus capacitance midpoint; the AC side is connected with the two triphase windings of the generator respectively; a Boost inductance of the Viennarectifier is directly provided by the leakage inductance of the windings of the generator; each Vienna rectifier device is controlled by a DSP controller to maintain the balance of the DC bus voltageby the phase current and line voltage collected in the AC side and the bus voltage collected in the DC side; and the variable speed control of the generator is realized by collecting the rotating speed of a fan and the current wind speed.

Owner:XI AN JIAOTONG UNIV

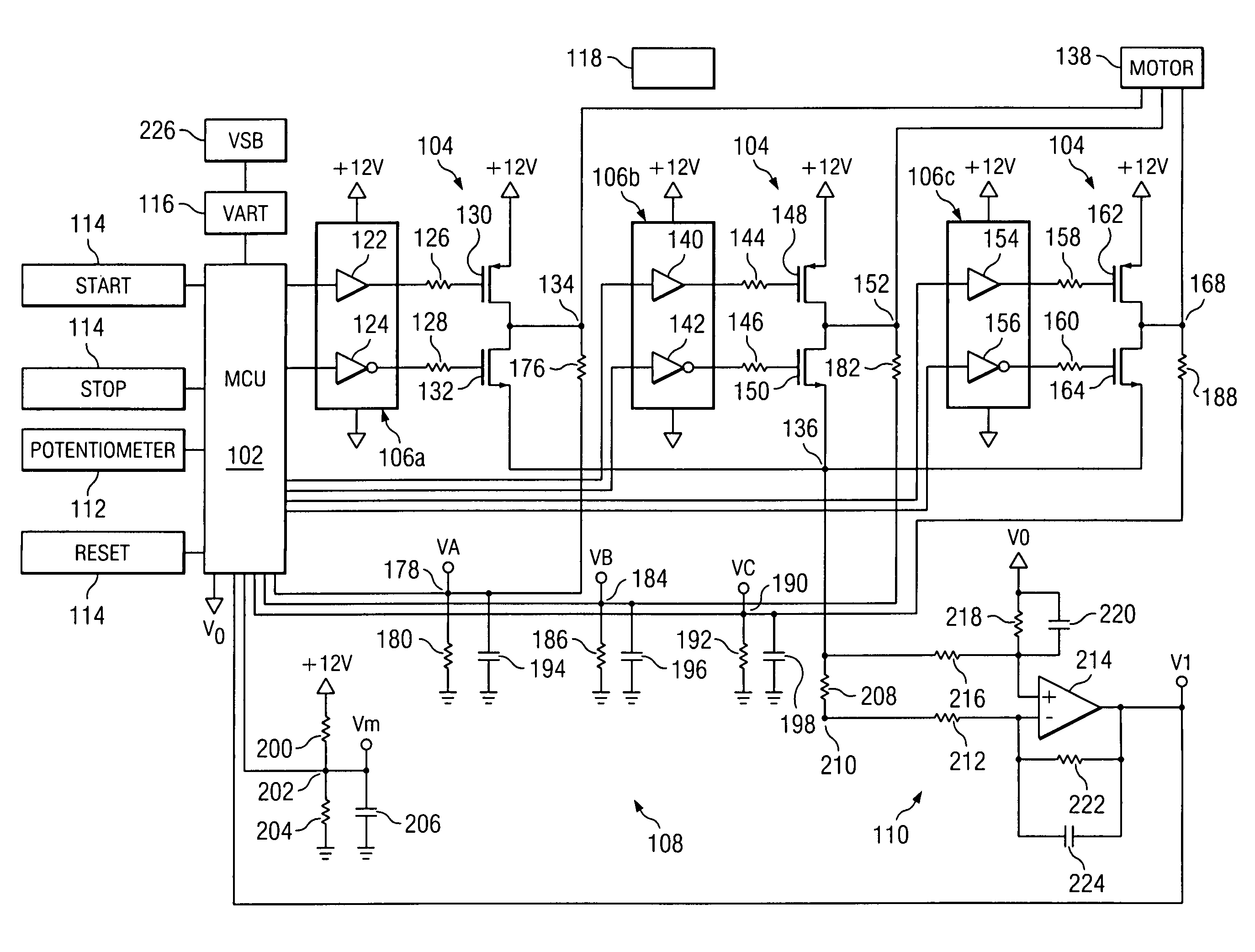

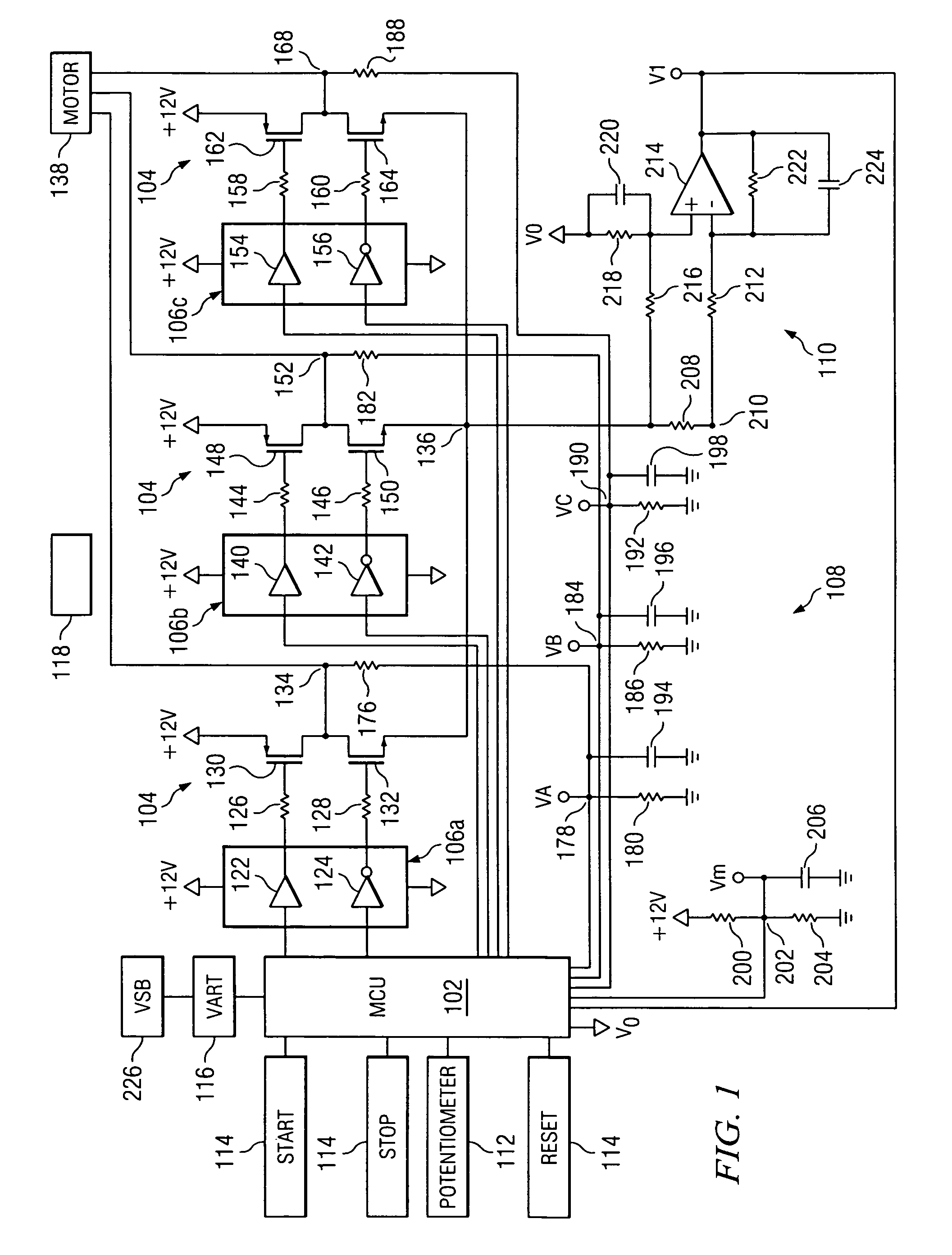

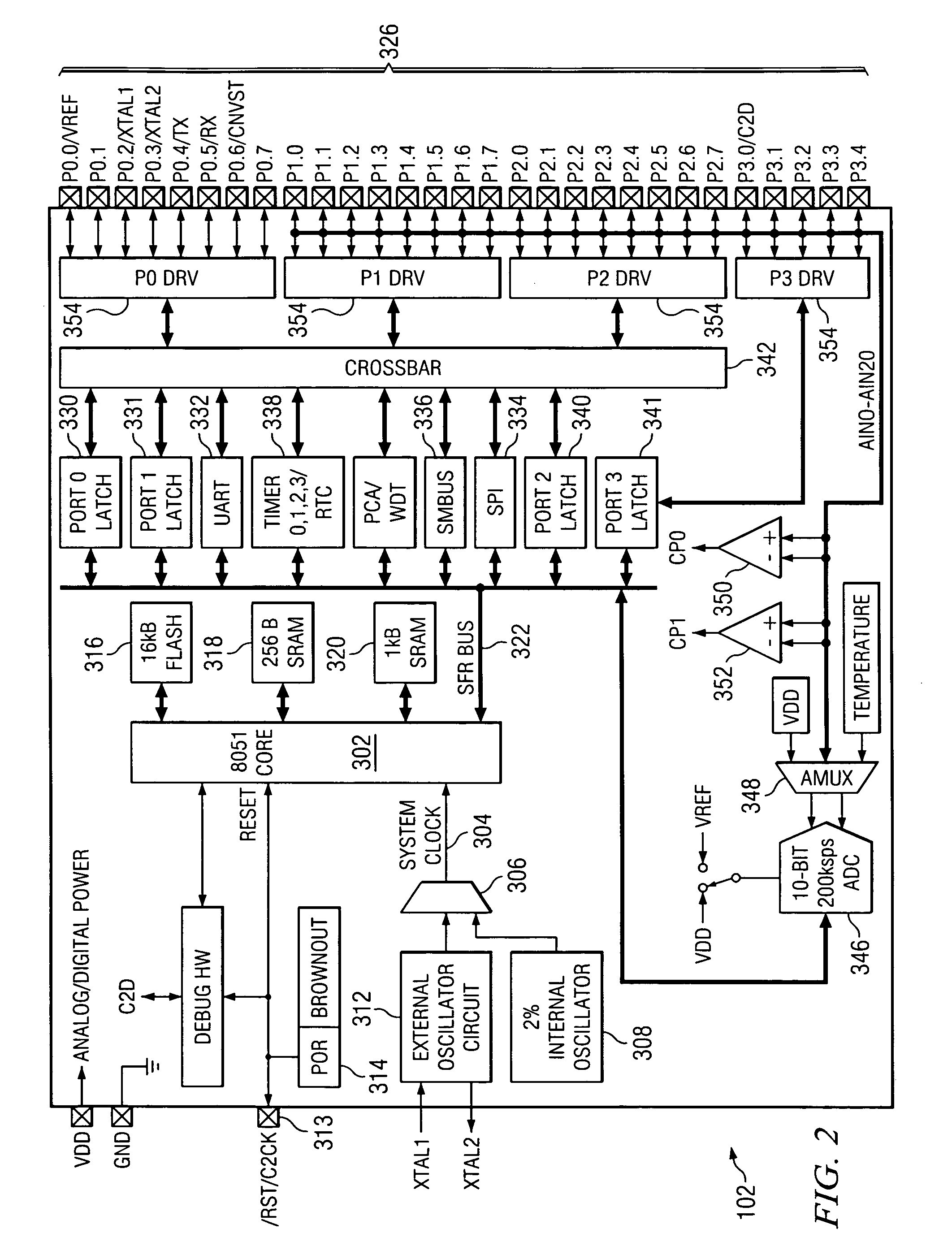

MCU control for brushless DC motor

ActiveUS6949900B1Reduce motor speedIncrease motor speedSynchronous motors startersAC motor controlPotentiometerThree phase windings

A processor for controlling a sensorless, brushless DC motor is disclosed comprising a first output for providing a control signal to a potentiometer controlling the speed and voltage of the DC motor. The processor also includes a second input for receiving a back-EMF voltage from an open phase of a three phase winding. The processor determines a digital error signal from the back-EMF voltage and generates a control signal responsive to the digital error signal. The control signal decreases the speed of the motor when the digital error signal is in a first range. The processor decreases both the speed and voltage of the motor when the digital error signal is in a second range. The processor increases the speed of the motor when the digital error signal is in a third range. The processor increases both the speed and voltage of the motor when the digital error signal is in a fourth range.

Owner:SILICON LAB INC

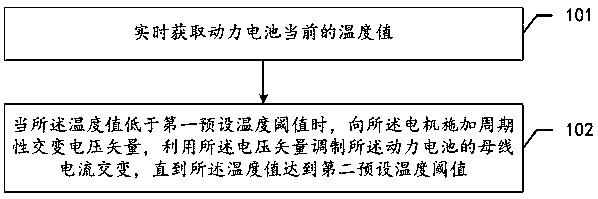

Control method of drive system, drive system and new energy vehicle

ActiveCN109823234AGet temperature value in real timeIncrease temperatureElectronic commutation motor controlVector control systemsPeriodic alternatingVoltage vector

The invention discloses a control method of a drive system, the drive system, and a new energy vehicle. The method obtains a current temperature value of a power battery in real time; when the temperature value is lower than a first preset temperature threshold, the temperature is raised to restore the drive capability of the drive system. A motor controller applies a periodic alternating voltagevector to a motor, the voltage vector is utilized to modulate bus current of a power battery to alternate, and during the process, the battery is driven to be repeatedly charged and discharged periodically to increase the temperature of the battery. Until the temperature value reaches a second preset temperature threshold, the battery is warmed to a desired operating temperature and the motor controller stops applying the voltage vector. Three-phase winding of the motor and three sets of bridge arms are used during the heating of the power battery. The recovery of the drive capability of the drive system is more economical without the need for additional external heating equipment. During the entire process of applying the voltage vector, the power battery is continuously and uniformly heated, the battery heating efficiency is very high, and rapid recovery of the drive capability is achieved.

