Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67 results about "Plant stanols" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plant stanols are like cholesterol but for plants. They are commonly found in plant related foods. Plant stanols are good at reducing the level of low-density lipoprotein cholesterol in blood when ingested, though to a much lesser degree than prescription drugs such as statins.

Cholesterol lowering supplement

InactiveUS6933291B2Lower Level RequirementsImprove the level ofBiocideAnimal repellantsIntestinal structureElevated blood

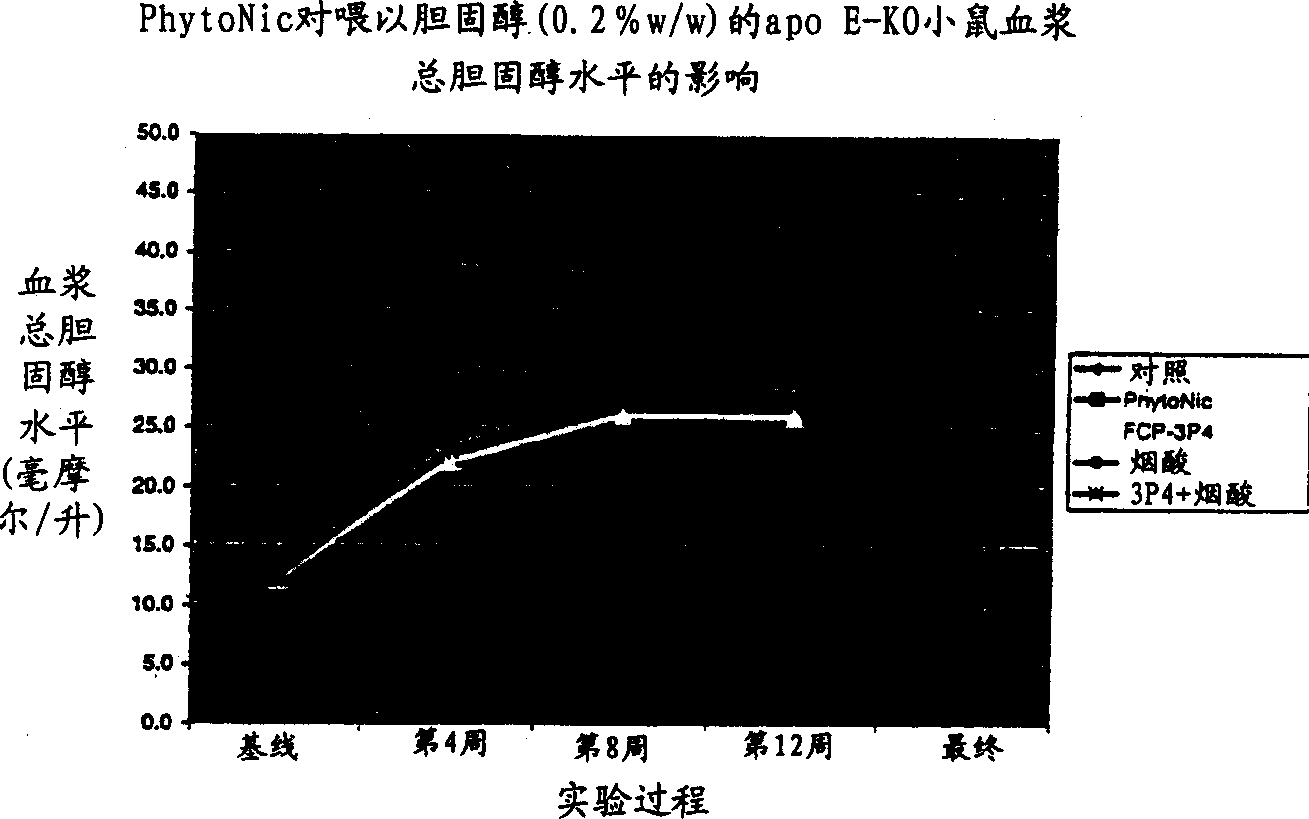

The invention provides a composition and a method for lowering blood serum cholesterol levels or for preventing elevated blood serum cholesterol levels, as well as suitable composition comprising (a) one or more phytosterols and / orphytostanols or a mixture thereof capable of reducing cholesterol absorption in the intestine, (b) a composition capable of inhibiting cholesterol biosynthesis, and (c) a composition capable of increasing cholesterol metabolism, wherein at least one of compositions b. and c. is preferably derived from plants.

Owner:UNICITY PROPERTIES

Composition for improving blood cholesterol levels

A nutritional composition for improving blood cholesterol by jointly and simultaneously inhibiting cholesterol absorption, decreasing blood LDL levels, increasing blood HDL levels and interfering with HMG-CoA reductase synthesis or degradation in an individual comprising, therapeutically effective amounts of plant sterols or plant stanols or derivatives thereof, procyanidins, policosanol and niacin or derivatives of niacin is provided. Both a composition and a method are provided by the present disclosure.

Owner:IOMEDIX DEV INT

Compositions comprising one or more phytosterols and/or phytostanols, or derivatives thereof, and high HLB emulsifiers

ActiveUS20070141224A1Reduce particulate pollutionReduce in quantityMilk preservationSpread compositionsPlant stanolsPhytosterol

A composition for use in foods, beverages and nutraceuticals that includes one or more non-sterol emulsifiers, each having an HLB value of greater than 14 and one or more sterols or stanols or mixtures thereof.

Owner:PHARMACHEM LAB INC

Methods and formulations for the treatment of medical conditions related to elevated dihydrotestosterone

InactiveUS20050153948A1Enhances small intestinal absorptionIncrease blood concentrationBiocideDispersion deliveryHydrogenAdditive ingredient

The present invention describes a composition that contains a plant sterol or plant stanol or their fatty acid esters and an emulsifier for treating conditions that are related to elevated dihydrotestosterone. The compositions can be prepared in a dry form for use as a food ingredient, tablet or capsule. Alternatively, the compositions can be dissolved in oil.

Owner:ZOMANEX

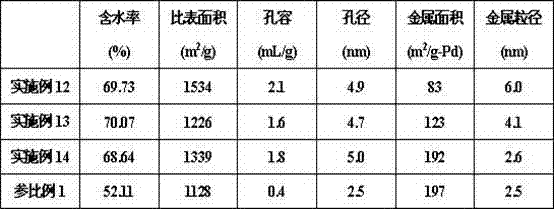

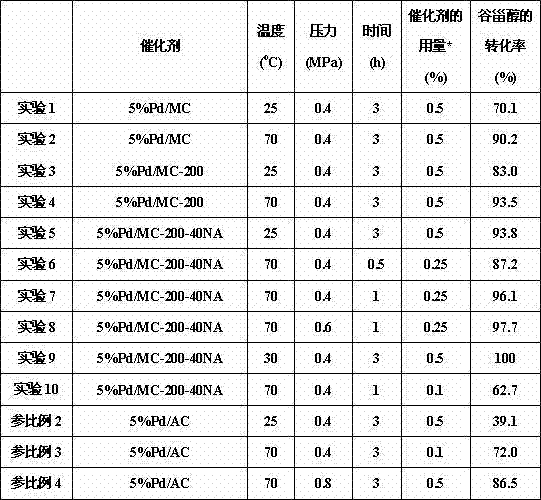

Palladium catalyst loaded by mesoporous carbon as well as preparation method and application thereof

InactiveCN102407108AHigh activityImprove conversion rateSteroidsChemical recyclingHydrogenPlant stanols

The invention relates to a palladium catalyst loaded by mesoporous carbon. The content of metal palladium in the catalyst is 1-5%, and the carrier is mesoporous carbon. The palladium catalyst loaded by mesoporous carbon has large activity superficial area; and in the presence of solvent, phytosterol is prepared from unsaturated phytosterol through catalysis and hydrogenation. In the invention, the used reaction temperature and the pressure of hydrogen are low, the consumption of the catalyst is less, the required reaction time is short, the cheap mesoporous carbon is used as a carrier, the catalyst cost is lowered, and the precious metal components in the catalyst is convenient to recycle; and under the condition of optimizing, the conversion rate of sterol is nearly 100%.

Owner:HIGH TECH RES INST NANJING UNIV LIANYUNGANG +1

Cholesterol lowering supplement

InactiveUS20050100619A1Preventing elevated blood cholesterol levelInhibiting cholesterol synthesisOrganic active ingredientsBiocidePlant stanolsElevated blood

The invention provides a composition and a method for lowering blood serum cholesterol levels or for preventing elevated blood serum cholesterol levels, as well as a suitable composition comprising (a) one or more phytosterols and / or phytostanols capable of reducing cholesterol absorption in the intestine and / or one or more soluble fibres capable of inhibiting ileal bile acid absorption, (b) a composition capable of inhibiting cholesterol biosynthesis, and (c) a composition capable of increasing cholesterol metabolism, wherein at least one of compositions (b) and (c) is preferably derived from plants.

Owner:NUTRICIA

Method for preparing phytostanol ester under solvent-free condition

InactiveCN103122020ASuitable for food industry productionSimple processSteroids preparationInfraredChemical industry

