Method for improving batch procedure capability of tobacco shred making process

A technology of process capability and process capability index, applied in the direction of tobacco preparation, application, tobacco, etc., can solve problems such as difficulty in making optimization adjustments, increasing labor costs and time costs in the optimization process, and not being able to reflect the process quality well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

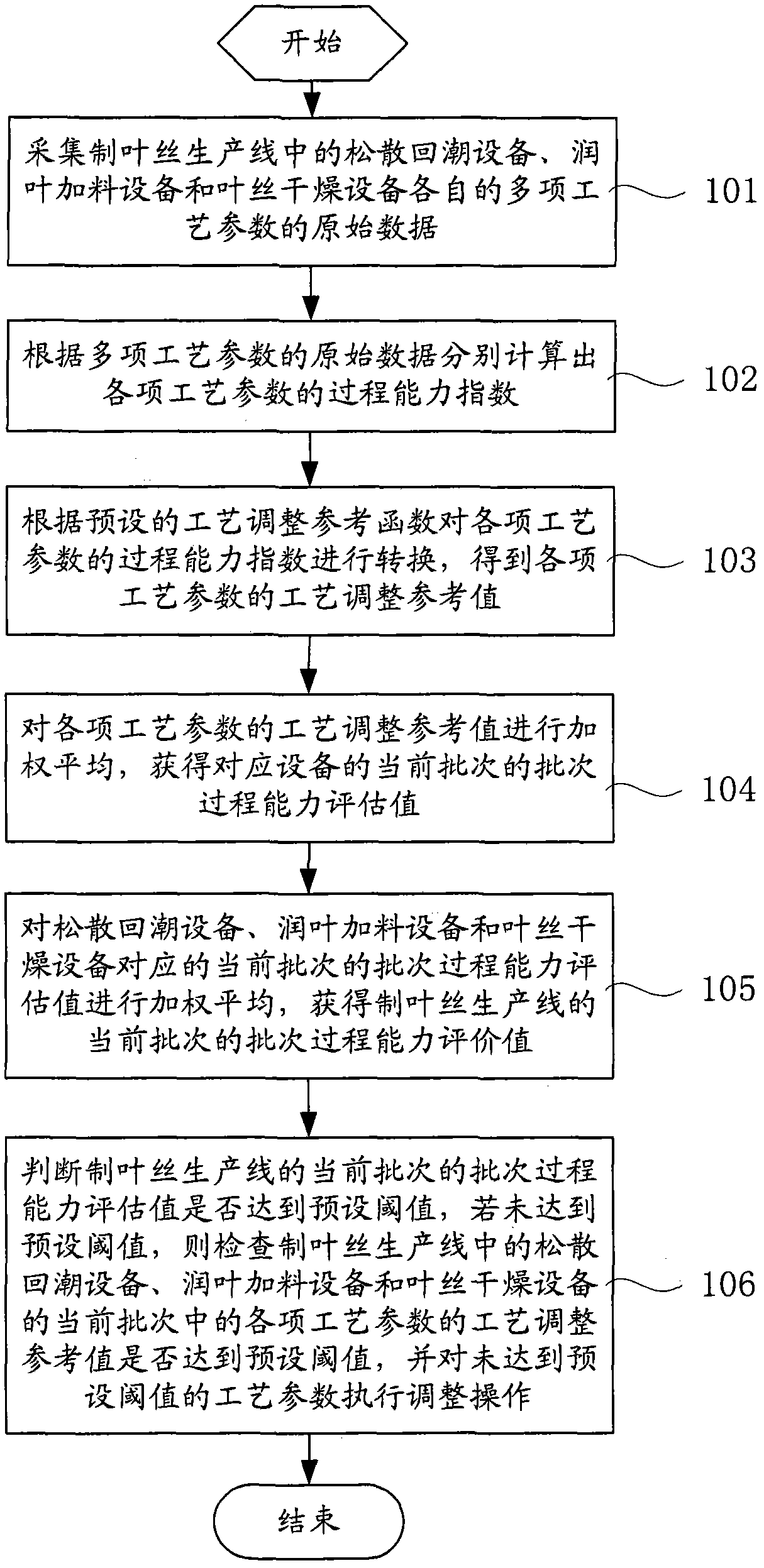

