Splicing machining method for ion beam machining optical element

A technology of an optical element and a processing method, which is applied in the field of sub-regional splicing and processing of ion beam processing optical elements, can solve the problems of increased maintenance cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] The ion beam polishing modification process of the present embodiment is carried out on an ion beam polishing equipment (KDIFS-500 type can be selected), and the modification process parameters are set to: the working gas is argon, and the working vacuum is 0.8×10 -2 Pa, ion energy 1100eV, beam current 25mA.

[0049] The optical element to be polished is ordinary glass-ceramics with a diameter of 84mm.

[0050] Carry out ion beam polishing to above-mentioned glass ceramics by following method step:

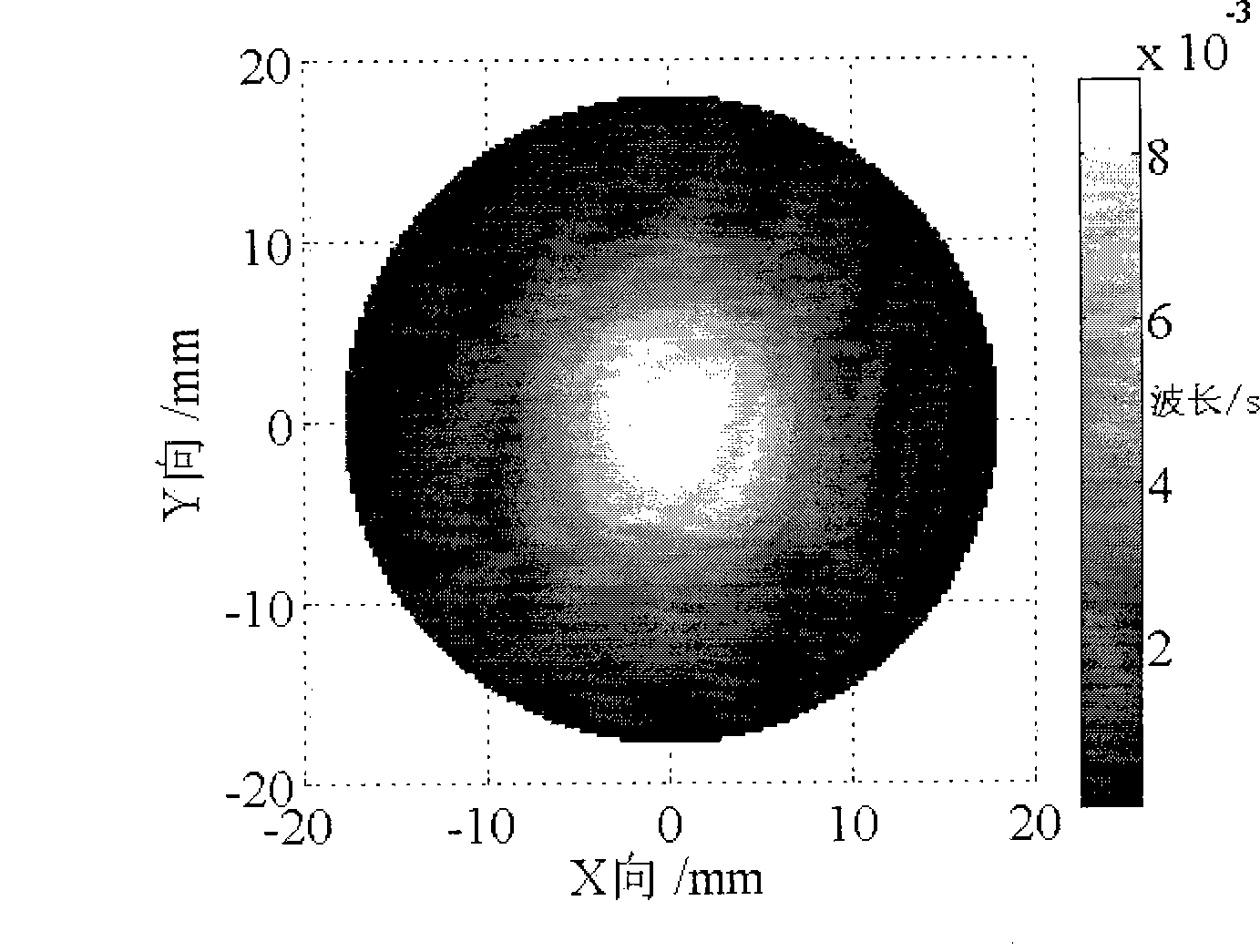

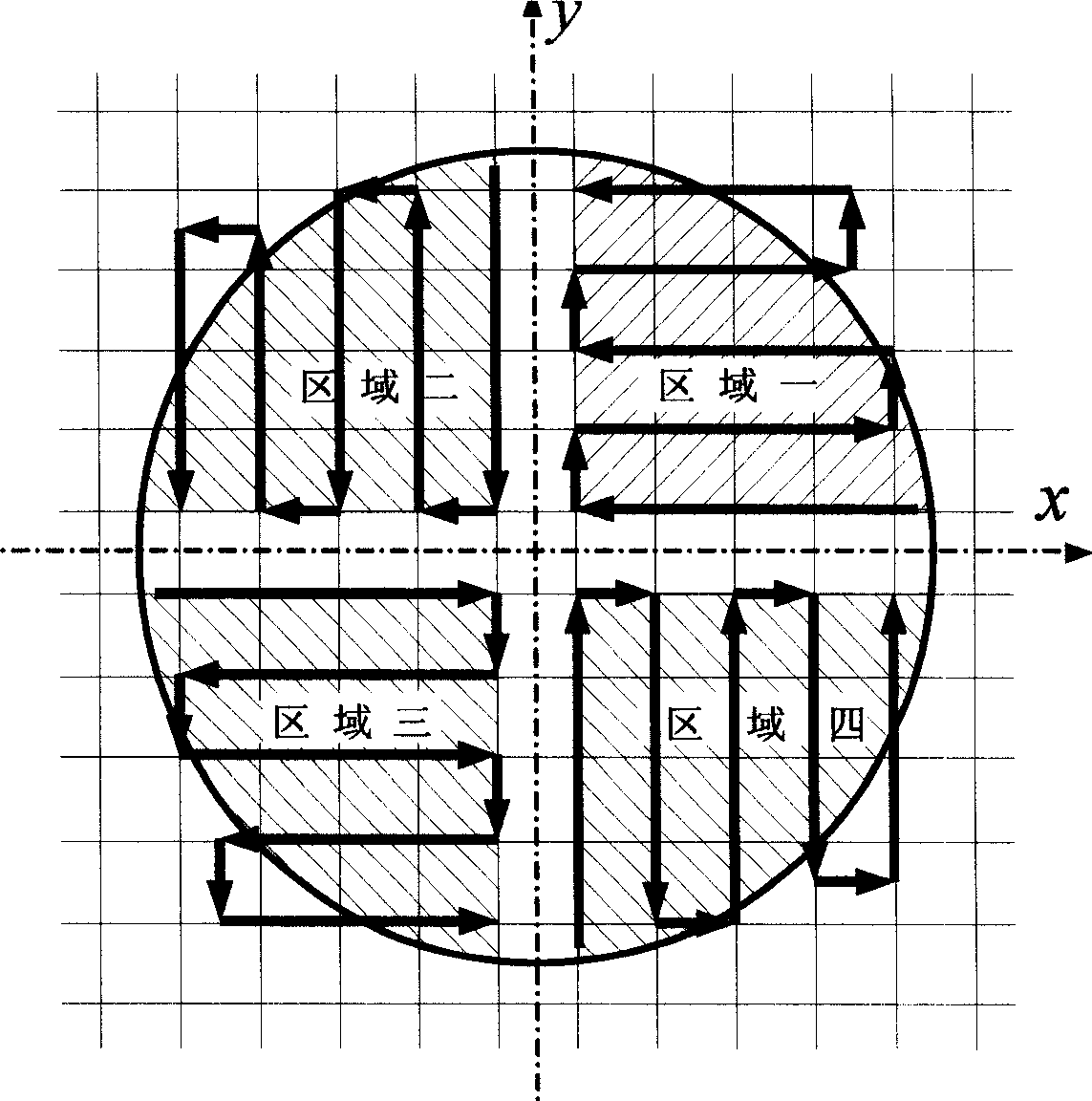

[0051] 1. Determine the removal function: apply the above-mentioned ion beam modification process to carry out the removal function experiment, and the obtained removal function is denoted as R(x, y), and its distribution is as follows figure 1 As shown, the diameter d=36mm of the removal function; the removal function is discretized with an interval S, and expressed as a matrix is R;