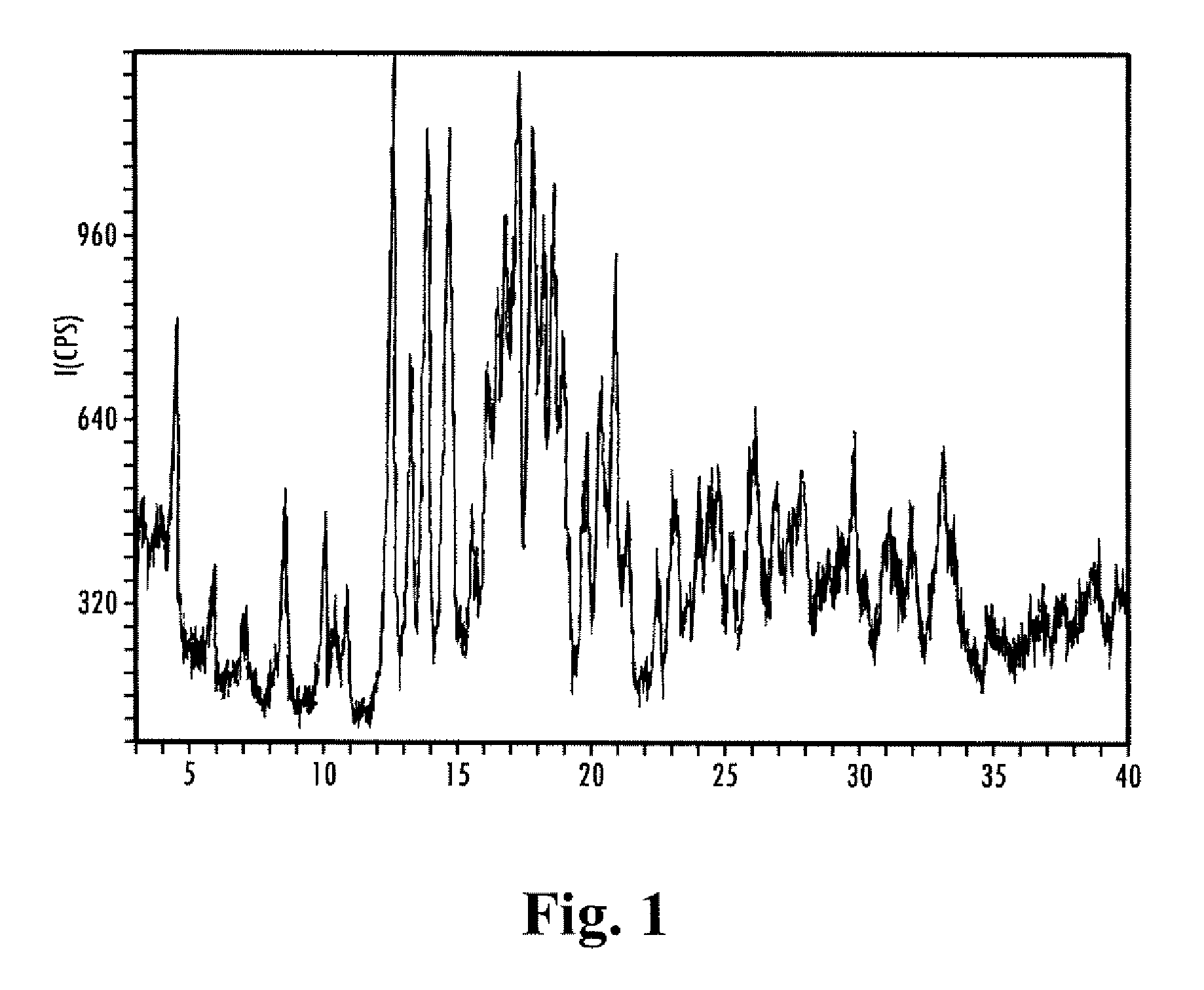

The invention relates to a method for preparing phytostanol ester under the solvent-free condition and belongs to the technical fields of food, medicine, chemical industry and cosmetics. According to the technical scheme, the method comprises the following steps of: adding fatty acid or aromatic acid, phytostanol and a catalyst at a certain molar ratio to a reaction tube with branched openings under the solvent-free condition; putting the reaction tube into a thermostatic oil bath with a magnetic stirring function; stirring for a certain time at a certain temperature in the atmosphere of nitrogen to enable materials to react to generate the product which is the phytostanol ester, wherein the phytostanol ester is generated after the reaction ends, the addition amount of the catalyst is 0.5-5.0mol% (relative to the molar weight of the phytostanol ester), the reaction temperature is 90-170 DEG C, and the reaction time lasts for 2-7 hours; sampling at fixed time, and measuring the conversion rate and the anisidine value to detect the reaction process; analyzing the product by infrared spectrum, mass spectrum and nuclear magnetic resonance spectrum to indentify the structure of the product, wherein the product is obtained by separating and purifying through column chromatography. The method is simple in process and high in efficiency and is suitable for large-scale production.

Owner:JIANGNAN UNIV

Compositions comprising edible oils or fats and phytosterols and/or phytostanols substantially dissolved therein

The invention relates to a composition comprises an edible oil or fat and one or more phytosterols and / or phytostanols, wherein the phytosterols and / or phytostanols are substantially completely dissolved therein by a method in which the phytosterols and / or phytostanols are heated to form a molten material which is then added to a heated oil or fat and the composition so formed is cooled to room temperature.

Owner:FORBES MEDI TECH

Combinations of Botanical Extracts for Promoting Cardiovascular Health

InactiveUS20100239603A1Eliminate side effectsEfficacyBiocideNervous disorderAcute hyperglycaemiaNervous system

