Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

107 results about "Process capability index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

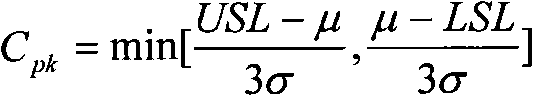

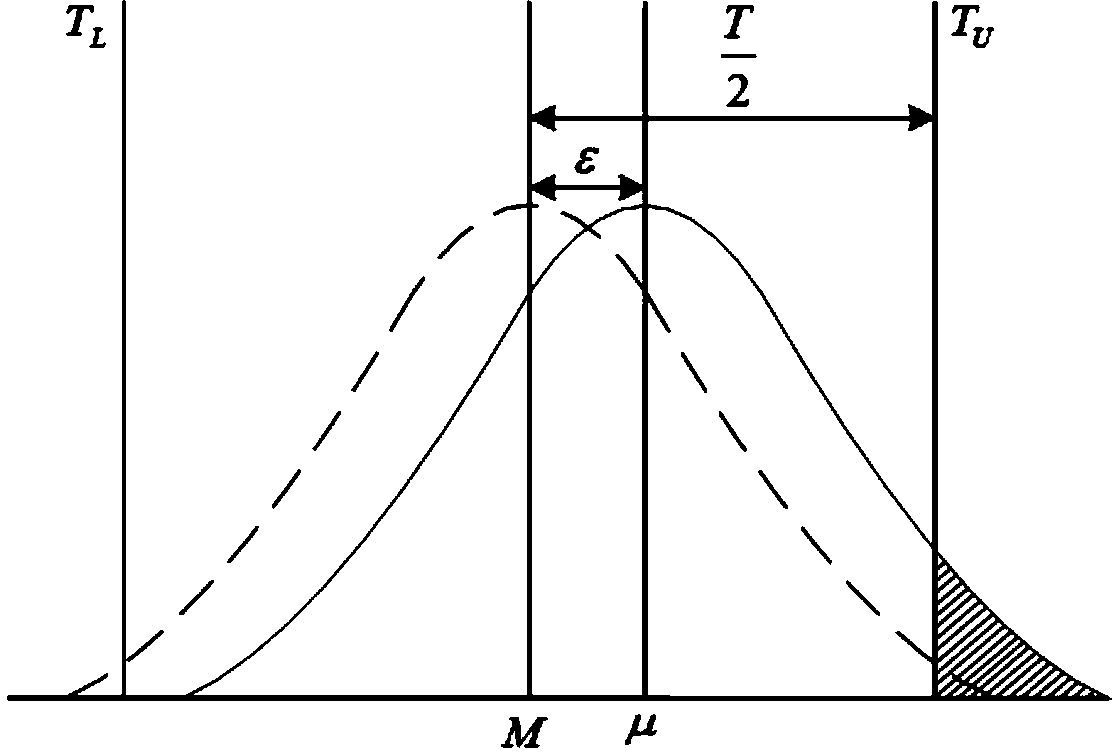

In process improvement efforts, the process capability index or process capability ratio is a statistical measure of process capability: the ability of a process to produce output within specification limits. The concept of process capability only holds meaning for processes that are in a state of statistical control. Process capability indices measure how much "natural variation" a process experiences relative to its specification limits and allows different processes to be compared with respect to how well an organization controls them.

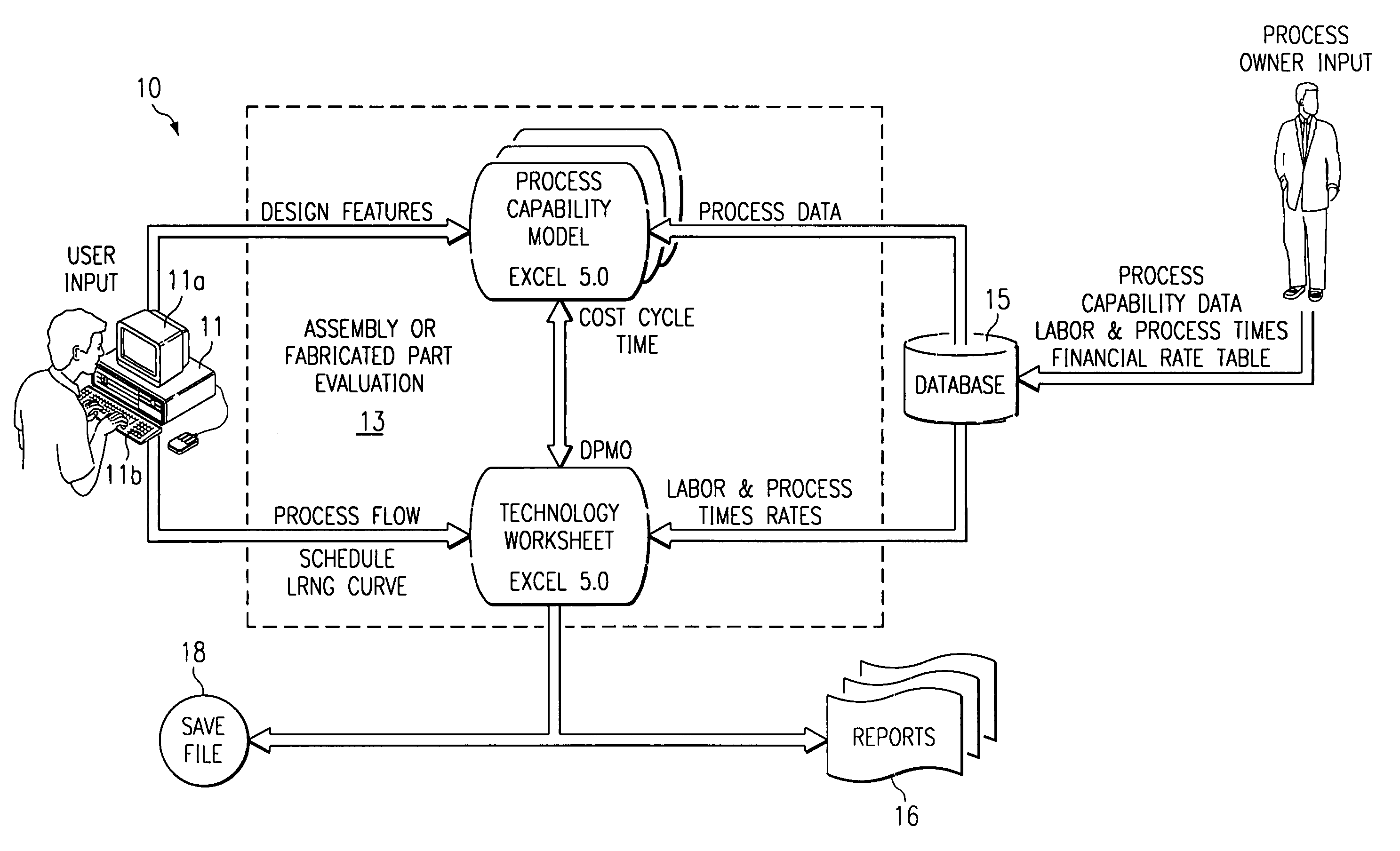

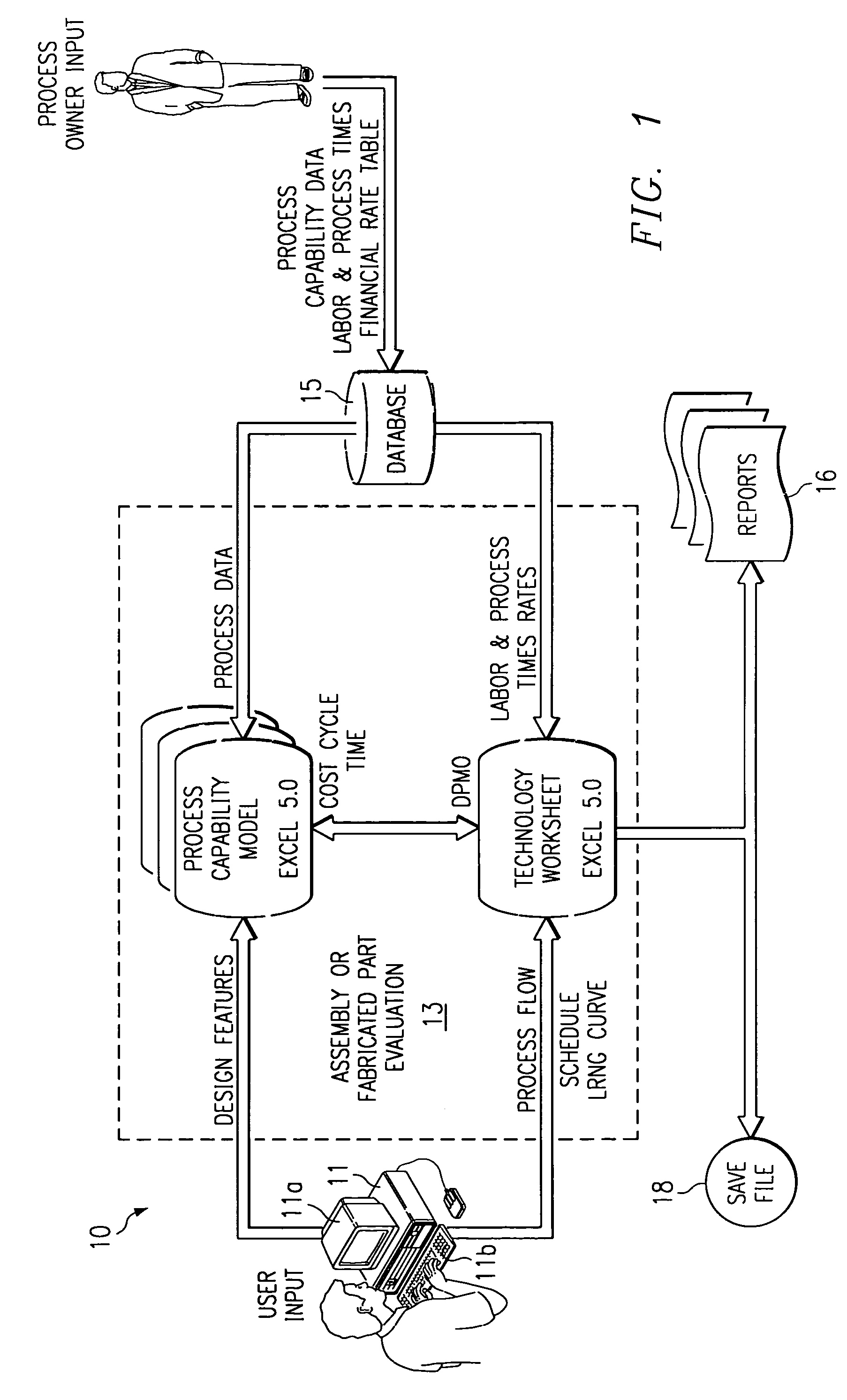

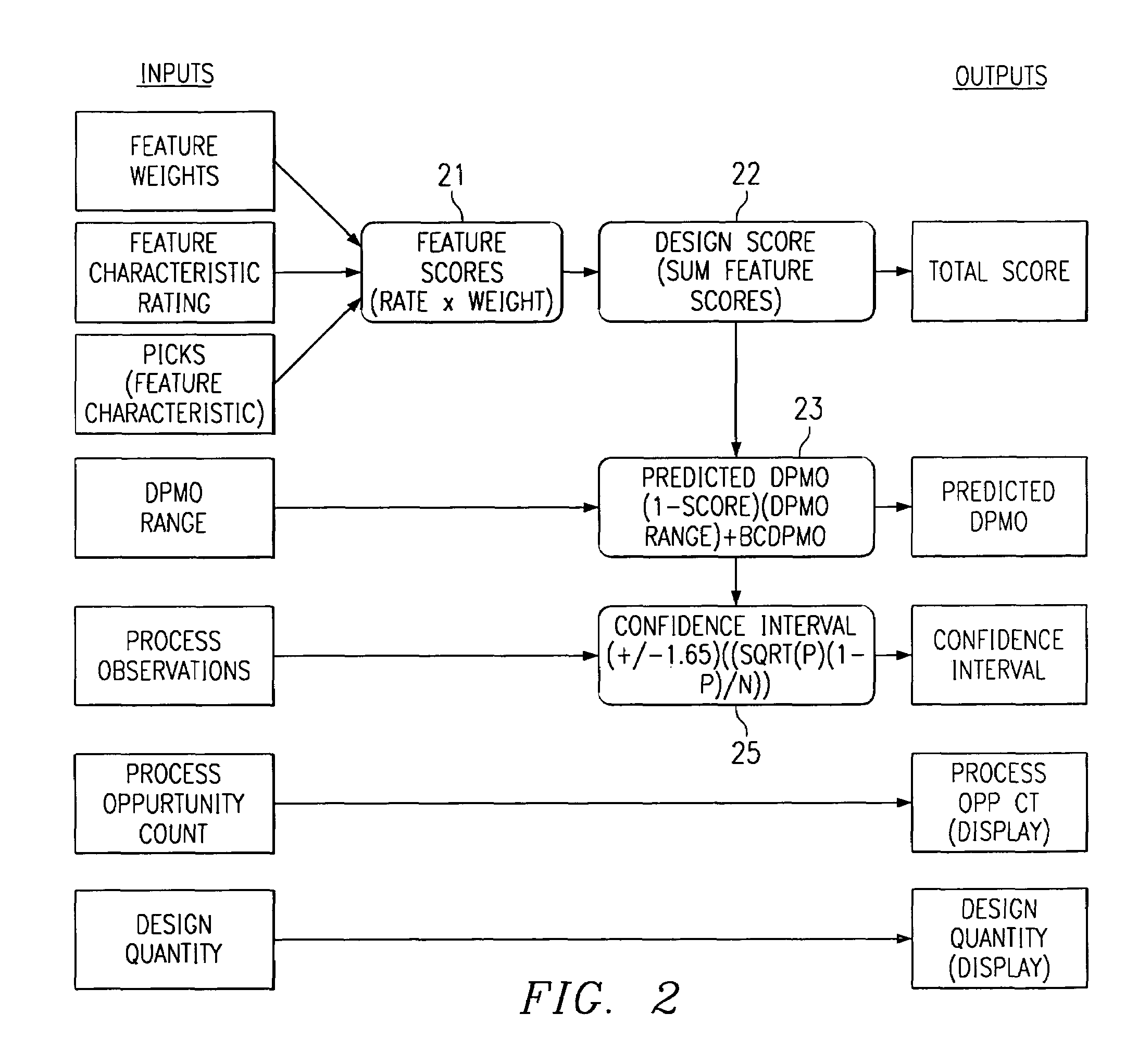

Capability predictor

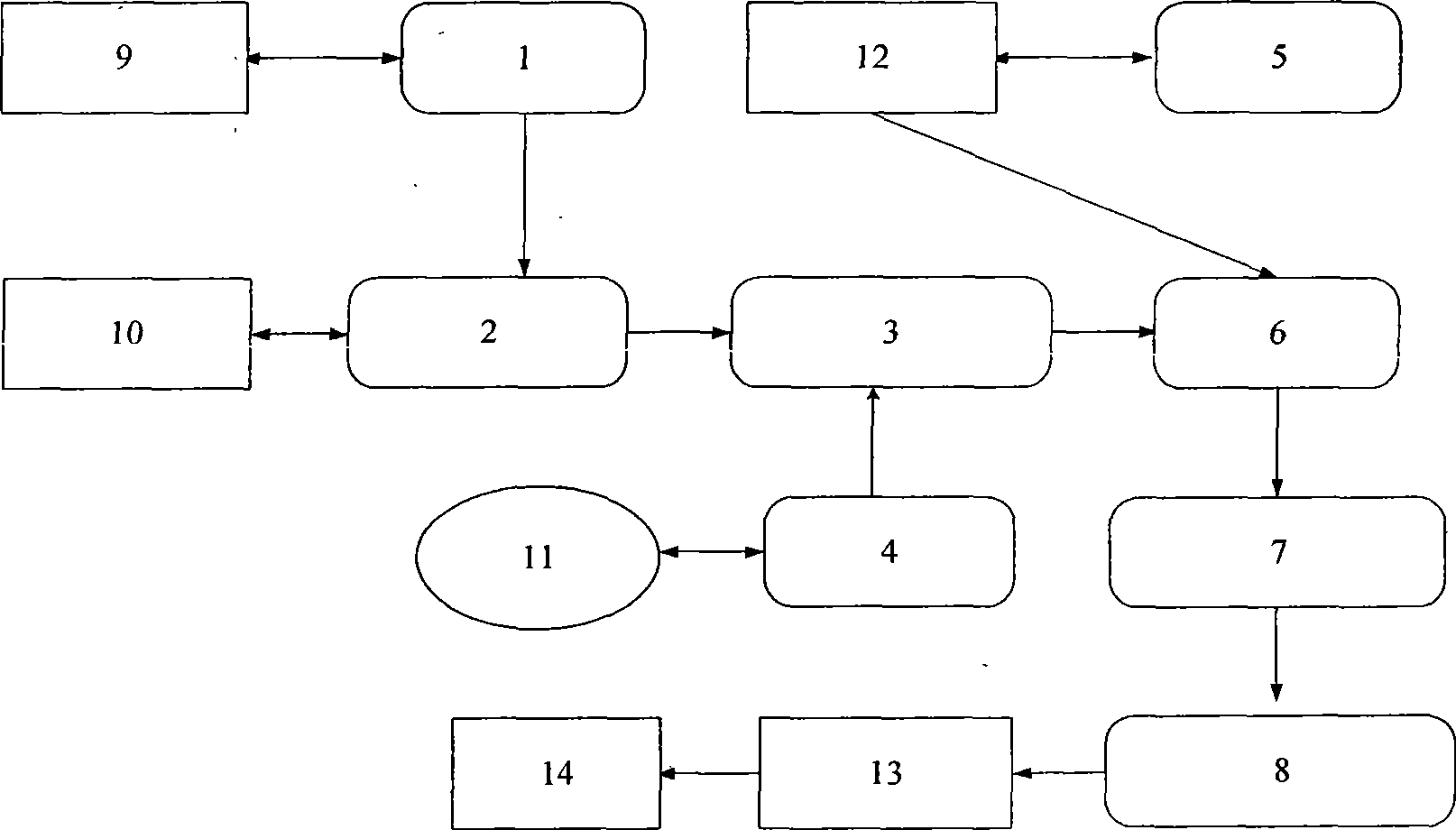

A capability predictor that comprises a database 15 of capability of multiple designs is disclosed. The process capability data includes costs, quality, cycle time, and performance models. The process owner (expert) provides the data. The developer inputs equations necessary to calculate the predictions based in the selected design characteristics and the user selects the design. A processor 11 calculates the prediction based on the selected design and a display, such as monitor 11a or printer 16, displays the results of the predictions.

Owner:TEXAS INSTR INC

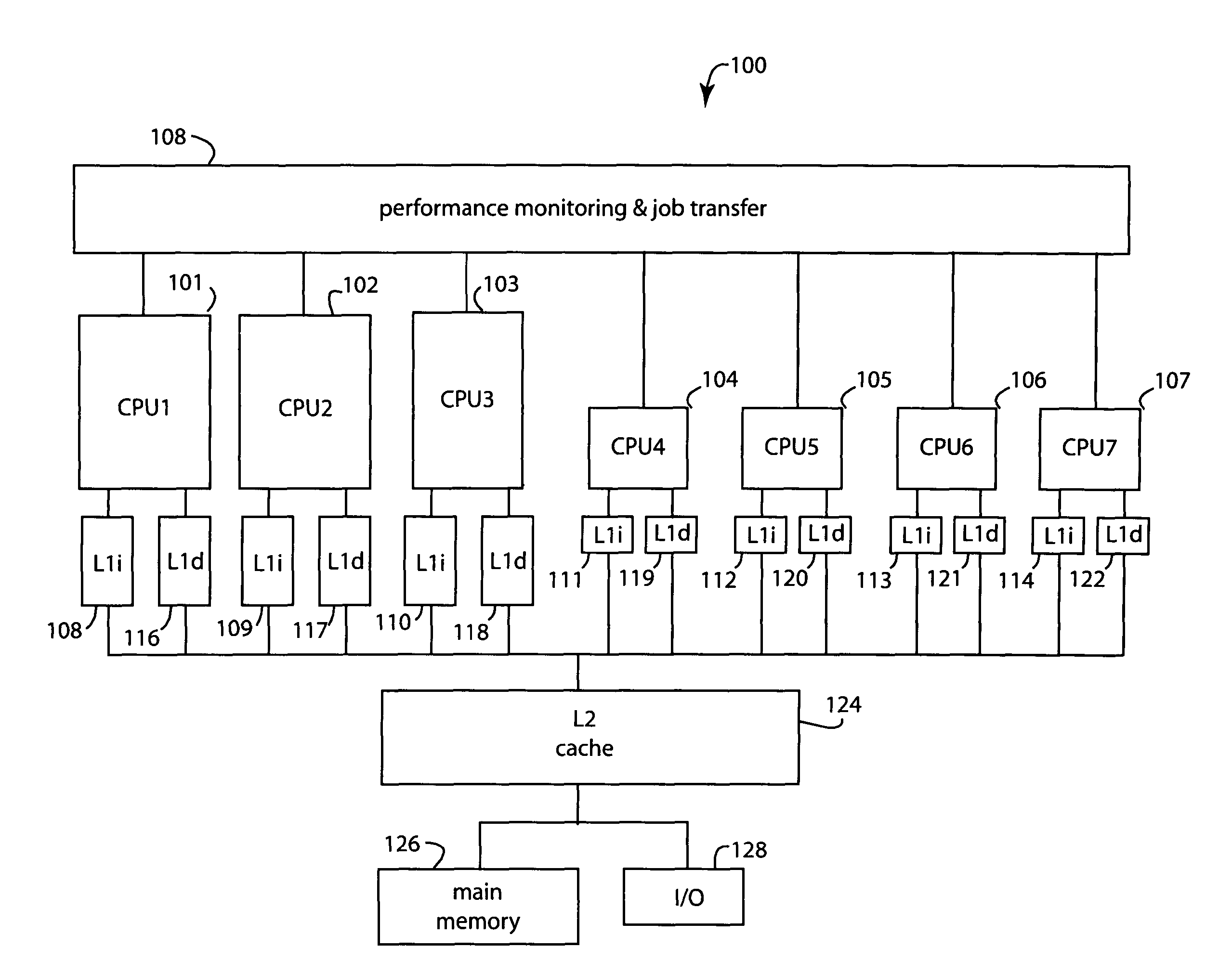

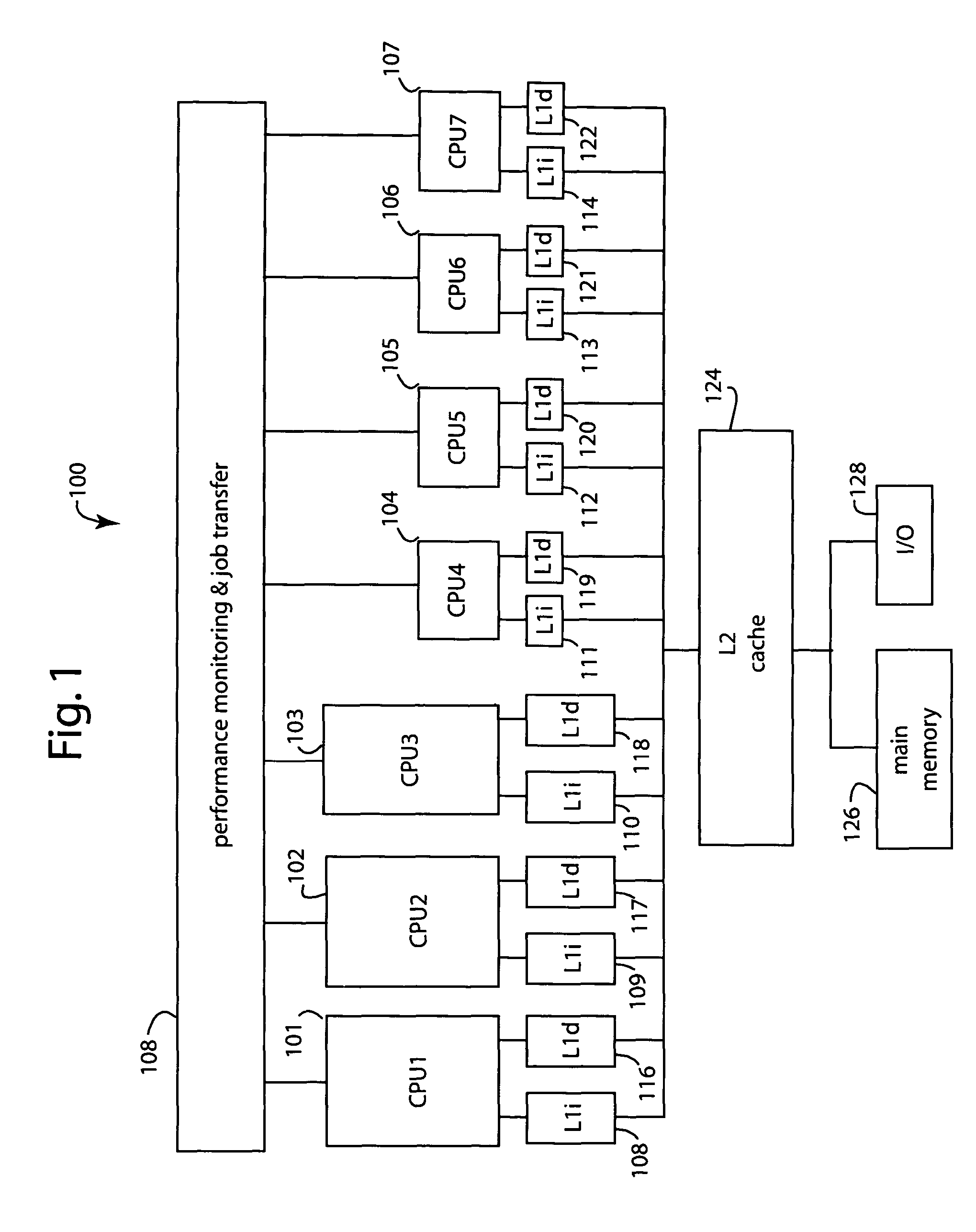

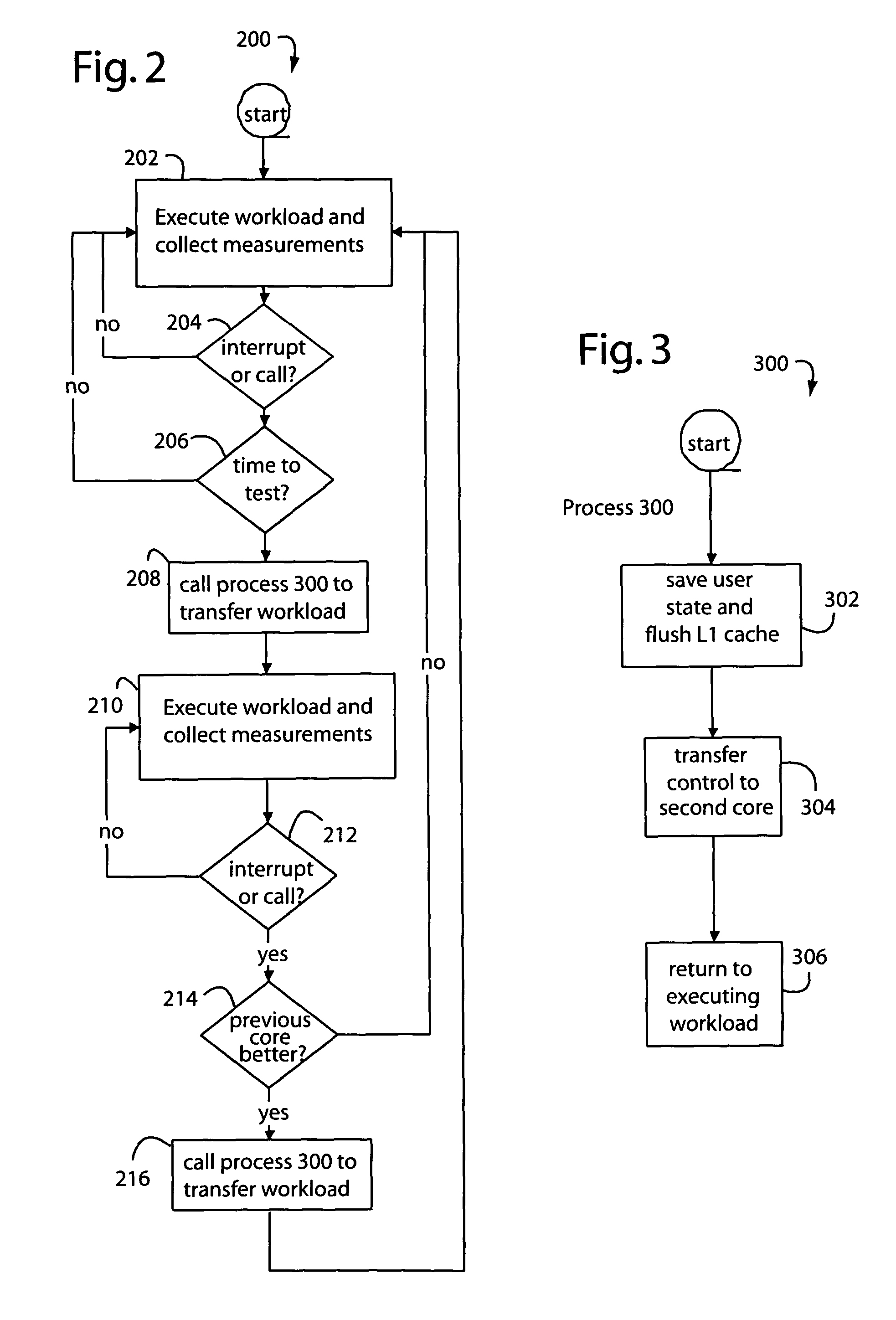

Heterogeneous processor core systems for improved throughput

InactiveUS7996839B2Improve performanceMaximize resource utilizationResource allocationNuclear monitoringComputerized systemParallel computing