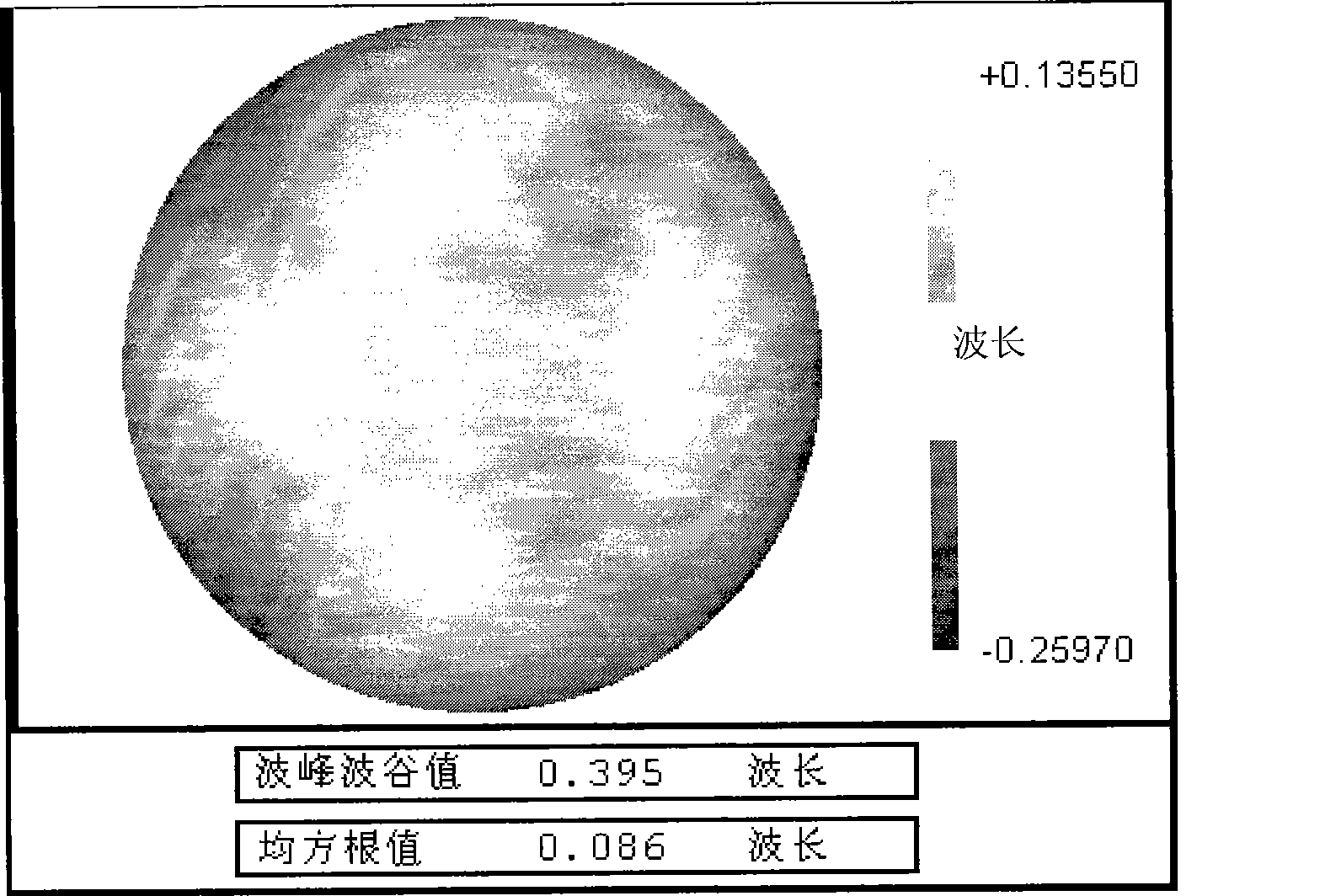

[0052] 2. Use the wave surface interferometer to measure the initial surface error o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com