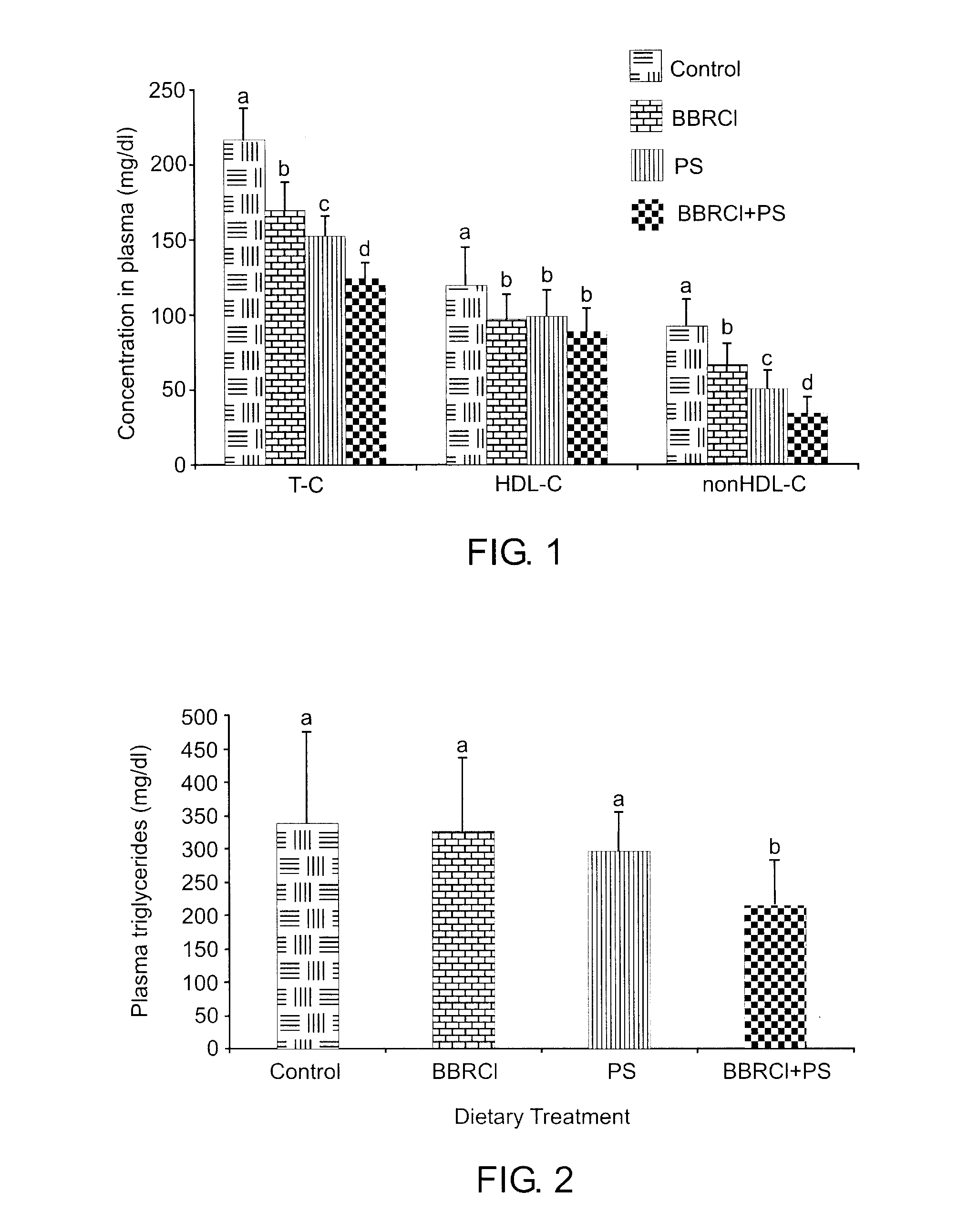

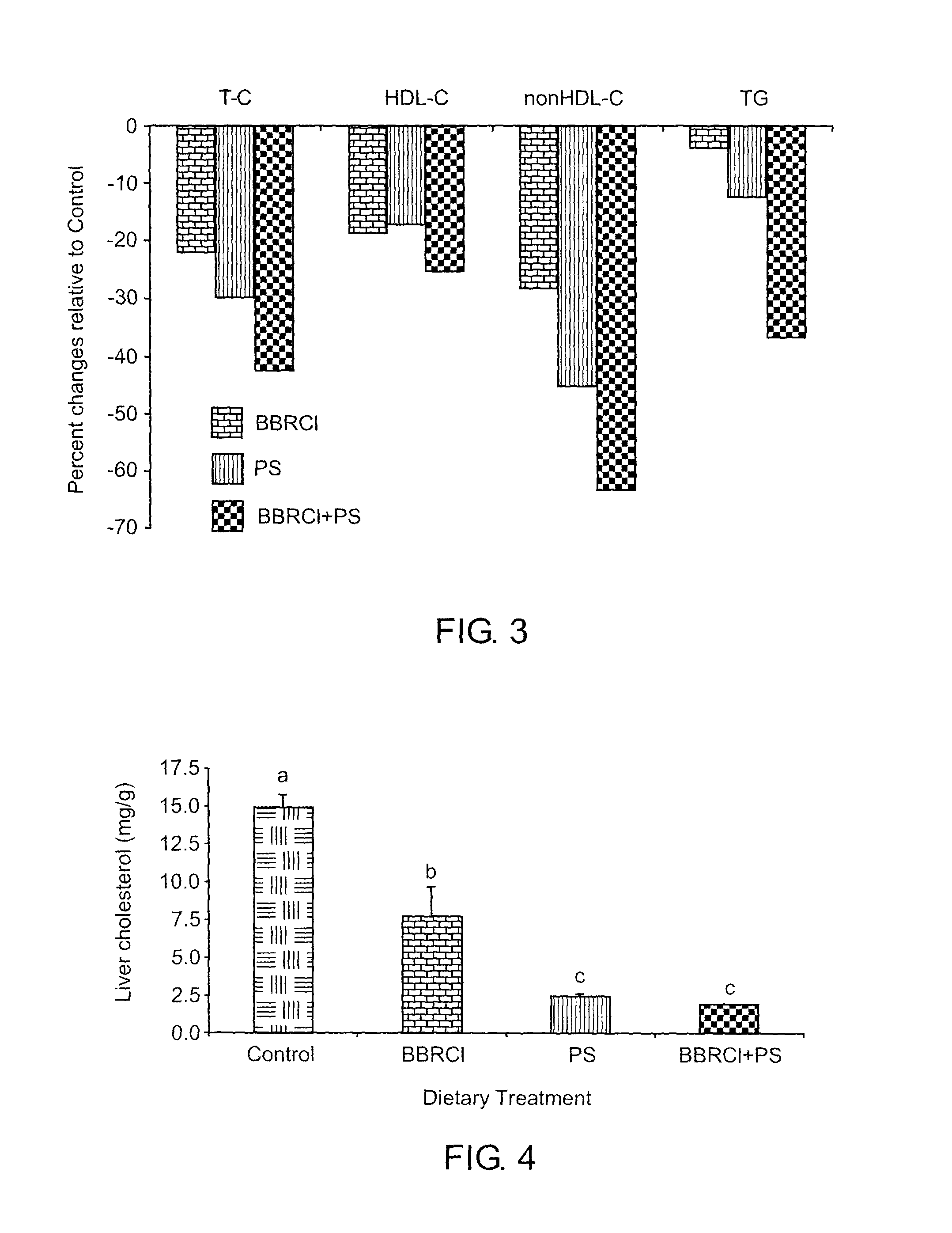

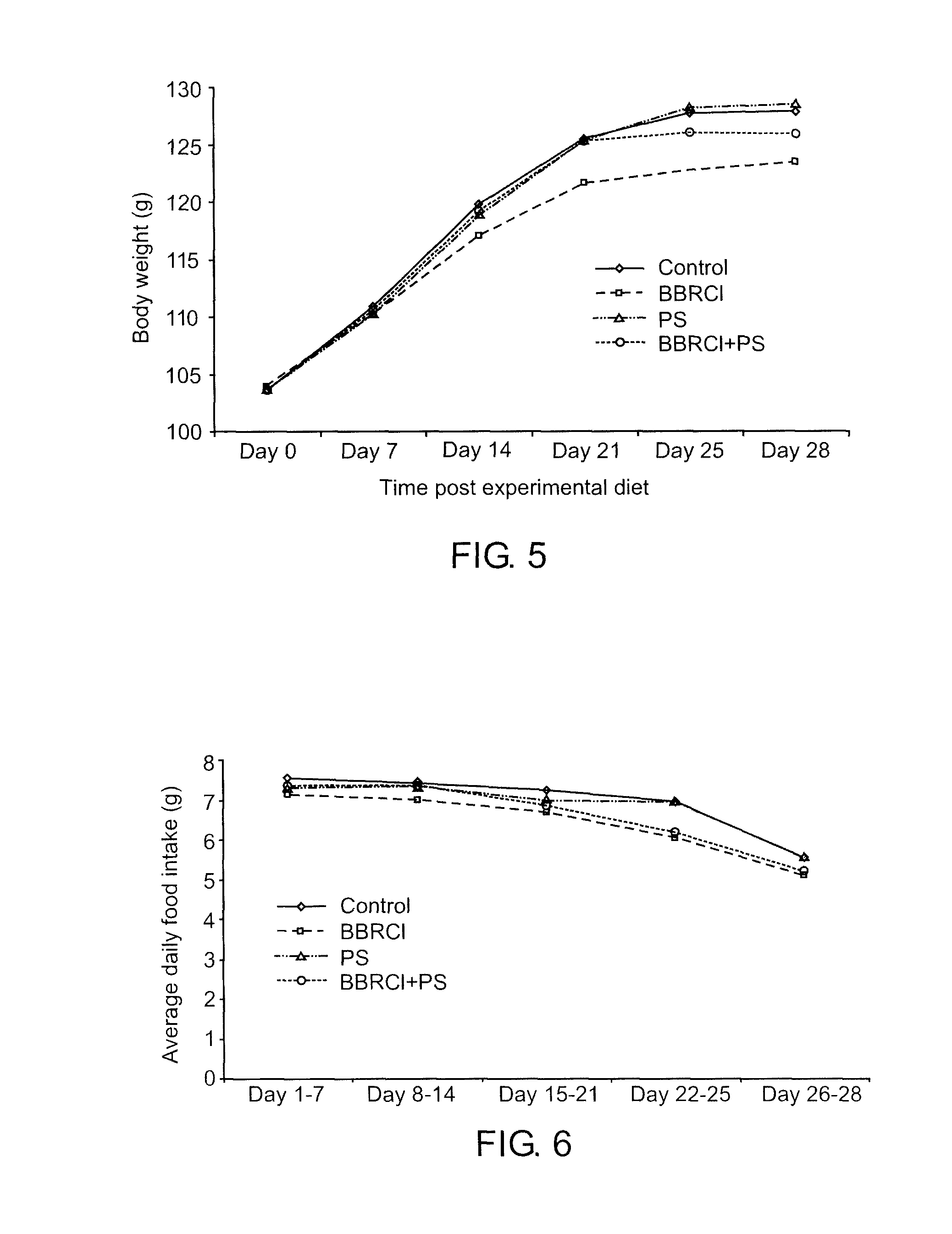

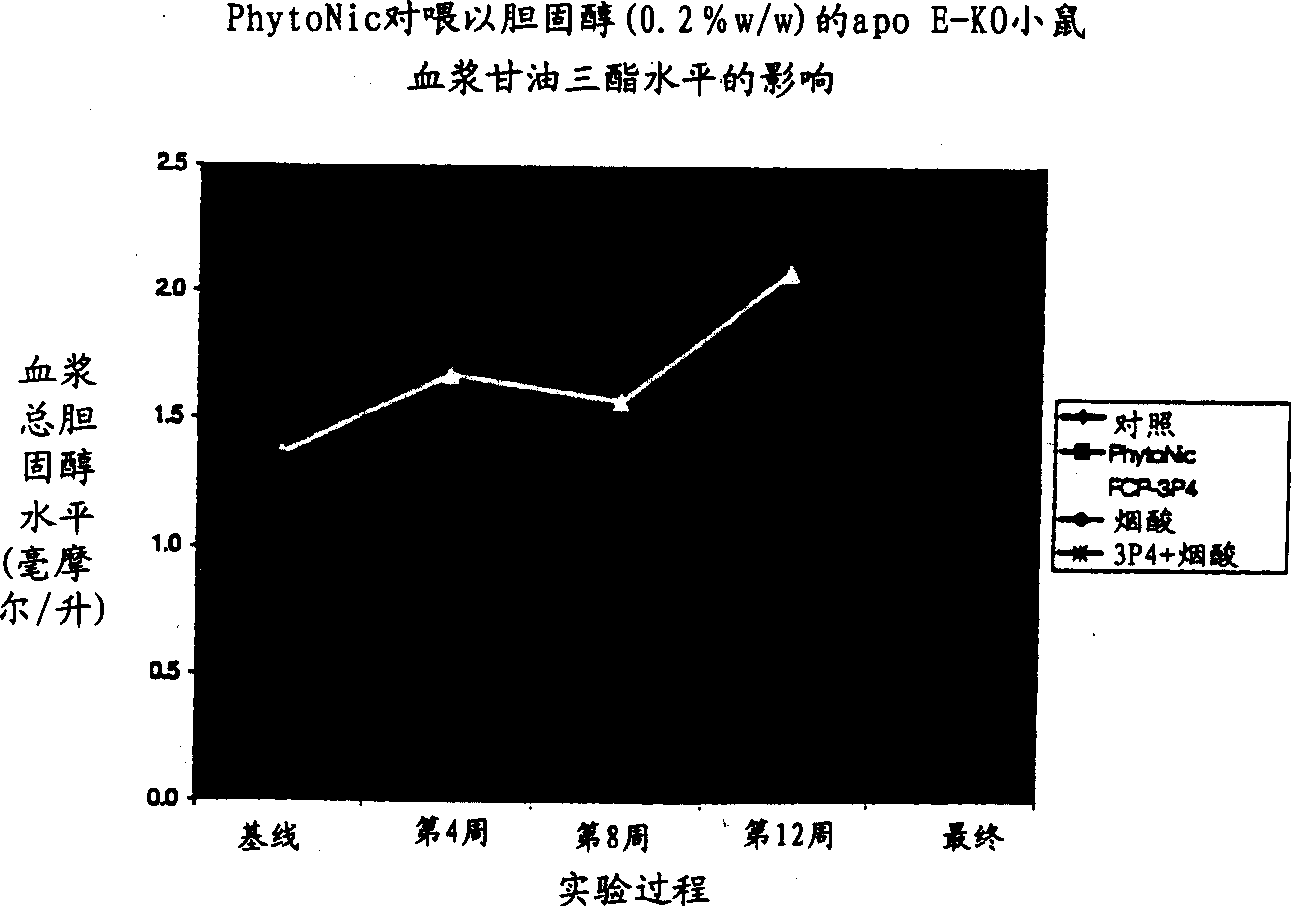

A blood lipid lowering agent that functions through a same mechanism as berberine (e.g. berberine, one or more pharmacologically acceptable salts of berberine or a mixture thereof) and a blood lipid lowering agent that functions through a different mechanism than berberine (e.g. phytosterols, phytostanols, esters thereof or mixtures thereof) act synergistically to improve blood lipid profiles, for example, lowering total cholesterol, LDL-C or nonHDL-C, and triglyceride, and increasing the ratio of HDL-C to nonHDL-C. The two may be used in combination to treat or reduce the chance of contracting cardiovascular disease, hyperlipidemia, atherosclerosis, coronary heart disease, angina, cerebrovascular disease, stroke, overweight or obesity, diabetes, insulin resistance, hyperglycemia, hypertension, arrhythmia, diseases of the central nervous system, diseases of the peripheral nervous system and / or inflammation. The blood lipid lowering agent that functions through a same mechanism as berberine, with or without the blood lipid lowering agent that functions through a different mechanism than berberine, may also be used to control weight.

Owner:NAT RES COUNCIL OF CANADA

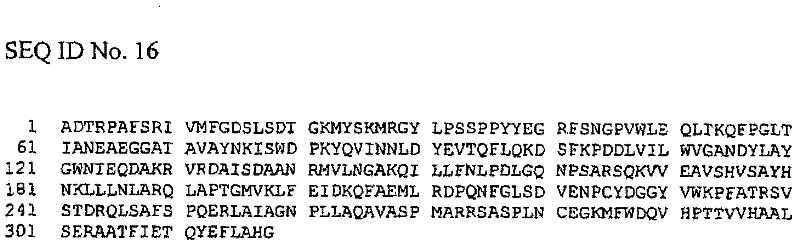

Aromatic and heterocyclic derivatives of phytosterols and/or phytosanols for use in treating or preventing cardiovascular disease

InactiveCN1370179AEasy to incorporateImprove solubilityOrganic active ingredientsMetabolism disorderHydrogenPlant stanols

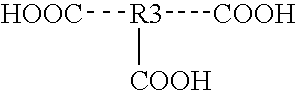

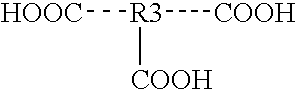

Novel phytosterol and / or phytostanol derivatives, including salts thereof, are represented by general formulae (I or II) wherein R is a phytosterol or phytostanol moiety; R2 is oxygen or hydrogen (H2) and R3 is an aromatic or heterocyclic unit. These derivatives are effective in treating and preventing cardiovascular disease and its underlying conditions including hyperlipidemia.

Owner:FORBES MEDI TECH

Novel phytosterol or/and phytostanol derivative preparation method

The present invention relates to a novel phytosterol or / and phytostanol derivative preparation method, and belongs to the technical field of food, medicine, chemical industry, cosmetics and the like. In the prior art, modification researches of phytosterol or / and phytostanol are only limited in liposolubility improvement, and an application range is limited. A purpose of the present invention is to improve water solubility of phytosterol or / and phytostanol. The preparation method comprises the following steps that: a) a certain amount of phytosterol or / and phytostanol and a polybasic organic acid or anhydride are subjected to a reaction under a catalyst effect to generate an intermediate product phytosterol or / and phytostanol polybasic acid monoester; and b) the intermediate product and a polyhydroxy compound are subjected to a reaction under a catalysis effect of a biocatalyst catalyst to generate a water-soluble phytosterol or / and phytostanol derivative, and the obtained water-soluble phytosterol or / and phytostanol derivative is subjected to column chromatography separation purification to obtain the novel phytosterol or / and phytostanol derivative.

