SPC (statistical process control)-based electric energy meter comprehensive error process capability evaluation method and evaluation system

A technology for comprehensive error and process capability, which is applied in the field of SPC-based comprehensive error process capability evaluation method and evaluation system for electric energy meters, which can solve the problem of not finding published patent documents and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail in the following specific examples. The following examples are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

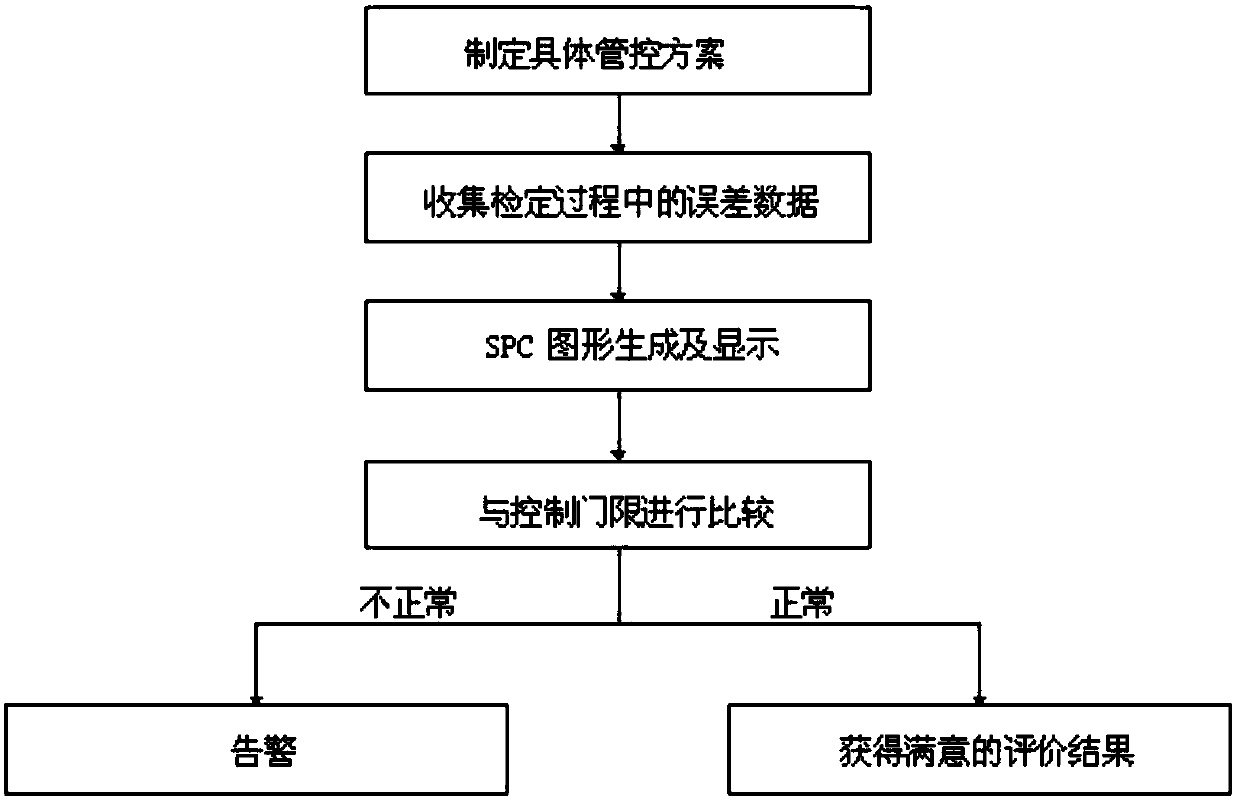

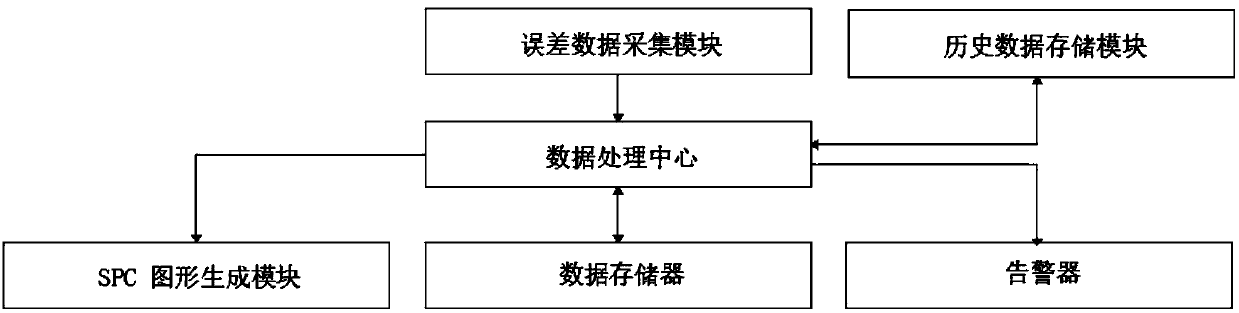

[0039] An SPC-based method for evaluating the comprehensive error process capability of electric energy meters, see attached figure 1 As shown, it specifically includes the following steps:

[0040] (1) Develop a specific control plan for the comprehensive error process capability of electric energy meters;

[0041] The specific implementation steps of the control plan are as follows:

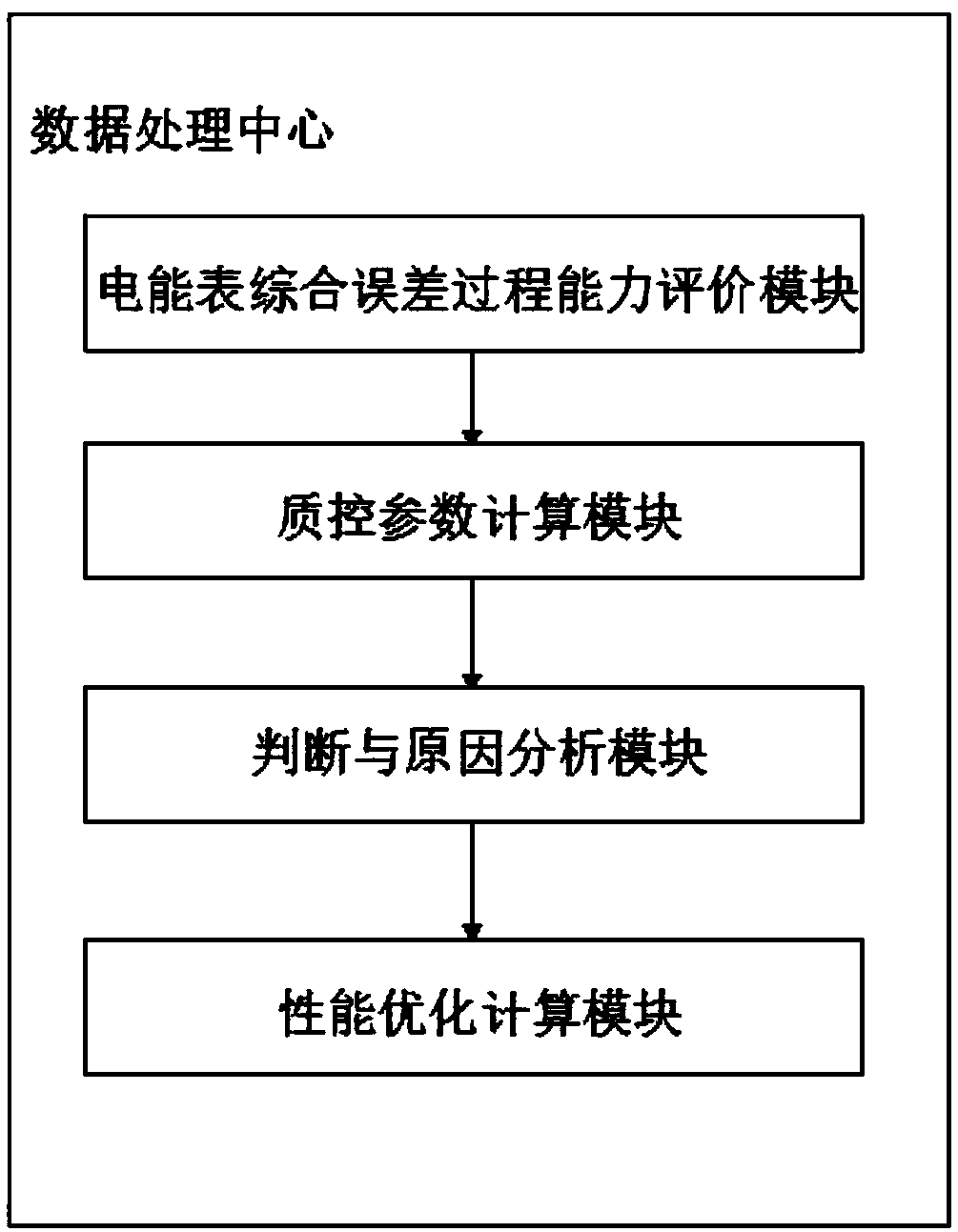

[0042] ①Generate the calculation model of the comprehensive error process capability index of the electric energy meter. In the calculation process, the process capability index CPK and PPK are introduced. The process capability index refers to the degree to which the process capability meets the technical standard. By calculating the process capability index of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com