Owner:SAIC MOTOR

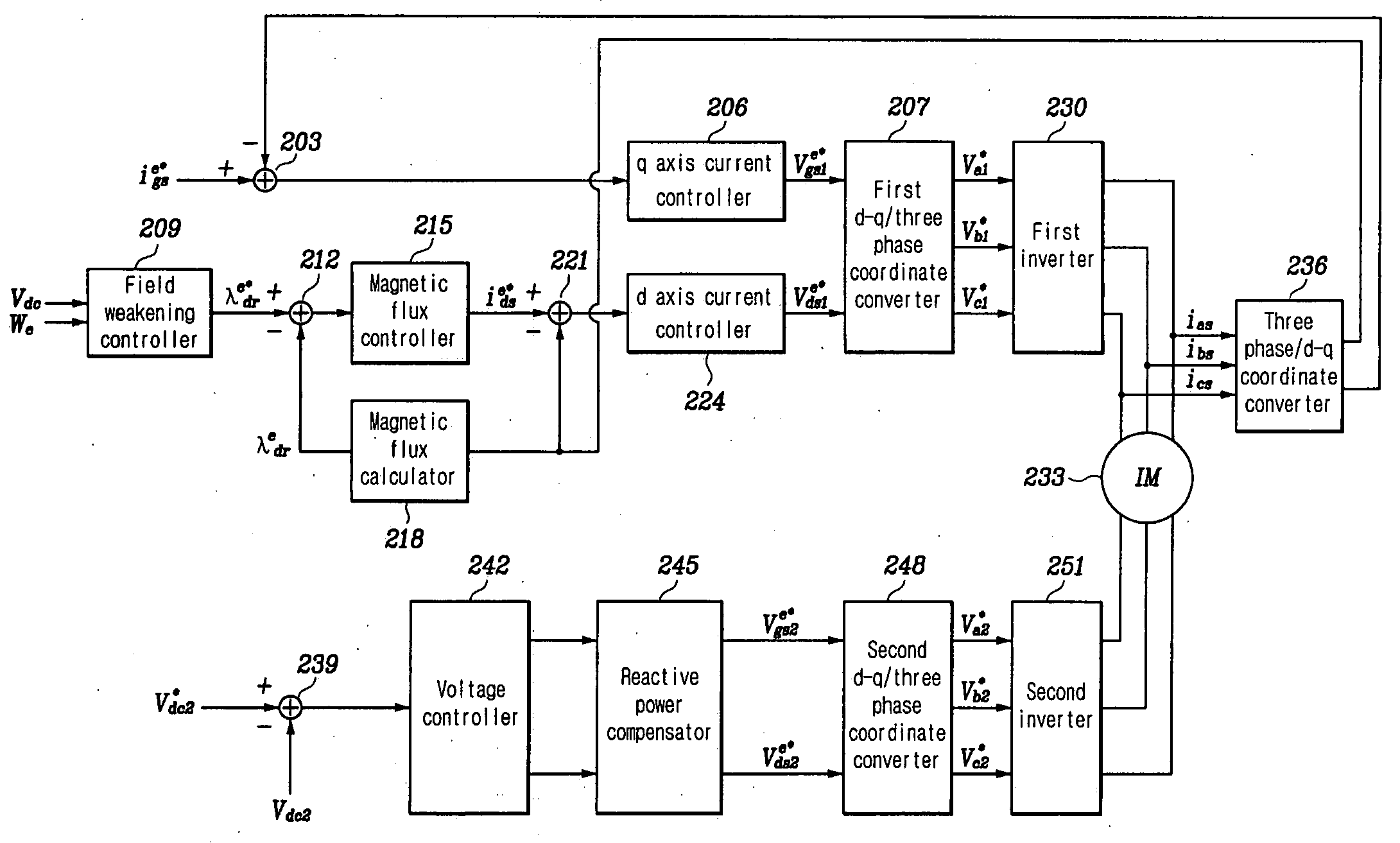

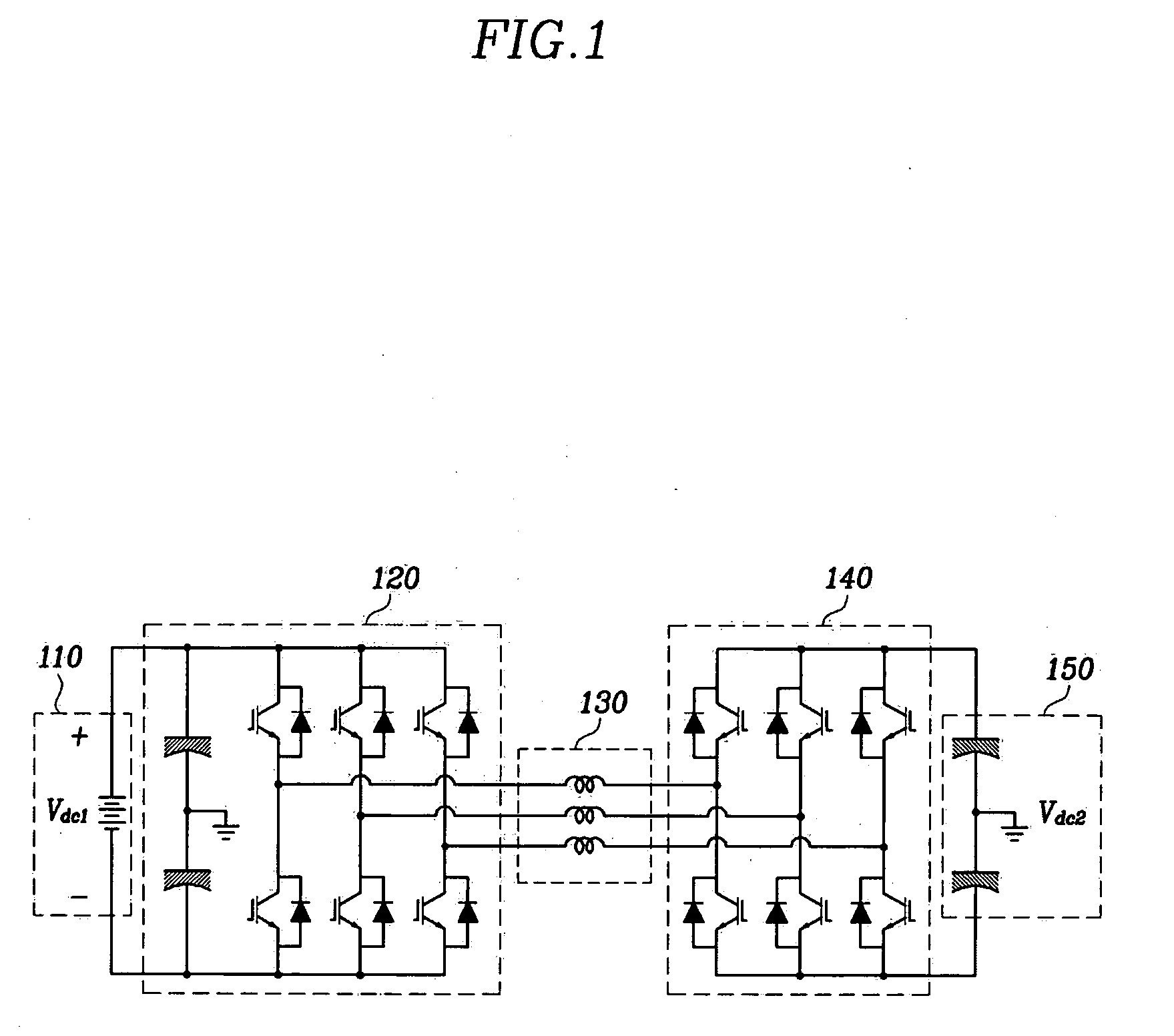

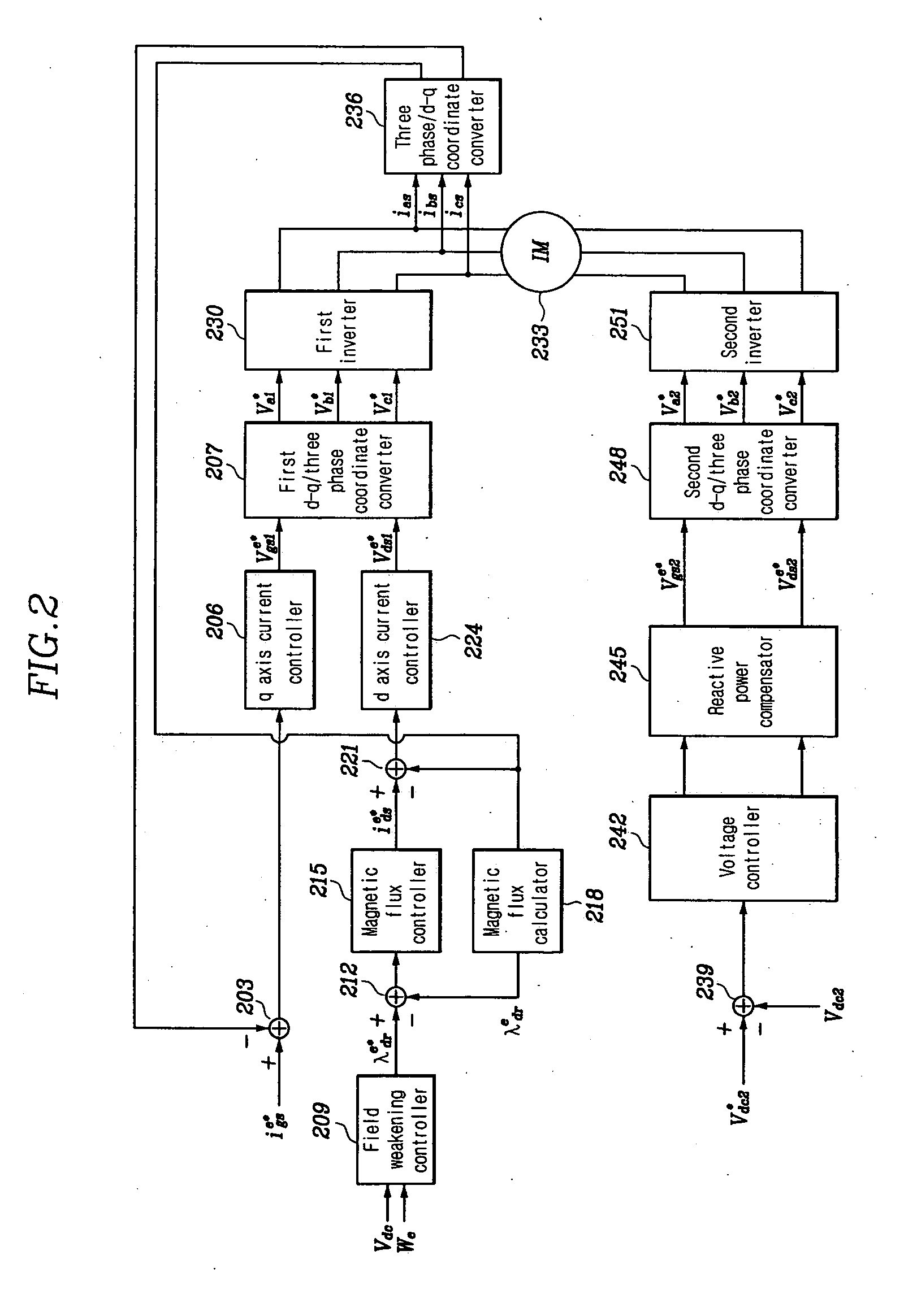

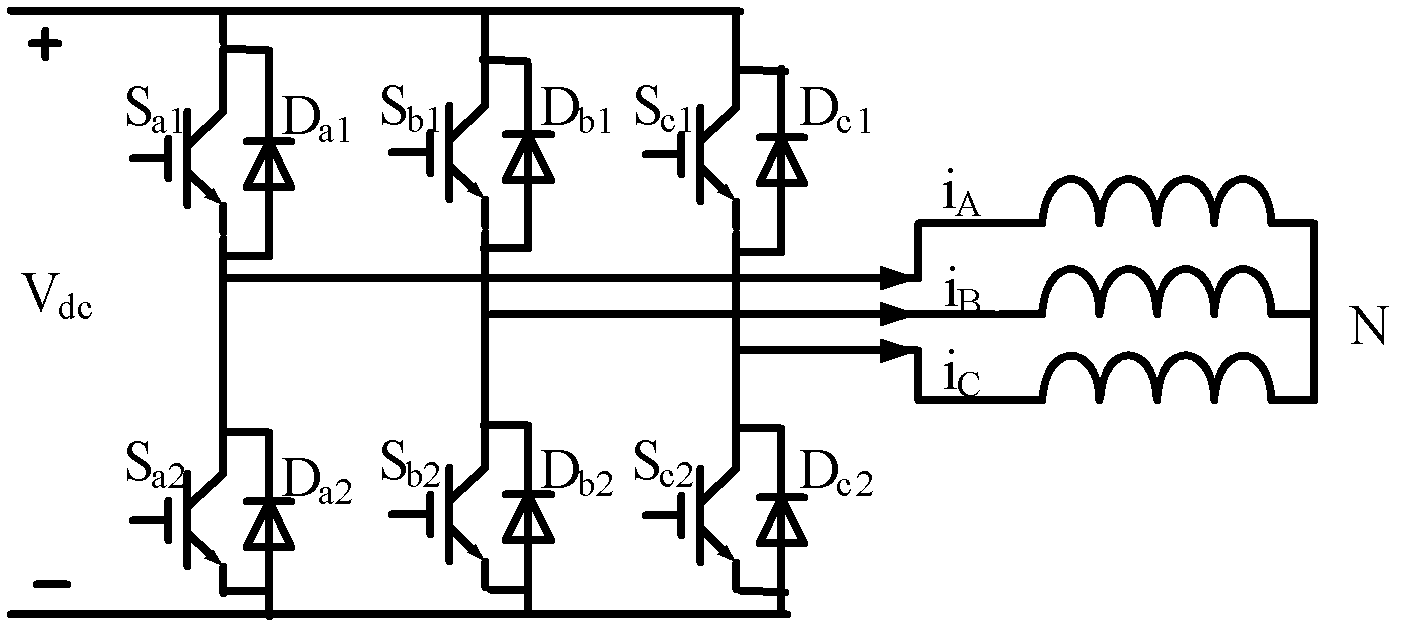

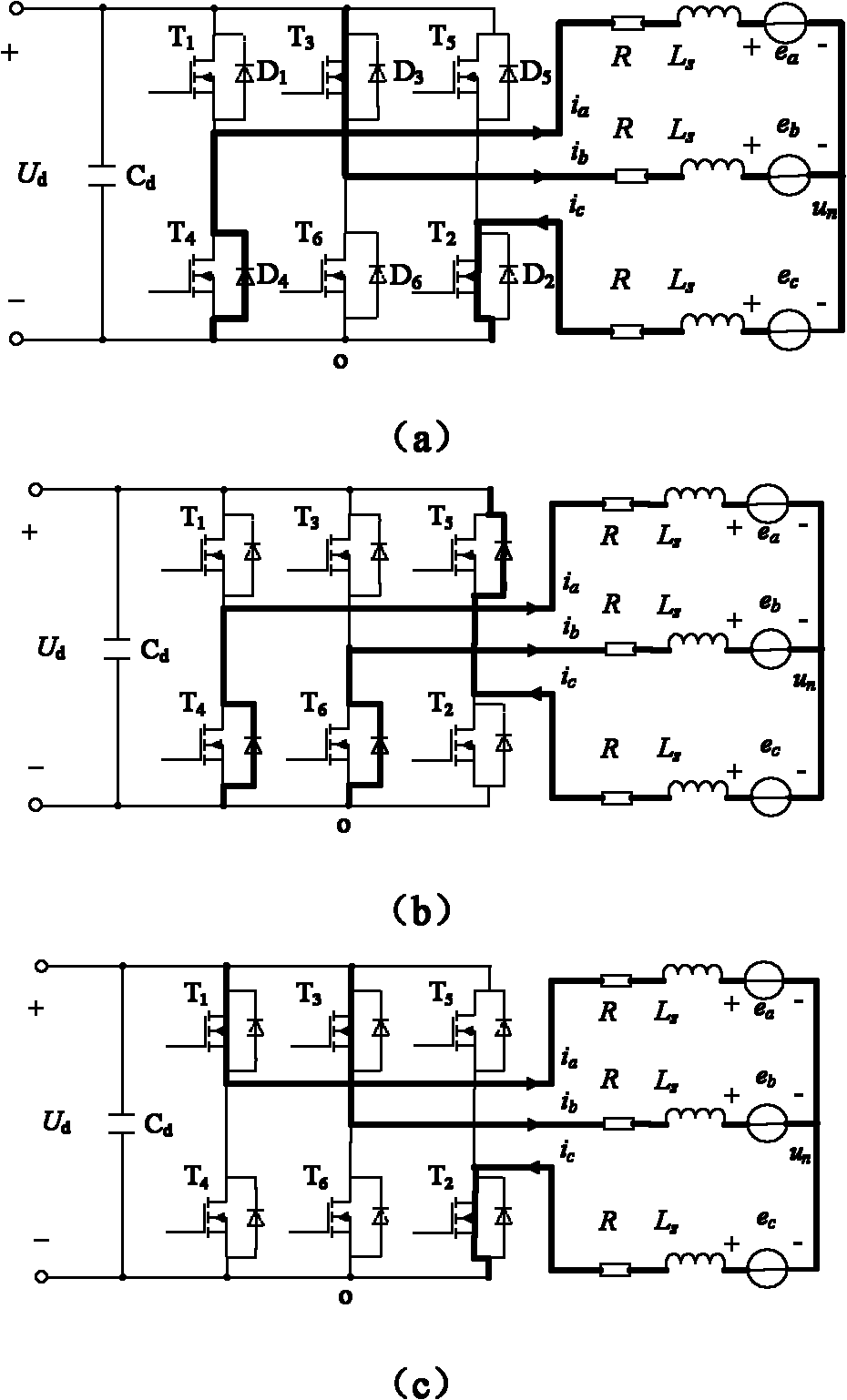

Vector-controlled dual inverter system and method for induction motor

InactiveUS20050002210A1Restrain output decreaseOutput power is preventedVector control systemsConversion with intermediate conversion to dcPower compensationControl vector

A vector-controlled, dual inverter system for a three-phase induction motor is disclosed. The inverter system comprises a first inverter system which is connected to one end of three phase windings of a stator and performs compensation of a back electromotive force; and a second inverter system which is connected to the other end of the three windings of the stator and performs reactive power compensation.

Owner:HYUNDAI MOTOR CO LTD +1

Linear generator for surf power generation

InactiveCN101106316ASmall dielectric lossImprove power generation efficiencyMechanical energy handlingPropulsion systemsWave power generationSynchronous motor

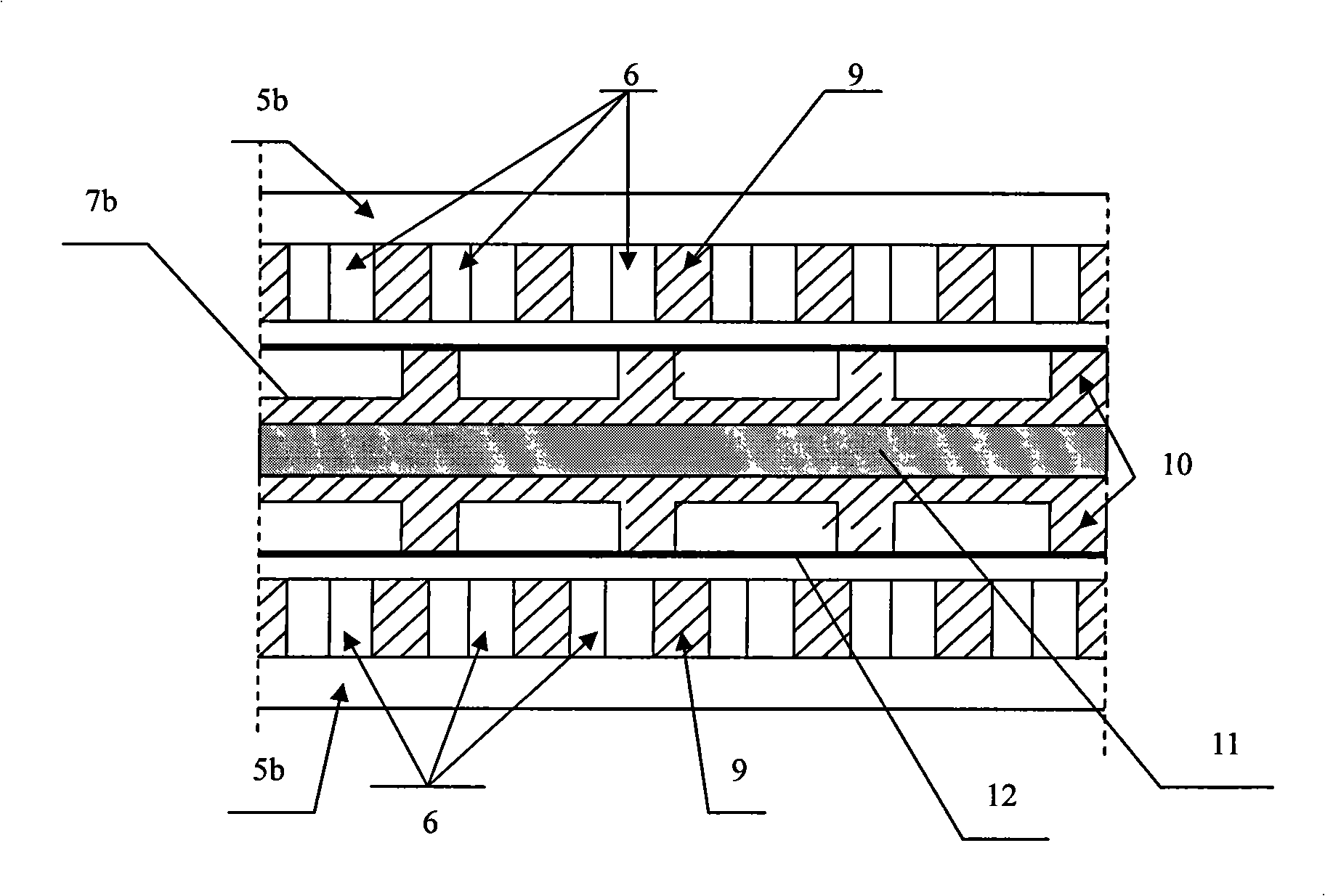

The linear dynamo used in wave power generation relates to a permanent magnetic linear synchronous motor, which comprises a primary pole and a secondary pole. The primary pole of the permanent magnetic linear synchronous motor comprises two primary iron cores (2), a primary tri-phase winding (3). The primary tri-phase winding (3) is bedded in the wire ducts of the primary iron cores (2). The secondary pole comprises a secondary permanent magnet (1) which is arranged on a buoy (6) by a spring (5). The bottom of the container which contains the linear dynamo is fixed on the seabed. Both the primary pole and the secondary pole of the linear dynamo are in rectangle shape. The secondary permanent magnet (1) is positioned between the two primary iron cores (2). And air gaps (4) are provided between the secondary permanent magnet (1) and the two primary iron cores (2). The invention uses the linear dynamo instead of traditional rotating dynamo, with non-contact driving, reduces the dielectric loss and increases the electricity generation efficiency; sustains the pressure of wave, with strong structure; has the advantages of no poisonous gas released, no extra noise, environment-protection and health, with the cost as low as common electricity generation.

Owner:SOUTHEAST UNIV

Stator for rotating electric machine

ActiveUS20170033630A1Reduce potential differenceAvoid it happening againWindings insulation materialMagnetic circuit stationary partsBusbarElectric machine

A stator includes a stator core having slots, a stator coil comprised of three phase windings, phase busbars each electrically connecting a corresponding one of the phase windings to an inverter, and a neutral busbar star-connecting the phase windings to define a neutral point therebetween. In each of the slots of the stator core, there are arranged K in-slot portions of the phase windings of the stator coil in K layers so as to be radially aligned with each other, where K is an even number. The phase and neutral busbars are electrically connected with those in-slot portions of the phase windings of the stator coil which are arranged at the radially outermost layer or the radially innermost layer in the respective slots of the stator core so as to be circumferentially spaced from one another by M slot-pitches or more, where M is a slot multiplier number.