Owner:JIANGNAN UNIV

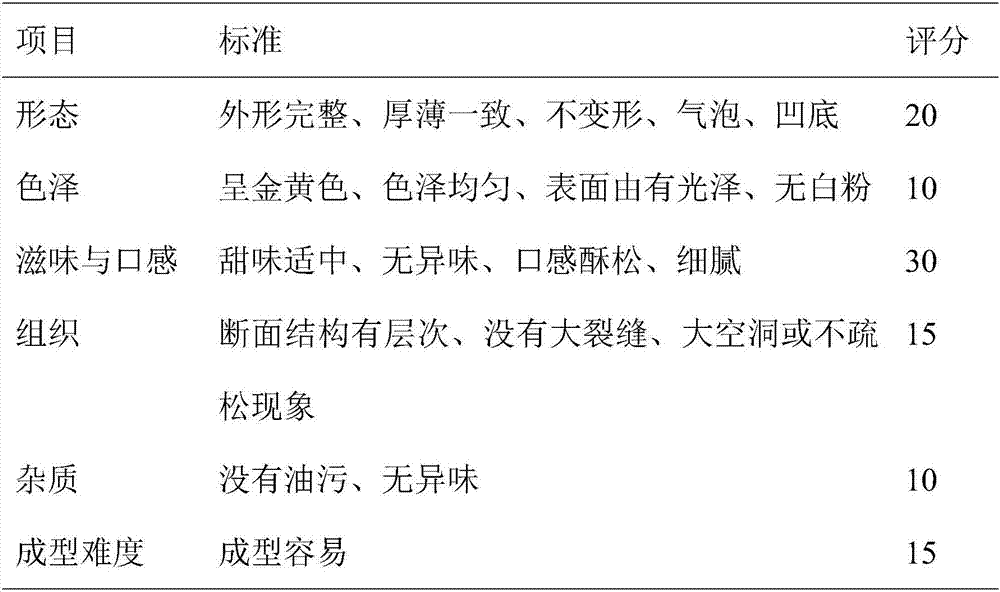

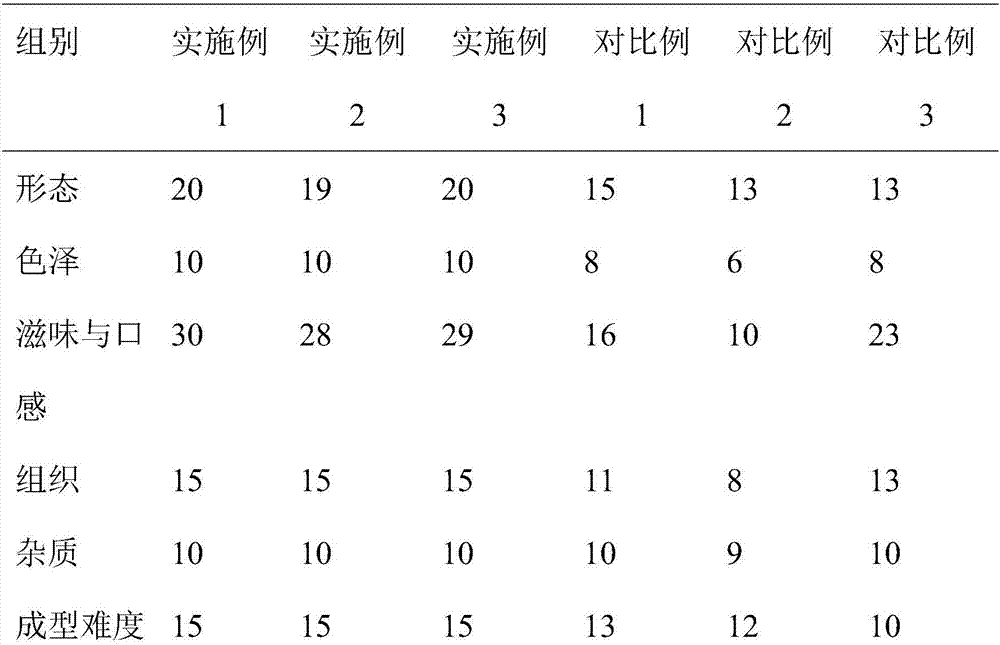

Biscuits capable of cleansing colon, expelling toxin, maintaining beauty and keeping young and preparation method thereof

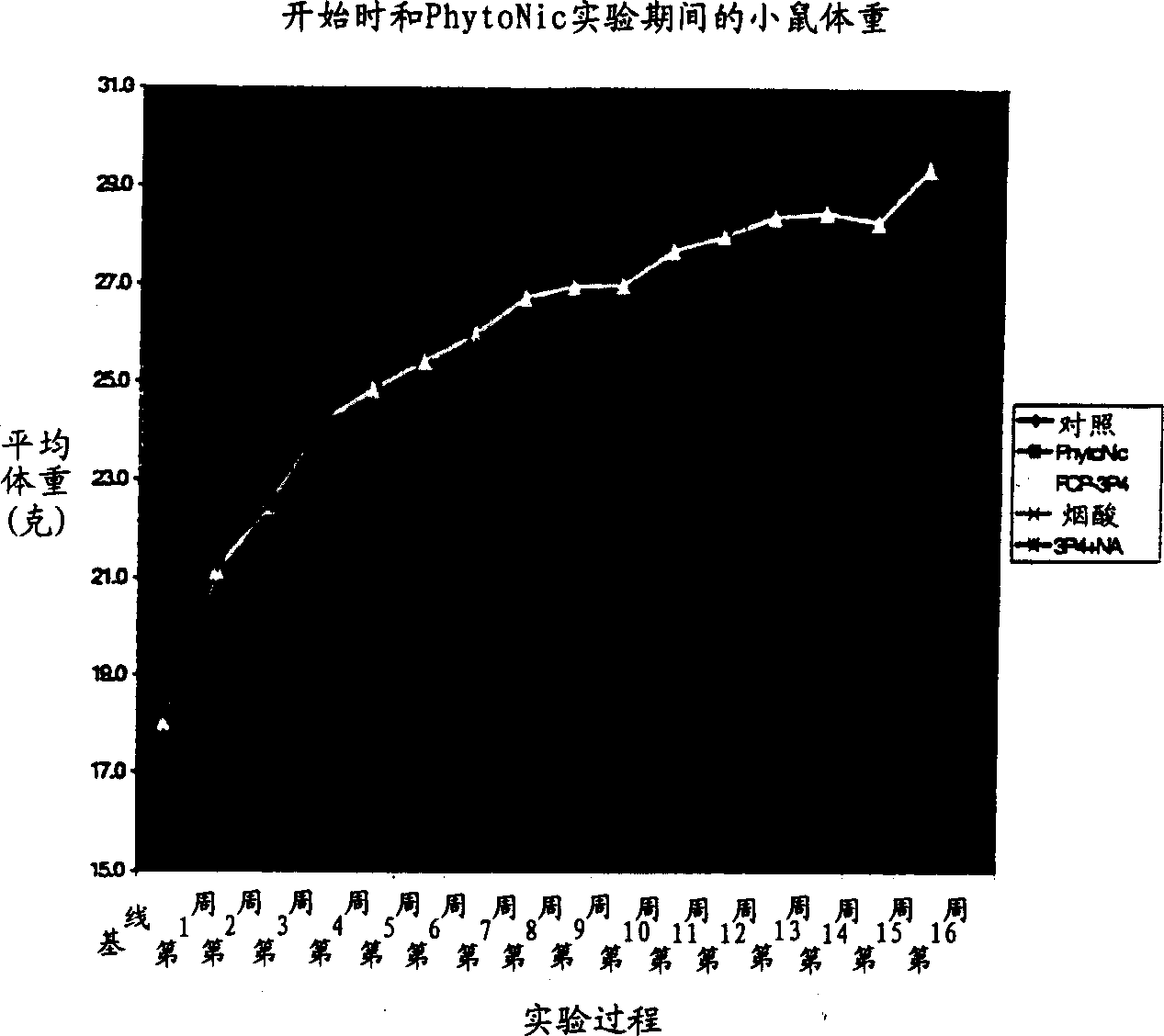

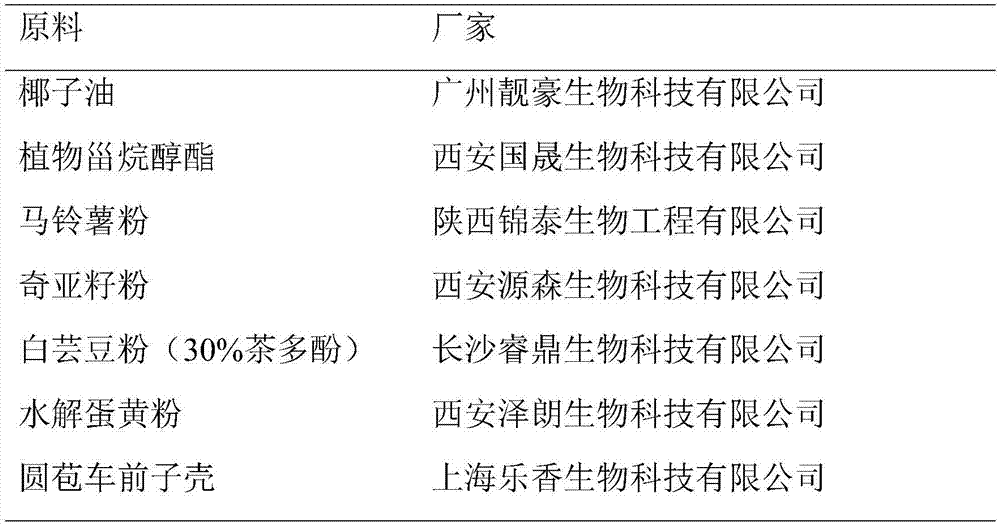

The invention belongs to the field of health care products, and specifically relates to biscuits capable of cleansing colon, expelling toxin, maintaining beauty and keeping young and a preparation method thereof. The biscuits are prepared by raw materials including, by mass, 10-25% of oat powder, 10-15% of Chenopodium quinoa powder, 0.1-0.3% of resistant dextrin, 3-5% of coconut oil, 1-3% of plant stanol ester, 2-6% of chia seed powder, 1-3% of potato powder, 1-4% of white kidney bean powder, 1-3 % of whey protein powder, 0.02-0.05% of hydrolyzed yolk powder, 3-8% of psyllium husk powder, 1-3% of trehalose, and residual water. The biscuits can be used as meal replacement biscuits, have the characteristics of low calorie, high dietary fiber and high protein, and have mouthfeel of crisp biscuits, and animal tests have proved that the biscuits have a certain fat-reducing effect.

Owner:HUIZHOU TONGFUKANG BIOTECHNOLOGY LTD

Process for producing food containing plant sterol

InactiveCN101048079AImprove dispersion stabilityPrevent crystallizationMetabolism disorderFood ingredient functionsPlant stanolsFood material

A food in which a plant sterol and / or plant stanol whose dissolution in water is difficult is stably dispersed homogeneously while suppressing any deposition or coagulation (ring formation) thereof; and a process for producing the same. An emulsifier of 6 to 16 HLB and a plant sterol are added to a food raw material in a weight ratio of 3:8 to 10:1 and heated at 110 DEG to 200 DEG C, thereby obtaining an intended food.

Owner:SAN EI GEN F F I

High-potency sweetener composition with phytosterol and compositions sweetened therewith

InactiveUS8524303B2Improved profileAdd flavorSugar food ingredientsMetabolism disorderPlant stanolsAdditive ingredient

The present invention relates generally to functional sweetener compositions comprising non-caloric or low-caloric natural and / or synthetic high-potency sweeteners and methods for making and using them. In particular, the present invention relates to different functional sweetener compositions comprising at least one non-caloric or low-caloric natural and / or synthetic high-potency sweetener, at least one sweet taste improving composition, and at least one functional ingredient, such as phytosterols, phytostanols, esters thereof, or combinations thereof. The present invention also relates to functional sweetener compositions and methods that can improve the tastes of non-caloric or low-caloric high-potency sweeteners by imparting a more sugar-like taste or characteristic. In particular, the functional sweetener compositions and methods provide a more sugar-like temporal profile, including sweetness onset and sweetness linger, and / or a more sugar-like flavor profile.

Owner:THE COCA-COLA CO

Use of ethoxylated phytosterols and phytostanols

The present invention relates to the use of ethoxylated phytosterols or phytostanols for the manufacture of an aqueous solution of a sparingly soluble substance for the prevention of cell damage in living cells.

Owner:ASTRAZENECA AB

Composition comprising one or more esterified phytosterols and/or phytostanols into which are solubilized one or more unesterified phytosterols and/or phytostanols, in order to achieve therapeutic and formulation benefits

InactiveUS20070254088A1Easy to pourSimple processOrganic active ingredientsDough treatmentPlant stanolsMedicine

A composition comprises one or more free (unesterified) phytosterols and / or phytostanols which are substantially completely dissolved in one or more esterified phytosterols and / or phytostanols. The present invention further provides a composition comprising one or more esterified phytosterols and / or phytostanols which are substantially completely dissolved in an edible oil.

Owner:PHARMACHEM LAB INC

Phytosterol and/or phytostanol derivatives

InactiveUS20020160990A1Reducing both serum cholesterol and triglyceridesLower levelOrganic active ingredientsMetabolism disorderPlant stanolsPlant stanol ester

The present invention relates to a phytosterol and / or a phytostanol ester compound produced from the reaction of a phytosterol and / or a phytostanol with a polyunsaturated fatty acid (PUFA), wherein the polyunsaturated fatty acid has from 18 to 22 carbon atoms and at least three carbon-carbon double bonds. Processes for producing and compositions and a process for using such compositions are also provided.

Owner:DSM NUTRITIONAL PROD

Syntehsis method plant sterol or/and plant steroid alkanol-beta-D-glucoside compound

InactiveCN1443771AMild reaction conditionsSimple and fast operationSteroidsBulk chemical productionPlant stanolsTrichloroethylene

The present invention relates to a method for synthesizing polytosterol or / and phytosteroalkanol-beta-D-heteroside compound. Said method includes the following steps: recrystallizing and purifying the phytosterol or / and phytosteroalkanol crude product to obtain crystal, then making said crystal and polysubstituted-D-glucose trichloroethylene imine ester produce glucosidation reaction in the presence of Lewis acid catalyst, and then removing protecting group so as to obtain the invented phytosterol or / and phytosteroalkanol-beta-D-heteroside compound.