Owner:HEWLETT PACKARD DEV CO LP

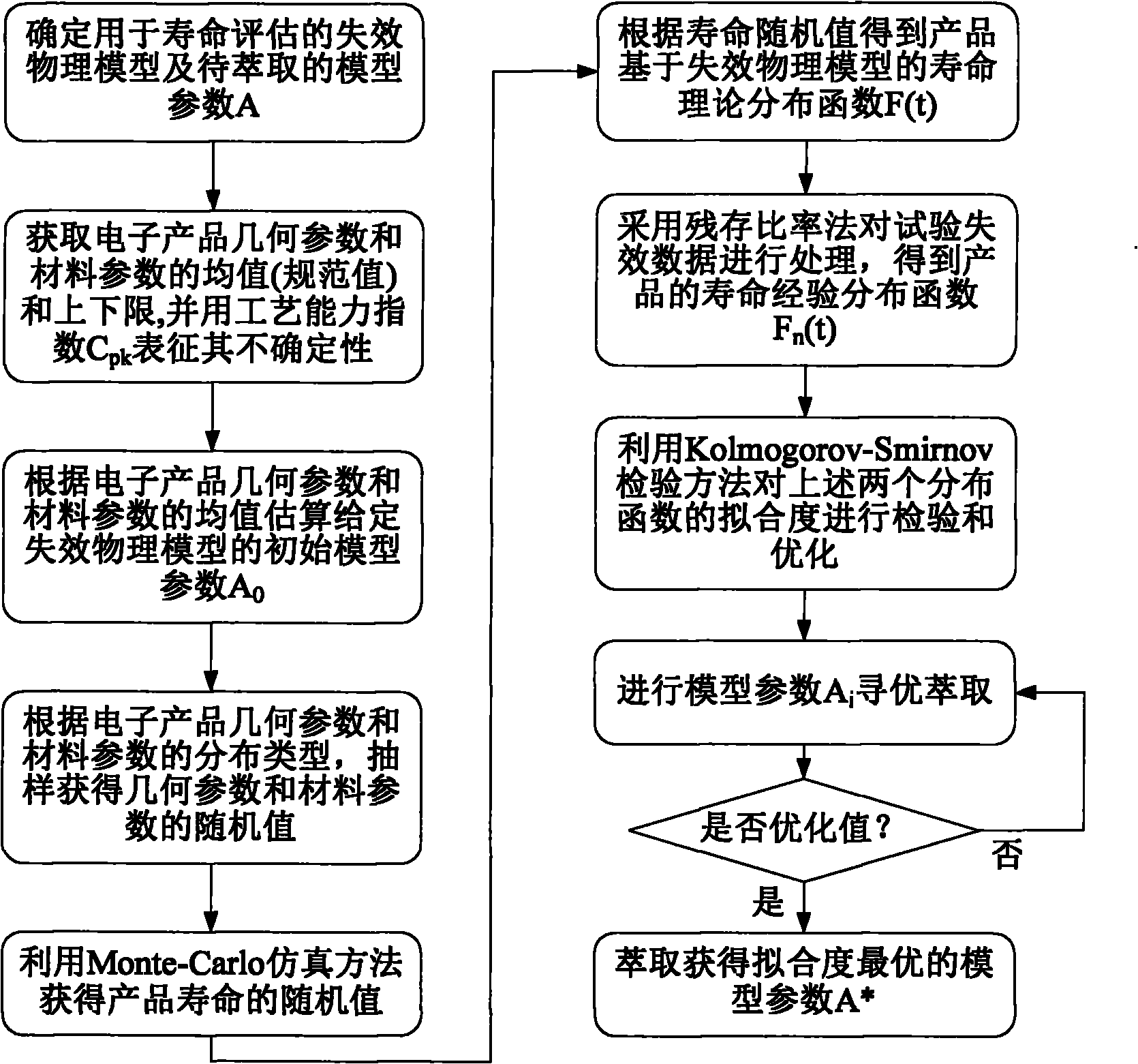

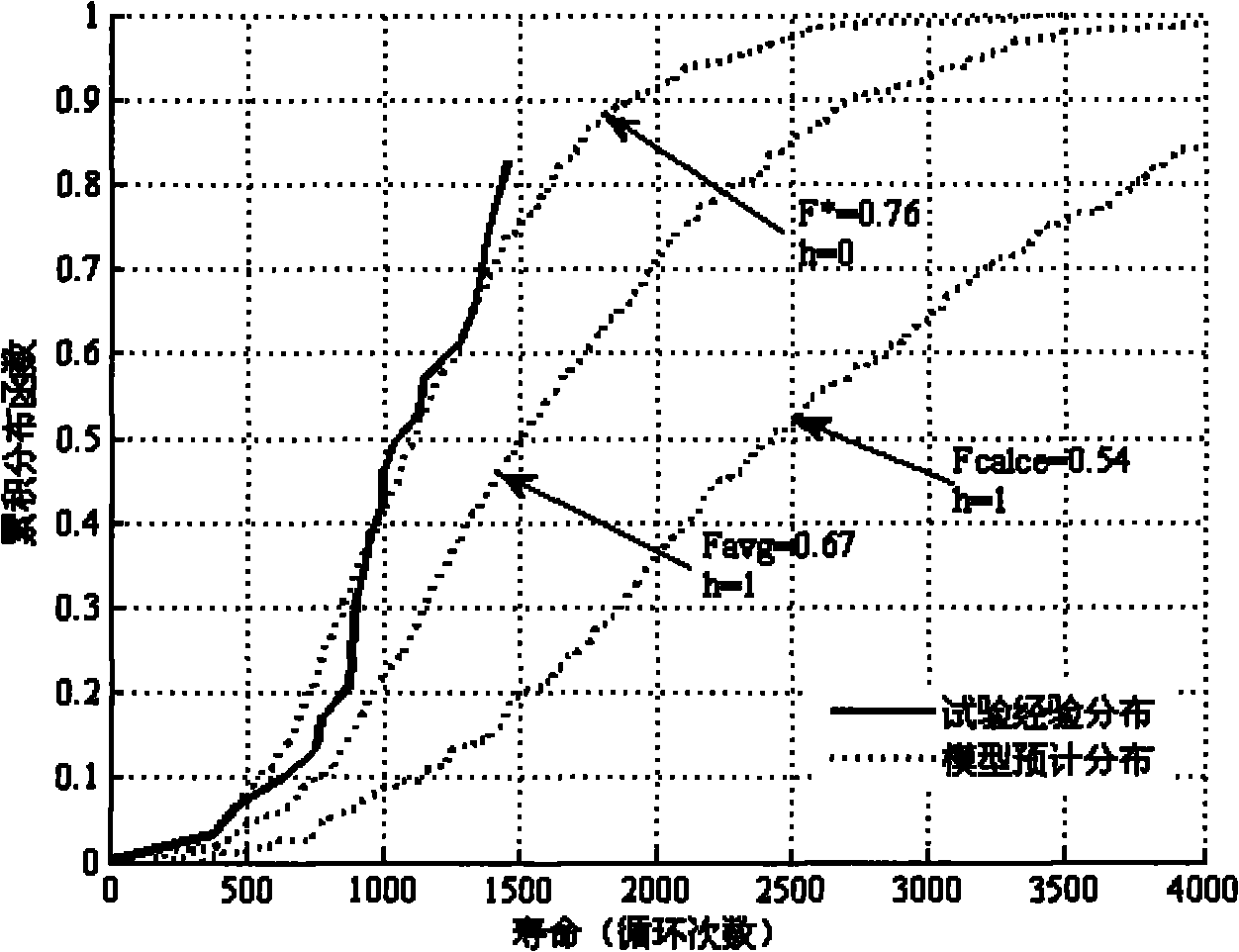

Practical electronic product service life evaluation model parameter high-accuracy extraction method

ActiveCN102103658AGuaranteed accuracyAddress usability bottlenecksSpecial data processing applicationsPhysical modelData mining

The invention discloses a practical electronic product service life evaluation model parameter high-accuracy extraction method, which comprises the following steps of: (1) determining a failure physical model and model parameters to be extracted; (2) acquiring mean values, upper limits and lower limits of geometric and material parameters of a product, and representing the uncertainty of the parameters by adopting process capability indexes; (3) evaluating initial model parameters of the failure physical model according to the mean values of the geometric and material parameters of the product; (4) performing sampling according to distribution types of the geometric and material parameters to obtain random values of the geometric and material parameters; (5) obtaining the random value of the service life of the product by combining a Monte-Carlo simulation method; (6) obtaining a theoretical distribution function of the service life of the product according to the random value of the service life; (7) processing experimental failure data by adopting a remaining ratio method to obtain an empirical distribution function of the service life of the product; (8) checking a degree of fitting of the two service life distribution function by utilizing a K-S checking method; and (9) performing optimal extraction on the model parameters until the model parameters with an optimal degree of fitting are obtained.

Owner:北京可维创业科技有限公司

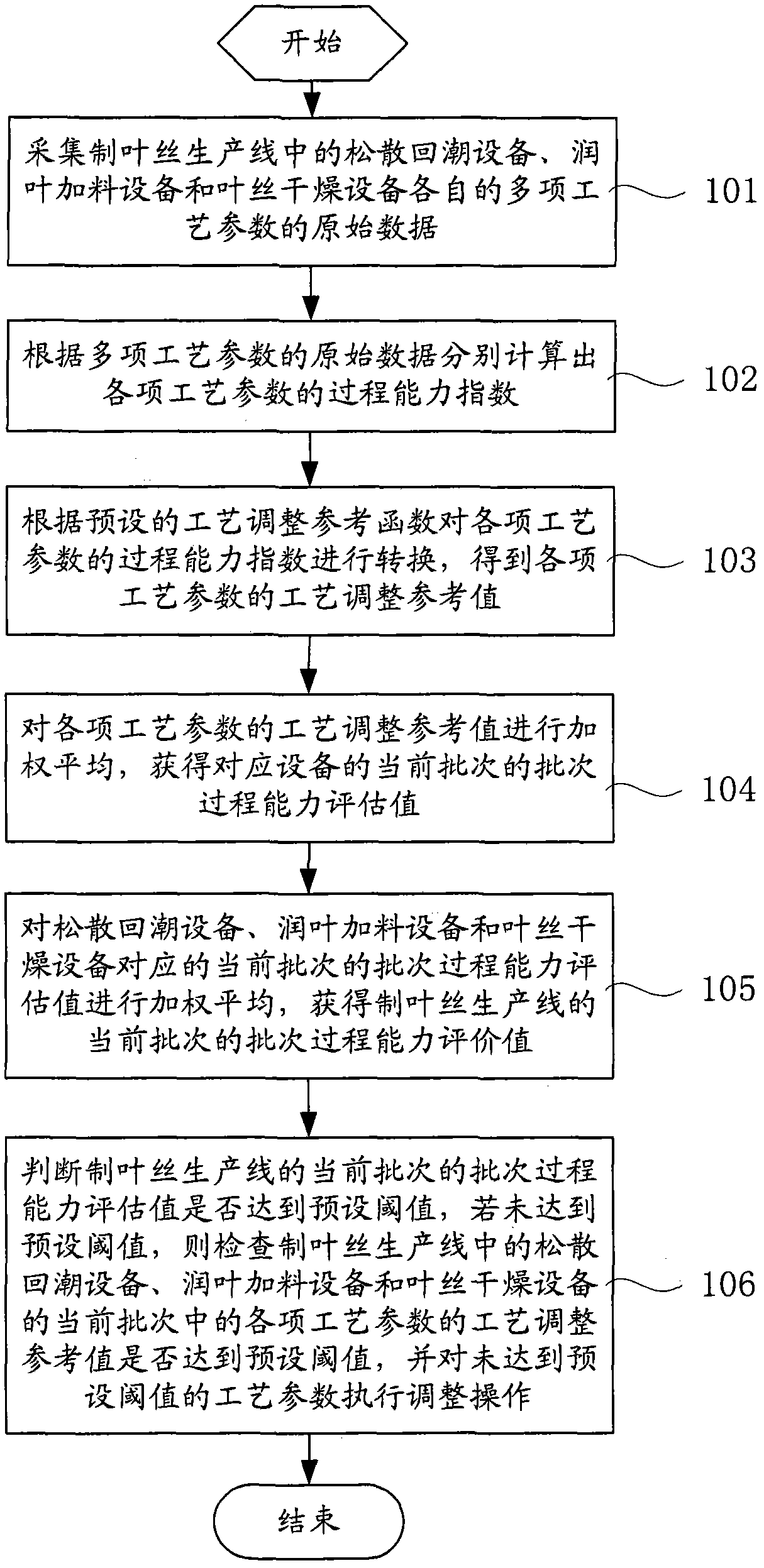

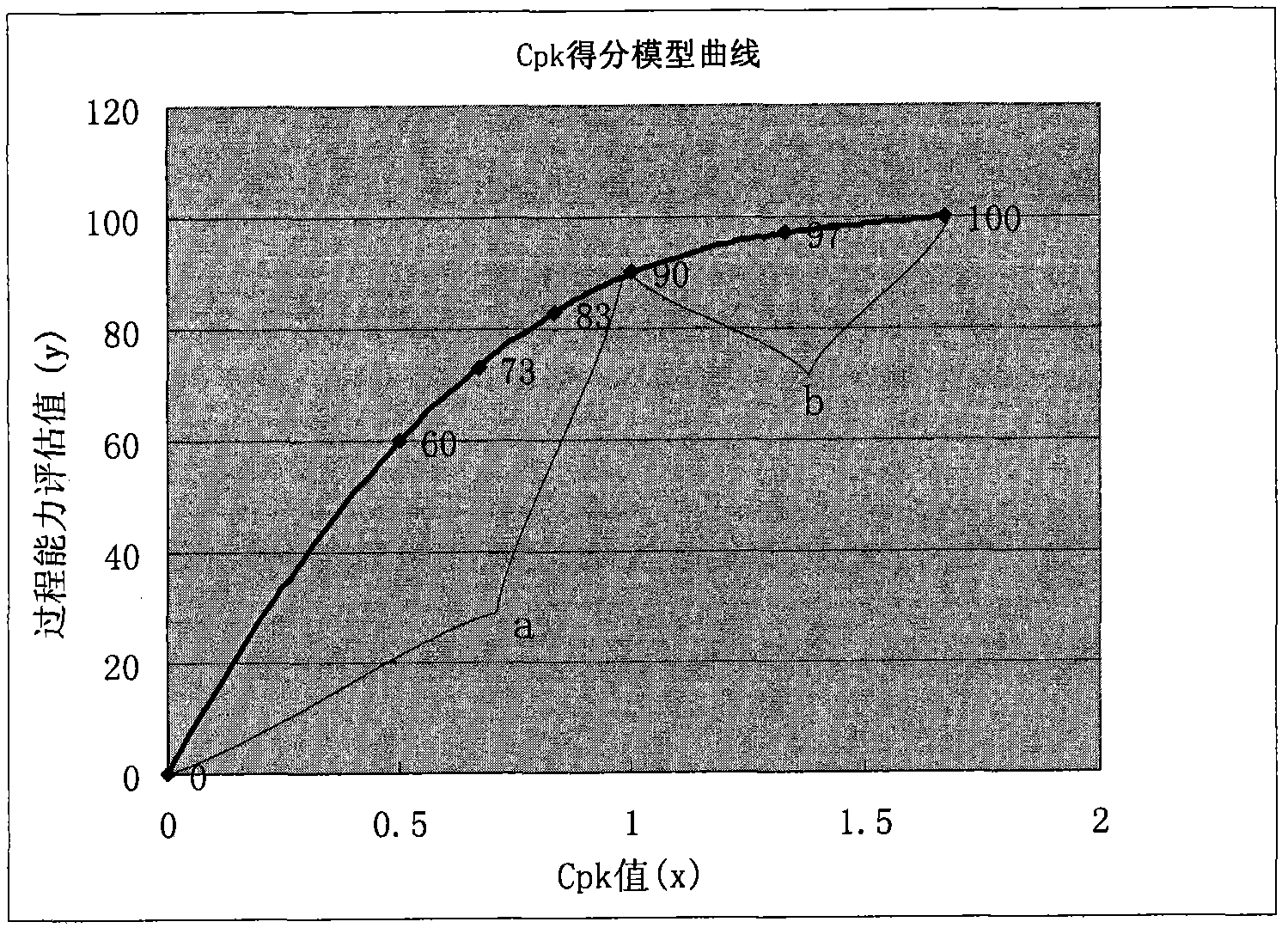

Method for improving batch procedure capability of tobacco shred making process

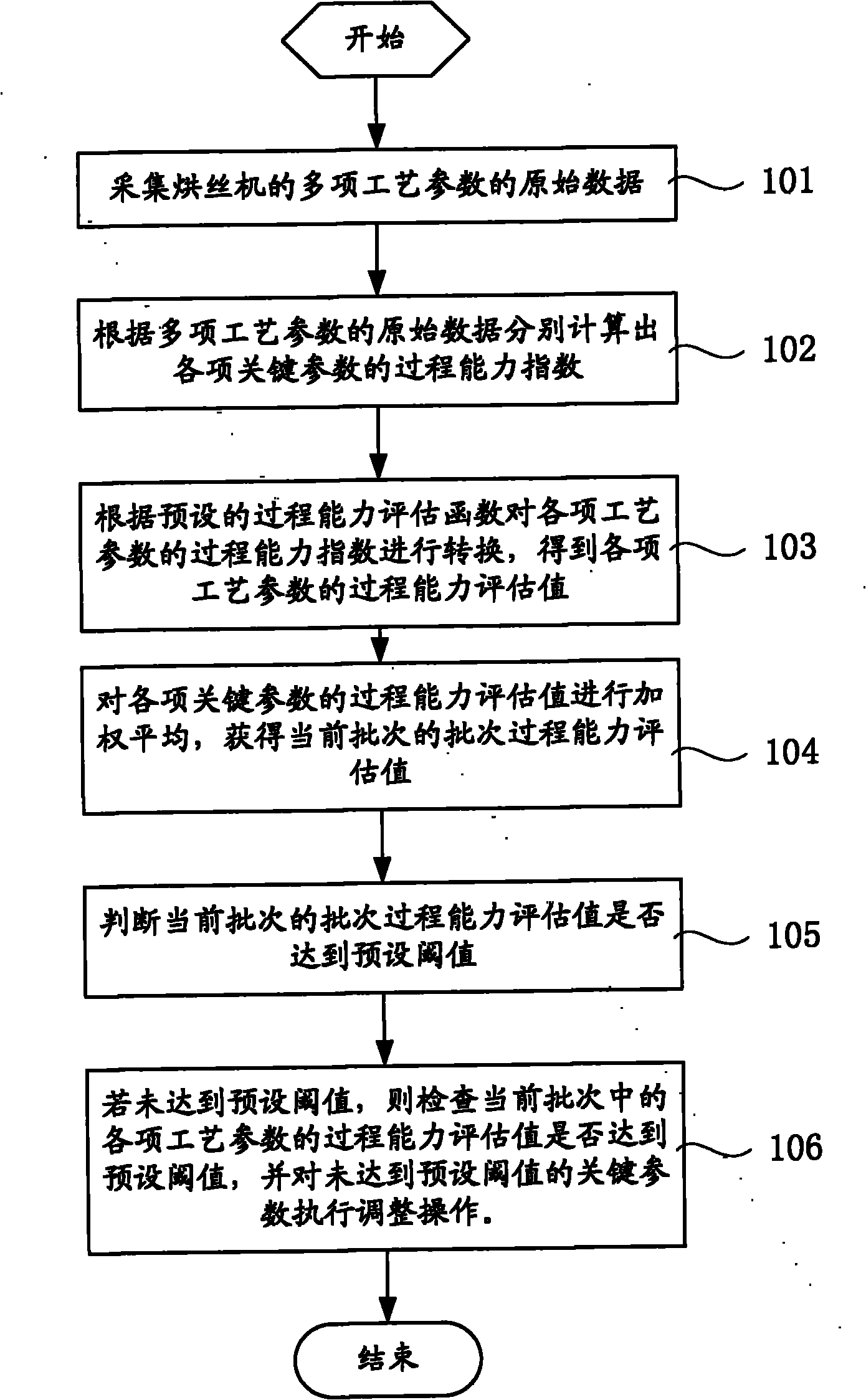

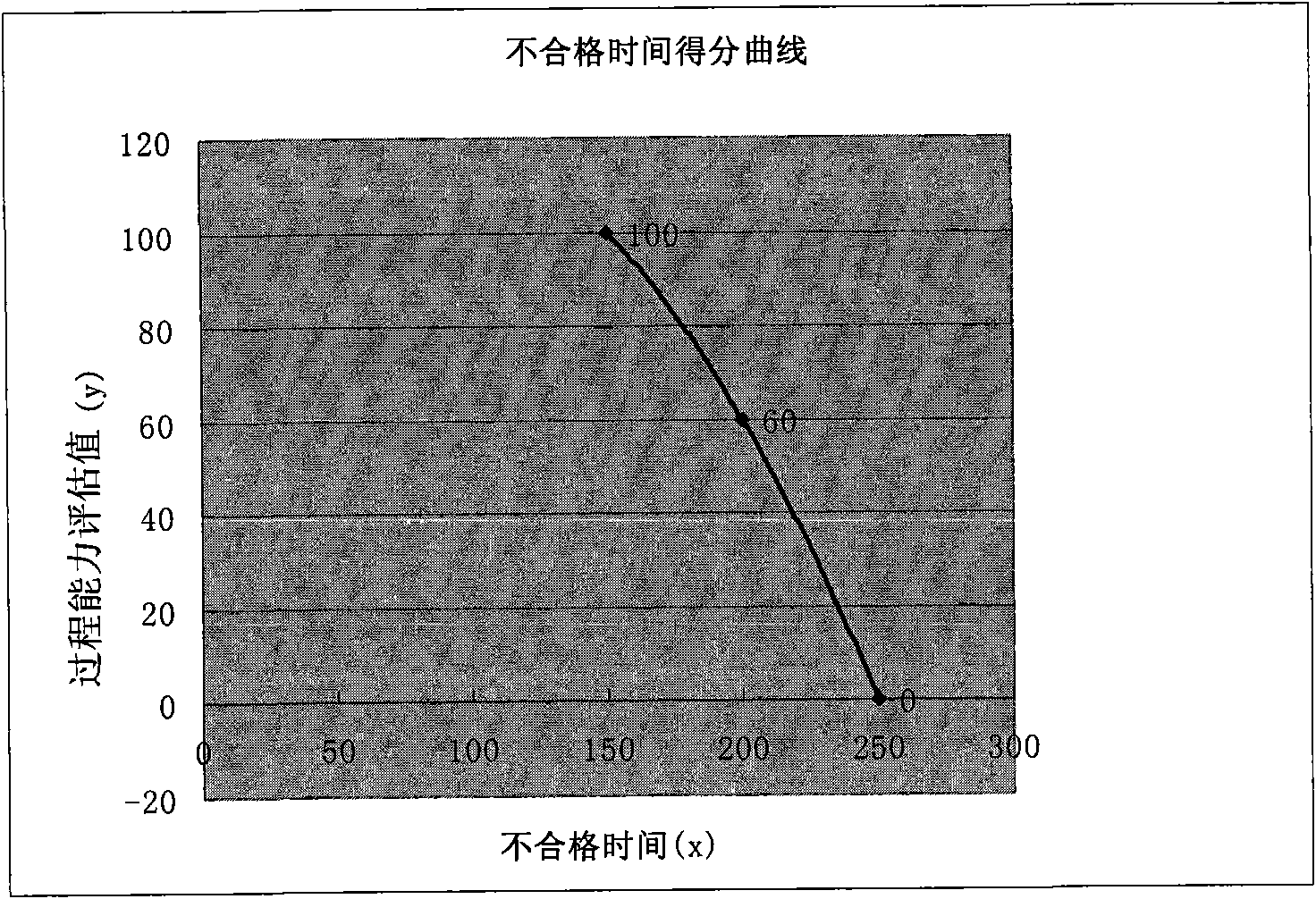

The invention relates to a method for improving the batch procedure capability of a tobacco shred making process, comprising the following steps of: acquiring original data of multiple process parameters of each device in a tobacco shred production line; respectively calculating procedure capability index of each process parameter; converting the procedure capability index of each process parameter to obtain a process regulation reference value of the each process parameter; carrying out the weighted mean on the process regulation reference value of the each process parameter to obtain an evaluation value of the batch procedure capability of the current batch of a corresponding device; obtaining an assessed value of the batch procedure capability of the current batch of the tobacco shred production line by the weighted mean; and judging whether the assessed value of the batch procedure capability of the current batch of the tobacco shred production line is up to a preset threshold; ifthe assessed value is not up to the preset threshold, detecting whether the process regulation reference value of the each process parameter in the current batch of the each device in the tobacco shred production line is up to the preset threshold, and regulating the process parameters which are not up to the preset threshold.

Owner:LONGYAN CIGARETTE FACTORY

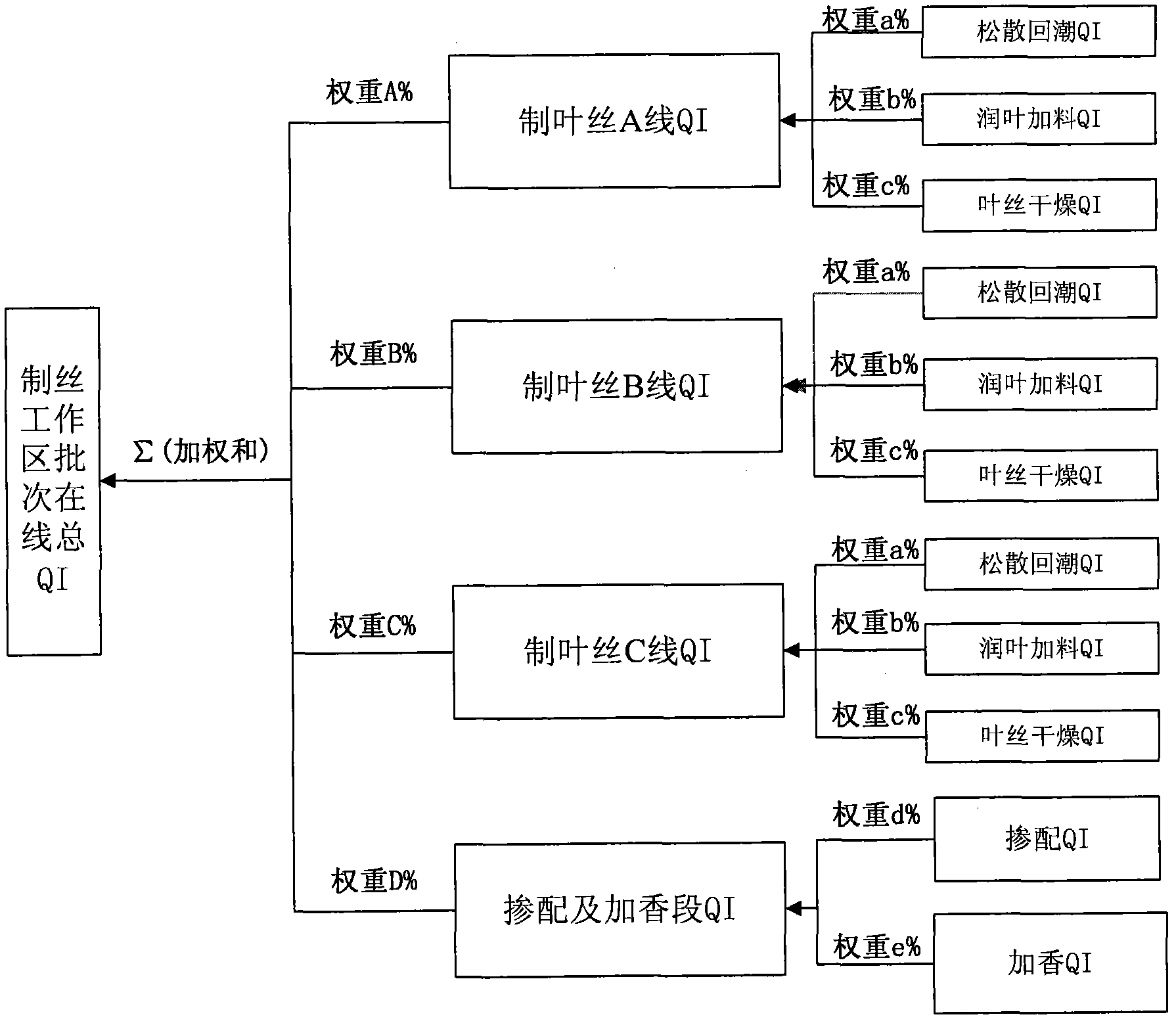

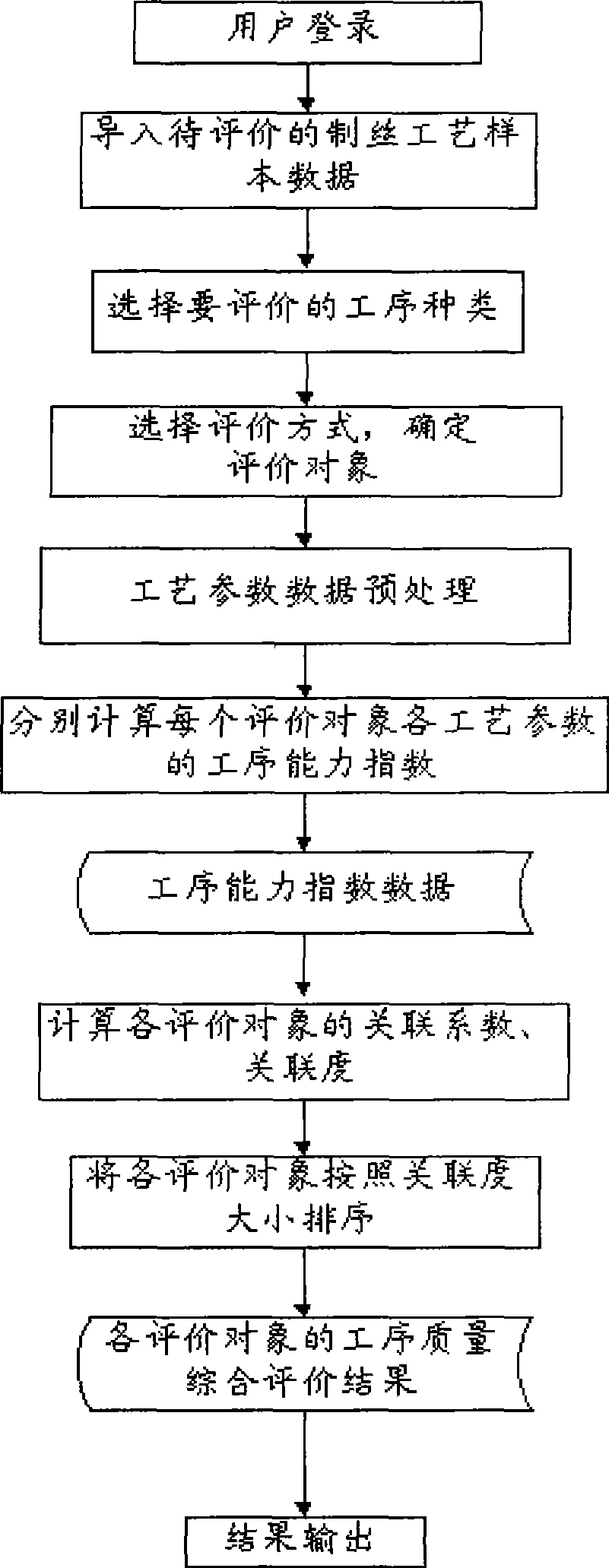

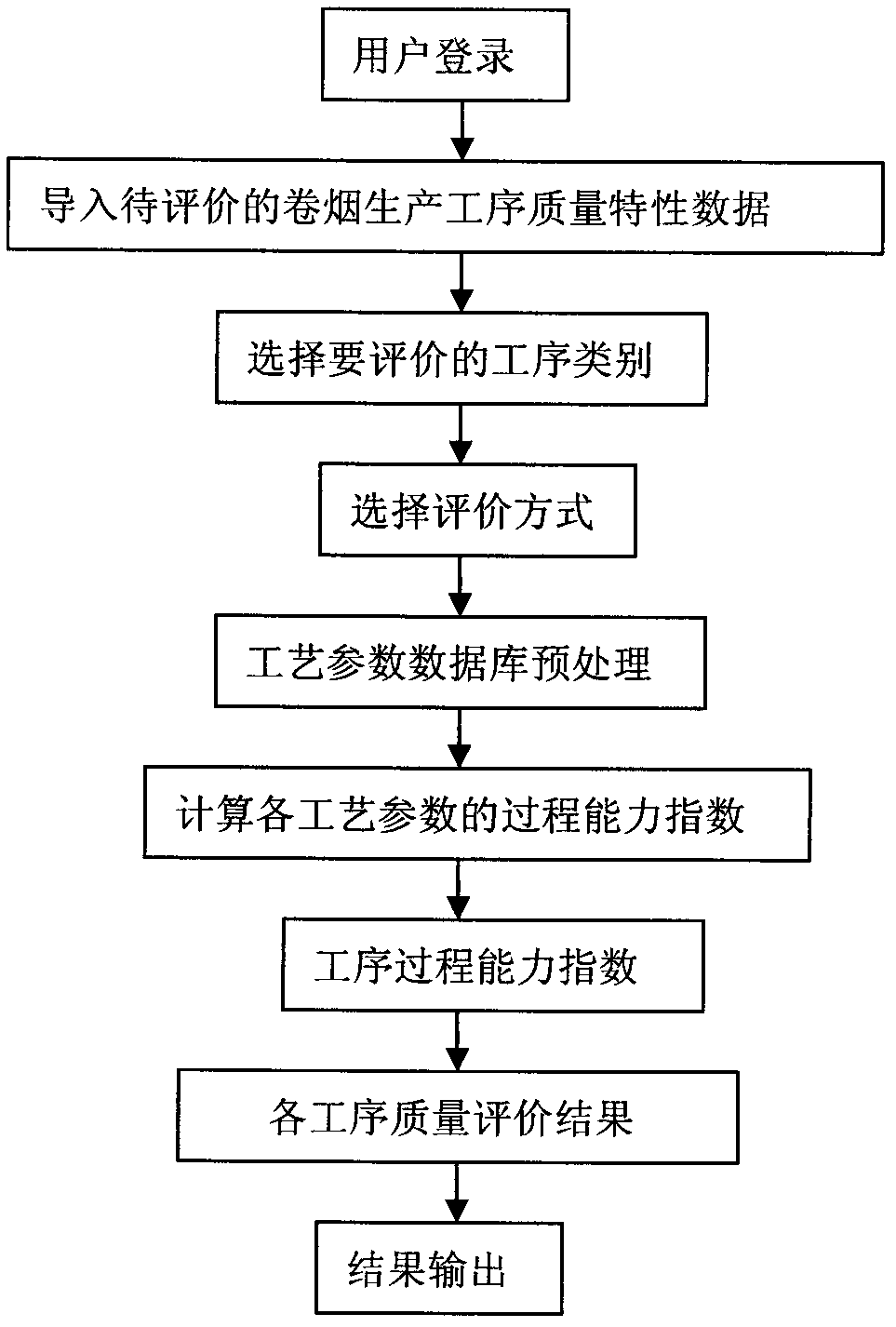

Cigarette working procedure quality overall evaluation system and method based on gray correlation analysis

ActiveCN101414183ASolve the ambiguous situation of process capability evaluationFunctional job improvementTotal factory controlProgramme total factory controlGrey correlation analysisProcess quality

The invention discloses a comprehensive cigarette process quality evaluation system based on grey correlation analysis and a method thereof, aims at overcoming the disadvantage that the existing single process evaluation method can not comprehensively evaluate the overall process quality of the cigarette process, and changing the situation of fuzzy process capability evaluation of a whole line at present. The evaluation system and the method thereof help comprehensively evaluates the quality of a plurality of processes, and can effectively grasp comprehensive situation of the process quality so as to provide basis for the continuous improvement in the process quality, and provide assurance for quality improvement of cigarette products. The system and the method combine the single-process quality evaluation method and the grey correlation analysis method. The method comprises the following steps: firstly, computing process capability indexes of various process parameters; then, comprehensively evaluating a Cpk value by the grey correlation method; finally, obtaining a comprehensive evaluation result which is taken as a process quality rank of various evaluated objects. Production practice can be effectively directed by analyzing the Cpk and the process quality ranking result.

