Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Inorganic sulfide compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A high-temperature wet oxidation method for treating waste caustic soda

InactiveCN102285729ANo impactNo secondary pollutionMultistage water/sewage treatmentWater/sewage treatment by oxidationHigh concentrationGas phase

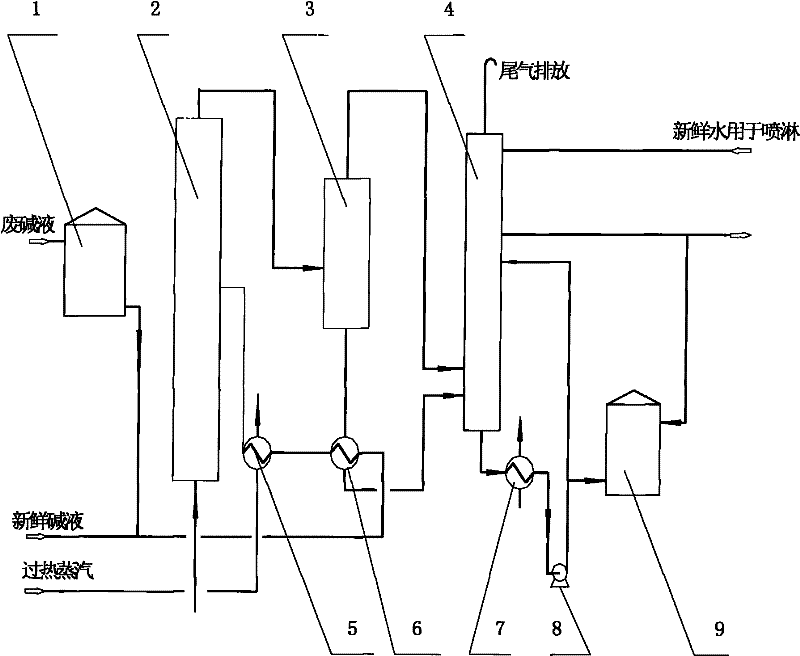

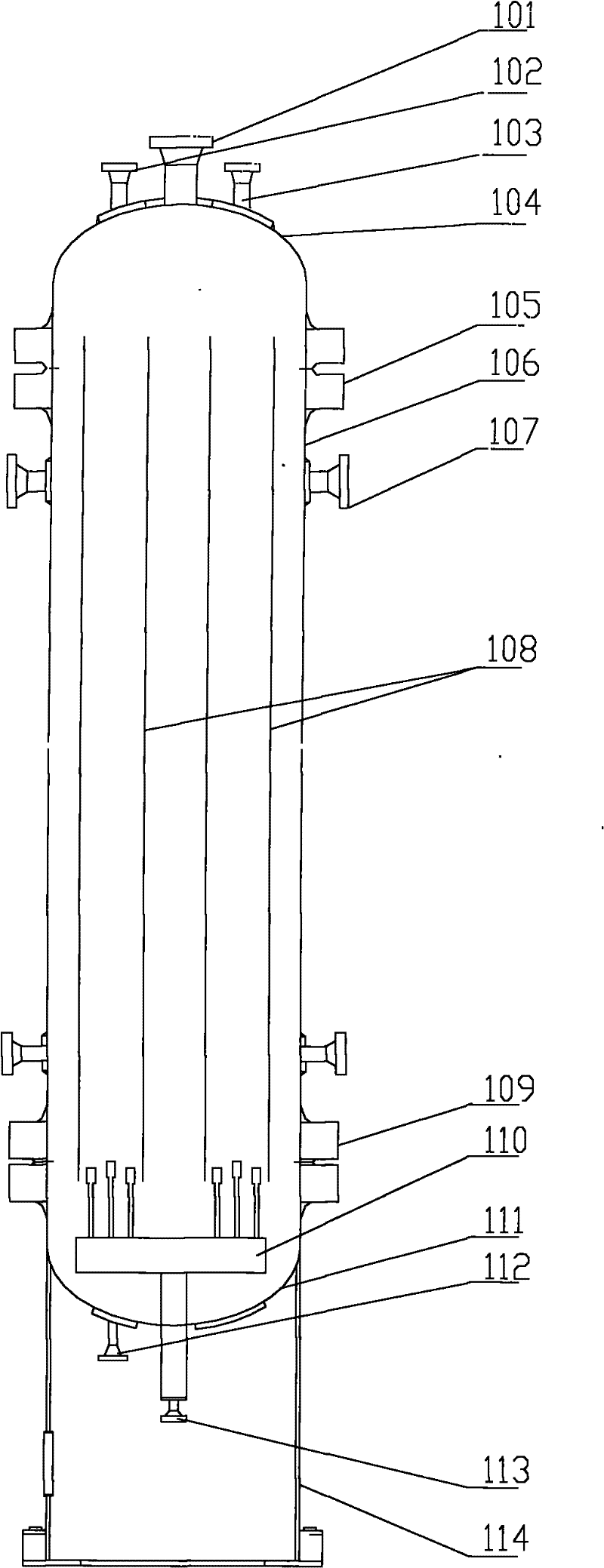

The invention discloses a method for treating waste lye by high-temperature wet oxidation. At 220°C to 260°C and under the pressure of keeping the waste lye in liquid phase, the waste lye is contacted with air exceeding the theoretical oxygen demand, and the waste lye is used The oxygen in the air oxidizes the inorganic sulfide and organic matter in the waste caustic so that the sulfur in it is converted into sulfate, and the organic matter is oxidized and decomposed into water and carbon dioxide; the reacted material discharged from the wet liquid phase oxidation reactor enters the high-pressure gas-liquid separator , The oxidized spent lye after gas-liquid separation and the waste lye feed are exchanged for heat, and the oxidized spent lye after heat exchange and the gas phase separated from gas and liquid enter the cooling and washing tower. Compared with the prior art, the method of the present invention has low energy consumption, the removal rate of S2- can reach 100%, the removal rate of COD can reach 75%-85%, and the waste lye after treatment can be directly discharged into the sewage treatment system, effectively alleviating the The pressure brought by the high concentration of wastewater in sewage treatment plants.