Owner:DENSO CORP

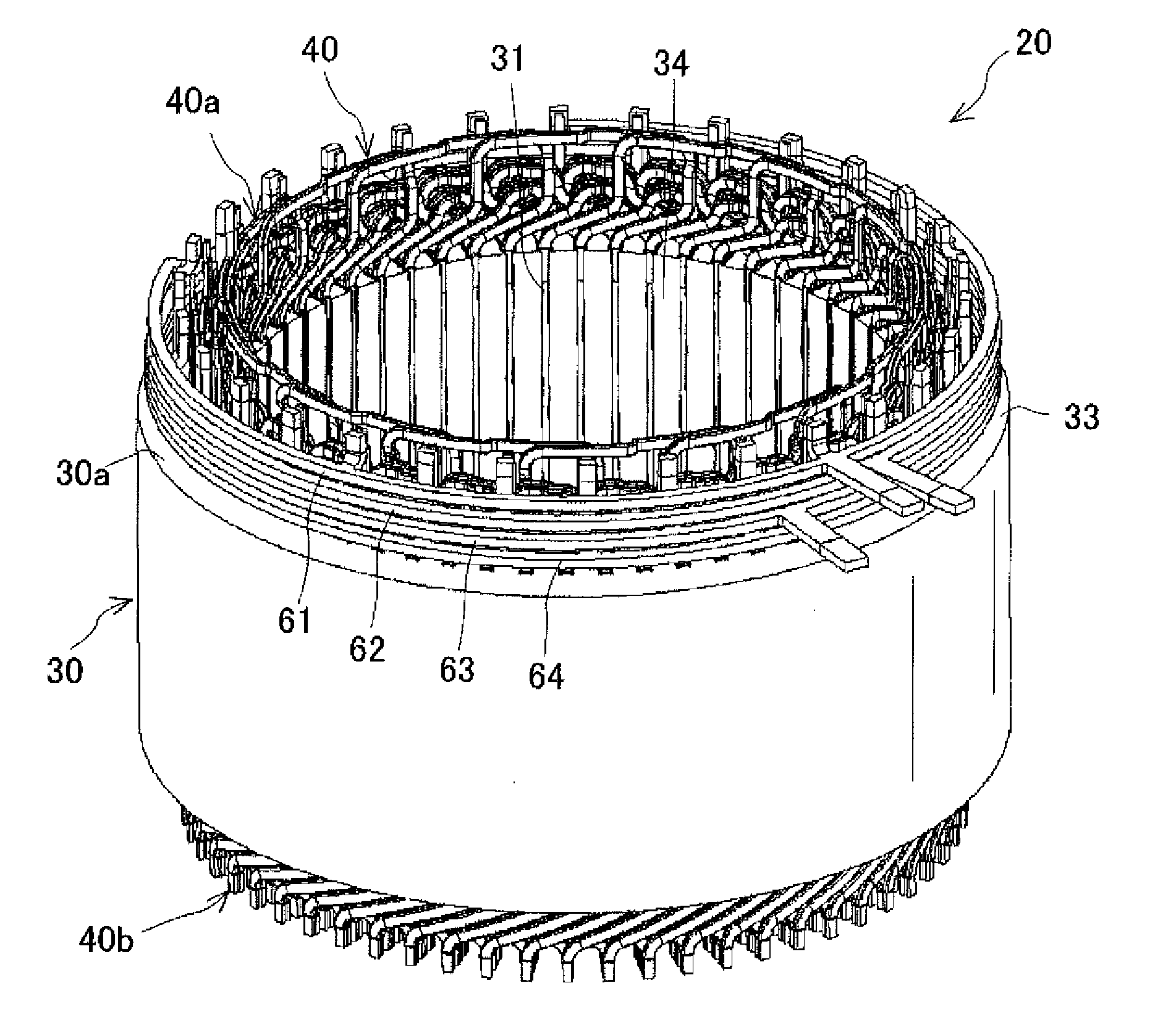

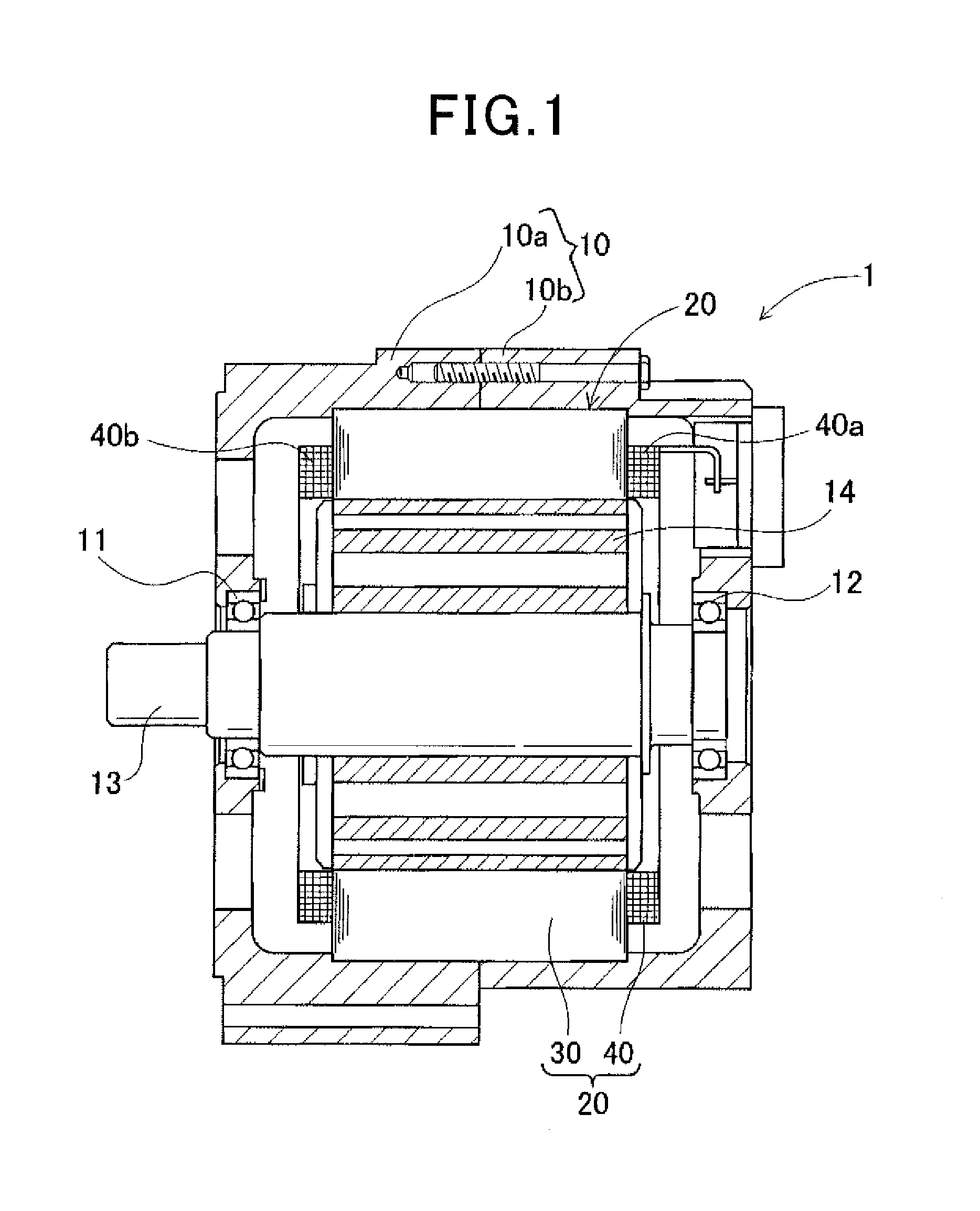

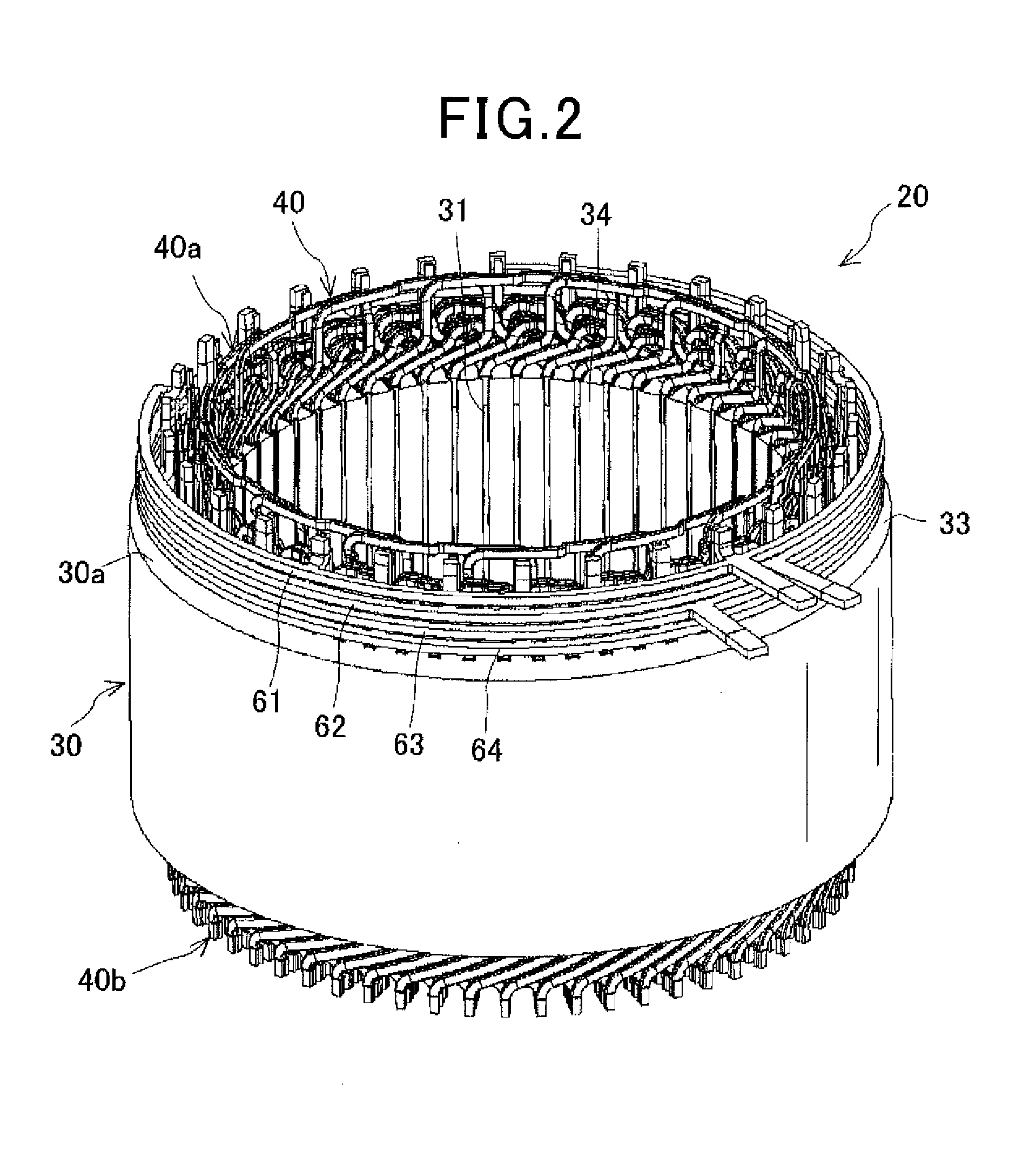

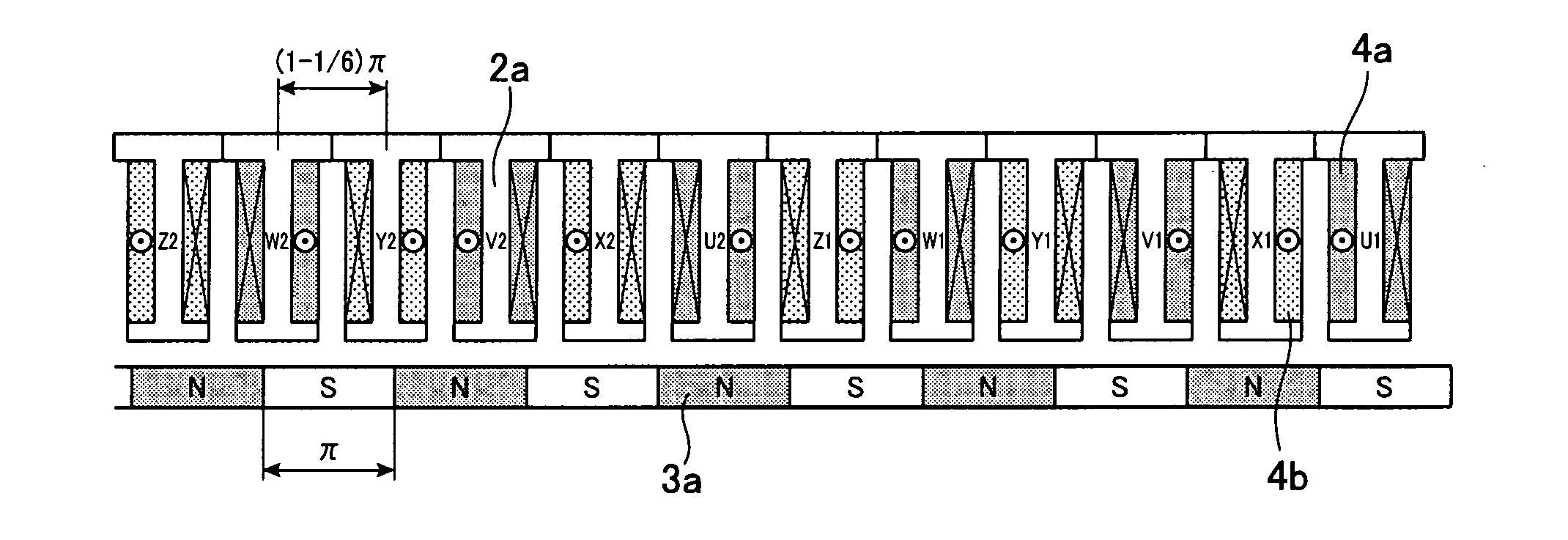

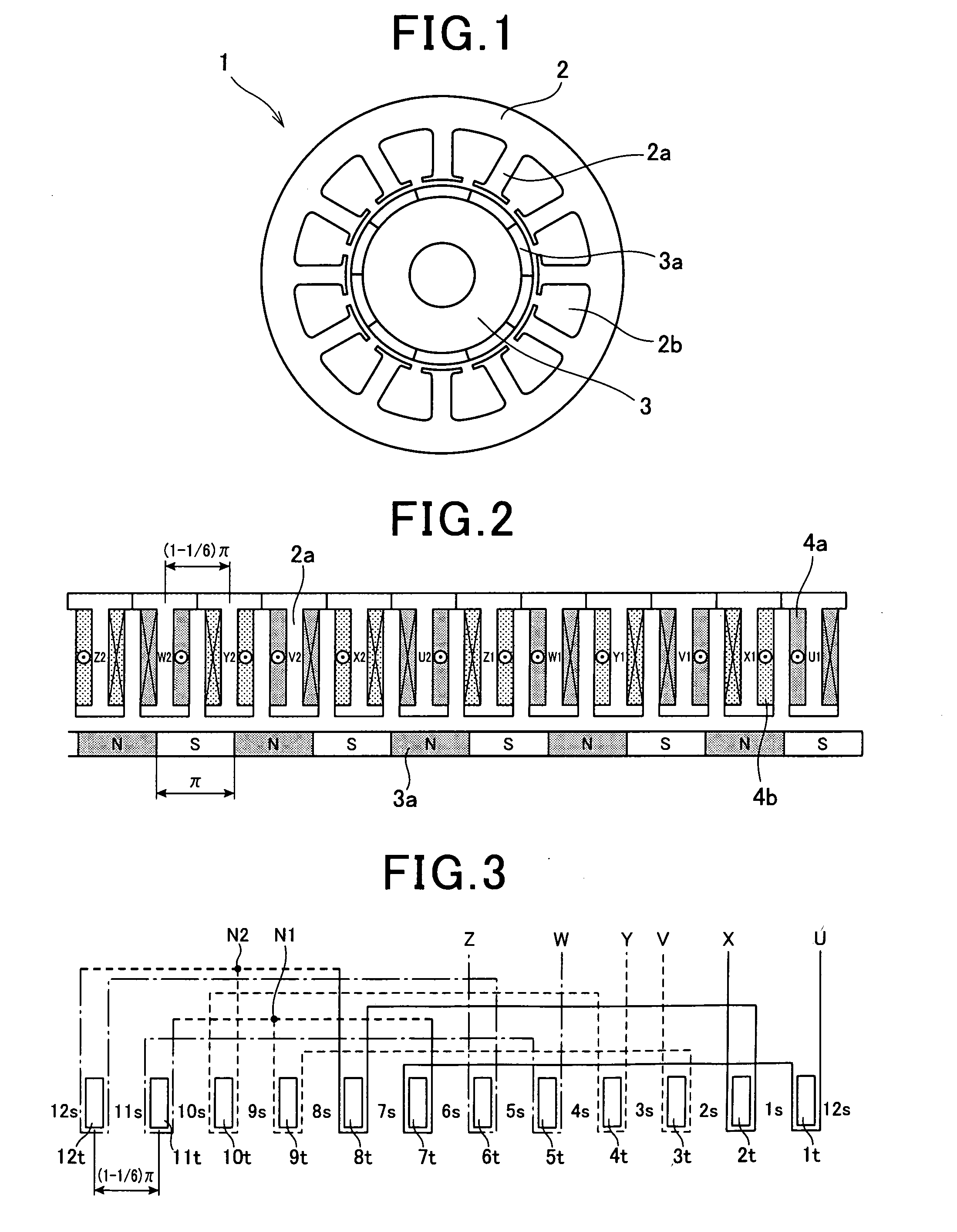

Electric rotating machine having improved stator coil arrangement for reducing magnetic noise and torque ripple

ActiveUS20100289372A1Minimized in sizeReduce magnetic noiseSynchronous generatorsMagnetic circuitPhase differenceElectrical polarity

An electric rotating machine is disclosed which includes a stator and a rotor. The stator includes a hollow cylindrical stator core and first and second three-phase stator coils. The stator core has a plurality of stator core teeth formed at a predetermined pitch in a circumferential direction of the stator core. Each of the first and second three-phase stator coils is comprised of three phase windings. Each of the phase windings of the first and second three-phase stator coils is wound around each of a predetermined number of the stator core teeth by a predetermined number of turns. The rotor has a plurality of magnetic poles the polarities of which alternate between north and south in the circumferential direction of the stator core. Further, the first and second three-phase stator coils are offset in the circumferential direction of the stator core to have a phase difference of π / 6 therebetween.

Owner:DENSO CORP

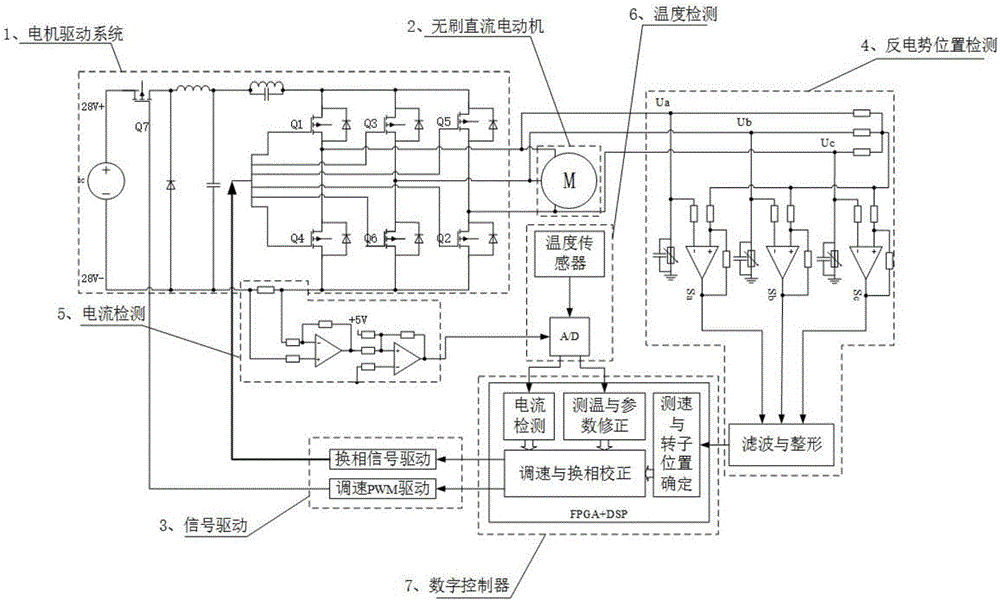

Counter-potential zero-crossing detection circuit and counter-potential zero-crossing detection method for brushless direct-current motor

InactiveCN103018541AEasy to detectEasy to implementCurrent/voltage measurementLow speedControl signal

The invention discloses a counter-potential zero-crossing detection circuit and a counter-potential zero-crossing detection method for a brushless direct-current motor, wherein in the counter-potential zero-crossing detection circuit for the brushless direct-current motor, a three-phase winding of the brushless direct-current motor is connected with a direct-current power supply via a bridge-type inverter, and the bridge-type inverter is formed by connecting six power switch tubes; the counter-potential zero-crossing detection circuit is characterized by comprising three detection modules used for detecting the counter-potential zero crossing of a phase A, a phase B and a phase C, and provided with the same structure; and each detection module comprises a comparator, and two electronic switch voltage-dividing module provided with the same structure and same circuit parameters. Via the counter-potential zero-crossing detection circuit and the counter-potential zero-crossing detection method disclosed by the invention, the danger that a counter-potential amplitude value is greater than the power supply voltage value of the detection circuit in case of high speed can be avoided. Simultaneously, as a mode that low-speed-area counter-potential sampling and high-speed-area counter-potential sampling are switched by controlling the signal duty ratio is adopted, the counter-potential zero-crossing detection effect in a low-speed area can be effectively improved. Experimental results indicate that the counter-potential zero-crossing detection circuit and the counter-potential zero-crossing detection method for the brushless direct-current motor can ensure the working of the motor within a relatively wide rotational speed range.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