Owner:CHINA TOBACCO SHANDONG IND +1

Tin-lead welding strip for solar photovoltaic assembly and manufacturing method thereof

InactiveCN102254978AImprove adhesionImprove conductivityFinal product manufacturePhotovoltaic energy generationMicrometerDross

The invention discloses a tin-lead welding strip for a solar photovoltaic assembly, which comprises a copper strip base material, wherein a compact tin-lead alloy layer with a thickness of 3-20 micrometers covers the surface of the copper strip base material. A manufacturing method of the tin-lead welding strip for the solar photovoltaic assembly comprises the step of: covering the compact tin-lead alloy layer on the copper strip base material by adopting an electroplating method, wherein the thickness of the tin-lead alloy layer is 3-20 micrometers. Because the electroplating method is adopted, a cladding material has a crystal lattice characteristic and capacities of enhancing adhesive force of the welding strip and improving the conductivity of the photovoltaic welding strip. The welding strip has a volume resistivity of 0.0185-0.021omega mm<2> / m which is lower than that of the welding strip manufactured through thermal tin immersion and a melting point of 183-190 DEG C lower than that of a lead-free welding strip, and has no abnormal phenomena such as tin knobs, tin dross, copper cuttings, discoloration and the like. A process capability index (CPK) value is effectively increased.

Owner:SHANGHAI WELNEW MICRO ELECTRONICS

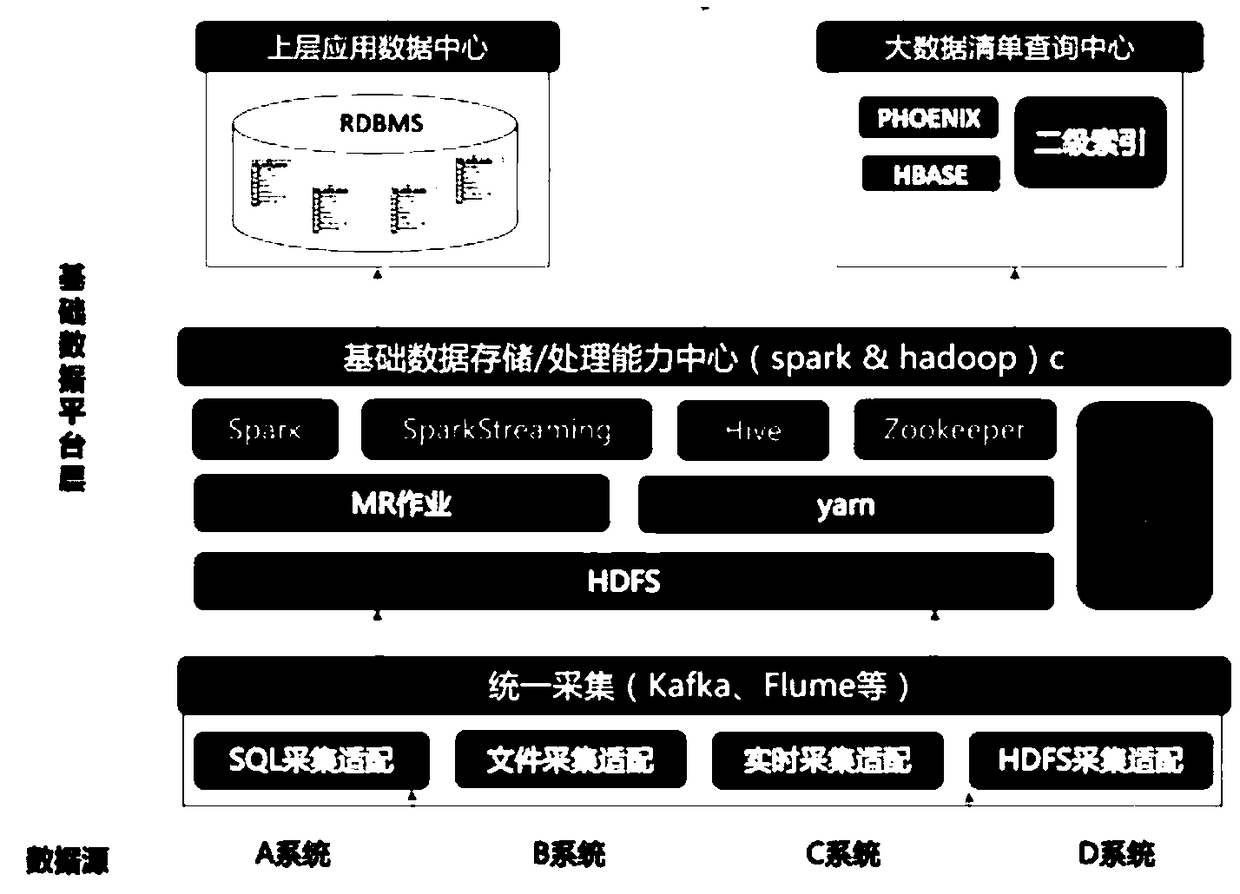

Big data security analysis platform system based on network security

InactiveCN108833397AImprove securityImprove perceptionPlatform integrity maintainanceData switching networksData centerData acquisition

The invention relates to a big data security analysis platform system based on network security. The big data security analysis platform system comprises a unified collection platform, a basic data storage and processing capability center, an upper layer application data center and a big data list query center, the unified collection platform adopts Kafka as a message management layer of the unified collection platform to achieve flexible docking and adaption to various data source collection and to provide flexible and configurable data collection capability, the basic data storage and processing capability center utilizes the spark and hadoop technologies to provide powerful data processing capability, the upper layer application data center provides highly aggregated statistical data ofan enterprise through the RDBMS / ES, and the big data list query center provides fast query capability of big data by constructing an HBase cluster.

Owner:武汉思普崚技术有限公司

Cigarette quality evaluation method and system based on principal component analysis

InactiveCN103324147AImprove quality controlProcess quality management innovationTotal factory controlProgramme total factory controlKernel principal component analysisPrincipal component analysis

The invention discloses a cigarette quality evaluation method and system based on principal component analysis. The cigarette quality evaluation method and system solves the problem that an existing single-variable evaluation method cannot carry out procedure quality evaluation on multiple-variable procedures. The cigarette quality evaluation method and system uses a principal component analysis method to evaluate processing quality of the multiple-variable procedures and can provide basis for comprehensively grasping procedure quality processing states and procedure quality improvement. The method comprises the steps of firstly, calculating process capability indexes of all processing parameters, then using the principal component analyzing method to analyze all processing parameter data, confirming the number of principal components according to the principle that the accumulative total contribution rate is larger than or equal to 90%, confirming weights of all components according to the explanation variances of all principal components, and finally using an arithmetic weighting method to obtain procedure comprehensive process capability indexes. The cigarette quality evaluation method and system can provide more comprehensive and objective results and provides an effectively tool for an enterprise to know procedure total processing quality situations.

Owner:陈景正

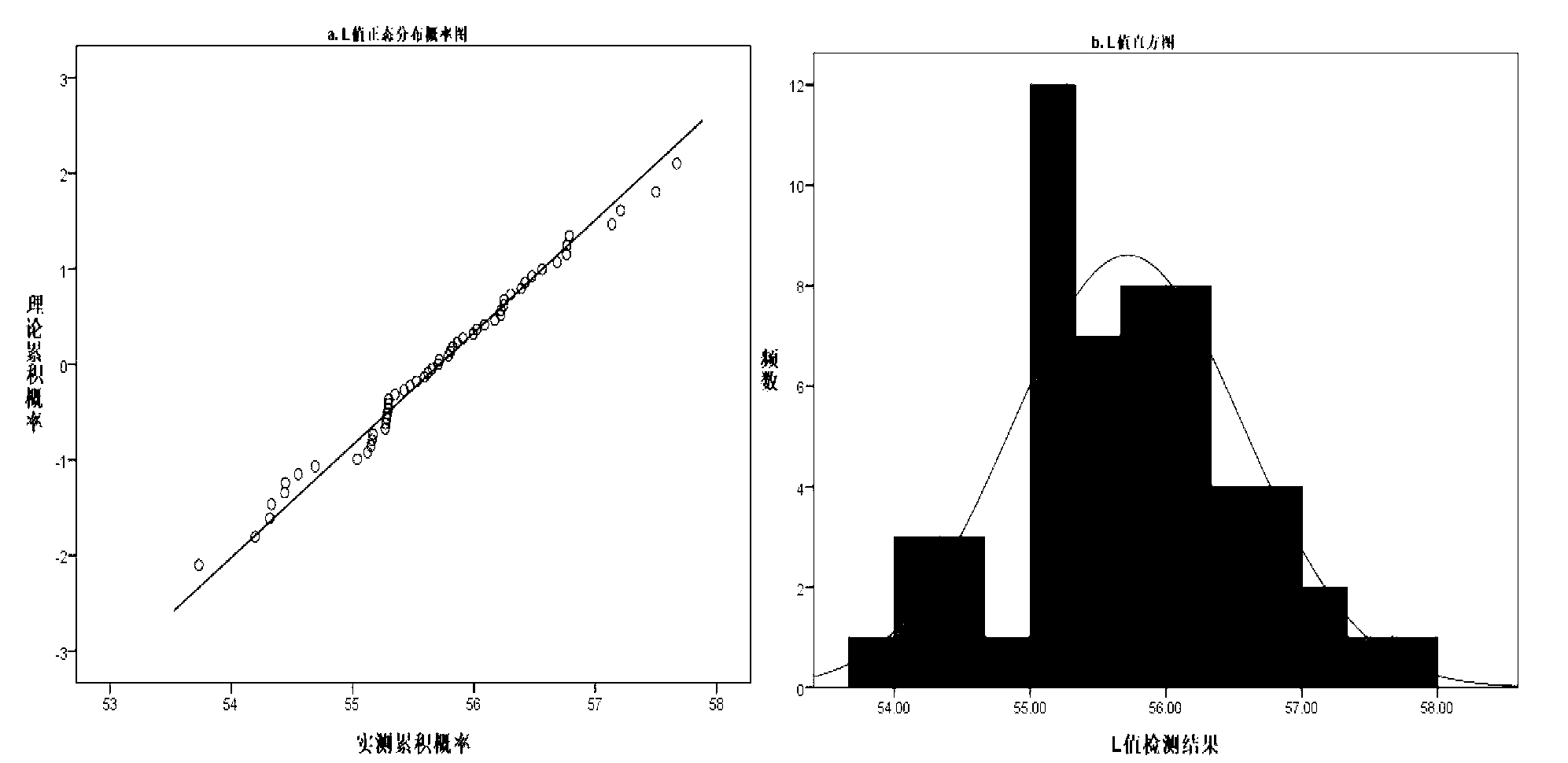

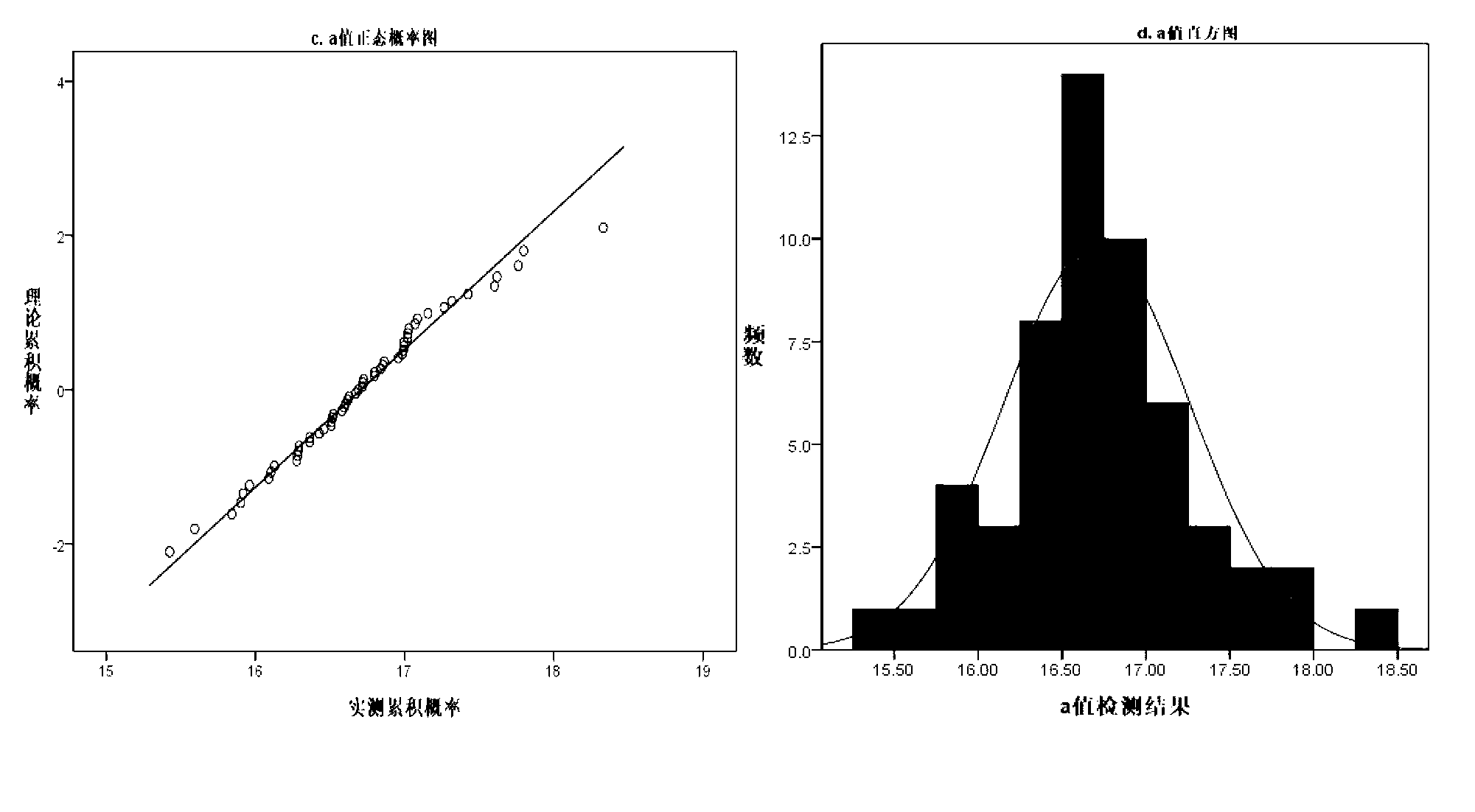

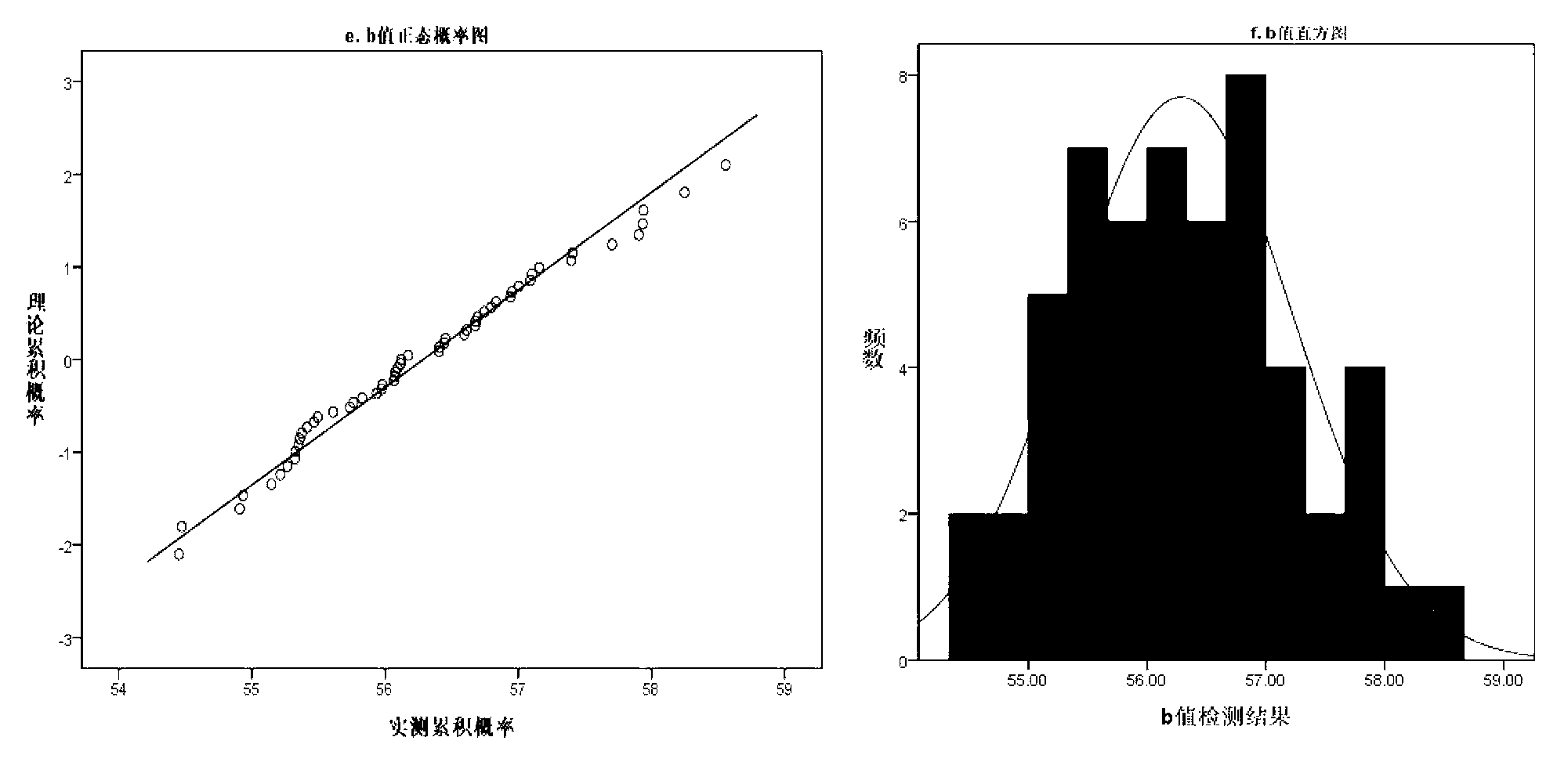

Method for evaluating quality stability of redried finished sheet tobacco

InactiveCN102798596AOvercome limitationsSimple methodColor/spectral properties measurementsStable stateComputer science

The invention discloses a method for evaluating the quality stability of redried finished sheet tobacco. The method comprises the following steps of: converting a qualitative description of the appearance color of the tobacco into quantifiable constant indexes L*(lightness value), a*(red and green value) and b*(yellow and blue value) based on the CIE1976L*a*b*color space; constructing a mean value and Xmax-Xmin graph (X-Rs control graph) by checking the normal distribution conformance of data of the L* value, the a* value and the b* value of the tested tobacco; and calculating a process capability index Cp of each index to determine the quality stability of the redried finished sheet tobacco. If the process capability indexes of the L* value, the a* value and the b* value meet the condition that Cp is greater than 1.00 and less than or equal to 1.33, the quality of the redried finished sheet tobacco is in a stable state, otherwise, the quality stability of the redried finished sheet tobacco is relatively low. By the method, the problem of limitation that the quality stability of the conventional redried finished sheet tobacco is only evaluated by subjective evaluation; and the method has the characteristics of simplicity in operation, reliable result and high adaptability.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD +1

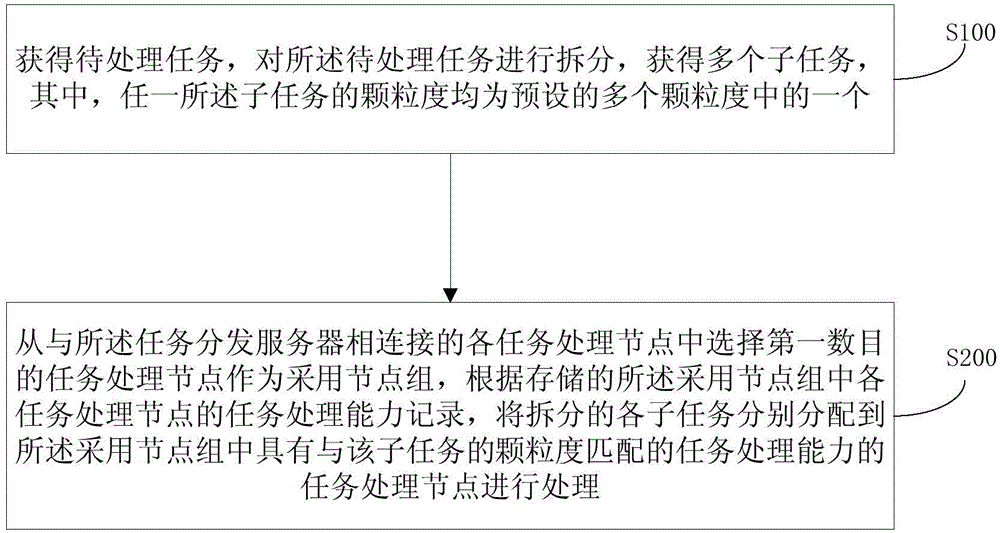

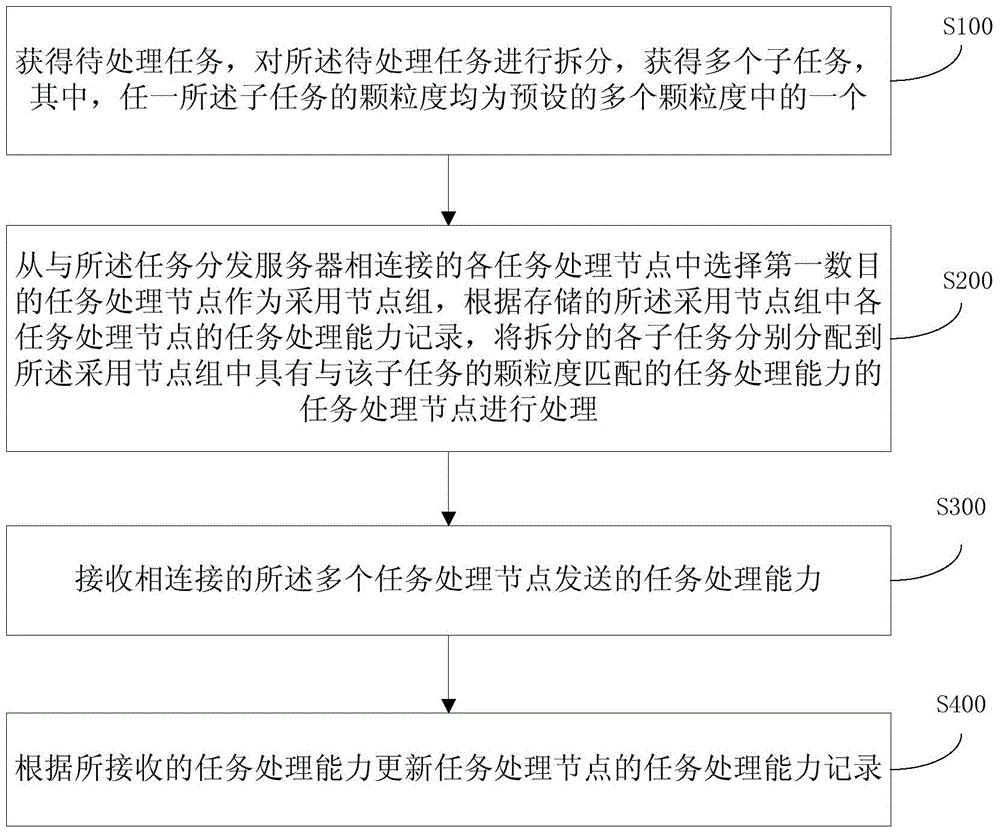

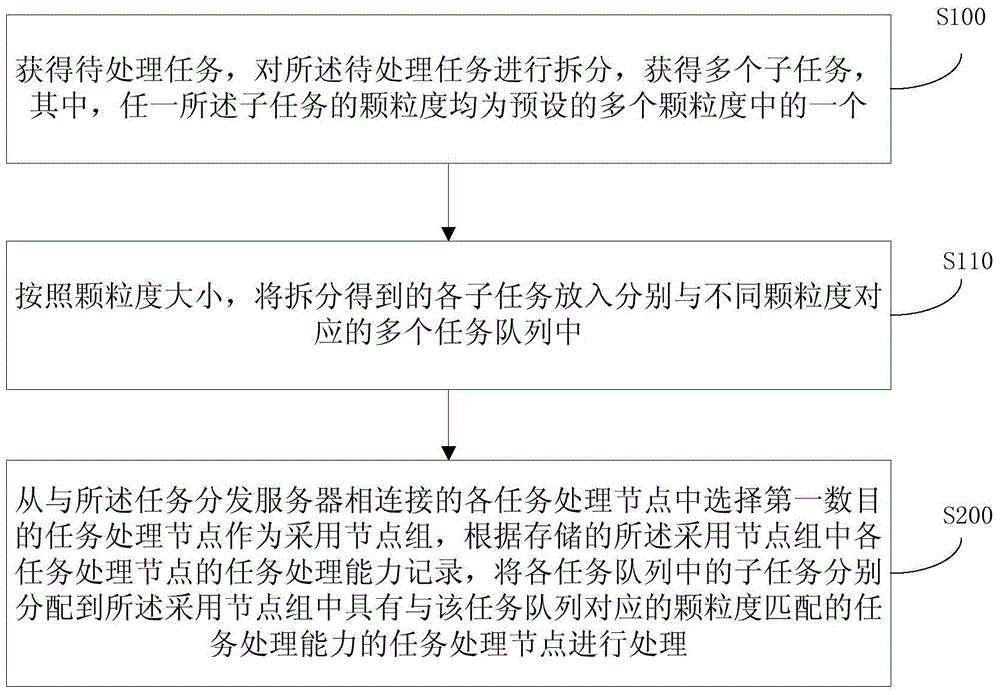

Task processing method and system

An embodiment of the invention provides a task processing method and system. The method includes: separating a to-be-processed task into multiple sub-tasks, wherein the granularity of one optional sub-task is one of the multiple preset granularities; selecting the first-number task processing nodes from task processing nodes to serve as adopted node groups, respectively distributing the sub-tasks to the task processing nodes, with the task processing capability matched with the granularities of the sub-tasks, in the adopted node group for processing according to the task processing capability records of the task processing nodes in the stored adopted node groups. Due to the fact that the granularities of the tasks to be processed by the task processing nodes are matched with the processing capability of the task processing nodes, the task processing time of the task processing nodes is identical, and the situation that the task processing nodes with high process capability are idle for a long time is avoided. By the method, resource utilization rate and task processing speed are increased effectively.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

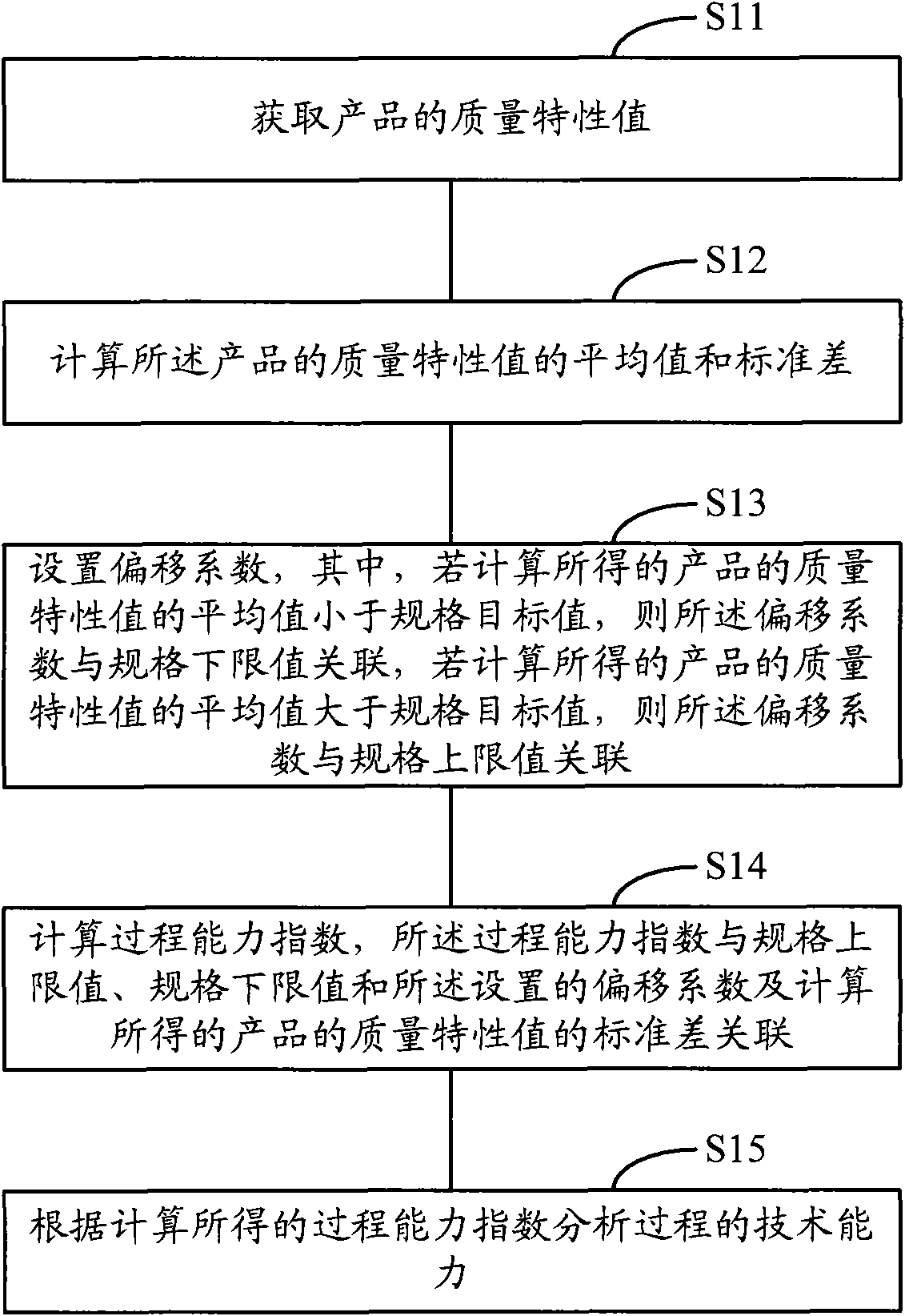

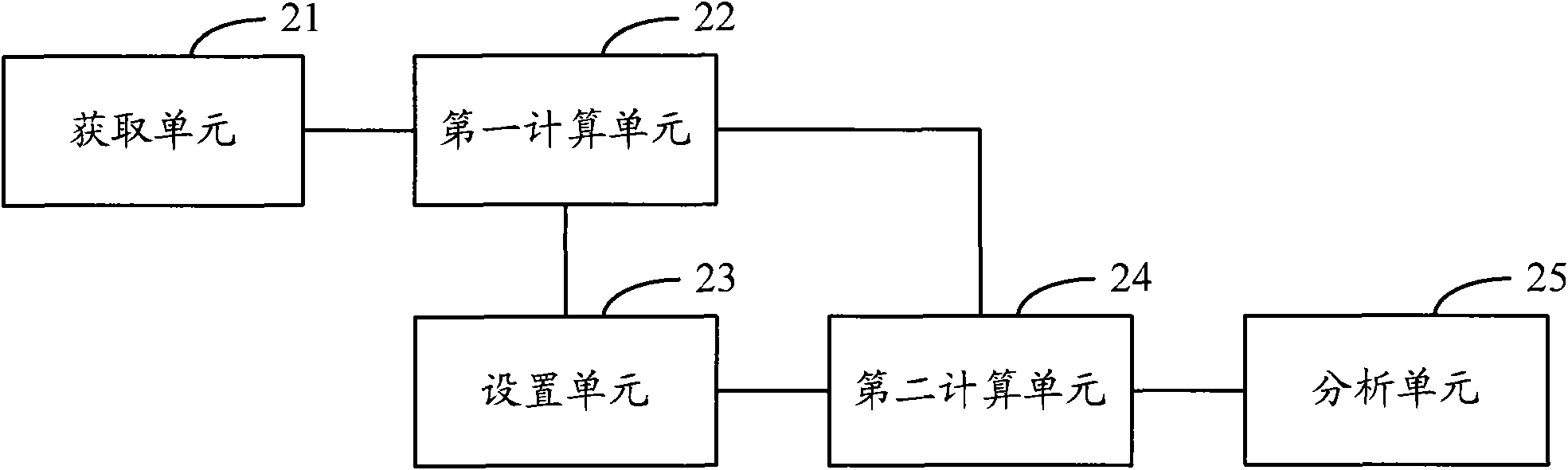

Process detection method and device

InactiveCN101937212AAccurate analysisTotal factory controlProgramme total factory controlLower limitEngineering