Owner:CHINA PETROLEUM & CHEM CORP +1

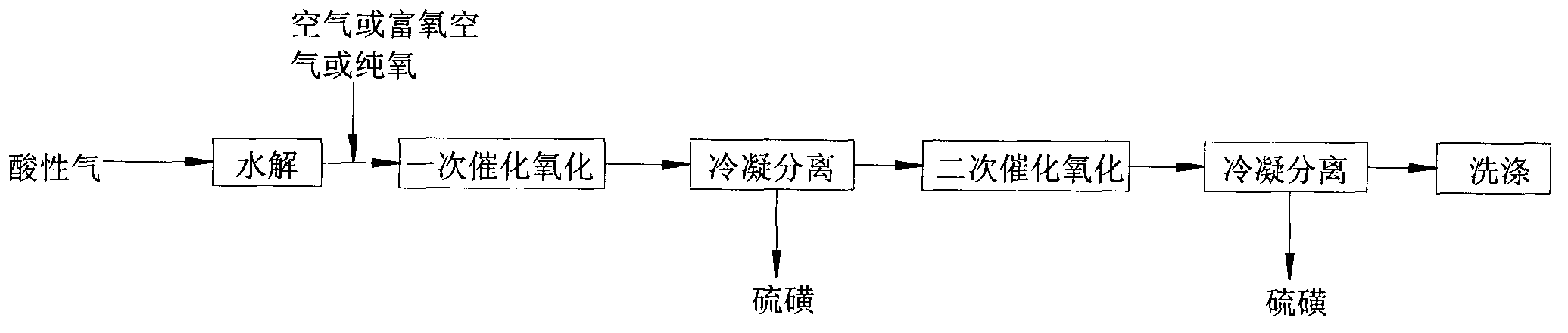

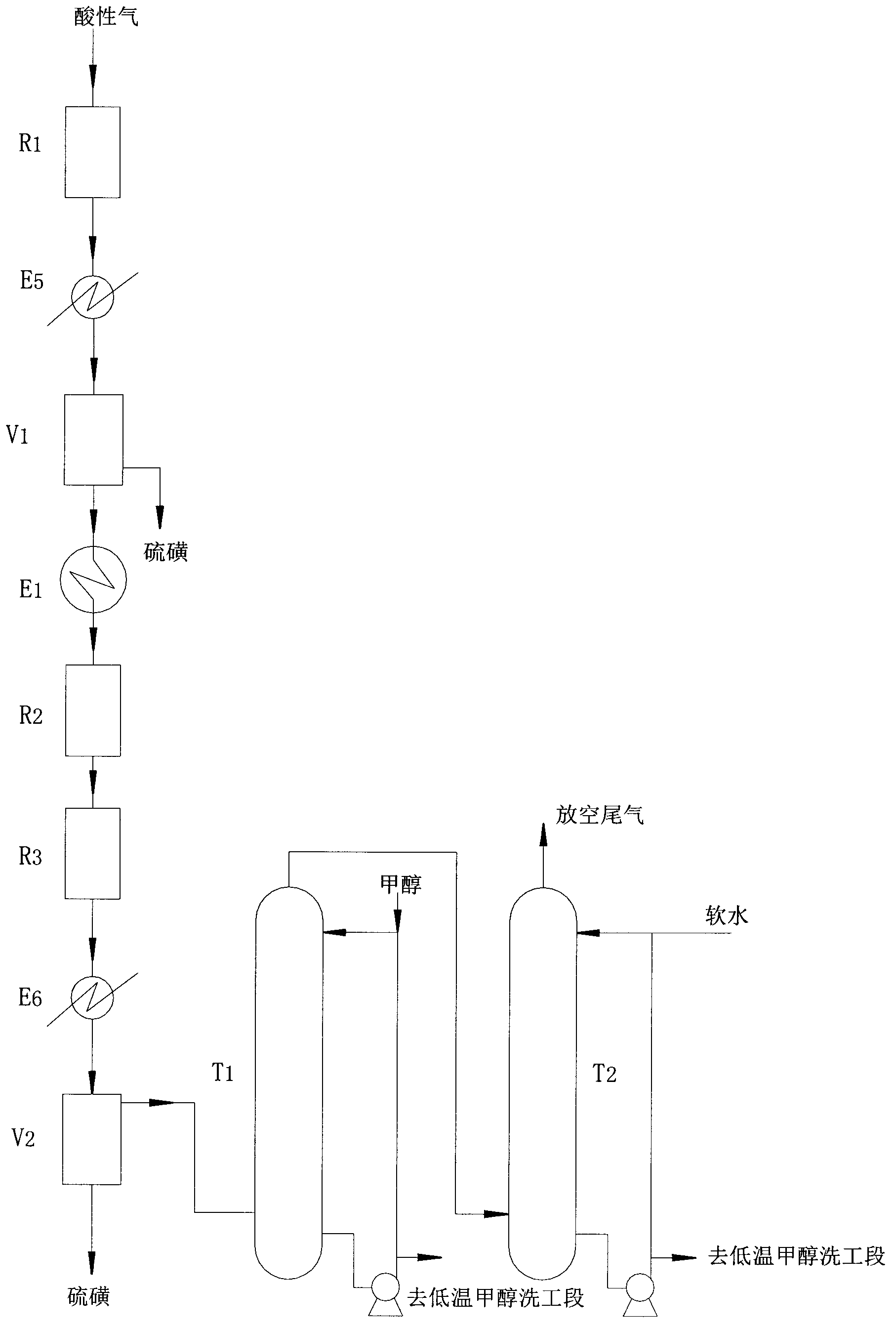

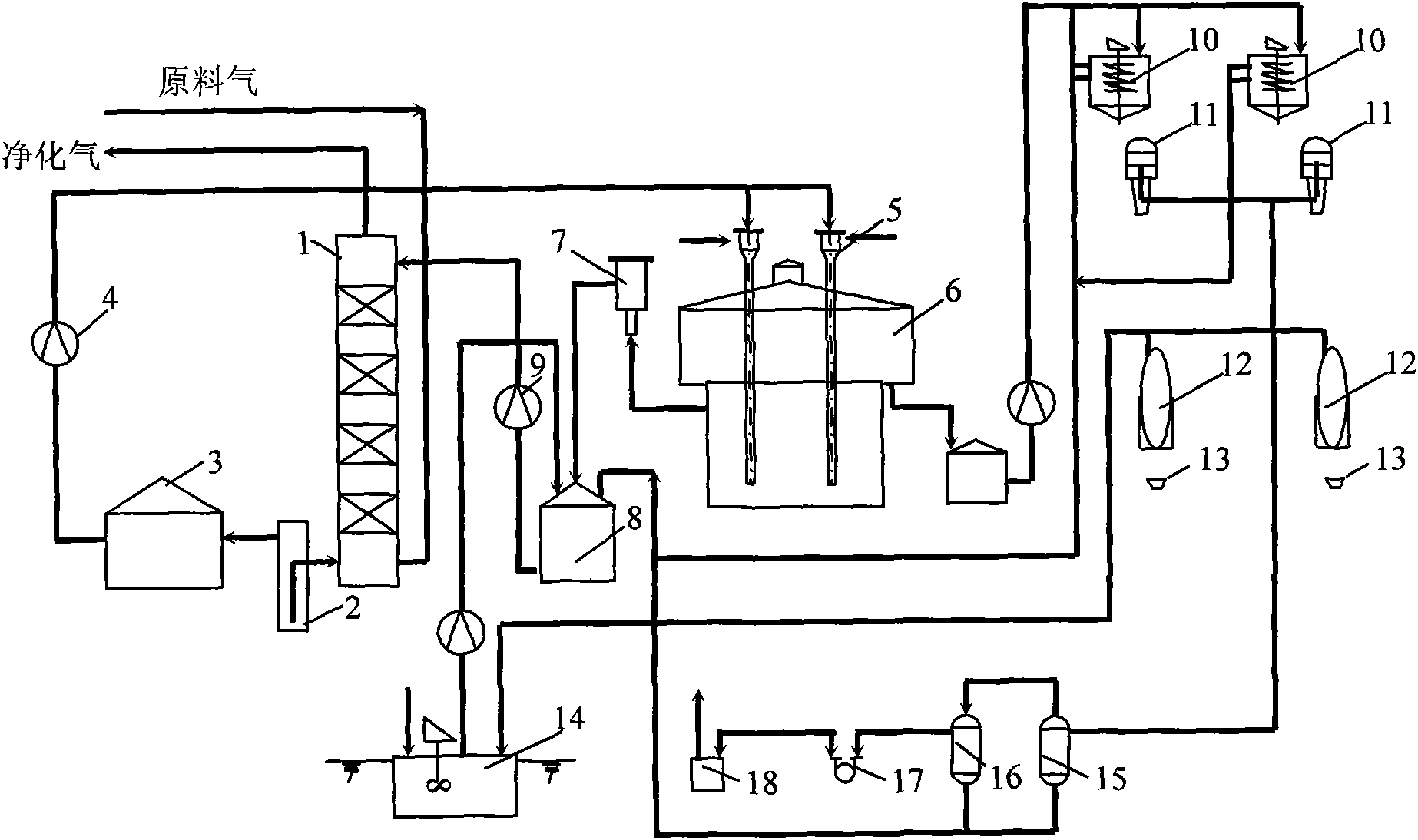

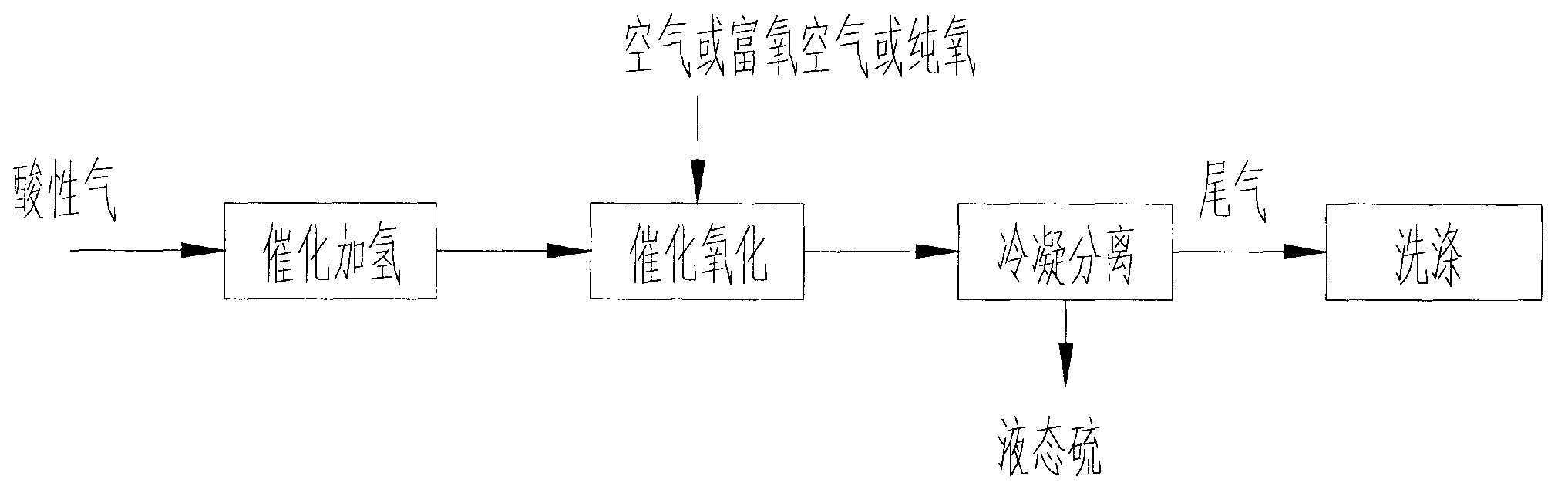

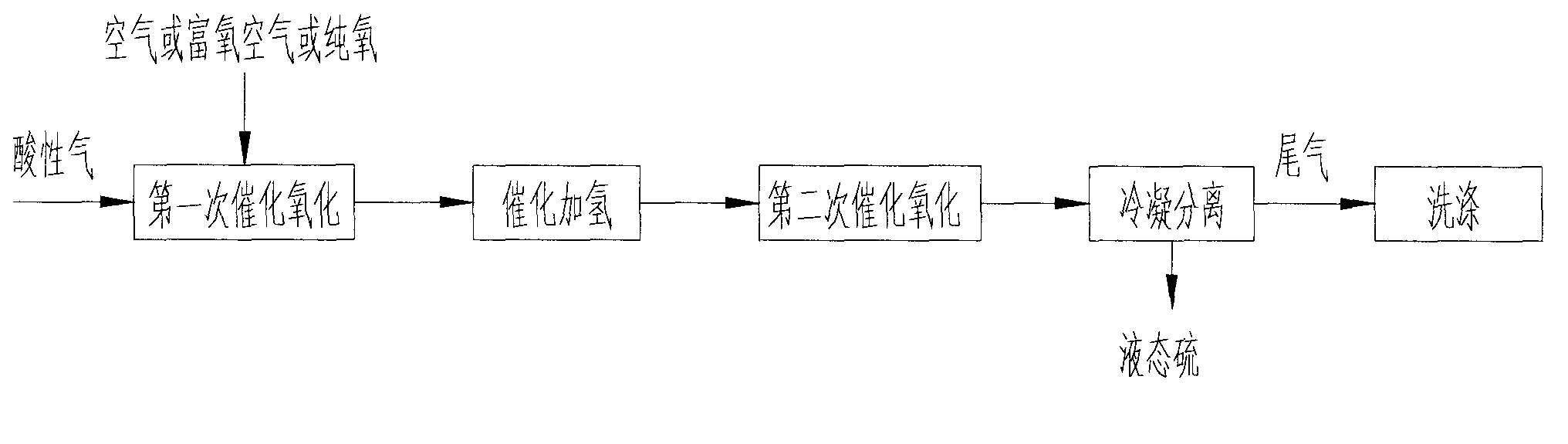

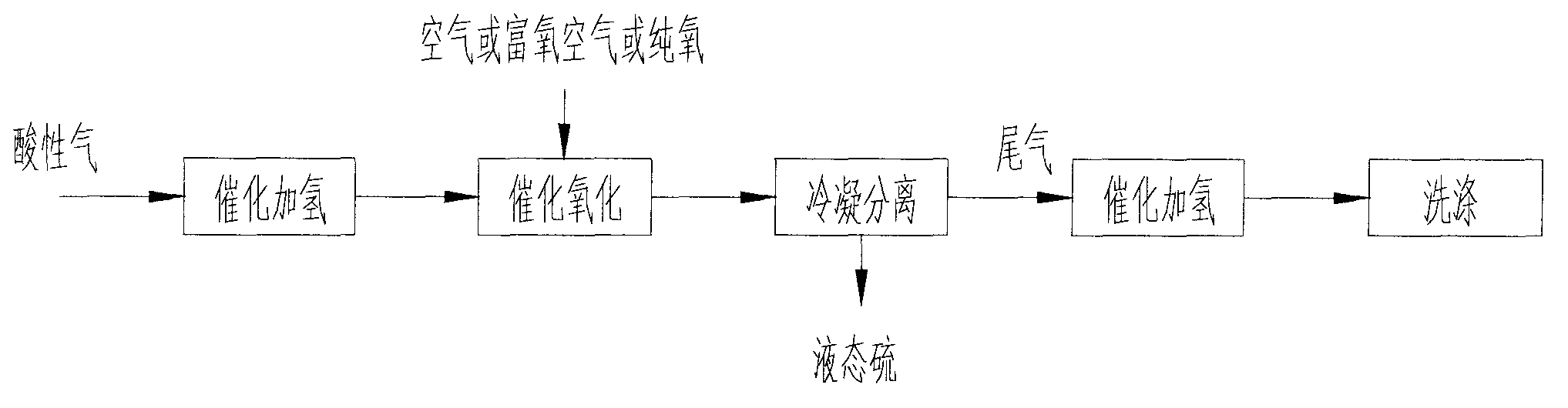

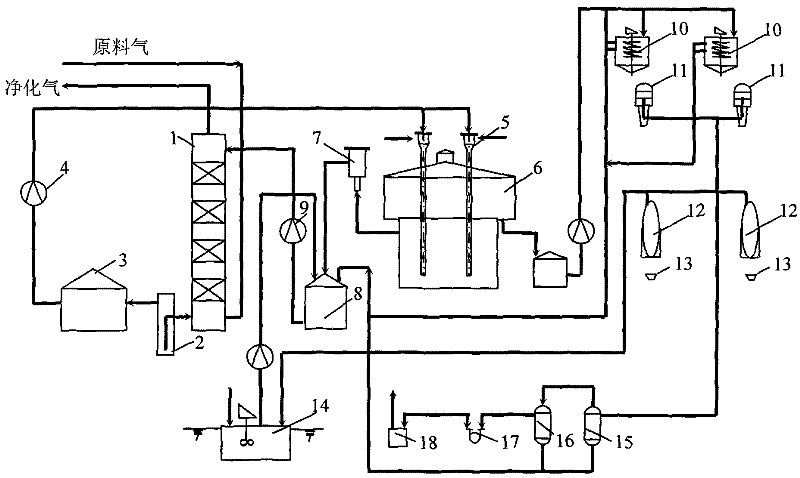

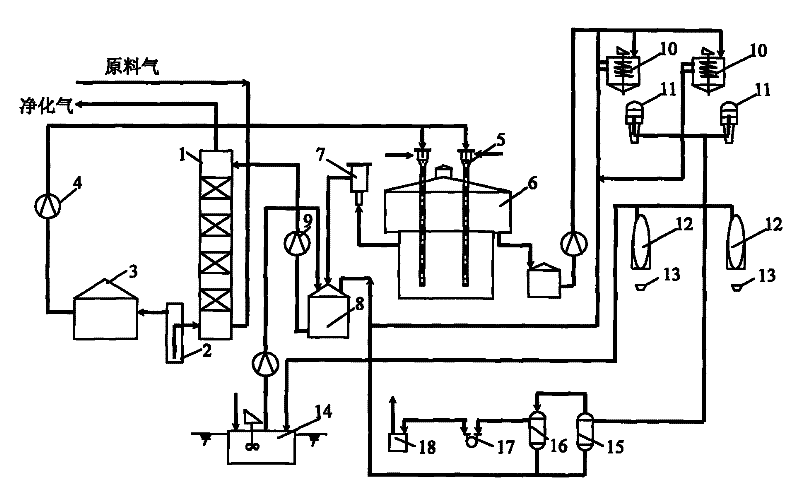

Method, device and reactor for recovery of sulfur from acidic gas

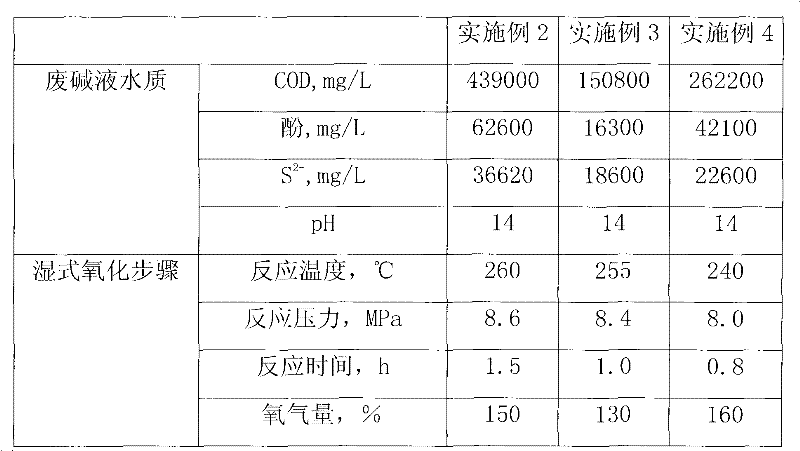

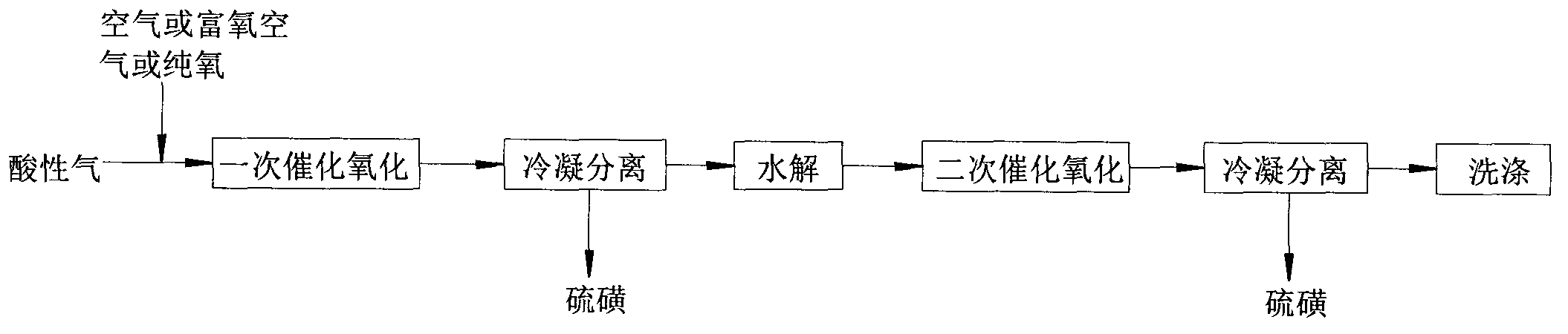

InactiveCN104138713AAffect conversion performanceImpact protectionDispersed particle separationSulfur preparation/purificationAlcoholSulfur

The invention discloses a method, device and reactor for recovery of sulfur from acidic gas. An inorganic sulfide in the acidic gas is catalyzed and oxidized into sulfur by catalytic oxidation reaction, then the organic sulfur in the acidic gas is hydrogenated and hydrolyzed into an inorganic sulfide through catalytic hydrolysis reaction, finally the residual inorganic sulfur in the reaction gas is oxidized into sulfur through secondary catalytic oxidation reaction, and the tail gas is washed by a methanol lotion and / or water, thus realizing complete recovery of sulfur. The invention also discloses the device and reactor for realizing the method. The method and device provided by the invention are suitable for sulfur recovery of low H2S content acidic gas. An alcohol-containing solution is utilized for washing treatment of desulfurized tail gas according to the low temperature methanol washing process, the content of sulfide in the tail gas is reduced, and the environment is protected. At the same time, the reactor involved in the invention has a simple and reasonable structure, saves land occupation of equipment, and lowers the project investment.

Owner:杭州林达化工技术工程有限公司

Absorption liquid for gas desulfurization and its application

ActiveCN1621133AGood choiceHigh selectivityDispersed particle separationOrganic sulfide compoundLight irradiation

The present invention discloses one kind of gas desulfurizing absorption liquid and its desulfurizing method. The gas desulfurizing absorption liquid has nanometer alpha- or gamma-ferric oxide and iron chelate as catalyst. In the presence of organic compound and alkali compound and light irradiation, air is introduced and the absorption liquid absorbed inorganic and / or organic sulfide are oxidized into simple substance sulfur. The gas desulfurizing method of the present invention has the advantages of low catalyst consumption, fast regeneration of catalyst, no jamming of the absorption tower, etc.