Owner:上海药谷药业有限公司

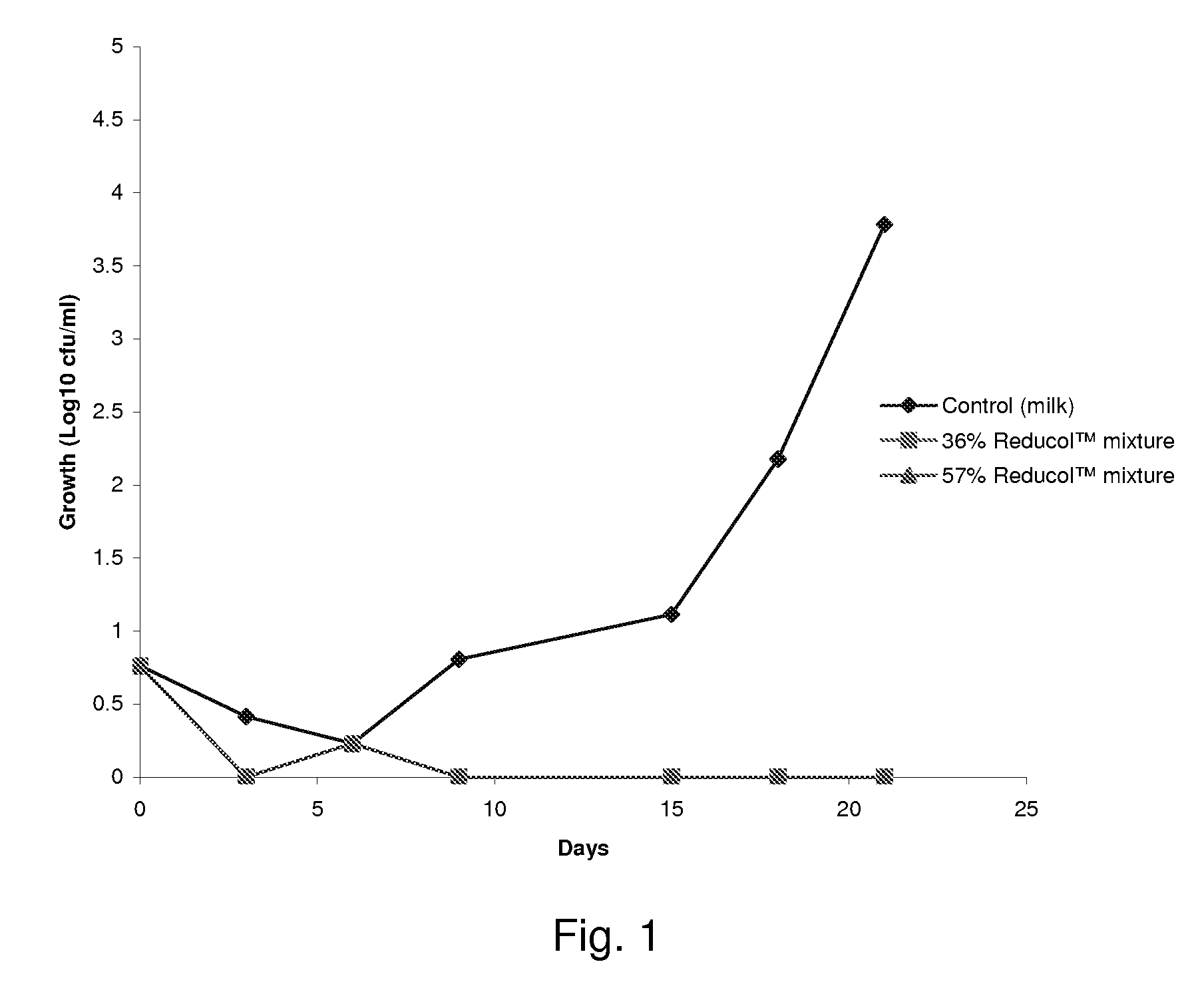

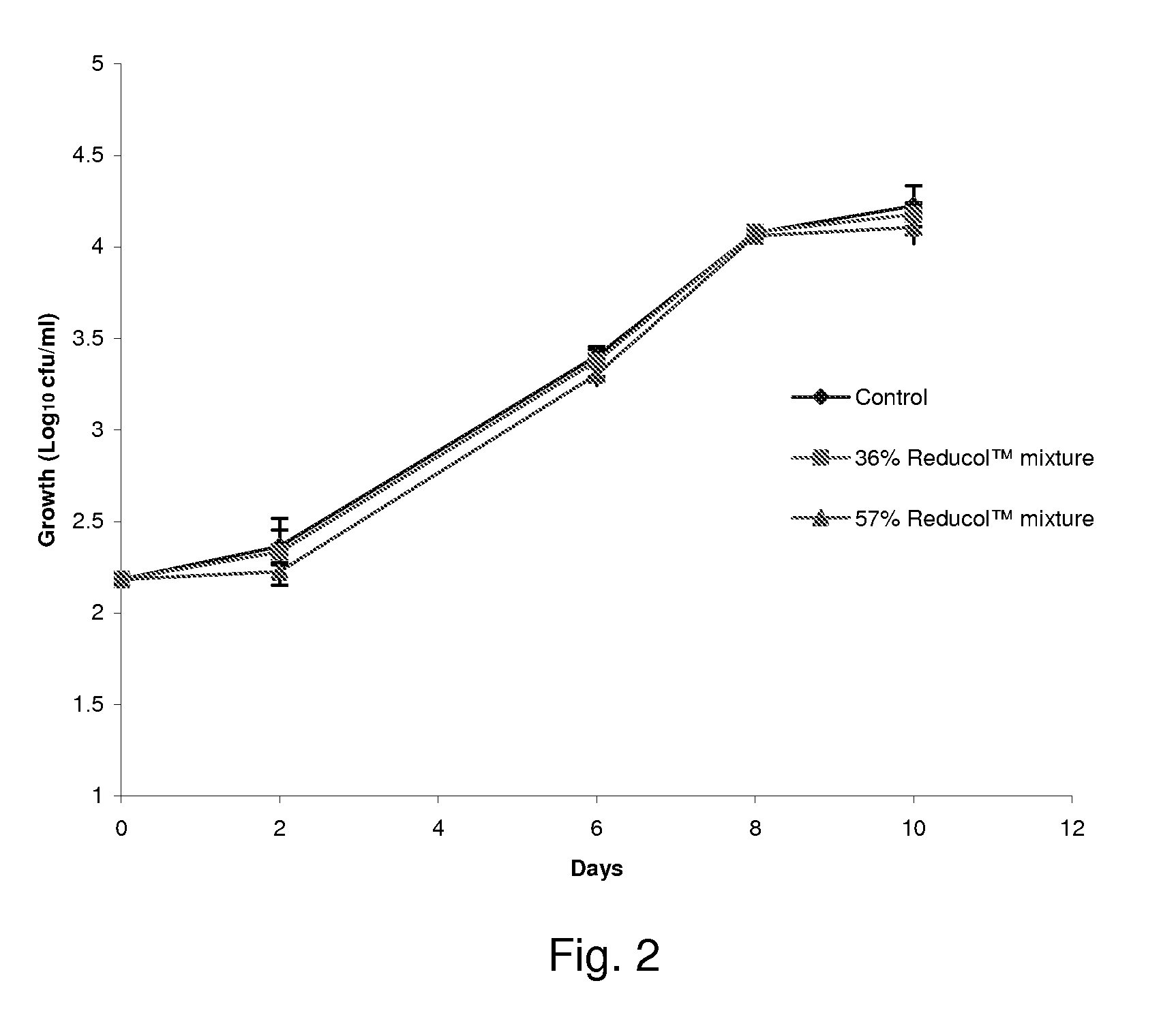

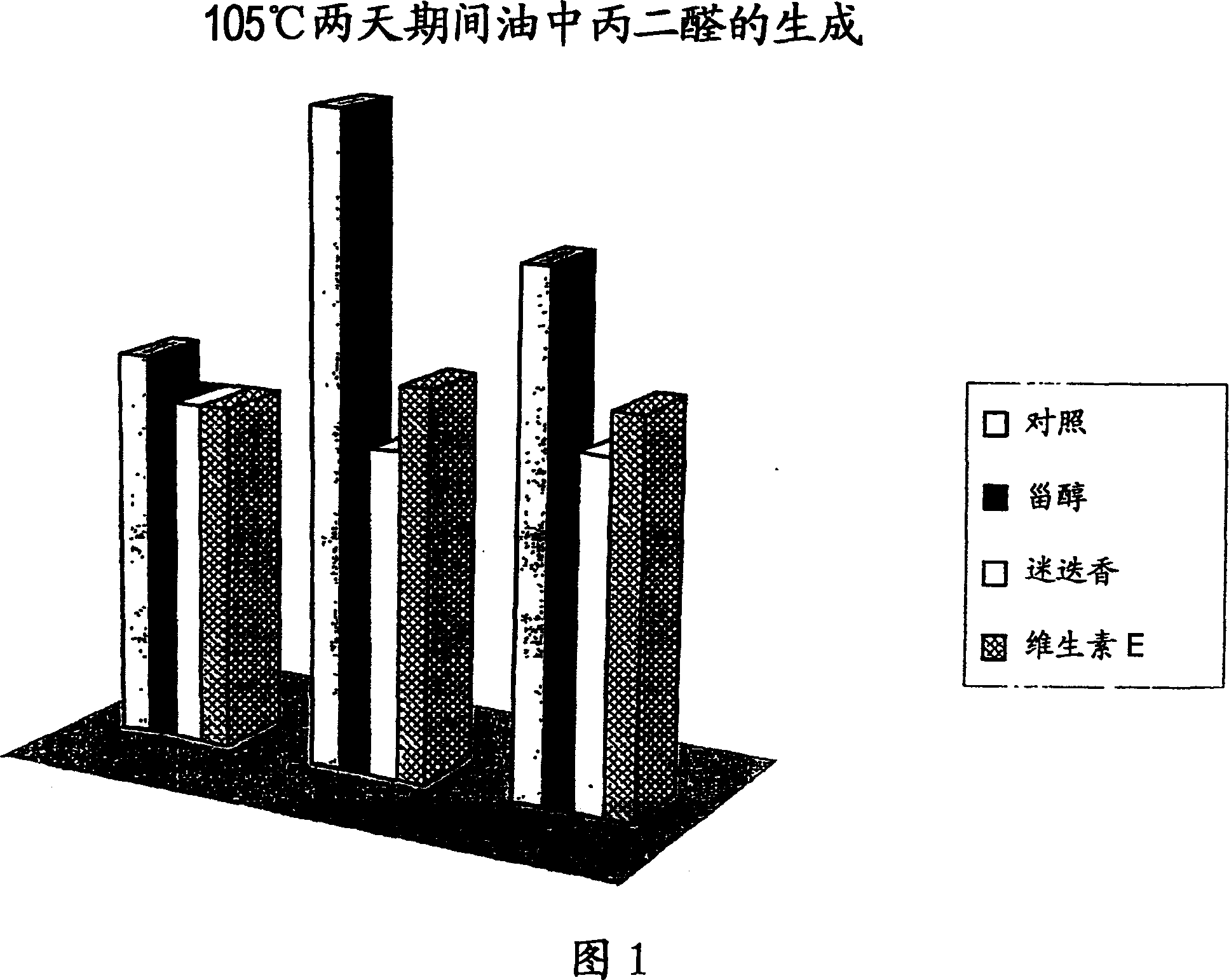

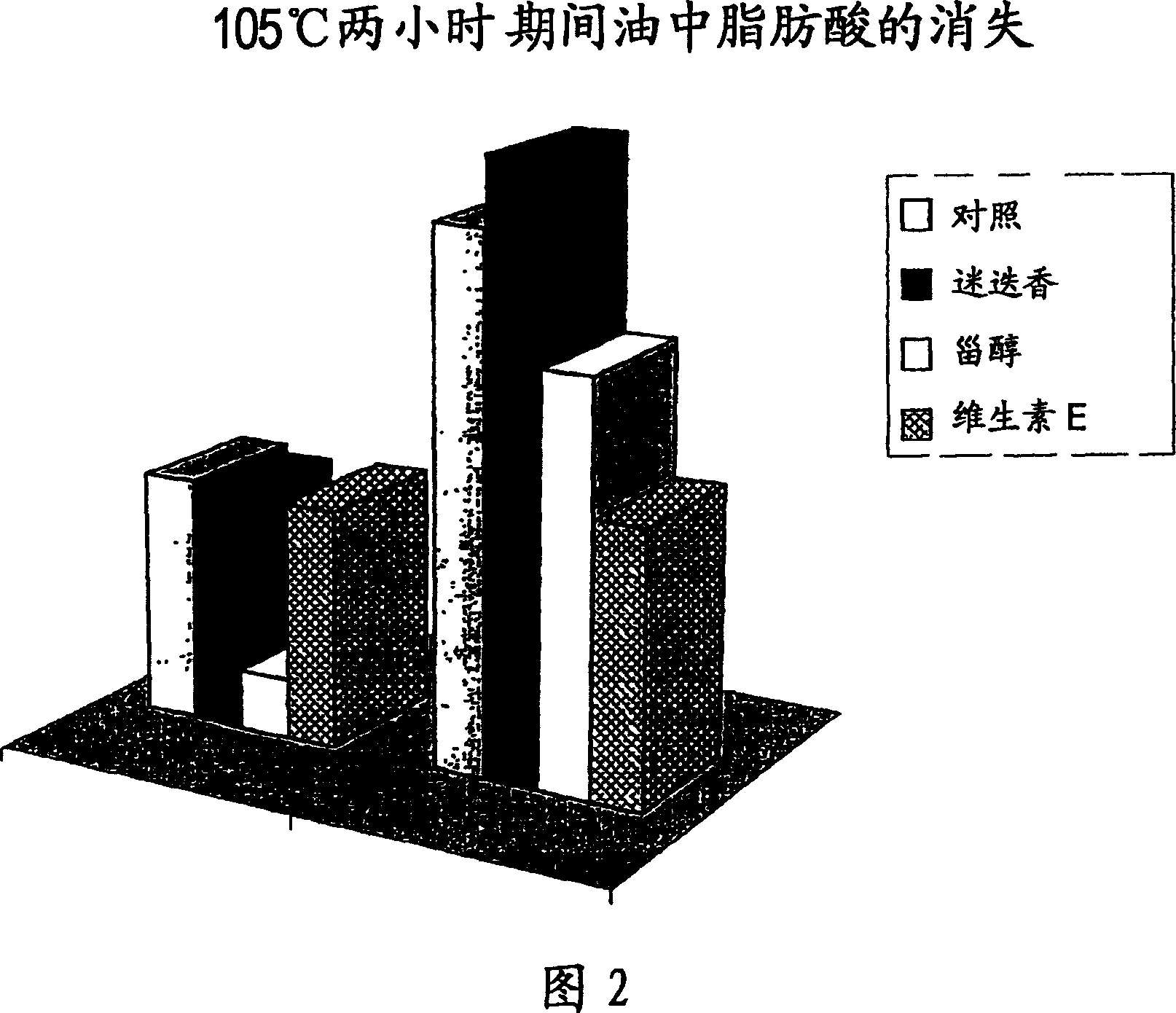

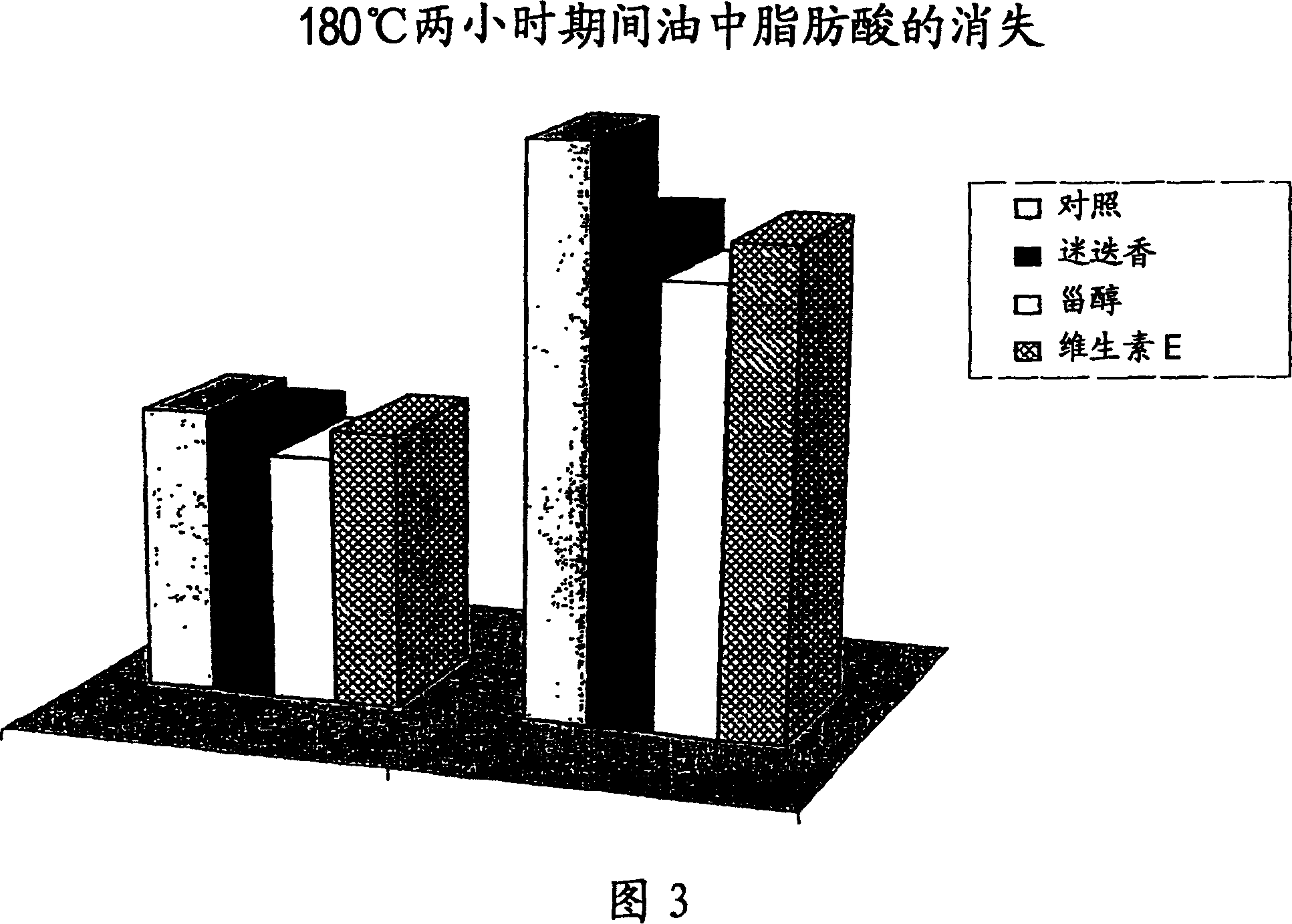

Method of preservation of a food prodcut and composition comprising one or more phytosterols and/or phytostanols useful for this purpose

InactiveCN1925756APromote growthReduce oxidationMilk preparationEdible oils/fats ingredientsPlant stanolsPreserved Foods

Owner:FORBES MEDI TECH

Sitosterol Compound-Containing Composition and Process For Producing the Same

InactiveUS20090004359A1Superior aqueous dispersibility aqueousImprove stabilityMetabolism disorderAnimal feeding stuffPlant stanolsChemical compound

A method for producing a phytosterol / phytostanol-containing composition is provided that facilitates dispersion in-water of a phytosterol and / or phytostanol (phytosterol / phytostanol), which are difficult to dissolve in water, inhibits the occurrence of precipitation and coagulation (ring formation) for a long period of time even when incorporated in water, and can maintain a stable dispersed state. The method of the present invention has at least one of the following steps (1) to (3): (1) mixing at least one type selected from a pulverized phytosterol and