The invention provides process detection method and device. The method comprises the steps of: obtaining the quality characteristic values of a product; computing the average value and standard deviation of the quality characteristic values of the product; setting an offset coefficient, wherein if the computed average value of the quality characteristic values of the product is less than a specification target value, the offset coefficient is associated with a specification lower limit, or else, the offset coefficient is associated with a specification upper limit; computing a process capability index which is associated with the specification upper limit, the specification lower limit, the offset coefficient and the standard deviation of the quality characteristic values of the product; and analyzing the technical capability of the process according to the process capability index. The process detection method and device can correctly analyze the state of the process and correct the difference or abnormal phenomenon in the process by adopting corresponding measures, so as to make the work procedure in a control (stable) state.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

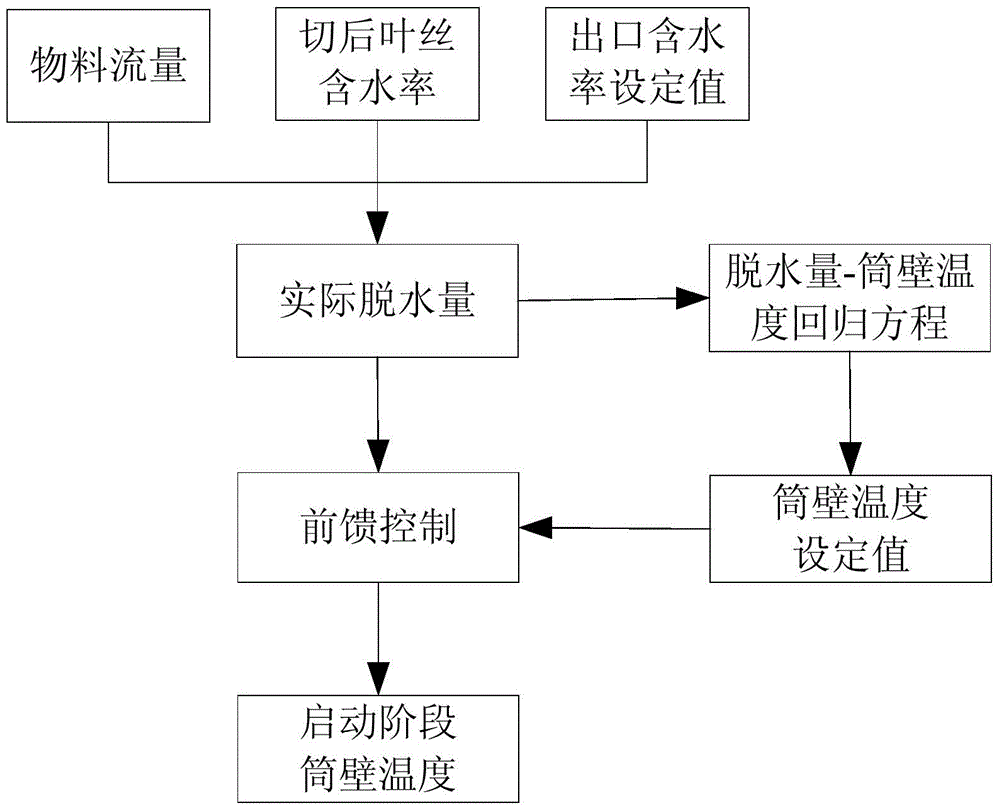

Shred drier cylinder wall temperature prediction model based on cut tobacco shred moisture content

InactiveCN104886751AImprove accuracyIncrease the steady state timeTobacco preparationPulp and paper industryMoisture

The invention discloses a shred drier cylinder wall temperature prediction model based on the cut tobacco shred moisture content. The shred drier cylinder wall temperature prediction model includes the following steps: (1) the after-cut tobacco shred moisture content (W1) is collected through a moisture instrument at the position of a belt at an inlet of a tobacco shred temporary storage cabinet; (2) the actual dehydration amount deltaFW is calculated according to the tobacco shred drying outlet moisture content setting value (SPW4); (3) according to the dehydration amount-cylinder wall temperature stepwise regressive equation, the cylinder wall temperature setting valve TSP is calculated; and (4) an operating person inputs the TSP into a formula list, a drier gets into the starting stage, feedforward control is carried out according to the formula, and calculation is carried out to obtain Tpv. By means of the shred drier cylinder wall temperature prediction model based on the cut tobacco shred moisture content, through decreasing of the difference value between the cylinder wall temperature setting value at the starting stage and the cylinder wall temperature actual value in the production steady state, the non-steady-state time of the starting stage is shortened, and decreasing of the number of dry head materials in the thin plate drying process and improving of the moisture content process capability index of discharged materials are achieved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

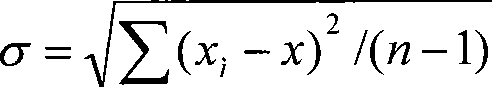

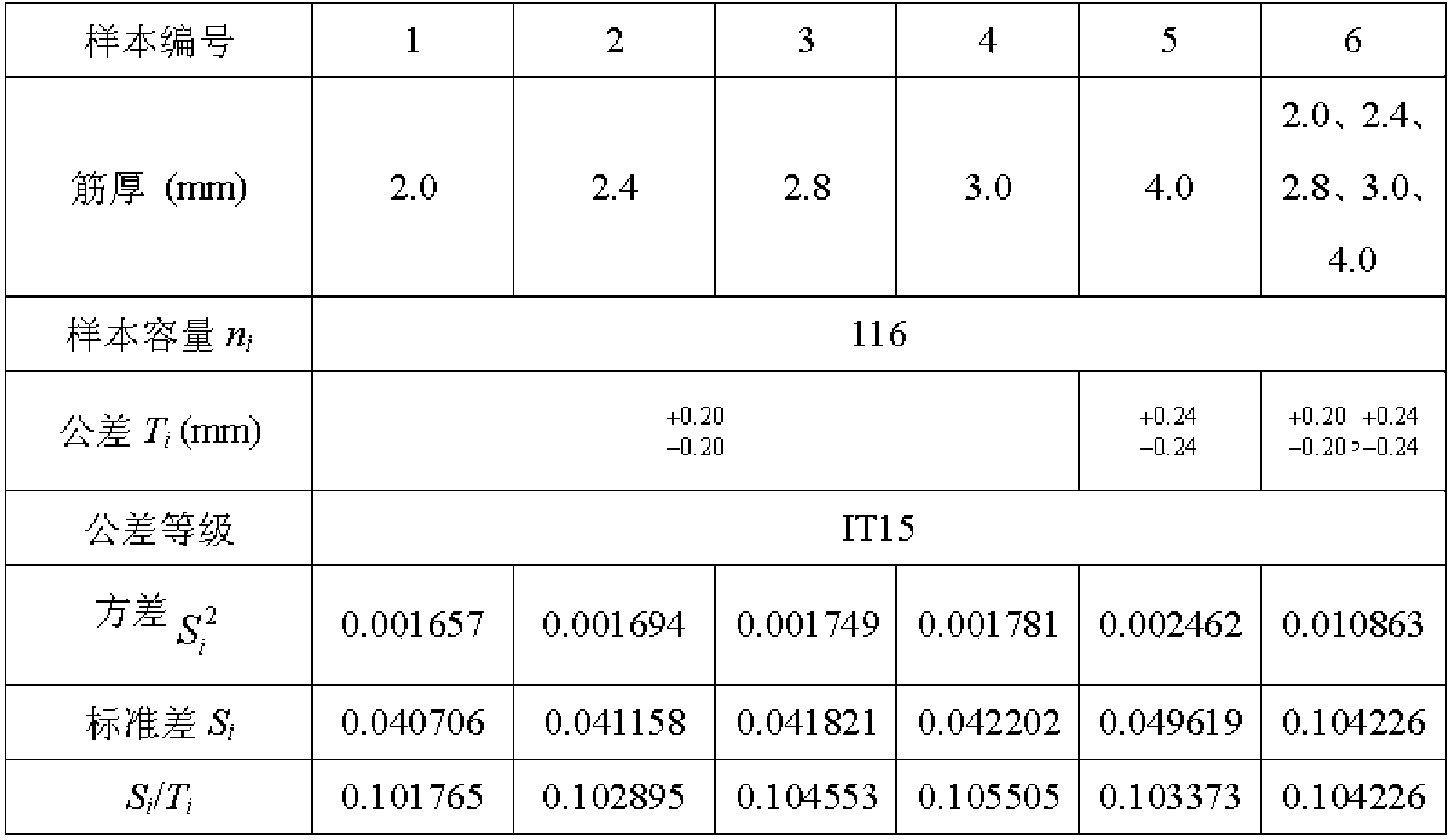

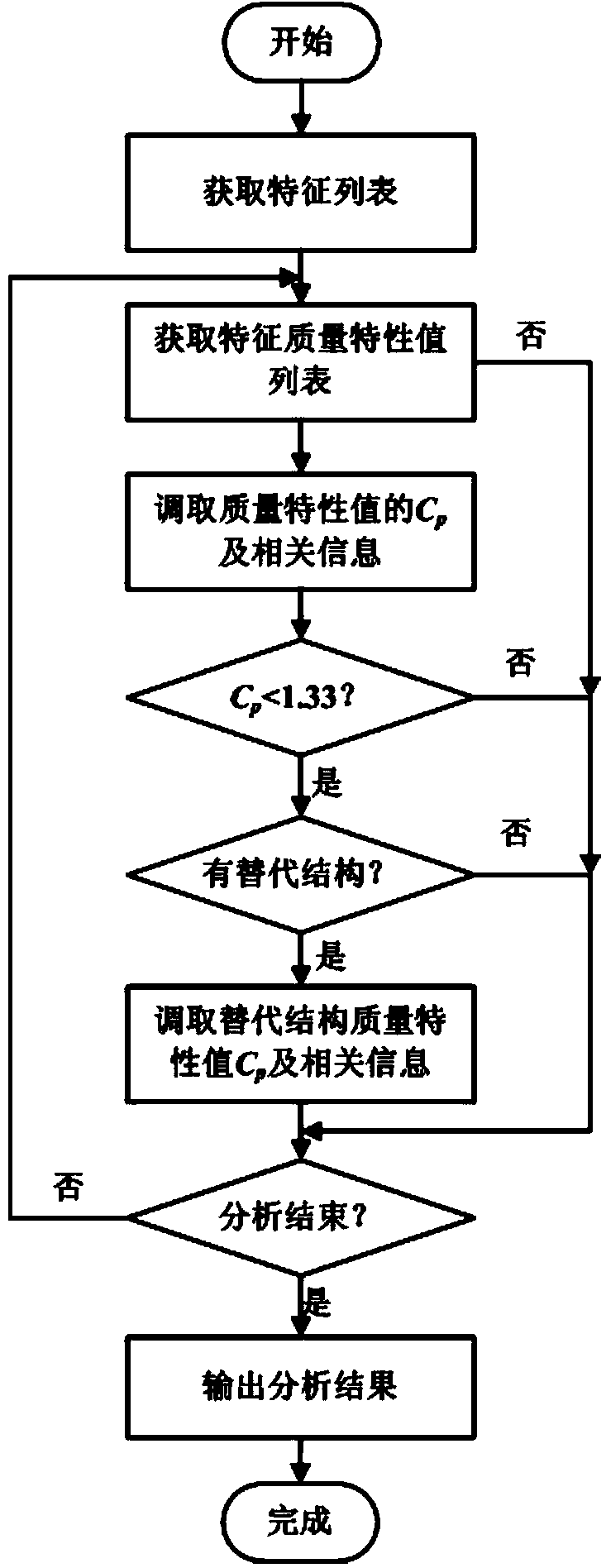

Multi-kind and small-quantity part production process capability index determining method based on features

The invention discloses a multi-kind and small-quantity part production process capability index determining method based on features. The multi-kind and small-quantity part production process capability index determining method based on the features is characterized in that firstly, processing features are taken as objects, processing feature quality characteristic values which are different in size and identical in processing technology and tolerance grade are defined as the same processing feature sample, wherein the ratio of the standard deviation and the tolerance of the processing feature quality characteristic values is a constant; secondly, sample individuals are normalized, the mean values of the sample individuals are the same, namely the sample individuals conform to the same type of distribution; finally, a process capability index is calculated based on processing feature samples. According to the multi-kind and small-quantity part production process capability index determining method based on the features, the problem of sample size of multi-kind and small-quantity production is fundamentally solved, and conversion from interval estimation to point estimation of the process capability index oriented to multi-kind and small-quantity production is achieved. The obtained process capability index can be used for calculating the disqualification rate of the processing feature quality characteristic values, the processibility analysis is performed on feature design structures according to the disqualification rate, the proper design structures are selected, 100 percent detection is avoided, and the detection efficiency is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

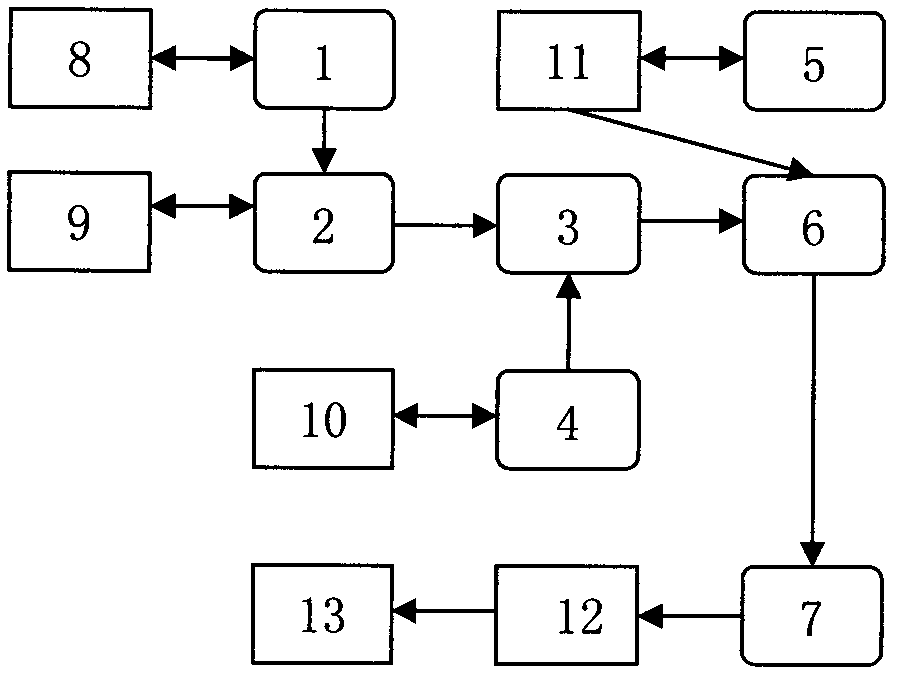

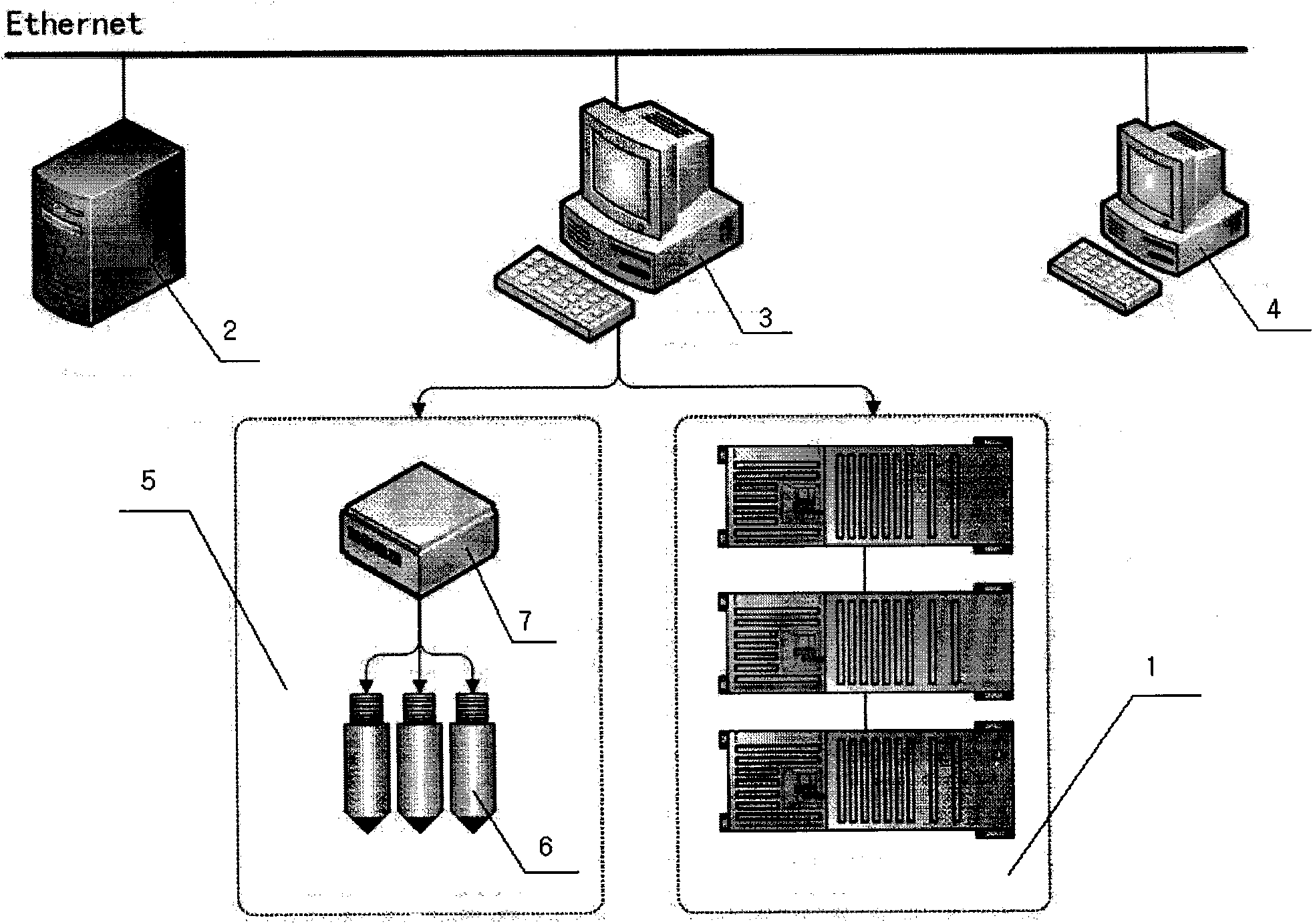

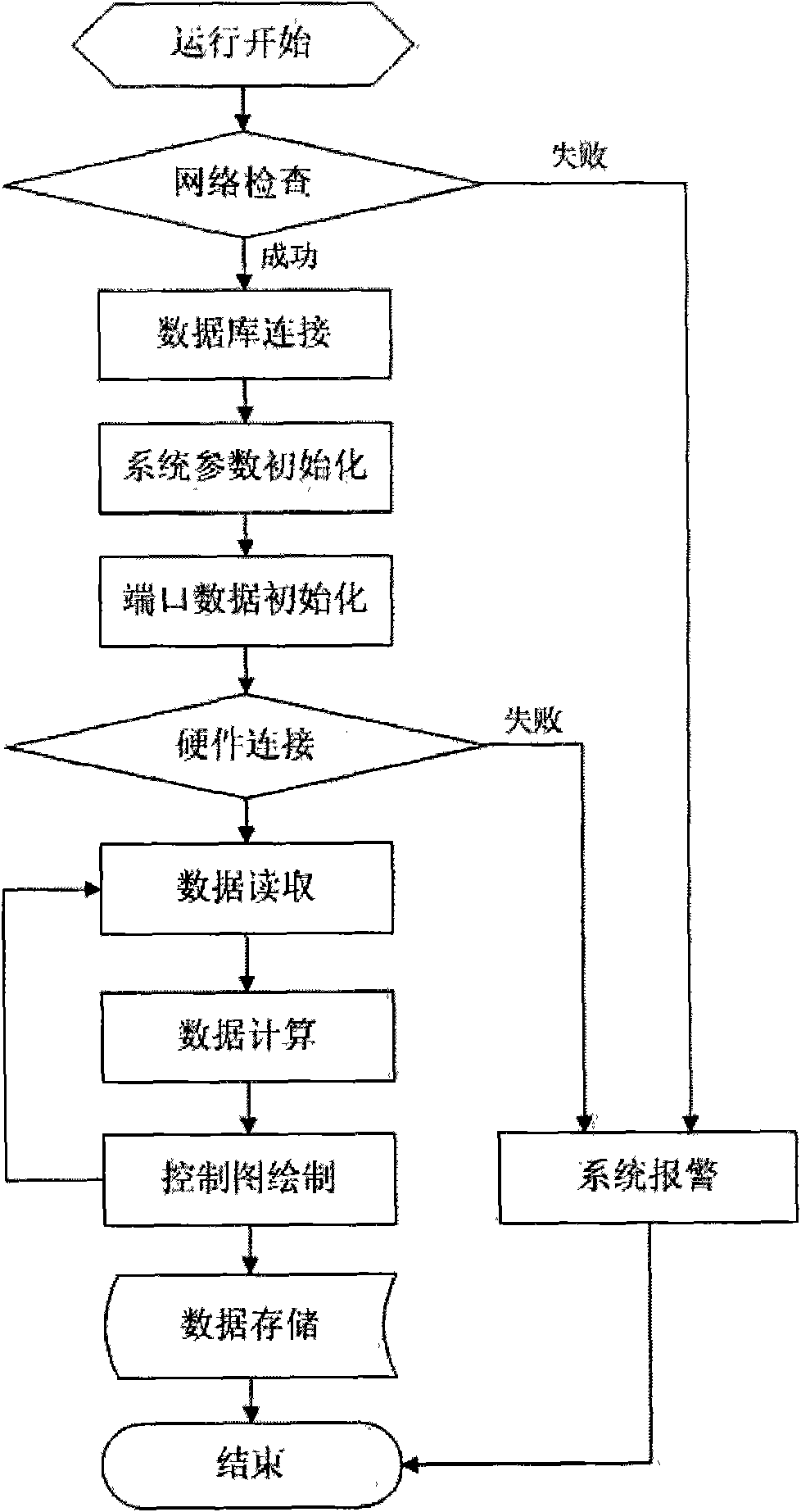

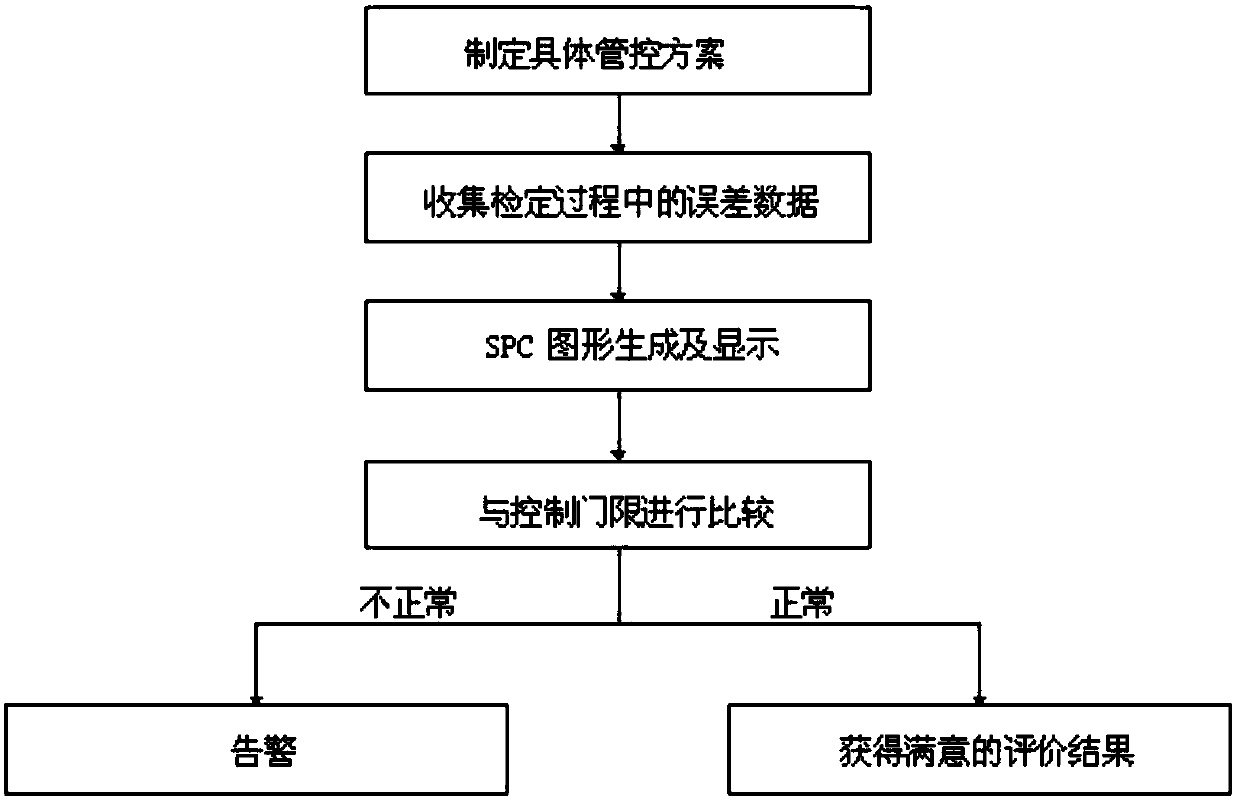

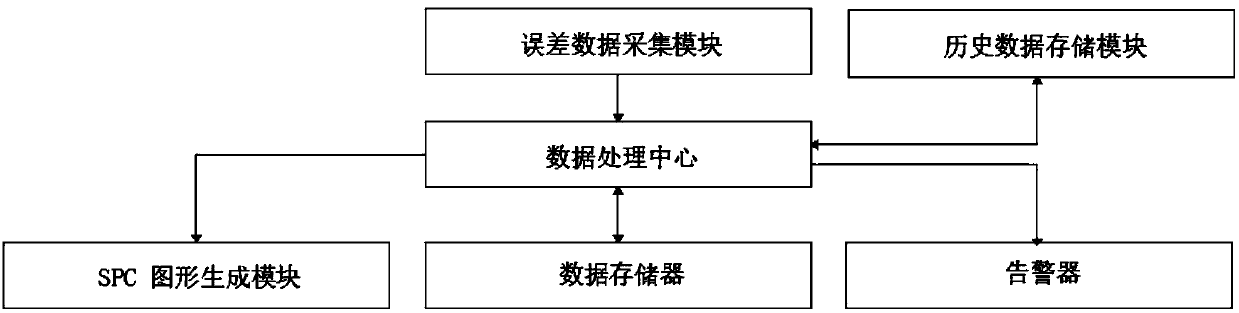

Online monitoring system and monitoring method of oilless bushing sintering production line

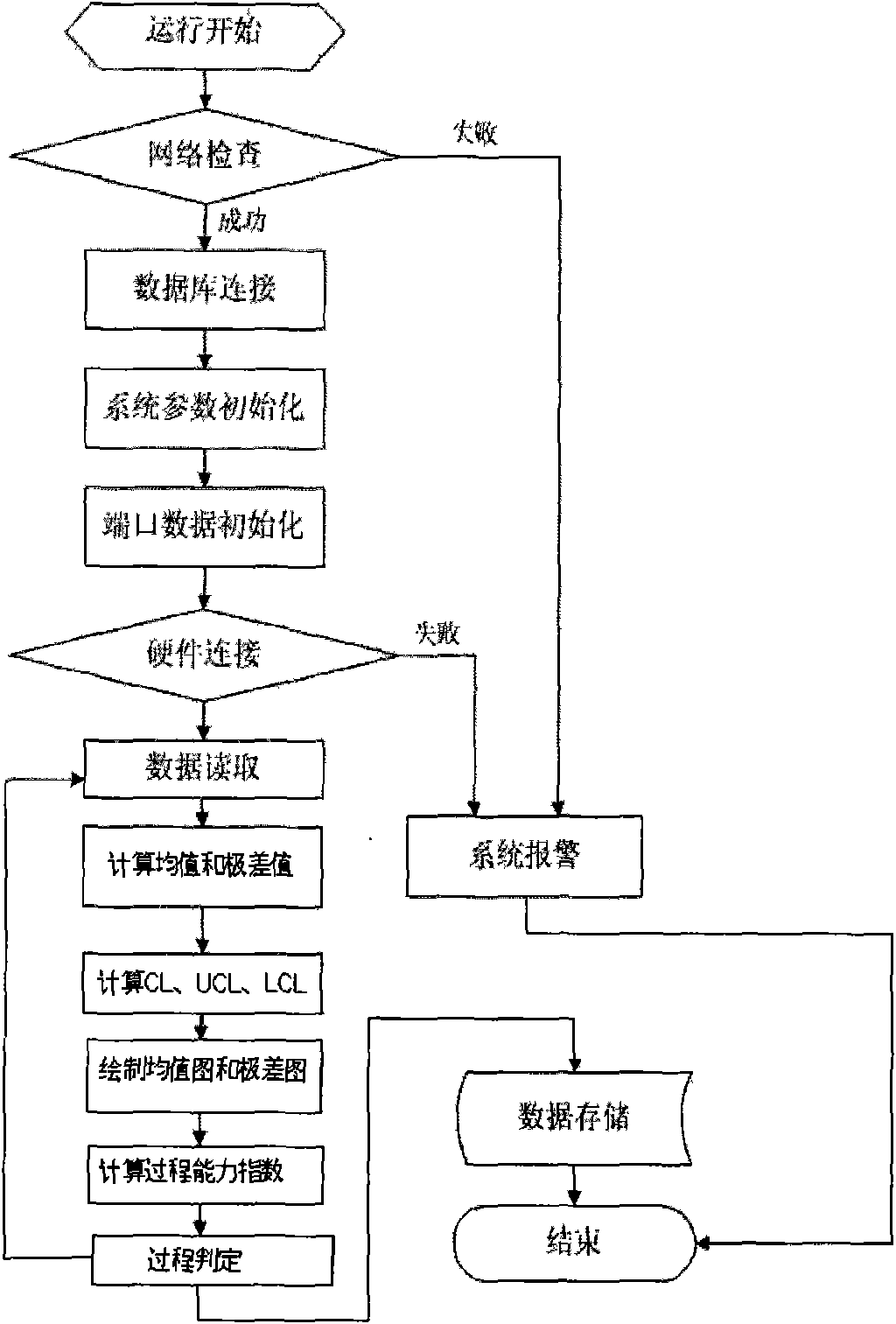

The invention discloses a monitoring system and a monitoring method of an oilless bushing sintering production line. By means of the thought and method of the SPC process management theory, the operation process of the sintering production line is monitored all the way; by automatic interpretation of mean value-range chart, the vibration of the process is prewarned and warned, ensuring that the process capability executed by the system conforms to requirements and ensuring the quality conformity of final machined parts as well. The monitoring system of the oilless bushing sintering production line comprises a PLC 1, a server 2, a workstation computer 3, a client computer 4 and a sensor-based system 5. The monitoring system of the oilless bushing sintering production line mainly comprises the following steps: reading data; calculating the mean value and range value of all data; respectively calculating the centerlines, upper control lines and lower control lines of mean value chart and range chart; drawing mean value chart and range chart; calculating process capability indexes Cpk and Ppk; judging the process; returning to data reading to carry out dynamic update of continuous fetching.

