Cigarette quality evaluation method and system based on principal component analysis

A technology of principal component analysis and quality evaluation, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of not truly reflecting the process quality level, no improvement, and affecting the overall process quality of the silk making process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

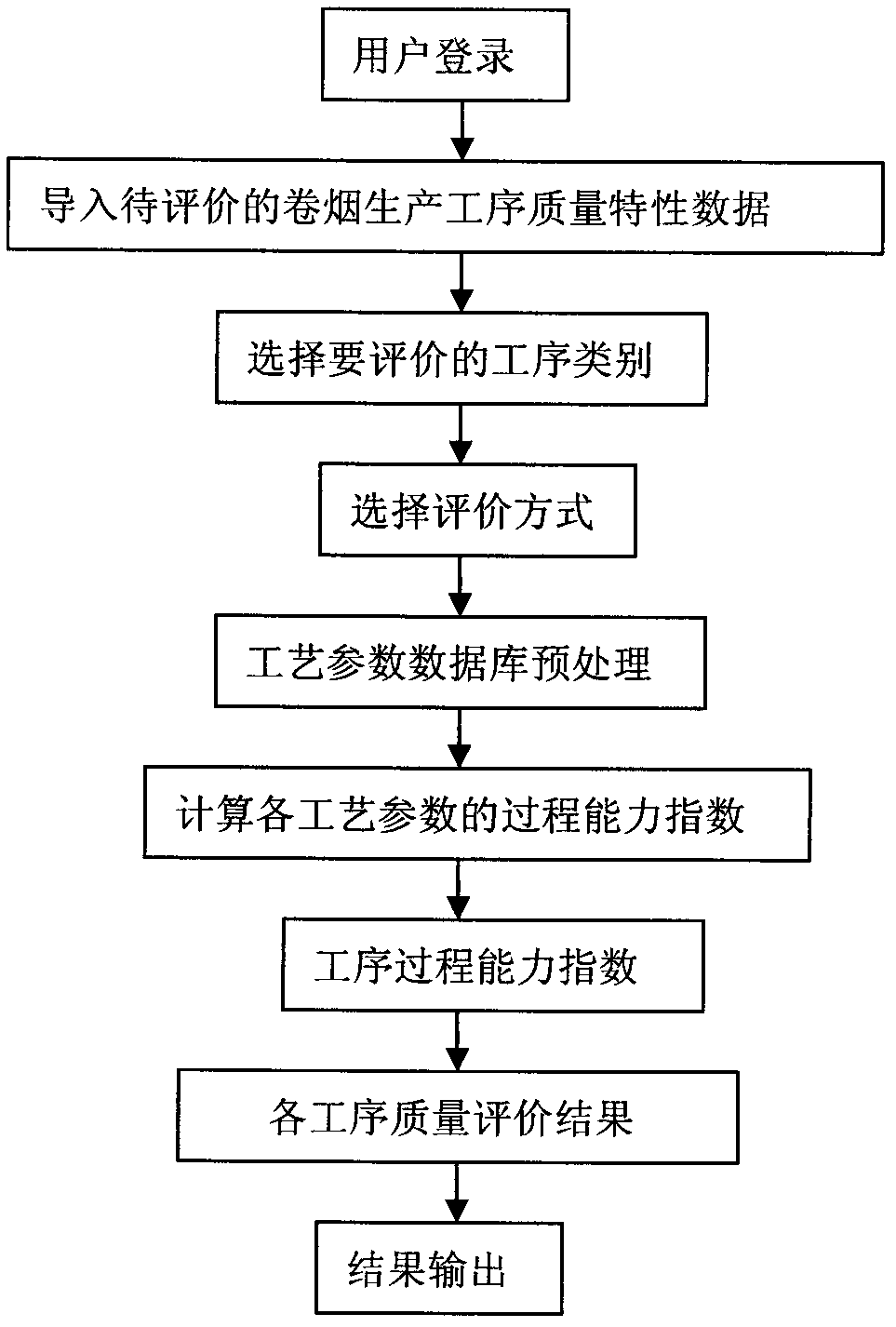

[0064] Embodiment 1 (cigarette process quality evaluation method):

[0065] Just operate according to the technical solution one in the summary of the invention above.

