Method for removing sulfides in light oil

A light oil and sulfide technology, which is applied in the treatment of hydrocarbon oil, petroleum industry, and multi-stage series refining process treatment, etc., can solve the problem of low desulfurization precision, complicated light oil removal steps, and ineffective removal of many sulfide and other problems, to achieve the effect of low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

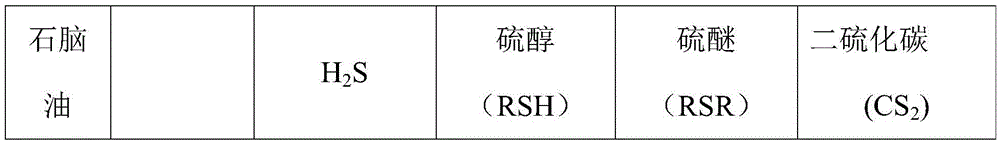

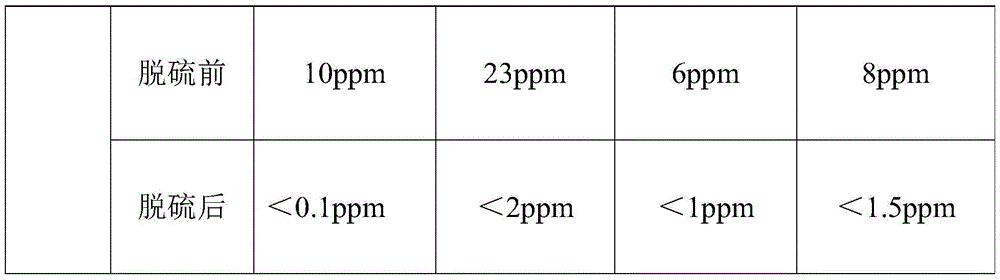

[0035] Embodiment 1, the removal of sulfide in naphtha:

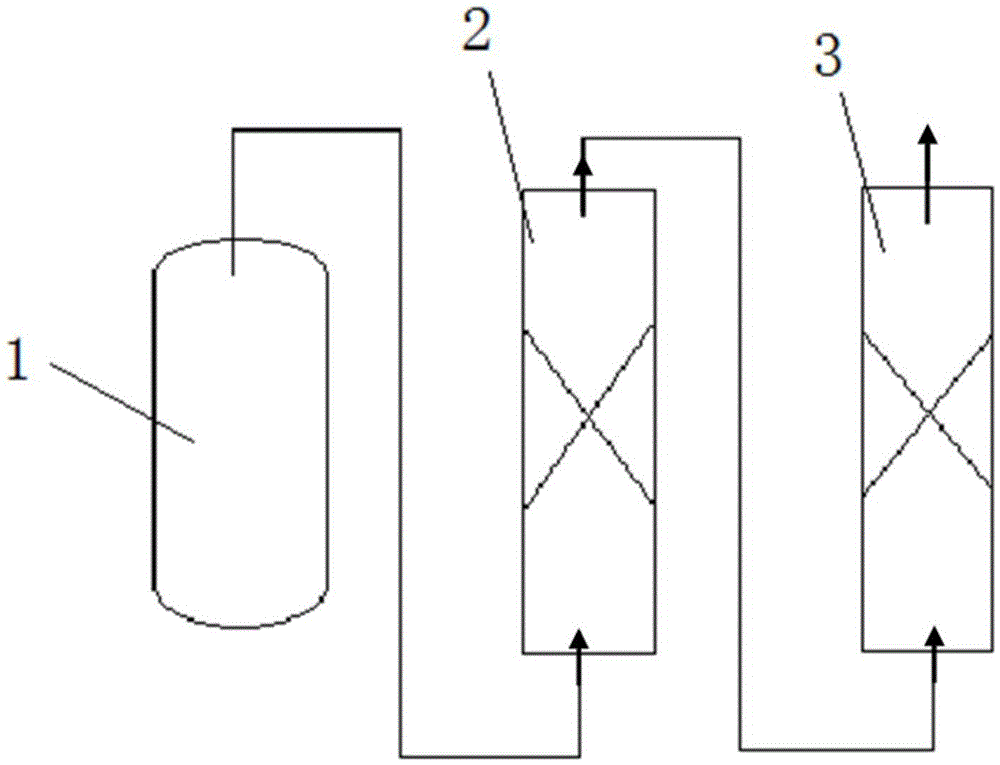

[0036] combine figure 1 , the removal of sulfide in naphtha, comprises the steps:

[0037] 1) At 5°C and 0.3MPa, the naphtha in the raw material tank 1 is fed for 1 hour by adopting the bottom-in and top-out method. -1 The volume space velocity is contacted with the magnetic iron oxide placed in the reactor I (in this embodiment, the reactor I is specifically a fixed bed reactor) to perform primary desulfurization and remove the H in the naphtha. 2 S, obtained by removing H 2 The naphtha of S, wherein the preparation method of magnetic iron oxide in the present embodiment is the iron oxide black Fe of 500g 3 o 4 In a muffle furnace, it was calcined at 500°C for 2 hours, and then prepared into a spherical shape. The magnetic iron oxide obtained by the above method has the following characteristics: reddish-brown spherical particles, the composition is Fe 21.333 o 32 , the strength is 30N / cm, and the specific surfa...

Embodiment 2

[0043] Embodiment 2, the removal of sulfide in kerosene:

[0044] The removal of sulfide in kerosene comprises the following steps:

[0045] 1) At 90°C and 3MPa, take the method of bottom in and top out, and kerosene for 10h -1 The volume space velocity is contacted with the magnetic iron oxide placed in reactor I (in this embodiment, reactor I is specifically a fluidized bed reactor) to perform primary desulfurization and remove H in kerosene. 2 S, obtained by removing H 2 The kerosene of S, wherein the preparation method of magnetic iron oxide in the present embodiment is the iron oxide black Fe of 500g 3 o 4 In a muffle furnace, it was calcined at 350°C for 4.5h, and then prepared into a spherical shape. The magnetic iron oxide obtained by the above method has the following characteristics: reddish-brown spherical particles, the composition is Fe 21.333 o 32 , the strength is 50N / cm, and the specific surface area is 200m 2 / g,H 2 S sulfur capacity is 50%; at the sam...

Embodiment 3

[0050] Embodiment 3, the removal of sulfide in gasoline:

[0051] The removal of sulfur compounds in gasoline includes the following steps:

[0052] 1) At 45°C and 5MPa, take the method of bottom-in and top-out, and put the gasoline in 5h -1 The volume space velocity is contacted with the magnetic iron oxide placed in reactor I (in this embodiment, reactor I is specifically a fixed bed reactor) to perform primary desulfurization and remove H in gasoline. 2 S, obtained by removing H 2 The gasoline of S, wherein the preparation method of magnetic iron oxide in the present embodiment is the iron oxide black Fe of 500g 3 o 4 In a muffle furnace, it was calcined at 250°C for 5 hours, and then prepared into a spherical shape. The magnetic iron oxide obtained by the above method has the following characteristics: reddish-brown spherical particles, the composition is Fe 21.333 o 32 , the strength is 45N / cm, and the specific surface area is 210m 2 / g,H 2 S sulfur capacity is 43...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com