Global operating condition evaluating and quality tracing method for hydrocracking process

A technology of hydrocracking and operating conditions, applied in data processing applications, instruments, calculations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

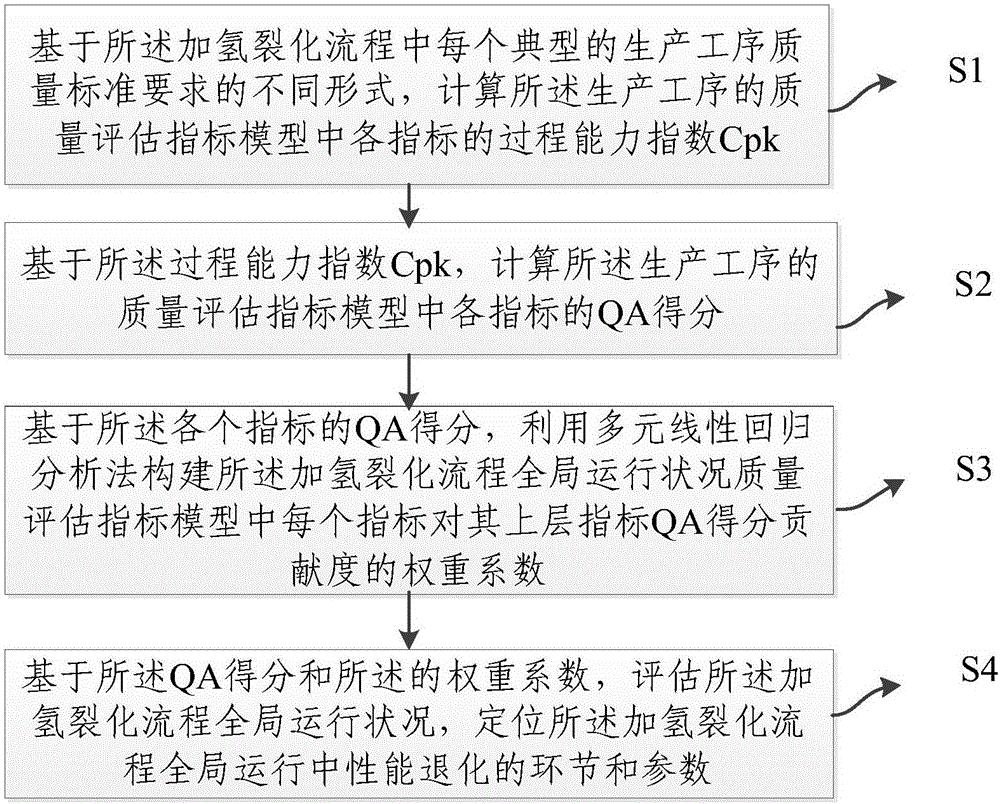

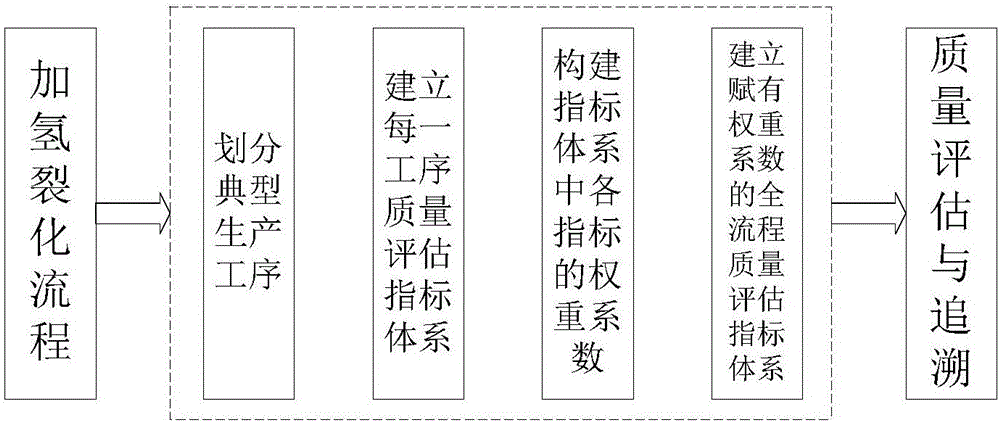

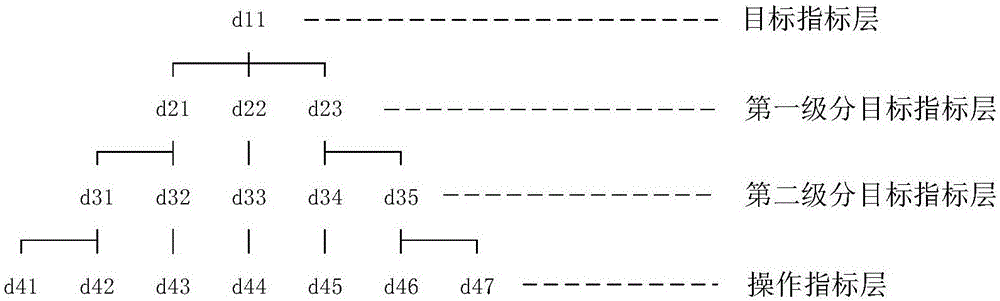

Method used

Image

Examples

Embodiment 1

[0076] a. According to the process plan, the hydrocracking process is simplified into three parts: hydrofining, hydrocracking and fractionation systems, such as Figure 4 Shown. Combined with the production characteristics of the hydrocracking process, the inlet conditions are added as a virtual process to the division of typical production processes in the hydrocracking process. The inlet conditions include feed oil flow and feed oil composition. The hydrorefining process is mainly to remove sulfides, nitrides, and oxides in the feedstock oil, while saturating olefins and thickened aromatics to provide qualified feed for the hydrocracking part; the hydrocracking process mainly uses inferior heavy raw materials The oil is converted into high-quality light oil; the fractionation system removes hydrogen sulfide and obtains a reaction effluent with less S, and separates the reaction effluent into light naphtha and heavy naphtha according to different distillation ranges. There are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com