phytostanol with an aqueous raw material containing an emulsifier having an HLB value of 6 to 16; (2) pulverizing at least one type selected from a phytosterol and a phytostanol followed by mixing with an aqueous raw material containing an emulsifier having an HLB value of 6 to 16; and (3) mixing at least one type selected from a phytosterol and a phytostanol with an aqueous raw material containing an emulsifier having an HLB value of 6 to 16, and pulverizing the phytosterol and / or phytbstanol in the mixture.

Owner:SAN EI GEN F F I

Blood pressure-reduction composition

ActiveCN103070328AOvercome the defect of single functionAvoid side effectsFood preparationPlant stanolsPlant stanol ester

The invention relates to a blood pressure-reduction composition. The blood pressure-reduction composition comprises, by weight, 15 to 20 parts of konjaku flour, 10 to 20 parts of bunge auriculate root powder, 5 to 10 parts of black sesame powder, 13 to 18 parts of soya bean lecithin powder, 11 to 14 parts of xylitol, 2 to 6 parts of hawthorn, 2 to 5 parts of tea flower, 4 to 9 parts of plant stanol ester, 1 to 5 parts of asparagus, 7 to 9 parts of kelp and 2 to 4 parts of honey. The blood pressure-reduction composition as a nutriment adopts the natural raw materials and has no toxic and side effect.