[0066] Below in conjunction with the process quality evaluation example of the loose moisture regain process in the leaf silk workshop section further illustrate this method:

[0067] 50 sets of data are collected for each of the five main process parameters in the loosening and moisture regaining process as shown in Table 1.

[0068] Table 1 Monitoring table of process parameters in the loosening and moisture regaining process

[0069]

[0070]

[0071] The specification requirements of various process parameters in this process are: moisture content (19.0±1.0)%, temperature (53.0±3.0) ℃, flow rate (6000.0±100.0) Kg / h, hot air temperature (70.0±3.0) ℃, steam injection Amount (1000.0±50.0) Kg / h.

[0072] The data in Table 1 are subjected to the standardization process, and the standardized data are sh...

Embodiment 2

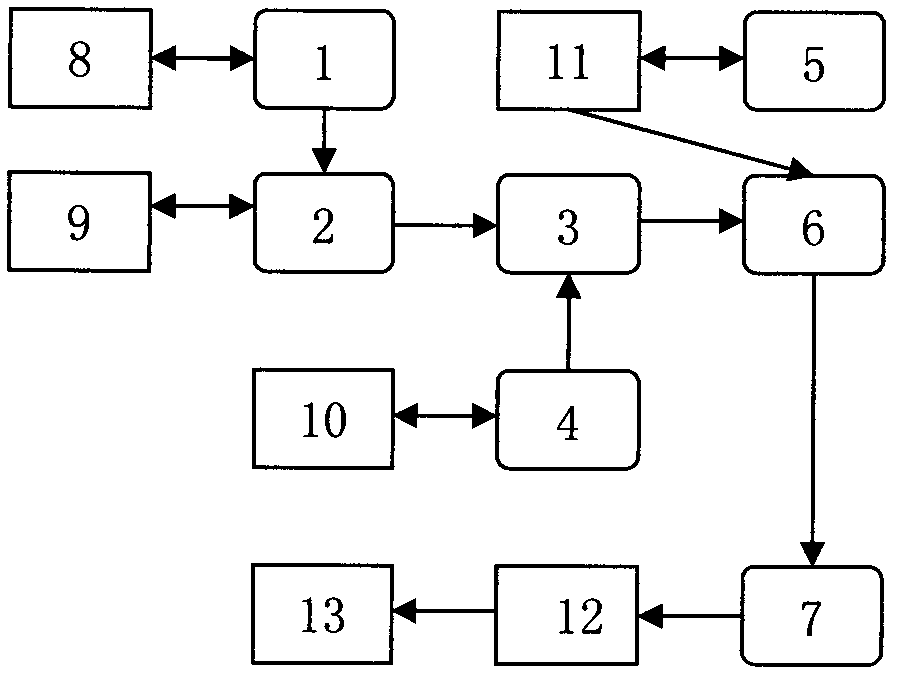

[0089] Embodiment 2 (cigarette process quality evaluation system):

[0090] It can be implemented according to the second technical solution in the above summary of the invention.

[0091] Operation steps of the present invention are as follows:

[0092] (1) The user inputs the user name and password, and the authority management module 1 searches the user authority according to the data in the authority database 8 . If the conditions are met, the user is allowed to operate and use, and is responsible for forcing the user to log out of the system;

[0093] (2) the user imports the data in the process parameter value database 9 into the system through the data import module 2;

[0094] (3) The user selects the process category to be evaluated from the process category database 10 through the process category selection module 4, and sends the data to the data selection and preprocessing module 3;

[0095] (4) Data selection and preprocessing module 3 preprocesses the data imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com