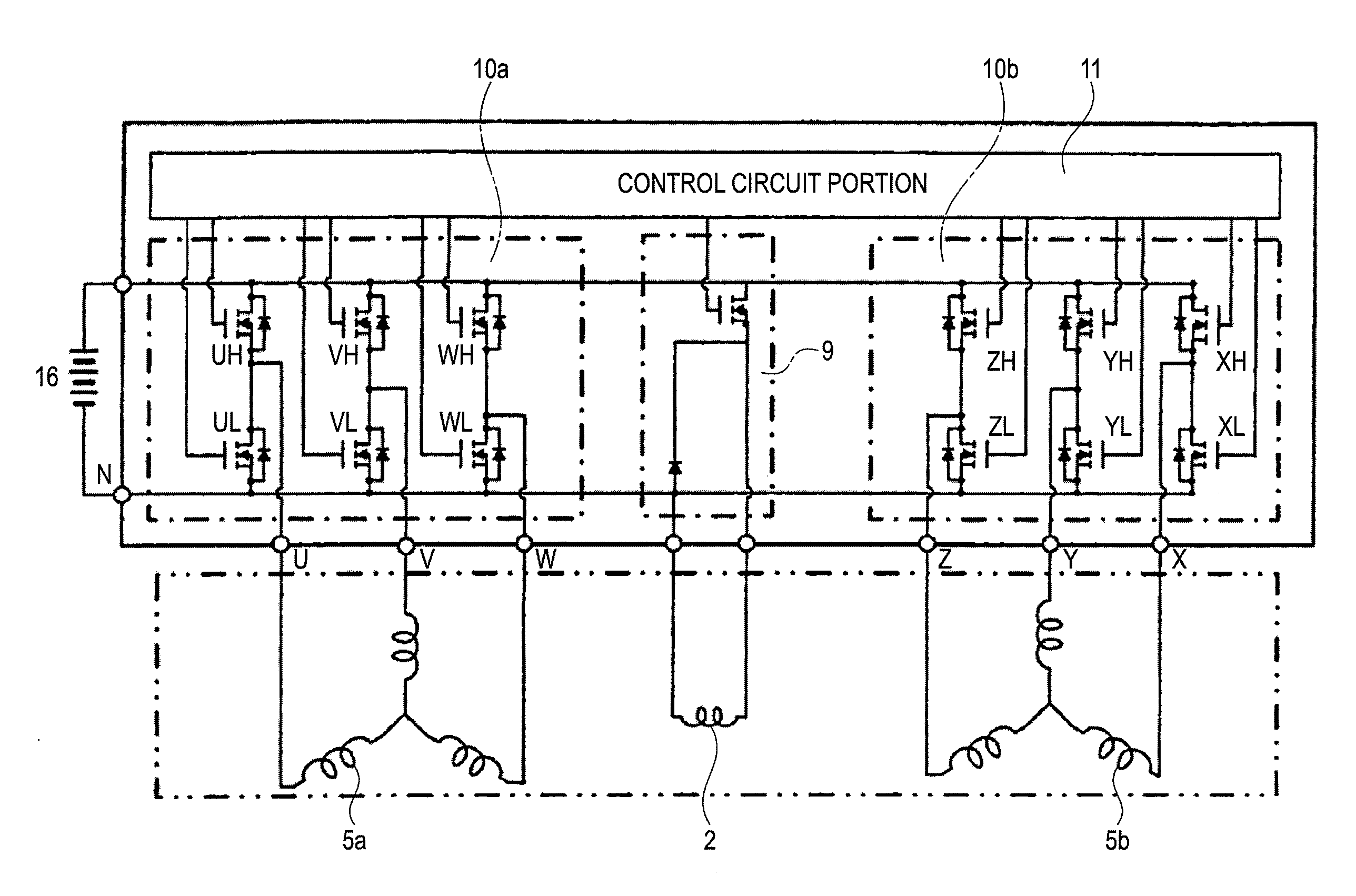

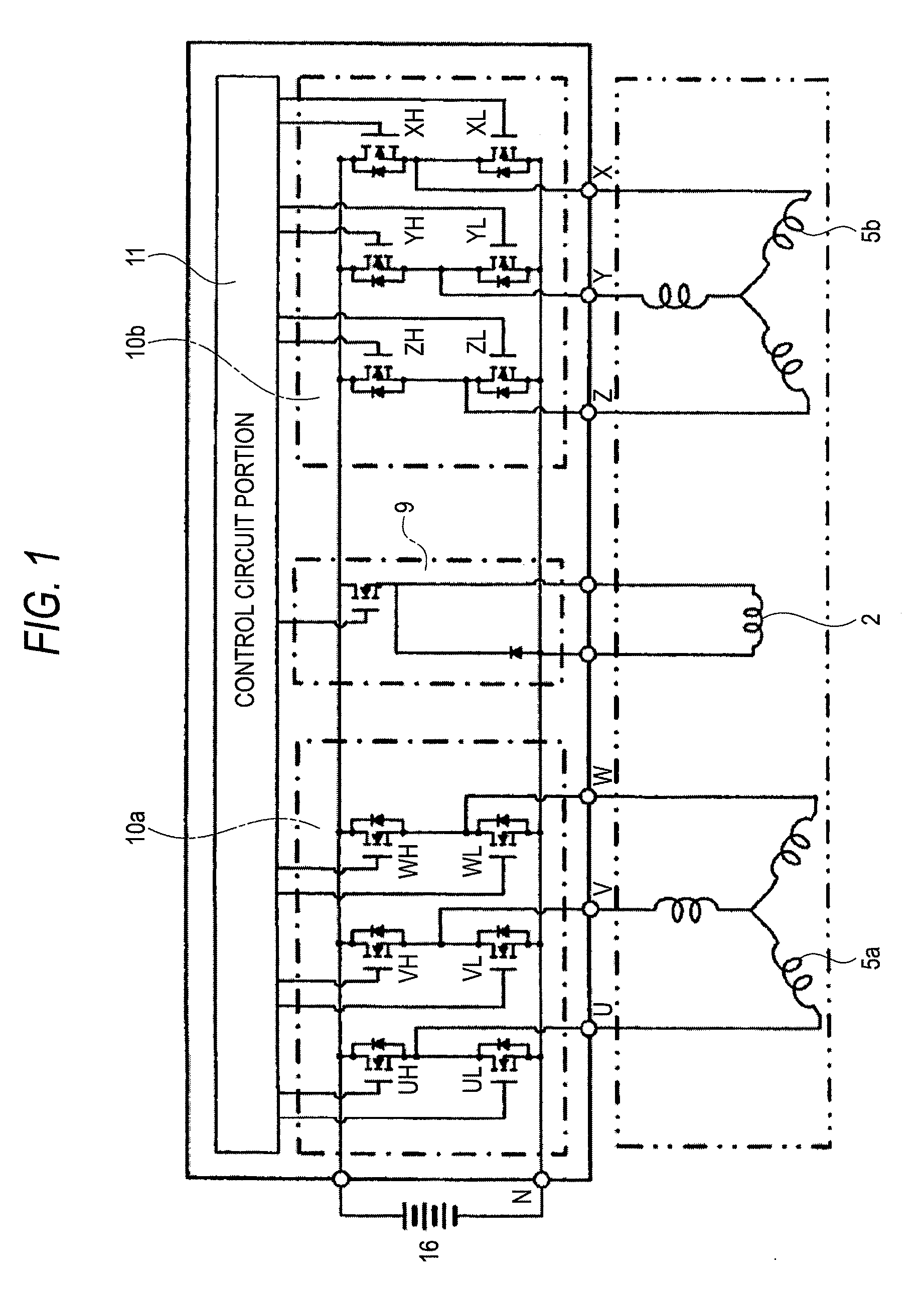

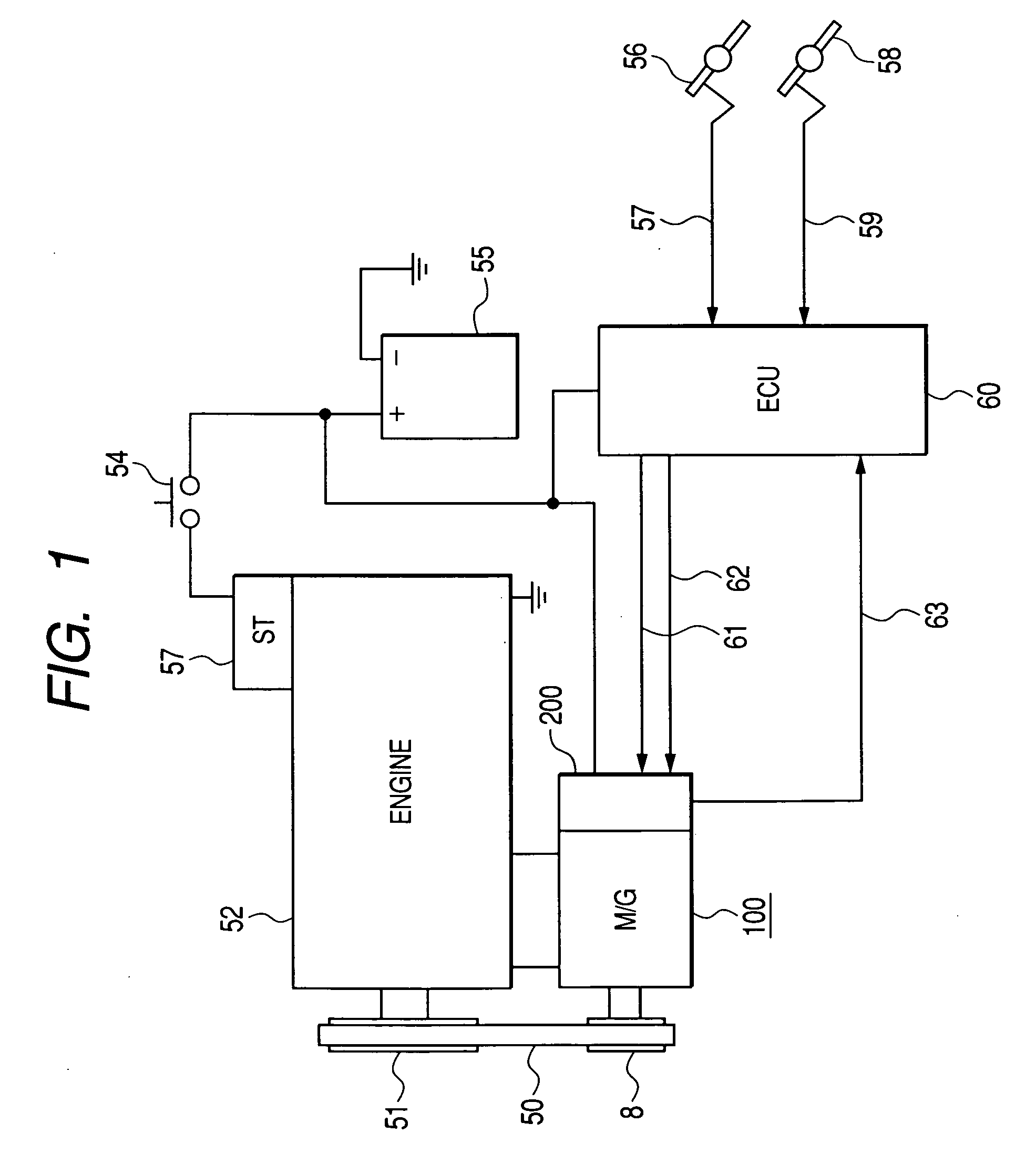

Generator motor for vehicle and control method for the same

ActiveUS20100001672A1Quick changeSingle-phase induction motor startersHybrid vehiclesEngineeringInternal combustion engine

A vehicle generator motor has a generator motor that is connected to an internal combustion engine and plural sets of three-phase windings, plural sets of inverter portions connected to the respective sets of the three-phase windings, and a control circuit portion for controlling the inverter portions in accordance with the operation state of the generator motor. When the generator motor operates as a motor and a variation value of an output torque or power generation amount thereof exceeds a predetermined value, the control circuit portion controls the inverter portions so as to stop armature current flowing in at least one set in plural sets of three-phase windings.

Owner:MITSUBISHI ELECTRIC CORP

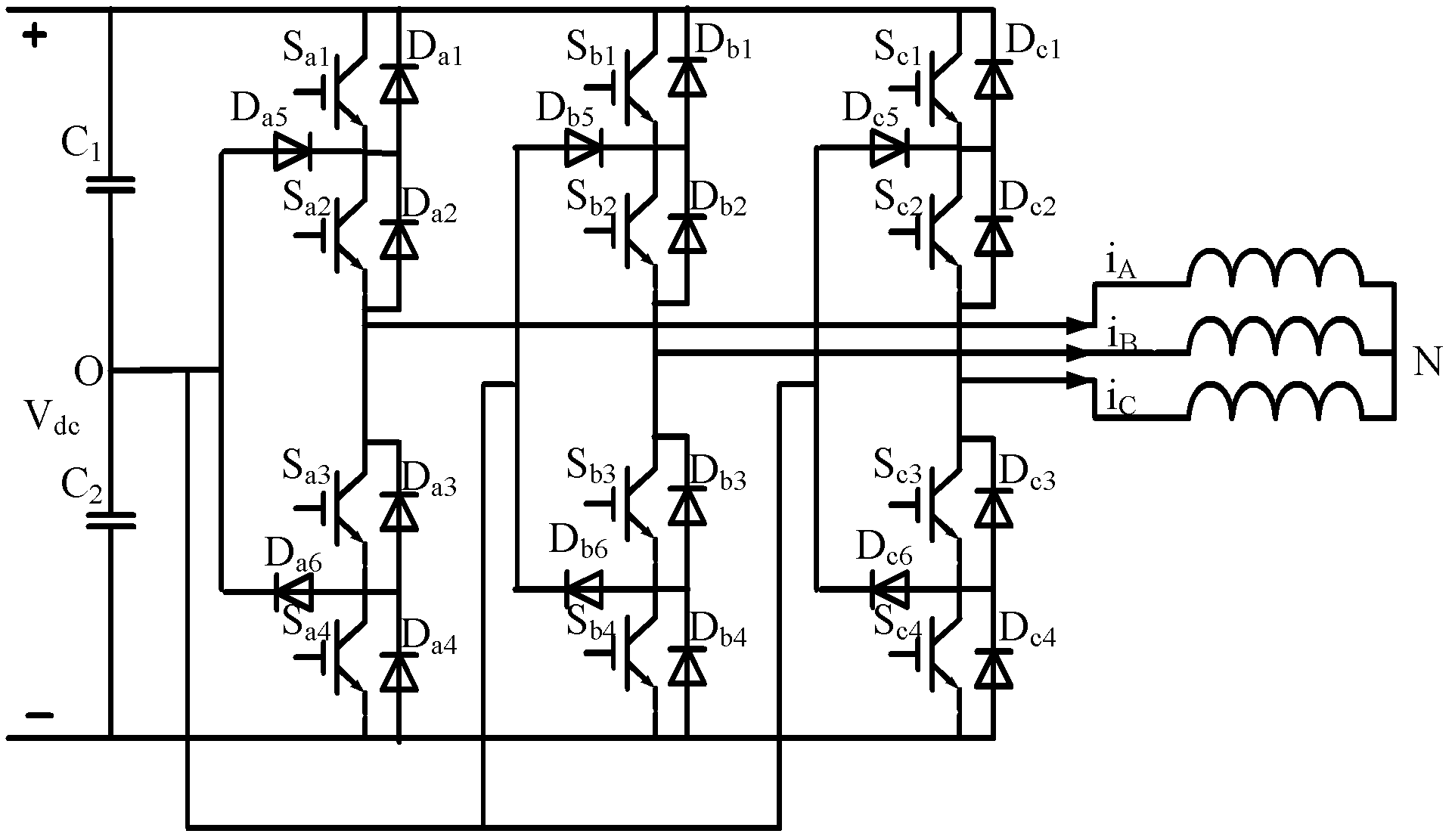

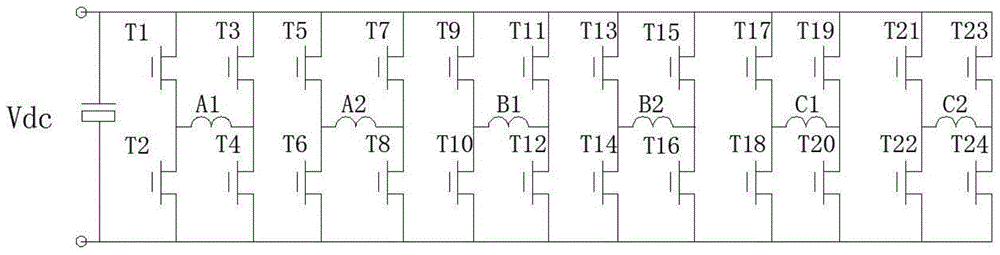

Open winding type permanent magnet motor driven reconstructed vehicle-mounted charging system for electric vehicle

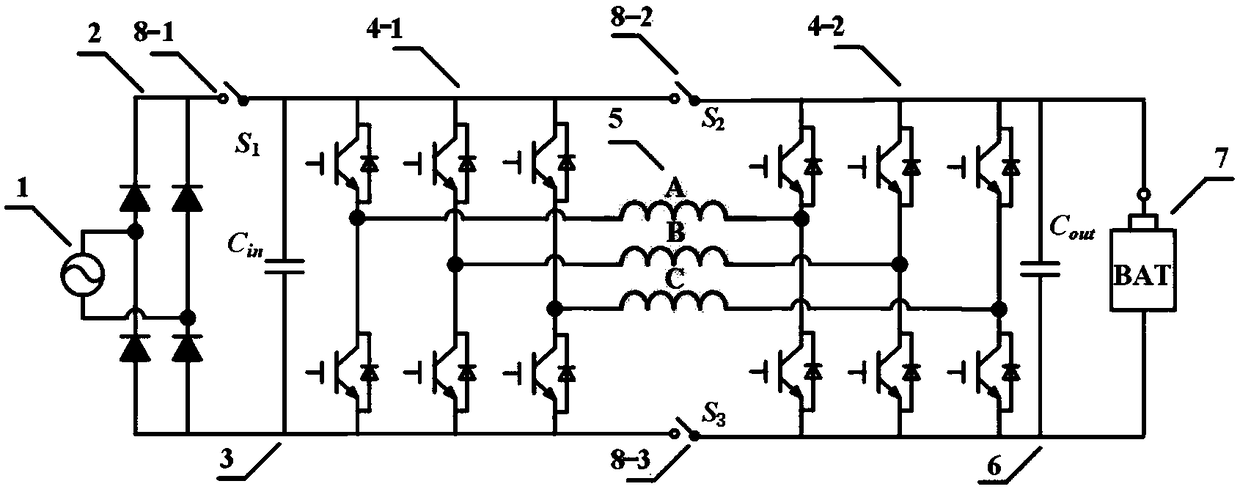

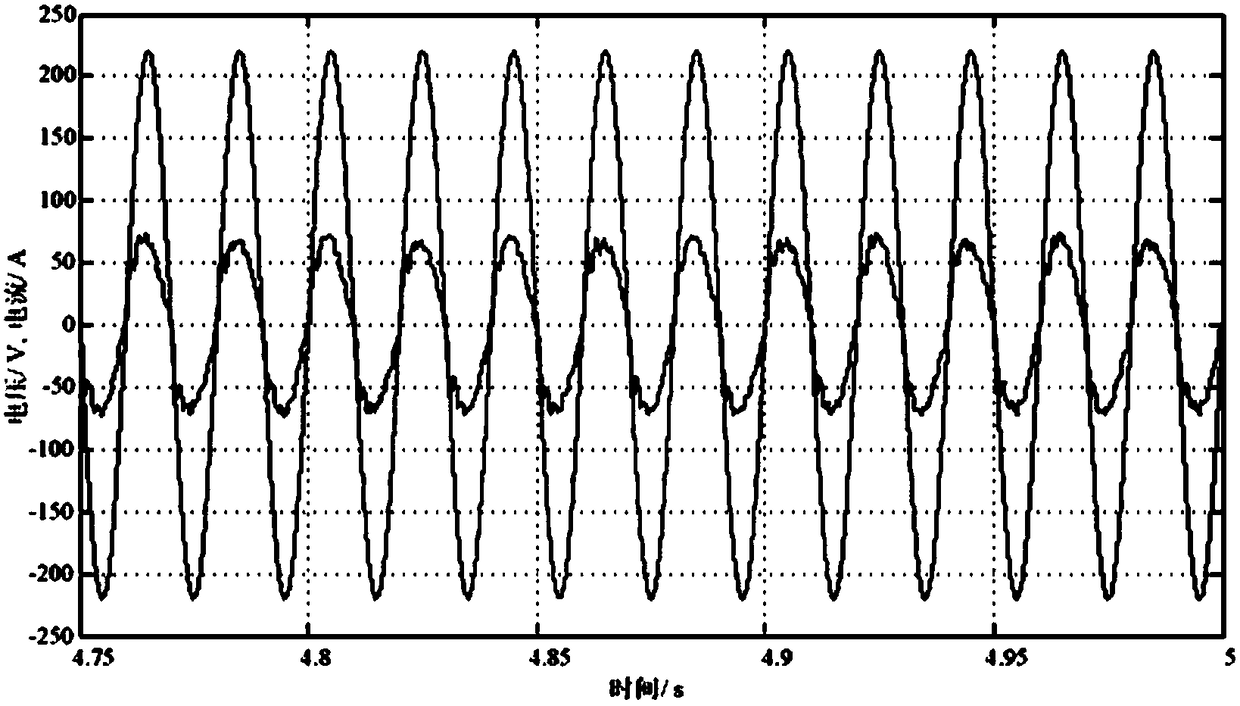

ActiveCN108539833AImprove reliabilityEliminate the effects ofBatteries circuit arrangementsAC motor controlHarmonic controlElectric vehicle

The invention relates to an open winding type permanent magnet motor driven reconstructed vehicle-mounted charging system for an electric vehicle. The system comprises a single-phase AC power supply,a rectifier bridge, an input filtering capacitor, three-phase voltage inverters, a three-phase permanent magnet motor winding, an output filtering capacitor, a storage battery and mode switches. The charging system sufficiently utilizes original double three-phase inverters, the permanent magnet motor winding, control and sensor units and the like of electric vehicles, and total integration of functions such as motor driving, high-power factor charging, harmonic control and the like is realized by optimizing topology to complete rectification, inversion and power factor correction. During charging, two three-phase voltage inverters are reconstructed into a three-phase cascading Buck-Boost circuit; the permanent magnet motor winding serves as an energy storage inductor of the three-phase cascading Buck-Boost circuit. By means of the charging system, the cost of a device can be effectively reduced and high-power factor charging can be realized.