Owner:BEIJING BAIAONA HI TECH

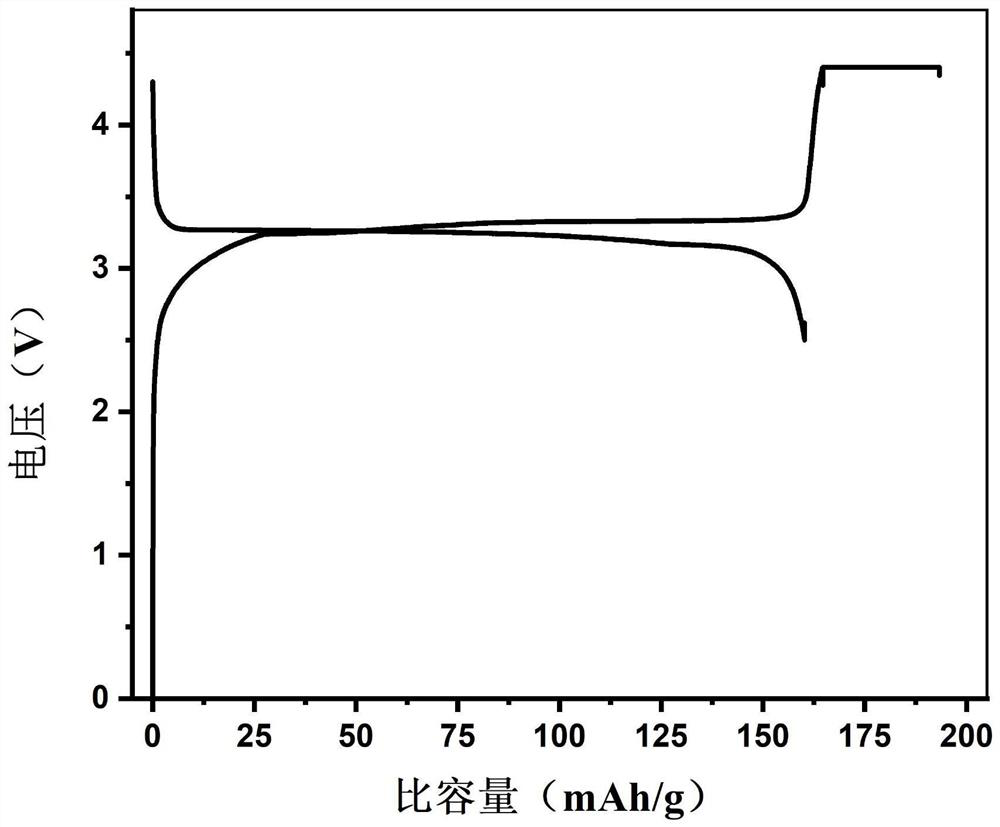

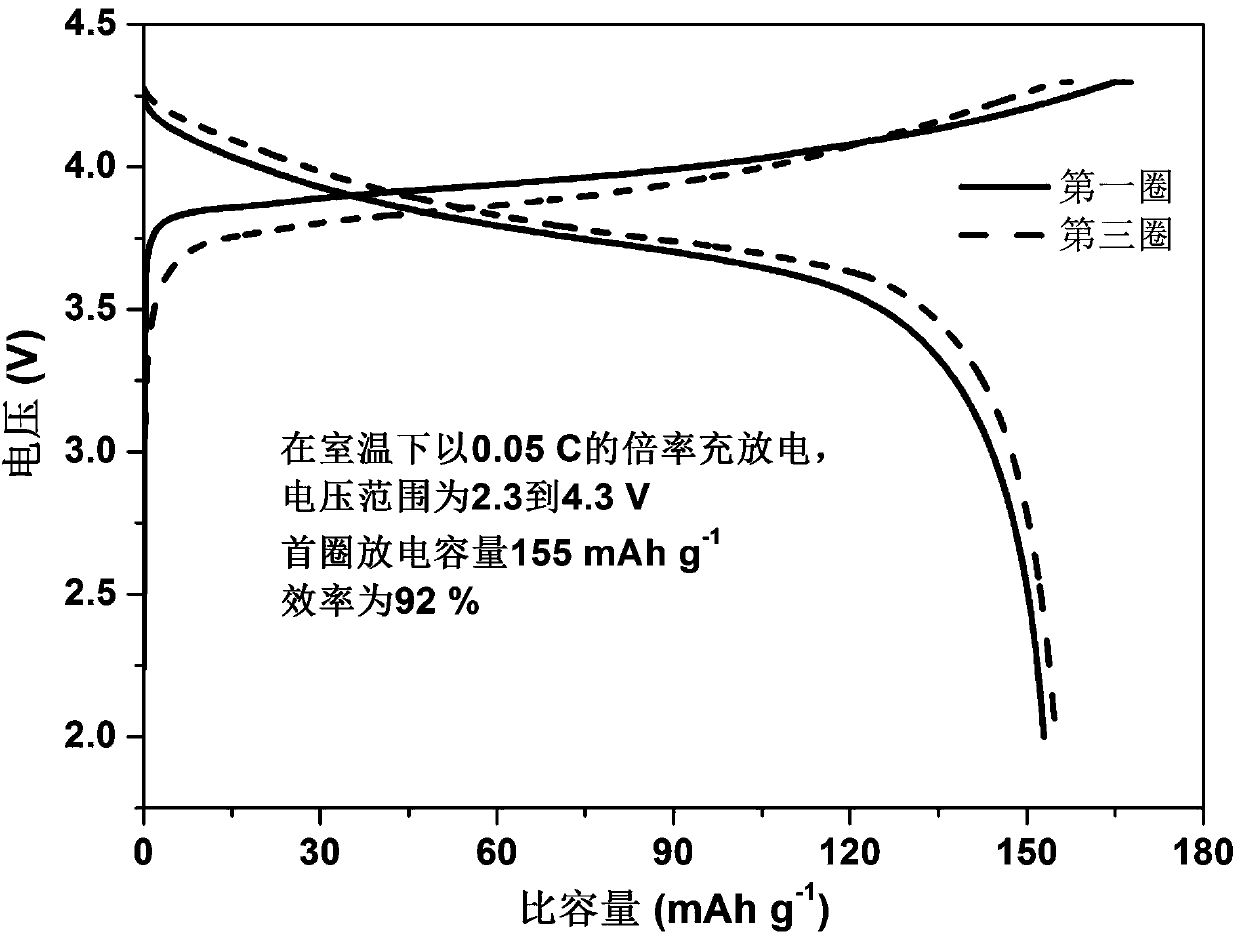

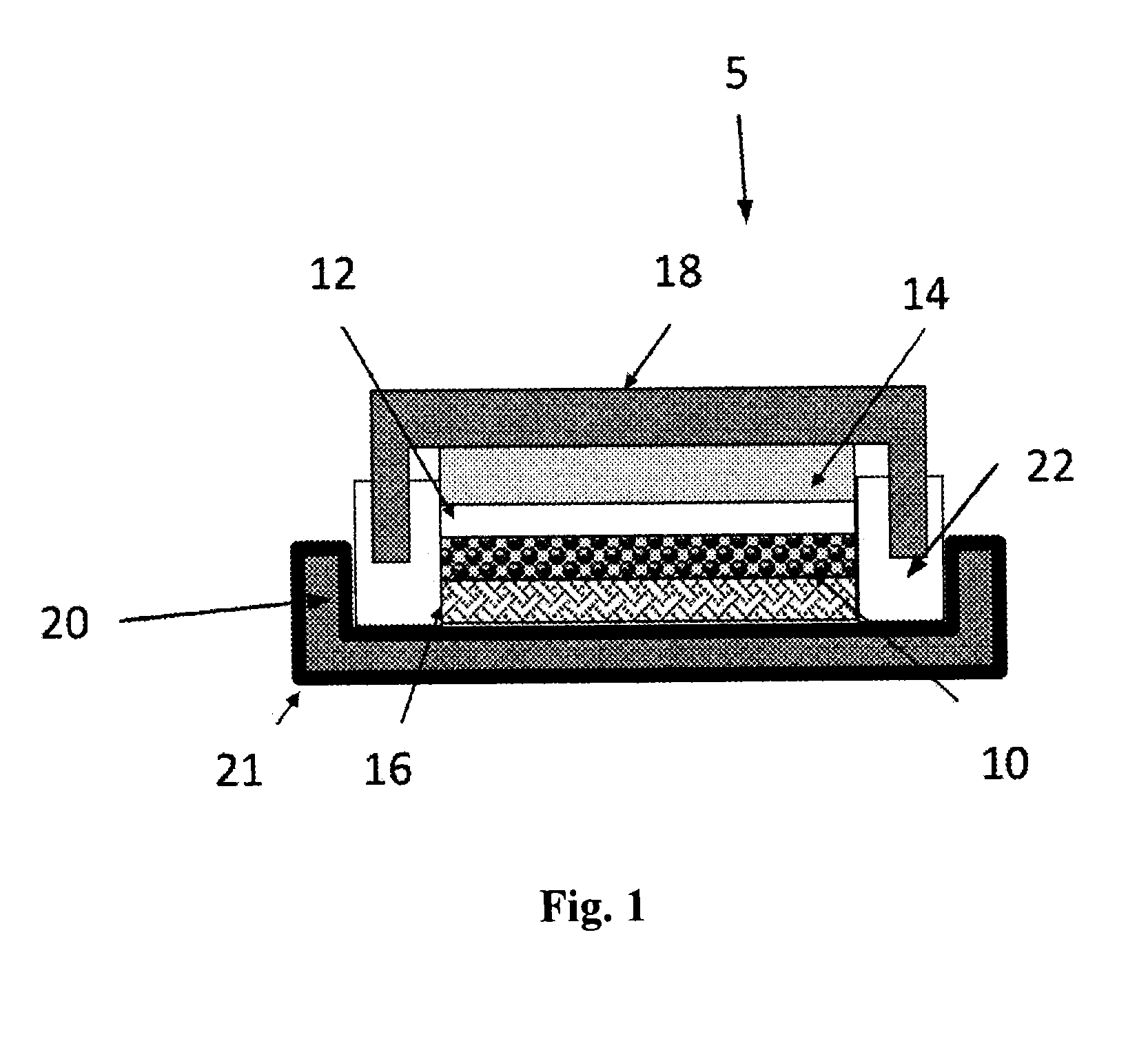

Lithium supplementing material and preparation method and application thereof

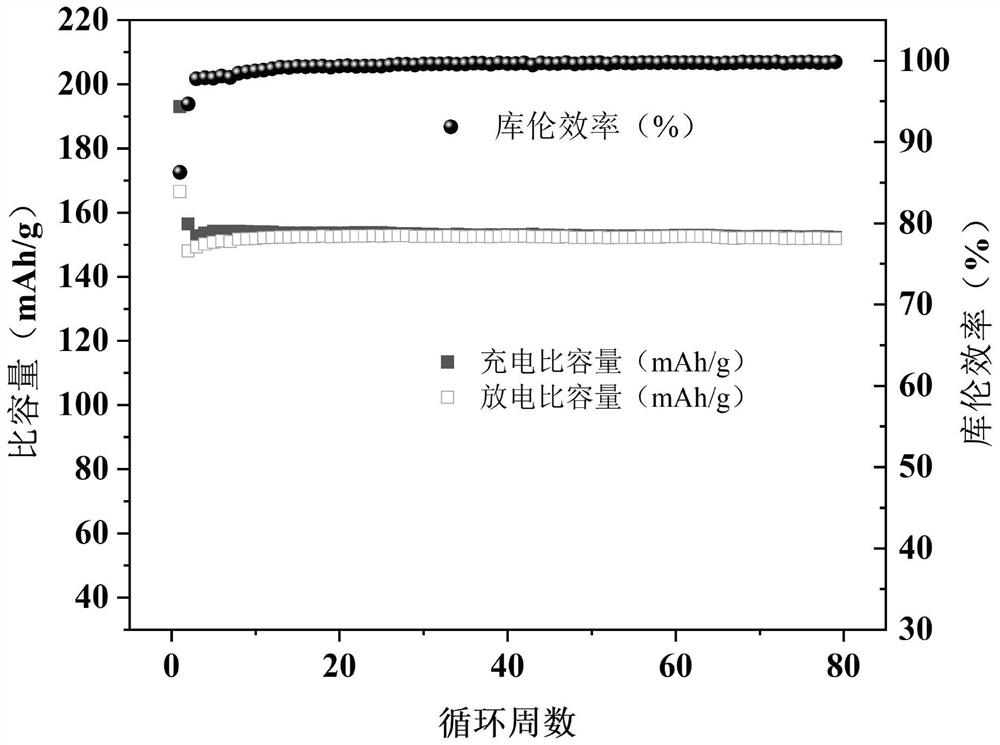

PendingCN112002894AReasonable formulaLower potentialCell electrodesSecondary cellsElectrolytic agentPtru catalyst

The invention discloses a lithium supplementing material for a lithium secondary battery as well as a preparation method and application thereof. The lithium supplementing material comprises a lithium-containing compound and an inorganic nonmetal reducing agent. According to the lithium supplementing material provided by the invention, inorganic sulfide is used as a reducing agent; meanwhile, metal and nonmetal catalysts are added; the potential of the lithium supplementing agent for exerting the capacity can be effectively reduced, and no gas is generated in the process of releasing lithium ions; the lithium supplementing material has good compatibility with the current commercial positive electrode and negative electrode, can be suitable for various battery systems, does not need to adjust and redesign an electrolyte and a battery manufacturing process, and is very suitable for the current secondary lithium ion battery. The preparation method of the lithium supplementing material provided by the invention is simple in process step, compatible with the existing lithium ion energy storage device preparation process, low in cost and suitable for mass production.

Owner:SONGSHAN LAKE MATERIALS LAB +1

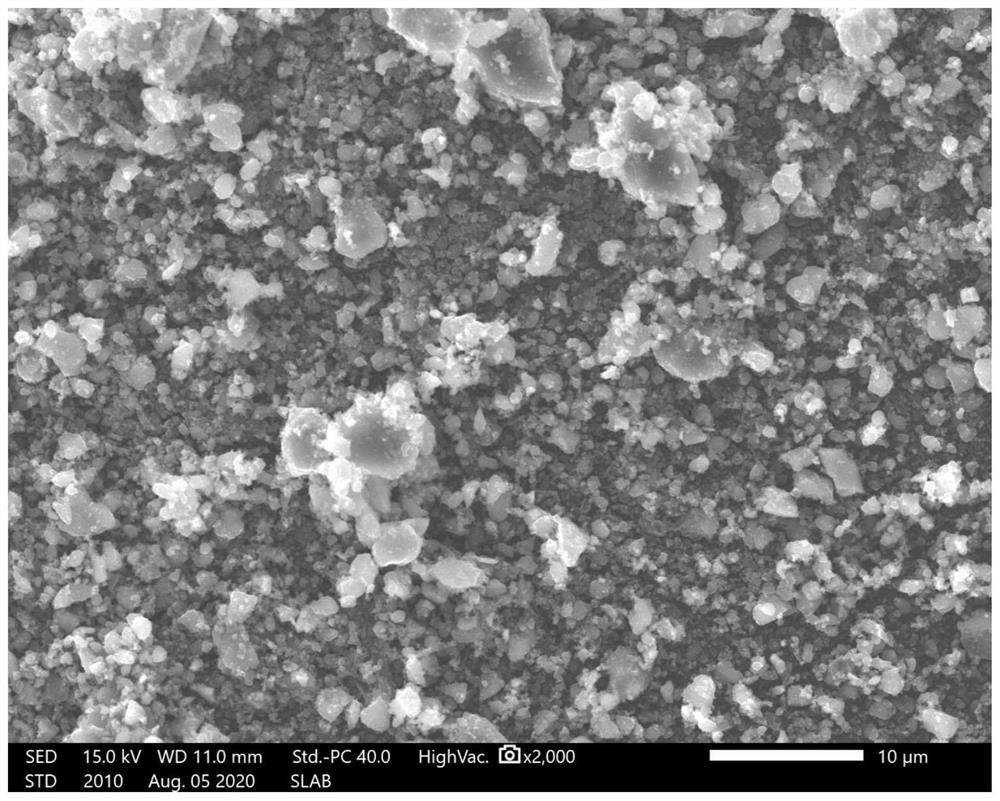

Preparation method of inorganic sulfide electrolyte

InactiveCN107195955ARich reservesIncrease energy densitySolid electrolytesSecondary cellsSulfideElectrolyte

The invention discloses a preparation method of an inorganic sulfide electrolyte. The inorganic sulfide electrolyte is Li<9.54>Si<1.74>P<1.44>S<11.7>C<10.3> and is prepared by taking Si, S, Li<2>S, P<2>S<5> and LiCl as raw materials and performing mixing, ball-milling and sintering. The electrolyte prepared by the method is in a solid state, is good in safety and has ion conductivity equivalent to that of a liquid electrolyte; and moreover, the raw materials used in the electrolyte are low in cost, and industrial application on a large scale can be expected.

Owner:HARBIN INST OF TECH WUXI RES INST OF NEW MATERIALS +1

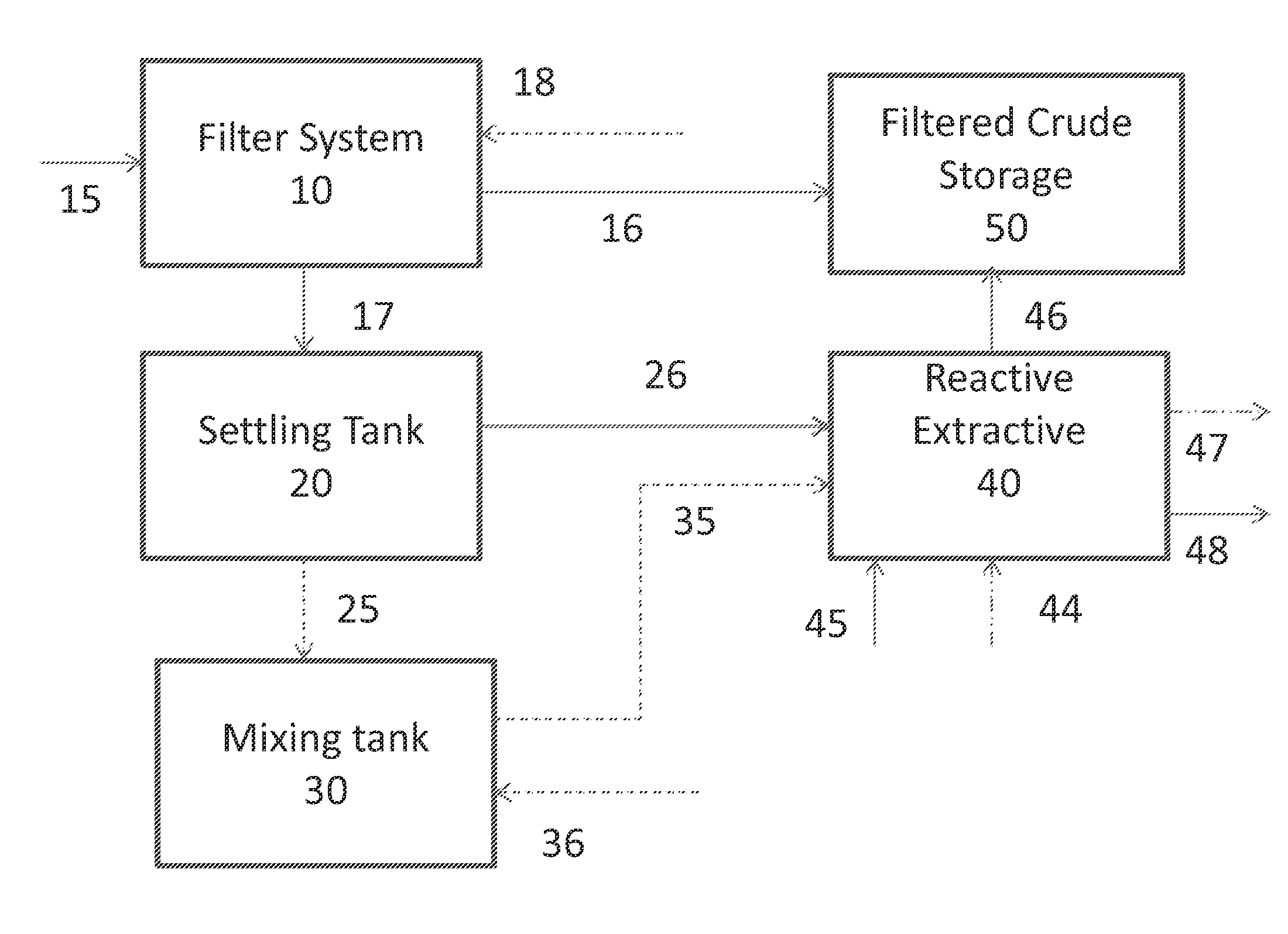

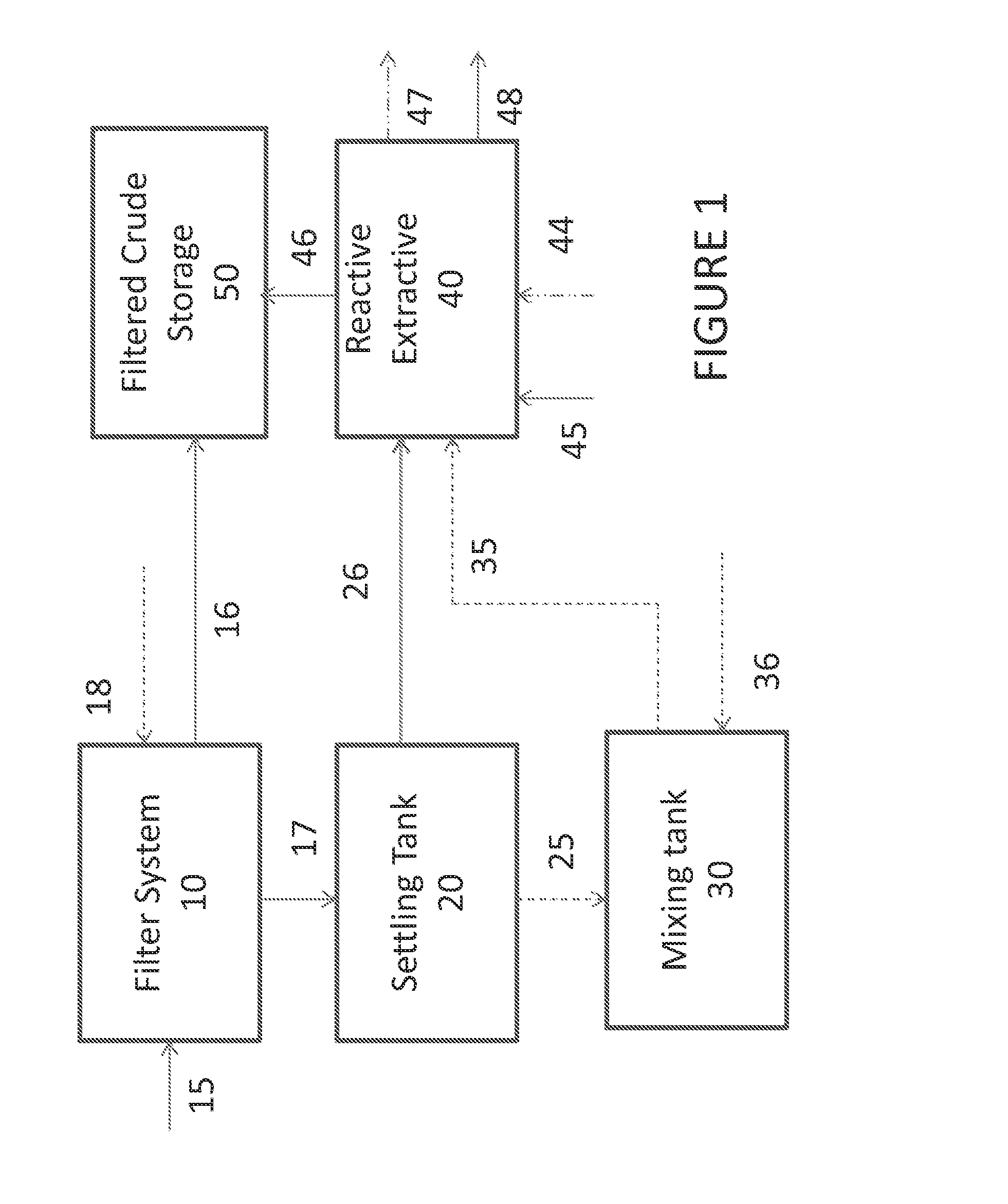

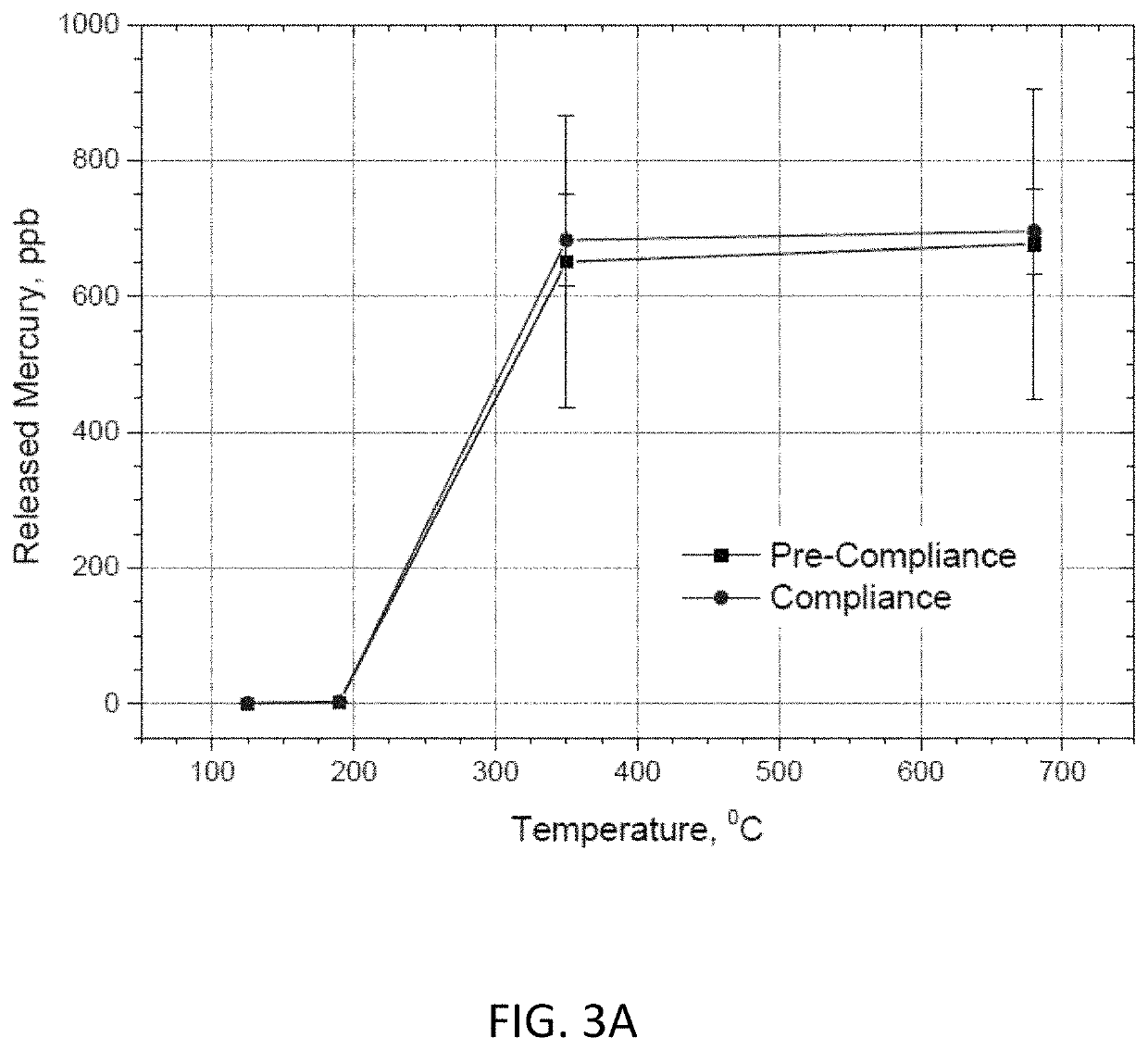

Process, Method, and System for Removing Heavy Metals from Fluids

ActiveUS20140262955A1Reduce its mercury concentrationRefining with non-metalsRefining with oxygen compoundsPhosphoniumFiltration

Trace element levels of mercury in crude oil are reduced by first passing the crude oil through a filtration device to generate filtered crude having a reduced concentration of mercury and a reject stream having a concentrated mercury level. In one embodiment, the filtration device is back-flushed to generate the reject stream. In another embodiment, the reject stream comprises a portion of the retentate from a cross-flow filter device. The reject stream is treated with an extractive agent selected from tetrakis(hydroxymethyl)phosphonium sulfate; tetrakis(hydroxymethyl) phosphonium chloride; an oxidizing agent; an organic or inorganic sulfidic compound to extract a portion of the mercury into a water phase for subsequent removal. In one embodiment, the extractive agent is a reductant to convert non-volatile mercury into volatile mercury.

