Process detection method and device

A technology of process detection and process capability index, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as inaccurate status, and achieve the effect of accurate analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

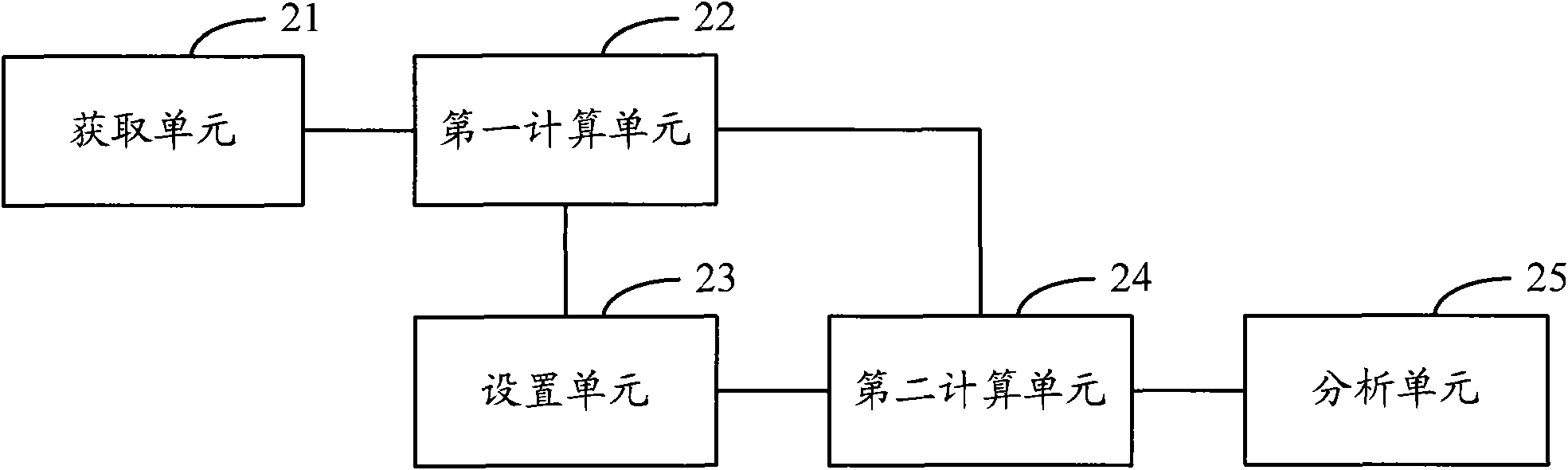

[0041] According to the relationship between the average value of the quality characteristic value of the product and the specification target value, the embodiment of the present invention sets the offset coefficient of the process capability index respectively, so as to obtain the process capability index that can accurately reflect the state of the process.

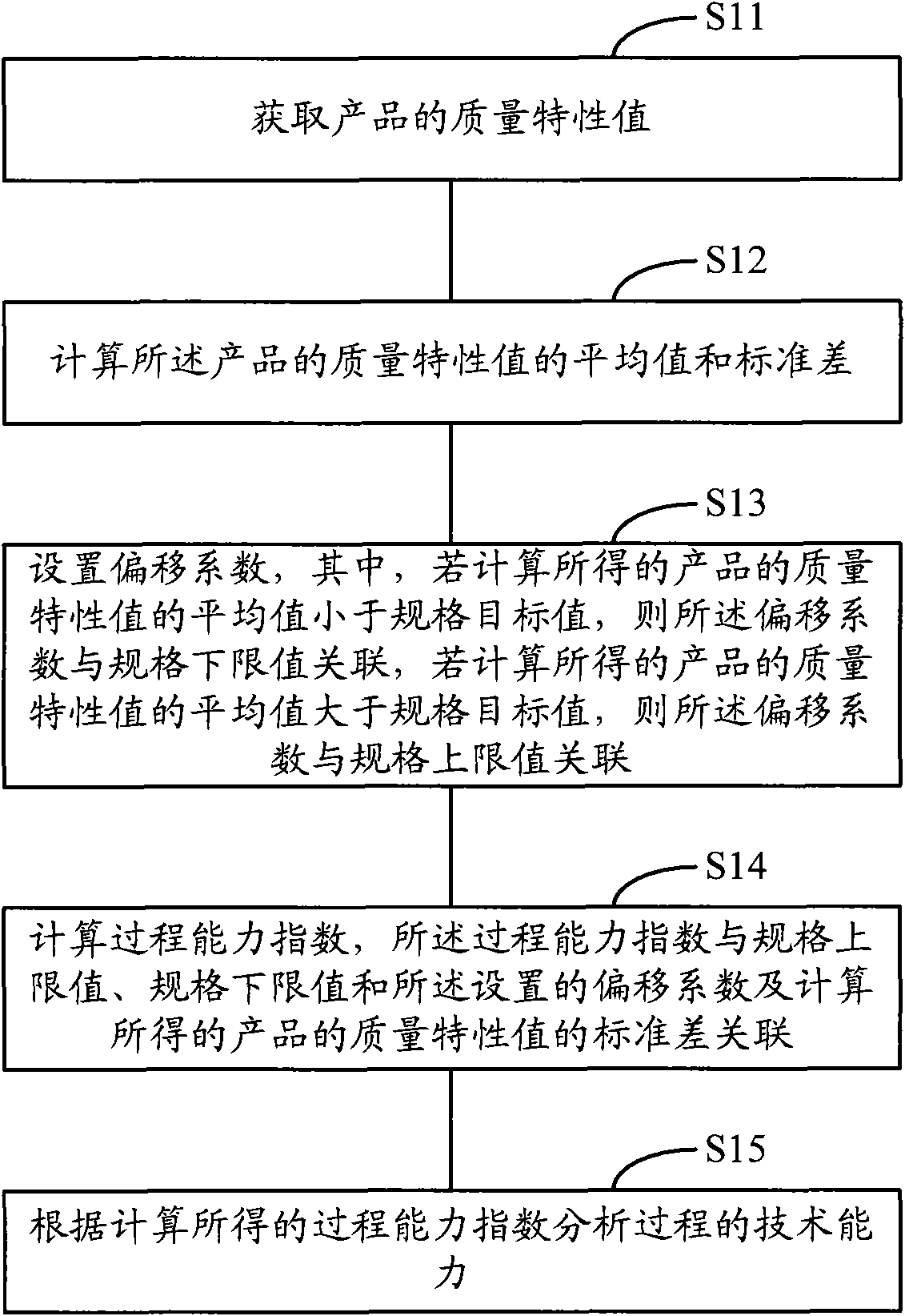

[0042] figure 1 It is a flow chart of the process detection method of the embodiment of the present invention, comprising the following steps:

[0043] Step S11, acquiring the quality characteristic value of the product.

[0044] Step S12, calculating the average value and standard deviation of the quality characteristic values of the product.

[0045] Step S13, setting the offset coefficient, wherein, if the calculated average value of the quality characteristic value of the product is less than the specification target value, the offset coefficient is associated with the lower limit value of the specification, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com