Owner:NANTONG WELL ELECTRIC MOTOR

Novel electric vehicle drive system of integrating charger functions

ActiveCN105743175ASpace weight limitReduce torque rippleBatteries circuit arrangementsDc-dc conversionLow voltageOn board

The invention discloses a novel electric vehicle drive system of integrating charger functions. A motor driver and a charger share a power electronic conversion circuit between energy storage units, and also share a motor winding inductor, so that an electric vehicle motor driver and an on-board charger are organically integrated into a whole; and the limitation of an electric vehicle on the space weight is avoided. Double three-phase motors meet the low-voltage and high-current design requirements of electric vehicle motors, have relatively small torque ripples, meet the comfortable and smooth operating requirements of the electric vehicle, have relatively good fault tolerant capability and meet the high-reliability operating requirements of the electric vehicle. Permanent magnets NdFeB and AlNiCo are organically compounded on a rotor, so that the novel electric vehicle drive system has the advantage that the magnetic field of the permanent magnet AlNiCo is easy to adjust; the characteristic of high energy density of the permanent magnet NdFeB is reserved; the large starting torque and flux-weakening speed expansion operating requirements of the electric vehicle are met; the double three-phase windings can provide a torque current and a magnetization current respectively; and the magnetization efficiency is relatively high.

Owner:SOUTHEAST UNIV

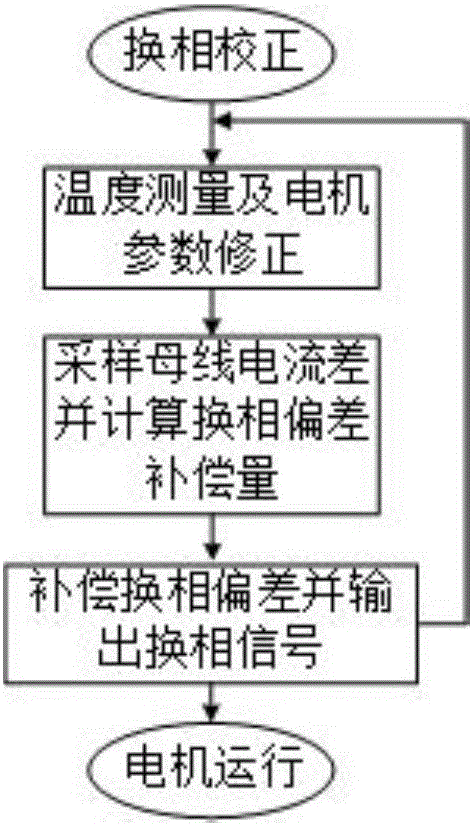

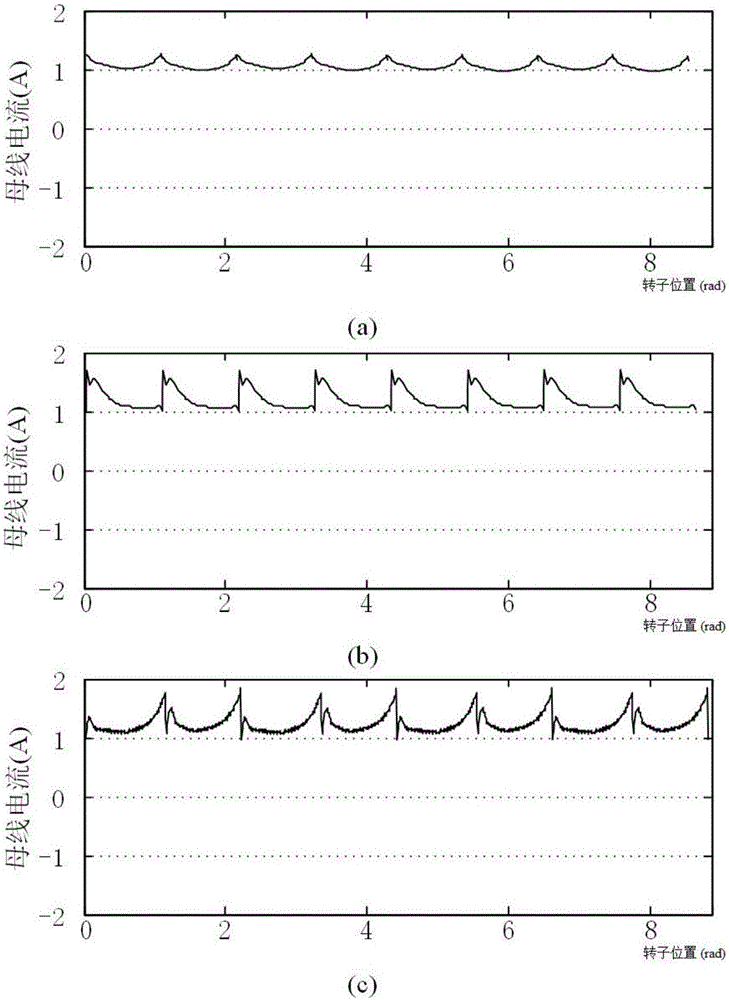

Sensorless brushless DC motor commutation deviation fast correction control system

ActiveCN106655918AShorten convergence timeAccurate calculationElectronic commutation motor controlElectric motor controlPower flowControl system

The invention relates to a sensorless brushless DC motor commutation deviation fast correction control system and a method. An analytical equation between the bus current difference before and after commutation and commutation deviation is derived according to the bus current fluctuation value before and after commutation. In view of the influence of commutation ripple and motor three-phase winding asymmetry on the accuracy of sampled current during actual bus current sampling, a method for current offset sampling in the same conduction zone is designed. The bus current difference is obtained according to the designed current sampling method, the commutation deviation is calculated based on the analytical equation, and the commutation signal is compensated and corrected in real time. By designing the sensorless motor commutation deviation fast correction control system, the commutation deviation convergence time is reduced greatly, and the commutation precision is improved.

Owner:BEIHANG UNIV

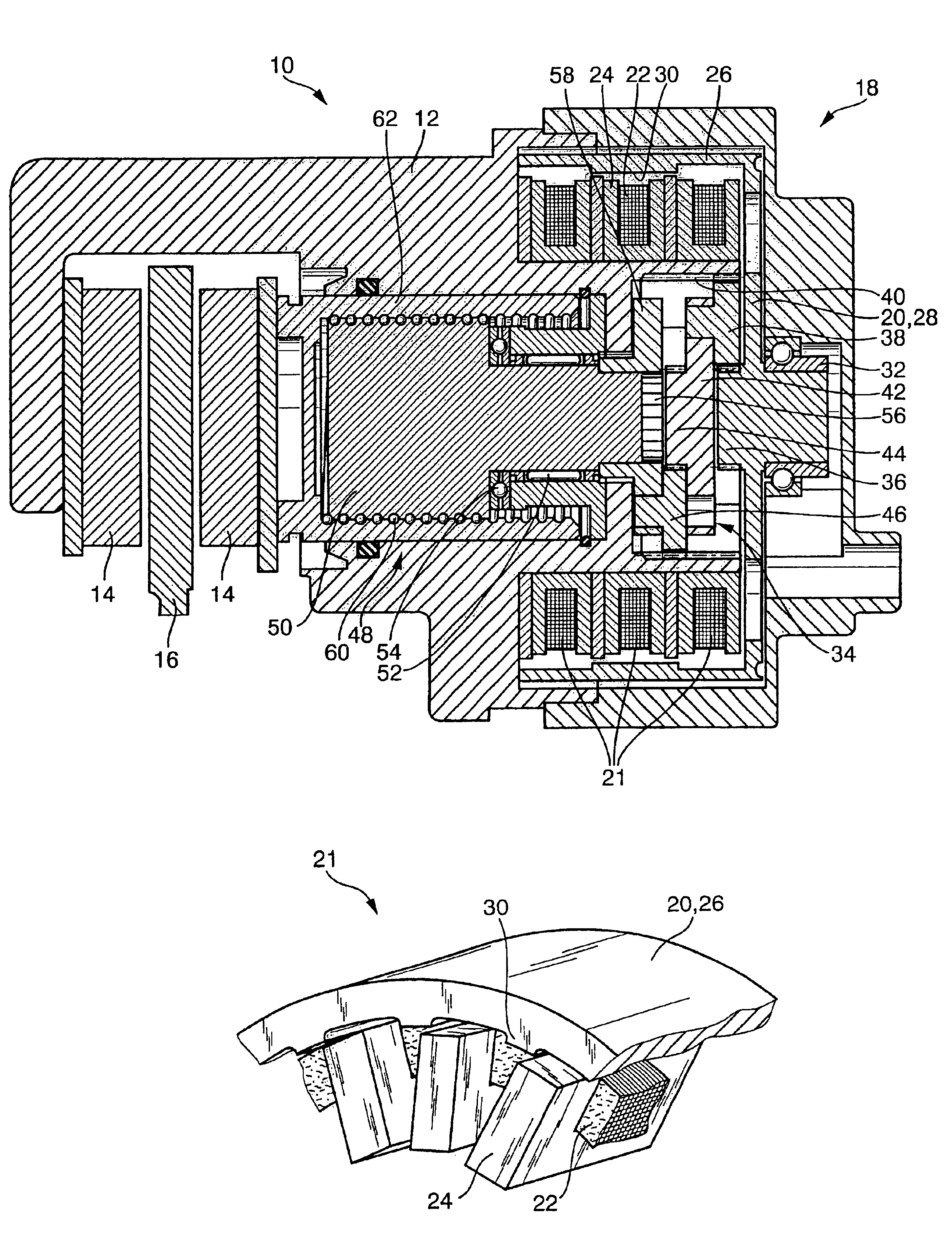

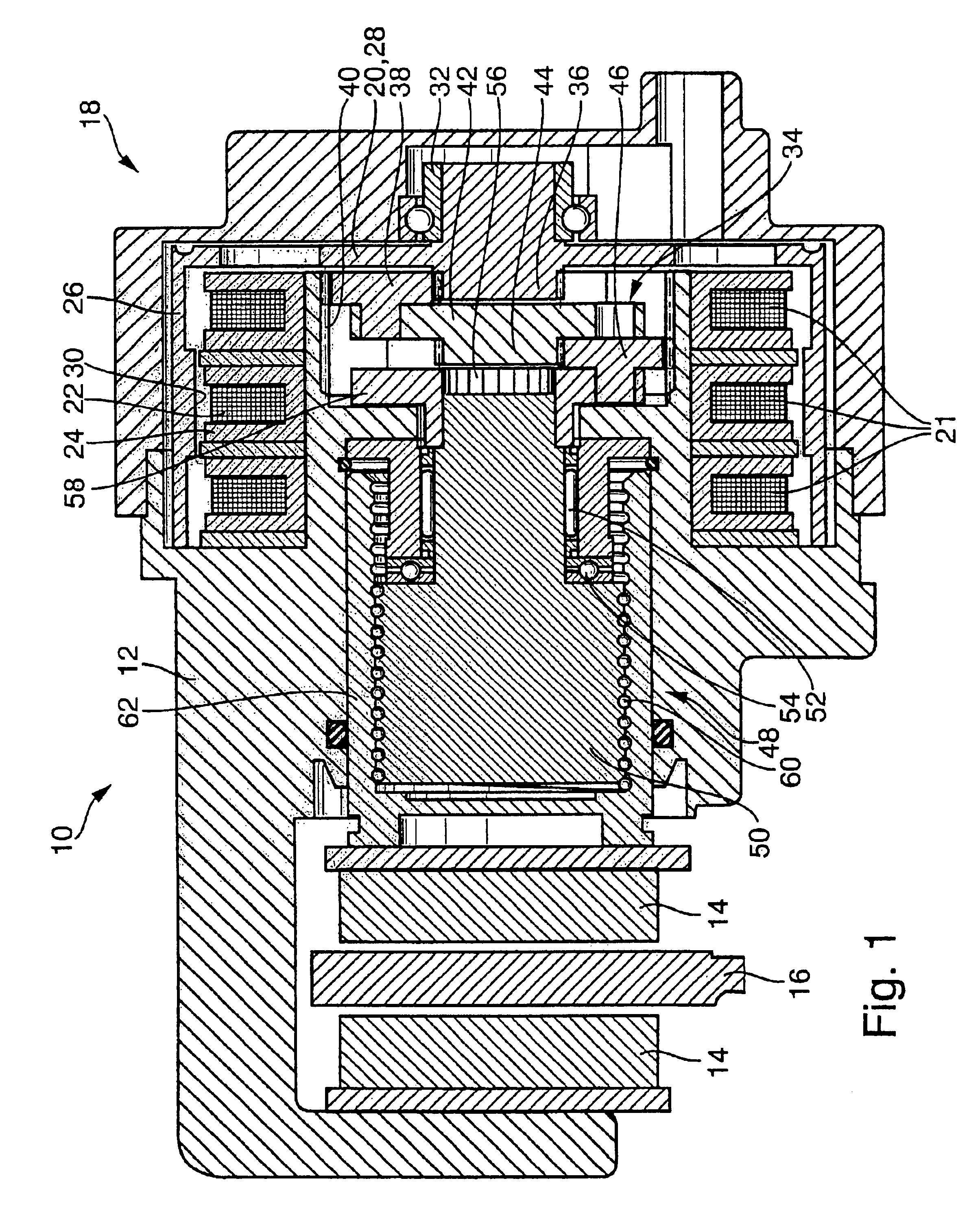

Electromechanical wheel brake device

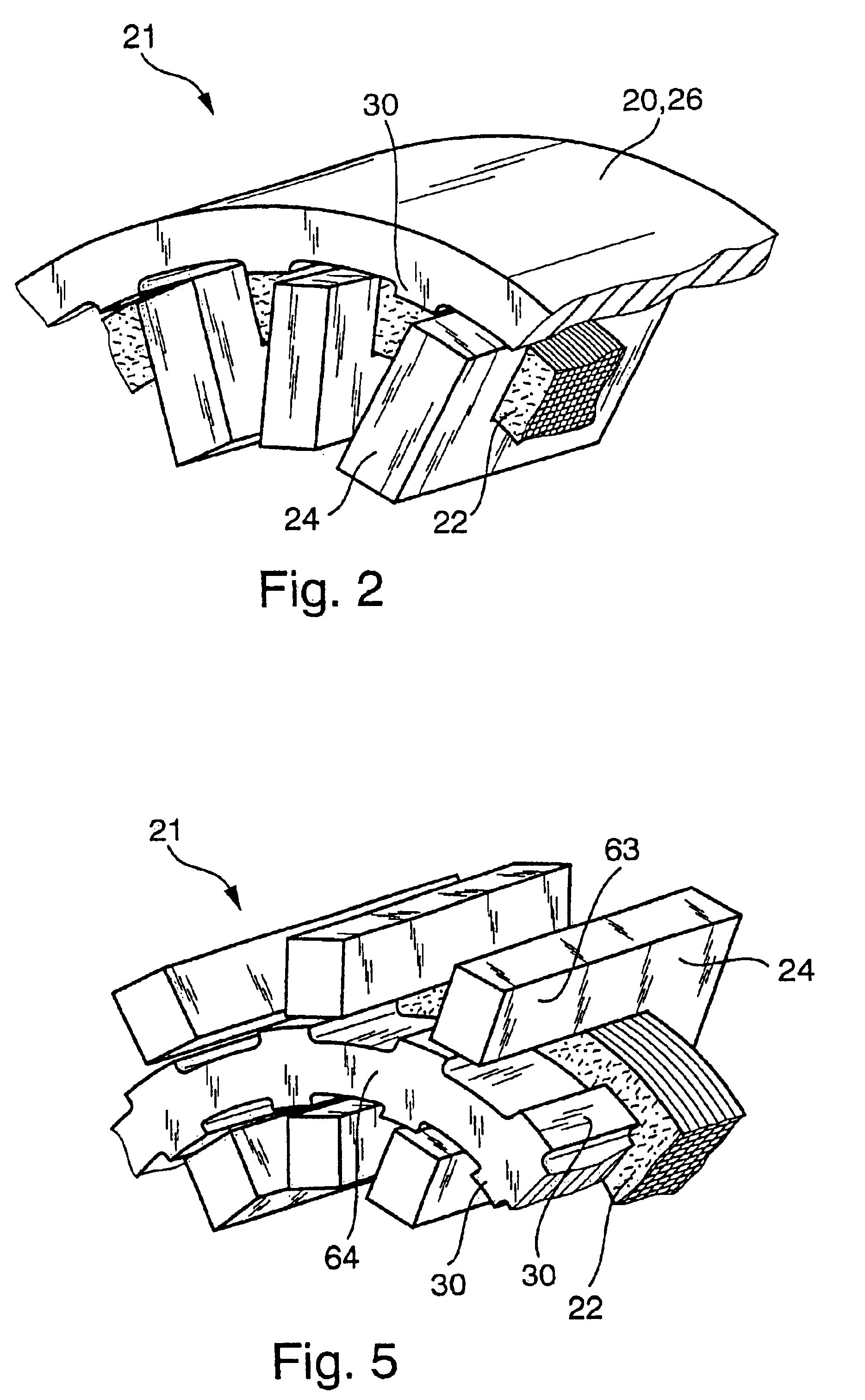

InactiveUS6806602B2Improve power densityInterrupt supplyDynamo-electric brakes/clutchesBraking action transmissionTransverse fluxBall screw

The invention relates to an electromechanical wheel brake device, with an electric motor that can press a frictional brake lining against a brake body (brake disk) by a reduction gear (planetary gear) and a rotation / translation conversion gear (ball screw). The invention proposes embodying the electric motor as a transverse flux motor with three phase windings; each phrase winding has a circular, annular excitation winding that is disposed inside U-shaped yokes, which are distributed over the circumference of the excitation winding. This embodiment of the electric motor permits a compact design of the electric motor in an annular, hollow shaft design so that the reduction gear and the rotation / translation conversion gear can be disposed at least partially inside the electric motor.

Owner:ROBERT BOSCH GMBH

Wound rotor brushless double fed motor

ActiveCN101510702AFlexible change of spanSuppresses higher harmonicsAsynchronous induction motorsWindings conductor shape/form/constructionHarmonicAlternating current

The invention discloses a brushless doubly-fed motor of a wound rotor, pertaining to the technical field of motors. In an AC (alternating current) brushless doubly-fed motor of the invention, two sets of three-phase windings with respective numbers of pole pairs as P1 and p2 are arranged on a stator; a rotor adopts a multi-phase winding and a phase number m meets the relational expression: m= (P1 + p2) / mk, wherein, when P1+ p2 is an odd number, mk is equal to 1; when P1 + p2 is an even number, and mk is equal to 2 and rotor slots are uniformly distributed along the circumference of an air gap. Number of rotor slots Z' meets the relational expression: Z'=n (P1 + p2), wherein, n is a positive number; coils of rotor winding are multi-turn structures; the coil number of each phase winding is nmk; the span of each coil is equal but the specific value of turn number between the coils is different; and when the number of coils of the phase windings is less than or equal to nmk, all coils in phase windings are coupled when in short circuit after being series-connected. The brushless doubly-fed motor has the advantages that the span of winding coil can be flexibly changed and the turn number of each coil can be different, thereby realizing the purpose of maximally reducing the higher harmonic.