Owner:江苏网商精益管理软件有限公司

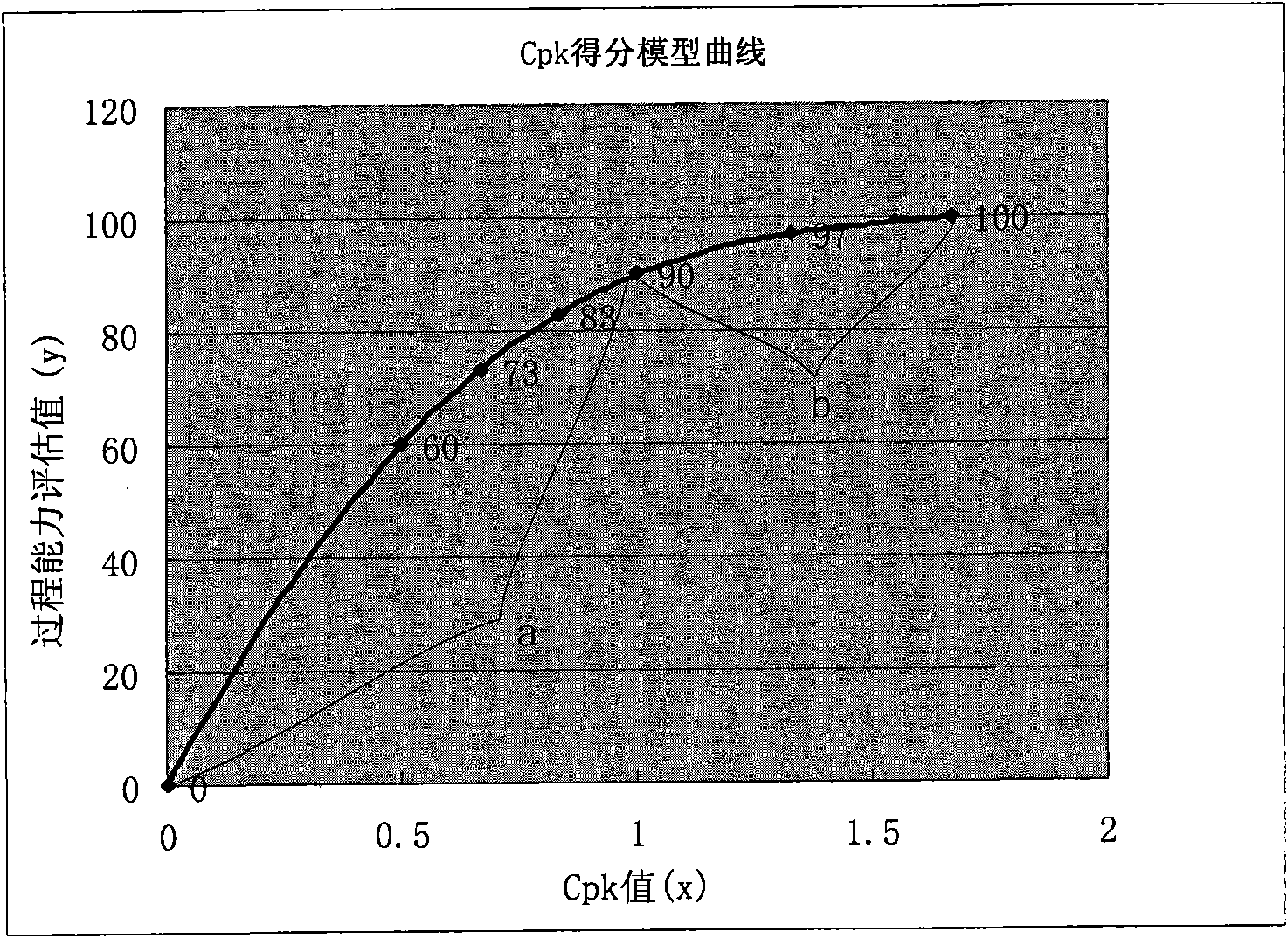

Method for improving tobacco-drying process capability

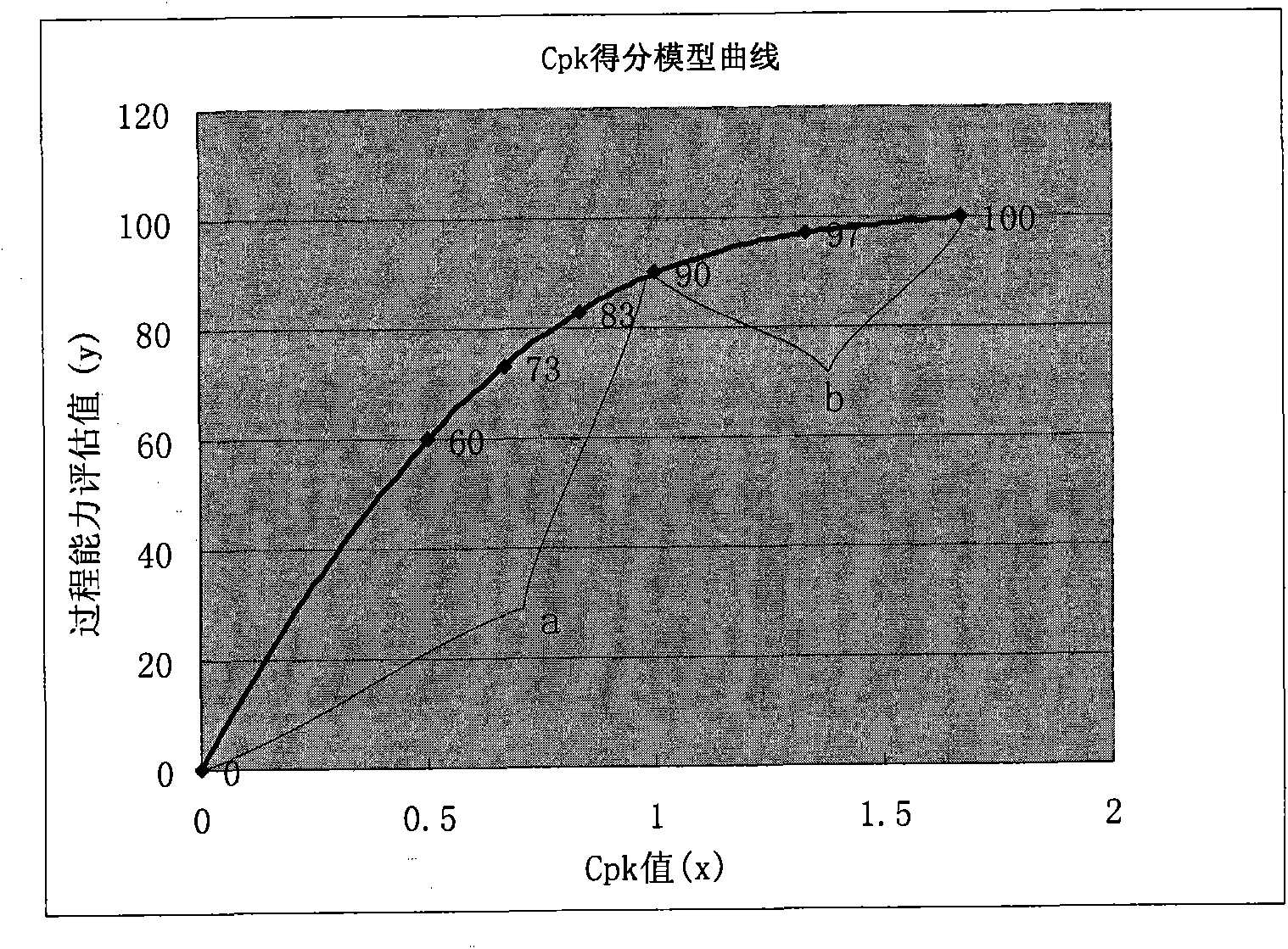

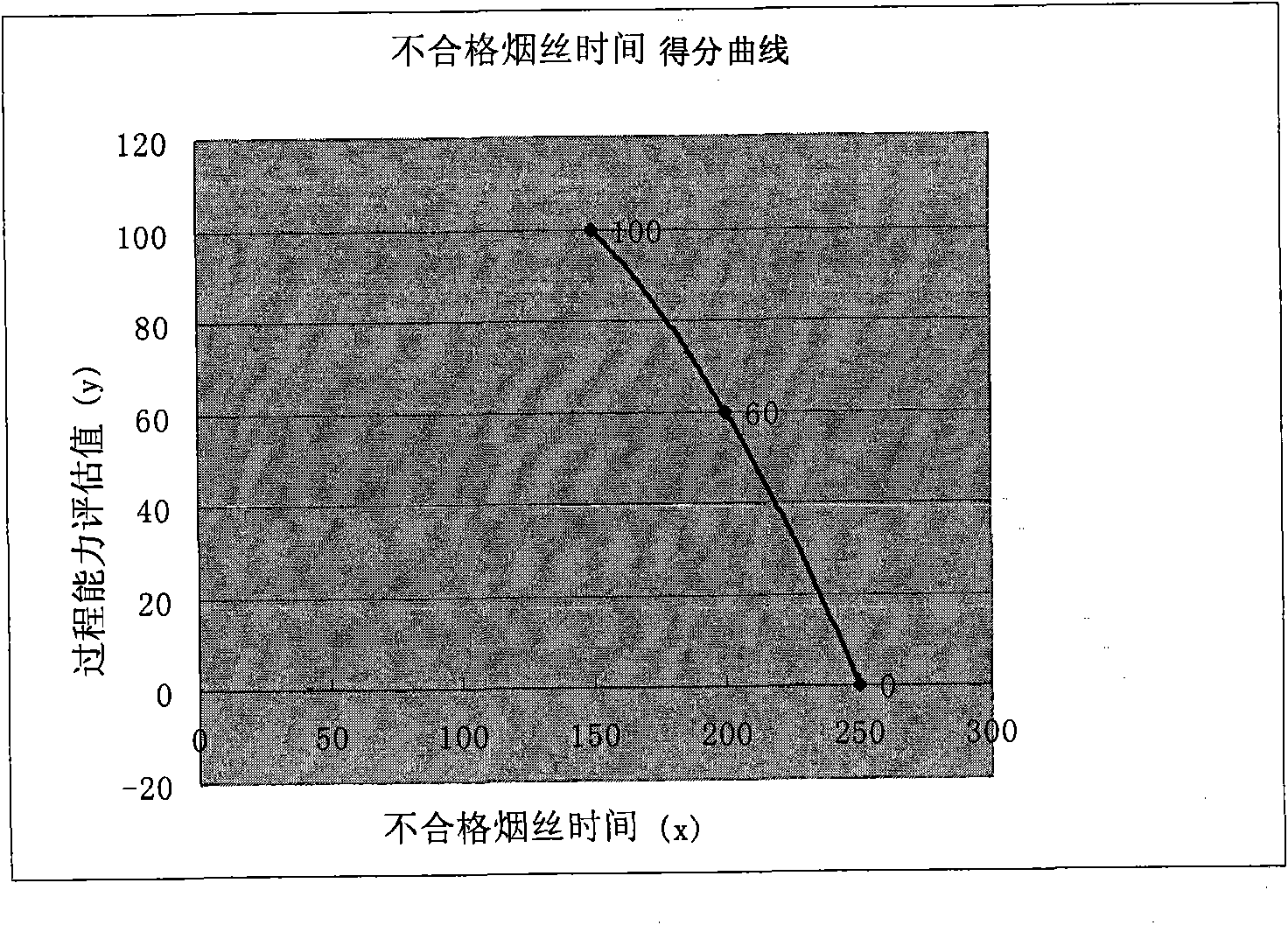

The invention relates to a method for improving the tobacco-drying process capability. The method comprises the following steps of: acquiring raw data of a plurality of process parameters of a tobacco-drying process; according to the raw data, calculating the process capability index of all process parameters respectively; according to a preset process capability evaluation function, converting the process capability indexes to obtain process capability evaluation values; performing weighted average of the obtained process capability evaluation values to obtain the batch process capability evaluation value of the current batch; and judging whether the batch process capability evaluation value reaches the preset threshold value, if the batch process capability evaluation value does not reach the preset threshold value, checking whether the process capability evaluation values of all process parameters of the current batch reach the preset threshold value and performing optimal operation of the process parameters, of which the process capability evaluation values do not reach the preset threshold value. In the method, the batch process capability evaluation value of the current batch is obtained by calculating the dispersibility of the characteristic values of all process parameters of the tobacco-drying process to determine the batch having problems, and the process parameters having defects are traced, so that a solid foundation is provided for technicians to adjust and optimize the tobacco-drying process.

Owner:LONGYAN CIGARETTE FACTORY

Polynary intelligent evaluation method and polynary intelligent evaluation system for child comprehensive development ability

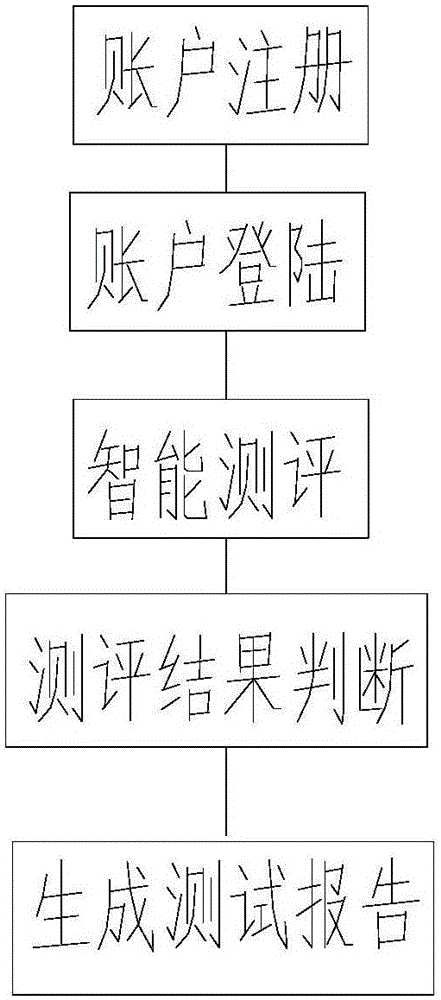

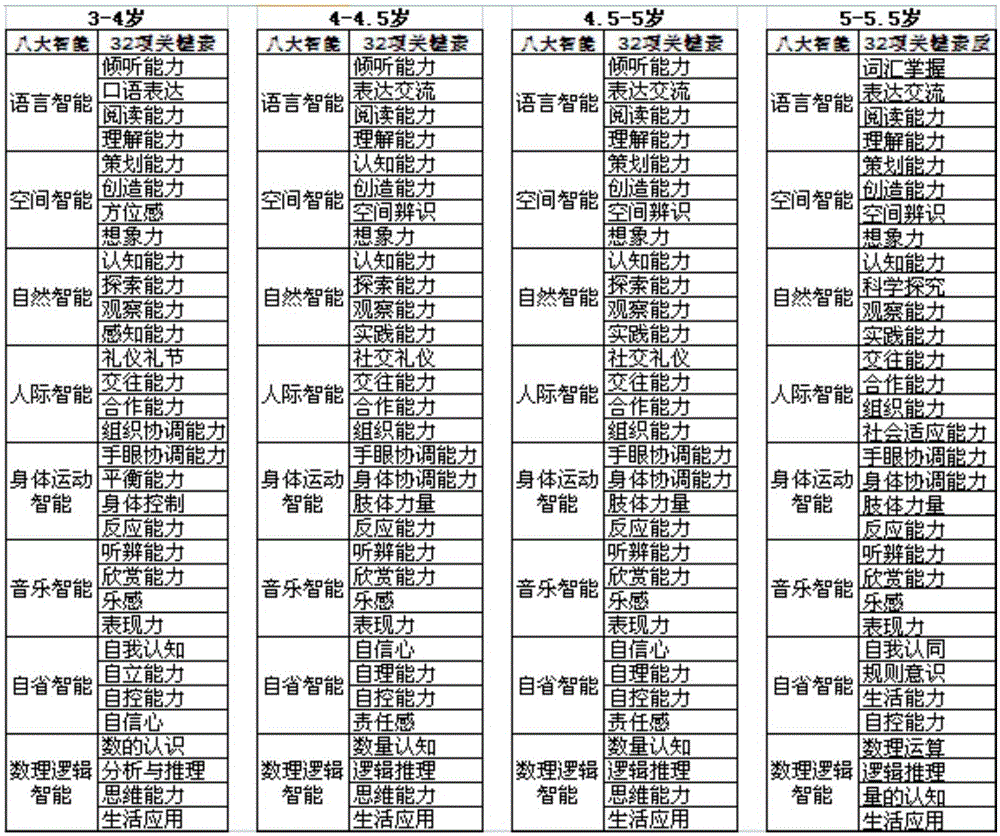

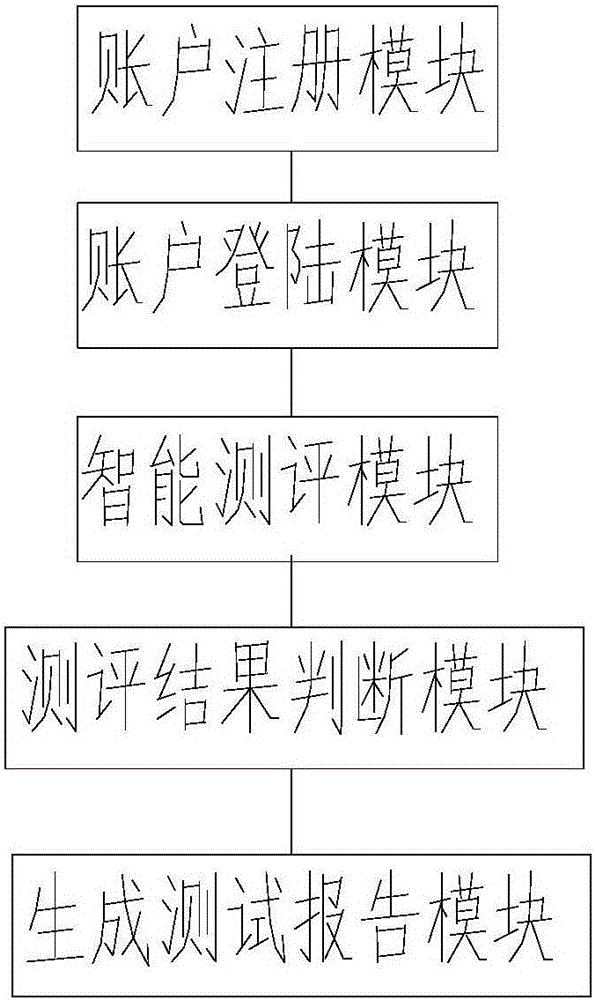

InactiveCN105956959AEasy to trainScientific and effective parenting guidance and suggestionsData processing applicationsTeaching apparatusEvaluation resultPhases of clinical research

The invention discloses a multi-intelligence evaluation method for children's comprehensive development ability. The method includes: account registration, account login, intelligent evaluation, evaluation result judgment and test report generation, wherein the evaluation result judgment includes the test and evaluation of each key quality evaluation index. According to the average score of the corresponding two test questions, the corresponding key quality judgment level is given; the corresponding core ability index judgment level is given for the total score of each core ability index; Judgment level of superior intelligence; Judgment of weak intelligence level is given according to the score of weak intelligence combination. The present invention uses 8 core ability indexes of children to be tested and the test covers the entire toddler stage of 2-6.5 years old, can better train children, provides teaching guidance basis for kindergarten teachers, and provides scientific and effective child-rearing guidance for parents Suggest.

Owner:广州乐幼教育科技有限公司

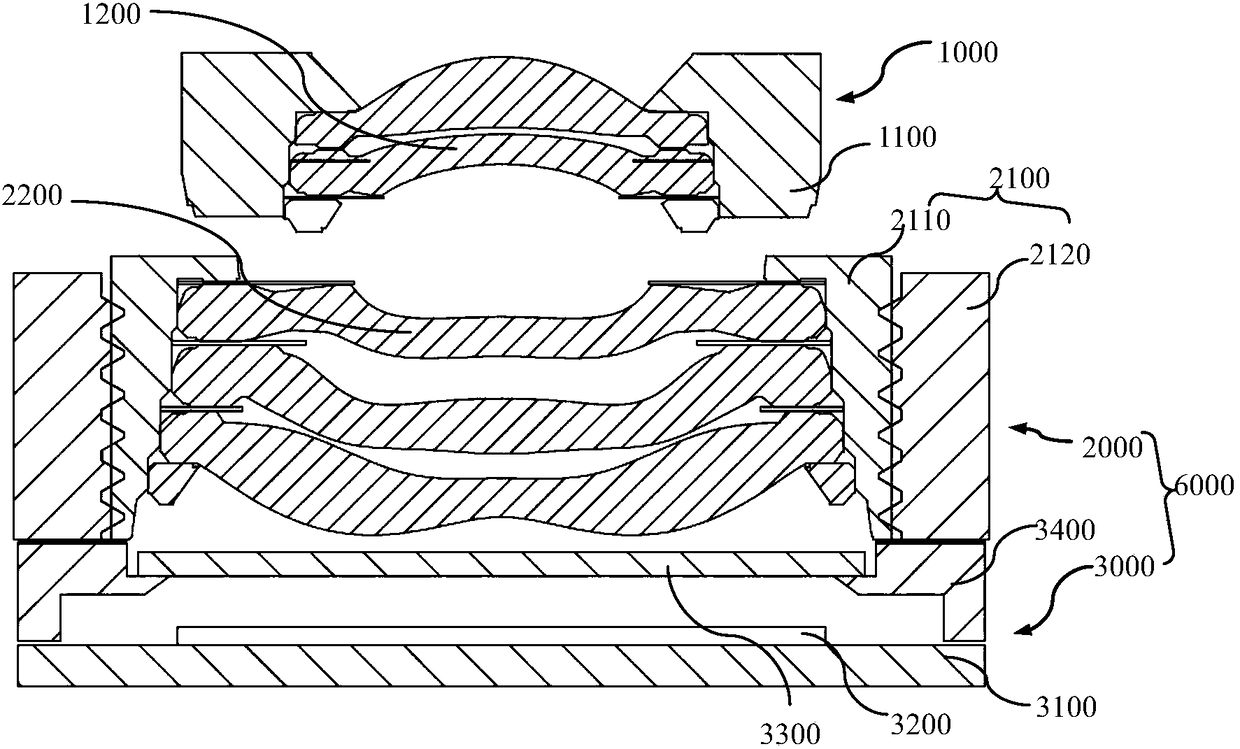

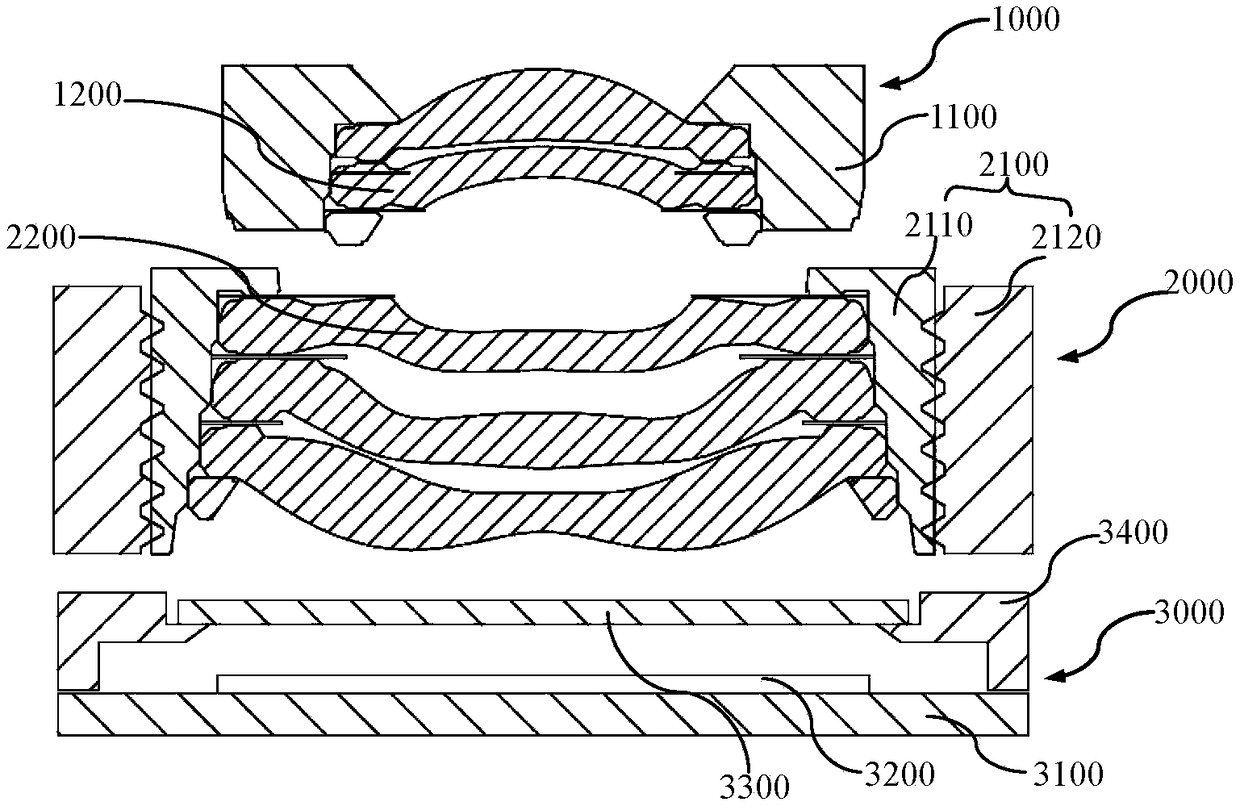

Camera module and assembling method thereof

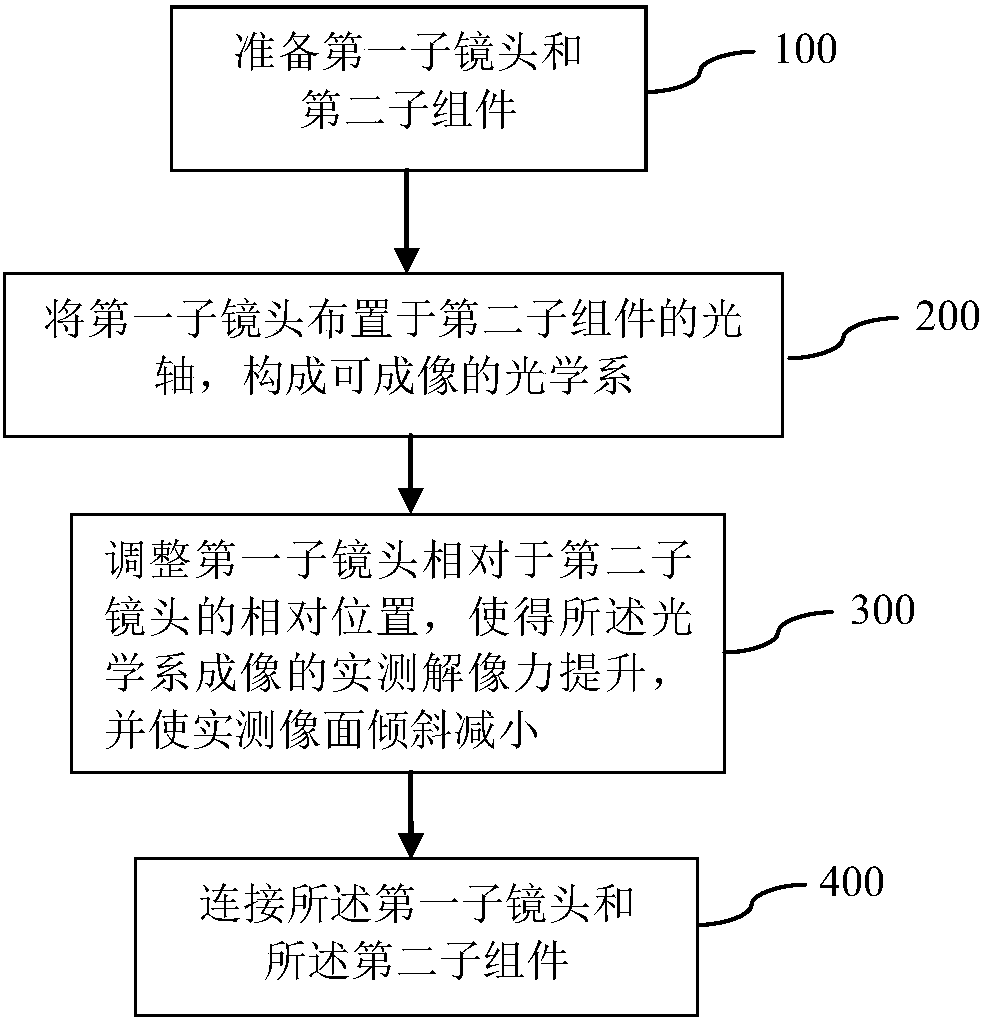

ActiveCN109495672AHigh resolutionImprove performance indexTelevision system detailsColor television detailsCamera lensHigh volume manufacturing

The invention provides a camera module assembling method, which comprises the following steps: preparing a first sub lens and a second sub assembly, wherein the second sub assembly comprises a secondsub lens and a photosensitive assembly which are fixed together; disposing the first sub lens on an optical axis of the second sub lens to form an imageable optical system; increasing an actually measured resolving power, acquired through the photosensitive element, of imaging of the optical system by adjusting a relative position of the first sub lens relative to the second sub lens, and reducingthe inclination of an actually measured image plane acquired by the photosensitive element to a second threshold value; and connecting the first sub lens with the second sub lens. The invention further provides a corresponding camera module. The camera module assembling method can increase the resolving power of the camera module; the process capability index of a large batch of produced camera modules can be increased; the entire cost of an optical imaging lens and module can be reduced; the disqualification rate can be reduced; the production cost is reduced; and the imaging quality is improved.