Owner:CHEVROU USA INC

Quick impurity removing method for rare earth leach liquor of weathering crust elution-deposited rare earth ores

InactiveCN104962739AIncrease productivityQuality improvementProcess efficiency improvementRare earthSulfide

The invention provides a quick impurity removing method for the rare earth leach liquor of weathering crust elution-deposited rare earth ores, and aims to solve the problems that the content of metal ions of impurities in the leach liquor of the weathering crust elution-deposited rare earth ores is high, a conventional impurity removing method is longer in process flow and complicated in operation, the precipitation and sedimentation speed of generated flocculated impurities is lower, and the quantity of adsorbed and carried rare earth is large. The method specifically comprises the following steps of (1) directly adding a mixed solution of ammonium hydrogen carbonate and inorganic sulfide into the rare earth leach liquor; (2) adding ammonia water or sulfuric acid to adjust the pH value of the mixed solution; (3) under the condition of stirring, adding a flocculating agent solution into the mixed solution, continuously stirring for 1h to 3h, then standing for sedimentation, and extracting supernatant liquor to obtain low-impurity rare earth leach liquor. According to the method, the sedimentation time of the impurities can be effectively shortened, the production efficiency is greatly improved, quick and full sedimentation of the impurities can be achieved, the rare earth of the obtained low-impurity rare earth leach liquor is high in recovery rate and high in purity, and the method is suitable for popularization and application.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

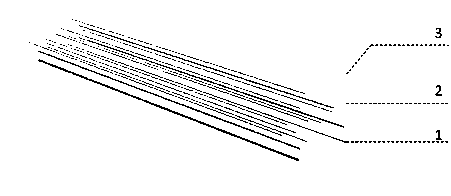

Sulfide composite electrolyte with toughened polymer conductive fiber

ActiveCN107978789AHigh breaking strengthSolid electrolytesFinal product manufactureFiberElectrical conductor

The invention discloses a sulfide composite electrolyte with toughened polymer conductive fiber and application thereof in a room temperature all-solid-state lithium battery. By bionic-simulating thetoughening behavior on the bamboo by the bamboo fiber in the natural world, compounding one-dimensional nanometer polymer lithium ion conductive fiber in a sulfide inorganic fast ion conductor, wherein the fiber length is 1-1000 microns, and diameter is 10-1000nm, arranging the fibers in parallel according to the same direction, wherein the conductive fibers are uniformly distributed on the surface or in the composite structure. This structure improves the capacity for defensing the stress deformation of the sulfide inorganic fast ion conductor, the breaking strength of the inorganic sulfide fast ion conductor is improved to 1.2-1.4MPam1 / 2 from the situation of not greater than 0.70MPam1 / 2. The invention further discloses all-solid-state lithium battery assembled by the composite electrolyte structure.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Absorption liquid for gas desulfurization and desulfurization method thereof

InactiveCN101613089AShort regeneration timeOvercoming the problem of slow real lifeDispersed particle separationSulfur preparation/purificationOrganic sulfide compoundCatalyst degradation

The invention relates to an absorption liquid for gas desulfurization and a desulfurization method thereof, solving the problems that catalysts in the prior art have slow regeneration, absorption tower clogging, high degradation speed of desulfurater and the like. Phenol, quinine, microbial enzyme, vanadium and complex preparation serve as catalysts; under the condition of alkaline compounds, gas is led in to quickly oxidize inorganic sulphide and organic sulphide in absorption liquid to be sulphur. The gas desulfurization method of the invention has the advantages of small amount of catalyst, high regeneration efficiency of catalyst, low degradation speed of catalyst, no absorption tower clogging and the like.

Owner:苏喜太

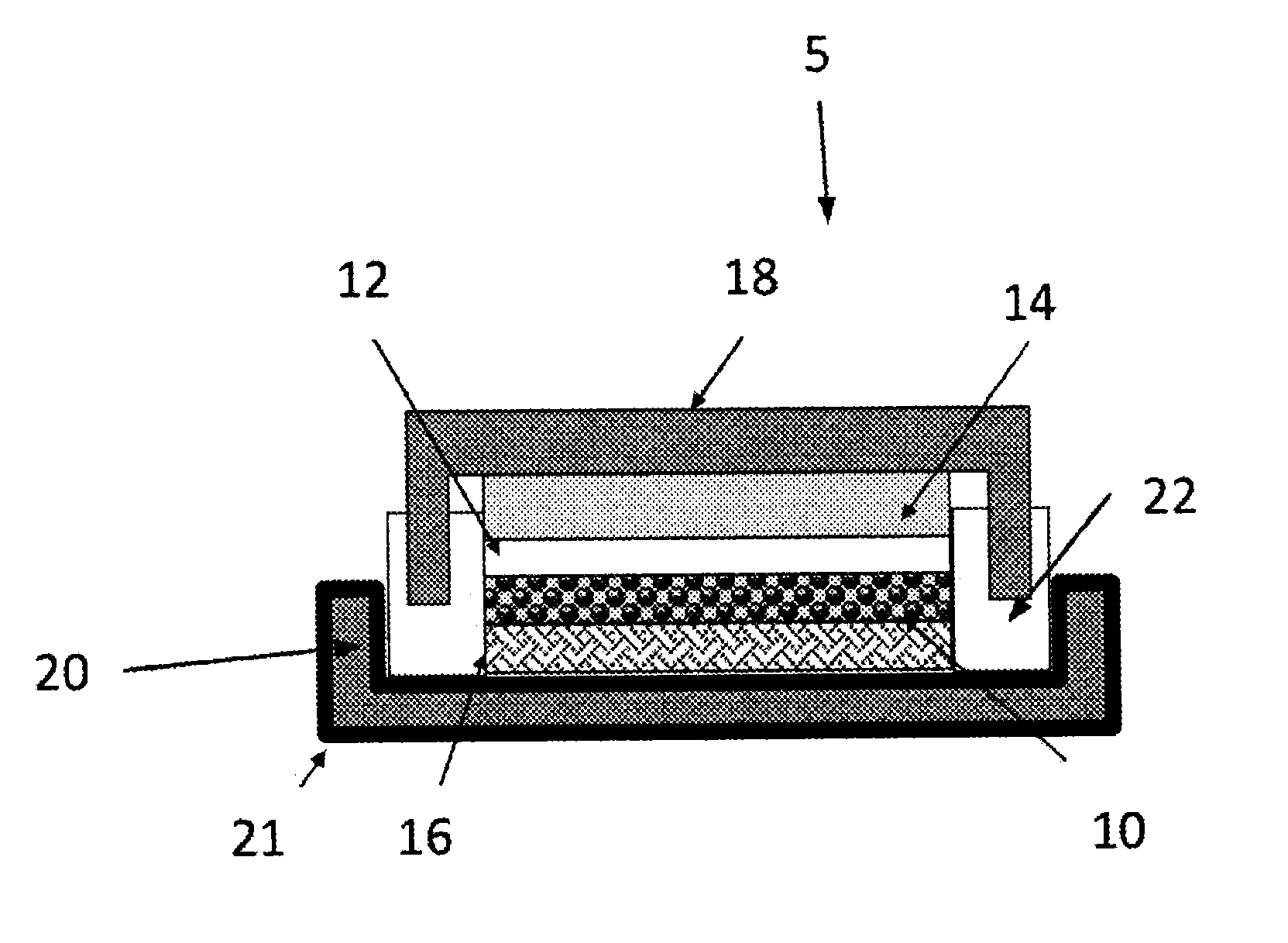

Vanadium oxysulfide based cathode materials for rechargeable battery

A cathode active composite containing an amorphous composite of vanadium oxide and an inorganic sulfide is provided. In one embodiment the composite contains vanadium pentoxide and phosphorous pentasulfide. In a further special embodiment, a cathode active material comprising a nanoparticle composite of an amorphous matrix containing vanadium, oxygen and sulfur and crystalline regions of vanadium and oxygen embedded in the matrix is provided. Electrochemical cells and a reversible battery having a cathode containing one of the cathode active composites are also provided. In specific embodiments the battery is a magnesium battery.

Owner:TOYOTA JIDOSHA KK

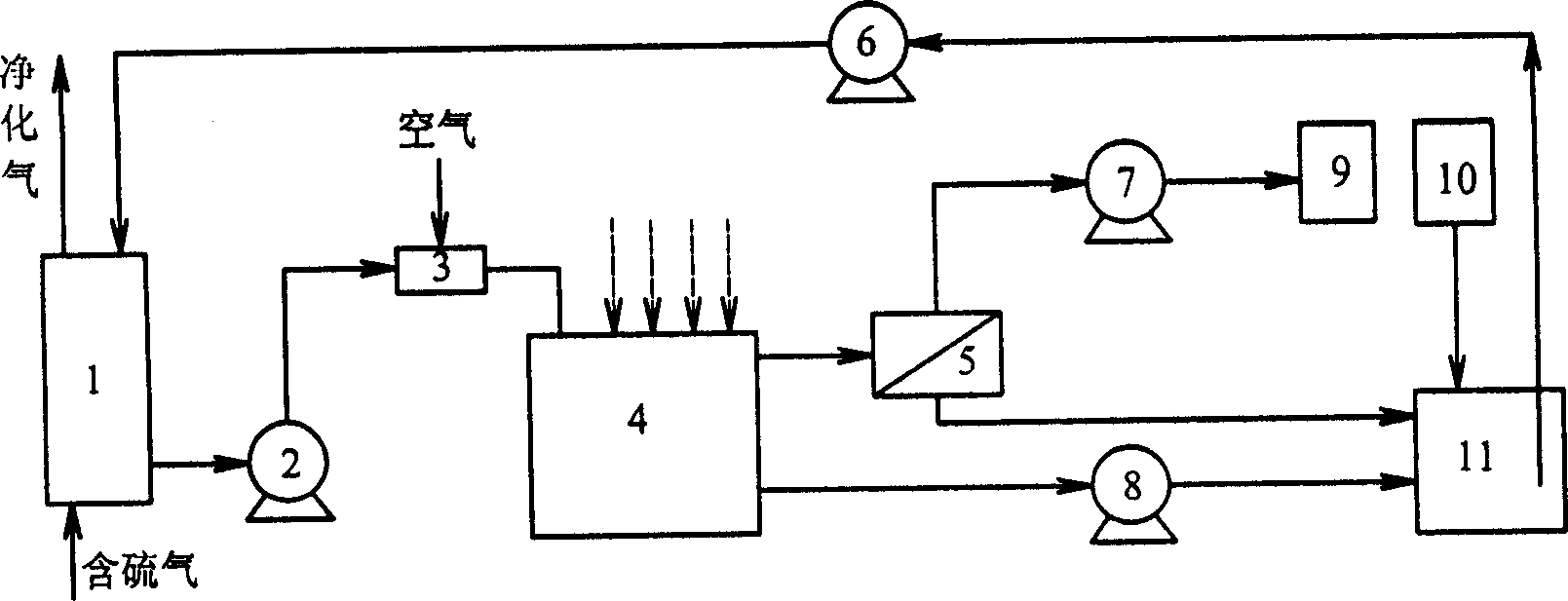

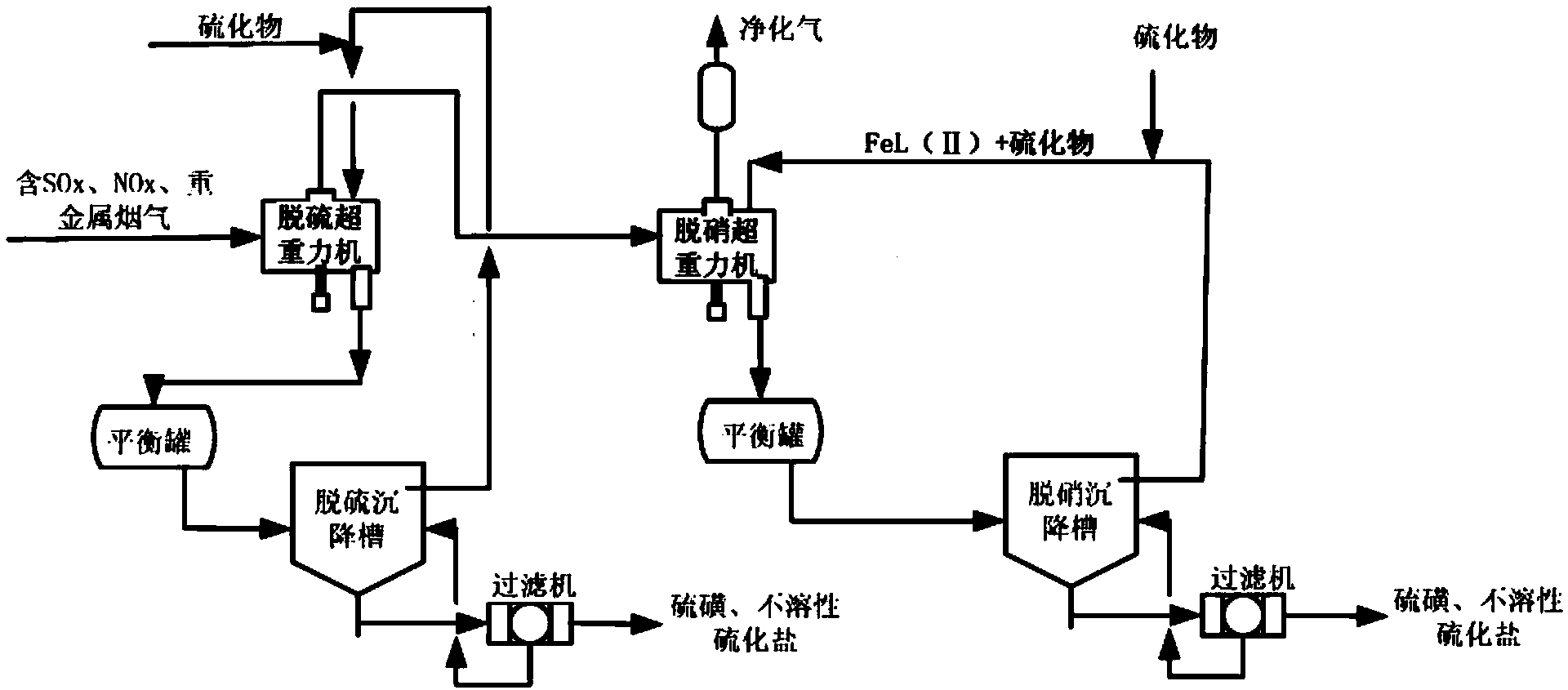

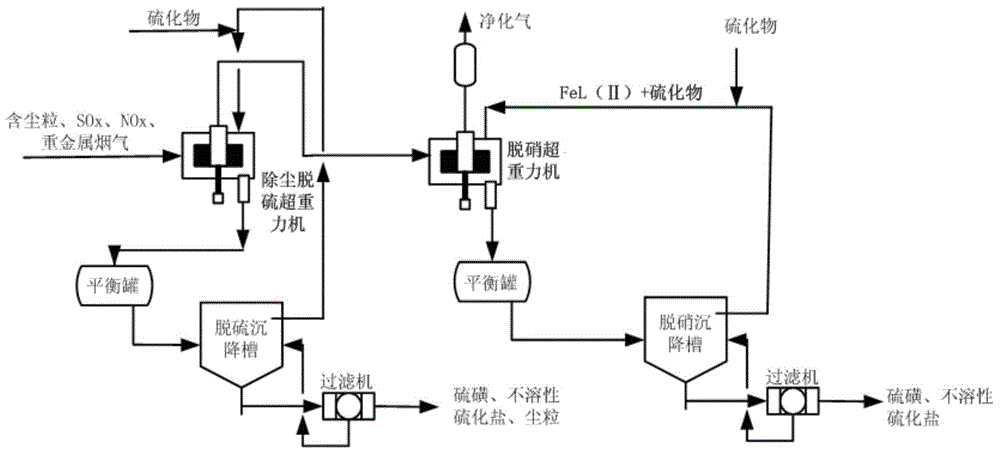

Integrated method for wet-process desulfurization, denitrification demercuration and dearsenification of complexing ferroporphyrin smoke based on supergravity

InactiveCN103432878AEasy to removeImprove regeneration efficiencyDispersed particle separationAir quality improvementToxicantSulfide

The invention discloses an integrated method for wet-process desulfurization, denitrification demercuration and dearsenification of complexing ferroporphyrin smoke based on supergravity. The method comprises the following steps of firstly, absorbing SOx by utilizing inorganic sulfide, desulfurating, meanwhile, reacting inorganic sulfide with toxic heavy metals such as mercury and arsenic in the smoke so as to generate an insoluble vulcanized salt; utilizing a complexing ferroporphyrin to absorbing NOx by utilizing complexing ferroporphyrin for denitration; and regenerating ab absorber by utilizing inorganic sulfide as a reducing agent. The method provided by the invention has the advantages that a supergravity machine is adopted as gas-liquid mass transfer strengthening equipment, the method is beneficial to removal of toxicants such as SOx, NOx, mercury and arsenic, the regeneration efficiency of the absorbent is high, an absorption liquid is applied in a circulating manner, a reducing agent inorganic sulfide is oxidized so as to generate sulphur which can be recovered, sulphur is processed into a high quality sulphur product, and the secondary pollution is not generated; the process is simple, the absorption efficiency is high, the dust is thoroughly removed, the desulfurization degree is more than 99%, the denitration rate is more than 96%, and mercury and arsenic in the smoke are fully basically removed.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD

Converting and absorbing fine desulfurizer and its prepn

ActiveCN1706921AImprove stabilityImprove conversion rateGas purification by catalytic conversionOrganic sulfide compoundSulfide

The present invention is converting and absorbing fine desulfurizer and its preparation. The present invention features that the fine desulfurizer consists of Co 0.01-0.2 wt%, Mo 0.01-0.2 wt%, Cu 1-15 wt%, Zn 1-10 wt%, K 0.1-5 wt% and manganese ore 70-95 wt%, and is prepared with manganese ore bar as carrier and Co(Ac)2, (NH4)6Mo7O24, Cu(NO3)2, Zn(NO3)2 and KNO3 as precursors, and through precipitation process. The fine desulfurizer is suitable for fine eliminating organic sulfide and inorganic sulfide from natural gas, semiwater gas, coke oven gas, petroleum cracking gas, etc. to result in high desulfurizing precision and total outlet sulfur content lower than 0.1 ppm. The fine desulfurizer has high heat stability, high conversion rate, long service life and other advantages.