Owner:WUHAN YANGHUA ELECTRIC CO LTD

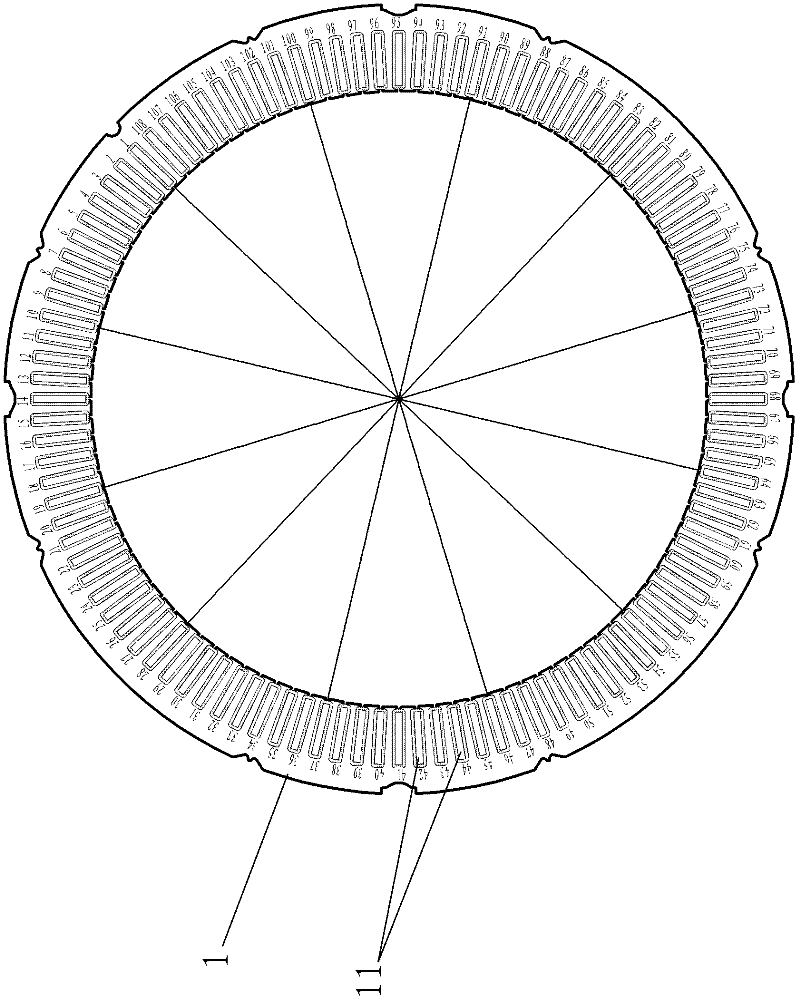

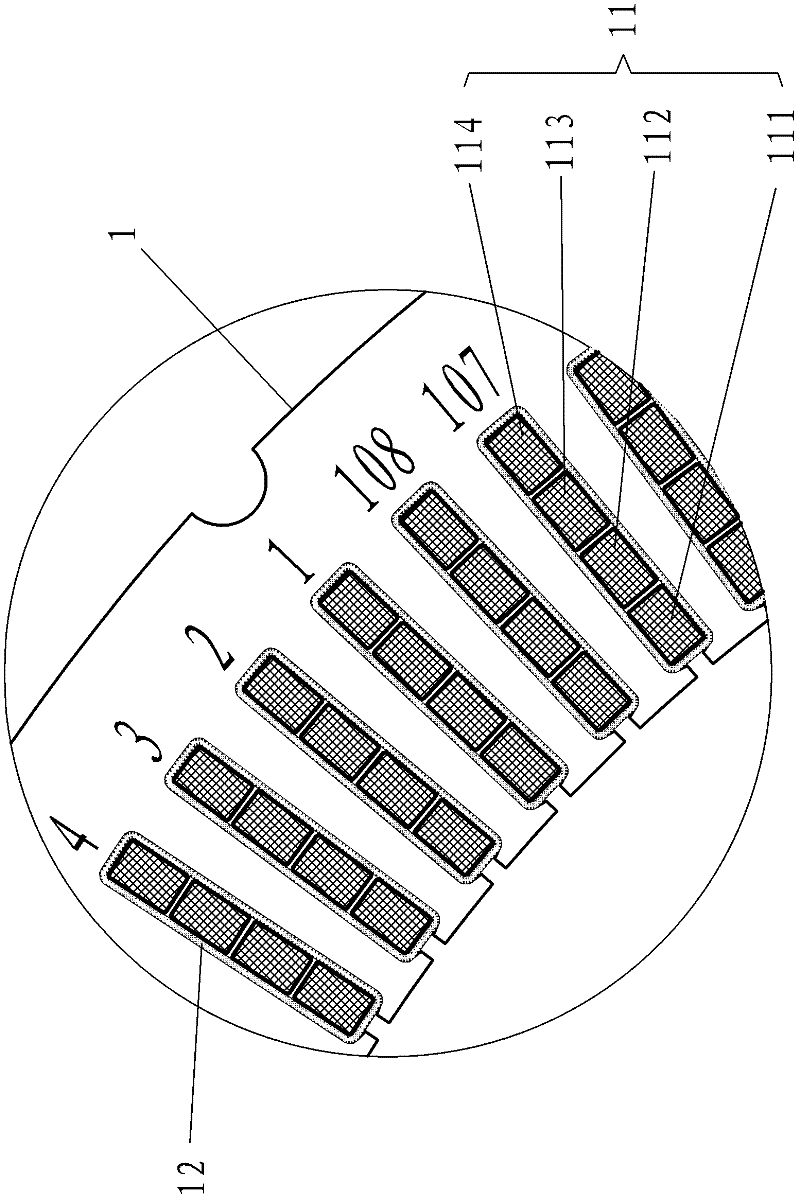

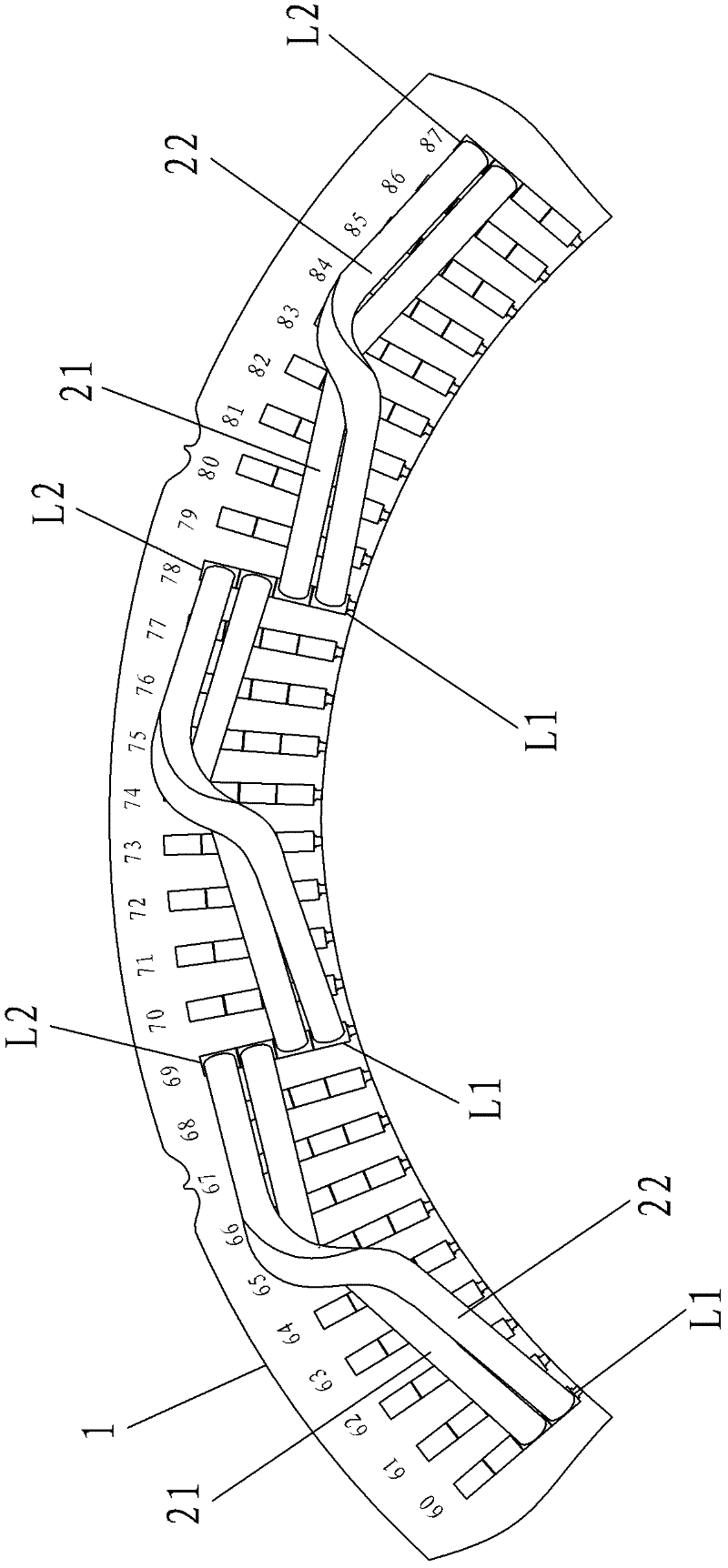

Stator of alternating-current generator and winding method thereof

ActiveCN102412638AIncrease slot fill rateIncrease output powerMagnetic circuit stationary partsManufacturing dynamo-electric machinesStator coilMagnetic poles

The invention discloses a stator of an alternating-current generator and a winding method thereof. The stator comprises an iron core and a stator winding wound on the iron core, wherein 108 rectangular grooves are formed on the iron core at equal intervals; groove insulating paper which is matched with each rectangular groove is paved in the rectangular groove along the wall of the rectangular groove; the rectangular grooves are distributed in four layers according to inner stator coils, including an inner upper layer, an inner lower layer, an outer lower layer and an outer upper layer in sequence from inside to outside along the radial direction of the iron core; the stator winding is a three-phase winding; the number P of magnetic pole pairs is equal to 6; the quantity q of grooves on each phase at each pole is equal to 3; the coil of each phase can be partitioned into three coil groups; and the stator coil of each phase comprises thirty-three upper coils, thirty-three lower coils, three middle spanning coils, two connection spanning coils and two winding outgoing lines. According to the invention, the problem of conflict between the generator size and the generating amount in the prior art is solved; and the stator has the characteristics of compact structure and high output power, and is suitable for other generators needing high power such as automobiles and the like.

Owner:FUJIAN YIDA ELECTRIC DRIVE CO LTD

Driving/electric-power generating system for vehicle

InactiveUS20060006655A1Reduce heatImprove driving efficiencyDc network circuit arrangementsBatteries circuit arrangementsConductor CoilElectric power

An AC generator comprises a rotor and a stator having a three-phase winding. A three-phase inverter is connected to the three-phase winding. Here, the three-phase winding comprises at least two independent three-phase windings. Switching elements for respective phases of the three-phase inverter are connected in parallel by the number of the independent three-phase windings, and in-phase windings are individually connected to their parallel switching elements.

Owner:HITACHI LTD

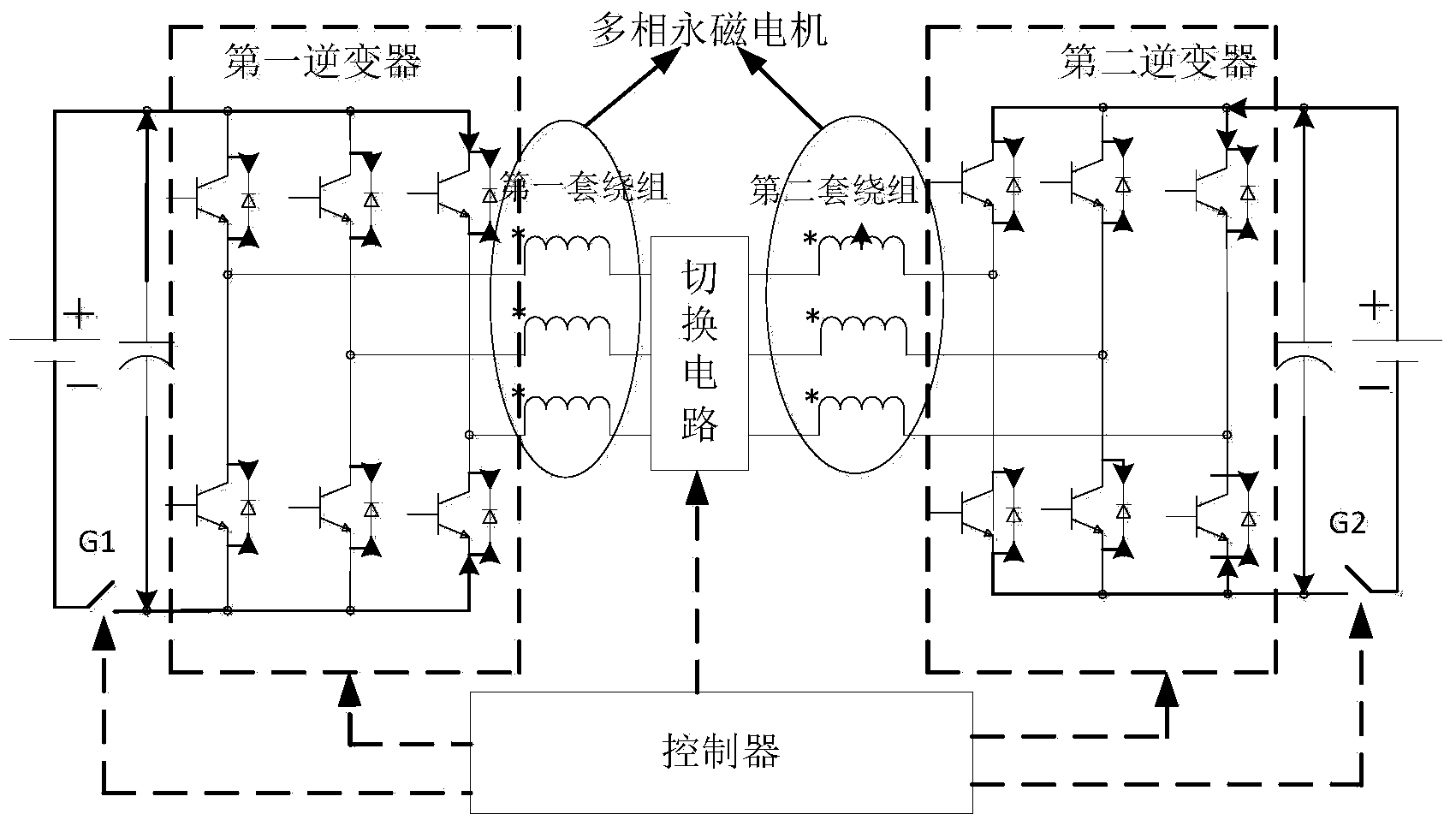

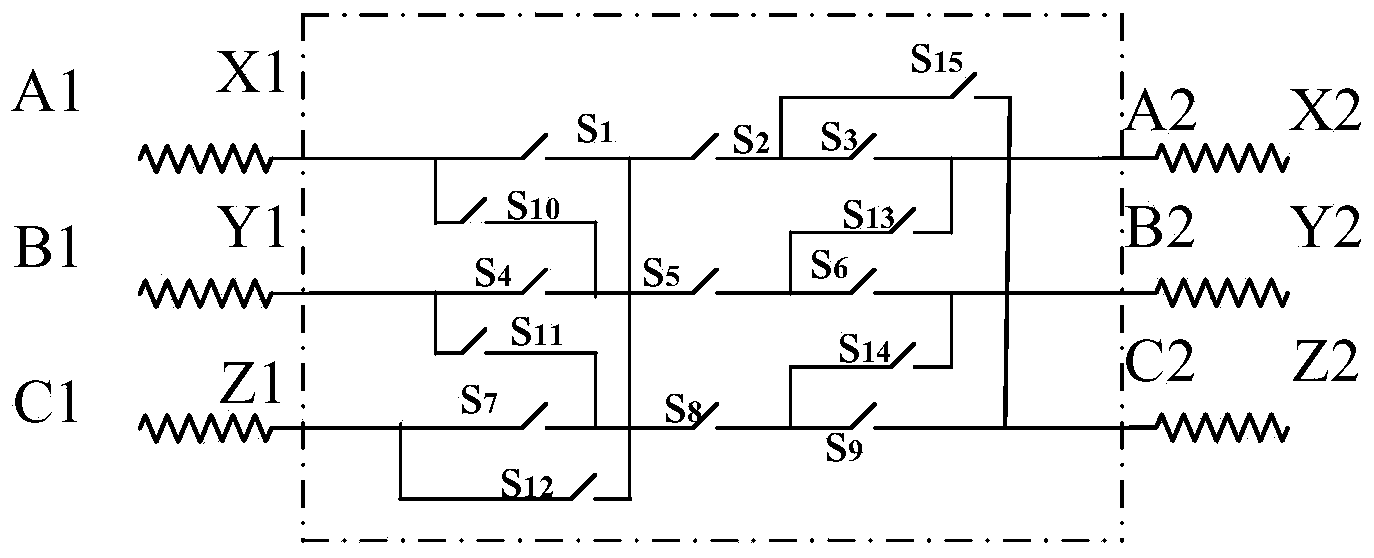

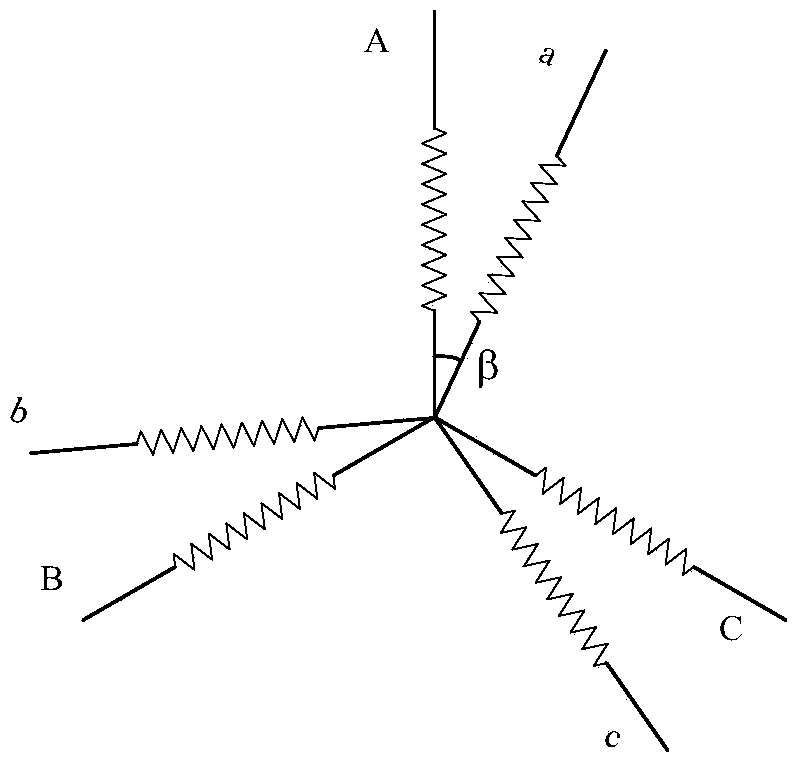

Multiphase permanent magnet motor speed regulating system based on phase switching and speed regulating method thereof

InactiveCN104167975AReduce back EMFAvoid the risk of demagnetizationAC motor controlPermanent magnet motorConductor Coil

The invention discloses a multiphase permanent magnet motor speed regulating system based on phase switching and a speed regulating method thereof. The multiphase permanent magnet motor speed regulating system comprises a first inverter, a second inverter, a change-over circuit, a first circuit breaker, a second circuit breaker and a multiphase permanent magnet motor. The multiphase permanent magnet motor is of a structure including two three-phase windings. The three-phase output end of the first inverter is respectively connected with the three-phase positive end of the first winding of the motor, the three-phase negative end of the first winding is respectively connected with the three-phase positive end of the second winding of the motor, and the three-phase negative end of the second winding is respectively connected with the three-phase output end of the second inverter. The first inverter and the second inverter are respectively powered on by two independent direct current power supplies, the first circuit breaker and the second circuit breaker are respectively arranged at the low potential ends of direct current buses of the first inverter and the second inverter. The change-over circuit is used for adjusting connecting modes of the first winding and the second winding so as to adjust counter potential of the motor. The multiphase permanent magnet motor speed regulating system can widen a speed regulating range and improve speed regulating flexibility of the permanent magnet motor and the error-tolerant rate.

