Method for evaluating quality stability of redried finished sheet tobacco

A technology of quality stability and sheet cigarettes, applied in the measurement of color/spectral characteristics, etc., can solve the problems of difficult to reflect the internal quality status of red-cured cigarettes, different test results of samples, and inconsistency with actual conditions, etc., to ensure reliability. , reliable results, scientific method effect

Inactive Publication Date: 2012-11-28

HONGYUN HONGHE TOBACCO (GRP) CO LTD +1

View PDF0 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Existing evaluation methods of rebaked finished tobacco sheets mainly focus on the temperature and moisture uniformity of the tobacco sheets, or subjective evaluations such as human eyesight, hand touch and nose smell, etc., and can only be described qualitatively rather than quantitatively.

Therefore, it is difficult to reflect the internal quality of the re-cured sheet tobacco. At the same time, because people's senses are often affected by factors such as the surrounding environment and their own psychological conditions, the test results of the same batch of samples by different testers and at different times are different or different from the actual ones. The situation does not meet

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

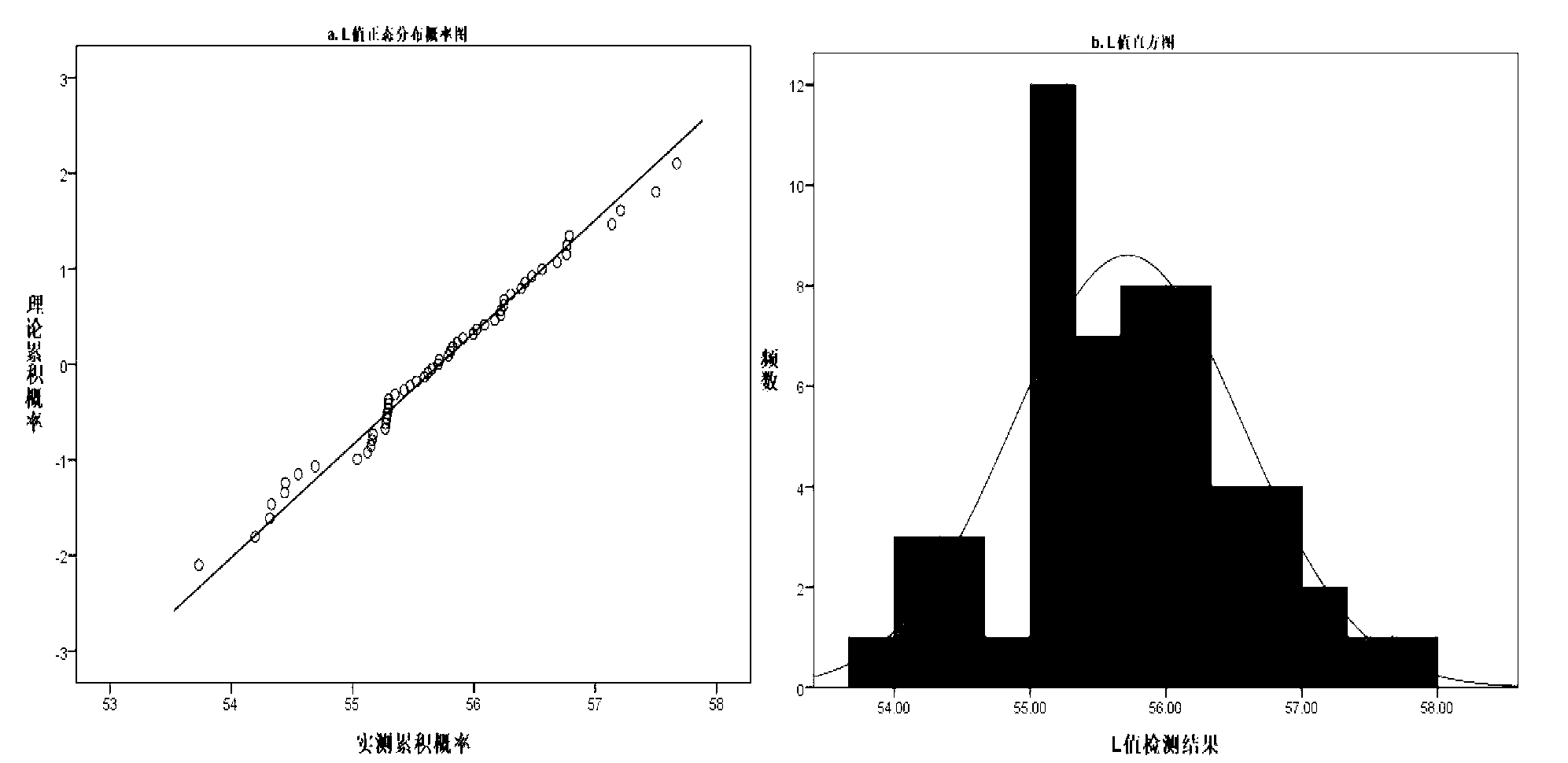

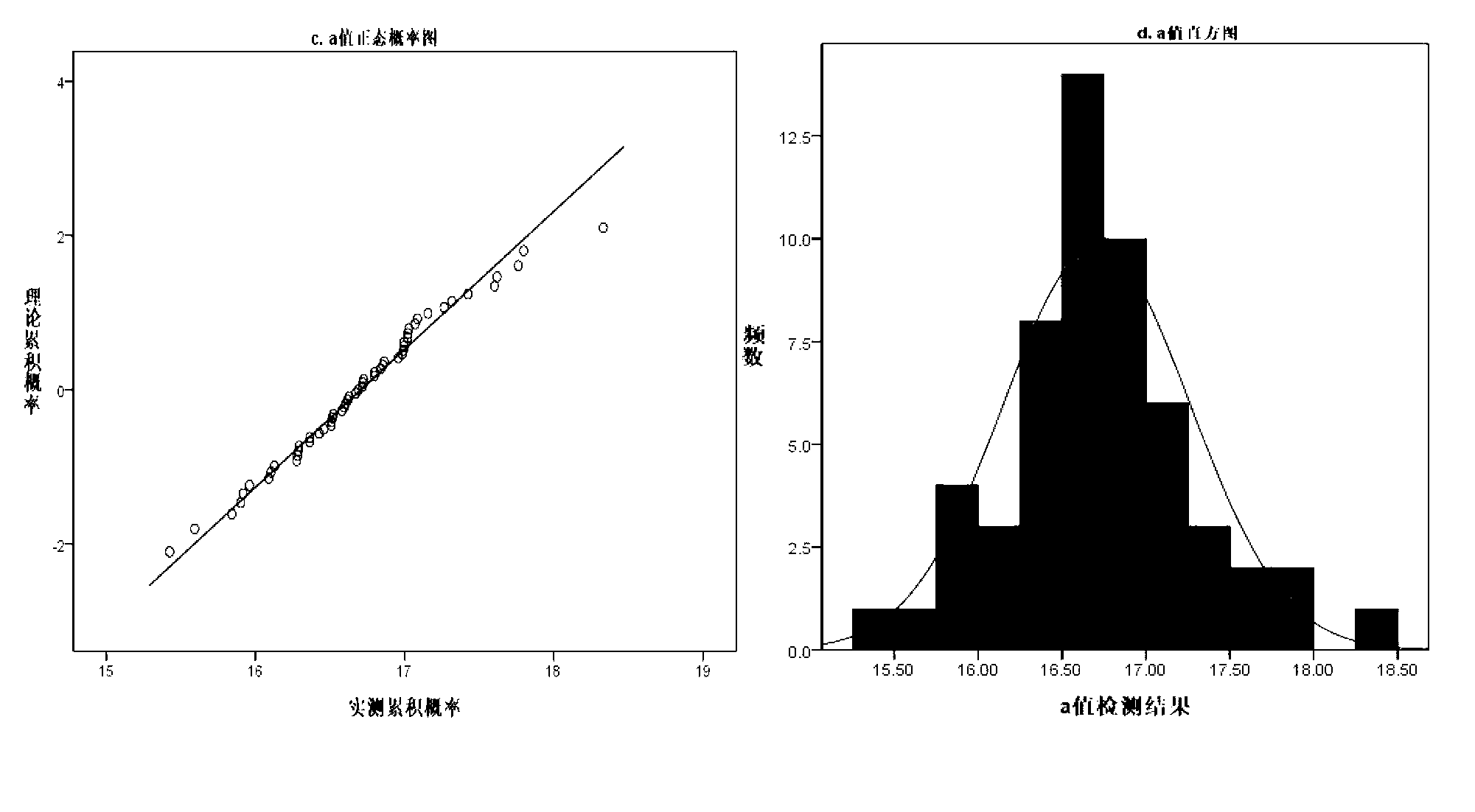

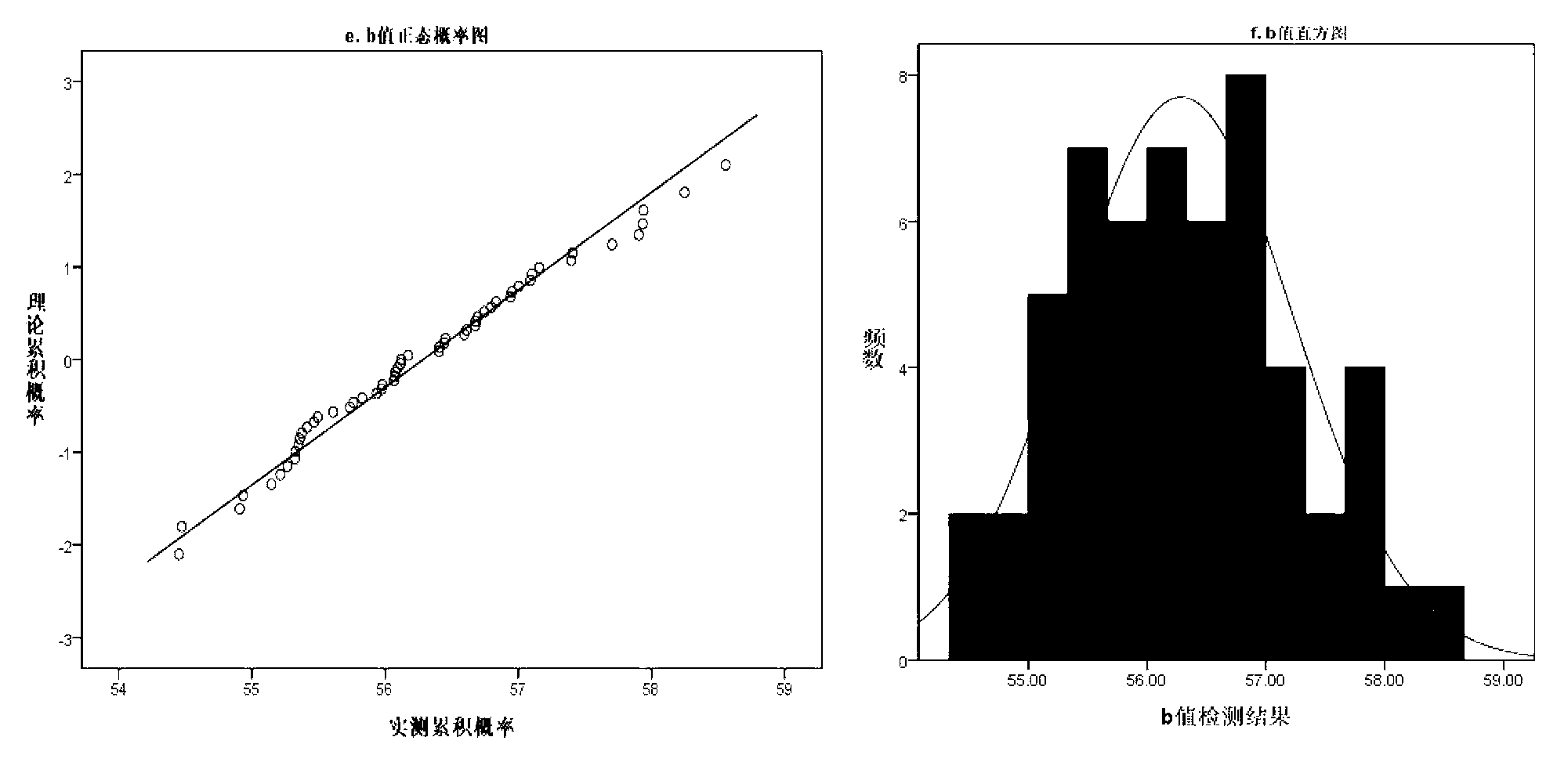