Owner:HAISO TECH

Method and device for recovering sulphur in acidic gas, and reactor

InactiveCN103566754AAffect conversion performanceImpact protectionDispersed particle separationSulfurLiquid state

The invention discloses a method for recovering sulphur in an acidic gas. The method comprises the following steps of: carrying out hydrogenating hydrolysis on organic sulphur in the acidic gas by a catalytic hydrogenation reaction to obtain an inorganic sulphide, catalytically oxidizing the inorganic sulphide to obtain sulphur, then cooling and condensing the reaction gas after the catalytic oxidation to separate liquid-state sulphur, then washing and absorbing the residual sulphide in the tail gas after sulphur separation by alcohol-containing washing solution from low-temperature methanol washing, so as to realize complete recovery for sulphur. The invention further discloses a device used for realizing the method aforementioned and a reactor. The process, device and reactor disclosed by the invention are suitable for sulphur recovery for the acidic gas with a low-concentration H2S content, and the tail gas after desulfurization is washed and treated by virtue of alcohol-containing solution in a low-temperature methanol washing process, thus reducing the content of sulphides in the tail gas and protecting environment; meanwhile, the reactor disclosed by the invention is simple and reasonable in structure, and capable of saving equipment floor space and reducing project investment.

Owner:杭州林达化工技术工程有限公司

Absorption liquid for gas desulfurization and desulfurization method thereof

InactiveCN101613089BShort regeneration timeOvercoming the problem of slow real lifeDispersed particle separationSulfur preparation/purificationOrganic sulfide compoundCatalyst degradation

The invention relates to an absorption liquid for gas desulfurization and a desulfurization method thereof, solving the problems that catalysts in the prior art have slow regeneration, absorption tower clogging, high degradation speed of desulfurater and the like. Phenol, quinine, microbial enzyme, vanadium and complex preparation serve as catalysts; under the condition of alkaline compounds, gasis led in to quickly oxidize inorganic sulphide and organic sulphide in absorption liquid to be sulphur. The gas desulfurization method of the invention has the advantages of small amount of catalyst, high regeneration efficiency of catalyst, low degradation speed of catalyst, no absorption tower clogging and the like.

Owner:苏喜太

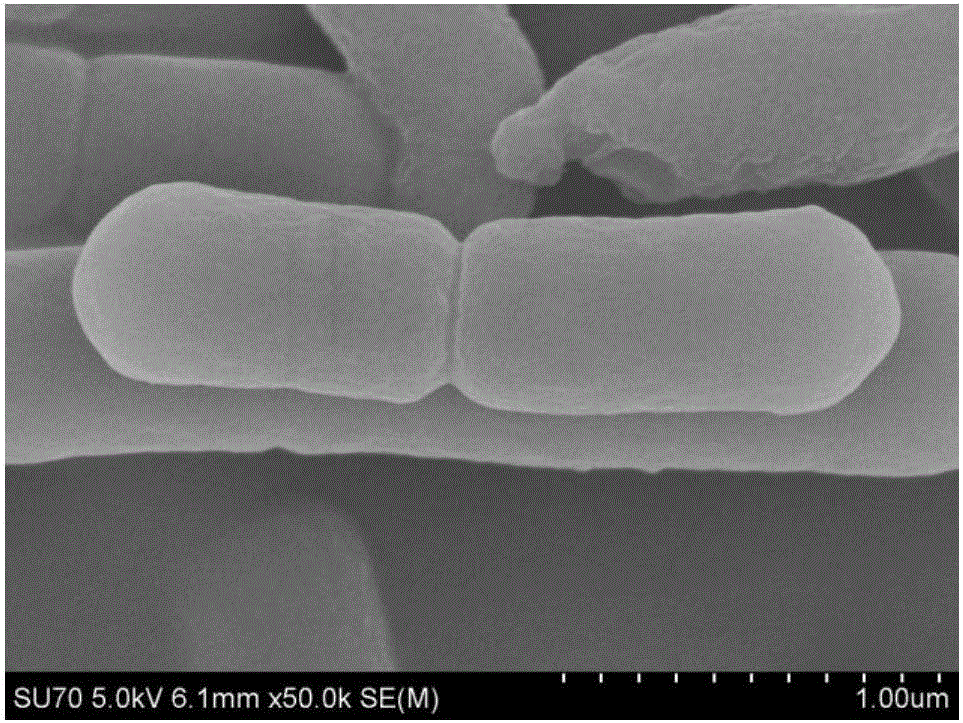

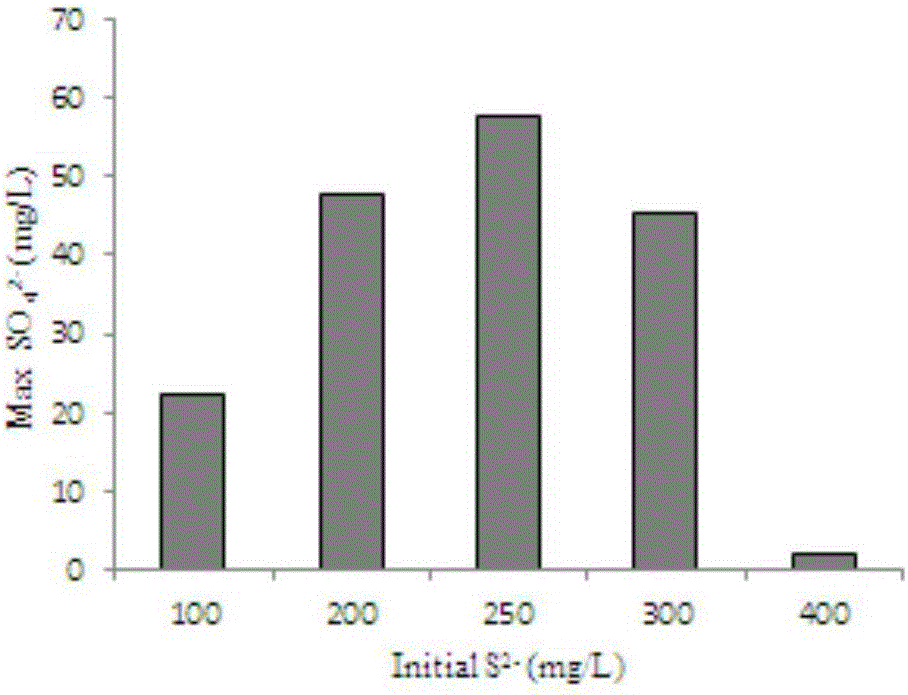

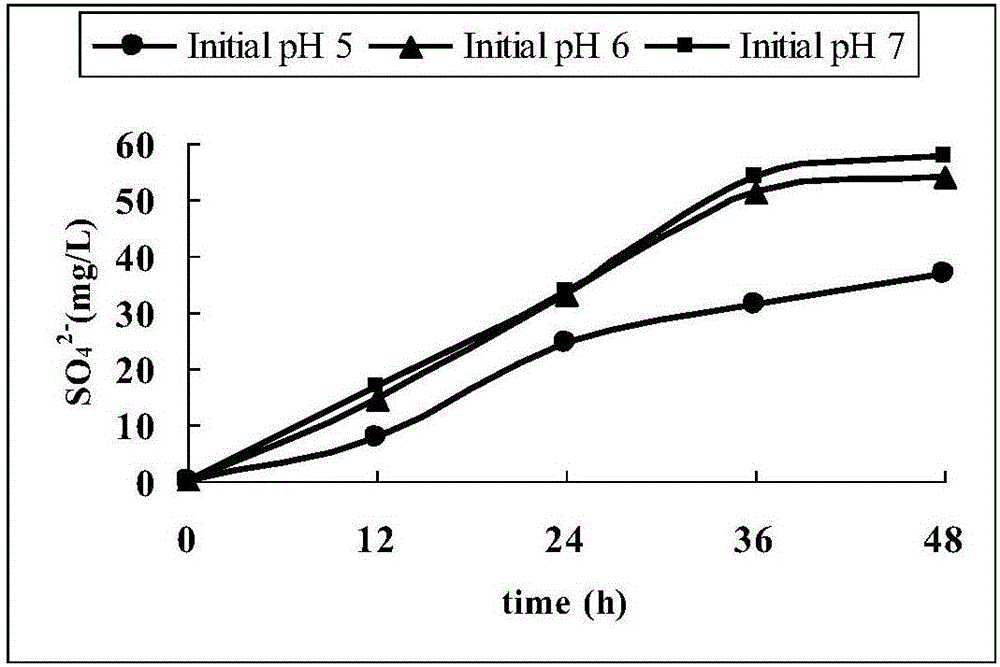

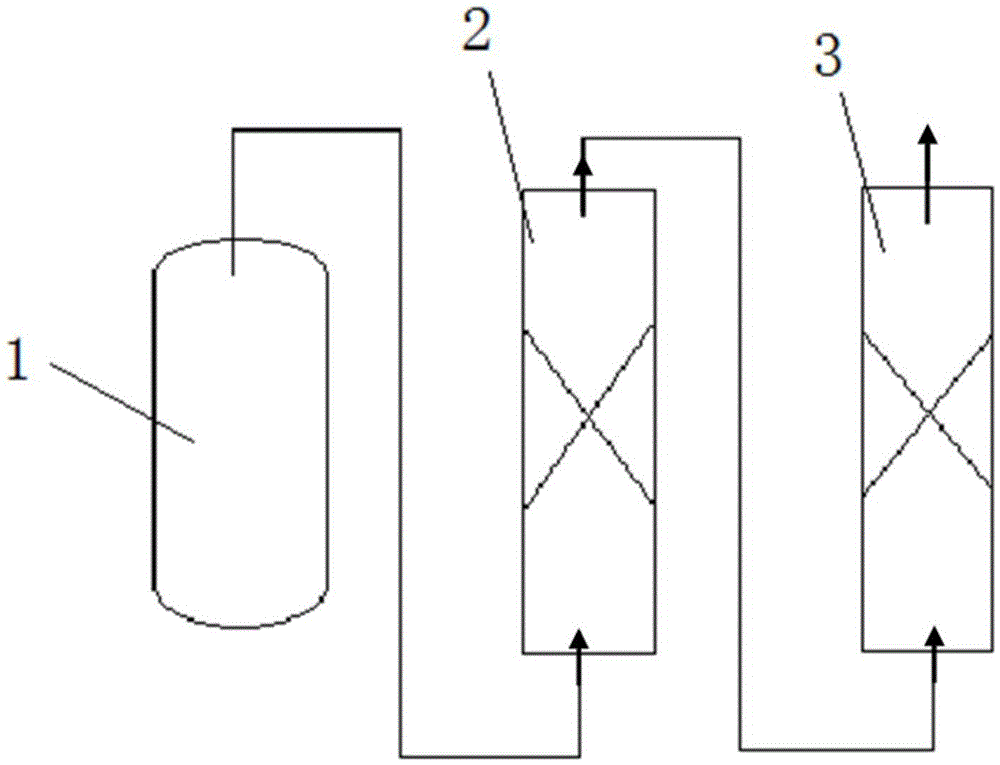

Bacillus cereus and application thereof in oxidizing inorganic sulfide

ActiveCN106676046AImprove oxidation capacitySimple nutritional conditions for growthBacteriaMicroorganism based processesBacillus cereusSulfide

The invention relates to bacillus cereus and application thereof in oxidizing inorganic sulfide, which belong to the technical fields of biology and environment protection. The invention discloses an inorganic sulfide-oxidizing bacterium, which is classified and named as Bacillus cereus ZJNB-B3, and preserved in China Center for Type Culture Collection with the preservation number of CCTCC NO: M2016337. The bacterium has a higher oxidizing ability on reduced state inorganic sulfide. The bacillus cereus provided by the invention can tolerate a natural environment with the pH ranging from 4.5 to 9.1, can be applied in desulfuration innocent treatment of natural biological desulfurization systems with mild conditions, such as malodorous hydrogen sulfide gas generated by livestock slaughter processing and feed fish meal processing.

Owner:湖北宜水环保科技有限公司

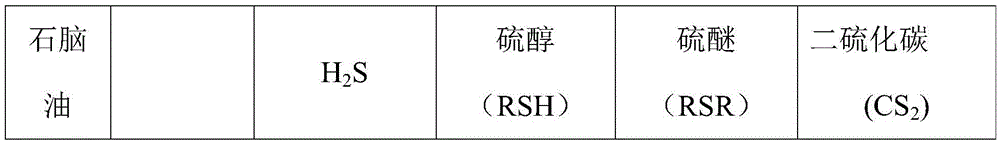

Method for removing sulfides in light oil

ActiveCN105623719ALow densityImprove bindingTreatment with plural serial refining stagesOrganic sulfide compoundActivated carbon

The invention discloses a method for removing sulfides in light oil. The method comprises the following steps that 1, on the condition that the temperature ranges from minus 5 DEG C to 90 DEG C and the pressure ranges from 0.1 MPa to 5 MPa, the light oil makes contact with magnetic iron oxide, first-stage desulfurization is conducted, inorganic sulfides in the light oil are removed, and the light oil with the inorganic sulfides removed is obtained; 2, on the condition that the temperature ranges from minus 5 DEG C to 90 DEG C and the pressure ranges from 0.1 MPa to 5 MPa, the light oil with the inorganic sulfides removed makes contact with activated carbon loaded with copper, second-stage desulfurization is conducted, organic sulfides in the light oil are removed, and the light oil with the organic sulfides removed is obtained, that is to say, the light oil with the sulfides removed is obtained. By means of the removing method, various sulfides in the light oil are effectively removed, the total sulfur content of the light oil with the sulfides removed does not exceed the national standard or the industrial standard, and the method has the advantages of being capable of achieving normal temperature operation, large in treatment capacity, free of waste alkali, low in energy consumption, simple in technology, easy and convenient to operate and the like.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Vanadium oxysulfide based cathode materials for rechargeable battery

A cathode active composite containing an amorphous composite of vanadium oxide and an inorganic sulfide is provided. In one embodiment the composite contains vanadium pentoxide and phosphorous pentasulfide. An elctrochemical cell and a reversible battery having a cathode containing the cathode active composite are also provided. In one embodiment the battery is a magnesium battery.

Owner:TOYOTA JIDOSHA KK

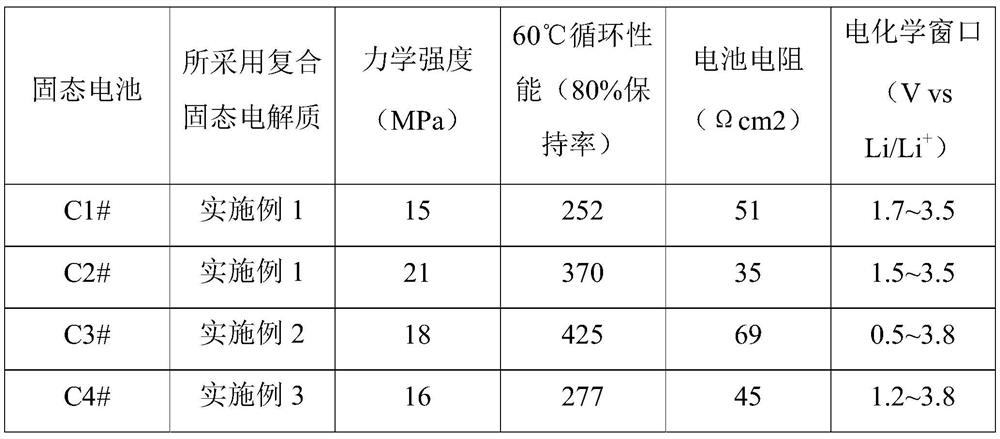

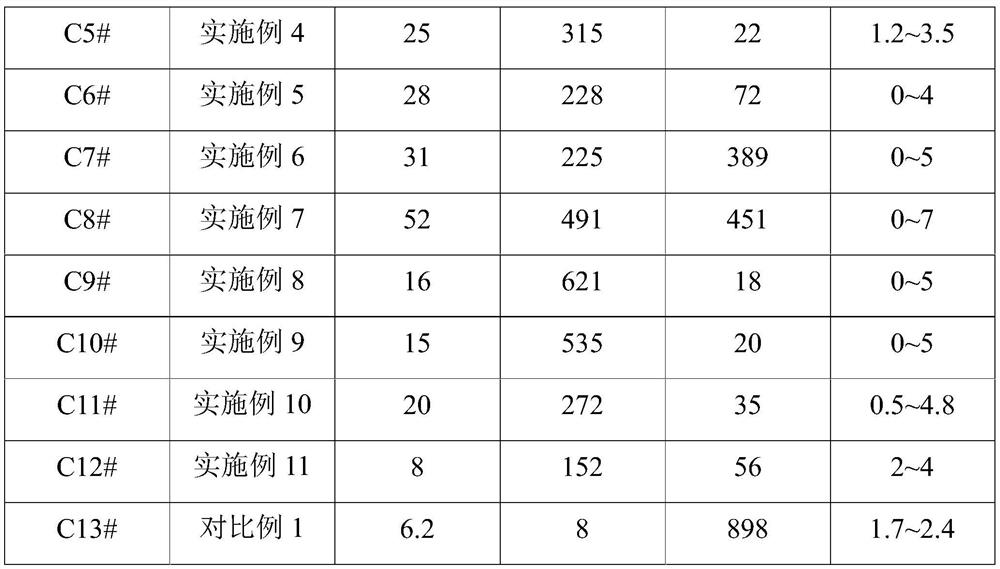

Composite solid electrolyte, preparation method thereof and solid-state battery

InactiveCN113363572AImprove mechanical propertiesImprove conductivitySecondary cells servicing/maintenanceElectrolyte immobilisation/gelificationSolid state electrolytePhysical chemistry

The invention discloses a composite solid-state electrolyte, a preparation method thereof and a solid-state battery. The composite solid-state electrolyte comprises the following raw material components: a polymer containing a sulfur element, a lithium salt and an inorganic sulfide electrolyte, wherein the polymer containing the sulfur element contains C-Sx-C bonds, and x is a positive integer. According to the present invention, the composite solid electrolyte is formed by compounding the specific sulfur-containing polymer, the lithium salt and the inorganic sulfide electrolyte, and has advantages of excellent mechanical property, high ionic conductivity and low raw material cost.