Owner:HUAZHONG UNIV OF SCI & TECH

Parameter off-line identifying method and device of three-phase asynchronous motor

ActiveCN102594253ASmall inaccuracyImprove accuracyElectronic commutation motor controlAC motor controlThree phase asynchronous motorOmega

The invention discloses a parameter off-line identifying method of a three-phase asynchronous motor. Through the current output by an inverter, the connecting method of the three-phase winding of a motor is equivalent to the terminal current of a phase winding, which is detected by a sensor when any two phase windings are connected in parallel and then are connected with the other phase winding in series every time, thereby obtaining the direct voltage and the direct current or the alternating current voltage and the alternating current of the motor winding; the impedance of reverse gamma equivalent circuit of the motor is calculated by the alternating voltage and the alternating current, and then the equivalent rotor resistance, the total leakage inductance and the equivalent mutual induction parameter of the motor are calculated by two impedances under the condition of different frequencies omega 1 and omega 2. The method disclosed in the invention can indentify the motor parameter without the rotation of the motor, thereby avoiding the empty load test required in the process of identifying parameters in prior arts, enlarging the application scope of indentifying the motor parameter and improving the accuracy of the identified motor parameters. The method and the device of the invention are applicable to the motor parameter off-line identification of a three-phase asynchronous motor speed control system controlled by an inverter.

Owner:CHANGZHOU LIANLI AUTOMATION TECH +1

Duplex winding asynchronous motor

InactiveCN101136572AReduced structureLow costMotor control for low load efficiencyAsynchronous induction motorsCapacitanceConductor Coil

This invention relates to a double-winding asynchronous motor including a stator and a rotor, in which, a master winding and a sub-winding are set in the stator, the three-phase windings of the master one and the sub-one are two sets of stator windings arrayed in single-layer, coil elements contained in them are same, and the windings in a same phase of them are arrayed in 180deg. or 360deg. potential phase angle and the three-phase windings of the main one form a triangle, branches formed by windings of the sub-winding serial with a 2-way thyristor and a capacitor are parallel at both ends of windings of a selected phase of the master one.

Owner:TAIYUAN UNIV OF TECH

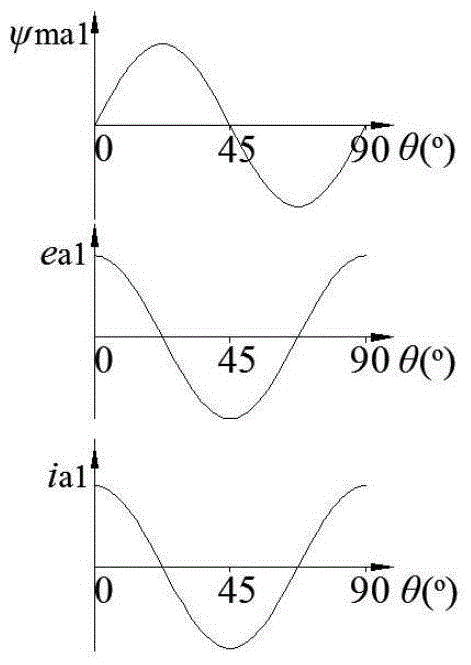

Method for testing parameters of synchronous motor and device for achieving same

ActiveCN101603997AAvoid influenceSimple structureCurrent/voltage measurementWork measurementSynchronous motorElectric machine

The invention provides a method for testing parameters of a synchronous motor and a device for achieving the same, which relate to the field of motor tests. The method and the device solve the problems of low testing accuracy of quadrature and direct axis inductance parameters, complex method for testing moment coefficient, and strong dependency on driver performance in the prior method. The method comprises the following steps: energizing any two phases in three phases of windings of a tested synchronous motor with single-phase alternating current (square root 2I sin omega t), driving a rotor of the tested synchronous motor with an external force to rotate at a uniform speed for at least one revolution, testing voltage signals at two ends of the energized windings, and obtaining the quadrature axis and direct axis inductances of Lq and Ld respectively of the tested synchronous motor according to the voltage signals; and energizing any two phases of the three phases of the windings of the tested synchronous motor with direct current I1, driving the motor of the tested synchronous motor with the external force to rotate at a uniform speed for at least one revolution, and calculating the moment coefficient KT of the tested synchronous motor according to the tested maximum moment value Tmax1. The method and the device are applied to the field of testing the parameters of the synchronous motor.

Owner:HARBIN INST OF TECH

Commutation torque ripple suppression method for permanent magnet brushless DC motor

InactiveCN102163947AImplement controlCommutation Torque Ripple SuppressionTorque ripple controlControl signalElectric machine

The invention belongs to the technical field of motor control, and relates to a commutation torque ripple suppression method for a permanent magnet brushless DC motor. The method comprises the following steps of: detecting a rising edge or falling edge of a Hall signal, starting commutation, and executing the commutation torque ripple suppression method; acquiring a non-commutation current sampling value and a motor running speed at a current moment; calculating back electromotive forces of phases of a three-phase winding at the next moment according to the motor running speed and a commutation mode respectively; obtaining the voltages to power earth of end points of the three-phase winding in different inverter circuit switching-on states at the next moment respectively; predicting predicted values of non-commutation current in the different inverter circuit switching-on states at the next moment respectively; performing estimation on the predicted values of the non-commutation current in the different inverter circuit switching-on states by utilizing a value function; selecting the inverter circuit switching-on state in which the value function has the smallest value as the inverter circuit switching-on state of the next moment, and generating a corresponding inverter circuit control signal; and detecting the current of a corresponding switched-off phase is reduced to zero, finishing the commutation process, and stopping the commutation torque ripple suppression method. By the method, the commutation process can be accurately determined, and control over the inverter circuit switching-on state can be realized relatively better at the moment of commutation to realize commutation torque ripple suppression.

Owner:TIANJIN UNIV

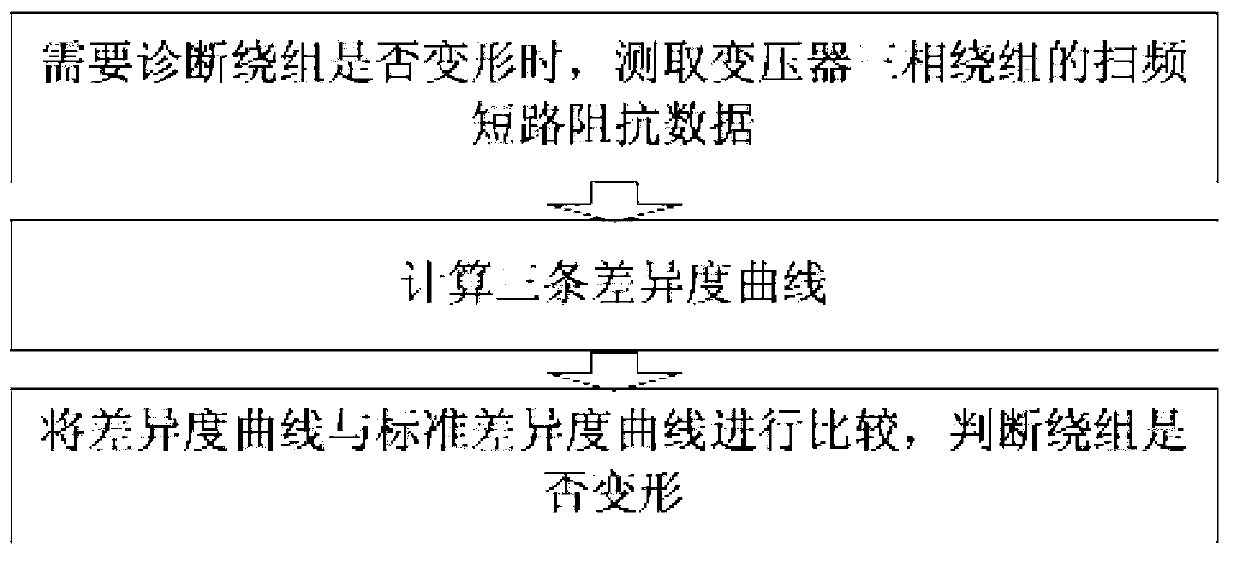

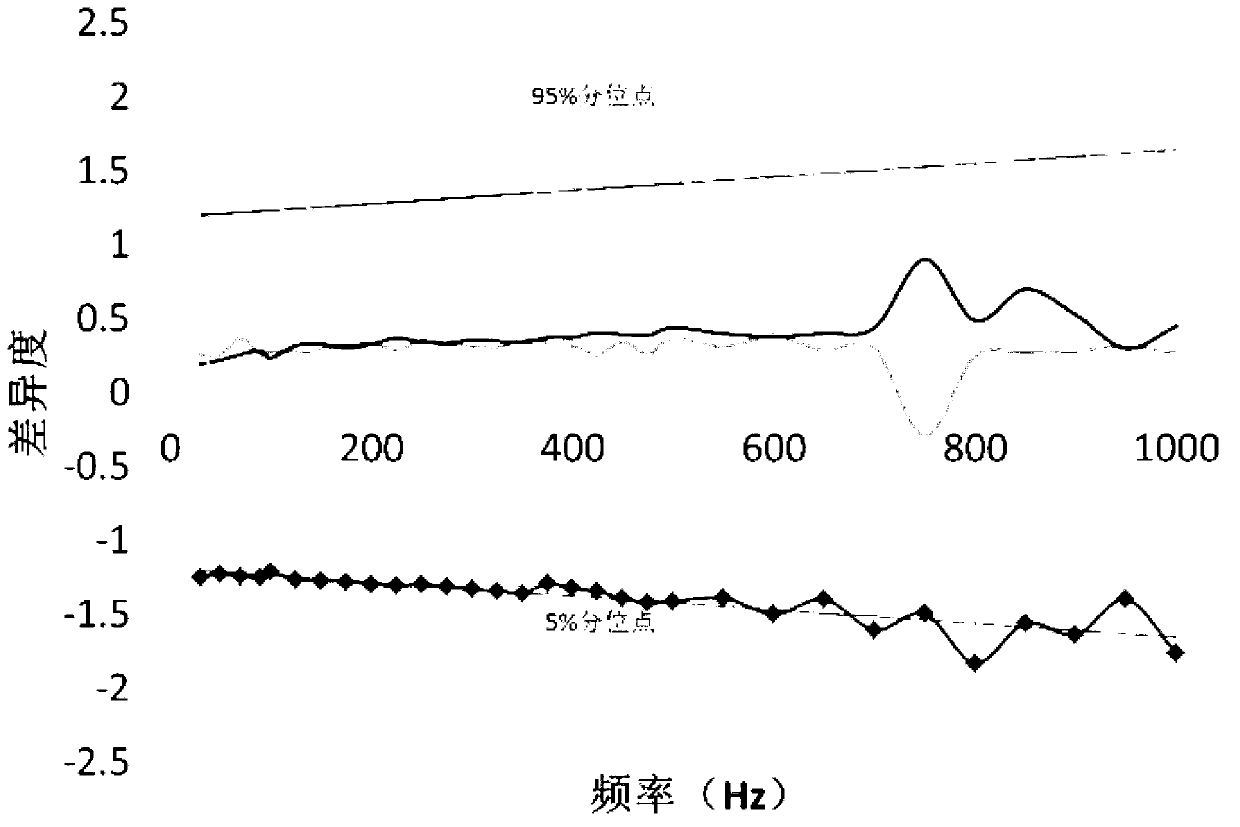

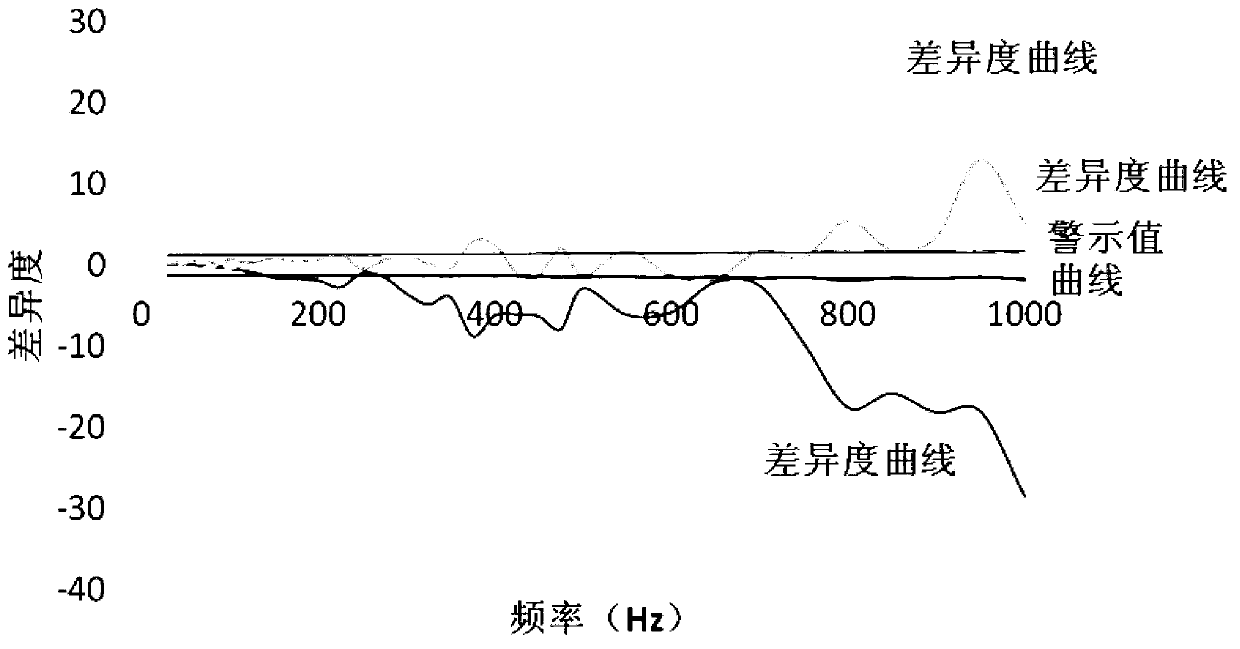

Transformer winding deformation fault diagnosis method based on frequency sweep short circuit characteristics

ActiveCN102997838AWith quantifiable judgmentAccurate judgmentElectrical/magnetic solid deformation measurementDBcDiagnosis methods

The invention relates to a transformer winding deformation fault diagnosis method based on frequency sweep short circuit characteristics. The transformer winding deformation fault diagnosis method comprises the following steps: 1) measuring frequency sweep short circuit impedance data of a transformer three-phase winding through a testing device under the power failure state of a transformer; 2) obtaining three diversity factor curves of the frequency sweep short circuit impedance data of the three-phase winding measured in step 1); 3) comparing three diversity factor curves DAB, DBC and DCA calculated from step 2) with standard diversity factor curves, diagnosing that the winding has slightly deformation when any one diversity factor curve exceeds attention value curves of the standard diversity factor curves; otherwise diagnosing that the winding has no deformation; and if the diversity factor curves exceed alarm value curves of the standard diversity factor curves, diagnosing that the winding has obvious deformation. The transformer winding deformation fault diagnosis method is accurate and sensitive to diagnose, easy to implement, and strong in field maneuverability and can be widely applied to fault diagnosis of transformer winding.

Owner:CHINA ELECTRIC POWER RES INST

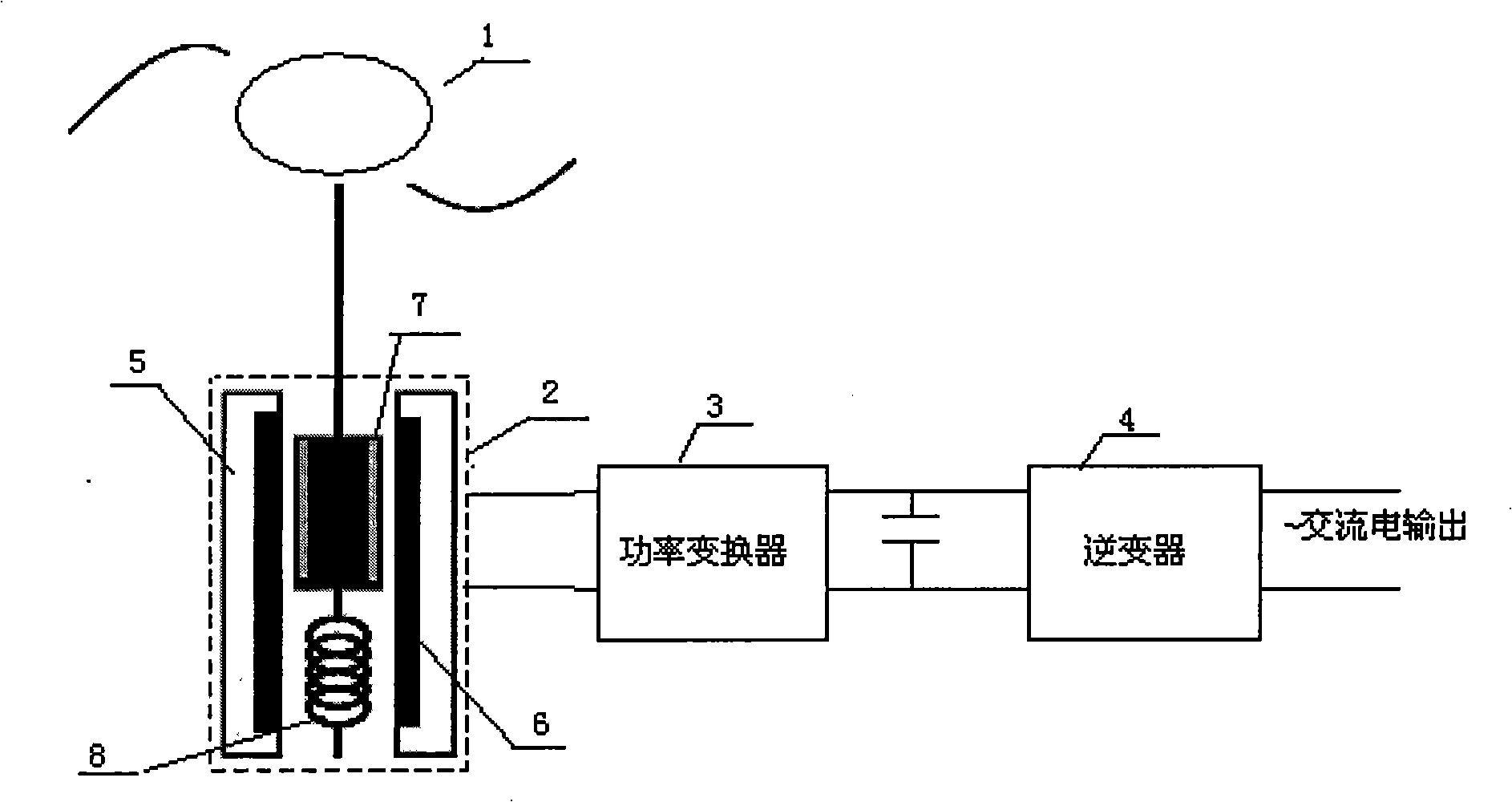

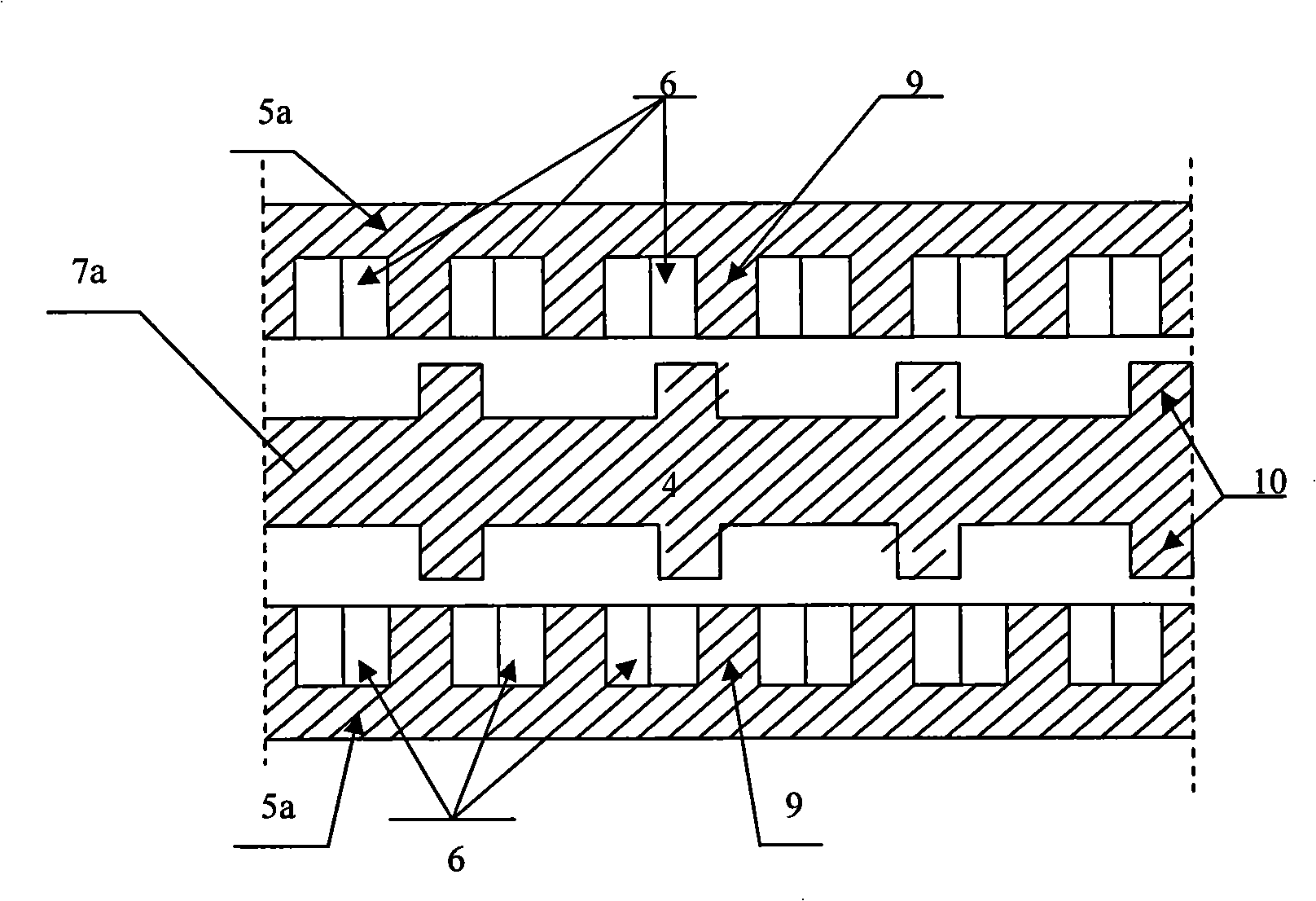

Wave straightly-drive type straight-line magneto resistance power generation system