Owner:NINGBO SUNNY OPOTECH CO LTD

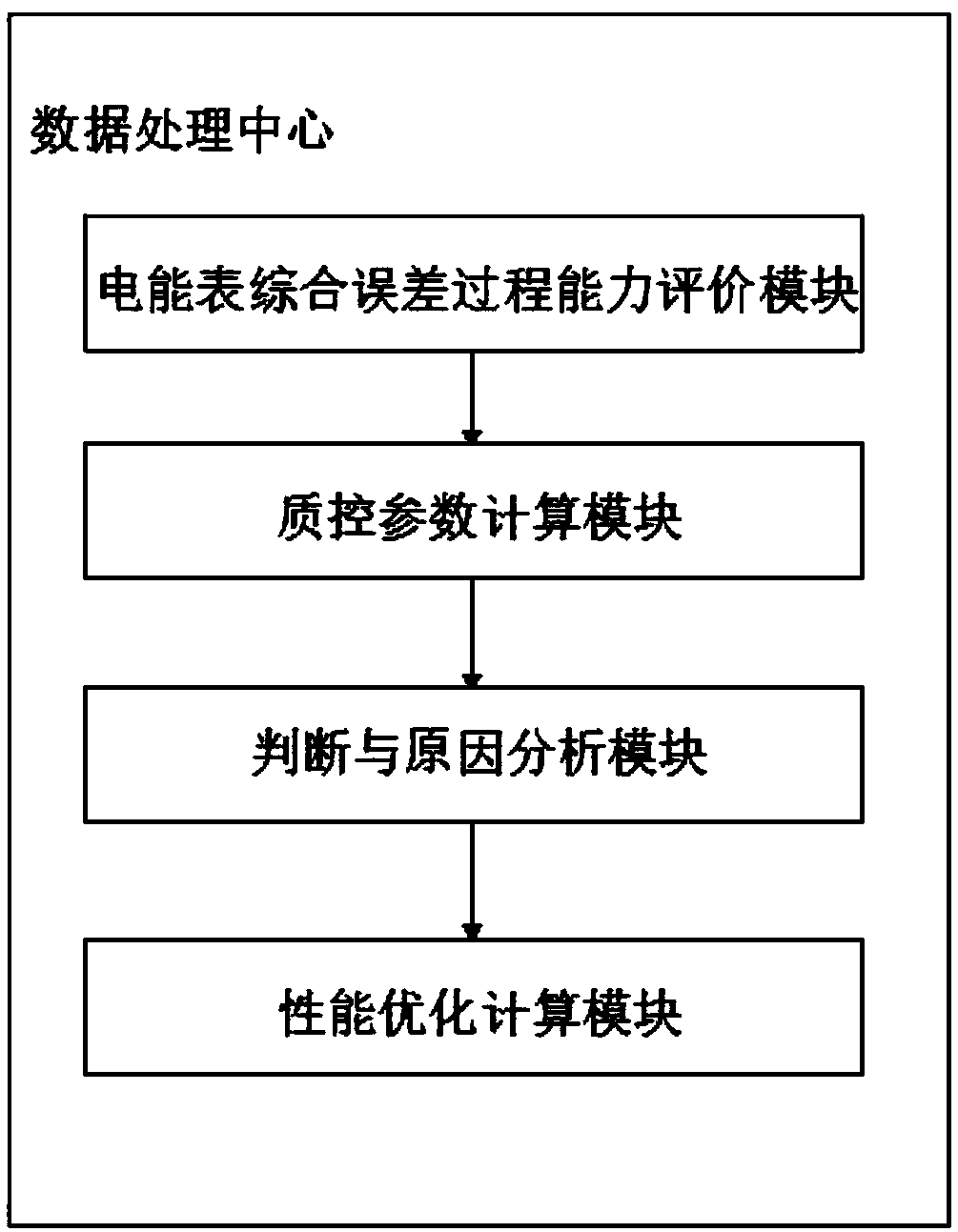

SPC (statistical process control)-based electric energy meter comprehensive error process capability evaluation method and evaluation system

InactiveCN107679715AEffective evaluationEffective controlResourcesWeight coefficientDistribution law

The present invention relates to an SPC (statistical process control)-based electric energy meter comprehensive error process capability evaluation method. According to the method, process capabilityindexes CPK and PPK are introduced into an error analysis process; the process capability indexes of each different load error point are calculated, and weighted calculation is performed according tothe weight coefficients of different loads, and therefore, the comprehensive error monitoring index of an electric energy meter can be determined; parameters which characterize single-phase smart electric energy meter comprehensive error distribution features are researched; the distribution law of smart electric energy meter output feature parameters are calculated finally; daily verification data analysis is reinforced, and the quality of batch products is controlled. An SPC-based comprehensive quality control mechanism is built for electric energy meter comprehensive error; the SPC technology is applied to electric energy meter comprehensive error process capability evaluation; random factors and abnormal factors that affect the quality of a teaching mode can be reasonably differentiated; an electric energy meter error verification process is always in a statistically controlled state; and the error level of a metering device can be under effective control.

Owner:ELECTRIC POWER SCI & RES INST OF STATE GRID TIANJIN ELECTRIC POWER CO +3

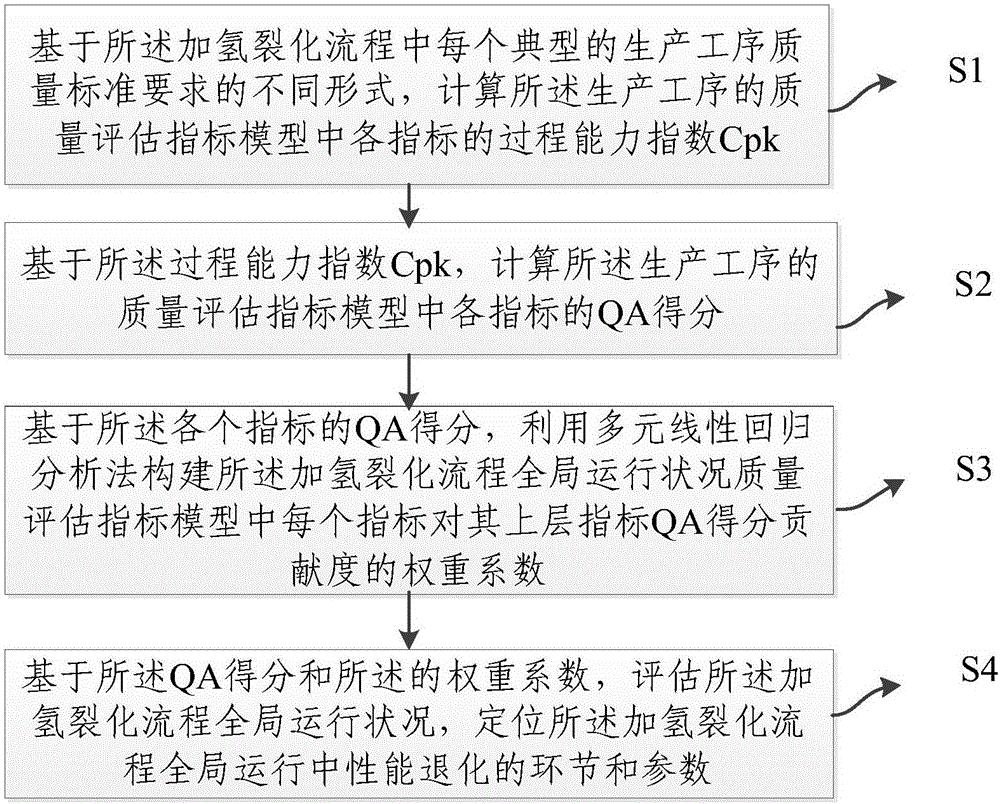

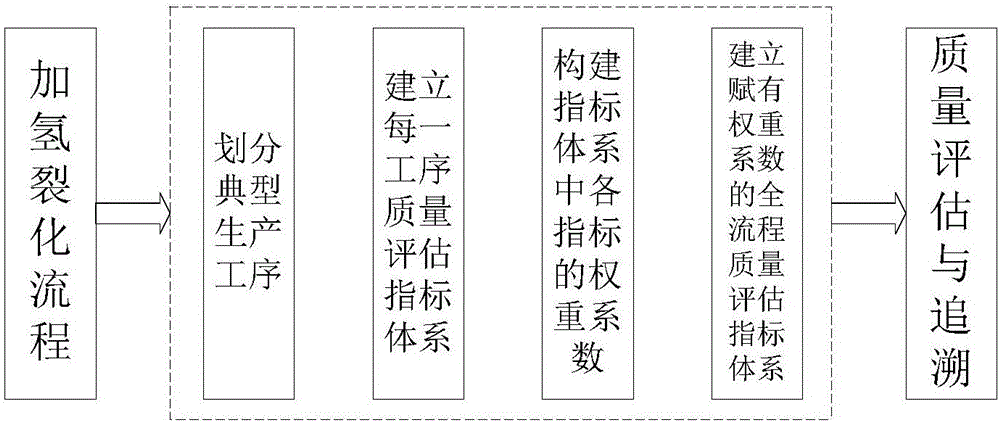

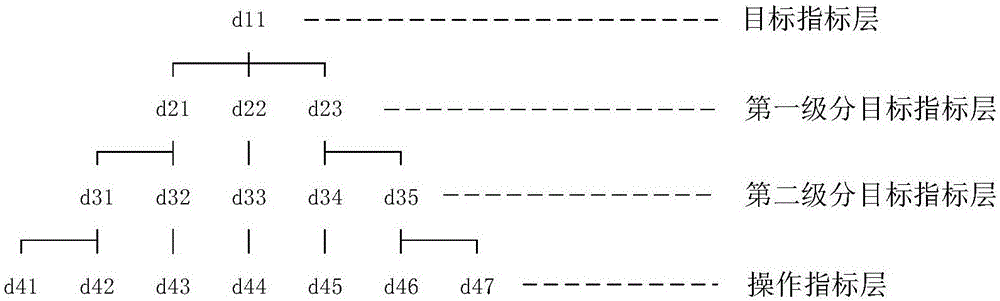

Global operating condition evaluating and quality tracing method for hydrocracking process

InactiveCN106709654ATechnology managementResourcesMultiple linear regression analysisWeight coefficient

The invention provides a global operating condition evaluating and quality tracking method for the hydrocracking process. The method comprises the steps of based on difference forms of quality standard requirements of each typical production procedure in the hydrocracking process, calculating a process capability index of each index in a quality evaluating index model of each production procedure; based on the process capability indexes, calculating a QA score of each index in the quality evaluating index model of each production procedure; based on the QA score of each index, building a weight coefficient of each index in a hydrocracking process global operating condition quality evaluating index model for the QA score contribution degree of an upper layer index by using multi-element linear regression analysis method; and based on the QA scores and the corresponding weight coefficients, positioning global operating performance degradation links and parameters of the hydrocracking process. The method provided by the invention can realize an operating condition evaluating function and a product quality tracking function, and realize efficient, economic and green production of refining and chemical enterprises.

Owner:CENT SOUTH UNIV

Splicing machining method for ion beam machining optical element

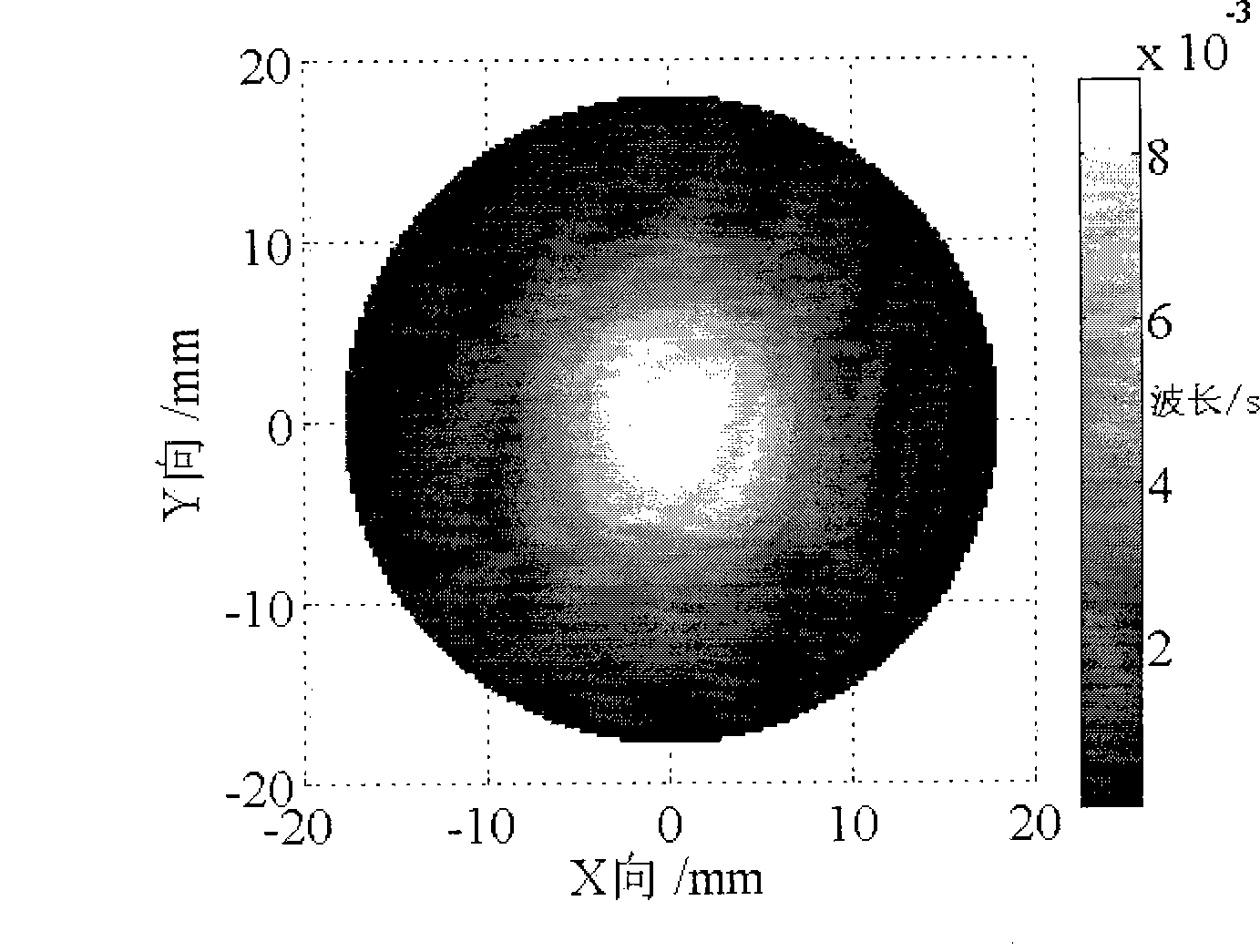

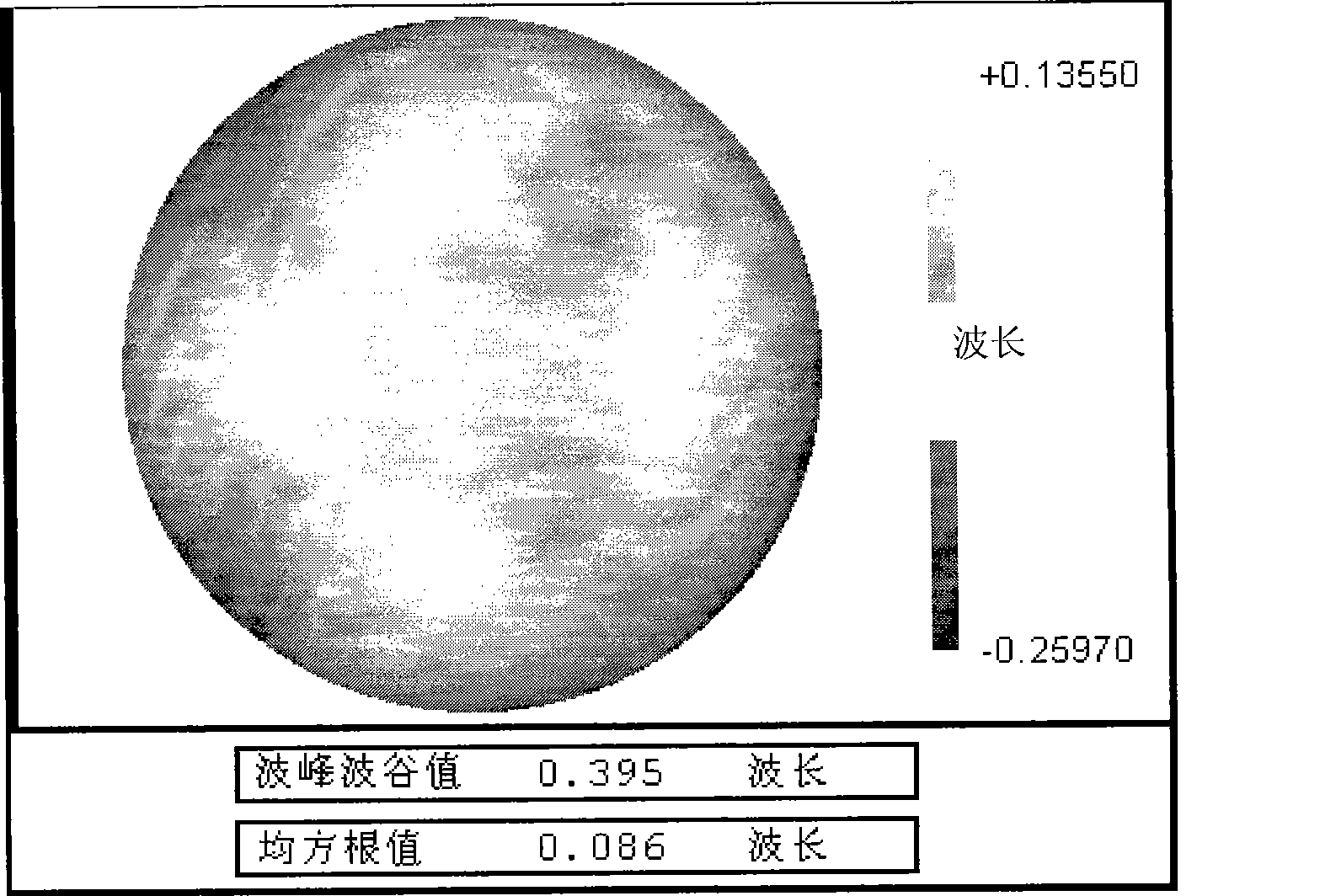

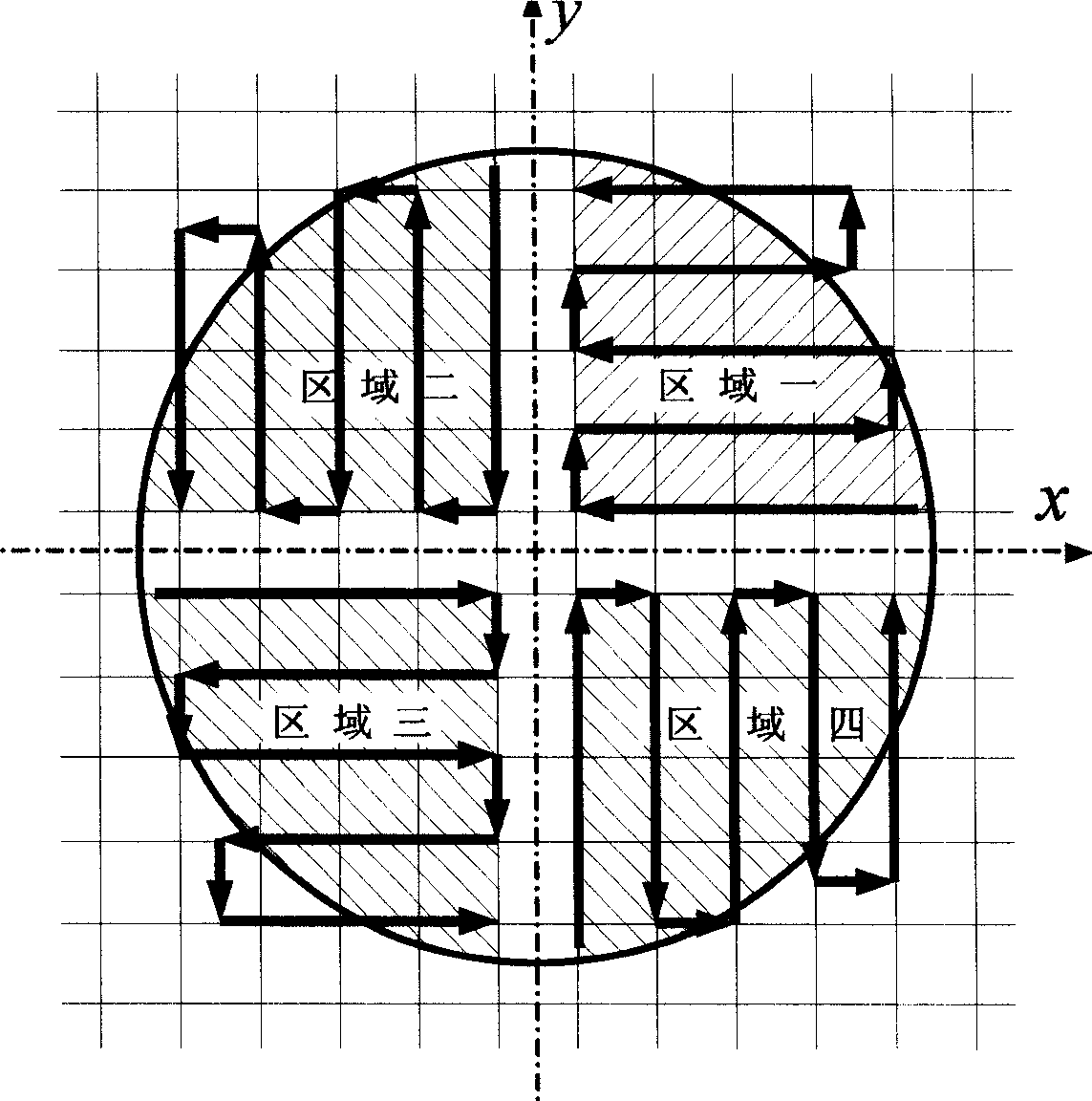

InactiveCN101481220ASolve a series of key technical problems in the splicing processEasy to processOptical processingIon beam

The invention discloses a method for splicing and processing an optical element by ion beams, which comprises the following steps of acquiring a removal function by experiments, acquiring a surface-shaped error function by a wave-front interferometer, dividing the processing area of an element, preparing data, confirming area frontiers, correcting the surface-shaped error, establishing a model, calculating out the residency time, processing the first shape correction according to the calculated-out residency time, identifying and error of the first shape correction processing, and repeating the processing step according to the condition of the error identification result until the requirements of the surface-shaped precision is satisfied. The processing method of the invention improves the processing capability of the prior optical processing system, solves the technical problem of processing large-caliber optical elements by the prior small optical processing system and can greatly lower the production cost and the processing cost of the optical processing system.

Owner:NAT UNIV OF DEFENSE TECH

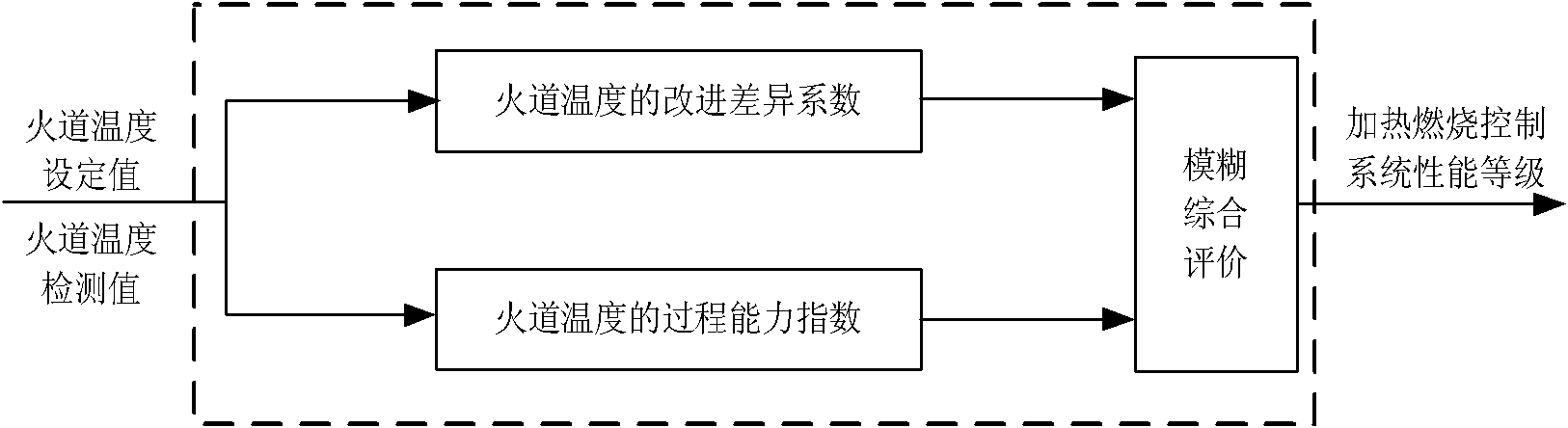

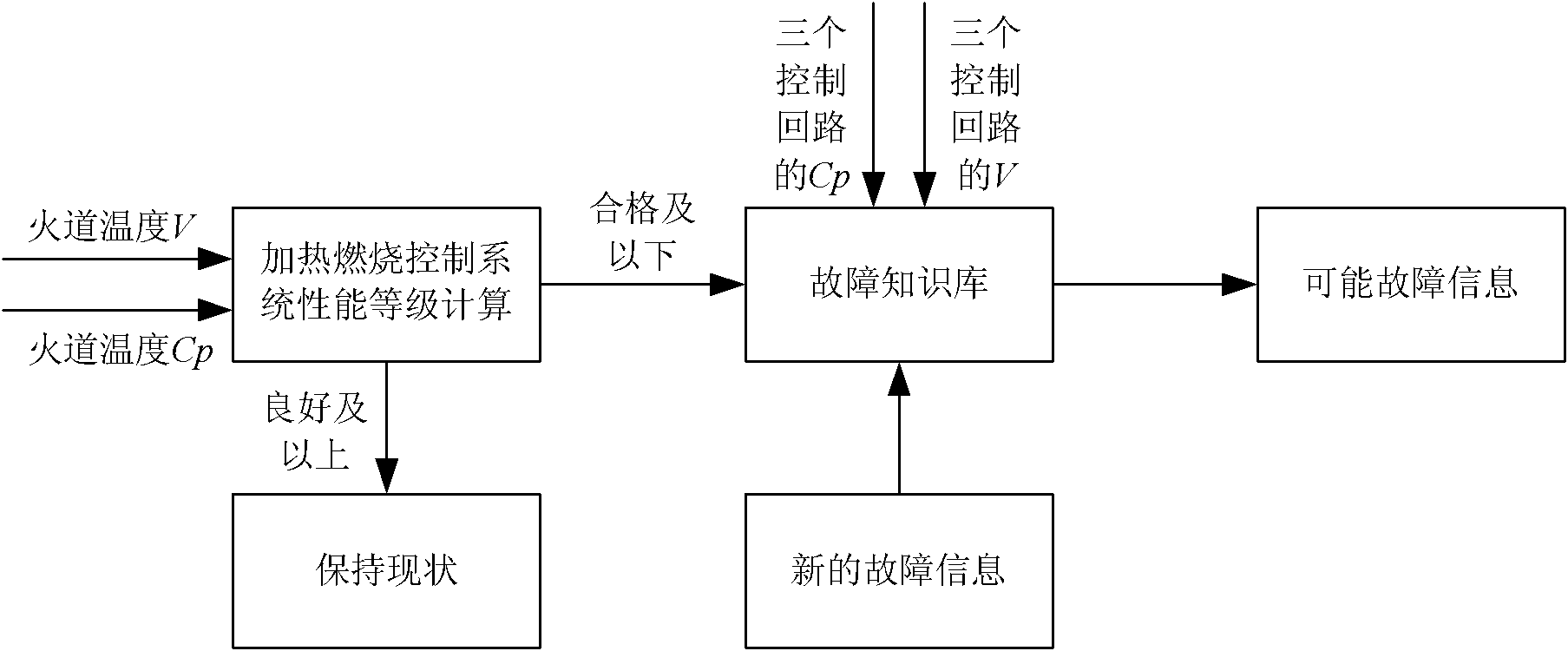

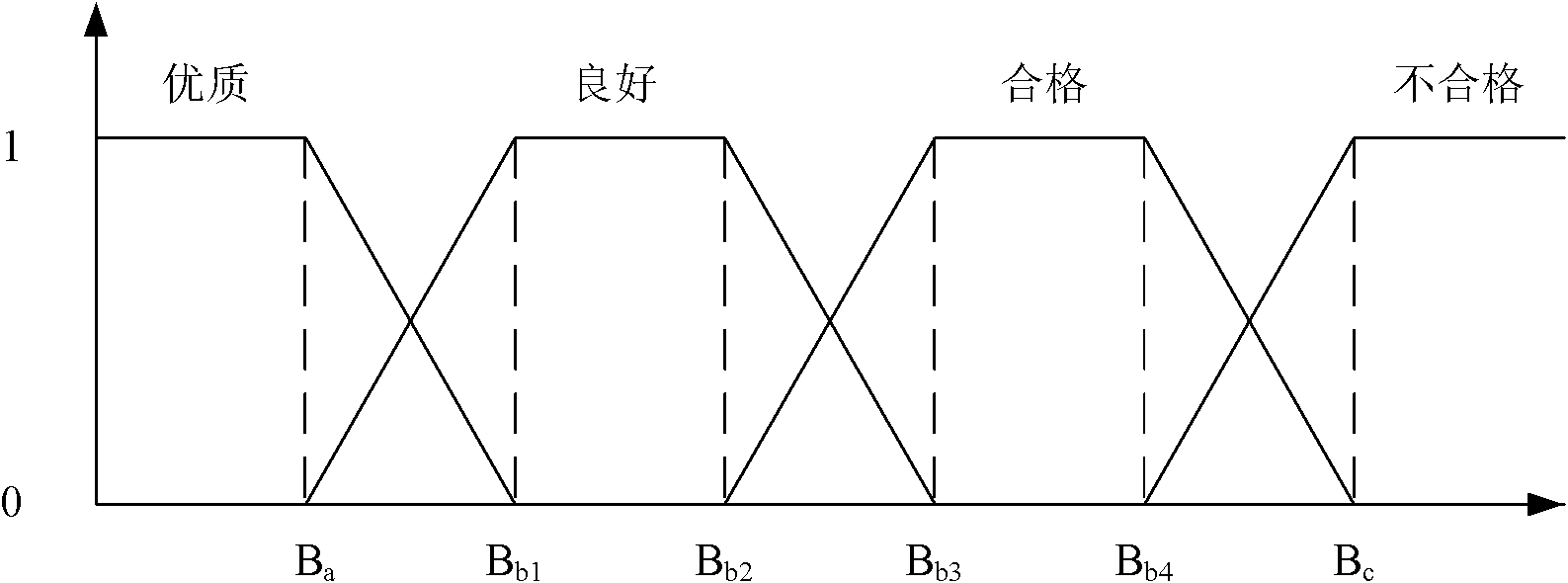

Method for performance evaluation and failure diagnosis of coke oven multi-loop control system

InactiveCN101847004AReduce labor intensityHigh degree of automationElectric testing/monitoringProgramme total factory controlLoop controlMulti loop control

The invention provides a method for the performance evaluation and the failure diagnosis of a coke oven multi-loop control system; the method for the performance evaluation of the coke oven multi-loop control system adopts a fuzzy comprehensive evaluation method to calculate performance level of a coke oven heating combustion control system; the fuzzy comprehensive evaluation method includes two evaluation factors: improved difference coefficient and process capability index; the method for the failure diagnosis comprises the steps: firstly establishing a failure knowledge base based on the improved difference coefficient and the process capability index of multi-loop control, searching for all the possible failure resources according to the optimal matching principal by regarding the improved difference coefficient and the process capability index as index in case that the performance level of the coke oven heating combustion control system is qualified or below, and embodying these failure sources visually in the form of text. The method enhances automation degree of failure elimination, dramatically lowers labor intensity of staff and raises working efficiency.