Owner:KUNSHAN BAOTRON NEW ENERGY TECH CO LTD

Single-step impurity removal method for re dip solution of weathering crust infiltration-type rare earth ore

InactiveCN104975193AReduce lossIncrease productivityProcess efficiency improvementIon contentRare earth

The invention discloses a single-step impurity removal method for a re dip solution of weathering crust infiltration-type rare earth ore. The single-step impurity removal method aims at solving the problems that the metal ion content of a re dip solution of weathering crust infiltration-type rare earth ore is high, foreign ions can be removed only through a multi-step impurity removal method which is long in technical process and complex in operation, and the rare earth loss is high in the impurity removal process. The single-step impurity removal method is simple in process and convenient to implement, and includes the following specific steps that (1), a mixed solution of ammonium bicarbonate and inorganic sulfide is directly added to the re dip solution; (2), ammonium hydroxide or sulfuric acid is added to adjust the pH value of the solution; and (3), the re dip solution is stirred continuously, supernate is obtained after standing, and a saturated ammonium bicarbonate solution or oxalic acid solution can be directly used for rare earth precipitation to obtain rare earth products. The single-step impurity removal method can reduce the foreign metal content in rare earth products, improves the purity and recycling rate of rare earth products, and is suitable for application and popularization.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

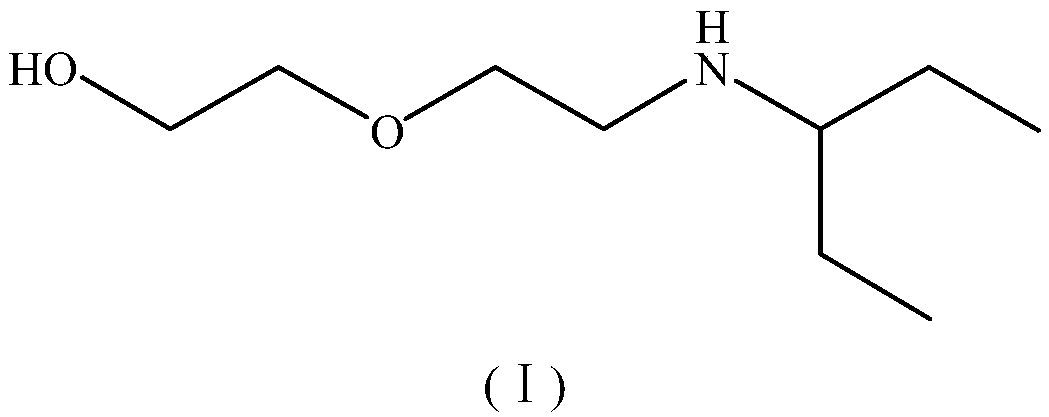

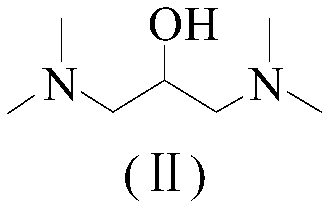

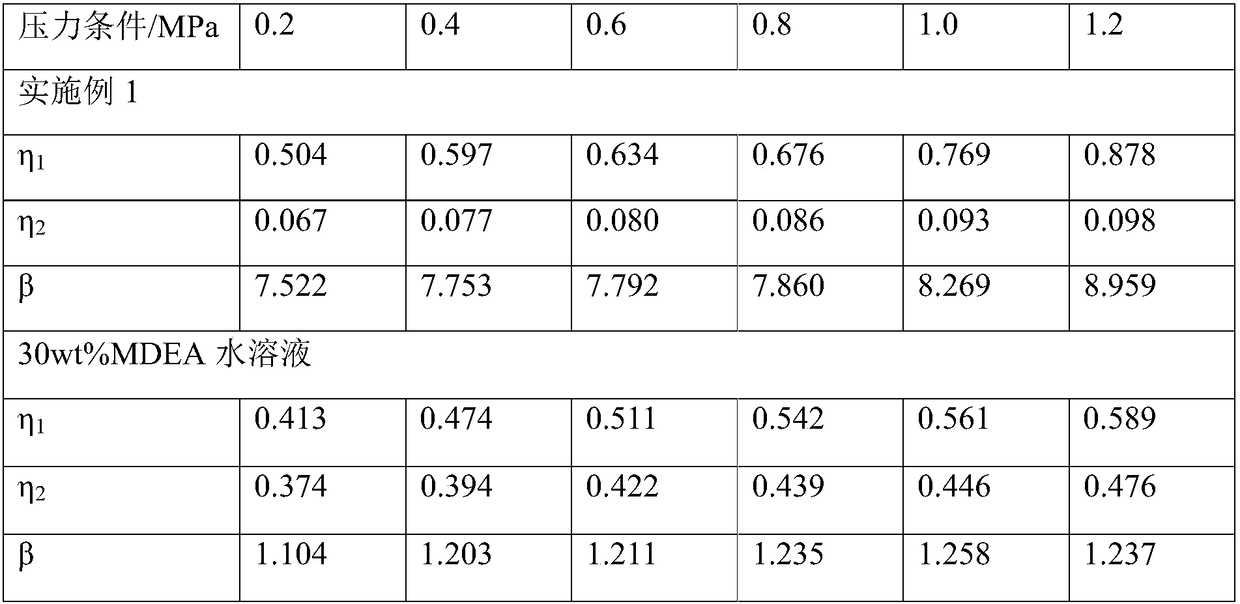

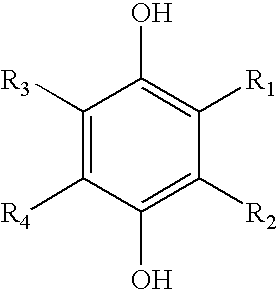

Steric hindered amine compound desulfurizer

InactiveCN109499335AIncrease physical solubilityIncrease polarityGas treatmentDispersed particle separationHindered amine light stabilizersSulfide

The invention discloses a steric hindered amine compound desulfurizer. The steric hindered amine compound desulfurizer is an aqueous solution which takes 2-[2-(1-ethylpropyl)amino]ethoxyethanol and 1,3-di(dimethylamino)-2-propanol as main effective components, wherein the concentration of total amine in the solution is 10 to 40 wt% and the mol ratio of the 2-[2-(1-ethylpropyl)amino]ethoxyethanol to the 1,3-di(dimethylamino)-2-propanol to N-methyldiethanolamine is (1.5 to 4) to (1 to 3) to 1. The steric hindered amine compound desulfurizer disclosed by the invention can be used for effectivelyremoving organic and inorganic sulfide in sulfur-containing gas, and the removal selectivity on the sulfide is better than that of a conventional desulfurization solvent; the steric hindered amine compound desulfurizer has a good desulfurization effect and a small hydrocarbon common absorption amount.

Owner:JIANGSU KECHUANG PETROCHEM

Method of Treating Rubber Composition with Cure Inhibitor to Create Soft Skin in Golf Ball Core

InactiveUS20090023865A1Improve surface roughnessLamination ancillary operationsLaminationOrganosulfur compoundsHardness

A method of making a golf ball comprising the steps of providing a preform comprising an uncured polybutadiene composition; coating the preform with a cure-altering material comprising an organosulfur compound, an inorganic sulfide compound, or a metal-containing organosulfur compound; curing the coated preform at a predetermined temperature to form a crosslinked golf ball core having an outer surface having a first hardness and a geometric center having a second hardness greater than the first to define a negative hardness gradient; and forming a cover layer about the core to form the golf ball.

Owner:ACUSHNET CO

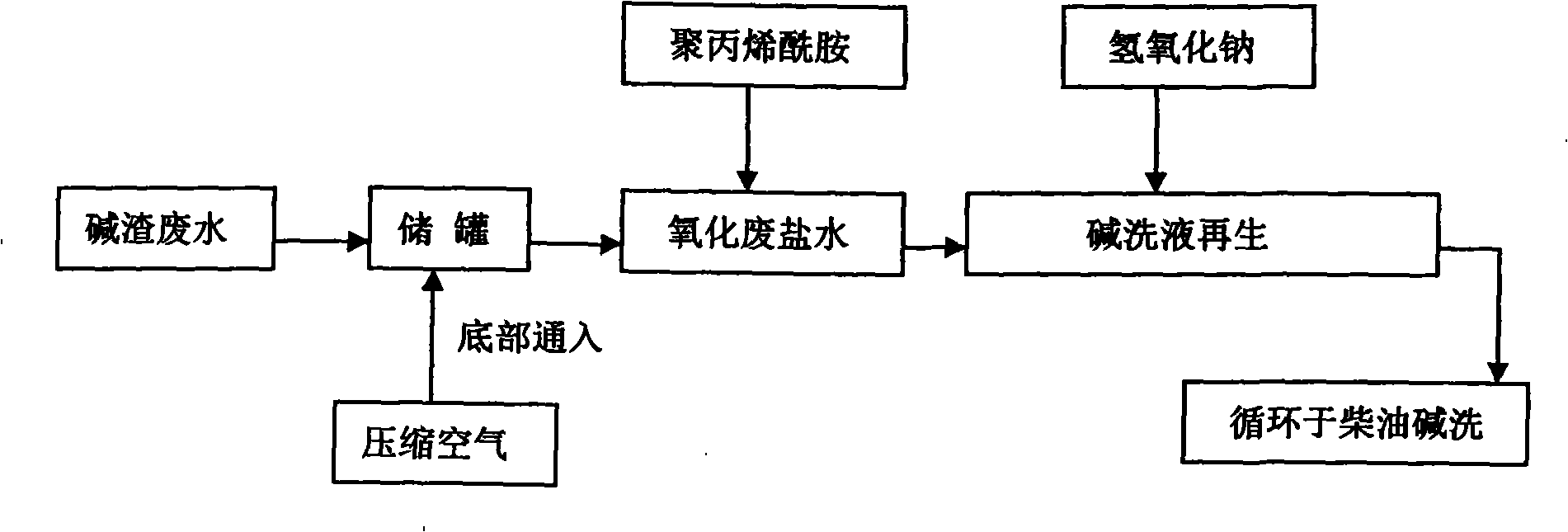

Method for using diesel oil caustic sludge wastewater for diesel oil caustic washing

InactiveCN101280214AReduce consumptionTake advantage ofRefining with aqueous alkaline solutionsSaline waterSludge

The invention discloses a process of using diesel alkaline dregs wastewater as diesel alkaline washing, which solves that problems of serious wastewater pollution and complex disposal process; the process includes the steps as follows: the diesel alkaline dregs wastewater is fed into a storage tank; the solid wastes are discharged after the sedimentation through the standing for 1-8 hours; the compression air is fed from the bottom of the storage tank to enable the alkaline dregs to be mixed with the air sufficiently so that the organic or inorganic sulfides are transformed into sulfates through oxidation; and then 1-5ppm of polyacrylamide with the molecular weight of 0.01-0.02 million is added to be mixed evenly with the sulfates according to the weight of the saline; and then NaOH is added to obtain the 3% NaOH solution which contains Na2SO4 and is circulated for the alkaline process.

Owner:SHANDONG UNIV

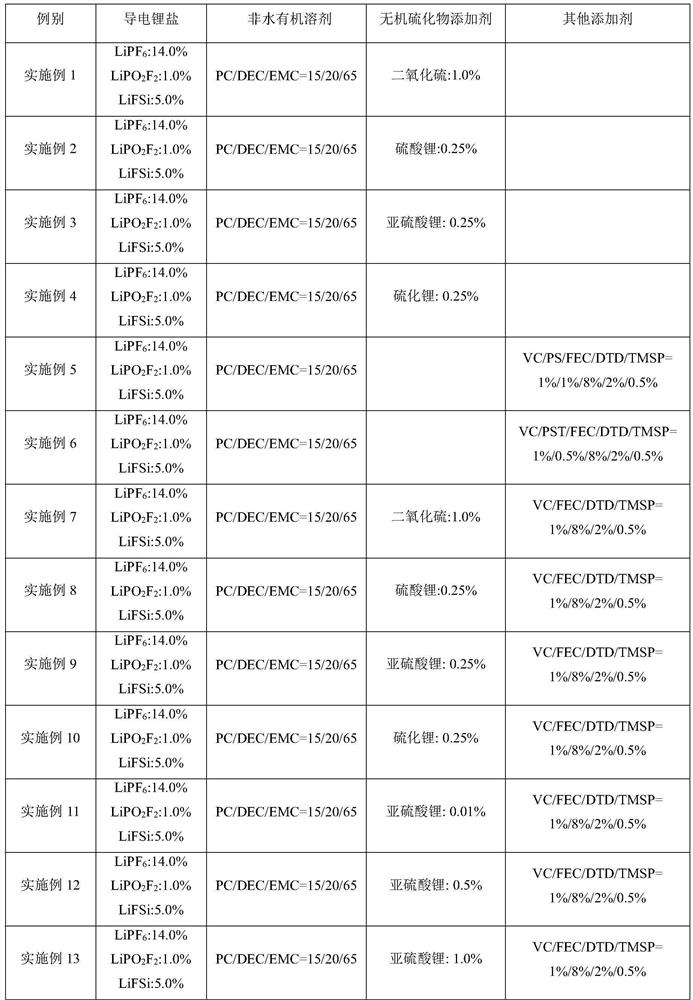

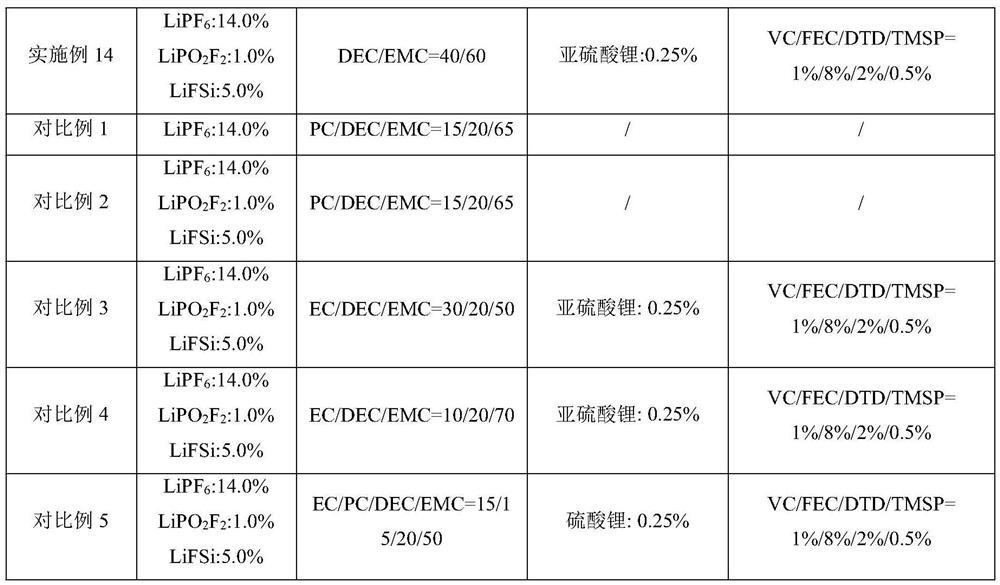

Lithium ion battery non-aqueous electrolyte without ethylene carbonate solvent and battery

InactiveCN112331914AFacilitate conductionRaise the reduction potentialSecondary cells servicing/maintenanceOrganic electrolytesElectrolytic agentOrganosolv

The invention belongs to the technical field of lithium ion batteries, and discloses a lithium ion battery non-aqueous electrolyte without an ethylene carbonate solvent and a lithium ion battery containing the electrolyte. The lithium ion battery non-aqueous electrolyte without the ethylene carbonate solvent comprises an electrolyte lithium salt, a non-aqueous organic solvent and a film-forming additive, wherein the film-forming additive comprises inorganic sulfide. The inorganic sulfide additive can be reduced on a negative electrode graphite interface prior to a solvent and other film-forming additives under the condition of a small addition amount to form an excellent lithium-conducting inorganic substance, and meanwhile, the electrolyte does not contain an ethylene carbonate solvent, so compared with a conventional electrolyte containing a carbonate solvent, the electrolyte has more excellent low-temperature performance, rate capability and safety.