Owner:陕西超群制药有限公司

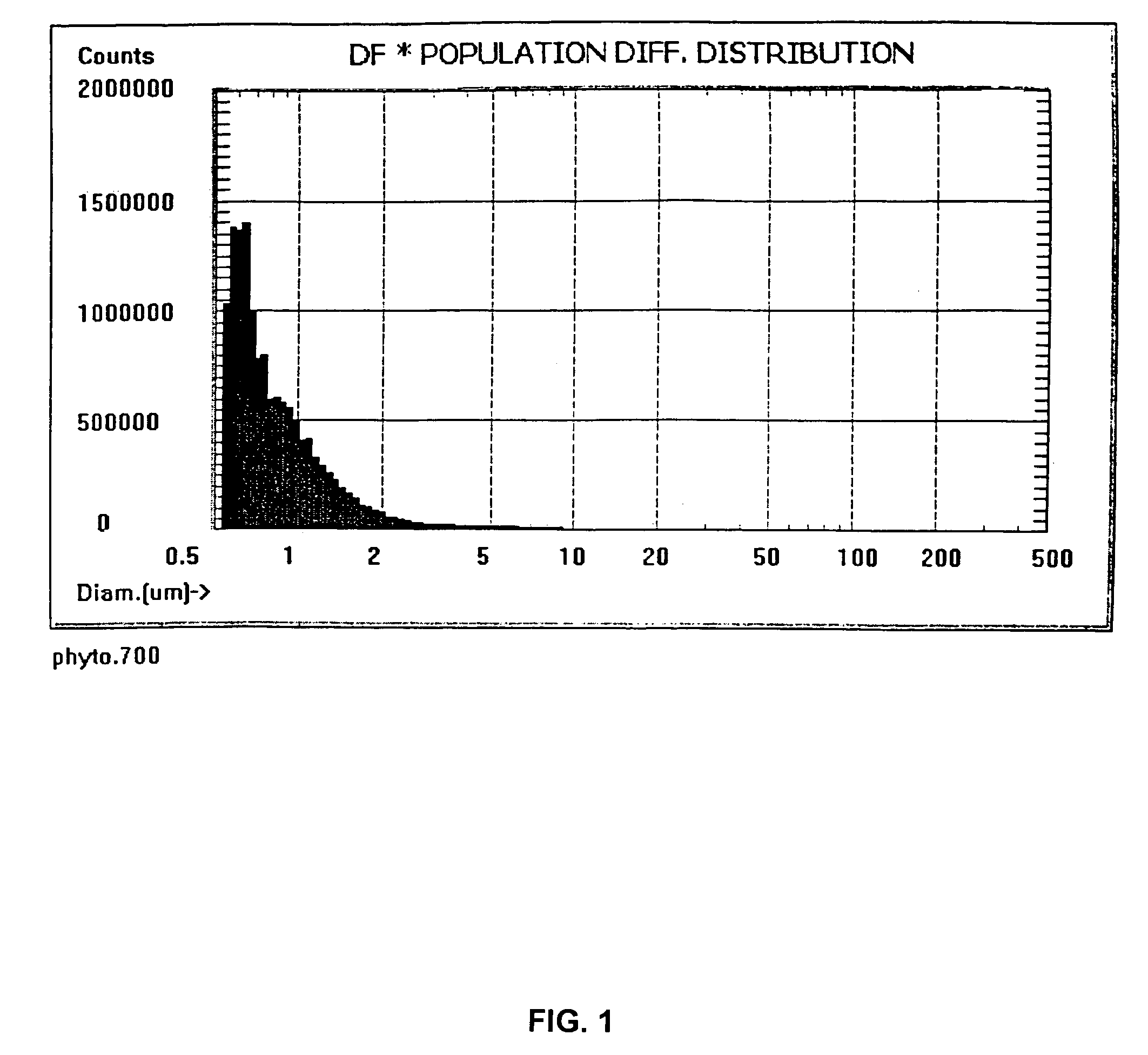

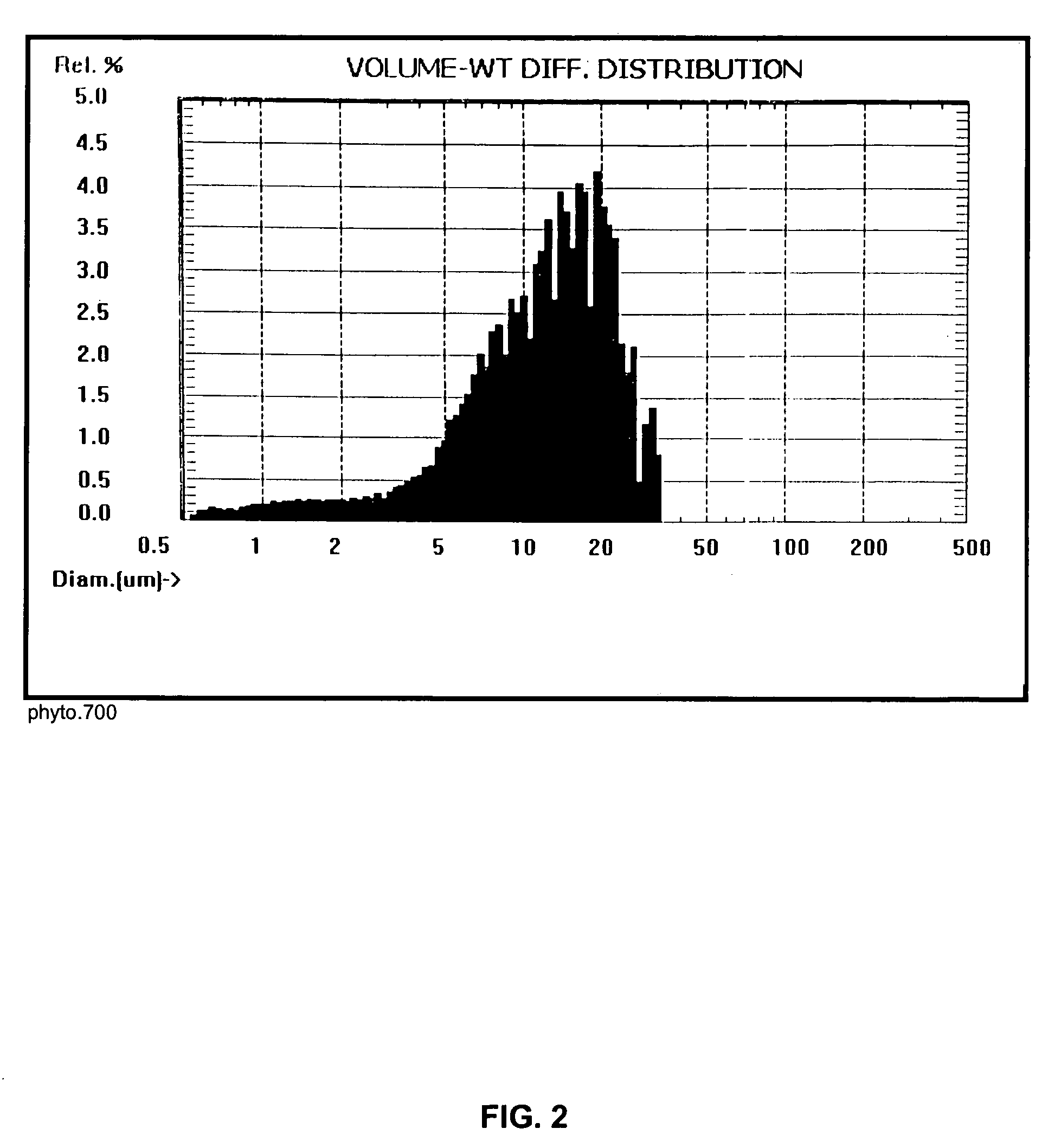

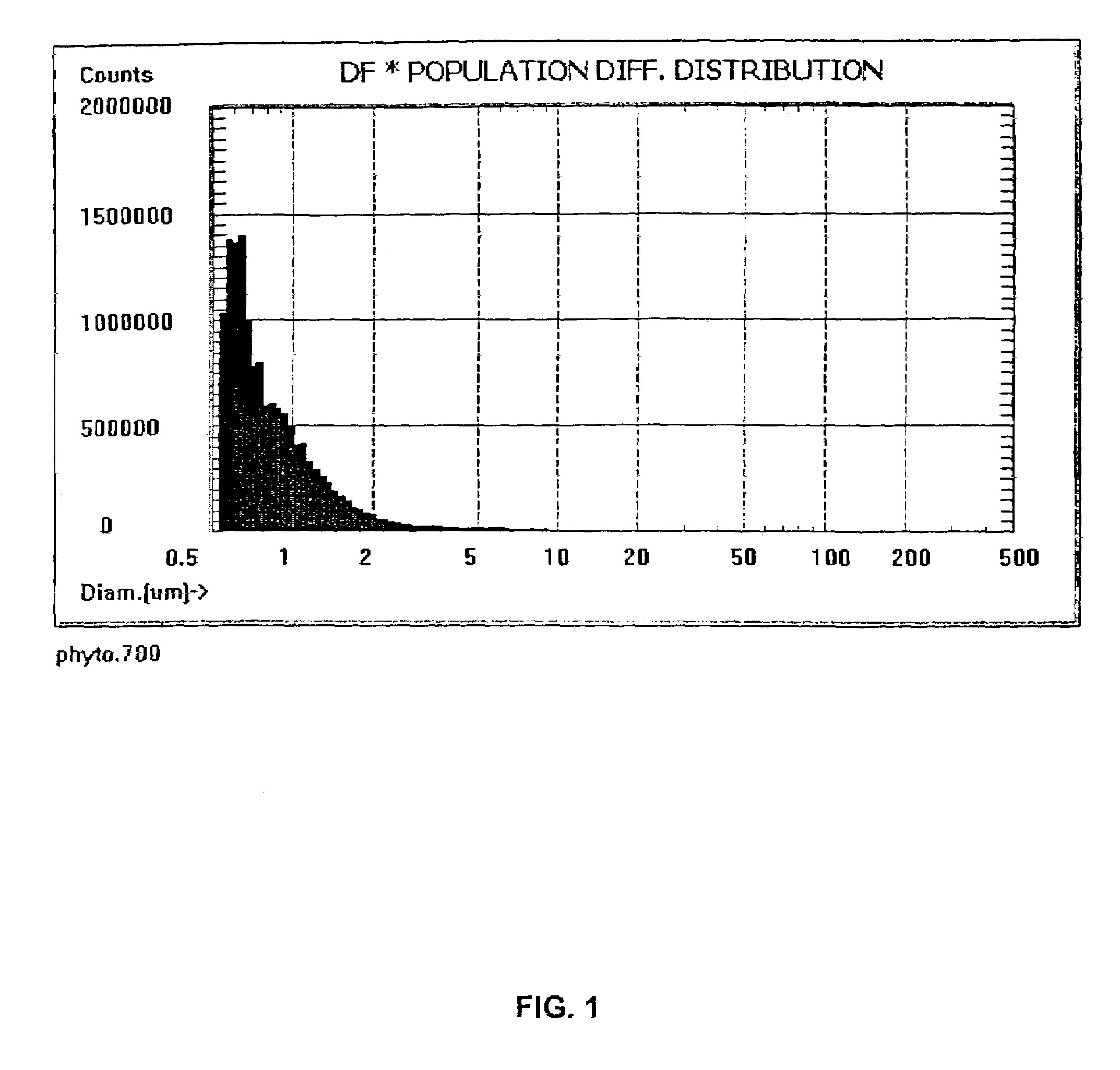

Beverages containing plant sterols

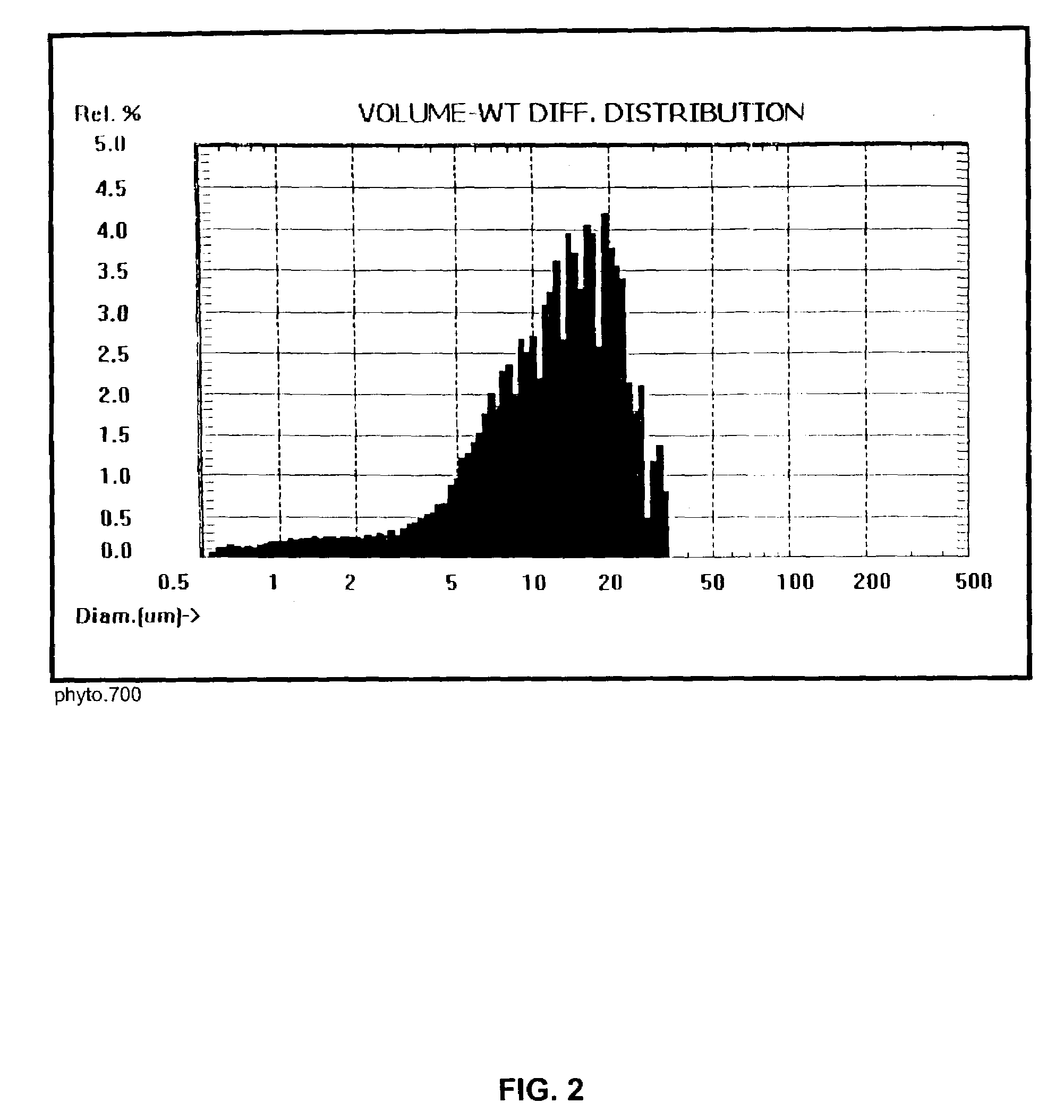

The invention relates to a process for producing a substantially stable dispersion without manufacturing aids, where the dispersion comprises at least one hydrophobic plant sterol and an aqueous material, wherein the plant sterol is selected from plant sterols and plant stanols. The process comprises mixing the plant sterol with the aqueous material to form a first dispersion, homogenizing the first dispersion to obtain a second dispersion of particles wherein the particle size of the hydrophobic plant sterol particles in the first dispersion and the second dispersion is from about 0.1 micron to about 100 microns. Optionally, the process may comprise heating the first dispersion prior to homogenizing, heating the second dispersion after homogenizing, or heating both. In one embodiment, the aqueous material comprises a beverage concentrate, which includes a juice concentrate, such as a citrus juice concentrate, e.g., an orange juice concentrate. In one aspect of this invention, in order to substantially avoid a powdery taste in the dispersion, the particle size of the plant sterol particles is from about 0.1 micron to about 30 microns and the majority of hydrophobic plant sterol particles within this range will be from about 0.2 microns to about 10 microns and will substantially follow a bell curve distribution.

Owner:THE COCA-COLA CO

Method for producing phytosterol / phytostanol phospholipid esters

InactiveCN102365031AReduce fatOrganic active ingredientsCosmetic preparationsLipid formationPhytosterol esters

The present invention relates to a method of producing a phytosterol ester and / or a phytostanol ester comprising: a) admixing a phospholipid composition comprising at least between about 10% to about 70% plant phospholipid and at least about 5% water; a lipid acyltransferase; and a phytosterol and / or a phytostanol; and b) separating or isolating or purifying at least one phytosterol ester and / or phytostanol ester from said admixture. The present invention also relates to compositions comprising the phytosterol ester and / or phytostanol ester produced by this method, including foodstuffs and personal care product (cosmetic) compositions.

Owner:DUPONT NUTRITION BIOSCIENCES APS

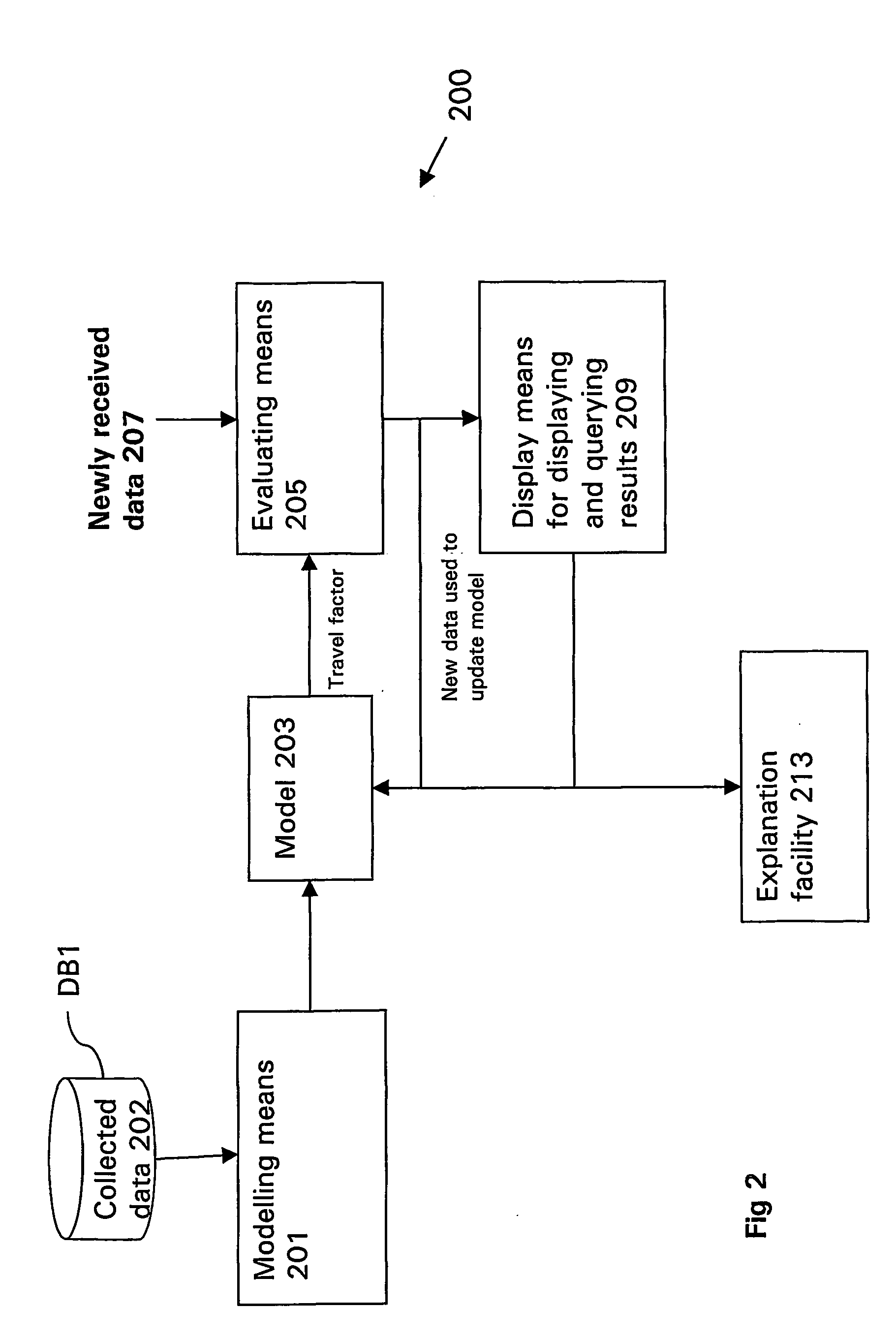

Data analysis method

The invention relates to a pharmacological substance based on biologically active substances obtained from the plant Tribulus terrestris L. to be used as an agent reducing blood sugar, improving blood circulation and especially blood circulation in veins and capillaries of the limbs of diabetic patients, reducing bad cholesterol level, increasing good cholesterol concentration, maintaining cardiovascular and liver functioning with an additional prophylactic or healing effect on the immune system and the immune resistance. The pharmacological substance represents a combination of bio-active trivalent chromium and a complex of steroid saponins obtained from the plant Tribulus Terrestris l. and consisting of furostanols, spirostanols, sapogenins, sterols, flavonoids and other biologically active substances typical of this plant.

Owner:ALEXIEV BLAGOY PETROV

Phytosterol and/or phytostanol derivatives

InactiveUS20020055493A1Improve solubilityOptimal for incorporationOrganic active ingredientsBiocidePlant stanolsPlant stanol ester

The present invention relates to a phytosterol and / or a phytostanol ester compound produced from the reaction of a phytosterol and / or a phytostanol with a polyunsaturated fatty acid (PUFA), wherein the polyunsaturated fatty acid has from 18 to 22 carbon atoms and at least three carbon-carbon double bonds. Processes for producing and compositions and a process for using such compositions are also provided.

Owner:DSM IP ASSETS BV

Phytosterol and/or phytostanol derivatives