Owner:CENT SOUTH UNIV

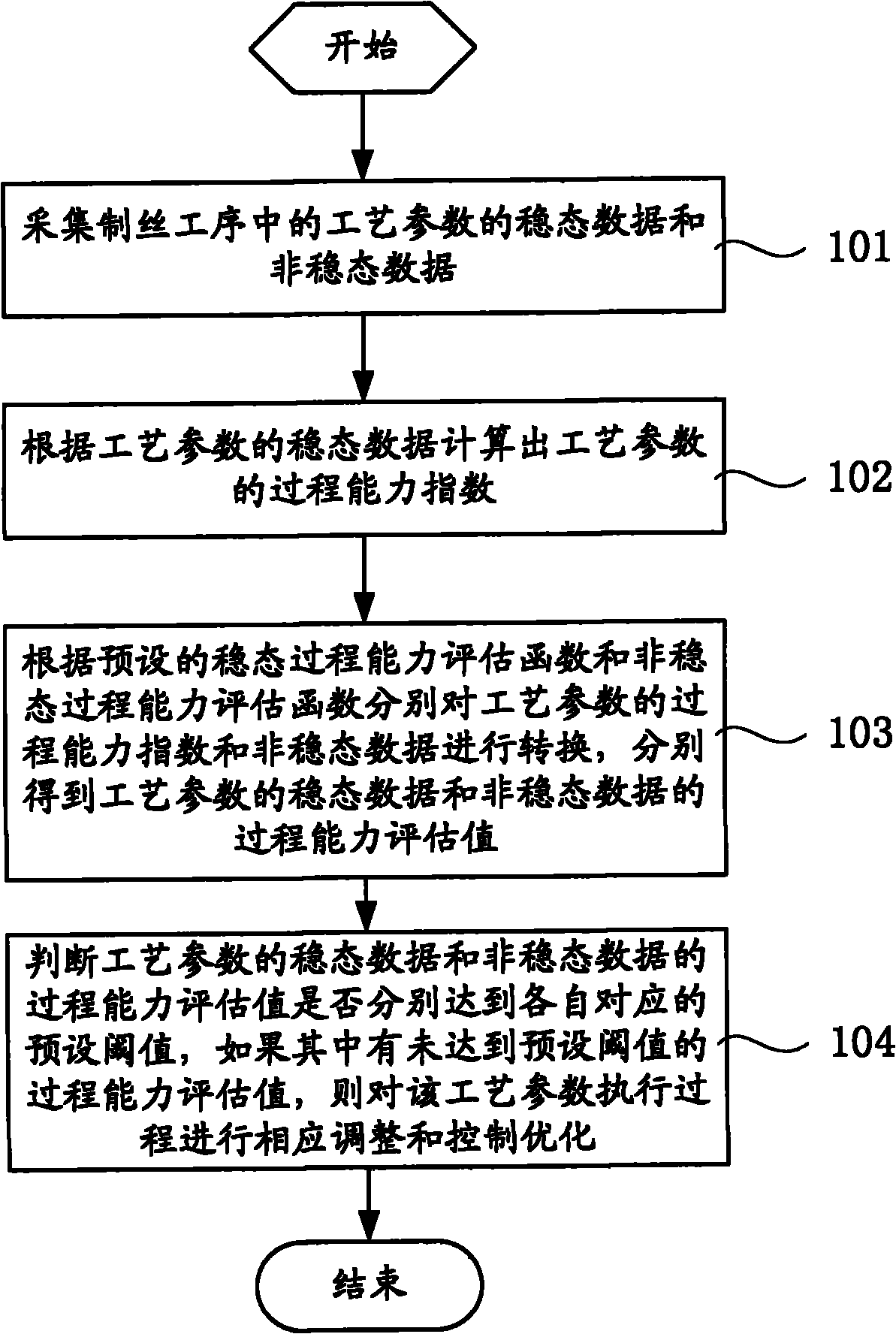

Method for improving parameter control effect in silk making technology

The invention relates to a method for improving the parameter control effect in the silk making technology, comprising the following steps: collecting the stable data and non-stable data of a technology parameter in the silk making process; calculating the process ability indexes of the technology parameter according to the stable data of the technology parameter; respectively converting the process ability indexes and non-stable data for the technology parameter to obtain the process ability evaluating values of stable data and non-stable data of the technology parameter; judging whether theprocess ability evaluating values of stable data and non-stable data of the technology parameter reach the respectively corresponding predetermined threshold value; if not, carrying out the adjustment operation for the technology parameter. In the invention, the process ability evaluating values of stable data and non stable data of the technology parameter are calculated to fully consider the quality condition of the technology parameter so that more complete and more practical basis for the subsequent parameter optimization is provided and the control effect after optimization is improved.

Owner:LONGYAN CIGARETTE FACTORY

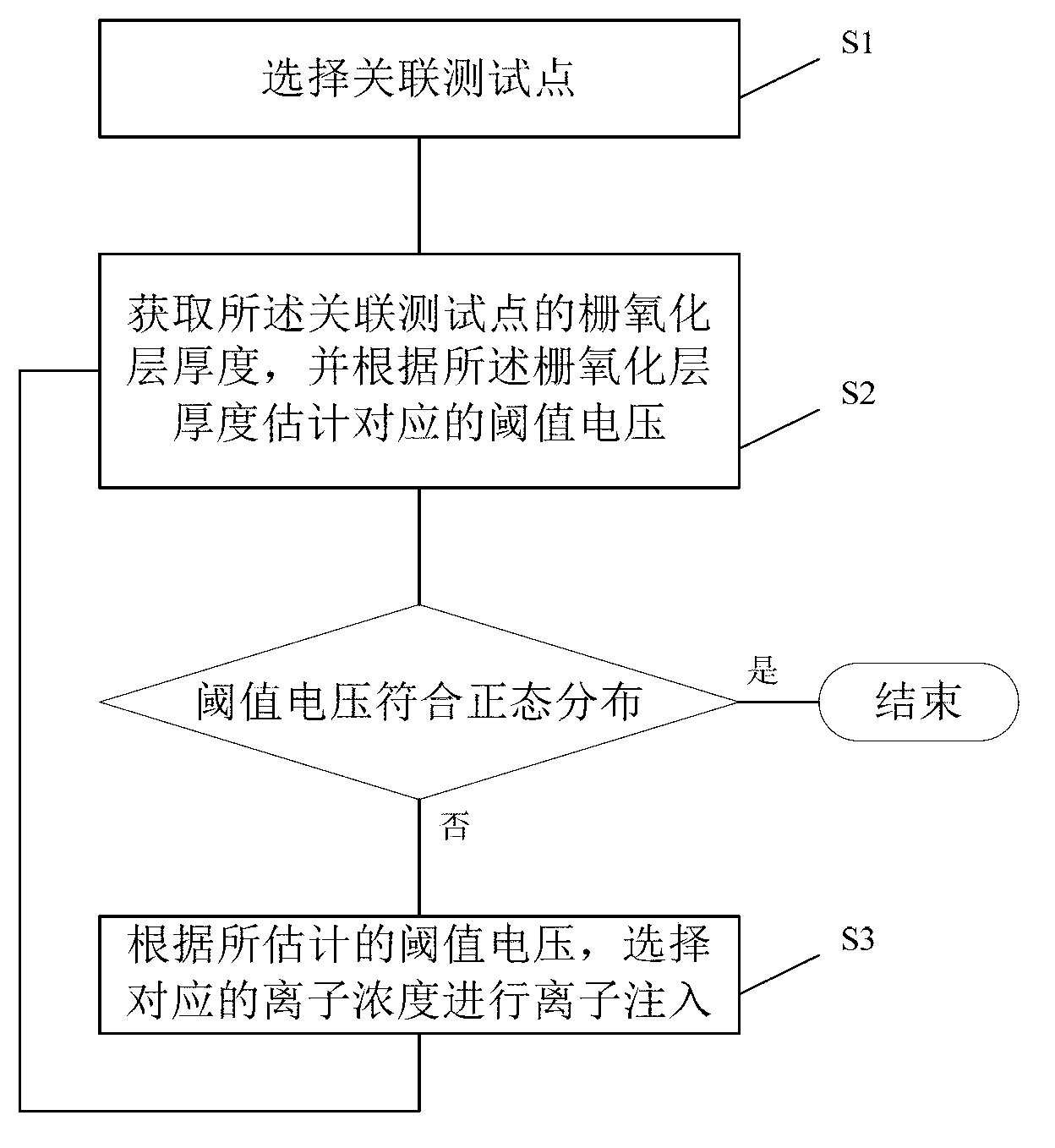

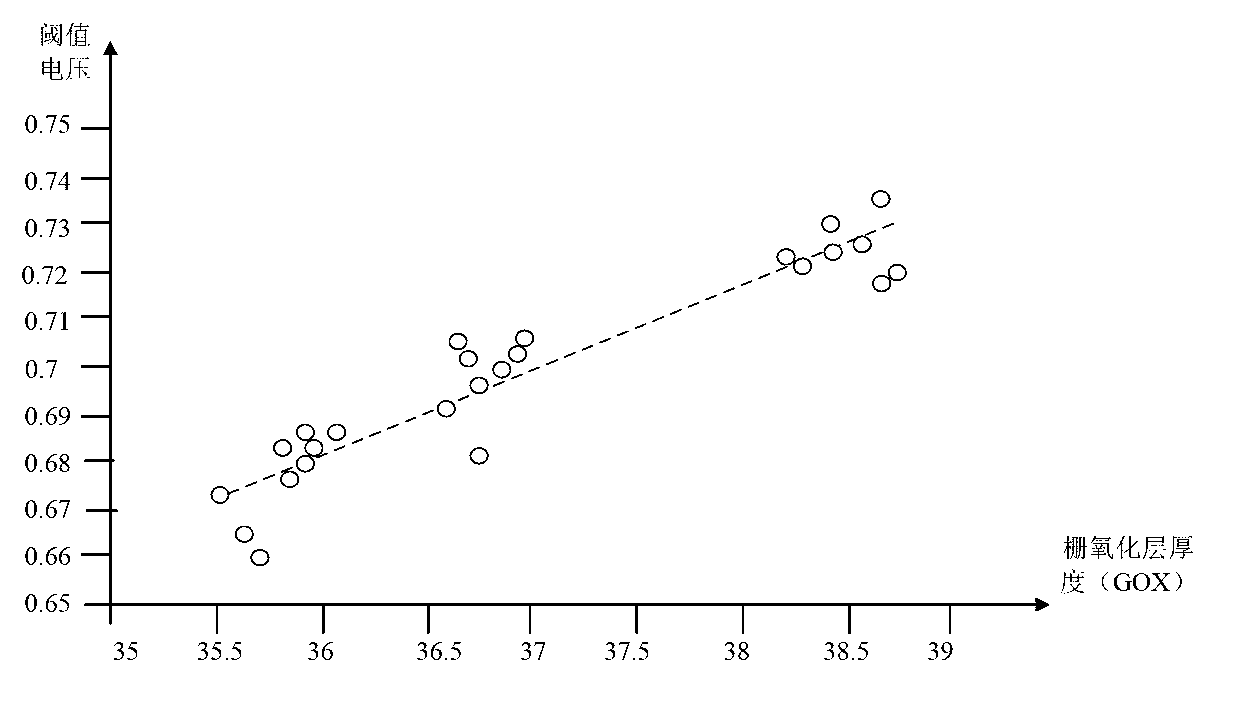

Method for improving process capability

InactiveCN102800607AProcess Capability Index ImprovementAvoid redesignSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringGate oxide

A method for improving the process capability comprises the steps as follows: a correlation test point is selected; the thickness of a gate oxide of the correlation test point is obtained; the corresponding threshold voltage is evaluated according to the thickness of the gate oxide; corresponding ionic concentration of a lightly doped drain (LDD) is selected for ion implantation according to the evaluated threshold voltage; and the threshold voltage evaluating step and the ion implantation step are performed repeatedly until the threshold voltage tends to normal distribution. The method adjusts the ion implantation concentration through the current measuring thickness of the gate oxide so as to lead the threshold voltage among various batches to tend to normal distribution, so that standard deviation is reduced, the process capability is improved, the redesign of the processing procedure can be avoided, a lot of manual labor and time can be saved, and the production efficiency is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

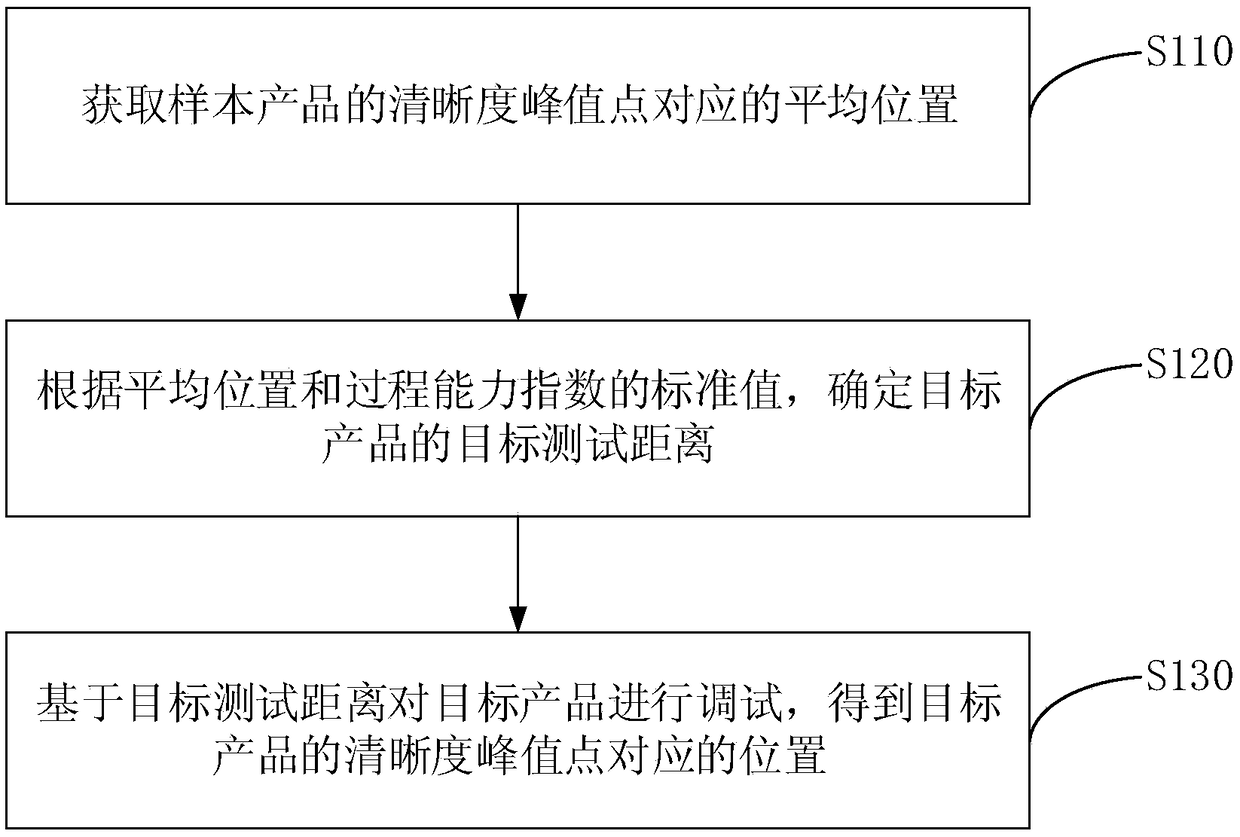

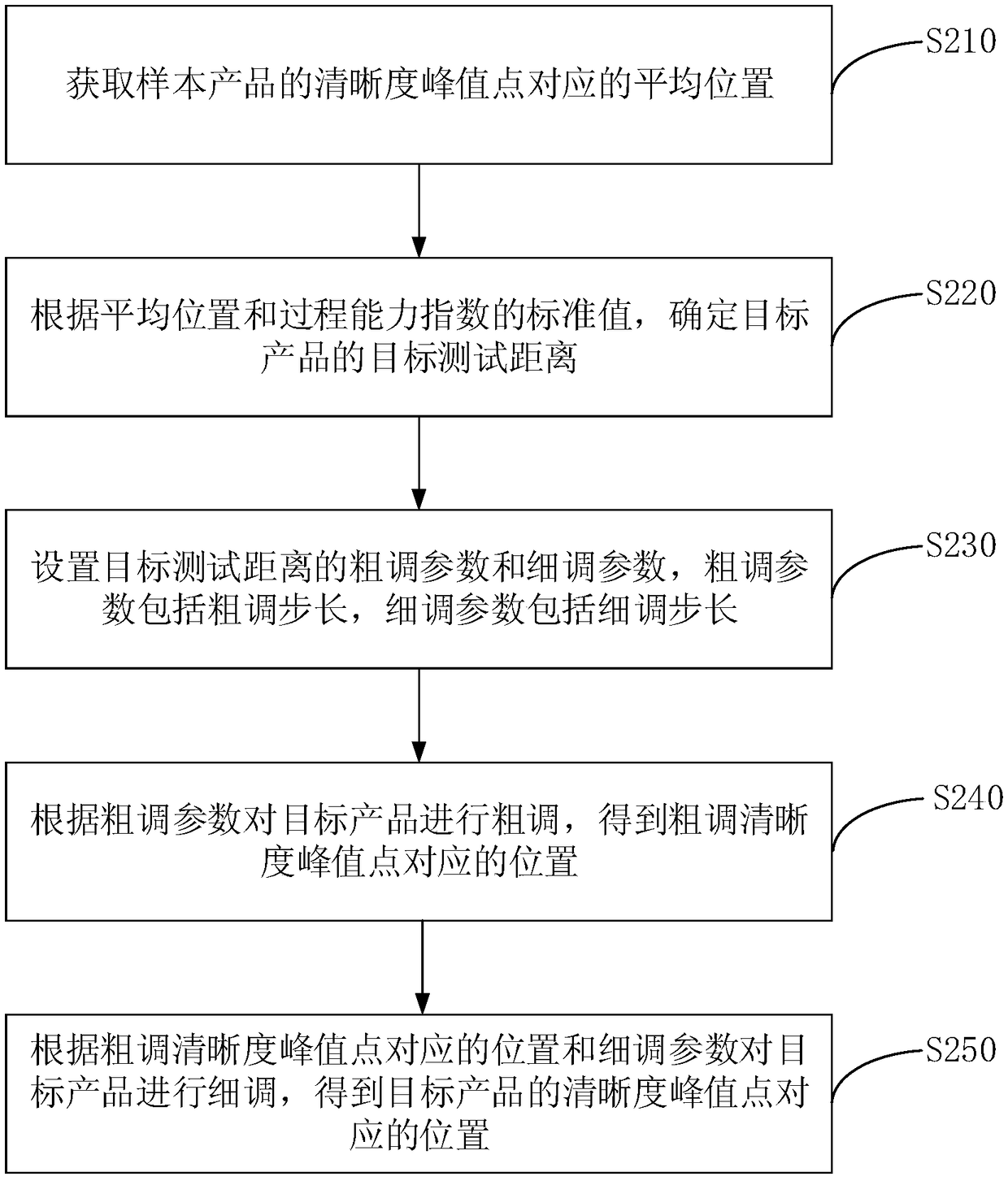

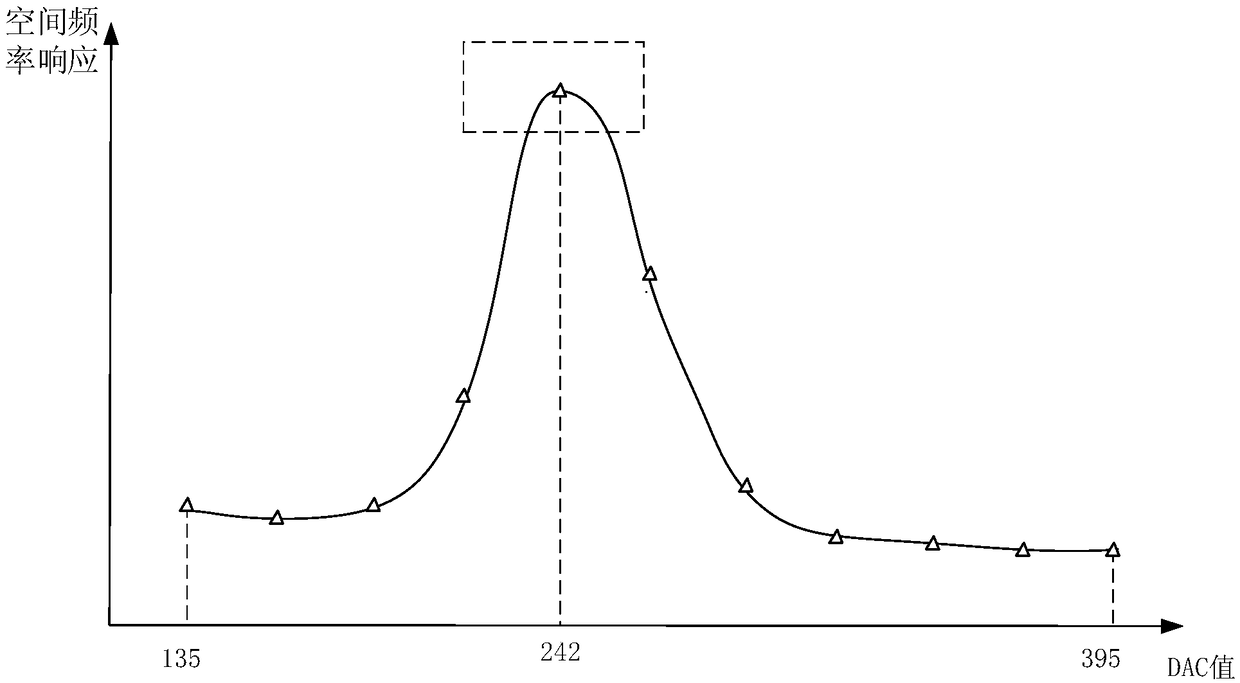

Auto-focusing debug method, device, apparatus and storage medium

ActiveCN109218718APrecise positioningShorten the timeTelevision system detailsColor television detailsCLARITYProduct base

The embodiment of the invention discloses an auto-focusing debug method, a device, an apparatus and a storage medium. The method comprises the following steps: obtaining an average position corresponding to a peak point of the definition of a sample product; obtaining an average position corresponding to a peak point of the definition of the sample product; determining a target test distance of the target product according to the average position and a standard value of the process capability index; Debugging the target product based on the target test distance to obtain a position corresponding to a peak point of clarity of the target product. The embodiment of the invention determines the specification range of the product satisfying the quality standard through the process capability index standard value related to the product quality in the production process, and takes the specification range as the test distance of the product, thereby realizing fast and accurate positioning, shortening the time of the product automatic focusing and debugging, and improving the debugging efficiency.

Owner:GUANGZHOU LUXVISIONS INNOVATION TECH LTD

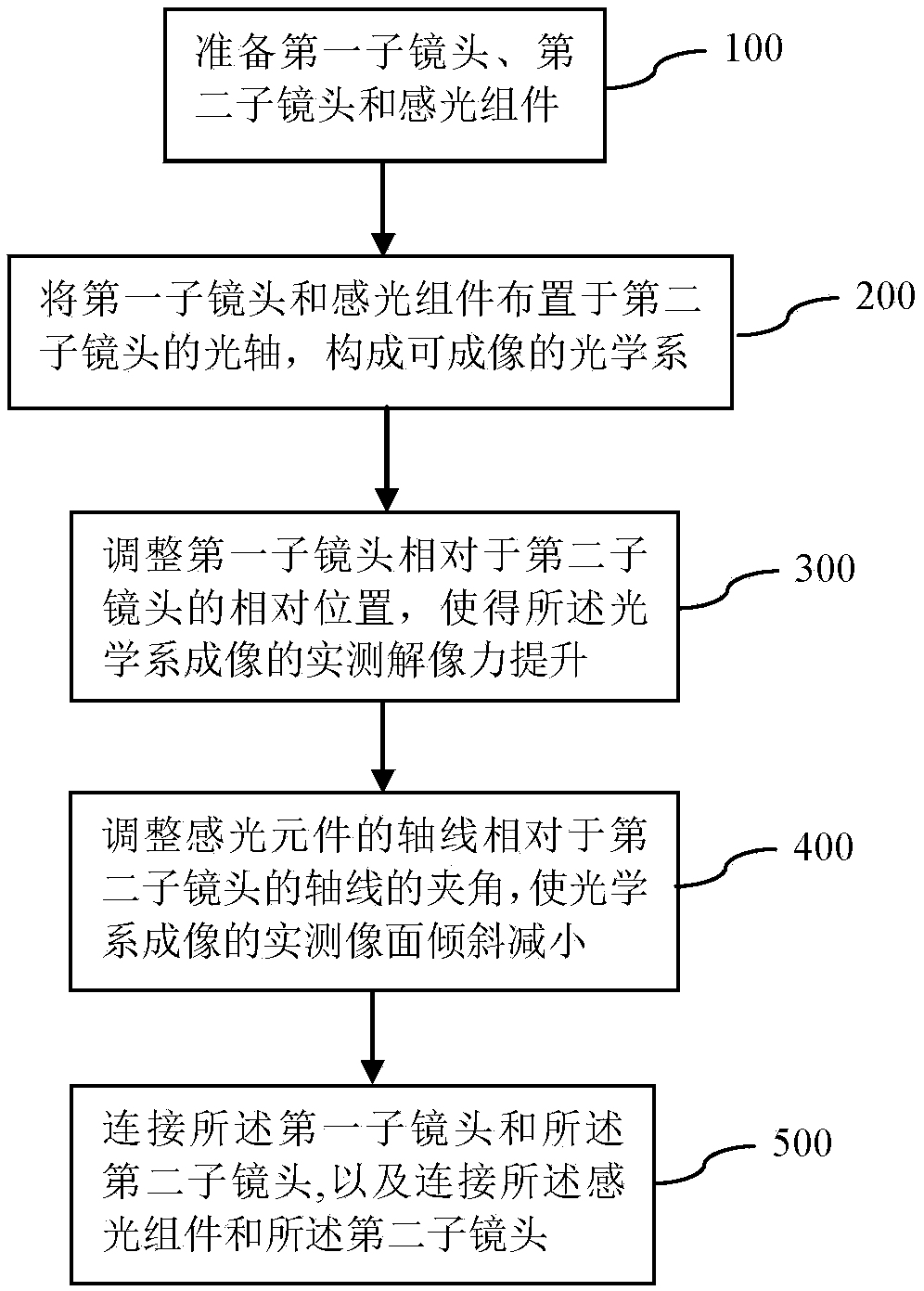

Camera module and assembling method thereof

ActiveCN109495673AHigh resolutionImprove performance indexTelevision system detailsColor television detailsCamera lensHigh volume manufacturing

The invention provides a camera module assembling method, which comprises the following steps: disposing a first sub lens and a photosensitive assembly on an optical axis of a second sub lens to forman imageable optical system; increasing an actually measured resolving power of imaging of the optical system by adjusting a relative position of the first sub lens relative to the second sub lens; reducing the inclination of an actually measured image plane, acquired by the photosensitive element, of the imaging of the optical system to a second threshold value by adjusting an included angle of the axial line of the photosensitive assembly relative to the middle axial line of the second sub lens; and connecting the first sub lens, the second sub lens and the photosensitive assembly. The invention further provides a corresponding camera module. The camera module assembling method can increase the resolving power of the camera module; the process capability index of a large batch of produced camera modules can be increased; the entire cost of an optical imaging lens and module can be reduced; the disqualification rate can be reduced; the production cost is reduced; and the imaging quality is improved.

Owner:NINGBO SUNNY OPOTECH CO LTD

Method for detecting process capability of inner and outer layers of circuit board

ActiveCN102111961ASolve the situation that different testing processes need to be separated, which is time-consuming and labor-intensiveIn line with the principle of compensationPrinted circuit manufactureEtchingCopper foil

The invention discloses a method for detecting the process capability of inner and outer layers of a circuit board. In the method, a testing plate is needed to be used, and a method for manufacturing the testing plate comprises the following steps of: preparing a copper-free substrate and copper foils with different thicknesses; integrating the prepared copper foils with the copper-free substrate; pressing a circuit board, and cutting the pressed circuit board; then drilling a plurality of tool holes by a drill point; performing V-CUT processing on the upper and lower surfaces in the middle of a short side of the circuit board on which the tool holes are drilled in a direction parallel to a long side of the circuit board, so that etching can be carried out in partitions; when the process capability of the inner and outer layers of the circuit board is needed to be detected, forming a pattern on the testing plate in a diaphragm, exposure, developing mode to perform the evaluation and check of the process capability; and then dividing the plate into two blocks along a V-CUT line for etching, and grasping an etching factor and the amount of lateral erosion. By the method for detecting the process capability of the inner and outer layers of the circuit board various wiring modes, the process capability of the copper foils with the different thicknesses, the amount of the lateral erosion and the etching factor of the wiring modes and the like can be detected precisely and efficiently.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

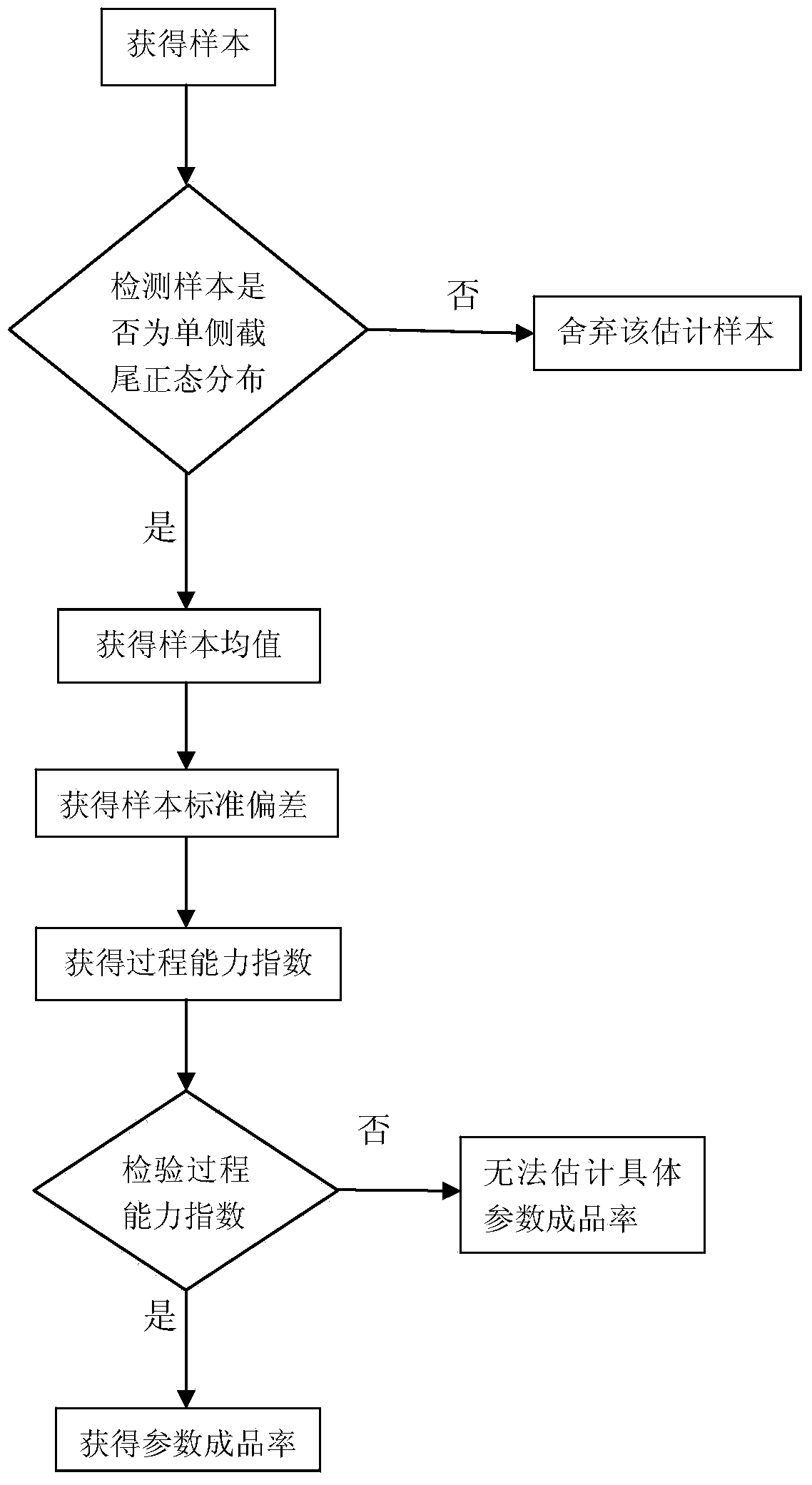

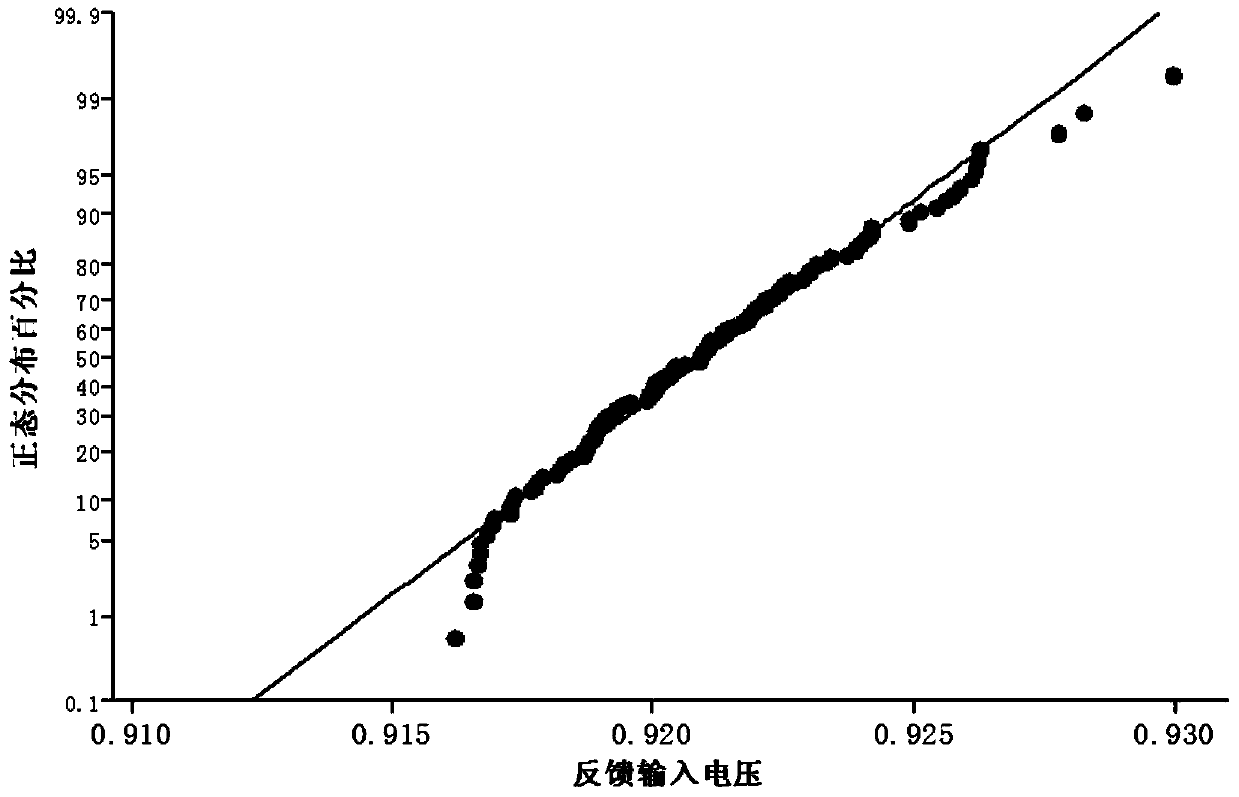

Product parametric yield estimation method

InactiveCN103425896ASmall amount of calculationBeat the meanSpecial data processing applicationsEstimation methodsSoftware engineering

The invention discloses a product parametric yield estimation method, which specifically comprises the steps of 1) obtaining estimation samples; 2) checking whether the estimation samples is in a state of one-sided truncated normal distribution or not and abandoning samples which are not in the state of one-sided truncated normal distribution; 3) obtaining the average value of the samples; 4) obtaining the standard deviation of the samples; 5) substituting the average value and the standard deviation of the samples into a process capability index formula to obtain process capability indexes; 6) checking the process capability indexes, wherein for the estimation samples with the process capability indexes which are not within an applicable interval, the specific parametric yield cannot be estimated; and 7) substituting the process capability indexes into a parametric yield and process capability index model to obtain the parametric yield. The product parametric yield estimation method disclosed by the invention can be used for estimating the parametric yield of performance testing data which is subject to truncation processing, and has the characteristics that the process is simple, the calculation is simple and convenient to perform and the practical value is high.