[0025] For tobacco leaf module A, after half an hour of normal operation and stabilization of the equipment, 55 consecutive samples were taken at the outlet of the roaster at intervals of 5 minutes, each time about 500g, and 30 samples with a flat surface and no wrinkles were randomly selected from each sample to form a test group , respectively mark 1, 2, 3...55 on the ziplock bag, set aside.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for evaluating the quality stability of redried finished sheet tobacco. The method comprises the following steps of: converting a qualitative description of the appearance color of the tobacco into quantifiable constant indexes L*(lightness value), a*(red and green value) and b*(yellow and blue value) based on the CIE1976L*a*b*color space; constructing a mean value and Xmax-Xmin graph (X-Rs control graph) by checking the normal distribution conformance of data of the L* value, the a* value and the b* value of the tested tobacco; and calculating a process capability index Cp of each index to determine the quality stability of the redried finished sheet tobacco. If the process capability indexes of the L* value, the a* value and the b* value meet the condition that Cp is greater than 1.00 and less than or equal to 1.33, the quality of the redried finished sheet tobacco is in a stable state, otherwise, the quality stability of the redried finished sheet tobacco is relatively low. By the method, the problem of limitation that the quality stability of the conventional redried finished sheet tobacco is only evaluated by subjective evaluation; and the method has the characteristics of simplicity in operation, reliable result and high adaptability.

Description

technical field [0001] The invention belongs to the technical field of tobacco processing, and in particular relates to a method for evaluating the quality stability of finished rebaked tobacco sheets. Background technique [0002] At present, leaf threshing and redrying of modular formula has become the mainstream trend of the development of the industry. It plays an important role in stabilizing the quality of cigarette products, but it also brings a series of problems such as how to evaluate the stability of the processing quality of modular finished tobacco sheets. Many scholars at home and abroad have found that there is a close correlation between the appearance color of tobacco leaves and the internal quality, which has laid a good foundation for using the appearance color of tobacco leaves to evaluate the quality stability of red-cured finished tobacco. Existing evaluation methods of rebaked finished tobacco sheets mainly focus on the temperature and moisture uniform...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N21/25

Inventor 何邦华袁逢春王跃昆华一崑资文华张晓龙龙明海左景键胡巍耀何川汪显国皇甫东有

Owner HONGYUN HONGHE TOBACCO (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com