InactiveCN101355284ASolve the problem of low secondary energy conversion efficiencyAvoid corrosionElectronic commutation motor controlMagnetic circuit rotating partsEngineeringElectric generator

The invention discloses a wave direct-drive linear reluctance generator system which comprises a generator, a power inverter, and an inverter, wherein the output of a primary three-phase winding of the generator is connected with the input of the power inverter, the output of the power inverter is connected with the inverter, and the output of the inverter is connected with a power grid or a use load. The system is characterized in that the generator is a direct-drive linear switched reluctance generator which comprises a primary iron core embedded with a three-phase winding and a secondary mover which is arranged in the primary iron core and is provided with tooth grooves, the primary iron core and the secondary mover are formed by overlapping silicon sheets, the lower end of the secondary mover is fixed on a generator base through an elastic component, and the upper end of the secondary mover is elastically connected with a wave energy absorbing device. The system replaces a permanent-magnet synchronous linear motor with the linear switched reluctance generator, which saves a secondary energy conversion device, can simplify the structure and the volume of the generator system, improve the efficiency of wave energy power generation, and also avoid problems of corrosion and excitation loss of permanent magnets and so on.

Owner:XI AN JIAOTONG UNIV

Series-coupled two-motor drive using double-ended inverter system

Owner:GM GLOBAL TECH OPERATIONS LLC

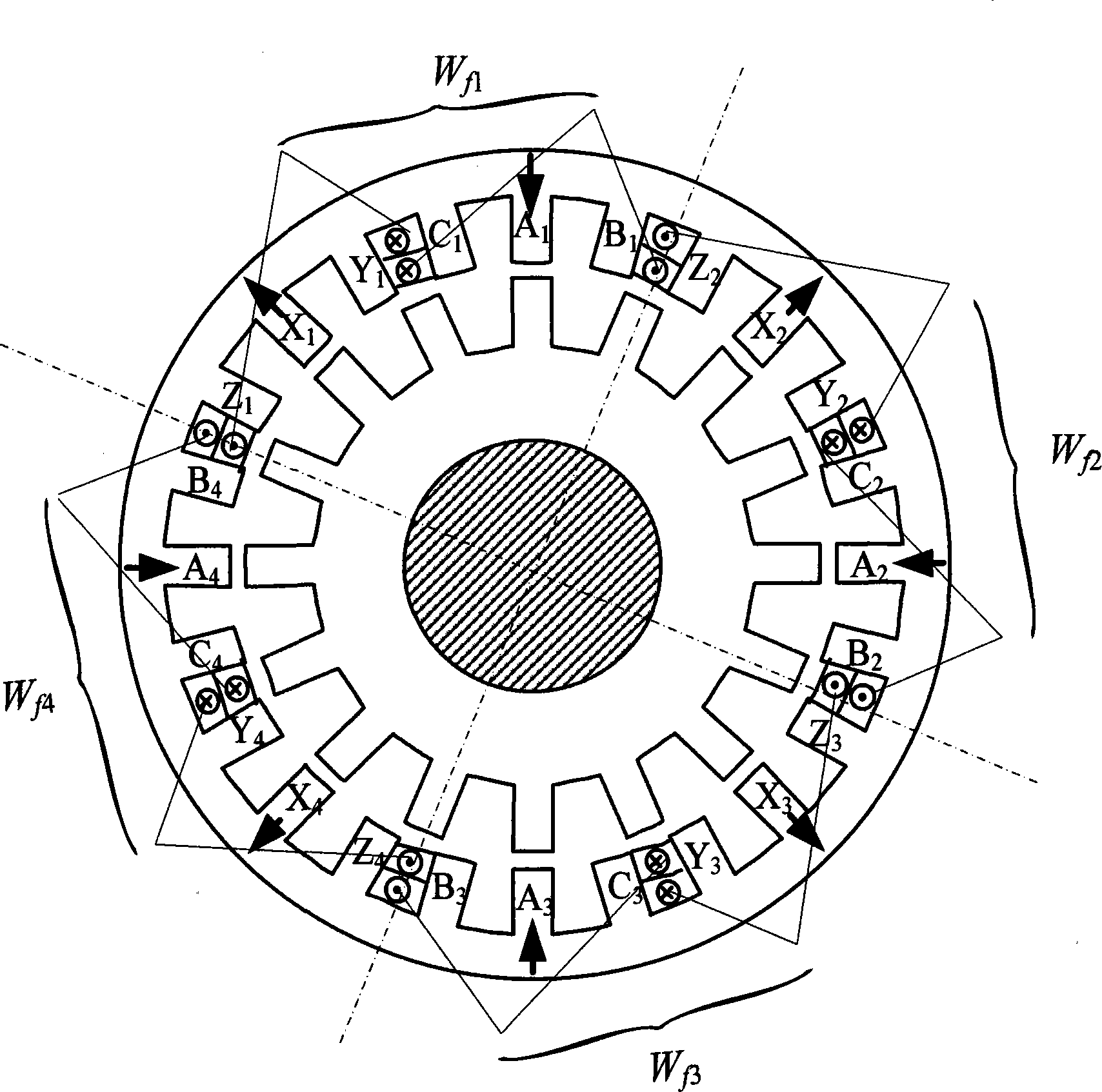

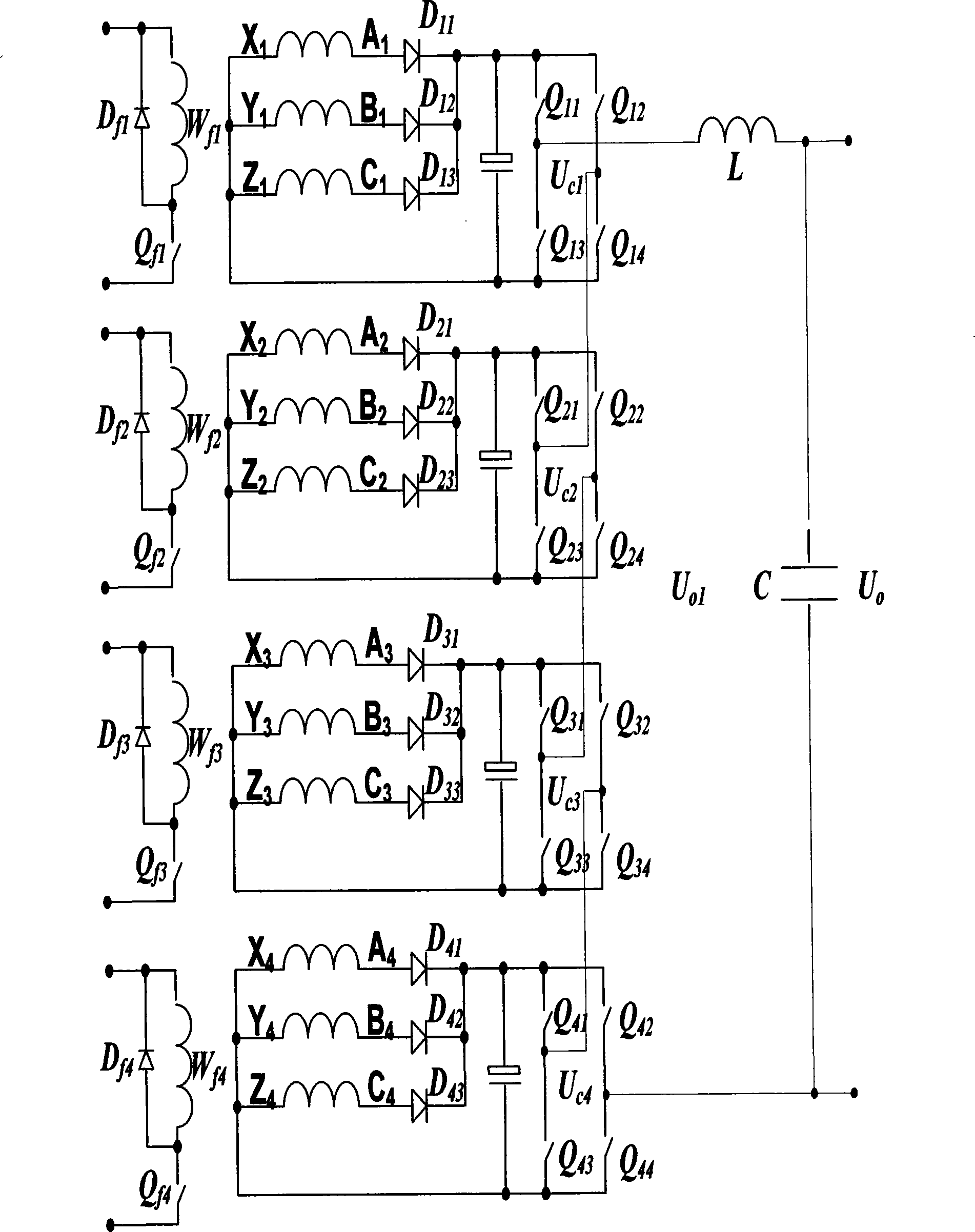

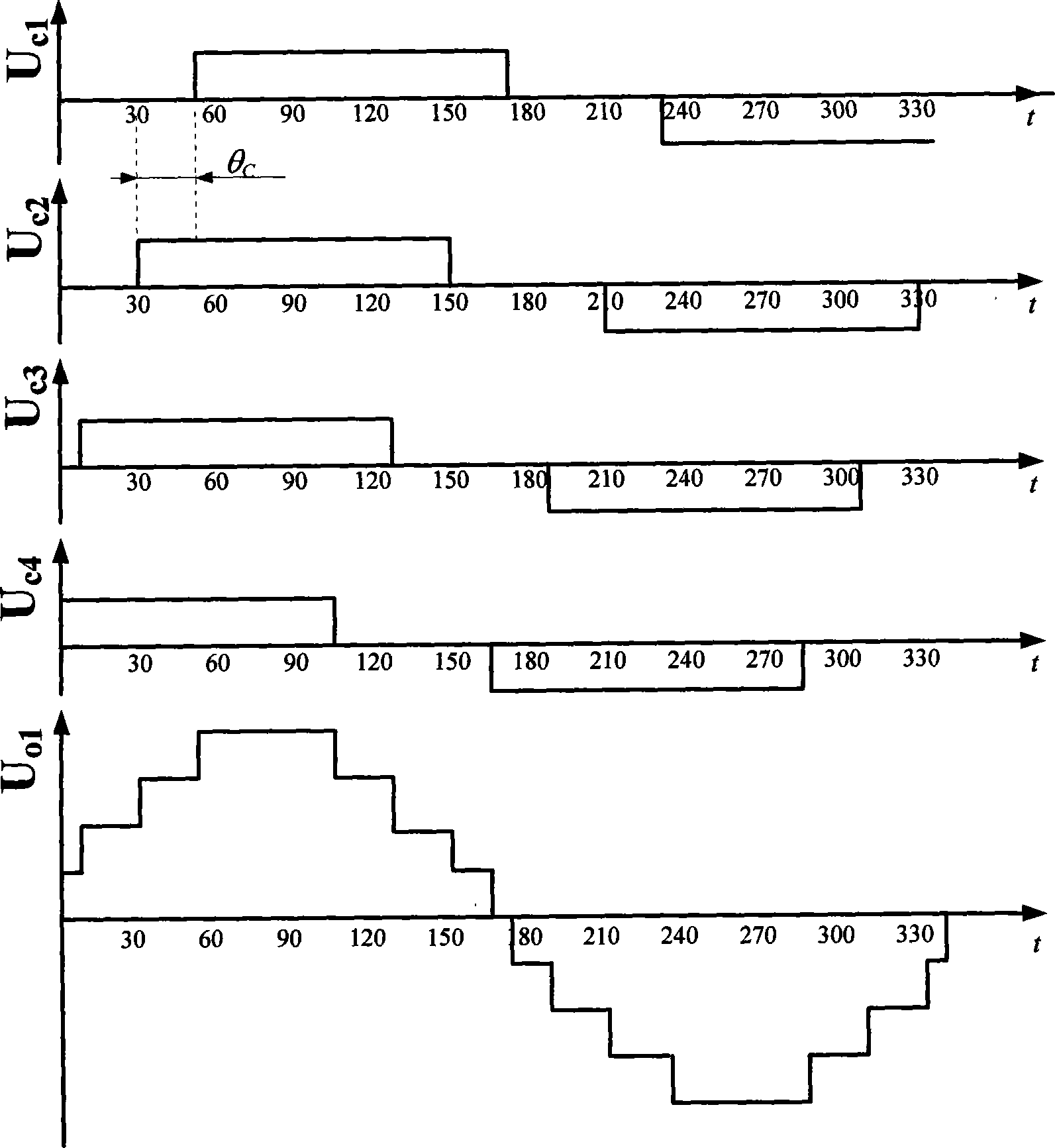

Direct-driving electric excitation double-salient pole fault-tolerance aerogenerator

InactiveCN101247065ARealize AC outputHigh reliability requirementsSynchronous generatorsMagnetic circuit rotating partsFault toleranceWind driven

A direct-driven electric excitation double convex pole fault-tolerant wind-driven generator belongs to the wind-driven generator. The wind-driven generator is composed of two parts of a multi-pole electric excitation double convex pole electric motor and a power device. The unit electric motor are divided into C groups (C>=3). The number of each group of unit electric motor is same. The three-phase winding of each group of unit electric motor is inverted to 120 degree step wave alternating current by the full-bridge inverter respectively after the commutation of the rectification circuit. The phase displacement between the step wave alternating current outputted by the inverters of each group of unit electric motor is 90 / C degree electrical degree. When the outputs of inverter of each group of unit electric motor have been series-connected the load is provided with alternating current, the generator can still work normally after the occurring of fault and satisfies the high-reliability request of the wind-driven generator and at the same time has the advantages of low switching frequency of the amplifier tube of the inverter, small electric voltage and current stress, small distortion factor of the power-line voltage and small cubic weight.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

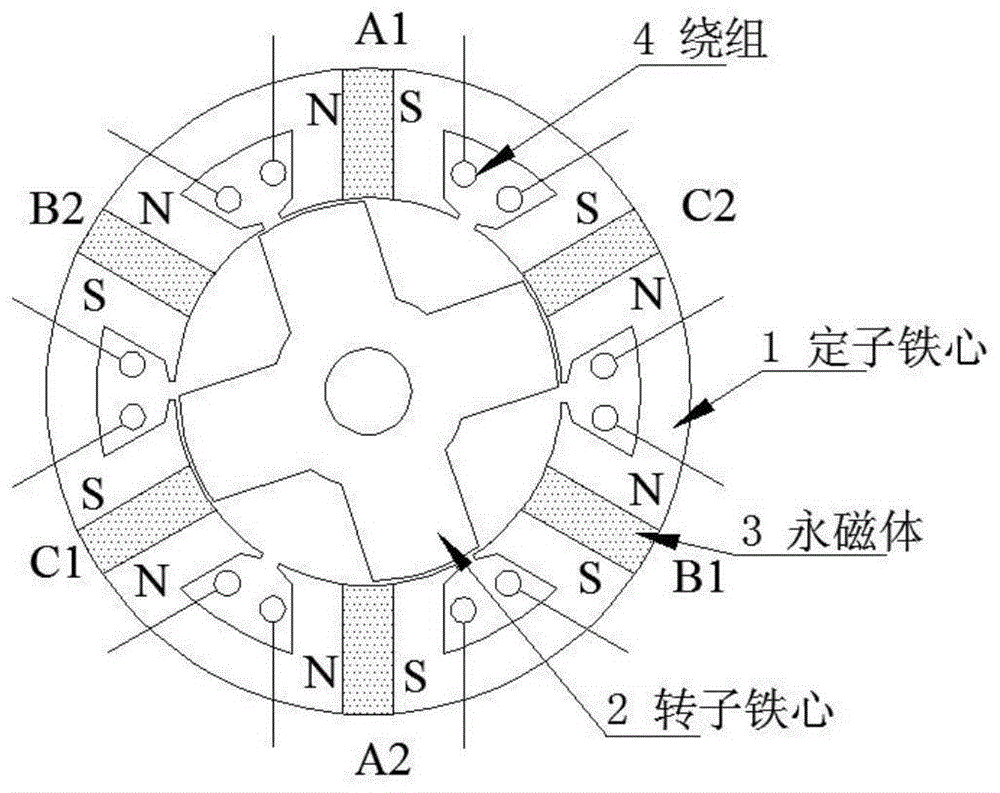

Single-winding non-bearing magnetic flux switching permanent magnetic motor

InactiveCN103825418AThere is no problem of sheddingImprove structural stabilityMagnetic circuit stationary partsElectric machineOperation mode

The invention belongs to the technical field of a motor, and relates to a single-winding non-bearing magnetic flux switching permanent magnetic motor. The single-winding non-bearing magnetic flux switching permanent magnetic motor comprises a stator iron core, a rotator iron core, permanent magnets embedded in the middle of stator teeth, and concentrated windings. A stator and a rotor are both of double-salient pole structures. The single-winding non-bearing magnetic flux switching permanent magnetic motor is characterized in that the stator iron core is composed of six U-shaped laminations; a permanent magnet capable of tangential alternative magnetizing is embedded between every two laminations so that a stator tooth which is axisymmetric is formed; the stator teeth are provided with the concentrated windings, the end portions of the windings are quite small, and the windings, which are opposite to each other in terms of space, on two stator teeth form a phase so that a three-phase winding is formed; and the excitation of winding currents is of a radial excitation mode, each winding is independently controlled, the winding currents can perform bidirectional flow in positive and negative directions, the current size can be controlled according to needs, and the currents has the same phase as a back electromotive force. The single-winding non-bearing magnetic flux switching permanent magnetic motor has the advantages of high speed, large power, high efficiency, high power density, high operation stability, high reliability, and adaptability to an AC operation mode.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com