Owner:XIDIAN UNIV

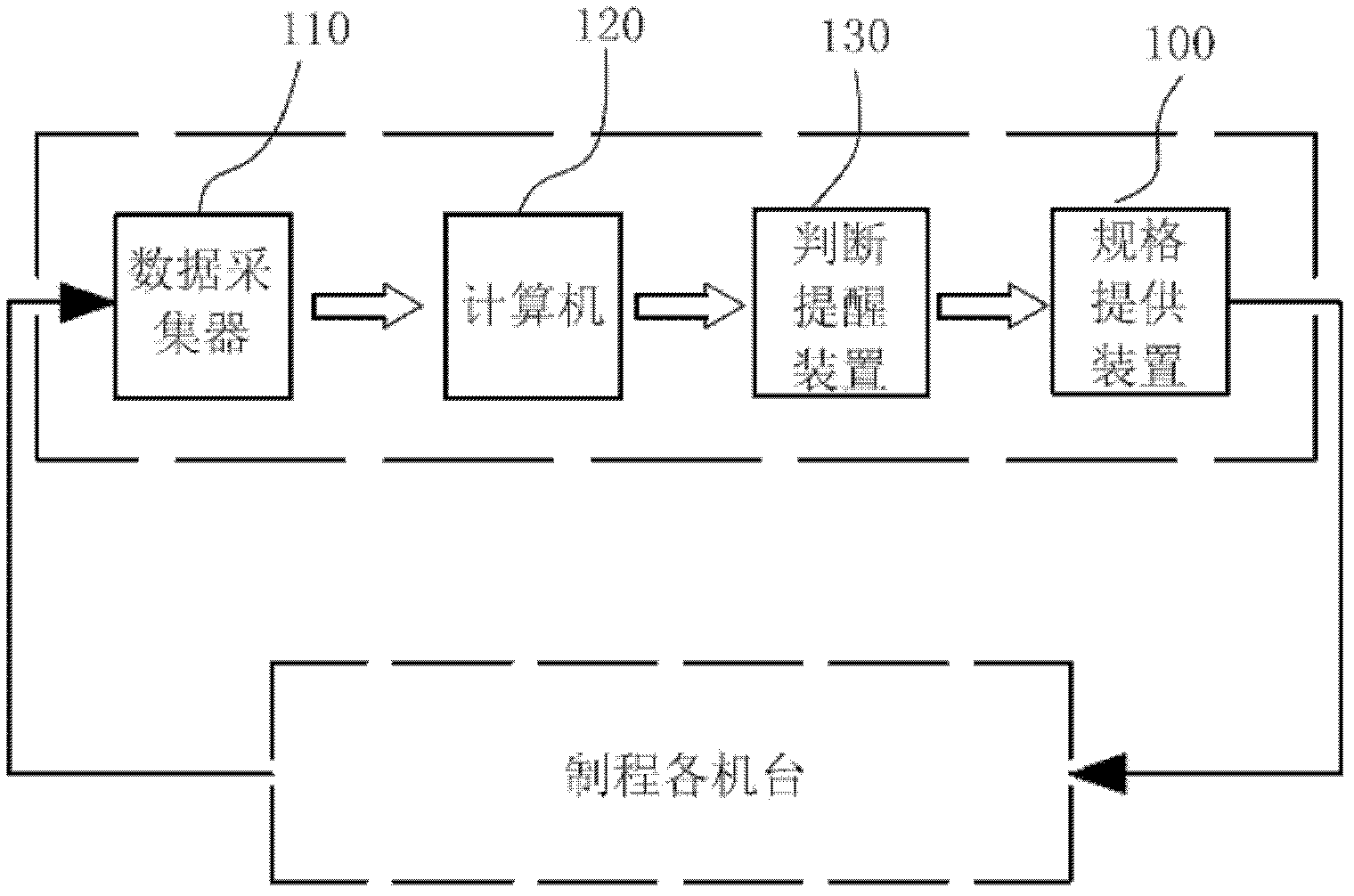

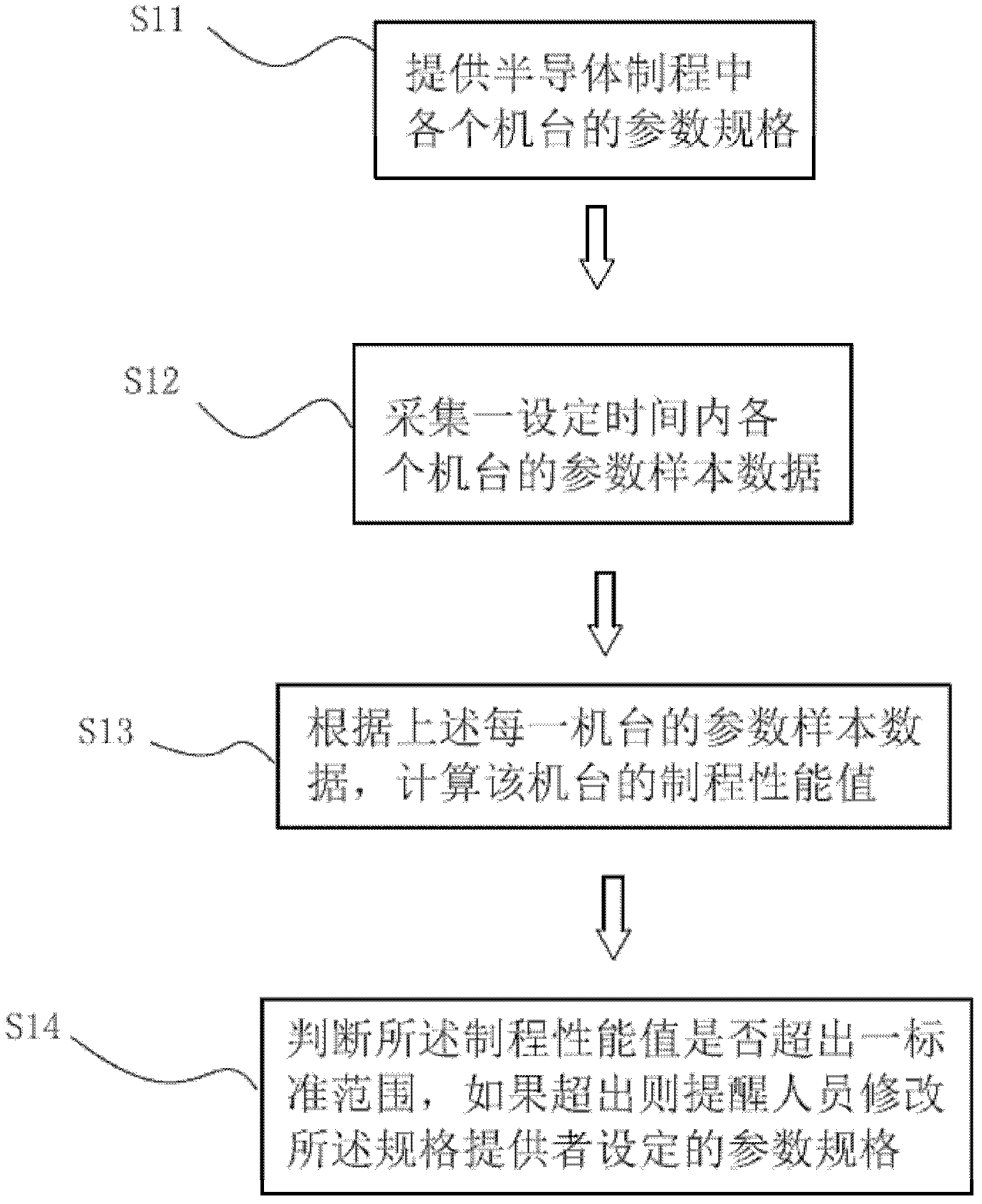

Semi-conductor processing management system and method

InactiveCN103107117AAvoid flawsSemiconductor/solid-state device manufacturingData acquisitionComputer science

Provided is a semi-conductor processing management system and a method. The semi-conductor processing management system comprises a specification providing device, a data collector, a computer and a judging and reminding device. On the basis of an existing flippy disc controller (FDC), the semi-conductor processing management method increases a function which can analyze the range of standard performance evaluation corporation (SPEC), thereby enabling the FDC to calculate the value of complex process capability index (CPK) under the appropriate range of the SPEC, so that support staff can correctly analyze working conditions of various computers, problems can be timely and effectively discovered and reasonability and effectiveness of the entire processing are guaranteed.

Owner:CSMC TECH FAB2 CO LTD

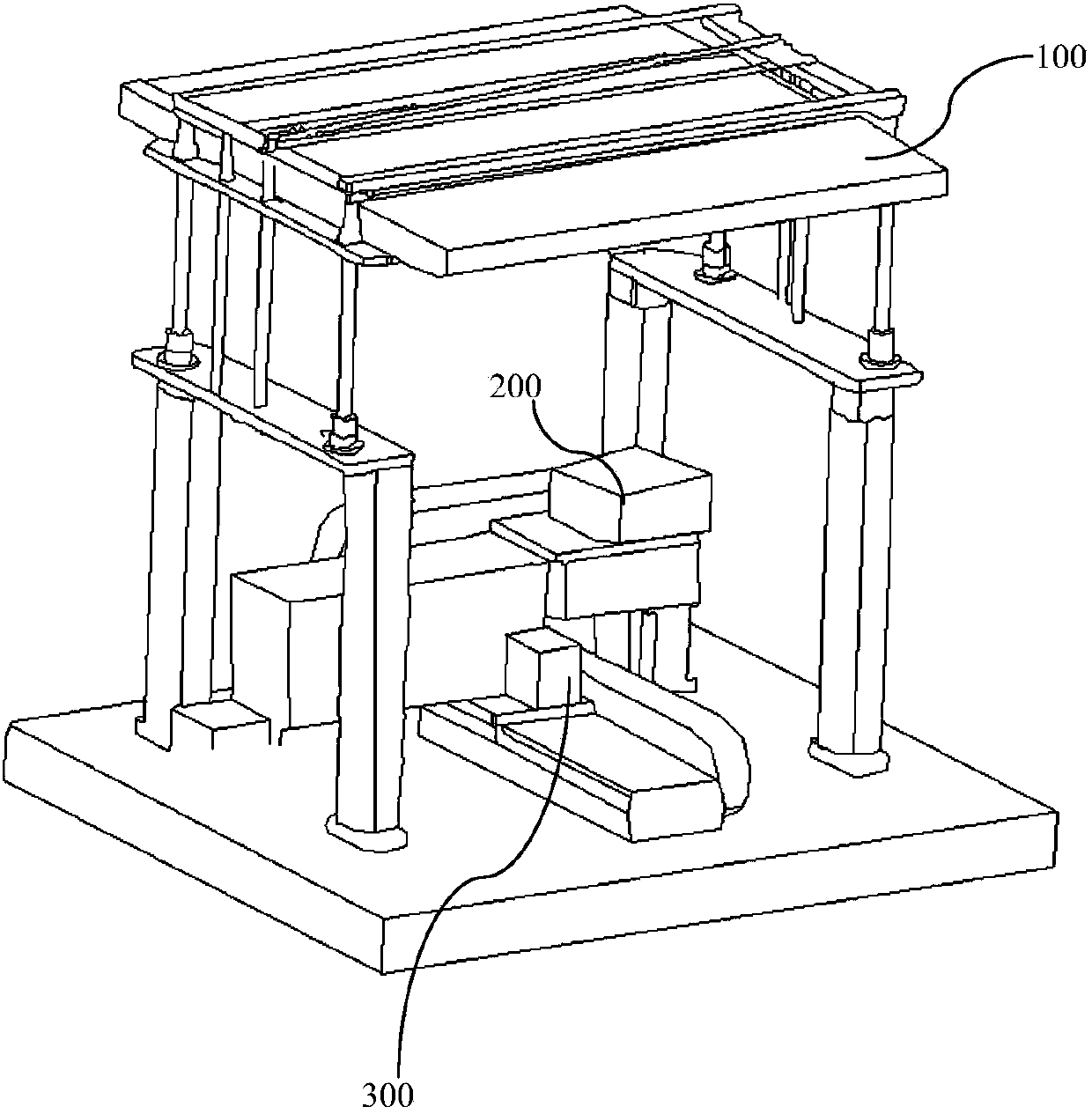

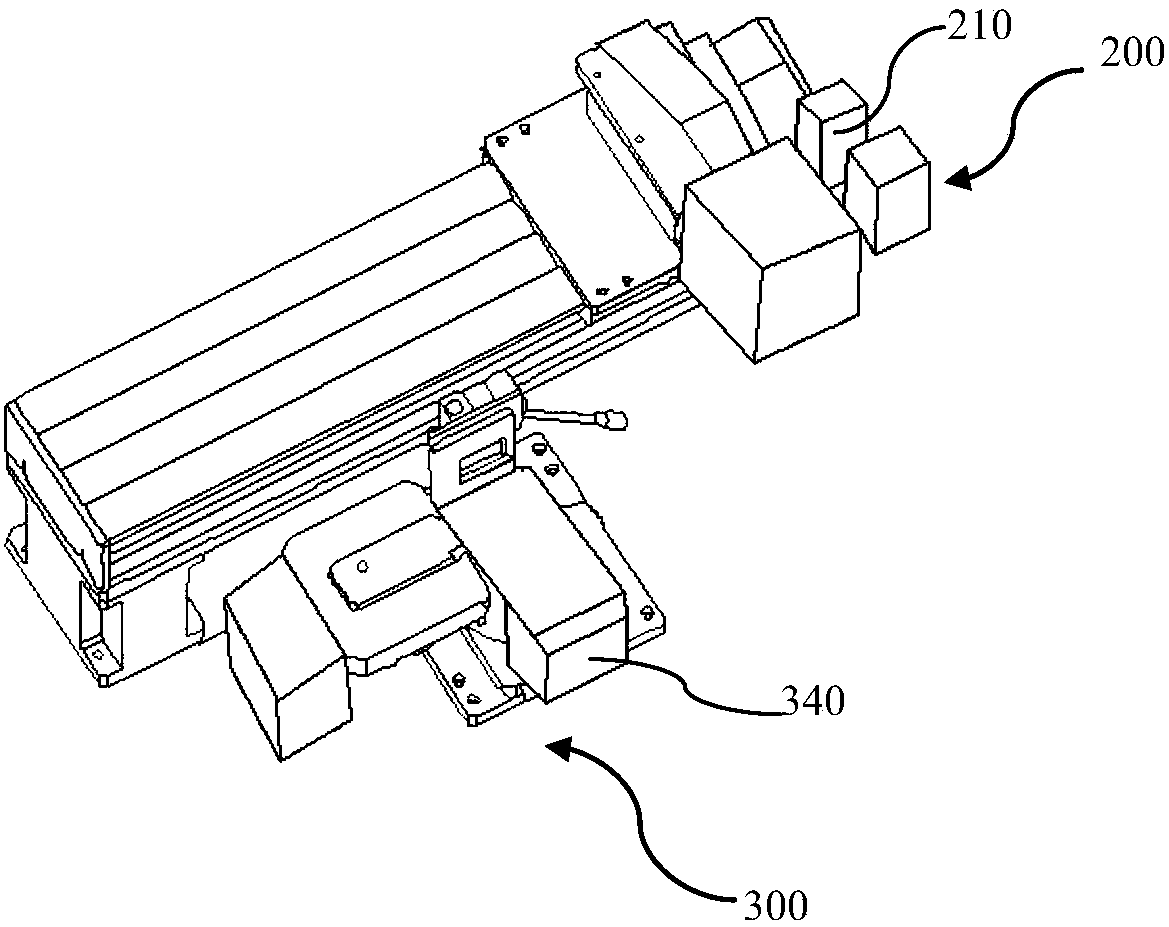

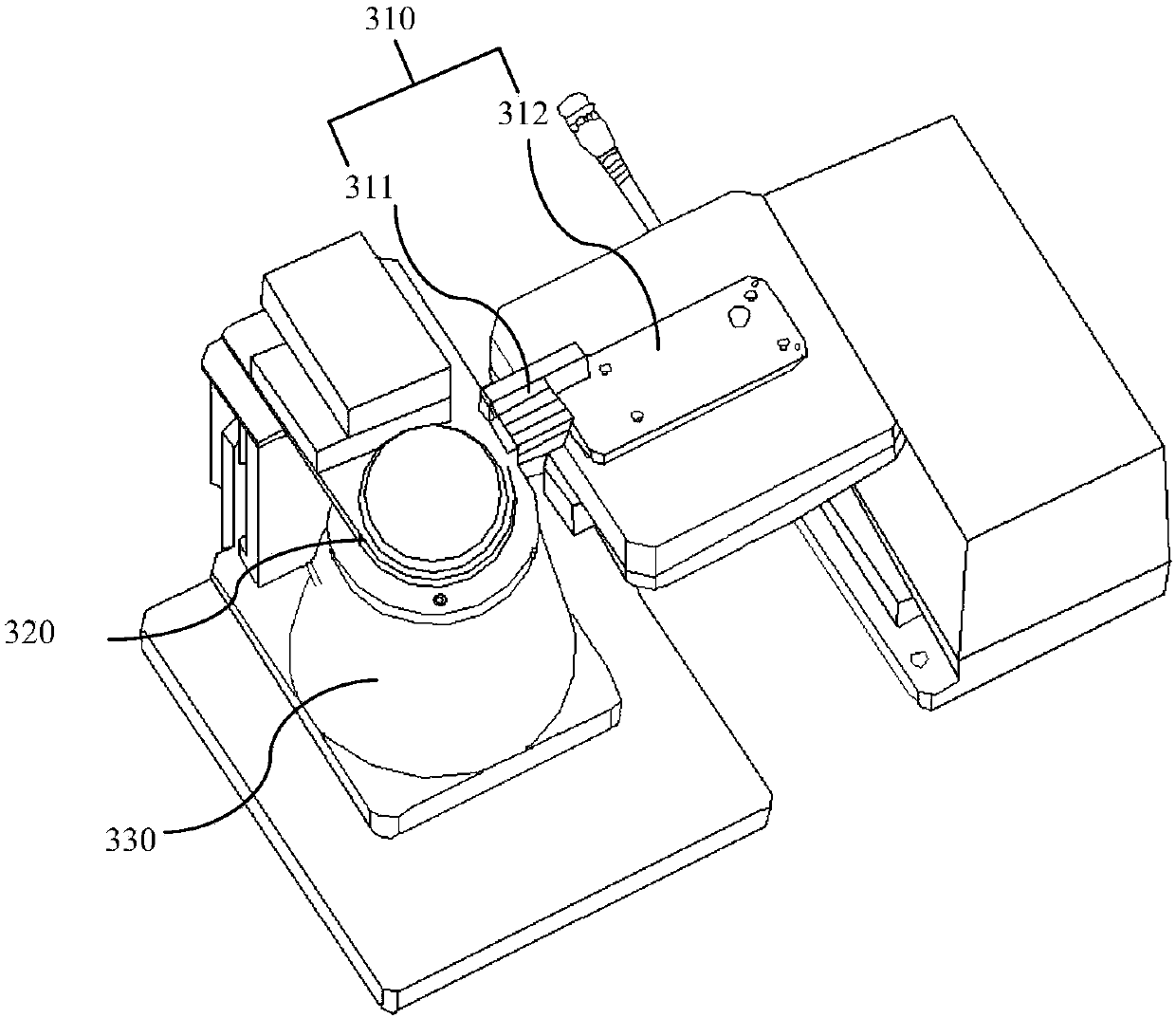

Assembling device and method for optical assembly

ActiveCN109773474AImprove performance indexLoose requirementsAssembly machinesMountingsElectricityLight sensing

The invention provides an assembling device for an optical assembly. The device comprises a shooting mechanism, a first fixing mechanism, a second fixing mechanism, a data acquiring assembly and a material connecting assembly, wherein the shooting mechanism is used for shooting a first secondary lens to be assembled and moving the picked first secondary lens by a plurality of degrees of freedom; the first fixing mechanism is used for fixing the second secondary lens to be assembled; the picking mechanism can move relative to the first fixing mechanism, so that the first secondary lens and thesecond secondary lens can form an imageable optical system; the second fixing mechanism is used for fixing a light sensing assembly; the data acquiring assembly is electrically connected to the lightsensing assembly fixed through the fixing mechanism and is used for acquiring image data output by the light sensing assembly; and the material connecting assembly is used for integrally fixing the first secondary lens and the second secondary lens. The invention also provides a corresponding optical lens and shooting die set manufacturing method. With the adoption of the device, the index of massive production capacity of an optical lens or a shooting die set can be greatly increased; the overall cost can be decreased; and the imaging quality can be improved.

Owner:NINGBO SUNNY OPOTECH CO LTD

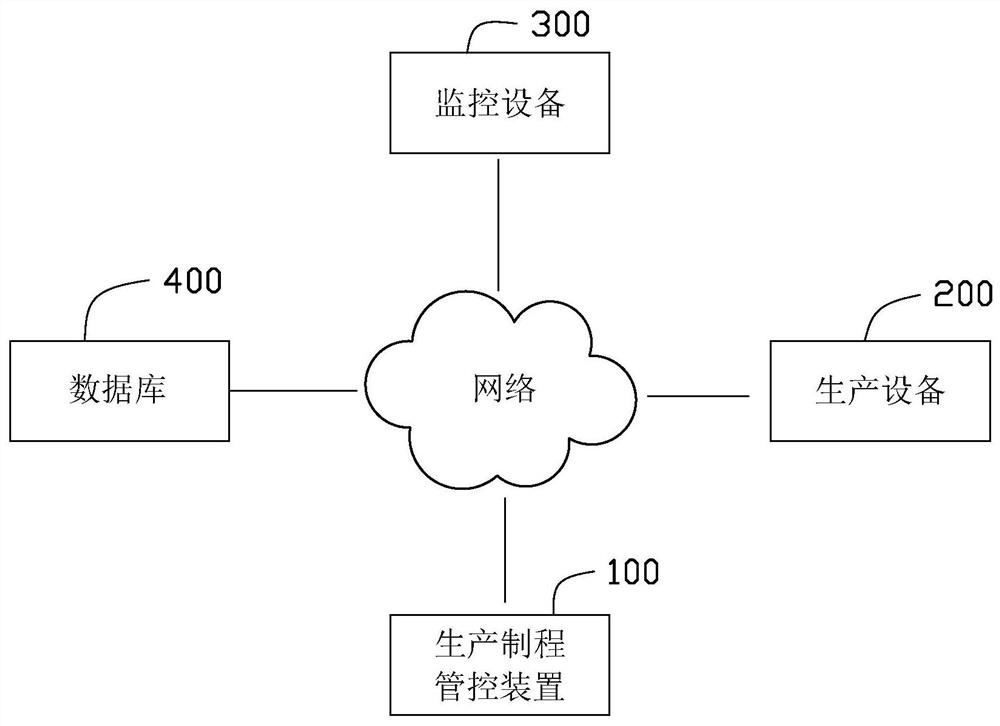

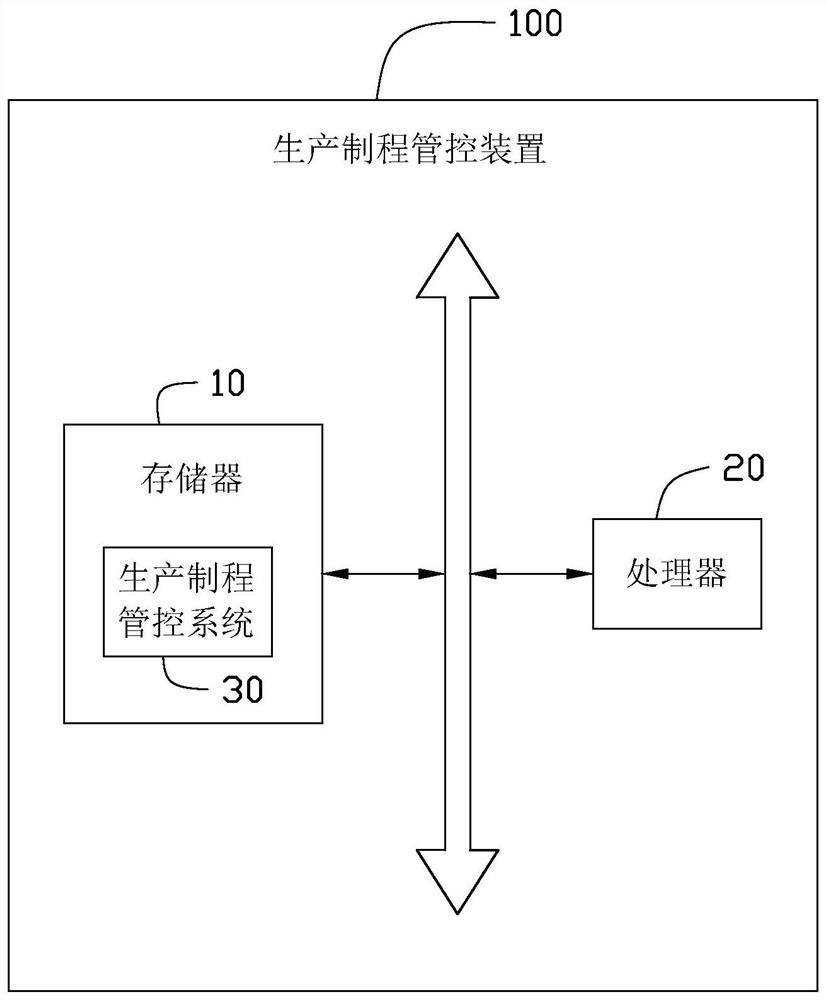

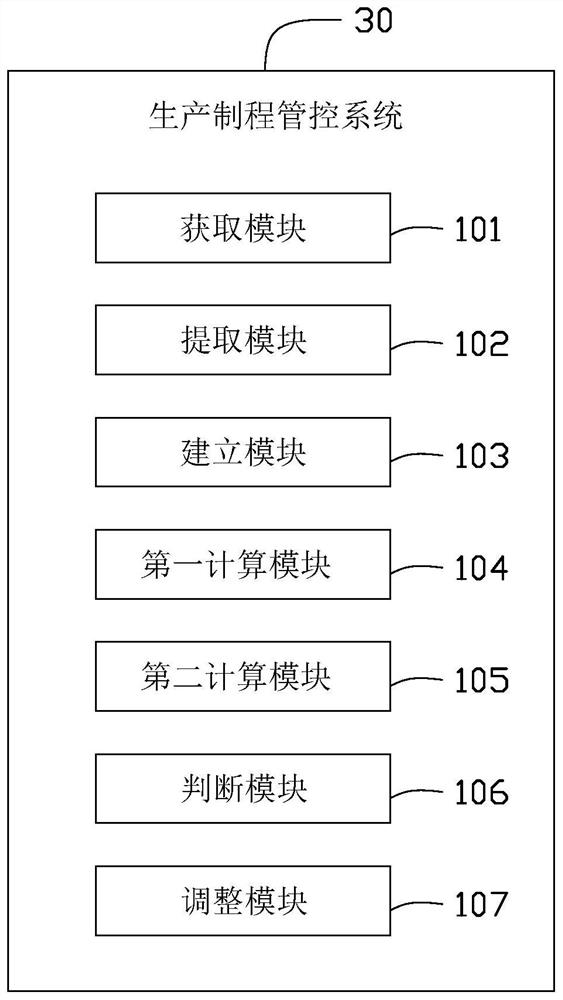

Production process management and control device and method and computer readable storage medium

PendingCN111861050AReduce production capacityReduce manual inspection costsProgramme controlSimulator controlProcess engineeringProcess capability

A production process management and control method comprises the following steps: acquiring production process information of a preset product in a historical production stage; extracting process information conforming to a preset rule from the production process information, and training based on the process information to obtain a matching model of the first parameter associated with the secondparameter and a process capability prediction model; inputting the first parameter value configured in the current production stage into a matching model to obtain a second parameter value optimally matched with the first parameter value; inputting the first parameter value and the optimally matched second parameter value into a process capability prediction model to obtain a process capability index; judging whether the process capability index reaches a preset standard or not; and if so, adjusting the process of the current production stage according to the first parameter value and the optimally matched second parameter value. The invention further provides a production process management and control device and a computer readable storage medium. According to the production process management and control device and method and the computer readable storage medium, intelligent process management and control can be realized, and the production defect and the manual detection cost are reduced.

Owner:WARECONN TECH SERVICE (TIANJIN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com