Stator of alternating-current generator and winding method thereof

A technology of alternator and winding method, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., which can solve the problems of high space factor, narrow engine room, high zero-current speed of generators, etc., and achieve high slot fill rate , the number of slots is large, to overcome the effect of volume and power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

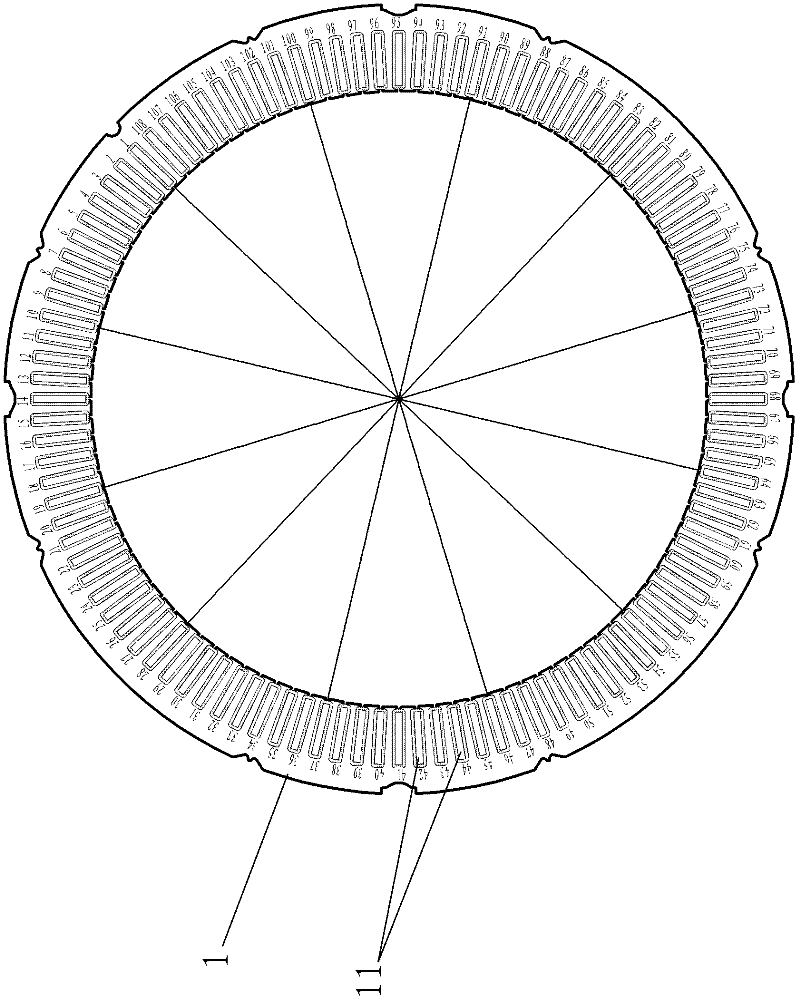

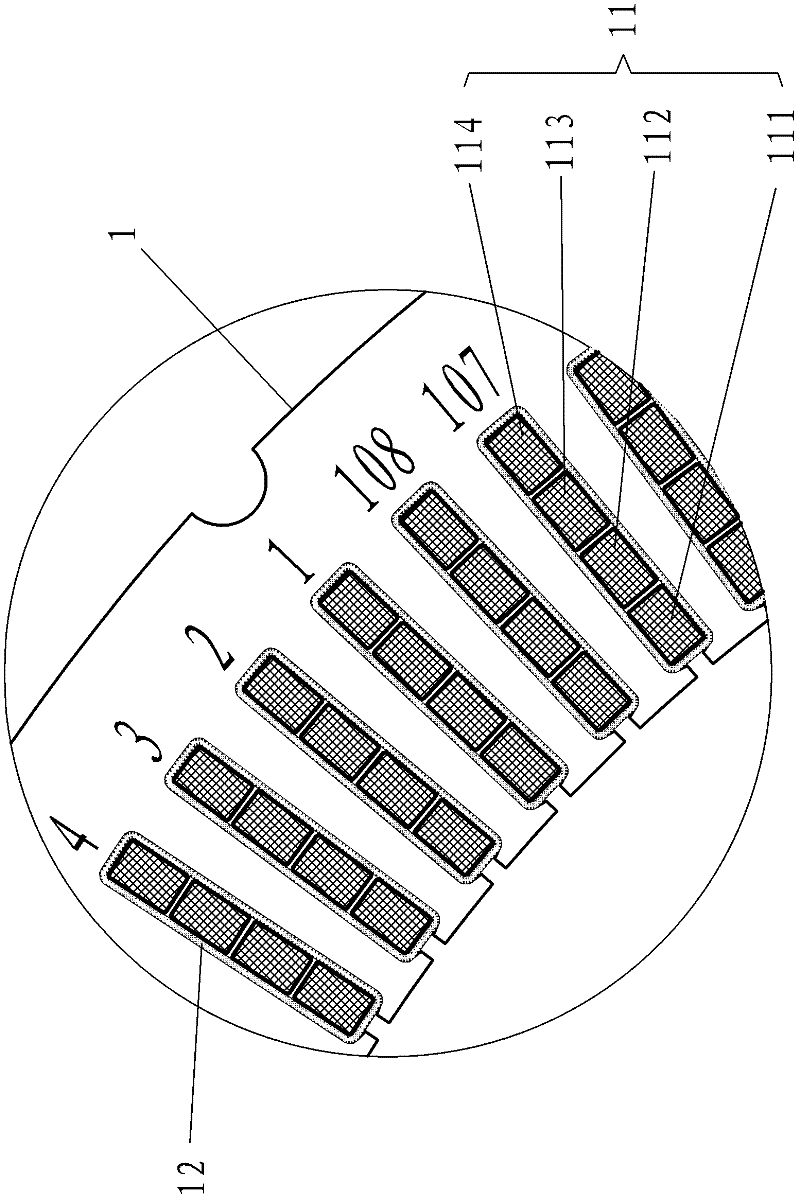

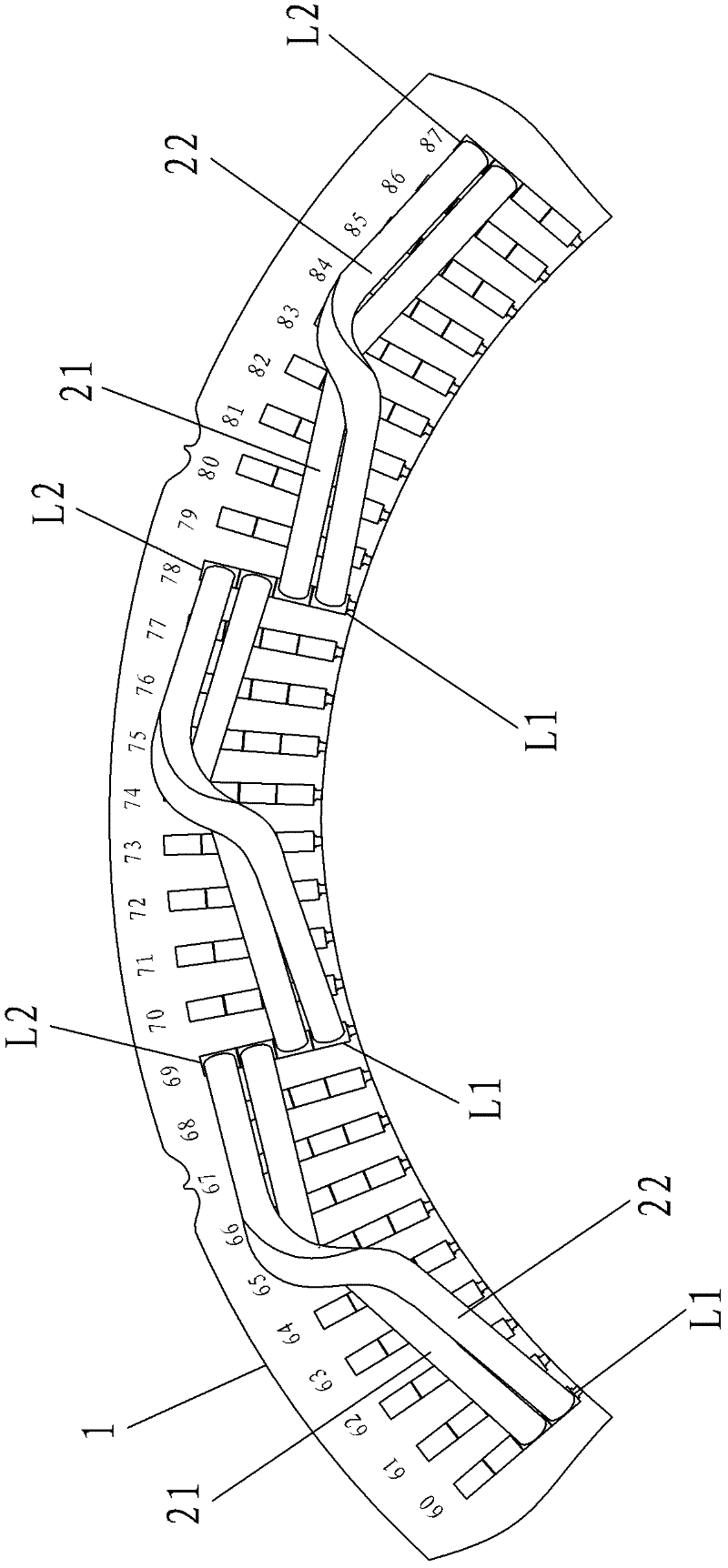

[0038] like Figure 1-5 It is a stator of an alternator involved in the present invention, Figure 6-10 For the stator winding winding method of the stator described in the present invention, the stator includes an iron core 1 and stator windings wound on the iron core 1 .

[0039] The iron core 1 is provided with 108 rectangular slots 11 at equal intervals, and a slot insulating paper 12 suitable for the rectangular slot 11 is laid in each rectangular slot 11 along its rectangular slot wall; The rectangular slot 11 is divided into four layers according to the arrangement of the stator coils 2 therein, as figure 2 As shown, it is an inner upper layer 111 , an inner lower layer 112 , an outer lower layer 113 and an outer upper layer 114 from inside to outside in the radial direction of the iron core 1 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com