The present invention relates to a phytosterol and / or a phytostanol ester compound produced from the reaction of a phytosterol and / or a phytostanol with a polyunsaturated fatty acid (PUFA), wherein the polyunsaturated fatty acid has from 18 to 22 carbon atoms and at least three carbon-carbon double bonds. Processes for producing and compositions and a process for using such compositions are also provided.

Owner:BURDICK DAVID CARL +3

Beverages containing plant sterols

ActiveUS7335389B2Good dispersionIncrease volumeOrganic active ingredientsSolution deliveryFood gradePlant stanols

The invention relates to a process for producing a substantially stable dispersion without manufacturing aids, where the dispersion consists essentially of a hydrophobic plant sterol and an aqueous material, wherein the plant sterol is selected from plant sterols and plant stanols. The process comprises mixing the plant sterol with the aqueous material to form a first dispersion The next steps involve heating the first dispersion to form a heated mixture, followed by homogenizing the heated mixture to obtain a second dispersion of particles wherein the particle size of the hydrophobic plant sterol particles in the first dispersion and the second dispersion is from about 0.1 micron to about 30 microns. In one embodiment, the aqueous material consists essentially of a beverage concentrate, which includes a juice concentrate, such as a citrus juice concentrate, e.g., an orange juice concentrate. The invention also relates to a product produced by this process and a composition of matter which is a substantially stable dispersion of a hydrophobic plant sterol and an aqueous material wherein the plant sterol is selected from plant sterols and plant stanols, where in order to substantially avoid a powdery taste in the dispersion, the particle size of the plant sterol particles is from about 0.1 micron to about 30 microns and the majority of hydrophobic plant sterol particles within this range will be from about 0.2 microns to about 10 microns and will substantially follow a bell curve distribution. This composition may be made by the process of the invention, or may further include manufacturing aids selected from food grade emulsifiers, gums, starches and pectins.

Owner:THE COCA-COLA CO

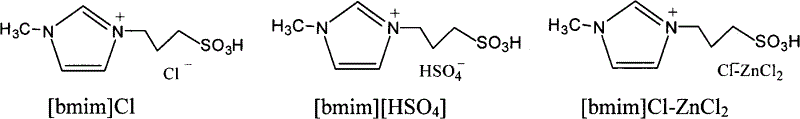

Preparation method of phytostanol ester by taking ionic liquid as catalyst

InactiveCN102617700AWide variety of sourcesEasy to manufactureSteroids preparationPlant stanolsPlant stanol ester

The invention relates to a novel preparation method of a phytostanol ester by taking an ionic liquid as a catalyst. The technical scheme adopted by the invention is as follows: in the absence of solvents and in the presence of nitrogen, a fatty acid (saturated or unsaturated acid) and phytostanol are heated to 90 to 180 DEG C to be melted completely, and are added with a catalyst to be subjected to an esterification reaction for 1 to 15 hours by controlling the temperature between 90 DEG C and 180 DEG C; a hydroxy acid, the phytostanol and the catalyst are added to a benzene, toluene or xylene solvent, and are heated to 80 to 115 DEG C to be subjected to the esterification reaction for 5 to 20 hours at this temperature; and after the end of the reaction, the phytostanol ester is obtained by separation and purification. The ionic liquid used in the method does not pollute the environment, has no obvious corrodibility, and is easy to recycle and reuse; the conversion rate of the phytostanol is high; and the product is convenient to recover, and the operation is simple.

Owner:JIANGNAN UNIV

Emulsions comprising non-esterified phytosterols in the aqueous phase

A stable emulsion in which an aqueous phase has one or more phytosterols or phytostanols, or mixtures thereof in free (non-esterified) form and an oil or fat phase has phytosterols or phytostanols, or mixtures thereof, in esterified form.

Owner:FORBES MEDI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com