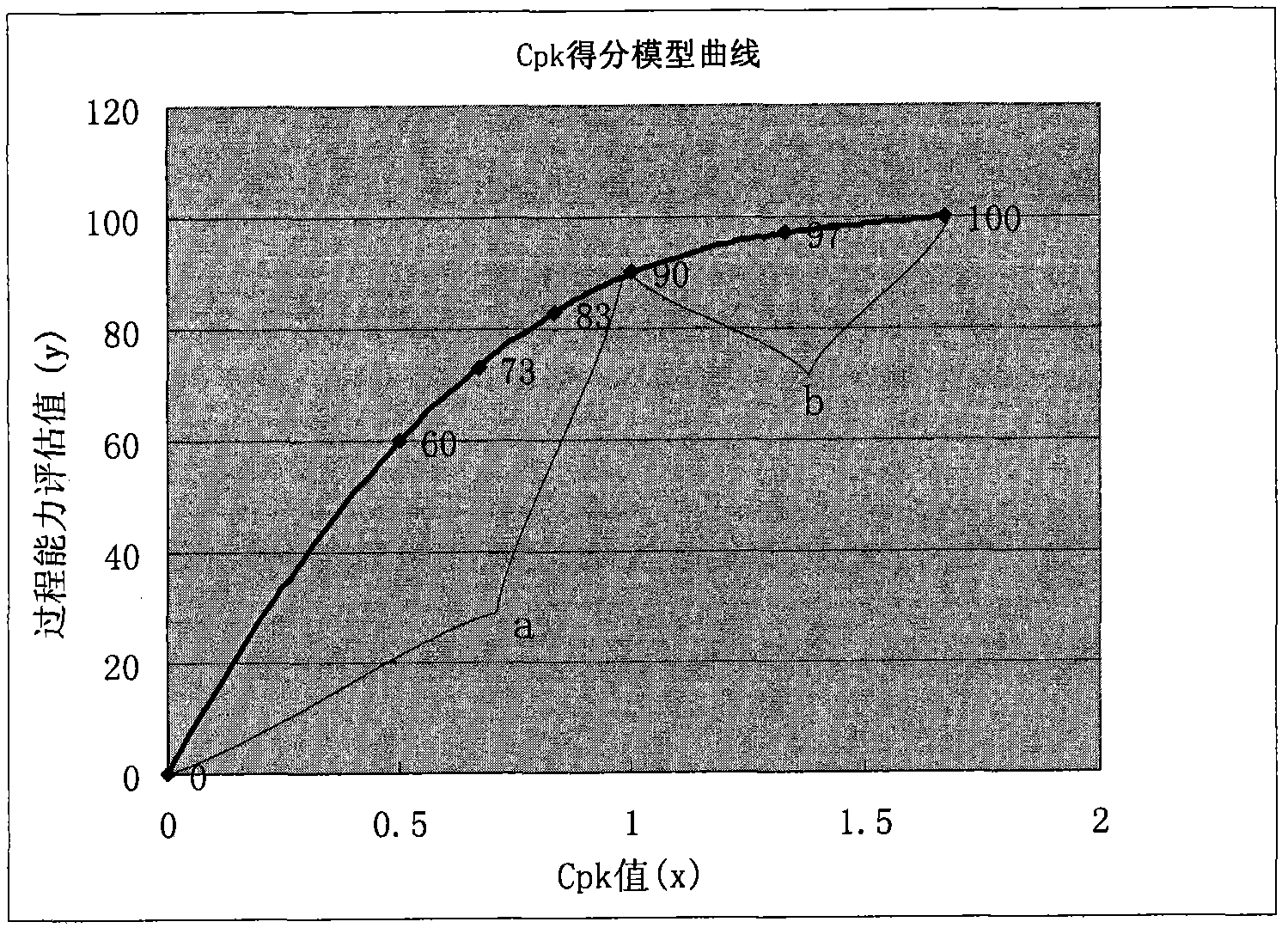

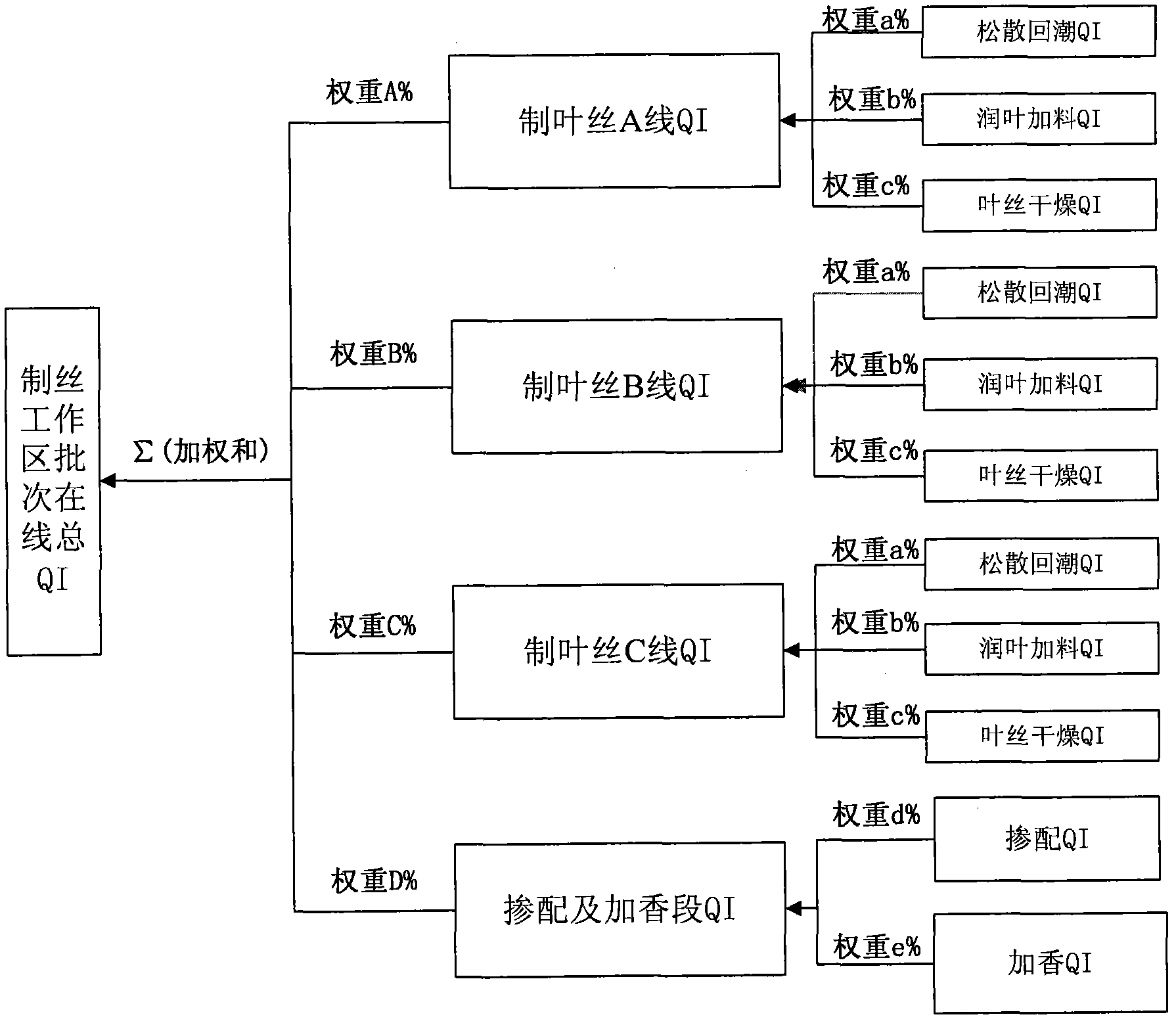

[0020] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0021] Definitions of terms involved in the present invention are first given. Process capability refers to the ability of the process to meet the technical requirements. Specifically, it refers to the actual processing capability of the process in a stable state, that is, the ability to ensure product quality. The process referred to here refers to the process of the comprehensive action of five basic quality factors such as operator, machine, raw material, process method and production environment, that is, the production process of product quality. Product quality is the comprehensive performance of the various quality factors in the process. For any production process, product quality always exists in a decentralized manner. If the process capability of the process is higher, the dispersion of product quality cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com