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

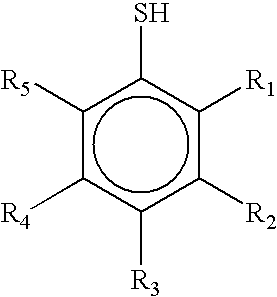

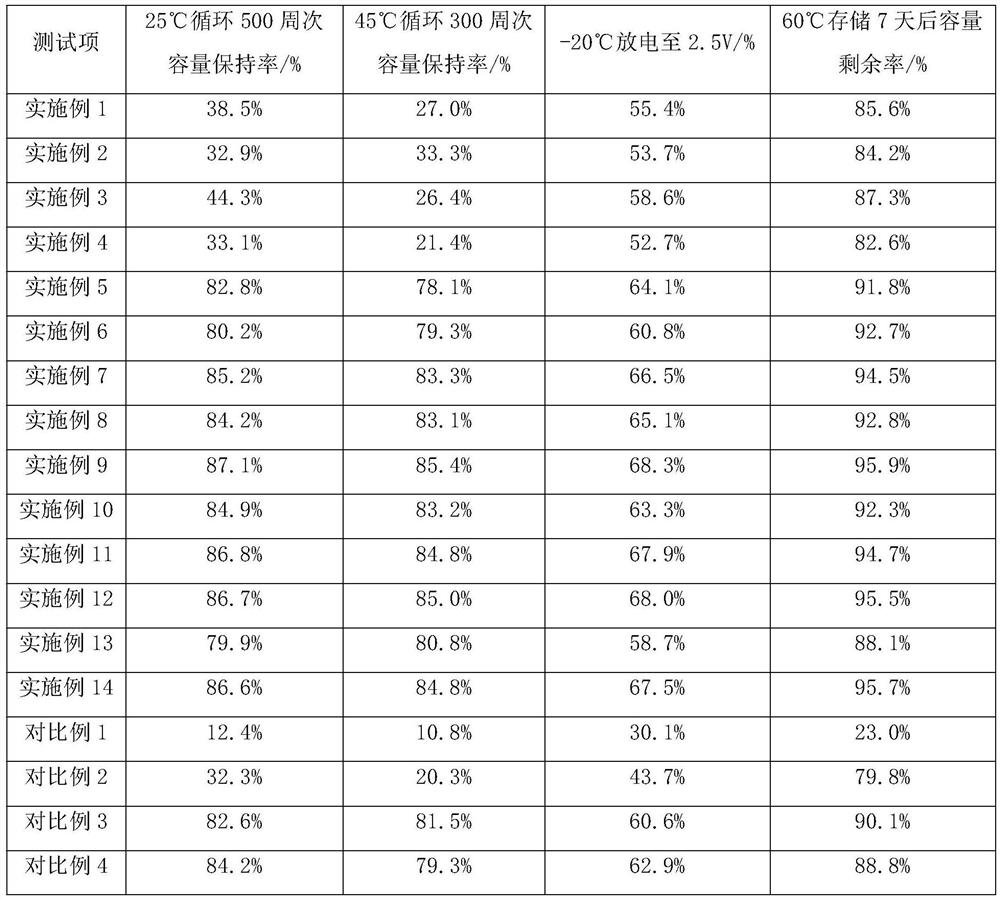

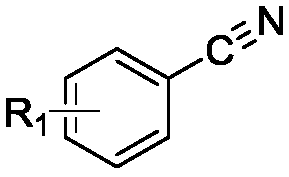

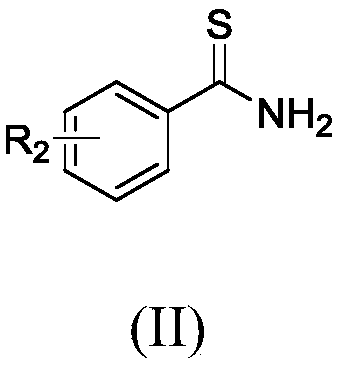

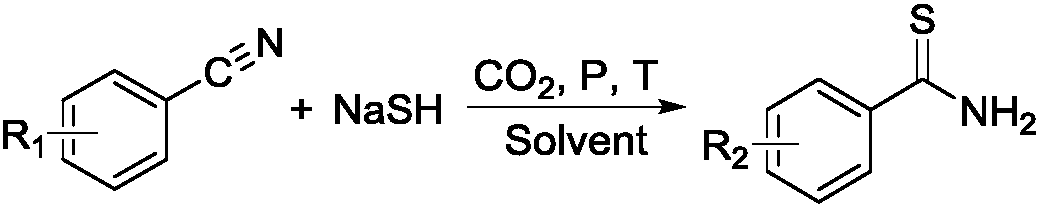

Method for synthesizing thiobenzamide derivative through CO2 regulation and control of substituted benzonitrile

The invention discloses a method for synthesizing a thiobenzamide derivative through CO2 regulation and control of substituted benzonitrile. The method comprises the following steps: taking the substituted benzonitrile as a raw material, an inorganic sulfide as a sulfur source and CO2 as an auxiliary agent for reacting in the presence of a reaction solvent, and concentrating and purifying a reaction solution to obtain the thiobenzamide derivative. The reaction system disclosed by the invention is relatively simple, other catalysts are not added outside a reactant and the inorganic sulfide, themethod is suitable for synthesis of high-additional-value thiobenzamide containing a plurality of substituent groups, the reaction is carried out at low temperature and low pressure, and the risk coefficient is reduced.

Owner:INNER MONGOLIA UNIV OF TECH

Alkaline process for preparing europium oxide in fluorescence level

InactiveCN1151969CReduce manufacturing costEasy to operateRare earth metal compoundsAlkalinityOxalate precipitation

The present invention is one wet chemical separation process and can produce product of fluorescence level through eliminating non-rare earth impurity in europium chloride or europium nitrate solution. The europium chloride or europium nitrate solution with the rare earth impurity eliminated through alkaline process is further processed through addition of inorganic sulfide solution, once oxalate precipitation and once burning to prepare europium oxide in fluorescence level. The process has low cost, simple operation and stable product quality.

Owner:包头钢铁公司稀土研究院

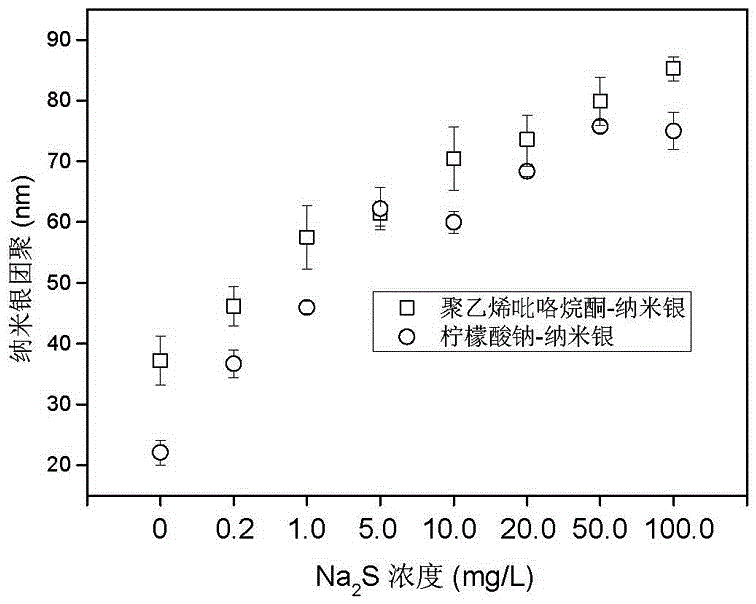

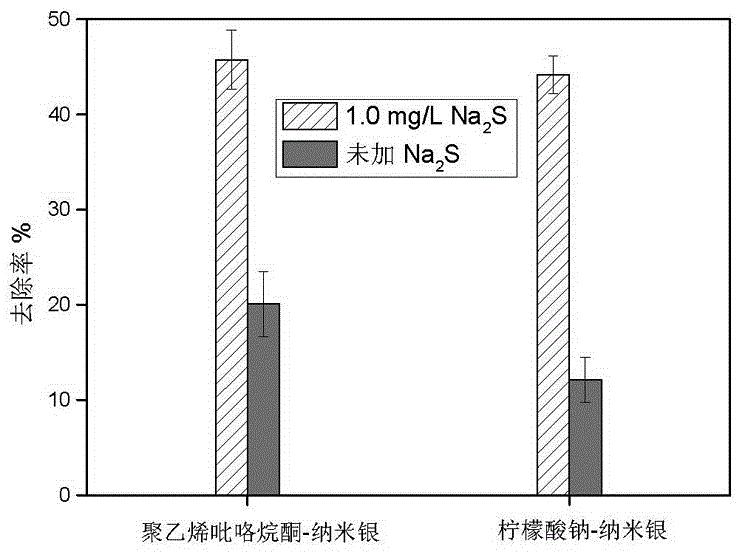

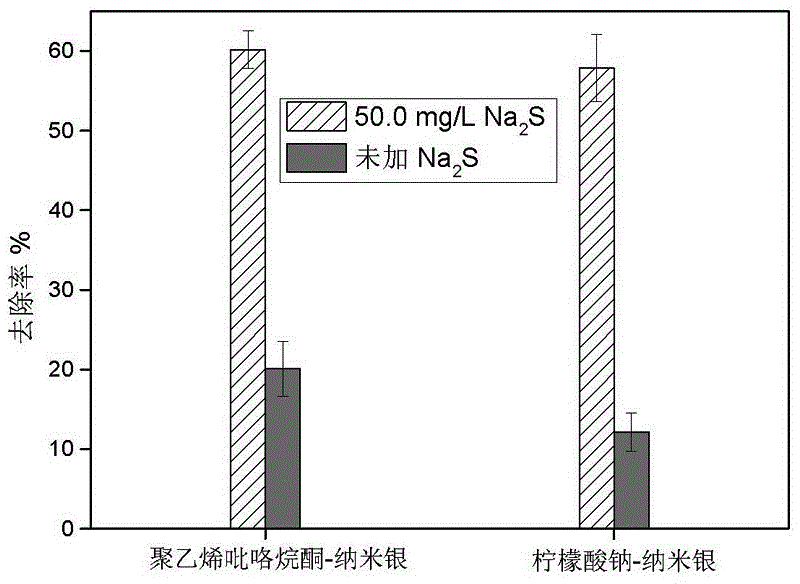

Method for removing nano-silver in water

ActiveCN105585211AEfficient removalEasy to handleWater/sewage treatmentMultistage water/sewage treatmentBiological membraneSulfide compound

The invention discloses a method for removing nano-silver in water. The method comprises steps as follows: an inorganic sulfide solution is mixed with nano-silver-containing water, and a mixed solution is obtained; the mixed solution after reaction is filtered by a biological membrane, and treatment of the nano-silver-containing water is finished. The method has the advantages that the operation is simple, utilized reagents are simple and available, the application is wide, the practicability is high, the removing effect is good and the like.

