Commutation torque ripple suppression method for permanent magnet brushless DC motor

A permanent magnet brushless DC and fluctuation suppression technology, applied in the direction of torque ripple control, etc., can solve the problems of increasing the complexity of the system and control strategy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

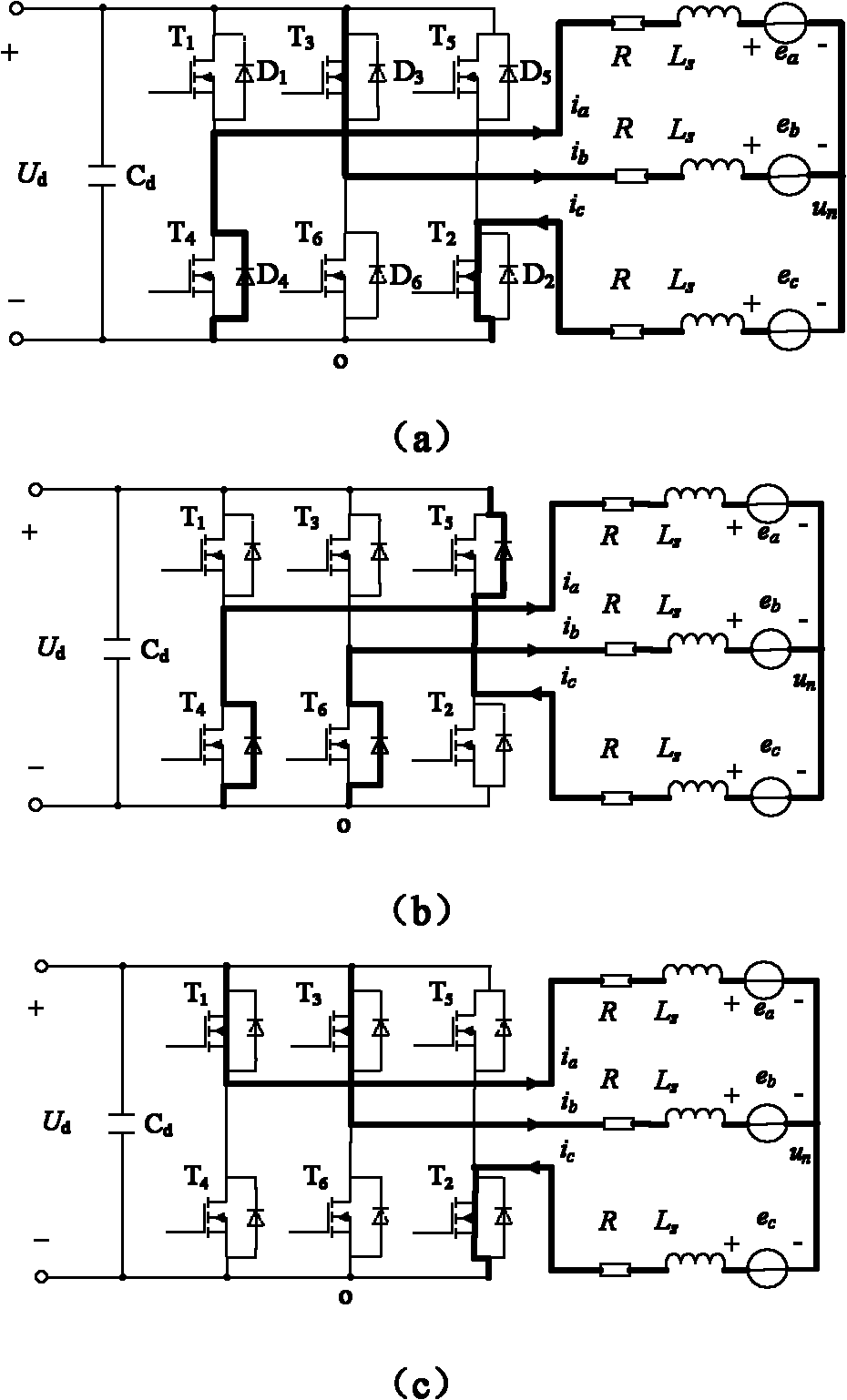

[0034] The method for suppressing the commutation torque fluctuation of the permanent magnet brushless DC motor proposed by the present invention can be applied to the permanent magnet brushless DC motor, and a typical permanent magnet brushless DC motor system such as figure 1 As shown, it includes a permanent magnet brushless DC motor (1), a current sensor (2), a three-phase full-bridge inverter circuit (3), a drive circuit (4) and a DSP controller (5).

[0035] The three-phase full-bridge permanent magnet brushless DC motor operates with two-to-two conduction commutation at an electrical angle of 120°. During the commutation process, the off-phase current refers to the off-phase winding current; the on-phase current refers to the on-phase winding Current; non-commutation current refers to the winding current that does not participate in commutation. During the commutation process of the permanent magnet brushless DC motor, due to the mismatch between the falling slope of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com