Owner:HUNAN UNIV

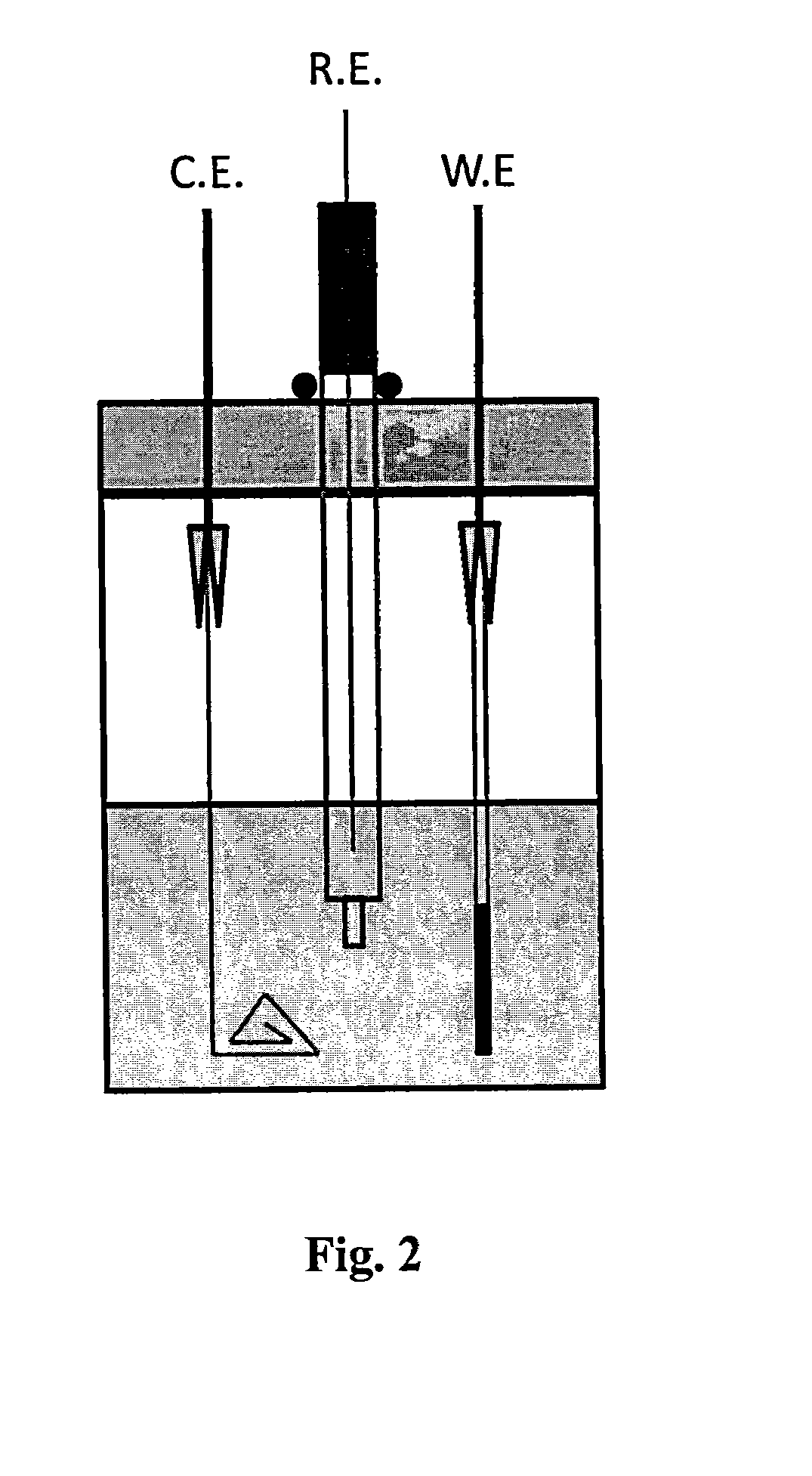

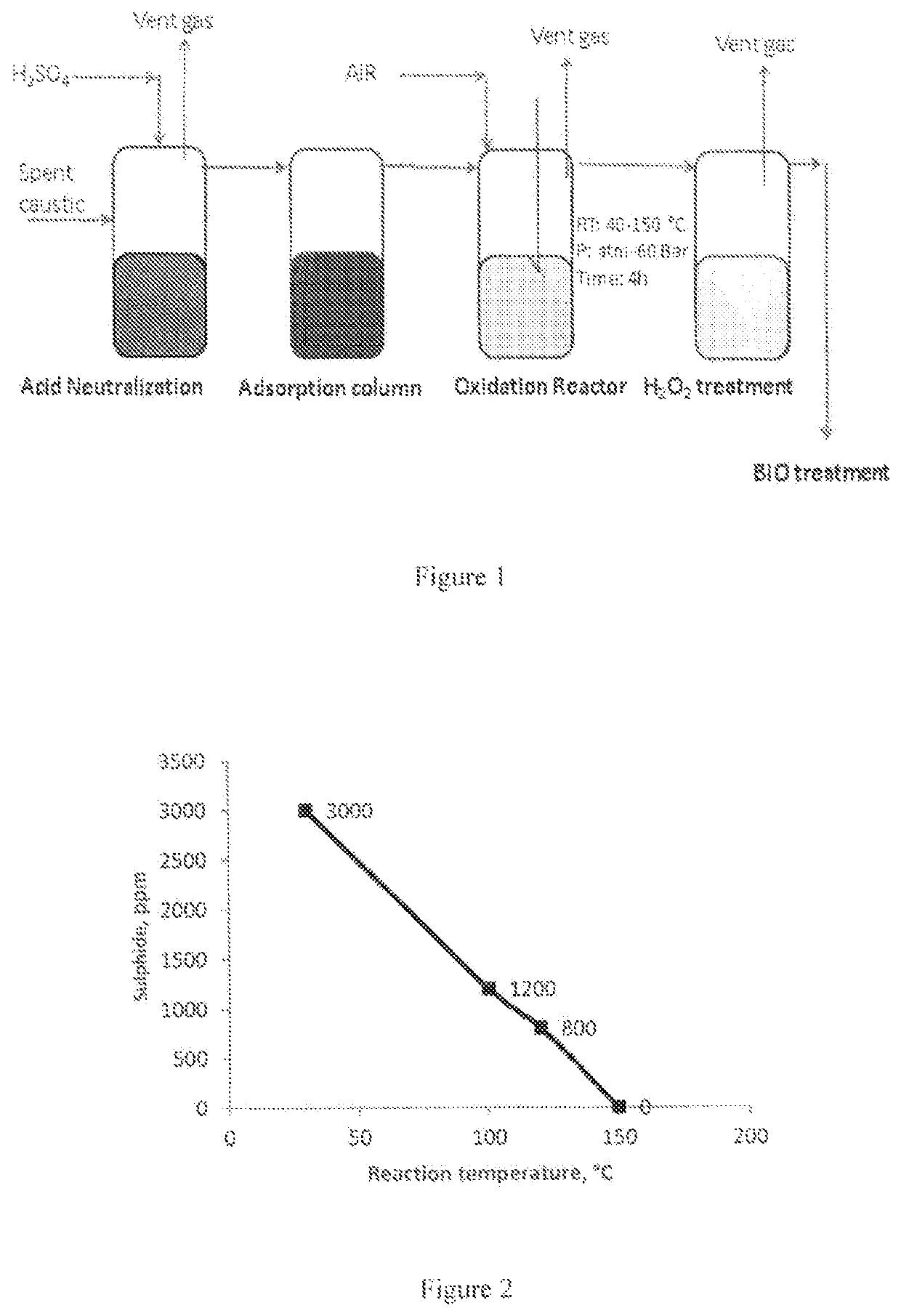

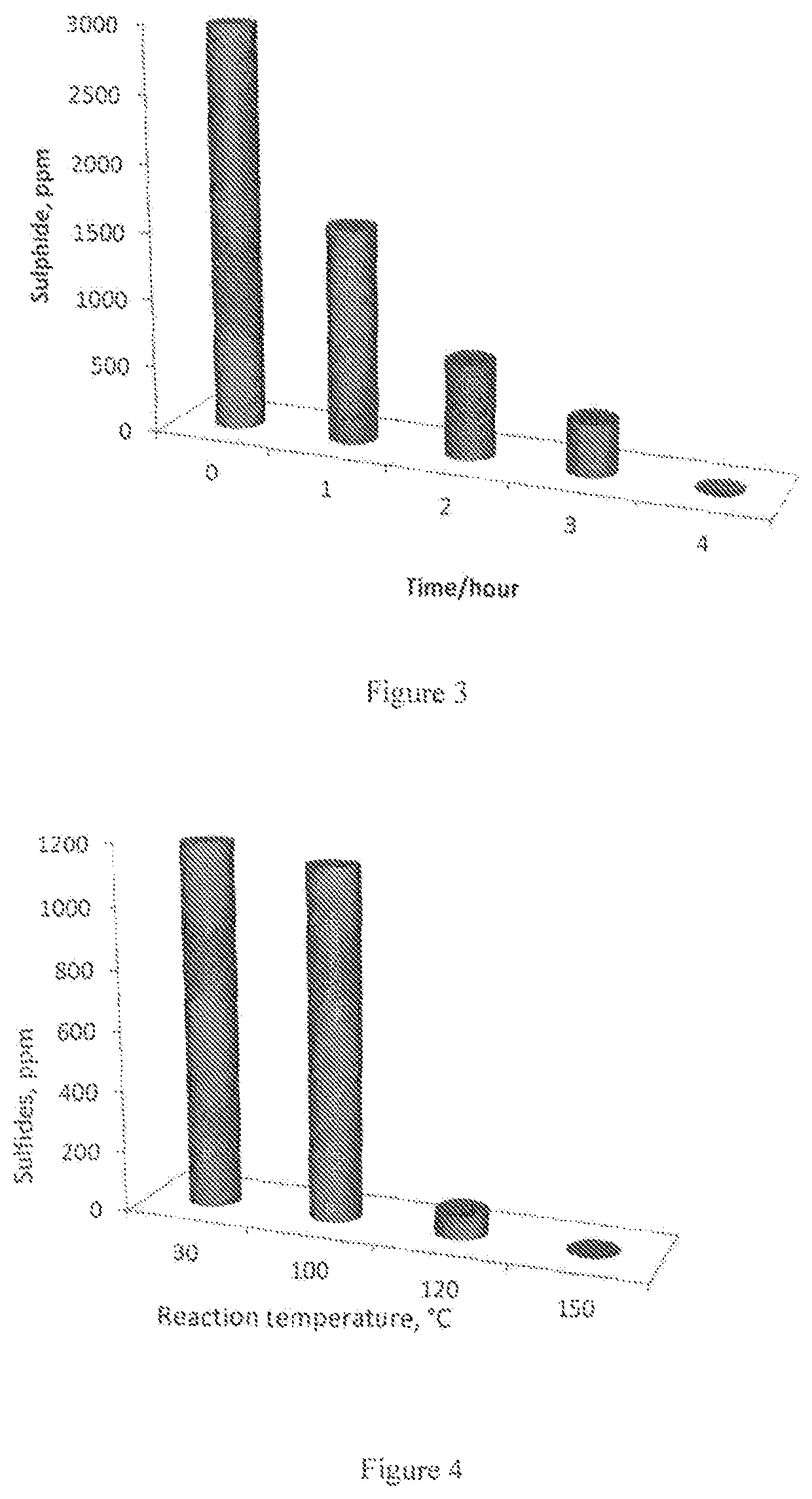

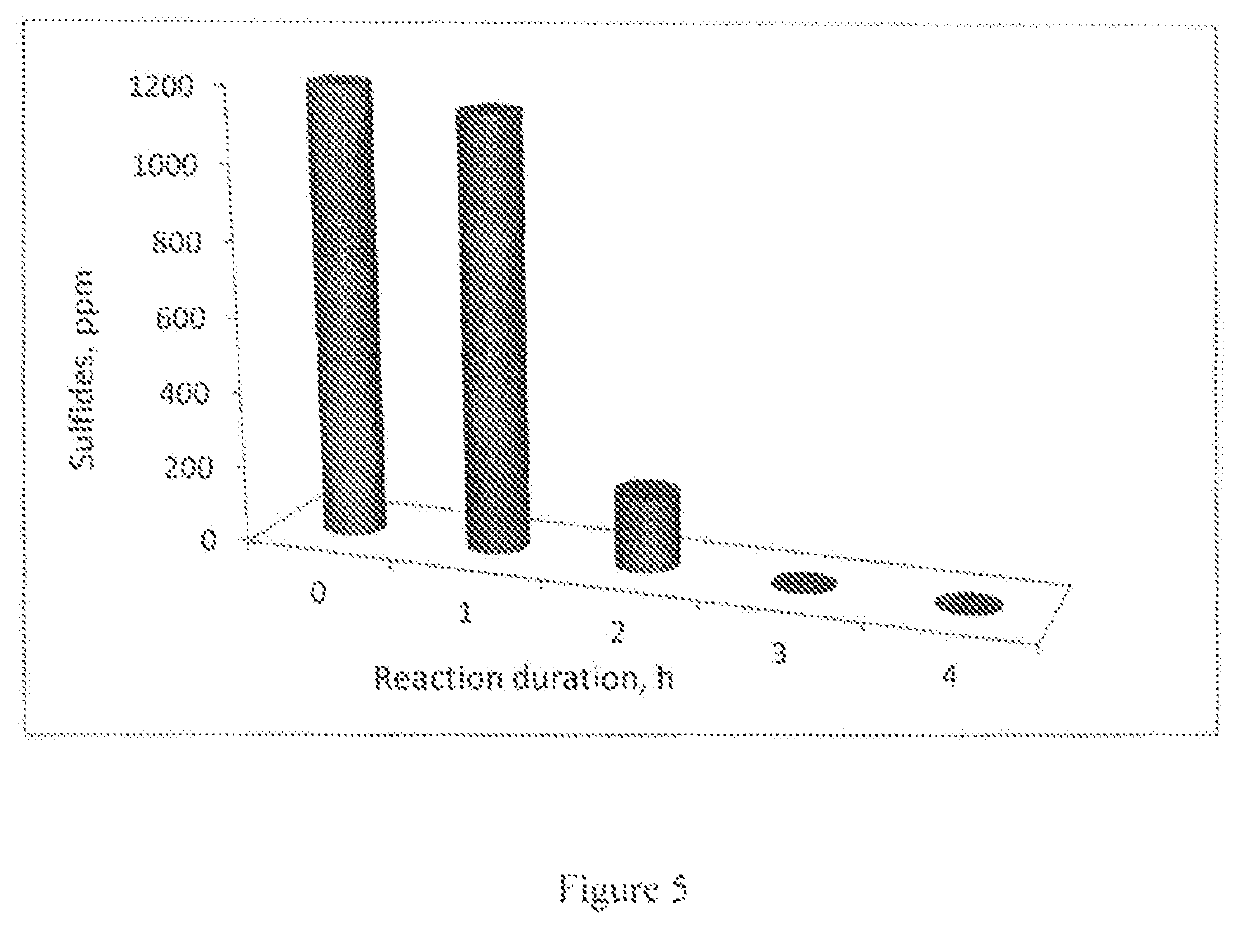

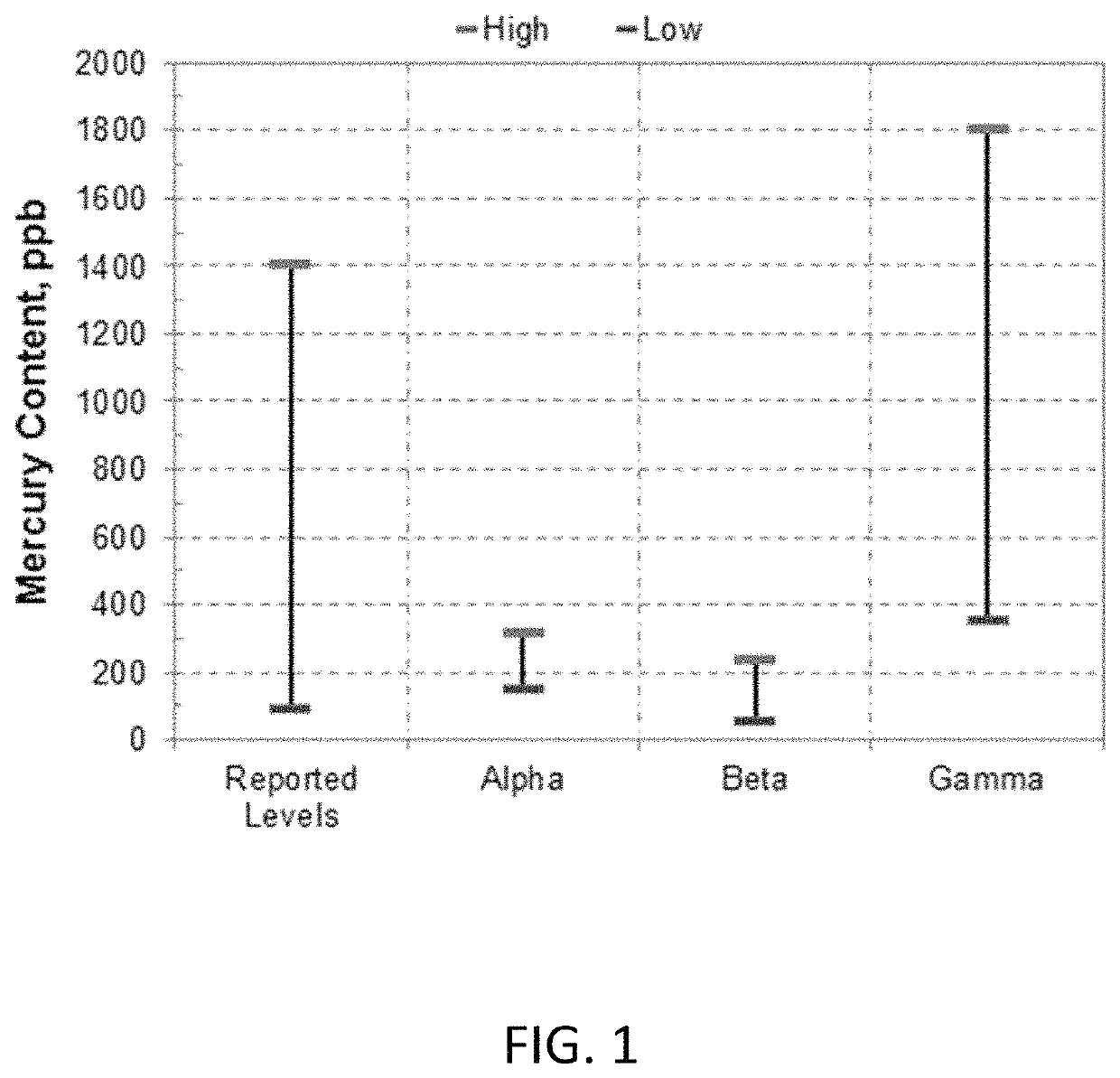

Removal of sulfides in spent caustic stream over active solid phase catalysts

ActiveUS10800691B2Efficient oxidationSpeed up the conversion processSludge treatment by oxidationMolecular sieve catalystsPtru catalystPhysical chemistry

The present subject matter relates to the development of active catalyst composite based on supported transition metal oxides, especially, Cu, Co that are effective in the removal sulfides in the diluted spent caustic. The process for the reduction of sulfides in spent caustic comprises of reacting various organic and inorganic sulfides with molecular oxygen in the presence of active catalyst at various reaction temperatures ranging ambient to 200° C. and pressures between atmospheric pressure to 60 bars. The process also relates to complete scheme for the removal of sulfides in spent caustic.

Owner:HINDUSTAN PETROLEUM CORP LTD

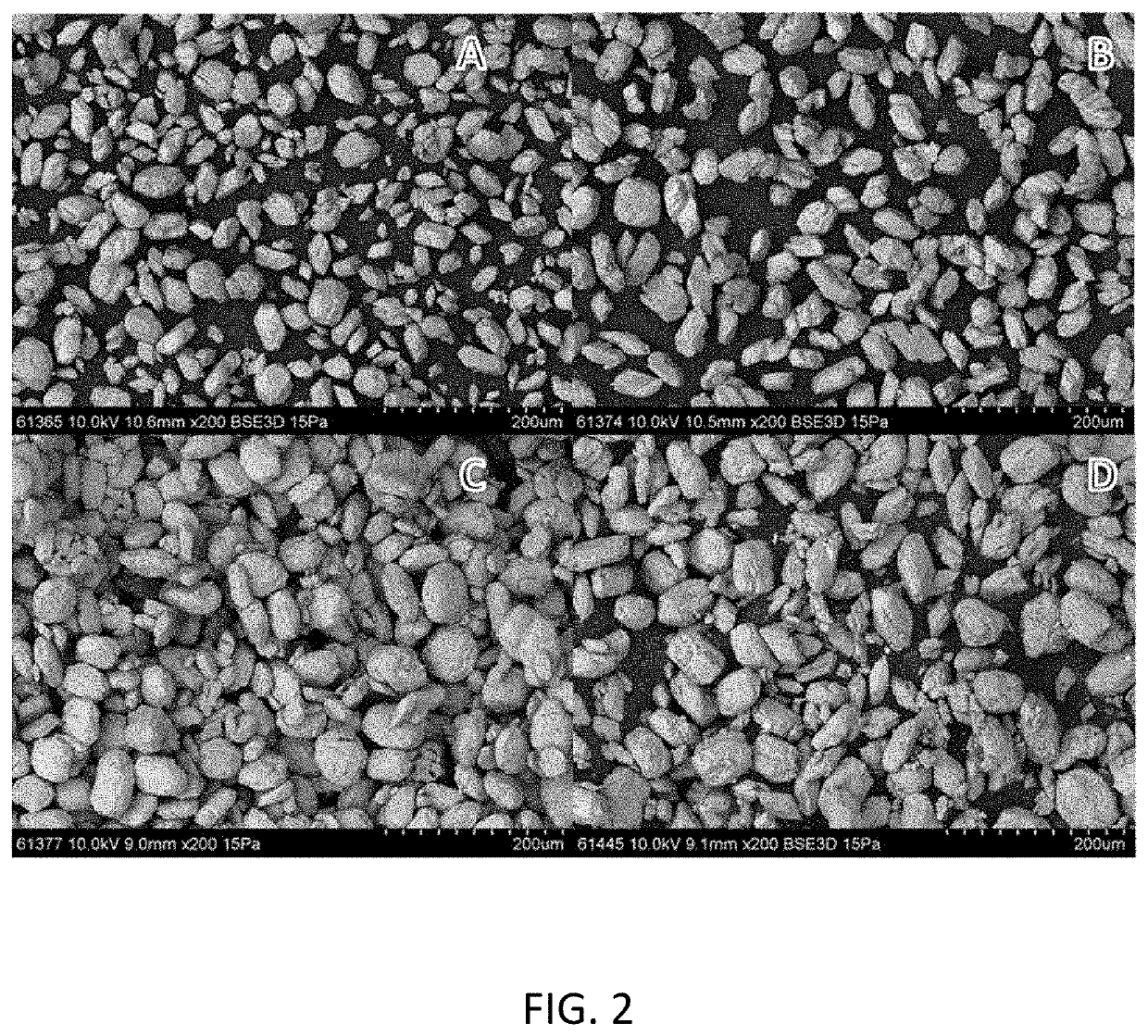

Gypsum additive to control mercury

Additives including sulfur-containing compounds are used in methods of treating synthetic gypsum. The additives can thermally stabilize heavy metals, such as mercury. This thermal stabilization reduces mercury release from the synthetic gypsum. Illustrative, non-limiting examples of sulfur-containing compounds include inorganic sulfides, organic sulfides, organic compounds containing nitrogen and sulfur, organic compounds containing oxygen and sulfur, and polymers containing sulfur.

Owner:ECOLAB USA INC

An integrated method of high gravity complexation ferrous flue gas wet dust removal, desulfurization, denitrification, mercury and arsenic removal

InactiveCN103432877BEasy to removeImprove regeneration efficiencyUsing liquid separation agentToxicantSulfide

The invention discloses an integrated method for wet dedusting, desulfurization, denitrification, demercuration and arsenic removal of supergravity complexed ferrous flue gas. The present invention first utilizes inorganic sulfides to absorb SOx, and at the same time, captures the dust particles in the flue gas. To absorb NOx, inorganic sulfide acts as a reducing agent to regenerate the absorbent. The invention adopts a supergravity machine as gas-liquid mass transfer strengthening equipment, which is beneficial to the removal of dust, SOx, NOx, mercury, arsenic and other toxic substances. The invention has the advantages of simple process, high absorption efficiency, thorough dust removal, a desulfurization rate of over 99%, a denitrification rate of over 96%, and can basically completely remove dust, mercury and arsenic in flue gas.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD

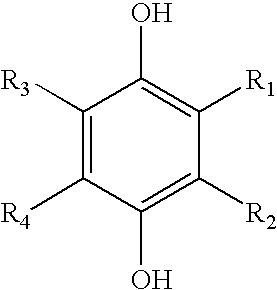

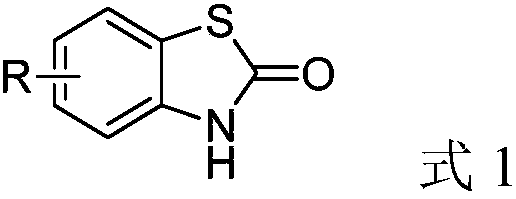

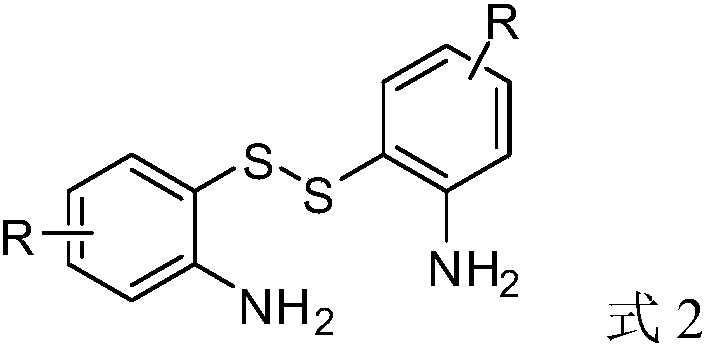

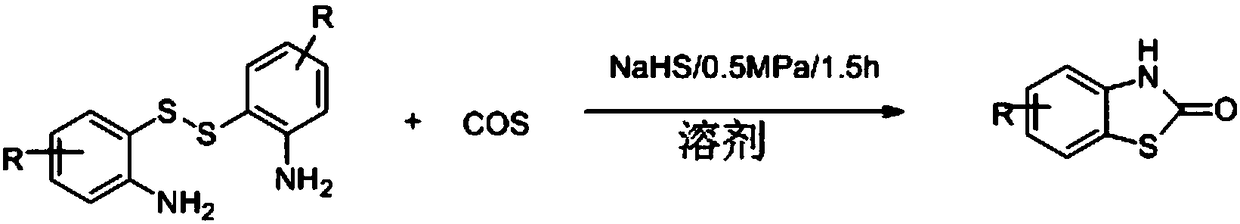

Method for synthesizing benzothiazole-2-ketone derivative from carbonyl sulfide and disulfide as raw materials

ActiveCN108101863ACheap and easy to getImprove economyOrganic chemistryOrganic solventCarbonyl sulfide

The invention discloses a method for synthesizing a benzothiazole-2-ketone derivative from carbonyl sulfide and disulfide as raw materials. The method comprises the following steps: mixing disulfide,inorganic sulfide and an organic solvent, introducing sufficient COS to implement a reaction, and concentrating and purifying a reaction liquid, thereby obtaining the benzothiazole-2-ketone derivative. The inorganic sulfide used in the method is adopted as an activation catalyst and is low in price and easy to obtain; a catalysis system is relatively simple, and no other catalyst promoter is addedexcept reactants and inorganic sulfide; direct dehydration is implemented in the reaction process, no other dehydration agent is used, and thus the atom economy is improved; the catalysis system is good in applicability, is applicable to synthesis of fine chemicals with high additional values, and is very good in substrate applicability to each fine chemical with high additional values; reactionsare implemented at normal temperatures, normal pressure or low pressure, and thus danger coefficients can be reduced; the reaction time is short, and the efficiency can be improved.

Owner:INNER MONGOLIA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com